IS THE MAN A CONTENDER?

PUBLISHED BY

Prime Creative Media Pty Ltd

ABN 51 127 239 212 379 Docklands Drive, Docklands VIC 3008 Australia

Telephone: 03 9690 8766

Fax: 03 9682 0044

Email: enquiries@primecreative.com.au

Perhaps the trucking industry should take a lesson from the Boy Scouts, always be prepared. This is something which the trucking industry doesn’t have a good track record on.

Where we do have a very good track record is reacting quickly and effectively to problems and issues and solving them in a straightforward and practical manner. It is this very can-do attitude of the trucking industry which has seen it become the predominant player in the transportation and movement of freight around this country, while other forms of transport have, pretty much, stayed the same.

Now, there are some problems which come along with this ability to solve problems quickly and effectively. There is a tendency to not look too far down the track ahead, because we are expecting things to go wrong and the conditions to change. Most of the time this is an effective strategy in the trucking industry, only concentrating on problems in front of you and not worrying about problems from a few years hence

The trucking industry does need to think now about how it’s going to be doing its business in 2040 and investigating what the likely legislative and economic limitations there are going to be to its activities at that point.

The big ticket item here is, of course, climate change and the restriction on carbon emissions. Statistically the only way to effectively bring down carbon emissions at the rate which the government has stated as its aim, is to go hard early on, to enable the more difficult carbon emissions to be reduced later, when technology exists to solve the issue.

This means there is going to be major change in the way that the trucking industry shifts freight soon. It’s not going to happen all at once, but it will happen over time, and we can be certain that the speed of change will accelerate as momentum picks up.

There’s no point in burying our heads in the sand. These things are going to change it’s not simply a matter of getting rid of your diesel truck and replacing it with a battery electric truck, or hydrogen truck, or a drone. There’s much more to it than that. The suitability of different forms of freight transport will have changed.

Transport businesses are likely to be organised in different ways into the future. The way that the vehicles powered by electric or hydrogen are used is likely to change the business model of any normal road transport business.

It may be that it’s smaller operations find it difficult to operate in the new environment, while the bigger larger national corporations find it easier to exist in the new paradigm. The thing is, we don’t know how it’s going to play out. What we need to be doing now is getting the best brains in the business to start thinking about this issue, creating models which will survive in the new era, and models which will make money for road transport businesses after 2040.

Chief Executive Officer: John Murphy

Managing Editor: Luke Applebee

Editor: Tim Giles

Contributors: Paul Matthei

Correspondent: Will Shiers (UK)

Advertising Manager: Trevor Herkess: 0411 411 352, trevor.herkess@primecreative.com.au

Client Success Manager: Salma Kennedy, salma.kennedy@primecreative.com.au

Production Manager: Michelle Weston

Circulation & Subscriptions Manager: Bobby Yung

Designers: Blake Storey, Kerry Pert, Tom Anderson, Louis Romero

Official Media Partner:

REGISTERED BY Australia Post - ISSN 1445-1158

SUBSCRIPTION

03 9690 8766 subscriptions@primecreative.com.au

PowerTorque Magazine is available by subscription from the publisher. The right of refusal is reserved by the publisher.

Annual rates: AUS $60.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate.

DISCLAIMER

PowerTorque Magazine is owned and published by Prime Creative Media.

All material in PowerTorque Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher.

The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in PowerTorque Magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

EDITOR

During a period when many multi-generational trucking businesses are selling up, it’s nice to find a thriving third generation operation looking to the future and looking to grow. Tim Giles talks to Mitch Kelly at his home base in Toowoomba, Queensland.

The latest on offer from the MAN brand brings the range bang up to date, they tick all of the boxes, but the question remains, in the B-double market, is the MAN a contender? PowerTorque takes the latest model out on the highway to test its credentials.

Marcay Transport is always searching for higher productivity in hauling grain and fertiliser in rural areas of in country Victoria and Southern New South Wales, but the operation is hampered by the complex rules and the interstate differences.

Every truck manufacturer in the world has to have an alt-power truck and some examples are starting to arrive in Australia, this

time Scania go electric and Tim Giles gets a chance to take the truck out for a test drive.

There is a building inevitability about the move to alternative power, PowerTorque sat down with Paul Ilmer, Vice President Emerging Technology Business development at Volvo, so he could explain how to start preparing a trucking business for electric trucks, and a for a future without diesel engines.

The next ten years are going to see major changes in the trucks on offer from the major truck manufacturers, so PowerTorque got a chance to ask some questions about how Daimler is taking Fuso forward in the next few years.

41

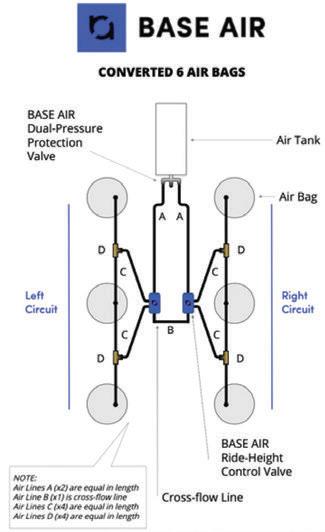

One of the priorities for trucking operators, especially those in the livestock game, is keeping trucks upright and stable. PowerTorque test drives a new technology to assess its effectiveness.

08 NEWS AND VIEWS

Three top awards for quick thinking, workshop management and technical achievement, plus there’s records broken in the truck market.

46 MINIMUM RATES, SAME DOG, DIFFERENT LEG

A leaked document has confirmed that the Albanese Labor Government is actively preparing to revive the RSRT.

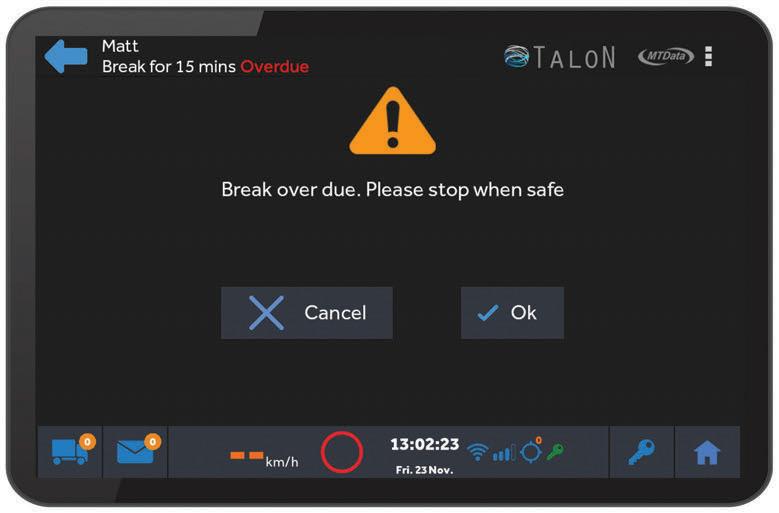

52 CONNECTED ROADS ARE SAFER ROADS

To increase safety on our roads, we need to utilise all of the technology we have at hand, reckons Anthony Laras, National Manager of Transport, Teletrac Navman.

54 ARTIFICIAL INTELLIGENCE ISN’T ABOUT TO MAKE US ALL JOBLESS JUSTYET

Warren Clark, NatRoad CEO is wondering whether artificial intelligence can do his job, instead of him, or your job, instead of you.

60 IDEAL ELECTRIC BREWERY WORKHORSE

PowerTorque’s European CorrespondentWill Shiers reckons battery-powered trucks might be the ideal brewery workhorse

64 TECH KNOW

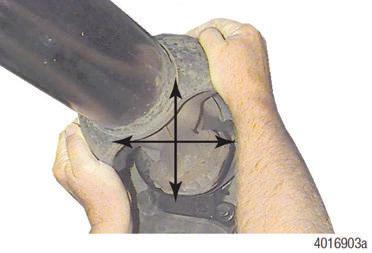

Meritor explains just how simple looking after a Permalube driveline can be.

60

• Supporting drivers for more than 50 years

• Seating – on a higher level

Adelaide truck driver James Rundle was recognised as a Bridgestone Bandag Highway Guardian after coming to the aid of a driver who had rolled off the side of a road and down a steep embankment in South Australia.

The Musico Refrigerated Transport driver was en route to deliver eggs when he came across suspicious tyre marks on the highway. After initially thinking it was a past incident, James doubled back to the scene to reinvestigate and discovered a driver trapped in their rolled over vehicle down the embankment.

He alerted emergency services and administered first aid to the crash victim, waiting alongside them until they were taken to hospital with non-life threatening injuries. The driver had been trapped for several hours when they were found, and James’ actions saved their life.

Yet again the instability created by the pandemic and the extraordinary demand for trucks in the past couple of years has created a situation where most truck sales records fall yet again, according to the2022 results released by the Truck Industry Council.

The market has been skewed by the white hot demand for both trucks and trailers. In many cases it is not the truck itself which affects sales numbers, but the ability of the truck makers to manage their supply chains and maximise sales numbers by getting as many trucks as possible into the hands of the customers.

This anomaly was demonstrated in December when Volvo out sold Kenworth in the heavy duty truck segment of the market. Kenworth is limited by the sheer number it can push through its Bayswater manufacturing plant. However, for Volvo, the production numbers from the Wacol plant were supplemented by trucks built in the company’s plants elsewhere in the world and imported fully built up.

The end of the year still sees Kenworth as the number one heavy duty truck brand in the market, with 3,002 trucks sold in 2022, and Volvo coming in second with a total of 2,539. Third in the heavy duty race was Isuzu, followed by Scania and then UD Trucks.

Overall truck sales topped the charts with a total of 44,379 trucks sold in 2022, up from the previous record of 41,404 from last year. Both of these results put the long standing 2008 record of 36,620 well into the shade.

Isuzu demonstrated its highly organised and well oiled supply chain machine by registering 1,250 trucks in December 2022, but still short of the 1,521 the brand managed to achieve back in June 2022.

Isuzu also dominated the medium duty sector and gained a considerable lead in market share, up to 46.4 per cent (in December it topped out at 52 per cent). These figures are aided by the ongoing hiatus in truck sales of some models for Hino, as the company works through its emission testing issues.

The Australian Renewable Energy Agency (ARENA) announced $20.1 million in funding to Team Global Express (Global Express) towards a $44.3 million project, the ‘Depot of the Future’, to integrate battery electric vehicles within its transport and logistics operations.

The order from Team Global Express is the largest order, to date, globally, for Volvo medium duty electric and the largest order

of electric trucks in Australia so far. 36 Volvo FL Electric have been ordered. These will be equipped with four 66kWh battery packs and utilise a 600-volt single motor electric drive system with twospeed automated transmission and a range of up to 300km, a GVM of 16T. Payload for the quad battery FL is expected to be 5,900kg in this application.

24 all-electric Fuso eCanters are

Jason Button, who works for CHS Broadbent, was named as the winner of the 2022 Craig Roseneder Award. Jason has been Maintenance Manager to CHS Broadbent for 8 years and has been in the technical and maintenance field for more than 30 years.

During his time at CHS Broadbent, Jason has implemented a system that has significantly

reduced down time for large fleet of vehicles. He also introduced an automated safety management system.

As the winner of the award, Jason will travel on an allexpenses paid trip to the US to attend the US Technology and Maintenance Council’s 2023 Annual Meeting and Transportation Technology Exhibition.

also part of a carbon reduction project. The pioneering eCanter was the first electric truck from an OEM in Australia and is designed for local distribution in high-density urban areas using six liquidcooled lithium ion batteries with 82.8kW/h of energy storage. Power output is rated at 135kW, while 390Nm of torque can be delivered the moment the accelerator pedal is pressed.

Mercedes-Benz Trucks will begin a local validation program for the zero emission eActros in Australia and New Zealand this year. An all-electric eEconic will also be subject to a validation program in Australia.

Four eActros and one eEconic electric trucks have rolled off the production line and will operate with a wide range of fleets in Australia, while one eActros will operate in New Zealand.

Both Mercedes-Benz electric trucks have received full approval to operate on Australian roads as both have been designed to fit within our region’s width restrictions. As a result, there are no operation restrictions and customers do not require any specific permits regarding Australian Design Rule exemptions for the Mercedes-Benz trucks.

MaxiPARTS Engineering Support Manager, Greg Brown was awarded with the 2022 Castrol Vecton Industry Achievement Award. He has been with the company for more than 30 years and been an active member of Australian Trucking Association’s Industry Technical Council (ITC) and plays a lead role with the ATA-ITC rigid drawbar Converter Dolly project.

NatRoad welcomed a long-awaited Productivity Commission (PC) report calling for broad reforms to Australia’s waterfront. The report identifies inefficiencies at the country’s big container ports that directly cost the economy about $600 million a year. The report finds “considerable variation” in Australia’s container terminals that have large impacts on businesses and consumers. Sustained disruptions to imports or exports magnify these costs across the economy.

“The point is well made that there’s a lot to be gained by making some practical and incremental

operational changes,” said Warren Clark, NatRoad CEO. “For example, truck operators have no choice about which terminal they use when picking up or dropping off a container, so must pay whatever price a terminal operator sets.

“Soaring increases in terminal access charges have flowed through to cargo owners (and consumers). The PC says voluntary protocols to address terminal operators’ abuse of market power should be strengthened and NatRoad endorses a proposal to regulate landside port charges by way of a federal industry code.”

A new $41 million injection of road repair funding by the Victorian Government is welcome but heavy vehicle operators need to keep reporting damage as it becomes apparent, according to NatRoad. It says truckies must continue to be the eyes and ears of state and territory road agencies as floodwaters recede and new road dangers emerge.

“The Andrews Government’s

roadworks commitment now stands at $165m but the extent of repair bills right around Australia isn’t yet clear,” said NatRoad Chairman Paul Fellows. “The best thing operators can do is keep reporting issues to the relevant transport authorities, whether they be states or local councils. Stay active on your UHF radio and let other operators know when you see a new road issue.”

Bendix’s Protrans HD Disc Pads have been specifically developed for high stress applications such as the stop and start conditions experienced by waste collection trucks, concrete agitators and buses working on inner city routes. The pads also feature Titanium Bedding-in technology to further reduce installation time as they’re ready to use without a bedding in procedure.

Protrans HD Disc features friction material that is formulated to cope with the high temperatures found in constant braking environments at high GVM loading, overcoming any fear of premature wear.

The National Heavy Vehicle Regulator (NHVR) has registered a new national code of practice developed in partnership with the Australian Livestock and Rural Transporters Association (ALRTA) to reduce the hazards and risks associated with effluent spillage during the transport of livestock.

“The ‘Effluent Code’ is a practical guide that helps livestock transporters and other parties in the livestock supply chain meet their primary duty and other obligations under the Heavy Vehicle National Law (HVNL) when managing livestock effluent during road transport,” said Sal Petroccitto, NHVR CEO.

“It combines industry knowledge and experience in suggesting measures to minimise effluent loss that can be implemented at each stage of a land transport journey –from preparing livestock for transit to unloading – without impacting animal welfare. I’d like to congratulate ALRTA and the other parties involved for addressing this difficult issue and helping make the livestock transport task safer for all road users.”

ALRTA President Scott McDonald said ALRTA had worked with a wide range of stakeholders – including livestock producers, transport operators and drivers, vehicle manufacturers, agents, saleyards, feedlot managers, processors, regulators, animal welfare advocates, government agencies and the community – to develop a code that was both practical and workable.

The new electric heavy-duty truck from MAN is already seeing high demand before the start of production. German transport giant, DB Schenker is driving forward the electrification of its fleet and road freight transport. It plans to add 100 new MAN eTrucks to its fleet by 2026. The first vehicles are to be handed over in

The National Heavy Vehicle Regulator (NHVR) has partnered with AFAC, the National Council for Fire and Emergency Services, to deliver a fatigue exemption notice enabling emergency service agencies to manage vehicle operations more effectively while preparing for emergencies.

NHVR CEO, Sal Petroccitto, said the National Heavy Vehicle Volunteer

Emergency Services Work Diary and Record Keeping Exemption Notice 2023 (No.1) – which comes into effect on 1 February – will exempt drivers of fatigue-regulated vehicles from Heavy Vehicle National Law (HVNL) work diary and record-keeper requirements when they are performing an emergency management activity for emergency services.

the first half of 2024.

“DB Schenker and MAN are walking the path to an electric future together,” said Alexander Vlaskamp, CEO of MAN Truck & Bus. “We are very pleased to have our first customer for the new eTruck. The demand in the market for this fully electric vehicle is already enormous.”

CMV Truck & Bus Derrimut have become Australia’s first fully certified Volvo Trucks Electric Vehicle (EV) Dealer in Australia. A team from the Workshop, Parts and Sales departments at CMV Truck & Bus undertook extensive training to become the first certified Volvo dealer in the country.

“We’re thrilled to have achieved all elements of Volvo Group’s rigorous EV certification process, allowing us to be the first certified Volvo Truck dealership in Australia” says Ross Greig, CMV Truck & Bus Derrimut Branch Manager.

CMV Truck & Bus Derrimut’s investments in these facilities and equipment has been made in order to service and maintain electric vehicles, with the site including dedicated bays for servicing electric trucks in addition to on-site charging stations.

Goldstar Transport has added the zero emission electric Fuso eCanter to its fleet. Goldstar Transport Managing Director, Sean Carren, runs the Perth-based company, which employs 400 people and has a fleet of more than 150 trucks. Sean says Goldstar Transport is pleased to invest in advanced trucks such as the eCanter.

RIGHTHAND

“Goldstar really strives to look after our people and give them the best equipment to do the job and the eCanter is part of our ongoing commitment to our people,”

explains Sean. “We have a social responsibility to do our bit and a quality product like the eCanter makes that a reality.”

The eCanter has a GVM of 7.5 tonnes and uses six liquid-cooled lithium ion batteries mounted in the eCanter frame to store 82.8kW/h of electricity (with 66kW/h of usable power) and feed a permanent magnet synchronous motor. Power output is rated at 135kW and 390Nm of torque can be delivered the moment the accelerator pedal is pressed.

In a commentary article from Global Volvo Group President, Martin Lundstedt, he says the proposed introduction of Euro7 is a mistake.

“We are powered up and on our way towards rapid decarbonisation of road transport in Europe, its biggest transformation yet and a technological turning point in its history,” said Martin in the article. “But our ambition and this development are now in political limbo with the Euro7 proposal for new pollutant emission standards for trucks and buses. As both a leader of a global manufacturer of trucks and buses, and representing the EU commercial vehicle industry in my role as Chairman of ACEA (European Automobile Manufacturers’ Association (ACEA)), I am deeply worried.”

When I took over the business, I think we had 11 trucks and 25 trailers, and now we’ve got 22 trucks and 50 trailers and dollies,” says Mitch Kelly, who now runs John Kelly Transport. “So, we’ve grown a lot in eight years and that’s been hard to manage. We’ve had to expand into freight management software which we’ve just gone through in the last 12 months.

“We’ve done away with the old connote books and everything’s online. Now we’ve got the freight management and we’ve got a long-haul console, so we can build loads on the computer, all integrated into one system.

“When I started running the show, my main goal was to build the company, increase our turnover, increase our profit margins, and start getting our own primary freight, which I’ve done. We do a mix of that; we complement some jobs with other jobs and we still do a lot of subcontracting work to bigger customers.

“We really pride ourselves on providing a really good service. We do that by making sure that the drivers are looked after and by trying to help them out as much as possible by minimising waiting time. It’s not perfect and we still have it every now and again but we’re doing our best to try and combat that.”

When an operation grows the business in this manner the owner has to keep looking ahead and maintain a clear strategy around the issues which come along with that growth. Mitch and his team have had a good look at the skeleton of the business to make sure it can support further expansion. It is important to look into the relationship with its financial structure and ability to manage cash flow.

“When your accounts receivable goes from $400,000 to over a million, there’s a lot of money to look for and that was one learning curve for me,” says Mitch. “Then the next one was trying to keep track of all the movements, all the paperwork, and that’s where the freight software system came in.

“We’ve just gone through that now, and I’m happy with where we are at the moment. Twelve months ago, I wasn’t, I was really stressed, it was all getting

out of control. Everything got too big, too fast, and it was just really hard to manage.”

The growth came from a number of factors coming together. Customers’ businesses were taking off, other trucking operators pulled out of the general freight market in Toowoomba, there were potential customers looking for another option, and Mitch is one of those people who hates to say no. However, he has had to learn to say that word more often, it’s just been so busy.

“At the start, people would come and see me and even if it seemed a bit too hard and outside of what we normally did. I was like: Stuff it we’ll have a go at it,” says Mitch. “We’ll try and make it work and we’ll do those smaller jobs. Then they grew into bigger jobs and then customers’ word of mouth gave us more growth.

“One of our biggest customers – we started off doing one or two movements a week for them. Now we’re probably doing 20 to 30 full trailers a week. Everywhere from Cairns to Adelaide, Sydney and Melbourne. We’re just grabbing the bull by the horns and having a good go at it.”

The business was started by John Kelly, Mitch’s grandfather, in 1974. They will be celebrating the business’ 50-year anniversary in 2024.

“We’ll probably do up a few trucks to mark the anniversary in style,” says Mitch. “We’ve got a different logo with a 50th anniversary ribbon on it. We’re currently prepping for all that sort of stuff.”

Before starting up on his own in the 70s, John Kelly had been working for the Anderson family. Cyril and Curly Anderson were Western Transport, an iconic yellow fleet of B model Macks from the Darling Downs

“He used to do the run down to Sydney in an old B-model V8 Mack with a fridge van,” says Mitch. “Then he used to bring ice cream home for Pixie Ice Cream to Toowoomba. When he retired, he took on a general store in Toowoomba but he sort of got itchy feet. He missed driving trucks and he went out and bought a little truck and started doing a run to Brisbane for groceries fruit and vegetables and stuff.

During a period when many multi-generational trucking businesses are selling up, it’s nice to find a thriving thirdgeneration operation looking to the future with prospects to grow. PowerTorque talks to Mitch Kelly at his home base in Toowoomba, Queensland.

“From a small operation picking up produce for the general store in Toowoomba it grew as people wanted other goods picked up from Brisbane. Then it sort of went on from there and he started doing a lot of work for Ansett and then NQX, with the Macks and the old UDs, and then it just went on from there.

“Then, we started doing Adelaide and we’ve always done a lot of Adelaide, for a long time and a little bit of Perth and Melbourne, and now we’ve branched into Sydney. We probably do 10 or 11 loads a week into Sydney.”

By the mid 90s Mitch’s Pop retired, he had become ill with diabetes and that’s when Mitch’s father took over. Since then he also retired from working in the transport business, going over to help with the general store in 2015.

Before taking on the business Mitch worked for someone else for a little while. He also tried university but couldn’t come to terms with the lifestyle and left. He then did an accounting diploma at TAFE. Later, he jumped into a body truck doing runs up to Kingaroy and claims that was the hardest job he ever had. He was 18 at the time and would start at 2am. Some nights

he didn’t finish until 8pm and would go home, get up and do the whole thing again.

“Everyone had pressured me into finding something else but it was my passion,” say Mitch. “When I was in school, I could hear a truck go past and could tell you what motor it was just from the sound of it. When I came back into the family business, I got my single licence, just doing local stuff, to Moree, out to Roma delivering chemicals, doing the cotton.

“That was a bit of an apprenticeship for 12 months. Then I got my MC and I was doing a lot of road train work out of Moree and Dirranbandi. Then I started doing Adelaide and Melbourne, and I did 10 years of interstate before I came off the road. I still love jumping in a truck and having a go.”

The John Kelly Transport business handles the chemicals, building supplies, plus a lot of work for Toll. It runs nine B-triples and road trains a week into Adelaide, loaded with freight from a wide selection of its customers. Loaded singles and B-doubles are consolidated in Toowoomba into the larger combinations for the haul South-West.

B-triples are able to run straight into Adelaide, unloading at a small, rented depot there. There is one employee based there, who organises all the trucks and loads in and out of Adelaide. This has become much more simple to manage using the freight management software, enabling them to plan and organise movements.

All of the work going elsewhere is full loads heading out from Toowoomba to their destination. Two or three full loads head into Melbourne each week, direct into customers premises. Return loads tend to be full loads straight back out. There is one road train direct into Melbourne each week running on Performance Based Standards, at 36 metres long.

South Australia has good access since it opened up all its road networks, making life a lot easier to run B-triples right into Adelaide.

“It’s given us the opportunity to be able to run at a profit and run three trailers instead of two,” says Mitch. “With two trailers, we didn’t have the time to swap trailers, it would add another hour or so, because of our time critical freight, but now it barely adds any time at all.

“We do a road train over to Perth every fortnight, for another customer.

We deliver confidence. We deliver it by the truckload, because we know companies can’t thrive without it. Penske is built around helping your day-to-day operations run as smoothly and efficiently as possible. Our commercial rental solutions will help you carry the load so you can focus on your core business.

The Northern Territory is really the only state we don’t service at the moment.”

In 2017, Mitch decided the business was switching over to Kenworth and Cummins as the truck and engine of choice.

“We had Freightliners with DD15s and then, I switched over to Kenworth and the Cummins engines,” says Mitch. “We’ve had Cats, we’ve had them all, we used to have Macks years ago. Realistically, the changes just came through with me.”

“I bought a lot of Kenworth T610 SAR trucks to do the Adelaide work and the B-triple work and they are smashing it, they’re fantastic. I highly rate them, the drivers like them. They’re comfy and they’re a bonneted trucks still.

“I’ve got a couple of manuals and we’ve got eight autos now, the ultra shift. I like them because of the fuel savings. We’ve got the Cummins Eaton ADEPT on them and we’re running them as down speeds, so they are 3.07:1 diffs. They are running B-triples at 80 tonnes sitting on 1400rpm, or thereabouts, all the way to Adelaide. It’s fairly flat road and they just plod along. With the Cummins Eaton ADEPT, they neutralise when they’re not using the engine.

“With the older trucks, we were putting in between 1250 and 1400 litres for a B-double from Adelaide to Brisbane. With the 610s, with the ADEPT in them, we’re putting in 1150 litres in at Adelaide with a B-triple, and it uses 1200 litres back into Brisbane. So, they are 100 to 250 litres a leg better off, and we’ve got an extra lead trailer.”

Even with the addition of the adblue needed on the newer Cummins X15 engines, the 1.85km/l is a major improvement on the previous trucks used.

“I’m definitely open to other options, I’m not blind,” says Mitch. “If there’s something out there that claims to be better fuel economy. I’ll give it every chance I can to make sure it is for real.

However, the Kenworth has other value for the business and workforce attraction is one of the reasons behind going with the brand.

“You can get that many blokes interested in them and people bang on about them,” says Mitch. “They look great, but they are great to ride in and they are smooth trucks. I used to think that they’re rough, because that’s what

people said, but when I got in one it was so smooth.”

The larger T909 trucks are manuals as is the Legend and a couple of the T610s, the rest are AMTs. This year will see another four trucks arrive as part of the business’ continued expansion.

“COVID changed our plans,” says Mitch. “I was happy at around 16 or 17 trucks and now we’re at 22. I’ve got four more coming. So, we’ll be at 26 in another six months’ time. That’s only because of the demand that we’ve had. I would have loved to have gotten rid of four or five of the older trucks between now and then.

“They’ve all had new motors in them now, new clutches and gearboxes. We do spend a lot of time and money on maintenance. I’ve got a full-time mechanic and we’ve got another mechanic, who’s a contractor, that we bring in, depending on what’s happening, two or three times a week. Outside of that we outsource it to Brown and Hurley, we’ve got a permanent booking every week there, if we need to, we book trucks in with Daimler.”

“We’ve got a fairly young crew. We’ve probably got two extremes, but I’d say that we’ve got a group between 23 and 35, and another group of 50 plus

While no one can predict the future with absolute certainty, we’re confident it’ll be brighter with the new Scania Super. Our new powertrain has already gained a reputation for not only providing the smoothest drive on the road but also being the most fuel efficient in it’s class. Our new 13-litre platform, which now extends to 560hp, delivers a fuel saving of at least 8 %* allowing you to increase your fuel efficiency while also reducing greenhouse emissions.

But it doesn’t stop there. As with our new V8 engine family the Scania Super 13L engine can also run on B100 biodiesel**, further reducing your CO2 emissions by up to 80% with no adverse impact on engine performance.

So if you’re ready to meet the commercial and environmental challenges of today and tomorrow, you’re ready to meet the all new lean green Scania Super.

Contact your nearest Scania Account Manager or go to www.scania.com.au to find out more.

drivers, then maybe one or two in the middle. We actually have a fairly young crew. I’ve had a few young blokes that have given me a few grey hairs, and I’ve had plenty of old blokes give me some grey hairs too.”

Coming out of the crisis around COVID has brought challenges to the business it did not expect to deal with. After the initial shock, when it became clear the transport industry would continue even during shutdowns, operators knuckled down and kept the wheels turning. However, coming out of the pandemic has been a shock for many businesses.

As the economy emerged from the crisis, another one developed as the global supply chains couldn’t keep up with demand, and shutdowns elsewhere in the world meant limited imports of equipment and components.

“Instead of being told a new truck will be here in three or four months,

it’s going to be here in years now.” says Mitch. “We’ve had to plan ahead. I’ve put in orders for what I foresee for the next three years and everybody seems to be doing that. That’s compounded their issue. I wouldn’t have ordered trucks for three years away if it wasn’t needed.

“You can see why some of these companies that might not have another generation coming through who are interested in running the company. If they’re going to get out in the next few years, they might as well get out right now.

“There’s a lot of big companies like that out there, which is probably going to put even more pressure on the on the freight task. Who knows what’s going to happen, there is a lot of expertise walking out of the industry. They’re just putting the trucks up for auction because that’s where they can get the best money right now.

“I know a lot of companies couldn’t

get decent drivers. It’s so hard to get good staff, underemployment is through the roof. It’s the worse we’ve ever seen it with that many jobs available. The only young people coming through are those that have a family legacy and passion for it as opposed to the ones that are there just to grab money that don’t actually have a passion for it. It’s pretty hard to get them to actually be a good operator.”

It’s not just a job, it’s a lifestyle, reckons Mitch, and he would like to see some sort of apprenticeship development. There’s also a need to pressure the insurance companies to accepting those apprenticeships without massive excesses. He would prefer to take someone on who has been through an apprenticeship and is 20-years-old, and would let them jump into a truck, rather than someone who’s 30-years-old, completed a one-day course in Brisbane and thinks they’re a truck driver.

The 11L Quon just got even better with its latest enhancements improving its already outstanding performance.

The upgraded driveline features an, improved ‘GH11 Engine’ with increased horsepower and torque, and the legendary ESCOT 12-speed automated manual transmission is now even better with new software enhancements that have to be tried to be believed.

These upgraded features have the added bonus of delivering an even smoother ride for comfortable driving with minimal fatigue.

For over 85 years, UD Trucks have delivered ultimate dependability. No wonder this is the truck Australia trusts.

To find out more, contact your UD Trucks dealer on 1300 BUY A UD or visit udtrucks.com/australia

The latest on offer from the MAN brand brings the range up to date; they tick all of the boxes, but the question remains in the B-double market: Is the MAN a contender? Tim Giles takes the latest model out on the highway to test its credentials.

Anew model and a new engine is always an exciting period for a truck brand. The arrival late last year of the TG3 for MAN was a big event, the range had been voted as the International Truck of the Year for 2021 after its launch at the start of the Covid pandemic in Bilbao, Spain, and was well received in the European truck market.

The time lag between that original launch in Europe, in 2020, until its arrival here does not help, and this has been the case for the brand over the years. In the past, MAN have seen high selling models on the European market arrive here a couple of years later and fail to engender a lot of excitement among Australian truck buyers.

There is no doubt about the truck maker’s design and engineering finesse and its ability to put a truck

together well. If there is one aspect of the truck’s development which may have hampered the brand’s progress it is probably an unwillingness to adapt a European design to Australian conditions.

The arrival of this new set of models for MAN presents the brand with an opportunity for a paradigm shift among potential Aussie buyers by demonstrating the effectiveness of these new technologies and designs in an Australian context.

Although on the outside, as you walk up to the truck, it retains a similar shape to its predecessors, the details become more obvious upon closer examination. There are tweaks to the exterior to improve airflow and overall aerodynamics, including a curved profile down low on the door to reduce spray on the side windows.

The catchphrase MAN use for the cabin is ‘driver fit’, emphasising the number of innovations and redesigns included in the TG3 range which are there because research has demonstrated their effectiveness for drivers.

Inside the cabin, the look has been transformed. There are a series of smart ideas included in the new cabin interior. One of the most practical changes is a bank of four switches positioned down low on the inside of the door which can be accessed when the driver is standing on the ground, and can be configured to activate hazards, light checks, work lights, or whatever you choose.

From the driver’s seat, there are

a number of innovations to be seen. Of course, the steering wheel now has a wide array of buttons, and the gear control and engine brake are on a stalk on the right-hand side of the steering column. The 12.3-inch digital display immediately in front of the driver features crisp visuals as well as a configurable layout.

Probably more intriguing is the triangular control sticking out of the dash to the left of the driver’s knee, with a shape having more than a hint of the fictional USS Enterprise starship about it. This is the MAN SmartSelect and it is used to control the information screens. The smartness comes from the fold out handrest which enables the driver to

“IT IS CLEAR TO SEE, FROM BOTH THE DRIVELINE PERFORMANCE AND THE DESIGN SMARTS INSIDE THE CABIN, WHY THIS MODEL HAS BEEN POPULAR IN EUROPE. THE CONUNDRUM IS WHETHER THAT ACCEPTANCE WILL BE REPLICATED HERE IN AUSTRALIA WHERE THE MAN BRAND HAS STRUGGLED TO MAKE ITS MARK.”

rest their wrist on this fold-out while driving. Even in bumpy conditions it is possible to smoothly switch between menus on the screen using the simple controller. This is clearly smart design with the driver in mind.

The truck tested in this run, up and over the Cunningham Gap out of Brisbane, followed by a descent down the old Toowoomba Range crossing, is fitted with the D38 engine which meets the Euro6e emission regulations.

Power comes out at 640hp (477kW) from the 15.2L engine and it produces 3000Nm (2213 ft lb) of torque.

Emissions are controlled using SCR

and EGR, and the engine is fitted with a two-stage turbo.

With a loaded B-double set the truck began climbing Cunningham’s Gap after coming out of Brisbane and kept up a good pace, around 44km/h at 1650rpm. The quality of the torque available is clear and the truck settles down quickly to get the job done, with minimum fuss, it never rushes anything. The driver can just let it lug its way up the grade and it just continues to pull. Because the control systems are precisely monitoring everything all of the time. The driver has to leave old perceptions behind and learn to trust it.

It does not feel like the D38 engine is overworking itself at all. It’s clearly got

more capacity available. The engines are built to cope with a control system, which will keep it below 1600rpm, at the point where horsepower will match torque. Watching the truck haul itself up the varying gradient on the Gap, it obviously likes a point around 1600rpm and changes to get into its comfort zone.

This change to running trucks at lower rpm ranges has two factors behind it. One is the fact that the extremely sophisticated control of diesel engines has reached a point where it can cope with the strain put on an

engine hauling 60 tonnes up a climb in high temperatures. The second factor is that after many decades of talking about fuel economy, the trucking community in Australia is genuinely looking for frugal fuel use.

There is now an expectation that a B-double prime mover will achieve 2km/L all of the time. Whereas, in the past, they were happy with 1.65km/L.

The engine meets Euro6e emission limits and the control system which help the engine meet them also give it the flexibility to meet the challenge of a climb like the Gap. This is illustrated at the very top of the grade when the trailers are still hanging down the hill and the final kick of the climb tests even the best truck. This MAN lets the truck drop down to 33km/h and it just hangs on over the top in eighth.

Once over the top another strength of this latest design comes into play, the excellent retardation from the engine brake, the EVBec, which MAN claim generates 840hp of stopping power. This is a very high number for a compression brake to offer, but in the drop off the top of the Gap and then the steep descent of the old Toowoomba Range, the Brakematic, as it is known, showed just how much control it offers to the driver in a situation where control is paramount.

The engine brake has the exhaust flap positioned upstream of the turbo, allowing it to generate more back pressure when activated. The airflow creates an increased turbine speed on

the exhaust side, which, in turn, ups the intake side speed. Pressure level overall increases and the effect of the braking increases correspondingly.

That’s the theory, and the practice bears this out. The engine brake doesn’t have to be finessed to avoid overbraking when on a descent. It’s not a matter of full engine brake and see if it holds, it’s more about modulating the brake to maximise speed down the grade while retaining full control and the ability to pull up if required.

At the top of the old Toowoomba Range the driver just has to apply the brake, and the system knows that they don’t want to go any faster than that. The driver is setting their speed at the crest of the hill and for 5km it is able to hold that speed going down the grade.

There is no need for driver intervention to help maintain the speed, no riding the brakes. The sensation is different, the driver presses the brake to signal the speed and then the trucks overruns a little bit and then pulls it back to a km/h that they’ve set.

The descent of the Toowoomba Range saw the truck passing most of the other trucks heading down the grade but able slow down or speed up, at will, just using the control switch. The service brakes were not needed even when having to slow behind another truck before being able to overtake.

This model is fitted with an all-new cabin interior and although it has

Meet the DAF XF – its proven 530HP MX-13 engine offers the perfect balance of power and efficiency.

When you’re driving coast to coast, the DAF XF is a quieter and more comfortable place to work, live, and sleep.

a familiar geography, it has been upgraded for the TG3. It uses full digital screens, both in the cockpit display, as well as to the left-hand side of the driver. The main 12.3-inch digital display, is one display, but it can be sectioned off into two separate screens.

Using the SmartSelect control the driver can go through the categories then hit the button at the top to select down to a sub-menu where the driver can find the item they want. This control proves to be easy to use even on some of the rougher roads because of the smart design of the handrest – something which probably originated in the luxury car side of the Volkswagen empire.

The control also features a break away hinge on the fold-out handrest, so that if a driver knocks it when it is folded out, it simply drops away undamaged. It’s designed well both for longevity and ease of use.

It also proves to be very easy to navigate around the sections and options. The driver can flick from navigation to the entertainment options or go to a split screen with a map on

one side and a list of music tracks on the other. The driver can control their phone through either the entertainment screen or the steering wheel controls.

The steering system is augmented with an electric input which gives the driver a slightly stiffer steering feel when driving down the highway. However, at slower speeds and when manoeuvring, the electric input makes steering easier and more precise. A system using this electric control to kick the truck back into the lane will be an option into the future.

The upcoming legislative requirements to include autonomous emergency braking in new trucks sees MAN include a full package of the latest safety systems in the new TG3 models. These include the Electronic Stability Program (ESP), which has been with us for some time, but has been augmented with a long list of other systems, most of which have the usual abbreviations.

There’s the Brake Assistant that optimises braking pressure and gives 100 per cent braking when an emergency stop is activated. Then we

have EBA, Emergency Brake Assist, which warns of collisions using radar and video and will activate retardation and emergency braking.

ACC is active cruise control, maintaining a set speed and then maintaining a safe distance to vehicles in front of the truck, also using the video and radar. LGS is the lane guard system which warns a driver drifting out of their lane.

These systems are becoming more and more familiar as they now appear in every brand of truck. They are also becoming easier to use as we are already into the second or third iteration of many of the modern electronic aids.

From the driver’s seat the way to monitor and control electronic equipment is made quite simple in this well-designed cabin interior. It is clear to see, from both the driveline performance and the design smarts inside the cabin, why this model has been popular in Europe. The conundrum is whether that acceptance will be replicated here in an Australia, where the MAN brand has struggled to make its mark.

The revolutionary new Volvo FL Electric

At Volvo Trucks, environmental care has long been central to our vision of the future. We care passionately about the world we live in, and as the shift towards electric vehicles gathers pace, we are more committed than ever to driving progress.

We are thrilled to announce the launch of our all-electric medium duty truck range for Australian transport operators.

The new Volvo FL and FE Electric medium duty range meet the demand from society and customers for dramatic cuts in CO2 emissions. To simplify the transition to sustainable transportation, the trucks are offered together with service and support packages for electromobility needs.

We are proud to partner with you in the transition to an electric truck future. Learn more by visiting www.volvotrucks.com.au/electrictrucks.

Volvo Trucks. Driving Progress

Marcay Transport is always searching for higher productivity in hauling grain and fertiliser in rural areas of country Victoria and Southern New South Wales. Its operations, however, are hampered by complex rules and interstate differences.

Based in Bolwarrah, about half an hour out of Ballarat in Victoria, Mark and Kaye Rix run a small rural bulk freight business from their small property on the edge of the settlement. This is rolling agricultural land and the local economy is based around small enterprises providing services to the agricultural community.

In this case, the business hauls grain out of the surrounding country, following the harvesting and transporting seasons around most of rural Victoria and across the River Murray into the Southern parts of NSW.

“We cart mainly grain and fertiliser around Victoria and Southern NSW,” says Mark. “We have a lot of regular work but it’s all over the place. A different place every day, although you might get a couple of trucks going to one place and carting out of there for the week. In the main, the trucks are pulling grain out of the Graincorp system, into the Port in Geelong.”

Mark started out in life as a spray painter by trade and then drifted into truck driving and back again into painting, before deciding to give it a go. Then when he decided he was going to drive trucks full time for a

living, he also decided he might as well do it for himself. The operation started life with the one truck and has now grown to a fleet of eight trucks. With the majority of tasks emanating from GrainCorp the balance is made up from other buyers and agents, however, the Graincorp work keeps the wheels turning. The fertiliser haulage comes through via an agent out of Benalla. The loads out of the Port, when they are available are mostly fertiliser, but there is also lime from January to April, in most years. Seventy-five per cent of the time the trucks return to country areas from the coast empty.

“Up until a couple of years ago, it was pretty ordinary, because everywhere had been in drought,” says Mark. “We had a 2016 and 2017 which was big, there was heaps to do. Then 2019 started to taper off. Then we had a couple of pretty ordinary years and that’s when the good old COVID hit.

“After that China stopped buying grain. It was pretty bad for three or four months. Which, looking back, probably wasn’t a bad thing, because I think a lot of people realised they had to find more markets than just China.

“It hasn’t been a bad thing, but it certainly was at the time, because everything just went to zero, practically overnight. The phone stopped ringing and everything just stopped.”

The Marcay fleet runs a mix of fiveaxle truck and dog combinations pulled by Freightliner Coronados and

the rest run as B-doubles. The trailers used in the fleet are a mixed bunch with some arriving second hand and others built specifically for Marcay.

Having grown to this many trucks, Mark can no longer be on the road all of the time. He and his son perform all of the heavy vehicle maintenance across the fleet. To compound the situation, there is a need for some relief with the driving – there is more than enough work to get on with for the business owner.

“The only thing we don’t do is rebuild motors, they go back to the manufacturer,” says Mark. “My son does a lot of it and we do all our tyres as well.

“The thing is, if we didn’t do all of our own maintenance and tyres, out of eight trucks, you’d have one off the road every week for a couple of days at least. You don’t want them off the road, and then you’re paying drivers to sit at workshops to get jobs done. The downside for us is that we do most of it on Friday, Saturday and

The business started back in 1998 with the first truck being a Kenworth, but when, some years later, Mark was looking for his first new truck, Freightliner offered him the best deal and he has pretty much stuck with them ever since.

The fleet runs three Cascadias, but the trucks over the years have included Century Class, Coronados and Columbias. The Coronados are the truck and dog combinations and the others, the prime movers, are now all Cascadias, bar one.

The engines used have been a mixture including Caterpillar and Cummins, but since 2007 most new trucks have consistently been fitted with Detroit engines. The last nonDetroit engine was a C12 powered Columbia, which was sold last year with two million kilometres on the clock.

One of the Cascadias is the 126inch cabin with a 48-inch bunk. Meanwhile, another couples the 126 with the 34-inch bunk and there’s also a 126 with the 60-inch bunk. The engines are all specified the same at 600hp with the Detroit DT12 AMT.

“You’ll never get your diehard Kenworth bloke into a Cascadia,” says Mark “I’ve got a mate who’s very Kenworth orientated and he had a Cascadia on demo for two weeks. He loved it, but said he can never buy

“THEY WANT US TO BUILD HIGHER PRODUCTIVITY VEHICLES. THAT’S WHAT THEY TELL US. THEY NEED TO REMOVE THE HURDLES. WE’RE ALL HAPPY TO BUY THEM AND ALL HAPPY TO RUN WITH THEM, BUT THEY NEED TO MAKE IT SIMPLE.”

one, because nobody would drive it.

“These trucks with the safety features on them, speak for itself. It really does matter and people need to grasp it and run with it. We bought our first AMT, which was a Gen2 back in 2005 and I haven’t bought a truck with a gearstick since. The Cascadia is so far ahead of the competition, in terms of quietness and comfort, as well.

“You buy what you think’s the best bang for your buck, and that’s why I’m happy with the Freightliner. I don’t monitor fuel as much as I should, but I check through them every fortnight and fuel use in the Cascadias is pretty consistent. It doesn’t fluctuate much, and they’re nudging around two km/L all of the time.”

“As far as the Detroits we have no trouble whatsoever, since the first one I bought. The Coronados have the DD15 and the Cascadias the DD16s. The 16 was a step up, probably quieter, and fuel consumption is better on the DD16 engines.

“Maintenance wise, on the first 500,000 I don’t even touch it. It’s part of the package. There’s no doubt it’s all incorporated into the cost of the vehicle when you buy it, but they’re still good value anyway. I get on really well with the team at Detroit, they have been fantastic. Always been good, couldn’t fault them.”

With any mass sensitive tasks like bulk tippers, the question of access and the type of combination which can work on any particular route is always critical to the success of the operation. Crossing borders into other states simply complicates the issue further.

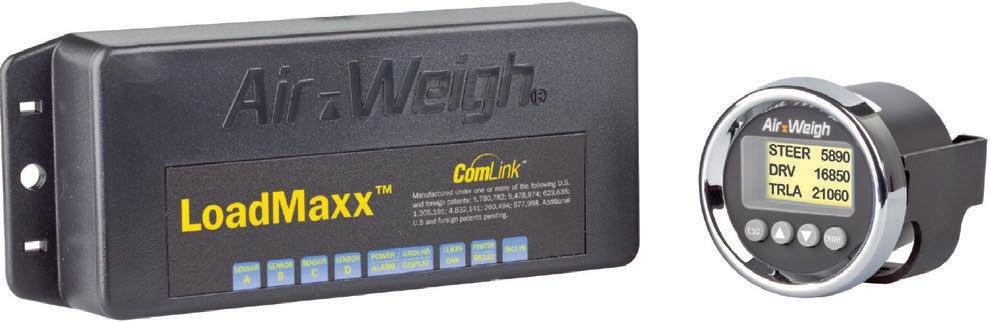

The fleet has moved over to working under HML rules and the trailers all have digital gauges, which can link into the VDaq system Marcay has had fitted in the trucks. This system is only needed to enable HML running in NSW.

Mark describes running in NSW

as a ‘challenging’, but admits, ‘it depends on what shire you are trying to get a permit in’.

“If you log on to look at the map system, you can see the stupidity of the whole system in NSW,” says Mark. “We had a couple of trucks which had to drop down off HML weights and go back to normal.

“This was because there was a road accident and detours in place. The detoured roads were not accessible for HML without a permit and it takes too long to get a permit approved.

“We were one of the first fiveaxle truck and dogs on the road in Victoria and one of the reasons I’ve moved away from PBS is because of the different laws when you cross the border. We started in 2011, when we built the five-axle dog sets and we’re now 2022 and the system still isn’t right. You’re still applying for permits to go places where you actually shouldn’t need to.

“They want us to build higher productivity vehicles. That’s what

they tell us. They need to remove the hurdles. We’re all happy to buy them and all happy to run with them, but they need to make it simple. With the five-axle dogs, now in Victoria, they’re pretty good. You don’t have to apply for many permits. Across the border, still has issues.

“We went back to B-doubles, because the system is still not right. If they want us to have these vehicles, they need to get the network right before we start buying vehicles to do the work.

This has become a major part of Mark’s work, simply organising where the truck can and can’t go. The operation bought the five axle dogs, and they’re not as useful as they should have been, because of access and permit issues.

The operation is not getting the utilisation out of a major investment that they should be.

According to Mark, the system functions in Victoria, but not in NSW. He has decided he will continue to apply for permits to run the trucks at HML in NSW, but will not apply for a permit, just for road access.

“You can drive a B-double or a road train in New South Wales on certain roads, but unless you get a PBS permit, you can’t drive a five-axle dog on the same road,” says Mark. “It’s like the A-doubles in Victoria, which are 30m road trains, that’s what they are. If they want us to run them. The governments need to get the system right.

“A lot of us in the industry, in 2013, when we heard the National Heavy Vehicle Regulator was coming, that it was going to be a national body, were very happy. The transport industry was excited about that, but it’s no closer to being national now.”

Mark and Kaye’s son, Ben, at 34 is a good mechanic working in the business, but has told his parents that when they want to think about retirement, he doesn’t want to take over the business. He doesn’t want any part of the problems around regulations and having to

deal with bureaucrats.

Getting drivers gets harder every year and the business does not have any answers to the conundrum around making the job attractive to young people. In fact, the age profile of the drivers they already have is better than it is for many fleets. The oldest driver in the fleet is 60 and the youngest is 35.

“No matter how much money you offer to pay, you can’t get them,” says Mark. “You’ve got to be realistic because you can’t pay more than what you can afford. We wouldn’t want to grow any more than what we are. But even if we wanted to, and the opportunity is there, we can’t find employees, we just can’t.”

“I honestly think the way the industry is heading as a whole if we can stick it out for another five years we’ll probably be doing good. It’s not going to get any easier to get drivers, unless the whole system changes, the whole compliance situation, everything has to change. It’s just not going get any easier.

“When we employ a driver they are always told that you will probably leave home Sunday and get home Friday, if you get home in between, that’s a bonus. Young people are not prepared to make a few sacrifices and the partners aren’t prepared to put up with it either.”

Every truck manufacturer in the world has to have an alt-power truck and some examples are starting to arrive in Australia. This time Scania goes electric and Tim Giles gets a chance to take the truck out for a test drive.

Demand for electric trucks in Australia is ramping up and the manufacturers involved are honing their expertise to be ready for the new technology when it starts to arrive in the years to follow.

It’s not just the new technology in the trucks, it’s also a different type of maintenance regime, ensuring there’s the right infrastructure to

support something like an electric heavy vehicle. There’s also an education process for the customers, bringing them up to speed on exactly how the new technology will handle their freight task.

This is the process Scania has engaged in to bring the first electric Scania, for evaluation and technician training, into the country. It will take time but operations like Scania need

to start preparing for the arrival of trucks in substantial numbers in the future.

The first introduction will serve as an evaluation vehicle and when the Scania organisation has become familiar enough with it, it will become a demonstrator for customers. So far, it has not had a body fitted because it has been busy visiting all of the dealerships.

Working on a battery vehicle is completely different, and Scania have had to rethink how they do everything to get the organisation prepared before it goes to market. There are many things to think about, like the provision at each site of a specially marked area where trucks with unstable batteries need to be placed, as a safety measure. There’s a whole different level of risk, one of those batteries has the same amount of power as the old electric chair.

Scania has always been a little bit more conservative than other truck makers and insists on dotting all of the Is and crossing all of the Ts before going to market.

“We are open for business on battery electric trucks,” says Ben

Nye, Director of Truck Sales at Scania Australia. “So, if people do want to order one, we’re set up correctly internally, if we sell one tomorrow and it comes back to us for work we know exactly what we have to do.”

The training means Scania now has M-techs, mechanical technicians, and E-techs fully trained to handle the electric technology when it arrives. When they work on a factory truck, they actually have to have two techs, one’s an observer and one’s a worker, as a safety precaution.

From Ben’s point of view, when trucks start arriving, customers will be able to work out the limitations of the technology in their business, from a payload perspective, and from a range perspective.

“WE ARE OPEN FOR BUSINESS ON BATTERY ELECTRIC TRUCKS. SO, IF PEOPLE DO WANT TO ORDER ONE, WE’RE SET UP CORRECTLY INTERNALLY, IF WE SELL ONE TOMORROW AND IT COMES BACK TO US FOR WORK WE KNOW EXACTLY WHAT WE HAVE TO DO.”So far, it has not had a body fitted because it has been busy visiting all of the dealerships.

“The first thing that we do before we quote is discuss the routes and charging infrastructure,” says Ben. Charging infrastructure is a growing issue for any operation considering electric trucks. Scania has sold a number of bio diesel gensets to those wanting electric truck and bus charging. The lack of capacity in the local grid has meant this is the only way to reduce emissions. They can use lower emission bio fuel to charge and get a better, more reliable power supply.

The evaluation truck Scania have been using is the 25 P, a 4x2 truck with a 16T GVM. Both Swedish

truck makers are bringing their smallest trucks in at the start of the electrification process as this is the sector of the market where the business case, and practicality of introduction, will make the strongest argument for the first move to an electric truck.

This truck come with five 33kWh battery packs (in Europe with longer wheelbases, you can get up to nine). This means the truck can carry 165kWh total when fully charged. The driveline includes the electric motor and a two-speed gearbox (AMT), producing 230kW (313hp) continuous and 295kW (401hp) peak power.

Just looking at this power rating

and the masses the truck is designed to carry illustrates the strength and the practical considerations which come along with electrification. With all that power, the driveline also gets full torque at the get-go. There is no torque curve, just a straight line. This means the driveline is more than capable of handling the task, but in some circumstances it has a too much and needs to be tightly controlled to get a safe and stable result.

All of that power and torque needs strict modulation to ensure the safe operation of the truck and a pleasant ride for the driver and freight. First impressions, the computer control on the takeoff is fantastic. It doesn’t

matter what the driver does, even if they floor it, it will just take off at about the same acceleration rate as an ordinary diesel truck. This means it is stable, safe and it’s not wasting power.

Then there is the deceleration phase, where the system uses the regenerative braking to recharge the batteries. In this case, using the two-speed gearbox, the truck has not got that same level of modulation finesse it has on the pick-up. It tends to be less smooth, especially if it’s decides to change gear. A gear change during deceleration seems to introduce a small jump in the driveline.

Out on the road, the truck is eerily quiet, definitely a lot quieter than the other electric trucks in Australia, which PowerTorque has been able drive.

In terms of visibility, this is excellent, the new P Series form Scania is definitely a city truck. It’s even got a quarter light behind the passenger seat, plus an array of mirrors around the cab.

The screen right in front of the driver is a different one to the diesel version and it’s set up for electric drive – no fuel gauge but the level indicator tells this driver the battery has gone from 82 to 72 per cent in the past few hour’s driving.

It is difficult to get a real impression of how the truck will handle, especially when the truck tested is a cab chassis which means that it’s light on the rear end but that’s perfectly understandable. On a couple of occasions, the 25 P had to pull up quite sharply when the lights changed quickly and the truck pulled up really cleanly, even with a wet road.

Trying to find the most economical driving style it was possible to accelerate and move up to travelling speed quite quickly, then when it was necessary to slow down, just take the foot off and get some regenerative braking out of the electric motor.

The engine brake has got five positions. On this test, with little weight onboard, position five is way too harsh. even four is still too harsh.

available, but they do occasionally. On a like-for-like comparison, there is no doubt which is more economical.

The future is not certain, but we can be sure that the technology in electric trucks is going to improve quickly, as the big players spend millions on research. Future models are going to be lighter.

At the same time, major companies are going to be looking for zero emission solutions. Government incentives are also likely to kick in and change the calculation around these trucks. City authorities may also start to charge carbon emitting trucks extra to work in the CBD.

Position one works okay, but position two is probably getting a bit more regenerative braking. It seems likely, with a load on, three or four would be prime candidates to get the best bang for your buck in conserving battery life. It is difficult to judge whether the retardation will bring itself in smoother in a real world, loaded situation.

This relatively low cab is a good design with a nice layout, well set up to run around in the city. It is so quiet that it needs some sort of warning sound for pedestrians in crowded urban situations. At pedestrian crossings, and traffic lights when setting off, this driver was just a bit nervous that people wouldn’t hear the truck coming.

Apart from the electric component, this truck is, basically, the same as any other Scania of this generation and it is just a comfortable drive.

Currently, the 25 P weighs 2.5 tonnes more than its diesel equivalent at this 4x2 configuration, with the sevenlitre engine. The tare comes out at just below nine tonnes, whereas the current diesel model is around 6.4 tonnes. This tells us the business case to go all electric is not there yet. The customer will be paying a lot more for a truck which can carry less freight.

There are plenty of trucks delivering around our cities which rarely need all of the payload

The move to alternative power is inevitable. PowerTorque sat down with Paul Ilmer, Vice President Emerging Technology Business development at Volvo, so he could explain how to start preparing a road transport business for electric trucks, and a for a future without diesel engines.

Although Australia is only in the early stages of the lowcarbon-emission transition, the preparation needs to be done now, by both operators and those in charge of the energy infrastructure.

The Volvo Group team is looking at existing customers and reassessing their business to see how electric could fit into the mix. It may mean starting again, if you want to run electric, the change in driveline behaviour or weight distribution may

cause operators to reassess their vehicle strategy. For example, an operator who uses a truck and dog, may find the electric version to be too heavy on the steer axle. They may need to move to a semi tipper, so Volvo will engage engineering to look at that.

“The thing that surprised me is how, in 99 per cent of cases, the demand is due to sustainability goals,” says Paul. “It is hardly ever the customer looking for an operational cost adjustment. It’s all around

corporate social responsibility, 99 per cent of the time.

“Customers are looking for solutions that give them a similar experience to what they have today. They want to talk to the same salespeople, they want to use the same dealer network, they kind of want to replicate what they have today. They want the trucks to be on the Volvo Connect portal. They don’t want a lot of switching complexity, they don’t want the disruption.”

Demand is increasing across the

board and the Volvo experience is that it is not confined to a particular industry sector. Transport operators around the country are setting sustainability goals, as well as monitoring gender ratios, diversity, their CO2 usage, recycling. Options like electric trucks feed into that.

This is not just a green sensibility, they’re also seeing a commercial advantage, driven by the large corporate customers who will also display in their boardroom and annual reports similar goals and metrics.

Volvo is waiting for the Government’s National Electric Vehicle Strategy due early this year which should give some certainty to the future direction. One of the options could be a price on carbon, which would alter the economic equations around alt-power trucks. Those on the electric truck route will already have the experience and knowledge to embrace these kinds of changes more quickly.

“There’s been a lot of commitments made. So, the National Electric

Vehicle Strategy is going to start to put some colour on what that looks like, and it’ll only increase the demand,” says Paul. “I think it should be up to the customer how they do the carbon abatement. Then if they choose electric, if they choose hydrogen, HVO renewable diesel, smarter trailer design, or whatever, I think it should down to the customer how they solve that.”

Volvo is going through a process of preparing its truck dealers because it has a launch program for its electric range. All areas of the business are involved to enable them to start selling in 2023. The company is working on the assumption that the regulations will happen. At the same time as trying to control as much as it can, it needs to be ready for the green light when it comes.

“We’re getting called to a lot of engagement pieces at the moment around ourselves and Daimler, primarily,” says Paul. “We speak together as a united front to say:

Volvo has got trucks, Daimler’s got trucks. These are here now, we’re not waiting for anything. That message seems to generate a lot of enquiries. It’s an exciting time.

“Operators are setting themselves a 10-year horizon, normally. They’re trying to map it out, within their operation, and a lot of our customers have a mixed fleet of applications. They’re trying to work out, from an electric perspective, what works, what works for hydrogen? A lot of it is the customer trying to understand, within their operation, what energy type is going to work for what application when. We try and lay the roadmap out to 2030. We can say, battery electric is going to be completely suitable here, and you wouldn’t put hydrogen into an application that battery can take care of because you’re adding cost, weight and complexity. So, you let battery take care of that.

“Then for any application that’s long and heavy, we’re saying, you’ll have a switch over into hydrogen in

the second half of the decade. For us, hydrogen is in the second half of the decade, but it’s too early to put a year on it. There’s so much R&D and testing and we need to work out what local adaptations we may have to make for our market because it is hot, with high average speeds and poor roads. But the lynchpin with all of this is the regulations.

“As soon as we get a regulation framework that supports zero emission trucks, what we’re hoping for is a lot more competition in the market. Competition builds confidence. Then we can see the development of recharging hubs, from private and government investment, with a growing population of electric trucks along the freight corridors. Then fast charging enabling those common freight corridors to become an EV corridor. But – they won’t invest until there’s confidence around a population of vehicles to take the energy or to take the hydrogen.”

“A lot of our customers are looking at a green ecosystem for themselves,” says Paul. “So, they’re looking at solar and charging trucks overnight, looking at battery storage to then use the energy that they have harvested during the day.

“The technology’s here now, it’s not difficult, and they’ve got big sheds with huge roofs. There’s an opportunity there. From an energy perspective, after they’ve paid off the investment, the solar is zero, it’s free energy.”

The perception is that maintenance costs are lower because there’s less maintenance required. However, at this point in time, all of the electric trucks Volvo have supplied in Australia are under a service agreement, a more secure option for companies putting their toe in the alternative power waters. There are few facilities able to service the latest electric trucks.

This level of security is in the

nature of the transaction, for now, an electric truck owner can’t go to Joe around the corner and get a truck fixed. These concerns are going to make the fully maintained contract more attractive.

The increase in the number of electric trucks is going to change the nature of the truck maker’s relationship with its customers because currently quite a lot of customers prefer to work on their own trucks. In the transition to electric, the trucking operator is probably going to become more reliant on the truck dealers with specialist staff and equipment.

“It’s a hard one to forecast,” says Paul. “There is a requirement to bring these trucks in for proper diagnosis and to make sure that people are working on them safely.”

The trend in the big cities towards large super dealerships with many repair bays looks set to continue as electric and hydrogen appear on the scene.

“Is there an opportunity where the workshop goes to the customer more?,” asks Paul.

Working on a truck at customer premises would be a lot less complex of a procedure, apart from the isolating of the truck from other equipment and trucks. So, the customer would have to have an area which is properly set up to work on an electric truck, but there wouldn’t be that much equipment required.

This is an area where truck makers like Volvo are having to wait and see, gauge customer feedback and develop the new procedures which fit with the operator requirement and the capabilities within the truck dealership groups. The most likely outcome will be a mix of several strategies before we get a clearer picture of just how the new technology will play out.

“I do think that there will be that requirement for it to come into a Volvo Group workshop, because of the amount of competence training needed,” says Paul. “The technology is completely different, and to work on that equipment safely and successfully is going to be a proprietary job and I think it’d be the same for all the OEMs.

“Our training of technicians on the new trucks will be proprietary training, to Volvo and the Volvo product,” says Paul. “Moving forward, how much of it is transferable? Because the isolation of the 600-volt system is relatively universal but working on the individual truck is really unique to that vehicle. It differs on how each manufacturer packages the cooling system and hydraulic system, and even from a software perspective, so I think it is going to be quite proprietary.”

“The enquiries are coming from everybody, from the most traditional dyed in the wool generational trucking companies,” says Paul. “Some very small and some are large, it is very surprising. I think the way that we work with common architecture and shared technologies with the Volvo brand, and we look at the heavy duty market, when we get to a maturity with electric power, we can lift that up and move it across to the other brands we have.

“Bus is a great example, our

batteries and electric motors, and now the transmissions in FL and FE came from the bus part of the business. That’s worked really well for us. I think that’s why we’re really confident about the heavy duty range. With the two FL models, we started with, there was a really good partnership with us and Linfox, a clear idea that this was a trial.

“We wanted to work out what we needed to change or do differently,

and then we worked out we didn’t need to do anything. But until we actually had the trucks here. You just don’t know environments.

“We have been completely surprised at the enquiry rate, how fast it’s gone. Also, the engagement from the dealer network, the engagement from customers, engagement from industry, as well as the various industry associations. The whole thing has

just completely surprised me.

“When I started doing this four years ago, if somebody said, ‘Hey, you’re going to commercialise these trucks in 2022, and you’ll sell the heavy duty 2023’ I could not have believed them, it’s taken us all by surprise.”