Direct Freight Express Hit the Ground Running

Carrier: Gibson Sand & Gravel Feature: Cropline Group Showcase: Service, Parts & Aftermarket Personality Profile: Tom Chapman

INNOVATION

Fleet: Alpine Truss

Telematics: Burdetts Group

Test Drive: Kenworth K220

Delivery: Last Mile Logistics Funds

MAGAZINE Delivery Magazine inside: Pages 74-81. ® August 2023 ISSN 1838-2320 9 771838232000 07 AUGUST 2023 $11.00 THE PEOPLE & PRODUCTS THAT MAKE TRANSPORT MOVE INDUSTRY

Don’t do your truck a disservice.

Congratulations. You made a very wise business decision by choosing an Isuzu truck. Now keep that smart approach going and protect your investment by having it serviced at an Isuzu-approved workshop. Our highly trained technicians use genuine parts designed specifically to help your truck deliver its very best performance. You’ll also protect your future re-sale value. Plus, you’ll have the peace of mind knowing that you’re helping to meet your chain of responsibility requirements.

To find your nearest Isuzu Service Centre, visit isuzu.com.au Care. It’s what we do.

FSA/ISZS1662

MEET THE TEAM

Australia’s leading truck magazine, Prime Mover, continues to invest more in its products and showcases a deep pool of editorial talent with a unique mix of experience and knowledge.

Christine Clancy | COO

With more than two decades of experience as a media professional, Christine has worked in newsrooms across Canada, Vietnam and Australia. She joined the Prime Creative Media team 12 years ago, and today oversees more than 43 titles, including a dozen print and digital transportation titles. She continues to lead a team that focuses on continuous improvement to deliver quality insights that helps the commercial road transport industry grow.

William Craske | Editor

Over the past two decades William has published widely on transport, logistics, politics, agriculture, cinema, music and sports

He has held senior positions in marketing and publicity for multinational businesses in the entertainment industry and is the author of two plays and a book on Australian film history. Like many based in Melbourne he is in a prolonged transition of either returning or leaving.

Peter Shields | Senior Feature Writer

A seasoned transport industry professional, Peter has spent more than a decade in the media industry. Starting out as a heavy vehicle mechanic, he managed a fuel tanker fleet and held a range of senior marketing and management positions in the oil and chemicals industry before becoming a nationally acclaimed transport journalist.

Louise Surette | Journalist

Louise joins Prime Mover after nearly 25 years as a writer. Starting her career as a reporter at the Toronto Star, she has spent much of the last 15 years as a design writer and editor. In 2020, she was shortlisted on the Richell Emerging Writers Prize list. Originally from Nova Scotia, she lives in Melbourne with her two children.

Peter White | Journalist

Peter has completed a Bachelor of Media and Communication (Media Industries) degree at La Trobe University, and he brings a fresh perspective to Prime Mover. He gained valuable experience at Upstart, La Trobe’s newsroom, work that has been supplemented by direct industry experience in a Council placement. Peter has a strong interest in commercial road transport, and in contributing to Prime Mover’s efforts in growing the industry.

Ashley Blachford | Business Development Manager

Handling placements for Prime Mover magazine, Ashley has a unique perspective on the world of truck building both domestically and internationally. Focused on delivering the best results for advertisers, Ashley works closely with the editorial team to ensure the best integration of brand messaging across both print and digital platforms.

www.primemovermag.com.au

ceo John Murphy john.murphy@primecreative.com.au editor William Craske william.craske@primecreative.com.au managing editor, Luke Applebee transport group luke.applebee@primecreative.com.au senior feature Peter Shields writer peter.shields@primecreative.com.au

business Ashley Blachford development ashley.blachford@primecreative.com.au manager 0425 699 819

art director

Blake Storey blake.storey@primecreative.com.au

design Kerry Pert , Louis Romero, Tom Anderson

journalists

Peter White peter.white@primecreative.com.au

Louise Surette louise.surette@primecreative.com.au

design production

Michelle Weston manager michelle.weston@primecreative.com.au

client success Salma Kennedy manager salma.kennedy@primecreative.com.au

head office 379 Docklands Drive, Docklands VIC 3008 enquiries@primecreative.com.au

subscriptions 03 9690 8766 subscriptions@primecreative.com.au

Prime Mover magazine is available by subscription from the publisher. The right of refusal is reserved by the publisher. Annual rates: AUS $110.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate.

articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

copyright

PRIME MOVER magazine is owned and published by Prime Creative Media. All material in PRIME MOVER magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information

Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in PRIME MOVER magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Direct Freight Express Hit the Ground Running Delivery Magazine inside: Pages 74-81. AUGUST 2023 primemovermag.com.au ® August 2023 THE PEOPLE & PRODUCTS THAT MAKE TRANSPORT MOVE Feature: Cropline Group Personality Profile: Tom Chapman Fleet: Alpine Truss Telematics: Burdett’s Delivery: Last Mile Logistics Funds

THE POWER TO SAVE ON FUEL AND EMISSIONS.

THAT’S ANOTHER HINO

UP TO 20% * IN FUEL AND EMISSIONS REDUCTIONS WITH AUSTRALIA’S ONLY SELF-CHARGING HYBRID ELECTRIC TRUCK.

The Hino 300 Series Hybrid Electric utilises an electric motor and a diesel engine working in parallel, intelligently switching between the two or a combination of both - to boost efficiency. Maximum torque generated at very low rpm minimises fuel use resulting in a reduction in carbon emissions. And as the Toyota Group hydride nickel battery automatically recharges whilst on road during operations, there are no recharging requirements. That’s the power of change, that’s the Hino Hybrid Electric. Visit hino.com.au

XAVIER_HINO38956.15

*Actual results will vary depending on the application of the vehicle and how it is driven.

COVER STORY

“We try to keep everything the same so we’re not carrying spare parts of everything – the less models, the less brands, the better.”

CONTENTS Prime Mover August 2023 70 32 52

54 72

Prime Feature

FLEET FOCUS

32 Hit the Ground Running

As one of the largest independently owned transport companies of its kind, Direct Freight Express reinforces the formidable national footprint it has forged with modern trucks from key supplier, Isuzu.

38 Persistence of Vision

Sunshine Coast carrier, Gibson Sand & Gravel, is one of three fleets in Australia asked to give a 12-month appraisal of the new Western Star 48X.

42 Through the Roof

Alpine Truss uses its own fleet of Mack trucks to deliver roof trusses and wall frames from its manufacturing facility in Wangaratta.

TRUCK & TECH

46 Access All Areas

Several new Freightliner Cascadia units have won favour with the team at Burdett’s in Melbourne owing in part to the clear gains shown by the sophisticated Detroit Connect telematics.

Running two transport businesses at once may be difficult at times, but Cropline Group has found SAF-Holland components across a large portion of both its fleets has made the process much more seamless.

TEST DRIVE

66 Home Grown

An interstate trip from Melbourne to Adelaide pulling a pair of Collins Transport refrigerated trailers proves a breeze for the new Kenworth K220.

Regular Run 08 From the Editor 10 Prime Mover News 30 Mindset 56 Service, Parts & Aftermarket Showcase 70 Personality Profile 72 Prime Movers & Shakers 74 Delivery 82 ARTSA-I Life Members 84 Truck Industry Council 85 Victorian Transport Association 86 Peter Shields’ Number Crunch

STORIES PERSISTENCE OF VISION 38

William Craske Editor

It’s time to talk rigids — rigid airships that is. It’s been more than a century since the modern airship transformed transatlantic travel, using fuel cell technology, that at least for the moment, is very much back in vogue. Today considered unique in terms of their variety of potential applications, fuel cells can use a wide range of fuels and feedstocks including hydrogen which is being afforded some particularly optimistic forecasts by those, namely OEMs, with skin in the game. Of the concepts long-gestating in closed-door research departments shrouded in secrecy for months, if not years, how many hark back to previous eras when the political capital necessary for high-cost ventures of research and development, had simply run dry?

The Zeppelin, which came to be commonly used to refer to all rigid airships, were first flown commercially in 1910 by Deutsche Luftschiffaharts, the world’s first airline in revenue service. By 1928, when a round trip transatlantic ticket cost $3,000 – equivalent to $40,000 today – the Graf Zeppelin was launched and soon set a new long-range voyage record in October. The largest airship of

Deep Fakes

its kind at 236.6 metres in length, it was designed to carry passengers, and mail to cover the costs. In another first, the Graf Zeppelin used Blau gas fuel for its five engines. As Blau gas, like propane, is nearly as light as air, it gave the Graf Zeppelin the advantage of not having to vent lift gas, a practice common to other airships, to maintain equilibrium. The ship’s range, as a result, was extended by 30 hours.

Blau gas was carried in 12 cells in the lower section of 12 of the ship’s 17 gas cell bays, beneath the hydrogen cells also known as the “lift gas cells”. The ship also carried a supply of gasoline, so that if the ship was heavily burdened, the engines could burn gasoline instead of Blau gas, alleviating the weight without the need to drop ballast.

By August, the Graf Zeppelin had completed a circumnavigation of the globe leaving Lakehurst, New York, at the behest of newspaper magnate William Randolph Hearst, one of its chief sponsors, before it took in Friedrichshafen, Tokyo, Los Angeles and returned to Lakehurst 21 days, five hours and 31 minutes later. It had travelled 49,618 kilometres. On board was reporter, Grace Marguerite Hay Drummond-Hay, who, by default, was the first woman to circumnavigate the globe by air.

In 1929, a group of investors erecting the Empire State Building, had announced that the height of the building would be increased by 200 feet so that a mooring mast for airships could be installed. Passengers, according to the plan, would exit the airship down a gangplank, and a mere seven minutes later could be on the street, ready to experience everything Manhattan had to offer. Up until then the Chrysler Building had been the tallest building in the world. The New York Times was the first to dismiss the project as impractical, noting that landings for zeppelins required dozens of ground

crew, not to mention hundreds of metres of rope. “The notion that passengers would be able to descend an airport-style ramp from a moving airship to the tip of the tallest building in the world, even in excellent conditions, beggars belief,” noted the Times. A sepia tea-stained photo of the Graf Zeppelin, which had been earmarked to dock on the building, was circulated in 1930, despite it never having done so. As a deep fake, it was something of another first.

The following year an airship did dock on top of the Empire State Building. No one, however, disembarked. The privately owned dirigible, amid 65 km/h gusts, brought traffic to a standstill for half an hour as “the pilot jockeyed for position in the half-gale about the tower 1,200 feet above the ground,” reported the Times The age of the airship came to a crashing halt in a New Jersey field in 1937 when the Hindenburg, the largest zeppelin ever constructed, fuelled by flammable hydrogen, immolated upon landing. In principle, zeppelins were a technology ordained by the few for the many that proved, like most trends, the reverse. As many people would have travelled on fixed wing aircraft as paying passengers as those on airships in one tenth of the time it took for the few thousand intrepid voyagers fortunate enough to take in the world from the unique vantage of a ‘giant of the air’. It remains, to this day, a fascinating point in history unlikely to be replicated.

But the age of digital swarms, bots and ChatGPT, is also the age of replicants. In economies starved of new ideas, everything old can be made new again with the right political clout, humanitarian messaging and cultural amnesia.

8 August 2023

PERFORMANCE AND ECONOMY

no compromise

Detroit’s DD16 delivers all the power you need.

With up to 600 horsepower and 2,050 lb-ft of torque, the big bore workhorse provides efficient and dependable power and performance without compromise. Detroit’s advanced technology also means GHG17 requirements are met through innovative fuel efficiency resulting in lower emissions.

This power, performance and efficiency prowess is backed by our industry-leading warranty and extended coverage packages that ensures the highest level of support for our customers.

Combined with superior fuel economy and the absence of a midlife change out, the DD16 delivers an enviably low total cost of ownership and maximum uptime.

This is all backed by our well-established and extensive national service and support network which, together with our highly skilled factory-trained technicians, means you can count on getting the right advice when you need it.

With Detroit, there’s no compromise.

detroitanz.com detroitanz

> Auswide Transport Solutions introduces first PBS B-triples

National transport company, Auswide Transport Solutions, has commenced its first Performance-Based Standards (PBS) B-triple roadtrain combinations between Melbourne and Adelaide and its first AB-triples between Adelaide and Perth. The units will carry predominantly parcel freight for its customers around Australia, as well as general freight and overnight express. The combinations join the fleet’s growing 500-plus compatible trailer units.

While the company has been running east-west roadtrain triples for several years, Auswide Transport Solutions CEO, Tom Pausic, told Prime Mover these units will give the fleet greater

flexibility on the east coast.

“They’re akin to what we’ve already been doing, but it’s just a new corridor for us,” he said. “So far they’ve been working really well.”

Along with bringing Auswide Transport Solutions a 30 per cent reduction in carbon production, General Manager, Gabby Singh, told Prime Mover the B-triples will benefit its customers especially when it comes to the eastwest trek.

“Efficiency gains will have a positive bottom-line effect for our customers, and it will also benefit them by contributing to carbon reduction,” he said. “The number of available drivers has been a concern of industry for

some time. Moving more freight with less trucks during peak times means fewer heavy vehicles on the road and reduces the wear on our nation’s infrastructure.”

The combinations are already demonstrating higher productivity and greater efficiency for Auswide Transport Solutions’ operations. According to Singh, plans are in place to extend the PBS fleet even further. “Melbourne and Adelaide has started and Sydney to Adelaide will commence in the near future,” he said. “We expect the presence of PBS combinations on our roads will become increasingly more common as benefits are realised.”

PRIME NEWS 10 August 2023 PRIME NEWS

One of the recently unveiled Kenworth B-triple sets.

Easily Retrofit to the Popular HOLLAND

FW351E & FW331

Fifth Wheel

FLASHING RED WARNING LED LIGHTS FOR FAILED COUPLING ATTEMPT

HIGH INTENSITY WHITE LED LIGHTS FOR SUCCESSFUL COUPLING ATTEMPT

helps drivers GET IT RIGHT!

FAILED COUPLING – In the case of a failed coupling attempt, bright red flashing LED lights assist the driver to quickly recognize a potentially costly mistake.

SUCCESSFUL COUPLING – A successful couple triggers highintensity white LED lights, strategically aimed at the kingpin and lock for enhanced visibility during the inspection process, especially in poor weather and low-light conditions.

Robust electrical components: sealed one-piece harness, long-life LED lights, durable inductive sensors, and steel encased logic module ensure reliable operation in the toughest conditions.

SAF-HOLLAND (Aust.) Pty. Ltd

ABN: 79004371215 | Sales: 1300 131 613

Email: sales@safholland.com.au

www.safholland.com.au

> Lindsay Australia makes $34M acquisition

Lindsay Australia has acquired merchandise company, WB Hunter, for $34.6 million. Founded in 1947, WB Hunter is a market leading retailer that provides a comprehensive range of rural supplies, agricultural services, trade essentials and pet products with an eight-store footprint across Victoria and New South Wales. The acquisition will directly contribute to Lindsay’s broader strategic direction by providing a range of complementary products and services to its extensive customer base.

Lindsay will also utilise WB Hunter’s network to further expand into the Victorian and NSW agricultural supply markets. This broadened operating footprint is expected to offer a robust platform for Lindsay to pursue growth opportunities across all service lines.

Lindsay Acting CEO, Craig Baker, commented on the acquisition.

“We are delighted to welcome WB Hunter into the Lindsay network,” he said. “WB Hunter has a longstanding and highly successful operating history, serving as an integral member of

>NatRoad issues survival guide

National Road Transport Association members have been given a sevenstep guide to weathering the current economic winter following a wave of price hikes from 1 July.

NatRoad CEO Warren Clark said his organisation was recommending strategies to navigate the challenges being thrown at the road transport industry and they involve pre-planning and managing relationships.

“There’s never been a more important time to be on good terms with your employees and customers,” said Clark. “You can’t do much directly about things like diesel prices – apart from using our Ampol discounts if you’re a NatRoad

Member because they’re the best available – but you can look at your own business, no matter how large or small. Clear communication with customers and employees, according to Clark, is not a ‘nice to have’ in tough times but a ‘must’.

“We’re facing a very complex business environment but our industry is nothing if not resilient,” he said. “Our Seven Step Survival guide provides some broad principles to staying afloat and our advisors are always on hand to answer specific questions from Members.”

Clark said operators should regularly update clients about the changes in operating costs and how they affect the

> ALRTA appoints new Executive Director

The Australian Livestock and Rural Transporters Association of Australia (ALRTA) has announced the appointment of Rachel Smith as its new national Executive Director. The appointment was made by ALRTA National Council following an extensive talent search and selection process. Smith, according to ALRTA President Scott McDonald, is the right person to carry on the ambitious work program of the association.

“ALRTA has a long history of punching above its weight across an ambitious work program,” he said. “I believe that

Rachel has the right mix of skills and experience to continue that tradition. I congratulate her on the appointment and look forward to working closely into the future.”

Smith has previous transport association experience. She worked for the Australian Logistics Council as Head of Government and Policy and served for a brief period as interim CEO. She has also worked for Australian Pathology and the Pharmacy Guild of Australia, bringing extensive experience in policy development, advocacy, government relations, member services,

Australia’s rural supplies market.”

Following the completion of the acquisition, Lindsay Rural will have a consolidated rural merchandising network across Australia’s east coast. Lindsay Rural represents a key component of Lindsay’s end-to-end food supply chain solution, supplying more than 1,500 farmers with an extensive range of agricultural products including packaging, fertilisers, chemicals, nutrients and irrigation equipment across a network of 21 stores.

pricing of services.

“We are recommending operators provide a detailed breakdown of costs to clients to help them understand where increases are coming from, such as fuel costs, insurance charges or wages,” he said. “This can help in negotiations as it shows the business is not arbitrarily raising prices.”

Clark said investing in efficiency improvements could help reduce operating costs.

“This could include more fuel-efficient vehicles or optimising routes using routing software, but when seeking efficiencies it’s important not to compromise safety,” he said.

projects, business development and management.

Smith said she is looking forward to the challenge of representing the interests of the livestock and rural transport sector, including the six state member associations compromising the federation.

“I am thrilled to return to the transport and logistics sector to advocate for outcomes that will advance the interests of ALRTA members to government and the wider Australian community and look forward to working with the membership,” she said.

PRIME NEWS PRIME NEWS 12 August 2023

Heavy loads All-electric

Our heavy-duty electric truck range is designed to minimise CO2, noise and air pollution. It’s a new driveline, but with the same high standards for quality, safety and flexibility that come with every Volvo truck. So, if you are looking for ways to lower your environmental footprint, we have a solution for you.

Volvo Trucks. Driving Progress

> Viva Energy secures ADF fuel supply contract

A new contract executed with the Department of Defence will see Viva Energy Refining supply aviation, marine and ground fuel to the Australian Defence Force (ADF).

The Fuel Supply Contract is for an initial six-year term which may be extended to 12 years. It will see Viva Energy play a key role in underpinning Australia’s national security through supply of fuel to the ADF both locally and internationally.

As part of the deal and as an important Australian Industry Capability activity, Viva Energy will resume production at Geelong Refinery of F-44 (Avcat) or JP-5, a military specification aviation turbine fuel used on aircraft carriers. Currently, this high-flash jet fuel is manufactured and imported from overseas.

The scope of the contract will see Viva Energy supplying fuel to all Defence Fuel Installations (DFIs) around Australia and the RMAF Base Butterworth in Malaysia. Viva Energy will also be responsible for fuel supply to ADF

aircraft and vessels at all commercial airports, ports and marinas in Australia and around the world.

Viva Energy CEO and MD Scott Wyatt said the agreement expands Viva Energy’s important role in fuel security and extends its strategic relationship with the ADF. “This is a significant contract for both our Refining and Commercial & Industrial businesses,” said Wyatt.

“We are delighted to extend our strategic relationship with the Commonwealth and look forward to supporting the ADF’s Australian and international fuel requirements as a key enabler of their capability,” he said. “The resumption of local manufacturing of F-44 (Avcat) at Geelong Refinery is a highlight, reinforcing our commitment to the nation’s energy security.”

The announcement also builds on Viva’s project to construct 90 million litres of diesel storage tanks on the site, due for completion in 2024.

Under the contract Viva Energy would work with the ADF on energy transition

and renewable fuels the company said in a statement.

“I would like to thank the Commonwealth for its confidence in Viva Energy and look forward to successfully implementing this contract and delivering a safer, simpler and more assured Defence Fuel Supply Chain in collaboration with the ADF,” said Wyatt. Minister for Defence Industry, Pat Conroy, said the Federal Government was proud to be supporting Australian industry and jobs rather than importing Specialist Military Aviation Fuel.

“Coming after years of declining local oil refining and fuel production, this will be good for Australia’s defence, good for Australia’s energy security and good for Australian jobs,” said Conroy. “We are really pleased about the difference this will make in the regional centre of Geelong in Victoria. The Government is working hard to build a resilient fuel supply for Defence and to strengthen Australia’s national security — and this domestic fuel supply contract will contribute to this.”

PRIME NEWS PRIME NEWS

14 August 2023

A RAAF C17 Globemaster is refuelled by Viva Energy.

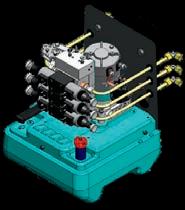

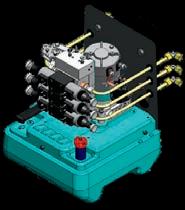

THE NEW D 190 FULL TIME PUMP HAS ARRIVED For more information contact Dana on 1300 00 DANA or visit us at www.Dana.com.au Strength • Power • Endurance ENGINEERED & BUILT IN AUSTRALIA

> Toll adds 30 new UD Quons

The supermarket arm of logistics powerhouse, Toll Group, has taken delivery of eight new UD Quons. These are the first units in an order of 30 trucks to service the Woolworths site at Minchinbury for deployment across the Sydney metropolitan area.

The Euro 6 UD Quon GW460 is powered by an 11-Litre engine delivering up to 460hp and 2200Nm of torque. It is paired with an ESCOTT-VI transmission.

A TN360 Teletrac Navman telematics system in the vehicles provides the capability of operating as an electronic work diary in the future and will accommodate other projects Toll is working on as it moves to a more digital environment according to Mark Haworth, Toll Operations Support Manager.

“We have also added the Seeing Machines Guardian DSS system in the trucks which detect driver fatigue

and driver distractions, alerting the driver to these events, as well as alerting supervisors of these events, of which fatigue events are acted upon immediately,” he said.

The Guardian technology has been at the forefront of the fleet for detecting fatigue and distraction related events. Other standard safety features in the truck include Traffic eye cruise control, lane departure warning system, and UD’s own stability system.

These new UD Quons will form part of Toll’s fleet, along with 2022 MercedesBenz Actros prime movers, presently in service for over 200 Woolworths stores in the Sydney Metropolitan area. According to Haworth, reliability, servicing, fuel economy, and a driverfriendly interface are a cut above on the new UD Quon. There are other immediate benefits, too, that have been relayed by the drivers.

“Definitely the turning circle, for getting into and onto loading docks,” says Haworth.

“This is a crucial aspect of the truck.

“The JOST JSK-42 Air Release Turntable, which we run already, but again is proving beneficial for the drivers,” he adds.

Visibility when in the truck, as one driver David Andrew relayed via Haworth, is also outstanding.

“All the blind spots are covered which is important when travelling in Sydney traffic,” he said.

“In cab safety features are less intrusive, cruise control works well and driver comfort is very good.”

The new Teletrac Navman systems are being introduced for the first time at Toll Minchinbury.

“All our new trucks will have it added, [it’s] much easier to use and a lot more driver-friendly,” said Haworth.

PRIME NEWS PRIME NEWS 16 August 2023

IN THIS BUSINESS, YOU NEED THE BEST TO SUCCEED

With Caltex Delo’s ISOSYN Technology, fleet owners and drivers can rely on extended service protection, maximised engine durability and minimised operating costs.

Talk to your local distributor or find out more about Caltex fuels and lubricants. www.caltex.com/au/business-solutions

> Carey’s Freight Lines unveils special edition Actros

Tamworth’s Carey’s Freight Lines has taken delivery of Australia’s first Actros 25 Driver Edition. The special edition model was developed locally to celebrate the 25th anniversary of the Mercedes-Benz Trucks Actros being introduced in Australia.

Carey’s Freight Lines Managing Director, Darren Carey, first put his hand up for one of the limited-run Actros trucks at the Brisbane Truck Show in May. The unit was delivered recently by Mavin Truck Centre salesman, Steve Pinkstone.

The first Actros debuted with the Carey’s Freight Lines fleet in 2017. Since then, the company has purchased 18 units of the 2663 model. According to Carey, the Actros has been a solid and reliable performer for the company.

“Right from the start, the Actros has given us great fuel economy and we also appreciate the safety features and the comfort,” he said. “The acceptance

welcome addition to the fleet said Carey. “It looked good on the stand, but it looks even better in the metal, in our yard with our trailers,” he said. It features a grey metallic paint scheme matched with Alcoa Dura-Bright wheels and a raft of upgrades that ensure it stands out on the highway.

The Actros 25 Driver Edition features the Gigaspace cab, which is taller and provides more headroom and space for front-mounted cabinets above the windscreen. One of these cabinets includes a microwave. On the rear wall of the cab, there are two beds including a fixed bed at the bottom and folding bunk at the top. Below the bottom bed are twin fridges that are within easy reach of the driver.

Mercedes-Benz Trucks Vice President, Andrew Assimo, is thrilled the milestone truck is joining the Carey Freight Lines fleet.

“The special edition Actros 25 Driver Edition is full of features that drivers

said. “Carey’s Freight Lines is known for its well-presented trucks, its customer dedication and safety-first approach and is a wonderful brand ambassador for Mercedes-Benz Trucks.”

Carey’s Freight Lines dates back to 1947, when Harold Carey bought his first truck after returning from World War II.

Having bought the company in the 1980s, his sons, Mick and John, grew the business. Now, Harold Carey’s grandsons Darren, Todd and Rick have assumed control of the business.

The Actros 25 Driver Edition is a 2663 that features the top-of-the-line 630hp 16-litre six-cylinder OM473 engine linked to the latest generation 12-speed Automated Manual Transmission (AMT). It also comes with the Predictive Powertrain Control system, which uses topographical information, including pre-mapped three-dimensional GPS data, to enable the truck to make the best, and most economical, choice of

This includes saving fuel by coasting for Darren Carey.

PRIME NEWS PRIME NEWS

ONE COMPANY, A FULL RANGE Transport Hydraulic Solutions • Power Take-Offs • Gear & Piston Pumps • Control Valves • Controls • Oil Tanks • DC Powerpacks • Hand Pumps • Winches • Underbody Hoists Mobile Hydraulic Solutions • Load Sense Pumps • Gear & Piston Motors • Proportional Directional Valves • Control Systems • Joysticks • Sensors Backed by dedicated local product support and expert technical knowledge, we’re focused on providing the most durable solution for your on-road or mobile application. OMFB Pacific Pty Ltd 29 Trevi Crescent, Tullamarine VIC 3043 Ph. 1300 040 600 | www.omfbpacific.com.au

> Industry bodies’ first update on coupling strength report

The first update on an investigation into dynamic loads on couplings fitted to heavy High Productivity Freight Vehicles (HPFV) and PerformanceBased Standards (PBS) combinations has been released. Led by the ARTSA Institute (ARTSA-i), Australian Trucking Association (ATA), Truck Industry Council (TIC) and Heavy Vehicle Industry Australia (HVIA), the coupling safety project is funded by the National Heavy Vehicle Regulator’s (NHVR) Heavy Vehicle Safety Initiative (HVSI) and supported by the Australian Government.

The project’s objective is to address the knowledge gap surrounding coupling forces experienced in roadtrains with a Gross Combination Mass (GCM) above 125 tonnes.

ARTSA-i Chair, Martin Toomey, said the project has conducted extensive onroad testing of high GCM combinations to enhance industry understanding of the dynamic forces experienced by fifth wheels and pin couplings, and

a tri-axle ‘test dolly’, to which 14 load cells were fitted beneath the fifth wheel and a further six mounted directly behind the tow eye, within the customdesigned drawbar manufactured by CIMC.

Northern Territory-based bulk fuel transportation specialist, Direct Haul, partnered with the project to facilitate the on-road testing between Darwin, Katherine and the surrounding areas. The test route covered a broad range of road conditions and speeds, both laden and unladen, including highspeed sections and rough roads with demanding conditions featuring hills, cattle grids and flood crossings. For each test run, the test dolly was placed in a different position within the BAA and AAB Quad combination to allow the coupling forces in the front, centre and rear positions to be recorded along the 473km test route.

Preliminary results showed that there are two major types of events that contribute to the life of a coupling.

constantly and less common large force events, stemming from low-speed shunting events within the combination when coming to a stop and high-speed rough road events.

The results found that coupling location within the combination and the road profile affects the forces transmitted through the coupling, with positions closer to the front of the combination typically seeing higher longitudinal forces. Using data obtained from the on-road testing, Smedley’s Engineers are developing a computer simulation that replicates the vehicle combination and road conditions of the physical test, enabling further testing and investigation of coupling forces to be carried out in a repeatable and costeffective environment. According to ARTSA-i, preliminary simulations of the virtual combinations travelling through recreated sections of the test road are promising.

The project is expected to be completed in the coming months, with

PRIME NEWS PRIME NEWS 20

Direct Haul quad combination.

Care. It’s what we do.

At Isuzu, we’ve always taken great care of our customers.

We’re Australia’s number one truck… an honour we’ve held for over three decades.

That means more businesses put their trust in us than any other truck brand.

We understand that reputations are riding on us and that’s why Isuzu Care is more than just an aftersales service package.

It’s part of our DNA.

From day one, we support customers and demonstrate that reliability is everything. We pride ourselves on being proactive and always going the extra mile.

And as we look to new frontiers, we’re finding new ways to help our customers exceed their goals.

Isuzu Care is what sets us apart. Always has, always will.

FSA/ISZS1660

> Autonomous truck convoy milestone for Australian Army

The Australian Army successfully operated an autonomous truck convoy on a public road for the first time earlier this year. The National Transport Research Organisation and Deakin University supported the leader-follower trial on 6 June, in which a convoy of four autonomous Army trucks followed a crewed ‘leader’ vehicle on a public road in Victoria. Colonel Robin Smith, of Army’s Future Land Warfare Branch, said the autonomous vehicles performed well. “This trial showed how a convoy could undertake a resupply mission between an airfield and a military base, giving us an idea of how this kind of technology could be used in the future,” Colonel Smith said.

“Driving on a highway in traffic meant the technology was tested to stop safely, and leave distances between other vehicles, while following the path

set by the leader.

“Down the track, technology like this could remove our soldiers from dangerous environments, or help free soldiers up for other roles.”

During the highway trials, Army simulated an autonomous resupply mission between Mangalore Airfield and Puckapunyal using the Goulburn Valley Highway and the Hume Highway.

The trial is part of Army’s modernisation, which includes exploring “human machine teaming”, quantum technology, artificial intelligence and electrification.

Prior to this five modified Land 121 40M cargo trucks were trialled at Royal Air Force Base Point Cook. The autonomous leader-follower vehicle technology, using Rheinmetall/MAN medium tactical vehicles, was initially developed under a contract between the Institute for Intelligent Systems

Research and Innovation (IISRI) at Deakin University, and the Army’s Robotic and Autonomous Systems Implementation and Coordination Office (RICO).

Eventually, it is anticipated the trucks will be able to travel on various roads, even without markings. First announced in late 2021, the $12.2 million project helps address future operational challenges, including for humanitarian assistance and disaster relief, and in combat operations.

Evaluations of autonomous M113

AS4 with BAE System installing hardware and software into Armoured Personnel Carriers to allow soldiers to operate them autonomously, however, date back to 2019. The Army said it would continue to collaborate with industry and academia to explore how technology can increase mission success and lower risk to soldiers.

PRIME NEWS PRIME NEWS 22 August 2023

Rheinmetall/MAN medium tactical vehicles.

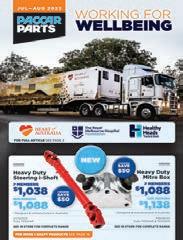

SEE PAGE 2 OF CATALOGUE FOR FULL ARTICLE

Cabin Shock Absorber MEMBERS $ 455

NON-MEMBERS $ 495

$40 MEMBERS SAVE

I COE front cab shock absorber CH6030B

Suits K104, K104B, K108, K200 with 2.3m/2.8m cab

Aluminium Wheels MEMBERS FROM $ 465

Axle Cover Kit

MEMBERS $388

NON-MEMBERS $ 408

I Stainless steel hub cover kit

I Contains: 4 drive hub covers, 2 steer hub caps, I 60 x nut covers plus a nut cover puller 1125-6AS4

To suit 10 x 285 PCD wheels

Stainless Steel Mudguards $239

I 1.1mm stainless steel shiny finish

I Curved edge

I Single guard

Whilst

JUL—AUG 2023 CHECK THE CATALOGUE ONLINE PACCARPARTS.COM.AU/CATALOGUE WELLBEING WORKING FOR * Calls from Australian landlines are generally free of charge whilst calls from mobile phones are typically charged based on the rate determined by the caller’s mobile service provider. Please check with your mobile service provider for call rates. DEALERS AUSTRALIA WIDE | Visit us paccarparts.com.au

more details, Freecall* 1800 PPARTS (772 787) 57

herein are recommended selling prices for both Privileges members and non-members, inclusive of GST. Recommended selling prices in this publication are provided as a guide. Prices may vary at the dealerships. Freight charges may apply. Core charges are not included in selling price however may be applied by the dealer. All items have been included in good faith on the basis that goods will be available at the time of sale. Promotion available at participating Dealers from 1 July to 31 August 2023 or while stocks last.

For

Prices

every effort

made to limit

of delays,

to current global supply chain challenges,

products may not be available in

retail outlets

the promotional period. Height Control Valve MEMBERS $297 NON-MEMBERS $322 I Used on Airglide suspensions H00500CP $25 MEMBERS SAVE First Aid Kits FROM $94 .95 KWF1RSTA1DK1T $94.95 179 Piece Medium - Suitable

Large

KWF1RSTA1DK1T C-KEN989 $20

SAVE

is

the impact

due

some

all

during

for 1 to 10 people C-KEN989 $179 $199 313 Piece

- Suitable for 1 to 25 people

MEMBERS

SS11S1NC Grooved

SS11S1NCNG Non-grooved SS11S1NC

$20

WITH:

MEMBERS SAVE PACCAR’S PARTNERSHIP

88U687

NON-MEMBERS FROM $515 88U687 $465 $515 8.25 x 22.5, 10 STUD 285 PCD. Buff finish, unique trapezoid cutout design SEE IN STORE FOR COMPLETE RANGE

$50 MEMBERS SAVE

> Mack Masters’ Australian teams to take on world-best

Round three of the Mack Trucks global aftersales competition, Mack Masters, wrapped up recently in a nail-biting finale. The third round ended in a sudden death knock-out between six perfectly scoring Australian teams from Mack Trucks’ dealerships. These included one team from CMV Truck & Bus Epping, one team from Western Truck Group Townsville, and two teams from both Truck Centre WA Forrestfield and Volvo Commercial Vehicles Prestons.

Mack Masters is designed to increase aftersales competencies, celebrate and promote teamwork among dealership service, warranty and parts professionals by putting teams against each other in knowledge-based aftersales questions.

The competition is ultimately aimed at improving customer satisfaction, and culminates in a global final in Allentown

and New York in October where the best aftersales teams from around the world face off over a series of workshop tasks.

The two Australian teams who reigned victorious in the 24-hour Sudden Death battle, Top Dogs from Truck Centre Forrestfield, and V Mac IV+ from Volvo Commercial Vehicles Prestons, are now preparing to take on the best teams from Latin America, Canada and the United States. Volvo Group Australia Vice President Services and Retail Development, Richard Singer, said he was thrilled to see the strong engagement from Australia for the country’s first year of Mack Masters.

“Mack Masters offers an engaging and challenging competition that doubles as an unparalleled training opportunity for dealer aftersales teams,” he said. “For our first year competing, we

had 79 teams register which really demonstrates the enthusiasm and commitment of our colleagues across the Mack Trucks dealer network.

“A big congratulations to everyone who has taken part, and particularly to our two Finalist teams.”

Mack Trucks Australia Vice President, Tom Chapman, said he is looking forward to watching the two Australian teams throw down in October.

“We take a lot of pride in knowing our dealerships are staffed by some of the most professional and capable staff in the industry,” he said. “We’re really looking forward to sizing up against some of the best in the world in what we hear is going to be a real spectacle of an event.

“We’re quietly confident that either one of our two dedicated Aussie teams have what it takes to bring home the title.”

PRIME NEWS PRIME NEWS

24 August 2023

The teams from Truck Centre Forrestfield, and Volvo Commercial Vehicles Prestons with Tom Chapman, fifth from right.

WE’RE WITH YOU FOR THE LONG HAUL.

With heavy duty knowledge, professional service and a leading range, NAPA Auto

Parts

is far more than just automotive.

From our wide range of heavy duty Auto Electrical, OE Replacement Alternators and Starter Motors, Air Conditioning, Lubrication, Service Parts and Braking to smarter technologies and efficiencies, we’re keeping you ahead of the curve. Our branches are located on the National Land Transport Network. We are working with you to have the parts where you need them, when you need them. We are as committed to your business as you are.

Visit napaparts.com.au/locations for your nearest branch.

> Parry Logistics unveils 50th new Kenworth purchase

Tamworth freight carrier, Parry Logistics, has taken delivery of a new Kenworth 610SAR. The milestone truck which represents the 50th Kenworth purchased by the business will spend half its operational life as a B-triple and the other half pulling a 34-pallet B-double.

Delivered by Alex Milne on behalf of the Brown and Hurley dealership in Tamworth, the prime mover is powered by a Cummins X15 600hp engine, paired with an 18-speed 22 series Eaton RoadRanger gearbox using a Meritor MT 46/160 driveline.

“It’s the first T610 we’ve bought,” said Owner Greg Parry.

“The driver wanted a bonneted truck and we were happy to give it to him,” he said.

That driver, Jeremy Mountain, has been with the company, which employs over 80 people, for eight years.

“These days drivers come and go so often it’s a great mark of service and loyalty we’re happy to acknowledge,” added Parry.

The new Kenworth T610SAR is the first of its kind in the fleet, which customarily runs K200s and T909s moving general freight across the eastern seaboard and central western NSW. Parry Logistics first established its presence in Tamworth in 2002 under

Greg Parry’s leadership. The business was founded by his father, the late Don Parry, in 1958 in Werris Creek after he purchased his first truck when he finished working for the railway. The fleet consists entirely of the Kenworth brand and now possesses 50 prime movers with over 100 trailers.

“Business has slowed down a little from what we’ve seen the last three years,” said Parry.

“That certainly makes it more manageable than what it was given how busy things had gotten not long ago.

“Now, with a return to some normality, we can return to giving the customer the service they deserve.”

PRIME NEWS PRIME NEWS

26 August 2023

Kenworth T610SAR B-triple.

FOR THE LONG HAUL

IT’S SECOND TO NONE”

MARC SOFTLY, WILLATON TRANSPORT

Navistar reveals results of hybrid International SuperTruck II

fuel system resulted in a 2 per cent fuel economy improvement when compared to International SuperTruck I. Aftertreatment system improvements included diesel exhausted fluid (DEF) dosing, improved mixing and lower restrictions, new selective catalytic reduction (SCR) formulations for highNOx reduction and reduced cold-start activation time.

Navistar, the company said in a statement, was able to identify new ways to push its engines to the next level of efficiency.

Outstanding advances in fuel efficiency are just some of the revelations offered by Navistar’s International SuperTruck II. For Navistar, the International SuperTruck II platform enabled it to focus on the next generation of vehicle efficiency improvements through hybridisation and aerodynamics resulting in a 170 per cent improvement in vehicle freight efficiency. Among notable gains was the 16 miles per gallon (MPG) fuel economy not to mention other advancements over the 2009 baseline vehicle, known as the International SuperTruck I.

Delivering 55 per cent engine brake thermal efficiency, the vehicle afforded an assessment of total cost of ownership (TCO) opportunities for individual technologies, and high-voltage electrification efforts modelling hybrid technologies that can be utilised for fully electric vehicles.

As part of an ongoing project in partnership with the US Department of Energy (DOE), the SuperTruck II program aims to reduce dependency on fossil fuels and increase Class 8 vehicle efficiencies.

According to Navistar, the SuperTruck II has also proven innovative technical approaches to weight reduction from rolling resistance technologies, aerodynamic improvements, and powertrain technologies.

“With co-funding by the DOE, Navistar engineers experimented with prospective

technologies not currently available in the Class 8 truck market to accelerate the impact of sustainable mobility,” said Russ Zukouski, Chief Engineer, Global Innovation and Principal Investigator for the Supertruck programs. “The team concentrated its design on high-voltage electrification, utilising hybrid technology on a path toward full electrification that has the potential to be commercialised in fully electric vehicles and improve customers’ total cost of ownership and business operations.”

Highlighting Navistar’s commitment to an electrified future, International SuperTruck II was built as a hybrid vehicle featuring a combustion engine with highvoltage accessories and technologies, developed in partnership with Bosch. Navistar was the only OEM to build a trailer to provide the most accurate testing results possible, according to Dean Oppermann, Chief Engineer, Advanced Truck.

“It includes a 100 per cent composite box designed for minimum aerodynamic drag with light weight, integrated cross members, controlled underbody flow with composite aero treatments, nextgeneration solar panels with connectivity options, and ride height control,” he said. Engine improvements were made in key areas including combustion, friction, gas exchange, and airflow through the engine. A redesigned cylinder head with dual overhead cam engine and enhanced

“A full system approach was required to achieve 55.2 per cent brake thermal efficiency,” said Jim Cigler, Chief Engineer, Advanced Engine. “Opportunities were identified by internal engineering teams along with research partner Argonne National Laboratory through detailed analysis and simulation. System suppliers such as Bosch, Jacobs Vehicle Systems, and Applied Nano Systems (ANS) brought new approaches to key systems that enabled laboratory success and yielded real-world fuel economy improvements.”

International SuperTruck II highlighted connectivity with next-generation predictive cruise control, as well as leveraging technologies and information within the larger TRATON Group, which includes MAN Truck & Bus and Scania, to explore vehicle-toeverything technologies to enhance safety and vehicle efficiencies.

“Our goal is to continue to advance internal combustion engine technology as efficiently and sustainably as possible until there is parity with zeroemissions vehicles,” said Oppermann. “Development of both technologies concurrently ensures a smooth transition of technology to best serve customer needs. We are focused on the entire product ecosystem — product development itself, as well as infrastructure charging, service and support of vehicle operation, end of life for batteries.”

GLOBAL NEWS >

28 August 2023

Navistar International SuperTruck II.

Business. The Clever Way. *Earn 3x Qantas Points plus save up to 5c off per litre for 6 months. Purchase 10,000 litres in 6 months for an additional 100,000 bonus Qantas Points. Limited time offer. Minimum spend criteria and conditions apply. Full T&Cs apply at www.bpplus.com.au Earn big & save bigger with BP Plus Scan or visit bpplus.com.au to sign your business up to a BP Plus fuel card to boost your Qantas Points & save on fuel. + UP TO 3XQANTAS POINTS FOR6 MONTHS* BONUS POINTSMINLITREAGE APPLIES + 100 K

Shayne Commons

Shayne Commons is the Director of Product & Performance at Volvo Group Australia. He has been working with sustainable transport solutions for the past three years ensuring market awareness, suitability and readiness as well as being the Commercial Project Manager for both medium and heavyduty Volvo Battery Electric Vehicle introductions to market. Shayne has been with Volvo Group Australia for 15 years.

UPSTREAM COLOUR

For many attending the Brisbane Truck Show this year the striking custom Volvo FH16 XXL taking centre stage at the Volvo Group Australia stand was a highlight. I also may be guilty of being just a little biased on the subject as that truck and its paint scheme was my idea and project! But there was more going on with this truck than just a fancy candy apple paint job. The multicoloured swirls and whirls flowing across the panels of this prime mover represents the movement of air around the truck in motion. A visual representation of aerodynamic drag. The design is based on the computer-generated drag modelling our design teams use to make our trucks more fuel efficient. Drag is a major factor when it comes to fuel efficiency. Air flowing around a moving truck is disrupted by mirrors, door handles, wheels and mud guards which then swirls along the vehicle creating drag. Sixty per cent of the aero effects are from the truck whereas the remaining 40 per cent is contributed from trailer wheels, chassis, and base wake from the rear. But since the truck is upstream quite often the downstream effects can be reduced by the truck spec. The truck pictured here, a Euro 6 FH16 550 is already a smooth operator when it comes to fuel efficiency. However, there are lots of different factors to take into account when it comes to maximising your bang for buck out on the open road.

It’s tempting to extol the features and benefits of terrain reading cruise control and more efficient low-drag

engines and transmissions. The latest generation I-Shift transmission shifts even faster while minimising unnecessary gear changes. And the availability of 13-speed and 14-speed variants means we have the option of downspeeding the engine by using taller (faster) final drive ratios while maintaining start-ability. While all these features will absolutely save fuel, there’s also some simple, relatively lowtech factors to bear in mind. Hence the Volvo FH aerodynamic study built for the show. Tyre choice alone can affect fuel use by up to 5 per cent per tyre class. Bullbars, stone guards, light bars and air horns all contribute towards creating drag and that’s not taking into account gaps between the prime mover and the trailers it is towing.

Of course, some of these things are application dependent. However, does a truck that rarely leaves the Pacific or Hume Highway really need a roof mounted light bar, two spotlights and a bullbar the size of an outback cattle grid? Probably not!

Does that same truck need to be carrying 1400-litres of fuel and 150-litres of DEF? It’s not that there’s a right or wrong answer to these questions. But I’d suggest that it doesn’t hurt to ask them when speccing a new truck. The internal combustion engine will continue to be the heart of many powertrain configurations for a long time yet when it comes to heavy transport and new fuel efficiency features will continue to be developed. It’s worth challenging some preconceptions when updating

30 August 2023 SUPERANNUATION MINDSET OEM MINDSET

Volvo Group has ambitious emissions targets. The first steps on the path to zero emissions start with more fuel-efficient trucks.

your truck fleet.

So next time you are looking to spec a new truck, think about how you could be more aerodynamic, how you pair the rear axle ratio with the engine torque curve specific to application, challenging the configuration of the vehicle. Doing something one way just because it has always been done that way will not continue to achieve results with evolving technology.

While I clearly will be biased towards choices around prime movers (after all that’s what we manufacture), trailers also have a big part to play when it comes to fuel efficiency. B-double combinations often live a hard life as they twist and turn from deliveries and pickups. I have already mentioned tyre impact to efficiency (which relates to trailers also) but regular maintenance

and assurance of pressures as well as axle alignment does wonders for reducing fuel consumption as does making sure trailer curtains are tensioned and not flapping in the wind. So while Brisbane Truck Show 2023 gave me an excuse to build a cool truck, it’s really so much more than that. The air that swirls and eddies down the side of a truck on the highway costs more than just money. As we talk more and more about sustainability and the environment, fuel efficiency has a part to play here as well. We think electromobility is the answer for low emissions urban transport but as I pointed out earlier the internal combustion engine will also be with us for quite a while in heavy long haul roles. Obviously, the less fuel you burn the lower your emissions.

It’s no secret that Volvo Group has some

ambitious emissions targets. And the first steps on the path to zero emissions start with more fuel-efficient trucks. You’ll note I used the words “internal combustion” engine rather than just plain old “diesel”? This is an area where there will no doubt be a lot more development. This multicoloured FH has HVO (Hydrated Vegetable Oil) in its fuel tanks rather than old fashioned dinosaur bones. While HVO isn’t zero emissions, as such, it still represents a significant reduction (up to 90 per cent) from well-to-wheel emissions as a synthetic fuel.

Despite not yet being readily available in Australia, HVO is just one example of what could be done to lower emissions now (without voiding your warranty). No doubt we’ll see more development in this area too.

primemovermag.com.au 31 SPONSORED BY

Pictured right: the custom Volvo FH16 XXL.

Thirty years is but a footnote in the histories of some nations. On the contrary, for a privately owned company, it can contain family legacies of longevity and triumph. Back in 1993, the year Direct Freight Express took flight, the country had entered something of a rebuilding phase. The first signs of economic recovery from a recession

then Prime Minister Paul Keating, who was re-elected that same year, insisted, assumptively, needed to happen, were at hand. But not before the Australian dollar had, by late January, slumped to its lowest level since early 1987, prompting international investors to abandon the currency which left the Reserve Bank to intervene as part of a rescue effort. Sydney winning its bid

to host the Olympic Games, however, promised a new decade of prosperity and for many businesses, this hope, helped propel them through a climate of economic uncertainty. It was a volatile time to start a freight moving business.

Direct Freight Express, nevertheless, hit the ground running. The fledgling company navigated this embryonic period of its history courtesy of Founder and Managing

32 August 2023

As one of the largest independently owned transport companies of its kind, Direct Freight Express reinforces the formidable national footprint it has forged with modern trucks from key supplier, Isuzu.

Director, Joe Catania. By June of 1993, the company commenced with less than ten staff working across two locations in Mascot, Sydney and Reservoir, Melbourne with an Adelaide office opening little more than a week later.

That same spirit of adventure and expansion continues to this day. Over the last ten years, the distribution network has been significantly enlarged. In just 2014 the company established new branches in Traralgon to service regional Victoria, Ballina in New South Wales and Darwin in the Northern

Territory. By 2017 its national depots numbered 43 adding new locations in Gosford and Bathurst in NSW. The opening of a $36 million facility in Keysborough, Victoria, in September that same year aimed, in part, to combat increased travel times and traffic across the greater Victorian metropolitan and regional areas. A Gold Coast depot, its newest site, brings the company’s current total number of locations nationwide to 62.

The truck fleet handles 120,000 individual pieces of freight each day.

While Direct Freight Express has continued to evolve and adapt to the market’s demands over the years, one thing has remained the same – its trust in Isuzu. The majority of its immense delivery fleet is manufactured by Isuzu, particularly across the FRR 107-210s, NRR 45-150s and NPR 75-190 ranges. Direct Freight Express’ FRRs are responsible for its bulk pallet work and larger bulk consignments, while the NNR and NPRs complete 95 per cent of its parcel deliveries to homes and shopping centres, carrying commercial,

primemovermag.com.au 33

One of the newest Isuzu FRRs out in Sydney.

small-item quantity type of deliveries.

The Isuzu units, assigned Direct Freight Express’ short haul operations, typically travel within a tight radius of each depot. On average the bulk trucks clock up 120 kilometres daily while the parcel delivery vehicles travel to 115kms. About 20 per cent of the total individual runs each day cover 250 kilometres.

The fleet also runs a large prime mover fleet, mainly Kenworths, for its long haul assignments. When required, these same units can complete a route as far as Brisbane to Cairns, Sydney to Melbourne, or Brisbane to Sydney.

It’s the Isuzu units, nevertheless, that are counted on to perform the frenetic intrastate tasks for Direct Freight Express. Isuzu is not only impeccably suited to the freight profile of the business, but according to National Operations Manager, Jason Elliott, it has consistently outperformed other brands in the array of tasks asked of them.

“We find Isuzu to be a good, reliable brand,” he says. “They especially suit our operation as far as the space goes inside the vehicles and their weight tolerances. We have different units for whatever we need – we’ll have a lightweight body on the chassis, but we will also have 4.5-tonne ones that are registered and rated for 5.5- and 6.5-tonne payloads instead of the 4.5-tonne car license ones, where required.”

A typical Isuzu order by Direct Freight Express involves three truck bodies. The fleet gravitates towards either a hard side body with a roller door on the back, a curtainside with a side door, and either a tailgate or a full curtainside. Elsewhere, specific pallet size is designated according to both application and environment. Direct Freight Express will go from the basic 4.5-tonne bodies to the larger 12-palleters – essentially from the smallest Isuzu can make to the biggest.

A consistency across the Isuzu brand, through aftermarket sales and support, and their ability to supply equipment has remained a major selling point

according to Jason.

“The fact that for a long time they didn’t change their models a great deal, was conducive to buying the same type of trucks and parts,” he says. “We try to keep everything the same so we’re not carrying spare parts of everything – the less models, the less brands, the better. And Isuzu weren’t dramatically changing the models every year or every couple of years, which made it easier on us to

Freight Express’ needs was evident as soon as the first trucks were put to work. “After they were purchased and we started using them, we found that we

34 August 2023 COVER STORY

why change?’”

Quite early on the fleet went from buying from Isuzu and other suppliers to dealing directly with North

at supplying the equipment as is required and North East Isuzu prepares them to get them on the road. It’s a very consistent product and supply is great.

A primary reason Direct Freight Express opts for North East Isuzu comes down to it being both a dealer and a body manufacturer. By supplying the cab

primemovermag.com.au 35

Jason Elliott.

chassis and building the body to go on the vehicles, it has become a one-stop shop for Direct Freight Express. “We don’t have to deal with multiple people and then have different bodies,” Jason says. “Because of that, our trucks are consistently the same in terms of changes we’ve made as we’ve gone along as a company. Whereas, if you’re using dealerships, they will use different body manufacturers and different bodies. We don’t have that.”

Direct Freight Express’ latest order with Isuzu mainly consists of FRRs, with another 50 currently on order. Each unit houses Isuzu’s 4HK1-TC engine which produces 154kW of power at 2,400rpm and 726 Nm of torque at 1,600rpm. Also fitted is Isuzu’s six-speed, two-pedal automated manual transmission with a torque convertor. Cruise Control, driver and passenger airbags, anti-lock braking,

anti-skid regulator and hill start aid also add to a long list of comfort and safety features within the FRR 107-210. The vehicle also features the ISRI 6860 air suspension driver’s seat with pneumatic lumbar support and weight adjustment. The family behind Direct Freight Express prides itself on living up to being one of the most reliable and respected road freight services in Australia. That also means staying true to its heritage. Part of that commitment involves providing its stakeholders today with the same family values the company was founded on 30 years ago. It’s not for mere promotional sloganeering either. That same culture helps assert flexibility and consistent growth pathways in an ever-changing industry. The fleet, subsequently, can now cater for a much larger range of professional freight requirements. These include its ‘book in freight’

service which ensures that all goods are delivered within timely arrangements and an express freight service – powered by the fleet’s linehaul vehicles, extensive company depots and agency facilities – which guarantees freight will arrive at the end destination in the shortest time possible. Backing these services is an ongoing dedication to safety with regular investments in equipment decked out in safety features, such as EBS on trailers and autonomous systems for braking and distance monitoring on its prime movers.

With regard to monitoring, all of Direct Freight Express’ facilities are surveilled by CCTV cameras 24 hours a day and are surrounded by electric fencing. The fleet is also monitored via satellite tracking to allow the precise location of any truck to be viewed at any time.

Following each of the company’s various

36 August 2023 COVER STORY

DFE driver Brendan Mani operates the truck tailgate.

Isuzu purchases Jason has received nothing but positive feedback from drivers. This, he says, has made it easy for him to continue to purchase more Isuzus in the near future.

“The drivers all seem to enjoy driving

them,” he says. “I don’t hear any negative feedback. Drivers don’t necessarily run over to tell you it’s wonderful, but they’re quick to come over and tell you when they’re not. And I haven’t had any of that.

“Overall, when it comes to warranty and the likes, it’s all supported by Isuzu Australia. I just find them a very professional and great organisation to deal with.”

Running a national operation like Direct Freight Express means fleet management must ensure the vehicles are always operating at the highest of standards. On this front, Isuzu’s reputation for reliability, according to Jason, perfectly aligns with the Direct Freight Express business model.

“It’s been a very long, profitable relationship for both parties,” Jason says. “I find them extremely good, especially if there’s been any small issues. They’re very responsive in finding the problem, fixing the trucks and getting them back working. I certainly can’t complain, and North East Isuzu is a huge part of that as well.”

primemovermag.com.au 37

“We find Isuzu to be a good, reliable brand. They especially suit our operation as far as the space goes inside the vehicles and their weight tolerances. We have different units for whatever we need –we’ll have a lightweight body on the chassis, but we will also have 4.5-tonne ones that are registered and rated for 5.5- and 6.5-tonne payloads instead of the 4.5-tonne car license ones, where required.”

Jason Elliott

Direct Freight Express National Operations Manager

Direct Freight Express Isuzu FRR 110-240.

PERSISTENCE OF VISION

Sunshine Coast carrier, Gibson Sand & Gravel, is one of three fleets in Australia asked to give a 12-month appraisal of the new Western Star 48X.

Based at Beerwah in the spectacular foothills of the Glasshouse Mountains, Gibson Sand & Gravel has been a permanent fixture for the better part of three decades on the Sunshine Coast, where it carts quarry products for major suppliers to concrete and asphalt plants. The business has undergone a few iterations since the 24th October, 1994 when owner Wayne Gibson established it. At first using body trucks supplying builders and plumbers from a yard, then as a truck hire business and finally, once the quarry work began to flow, as the truck and dog operation it is today.

Major contracts with Holcim encouraged further investments in equipment and with that came fleet expansion. Up until 2015, when Wayne purchased his first new truck, the business had been primarily relying on second hand equipment.

The Western Star fleet has since multiplied exponentially with a few older Macks maintained for miscellaneous work and spill over seasonal demand.

It was a CLR Mack powered by a Detroit Series 60 engine, that refused to quit, which first pointed Wayne in the direction of the Western Star 4800 product with its reputed Detroit DD15. Detroit was offering one million kilometres, 500,000 litres of fuel or a five-year warranty, which ever came first, that ultimately helped make the final decision for him.

“They’re a solid work truck and basic to operate,” he says.

“This is the main reason I got onto them.”

With each subsequent contract he secured, Wayne bought another Western Star 4800 — 19 of them to be accurate.

The Detroit DD15 with an Eaton 18-speed RoadRanger gearbox is entirely suited to his operations which are informed by distinct environmental considerations. No great distances are involved, but site access can be tricky with lots of lower gear shifting and confined jockeying of vehicles that are reliant on noticeable power to weight ratio, durability, low centre of gravity and traction.

All but two of the fleet are 20-metre-long truck and quad dog combinations. That’s the sweet spot for the business as it enables a 38.5 tonne payload at 57.5 tonne gross.

The Gibson Sand & Gravel yard is conveniently located ten kilometres either way of its main quarry partners. When the trucks aren’t shuttling between the two, they

FLEET FOCUS 38 August 2023

primemovermag.com.au 39

Western Star 48X truck and dog..

are deployed south to occasional jobs in Brisbane.

“We’re right smack bang in the middle of our working area,” says Wayne. “This is fortunate given we adhere to compliance within a 100-kilometres of our main site without filling out logbooks.”

Naturally they can go further than that with additional approvals from the PBS network. On non-PBS access routes, they are, however, restricted to 50.5 tonnes. The newest addition to the fleet will be from the X Series launched late last year by Western Star. Wayne has ordered a 48X after taking part in an evaluation program organised by importer and distributor Penske Australia for the better part of a year.

“The idea is for me to pick it to pieces and let them know where improvements can be made,” says Wayne. “It’s a good highway truck. I have been noting efficiencies and improvements that can be made to it.”

The Detroit DT12 automated manual transmission has taken some getting

used to at low speeds, given the rest of the fleet’s vehicles are shifted by stick and there are plenty of soft sites with sandy bases affected by heavy rains in the subtropical climes.

“It’s comfortable and you’re not crunching gears all day,” says Wayne. “Most of my drivers are well over 50, some in their 60s and one or two in their 70s. One of these days I’m going to run out of people who can handle a manual transmission.”

Wayne says it’s only a matter of time before

the older drivers get used to an AMT, given there has been some initial reluctance on

“It’s taken me a long time and they’re a different style of truck to drive, particularly in those tight situations,” he explains. “Most of the older fellas I know who drive trucks all day have some sort of issue with their left shoulders from changing gears. A lot of people who get into the automatic trucks won’t drive anything else. I imagine that will happen here eventually.”

Initial data confirms a noticeable 10 per cent improvement on fuel economy. According to General Manager Richard Hellings, the loan 48X, with its Detroit DD13 Gen 5 525hp engine, is impressing particularly thanks to improved power through its advanced engine management system.

“For a smaller engine than the 15-litre it produces about the same horsepower,” he says. “The fuel economy is way ahead of the older trucks and it’s pulling just as well as the DD15s.”

40 August 2023 FLEET FOCUS

The quad-axle dog trailer is loaded at a quarry site near Beerwah..

Wayne Gibson.

That’s vital, too, given the new Western Star 48X Detroit DD13, displacing comparable horsepower as the older trucks but at a significantly lighter weight, helps add extra payload capacity of 39.5 tonnes.

According to Wayne the Western Star 48X fuel burn is a healthy 43.6 litres per 100 kilometres. It’s also the only truck in operation at the business that uses AdBlue. That’s an advantage, given the 4800s use EGR which often requires a stationary regenerative burn that can take half an hour to complete.

“With the AdBlue that doesn’t happen,” says Wayne. “When the truck is working hard the EGR takes over when it’s idling. The AdBlue controls the emissions. They’ve got both systems.”

That has saved some additional time for the fleet. The next truck already on order, however, will have the larger 16-litre Detroit engine.

“I went for the bigger horsepower,” explains Wayne. “Not that we really need it but it’s handy to have when you want it.”

The majority of the tippers are designed and built by Hercules with a few made by Shephard Transport Equipment, keeping the partnerships local, Brisbane-based.

“I like to spend my money locally and keep local people employed,” says Wayne.

“I hail from the bush, so I tend to defer to the smaller guy to keep him going.”

This approach extends to the workshop or lack thereof. There’s no full-time mechanic as Wayne’s preference is to outsource to a local auto mechanic and air conditioning technician. To this end, investing in new and near-new trucks has brought an end to a reliance on an inhouse workshop.

Richard Hellings, 75, has been with Wayne since 2000. He oversees maintenance and performs the NHVR compliance, having driven himself for many years.

“Wayne had a Mack twin stick and everyone he tried to put in it refused because it was just too hard for them,” he recalls. “As I’m fairly old and had driven them before I ended up doing it.”

The eight wheel MIR700 was paired with a Mack 237 motor and a six-speed Mack box.

The main box had five gears and the joey contained high, low and reverse. That gave it six forward gears and five reverse modes. As complicated as the set-up sounds, it’s bread and butter for an experienced veteran like Richard.

As a driver, he started out in 1968 on the brutal Sydney to Perth trek, driving for his troubles a 126hp supercharged Foden and later “upgraded” to a truck five years younger, an AEC Mandator. They were all single drive in those days with a spread trailer.

“It was Gardiner-powered and the revs weren’t huge at around 900 and they went everywhere at 32 mp/h,” recalls Richard. “They pulled well enough hooked to a spread trailer and you could move the front axle on the bogie forward to get your weights right.”

According to Richard, 27.5 tonnes was the gross mass and the only good thing about it was there wasn’t many weigh stations and transport inspectors, as none of the states were synchronised by computer database.

“Most of us had two or three different licences from different states and then

they brought logbooks in and that sort of stuffed that up,” he says.

The Western Stars, in Richard’s observation, are quiet, much quieter than the Macks. “They’ve got plenty of grunt for what we want to do with them and we’ve dialled up the engine management system on a couple,” he says. “The fuel economy is not bad, normally just over 2 litres to the kilometre.”

Having the fleet standardised cuts down on unnecessary inventory in Richard’s estimation. Instead of carrying a quarter of a million dollars in parts to service a variety of different trucks means Gibson Sand & Gravel only holds $100,000 worth of parts on hand.

Richard’s son, named after him, is in his 40s. He’s the fleet tyre manager, who also helps out with general repairs. His son, who previously worked for the business, also carries the same name.

“I had all three of them on the books at one stage,” Wayne says. “The only way I could pick them apart was by their birthdates.”

Even so, Wayne acknowledges the longevity of the company owes much to Richard’s knowledge and business acumen.

“The business would not be where it is today without his assistance,” says Wayne, who recently turned 68. He worked on his birthday. That involved driving all day, before dinner at home in front of the football. Living on site, where he is in the process of building a new shed, installing a washbay and concreting the yard, doesn’t afford him much downtime.

“There’s always something to do,” he says. “When you live on site you just can’t get away from it.”

Wayne was raised on a farm in the Western Downs area of southwest Queensland. That was where he first became acquainted with tractors, trucks and heavy machinery. It’s stuck over the years. Despite many challenges, he has too.

“Wayne’s done a marvellous job persisting, and I think it’s the right word, trying to make a go of it and he’s finally got there,” says Richard. “Nothing’s easy in transport. But it just proves that if you set your mind to it with a decent team you can successfully drive a business.”

primemovermag.com.au 41

THROUGH ROOF THE

FLEET FOCUS 42 August 2023

A Palfinger crane mounted to a Mack truck at a building site at sunset.