Atlas Copco Shaping the future

Atlas Copco is focused on driving customer development via our energy efficient and innovative portfolio of compressors, blowers, dryers and generators. Real-time connectivity and energy optimisation solutions provide continuous uptime and operational improvement.

Page 2. Discover 10 easy steps towards energy efficiency for your compressed air needs

manmonthly.com.au MANAGEMENT >> TECHNOLOGY >> SOLUTIONS SEPTEMBER 2023

Team members are located where you are, and will provide sales and service for your compressed air needs. Contact our team on 1800 023 469

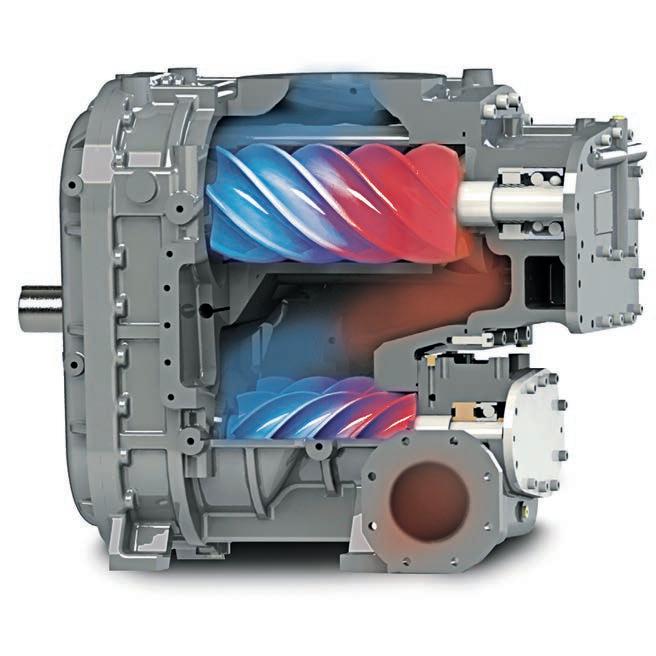

As much as 94% of the energy supplied to the compressor can be recovered, for example, as 90°C hot water from oil-free screw compressors.

Atlas Copco’s new next generation of inPassTM compressed air filters allow you to reduce installation costs and continued operations during maintenance.

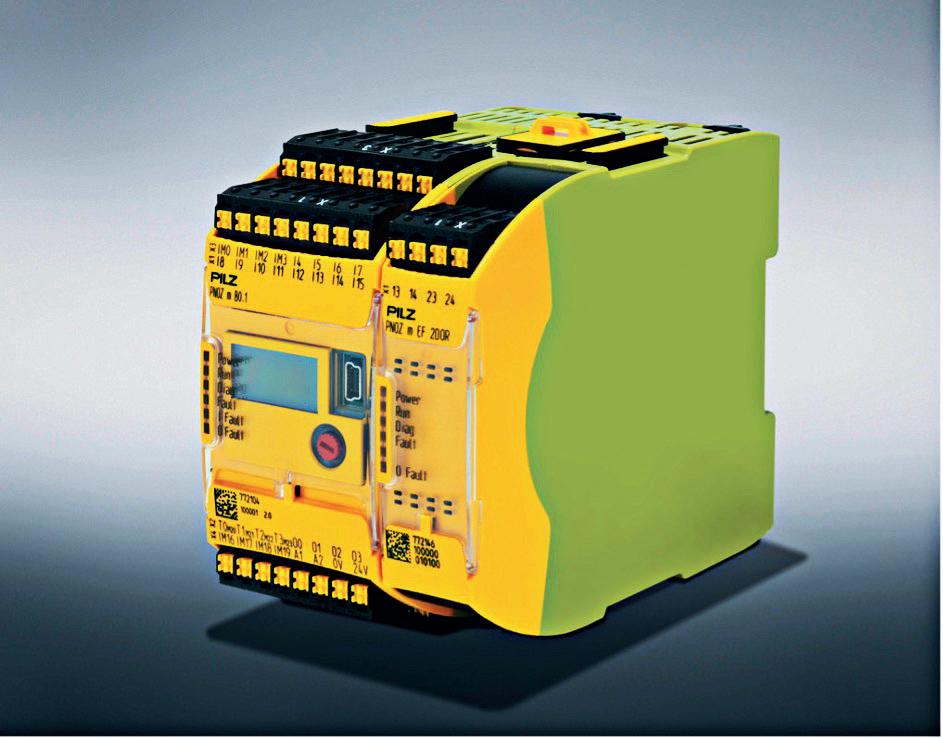

VSDs –Next-gen compressor

“We are extremely proud of our past, and we continue to shape the future through our technologies and service solutions,” said Mats Rahmström, CEO and President of the Atlas Copco Group.

By offering energy-efficient compressors, gas generators, industrial and aeration blowers, industrial cooling, and quality air products, we enable you to reduce energy consumption and help you meet your carbon emission goals.

Atlas Copco Shaping the

future

Atlas Copco brings you the GA VSDs – a truly groundbreaking compressor for the generation that demands it all. The GA VSDs grants energy savings up to 60% - the best yet!

Great ideas accelerate innovation. At Atlas Copco we have been turning industrial ideas into business-critical benefits since 1873. By listening to our customers and knowing their needs, we deliver energy efficient solutions and innovate with the future in mind.

SMARTLINK is a realtime compressor monitoring system providing you with a complete data insight of the compressed air production at your site. Available via your smartphone and PC.

2. Discover 10 easy steps towards energy efficiency for your compressed air needs

Page

Atlas Copco nitrogen and oxygen generators allow you to generate nitrogen at your own facility to desired purity level (up to 99.999 %). This ensures independence of supply and indirect carbon emissions.

AIRScan is a comprehensive audit of your entire compressed air installation, including energy input, air flow demand, system pressure and more.

manmonthly.com.au MANAGEMENT >> TECHNOLOGY >> SOLUTIONS >> INSIDE >> Sourcing a compressed air solution 37 SEPTEMBER 2023 Unpacking AUKUS 32 Technology that can create memories 52 Official Industry Partners REVOLUTIONISING TRAINING SKILLS

CEO: John Murphy

COO: Christine Clancy

Managing Editor: Syed Shah

Editor: Josh Farrell joshua.Farrell@primecreative.com.au

Journalist: Mignon D’Souza mignon.dsouza@primecreative.com.au

Production Coordinator: Michelle Weston michelle.weston@primecreative.com.au

Art Director: Blake Storey

Design: Kerry Pert, Tom Anderson, Louis Romero

Sales/Advertising: Danny Hernandez

Ph: 0431 330 232 danny.hernandez@primecreative.com.au

Subscriptions

Published 11 times a year

Subscriptions $140.00 per annum (inc GST)

Overseas prices apply

Ph: (03) 9690 8766

Copyright

is owned by Prime Creative Media and published by John Murphy. All material in Manufacturers’ Monthly is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Manufacturers’ Monthly are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated. © Copyright Prime Creative Media, 2023 Articles All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format. Head Office 379 Docklands Drive Docklands VIC 3008 P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au Sydney Office Suite 3.06, 1-9 Chandos Street St Leonards NSW 2065, Australia P: +61 2 9439 7227 Printed by: Manark Printing 28 Dingley Ave Dandenong VIC 3175 Ph: (03) 9794 8337 manmonthly.com.au twitter.com/Manmonthly facebook.com/Manmonthly linkedin.com/showcase/manufacturer’s-monthly/

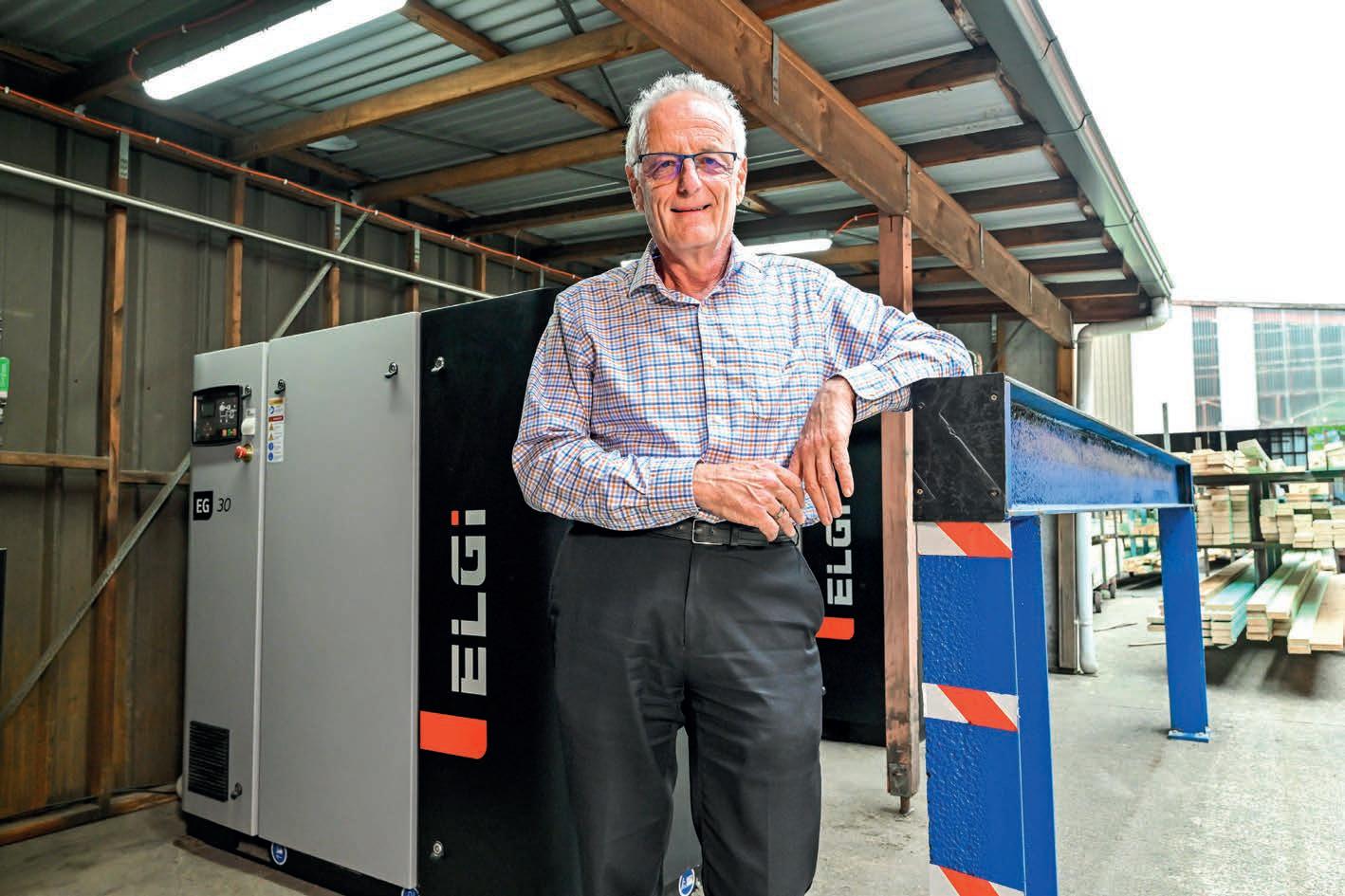

Manufacturers’ Monthly Contents

an everchanging industry. In this edition, we unpack AUKUS ahead of Indo Pacific 2023, look at a compressed air solution developed by ELGi and explore an engineering focus story that will see us delve into the world of technology that can form memories like humans.

4 SEPTEMBER 2023 Manufacturers’ Monthly manmonthly.com.au 6 Editor’s Note 10 Comment 12 News 20 Manufacturer Focus 24, 30, 37, 40, 44, 46 Compressed Air 26 Sustainability Strategies 28 Lifting Equipment 32, 42 Events 34 SEMMA Member Profile 49 Endeavour Awards 52 Engineering Focus 57 What’s New 58 Last Word For daily news visit manmonthly.com.au Inside SEPTEMBER 2023 26 Behind the cover manmonthly.com.au MANAGEMENT >> TECHNOLOGY >> SOLUTIONS >> INSIDE >> Sourcing compressed air solution 37 SEPTEMBER 2023 Unpacking AUKUS 32 Technology that can create memories 52 Official Industry Partners Revolutionising TRAINING SKILLS Page 2. Discover 10 easy steps towards energy efficiency for your compressed air needs Atlas Copco Shaping the future Great ideas accelerate innovation. At Atlas Copco we have been turning industrial ideas into business-critical benefits since 1873. By listening to our customers and knowing their needs, we deliver energy efficient solutions and innovate with the future in mind. Team members are located where you are, and will provide sales and service for your compressed air needs. Contact our team on 1800 023 469 As much as 94% of the energy supplied to the compressor can be recovered, for example, as 90°C hot water from oil-free screw compressors. Atlas Copco’s new next generation of inPassTM compressed air filters allow you to reduce installation costs and continued operations during maintenance. AIRScan is a comprehensive audit of your entire compressed air installation, including energy input, air flow demand, system pressure and more. By offering energy-efficient compressors, gas generators, industrial and aeration blowers, industrial cooling, and quality air products, we enable you to reduce energy consumption and help you meet your carbon emission goals. “We are extremely proud of our past, and we continue to shape the future through our technologies and service solutions,” said Mats Rahmström, CEO and President of the Atlas Copco Group. VSD Next-gen compressor Atlas Copco brings you the GA VSD a truly groundbreaking compressor for the generation that demands it all. The GA VSD grants energy savings up to 60% - the best yet! SMARTLINK is a realtime compressor monitoring system providing you with a complete data insight of the compressed air production at your site. Available via your smartphone and PC. Atlas Copco nitrogen and oxygen generators allow you to generate nitrogen at your own facility to desired purity level (up to 99.999 %). This ensures independence of supply and indirect carbon emissions.

The Manufacturer Focus feature for September looks at JRS Group and what the company is doing to change the way skills training is delivered. The company has developed its skills academy to give a better insight to the industry and have those who join it, leave with far more skills that set them up for success in 40 52

Manufacturers’ Monthly

1300 365 088 sales.au@ifm.com | www.ifm.com/au moneo is a self-service, easy to use, predictive maintenance toolbox that can integrate seamlessly into your existing system. It is revolutionising operations and facilities – digitalising facilities to protect what is needed now, well into the future. ifm have combined decades of expertise in sensor technology to bring you the latest in the IIoT technology space – moneo. What is moneo? How can it help your business? Need to digitalise your operation and quickly? Visit our brand-new website to discover how to enhance your business operations TODAY! moneosolutions.com.au NEW You can also register for a FREE 30 day trial!

Editor’s Note

JOSH FARRELL – Editor, Manufacturers’ Monthly

Government poised to grow manufacturing

MANUFACTURING continues to remain front of mind nationally and it is an exciting time for the industry as people continue investing in the growth of the sector.

Last month, the Manufacturers’ Monthly team had the privilege to be invited by Weld Australia to attend the National Manufacturing Summit in Canberra.

With a focus on manufacturing the energy revolution it is exciting to see the focus on the renewable sector and how Australian manufacturers can become a powerhouse of this industry. A full wrap will appear in the October edition.

Recently, Manufacturers’ Monthly held a poll on its LinkedIn page, posing the question, ‘What do you think will have a bigger impact on Australian Manufacturing in the next decade?’

The four options to vote on were: additive manufacturing, cobots, automation, and government

investment – with the latter taking top spot with 35 per cent of the vote.

The idea of government investment can mean so many different things. It can include purchasing Australian made on government projects or simply cofunding exciting projects.

Purchasing Australian made is an exciting prospect, as recently demonstrated with Victoria investing in locally made trains. In 2014 the state made a commitment to improving the rolling stock manufacturing in the state and the rolling stock industry is now responsible for 10,000 jobs in Victoria.

New South Wales has taken note - as you will see further in the magazineholding a roundtable to consider the future of the rolling stock industry in the state.

Just simply buying locally made transport has the potential to improve the manufacturing industry as a whole and – with some luck – may see the country

begin to export high quality rolling stock to the global market.

Besides buying locally manufactured products, co-investment strategies are showing promising signs of growing manufacturing in a range of sectors.

The $15 billion national reconstruction fund promises to provide fantastic support to the manufacturing sector and shows the government’s commitment to supporting the growth of manufacturing.

The fund will invest $15 billion across priority areas of the economy including renewables and low emissions technologies, medical science, transport, value-adding in resources, value-adding in agriculture, forestry and fisheries, defence capability, and enabling technologies.

It is almost weekly now that new funding is announced from state governments to support manufacturing, all of which promises to fund developments for the wider sector and

the nation as a whole. It also might mean people may stop telling us all that manufacturing is dead in Australia.

All these considerations and more mean the September edition of Manufacturers’ Monthly once again promises to be an exciting read.

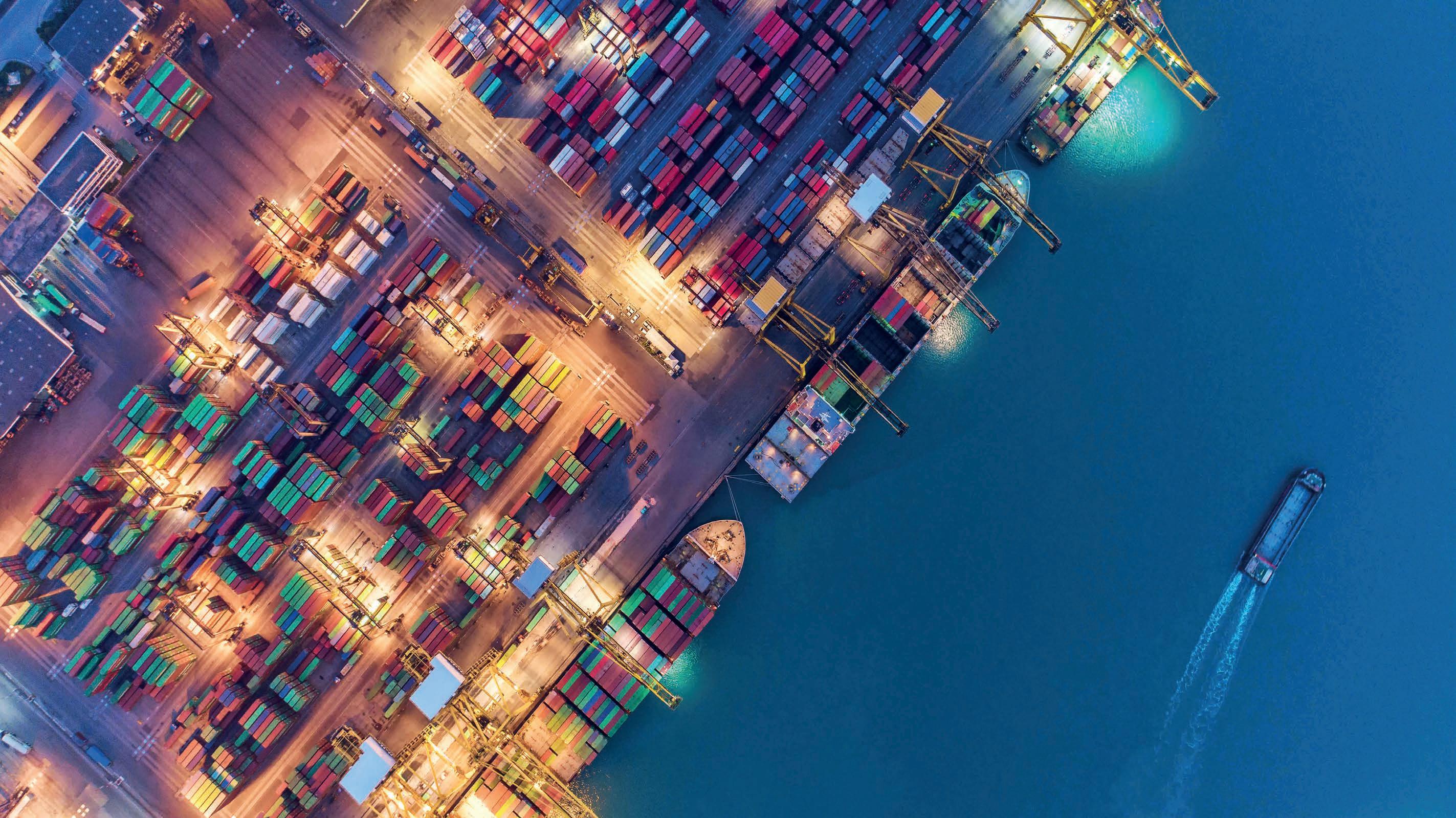

This month has a focus on compressed air as you will see throughout. While it may not be a glamorous topic, it is one of importance to manufacturing and deserves its time in the spotlight.

The manufacturer focus this month explores the JRS group which was an exciting story to work on with its COO Jasmine Riddle. The company is focussing on its skills academy which is exciting for the broader industry.

In other areas of the magazine you will see regular comments from Weld Australia and the Ai group plus hositing equipment from Kito PWB.

Happy reading!

6 SEPTEMBER 2023 Manufacturers’ Monthly manmonthly.com.au

COMPLETE AIR & POWER SOLUTIONS

CAPS Australia has been supplying best-in-class air and power solutions to the manufacturing sector for more than 43 years.

Specialising in end-to-end solutions, our in-house engineering allows us to design, supply and install bespoke, purpose-built systems to clients with specialised applications. As an independent company with the flexibility to search globally for the best technology, CAPS works alongside world-renowned partner brands like Ingersoll Rand, Kohler, AIRMAN and many more.

With ten branches nationwide and 24/7 service for maintenance and emergency breakdowns, CAPS Australia leads the industry in service and solutions.

POWER GENERATION

& SPARE PARTS AIR COMPRESSORS POWER ISO CLASS 0 OIL-FREE AIR AIR TREATMENT

OR VISIT CAPS.COM.AU

SERVICING

CALL 1800 800 878

FOR PRODUCTS OVER $2000

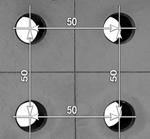

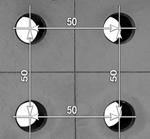

The Metalmaster M28 Pro Series welding tables features a welded & ribbed construction from heavy S355 plate steel, the frame is then CNC machined with the sides & top having a finished nominal thickness of 25mm. The CNC machining process is able to achieve a high flatness tolerance of +/- 0.1mm over 1m2 to give you a smooth precision welding surface. During this CNC machining process, the Ø28mm holes are precision bored to ensure a hole distance tolerance of +/- 0.05mm & with a diagonal style hole pattern it gives you a multitude of fixture holes to suit your application. Before removing the table from the machining centre, we engrave 100mm grid lines & perimeter ruler to give you millimetre precision helping you minimise mistakes while increasing productivity.

The Metalmaster M16 Pro Series welding tables features a welded & ribbed construction from heavy S355 plate steel, the frame is then CNC machined with the sides & top having a finished nominal thickness of 12mm. The CNC machining process is able to achieve a high flatness tolerance of +/- 0.1mm over 1m2 to give you a smooth precision welding surface. During this CNC machining process, the Ø16mm holes are precision bored to ensure a hole distance tolerance of +/- 0.05mm & with an industry standard 50 x 50mm hole pattern it gives you a multitude of fixture holes to suit your application. Before removing the table from the machining centre, we engrave 50mm grid lines & perimeter ruler to give you millimetre precision helping you minimise mistakes while increasing productivity.

SPECIFICATIONS

WIDE RANGE OF OPTIONAL ACCESSORIES AVAILABLE...

WT28-KIT42 - 42PC WELDING TABLE CLAMPING & FIXTURING KIT

The ideal addition to complement our METALMASTER M28 Pro Series welding tables, this kit will give you the basics while offering a wide variety of clamps & fixturing elements.

“Setting the standard for Quality & Value” VIEW AND PURCHASE THESE ITEMS ONLINE AT www.machineryhouse.com.au/MM2308 Specifications & Prices are subject to change without notification. All prices include GST and valid until 24-09-23 MM2308 ONLINE OR INSTORE! UNIQUE PROMO CODE

PLASMA NITRATING SURFACE FINISH PERIMETER RULER ENGRAVING 50X50MM HOLE CENTRES PATTERN 16MM DIAMETER HOLES

Order Code: W08255 W08257 W08260 W07804 W07811 W07812 Model: WT28-2010N WT28-2412N WT28-3015N WT16-2010 WT16-2010N WT16-2412N Table Top Size 2.0 x 1.0m 2.4 x 1.2m 3.0 x 1.5m 2.0 x 1.0m 2.0 x 1.0m 2.4 x 1.2m Table Side Height 200mm 200mm 200mm 100mm 100mm 100mm

PRICE ex GST $6,950 $8,950 $10,950 $4,500 $5,650 $7,500 BONUS

TABLES ACCESSORIES EXCLUDED USE UNIQUE CODE MM2308 MATERIAL THICKNESS APPROX 25MM PERIMETER RULER ENGRAVING 100X100MM HOLE CENTRES PATTERN 28MM DIAMETER HOLES Visit www.machineryhouse.com.au/welding-tables-accessories No counting or engraving W08015 W08072 W08532 W08520 W07997 W07906 W08517

Accessories

$250 GIFT CARD PR0-SERIES WELDING

16mm

WELDING FUME EXTRACTION

S-H13 & D-H13 - MOBILE WELDING FUME EXTRACTION UNITS

Designed for mobile use in manufacturing or fabrication facilities, the European quality Metalmaster Mobile Welding Fume Extractors are a compact fume extraction and filtering unit. They provide filtration of fumes from Mig, Tig and Arc welding on all materials that produce intense fumes. Featuring a three metre long, 160mm diameter Exo-Joint swivel arm provides high velocity fume extraction. This unique arm design delivers up to 56 percent more air flow efficiency with its low drag characteristics when compared to pleated hose arms that require internal support.

S-H13 - SINGLE ARM

• Exclusive Exo-Joint high velocity extraction arm (160mm diameter)

• 23m2 HEPA filtration surface area providing respirable air back into the work environment

• High volume 1300 m3/h air filtering capacity

• Dirty filter warning light

• 240V 10amp power

MOBILE WELDING FUME BENCH

METALMASTER ClearAir mobile welding fume bench is a compact all in one downdraft table with 1120 x 825mm work area (with fume shroud closed)

• HEPA H13 filtration ensures a safe & comfortable work environment

• Dual stage filtering

• High volume 2000 m3/h air filtering cap.Fume shroud with left & right hinged doors for larger work pieces

$6,690 ex GST (W2715)

D-H13 - TWIN ARM

• High volume 2600 m3/h air filtering capacity

• 46m2 HEPA filtration surface area providing respirable air back into the work environment

• 2 x Exclusive Exo-Joint high velocity extraction arms (160mm diameter)

• Dirty filter warning light

• 415V 10amp power

WE-100 - WELDING FUME EXTRACTOR

IDEAL FOR EXTRACTING HARMFUL WELDING FUMES

• 2 speeds

• 390 m3/hour

• 3 metre hose

• 2 x 800W 240V motors

• Captures 99.97% of 0.3 micron noxious fumes

$2,090 ex GST (W270)

SPECIAL OFFER ONLY AVAILABLE FOR MANUFACTURER’S MONTHLY READERS SYDNEY (02) 9890 9111 1/2 Windsor Rd, Northmead BRISBANE (07) 3715 2200 625 Boundary Rd, Coopers Plains MELBOURNE (03) 9212 4422 4 Abbotts Rd, Dandenong PERTH (08) 9373 9999 11 Valentine Street, Kewdale $70 FREE DISCOUNT VOUCHERS $70 FREE www.machineryhouse.com.au/signup MM 240823

Exo Joint with Gas Strut Support Air Flow Control Valve for TIG Welding High Volume Fume Extraction Head Two Stage HEPA Filter System

European Quality

Ensures the highest airflow efficiency with low drag characteristics.

$4,350 ex GST (W2710K) $6,250 ex GST (W2711K) NEW RELEASE Filter door open Side doors openRear upweards return Air Vent

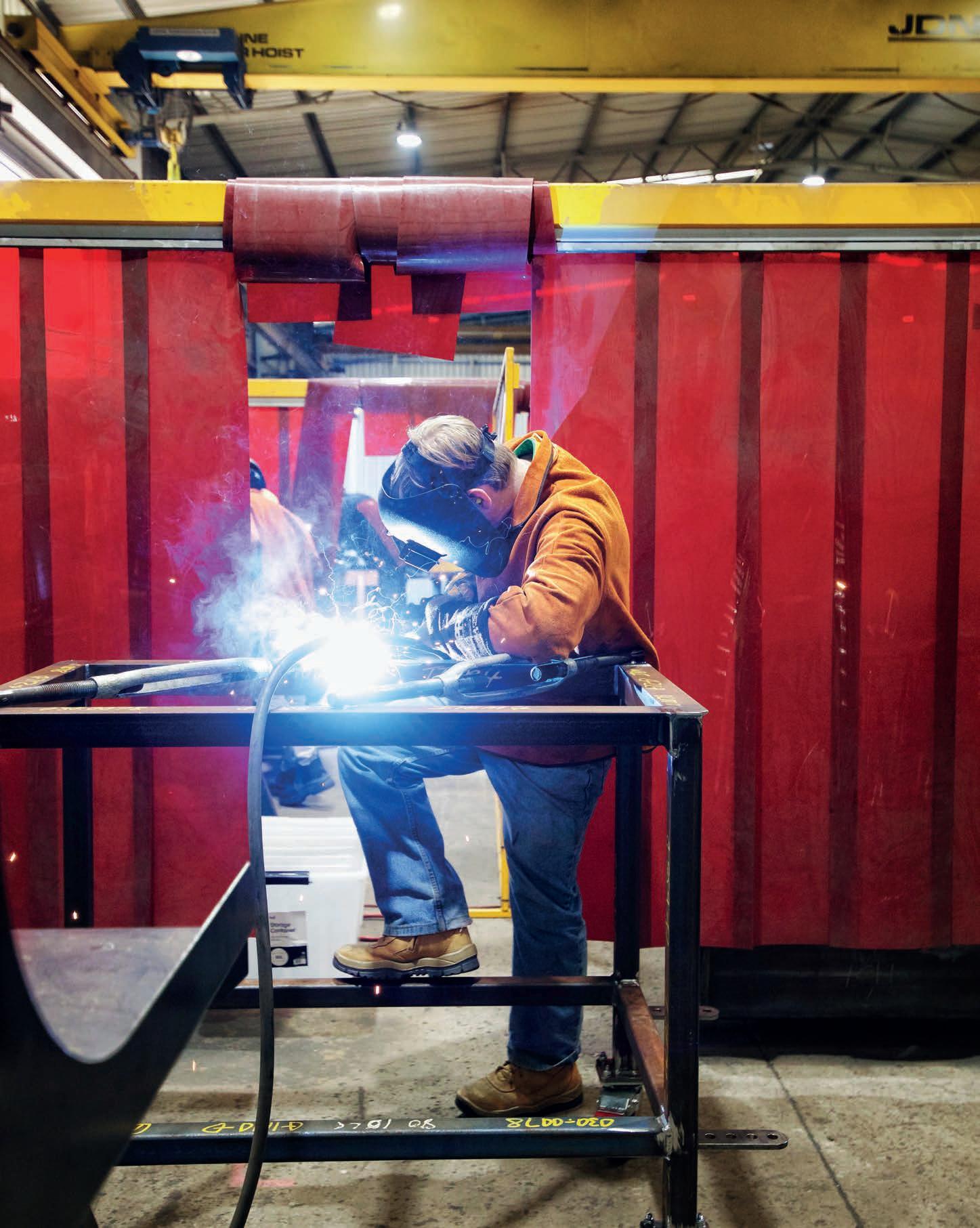

Revolutionising Welder Training: Introducing the New MEM Resources

WELDERS are more in demand than ever—labour shortages are inhibiting the growth of Australia’s welding industry. According to Weld Australia’s members, 50 per cent of Australia’s welding workshops are currently operating at 80 per cent of their capacity or below. When asked why this is, a lack of skilled workers was the overwhelming answer.

The Federal Government recently added an extra 39 occupations to the Australian Apprenticeships Priority List. The list has grown to encompass

to struggle with skills shortages across a range of different sectors—particularly welding and fabrication. 11 per cent of the occupations included in the Priority List are now related to welding.

This labour shortage comes as no surprise. Weld Australia has been calling for urgent action for over five years. We estimate that Australia will be at least 70,000 welders short by 2030.

And yet, the number of welding trade workers in Australia dropped by 8 per cent in the course of just five years, and completion rates of welding

much as 23 per cent annually.

For this reason, Weld Australia has designed and created a suite of resources for delivery of the 12 welding and fabrication units of competency in the Manufacturing and Engineering (MEM) Training Package. Our goal is to help ensure that high-quality welder learning is consistent across the country.

Our resources help simplify the learning process for students, teachers and training institutes and—most importantly—place the student at centre of the learning process.

Weld Australia believes that a national industry, which has a national learning package, needs national learning resources. Whether you’re an apprentice in Kalgoorlie, Ultimo or Davenport, you should have access to the same, highquality training.

How the resources were created

Weld Australia formed a national consortium of TAFEs to work on the project. Over the last two years, the consortium has collaborated with us to develop the most engaging, up-to-date resources possible.

Members of the consortium piloted use of the resources, and some TAFEs have already permanently adopted them.

South Metropolitan TAFE in Fremantle, Western Australia was the first training organisation to facilitate an official pilot. The feedback received from students and lecturers alike was extremely positive.

According to Jonathon Maile (Executive Director – Engineering, Transport and Defence, South Metropolitan TAFE), “The resources have been terrific, not only for our team here at South Metro TAFE, but we’ve also upheld these and shared these with some external customers as well. So from a quality perspective, the resources have been tremendous.”

“Being able to link in with Weld Australia and other TAFEs, improved training outcomes—there is a better consistency from a technical perspective Australia-wide. It has improved our focus on digitisation and e-learning, and

the increased the flexibility of how we deliver. We’re able to utilise these training resources in class to support lecturers. If apprentices miss classes, they can access the resources and catch up a lot more quickly than trying to reschedule another block later on.”

Brenda Micale (General Manager, Training Services at South Metropolitan TAFE) agreed. “The resources have improved our delivery across the fabrication area quite significantly. We’ve had some really great feedback from our industry partners too.”

“On our own, we could have developed an adequate suite of materials for the qualification. Through the national collaboration, we got a much higher quality resources. On a TAFE budget, we never could have got all the bells and whistles—the videos, the eLearning—it’s just financially out of our reach.”

“It’s great when I go out to Rockingham, the Thornley and Naval Base campuses where fabrication is taught and you can see apprentices engaging with the technology. They’re able to download it onto their mobile phones, they can play the videos, its interactive.”

A purpose built platform

The online platform that houses all the MEM resources is called Weldpool.

Weldpool is Weld Australia’s purpose-designed Moodle platform that integrates easily with your own Moodle, or a blackboard website. The purpose of Weldpool is to provide a simple user interface where student can find the resources they need as quickly as possible.

Weldpool helps ensure that the MEM resources are as flexible as possible. Students can use the platform to watch demonstrations before they get to class, or instructors can use the demonstrations as teaching aids during classes.

Online, accessible and engaging

The new MEM resources are completely online and accessible via phone, mobile device or computer. This allows students to access learning at the time, place and

10 SEPTEMBER 2023 Manufacturers’ Monthly manmonthly.com.au

Weld Australia has developed a digital platform to house its training information with a number of TAFEs.

– CEO, Weld Australia

Comment

pace that suits them best. In one of our units, you can expect:

Theory presentations

• Practical demonstrations

Written resources, including student and safety notes complete with hot tips, QR codes to access videos, and review questions

• Online review quizzes, which are fuelled by a bank of multiple choice, short answer and interactive questions.

There are also Soldamatic specific presentations available, for facilities equipped with augmented reality simulators.

How Weld Australia’s MEM Resources can help

Weld Australia’s MEM Resources have been built with students, teachers and training organisations in mind. It reimagines the learning process with its user-friendly interface, diversified delivery methods, and audited and accurate material.

resources are completely online and accessible via mobile device (like phones and tablets) or computer

This allows students to access learning at the time, place and pace that suits them best.

• Easy to use. The platform on which all the resources are hosted features a simple, easy to navigate user interface where students can find what they need as quickly as possible.

• Better use of on-campus time. With a comprehensive suite of resources at their fingertips, students can focus on developing their practical skills while on-campus, rather than reading through theory.

Unlimited access. Students have unlimited access to all resources, throughout their entire period of enrolment in the unit. This means students can go back and revise material if they need to.

multiple delivery methods available, including lock step, workplace delivery, institutional delivery, selfpaced learning and distance learning. Every option is covered, for a flexible solution.

• Avenues to provide regular feedback. Teachers can submit feedback which will be reviewed by Weld Australia’s team of experts and incorporated into the relevant resources as quickly as possible.

• Save time. With a comprehensive suite of resources at their fingertips, teachers slash preparation and administration. Leaving more time to devote to students or reducing overall working hours.

Peace of mind. Teachers can rest assured that all units of competency are covered in full by the up-to-date suite of resources. Students will be fully prepared to pass exams and enter the workforce.

costs on both the development and maintenance of resources. Resources will be reviewed annually and updated in line with latest technology and training packages.

Standardised. Training organisations can rest assured that all their teaching material is consistent across all their campuses, regardless of the staff involved.

• Audited and accurate. All resources are fully mapped to the units of competency and independently audited by a team of experts. All resources have been vetted by a consortium of TAFEs nationally.

• Easily integrated. The online platform that houses all the MEM resources is called Weldpool. Weldpool is a purpose-designed Moodle platform that integrates easily with your own Moodle, or a blackboard website.

For further information about the new MEM resources, email training@weldaustralia.com.au

manmonthly.com.au Manufacturers’ Monthly SEPTEMBER 2023 11

The online platform that houses all the MEM resources is called Weldpool.

$60 million in grants to transform plastics recycling

NSW businesses are being encouraged to apply for a grant under a new $60 million national program to transform plastic waste into valuable products.

The Australian Government’s Recycling Modernisation Fund (RMF) Plastics Technology stream will boost existing recycling infrastructure and uncover new methods of processing plastics that are difficult to recycle.

NSW businesses can apply for grants of between $1 million and $20 million per project.

There will be a focus on projects that take hard-to-recycle plastics, including soft plastics like shopping bags, bread bags and cling wrap, and recirculate them back into the economy in a safe and sustainable way.

NSW Minister for the Environment, Penny Sharpe spoke about why a project such as this is so important for the environment.

“NSW generates around 800,000 tonnes of plastic waste every year, but only

limiting impacts on the environment, but we can also transform waste materials into

technology and processes. This program will help NSW drastically

reduce its reliance on plastic and progress

For further information on the program and application process visit the NSW Environment Protection Authority launch.

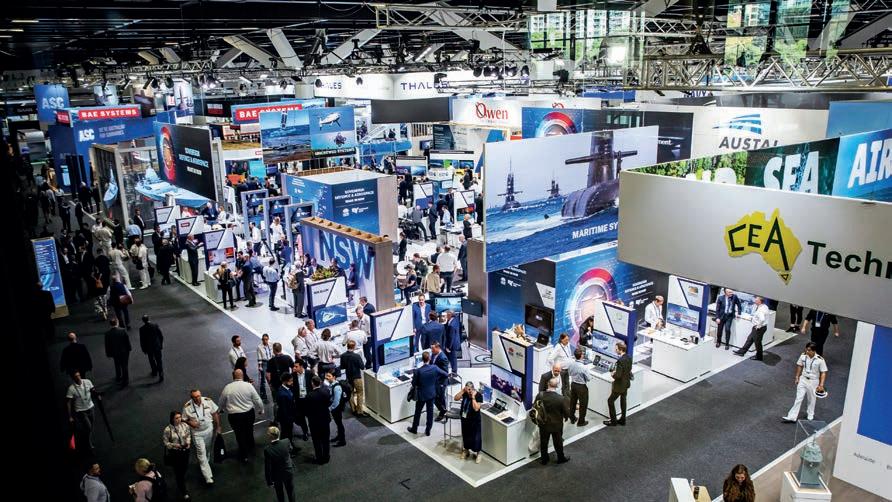

Victoria’s largest-ever land defence contract win

Hanwha Defense Australia has won a multi-billion-dollar defence contract to build Australian military vehicles in the Geelong region, delivering significant benefits for the state’s economy and creating hundreds of highly skilled local jobs.

Minister for manufacturing

sovereignty Ben Carroll congratulated Hanwha Defense Australia on its successful bid to deliver the Commonwealth Government’s LAND 400 Phase 3 program, which will see the company build and maintain 129 Infantry Fighting Vehicles called the Redback for the Australian Army.

Hanwha will deliver the LAND 400 Phase 3 program and the $1 billion LAND 8116 program – creating around 600 direct jobs and hundreds more indirect jobs throughout Victoria across the supply chain.

The vehicles will be made at Hanwha’s $170 million Armoured Vehicle Centre of Excellence site under construction at the Avalon Airport Industrial Precinct.

The Victorian Government is

supporting local businesses to join Hanwha’s supply chain through the $10 million Victorian Land Systems Fund. More than 500 businesses will have the opportunity to work with Hanwha and its global partners in delivering the Land 400 Phase 3 program – creating more job opportunities for Victorians.

Hanwha Corporation is South Korea’s largest defence company and operates in aerospace, fintech, mining and clean energy. Hanwha Defense Australia was established in 2019 and is headquartered in Melbourne.

Victoria’s defence sector is made up of 6,300 businesses, employing around 24,300 people and contributing $8.4 billion to the state’s economy each year.

Victoria continues to build on the state’s reputation as the destination of choice for high-value defence projects by attracting major global companies like BAE Systems, Boeing, Hanwha, Leonardo, Lockheed Martin and Thales.

Hanwha’s presence in Geelong, along with Thales’ operations in Bendigo and Benalla, positions Victoria as unrivalled

by any other state in Australia in the production of land system vehicles.

“Victoria is the nation’s manufacturing capital and our defence expertise has helped Hanwha to secure this project, creating hundreds of jobs for Geelong,” minister Carroll said.

Member for Lara Ella George said, “We’ve backed Hanwha to set up in

Geelong and the company winning this contract means hundreds of high-skilled jobs for our region,” she said.

Hanwha Defense Australia managing director Richard Cho said, “We are excited for the next phase of this program that will see HDA and Australian industry deliver a world class IFV to the Australian Army.

12 SEPTEMBER 2023 Manufacturers’ Monthly manmonthly.com.au News @MM

The announcement is expected to create 600 direct and hundreds more indirect jobs in Victoria.

The grants will allow businesses to upgrade or acquire new equipment.

NSW government to hold roundtable on future of rail manufacturing

The New South Wales and Australian Governments are holding a joint roundtable on the future of rail manufacturing, bringing together more than 100 of the most important and influential representatives of Australia’s rail manufacturing industry.

An initiative of the NSW and Australian Governments, this is another step in the process of mapping out a plan to restore and strengthen this critical industry in NSW and across Australia.

The roundtable included a wide range of representatives including rolling stock manufacturers along with small- and medium-sized businesses and unions involved in the wider rail manufacturing supply chain.

It will also involve academics, companies involved in research and development, along with transport and infrastructure department representatives from the Commonwealth, NSW and other states.

The NSW Government will use the roundtable as an opportunity to hear directly from the rail manufacturing industry about what is working while also discussing barriers to further industry investment.

NSW Premier Chris Minns spoke about the importance of this roundtable for the manufacturing sector.

“This is a critical first step on the path to our commitment to build the next generation of trains that replace the Tangaras here in NSW,” he said.

“The only way we can rebuild our NSW rail manufacturing industry in a sustainable way is if we work with the Federal Government on a coordinated, national approach.

“This important work will give our companies and workers the best chance to compete with their overseas rivals.

“I want to thank Assistant Minister Ayres and the Albanese government.

Today is a really good start,” Minns said NSW supports the development of a nationally-coordinated approach to rail manufacturing, supporting the development of a sustainable, ongoing work-stream for industry.

NSW will work with the Australian Government, industry and other states to see where we can put aside state rivalries and work together in the national interest.

Assistant Federal Minister for Manufacturing Senator Tim Ayres spoke to the announcement of the roundtable.

“We want trains and rollingstock that

are built and designed in Australia for Australian conditions,” he said.

“The National Rail Manufacturing Plan is the key component of the Albanese government’s plan to see more trains built and designed by Aussies.

“Our plan will ensure the sector is better placed to take advantage of the upcoming opportunities in rail procurement by driving a more nationally coordinated approach to rail manufacturing, to provide the certainty industry needs to invest in Australia,” he said.

manmonthly.com.au Manufacturers’ Monthly SEPTEMBER 2023 13 News @MM

Chicago Pneumatic

our end

and distributors’ performance,

our

providing reliable products

all times. www.cpcompressors.com.au 1300 555 284 YouTube-LinkedIn-Facebook Experience the Power of Red 0923 CP HP ManMonthly.indd 1 9/08/2023 2:40:22 PM

Brand new CPM, CPE series – 55-132kW Pioneering components make a revolutionary range, high performance in-house design element, high efficiency air filter, bionic design of fan and more.

value

users’

and do

ultimate best to make it easy to work with us while

with a passion. That is how we keep you productive at

The NSW government is committed to improving the rolling stock manufactured in Australia.

$5 million committed for green hydrogen project in Northam

Northam is set to be home to one of the first end-to-end green hydrogen production systems in Western Australia, aimed at supplying the domestic transport market.

The system, dubbed the MEG HP1 Hydrogen project, will be built in partnership by Infinite Green Energy, Korean Samsung C&T and Doral Energy Group with $5 million support from the WA Government’s Investment Attraction Fund.

Funding will go towards two five megawatt (MW) electrolysers to establish a hydrogen production ecosystem, hydrogen storage compression technology and general construction.

Hydrogen Industry Minister Bill Johnston spoke about the importance of this announcement.

“The $5 million, from the Investment Attraction Fund, will help Infinite Green

Energy establish Western Australia’s first renewable green hydrogen production system,” he said.

“This is an important step to help kickstart the development of an end-user market for locally produced green hydrogen.”

“The construction, commissioning and ongoing maintenance of the MEG HP1 Hydrogen project is expected to create over 100 jobs and help decarbonise the State’s economy,” Johnston said.

Green hydrogen produced by the project aims to be a cost competitive, environmentally friendly alternative to other forms of transportation fuels such as diesel.

Once operational, the project is expected to produce around four tonnes of hydrogen each day, for use in back to base and heavy transport

operations, including garbage collection trucks.

The first production of hydrogen is expected in late 2024 and will utilise an already existing 11MW solar farm.

Launched in March 2022, the WA Government’s Investment Attraction Fund was developed to attract new investment in the State and create local jobs.

14 SEPTEMBER 2023 Manufacturers’ Monthly manmonthly.com.au

News @MM

This is Western Australia’s first renewable green hydrogen production system.

News @MM

Harvard’s economic complexity ranking shows Australia’s luck is running out

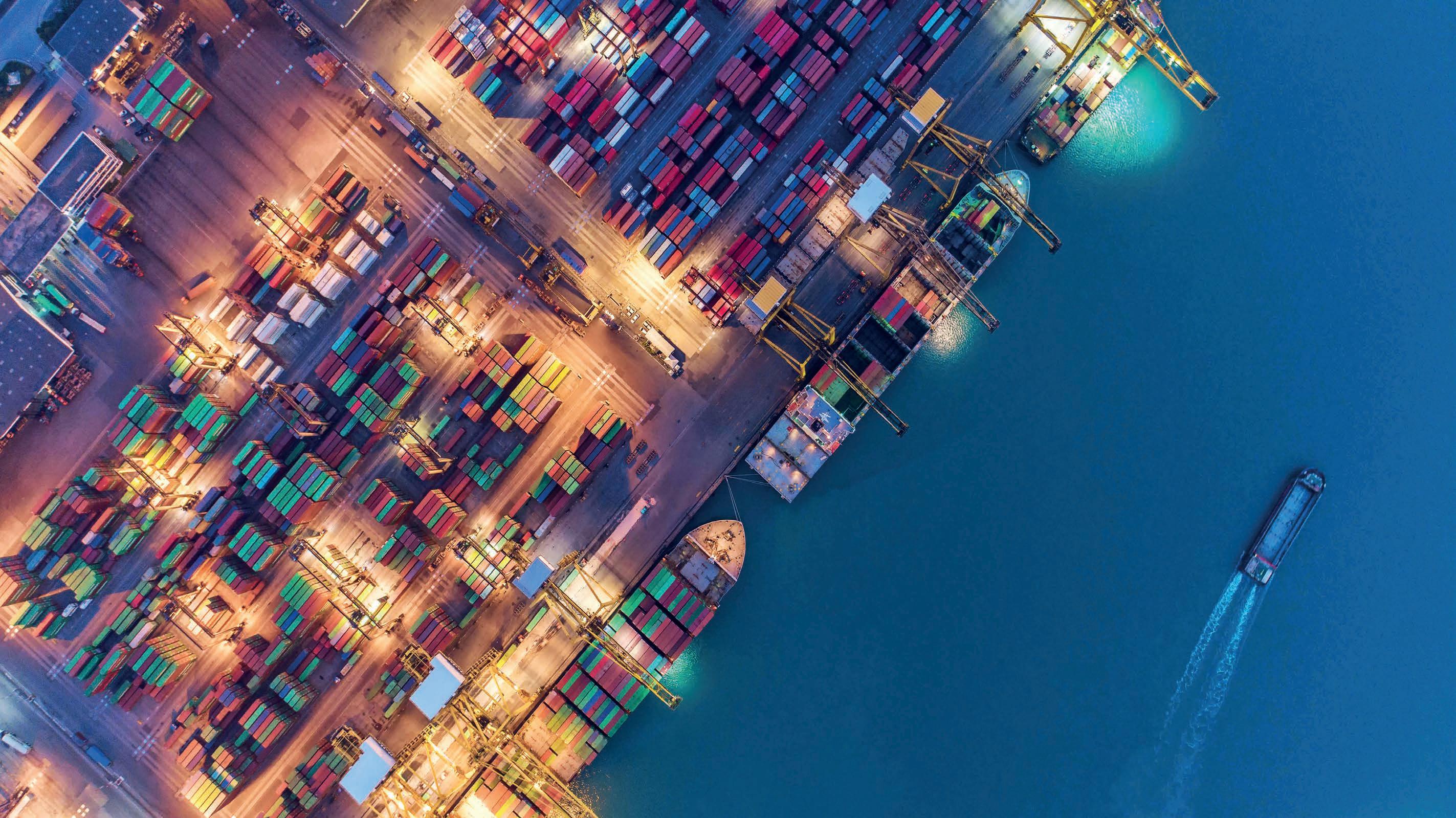

Australia’s over-reliance on exporting items of low complexity has been laid bare in data released by the globally respected Harvard Kennedy School which reveals that Australia’s Economic Complexity Index (ECI) rating has plummeted to 93rd, down 12 positions in the past ten years.

The Harvard Index systematically ranks 133 countries by their ability to manufacture and export diverse and complex items and services and has been a global benchmark of a nation’s global impact since 1995, when Australia ranked 55 on the index.

The continued fall in ECI rankings now places Australia between Uganda and Pakistan in the bottom third of monitored nations for economic complexity. The poor ranking means Australia continues to hold the unenviable position of the lowestranked OECD country, despite the nation’s high level of wealth.

The ECI brings into sharp focus the imperative for Australia to boost its economic complexity by adding value to its natural resources and commercialising world-leading ideas through making more complex things, which is also called manufacturing.

Managing director of the Advanced Manufacturing Growth Centre (AMGC) Dr Jens Goennemann spoke to the findings.

“Australia’s continued fall in ECI rankings is completely predictable. If this is to change, then we must focus on transitioning away from a luck-based economy to becoming smarter if we are to protect our high standards of living and prosperity into the future,” Goennemann said.

“There is no excuse for Australia’s poor ECI ranking and our continued decline shows Australia’s luck is on borrowed time. We have the human capital, abundant natural resources, and capable yet subscale manufacturers. The missing piece of

the puzzle is long-term focus through continuity of programs and investment for industry – which other countries do well.

“We must invest now while the times are good to ensure that we have a robust manufacturing industry making the high value, highly complex items the world needs to whether future bad times and to give our children meaningful and resilient jobs.” he said.

The report states that “Australia has seen a troubling pattern of export growth, with the largest contribution to export growth coming from low and moderate complexity products, particularly Ores, slag and ash and Mineral fuels, oils and waxes products.”

Goennemann explored how this can be rectified in the future.

“The future looks quite bleak unless

serious long-term strategy and capital commitments are made to turn the tide of Australia’s continued complexity decline. “It is also incumbent on Australian industry to band together, collaborate and focus its efforts beyond the Australian domestic market if we want to safeguard our future prosperity and lift our global influence,” he said.

Since its inception in 2015, the Advanced Manufacturing Growth Centre (AMGC) has advocated and demonstrated the potential of Australia to grow the complexity of its exports through co-investing in local manufacturing excellence.

More recently, AMGC has advocated that the Federal Government’s forthcoming National Reconstruction Fund (NRF) and Industry Growth Program

(IGP) should feature initiatives to assist Australia’s 40,000 small-to-medium-sized manufacturers commercialise their ideas and scale, generating jobs and prosperity along the way.

AMGC has successfully demonstrated how to build capability and scale through its well-managed $57 million coinvestments targeted directly to Australia’s manufacturing SME’s.

AMGC’s co-investments of 141 projects have committed a dedicated research partner to commercialise research findings by helping to resolve real-world manufacturing challenges and lifting product complexity along the way.

These projects are expected to generate over 4,200 new highly skilled, and wellpaid roles, and on completion will return $1.6 billion to the economy.

manmonthly.com.au Manufacturers’ Monthly SEPTEMBER 2023 15

Dr Jens Goennemann from the AMGC spoke about what Australia must do to arrest this decline.

News @MM

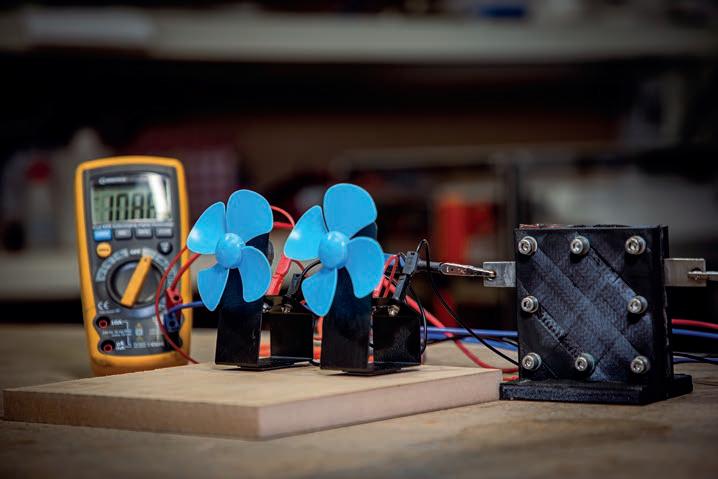

Proton battery promises cheap and sustainable energy storage

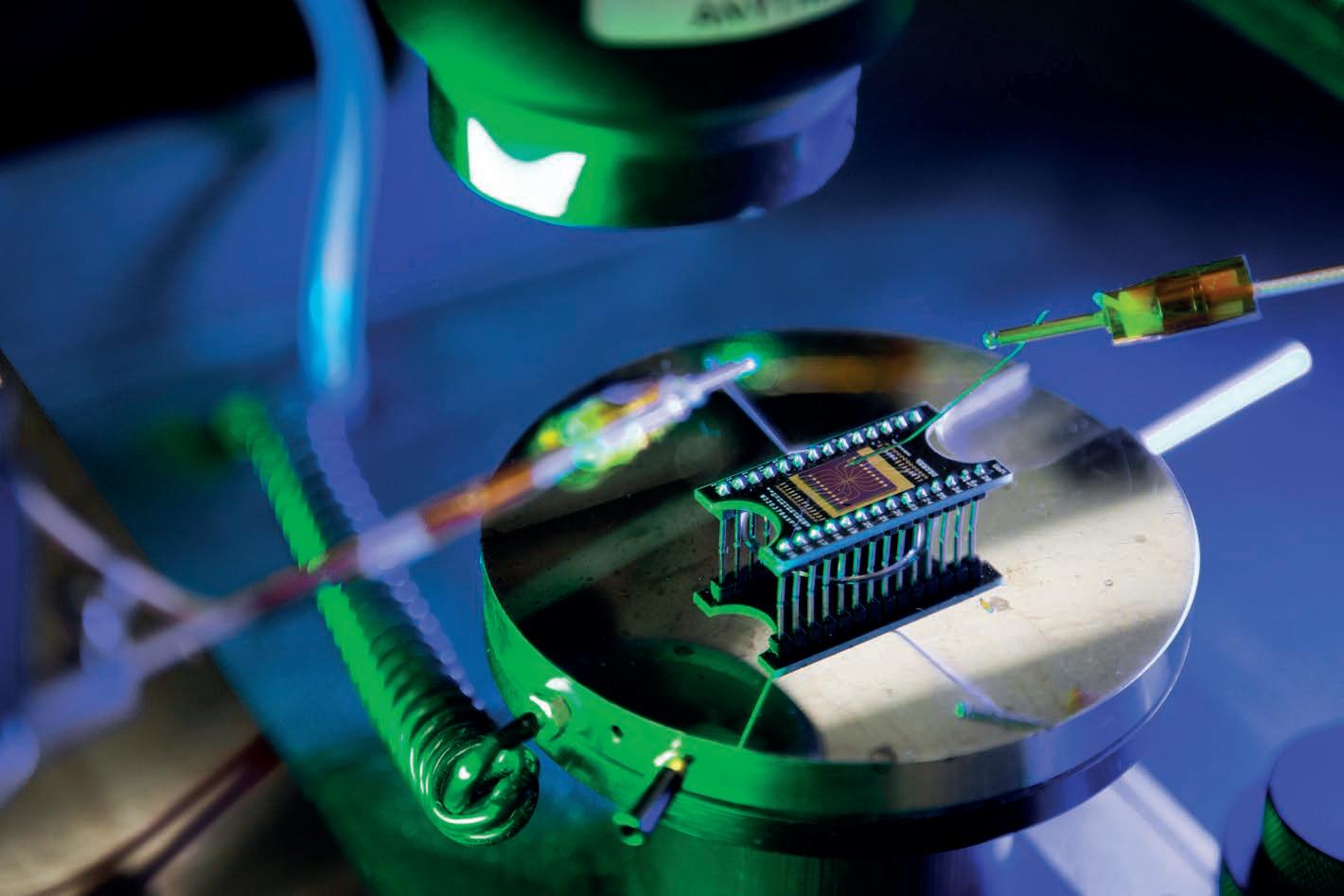

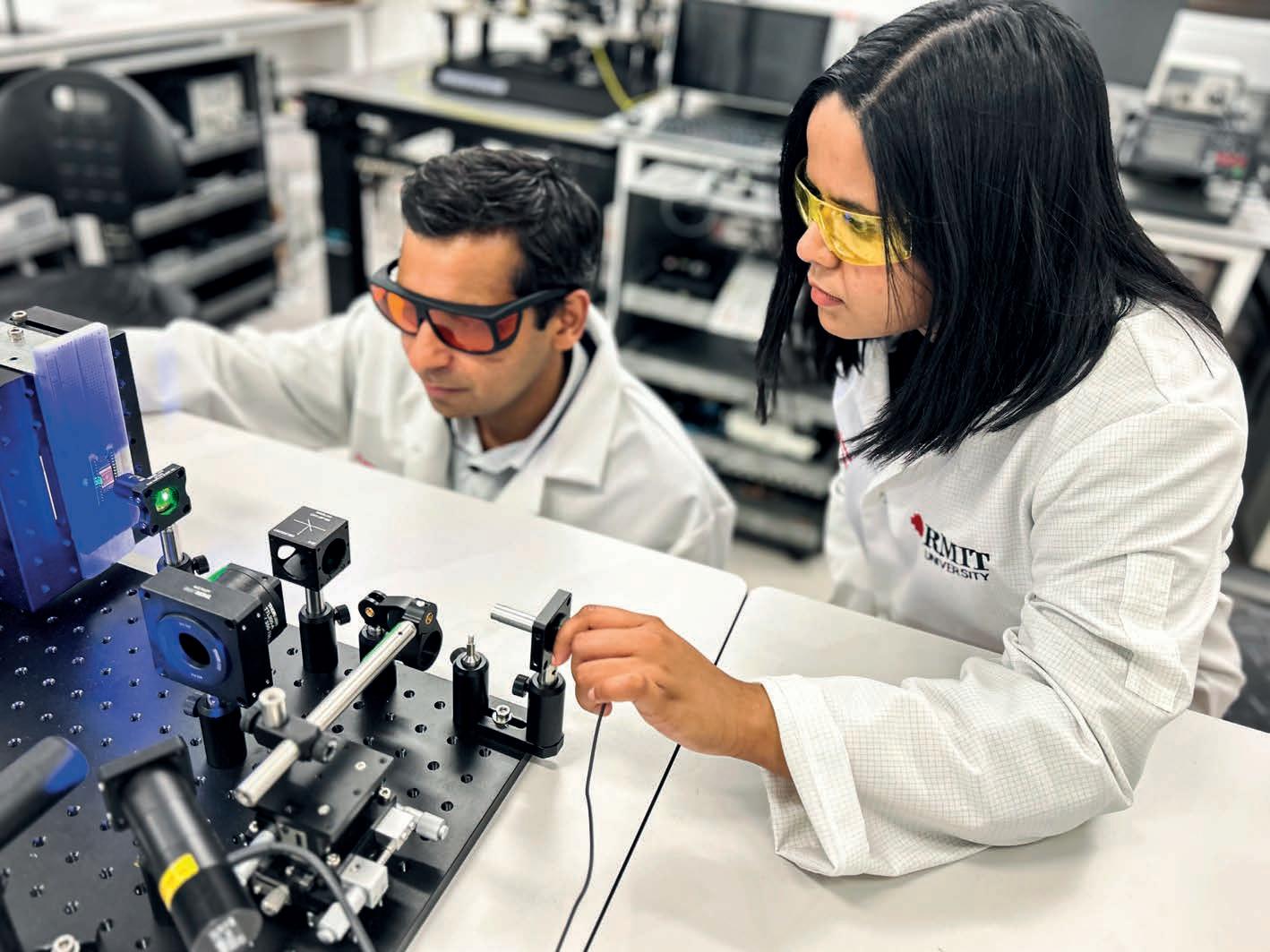

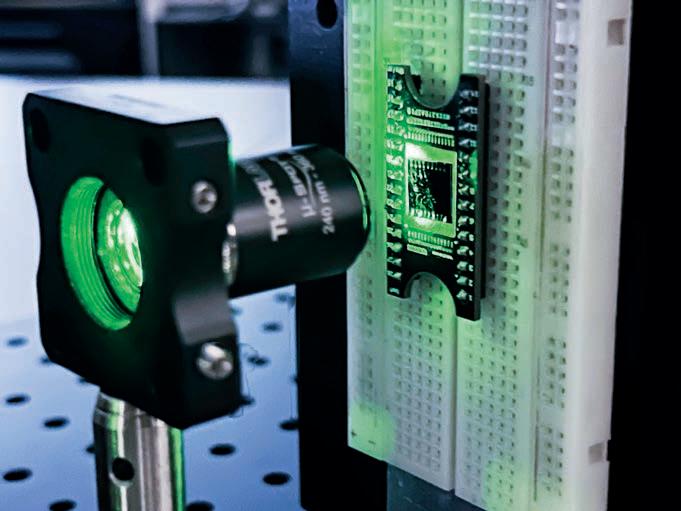

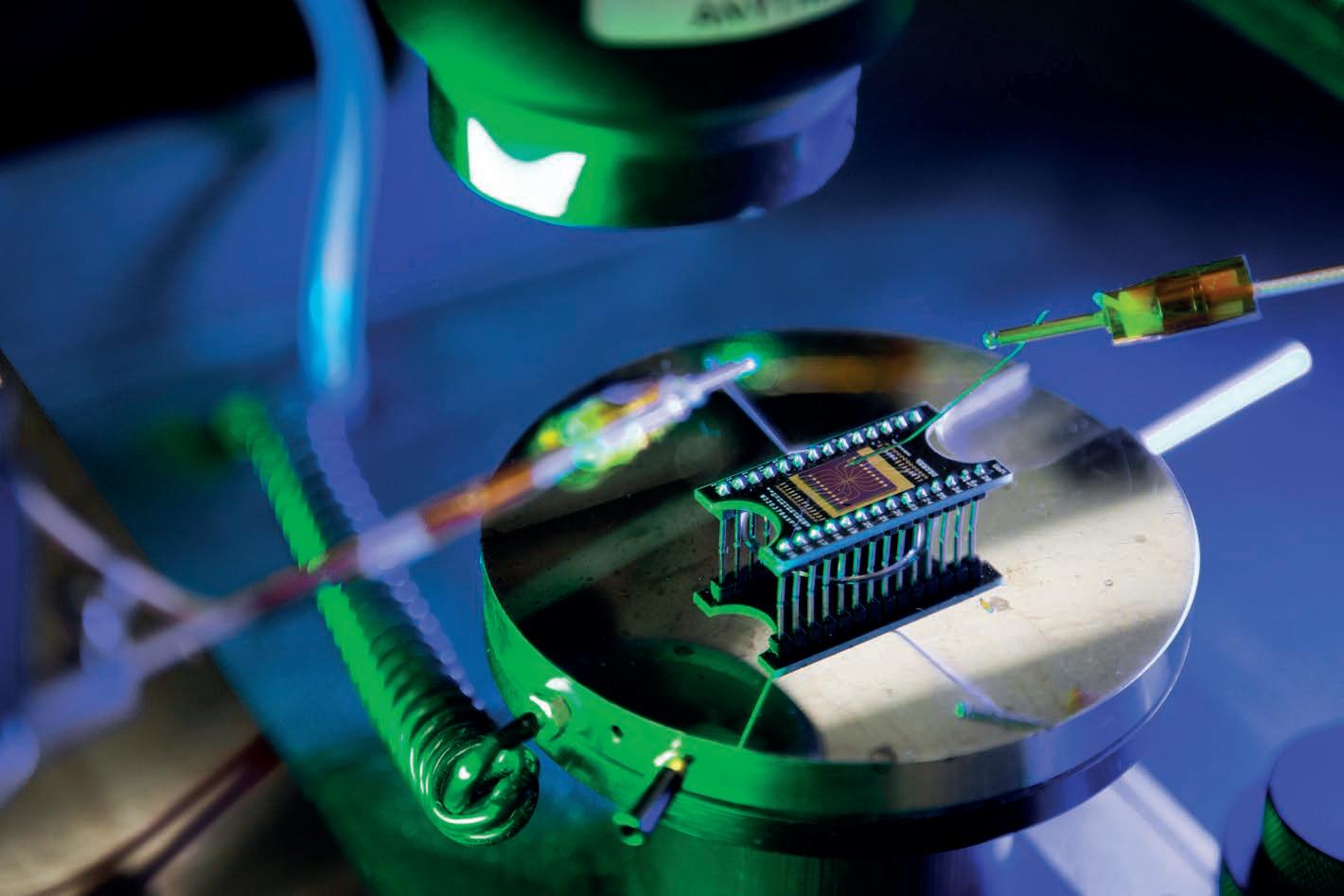

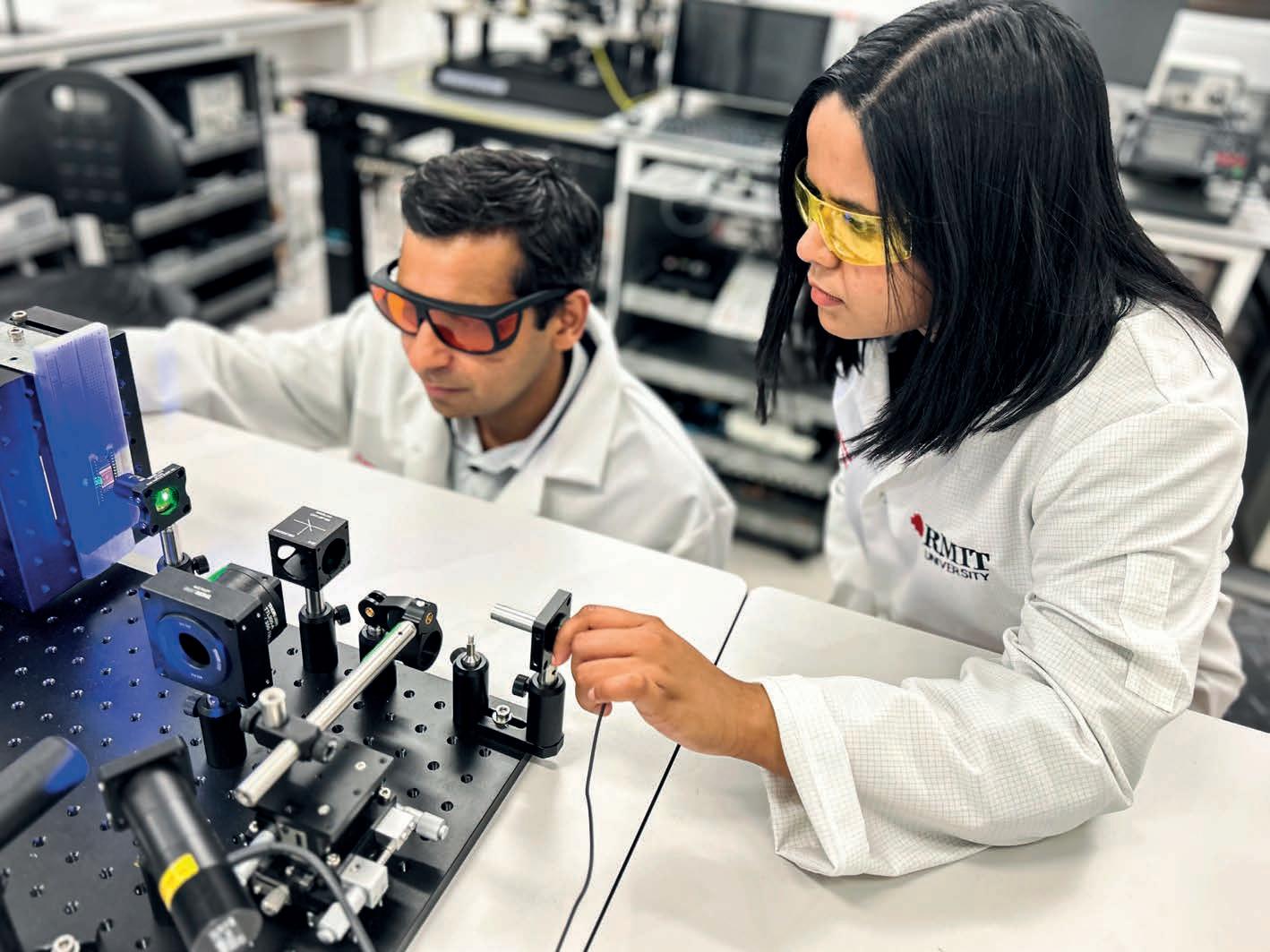

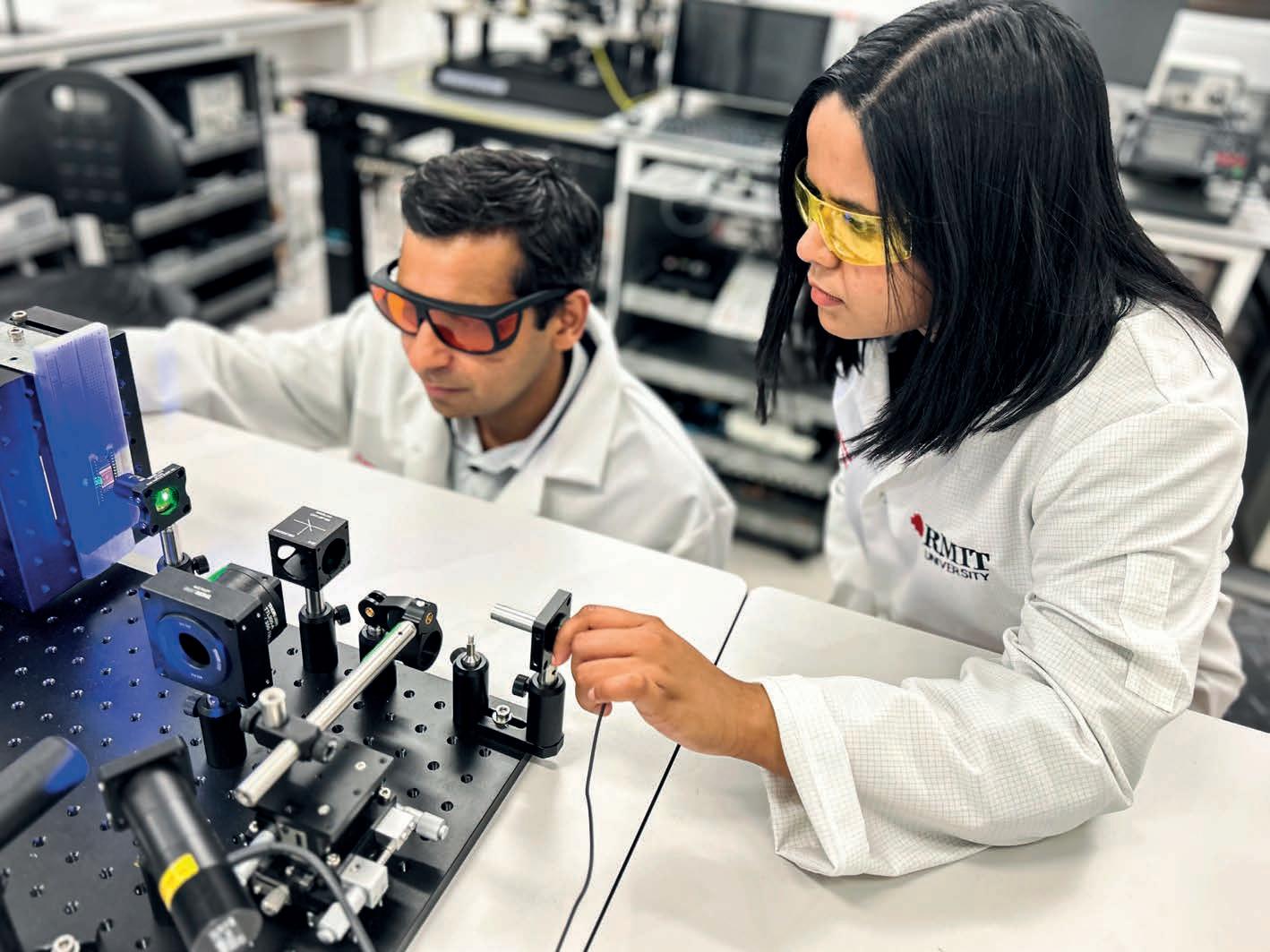

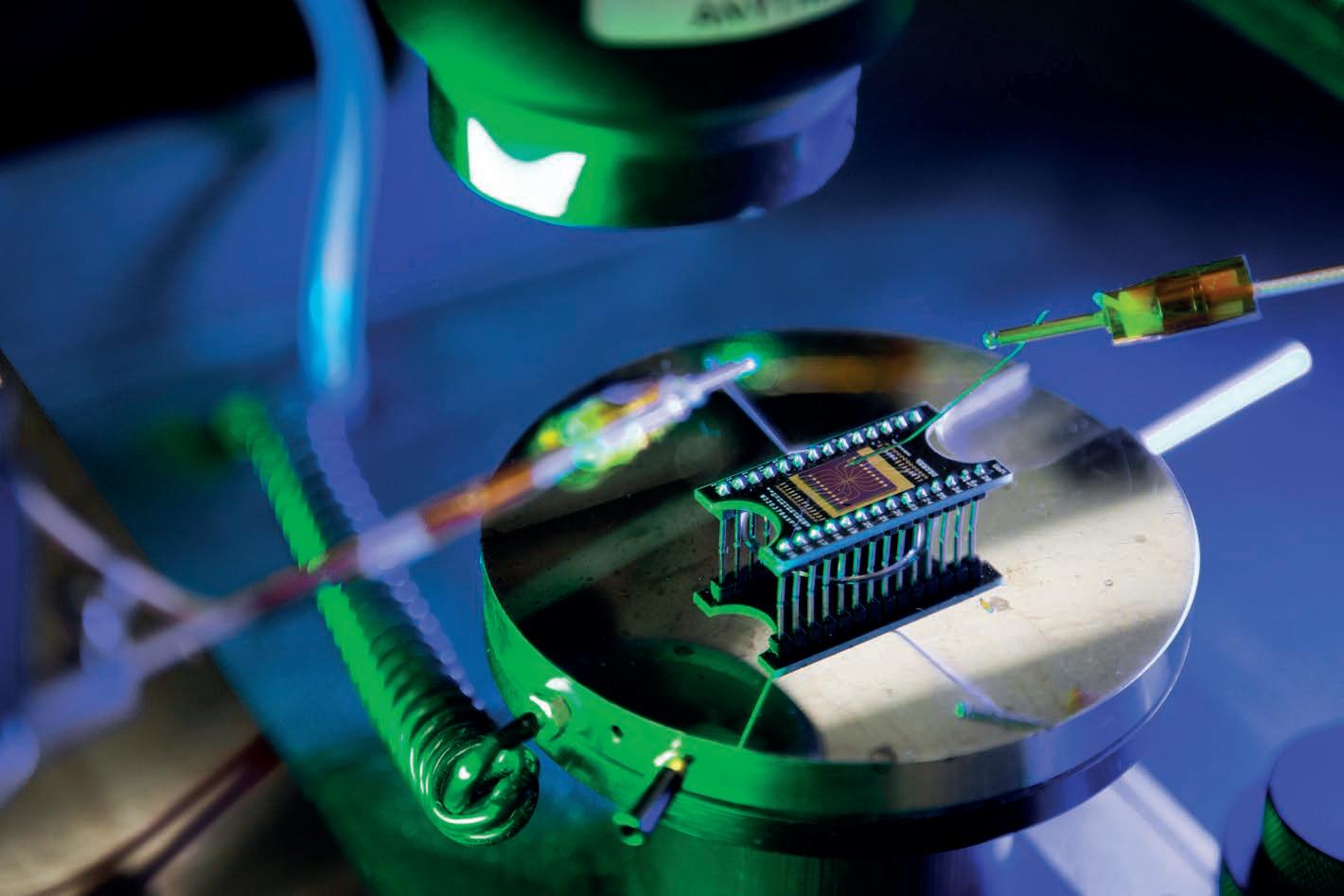

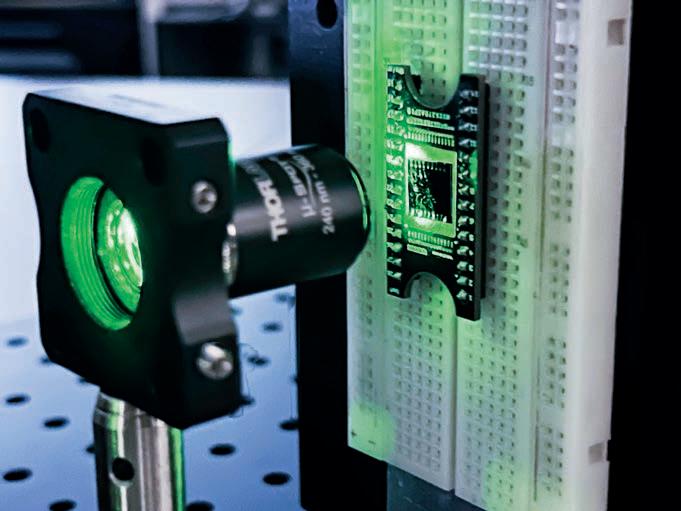

An experimental ‘proton battery’ by RMIT researchers could one day be developed to power homes, vehicles and devices –without the end-of-life environmental challenges of lithium-ion batteries.

RMIT has patented the latest developments in this technology internationally.

The battery uses a carbon electrode to store hydrogen that’s been split from water and then works as a hydrogen fuel cell to produce electricity.

The RMIT University team is now embarking on a two-year research collaboration with the Italian-based international automotive component supplier, Eldor Corporation, to develop further and prototype this technology. RMIT has been collaborating with Eldor over the past five years on the same technology.

Lead researcher Professor John Andrews said recent design improvements to their proton battery meant it was becoming competitive as a carbon-neutral alternative to lithiumion batteries.

“As the world shifts to intermittent renewable energy to achieve net-zero greenhouse emissions, additional storage

options that are efficient, cheap, safe and have secure supply chains will be in high demand,” said Andrews, from RMIT’s School of Engineering.

“That’s where this proton battery – which is a very equitable and safe technology – could have real value and why we are keen to continue developing it into a viable commercial alternative.

“There are also no end-of-life environmental challenges with a proton battery since all components and materials can be rejuvenated, reused or recycled,” he said.

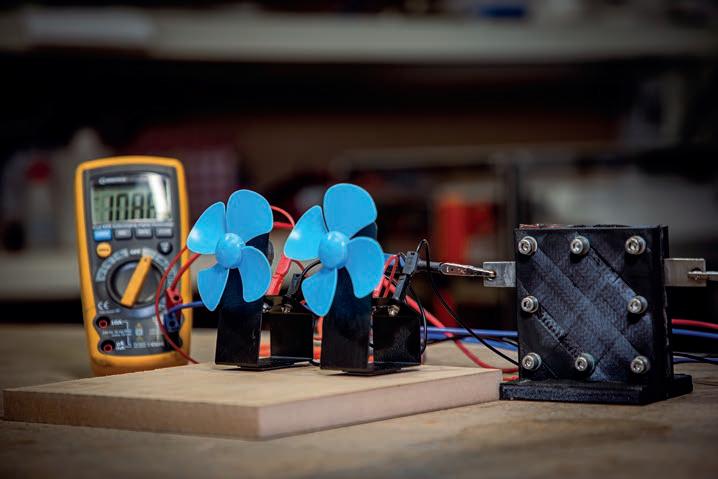

The team has demonstrated the proton battery as a working device that can power several small fans and light for several minutes.

Andrews said their latest battery’s storage capacity of 2.2 weight per cent hydrogen in its carbon electrode was nearly three times that of their 2018 prototype, and more than double other reported electrochemical hydrogen storage systems.

“Our battery has an energy-perunit mass already comparable with commercially-available lithium-ion batteries, while being much safer and better for the planet in terms of taking less

resources out of the ground,” he said.

“Our battery is also potentially capable of very fast charging.

“The main resource used in our proton battery is carbon, which is abundant, available in all countries and cheap compared to the resources needed for other types of rechargeable battery such as lithium, cobalt and vanadium.”

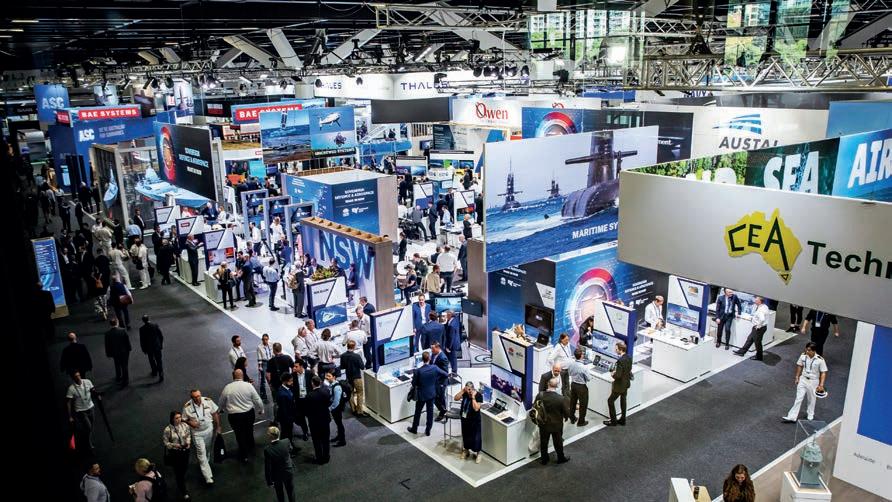

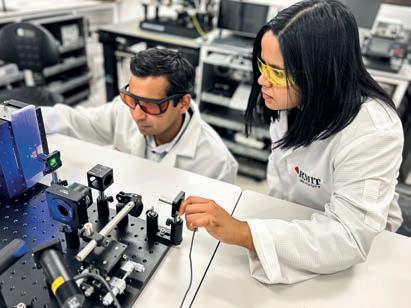

Trailblazer program to create defence industry of the future

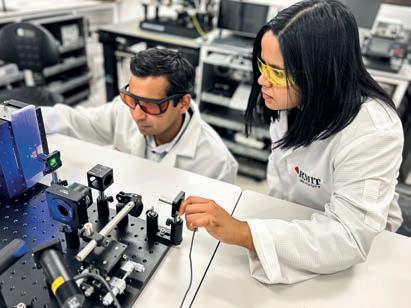

Assistant minister for education Anthony Chisholm has launched the $240 million Trailblazer Universities program in Adelaide, which will generate innovative defence solutions and create thousands of new jobs.

Assistant Minister Chisholm said the Defence Trailblazer: Concept to Sovereign Capability project at the University of Adelaide and University of New South Wales (UNSW) will herald in a new era of innovation for the country’s defence industry.

“The Albanese Government is committed to supporting collaborative initiatives that produce innovative solutions to bolster our national security, create more employment opportunities

and grow the economy,” Assistant Minister Chisholm said.

“This project will focus on key areas such as defensive hypersonics, cyber technologies, robotics and AI, as well as defence space technologies, where Australian university research is wellplaced to strengthen our nation’s security.

“This research will directly contribute to an evolving defence sector in which technologies will be developed by Australians and commercialised through local companies and international partnerships.”

Assistant Minister Chisholm said the project was estimated to deliver $1.5 billion in terms of net economic benefit for the Australian economy over the next 10 years.

“It’s estimated the Defence Trailblazer project will develop 100 new products, directly create more than 1,000 jobs and another 1,400 additional jobs throughout the wider defence industry,” Chisholm said.

The project’s Industry Research Program will also offer students the chance to study research degrees through the University of Adelaide and University of New South Wales. This will improve the acceleration of ideas into commercial application, while giving students the opportunity to work directly with industry partners.

These partners, who include Boeing Defence Australia, CAE Australia and Cisco, will contribute more than $140

The planet’s supply of lithium is concentrated in just a few countries, while other metals such as cobalt that go into lithium batteries are increasingly scarce and costly.

The recent performance gains have been achieved by design changes that enhance electrochemical reactions in the battery.

million to the project over the next four years. This is on top of the Australian Government’s $50 million commitment through the Trailblazer program, as well as the University of Adelaide and UNSW’s contribution of a further $50 million.

“Defence Trailblazer is a once in a generation opportunity to help transform the defence innovation ecosystem, bringing together defence, industry and academic partners to accelerate the delivery of sovereign capabilities for the nation’s security and prosperity,” said Defence Trailblazer executive director, Dr Sanjay Mazumdar.

The launch at the National Wine Centre, Adelaide, provided an opportunity for attendees to hear from a

16 SEPTEMBER 2023 Manufacturers’ Monthly manmonthly.com.au

The hydrogen fuel cell technology in the battery is an exciting development by RMIT.

News @MM

distinguished line up of speakers to gain invaluable insights into the program’s vision, mission, and key deliverables.

Keynote speakers:

Senator the Hon. Anthony Chisholm, assistant minister for education, assistant minister for regional development

Professor Peter Høj AC, vicechancellor and president, the University of Adelaide

Professor Attila Brungs, cicechancellor and president, UNSW

Sydney

• Dr David Kershaw, chief science strategic planning & engagement, Defence Science Technology Group Dr Scott Beinke, research engineer associate manager, STELaRLab, Lockheed Martin Australia

• Dr Sanjay Mazumdar, executive director at Defence Trailblazer. The event featured exhibits showcasing the technological capabilities of both universities as well as demonstrations from industry partners DTEX Systems, Quantx Labs and Silentium Defence.

manmonthly.com.au Manufacturers’ Monthly SEPTEMBER 2023 17

Defence is a strong focus for the Australian government.

News @MM Generative Ai could contribute $5 billion annually to Australia’s manufacturing sector by 2030

A new report says Australia’s manufacturing sector could unlo ck billions of dollars in value by 2030 if it accelerates the responsible adoption of generative artificial intelligence (GAI).

The report, Australia’s Generative AI Opportunity, is a collaboration between Microsoft and the Tech Council of Australia. It shows that GAI could contribute between $45 billion and $115 billion a year to Australia’s economy by 2030 through two major channels: improving existing industries and enabling the creation of new products and services.

Manufacturing has been identified as one of the four key sectors of the Australian economy poised to benefit from GAI. The report demonstrates that the technology could contribute between $2 billion and $5 billion annually to the manufacturing sector by 2030.

Kate Pounder, Chief Executive Officer at the Tech Council of Australia, said the report underscores the enormous economic potential of GAI for the manufacturing sector. However, she warned that the sector risks falling behind other industries in the adoption of this technology if it fails to accelerate its digital transformation.

“Generative AI has the potential to redefine the industry, playing to Australia’s strengths of producing highquality and highly technical products. But the sector needs to accelerate its

Ai promises to assist Australian manufacturing if used correctly.

digital transformation to make the most of this significant opportunity.”

Unlocking the potential benefits of GAI for manufacturing

AI is already applied by manufacturers in areas such as predictive maintenance (where data is used to enable manufacturers to predict equipment failures or maintenance needs), quality control (systems that can detect product defects or anomalies) and robotics (where AI is used to automate repetitive and labour-intensive tasks).

GAI technology can further uplift the sector by using data patterns to generate new content such as images, text or designs. This can impact manufacturing areas where AI hasn’t been used, including designing or recommending products based on trending features, upskilling apprentices and technicians, and automating supply network controls.

For managers in the manufacturing sector, the report estimates that GAI could automate approximately 30 per cent and augment 19 per cent of tasks, leaving more time for complex and strategic activities. It can also enhance the on-the-job learning for technicians –who comprise 27 per cent of the sector’s workforce – and trades workers through rapid upskilling and training.

“Generative AI will redefine the flow of work and drive efficiencies across enterprises, from the manufacturing

floor to knowledge workers. This presents significant opportunities for our industry, to make knowledge more accessible, increase productivity and the ability to address business challenges at scale.” said Angus Melbourne, Chief Technology Officer at Orica.

However, the report cites several challenges facing the sector in its adoption of GAI. While 72 per cent of manufacturers have increased their digital transformation efforts throughout the COVID pandemic, only 20 per cent currently use AI. If this is not addressed, the industry’s lagging investment in digital technologies could cause it to fall behind other sectors in harnessing the full potential of GAI.

Lee Hickin, Chief Technology Officer at Microsoft Australia and New Zealand, said: “We’re proud to partner with the Tech Council on this timely report. Generative AI has emerged as a transformative technology in 2023, with its adoption growing rapidly across various sectors in Australia. There’s a huge opportunity for the manufacturing sector as it deploys generative AI to support workforce transformation, enhance smart factories and supply chain resilience, and accelerate innovation.

“Microsoft is committed to fostering closer collaboration between industry and government to ensure the nation can realise the potential economic benefits of generative AI, and do so responsibly.

Building trust in this technology is critical to harnessing its innovative capabilities and enabling Australia to become a global leader in this space.”

The other three key sectors identified in the report are healthcare, retail, and professional and financial services. The report details potential use cases for GAI in each of these sectors and the subsequent economic value that could be generated using the technology.

Leveraging Australia’s comparative advantages and taking strategic actions

The report notes that industry and government are at a critical juncture in GAI adoption, with deeper collaboration needed for Australia to capture the economic benefits of this technology and to become a global leader in GAI.

Leveraging Australia’s comparative advantages in digital technology is key to spurring this collaboration. They include a large and highly skilled tech workforce, strong investment in digital infrastructure and a high level of cloud computing adoption.

The report – which is based on comprehensive economic analysis as well as consultations with industry, government, and academia – also identifies the barriers that industry and government face in capitalising on GAI in four key areas: technology capability, enterprise readiness, awareness and skills, and responsible AI.

18 SEPTEMBER 2023 Manufacturers’

manmonthly.com.au

Monthly

For over 59 years, Manufactures’ Monthly has lead and informed Australia’s manufacturing industries with its highly creditable editorial analysis of the market. manmonthly.com.au MANAGEMENT >> TECHNOLOGY >> SOLUTIONS 10yearsofMarkforged NEXT GENERATION medicalimplants manmonthly.com.au >> TECHNOLOGY >> SOLUTIONS >> INSIDE >> Exitplanningforbusinesses 32 JULY 2023 DevelopingaugmentedrealityfromAustralia 34 OfficialIndustryPartners * T&C Only organizations with relevant use cases qualify for the Complimentary 3D Printed Part at the discretion of the Markforged Application Engineer. By subscribing to the Complimentary 3D Printed Part campaign you agree for Markforged to use the part for marketing purposes. Offer valid in Australia. Get your 3DComplimentary Printed Part Are you looking to innovate faster and reduce supply chain issues by 3D printing everything from prototypes to end-use parts? We got you covered! At Markforged we are on a mission to bring industrial manufacturing to the point of need. To help manufacturer reduce lead time we are offering a Complimentary 3D Printed Part*, for a limited time only, to encourage manufacturers to improve their production processes. See for yourself the unmatched surface finish, strength and precision of our 3D printed parts in metals and continuous-fiber reinforced composites. Claim your Complimentary 3D Printed Part by simply scanning the QR code and filling out the form. Our Engineers will be in touch! MM_PressAd.indd 4/3/23 10:11 Filters Future The of manmonthly.com.au MANAGEMENT >> TECHNOLOGY >> SOLUTIONS >> INSIDE >> 10 years of Markforged 34 Exploring the DN range of machine tools 26 AUGUST 2023 Using a household item to solve climate change 52 Official Industry Partners Visit the Manufactures Monthly website to subscribe to the magazine or to view the digital edition. For all the latest news including government announcements and breaking news follow us on social media and subscribe to the newsletter by scanning the QR code. www.manmonthly.com.au For more information, contact Danny Hernandez 0431 330 232 Manufacturers Monthly Manufacturers’ Monthly Manmonthly

Manufacturer Focus

Transforming manufacturing

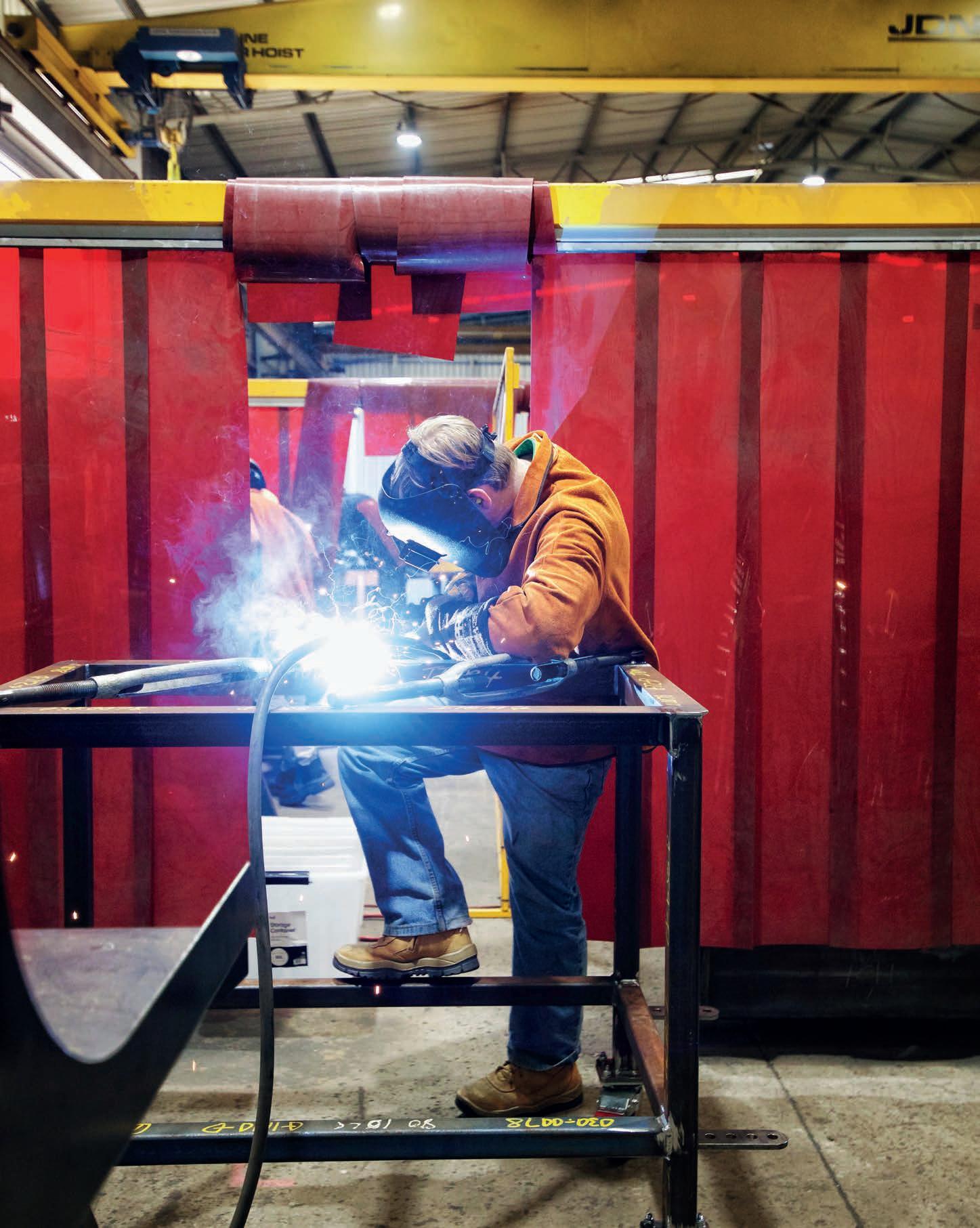

Manufacturers’ Monthly spoke with Jasmine Riddle from JRS Group to learn more about the company that has transformed itself into a beacon of modern manufacturing.

20 SEPTEMBER 2023 Manufacturers’ Monthly manmonthly.com.au

JRS is turning itself into a beacon of modern manufacturing.

Manufacturer Focus

JRS Group – better known previously as JRS Manufacturing Group – has recently undergone a rebranding to better capture the journey the company has been on and where it is today.

The company now has three distinct sections: manufacturing, a newly formed aerospace division, and its skills academy – all designed and geared towards JRS’s overall goal of being a modern manufacturer.

COO Jasmine Riddle explained the lofty goals the company has set for the coming years.

“The JRS Group of businesses is on the cusp of exciting and catalytic strategic industry growth within its manufacturing and aerospace production divisions,” Riddle said.

“The global and domestic demand of our customers in METS, defence, aerospace, civil, and environmental markets is informing and evolving our investments, which will see the $4m expansion of our steel fabrication, CNC machining and industrial coating entity, with JRS Group maturing from a team of 24 to 100 over the next five years.”

“The launch of JRS Aerospace Group will deliver Queensland's first regional critical high value, high volume processing facility, through a investment in facilities, equipment, training and technology.”

“This will create a new range of jobs for the region in the coming years, in chemical processing, specialised coatings, laboratory technicians, engineering and testing services for fixed wing, rotary wing, space, weapons, hypersonic, testing, and supply chain validation, that is critical to the development of the aerospace industry,” Riddle said.

Inside JRS Group

To better understand JRS Group and what brought it to the current juncture, it is important to understand how its COO Jasmine Riddle came to the manufacturing industry. A company’s people are its most precious resource –and Riddle’s story is emblematic of the kind of values, interests, and culture common prevalent across the entire JRS Group team.

“I joined the Navy as an opportunity to learn in a fast paced, real time environment that changed my thinking and personal skills.

“I learned very quickly that I am the type of person very comfortable with being uncomfortable.

“Being in the service was such a powerful and passionate tool for me. When I left and moved to Toowoomba where I owned and operated a café with my mum, I knew that I was going to need more excitement than that.”

While in Toowoomba Riddle met her husband – a boilermaker by trade – and the pair set their sights on starting their own manufacturing company.

“We had a vision to do bespoke manufacturing for customers who appreciated high quality manufactures and high value relationships and who wanted to go on a journey with us,” Riddle said.

“For us it was about building the best product possible for our customers so that they were positioned at the leading edge of their market, through prototyping, market testing and commercial and production models” she added.

Partnership-based relationships are a large part of what drives Riddle and her husband. But, at a more visceral level, she is equally inspired by on-theground work and the practicalities of the manufacturing process.

“I just love the smell of ground steel, it reminds me of a warship,” she chuckled.

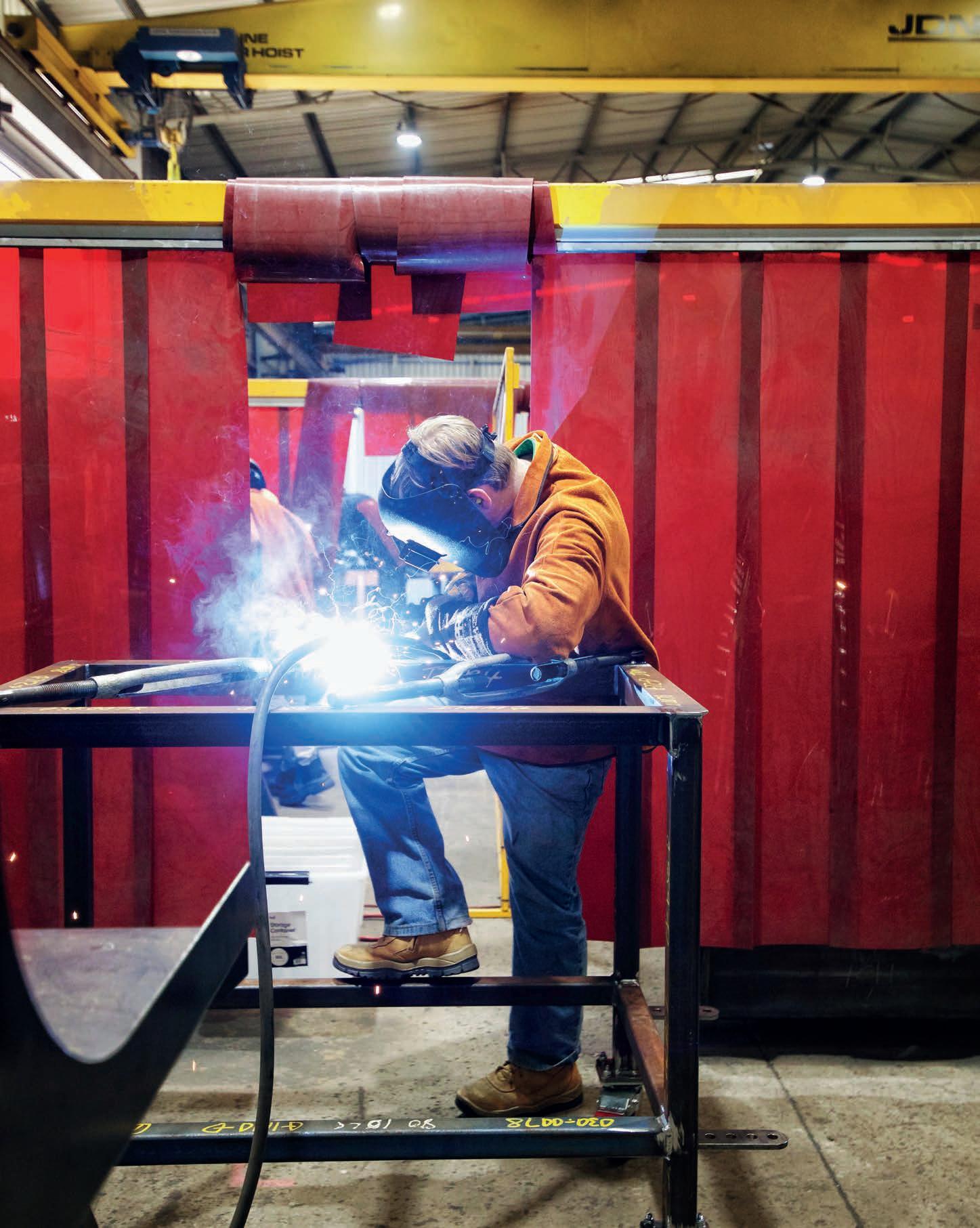

JRS Skills Academy

The JRS Group established the JRS Skills Academy to take on the task of upskilling and championing skills development, building programs that would deliver wise, decisive leaders for industry’s future and create a business incentivised model of training that would drive greater investment and higher performance outcomes for individuals and industry more broadly.

The JRS Skills Academy, a standalone entity, has a formal approach with the sole purpose to grow, sustain, and lead training culture. The goal is to ensure all personnel, regardless of their position, are aware of their career opportunities and to help them be achieved in a way that gives them additional skills –enabling lateral and vertical integration into business operations, not just within the JRS Group but in the broader industry, too.

Through the network of local and

state manufacturing alliances, industry reference groups, peak bodies, RTO, VET & tertiary institutions, and the local DYJESBT team, the JRS Skills Academy is able to extract and collate data that drives the development and strategy behind the future of skills at JRS Group and industry.

These relationships are used as a dual conduit with a feedback loop back into industry and institutions to share insights and solutions to challenges.

Riddle explained why the Skills Academy was started and what its broader goals will be for JRS and the wider manufacturing sector.

“The academy was developed to create industry led training, skilling, and engagement programs that are dynamic, future focussed, and designed to enable confidence in young people and job seekers,” she said. Our initiatives have created over 200 hands on engagements for young people, job seekers, veterans, educators and employment services.

“We found that there was often a

mismatch between expectations of how training was meant to work and the skills it actually equipped people with when they arrived to work at a manufacturer.

“We recognised that the next generation is looking for something different, varied and profound, from their working life and we had to be ready to connect with that to keep them in our industry.”

JRS Group has created the Skills Academy to ensure the people coming into industry are getting a real insight into what manufacturing could be moving forward. The Skills Academy is an exciting development and a test run for the manufacturing industry; Riddle believes it could be the first of its kind in Australia.

“Other people have created equivalent skills academies before to train their own workforce, but the JRS Skills Academy has been set up to repeat and scale what we have achieved and share it with the industry, to accelerate and maximise benefits.

manmonthly.com.au Manufacturers’ Monthly SEPTEMBER 2023 21

The goal of the JRS Skills Academy is to build programs that deliver wise, decisive leaders for industry’s future.

Manufacturer Focus

“Oftentimes, even after training their skills meet only the bare minimum. That is not the businesses’ fault, they are restricted by challenging economic and commercial relations of industry, but it is not sustainable in the long run and the industry suffers for it.

“So, this is what the JRS skills academy was all about: it was finding a way to incentivise the training to make

The team in the JRS Skills Academy has access to onsite training rooms and computer labs and are able to schedule their training hours during the working week with their mentors, allowing flexibility to the business and the individual, depending on training workload and the demands of day-today operations.

Capturing compliance data for on-

projects as it seeks to identify a modern business incentivised approach to verifying training and reducing waste.

Training and skilling will go beyond budgets and targets. At JRS Group the development of the Skills Academy has created an ecosystem of skilling and training where every team member knows and understands their responsibility to mentor, to communicate

Training for the future

The JRS Skills Academy’s approach is to not simply train for the here and now, but train for the future and what manufacturing might look like.

“We are future focused,” Riddle stated. “We want to have a sustainable workforce ready to take on our nations big projects.. A traditional apprenticeship takes four years, we are challenging that, so people are walking out better prepared and ready to apply proactive thinking and practices.

“Young people do not want to be defined by one thing, we need to find a way to give the unique individual value – value that adds to the individual’s personal worth as well as to the organisation.”

Current training programs, Riddle added, are too antiquated and rigid to suit the needs of the modern manufacturing industry.

While manufacturing is currently benefiting from increased focus from governments and growing as a result, the sector is still held back by the legacy of 30 challenging years and a culture that, as a result, disincentivised manufacturers from training the next generation.

“While industry continues to inform the evolution of our understanding of what is needed, the JRS Skills Academy is also tuned-in to the next generation of industry by way of our outward facing activities,” Riddle said.

“One thing we recognised early on was the need to ensure that training was delivered in a high-quality manner, otherwise the end result would be a workforce who are disengaged, lack confidence to innovate and are unable to lead our future industry.

“Then you find they will leave unsatisfied, and they won’t come back to our industry, and we lose every single dollar we put into them as well as the opportunity to build a sovereign capability for the nation.”

Riddle went on to explain how the certificate three works at the JRS Skills Academy. The organisation has taken an autonomous approach to the engineering certificate three and created a multidisciplined and multifaceted experience.

When someone leaves the Skills Academy, the aim is that they can have four separate qualifications effectively, making them a greater asset either at JRS or working for another organisation.

“The idea is that they have those four

22 SEPTEMBER 2023 Manufacturers’ Monthly manmonthly.com.au

The company will continue to grow the academy and diversify its program offerings to the manufacturing industry.

Manufacturer Focus

qualifications when they leave, and they can move laterally within the industry and flourish in manufacturing.

“If industry changes in the next 20 years, they are not restricted by what they’ve learnt – they will have been equipped with a multifaceted skillset such that they’ll remain employable and bring incredible value to industry long after they leave the Skills Academy.”

New facility

The Skills Academy is not the only exciting development for Riddle and the team at JRS, with the company recently expanding its site at Wellcamp in Queensland.

The Wellcamp facility has upgraded its CNC capabilities and added extra additive manufacturing facilities on site. This facility will be used to house that new equipment and is expected to be a consistently evolving part of JRS Group that houses new technology as it becomes available.

Riddle went on to explain the finer details of how the facility will be used.

“The facility at Wellcamp will allow us to bring the Skills Academy in and to work on state-of-the-art equipment, teach a range of skills, enable further community connection and further the variety of engagement opportunities,” she said.

The Wellcamp facility will also be the site of JRS’s aerospace division which will include chemical treatment and surface finishing on aerospace parts. This facility will house a research and development, laboratory and bespoke testing facility which will be important for further developing the aerospace supply chain in Queensland with a range of stakeholders.

“These facilities are all a physical descriptor of what we are trying to do with the Skills Academy, they are multi-disciplined and highly diverse,” Riddle explained.

The future

JRS Group is taking an opportunity to capitalise on government investment in the aerospace industry to grow the company.

Twenty-four Queensland businesses are sharing in more than $420,000 from Round 3 of the $1.5 million Defence and Aerospace Industry Development Fund (DAIDF) in which JRS group has received $30,000 for its development.

Riddle emphasises that JRS is taking a proactive approach to improving aerospace manufacturing in Australia.

“There is an opportunity to reshore and onshore global supply chain work in every manufacturing sector,” she said.

“There are not many facilities in Australia undertaking this type of qualified work and so by doing this the supply chain around us has the ability to expand more work opportunities can be undertaken and greater development of Australian IP.”

The strategy for JRS is to bring even greater thinking to Australia for the creation of new ideas, new IP, and new

innovations. The company aspires to become an end-to-end manufacturer –from research through to completion of new products.

For Riddle, her experience and career feed directly into her ambitions for developing JRS Group and the manufacturing industry in general.

“I’m very frank with our team in drawing on my experiences working in defence,” she said. “It’s important to demonstrate to people just how critical it is that when you’re on the front line,

on an operation, or even just in military training, that you have high quality items that work, are reliable and can be replaced or acquired at moment’s notice. i think this translates into any of our incredible customers, Defence or civilian.”

“What we are making here in our workshop really matters. We must make sure we deliver high quality, take pride in what we craft, and be ready for our next generation. That is what manufacturing should be all about.”

manmonthly.com.au Manufacturers’ Monthly SEPTEMBER 2023 23

The Skills Academy’s programs are offering young people the opportunity to experience industry first-hand, highlighting what it’s really like to work in the manufacturing industry.

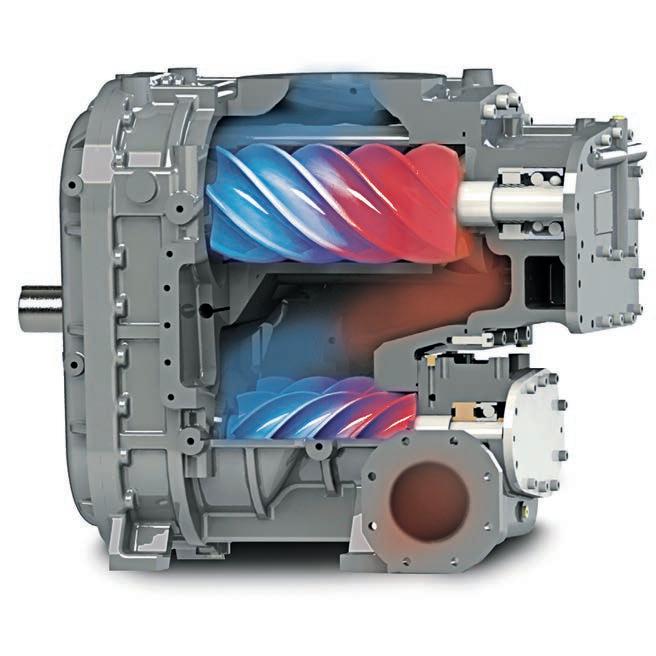

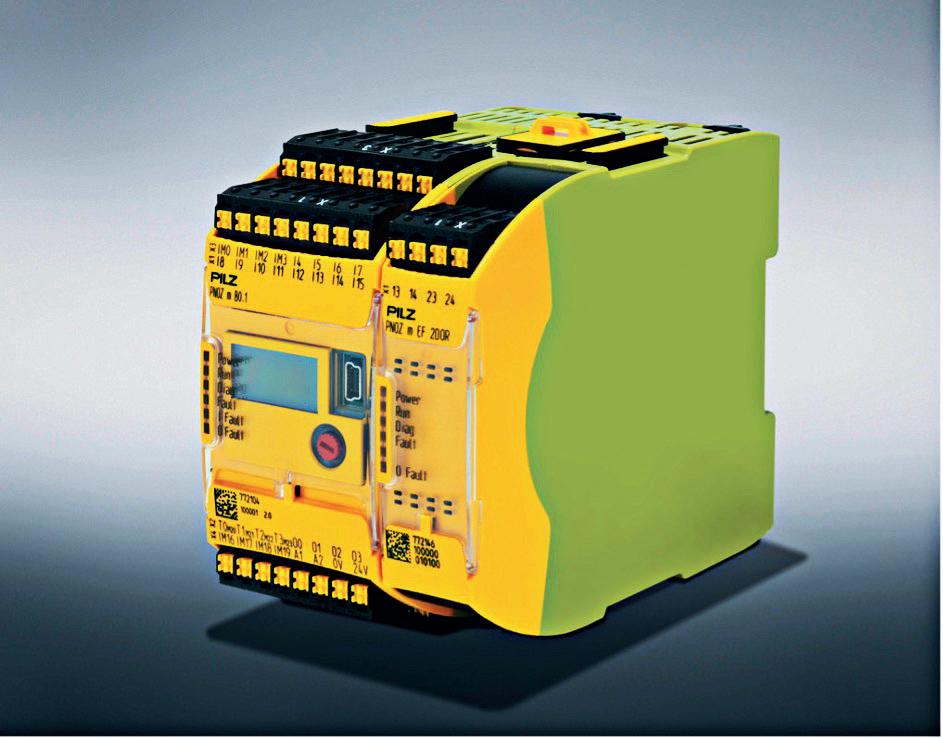

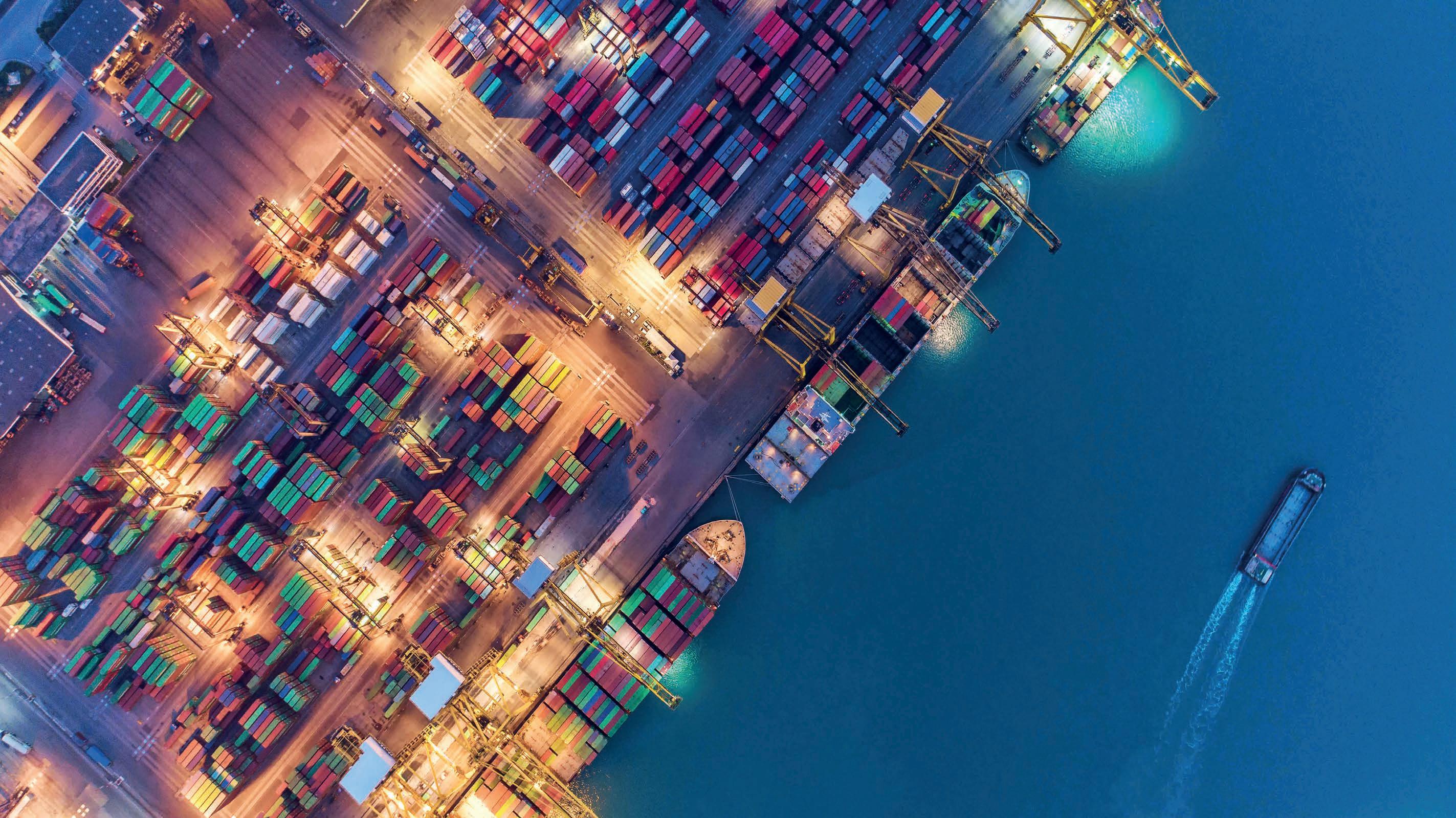

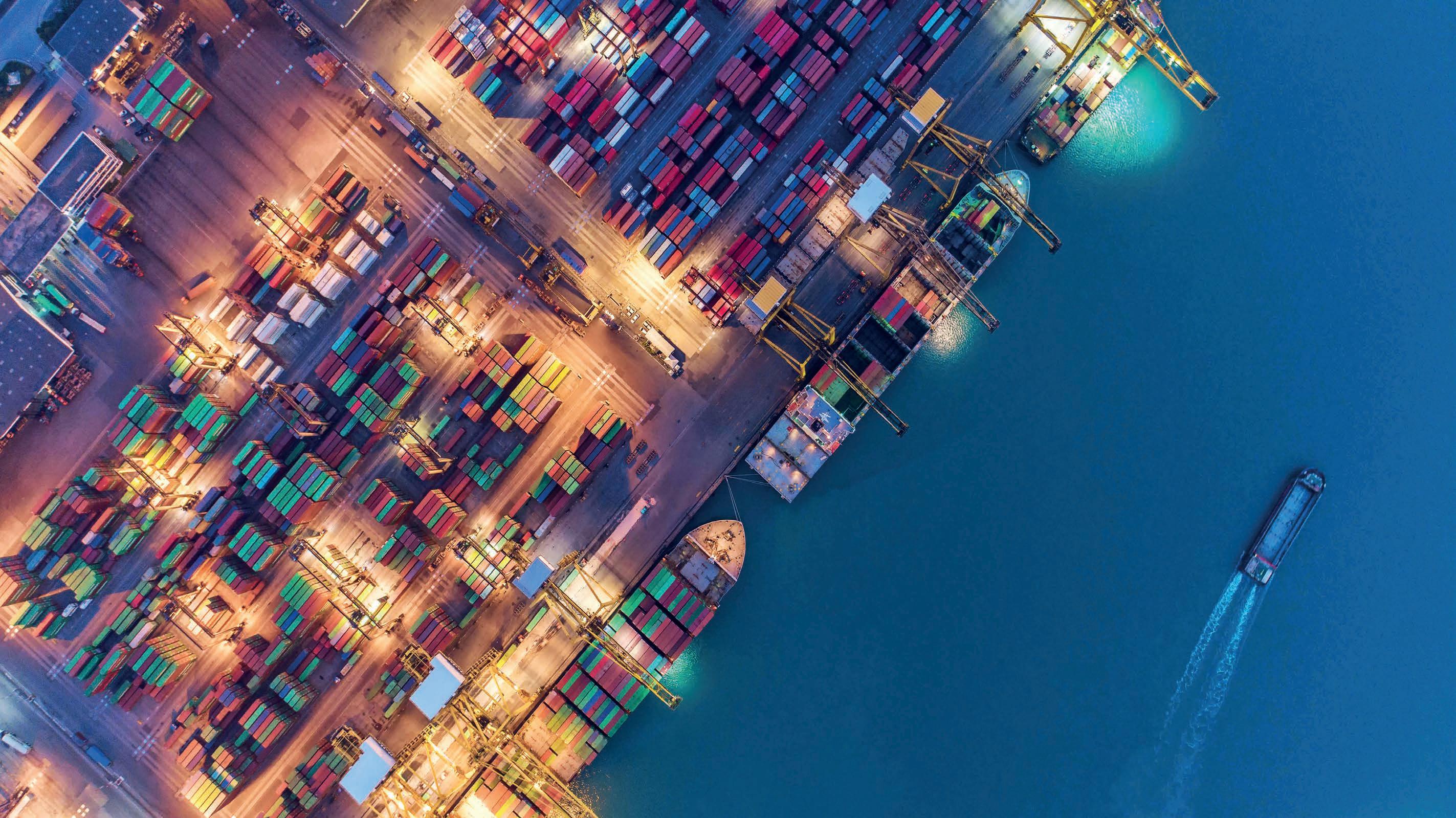

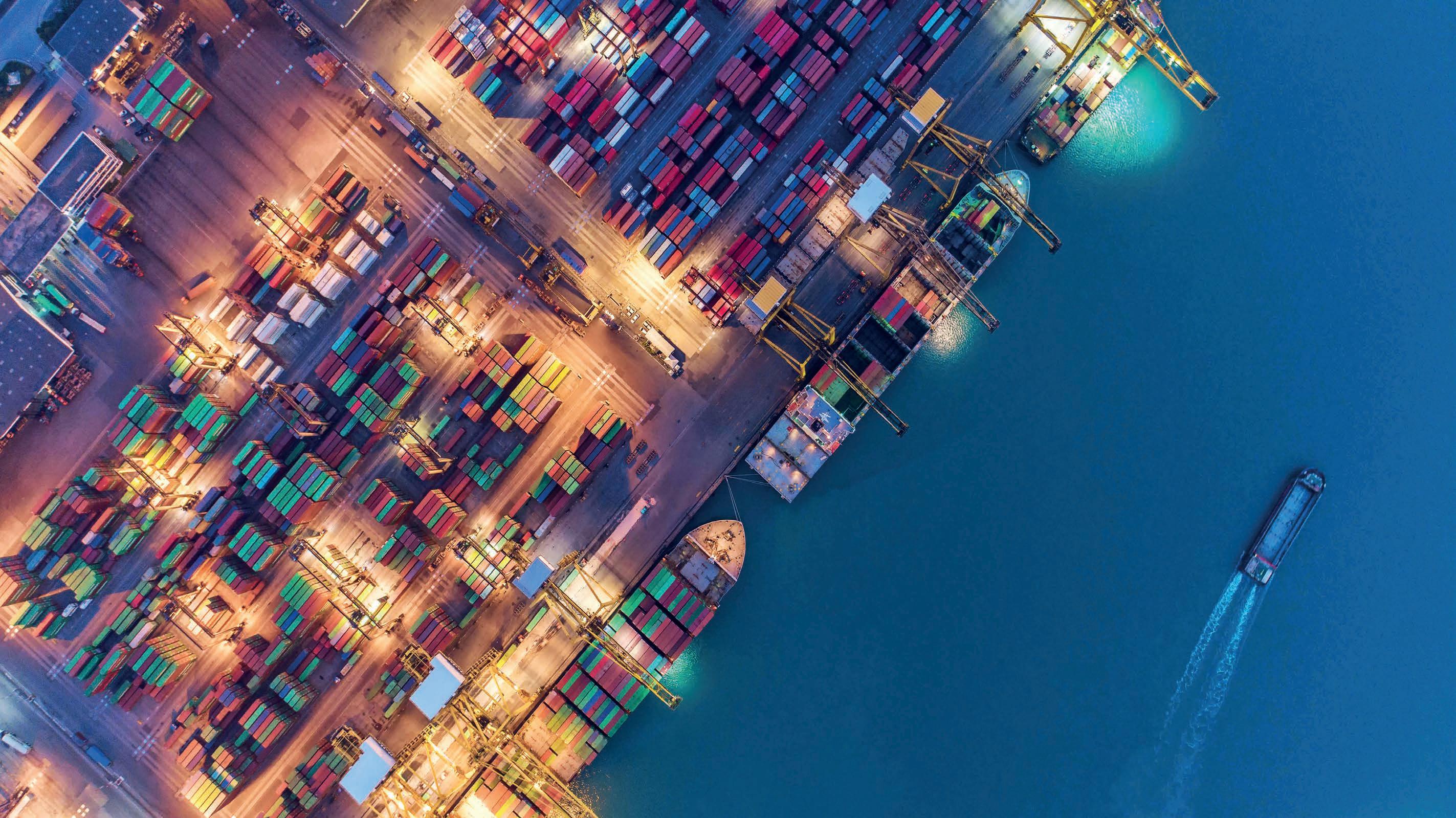

Energy Efficiency

Shaping the future with energy efficient compressed air solutions

Atlas Copco is empowering customer growth through the innovation of energy efficient solutions. Discover Atlas Copco’s cutting-edge compressed air solutions that are helping to drive towards a greener future.

AS the world evolves towards a greener tomorrow, Atlas Copco takes the lead in redefining compressor technology. Its cutting-edge solutions not only elevate performance but also significantly reduce energy consumption.

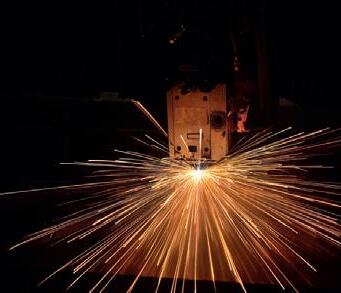

Groundbreaking compressor for the next generation

When consistency is key, a fixedspeed compressor steps up, providing unwavering power upon activation. However, the dynamic nature of many industrial operations demands adaptability. This is where a variable

speed compressor shines, flexing its output in harmony with demand, translating to remarkable energy efficiency. With the latest VSD compressor manufacturers can enjoy energy savings up to 60 per cent.

The revolutionary VSD is a highly efficient compressor that stands out in the market. It has raised the bar in performance, reliability, and connectivity to support an organisation’s sustainability goals. With the VSD you have as much energy as you need, no more no less.

Choosing an environmentally friendly air compressor can be an important and beneficial choice. Beyond immediate

benefits, the Total Cost of Ownership (TCO) plays a crucial role in selecting the ideal compressor for your production needs.

Unlock CO2’s potential for a sustainable transformation

Did you know that carbon dioxide (CO2) emissions can find a new purpose? The world of carbon capture is evolving, and compressed gas solutions are at its heart. This revolutionary process involves capturing CO2 emissions from various industries and compressing them for storage or beneficial applications. Central to this transformation are compressors and compressed gas solutions, which play a pivotal role in enhancing the efficiency of carbon capture and storage endeavours.

Atlas Copco have innovative solutions available that can unleash the untapped potential of CO2, delivering not only economic advantages but also substantial environmental benefits. Backed by its exceptional CO2 compressors, Atlas Copco offer unparalleled efficiency and reliability, setting new benchmarks in sustainability.

Harnessing wasted energy for sustainability and innovation

Energy recovery is the transformative process of capturing and utilising wasted energy to amplify efficiency while reducing environmental footprints. By converting discarded energy into useful resources such as electricity, heat, or mechanical work, energy recovery takes centre stage in the pursuit of enhanced energy efficiency and reduced environmental impact.

Atlas Copco specialises in tailoring solutions that align with diverse industry demands. Its energy recovery solutions not only cater to immediate needs but also pave the way for a more sustainable tomorrow. By salvaging untapped energy

and optimising operational efficiency, we’re committed to contributing to a future where innovation and environmental consciousness intertwine.

The importance of maintenance and control

Optimising an existing compressed air network opens doors to reducing your carbon footprint and cost-effectiveness. Nurturing and maintaining your compressed air system is a nonnegotiable. Overlooking maintenance can lead to disruptive downtimes and financial setbacks. Thus, the key lies in consistent system care, vigilant monitoring, and meticulous control. While scheduled maintenance plans with the supplier should be

24 SEPTEMBER 2023 Manufacturers’ Monthly manmonthly.com.au

Atlas Copco’s VSD compressors are pushing energy efficiency to new heights.

mandatory, daily engagement by the compressor user is equally important. Taking charge as a compressor owner involves recognising optimal pressure requirements and pinpointing pressure losses in the system.

Incorporating a state-of-the-art master control system stands as the ultimate strategy for managing a compressed air system. This control hub monitors compressor efficiency, availability, and reliability, promptly flagging issues and automatically adjusting pressure and energy consumption during periods of low demand. You can also pair your controller with smart connectivity technology to remotely supervise and optimise system performance.

Energy Efficiency

Beyond efficiency, the green system’s air quality must meet defined standards. A holistic approach to compressed air management ensures a sustainable and cost-effective environment.

Air compressor audits for actionable insights

An all-encompassing assessment delves into every facet of your compressed air system, including energy consumption, air flow demand, system pressure, air quality, pressure differentials, and more, all analysed over an extensive timeframe.

What sets Atlas Copco’s approach apart is its audit software, which can simulate various configurations of

your compressed air installation. The AIRSCan audit report is a game changer as it offers a concise overview of your compressed air system’s performance. This innovation enables Atlas Copco to project tangible energy savings, along with measurable environmental and financial advantages, providing a road map towards a more efficient future.

Celebrating 150 years of innovation

2023 marks the 150th anniversary of the Atlas Copco Group. They celebrate driving development and delivering breakthrough innovations, while also continuing to find ways to help shape the future.

“We are extremely proud of our

past, and we continue to shape the future through our technologies and service solutions,” said Mats Rahmström, CEO and President of the Atlas Copco Group.

Throughout its history, the company has maintained commitment to innovation, sustainability, and ethical business practices. Yet, above all, the driving force behind these accomplishments has been the passionate individuals who continuously channel their dedication and visionary ideas into shaping a brighter future.

Atlas Copco Compressors 1800 023 469 www.atlascopco.com/en-au manmonthly.com.au Manufacturers’ Monthly SEPTEMBER 2023 25

Regular maintenance and daily checks are pivotal for compressed air machines.

Energy efficiency is a high priority for manufacturers and Atlas Copco is meeing these needs.

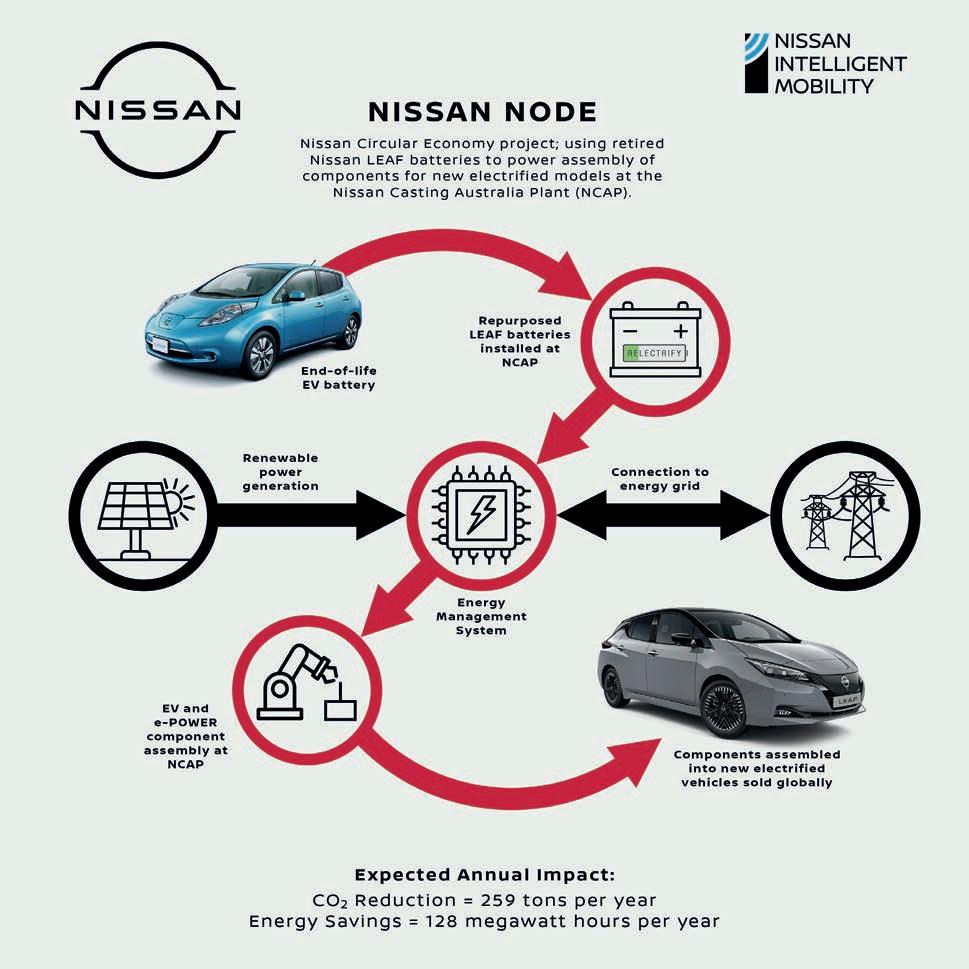

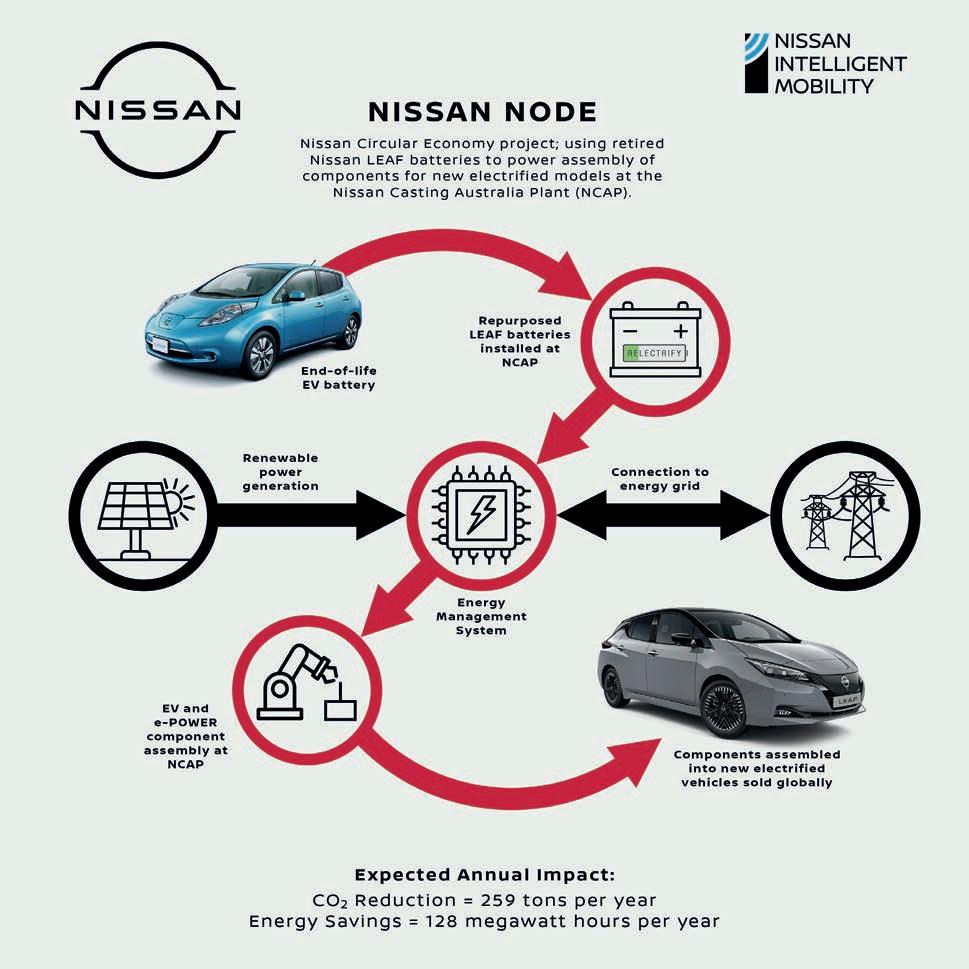

Sustainable Processes

Sustainability – more than a buzzword

RSM is taking a partnership approach to optimising sustainability in manufacturing, working closely with companies to unlock solutions to improve its Environment, Social and Governance initiatives.

NICOLE Mohan is a principal within Environmental, Social and Governance (ESG) and Climate Change Services and is RSM Australia’s National Sustainability Lead, responsible for developing and implementing initiatives to drive the adoption of sustainable practices and values across RSM. Starting as a Graduate and working with the company for almost 13 years, she has a passion for helping others and providing value added services. She has brought this passion to her role, by helping to improve ESG initiatives and practices both internally within RSM and externally for clients as well.

“All through my university degree and masters, I have been interested in the value that sustainable practices can generate for businesses, considering people, planet and economic prosperity. Now, as a leader within RSM’s ESG and Climate Services team, I enjoy demonstrating how critical these practices are in achieving strategic success in the current and future environment,” she told Manufacturers’ Monthly

What is ESG?

ESG is a reporting framework for measuring an individual or commercial impact on environmental, social and economic resources, which in turn informs the longer term sustainability of a company. This framework can be used to

evaluate a company’s overall performance based on non-financial criteria, which may ultimately impact the long-term financial performance of the company.

ESG is now mainstream, front of mind with stakeholders and used globally to promote transparency of a company’s footprint and to also influence positive change in society. This could mean taking measures to lower pollution, CO2 output and reduce waste. It also means having a diverse and inclusive workforce, at the entry-level and all the way up to the board of directors.

“It is important to remember that ESG performance is more than just climate change and the environment and that all elements should be looked at together, as one interrelated framework,” Mohan said.

Implementing sustainable practices within your company to improve your ESG performance

In terms of supporting clients on their ESG and sustainability maturity journey, one of the first steps a company can take is conducting a current state analysis of existing ESG and sustainability practices and data collection processes to identify areas for improvement, strengths, and weaknesses to help inform key stages and actions.

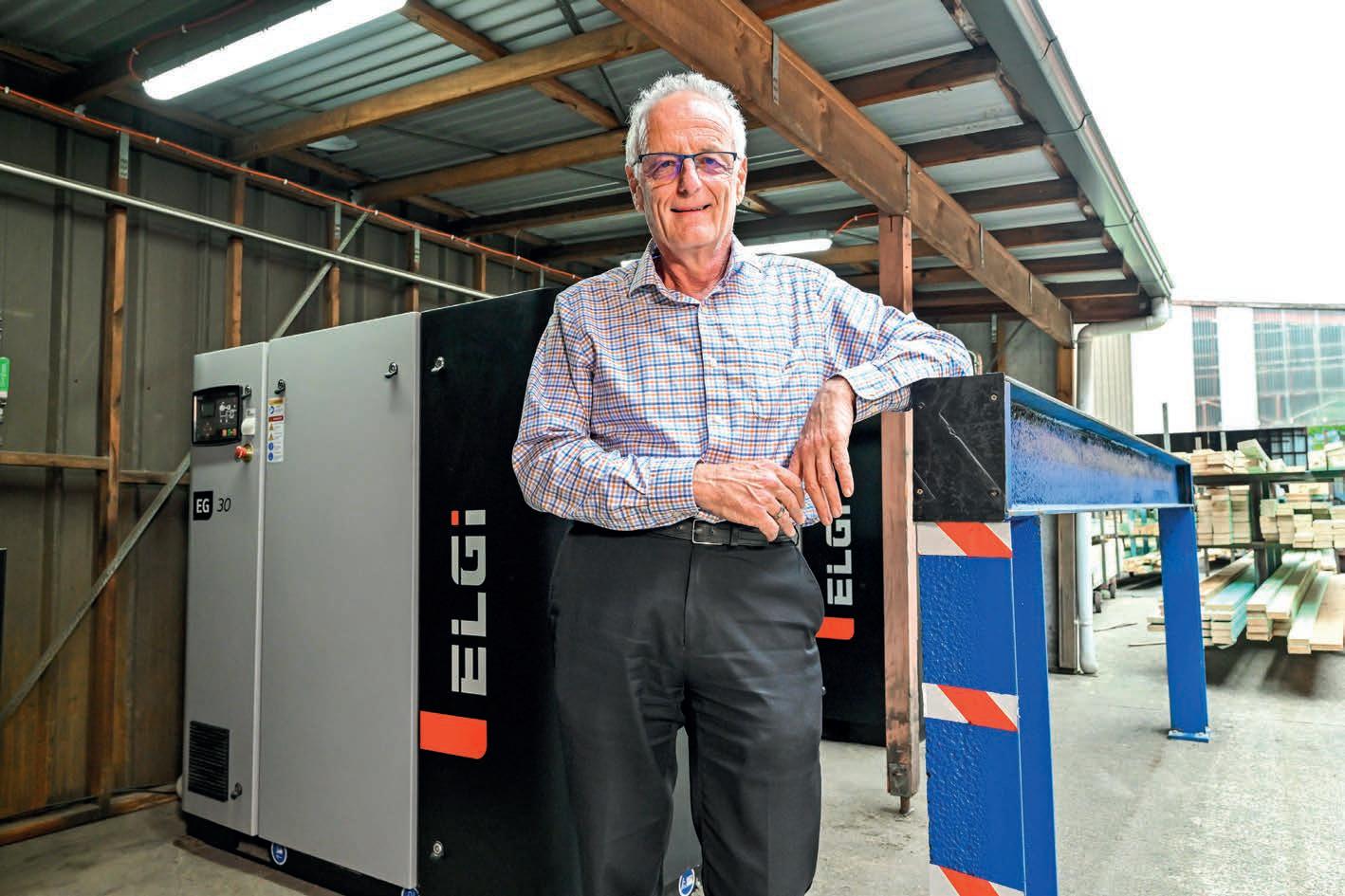

Following that, the company can then develop an ESG roadmap which