With more than two decades of experience as a media professional, Christine has worked in newsrooms across Canada, Vietnam and Australia. She joined the Prime Creative Media team 12 years ago, and today oversees more than 43 titles, including a dozen print and digital transportation titles. She continues to lead a team that focuses on continuous improvement to deliver quality insights that helps the commercial road transport industry grow.

Over the past two decades William has published widely on transport, logistics, politics, agriculture, cinema, music and sports

He has held senior positions in marketing and publicity for multinational businesses in the entertainment industry and is the author of two plays and a book on Australian film history. Like many based in Melbourne he is in a prolonged transition of either returning or leaving.

A seasoned transport industry professional, Peter has spent more than a decade in the media industry. Starting out as a heavy vehicle mechanic, he managed a fuel tanker fleet and held a range of senior marketing and management positions in the oil and chemicals industry before becoming a nationally acclaimed transport journalist.

Louise joins Prime Mover after nearly 25 years as a writer. Starting her career as a reporter at the Toronto Star, she has spent much of the last 15 years as a design writer and editor. In 2020, she was shortlisted on the Richell Emerging Writers Prize list. Originally from Nova Scotia, she lives in Melbourne with her two children.

Peter has completed a Bachelor of Media and Communication (Media Industries) degree at La Trobe University, and he brings a fresh perspective to Prime Mover. He gained valuable experience at Upstart, La Trobe’s newsroom, work that has been supplemented by direct industry experience in a Council placement.

Peter has a strong interest in commercial road transport, and in contributing to Prime Mover’s efforts in growing the industry.

Australia’s leading truck magazine, Prime Mover, continues to invest more in its products and showcases a deep pool of editorial talent with a unique mix of experience and knowledge. www.primemovermag.com.au

Handling placements for Prime Mover magazine, Ashley has a unique perspective on the world of truck building both domestically and internationally. Focused on delivering the best results for advertisers, Ashley works closely with the editorial team to ensure the best integration of brand messaging across both print and digital platforms.

ceo John Murphy john.murphy@primecreative.com.au editor William Craske william.craske@primecreative.com.au managing editor, Luke Applebee transport group luke.applebee@primecreative.com.au senior feature Peter Shields writer peter.shields@primecreative.com.au

business Ashley Blachford development ashley.blachford@primecreative.com.au manager 0425 699 819

art director

Blake Storey blake.storey@primecreative.com.au

design Kerry Pert , Louis Romero, Tom Anderson

journalists

Peter White peter.white@primecreative.com.au

Louise Surette louise.surette@primecreative.com.au

design production

Michelle Weston manager michelle.weston@primecreative.com.au

client success Salma Kennedy manager salma.kennedy@primecreative.com.au

head office 379 Docklands Drive, Docklands VIC 3008 enquiries@primecreative.com.au

subscriptions 03 9690 8766 subscriptions@primecreative.com.au

Prime Mover magazine is available by subscription from the publisher. The right of refusal is reserved by the publisher. Annual rates: AUS $110.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate.

articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

copyright

PRIME MOVER magazine is owned and published by Prime Creative Media. All material in PRIME MOVER magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information

Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in PRIME MOVER magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

MAN’s powerhouse, the TGX with 26 t GVM powered by MAN’s mighty 15 L 640 hp D38 engine, comes with a range of cabs including the maximum GX cab – the king of the jungle!

Excellent in line haul, roadtrain and heavy haulage applications, the TGX 26.640 GX is MAN’s premium offering. With a class-leading 840 hp engine braking capability, no load or terrain is too challenging.

Visit man.com.au to learn more about our new MAN truck generation and how it delivers excellent driver fit, great efficiency and economy features, and optimised uptime, and makes for a strong business partner.

“You need to stay in front of the game. Everyone can cart fuel. It’s how you do it differently that makes you the place that people want to work and the place of choice for customers.”

28 Chain of Command

Carrying the largest jet fuel spec’d fleet in the country, Hills Tankers possesses over 100 prime movers that it deploys along the northern eastern seaboard servicing airports, mines, retail outlets and military bases.

34 Chemical Brothers

As a niche segment, chemical transportation by road often involves a different mindset to fuel haulage. Unanderra Tanker Hire is one of the industry’s leading practitioners.

In the latest step in its national fleet renewal program, Lineage Logistics took delivery of ten brand-new Kenworth K200s which are now transforming its linehaul operations.

42 Coming Attractions

While it may come as a surprise to some, the Phillip Island Penguin Parade and Isuzu both have one thing in common.

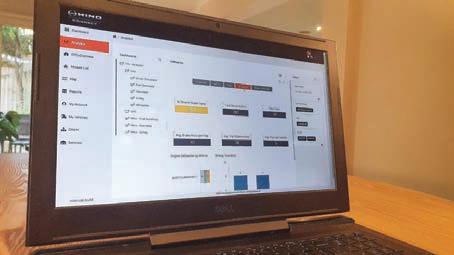

Hino has set a course embracing the latest in commercial vehicle technologies, while also committing to its hybridelectric developments.

TEST DRIVE

62 Diesel Lives!

Scania’s all-new 13-litre diesel engine is an important step in the decarbonisation of road transport.

White paint markings found outside of Faya-Largeau, the largest city in northern Chad, serve as reminders even today of the hundreds of mines left behind from the war with Libya. The conflict itself lasted for nearly a decade and by the mid-1980s escalated to the point that Gaddafi’s Libyan forces occupied most of the country’s north. Despite having numeric advantages mostly in foot soldiers, Chadian forces were hopelessly outgunned, as it possessed little military equipment capable of going up against Libya’s Soviet T-55 tank. That is until France and the United States intervened. In an unconventional move, the French Air Force supplied Chad’s military with some 400 Toyota HiLux pickup trucks. This dramatically turned the war in Chad’s favour.

The HiLux proved a versatile, makeshift armoured vehicle in the harsh environment often with a .50 calibre assault weapon or MILAN anti-tank guided missile system rigged to the truck bed. Fuel consumption, manoeuvrability and ease of conversion, what’s more, made it formidable for desert skirmishes.

Even so, the dangerous terrain laden with ‘sleeping policemen’ still posed a major challenge for Chadian forces until it was discovered that the HiLux could be jounced over Libyan anti-vehicle mines without setting them off. To do so safely, irrespective of payload, they needed to exceed speeds of 62 mp/h. How this exact speed was arrived at is a matter of contention. Whether it was discovered via kamikaze R&D or brilliantly intuited by the young commander, 31-year-old Hassan Djamous, who was responsible for major victories at Audi Doum and Fada, or rather the result of simply converting the speed to the metric system, an equivalent of 100 km/h, which was in practice at the time in both North Africa and France, speculation mostly eclipses material facts. Djamous personally led troops in trucks over Libyan-laid minefields at Ouadi Doum as proof of concept. Initially, driving at a speed of 90 km/h was thought to cause a three-second delay before the mines exploded. Djamous was not soon after badly injured demonstrating his three-second technique leading, not surprisingly, to an increase in the required speed. He later returned to the fray at Maaten al-Sarra. The wheels of the vehicles when travelling at 100 km/h, as another theory would have it, were in contact with the mines for an estimated 1.8 milliseconds. Legacy armoured vehicles typically can’t travel at this speed leaving more time for the mine, which relied on a magnetic field, to be triggered. As a diesel engine, especially one made before 1984 when many of the Toyotas were produced, is averse to being revved for extended periods in top gear, a long-range speed is likely to have been maintained before any of the pickups entered a minefield.

What kind of timing was involved? How much downward force would it take to set the mines off? More questions abound. How low was tyre PSI to reduce contact pressure? If downward force does not change with momentum, how would velocity alleviate the pressure? Could the huge rear leaf springs of the HiLux, presuming the theory is accurate, have helped it to stay level with extra weight? On 2 January, 1987, Djamous deployed 3,000 men into battle at Fada where Libya lost almost 800 soldiers, 92 tanks, and 33 infantry fighting vehicles. Chad’s losses were minimal, just 18 soldiers and three pickups. The “pale ectoplasm of statistics” as Robert Penn Warren likened the cold application of data in the American Civil War, of course, doesn’t account for the 7,500 dead nor the $1.5 billion dollars’ worth of military equipment destroyed or captured during hostilities that finally ended when Libyan forces were expelled in 1987. The HiLux has since become an indispensable vehicle for military groups across the Middle East and Northern Africa. Indeed, it was so effective in the Chad-Libya conflict historians often refer to it as the Toyota War. In nearby Liberia, where unrest at the time was already mounting, civil war would soon break out. The Toyota HiLux again would have a major role to play. Although with cannibalism, witchcraft and rebels often affixing human skulls to the grilles of their vehicles during the conflict, historians have naturally been less than earnest in associating any major manufacturer with it.

Change is inevitable, by embracing it with the Hino 300 Series Hybrid Electric, you can gain a genuine competitive advantage. Make real savings from your fuel and maintenance costs, reduce your operating costs and more. With superior technology at work, the Hino Hybrid Electric will deliver up to 20%* reduction in both fuel use and emissions, compared to a traditional diesel truck. As there is no starter motor, the regenerative braking system charges the batteries which means increased on-road time with no recharge requirements, and a 16% annual maintenance cost reduction due to less wear and tear on the brakes. That’s the power of change, that’s the Hino Hybrid Electric. Visit hino.com.au

A double stacked container vehicle has been trialled for the first time on port and public roads in Australia.

The Super B-double Double Stacked vehicle was operated by Qube as part of a trial conducted under stringent safety and operational conditions at the Port of Brisbane.

Both the National Heavy Vehicle Regulator (NHVR) and the Australian Road Research Board (ARRB) oversaw the trial which involved the vehicle carrying eight empty twenty-foot equivalent (TEU) containers on a defined route within Qube’s port facilities and limited public port roads. The trial was conducted under a temporary permit from the NHVR and temporary consent granted by PBPL as the Port’s road manager. The Super B was pulled by a Scania

prime mover.

Nicknamed ‘the London Project’ in homage to London’s iconic double decker buses, the high productivity vehicles have the potential to increase operational efficiencies, given their ability to move 12 TEUs at a time. Qube also expects the double stacked triple trailing units produced by O’Phee Trailers and the Drake Group, will lower emissions by eliminating truck movements.

PBPL CEO, Neil Stephens, congratulated all who were involved on the successful trial which followed a significant period of design, engineering and consultation by Qube with its stakeholders, including PBPL. “This is a fantastic outcome for Qube and all parties involved today. It’s also a clear demonstration of

the collaboration and innovation being achieved by our customers and partners here at the Port that’s enhancing productivity and efficiency in their operations,” said Stephens. “As Port Manager, one of our key priorities is investing in infrastructure to support supply chain efficiency,” he said.

“We were pleased to deliver road improvement works and upgrade the access/egress to a number of facilities to support this new vehicle and Qube’s innovation.”

Under its current permit and consent conditions, the new double stacked vehicle will transport empty containers on a defined route within Qube’s facility and limited public port roads, under stringent safety and operational conditions.

Updated laws introduced by the Western Australian Government to safeguard the rights of ownerdrivers of heavy vehicles operating in the road freight transport industry have recently come into effect. The amended Owner-Drivers (Contracts and Disputes) Amendment Act 2022 passed Parliament in October last year and is the result of extensive consultation with the Road Freight Transport Industry Council and the Road Freight Industry Tribunal.

The amendments will help improve business dealings between ownerdrivers of heavy vehicles who transport freight and the people who hire them, by clarifying the regulatory responsibilities of both parties.

The changes include the introduction of minimum notice periods of 90 days

for termination of a contract longer than three months, and seven days for contracts less than three months.

The role of the Road Freight Transport Industry Tribunal has also been clarified to make sure it can deliver fair and efficient outcomes in dispute resolution between owner-drivers and hirers. Non-compliance with owner-driver guideline pay rates will now be factored into dispute resolution decisions made by the Tribunal. This change places more responsibility on hirers to offer fair pay for owner-driver services. In addition, workplace right of entry provisions have also been updated to allow an authorised owner-driver’s representative to enter a workplace to investigate suspected breaches of the Act.

WA Transport Minister Rita Saffioti said

Brisbane based refrigerated transport rental company, Eurocold, has announced significant expansion plans for key stakeholders. A pipeline of initiatives will be bolstered by an $100 million investment according to Managing Director, Avraam Solomon which will see expansion through new markets, including New Zealand and further development set for sister company Revora.

After it launched a Western Sydney facility earlier in May, Solomon’s vision is expansive, committing to a $100 million spend within the refrigerated transport industry with the focal point being expansion into Melbourne, Perth and ultimately New Zealand. This commitment over the next three years will see up to 800 trucks being deployed, the initial goal being 500 trucks. The nexus of Eurocold’s establishment three years ago was securing the Australian rights for Isokit refrigerated bodies. In that time, Eurocold has become one of the leading companies in the space combining decades of experience, innovation and a customer

service focused approach.

Solomon and his key executives have spent significant time researching global trends in refrigerated trucking – both in person and anecdotally – and, when it comes to renting or leasing trucks, the Australian market lags in uptake when compared to global counterparts –something Eurocold wishes to change.

“I’ve spent a lot of time in Europe in the last 12 months looking at large businesses that specialise in refrigerated truck leasing and rentals,” he said.

“For example in Europe, of all the vehicles that are produced every year, we know that 58 per cent of the builds go into long-term rentals trading to leasing off balance sheet.

“Currently in Australia, it is a fraction of that – the percentage of rental take-up is more like 1 to 3 per cent – so there is significant opportunity for transport fleet operators to scale with flexibility and ensure their fleets feature the latest technology, which then flows onto a second hand market,” said Solomon.

“We see ourselves as a large participant in the industry to get rigid vehicles that

the updated laws protect the rights of small businesses and independent operators who own and drive trucks in the freight industry.

“These are the small operators who are making a big difference to our economy and our lives, by helping to keep our supply chains going and delivering goods across our State,” Saffioti said in a statement.

“Our new laws will provide them with better protection and improve their position in matters including job security and fair pay, as well as clear processes to follow to resolve disputes.

“We have consulted extensively with industry to update these laws which will result in more streamlined and reasonable business dealings between owner-drivers and people hiring their services.”

are of the highest quality and standard onto the road, so we’re always using the most modern chassis’ and sourcing the best Isothermal bodies from around the world.”

Revora, which was launched in March, will be a fully owned sub-brand that specialises in the rental of rigid, electrified trucks.

General Manager, Nathan Gore-Brown announced that Carrier will be a supplier of new technologies for the electric, refrigerated transport industry in Australia.

“Revora is a real investment to us. It is something that is costing us money every month, which we forecast will take 12 months or two years before starting to see significant returns,” said GoreBrown. “Revora and Eurocold for that matter are companies that really want to see the industry make a difference in the long-term sustainability of refrigerated transport – and to our environment –because we believe in it.”

Gore-Brown said the usage situation for clients is what will drive the selection of chassis and body size.

Heavy Vehicles that disrupt traffic and shutdown tunnels could be sidelined for up to six months under new laws proposed in New South Wales. The NSW Government has been prompted to take action after repeat incidents saw tunnel closures in one week caused by incidents involving overheight trucks. Under a new proposal, the State Government is advocating heavy vehicles that cause Sydney tunnel closures are to be stripped of registration.

Overheight trucks were repeatedly compromising the safety of motorists and testing the patience of the entire city according to Minister for Roads John Graham.

“A small minority of drivers are holding the city to ransom,” he said. “They are neither professional nor responsible, and they are continuing to ignore the message about overhead height restrictions. They are threatening the safety and the patience of motorists.” In response, the NSW Government this week approached the National Heavy Vehicle Regulator (NHVR) to work closely with Transport for NSW to initiate more investigations and bring charges against trucking companies and owners under “aggravated circumstances” provisions. Graham said prosecutions of companies under the rules, including heavy vehicle chain of responsibility provisions, had so far been limited and the NSW Government was keen to see more action and referrals from the NHVR that allows NSW Transport to take an offending truck off the road for up to six months.

Since August 2022, when heavy vehicle regulatory functions were transferred to the NHVR, just four registration sanctions have been completed against trucking companies by Transport for NSW on referral from the NHVR for overheight breaches in relation to tunnels in NSW and of these one was thrown out by the court.

To enhance warning systems for

the Sydney Harbour Tunnel, the NSW Government has approved the immediate deployment of $5 million in infrastructure upgrades, sensors, signage and enhanced slip ways for trucks that approach tunnels with overheight loads.

For the Sydney Harbour Tunnel, this will involve moving warning signs and sensors further back along the Warringah Freeway to ensure heavy vehicle drivers can take earlier evasive action to avoid blocking traffic at the tunnel portal or worse. This work will start in July and is intended to be fully completed by December.

Police will continue to focus on roadside compliance on overheight trucks, targeting key corridors such as the Sydney Harbour Tunnel. A social media education campaign in collaboration with the NHVR was recently launched. The NSW Government has ruled out closing the Harbour Tunnel to trucks altogether because the majority of heavy vehicles are already prevented from crossing the Sydney Harbour Bridge due to mass constraints.

Closing the tunnel to heavy vehicles would precipitate truck drivers using alternative routes across Sydney that in some cases would add 42 kilometres to the current route between Port Botany and the M1 at Wahroonga and involve many more truck movements through

Sydney suburbs.

Recently a number of penalties for over-height vehicles were increased, with some being doubled. These include on-the-spot fines for over height trucks entering Sydney tunnels of up to $4,097; demerit points for the offence are 12; suspension period for a driver’s licence up to six months; and registration suspension period for trucks up to six months.

According to Graham, good drivers know the height of their truck and stick to the tunnel height limit.

“My message to that handful of bad drivers and their truck companies is you will be hit with the harshest penalties possible, more often,” he said. “We have agreed to work with the National Heavy Vehicle Regulator to increase awareness amongst truck drivers, but also to crack down on trucking companies who breach these rules. We will be taking their trucks off the roads,” Graham continued.

“One thing I do not want to do, is to close the Harbour tunnel for the vast majority of good truck drivers. That would simply send trucks into our suburbs, creating city-wide chaos and congestion.”

Road Freight NSW last month cautioned the NSW Government from banning high productivity vehicles from Sydney tunnels.

Volvo Trucks has confirmed Followmont Transport has made the first Australian order of the recently unveiled heavyduty FH Electric. The FH Electric is the largest e-powered truck in Volvo’s fleet of electric vehicles.

With a range of 300km, it is considered a well suited platform for extended transportation routes and intercity travel. The deal also includes the mid-sized FL Electric, which has a range of 400km and is designed for urban delivery and intercity transportation. Both trucks are anticipated to be delivered to Followmont Transport in late 2023.

Martin Merrick, President of Volvo Group Australia said it was a huge milestone for Volvo Group.

“The FH Electric is set to be a game changer for transportation in Australia. It will play an important role in the decarbonisation of Australia’s transportation sector,” he said. “This investment allows Followmont to set itself apart as a company that is stepping up and helping realise a future with cleaner and greener vehicles on Australian roads.”

Investing in the two e-powered trucks was a landmark occasion for Followmont, according to CEO Mark Tobin, as it looked to help its partners decarbonise.

“At Followmont, we take our responsibility seriously and understand this is the time for change,” he said.

“We’re excited to take delivery of our first electric units later this year, getting on the front foot to further reduce our impact on the environment and taking our strategy to the next level. “Through investing in vehicles, technology, infrastructure, and our communities, we will continue to play our part in supporting present and future generations.”

As Volvo celebrates the inaugural order, it continues to call for urgent regulatory change to the current rules that limit steer-axle-to-mass ratios to 6.5 tonnes in Australia. This stops heavy-duty vehicles including the FH Electric from driving on Australian roads.

increase the fitment of safety technologies to new heavy vehicles by aligning local width regulations with those in major markets such as Europe,” said Hourigan. “These reforms will give industry access to a greater range of heavy vehicles fitted with the latest

“We want to hear from industry and further unpack how to implement these Australian Design Rule (ADR) changes into the Heavy Vehicle National Law

details of these reforms, the NHVR is proactively considering how these changes might change the HVNL.

“The heavy vehicle industry and truck manufacturers are ready for this next generation of safer trucks. The NHVR wants to make sure the HVNL is prepared to get these safer trucks on our roads,” Hourigan said.

The release of the paper means that the NHVR is seeking public comment on regulatory changes that have not yet been signed off by Ministers.

on how to implement the Australian Government’s Safer Freight Vehicle (SFV) reform proposals. It includes increasing the width of heavy vehicles fitted with modern safety technologies.

NHVR Chief Regulatory Policy and Standards Officer David Hourigan said the reforms would support the uptake of safer heavy vehicles by increasing the overall width up to 2.55m or 2.60m.

“The proposed SFV reforms would

According to the proposed SFV reforms, any vehicles exceeding 2.50m in width would need to be fitted with a mandatory technology package. This technology package includes features such as: Advanced Emergency Braking (AEB), Improved rear vision mirrors and systems; lane departure warning; side underrun protection (SUP); and improved conspicuity markings. Once finalised in Europe, blind spot information systems and advanced systems that detect pedestrians and cyclists on the passenger side of heavy vehicles will also be required as part of the mandatory technology package. Hourigan said while the Australian Government is still finalising the finer

HVIA Chief Technical Officer Adam Ritzinger acknowledged there was enormous interest regarding the reforms but expressed concern that the move would likely cause confusion within the industry.

“Up until now, the big question has been when an announcement will be made by Ministers,” said Ritzinger.

“In that sense, the release of the NHVR’s implementation plan has confusingly put the cart before the horse.

“Yet despite that, a greater concern is that the NHVR has considered implementation of wider trailers, which needs further detailed impact assessment before any decision can be made.”

Woolworths Group has kick-started the transition by welcoming the first of 27 new EVs, which will begin delivering groceries to Woolworths’ Sydney customers over the next two months.

The supermarket giant’s home delivery fleet is currently made up of 1,200 trucks. It is anticipated that the very last combustion engine vehicle will join the home delivery fleet by 2027, as they are gradually decommissioned and replaced with EVs.

“Our home delivery trucks are a familiar sight in neighbourhoods across Australia, and within the next seven years, we want to make every one of them electric, and free of fossil fuels,” said Brad Banducci, Woolworths Group CEO.

“The case for a low carbon future has never been clearer and we’re backing a better tomorrow for our communities and the planet by starting the transition now,” he said. “We’re proud to be putting 27 new EVs on the road in the coming weeks – in one of the many ways we’re working

All 27 of the new home delivery EVs will be based in Sydney, delivering groceries to customers across the CBD, Inner West, Sutherland Shire, St George region and Eastern Suburbs.

At present, public EV infrastructure to support commercial fleets remains limited. The trucks will operate out of Woolworths’ Customer Fulfilment Centres (CFC) in Mascot and Caringbah, which are dedicated to picking and packing the supermarket’s online orders. The CFCs have installed new EV charging infrastructure in preparation. Woolworths Group’s new EVs, according to a company statement, consist of two models manufactured by Foton Motor and SAIC Motor, which both offer sufficient working range to complete daily metro home deliveries before returning to base to charge overnight. They are fitted with a new, state-of-the-art electric refrigeration system that runs off the vehicle’s battery, ensuring groceries stay cold.

rigid vehicles, as it trials emerging technology to help decarbonise its fleet in the long-term.

Currently, the technology and infrastructure to support the load intensity and distances of long haul freight is still in its infancy. Woolworths Group also hopes to contribute to public infrastructure. It plans to ensure the right charging technology and locations are considered to meet the needs of electric metro fleets, as well as low emissions long haul freighter trucks which will require accessible recharging points across regional Australia.

By 2030 Woolworths Group intends to have reduced its overall operational transport emissions by around 60 per cent compared to today, and to have decomissioned more than 3,000 internal combustion engine vehicles from its company-wide fleet. Woolworths Group supply chain arm – Primary Connect –first launched an electric truck trial in Melbourne September, 2021 with Linfox.

With undisputable road presence and trusted reliability, there’s no place you’d rather be than behind the wheel of a Kenworth.

Cement Australia has been awarded grant funding to lease 24 batteries and convert six diesel prime movers in its Melbourne fleet to electric drivetrain. Backed by the Zero Emissions Vehicles Commercial Sector Innovation Fund (CSIF), Cement Australia will also install swap-out charging infrastructure with a minimum of three charging units. It will then complete a trial/demonstration stage for 12 months, which will include the testing and observation of

performance of Battery Electric Vehicle (BEV) prime movers in 24 hour operation; maintenance and repair requirements of BEVs; training of personnel; and reliability and wear and tear of charging infrastructure.

Upon completion, Cement Australia will also undertake a post-trial assessment of outcomes.

In December last year, Cement Australia delivered its first load in New South Wales with a BEV-converted Kenworth

Isuzu Australia Limited (IAL) has announced changes to dealer partners in Northern New South Wales, Far North Queensland and the Sunshine Coast. Northern New South Wales and regional Queensland, where the brand is opening a new Isuzu Trucks dealership, are recognised as key markets. The changes are expected to bolster the brand’s operations throughout the state, by further strengthening customer access to industry-leading road transport sales and aftersales support.

In Moree and Goondawindi Harvey Black Group has purchased Kenway & Clark. The new Dealership – Black Truck & Ag will commence on 9 June 2023.

In Cairns, shares of FR Ireland have been transferred to Eacab (effective 1 June 2023) — Eacab being an Eagers Automotive Group (EAG) subsidiary.

On the Sunshine Coast, ownership of Sunshine Coast Isuzu is being transferred from Perth-based CJD Group to the Toowoomba-based Prime Truck Group.

The newly established Prime Truck Group, with common shareholdings from the well-known Western Truck Group, now stretches from the Sunshine Coast to the Wide Bay and Burnett regions. Their expansion continues throughout the Bundaberg, Hervey Bay and Maryborough regions, with a new Isuzu Trucks dealership planned for the Fraser Coast – under the Prime Truck Group banner.

CJD Group will continue to operate Isuzu dealerships in Darwin and Alice Springs. IAL Head of Network Development, Ella Letiagina, acknowledged the changes and noted the Isuzu brand would be in

T410 Glider. The same vehicle was showcased at this year’s Brisbane Truck Show.

CSIF is a $5 million program that seeks to accelerate the uptake of ZEV technology in commercial settings, including the commercial passenger vehicle, freight and infrastructure industries.

Australia Post, UPS, IVECO Trucks, LumiRide, Mulgrave Automotive Innovation Centre and 13 Cabs have also received grants from the fund.

experienced hands moving forward. “Isuzu is looking forward to working with Dealer Principal Michael Watt and the team from Black Truck & Ag in Goondiwindi,” she said. “Up in Cairns, the Ireland family has a long and storied automotive history dating back nearly 100 years—in fact this business commenced on 4 June, 1923. We would like to thank Ireland Isuzu for their hard work and loyalty to the brand.”

With the change of ownership, Letiagina said there was confidence that Isuzu would continue to be strongly represented in Far North Queensland by Dealer Principal Jon Maurice and his experienced team.

“On the Sunshine Coast, CJD have been a great partner over the past five years,” continued Letiagina. “The team’s consistency has allowed the Isuzu business to grow and build outstanding customer relationships.

“I’m sure this next phase, under the Prime Truck Group led by Dealer Principal David Ohlberg, will see the operation go from strength-to-strength.

“In Queensland the Prime Truck Group is also enjoying strong growth and I’m pleased to confirm that Isuzu Trucks will be expanding with an all-new dealership opening shortly on the Fraser Coast.

“Given their experience with the Isuzu brand already, IAL is confident the collaboration will continue to yield excellent outcomes for all parties involved.”

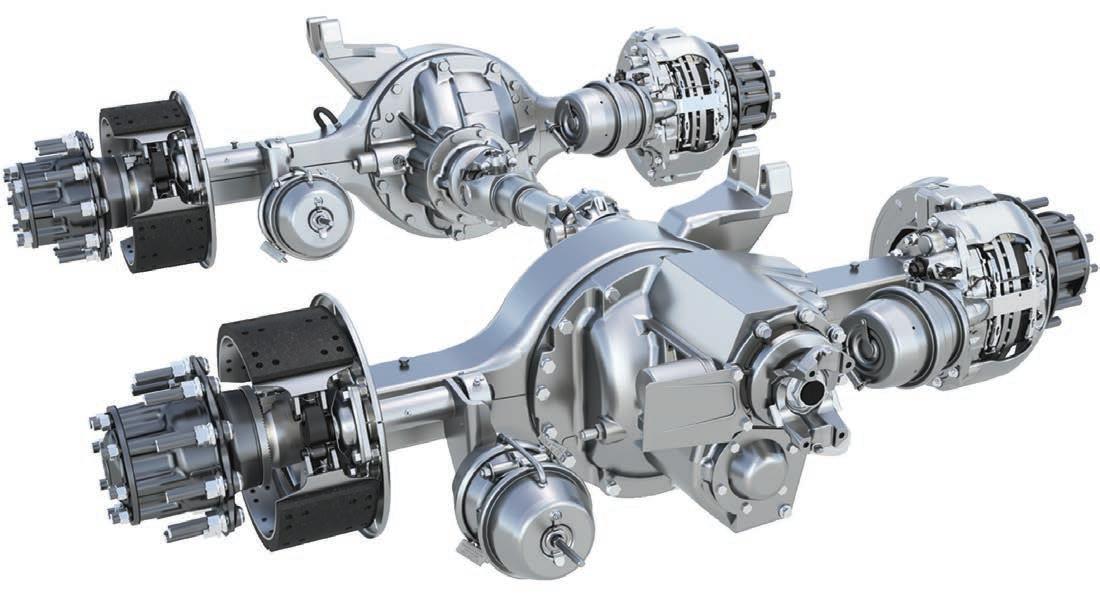

Australia’s most popular heavy-duty axle

Available in Linehaul (Pumpless) or Vocational (Pumped) configurations

Built tough to suit Australian conditions

The Victorian Government has opened a $1.5 million innovation centre for smart technology in fleet vehicles such as freight and emergency services trucks. The Connected Mobility Innovation Centre, developed by Directed Technologies, will enable it to develop smart sensors that can keep track of driver fatigue, tyre pressure and temperature of refrigerated cargo. The new centre’s system also considers a vehicle’s dimensions, weight and clearance when planning routes to help drivers travel safely and

efficiently to their destination. According to the State Government, this will therefore allow clients such as Australia Post to know exactly what is happening to their vehicles on the ground — improving safety and service reliability.

“We’ve built a world-class facility right here in Victoria thanks to the assistance of the Victorian Government and developed innovative solutions for the world’s biggest transport companies,” said Directed Technologies Executive

Director, Brent Stafford. Minister for Small Business, Natalie Suleyman, opened the Connected Mobility Innovation Centre yesterday. “We support businesses like Directed Technologies because they bring skilled jobs and investment to Victoria, which further cements our status as the nation’s advanced manufacturing hub,” she said. “Our advanced manufacturing industry supports many small businesses along their supply chain – boosting the economy and creating local jobs.”

She’s loved trucks from the moment she was introduced to them, and that passion has paid off. Coralie Chapman has been awarded the Excellence in Transport Award at the 2023 Women in Industry Awards night.

“The only thing that is not delivered on a truck is a baby,” is a line Coralie Chapman loves using, especially on those not familiar with the industry.

“When you use that line, people really start to think about it, and how much we depend on trucks,” she said. Chapman should know, she’s worked in almost every aspect of the industry over the last two decades. From having her own trucks and holding a heavy rigid license, to becoming a logistics expert and a passionate safety advocate. She was honoured at this year’s Women in Industry Awards in Melbourne, taking the Excellence in Transport award. “I love working in transport and have loved it since day one,” she said, accepting her award. “I’m quite lucky these days. I work for Humes Concrete, so I also do construction manufacturing, but I also get to play with my trucks every day.”

Chapman is well known within transport for working tirelessly to ensure the safety and viability of the industry, as well as encouraging women to choose transport as a career path and advocating for diversity and inclusion.

She took the opportunity during her acceptance speech to highlight the importance of making women feel invited into the world of industry, rather than intimidated.

“If there is a takeaway tonight, my hope is that instead of saying ‘male dominated industry,’ which can sound very threatening, especially for young women, we change it to ‘predominantly male’,” she said. “’Predominantly male’ sounds more inviting. If we can learn to change our language when we’re talking to women, it’s a big step towards getting more women into any predominantly male industry.”

Chapman got her foot in the transportation door almost 25 years ago, accepting a traineeship at Linfox, after hearing a talk by a Linfox employee.

“When he was on stage, he was so passionate and I knew I wanted that, come hell or high water,” Chapman said. She beat out two male applicants to get the position and although she admits she was “as green as they come,” has worked her way through the ranks, with posts in administration and operations, to become a scheduler.

Today she is the National Logistics Manager for Humes Concrete Products. In 2016 Chapman joined the Transport Women Australia board, serving as Secretary and now as Vice Chair. By 2018, she was one of 11 industry representatives handpicked for the Daimler Truck and Bus Future Leaders professional program where she developed a project to enhance the image of the industry and raise safety awareness.

Her previous awards have included the Cummins South Pacific Trucking Australia competition, and she was named the National Trucking Industry Woman of the Year at the 2019 Trucking Australia Awards Gala after being a finalist for two years running.

“I think the future of the industry is in good hands,” Chapman said, following her win. “We need people who are passionate whether they are male or female. There is so much more to this industry than meets the eye and so much more to do.”

The Connected Truck is transforming the way our teams work by bringing real-time visibility and information to the workplace. This technology enhances not only our driver’s safety with fatigue and maintenance tools, but also promotes sustainability through fuel efficiency and effective job management.

1300 111 477 TeletracNavman

A second CMV Truck & Bus site has become a fully certified Volvo Trucks Electric Vehicle Dealer. The Clayton dealership joins the Derrimut dealership which was certified in December last year.

As part of its certification, the CMV Clayton workshop, parts and sales teams undertook extensive training and completed all elements of Volvo Group’s rigorous EV certification process. The Clayton facility offers state-ofthe-art equipment and diagnostic tools, comprehensively equipped work bays, underground pits and before long brake and suspension testers. Further investments in these facilities and equipment have been made in order to service and maintain electric vehicles with the site including dedicated bays for servicing electric trucks in addition in addition to on-site charging stations.

The Volvo Trucks Certified EV Dealer program was designed to ensure

that dealerships are fully prepared to support customers with electric trucks. Sales teams are trained to consult with their customers who are considering adding a Volvo EV to their fleet to ensure they are selecting the right vehicle and charging configuration for their operating requirements.

As part of the certification process, technicians received in-depth technical training to ensure they have the skills and knowledge required to maintain electric vehicles. Technicians also received training in relation to safety and procedures to follow when working with high-voltage systems.

“Qualified support personnel are vital on our path to zero emissions,” said Martin Merrick, President and CEO, Volvo Group Australia.

“As newer, cleaner mobility solutions emerge we will always ensure that our dealer partners are at the cutting

edge in terms of knowledge and competence,” he said. “I am delighted to see our EV capability grow, ensuring that our customers have the best business partner for their transformation journey.”

The next of CMV Truck & Bus’ eight dealerships in line for the Volvo Trucks Certified EV Dealer status is Dandenong.

“We’re incredibly proud that CMV Truck & Bus is at the forefront of supporting customers in their transition to more renewable energy sources,” said Miles Crawford, CMV Truck & Bus General Manager.

“While both our Clayton and Derrimut dealerships are EV certified, we acknowledge that this is just the beginning,” he said. “We are focused on supporting our customers and business partners in this transition and we are in the process of rolling out EV certificiation across all of our dealerships.”

Cahill Transport has unveiled a new Kenworth W900SAR Legend III Limited Edition.

The 50th anniversary edition truck is a special addition to the fleet as it shares many similarities with the Kenworth first ever purchased by the company back in the late 1970s.

Operating out of Cahill’s depot in Laverton, the new truck commemorates the iconic W900SAR, the very first Kenworth truck designed, engineered and produced in Australia.

As an anecdotal side note, the new Kenworth is adorned with the recovered original number plate ID of the first Kenworth delivered to Cahill Transport in 1977.

Kenworth W900 SAR is rated to 97 tonnes GVM and will interchange on A-double and B-triple work between Melbourne and Brisbane. At this stage it has been earmarked for general freight assignment.

The Kenworth is powered by a Cummins X15 Euro V 600hp engine using a manual Eaton Fuller 18-speed transmission. It features Meritor MT21-165GP axles and an Airglide 460 suspension.

Other features specific to the truck include a 50-inch sleeper bunk, TV/DVD player, painted fuel tanks and Kent weld Texas Bumper.

The driver, according to Cahill Transport General Manager Shane Lovell, is a

ecstatic to have a piece of modern kit with such nostalgic origins.

“The key to success is to look forwards while never losing sight of our family business values,” said Lovell. “With the rapid changes occurring in our industry, it is critical to keep moving forward and keep up with the latest technology, while not losing sight of the core values that have driven the business thus far. “We can continue to grow and thrive in the face of competition by upholding our family business values of honesty, integrity, and commitment to our customers. We’re optimistic about the future and believe that sticking to our roots while embracing new opportunities will lead to continued

welcomed a proposal to redevelop the commissioned Bell Bay Power Station into a $1.2 billion green methanol and hydrogen plant. According to Minister for Energy and Renewables, Guy Barnett, one of the beneficiaries is likely heavy vehicles.

“Green methanol/hydrogen can be used to transition advanced manufacturing, heavy transport and energy intensive industries to renewable energy, as well as for export,” he said. “This is an

towards the creation of a new $1.2 billion clean energy production facility, but it also provides an innovative solution to re-develop the mothballed oil-fired Bell Bay Power Station that was built in 1971.”

The proposal comes after ABEL Energy successfully negotiated a deal with Hydro Tasmania as the preferred proponent for the Bell Bay site, following an EOI process launched in December 2022. The Tasmanian Government is

will play a pivotal role in Australia’s affordable clean energy future and will foster ongoing collaboration between industry, universities, other research institutions and innovators.

“With our world class wind resource, Tasmania is an ideal location to produce cost-competitive renewable methanol/ hydrogen on a large-scale to meet this emerging export and domestic demand and become a global leader in renewable energy supply,” Barnett said.

Daimler Truck, Mitsubishi Fuso, Hino and Toyota Motor Corporation have concluded a Memorandum of Understanding (MOU) that facilitates the merging of Mitsubishi Fuso and Hino Motors. It is understood that Mitsubishi Fuso and Hino will merge on an equal footing and collaborate in the areas of commercial vehicle development, procurement, and production. A major focus of the collaboration will be the development of hydrogen and other CASE technologies to support the competitiveness of the new company. Daimler Truck and Toyota have, as part of a joint statement, said they will equally invest in the holding company of the merged Mitsubishi Fuso Truck and Bus Corporation (MFTBC) and Hino. By joining forces, MFTBC and Hino would create synergies and enhance the competitiveness of Japanese truck manufacturers, helping to strengthen the foundation of the Japanese and Asian automotive industries and contributing to their customers, stakeholders and society.

Both Daimler Truck and Toyota count global full lineups tailored to local needs among their corporate strengths and—toward achieving carbon

provide diverse options based on local conditions and how their customers use vehicles.

“Today’s announcement is a crucial step in making that future work economically and in leading sustainable transportation,” said Martin Daum, CEO of Daimler Truck at the time.

“The planned new company will be a major force in Southeast Asia and an important associate of the Daimler Truck family.”

Fuso will more-than-double its resources through the move. The organisation expects, as part of the windfall, to increase its access to knowledge, expertise and a wider network of suppliers and infrastructure with more people working together to develop technology faster.

Karl Deppen, CEO of MFTBC said the close collaboration will enable the four companies to accelerate the decarbonisation of the transportation industry, which in turn, will create an even stronger Japanese commercial vehicle manufacturer.

“This merger will position us as the foremost player in the Asian transportation industry, strong enough to compete with all the new brands we see

Japan,” he said.

The merger is anticipated to also help overcome increasingly fierce global competition in the commercial vehicle sector as OEMs jostle to achieve carbon neutrality.

“Through these efforts, we will strive to tackle societal challenges such as achieving carbon neutrality,” said Satoshi Ogiso, Hino CEO.

Details on the scope and nature of the collaboration including the name, location, shareholding ratio and corporate structure of the new holding company will be decided over the course of the next 18 months.

The parties envisage signing of definitive agreements in the first quarter of 2024 and aim to close the transaction by the end of 2024. Once all parties involved reach an agreement, they will move forward based on the approval of the relevant boards of directors, shareholders, and authorities.

“Our four companies will work together with a shared vision of achieving carbon neutrality by strengthening CASE technologies and of changing the future of commercial vehicles and building the future together by solving social issues,” said Koji Sato, CEO of Toyota Motor

Einride and DAF have signed a letter of intent to supply a significant order of battery electric trucks.

Deliveries are already underway for the Swedish transport company, who first signalled its intention to purchase 50 fully electric new generation trucks from DAF in May.

The order will comprise DAF XD electric trucks powered by between three and five battery packs for ranges of up to 500kms, in a broad range of specifications,

Einride confirmed they will deploy the new vehicles across a wide spectrum of customers.

All vehicles will be delivered with DAF repair and maintenance packages. Maintenance will be carried out throughout the DAF dealer network, with more than 1,100 locations listed across Europe.

Einride operates in the US, the UK, Sweden, Norway, Germany and the

industry,” said Robert Ziegler, Einride Europe General Manager.

“In DAF, we have found an excellent partner as we continue to expand our global fleet of electric vehicles,” he said. “By leveraging DAF’s technological edge, combined with our own freight mobility solutions, we look forward to

Longer vehicle combinations, thanks to new legislation, have been permitted on British roads starting back on 31 May. Operators will be able to use longer semi-trailer (LST) combinations up to 18.55 metres – 2.05 metres longer than standard size.

The extra length is expected to reduce journeys by 8 per cent while moving the same volume of goods as those transported on current trailers.

The move comes after a trial lasting 11 years to evaluate the safety efficacy of the longer trailers on UK roads. It showed that LSTs were involved in around 61 per cent fewer personal injury collisions than conventional lorries.

Vehicles which use LSTs will be subject to the same 44-tonne weight limit as those using standard trailers, and the new vehicles are expected to cause less wear on the roads than conventional lorries due to the type of steering axle used.

Operators will be legally required to ensure appropriate route plans and risk assessments are made to take the unique specifications of LSTs into account.

Operators will also be expected to put in place extra safety checks including driver training and scheduling, record keeping, training for transport managers and key staff, and loading of LSTs on top of these new legal requirements.

More than 300 companies in the UK have already taken part in the trial, with some of the biggest brands including Greggs, Morrisons, Stobart, Royal Mail, and Argos, expected to introduce the longer semi-trailers in their daily operations.

The trial also revealed the important environmental benefits associated with the introduction of LSTs, included a reduction of 70,000 tonnes of CO2 and 97 tonnes of NOx over the trial. The average CO2 reduction across

Richard Zink, DAF Marketing and Sales Director described Einride as a leader in the supply of innovative mobility packages, purely based on fully electric vehicles.

“As the partner of choice, we offer a total solution aimed at getting the best out of the vehicle,” he said.

the lifetime of the trial is similar to the amount of CO2 captured by roughly 11,600 acres of forest per year.

The Department for Transport (DfT) considers LSTs an important, easy and affordable measure to reduce CO2 emissions in the haulage industry without significant technological and infrastructure development.

“The introduction of longer semi-trailers into general service will increase the scope and scale of the goods which our industry is able to transport, increasing efficiencies and reducing the environmental impact of delivering for the UK’s economy,” said Chris Yarsley, Senior Policy Manager at Logistics UK.

“Over the past few years of the trial, our members have proved that LSTs provide operators with a cost-efficient, environmentally prudent alternative to conventional vehicles and our members remain committed to rolling them out across the wider industry as soon as possible.”

Daimler Truck applauds the Federal Government for mandating AEBS for new models from late this year and all existing models over 3.5 tonnes sold from February 2025. However, customers don’t need to wait for the mandate to kick it and can choose to put safety first now.

If I can get one message across to you, it would be this: Make sure any truck you buy from now on has Advanced Emergency Braking System technology. It can protect your driver and other road users and even reduces repair costs. With awful regularity, we see heartbreaking cases of lives taken or ruined by collisions between trucks and other vehicles that could have been prevented, or at least mitigated, with AEBS.

AEBS uses radar and sometimes a camera to apply the full braking force of a truck in certain circumstances where the driver is slow to respond. Drivers are only human and can be affected by fatigue, distraction or low visibility due to fog or sun glare. AEBS works and it is cost effective, and yet some manufacturers continue to introduce new trucks without installing this technology as standard equipment.

As the President and CEO of Daimler Trucks Australia Pacific, I’m proud that our Mercedes-Benz Trucks, Freightliner and Fuso brands take a leading role in the industry when it comes to sustainability and safety. But don’t think this column is about getting you to buy our trucks. I want you to buy a truck that has AEBS because it saves lives.

Daimler Trucks introduced AEBS for the first time locally all the way back in 2010 on a Mercedes-Benz Actros

and it has been standard on that truck ever since.

We decided that when we launched our bonneted Freightliner Cascadia here in 2019 that it would have AEBS standard. We were first to fit AEBS as standard in the light truck class with the Canter in the same year and it was soon added as standard on select Fighter and all Shogun trucks.

Apart from the trauma that it can prevent or reduce, AEBS even makes sense from a financial perspective. Key customers of ours have pointed to an extreme reduction in costs related to accidents that have been avoided by the automated braking function. A Daimler Truck customer with thousands of trucks in the United States told me its repair costs “fell off a cliff” when AEBS was introduced to its fleet. However, not all companies are prepared to show leadership in this field and either don’t offer this simple technology, or banish it to the options list. In some cases, you can spend a lot of money on a new truck in Australia and still be asked whether you would like to pay extra for AEBS. It’s like asking if you want fries with that. And it’s not a token amount either.

The Federal Government is moving to mandate this technology for new models from late this year and all existing models over 3.5 tonnes sold from February 2025. This means it will continue to be optional in many trucks for another 18 months.

While we commend the Albanese Government for this move, Daimler Truck prefers to take a leading role in the industry by introducing features that benefit our customers and road users, rather than being forced to introduce it by regulators.

We don’t need to be the only company to fit a steering-wheel mounted airbag in a conventional bonneted truck, but we are, and it is standard. Customers of that truck, the Freightliner Cascadia, can also select a side head protecting airbag. We are also the only one with a light bus, the Fuso Rosa, with AEBS. That is something we are particularly proud of because buses carry the most precious cargo.

Our Fuso eCanter is the only small electric truck with AEBS, despite a slew of new arrivals drawn by the appeal of making some quick sales. The idea of a truck, which operates in near-silence,

not featuring the latest safety to assist in identifying and braking for pedestrians as well as other vehicles, is concerning.

We are also prepared to lead when it comes to helping our customers reduce their emissions.

Back in 2016, we introduced the first complete model range with engines that met Euro 6 emissions standards. It was the Mercedes-Benz Actros. It soon proved to be a win-win for our customers and the environment and the Actros has become legendary for its low running costs.

We did the same with the new Freightliner Cascadia and Fuso Shogun, demonstrating that Daimler Truck leadership is across the board and not brand-specific.

In 2021, Daimler Truck was the first in Australia to introduce an Original Equipment Manufacturer electric truck with the Fuso eCanter. Some of the

biggest brands have introduced this pioneering truck into their fleet and drivers are reporting just how good zero emission driving can be.

We are gearing up to introduce the second-generation eCanter, as well as the eActros and eEconic from MercedesBenz Trucks. We have thrown everything at their development because we are Daimler Truck and it is what we do. We don’t rush to market. We make sure our product is the best. That’s why these trucks will run efficient eAxles, with no legacy driveshafts or gearboxes left in to add weight. Importantly, they will have our latest active safety features. Going electric might be a bit further down the track for many of you, but when it comes to safety, you can all demand active safety including AEBS now. Please give it a thought when it comes time to replenish or expand your fleet.

Carrying the largest jet fuel spec’d fleet in the country, Hills Tankers possesses over 100 prime movers that it deploys along the northern eastern seaboard servicing airports, mines, retail outlets and military bases.

An airport like Coolangatta is a nexus for economic interests even before a tourist steps off a plane. Hundreds of other service-orientated businesses converge here daily to help maintain infrastructure vital to the Gold Coast whose growing population is no longer strictly a consequence of seasonal activity. In recent years the airport has undergone myriad upgrades to fortify, for instance, its fuel infrastructure as part of an ongoing project to provide it with greater flexibility during peak times and busy periods, which for any world-renowned holiday destination, can surge to many times the customary capacity. An event like the Magic Millions race in January alone attracts 19,000 unique travellers to Coolangatta.

The airport, starting in 2018, underwent an $86 million airside upgrade that expanded the apron 20,000m2 to facilitate four additional aircraft, and a new taxiway. Further reconfiguration of the apron layout since then now allows the flexibility to switch between narrow and wide body aircraft depending on demand. Through a joint venture between Caltex and BP for fuel operations at the airport, 900 metres of new underground hydrant pipe to reticulate fuel, 31 new hydrant points for refuelling, two new underground valve chambers and relocation of all existing aircraft bays along the front of the terminal have also taken place. Surges have made these changes necessary. Hills Tankers, a family-owned fuel carrier, delivers jet fuel on four dedicated A- and B-double units here seven days a week. Earlier this year, it introduced a third generation MAN TGS 540hp prime mover on this run. The new truck has impressed to the point the other three vehicles will be converted to MANs by the end of the year according to Scott Cullen, Hills Tankers Chief Operations Officer.

“The driver acceptance has been outstanding,” he says. “Fuel economy, according to our data, is awesome. They

feature all the latest safety tech and intelligent cruise paired with the Brakematic descent control but they’re also simple to operate. That’s what the drivers especially love about them.”

The third generation TGS 13-litre 540hp is undoubtedly a sophisticated modern commercial vehicle. The Smart Select control module for the 12.3-inch screen of the navigation system and the return to neutral gear selector, are among the notable new features. That said, activating the primary functions can all be done via switch. Operation isn’t made unintelligible through a dependence on a digital interface.

“Some of the OEMs have gone too far with the technology in the cab and the drivers don’t like it,” says Scott. “They’re driving along at 2am trying to work through an electronic screen when they just want to turn the lights on.”

The MAN TGS 540 is part of a recent order that included two new generation MAN TGS 440s that are working on retail deliveries in Brisbane with six more expected later this year and a further seven units due early next year.

“The new 440s are delivering around 2.7 kms/l on the metro circuit which is phenomenal,” says Scott. “It’s the quietest truck our operators have ever driven.”

These trucks are all operating out of Brisbane, where Scott himself is based at Pinkenba. The new site, which is currently under council approval for a $5 million purpose-built facility with an internal wash for tankers, is fast turning into an operational hub. They hope to turn soil by the end of the year.

Scheduling in Brisbane recently expanded to 24/7. Members of the team are shifted on through the night to answer calls and respond to any fatigue incidents brought to their attention via Guardian’s Seeing Eye driver monitoring technology, which is being rolled out across the company. The TG3 MANs were the first vehicles in the fleet to be fitted with it. Drivers, according to Scott, were

Scott Cullen with Jayme Deves, MAN Trucks SEQ.

Scott Cullen with Jayme Deves, MAN Trucks SEQ.

At nearly 18,000 kilometres into its maiden run, the DAF XF530, one of three new Euro VI prime movers purchased earlier this year by Unanderra Tanker Hire (UTH), is excelling in the areas that count: Fuel economy, driver acceptance and safety. These latest vehicles in the fleet are largely working independent from each other within the business. The first unit in Brisbane is carting laundry chemicals and delivering chemicals to breweries. The other two DAF XF530s have been designated on more traditional tanker tasks.

The Port Kembla-based company specialises in carrying chemicals, something of a kindred application to fuel haulage, but generally is considered an entirely different beast. Demand, not to mention customer expectations, diverge and as a result far less onus is placed on optimising high productivity combinations compared to what the market asks of fuel or even milk tankers. There is little need, given current trends, for multi-combinations. As the fleet must balance the challenges of tight entrances at metropolitan

water treatment plants and waste station sites in regional settings, a semi-trailer remains the best, least compromised option.

The prime mover fleet runs single trailers at 44 tonnes. UTH also delivers smaller loads around Sydney where an 8-tonne or 10-tonne job might require it go into a water treatment plant. The trucks also frequent waste disposal facilities and supply chemicals to leachate plants.

Drivers at these sites are often confronted by problematic access that require trucks to have cross-locks and power-dividers according to UTH General Manager Jeremiah Justice Wiedl or JJ, as he is better known.

“Most of these entry points are just little dirt roads better suited to a 4x4 passenger vehicle,” he explains. “That’s where the big trucks don’t fit. We can make it work using a semi with a compartment of a product and then we’ll leave, reload the semi elsewhere and go away on a long trip.”

Unlike carriers in the cement sector, a chemical hauler like UTH is not always loaded to capacity. That’s because the trips are governed, according to JJ, by the

destination of the customer’s site tank. “If they’ve got a 5000-litre tank, we’ve got to deliver them a 5000-litre load,” he says. “If they’ve got a 20,000-litre tank we’ve got to deliver a 20,000-litre load. Most of the customer storage tanks we do are only taking a single trailer load of product.”

The fleet contains 21 rigids mainly for urban assignments. However, the bulk of the vehicles are prime movers, nearly 60 in fact; and the three new DAFs join another five already in circulation for the Dutch brand. The first of which were introduced following the successful tender of a new contract in 2013 recalls JJ.

“We were looking at buying a DAF CF85 back then, but the dealer offered us a DAF XF105 with an automatic for considerably less than what I wanted in a smaller model truck,” he says. “I don’t recall if it was a product promotion, but we bought two of the larger DAFs initially and it proved a masterstroke.” Still going strong in their tenth year, the DAF XF105s were bigger than what JJ and his team felt they initially needed. Because dangerous goods drivers can

As a niche segment, chemical transportation by road often involves a different mindset to fuel haulage. Unanderra Tanker Hire is one of the industry’s leading practitioners.

carry lots of extra safety equipment, the truck, it was discovered, provided the team with superior storage options. In turn, this led to another advantage regarding fleet utilisation. UTH soon found it could complete smaller jobs challenged by the urban confines in metropolitan Sydney and, then afterwards load up much heavier for regional trips.

“You can live in that truck,” says JJ. “They were more versatile to what we had been accustomed to and that made it possible to maximise our hours with drivers.”

One prevalent area of the business involves transporting hydrochloric acid for the galvanising industry. As these deliveries are usually actioned early in the morning, the flexibility afforded by the DAFs has enabled the driver to reload and trek out, for example, to one of the gold mines in the state’s central west.

“These guys want to earn a decent living,” says JJ. “They don’t want to just work an eight-hour day. They would rather put in a six-hour shift in the morning, do a local delivery and then go on long haul.”

These and other chemicals are also used in the steel industry for preparation processes, for various uses in the mining sector and are crucial for correcting ph

DAF XF530.levels at water treatment plants where it is necessary to drop the solids found in the water. These plants are now located across the country. UTH, in keeping with this, runs trucks in four mainland states. As chemicals are sometimes loaded in places where fuel is also loaded, the application is comparable at least in its categorisation. The trucks also, like fuel haulage vehicles, need to have battery isolation switches installed. Many of the similarities with chemical transport,

however, end there.

“The milk guys and the fuel guys are always looking at optimising payloads and finding the optimum trailer combinations,” says JJ. “We used to have a delivery where we would take a load of hydrochloric acid from Sydney to remote treatment plants outside of Alice Springs. We only went out there with 15,000-litres of product. That’s only 17-tonne.”

It would be unheard of, JJ notes, in the

fuel and milk markets. Working under HML, UTH has provision to load up to 46 tonnes GCM although payload rarely exceeds 25 tonnes.

Business models evolve differently. Often for reasons of timing, economies of scale and sheer necessity. All three have applied to UTH, at different times. Even so, its measured approach to total cost of ownership has made for linear, steady growth. That’s not uncommon either for businesses managed by people with technical proficiency. JJ after all is a mechanic by trade.

“I was brought up to try and maintain things and keep them going,” he says. “That’s always been something dad has emphasised from the start.”

For the family that start takes place in 1980 when Oskar and Wendy Wiedl, JJ’s parents, purchased the business. It was historically established in 1975. Today it remains a family business in the truest sense with JJ’s partner, Belinda, sons Hayden and Joshua, daughter Julianne, and brothers Wayne and Paul, all integral members of the team.

Over the years the company has diversified operations from a traditional liquid waste haulage provider to the chemical transport specialist it is today. That transition was accelerated in the mid-1990s when environmental regulations, designed to crack down on businesses dumping waste illegitimately, created an opportunity for small businesses like UTH which it seized upon. It took well over a decade to expand its working vehicles from a solitary second hand Leyland Reiver to six trucks by the time JJ joined the company.

The truck mix today is varied. As UTH relies heavily on versatility as much as anything, the latest in prime mover technology, as represented by the new DAFs, sits side by side with vigilantly maintained older models, some of which are maturing into a second decade of operations.

One of the big discoveries for the business that helped it choose a

direction was when it realised the aftersales costing of say, parts, was making it uncompetitive in the market.

“We sat down with the accountant, who has been with the business for 15 years and got all the American branded trucks, the Kenworths and Western Stars, and put them beside the European trucks in the fleet and we decided we had to do something to remain competitive,” says JJ. “So, we steered away from the European truck.”

That decision was made in 2008. But changes in traffic conditions and cramped site access of new customers that had been secured, made it evident that sending in bonneted traditional American trucks into these locations wasn’t necessarily the smartest move. “Drivers were having minor accidents and customers were starting to notice our competitors were sending smaller vehicles in,” says JJ. “So that gave us pause. That’s around about the time the first DAFs were purchased.”

The newest Euro VI DAF XF530s are not, unlike some other European brands in the fleet, on contract maintenance schemes. Maintenance of the fleet in the main is performed inhouse. The workshop employs six personnel including a fabricator.

“The challenge with contract maintenance is you need to go back to the dealer,” JJ says. “If the fleet is not profitable, you’re paying a bloke to just sit with a truck at a dealership all the time. That becomes a false saving when you look at the wage component.”

JJ will use external providers, where appropriate, for parts. He often relies on both Gilbert & Roach and Illawarra Truck Repairs & Spares for this and is content with the arrangement.

“Our gear is kept well-presented and maintained. We might downgrade it so it’s not on the same high-profile work or doing the big kilometres anymore,” he says. “If it’s still serviceable, we keep it.”

Being a mechanic by trade informs JJ’s organisational philosophy whereby expertise and resources mean there is

no need to take leave of material reality. Reliability when it comes to good working equipment is not something merely inherited.

“Most of the guys are happy to drive the older gear as long as it’s well maintained,” he says. “You can’t have everything new. Everything gets to an age where you must repurpose it to a different application. This is the thing with the PACCAR product. We’re getting support everywhere. It doesn’t matter where you are you get the support you need. You get the network.”

Diehard Kenworth and Western Star operators, over a beer might joke about driving a DAF in JJ’s experience, but once they do drive it, they “come down-toearth”, to use his words, abruptly. Given where it is they need to go and what it is they need to do when they get there, it can be a rude awakening at first.

“The chief reason is the impossible places we need to get into. You need a conventional truck. You need a truck with a really good turning circle,” says JJ. “They’ve never let me down and the drivers now love them.”

The new Euro VI DAF XF530s, by way of neat coincidence, are made in the old Leyland factory in the north of England, where the first truck of the business was manufactured. With readily available parts and a competitive price point, the new trucks offer him a significantly better cost of life than the other European branded vehicles he has owned.

“I just think the DAFs are far better,” says JJ. “The DAF slogan two or three years ago was ‘Do the math buy a DAF’ and not a truer word was spoken. It all comes down to cost of life of the vehicle.”

Lineage Logistics entered the Australian market in 2019 through the acquisition of Emergent Cold. Through various warehouse acquisitions since, it has completely transformed its operations. Perhaps the biggest change requested and subsequently applauded by customers was the evolution of its national, integrated solution. Lineage Logistics now boasts operational sites in New South Wales, Victoria, Queensland, South Australia and Western Australia — with a fleet powered by 110 prime movers, 130 trailers, 180 refrigerated trailers and 15 tail lift units.

While the Emergent Cold purchase helped address customer needs, it also led to the company solidifying its presence in the Asia-Pacific region. With over 53 million square feet across more than 300 facilities in 12 countries, Lineage Logistics now considers itself the largest temperature-controlled facility network in the world.

In its Australian operations specifically, Lineage Logistics offers a wide range of services for storage solutions, integrated solutions and strategic solutions. The storage option provides clients with cold storage warehousing, port-centric warehousing, automated warehousing, built-to-suit warehousing and sustainable warehousing. Its integrated solutions area includes managed and on-demand transportation services, temperaturecontrolled rail, customs brokerage, freight forwarding, drayage and multivendor LTL consolidation. The company’s strategic solutions offerings, meanwhile, provides

In the latest step in its national fleet renewal program, Lineage Logistics took delivery of ten brand-new Kenworth K200s which are now transforming its linehaul operations.Kenworth K200.

resolutions for food services, directto-consumer fulfilment, supply chain engineering and food processing and manufacturing.

So, in order to continue to back these expanding operations, Lineage Logistics has devised a master plan to get its drivers out of older vehicles and into some new, purpose-built linehaul trucks. “We’re going to be progressing with a multi-year fleet replacement program,” says Director Transport, Australia, Justin

what brands and OEMs we engage with to have as much standardisation as possible across our fleet. Growth will be budgeted and planned as we acquire new customers and continue to grow the business.”

In the last two years alone, Lineage Logistics has invested over $20 million into its fleet with new prime movers and trailers. More recently though, the fleet paid its first visit to Brown and Hurley for ten new Kenworth K200s.

Kenworth track is because it’s a very mature product in linehaul, long haul and in the roadtrain space,” says Justin. “Their proven ability in those sorts of corridors is the most attractive thing about the Kenworth product, and looking back, it’s that reliability that has really benefitted us the most. That’s essentially why we wanted them in the fleet, just to set that standard and get some reliability in our long haul operations.”

Lineage Logistics’ new K200 Aero

550-horsepower X15 engine and Eaton’s FO22E318B-MXP Ultrashift Plus transmission, which has been programmed for better fuel efficiency thanks to Cummins’ Advanced Dynamic Efficient Powertrain Technology (ADEPT).

Rear suspension is covered with Kenworth’s Airglide 450 and a Meritor MT21-165GP Rear Axle with a 4.1 ratio, which has proven its capabilities in Australia for many years.

On the safety side, Lineage Logistics’ Kenworths are fitted with a fusion

integrated safety system, stationary vehicle braking, Active Cruise Braking (ACB) with collision mitigation, a full guardian system to help with driver safety, and a JOST fifth wheel hookup sensor system with a monitor dash mounted in the cab to make trailer coupling and uncoupling a thoughtless process.

Although Justin had little previous experience in dealing with Brown and Hurley or Kenworth to go by, he says their ability to meet Lineage Logistics’ lead expectation times, while offering the

fleet everything it could ask for, is what sealed the deal.

“They just gave us everything we needed in our fleet to settle it into a linehaul rhythm without too much fuss, as we didn’t want to recreate the wheel,” he says. “We wanted to make sure that the X15 Cummins matched with the Eaton Ultrashift, and it did making it reasonably seamless. We get a lot of good feedback from drivers around how the transmission and engine communicate, so essentially, we’ve gone to the premium end of what we want for the drivers.”

The new Kenworth K200s have been assigned freight transportation for a range of food producers. It makes for relentless work right around Australia. The B-double combinations (with roadtrain capabilities as well) travel along the east coast to Melbourne and Brisbane, Adelaide to Brisbane and Adelaide to Perth — where in Lineage’s peak periods they will also be running B-triple combinations. The next step, Justin says, will be Performance-Based Standards. While it’s still too early for Justin to compare the new models to his older

vehicles, he has noticed an increased interest in the fleet’s operations by the general public.

“It’s like apples and oranges at the moment because we’ve got such an older fleet, so we really can’t compare them,” he says. “But we’re actually getting some calls because drivers are seeing them and they want to drive brand new Kenworths. There’s a great cohort of drivers out there who just love driving Kenworths, so you attract that sort of linehaul driver in your business.”

As a sidenote, Justin is most pleased