THE CTR9 AND CTR7 FULLY AUTOMATIC WELDERS COME WITH A NEW, REVOLUTIONISED LIGHT-WEIGHT TRANSFORMER GUN.

With its 355° swivel handle and ergo-grip, it enables perfect working positions for anyone, for any job. The gun is supported by a telescopic arm in a durable and lightweight extruded aluminium that can be easily adjusted both vertically and horizontally.

A compact power unit with a low centre of gravity gives mobility and stability, while a 16,000-amp transformer and CANBUS communication ensure a perfect weld every time.

T TRADE-IN DEAL:

The Trade-in deal is offered in conjunction with our Special Deals ‘Promotion’ on Car-O-Liner CTR9 and CTR7 Spot Welders, which means we will trade any type of spot welding system regardless of age or condition.

CEO John Murphy john.murphy@primecreative.com.au

COO Christine Clancy christine.clancy@primecreative.com.au

SALES DIRECTOR Brad Buchanan bradley.buchanan@primecreative. com.au 0413 672 403

EDITOR Eugene Duffy eugene.duffy@primecreative.com.au 0412 821 706

BUSINESS DEVELOPMENT MANAGER Kerri McCauley kerri.mccauley@primecreative.com.au 0404 898 362

PUBLISHED BY Prime Creative Media 379 Docklands Drive, Docklands, VIC 3008 03 9690 8766 www.primecreative.com.au

DISCLAIMER

The National Collision Repairer is published by Prime Creative Media, 379 Docklands Drive,Docklands. This publication is copyright. Apart from any fair dealing for the purpose of private study, research, criticism and review under the Copyright Act (1968), no part may be reproduced by any process without written permission. Enquiries should be addressed to the publisher. The publisher believes all the information in this publication to be correct at the time of printing, however is not in a position to make a guarantee to this effect and accepts no liability in event of any information proving inaccurate. Prices, addresses and phone numbers were, after investigations and to the best of our knowledge and belief, up to date at the time of printing. It is also not feasible for the publisher to ensure that advertisements which appear in the publication comply with the Competition and Consumer Act (2010). The responsibility must therefore be on the individual, company or advertising agency submitting the advertisement for publication. Whilst every endeavour has been made to ensure complete accuracy, the publisher cannot be held responsible for any errors or omissions. ACN 117 914 235

Welcome to the September edition of National Collision Repairer, where we hope to bring you new insight into the dynamic and ever-changing collision repair industry in Australia.

The COVID pandemic was perhaps one of the greatest business disrupters many of us will ever know. Putting aside the human costs, which were significant, the prospect of at least two years of substandard income was

At the same time, it was the capacity to adapt and work collectively that minimised these costs. This was particularly evident in Australia where, sad as it was, the death rate was low. The ability to adapt and innovate was also evident in business, despite how hard the COVID shutdowns hit outlets and created long-lasting supply chain issues.

While revenues almost universally took a hit, many businesses came out of the pandemic with a new sense of purpose and flexibility. Agility became the buzzword in those years and in many ways the concept is just as important now.

As the pandemic shadow recedes, many businesses have learnt that with this agility and the right attitude, just how much change they are capable of dealing with. And one thing is sure in business, change is almost certainly round the next corner.

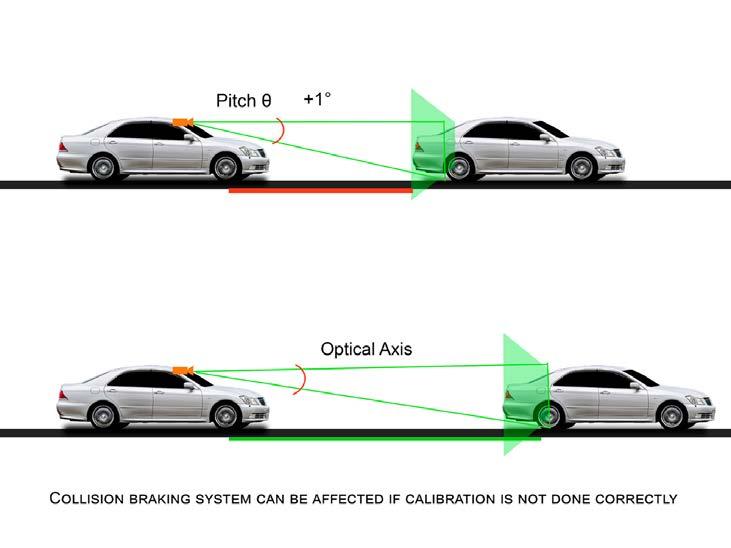

The next big disruptor for the collision industry could broadly be termed as technology. This is not only in the quantum leaps being made in how cars are powered, reflected in the steady upsurge of EV growth, but also in new high-tech safety and warning systems becoming standard in new vehicles. All this means big change for the industry.

There are some constants though. Cars will still crash and they will still need to be repaired, so the collision industry will remain a vital service. The challenge for individual businesses will be to stay relevant in this fast-changing world. So, one of the keys to this remains access to training and knowledge.

This is why The National Collision Repairer is committed to

bringing you the latest news and views on these changes, to not only reflect the industry but to help it grow.

Car-O-Liner is one respected business that has weathered many waves of change over the 50 years of its operation that we look at this month. The Australian business, which is nearly as long-lived as the parent company, has accumulated a long list of honours in the collision repair industry and, as Julie Thomas shows, it is still an industry that is very much about valuing people and their partnerships.

This month we also look at another kind of partnership between Fix Auto and Axalta, not just a commercial arrangement but revealed in the eyes of both parties to be a genuine mutually-beneficial partnership built on trust and support.

And on the subject of people, this September edition we were privileged to see in action some of the young competitors at the WorldSkills event held at Kangan TAFE. These skilled young people are not only gifted and dedicated but represent an important part of the industry’s future as it tackles the pervading issues with recruitment and skills shortages.

This edition we also look at the milestone of what has happened in the big year since the Right to Repair became enshrined in legislation. Two key industry bodies, the AAAA and AASRA, have been giving repairers better access to the knowledge that is increasingly vital to repair the vehicles in their workshops. It hasn’t all been plain sailing over that year. There have been some IT hiccups, qualifications to be registered and some reluctance on the part of OEMs to share information, but overall, it is huge step for the industry and most repairers can look forward to better cooperation and quicker resolution of issues. The result will lead to more efficient businesses in an increasingly technological age and that is good for the industry.

These stories and much more in our regular features should show that while it is an industry with its challenges, it is also one that is up to the task to tackle them and ensure it continues to grow.

We hope you enjoy the September edition.

Eugene Duffy Editor The National Collision Repairer

Scan the QR Codes in all our RPS boxes with the SATA Loyalty App, collect coins and convert them into attractive rewards. Each RPS cup corresponds to one coin! Further information: www.sata.com/loyalty-int

Weststar Prestige Paint & Panel is the latest automotive repairer determined to make the most of training opportunities, as it notches up the coveted I-CAR Gold Class status.

The Sunshine North business in Melbourne which is also an authorised Mercedes Benz repairer is the latest business to join I-Car’s Gold Class accreditation for achieving training levels.

Weststar Prestige Paint & Panel has been using I-CAR’s training platform since November 2018 and began the Road to Gold program during the final stages of the COVID-19 pandemic, where access to online and virtual classes anywhere helped them continue training.

After the pandemic, I-CAR Australia’s industry alliance partners provided additional key training and education for their lead technicians which

included Tesla Welding Certifications and accredited PPG training.

Weststar, director and dealer principal Brad Kolich said the Road to Gold training program had given them the additional assistance in making the accreditation possible and had had a wider positive impact on the business.

“Our staff are to be commended for embracing the training modules with enthusiasm and vigour,” Kolich said.

“And we look forward to their efforts and commitment reflecting positively in our organisation, which will further cement our approach to the Collision Repair Industry and add another element to potential OEM partnerships moving forward.”

Kolich also extended his thanks to I-CAR staff for their ongoing support and professionalism throughout the journey in achieving I-Car Gold Accreditation.

But the Gold Class accreditation is only the beginning for Weststar Prestige, who have pledge as part of the agreement to continue training to meet the ongoing and demanding technological advancements in the demanding collision repair industry.

I-CAR was founded in 1979 and is an international, not-for-profit, training organisation with a organisational mission to improve the quality, safety and efficiency of auto collision repair for businesses and consumers.

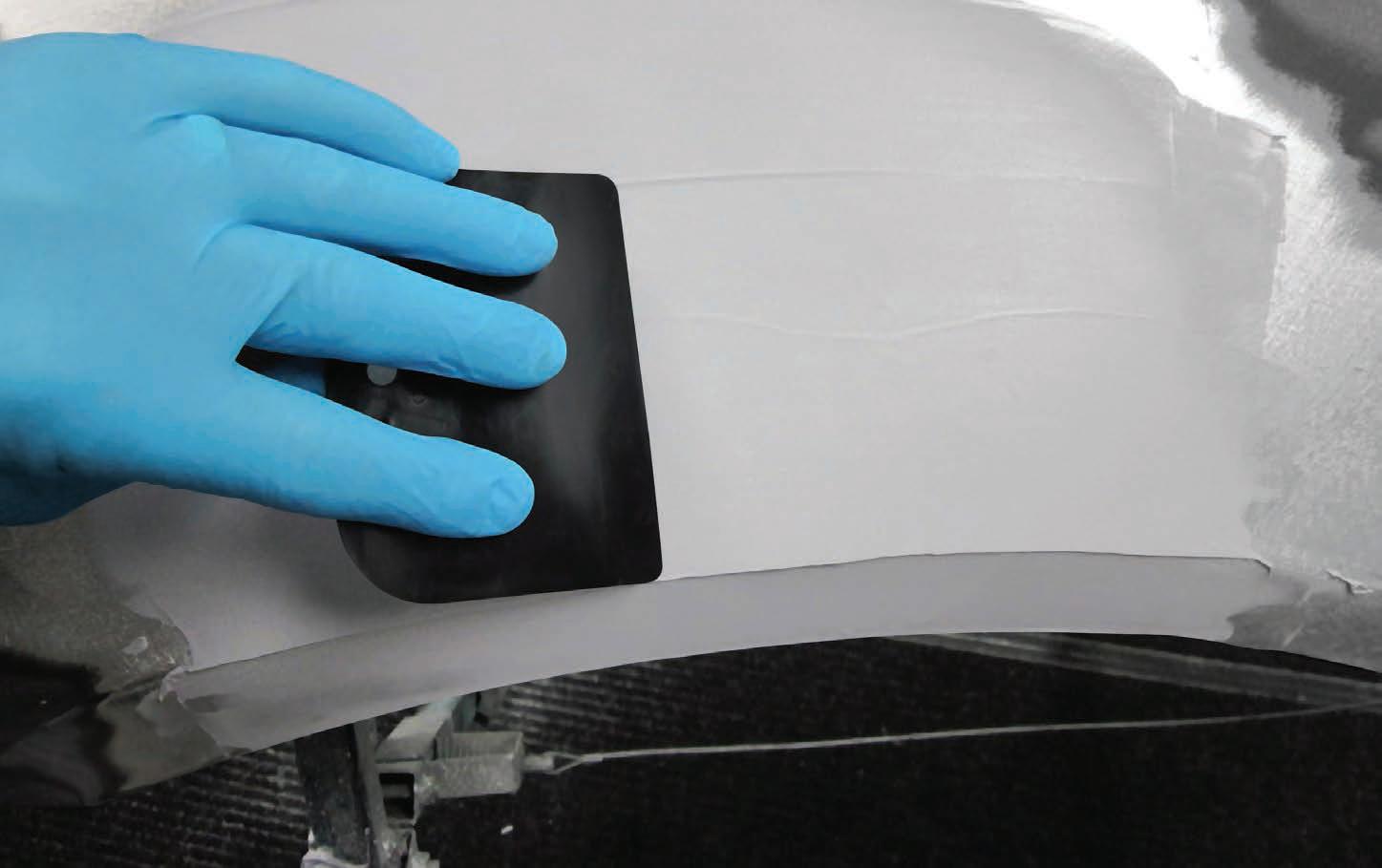

After a career spanning more than four decades, Howard Astill, revered elder statesman of the Australian custom car scene – has a new way to share his treasure-trove of experience and knowledge.

Beginning last month, Howard is hosting a special ‘Muscle Car Respray’ video series, brought to you by PPG and MIRKA, which will roll out on his Astill Design YouTube channel.

Throughout a 13-part series, Howard will follow the processes involved in taking a 1971 Camaro body from bare metal, all the way through to a quality, ‘streetcar’ paint finish.

According to Howard, each episode is set out in step-by-step format that is easy to follow and, importantly, enjoy.

Over a 25-year partnership, Howard

credits PPG with helping him produce some of the best paint finishes in the country and the new initiative was a fantastic evolution of the relationship.

“One thing I have recognised over the years is that products and processes are constantly changing so this is about providing people with the latest information, as well as tips, techniques and hacks that can make the job more efficient and produce a better end result,” Howard says.

“While we will be covering technical subjects, I will be keeping it grassroots by explaining things in layman’s terminology as much as possible.

“Our target audience is primarily the small custom / restoration business who often find it difficult to keep up with the latest trends, as well as DIY people who

have enthusiasm and basic skills but are looking for some expert guidance.”

He said having industry experts on hand, such as PPG customer support specialist Terry Noble and training manager NSW Trevor Duke to explain why certain things are done at certain times helped the videos.

“For example, there are a variety of different primers we use and the PPG guys are able to explain when we use each one, why and how to get the best from it. We are also able to introduce viewers to the latest MIRKA electric and battery tools range, as well as products like the new MIRKA Galaxy selfsharpening abrasive range.”

Astill Design YouTube channel (www. youtube.com/@AstillDesign)

FIX AUTO CAN HELP PROVIDE SECURITY.

Whether it’s the threat of consolidation, managing the increasing pressures on the business, or just the thought of pushing on alone, in an ever more challenging industry, being an independent repairer has never been more difficult.

That’s why at Fix Auto Australia we are uniting independently owned businesses and providing them with the security, support and expertise that comes with being part of the largest collision repair network in the world. If you want to take your business into the future with a global partner at your side, Fix Auto can help.

With over 730 locations in 12 countries, Fix Auto is the world’s largest network of independent repairers.

Secure the future of your business. Call 1300 349 2886 now or visit fixauto.com and discover how we can help your repair shop reach its full potential.

Two leading bodies in the automotive industry are urging Australian repair shops to join the EV transition and are hoping the much-loved ute could be the lure to get them to take the first step.

The Australian Automotive Aftermarket Association and Auto Innovation Centre took delivery of two electric vehicles in July, including the rarely seen Ford Lightning, a full-size electric utility, at their Mulgrave centre as part of a State Government program aimed at increasing the uptake in zero emissions vehicles.

The program is part of a joint AAAA & AIC campaign to support the aftermarket through the coming EV transition with training and product development opportunities.

While the program is also aimed at fleet uptake, the AAAA believes the models will help with wider industry knowledge and help create confidence in the market and reduce possible scepticism around the vehicles.

AAAA chief executive Stuart Charity said what could be learnt from the vehicles represents an important step in an industry-wide approach to the EV transition.

and equipped to service, repair and modify EVs for commercial use and these vehicles will help us train technicians, and guide our strategy and communications surrounding the coming EV transition,” Charity said.

The AAAA’s first priority in the transition strategy to EVs is safety and ensuring repair technicians are suitably trained and qualified to safely work on the cars.

Following this, it will be important to develop a wider industry understanding of both the electric battery and electric motor components, along with other advanced technology including the vehicle’s safety elements.

“We know that earlier access to data and diagnostics for vehicles makes it easier for the repair industry to work on these vehicles. We hope that with this earlier access the industry can get on the front foot ahead of any future roll out,” he said.

One of the key steps of the shared campaign is getting feedback from the whole industry about their particular needs in relation to the vehicles.

Underlying the choice of vehicles for the AIC centre is the enduring love affair with dual cab utes in Australia both in purchases and with fleets. For the other vehicle, the Polestar 2, affordability and long-range should pique new interest in the repair industry.

“The F150 is the only commercially available Ford F150 Lightning in the country and one of the very few full sized pickup EVs in the world,” AIC managing director Luke Truskinger said.

“This one has a dual motor, extended range Lariat with a towing pack. So it’s got massive amounts of torque and feature content.

“The Polestar 2 we’ve got is a performance long-range dual motor. It has amazing styling, technology and incredible performance. It really gets moving and it’s very refined, very quiet. And a great example of a passenger EV in Australia.”

He said the initiative would also help the aftermarket develop products for the new generation vehicles.

The AAAA and AIC is encouraging

New collision industry body, ACIA, has taken the next step toward helping shape a unified voice in addressing the industry’s skill challenge.

Last month the collision industry’s new key alliance completed a three city tour across Australia in a bid to reinforce the message around future careers.

The recently formed Australian Collision Industry Alliance (ACIA) took its information nights aimed at briefing industry stakeholders on their vision and purpose to Sydney, Melbourne and Perth.

Audiences that included repairers, suppliers, associations, TAFE and other training organisations heard about the pressing need for a new generation of skilled professionals and how the ACIA was at the forefront of promoting apprenticeships within the collision industry.

ACIA founding director, Rob Bartlett said attracting and developing skilled professionals was key for a sustainable future for the industry.

“We are fortunate enough to have a group of people that are passionate about the future of the industry, and prepared to stand up and talk about the Australian Collision Industry Alliance and why it was formed,” Bartlett said.

“We are very grateful to the support we received from TAFE Ultimo (NSW), Kangan Institute in Melbourne and Renew Collision Repair Centre in Perth for hosting these events. All were welcoming venues for engaging discussion on the Australian Collision Industry Alliance and what it aims to achieve.”

Since then, ACIA has taken its advocacy to a range of industry players including in May at the Trades Fit Exhibition for young women in Melbourne and its recent three city tour.

The ACIA also appointed Hiliary Bradbury as an executive administrator in August to further enhance the organisations abilities as a unified group to voice collision industry issues.

ACIA founding Director Rob Bartlett said Bradbury has had previous experience in administration of a not-for-profit entity through her role as Secretariat with the Auto Glass Association.

“Hiliary brings to this new role a wealth of relevant experience in providing administration support for an industry body” Bartlett said.

“She has expertise in understanding the challenges and opportunities that present in representing and managing an emerging entity that has a variety of different members and stakeholders.”

One of her key responsibilities, will be to manage memberships and liaison with repairers. Following on from recent information nights, registrations for membership of the ACIA are starting to come in from repairers, along with support from industry partners.

Bradbury said she was excited to take on the role at the newly formed industry body.

“I fully appreciate the task ahead for the industry in increasing its attractiveness and making career pathways easier to navigate,” Bradbury said.

“I look forward to supporting the board and the members on initiatives to sustain the industry.”

The alliance’s goal is the sustainability and long-term success of the collision repair industry. Contact the alliance at theacia2023@gmail.com

The TOUCH facilitates the measuring and the diagnosis of damaged vehicles within just a few minutes. By employing the measuring probes of different lengths, the TOUCH is the only measuring system available that can reach the most complex measurement points of the vehicle body, including the external and mechanical parts.

Axalta’s business services arm has undergone a major rebranding with a renewed focus on providing help specific to the challenges faced by repair and body shops.

The services program, which will include consultancy, digital services, management training and network services has been rebranded as Drivus, aligning it to services offered in other regions, including Europe.

Axalta hopes that the 150 year history of the parent company as a leading coatings producer and with networks across 130 countries, will bring to Drivus the experience and innovation for which company has become renowned.

Axalta’s national Drivus manager Robin Taylor says the business program was part of Axalta’s ongoing commitment to providing innovative solutions to the Australian and New

Zealand collision repair industry.

“We have a long history of working with and understanding the specific challenges faced by body shops of all sizes – from small independent to large multi-shop operations,” Taylor says.

“As a complete business partner to the refinish industry, Drivus helps meet the needs of our customers, providing essential business services for body shops looking to drive future innovation.”

Taylor says Drivus’ focus for repair and body shop owners was to improve productivity, performance, profitability, and build better businesses across the industry.

“By implementing initiatives designed to work faster, smarter and with less waste, efficiency is improved, allowing body shops to diversify new offerings. It is built on constant,

long-term improvement, allowing for future planning.”

For more information on Drivus Business Services, contact Axalta on 1800 292 852 or visit: axalta.au/drivus

Gemini Ballarat is one of a growing number of repair businesses dedicated to training that has been awarded I-CAR Gold Class Collision status.

AMA Group technical training, prestige and OEM manager Scott Donnelly said the process to get to the gold status encouraged a healthy and competitive environment.

“It is good recognition for the site, but it also becomes competitive between the sites and states, which builds a great competitive but collegiate environment,” Donnelly said.

Gemini Ballarat centre manager Stuart McIntosh said the business had incorporated I-CAR Australia’s training to guide their apprentices into role relevant training.

“We have apprentices beginning to do relevant courses to introduce them to the learning culture that is required in the

modern repair facility.,” McIntosh said.

“The ability to access training via multiple platforms really helps – online, on site, classroom, and hands on. A number of our technicians have achieved Platinum Status so it would be nice to see more technicians reach this level.”

Gold Class accreditation is a great achievement for Gemini Ballarat and continues to elevate the business to achieve the highest standards he says.

“Technology is changing at such a great rate that all facilities need to be well trained. The I-CAR Road to Gold program offers a comprehensive program of training to ensure that all technicians are fully equipped to perform their roles safely and to a high standard.

“With ADAS, EV and Hydrogen becoming an everyday part of our business, it is critical that repair facilities

are ahead of the game with regards to awareness, correct processes, and training.” Donnelly says.

I-CAR Australia supports industry training through a network of approved training providers, as part of its Industry Training Alliance program.

Gemini Ballarat’s accomplishments are also supported by Industry Training Alliance partners.

I-CAR chief operating officer Jason Trewin said the training alliance supported by Car-O-Liner, BASF and Glasurit was key in building a long-term vision in the collision repair industry based on their vision.

“That every person in the Collision Repair Industry has the information, knowledge and skills required to perform complete, safe and quality repairs for the ultimate benefit of the consumer,” he says.

Our product range is built one Genuine Part at a time, giving you the experience of driving the cars of tomorrow, today. Hyundai Genuine Parts have been designed to meet Hyundai’s exact engineering specifications. They are then rigorously tested to meet Australian standards, and given a 12-month manufacturer’s warranty+. Choosing Hyundai Genuine Parts gives you quality assurance, reliability and total peace of mind.

Electric vehicles have experienced a continuing surge with the latest sales estimates for 2023 already exceeding last year’s total.

But international supply is still deterring many potential buyers as they wait on delivery according to a new report from a leading alternative transport advocacy group.

The figures compiled by the Electric Vehicle Council for their State of Electric Vehicles report has also highlighted policy barriers to the uptake, with demand and forward orders far exceeding the supply of cars coming in from overseas.

According to the report electric sales from January to June this year rose to 8.4 per cent of new car sales across Australia compared to 3.8 per cent in 2022.

The 46,624 EVs sold in the first six months of 2023 mean there are approximately 130,000 EVs on the road in Australia – made up of about 109,000 battery powered cars and 21,000 hybrids.

But more than two thirds of these sales are made up of only 3 models, the Tesla Model Y, the Tesla Model 3 and a massive emerging player in the market, China’s BYD with its Atto 3 model.

These three models represent over 68 per cent of Australian EV sales despite

there being 91 electric vehicle models available on the local market, including cars, vans and utes.

The Electric Vehicle Council maintains the small volumes of supply coming in from overseas for many of these models are the result of Australia not having a New Vehicle Efficiency Standard to ensure car manufacturers increase the supply of EVs to Australia.

The council is pushing the federal Government to implement the fuel efficiency standard by the end of the year, giving an incentive for manufacturers to increase the per centage of zero-emissions sales, By this time the council is hoping the EV fleet across Australia will reach 180,000 vehicles.

The Electric Vehicle Council has also highlighted which states have the most conducive policies to EV uptake with Victoria scoring a bare pass with five out of ten, compared to top scorers, ACT and NSW, that both scored nine out of ten in the report.

The report outlined the result for Victoria was due to a sudden cessation of the EV rebate incentive in July 2023 and “the world’s worst” approach to taxing EV ownership through road use.

in Victoria acts as a disincentive with EV purchasers, who are left by the government in a negative net position after paying the road user tax which amounts to $1612 over five years.

It would also put Victoria at the back of the queue for international supply of vehicles should the Federal Government implement a New Vehicle Efficiency Standard, it says.

“Australians should not be unfairly or prematurely taxed for embracing zeroemission technology which will be critical to achieving emissions reduction targets,” the EV Council report notes.

“The Electric Vehicle Council awaits the outcome of the challenge brought in the High Court to the validity of the Victorian Government’s Zero and Low Emission Vehicle Distance-based Charge in late 2023.”

The Victorian Government has maintained the road user charge was introduced to ensure all road users contribute financially to the upkeep of the state’s roads.

The EV Council’s report also highlighted a 57 per cent increase in the number of charging station points since last year at 558 locations across Australia but maintained more

Planning is well under way for one of the ‘must-attend’ events of the automotive calendar and a date change in 2024 will ensure that in 2024 no clashes for enthusiasts.

The Australian Automotive Aftermarket Association (AAAA) has locked in the new dates of the highly anticipated 2024 Australian Auto Aftermarket Expo and co-located Collision Repair Expo taking place at the Melbourne Convention & Exhibition Centre.

In 2024 the Expo was initially scheduled for March but again, late scheduling dates for Melbourne’s 2024

Australian Formula 1 directly clashed with the original timing. AAAA chief executive Stuart Charity said the new dates would ensure the Expo had the full attention of the entire industry and was a successful and valuable experience for exhibitors, sponsors, and the thousands of Australian and international trade visitors.

“Given the impact the unavoidable clash with the Melbourne F1 Grand Prix had on +2022 Expo visitor numbers, the spike in accommodation rates and flight costs for interstate and international exhibitors and visitors, and complications for companies

who are involved in both events, retaining the original dates in March was an unacceptable proposition,” Charity said.

“With the new dates locked in, the AAAA looks forward to delivering the biggest and most impressive Australian Auto Aftermarket Expo and Collision Repair Expo ever. We invite everyone in the automotive trade to join us in April for this valuable event to learn, network and experience the best our industry has to offer.”

The combined Expos are the nation’s only comprehensive exhibition for Australia’s $25B aftermarket industry.

The global automotive industry represents a massive consumer of natural resources and energy, so the inroads it has taken into reuse and recycling are valuable not only in their sustainability of precious natural resources but in the long-term impact on the environment.

In Europe, where the industry must deal with up to 5.6 million scrapped cars per year, the EU Commission has stepped up its proposal to ensure manufacturers have an obligation to recycle their own cars under ELV legislation.

Currently the European industry has targets where up to 85 of materials from an old car are reused and recycled with a further 10 percent of materials converted to energy production.

But there is broader debate on sustainability issues in the automotive industry including Europe’s peak body, the ACEA that argues any mandate on reuse percentages should be backed up by a sustainable circular economy that can ensure the economic value of recycled products, so waste, stockpiling and dumping are minimised.

In Australia, one valuable example of the practice of reutilising resources is the market for used automotive parts. More than 800,000 vehicles are deregistered each year through use, condition or collisions that write them off.

This makes the reuse of otherwise sound vehicle parts even more valuable not only in the sustainability it adds to the industry but the end costs that can flow onto customers.

ACM Parts has been in the reclaimed parts market for almost a decade and is able to rescue more than 10,000 vehicles each year.

It ensures that the most valuable parts of the four fifths of a car’s material that can be reused, continue back into the repair market.

ACM Parts, with its economy of scale and sites across Australia, rescues the parts which are then taken through

their production process and form ACM’s Reclaimed range.

The Reclaimed range further adds to ACM Parts’ sustainability credentials for a company that is Australia’s largest provider of alternative and specialty parts to the repair industry, thus ensuring cars stay on the road longer by providing more repair options and extending the life of a vehicle.

ACM Parts can also bring its expertise in the industry to ensure only the best parts are reused, that they are the best available part for fit and function, and in turn ensures maximum uptake of the used parts and the resources that go into them.

This process also comes with the added advantage of saving consumers as much as half the cost of new parts.

Parts that are regularly reused include large and costly when-new elements like engines and gear boxes, along with smaller components for clutches, brakes suspension, alternators, ignition systems, sensors, heating and aircon.

ACM Parts Reclaimed also deals in

exterior pieces like body components, doors, headlights, and indicators.

All the reclaimed automotive parts are taken by ACM through an extensive quality control process to ensure the part received is as described.

All pieces are catalogued and distributed through one of four ACM Parts warehouses across Australia. ACM Parts also says recycled parts offer convenience, coming with most necessary attachment and adding to the ease of installation.

ACM’s sustainable recycling of deregistered vehicles extends to other material from the vehicles which are separated and re-purposed; all fluids are drained separately and filtered, to be re-used. While other left over metals including plastics and rubber are melted down and returned into the circular economy including in the production of a diverse range of products from roads to containers and ducting.

The Reclaimed range features both collision and mechanical parts and is sold to repair shops across Australia.

A renewable energy group has travelled regional Australia in one of the country’s first fully electric utes to learn the key actions to drive EV uptake.

Solar Citizens travelled more than 10,000km as part of its Electric Ute Roadshow to talk to regional communities about what was holding them back from embracing the new clean technology.

The report highlighted range anxiety in the regions, along with the need for increased charging infrastructure as high on the list of recommendations that would not only boost uptake but add to regional prosperity.

The group also wants the Federal government to implement a strong mandatory Fuel Efficiency Standard (FES) to unblock the supply of electric vehicles for Australians. It is also advocating for solar-shaded roofs in carparks and on charging stations, to increase supply of clean energy to charge electric vehicles.

Its final recommendation is to remove barriers to charging from the electric vehicle including vehicle-to-home and vehicle-to-grid technology to free up versatility so that tradesmen could run tools using their EV batteries.

Ballarat driver and transport advocate

Ben Lever, who drove the LDV eT60 said he had become a strong advocate.

“I’m lucky enough to have captained one of the first commercially available electric utes on a six month trip through regional Australia. “ Mr Lever said.

“I discovered that EVs are great to drive. The electric ute I’ve been driving is incredibly smooth and quick off the line, but I’ve been even more impressed by the cost savings.”

The Electric Ute Roadshow report also estimates a mandatory FES could boost the economy by $11 billion Australia-wide in five years, $4 billion in the regions.

The Hyundai Motor Company has outlined its strategy as it speeds up its pace toward a new high-tech and electric future, aiming to spend more than $10 billion per year in a bid to be a global mobility leader in the brave new world of transportation.

A third of the investment will accelerate the company toward electrification and transition out of ICE vehicles, with massive investments in new battery development and a new electric platform model.

The company is also aiming to raise its global sales of EV’s to 2 million vehicles per year by 2030.

The new strategy called ‘Hyundai Motor Way’ launched mid-year will also focus on future businesses, such as autonomous driving, hydrogen, robotics and advanced air mobility.

The key parts of the strategy include introducing a next-generation modular architecture for EVs, strengthening EV production capacity and reducing cost along with battery development capabilities.

The company’s second-generation dedicated EV platform, under the new Integrated Modular Architecture (IMA), will replace its current and be used on 13 new dedicated EV models in the group’s automotive brands Hyundai, Kia and Genesis. This will standardise modules and parts between the models, expanding economies of scale and significantly reduce EV development complexity and costs.

Under the IMA development system, over 80 common modules can be utilised across different segments, irrespective of vehicle type, allowing for greater flexibility

and efficiency in the development process and cost savings. This will also feed a target of 10 percent profitability for EVs in 2030

This platform will extend vehicle development beyond current mid-sized SUVs to encompass more vehicle classes, ranging from small and large SUVs to utes.

Part of the plans will be to develop and apply next-generation NCM batteries and LFP batteries, for the secondgeneration platform. It will also implement technology that enables battery charging and discharging while driving, utilising an independent power bank to further extend the driving range.

Integrating AI-based battery management systems to real-time monitoring and diagnosis of battery conditions will be aimed at enhancing safety and preventing thermal runaway. Other large-scale investments are being made into improving solid state batteries and into the innovation of alternative battery research a specialised battery development organisation within its Namyang R&D Center for next generation batteries.

Other major changes in the transition include shifting its manufacturing focus. Currently Hyundai utilises mixed production lines for EV and ICE vehicles for efficiencies but as the market demand grows toward the 34 percent of all car sales expected in 2030, they intend to shift accordingly. It is already investing in dedicated EV factories Including its first dedicated EV factory in Georgia in the United States U.S., with a targeted

start-up date in late 2024, and an annual production capacity of 300,000 vehicles. Another EV-dedicated factory in Korea aims to start mass production in 2025.

The strategy also outlines securing material sources with partnerships including recycling raw materials, and is focusing on lithium and nickel which are essential for electrification, a

It also maintains it is securing recycling technology to reutilise materials for battery manufacturing.

The plan also wants to develop ventures into autonomous driving. Their IONIQ 5-based driverless robotaxi business operated by Hyundai is set to launch in Las Vegas at the end of 2023 but plans to expand this globally and is conducting pilot services with Uber under an agreement in the U.S. for the next 10 years. Hyundai will develop the vehicle but also the sales network, infrastructure and after-sales service.

Advanced air mobility (AAM) Supernal, LLC in Washington, D.C. in 2021 and is developing a full-scale technology model planning pilot-ridden flight tests and securing the infrastructure for airframe manufacturing.

In addition, Hyundai Motor is working with Microsoft, aircraft engine manufacturer Rolls-Royce, KT, Hyundai Engineering and Construction as well as other Korean and foreign partners in the telecommunications and construction sectors to expand into various related businesses. Through these efforts, the company expects to lead the way in building the entire AAM ecosystem.

Finally, Hyundai wants to continue its role in using hydrogen expanding its current commercialising hydrogen fuel cell electric vehicles and plan for the production of resource-circulating hydrogen. This will be utilised in the manufacturing of green steel in the energy and resources sector, and decarbonisation of heat and power sources for business sites through hydrogen. The suite of planned uses includes hydrogen mobility, fuel cells and accompanying infrastructure, and eco-friendly logistics systems. This will also help company in its plans to realise carbon neutrality along the use of biogas and waste plastic-based hydrogen, powering its EV production facilities.

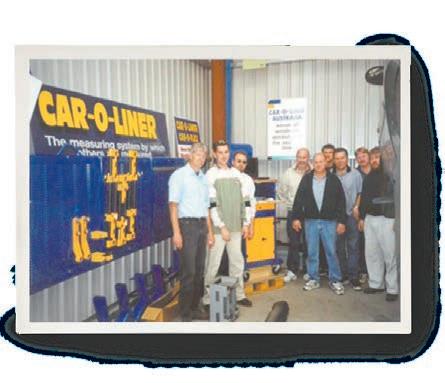

In 50 years, industry leader Car-O-Liner, has seen the collision repair world change but as they have kept pace with these transitions their principle remains the same, finding innovative solutions.

Car-O-Liner, the global company based in Sweden, is celebrating 50 years in 2023 and will mark the year with a number of celebrations but perhaps lesser known is the fact that Car-O-Liner Australia has been there on much of that same journey.

Industry watchers will notice the company is marking the milestone with a special commemorative logo but for those involved, what the company has stood for and achieved is about so much more than logos.

Car-O-Liner reputation is built on the complete line of collision repair solutions, including alignment, and straightening systems, joining and heating equipment, measuring systems, workshop solutions, and testing and calibration systems.

Car-O-Liner market development manager Tim Garner said beyond the products, Car-O-Liner’s history and ongoing dedication was about providing customers continual sales support and some of the finest training options in the industry.

“Since 1973, Car-O-Liner has been known for excellence, innovation and

passion, offering customers a full line of state-of-the-art collision repair solutions,” Garner said. “From alignment and measuring equipment to state-ofthe-art ADAS calibration, Car-O-Liner continues to lead the industry as we enter our next 50 years.”

But one of the themes that seems to run through the celebrations is an appreciation of all those who have shared the journey.

“We thank employees past and present and our loyal customers for being part of Car-O-Liner’s successful journey,”

In Australia this is epitomised by industry stalwart Julie Thomas who joined the company with husband Barrie in 1990.

“As a global player, our reputation for quality, reliability, innovation and longevity is exceptional,” Thomas said

“In addition, our extensive range of global OEM approvals means that our customers can continue to rely on Car-O-Liner as the car manufacturers accelerate their influence in our industry.”

“I firmly believe, however, that it’s so

much more than that. It’s the service, knowledge, capabilities, relationships and commitment to continuous improvement that we here at Car-OLiner Australia deliver to our customers on an ongoing basis. In addition, our team of globally trained practitioners are passionate about our brand, our products and our customers - it doesn’t get any better than that.”

The Car-O-Liner journey for the Thomas family began in 1984 when Barrie Thomas was working as a sales technician for the Australian Car-O-Liner distributor. Julie Thomas came to the industry as an outsider and her first involvement was in implementing the ISO 9000 quality management system, she had experience in.

But it was in 1990 their involvement really stepped up when Julie and Barrie Thomas bought the Australian company. From there, with the support of advisors and the parent company in Sweden, the huge commitment they made slowly paid off and the company was off and running.

Since taking on the Australian distribution for Car-O-Liner in 1990, Julie Thomas and her team have won the international sales award on six occasions, an award which is per-capita based, makes the Australian division one of the most successful, and highlyregarded distributors in the global CarO-Liner organisation.

Julie Thomas was also awarded the prestigious National Collision Repairer Lifetime Achievement Award in 2014. Car-O-Liner Australia was also honoured by the Snap On Corporation in the Asia Pacific Million Dollar Club.

Then recently, Julie Thomas was awarded Car-O-Liners Lifetime Achievement Award, the first time this honour has ever been bestowed.

But putting aside these plaudits, Julie Thomas remains constant in her admiration of the people who have made up the company and forged this reputation.

When celebrating 30 years with CarO-Liner in 2020, in an interview with The National Collision Repairer, Julie was unstinting in her praise of those who have shared the journey.

“I’ve been fortunate to have the staff I’ve had over the years, and I’m extremely grateful for their dedication and commitment.

“I’ve also met some wonderful people in our industry, many of whom have become personal friends, and I’ve also met some very inspiring people at various seminars around the world.”

“You know, many people walk through our lives but only a few leave footprints on our heart. I have been so fortunate to have met quite a few

of these people, some not with us anymore and many more who are still here today. If you ask me if I would do it all again, the answer is absolutely.”

When it comes to a long list of those she singles out for commendations, foremost on the list was her husband Barrie, who sadly passed away in 1997, who she described as the real driver and inspiration for the business.

One of the key legacies for Julie Thomas from Barrie was the importance of appreciating, recognising and rewarding your staff, which in turn engendered dedication, engagement and commitment.

“He truly was a unique individual, loved by everyone and a one-of-a-kind human being who had a truly great outlook on life. Barrie showed how we should treat people, manage people and lead people in so many different circumstances.”

Losing Barrie in 1997 was clearly one of the great obstacles of the Car-O-Liner journey in Australia, but again Julie harnessed her trademark dedication and commitment to people.

At that time the couple’s youngest daughter Nicolle joined the business straight from school and

them make the business work together.

Julie Thomas also speaks proudly of business mentor and coach, John Ryan, who continued to provide guidance over the decades. She maintains that such a mentor is critical for anyone in the industry. She is adamant everyone should have a go-to person within the industry not only for inspiration but for when times are tough.

And over that more than threedecade journey, there have certainly been tough times including several economic recessions and the unprecedented blow that the COVID pandemic dealt business across Australia and the world.

Emerging from this and moving into the future, Julie Thomas maintains it is reassuring to have a market leading brand dedicated to innovation and customer service.

“One of the first things he (John) taught me was the importance of the brand, and how to make Car-O-Liner the brand that’s top of mind whenever you think of equipment in our industry. I have also used someone to create our promotional material, as I knew we needed to make a statement in the industry that we were still here, and

Safety and training are two of the most critical factors affecting the long-term success of any business in the collision repair industry, so the SAPE groups

Automotive Training Academy makes a lasting contribution to the wider industry.

In the five years since opening in 2018 the facility has seen multitudes of trainees take advantage of the revolutionary purpose-built training facility for the collision repair industry.

It attracts a diverse range of attendees, from experienced technicians looking to upgrade their skills to newcomers wanting to enter the field.

The Training Academy creates a virtual workplace for participants to confront the challenges of a real body

shop in a risk-free environment. The venue can be hired to run workshops, planning or training sessions or team development activities.

The purpose-built setup can provide a comprehensive learning experience for professionals in the industry, allowing them to get hands-on experience with the latest tools and products, enhancing their skills and knowledge in collision repair.

Centrally located in Sydney at Condell Park and situated just off the M5 it offers convenience for many attendees.

It serves a dual role, firslty where the SAPE Group can use the academy as the company’s internal training centre. It also acts as a hire venue for training

and upskilling of industry-wide collision repair technicians in best OEM practices, where whoever hires the venue can conduct or arrange their own training.

The SAPE Automotive Training Academy is available to anyone that requires a theory training room or workshop style practical area. Accommodating larger groups in its expansive area, it also has the capacity to smaller niche groups in specialised areas. The classroom can accommodate 20 participants and is fully equipped with modern technologies.

Sydney Automotive Paints and Equipment has a strength in staying up date to date with the latest gear in the industry and they have carried this

When a workshop is cluttered or tired loooking, a change of scenery may be what is needed to inspire staff and get them motivated for training. This well equipped and spacious location in inner Sydney could be the solution.Training with the latest tools and technology at the SAPE academy.

though to the Academy which utilises state-of-the-art equipment from leading brands such as GYS, Spanesi, Celette, Autorobot, Jollift, IRT, Wielander+Schill, Kamatec, and Scangrip.

Having a wide range of the latest European-made collision repair products is likely to be a great advantage for those looking to learn and work with cutting-edge technology and techniques in collision repair without the inital large outlay of purchasing.

It is the chance to work with a diverse range of up-to-date equipment, along with the spaciousness, modern design, that make up the most positive feedback from participants who have experienced the training academy according to SAPE

equipment division manager Beau Knowles.

“The SAPE Automotive Training Academy allows for training & upskilling across a broad spectrum of collision repair methods,” Knowles says.

“Those hiring the venue normally run their own training programs designed to teach individuals the skills and techniques necessary to repair vehicles that have been involved in collisions or accidents.”

The technological edge it can add to the knowledge and skills of repairers is one of the key benefits that the SAPE Training Academy can offer businesses.

“It’s important for OEM Collision Repairers to stay up-to-date with the latest repair techniques and industry standards, given the complexities of modern vehicles,” he says.

“Utilising the SAPE Automotive Training Academy can help these repairers enhance their skills and knowledge, ultimately leading to better service for their customers and safer repairs for vehicles.

“As vehicles become more technologically advanced and intricate,

proper repair and maintenance become increasingly important. Following OEM repair procedures ensures that the vehicle is repaired in a way that maintains its original safety features and structural integrity,” Knowles says.

“This is critical to ensure the safety of the driver, passengers, and others on the road. Training plays a pivotal role in ensuring that technicians have the necessary skills and knowledge to carry out repairs according to OEM standards.”

SAPE intends to ensure that the academy stays at the forefront of one of the industries most challenging areas; ever-evolving technology.

As vehicles become more technologically advanced, their systems and components require specialised tools and equipment for proper diagnosis and repair.

“Remember, staying at the forefront of vehicle repair technology is an ongoing effort,” Knowles says.

“At SAPE, we’re commited to visiting all corners of the globe to bring the best collision repair equipment available in the market today.”

In the 13 months since the right to repair legislation was implemented in Australia, it has been administered by the Australian Automotive Service and Repair Authority (AASRA), an agency that has two key purposes; to work with both the repairers and the OEM’s to free up information for the collision and mechanical repair industry.

Stuart Charity, AAAA chief executive, and also an AASRA director, outlines its key role in bringing about practical benefits for the repair industry from the long journey to forge legislation.

“Really, it’s about creating a level playing field - removing all the impediments to a vehicle owner’s right to be able to choose who repairs the

vehicle and what parts are put on that vehicle.” Charity says.

“Essentially, it provides a front door to the portal of each of the car companies data sharing offerings on the website.

“The other important role is if there are any issues with accessing information. If any information is missing or information that technician believes should be provided under the scheme is not provided by the car companies, AASRA can come in and try and resolve it.

“If they’re not able to resolve it, and it’s an ongoing issue, then they have the powers to refer it on to the ACCC for review and possible compliance and enforcement action.

“The second thing AASRA does

is work with the car companies to help them comply with the scheme, its obligations, and the requirements under law.

“The service that AASRA provides to the car companies is essentially a vetting service to make sure that a technician is working in the industry. If they’re working on high voltage information, they’ve done the training and if they’re working on security information that there’s a police background check.”

Charity stresses that using AASRA’s services is optional for car companies, but AASRA now has more than two thirds of OEMs operating in Australia signed up and importantly car companies must comply with the rules

of the scheme even if they don’t use AASRA’s vetting services.

AASRA executive officer Rodger Nardi describes the scheme as a “game changer” in the level of information the scheme makes available to the industry.

“Any service or repair information that a car company provides to the dealership network has to be made available to the aftermarket,” Nardi says.

“That covers the repair manual procedures, technical service bulletins, wiring diagrams, and it also includes diagnostic software and hardware.”

Many workshops will continue to use data aggregators for basic repairs, he says but the increasing technological complexity of cars with increasing coding requirements will make the added information more important for successful completion of a job.

“And so having that ability to get that information on the same level as a dealer is going to be important for the ongoing viability and growth of the business.”

He says that while some workshops will continue to do things the way they always have, others will see it as a game changer particularly in an ability to access information to complete high value jobs like programming and reflashing.

“These are high dollar items, so this is an area of revenue that that an aftermarket workshop can grab, along with the components.”

Nardi says while the access comes at a fee, often a daily rate ranging from $15 to $50 depending on the OEM, it is how repairers incorporate this into their businesses that can make all the difference.

“And importantly, if it’s used properly, this can really increase the efficiency in the workshop,

“You’ve got a car that comes in with a dozen trouble codes. You’d say, I’m going to pay $21 a day for example, to look at the genuine repair manual. I’m going to look for technical service bulletins to diagnose the fault. You might even want to go the next step and say I’m going to pay $50 for the day and run the trader’s own tech-stream genuine software across the car. It is a bit of a game changer with all those bits you could not do before the legislation.”

The efficiency really comes when

repairers can use the accessed information for multiple jobs, he says.

“You are looking at that fee for a day and you’re billing it to one job, you saved yourself 15 minutes and would probably breakeven. But it’s not unrealistic to jump on and do this multiple times a day.”

He says a specialist in a particular brand can buy the genuine diagnostic tools and diagnostic software which though they can come at higher prices, represent good value where repairers are working on high value jobs.

What have been the hurdles so far?

One of AASRA’s key roles is to help repairers with missing information and members can lodge a missing information report.

“So that might be for information that the repairer can’t find on the OEM’s website,” Nardi says.

“Or they might get to a point where the car company says you’re not entitled to that information under the scheme and the repairer believes they are.”

“We record all that and it’s logged. We know exactly how many missing information reports are logged against each car company and what percentage of the market that car company has and that’s part of tracking but in most cases, they’re solved.”

Under the scheme car companies can be fined if they are found to be in breach of the law.

But Nardi says the largest number of issues arise not from information being withheld but the navigation of OEM websites.

“The majority of cases centre around

being able to find the right information,” Nardi says.

“It’s probably the biggest question I’m continually asked.. They don’t have to provide navigation. It’s not in the legislation. But my argument is, we get the missing information report where a collision repairer can’t find a repair method. We then go to the car company contact which creates work for us and work for them. But the information was there all along. So I say well, why don’t just they give us a navigatable PDF of the website? At this stage, we’ve managed to get that out of Mazda, Isuzu, Nissan and Ford.”

Nardi says it is one of the agency’s key priorities and more cooperation on navigation would improve handling complaints and benefit the whole industry.

“We’ve just got to make navigation easier and demystify the whole scan tool software process.”

AASRA is hopeful with feedback from both repairers and the OEMs they may be able to create PDF’s to assist in navigating most major brands websites.

“If you’re dealing with dozens of brands, it can be challenging. For aftermarket workshops, I would like to think that if we can’t get the navigation information we may be able to collectively create some documents to do that.”

Other pressing priorities are to encourage car companies to offer software by the day.

“That’s critical for an ordinary workshop because nobody wants to be dealing with one brand and then having to try and pay an annual subscription just to fix one car,” Nardi says.

Another issue is that some car companies do not differentiate between access to their information on EV and ICE vehicles, meaning those seeking access to any information must have basic EV training. Currently five car companies; BMW, Jaguar Land Rover, Mercedes and Volvo do not differentiate. This access proved a challenge on launching more than a year ago because no one had the specific qualificatiown.

Charity says this has also resulted in huge demand and growth for EV Training in workshops which will ultimately help the industry adapt to the future.

“You’re talking about a one-day course in most cases $600-$800. It’s not highly prescriptive training or training that requires a huge amount of time, or capital investment.

“There are 700-800 technicians that are now accredited for EV access through AASRA but we expect that to grow massively over the next few years not only because hybrid technology has been out there for about 15 years but we are seeing a massive uptick in sales of full EVs as well. The EV qualification is all about safety, and is designed to

ensure that a technician knows how to safely depower a vehicle, plus use PPE and the correct tools,” Charity says.

“As business owners, and managers if you are working on EVs and hybrids you need to ensure that your staff are protected and adequately trained because we’re talking about up to 800 volts of electricity in some vehicles. So that could be deadly if you don’t have the correct tools and training.”

Charity makes it clear the implementation of the legislation has been a long journey and it is a journey that AASRA will continue refining and developing to improve the service and support the industry.

Although the launch in July 2022 saw some IT complications, since January this year AASRA has cleared the backlog of applications and simplified the website. They also have extra staff and most emails are cleared within a day. Where the documentation is approriate, some urgent requests like security codes can be sent back within minutes.

“We’ve essentially seen a world opened up to us that had been closed before but it’s a pretty complex world

and there’s no easy way around this,” Charity says.

“I think a lot of people thought that AASRA was going to be the holder of all information. It was all going to be catalogued, like a data aggregator but it’s not how the scheme works here or in any other country that has data sharing. It has to go through the vehicle manufacturers websites and we’ve got a multitude of manufacturers all coming from different countries and doing it different ways. It is challenging for independent repairs, but I think that that knowledge base will build over time (along with) those networks and education.”

While Australia now has its right to repair legislation, the legal battle playing out in the United States has also highlighted another future unresolved element in automotive information. This time it is telematics; the combination of vehicle technology and communications technology, such as mobile phone notifications about a vehicle.

“Telematics is the next battleground for right to repair,” Charity says.

“In Massachusetts about a year and a half ago they got another law through to ensure that the car owner controls the data in the car and they have control on who it is sent to and under what terms. Unfortunately, that legislation has been challenged by the car companies in the federal court and there still isn’t a verdict on that.

“We do know every vehicle sold these days has got telematics and it is only a handful of the prestige brands that have operationalised it at the moment. But it’s something that that will need to be addressed in this country and it’s something that the AAAA is actively involved in.”

“Our government has made a clear line in the sand here that they’re going to protect consumer choice. And we think this is just an evolution of that due to changes in vehicle technology.”

AASRA

numbers; 35 participating brands / 19 nonparticipating brands.

+3,200 technicians as members. 567 completed EV certification. 844 checked as vehicle security professionals.

Ever-changing technology is one of a repair workshop’s biggest challenges. A new Capricorn partnership is bringing a suite of exciting new diagnostic tools

Australia’s largest repair industry cooperative wants its latest partnership to provide new cutting-edge resources and solutions for one of the biggest issues facing workshops, keeping pace with technology.

Capricorn Society Limited has entered into a joint venture agreement with leading automotive diagnostic service provider Repairify Australia Holdings Pty Ltd to boost the repair industry’s ability to deal with ever changing vehicle technology.

Repairify provides market-leading remote automotive diagnostic services across North and South America, Canada and Europe, with strong long-term relationships with a wide range of OEM’s.

Capricorn and Repairify each have a 50 percent ownership of the joint venture, branded Repairify, and will deliver advanced automotive remote diagnostic services to repairers across Australia and New Zealand as a Capricorn preferred supplier.

Repairify will be bringing to market the full suite of asTech diagnostic and calibration products including Repairify Remote Services. The propostion will cover over 98 percent of makes and models in the Australian and New Zealand car parc.

Additional Repairify products will be considered in the future based on the needs of the market.

Repairify has the goal of pushing all boundaries to stay at the forefront of innovation. It has built its reputation across the globe with its specialist knowledge of Diagnostics, ADAS and specialist electrical repairs and is the leading provider in remote diagnostics,

calibrations, and programming for the collision repair industry.

Capricorn Group chief executive officer David Fraser says the exciting joint venture was all about Capricorn’s commitment to providing support for its more than 25,000 member businesses, with the best equipped and connected technology to deal with modern vehicle servicing.

“Being able to efficiently and effectively diagnose and calibrate remotely connected vehicles is imperative to the long-term business success of the smallest to the largest automotive workshops across Australia and New Zealand,” Fraser says.

“We are delighted to have formed this joint venture with Repairify who have built a strong reputation across the world for their patented technology and experience, sharing the same commitment to the success of the

automotive aftermarket repair and service industry.

“Capricorn’s core purpose is to support its members to build stronger businesses and we are confident that this exciting joint venture represents a major leap forward in actioning this commitment by providing unparalleled Member and industry support,” Mr Fraser says.

Leveraging digital tooling and remote service expertise enables automotive repairers and service centres to deliver a superior customer experience with faster turnaround times and increased workshop productivity.

Repairify president Cris Hollingsworth says the deal would enable them to leverage Capricorn’s more than fifty years of strength and leadership in the industry.

“We see a huge opportunity to support Australian and New Zealand

repairers as the technology evolves and we are keen to introduce our proposition to the market,” Hollingsworth says.

“Capricorn is a natural choice

for a strategic partner due to their unparalleled position in the marketplace in Australia and New Zealand. We are confident that with our products and services and the

Capricorn network, we can rapidly introduce our technology to ensure that the market can undertake and complete complex vehicle repairs.”

Capricorn Members will benefit from being able to utilise their Trade Account for all payments under the agreement and earn Rewards Points on all purchases.

Repairify said it would be announcing its commercial strategy shortly and was confident it would give both Capricorn Members and non-members access to services at an exceptionally costeffective price point.

Repairify products and services will be available to all automotive aftermarket workshops across Australia and New Zealanwd, regardless of whether they are a Capricorn Member or not, this was to underly Capricorn and Repairify’s commitment to best support the whole industry towards a stronger future.

More information: repairify.com.au

ACM Parts’ range of quality assured aftermarket parts guarantee material, fitment, and functionality, offering peace of mind when selecting an aftermarket part. This range includes collision parts, lighting, and cooling components to suit a large range of major makes and models.

ACM’s Aftermarket range is focused on quality and reliability. You can rely on every part to meet all the OEM lifecycle performance standards — offering repairers an easy, fast, and cost-effective solution for sourcing parts.

Each collision part has been individually verified to ensure fitment, functionality, and quality. To guarantee this before moving into production each part undergoes thorough assessment testing against its genuine equivalent.

For more information on our wide range of ACM Aftermarket parts with nationwide delivery call our customer service team on 1800 226 727.

From Renaissance art to modern fashion, it is hard to match the skill and innovation of the Italians when it comes to colour, so what better place than Italy to establish and invest in a colour centre of excellence for a leading coatings manufacturer.

PPG’s Automotive Coatings in Europe has inaugurated an innovative centre of excellence facility at its Quattordio site in Piedmont, northern Italy, aiming to help vehicle OEMs get the most from the critical role of colour in automotive design.

As well as being a key production site and innovation hub also includes a styling centre which is used to support the study and development of new automotive colours.

PPG has invested 2.3 million euros (AUD $3.85 million) into the site that incorporates a centre of excellence

aimed at combining colour development and application in a single process.

PPG says the benefits include reducing the lead time to bring new colours to market, optimising costs and maximising colour performance.

In addition, the facility is equipped with artificial intelligence tools that will be used in the colour development and quality control processes.

These include a statistical and machine learning tool that can reduce the number of colour adjustment steps, reducing costs and overall cycle-time during the development of basecoats and coloured products.

PPG Operations Director EMEA, industrial coatings segment Isabella Ercole says the new centre isset to be a game-changer.

“This project reflects PPG’s ambition to be the first-choice partner to meet

The only car awards in the world composed exclusively of women automotive journalists has added new credentials to the line up on its international jury.

The Women’s World Car of the Year announced Tanya Gazdik, an automotive journalist from the US, has joined the jury in August with the award panel now covering 71 judges from 49 countries.

In the US, Women buy 65 percent of new cars sold and influence more than 85 percent of all car purchases, according to GirlPower Marketing and Snapcell, so it is argued the focus of the awards and the makeup of the jury has real market power.

Female buyers and the influence of female experts can also have formative power in shaping buying and

manufacturing trends.

Currently in the US, fuel economy is a big issue for most consumers making hybrids, PHEVs and electric vehicles more and more popular. SUVs continue to gain popularity while crossovers blending SUV’s and sedans are also very popular.

Tanya Gazdik currently covers automotive marketing for MediaPost and she programs and runs two conferences for them at the New York and Los Angeles auto shows that are attended by several hundred C-suite automotive executives as well as agency and suppliers.

MediaPost.com is an online publishing resource that works across multiple platforms.

Gazdik has just started freelancing for A Girl’s Guide to Cars, which she says gives

customers’ evolving needs for innovative paints and coatings and provide industryleading solutions that provide productivity and sustainability benefits,” Ercole says.

“This new centre of excellence, an end-to-end combination of the development and application of colours, is also an investment in our employees, who will benefit from an innovative workspace and will be able to improve their skills working together as a One PPG Team.”

her a chance to write more creatively and in the first person about the aspects of a vehicle that appeal most to women.

Leading global coatings company, Axalta announced a 4.8 jump in sales driven in part by strong volumes in its transportation coatings sector.

Axalta Coating Systems’ quarterly result released in August for the period up until June 30 show the improvement over the same period in 2022 including a 6.8 per cent higher average price mix.

Axalta released the results to the North American market with highlights including mobility coatings net sales increased 15.5 per cent, led predominantly by strong volumes and modest improvement in price-mix.

Performance Coatings net sales were flat compared to last year the company reported.

The 2023 figures were also boosted by absence of the commercial agreement restructuring charge incurred in quarter two in 2022.

“Income from operations in the quarter was impacted negatively by

higher year-over-year compensation expense and approximately $15 million of costs associated with consulting spend and the ERP implementation,” Axalta said in a statement.

Mobility Coatings net sales were $437.9 million for the quarter, an increase of 15.5 per cent compared to 2022. Volume growth of 12.8 per cent was driven by improved Light Vehicle and Commercial Vehicle production rates.

The company also highlighted that volume decline was primarily due to production constraints following an Enterprise Resource Planning

“Volumes decreased by 3.7 per cent as market demand in Mobility Coatings and Refinish were more than offset by temporary operational delays impacting our ability to meet customer demand from an ERP implementation in North America.

“Despite notable stabilisation in June, warehouse management and

slower shipping activities in the quarter resulted in an estimated negative 2-3 per cent year-over-year net sales impact and drove an elevated quarterend sales backlog, most notably in Refinish.”

Axalta’s CEO and President Chris Villavarayan said the quarter result including the strong sales result was much closer to how they wanted the company to be performing.

“I am particularly proud of how our teams rebounded from a broad and complex ERP implementation in May and delivered a solid quarter, including a sales performance for North America in June that was one of the strongest in our history,” Villavarayan said in a statement.

“This launch was a crucial step towards achieving the margin improvement trajectory we want for Axalta.”

Global paint producer PPG has notched up its fifth consecutive year winning approval on an international yardstick measure for environmental and social practices.

FTSE4Good Index Series is designed to measure the performance of companies demonstrating strong environmental, social and governance (ESG) practices and was created by the global index and data provider, FTSE Russell.

It is one of the indexes used as a measure for the growing appetite for responsible investment funds across multiple industries.

FTSE Russell evaluations are

based on performance in areas, such as corporate governance, health and safety, anti-corruption, climate change and other ESG criteria.

PPG has unveiled its 2030 sustainability targets, including greenhouse gas emissions targets which have been validated by the Science Based Targets initiative (SBTi).

PPG vice president, global sustainability, Diane Kappas said the recognition highlighted its global commitment to sustainability in its steps to reduce packaging, increase resource efficiency, and improve environmental impacts and use innovation to move

“Sustainability is embedded into how we operate as an organisation. It enables us to achieve greater operational excellence and meet the evolving needs of our customers,” Kappas said.

“We are honoured to be a constituent of the FTSE4Good Index and recognised for our strong focus on sustainability and ESG priorities.”

PPG has recently been recognised for its sustainability and ESG efforts by a host of other organisations, including EcoVadis, MSCI, Newsweek Magazine America’s Most Responsible Companies and JUST Capital.

Yohanna Peet, who leads the “Technician Apprenticeship Program” (TAP) for Caliber Collision, the largest collision repair chain in the United States, believes collision repairers need to develop a broader pool of potential candidates when looking for the employees they need. Speaking at a recent conference for women working in the industry, Peet said she watched technicians during the pandemic leaving not just Caliber’s more than 1,700 shops, but the industry as a whole.

“They found roles where they don’t

have to put the wear-and-tear on their bodies anymore,” she said.

“One of my painters is now working at a theme park, painting carousel horses. They found ways to make themselves more valuable and to bring purpose to what they’re doing and to themselves.”

In working to help replace that talent, she’s learned that “literally anybody is a candidate at this point,” even a waiter or waitress who clearly understands customer service.

“My selection pool is anybody who could potentially be an asset to the

team,” she said. “In our industry, we’re teaching you how to do the work. I live by one motto: I can teach you how to do anything I know how to do, but I can’t teach you how to care. To care about people, to care about being at work on time, to care about your own learning and development.”

Caliber’s TAP is a paid, on-the-job apprenticeship program that graduated more than 250 new technicians in 2022. Overseeing the program has shown her that contrary to what some people think, young people do want to learn new skills, but how they want to learn has changed.

“They just want 45 seconds of learning or three minutes of learning,” she said, noting they are accustomed to finding a YouTube video with whatever information they are looking for. “They want to be taught what they need to do right then so they can take action right away and get a star on the board. We have to find a way to give them the learning they need because when we don’t, they may find the wrong information online. So that’s one of the things we’re working on.”

Other speakers at the conference offered their own take on how the industry can find the new employees they need. Olivia Peterson, a technician with Gerber Collision and Glass, another large North American chain, agreed that shops should look beyond traditional sources. She learned early on in the pandemic that she didn’t want to work remotely.

“I needed to get back to a place where I needed to be at the work onsite, I needed to be using my hands,” said Peterson, whose career in the industry started just three years ago. “Try to find pools of people who have just those sort of hand skills but not necessarily automotive backgrounds. One of the things my [autobody] instructors noted

The industry skills shortage is being felt around the world and the question on many minds is how to attract and keep a new generation, including female candidates, to keep businesses strong.TechForce Foundation’s Jennifer Mayer.

is that some of the most successful students are ones who came in knowing absolutely nothing about cars. So we need to really foster the development of people from non-traditional backgrounds, and finding ways to transform skills that may seem completely unrelated into something they can do in the collision repair field.”

Jennifer Mayer of the TechForce Foundation said the industry suffers because fewer than 3 percent of technicians are women.

“If you want to solve the tech shortage, welcome women,” Mayer said, drawing applause from the mostly female audience at the conference. “The No. 1 way to do that: Make sure if you have any women working for you that they are part of the interview process, that you’re pushing that out in your ads and marketing, getting them out in the community in order to inspire. People need to see it to be it.”

She said Gen Z is one of the most socially conscious generations since World War II. “That means they want to make the world a better place,” she said. “They want to have a positive impact. They want to know why what they are