MAMS Group Tropic Thunder

INDUSTRY

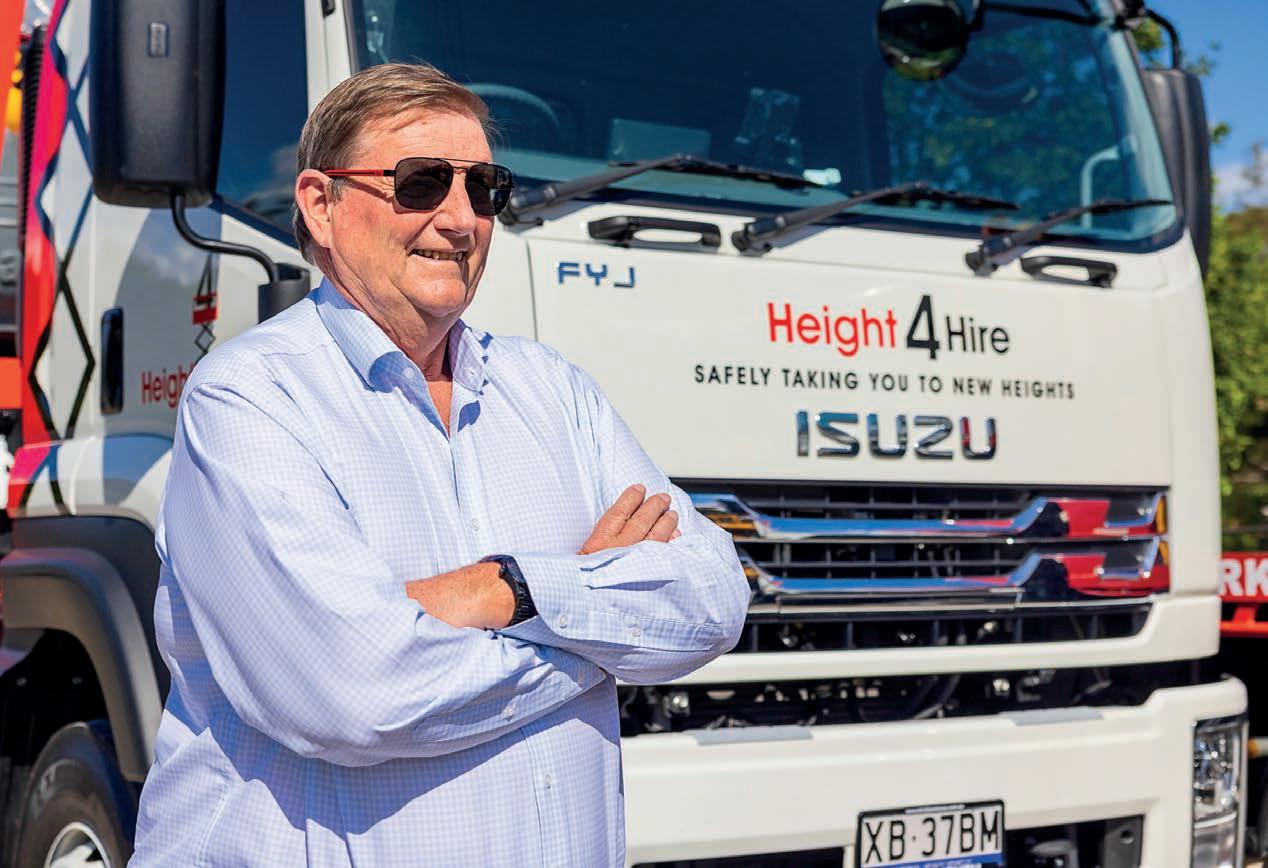

Carrier: Fred’s Interstate Transport

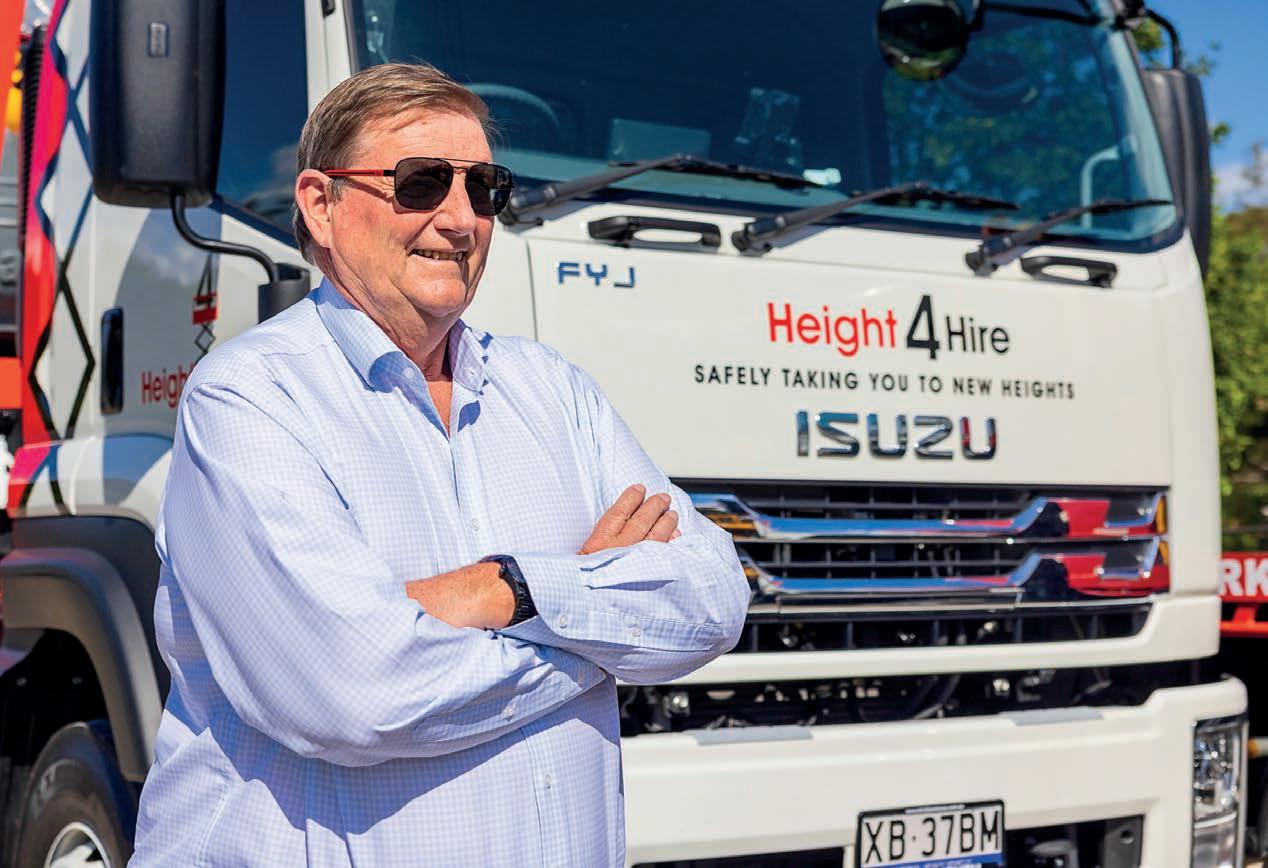

Feature: Height 4 Hire

Showcase: Brisbane Truck Show Preview

Personality Profile: Ryan Laskey

INNOVATION

Fleet: Gavin Sut ton Transport

High Productivity: SRH Milk Haulage

Test Drive: IVECO S-Way

Delivery: Blanc Robot

MAGAZINE Delivery Magazine inside: Pages 105-111. ® May 2023 ISSN 1838-2320 9 771838232000 04 MAY 2023 $11.00 THE PEOPLE & PRODUCTS THAT MAKE TRANSPORT MOVE

You hear people talk about the “building game”. But it’s no game, it’s serious business. And you need a serious truck to handle bigger payloads. Isuzu Ready-to-Work trucks can carry around a tonne more than a typical ute, most only requiring a standard car licence. And you’ll be covered with Isuzu’s industry-leading six-year warranty. So, stop playing around. Head to isuzu.com.au or visit your nearest Isuzu Truck Dealer now. Warranty is subject to the conditions outlined in the IAL New Vehicle Warranty. 6 year warranty applies to cab chassis only with a 3 year warranty on ready-to-work truck body. For further information please visit isuzu.com.au or contact your local dealer. Children depicted are actors and not actually engaged in workplace activities. FSA/ISZS1462 READY-TO-WORK RANGE Playtime’s over. Visit twusuper.com.au/insurance

MEET THE TEAM

John Murphy | CEO

John has been the nation’s foremost authority in commercial road transport media for almost two decades and is the driving force behind Prime Creative Media becoming Australia’s biggest specialist B2B publishing and events company. Committed to servicing the transport and logistics industry, John continues to work tirelessly to represent it in a positive light and is widely considered a true champion for the growth of the Australian trucking and manufacturing industry.

William Craske | Editor

Over the past two decades William has published widely on transport, logistics, politics, agriculture, cinema, music and sports

He has held senior positions in marketing and publicity for multinational businesses in the entertainment industry and is the author of two plays and a book on Australian film history. Like many based in Melbourne he is in a prolonged transition of either returning or leaving.

Peter Shields | Senior Feature Writer

A seasoned transport industry professional, Peter has spent more than a decade in the media industry. Starting out as a heavy vehicle mechanic, he managed a fuel tanker fleet and held a range of senior marketing and management positions in the oil and chemicals industry before becoming a nationally acclaimed transport journalist.

Peter White | Journalist

Having recently completed his Bachelor of Media and Communication (Media Industries) degree at La Trobe University, Peter brings a fresh perspective to Prime Mover. Invaluable experience obtained during his time at upstart, La Trobe’s newsroom, has been supplemented by direct industry experience in a Council placement. Peter is looking forward to contributing to the magazine’s image as the leading publication for commercial road transport with his developed skills.

Ashley Blachford | Business Development Manager

Australia’s leading truck magazine, Prime Mover, continues to invest more in its products and showcases a deep pool of editorial talent with a unique mix of experience and knowledge. www.primemovermag.com.au

Handling placements for Prime Mover magazine, Ashley has a unique perspective on the world of truck building both domestically and internationally. Focused on delivering the best results for advertisers, Ashley works closely with the editorial team to ensure the best integration of brand messaging across both print and digital platforms.

ceo John Murphy john.murphy@primecreative.com.au editor William Craske william.craske@primecreative.com.au managing editor, Luke Applebee transport group luke.applebee@primecreative.com.au senior feature Peter Shields writer peter.shields@primecreative.com.au

business Ashley Blachford development ashley.blachford@primecreative.com.au manager 0425 699 819

art director

Blake Storey blake.storey@primecreative.com.au

design Kerry Pert , Louis Romero, Tom Anderson

journalists

Peter White peter.white@primecreative.com.au

Louise Surette louise.surette@primecreative.com.au

design production

Michelle Weston manager michelle.weston@primecreative.com.au

client success Salma Kennedy manager salma.kennedy@primecreative.com.au

head office 379 Docklands Drive, Docklands VIC 3008 enquiries@primecreative.com.au

subscriptions 03 9690 8766 subscriptions@primecreative.com.au

Prime Mover magazine is available by subscription from the publisher. The right of refusal is reserved by the publisher. Annual rates: AUS $110.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate.

articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

copyright

PRIME MOVER magazine is owned and published by Prime Creative Media. All material in PRIME MOVER magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher.

The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information

Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in PRIME MOVER magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

MAMS Group Tropic Thunder Delivery Magazine inside: Pages 105-111. MAY 2023 primemovermag.com.au ® May 2023 THE PEOPLE & PRODUCTS THAT MAKE TRANSPORT MOVE Carrier: Fred’s Interstate Transport Feature: Height Hire Personality Profile: Ryan Laskey Fleet: Gavin Sutton Transport High Productivity: SRH Milk Haulage Test Drive: IVECO S-Way Delivery: Blanc Robot

AUSTRALIA’S ONLY HYBRID ELECTRIC TRUCK

THAT’S ANOTHER HINO

UP TO 20%* FUEL SAVINGS WITH THE SELF-CHARGING HINO HYBRID ELECTRIC.

The Hino 300 Series Hybrid Electric light-duty truck is the perfect solution for your business. Delivering up to 20%* fuel and emissions reductions - with no recharging or range limitations, it has led the way for over 15 years. It’s the first and only light-duty Hybrid truck to meet Euro 6 exhaust emissions standards and customers can also benefit from a 16% reduction in maintenance costs. Driven by Toyota Group technology, experience Australia’s only Hybrid Electric truck that reduces your operational cost to gain a genuine competitive advantage. Harness the Hino Hybrid Electric today! Find out more at hino.com.au

XAVIER_HINO38956.30

*Actual results will vary depending on the application of the vehicle and how it is driven.

COVER STORY

“We needed a cabover and something that was exceptionally manoeuvrable. Most of the other trucks I drove didn’t have a chance of getting into some of these places we need to get into.”

CONTENTS Prime Mover May 2023 100 44 56

68 90

Prime Feature Stories

FLEET FOCUS

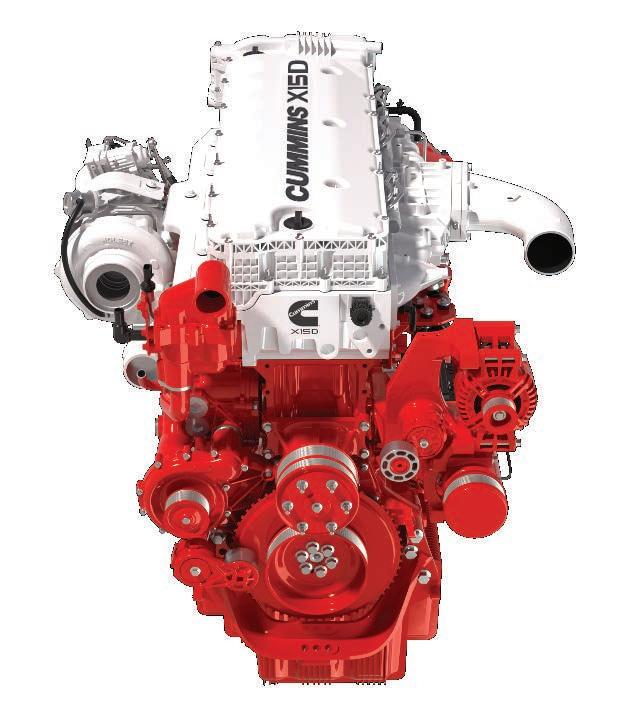

44 Tropic Thunder

Waste collection specialist, MAMS Group, covers a vast municipal area in North Queensland the size of a European country. For this it relies on a dedicated fleet of commercial vehicles.

52 Smoke Stack Lightning

Gavin Sutton Transport demonstrates that commitment and agility are vital to create a successful modern transport operation.

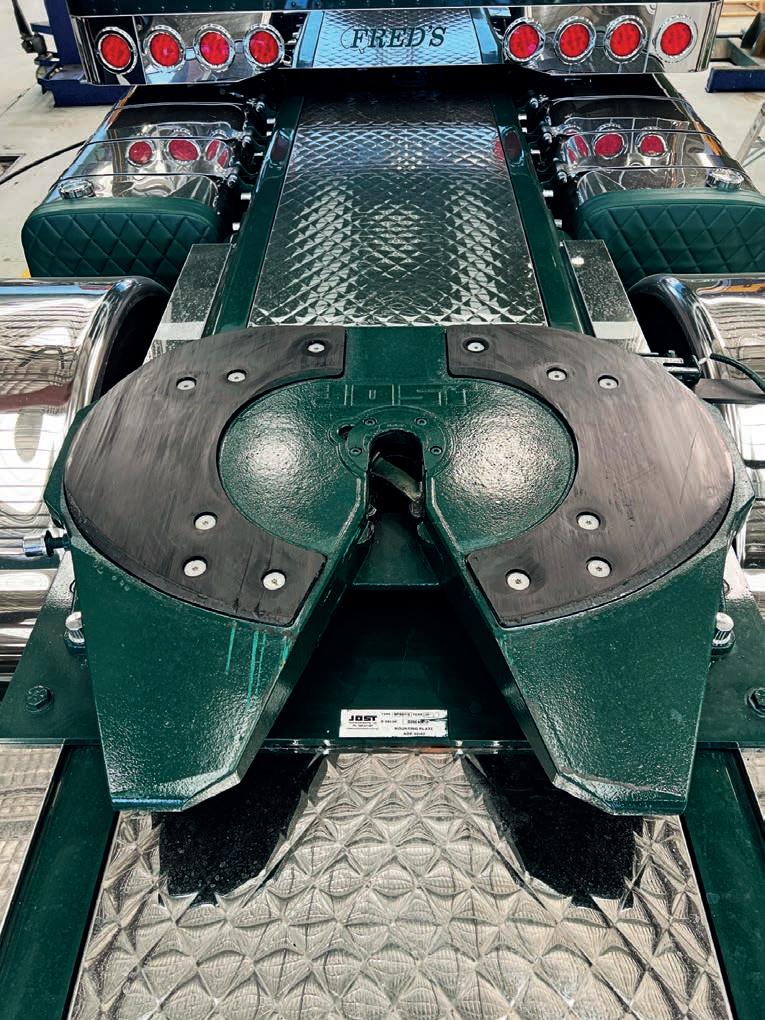

56 High Speed Connections

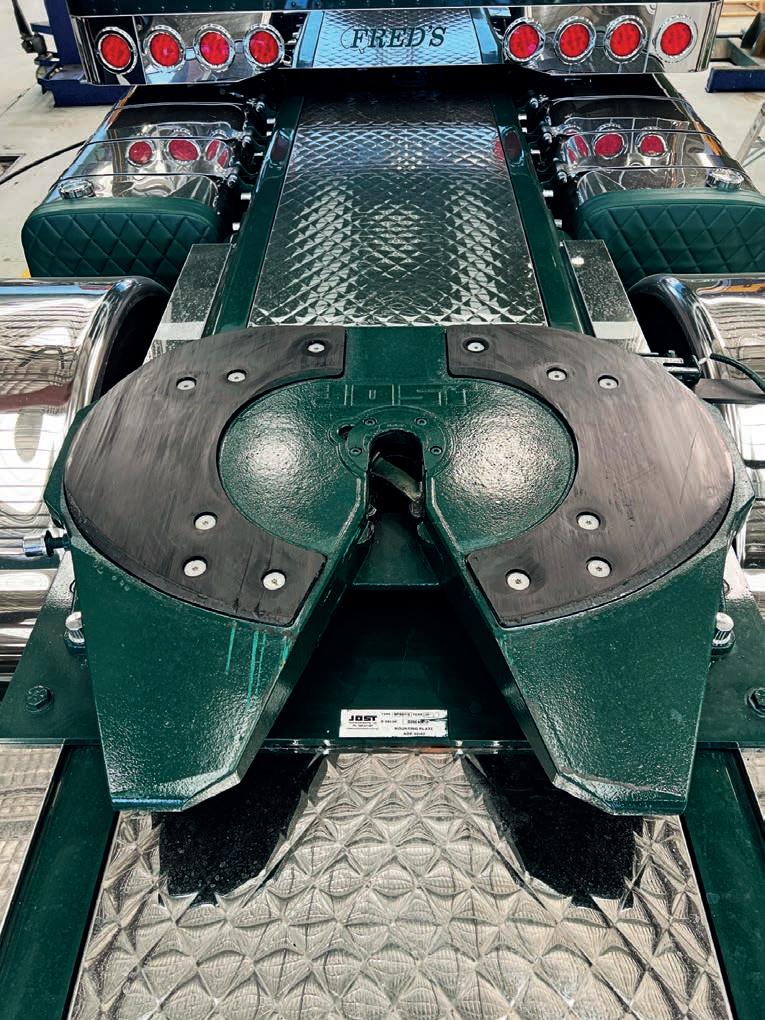

By having its entire fleet fitted with JOST components, Fred’s Interstate Transport has been able to gain an extra advantage in the field of efficiency.

TRUCK

& TECH

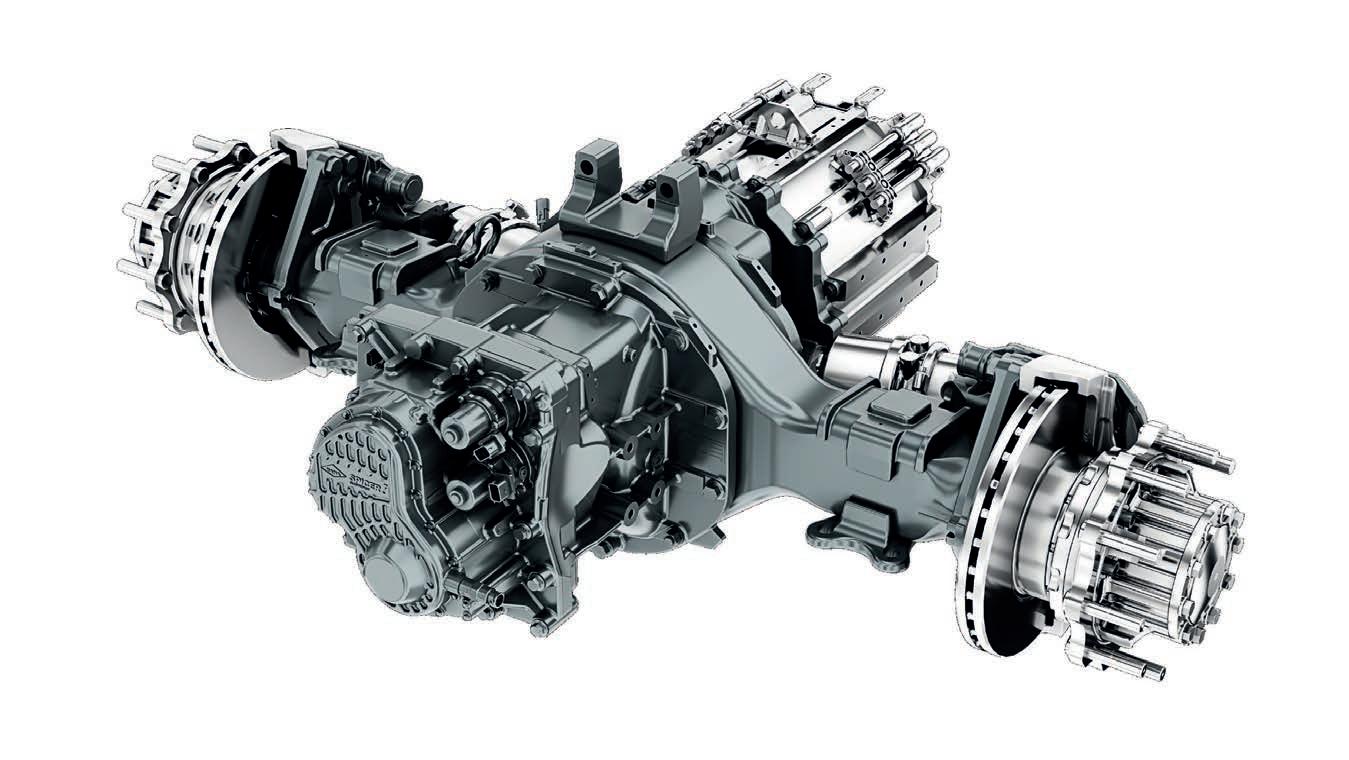

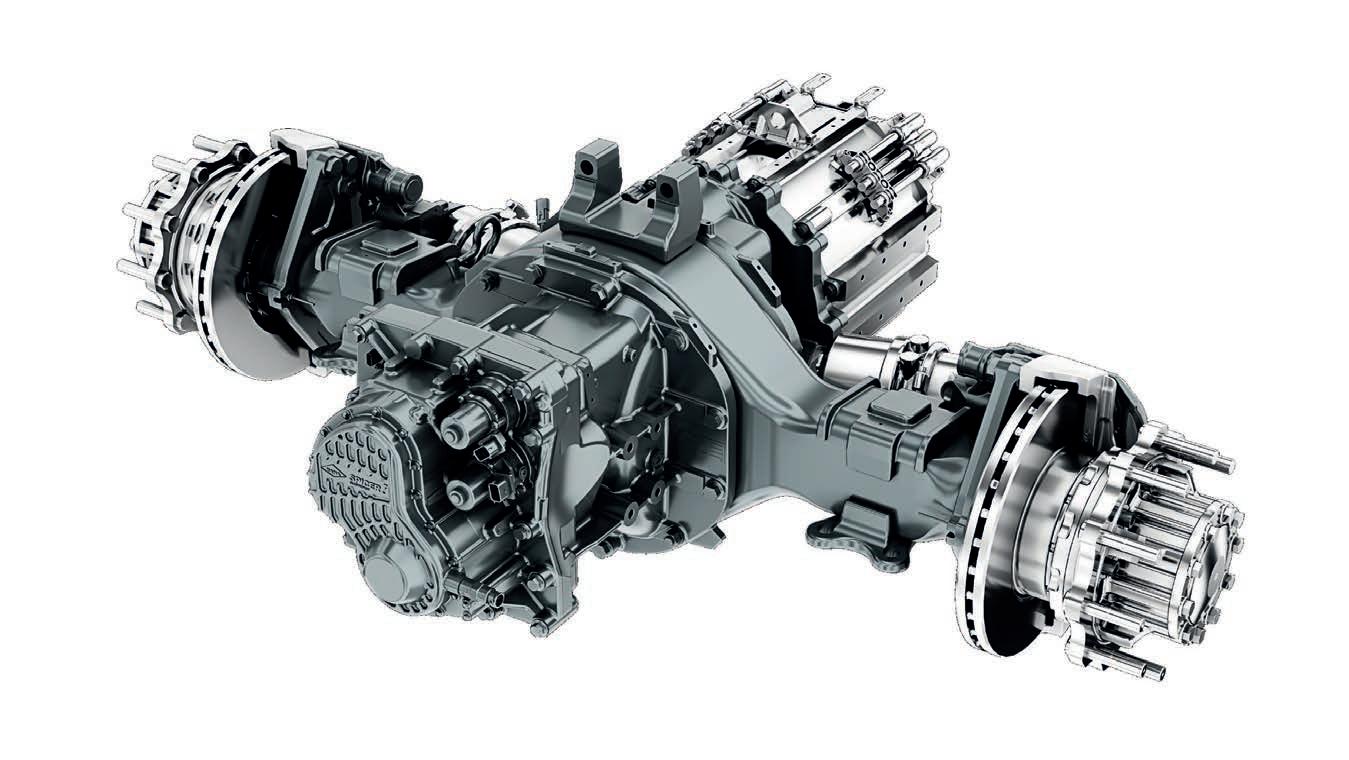

64 Think Tank

The SAF-Holland Kompensator fifth wheel is such an application defining piece of equipment in the road tanker category SRH Milk Haulage specify it across the entire fleet.

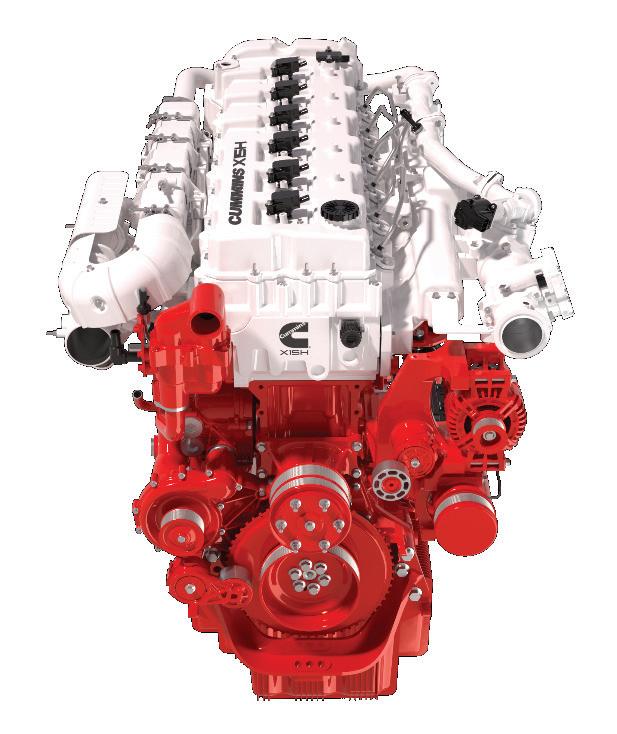

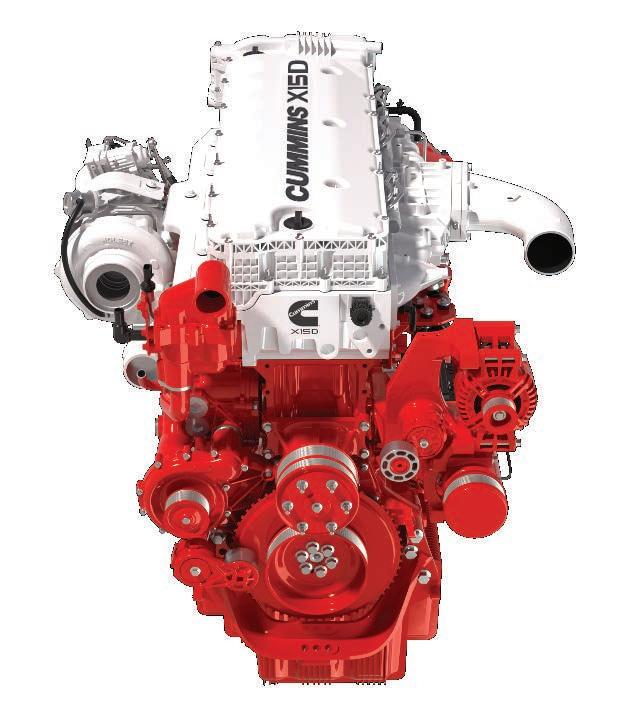

68 A Tale of Two Technologies

A real-world comparison between diesel-hybrid and current diesel technologies produces some impressive results.

TEST DRIVE

96 Go with the Flow

Following its successful introduction to the European market, IVECO’s latest heavy-duty S-Way range arrives Downunder.

Regular Run

08 From the Editor 10 Prime Mover News 42 Mindset 78 Brisbane Truck Show Preview 100 Personality Profile 102 Prime Movers & Shakers 105 Delivery 112 ARTSA-I Life Members 114 Truck Industry Council 115 Victorian Transport Association 117 T WUSuper 118 Peter Shields’ Number Crunch

SKY HIGH 60

William Craske Editor

Human footprint, a now common phrase in the lexicon, is for some of us, too frequently used in a negative context. As if there were no criterion of cognitive meaningfulness inherited from centuries of exploration dependent on abandoning the comforts of the known physical world. Transport as an industry is a direct descendent of the same pioneering spirit of the Greeks and Phonecians, who expanded global networks in pursuit of trade, land and military supremacy by reaching remote places like Scandinavia and West Africa with technology so unfamiliar, most of it cannot be reproduced accurately today.

The Greeks, as early as 600 BC, had even dreamt up Antarctica. Its name comes from the Greek word “antarktike,” which loosely translates as “opposite to the north.”

By the turn of the previous-to-last century, the dream had become reality for intrepid Australian explorer, Douglas Mawson. Mawson, a member of Shackleton’s Nimrod Expedition to Antarctica in 1909, had been part of the heroic team that discovered the magnetic

Inherit the Wind

south pole. In late 1911, he returned, along with Belgrave Ninnis and Xavier Mertz. Setting up base camp in Cape Denison, where winds often got above 100 km/h, they set forth on a journey 560 kilometres to the southeast near the edge of Mount Glacier. Supplies were already short when they lost a team of dogs down a fissure in the ice 25-feet wide. As they summitted Mount Glacier, the crevasses grew more frequent. To gain some respite from the wind they pitched their tent, unknowingly on top of one. They strolled off to photograph a blue abyss nearby when it opened taking Ninnis with it. They hauled the Englishman out, noting the black space below.

By the 21st November they had trekked 117kms from Winter Quarters, not counting detours. It was a quarter of the total distance the men had hoped for. They were due back at base camp on 14 January when the Aurora would pick them up. At their pace of 11.2kms a day they were going to be short of making the ship. On 14 December tragedy struck. Ninnis was lost down a crevasse with the best of the sledging dogs and supplies. Mertz and Mawson had only crossed it moments beforehand. As the two men made their exhausted attempt back to base camp the lack of supplies meant that they had to eat their way through the remaining dogs.

“We tried to drive the nightmare from

our thoughts,” noted Mawson in his journal. “We strove to forget it in the necessity of work.” Mertz who had been battling bouts of dysentery and depression eventually went insane. He later succumbed to fever and died in his sleep. Mawson, now alone, was still 120kms from the Commonwealth Bay with almost nothing left.

On the 17th January, Mawson falls down a crevasse, and plunges through a snowbridge. Tied to a sledge that had become pinned to the wall, he slides several metres down through the ice. Instead of suffering the same fate as Ninnis, the sledge anchors to the snow, and holds him there as he dangles with his feet unable to touch the edges of the crevasse. He contemplates slipping out of the harness and ending his life. He doesn’t, however. What happens next is extraordinary. For those unfamiliar with the events, it is well worth looking up. It was Seneca who first conveyed the idea that we suffered more in imagination than in reality. To the degree this is obviously true, Mawson might have a dissenting voice. At the very least it puts one at a remove from the new frontiers, which aren’t so much awaiting to be conquered as they are disembodied fears, already in our midst, hungrily conquering the unfit and vulnerable.

8 may 2023

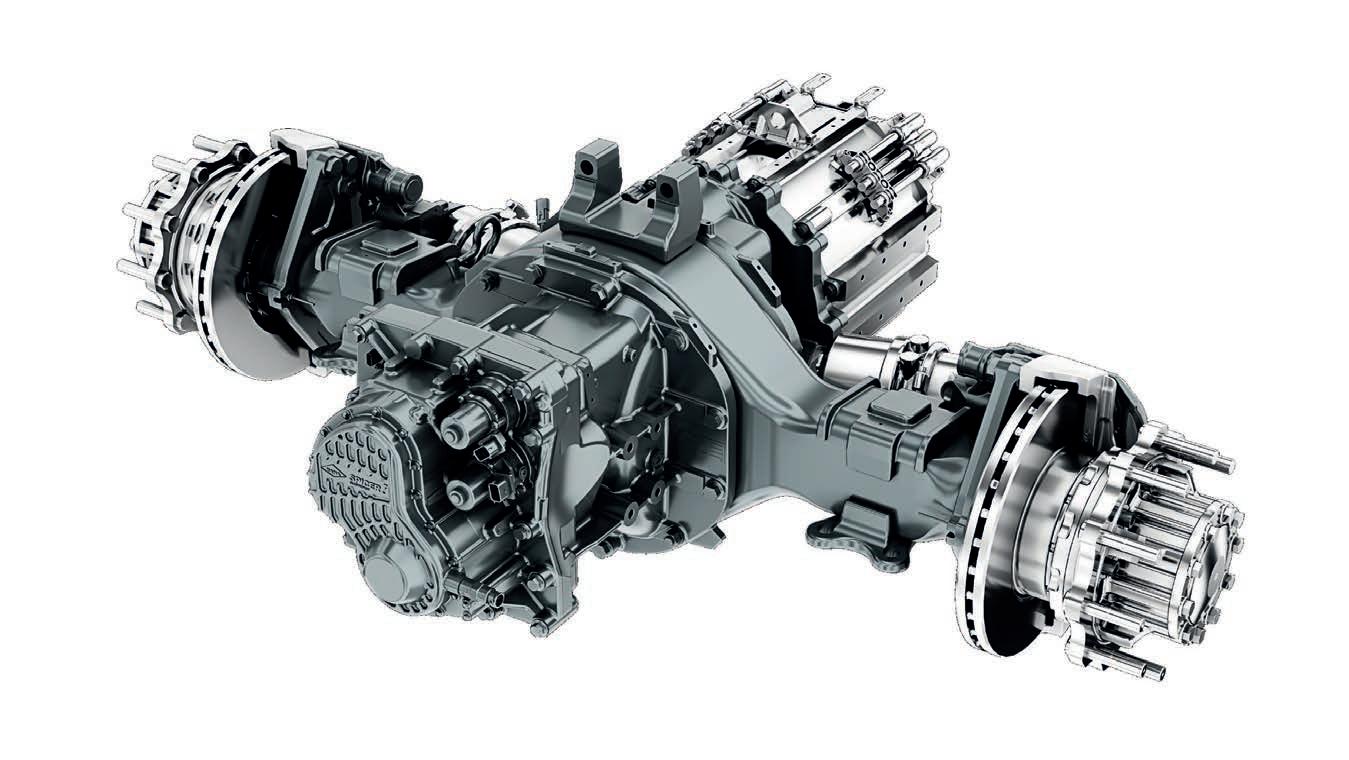

THE NEW D 190 FULL TIME PUMP HAS ARRIVED For more information contact Dana on 1300 00 DANA or visit us at www.Dana.com.au Strength • Power • Endurance ENGINEERED & BUILT IN AUSTRALIA

> Viva Energy lays out $1.15B on retail chain

Viva Energy has announced another acquisition, helping cement its goal of becoming Australia’s leading convenience retailer. The energy company will purchase On the Run (OTR) Group from Peregrine Corporation, a South Australian familyowned business with 205 integrated fuel and retail sites around the country. Coupled with its purchase of Coles Express convenience retailing business for $300 million last September, Viva Energy has added an extra level of diversity away from fossil fuels and is on track to establish more than 1,000 stores across Australia. The acquisition, valued at $1.15 billion, brings Viva Energy the opportunity to include major quick service

restaurants, such as Subway and Hungry Jack’s, in its retail sites.

As a strategic move, the acquisition will help reduce the company’s dependency on traditional fuels in the face of a growing electric vehicle market.

“We can’t wait to welcome 6,500 OTR team members to the Viva Energy business,” said Viva Energy’s CEO, Scott Wyatt. “We look forward to learning from them and working to deliver a leading convenience offer across the country.”

The deal will see Viva Energy, who run the second-largest oil refinery in the country, become the biggest non-government employer in South Australia.

> Heavy vehicle CoR training grants made available

Chain of Responsibility (CoR) federal grants from a pool of $1.7 million is being invested by the Federal Government to help boost safety across the supply chain. The funding will support businesses who use heavy vehicle transport to deliver tailored training programs focused on the CoR.

Grants will be awarded to projects aimed at educating participants on how to improve the safety of heavy vehicle transport activities. Priority will be given to projects that focus on ‘off-road’ parties in the CoR, particularly for industries where there is a lack of existing training resources. Additionally, preference will be given to proposals that also guide executives to use due diligence to ensure that a business discharges its primary duty.

Successful applicants will be able to access up to $300,000 of funding.

The CoR provision in the Heavy Vehicle National Law ensures all parties that work with heavy vehicles, from the business that employs a driver to the place where goods are

delivered, are accountable for safety. An executive of a business that is a party in the CoR must use due diligence to ensure that the business complies with that provision. The funding will be administered by the National Heavy Vehicle Regulator (NHVR).

Submissions open on Tuesday 11 April and close at 5pm AEST Friday 5 May 2023.

Assistant Minister for Infrastructure and Transport Carol Brown described the funding as an exceptional opportunity for businesses to improve their safety practices.

“The Australian Government is committed to creating a safer heavy vehicle industry, and key to this is an understanding from all relevant parties in the supply chain on how they influence safety,” she said. “This grant scheme will see successful organisations access funding to provide greater training and education in primary duty responsibilities across the sector ultimately delivering safer transport and roads.” Applicants will be assessed against

a range of measures to ensure productive outcomes.

“We are focused on businesses’ capability to deliver quality training, the reach of their audience, their capacity to deliver each project, principles about the primary duty or executive due diligence duty and how each project will address a gap in existing training,” said Brown. NHVR Chief Executive Officer Sal Petroccitto welcomed applications that met the criteria.

“Projects under the CoR grant scheme will need to focus on ensuring the delivery of training to manage risks and hazards in transport activities as required under primary duty obligations,” he said. “All parties in the chain have a responsibility to identify, assess and manage or eliminate risks within their transport activities. We want this funding round to deliver state of the art education across the sector.

“We look forward to seeing tangible, targeted training and education campaigns delivered through this grant.”

PRIME NEWS

10 may 2023

PRIME NEWS

Yasser Shahin, Executive Chairman Peregrine Corp with Scott Wyatt.

ON-ROAD

FOR DRIVERS... THERE’S ONLY ONE CHOICE

With undisputable road presence and trusted reliability, there’s no place you’d rather be than behind the wheel of a Kenworth.

kenworth.com.au

> Separation of law enforcement and data collection proposed

Fair and transparent regulation of telematics was fast becoming a priority to encourage adoption. This is the position of the National Road Transport Association as it relayed its concerns in a submission to a discussion paper on telematics to the National Heavy Vehicle Regulator. According to NatRoad there is a case to be made in keeping law enforcement and data collection separate.

Warren Clark. “In fact, NatRoad has partnered with Teletrac Navman to promote the adoption of telematics by members across Australia.

“We are generally opposed to the use of telematic data, collected under the provisions of the HVNL, for any purpose other than one clearly authorised under the HVNL.

“Of course that doesn’t include private arrangements that are lawfully and transparently done with the consent

> A-double access win following $20M commitment

Heavy vehicles and their freight routes have taken priority with the Federal Government announcing the location of 125 bridges and culverts to get engineering assessments. The key infrastructure, found in 33 different councils around the country, were selected based on their position along key freight routes, and their potential to improve access for heavy vehicles.

The engineering consultants working

on the project will provide the corresponding local government road managers with the bridge and culvert assessments which will help them make informed decisions about heavy vehicle access.

“No bridge or culvert is considered in isolation,” said Assistant Federal Minister for Infrastructure and Transport, Carol Brown.

“Rather, they are selected based on if an assessment may unlock access

“This impedes the significant advances in safety, efficiency and productivity that the widespread adoption could deliver,” he continued. Clark said labour shortages and recent significant weather events made the national freight task more challenging than ever before.

“The challenge is to drive the uptake of telematics with regulation and enforcement of mass and dimension access conditions that is transparent

Trailer Axles and Suspension

Trailer Axles and Suspension

Trailer Axles and Suspension

Intra Series Duratrac Series

Intra Series Duratrac Series

Trailer Axles and Suspension

for more classes of vehicles such as A-doubles, to travel more extensively on Australia’s freight network.”

The funding for the assessments is part of the National Heavy Vehicle Regulator’s Strategic Local Government Asset Assessment Project, supported by the Australian Government’s $20 million commitment to the project which is expected to continue through to late 2024.

PRIME NEWS

12 may 2023

PRIME NEWS

A roadtrain moves through central Australia.

Easily Retrofit to the Popular HOLLAND

FW351E & FW331

Fifth Wheel

FLASHING

RED WARNING LED LIGHTS FOR FAILED

COUPLING

ATTEMPT

HIGH INTENSITY WHITE LED LIGHTS FOR SUCCESSFUL COUPLING ATTEMPT

FAILED COUPLING – In the case of a failed coupling attempt, bright red flashing LED lights assist the driver to quickly recognize a potentially costly mistake.

Robust electrical components: sealed one-piece harness, long-life LED lights, durable inductive sensors, and steel encased logic module ensure reliable operation in the toughest conditions.

SAF-HOLLAND (Aust.) Pty. Ltd

ABN: 79004371215 | Sales: 1300 131 613

Email: sales@safholland.com.au

www.safholland.com.au

Visit us at the Truck Show STAND 82 FOYER

> Truck simulator launched by Fenix-Newhaul

Fenix Resources launched the world’s first truck driver simulator in April at its Geraldton depot as part of its Kick Start Training Academy for new recruits.

The logistic company’s haulage subsidiary, Fenix-Newhaul, established the simulator to help modernise driver training, respond to driver need for upskilling and maintain a good supply of heavy haulage operators. It will be used in both of the Academy’s programs — Driver Upskill for an existing local mature

those 18-20-years-old.

The simulator was made possible through a $250,000 grant, with FenixNewhaul among five businesses to share in approximately $700,000 from Western Australia’s Regional Economic Development Grants program.

Kyle Owen McGinn MLC, Parliamentary Secretary to the Minister for Regional Development, joined the attendees at Fenix-Newhaul’s Kickstart simulator launch.

In recognition of Fenix-Newhaul’s interest

> Isuzu appoints new Head of Sales

Following an all-time record truck sales performance last year, Isuzu Australia Limited (IAL) has promoted Craig White to Head of Sales. White’s appointment follows a realignment of IAL’s structure to build efficiencies into an expanding business model.

The broader organisational restructure included the combining of key divisions into a new Sales and Aftersales department, the appointment of Ella Letiagina to Head of Network Development and more recently the promotion of Matt Sakhaie to Head of Product.

Joining Isuzu in 2017, White had a range of experience across the automotive sector before becoming IAL’s National

Dealer Sales Manager in 2017.

In his new role, White will be responsible for developing and managing all aspects of the sales functions and the brand’s off-highway engines under the Isuzu Power Solutions (IPS) banner. With oversight of national and major fleet, including government, and sales through the extensive Isuzu dealer network, White’s focus will be on further developing sales opportunities through customer demand across a wide range of industries.

“I’m really excited for the road ahead and look forward to implementing the strategies of the executive team,” he said. “One of my immediate priorities will be getting out in the field to meet

Midwest, the Kickstart program has also received funding support from the National Heavy Vehicle Regulator’s Heavy Vehicle Safety Initiative.

Mack Trucks Australia Vice President Tom Chapman congratulated the Fenix Resources team on the launch of the truck simulator.

“This will be a fantastic asset for attracting and up-skilling professional truck drivers,” he said. “Well done on taking such initiative to address the critical professional driver shortage.”

with our customers and dealers faceto-face across the country.”

IAL Director and COO, Andrew Harbison, said he was thrilled for both IAL and White.

“The past 12 months has seen incredible sales growth at Isuzu and Craig’s work in the National Dealer Sales Manager position has been a major role in our overall success,” he said. “Craig’s background in both passenger and commercial automotive sales brings a wealth of broader industry knowledge and his understanding of the brand, our customers and our professional dealer network really cemented this crucial appointment.”

PRIME NEWS

14 may 2023

PRIME NEWS

Fenix-Newhaul’s new truck simulator.

We’re on Emission

At Volvo Trucks, environmental care has long been central to our vision of the future. We care passionately about the world we live in, and as the shift towards electric vehicles gathers pace, we are more committed than ever to driving progress.

We are thrilled to have launched our all-electric medium duty truck range for Australian transport operators.

The new Volvo FL and FE Electric medium duty range meet the demand from society and customers for dramatic cuts in CO2 emissions. To simplify the transition to sustainable transportation, the trucks are offered together with service and support packages for electromobility needs.

Come and visit us at the Brisbane Truck Show Stand #49, Hall 3 between 18 - 21st May and learn how we can partner with you in your transition to an electric future.

Learn more by visiting www.volvotrucks.com.au/electrictrucks.

Volvo Trucks. Driving Progress

REMONDIS embark on fleet replacement with Anthem

operators drop the compacted waste into the tippers.

“We have a weighbridge in the tunnel and another on the way out to ensure our loads comply with approved axle mass limits,” explained Collins.

This kind of efficiency in loading is matched at the other end at Swanbank, where the Macks manoeuvre to the edge of the landfill and simply open up the sidetippers to empty them.

“The sidetippers just open up like a big mouth, it’s very cool and they’ve made a huge improvement in our productivity. We used to use trailers with walking floors, but the sidetippers are significantly faster to unload,” said Collins.

As the trucks do most of their travelling on the motorway, the real issue is getting the trailers up to the top of the disposal site.

Waste and recycling specialist, REMONDIS, have begun the process of replacing long-serving trucks in their fleet with new Mack Athems. Since 2014, the Mack Trident has been the truck of choice hauling thousands of tonnes of recyclable materials to processing plants and non-recyclable waste to disposal sites every year.

The fleet is undergoing, as part of a replacement program, a refresh with many of the Mack Tridents coming to the end.

“We’ve got sixteen Tridents from 2014 and two Anthems from 2021,” said Sarah Collins, Resource Recovery Manager at the REMONDIS Swanbank Renewable Energy and Waste Management Facility, which is situated 30 kilometres west of Brisbane. “They’ve been the backbone of our local fleet for nine years but we work them pretty hard, so we’ve decided to start replacing them with Anthems before we wear them out.”

Vice President of Mack Trucks Australia, Tom Chapman said the Mack Anthem is a natural and exciting progression for REMONDIS in renewing and improving the efficiencies of their fleet.

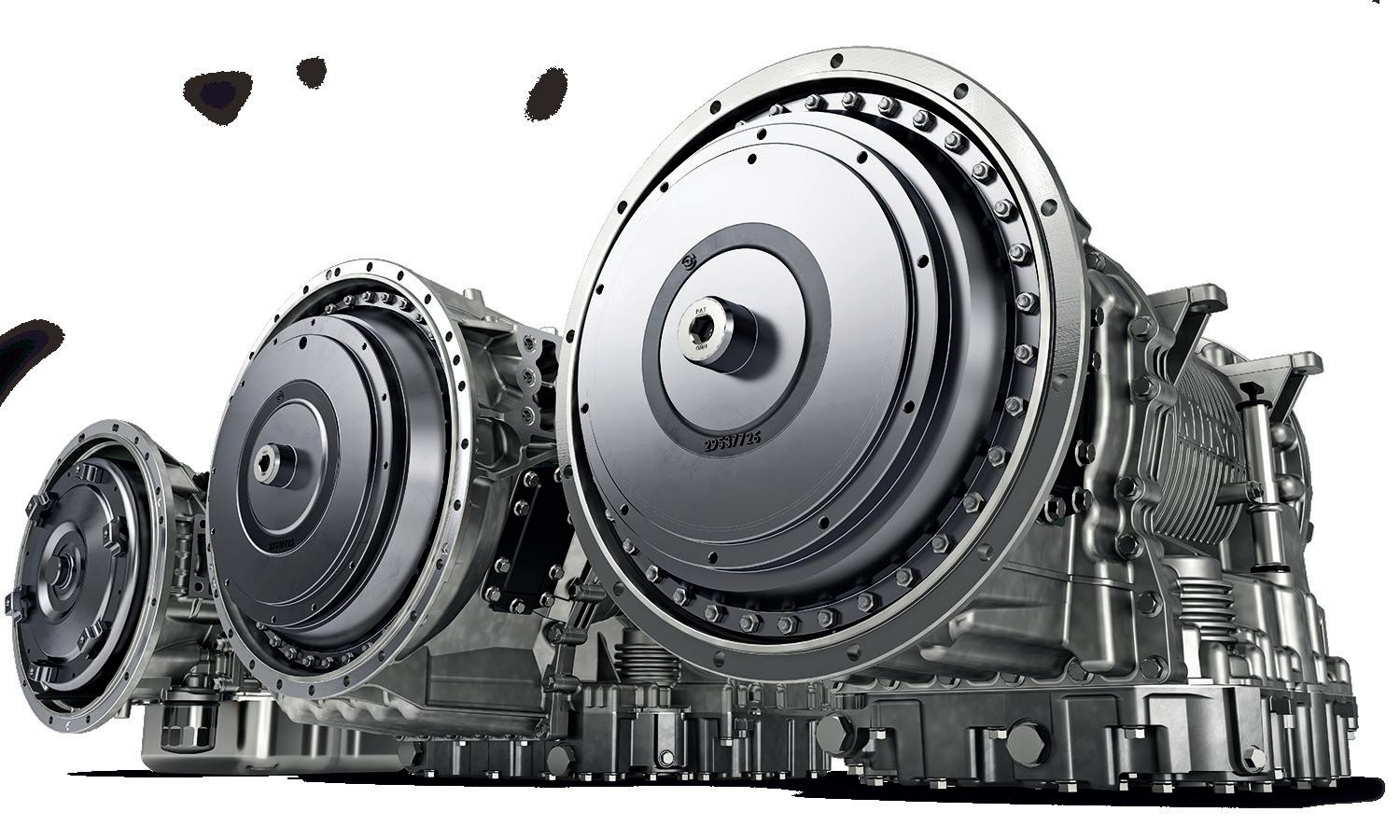

“The Mack Anthem has built a strong reputation for itself in terms of fuelefficiency. Paired with mDRIVE-HD with

deep reduction gears, the benefits are compounding in applications such as this one where controlled manoeuvrability on sometimes uneven, steep or low traction surfaces is critical,” said Chapman.

“For us, success is really forged in the strong relationships we build with our customers. REMONDIS perform the waste removal functions of both our factory and Head Office operations at Volvo Group Australia, so there’s great trust in the partnership and it swings both ways.”

The trucks travel between the Swanbank site and transfer stations at Rocklea and Northgate, making up to six trips a day, five-and-a-half days a week. Averaging about 60,000 kilometres a year, the Macks are hauling single trailer and B-Double payloads in sidetippers, with net weights approaching 36 tonnes.

“The fleet is NHVAS Mass and Maintenance Accredited and is enrolled in IAP so that we can operate Higher Mass Limits (HML) so we’re maximising our payloads on every trip,” said Collins. Commercial customers bring loads of waste to the transfer stations, where they’re compacted and loaded onto the trucks. At the transfer stations the trucks drive into the loading tunnel at the end of the pit. It’s here where REMONDIS

“It’s a steep slope, and if the weather is bad it can take a lot of low-end torque to get the load up there,” continued Collins.

“The Anthems don’t have any trouble at all. The mDRIVE-HD with an extended range of deep reduction gears, is ideally configured to climb steep slopes – a key safety consideration for us – so they’re more than up to the task. They’ve also proven to be fuel-efficient, which is increasingly important to the business.”

As the trucks only do day trips, the Anthems don’t require a sleeper cab but come with Mack’s full Safety Pack.

“Our drivers spend a lot of time in them, and VGA delivered a complete product, fully outfitted. Our drivers are really chuffed with the new Anthems and are happy we’re buying more of them,” said Collins.

With five scheduled for delivery in 2023, the Mack Anthems will soon be a familiar sight on the highway.

“We’ve been using Volvo Group products in southeast Queensland for over 20 years now and they’ve proven to be reliable and an ideal fit for the task,” said Collins. “We’re looking forward to bringing the rest of the new Anthems into the local fleet and enjoying the continued support of Volvo Group Australia.”

PRIME NEWS 16 may 2023 PRIME NEWS >

Luke Barnes, Volvo Group Australia hands keys to Robert Mason Operations Manager, REMONDIS.

> JATEC Transport announces scholarship program

NSW carrier, JATEC Transport, has launched a scholarship program to bolster its driver talent pool. The program, launched earlier in the month, is expected to bring a range of benefits to the business as it navigates the challenges of the current labour market. Finding new, innovative ways to attract quality drivers was a prerogative according to Caitlin Barlow, JATEC Transport Business Development Manager.

“For a while we have been discussing a feeder program where we can bring HR drivers into the business and train them the JATEC way,” she said. “This means they are competent in driving, customer service, chain of responsibility requirements, legislation and fatigue management.”

It was the perfect time to launch with a Volvo FH99 rigid now available in the fleet. Successful applicants will start in the rigid truck where they will gain experience

and knowledge in JATEC operations and expectations before the company invests in their upgrade to heavier applications.

Conditions of entry to the program include a minimum of 12 months Heavy Rigid experience, and the ability to drive a synchro gearbox.

JATEC intends for drivers to spend around two months in the rigid to complete a comprehensive training program before they are enrolled into a driving school to upgrade their licence to Heavy Combination.

“By having a shorter induction period we hope to provide this opportunity to multiple applicants as candidates progress,” said Barlow.

Applications are now open with range of people having already applied according to Barlow.

At present there is no baseline of driver numbers in place.

As the business grows operations the expectation, at this early stage, is that

it will be able to continue the program indefinitely.

“The transport industry is ageing, we are acutely aware of this, and so we hope to attract young people through the program,” said Barlow, who recently was awarded the Emerging Leader by the Road Freight NSW. “We are looking to contribute to the longevity of the industry. In saying this, if there are applicants outside this demographic who are overtly interested in the program and looking to join the team, we are open to everyone.

“JATEC Transport is always willing to give anyone with the right attitude a go.” Barlow, over the past 12 months, has assisted Transport Women Australia Limited in their career initiatives in NSW. One of the initiatives has been the EDGE Program, which helps young people enter the workforce with confidence through online courses and interactive workshops.

As the Transport Industry representative, Barlow has attended workshops and spoken with students about considering the transport industry as a career. This work, which caught the attention of RFNSW, has involved visiting high school career days and markets to raise awareness about the transport industry and point high school students in the right direction should they be interested. “Whether this be driving, heavy mechanic, insurance, sales etc I am able to recommend pathways and put them in touch with potential employers,”

Barlow said the acknowledgment she received from the RFNSW conference and Emerging Leader award is a definite career highlight for her.

“It was gratifying to be nominated by Transport Women Australia Limited for my contribution, and to then win the award I was ecstatic,” she said. “It was a proud moment to represent TWAL. The achievement was made even more special by having my parents there, and that’s the beauty of being in a family business.”

PRIME NEWS 18 may 2023 PRIME NEWS

Caitlin Barlow accepting her RFNSW award.

Proven Concept.

Meet the DAF XF – its proven 530HP MX-13 engine offers the perfect balance of power and efficiency.

When you’re driving coast to coast, the DAF XF is a quieter and more comfortable place to work, live, and sleep.

DAF XF PURE EXCELLENCE

Get into a DAF today!

WWW.DAF.COM.AU/XF Discover DAF XF

> Roadtrain innovator at the crossroads

An independent assessment of the financial position of Rivet Mining Services (RMS) is currently underway by receivers EY and FTI Consulting in the wake of the bulk haulage specialists’ recent demise.

The firm, chaired by ex-Toll executive Mark Rowsthorn, entered administration last month, according to Australian Securities and Investments Commission (ASIC) documents.

A provider of transport services to miners in Western Australia, Rivet had been carrying base metals in the Pilbara and Kalgoorlie goldfields, loading and hauling lithium, iron-ore, manganese and gold ore across its fleet of roadtrains.

The heavy vehicle fleet, utilising quad roadtrains, super quads and quin 60-metre multi-trailer combinations, had built a reputation on pushing the envelope on mass loads and payloads having eclipsed 200 tonne gross masses in partnership with key suppliers, Kenworth, JOST and Mack among them. Unfavourable inflationary financial pressures, labour shortages and a series of adverse weather events that led to costly project disruptions brought to a head the precarious viability of the Perth-based Rivet leading receivers in April to seize control of Rowthorn’s holding company, Blondie Trading.

“RMS will continue to trade on a business-as-usual basis while the Receivers conduct an independent assessment of its financial position and seek to sell the business as a going concern,” FTI Consulting said in a statement it issued to media. The appointment of receivers relates only to the mining services business, with other entities of the Rivet Group continuing to trade in their usual manner. While receivers attempt to sell the business as a going concern, the latest accounts lodged by Blondie Trading reported earnings of $82 million and a net loss of $6.6 million for the year ending to June 30, 2020.

PRIME NEWS PRIME NEWS

20 may 2023

One of Rivet’s unique multi-combination roadtrains in Western Australia.

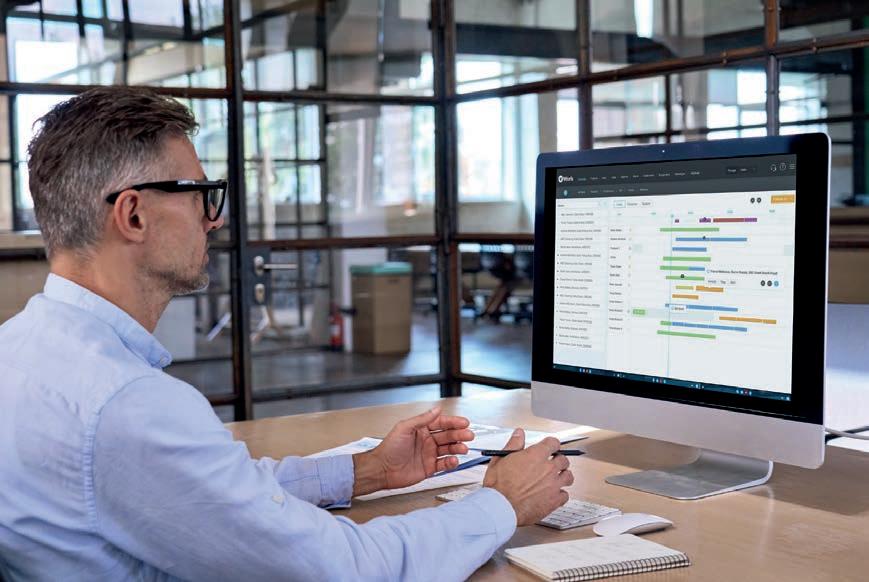

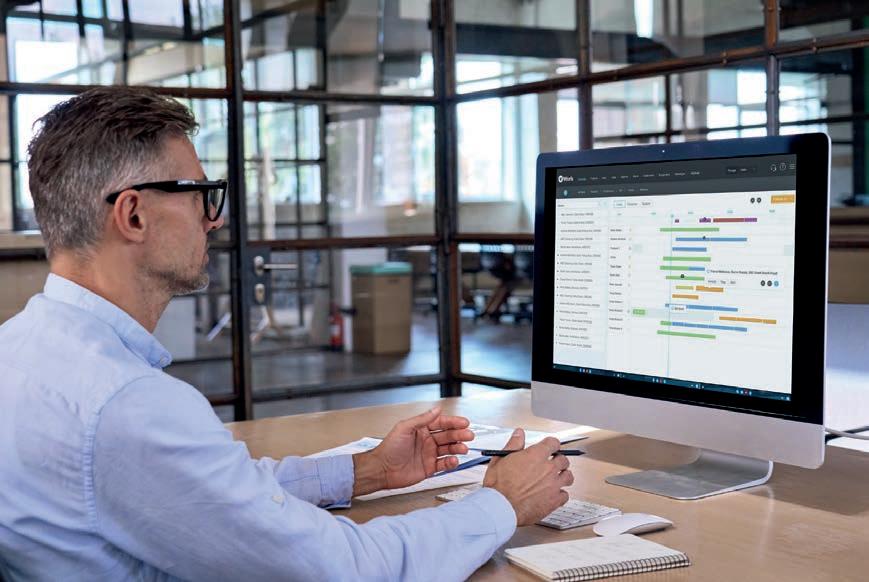

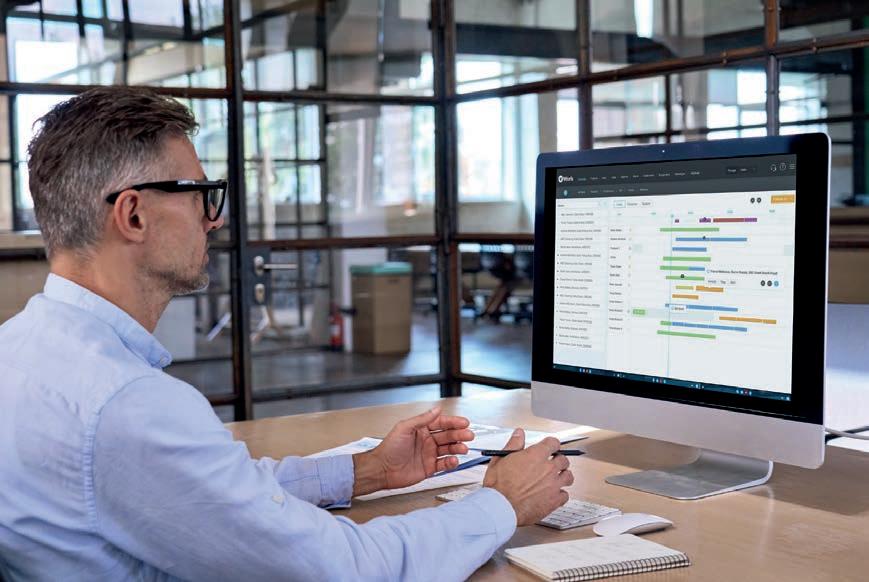

Optimize your fleet with data-driven insights and AI powered by the #1 global telematics provider.

One platform for connected and sustainable fleet performance.

Geotab’s AI-driven platform transforms real-time data from any source into actionable insights that provide measurable business value, help reduce fleet’s emissions and costs while improving operational efficiency. Optimize your fleet’s performance and stay ahead of the competition.

geotab.com.au

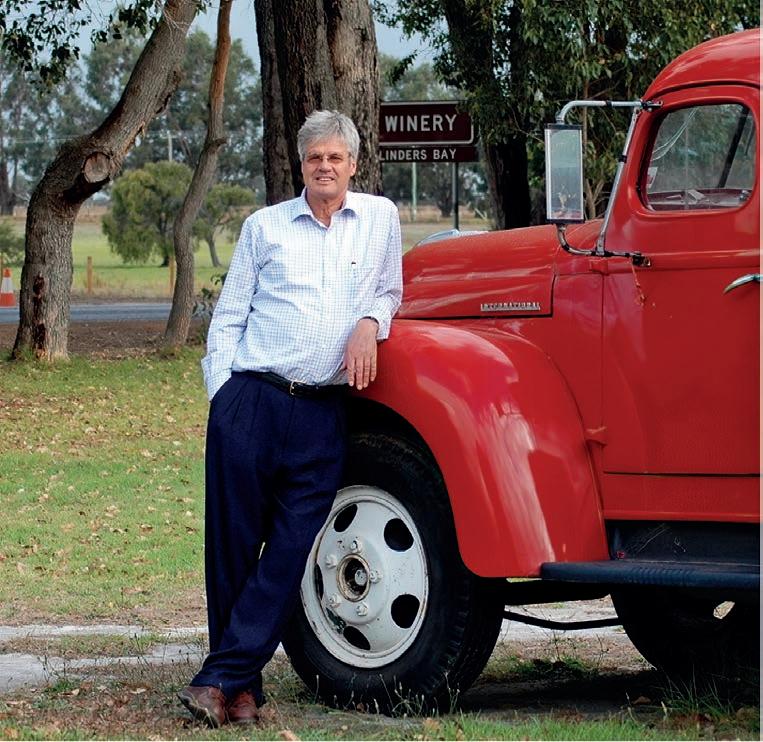

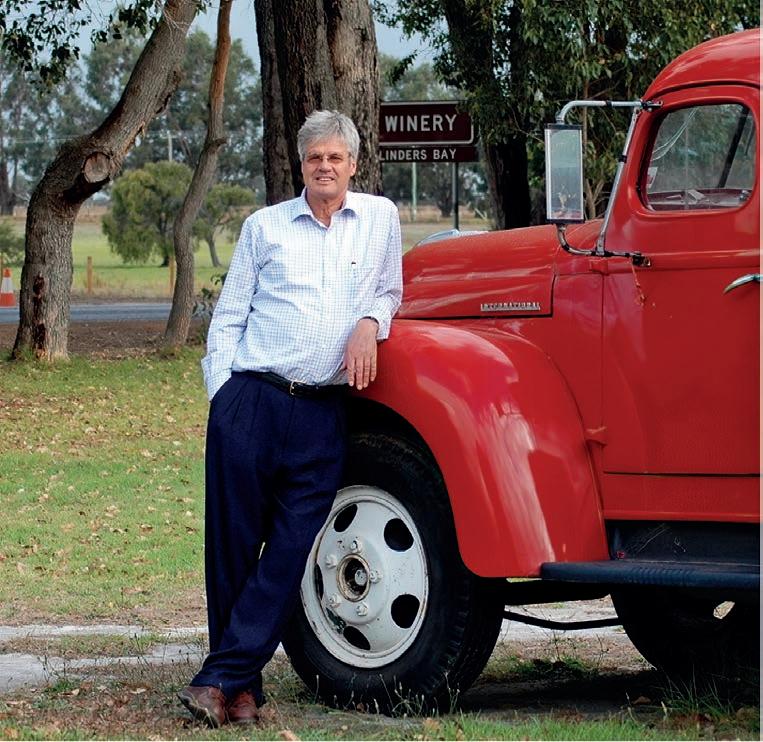

> Outback operator builds on the back of UD partnership

Kununarra-based JSW Holdings has grown from brickmaker to remote infrastructure specialist. For almost 50 years the company has been running trucks in an environment that is as beautiful as it is challenging. The scope of the business incorporates concrete, plant hire, civil contracts and aggregate supply in partnership with UD Trucks.

That trust and confidence in the UD truck products has been ongoing given the desolate and challenging conditions.

“Probably the biggest pressure is our isolation with parts supply and getting and keeping things running,” said JSW Owner Peter Woodhead, who needs to have a strong inventory of backup parts on hand.

“People are also a big shortage. I know we’re not alone with that but it’s pretty hard to entice people to come up and live in extreme conditions at the moment,” he said.

In winter, weather is idyllic, hovering between day time temperatures of 25 to 30 degrees. But that all changes once the wet season arrives according to Woodhead, whose father founded the original brick manufacturing business in 1975.

“From November until April it’s 40 degrees, wet and an afternoon shower can see 25 to 50ml of rainfall,” he said. “Roads become impassable, so we’ve got to be careful where we go and don’t go, depending on the time of year.”

JSW currently have five UD Trucks in their fleet for a total of ten purchases from the brand all up.

“Our business was built on them,” said Woodhead, who along with his brother joined their father at the company once they had finished high school.

“What I like about UD Trucks is that they’re built solid, reliable, low maintenance, easy to drive and are comfortable,” he continued. “Our guys love driving the UD Trucks and out of all the vehicles in our fleet they

probably spend the least amount of time in the workshop.”

Distances travelled by the fleet annually can vary due to the kind of work required of it. These range anywhere from 100,000kms to 250,000kms.

“Engine hours are probably more,” said Woodhead. “It’s a lot of work off road on dirt roads so we generally reach speeds of 40 to 50kms per hour.”

Despite these locational challenges, Woodhead said his UD Trucks have provided a solid and reliable platform to keep JSW running and with minimum downtime. A 1983 UD CW40, the very first UD vehicle JSW bought, is still in operation for the business today.

“It was purchased as a 6-wheel tipper. The customer decided they wanted to go to a semi so it was converted to a prime mover and towed a bogie tipper around for probably five years of its life and then as things got bigger, we converted it back to a tipper,” recalled Woodhead.

As part of Lap of the Map, an initiative launched by UD Trucks, to customers in less central locations, Woodhead

was full of praise.

“I think the UD Trucks Lap of the Map is an awesome incentive.” he said. “We get to have a look at these trucks in person. We’re fairly remote so we don’t get to go down to the dealer often and see what’s new and what’s out there so it’s really good for companies like ours.”

Vice President of UD Trucks Australia, Lauren Pulitano described the journey of JSW Holdings over the decades as unique and inspiring.

“Considering JSW Holdings was established nearly 50 years ago and has been able to thrive in such a remote and extreme part of Australia, it is truly a testament to the entrepreneurship and strong leadership of Peter and originally, his father,” she said in a statement. “Our UD Trucks are built to sustain the unique and demanding conditions of Australia and to hear of a remote business like JSW building their business on UD Trucks that is extremely humbling. The story of JSW is truly one that UD is proud to be a part of and we thank Peter and the JSW team for continuing to put their trust in UD Trucks all these years on.”

PRIME NEWS

PRIME NEWS 22 may 2023

Peter Woodhead at his depot.

This information is general advice only and does not take into account your objectives, financial situations or needs. You should obtain and consider the relevant Product Disclosure Statement and Policy Wording (as applicable) from zurich.com.au before making a decision. A target market determination is available at zurich.com.au/GI-TMDs or by calling us on 132 687. The issuer of general insurance products is Zurich Australian Insurance Limited (ZAIL), ABN 13 000 296 640, AFS Licence Number 232507 of 118 Mount Street, North Sydney NSW 2060. ZU233775 V4 12/22 LEWG-019393-2022 Much more than truck insurance. Zurich seeks to improve safety in the trucking industry through its fleet risk management services. We work closely with customers on request and aim to optimise business processes and driver behaviour. This can help to reduce claims, keeping trucks on the road. Ask your broker about Zurich today.

> Mercedes-Benz to debut eActros at Brisbane

for sustainable road transport in our region,” he said.

electric truck, will make its Australian debut at this month’s Brisbane Truck Show. The long-awaited vehicle is focused on heavy-duty, short radius distribution with development trucks having been put to work in select fleets

Benz Trucks Australia Pacific Director, Andrew Assimo, said he looked forward to presenting the heavy-duty electric truck to the Australian public.

“The local debut of the eACtros represents the start of a new chapter

> Booth Transport leader mourned

Booth Transport Director, Brian Booth, has sadly passed at the age of 79. Booth Transport was founded in 1936 by Brian’s father, Lindsay Booth, with just a single vehicle which transported wine and farm goods south of Adelaide.

Booth joined the company in 1958 and played a key part in the fleet’s growth to become a leading carrier of bulk food, container transport and logistics today. Due to this growth, Booth Transport now has a fleet of 270 commercial vehicles nationwide along with depots in every state.

The long-standing company is now run by the third generation of the Booth family. Booth Transport CEO, Nathan Falconer, extended his condolences.

“He was proud of the where the business is today, and he was excited about the possibilities in the future,” he told Prime Mover

“Whenever Brian travelled to a depot, he always made time to engage with staff. Leaning against a bullbar of a prime mover, talking, and listening to a driver was a common sight.

“He was always the first to be on any meeting, and he would say, if you’re not 15 minutes early, you are late.”

Booth Transport has been active in dairy transport since the 1990s when

it diversified the business with the purchase of a Deniliquin-based milk transport company. Operations have since grown to see linehaul tankers of milk and dairy

A local validation program is also expected, designed to ensure the vehicle specification is tailored for Australia’s unique conditions, as well as to meet the specific requirements of local customers. The program will include four eActros trucks in Australia and one in New Zealand. The company is quick to point out, however, that although they are keen to move forward with battery electric technology, they are committed to providing solutions to help traditional internal combustion engine customers drive down their emissions as well.

products travel up and down the east coast of Australia, in addition to the handling of interstate containers from the port in Devonport to Melbourne and also from Melbourne via rail into Perth.

PRIME NEWS PRIME NEWS

24 may 2023

Mercedes-Benz eActros lands in port.

Brian Booth.

www.omfbpacific.com OMFB Pacific Pty Ltd Phone: 1300 040 600 Email: sales@omfbpacific.com •Power Take-Offs • Gear Pumps • Piston Pumps & Motors •Control Valves • Control Systems • DC Powerpacks •Oil Tanks • Hand Pumps • Winches, and more... Backed by dedicated local product support and expert technical knowledge and assistance we’re focussed on providing the most durable solution for your on-road application. With over 70 years of innovation and thousands of customers in over 100 countries, OMFB has become a worldwide manufacturing leader of hydraulic components suited to Transport, Agricultural, Mining, Industrial, Marine, Oil & Gas and Mobile applications. Complete Hydraulic Solutions Tippers Bin trucks Vacuum trucks Truck-mounted cranes Waste management trucks

> Eurocold launches electric truck company

Refrigerated truck assembler, Eurocold, has launched a refrigerated electric truck division. The offshoot known as Revora will be based in Brisbane, Queensland. Revora will reportedly use the knowledge built by its Founder and Managing Director, Avraam Solomon through three generations in the refrigerated transport industry, along with the expertise in the low-to-zero emissions space brought by General Manager, Nathan Gore-Brown. The stated goal of the company is to help move the refrigerated transport industry towards a sustainable future.

Key components such as chassis and fridge, body will be sourced from “best of breed” operators in Australia and internationally.

Gore-Brown comes to Revora with an extensive automotive background from Aston Martin in the UK. He launched Tesla’s initial flagship Brisbane outlet and more recently was a Senior Consultant to government and private sectors on transport decarbonisation with advisory agency, MOV3MENT. The first refrigerated electric truck will be on display at the Brisbane Truck Show, May 18-21.

“Revora is a completely separate and new brand to Eurocold – aimed at future-proofing the sustainability of the refrigerated transport industry,” said Avraam Solomon. “Revora will be Australia’s first fully integrated, electric refrigerated truck fleet supplier.” The program, being headed up by GoreBrown, will assess fleet suitabilities to embrace electrification before assisting customers into the crossover. The trucks and energy solutions will be all on a long-term lease with Revora. To optimise efficiency once going electric, Revora is devising a technology-led process that will assist fleet owners to ensure they are maximising opportunities through telematic data tracking on the vehicles and software to monitor energy systems. “Avraam has the vision to provide a sustainable future for the refrigerated transport industry through establishing a line of highly efficient, cutting-edge green transport solutions. Our customer base, partners and alliances are in third party logistics, broadline food services, along with the meat, seafood, dairy and produce industries,” said Gore-Brown. With the majority of refrigerated

transport deliveries being ‘last mile’ deliveries and in urban areas, GoreBrown explained that electric trucks are perfect for this duty cycle.

“EVs are particularly well suited to urban and stop-start tasks,” he said. “This is down to their ability to recapture energy through regenerative braking. Typically, the refrigerated transport industry has a large portion of the fleet running last mile delivery and that’s where electric trucks excel.

“In addition to this, as we move towards government-mandated net zero emission targets, electric trucks will provide opportunities for our customers to gain new contracts due to businesses wanting to reduce their carbon footprint.”

Revora’s offering includes initial consultation on current fleet makeup and measurement of diesel usage; suitability to cross over to electric refrigerated trucks; supply of optimised zero-emission refrigerated commercial vehicles energy/charging stations (optimised for fleet size and operations model) staff training; and oncall support.

PRIME NEWS PRIME NEWS

26 may 2023

Revora electric truck concept.

> Spudshed aligns with UD Trucks in Perth

Western Australian supermarket chain, Spudshed has undergone a serious period of growth in recent years. An ongoing relationship with UD Trucks, for whom it has purchased 17 commercial vehicles to date, has helped it build its brand and footprint, harvesting and delivering fresh, locally grown produce to Perth where it operates 17 retail stores offering a large range of quality produce including meat, dairy and groceries.

With farms spanning all the way from Manjimup up to Kununurra, and more than 1100 Spudshed employees to see through business operations, the Galati family business has become a key identity in Perth.

From the beginning, the business philosophy for Spudshed was simple in bringing down the cost of weekly shopping and making healthy fresh produce affordable for the people of Perth.

Decades on little has changed.

Owner Tony Galati and his brothers Vince and Sam, grew up helping their Sicilian parents run a two-hectare market garden that was established in Spearwood in the 1960s.

By 1998, a simple farmer’s market had evolved into Spudshed and the business has since bolstered itself into the multimillion-dollar operation that it is today. With rapid expansion comes the necessity for reliable and efficient transport in getting food delivered to their stores consistently and on time. At the Canning Vale depot Spudshed moves between 400 – 500 pallets daily. The trucks are loaded every morning according to Galati.

“You don’t realise how much is involved in getting produce to a retail store or to the markets – and if you don’t have the reliability of your trucks, you’re in trouble,” he said.

Reliability was one of the main factors

that steered the family towards UD Trucks after time spent researching the products.

The majority of the fleet comprises UD Quon GW26 460s. Spudshed’s trucks typically travel between 600 to 700 kilometres a day, and close to 1200 kilometres during the busier season, making reliability a non-negotiable.

“We bought one truck and then another one and now we’ve got 17 UDs at this stage and we’re looking at buying a few more,” said Galati. “They’re great on fuel efficiency and for the horsepower they’ve got and for the tonnage we cart, they’re really good. Probably the best in the market that I’ve seen.”

It’s been a bonus for Galati that his drivers enjoy driving the UD Trucks every day.

“The air-conditioning, the driving, the way they steer, the way they handle the road – they’re really happy with the trucks. I tell some of my drivers that they should be paying me for driving these trucks,” he said.

Spudshed also runs a nursery where it propagates all of its own seedlings.

“We virtually plant them from the seed, then six or seven weeks after being in the nursery, we put them out in the fields and grow them out over ten to 12 weeks,” said Galati.

After they have been picked they are brought to one of the packhouses where they will eventually be dispatched to markets, chain stores, Spudshed or exported.

The success of Spudshed, despite being in an industry known for challenges, is dependent on a series of factors according to Galati.

“For us, success in the business is what you put into it. You’ve got to nurture your business, you’ve got to live in it,”

“I’ve been in the game since I was a young kid and grew up on it. And my kids did the same thing. They grew up in it, they were born into it.

“It’s a family business and we do it to the best of our ability.”

PRIME NEWS PRIME NEWS 28 may 2023

UD Quon GW26 460hp being loaded up in Perth.

Safety. Performance. Comfort. ALL THE WAY

The new IVECO S-WAY range takes the on road and liveability experience to the next level.

Drivers enjoy a SAFER driving experience with world class driver assist technology. The S-WAY cab’s improved aerodynamics maximises the fuel efficiency without compromising the PERFORMANCE. The driving ergonomics and cab have been reimagined and designed for supreme COMFORT.

S-WAY makes tomorrow safer, more productive, and even more comfortable.

iveco.com.au Drive the road of change

Fujian Motor range of heavy-duty hydrogen trucks bound for Australian distributor HDrive has taken place. The vehicle was recently shipped from the Zhangzhou Development Zone.

Present at the ceremony were Liu Yongxiang, Deputy Secretary of the Party Committee of Zhangzhou Development Zone and Executive Deputy Director of the Management Committee, Scott Brown, Managing Director of Pure Hydrogen in Australia, Jason Pecotic, Managing Director of HDrive in Australia, and the Economic Development Bureau of Zhangzhou Development Zone.

“We are pleased to cooperate with Wisdom Motor. Currently, countries around the world are striving to achieve carbon neutrality, and the demand for green travel is increasing,” said Pecotic. “We hope to work with Wisdom Motor to create a high-efficiency and lowenergy consumption green smart manufacturing path.”

In November last year, Wisdom Motor signed a memorandum of understanding with Pure Hydrogen and HDrive in Australia to deliver 12,000 hydrogen-fuel heavy-duty trucks over the next five years.

will be the first hydrogen fuel heavyduty truck to be delivered after the agreement was signed.

Its hydrogen fuel cell system delivers 110-400kw of power and a range of up to 1,000 kilometres. The vehicle, which is being marketed as an ideal intercity freight and provincial long-distance transportation solution, derives power from Ballard Power fuel cell stacks, and relies on an integrated control system with what Wisdom has described as a “360° multi-sensor fusion perception system.”

The body adopts a patented annular gantry beam with full load-bearing structure in addition to high-strength stainless steel and composite materials. With the streamlined design of a ventilated motorcycle helmet, the fluid sculpture of the cab achieves a modern aerodynamic look.

The OEM claims the fibre body covering technology has helped reduce its weight by 10 per cent compared to similar products on the market.

The interior is driver-centric and is defined by a homely concept design with a cockpit conceived as an “intelligent mobile home”.

In addition to a wrap-around centre

instrument cluster, and multi-function steering wheel, it also comes with a massage seat.

Wisdom Motor is confident the truck can have a service life of 20 years.

“Wisdom Motor will work with its partners HDrive and Pure Hydrogen in Australia to lead the innovation of zero-emission commercial vehicles with world-leading new energy technologies, better serving our customers in Australia and around the world,” it said in a statement.

In 2022 HDrive became the first company in the world to deliver hydrogen fuel cell coaches for Fortescue Mines in Western Australia. In March of last year, Pure Hydrogen announced that it would provide JJ Richards & Sons, Australia’s largest privately owned waste management company, with a hydrogenpowered waste truck and hydrogen refuelling services.

Beverage giant, PepsiCo, is anticipated to begin a trial of the hydrogen-powered truck jointly designed by HDrive and Wisdom Motor in Brisbane later this month as it evaluates commercial use cases for the fuel cell vehicles in Australia.

30 may 2023

HDrive executives attend handover ceremony in Zhangzhou, China.

> Port Lincoln freight route improvements get greenlight

A key freight route in Port Lincoln, South Australia will receive important upgrades as part of the latest Federal Government funding release. The upgrades are aimed at increasing safety outcomes and productivity for heavy vehicle operations in the region. The intersection of Porter Street, Liverpool Street and Railway Place, at the end of the Lincoln Highway, will receive traffic signals, a dedicated right-hand turn lane, improved drainage, widening and pavement works. “Investment in segments of our roads which are well-utilised by heavy vehicles has never been more important, with many of our communities grappling with ongoing flooding and tightening supply chains,” said Carol Brown, Federal Assistant Minister for Infrastructure and Transport.

The $3.6 million put towards the project comes from the Heavy Vehicle Safety and Productivity Program which has committed an ongoing $65 million per year to state, territory and local

> Centurion champions regional road safety in WA

Thirty Centurion trucks are on tour across Western Australia to promote the Road Safety Commission’s latest campaigns. The sides and backs of the trucks will display the campaigns ‘Don’t drift off’ and ‘No one plans a crash’. Every year approximately two thirds of the state’s road fatalities occur in regional areas and 2022 was no different, with 64 per cent of people who died on

48 per cent of fatalities. While there are many factors that can cause a vehicle to leave the road, fatigue can and does play a role.

At 13 metres in length, the trucks will be highly visible to regional drivers as they transport groceries and other essentials from Perth to the north of the State. They will be on the road during the busy April school holiday period and visible to

governments. This builds on the Federal Government’s $140 million commitment to upgrade heavy vehicle rest areas over the next ten years which is expected to begin later this year.

distances for the eclipse, particularly those not familiar with WA roads, the Road Safety Commission recently launched its ‘Welcome to Country Roads’ campaign. The campaign is a collaborative effort with Aboriginal Elders which celebrates the connection First Nations people have to their Country and provides drivers with tips for a safe journey through it.

“This partnership with Centurion is a fantastic visual way in which to share our latest road safety messages where they are needed most — our regional roads,” said Road Safety Minister, Paul Papalia.

“These trucks will serve as a mobile road safety reminder for drivers while they are behind the wheel. We’re asking drivers to be warned against fatigue and to be mindful of other behaviours that can lead to a crash like using a mobile phone or rushing to overtake.

“Road safety is everyone’s business, and this is a great example of how the private sector and Government can work together to reduce deaths and serious injuries on our roads.”

PRIME NEWS PRIME NEWS

32

A bend in the highway to Port Lincoln in South Australia.

Paul Papalia, Road Safety Council Chair Katie-Hodson Thomas and Centurion CEO Justin Cardaci.

THE CONNECTED TRUCK

The Connected Truck is transforming the way our teams work by bringing real-time visibility and information to the workplace. This technology enhances not only our driver’s safety with fatigue and maintenance tools, but also promotes sustainability through fuel efficiency and effective job management.

Scan the code to find your way to us!

Stand 104, Hall 4

1300 111 477

TeletracNavman.com.au

> McGrath Newcastle endorses new Freightliner fleet

A Newcastle container hauler has sung the praises of its latest additions — four Cascadia prime movers. After encountering a supply issue with another truck brand, Tony McGrath, who runs McGrath Newcastle, turned to the Freightliner Cascadia, a vehicle he hadn’t considered previously. The first Cascadia, purchased through Daimler Trucks Newcastle and salesman, Phil Mason, performed so well McGrath has since ordered three more.

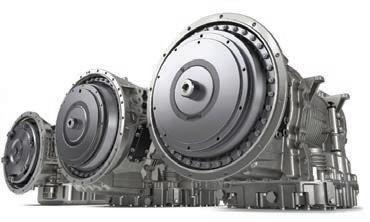

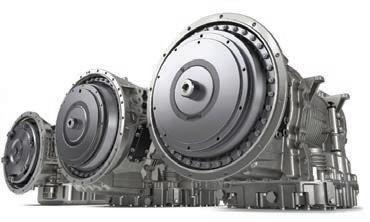

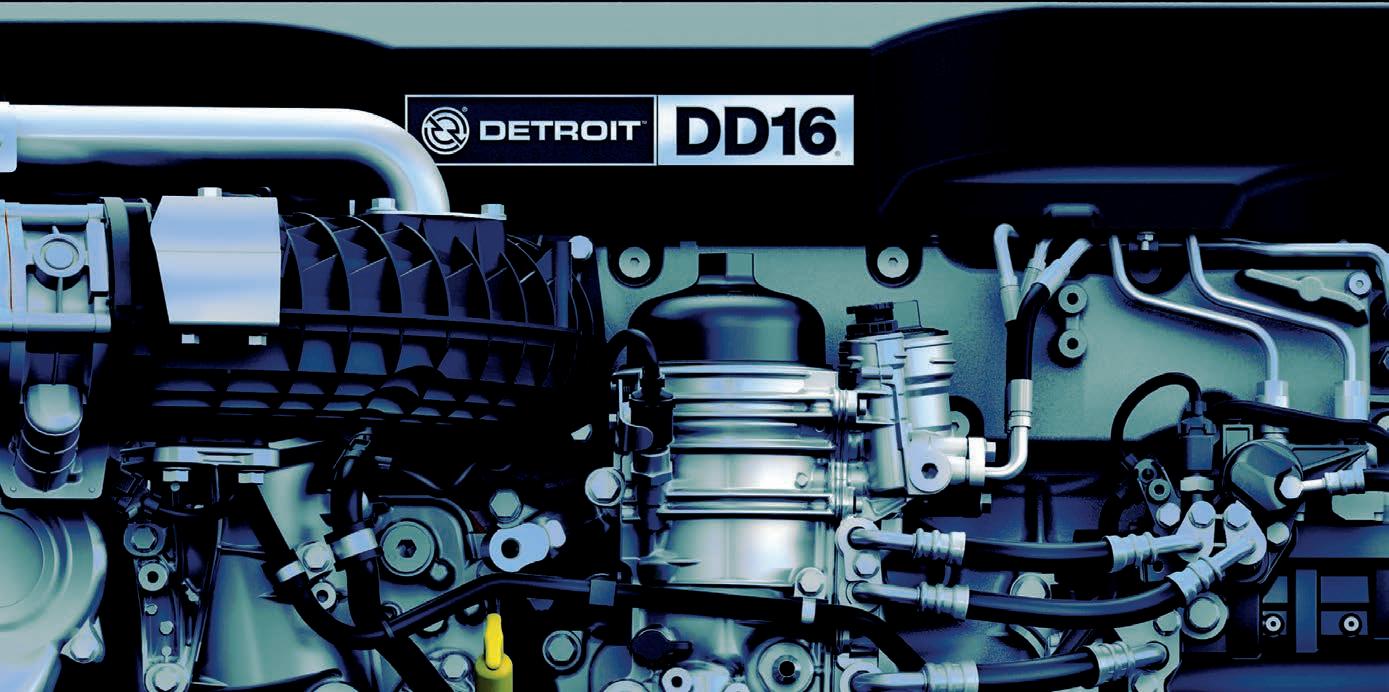

McGrath Newcastle now has four 126 Cascadia models in the fleet, which feature the range-topping 600hp 16-litre DD16 engine, teamed up with the latest generation 12-speed automated manual transmission

(AMT). Having had a positive Detroit experience previously, McGrath thought the engine would perform well — and he was correct.

Two of the trucks running as 79.5 tonnes A-doubles between Sydney and Newcastle are returning best-infleet fuel economy of 2km per litre despite the high drag profile of the two 40ft shipping containers on the back. Fuel economy, so far, is better than the other trucks in the fleet according to McGrath, who notes the Cascadias have also been wellreceived by the company drivers, many of whom were fans of other trucks in the fleet before the new Freightliners arrived.

“They have been very, very positive

about the Cascadias,” he said. “Once they drive a Cascadia, they are asking if they can stay in them, which is certainly a good sign.”

Comfort, according to McGrath, is one of the major reasons it is winning over the drivers.

“It is a lot of more comfortable than the other trucks we have in the fleet — that is clear,” he said.

The 126 Cascadias also deliver when it comes to safety and Cascadia is the only conventional truck in Australia with a driver’s airbag.

McGrath knows a lot about customer service. To this day he still delivers for one of the two customers he had when he first started his business all the way back in 1980.

PRIME NEWS PRIME NEWS 34 may 2023

Freightliner Cascadia 126.

CHARGED AND READY. The new eActros and eEconic. and Mercedes-Benz are trademarks of Mercedes-Benz Group AG. Overseas model shown.

> Flood-impacted WA receives new fatigue exemption notice

The National Heavy Vehicle Regulator (NHVR), Main Roads Western Australia, and the South Australian Department for Infrastructure and Transport have collaborated to deliver a new fatigue exemption notice. Its aim is to enable drivers operating under the National Class 3 Supplementary Access (Western Australia Assistance) Exemption Notice 2023 (No.3) to legally operate under ‘Exemption’ work and rest hours instead of Standard Hours when transiting through South Australia.

NHVR CEO Sal Petroccitto said that drivers who work for an operator that holds current accreditation through WA Heavy Vehicle Accreditation (WAHVA) can use the new National Heavy Vehicle Western Australia Supplementary Work

and Rest Hours Exemption (No.1) when operating under the National Class 3 Supplementary Access (Western Australia Assistance) Exemption Notice.

“In addition to the WAHVA requirement, to use this fatigue exemption, drivers must be delivering goods from southern Western Australia to the flood-affected Kimberley Region, and have had a medical check in the past three years if aged 49 or younger, or in the past year if aged 50 or older,” he said in a statement.

The NHVR has also recently extended the National Class 3 Supplementary Access (Western Australia Assistance) Exemption Notice until 30 June, 2023. “The extension of this notice is an important step in supporting the ongoing recovery efforts in the

flood-affected regions in the north of Western Australia, by authorising the continued access of Class 3 heavy vehicles that are roadtrains up to 53.5m in length to a specified network from Western Australia to South Australia,” said Petroccitto. “We ask that drivers of these vehicles please remember that the roads on this route are not designed for these longer vehicles, and to exercise particular caution and drive carefully when travelling to and from the affected regions.”

Back in February, the NHVR released a temporary notice to support the movement of essential food items from South Australia to Western Australia during the flooding events that impacted large parts of central Australia.

PRIME NEWS PRIME NEWS

36 may 2023

A CTI Logistics B-double navigates receding floodwaters in Western Australia.

YOU DESERVE A SMOOTHER, BETTER BUSINESS WITH CALTEX

Caltex, we

premium industrial lubricant technologies available for every kind of operation – from mining to agriculture, power generation to construction, trucking to global marine. No matter what challenges you might face, the journey will be Smoother, Better, Together with Caltex. To find out more about Caltex fuels and lubricants, visit www.caltex.com/au/business-solutions or call us on 1300 723 706

At

are committed to providing the most advanced

Nissan throws in with heavy duty BEVs

Nissan is delivering new vehicles from the Port of Los Angeles to dealerships in the Los Angeles region using two battery electric vehicle (BEV) heavyduty, Class 8 trucks.

Two major manufacturers of electric heavy-duty trucks, Nikola and Kenworth, will each provide trucks that will pull traditional car haulers. The program is being conducted in collaboration with logistics partner Avant-Garde Auto Logistics LLC, a woman-owned transportation company headquartered in Smyrna, Tennessee.

Nissan has also collaborated with current logistics partner Wallenius Wilhelmsen to install a charging solution to support the trucks operating from the Port of Los Angeles.

“Exploring the use of BEV trucks for new vehicle delivery is an important

milestone in our journey toward carbon neutrality throughout our business,” said Chris Styles, Vice President, Supply Chain Management, Nissan North America. “By being an early adopter of this technology, we’re showcasing our innovative spirit and positioning ourselves to meet our longterm goals for zero-tailpipe-emission transportation.”

Appropriately, the first dealership deliveries with the BEV trucks, to Downey Nissan in California, included Nissan’s all-new, all-electric crossover, the 2023 Ariya.

The company anticipates the proof-ofconcept project will help Nissan and its logistics partners understand more about the use of all-electric trucks for vehicle delivery.

Following the initial trial with four BEV

car hauler trucks, Nissan plans to deploy additional trucks in the Los Angeles area. Building on lessons learned from these projects, Nissan could eventually begin using BEV trucks for a variety of logistics uses.

As one of the first automakers to use allelectric heavy-duty trucks to transport new vehicles to dealerships, Nissan is now building on its commitment to achieving carbon neutrality across its operations by 2050.

Along with launching EVs to make accessible electric mobility widespread, Nissan is looking for opportunities to reduce emissions from other parts of its business. As part of the company’s Ambition 2030 plan, Nissan has a target of 40 per cent of its US sales being electric by 2030, with more to be electrified.

38 may 2023

GLOBAL NEWS

NikolaTre Class 8 semi at the Port of Los Angeles.

Mexico’s biggest truck fleet expands

KenMex compressed natural gas powered trucks have been added to Mexico’s biggest truck fleet operated by Trayecto.

Recently formed following the merger of Alianza Trayecto, Grupo Larmex and Grupo Transportes Monterrey, Trayecto operates over 300 CNG prime movers in its fleet of 4,000 trucks throughout Latin America.

The company, at present, provides the most complete portfolio of transportation services in Mexico, including regular and specialised cargo

in Mexico, USA and Canada, transporting different types of goods including domestic, food grade, hazmat, gases, chemicals, beverages, intermodal, controlled temperature and vehicles. The compressed natural gas powered trucks have Hexagon Agility fuel systems.

Hexagon Agility claims its ProCab 175 and ProRail 30 CNG fuel systems with integrated Blue iQ provide a driving range on par with counterpart diesel trucks, enabling Trayecto to utilise CNG, and obtain its environmental benefits,

without sacrificing performance.

“Our goal is to address the challenge of decarbonisation and implement technologies like natural gas where it makes sense,” said Jorge Casares, CEO of Trayecto. “Hexagon Agility has been instrumental over the last decade helping Grupo Transportes Monterrey transition diesel trucks to reduce our carbon footprint with natural gas. We value our partnership and look forward to many years of delivering safe and reliable transportation throughout Latin America.”

GLOBAL NEWS 40 may 2023

Jorge Casares.

PERFORMANCE AND ECONOMY

no compromise

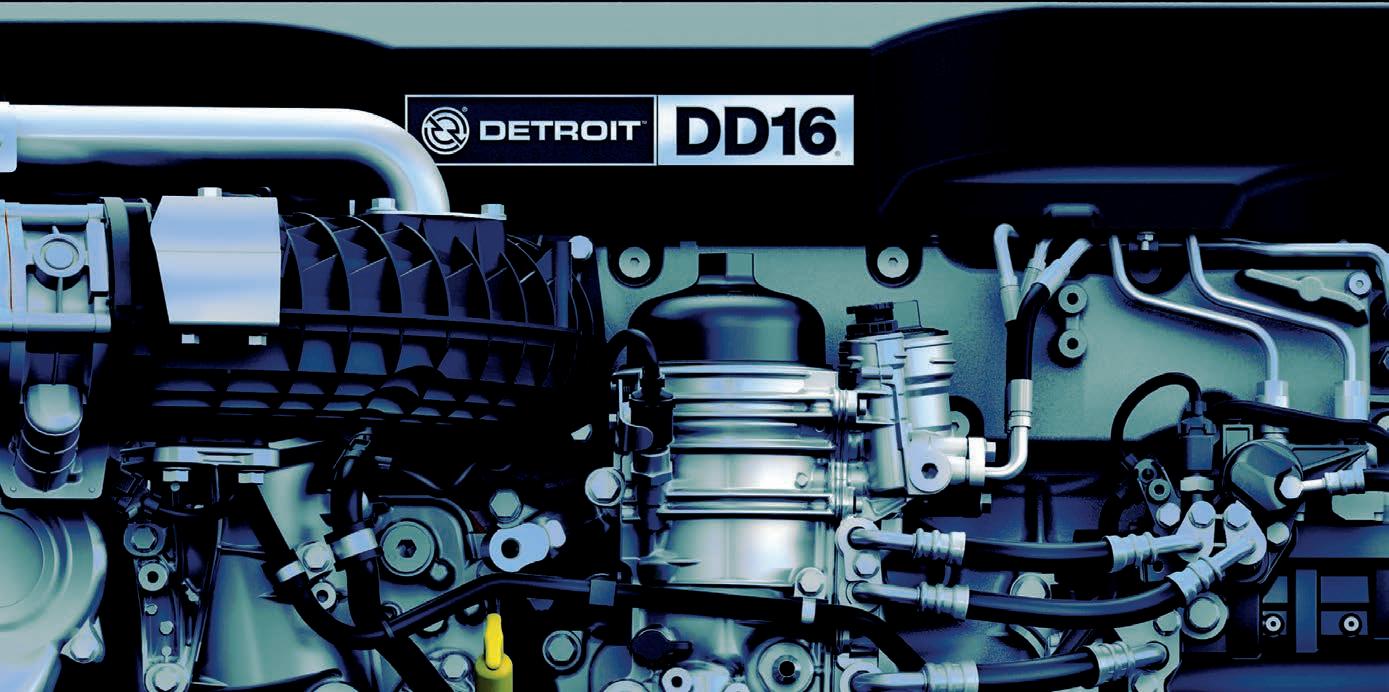

Detroit’s DD16 delivers all the power you need.

With up to 600 horsepower and 2,050 lb-ft of torque, the big bore workhorse provides efficient and dependable power and performance without compromise. Detroit’s advanced technology also means GHG17 requirements are met through innovative fuel efficiency resulting in lower emissions.

This power, performance and efficiency prowess is backed by our industry-leading warranty and extended coverage packages that ensures the highest level of support for our customers.

Combined with superior fuel economy and the absence of a midlife change out, the DD16 delivers an enviably low total cost of ownership and maximum uptime.

This is all backed by our well-established and extensive national service and support network which, together with our highly skilled factory-trained technicians, means you can count on getting the right advice when you need it.

With Detroit, there’s no compromise.

detroitanz.com detroitanz

Fran De Sanary is a Senior Risk Engineer and Sustainable Mobility Consultant with Zurich Resilience Solutions (ZRS). He has been involved in the Heavy Vehicle and Transport industry for over 40 years, including many years working as a Group Fleet and Risk Manager. At ZRS, Fran provides practical and costeffective risk management solutions for Fleet, Process, and Transport businesses that maximise asset protection whilst minimising financial risk.

THROUGH THE MOTIONS

Iremember being at a convention back in 2016, when, to much fanfare, a significant European manufacturer unveiled its new electric vehicle. By the time the convention finished, however, the vehicle was practically redundant due to the tech advancements that had subsequently occurred. Seven years ago, EV technology was moving so quickly that new advancements soon became yesterday’s news.

That steep development curve is common in most new technology, and at some point the curve plateaus. Technology will still continue to develop and evolve, but at a significantly reduced pace. Reaching that plateau triggers large-scale adoption – and, from a commercial vehicle perspective, that’s where we’re now at with EVs. That’s why it’s imperative companies take time to understand the impact the transition to EVs will have on their business, and how they will navigate this transition. Because it will have a major impact, and it’ll come much sooner than many people realise. Some think the EV transition is 20-30 years away. No, think more like five to 15 years.

In the not-too-distant future, you’ll be unable to purchase petrol or dieselfuelled vehicles. Regardless of what’s happening here, the European, Chinese and US markets dictate our vehicle supply, and they’re not going to continue manufacturing petrol and diesel vehicles just for us.

The move to alternate-powered vehicles is coming – quickly – and those businesses that are ready to adopt the new

technology will be in a far better position than those that aren’t.

The EV challenges that businesses need to consider

To transition successfully, businesses will need to have a strategy and processes in place to manage the risks that will consequently present themselves. A consideration is how the cost and depreciation of vehicles is viewed. New business models will be needed, as the cost of electric and hydrogen-powered trucks will be significantly greater than current petrol and diesel counterparts. Of course, grants are currently available and carbon credits can be accumulated. But that cost outlay will need to be factored into the long-term financial strategy, and how that return on investment is modelled will need to change. Other factors will need to be brought into the ROI process rather than the direct and obvious.

Some costs may be offset by customers. For example, in the short- to mediumterm, customers may be willing to pay a premium to have their deliveries made by an electric vehicle.

But other returns will need to be identified and quantified. Having a consistent and reliable stream of power to charge EVs is another challenge. Is the infrastructure that’s currently in place suitable to charge the number of vehicles you need now and into the future? Recently, I worked with a company that spent $250,000 to get new transformers in the street to satisfy demand. Without it, they wouldn’t have been able to power their fleet.

42 may 2023

RISK MINDSET

The biggest EV risk businesses face? Doing nothing.

Fran De Sanary

Driver education holds the key to adoption

The experience of driving an EV is different, and how you transition drivers will determine how well new vehicles are adopted. I know of two fleet businesses that began using electric vehicles –exactly the same models – with very different results.

The first company undertook a thorough training and education program with their drivers; the second practically handed over the keys and that was it.

While the first company enjoyed a very successful transition, the second company had a group of dissatisfied drivers to placate. Training is important, because driving an electric vehicle is different. Range anxiety is real, and regenerative braking and eco-safe driving techniques are key to maximising range. Regenerative braking, however, mostly happens when the foot is off the accelerator and not on the brake — and for drivers who are used to driving foot-to-brake it will mean a change in driving style.

Those drivers who’ve been managed well,

and have been part of a structured change management program, tend to prefer EVs. They are less fatigued and it’s a smoother ride — once you know how to drive them.

There are also practical risks to consider. What happens if someone trips over a charging cable? What eventuates if an employee is charging their work vehicle at home and there’s a fire?

These are just examples of the considerations that together, over the coming years, we need to understand and make provision for.

The transition to EVs is going to be a logistical and financial challenge. It’s new, it’s different, and it’s not simple or easy. However, the biggest risk for businesses regarding EVs is to sit there and do nothing.

Currently, the EV uptake is voluntary, but this will not always be the case. In the near future you’ll be forced to take action. Those businesses that have taken the time to map out their EV strategy, adapt to the challenges and maximise the opportunities, will be the businesses that have a far greater chance of success.

Starting your EV transition journey Of course, knowing where to start is sometimes the biggest hurdle. The business I work for, Zurich Resilience Solutions (ZRS), a business unit of Zurich Insurance, offers resilient risk engineering services that support businesses in this transition to electric vehicles. The early identification of risks and understanding your business’s resilience to this changing environment is vital and the quality and respected risk engineering services are paramount. We work with businesses to review all processes and procedures, including procurement, driver training and awareness, maintenance, charging infrastructure and placement, through ‘whole of life’ ownership to disposal. Once those risks are identified and mapped, we offer not only pragmatic risk improvement actions, but also assist you to achieve your resilience goals.

If you’d like to speak to the team at ZRS to help you plan your business’s transition to electric vehicles, email resilience.solutions@ zurich.com.au.

primemovermag.com.au 43 SPONSORED BY

New generation DAF Electric vehicles with charger.

TROP THUN

COVER STORY 44 may 2023

UD Quon emerges from the Gillies Range near Cairns in North Queensland.

IC DER

Waste collection specialist, MAMS Group, covers a vast municipal area in North Queensland the size of a European country. For this it relies on a dedicated fleet of commercial vehicles.

primemovermag.com.au 45

ARange, an 800-metre-high partition that divides the enclave of the Far North Queensland coastal plain from the interior Atherton Tableland. In this elevated region headwaters flow southeast into the Herbert River Valley where two historic mill towns are located. The Victoria Mill, established in 1883, on the Herbert River near Ingham was the country’s biggest sugar mill until 1999. Local family business MAMS Group, still a far cry from the guise it operates in today, got its start here. Back then it was carting mill mud and ash out of the refinery for the Colonial Sugar Refining Company, better known now as CSR. That contract was limited to seasonal work, restricted for the best part to six months of the year. In the slack season, MAMS occasionally

term. By the turn of the century, the company had moved into the waste sector having landed a successful tender for a wheelie bin contract awarded by the Hinchinbrook Shire Council. It was its first foray into hook lift and front lift trucks. That contract, three decades later, is still in service today.

The policy writ large for the company, circa 2023, is to consolidate after an expedited period of growth. The resultant legacy is five depots across an area the size of Poland, 60 staff, most of whom are permanent, multiple revenue streams and a growing truck fleet including four new UD Quons.

General Manager Josh Lannen has been with the company since 2010. You might say he married into it because that’s exactly what he did. After meeting his

business which he sold to his two business partners before heading to the tropic far reaches.

MAMS Group, by then, had been servicing a major waste management contract on Palm Island. It had included the construction of transfer stations on the island and the purchase of a barge it initially operated one day a week.

“We were the only way to get anything bigger than a suitcase on and off Palm Island,” recalls Josh. “That business eventually expanded to have multiple prime movers and fridge vans running out of a depot in Townsville to Palm Island for freight and food.”

When MAMS sold the business in 2011 to a group of investors, so that it could concentrate on its mainland waste business, it was operating two barges six

46 may 2023

Josh Lannen at a recycling depot in Cairns.