At Isuzu, we’ve always taken great care of our customers. We’re Australia’s number one truck… an honour we’ve held for over three decades.

That means more businesses put their trust in us than any other truck brand. We understand that reputations are riding on us and that’s why Isuzu Care is more than just an aftersales service package.

It’s part of our DNA.

From day one, we support customers and demonstrate that reliability is everything. We pride ourselves on being proactive and always going the extra mile.

And as we look to new frontiers, we’re finding new ways to help our customers exceed their goals.

Isuzu Care is what sets us apart. Always has, always will.

PUBLISHED BY Prime Creative Media Pty Ltd

ABN 51 127 239 212

I’ve been looking back at the trucking industry and think about the people I worked with, in my early years in the game. What the world was like and what the people were like in the industry.

The industry itself was a lot more dynamic, change happened quickly and people were trying new ideas all the time. Coming up with different solutions to different problems.

People were coming into the industry and having a crack and realised that they could make it. They could leave school in year 10, or even earlier, could have a go and, if they had a bit of a get-up-and-go about them, they could make money.

That is the era where a lot of our current reasonably large fleets emerged, it was a period when it was possible to work out how to grow a business fast. You could go for it, and there were plenty of young people willing to have a go.

Foerty years later, going though the process to find the Rural Transport Rising Stars, we have found that, and this isn’t just in the rural sector, there may not be plenty of people out there, but there is some real quality.

We had nine candidates for the award, and all of them could easily have won the trophy, that’s how close it was. In our deliberations as a judging panel, we were picking on very small differences, as positives and negatives, to try and work out who who should be receiving the award.

These people we found are young, dynamic people in trucking, who are making a difference. The problem is there’s just not enough of them. We just need moreof them, and this is what the RTRS was trying to encourage. Let’s hope we can develop this further and extend it elsewhere, so that we can get it publicised outside of the trucking media itself and into other forums.

We need people who will be able to understand that we need, people from outside the industry. We need them to understand what it’s like to be inside trucking and how dynamic the it is. Then we might be able to get a few more recruits in the years coming, going forward.

One of the things that I did notice was that most of those rising stars, that we looked at in the judging process, already had a connection of some sort with the trucking industry and had understood and experienced it at quite a young age.

What we need is for young people without that experience to be brought into the industry. Where do we start?

379 Docklands Drive, Docklands VIC 3008 Australia

Telephone: 03 9690 8766

Fax: 03 9682 0044

Email: enquiries@primecreative.com.au

Chief Executive Officer: John Murphy

Managing Editor: Luke Applebee

Editor: Tim Giles

Contributor: Bob Woodward

Correspondent: Will Shiers (UK)

Advertising Manager: Trevor Herkess: 0411 411 352, trevor.herkess@primecreative.com.au

Client Success Manager: Salma Kennedy, salma.kennedy@primecreative.com.au

Production Manager: Michelle Weston

Circulation & Subscriptions Manager: Bobby Yung

Head of Design: Blake Storey

Designers: Caterina Zappia, Kerry Pert

Official Media Partners:

REGISTERED BY Australia Post - ISSN 1445-1158

SUBSCRIPTION

03 9690 8766

subscriptions@primecreative.com.au

PowerTorque Magazine is available by subscription from the publisher. The right of refusal is reserved by the publisher.

Annual rates: AUS $60.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate.

DISCLAIMER

PowerTorque Magazine is owned and published by Prime Creative Media.

All material in PowerTorque Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher.

The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in PowerTorque Magazine are not necessarily the opinions of, or endorsed by the publisher unless

EDITORWith Caltex Delo’s ISOSYN Technology, fleet owners and drivers can rely on extended service protection, maximised engine durability and minimised operating costs.

Talk to your local distributor or find out more about Caltex fuels and lubricants. www.caltex.com/au/business-solutions

55 FIRST HYDROGEN TRUCK ON AUSSIE ROADS

PowerTorque gets behind the wheel of the the fuel cell powered truck in Australia.

62 MOVING TO TRUCKING ELECTRIFICATION

Volvo Trucks has been pushing ahead with new electric models.

72 LOOKING INTO THE TRATON FUTURE

PowerTorque asks the MAN CEO about the next truck generation.

78 TRUCKING WITH LIQUID HYDROGEN

Creating zero-emission heavy-duty vehicles is a huge challenge

Taking the latest Scania out for a test with top horsepower and the extended cabin, the question PowerTorque is asking , is bigger necessarily better? The answer is a bit more complicated than you would think.

WINNER ANNOUNCED

The award, aimed to seek out and reward rising stars in the rural transport sector, was presented at the Australian Livestock and Rural Transporters Association conference in Busselton WA

85 ALTRA

Introducing the new Executive Director to the rural trucking world.

Warren Clark, NatRoad CEO looks back at the history of problems caused by our federal system, states have always been at odds with the federal government and vice versa.

Updates are underway for the National Heavy Vehicle Regulator Portal to deliver a seamless experience for operators, says Sal Petroccitto OAM, Chief Executive Officer, NHVR.

Taking the latest Scania out for a test with top horsepower and the extended cabin, the question PowerTorque is asking , is bigger necessarily better? The answer is a bit more complicated than you would think.

PowerTorque’s European Correspondent, Will Shiers, meets a switched-on 20-something-year-old British haulier, whose family firm has an amazing past, and an even brighter future.

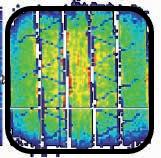

Bob Woodward reports on the findings of the ARTSA-I Coupling Project on the dynamic loads being put on the couplings on multiple combinations.

• Supporting drivers for more than 50 years

• Seating – on a higher level

The truck sales figures for the first half of 2023 shows that this year the record breaking demand of last year has continued. June recorded extra truck sales boosted by the ending of the instant tax write off for capital equipment, as the financial year drew to a close.

Total truck sales figures are up over 3,500 on the record mark reached at the half way point in 2022. Isuzu, Fuso, Volvo and Kenworth are all well up on the sales figures from 12 months ago.

In the heavy duty segment, just about every major player in the market sold trucks in numbers well above the excellent results from 2022. Volvo with 497 and Kenworth close behind at 473, achieved a result which is more than double the monthly result in recent years. In fact, nine brands sold over 100 trucks in June, an unprecedented result.

National Heavy Vehicle Regulator (NHVR) has launched a new Advanced Fatigue Management (AFM) digital application pack in the NHVR Portal where operators can access safe and tailored fatigue risk management options.

“AFM provides transport operators with the ability to tailor work and rest options within outer work limits, so long as they can demonstrate appropriate risk controls and transparency in their operations,” said Raymond Hassall, NHVR

Acting Chief Executive Officer. “As Australia’s safety regulator, we are committed to supporting operators and drivers to work together to ensure drivers are behind the wheel when they are most fit, and resting when they are tired.

“The new AFM application pack has reduced 40 pages of paperwork into an online tool that includes a step-by-step process with templates, real world work and rest hour examples and risk controls so there is no need to start from scratch.

This year has been one of a series of new model releases for Iveco and after the latest announcement,the Acco completes the set, with the Iveco brand offering a new model in every segment. The replacement for Australia’s longest-standing commercial vehicle nameplate is returning to the Iveco product lineup, with Iveco Australia engineers currently testing and validating the latest model prior to a full release.

The original Acco can trace its history back to the fifties, with the last radical change in design taking place in 1972. That basic design was adapted and refurbished many times over the years as new technology came along, but Euro 6 was the last straw.

As a result, the hunt was on to find a solution which fits into the specification envelope which the original, itself, developed using the components available across Iveco. The process has been a difficult one for Iveco, with a few false starts, but the final solution is now coming to market.

The range will be available in both 6x4 and 8x4 configurations and will feature Iveco’s 8.7L, Euro6 (Step E) Cursor 9 engine. Buyers will be able to select from three output ratings spanning from 310hp and 1,300Nm to 360hp and 1,650Nm. The standard transmission across all models will be the Allison 3200 6-speed full automatic.

and those driving in remote areas, GME has partnered with Rural Outreach Counselling to launch a new initiative for people on the open road to open up about their mental health.

“For truck drivers in remote and regional areas, staying in touch

Earlier this year, the National Heavy Vehicle Regulator (NHVR) released the newest version of its route planner and, after a trial period, has decided it’s time for the new planning system to go ahead and close off the previous iteration.

The system is used to map and display approved routes by heavy vehicles), and is known as the Next Generation Route Planner (NGRP). It provides more real time data updates which ensures improved reliability, quality, and completeness of data for industry when planning journeys.

It supports the delivery of the NHVR’s new single national enforceable network map which will allow industry for the first time to plan and manage journeys across borders and is designed for heavy vehicle travel, rather than light vehicles.

GME Group Marketing Manager. “GME is proud to partner with Rural Outreach Counselling, and our good mate Rod Hannifey to launch ‘Open Road, Open Up’, an initiative that we hope can help change the statistics surrounding truckies’ mental health through the

power of a UHF radio.” part of the initiative, UHF CB Channel 24 will be used as a free support network for those who need it. By tuning into Channel 24 on a GME radio, truckies will be able to access mental health support delivered by mental health advocates and truck drivers, spearheaded by truckie and road safety advocate, Rod know firsthand how hard it can be out there on the road alone,” said Rod Hannifey, Truck Driver and Mental Health Advocate. “I have seen friends struggle with their mental health because they don’t have the opportunity to open up properly and talk about their feelings. I want truck drivers to know, if you see my truck, tune in. I’m here on Channel 24 to have a chat whenever you feel like talking.”

Volvo Trucks is introducing new, more powerful batteries for its medium-duty electric trucks, capable of delivering an increased range of up to a claimed 450 km and making it possible to electrify even more city transport tasks.

trucks offer up to 450 km in total range from one charge. Thanks to more powerful batteries in Volvo’s mediumduty truck range, the Volvo FL and Volvo FE Electric, the new batteries offer 42 per cent extra energy capacity and can, as a

Australian all-electric truck manufacturer SEA Electric has announced the appointment of transport industry veteran Marco Quaranta as the company’s new Sales Director for the Asia Pacific.

Marco brings to SEA Electric, 35 years of experience from his previous roles at Iveco, with various tenures based in Australia, Korea, Thailand, Hong Kong and his native Italy.

Within Iveco Australia, Marco held several roles over the last 17 years, including Institutional Relations and Alternative Propulsions Manager, National Product & Marketing Manager, Branch Manager, and National Sales Manager.

A joint venture between between Volvo Group and Westport is planning to develop a zero emission truck power concept.

Westport has been a supplier of alternative fuel delivery systems and components for the global transportation industry for some time, including a joint venture with Cummins to produce natural gas engines in the early 2000s.

Volvo and Westport’s joint venture aims to accelerate the commercialisation and global

adoption of Westport’s HPDI fuel system technology for longhaul and off-road applications. Westport’s HPDI fuel system will enable truck and engine makers to meet the regulatory requirements of Euro 7 and the US EPA.

While Volvo will be a key customer of the joint venture, the joint venture’s mandate will be to enhance commercialisation of HPDI through the addition of new trucking and equipment manufacturers as customers.

Scania Australia welcomes Heath Walker to the position of Director of Marketing and Communications, effective immediately.

Walker, 42, joins the heavy vehicle specialist business with a rich background in automotive, as well as sports and IT marketing.

With a renowned track record of storytelling and brand

building, he says he is delighted to head the Scania marketing team at this time when there is a shift towards a sustainable transport system.

“Scania in Australia and globally has a strong and enviable reputation as a brand that leverages innovation in technology and safety, as well as environmental leadership,” said Heath Walker.

DIRECTOR

The National Heavy Vehicle Regulator (NHVR) has prosecuted a driver in Goulburn, New South Wales for working 19.5 hours in a 24-hour period. The driver was convicted and fined with two critical risk breaches under the Heavy Vehicle National Law (HVNL).

An inspection was carried out byCompliance Officers who identified the breaches after checking the driver’s National Driver Work Diary.

The driver’s longest rest break during the 24-hour period was only one hour and 30 minutes. Solo drivers can work a maximum of 12 hours within a 24-hour period, with seven continuous hours of stationary rest time.

NHVR Director Prosecutions

Belinda Hughes said it’s alarming to see such long hours worked.

EnergyAustralia has partnered with Foton Mobility Distribution (FMD) to trial replacing diesel trucks with electric trucks at its Yallourn and Mt Piper power stations, as it continues to accelerate the clean energy transformation in transport.

The trial will see one FMD T5 electric truck deployed at two of EnergyAustralia’s power generation sites to explore the viability and efficacy of integrating electric vehicles

into power generation operations, with the power used to charge the truck being completely carbon offset. The trial is taking place over four to eight weeks at each location.

This forms part of an ongoing partnership where EnergyAustralia offers to provide Green Transport Energy infrastructure which includes solar, battery, and electric vehicle (EV) charging solutions, to FMD’s electric truck buyers.

The National Heavy Vehicle Regulator (NHVR) is making it easier for operators to view defect notices issued across their entire fleet with the release of a new online module within the NHVR Portal.

National Heavy Vehicle Accreditation Scheme (NHVAS) operators will be the first to experience the NHVR PortalCompliance Module, which offers a comprehensive overview of defect notices issued to individual vehicles across an entire fleet, enabling more effective tracking and earlier management of defects.

NHVR Chief Operations Officer

The National Heavy Vehicle Regulator (NHVR) is seeking expressions of interest to participate in an NHVR commissioned safety project to improve the use of Fatigue and Distraction Detection Technologies (FDDT).

NHVR Chief Executive Officer

Sal Petroccitto said the FDDT safety project will provide practical support to heavy vehicle transport businesses to help them implement

and use the technologies.

“FDDT is proven to play a positive role in reducing driver fatigue and distraction events by better ensuring drivers are behind the wheel when they are most fit for duty, as well as alerting drivers to potential incidents,” said Sal. “We know the heavy vehicle industry and regulatory partners support the safety benefits of FDDT, but they want to see greater guidance and safety management

Paul Salvati said the new module reflects the regulator’s commitment to exploring innovative ways to make it easier and safer for the heavy vehicle industry to manage their compliance.

“Improving productivity and safety in one of the most important industries in Australia is a key objective of the NHVR and this new Portal module helps achieve this through timely and simplified access to important compliance related information” said Paul. “Currently, operators face challenges with timely notifications of defects, which affects fleet management.”

systems to support its use.

“As the safety regulator, the NHVR is committed to partnering with industry to develop an agreed approach to what good practice in the use of FDDT looks like. Critical to the project will be the development of practical FDDT event procedures and processes that transport companies can consider implementing to help them reasonably respond to FDDT events.”

DSE (Delivering Service Excellence) Transport, has expansion plans which are well afoot, with three new S-Way AT 360 6x2 rigid trucks recently joining the company’s fleet.

With a team of almost 50 company employees and over

homewares, building materials and supermarket sectors.

According to DSE Transport State Manager NSW, Mitch Sherry, after a long search, the company eventually settled on S-Way, and it was the first–time purchase of the Iveco brand.

features of the S-Way, the added safety

An order by Consortium Purchasing group in the UK will see a large number of trucks delivered to three divisions of the company across the Culina Group, WS Group and A.W. Jenkinson Group, in a massive Scania deal, which dwarfs the kind of number we get excited about in Australia.

The complete order consists of 2,500 trucks to be delivered over 12 months. The deal includes diesel

internal combustion engine trucks powered by the latest generation 13-litre Super drivetrain, as well as 100 battery-electric trucks, some of the first Scania regional-haul batteryelectric 4x2 prime mover units to be used on UK roads.

Each vehicle will be supported by three years of full repair and maintenance contracts, with some trucks financed through Scania Financial Services.

Mercedes-Benz Trucks is introducing the all-electric eEconic, a truck that not only produces no local emissions, but also operates in near silence. The truck maker is beginning a local validation program for the eEconic that will become available in Australia and New Zealand in the near future.

The electric eEconic has been developed from the diesel Econic, which was designed from the ground-up to work in densely populated areas and is known for its visibility, practicality and active safety features.

With production starting last year, the eEconic is said toi have impressed European customers with its advanced design, strong performance and efficiency.

A new industry-led data sharing initiative between Transport Certification Australia (TCA) and the National Bulk Tanker Association (NBTA) aims to provide better understanding of the movement of vehicles transporting dangerous goods and bulk liquids on the road network.

Speaking at the Bulk Tanker Day

2023 in Brisbane, TCA’s General Manager of Strategy and Delivery, Gavin Hill, said the new initiative builds upon the success of an earlier data sharing arrangement between TCA and the NBTA, which involved transport operators in the dangerous goods sector.

“What we found from the previous study was that many

team of dealers and head office staff have to our customers,” said Greg Bleasel, Vice President – Product Support for Hino Australia.

Parts Excellence Award is awarded to a small number of distributors that demonstrated overall excellence including ensuring a consistently high supply of parts to dealerships and customers.

Hino Australia’s commitment to its customers has been recognised by Hino Motors, globally. with a 15th successive Parts Department of the Year Award and a 12th consecutive Service Department of the Year Award.

“These accolades, in addition to receiving the Parts Excellence Award for the third time, reinforce the outstanding commitment that our tireless

“Featuring innovative technology and almost twice the capacity of the previous facility, our new Parts Distribution Centre (PDC) provides us with the flexibility to further improve efficiencies with the distribution of Hino Genuine Parts to our dealer network, providing our customers with even higher levels of support and service,” said Greg.

dangerous goods transport operators had not necessarily seen a macro view of their vehicles’ footprint across the network,” said Gavin. “So, instead of leaving that as a one-off study, we’ve decided to launch an evergreen study, where we’ll work with the industry to make sure they get true benefits out of it.”

The National Heavy Vehicle Regulator (NHVR) is urging heavy vehicle drivers to remain vigilant with their National Written Work Diary (WWD) or Electronic Work Diary (EWD) and follow work and rest requirements.

A state-wide operation was triggered in New South Wales, after a considerable number of penalty notices issued in NSW were found to be linked to fatigue related offences.

NHVR Director of Operations Central Region, Brett Patterson, said the operation is crucial to promote compliance, reduce fatigue related incidents and will target drivers who fail to comply with work diary requirements.

“Driving a heavy vehicle while feeling sleepy, physically or mentally tired, or lacking in energy, is a major safety hazard,” said Brett. “Falling asleep behind the wheel can be disastrous, but even a brief lapse in concentration can have serious consequences.

Alemlube Automatic Lubrication Systems allow you to eliminate manual greasing, stay on the road and deliver on time.

The new S-Way is hoped to be the model which will bring back the Iveco brand, after test driving the model, Tim Giles reckons it is bringing Iveco up to date. The next question is, will it save the brand?

It has been a shaky last ten years for the Iveco organisation here in Australia. Coming off a long history in the Australian truck market, as a major player with the International brand and one of the alltime classic Aussie trucks, the Acco, the brand seemed to have an identity crisis, where it wasn’t sure exactly what it stood for.

Now with a new boss and a slimming down of the organisation, including closing the manufacturing plant in Dandenong in the Eastern suburbs of Melbourne, this year has seen a series of model releases, which represents a cleanskin offering in every market segment.

The S-Way was released a few

years back in Europe and has been well received. The fact it has taken so long to reach us here illustrates the past issues. The process of adapting a model designed for Europe for production in a factory in Australia, and adapted for Aussie conditions and preferences, was a long and expensive one.

The S-Way which has arrived here is now the latest iteration of the model and the production facility on the outskirts of Madrid in Spain is now geared up to build a model suitable for Australian conditions down its production line.

The truck tested in this run from Brisbane down to Sydney with a fully loaded B-double set, is the S-Way with

AS cab and the 550hp 13 litre Cursor engine, putting out 2500Nm of torque at 1000rpm.

The technology of the modern diesel engine has caught up with us and the latest generation of European truck engines have been designed for, and have proven capable of living with Australian road conditions. These improvements have seen European brands gain market share as fuel consumption has moved to the top of the list for truck buyers.

Another side effect of this drive for low fuel consumption has seen the European manufacturers specifying 13 litre engines more and more into the heavier B-double type freight tasks and operators achieving the kind of

durability they are looking for.

This trend means that the new S-Way is being introduced to a market which is looking for a product with specifications very like those the S-Way has to offer. Iveco don’t offer an engine over 13 litres and it does have the kind of cabin and level of sophistication in electronics which are on just about everybody’s shopping list.

The S-Way is definitely a very different beast to its predecessors, but that only becomes clear when you are out on the road with the B-double in tow. Although the basic truck looks quite familiar, this really is a new design and a new truck. The basic driveline is very similar to the one on offer in the X-Way before it, but the rest of it is a revelation.

This shouldn’t come as a surprise, the change from the last Iveco prime movers built at Dandenong to these new trucks being introduced involves several steps of truck development. Australia was two or three steps behind Europe, in Iveco terms, but now we are on par with the latest trucks on sale there. We have caught up, and Iveco needed to catch up.

How can you tell it is so different?

Because it is better in just about every aspect. Climbing up into the cab is better, the interior of the cabin is much better designed. Driving, the noise levels in the cabin are low, the look and feel of the dashboard is very good, it feels like a different truck altogether, and it is.

Driving down the Pacific Highway, it pulls really well. This may be because at 100 km/hit’s the engine is running at 1600rpm, a higher level than the most frugal trucks tested in recent

times. What we’re looking at here is a driveline that we’ve known for a while, it’s the Cursor 13 engine, pushed out to 550hp, but it does feel like a valid B double prime mover, there’s no doubt it could do the job.

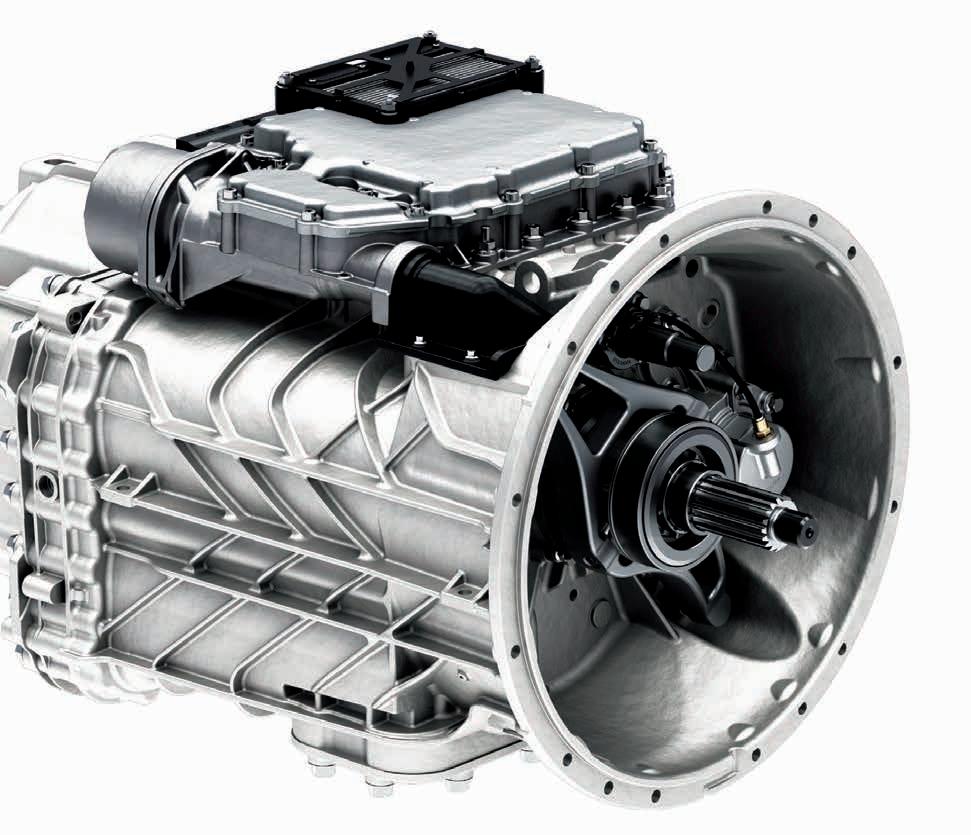

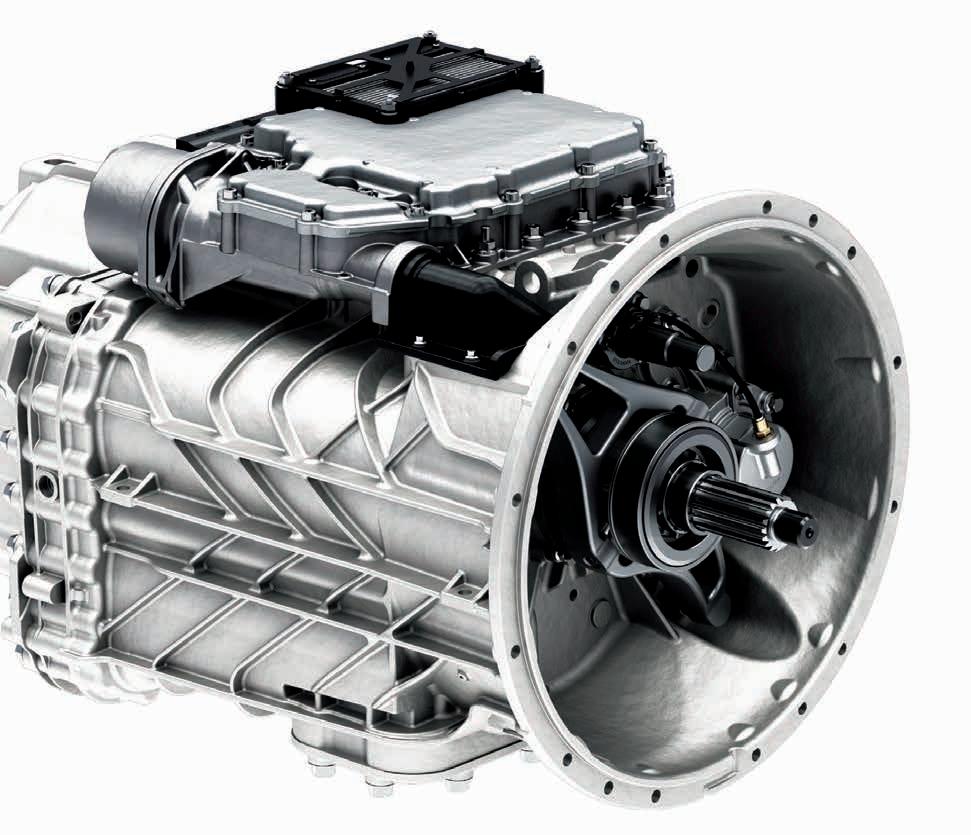

It uses the 16 speed gearbox, known as the Hi-Tronix 16 an AMT, made by ZF but using the Iveco software control system. This has been a good go-to box for some time and continues to be well up to the task. The job of differentiating between AMT

transmissions gets harder every year, as their performance levels get closer. This driveline is just a solid performer, it may not be the best in the world, but it does an excellent job.

At the same time as the Traton brands are moving away from retarders, Iveco are moving towards them. Previous Iveco drivelines relied only on compression braking, but now, when the driver takes power off, they get a little bit of compression braking and then a lot of retarder braking.

On the steering wheel are the controls for the cruise control and they’re pretty good. With these Iveco have come up with a smart idea which makes life a little easier. The problem on many active cruise control systems comes when following a vehicle at 100 km/h. If that vehicle slows, the truck slows and often the driver doesn’t realise for some time. They then have to knock off active cruise and get the vehicle up to speed to overtake the slower vehicle ahead.

On these new Ivecos, there is a button to toggle in and out of active

behind the wheel. On the right are buttons to turn volume up and down and on the left, they change channels on the radio, or scroll through modes on the screen.

designed, there were no false positives

Apart from the driveline, which is a known quantity, Iveco have added to and recreated the cabin into something which is much better. It’s going to work well and it’s a useful tool. Iveco haven’t done anything with the dimensions. It’s the same size box as it was originally, but they’ve done a better job with this space than they have done before in the past.

It’s not that it’s such a radical change in design, it’s just the design elements have been done better. Essentially, this is the cabin Iveco sell in Europe and it has been tweaked a bit for Australian purposes.

When it comes to the mirrors (no camera mirrors yet), there is a gap between the A-pillar and the mirror. When the truck came to a roundabout, the, quite big, driver’s side mirror was almost perfectly in place so that you couldn’t see any of the traffic coming around the roundabout from the right. It meant a lot of rocking back and forth to check the road was clear.

The telematics system was, in the past, an Australian fitment, now

it’s the global system, which seems much more aligned to the truck’s own systems and comes with a well designed interface, which looks good. The information screen directly in front of the driver in the middle of the dash is similar to the previous model, but the screen on the binnacle has a new look and feel.

There’s good adjustment on the steering wheel, with the wheel’s design curve matching exactly the curve around the top of the central instrument cluster on the dashboard. Ever since the first iteration of the Stralis this central screen was has been easy to read and well designed. It gives you all the information you need, selected gear, auto mode, cruise control activation, speed limiter, following distance etc. In terms of the auto, there is an auto and there’s semi auto, which allows the driver to scroll up and down the gears manually, when required.

A few of the controls on top of the door handle the mirrors, but they are not the same as most trucks. Instead of the left/right, up/down buttons, pressing the button brings up a screen on the dash. This screen shows the four mirrors and one of them is highlighted, so that’s the one you’re changing. The driver scrolls through these mirrors and can adjust the one highlighted.

The model tested had a bunk down at the bottom and bunk up top, but if you didn’t have that bunk up at the top, there’s a lot of potential locker space. Then there’s three biggish lockers along the front wall, because this has got the high roof. The driver can stand on the engine cover and has to stretch up to touch the roof.

Cross cab access is really easy, it feels roomy because, although the binnacle is quite close, it’s actually

with useful storage and odds and ends included, like a simple mobile phone shelf.

At the base of binnacle is actually quite a wide storage shelf with loads of room and holders for bottles and plenty of room for other items needed regularly. Underneath this is a big drawer which you can pull out when you’re driving.

on this model are a big fridge and a big freezer. You can lift up the bunk and then you’ve got access to the side lockers as well.

Curtains in a cabin can be an issue, as any truck driver will tell you, having done a full shift, filled in the logbook and then trying to pull the curtains around to go to sleep. Very rarely are

Since 1963, Mack has been designing and building trucks to handle Australia’s unforgiving conditions. Mack Titan has always taken on the toughest of road train, triple and quad assignments, tackling long distances and big payloads with ease. Its powerful Mack MP10 engine delivers up to 685hp and 2,300 lb-ft torque, while the innovative mDRIVE automated manual transmission delivers the grunt to the gravel with the minimum of effort. Titan delivers excellent fuel efficiency and low emissions, making it the ideal truck when you’re clocking up the k’s. Make your own history with Mack, and talk to your dealer today, or visit MackTrucks.com.au/Trucks/Titan/

they free running, catching in the rails, the driver has to pull a little bit at a time. Not on the S-Way, the curtain rails go right around by the windscreen and they work smoothly, without a hitch, they are really well designed. Then there’s also a big curtain which comes across in front of the bunk, also easy to use.

This was a fully loaded B-double and it does lose momentum on the hills, but it doesn’t lose that much. On climbs there were no fully loaded B-doubles flying by and the truck never seemed to be working too hard.

After descending down through Mooney Mooney, the truck started climbing back up the grade, it handled it with comparative ease at 1600rpm and 70 km/h. It moved up to 1700rpm but held onto its gear, running above the green zone on the tacho, well aware it’s heading up a serious grade. As the grade tightened up, it held 14th gear, at about 63 km/h, slowing down to 1300rpm. Just before it got to

1200rpm it grabbed a gear or two and got back up to 1750rpm. The system work in a very traditional mode, not letting the revs lug down and relying on torque to pull the truck through.

The fact that Iveco hasn’t got a 15 litre engine may not matter, because a lot of its competitors are also selling 13 litre engines into this size of set-up now. These 13 litres are capable of doing this job and are working. The engine control systems are much more precise on these modern trucks. Ecoroll comes in quite a lot as it drops down to just over 500rpm. What we’ve got here is a truck which can match others, that’s really competitive.

At its slowest the truck was in 13th gear at 55 km/h, but as soon as the grade backed off, it jumped straight up to 15th in order to try and save as much fuel as possible. Skipping a gear when still on an upgrade is going well on this reasonable climb.

At the end of the journey, the trip had been comfortable, the cabin is quiet, even when the truck is working

hard. How hard it was working was illustrated when looking at the telematics results after the run.

The readout and display from the Iveco telematics is easy to use and clear. Luckily for this driver the driver score function had not been switched on. So despite the driving style and being loaded to just under 55 tonnes, the fuel consumption over the whole journey was 1.93 km/l over the 900km plus route. This was running with the AMT on auto most of the time, but not driving in the most fuel efficient manner at all times, scoring 52 out of 100 on that measure. The vehicle care score was 79 and safe driving score 89, just an average day in the cab.

The driving may have been average, but the truck itself will surprise, because Iveco have put a lot of smart design into a valid contender in the B-double space, it’s now up to the organisation here on the ground in Australia to get that message out into the market.

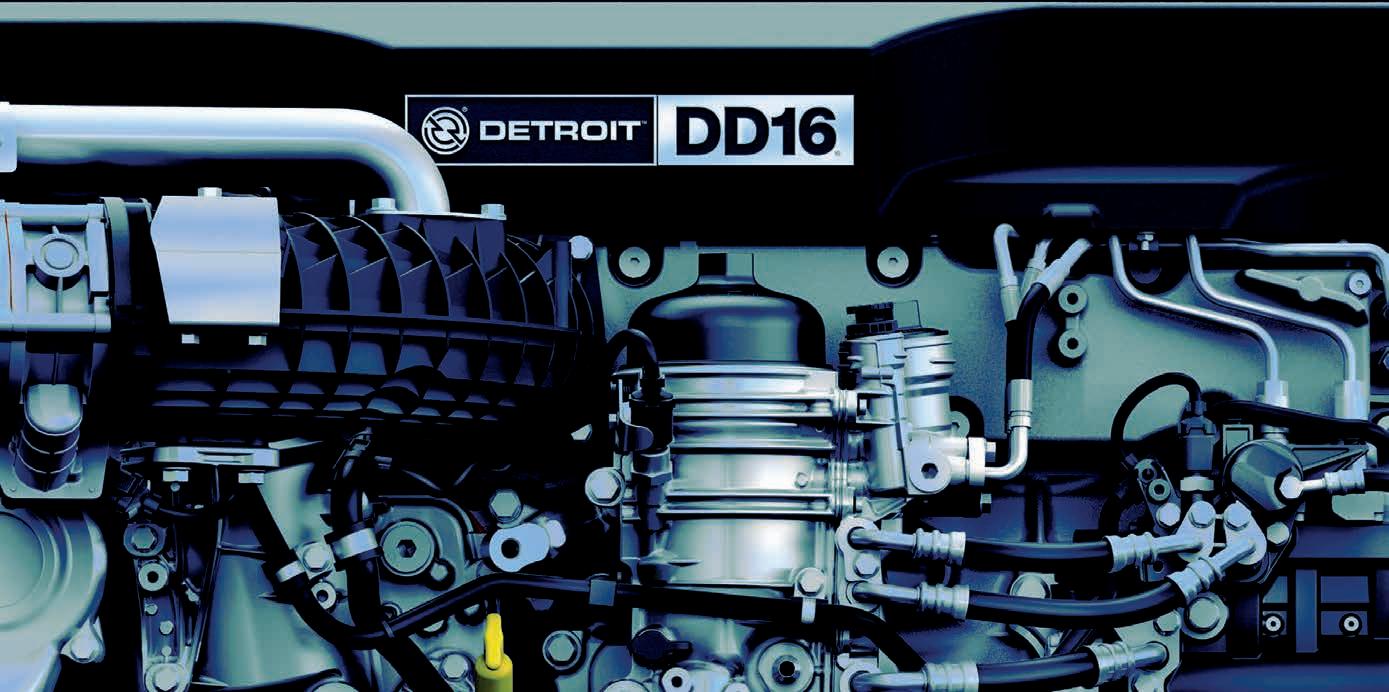

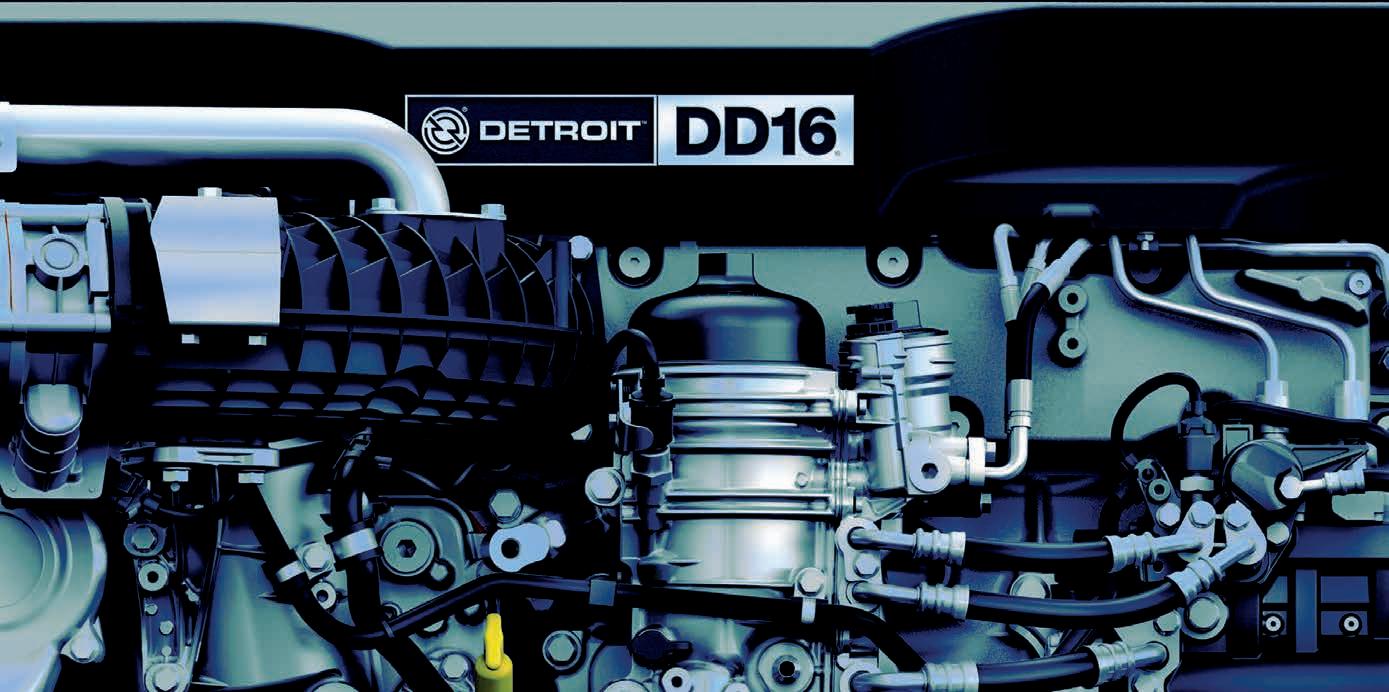

With up to 600 horsepower and 2,050 lb-ft of torque, the big bore workhorse provides efficient and dependable power and performance without compromise. Detroit’s advanced technology also means GHG17 requirements are met through innovative fuel efficiency resulting in lower emissions.

This power, performance and efficiency prowess is backed by our industry-leading warranty and extended coverage packages that ensures the highest level of support for our customers.

Combined with superior fuel economy and the absence of a midlife change out, the DD16 delivers an enviably low total cost of ownership and maximum uptime.

This is all backed by our well-established and extensive national service and support network which, together with our highly skilled factory-trained technicians, means you can count on getting the right advice when you need it.

With Detroit, there’s no compromise.

When you first see this combination of the road, the question is, is it a triple quad or a quad triple? In fact it’s a quad axle triple road train running for the Emerald Carrying Company and Tim Giles checks it out.

Alarge yard on the outskirts of Townsville is the home to the fuel hauling branch of Emerald Carrying Company (ECC). From this base the operation services fuel customers all over North and Western Queensland, covering the biggest runs across to Mount Isa, 896km to the West, and beyond.

The business uses over 100 trucks and employs over 200 drivers, and is a family-owned business. ECC was established in 1965 in Emerald Queensland by Bill and Joan Haylock. Originally, it grew from supplying Central Queensland with freight, which was brought out to Emerald by

train, and distributing it further. The fuel side of the operation grew out of that business and now runs depots in Townsville, Mackay, Gracemere, Emerald, Geebung and Lytton, all in Queensland.

The business services mining, commercial retail and agricultural customers and operates a fleet from body trucks all of the way up to triple and quad road trains.

The core values held by the business are written on the truck doors

• P ride, in our workplace, our culture and partnerships.

• Care, for our staff, ensuring a safe and prosperous workplace and future.

• Respect, fairness and integrity in our dealings, providing sustainable outcomes for all parties

• Excellence, in striving to achieve a safe working environment at all times, being innovative in our approach to problem solving whilst being aware of our social and environmental obligations.

As in any business on the highway and especially one hauling combustible liquid, safety is paramount and the business ensures appropriate health, safety and environmental policies, guidance material, documentation, procedures and training contribute to the target of ‘nil harm’.

ECC runs a well presented fleet and is proud that it’s involved in the NHVAS Mass, Maintenance and Fatigue Accreditation. sections of the fleet are operated under Performance Based Standards (PBS), Intelligent Access Program (IAP), and GPS tracked.

The longest runs with fuel are those where the highest productivity vehicles are needed and ECC have been pushing the envelope on trucks running out of the Townsville depot to achieve those gains. The most productive combination on the road is a typical triple road train, with one major difference, instead of triaxle trailers and tandem axle dollies, it uses quad axle trailers and triaxle dollies. The prime mover used to pull the set-up featured here, is a tri-drive Kenworth T909.

“When you look at what we do, they’re called dangerous goods for reason,” says Troy Sabin, Driver Trainer at the Townsville Depot. “When you look at the adverse conditions that we drive in, when we look at our western roads, they can be less than optimal.

“What I’ve noticed with the trailers, with the standard air system, compared to what the Base Air fitted trailers do, is there seems to be a bit more stability there. It seems to make the air flow quicker, as opposed to the standard system.

“The quad axle triple is grossing

out at 152 tonnes GCM, as opposed to the 136 tonnes achievable with triaxle trailers. You can see the difference in the way those trailers respond to what the driver is doing. Whether it’s at 70km/h at 90km/h or at 30km/h. You can see with that improvement to the suspension system, what an improvement it makes to the handling. You notice the difference straight away. You can see the difference when you sit behind them on the road.”

On some combinations the Base Air system is on the trailers only, but with ‘The Big Picture’, the truck PowerTorque came to see and photograph it’s on the prime mover and the trailers.

“The comparison that I have come back to is that it’s very similar to driving with a steel spring suspension,” says Troy. “It doesn’t have the kick like the old heavy six rod does. but it has that stability aspect, and it gives you that confidence.”

The combination runs to Mount Isa from the Townsville ECC depot three times a week. It is double shifted with one driver handling three runs out and back, making the run from Townsville to The Isa in one 14 hour shift, taking a break there and heading back the following day. After the three are completed the truck gets washed and checked over before a second driver takes over and drives the next three trips.

There’s always improvements, in the industry and when improvements are warranted the leaders in the business will look at them and and make the decision as to whether they’re viable if they suit what what the business needs.

The issue in tankers is that the centre of gravity is constantly on the move in the tankers and that does have a detrimental effect on stability. Long term drivers learn though experience just how to handle the three trailers and any movement or sway which eventuates.

The Base Air system has the effect of reducing the effect of any sway and improving the suspension’s ability to

keep the trailers upright along the length of the more than 50 metres long combination..

“This suspension now gives you more control over what’s going on,” says Troy. “It gives us the ability to stiffen up the suspension, where it needs it. It takes out the slosh factor. There’s less chance of that EBS coming on, if the suspension is stabilised. You have still got to watch what you’re doing, you can’t be a drongo. You can’t just think ‘I’ve got this wonderful air system’.”

There are 14 triple road trains running out of Townsville, and there’s another seven units running single, B-double and double road train combinations. All of the road trains head west out the area. Another road train or B-double heads northwest into the Cape York peninsular supplying the power station at Weipa and others on the way.

The so-called ‘local’ deliveries go out to service stations, airport etc. They go as far as Hughenden 380km south-west, as well as to the other major population centre in North Queensland, Cairns, which is 350km to the north. There are also runs south along the Bruce Highway, as far as Rockhampton, 720km away.

The trucks going to the west handle service stations, but are also supplying major mine sites directly and some power stations, the farthest west is at Camooweal, still in Queensland, but over 1000km to the west and just 13km from the Northern Territory border.

Altogether there is over a million

terminals, and ECC pull fuel out of all three.

The operation also has local trucks pulling fuel out of the Cairns oil terminal, as well as 40 trucks working out of the Mackay depot hauling fuel. Gracemere has 20 trucks which load fuel out of Gladstone.

Monaro Fuel Haulage operates

ECC have moved away from trying to recrui skilled and experienced drivers and have resorted to employing ‘green’ drivers having put driver trainers into place to teach the skills and procedures necessary, until they are ready to handle local work, and then work their way up into the longer distance fleet.

“Three years ago, we actually started going down that avenue of training,” says Troy. “I stepped out of out of driving at the start of this year to take on this role. We go through everything from what we expect in presentation, to delivering the product and the truck. All of the terminals have inductions that need to be done.

“Our trucks are very noticeable, and we have we have a high expectation of that presentation, not only the vehicle, because those people out there are the face of the business, they’re the ones that the people see.

“Then you look at the vehicles, not only is it clean and tidy on the outside, we want it like that on the inside, and mechanically sound.”

ECC has the Guardian system in its triple shifted trucks, because the company’s statistics showed over the years that wqas found to be where the fatigue incidents were happening.

“Blokes were pushing through and and things were going wrong,” says Troy. “We can talk to those fellows. There might be an undiagnosed medical condition now and we can say, hey, here’s the footage. We will assist them wherever we can.

“We have the Guardian in our triple shifted trucks, in our single trucks, but we don’t in the road trains, because they have the opportunity. They can just stop when they choose to. They take the rest they need. But we also have satellite tracking, and cameras. We have a forward facing camera and a camera facing into the truck and we run electronic work diaries as well. We have a lot of systems in place electronically as well, to assist with that sort of stuff.”

The BaseAir product comes in the form of a kit which can be fitted to both trucks and trailers. Initially, operators were fitting the system just on the trailers, but later are often adding them to the prime mover’s rear suspension resulting in an even better solution.

In essence, what has been developed is an enhancement of the existing air suspension system. The normal system will be fitted with one height control valve (HCV). The combination of the HCV with the road conditions sees air flowing around a unitary air system to keep the truck chassis at the desired height from the road.

What the BaseAir system does is separate it into two parallel systems, one on the left and one on the right. When the truck is running in a steady condition, the two separate air circuits are selectively combined to have the same effect as we would expect from a standard air circuit.

This situation changes when the trailer starts to lean over. There are two HCVs, one on either side of the truck and when a discrepancy appears, the HCVs limits the movement of air from one side of the truck to the other.

At a basic level, in a normal system, as the trailer starts to lean

to the left, for example, air would normally flow from the left across to the right, to equalise pressure across the unitary circuit. When this lean happens in the BaseAir system, the valves close and hold the air in the airbags on the left, to hold the trailer up and reduce the lean.

The Dual Pressure Protection Valve is placed at the point where the two separate circuits diverge at the connection from the air tank. The airlines to the two HCVs are the same length, as are the lines from the HCV to the airbags.

There is an extra airline in this system, the cross-flow line passing air from one side to the other, shut off and released by the HCVs on either side. Anytime the HCVs detect a lean of less than 1.5 degrees, the crossflow is fully open and allows air to flow feely between the two circuits, exactly the same as in a normal system.

Once that lean exceeds the 1.5 degrees the system will limit air flow, the cross-flow is no longer available, and the two sides of the suspension act separately. This is how the effect of holding the trailers and prime mover up straighter is achieved, by simply stopping the suspension from allowing the lean in the trailer when it reaches a certain level.

Drive

The new IVECO S-WAY range takes the on road and liveability experience to the next level.

Drivers enjoy a SAFER driving experience with world class driver assist technology. The S-WAY cab maximises aerodynamics, while the Fuel Efficiency System continuously evaluates conditions boosting PERFORMANCE. The driving ergonomics and cab have been reimagined and designed for supreme COMFORT.

S-WAY makes tomorrow safer, more productive, and even more comfortable. iveco.com.au

For a fleet that hauls up to 300,000 cartons of bananas a week out of north Queensland and has a monthly fuel bill of $3.5 million, future power options are obviously high on the agenda of Blenners Transport.

Les Blennerhassett, head of the Tully-based family company he started in 1988 with wife Judy, realises that while diesel will dominate for a long time yet, he must also look closely at next generation power options.

Higher productivity vehicles such as 38-pallet B-doubles, achieved under PBS (Performance Based Standards) guidelines, are another priority for a company with massive involvement in the banana industry in north Queensland.

Blenners currently operates 185 Kenworths, around 100 of which are linehaul B-double and road train units with Cummins X15 Euro

5 power – a specification providing the high utilisation needed to move the tidal wave of bananas from north Queensland to Australia-wide markets.

The strong relationship with Cummins has seen more than 200 red engines specified by Blenners in Kenworths since 2008.

Twenty-two road trains alone are dedicated to banana haulage across the country to Perth, WA. Overall, Blenners moves around 60 per cent of north Queensland bananas to the capital cities – a task that is carried out 52 weeks of the year since bananas are not seasonal.

Bananas aren’t the only high volume fruit transported by Blenners from north Queensland. “We had to diversify our customer base in 2006 after Cyclone Larry destroyed most of the banana crop. We went from doing

110 loads a week to four loads,” Les Blennerhassett recalls.

Blenners this year transported more than 100 pallets of seedless lemons a day out of the Mareeba region on the Atherton Tablelands during the peak period, while thousands of pallets of mangoes and avocados will be moved during their peak.

With a monthly fuel bill totalling $3.5 million, any measure to improve fuel consumption just a fraction is looked at closely by the Blenners team.

The entirely new next generation 15-litre Cummins X15D, unveiled at the 2023 Brisbane Truck Show, will be the next major engine step for the fleet. Reports from field trials of a fuel consumption improvement of up to eight per cent over the current best from X15, obviously has huge appeal.

While the diesel truck engine still has a long life ahead of it, especially in Australia’s challenging operating

The transport industry has had a difficult few years, but has remained buoyant with demand for its services powering ahead. Now the need to combat climate change means the trucking industry will be powering into the future with new technology.Higher productivity vehicles such as this 38-pallet B-double are finding their way into the Blenners fleet.

environment, studying alternative powertrain technologies and their impact on carbon reduction is of interest to Les Blennerhassett.

He sees Cummins’ much-discussed hydrogen-fuelled internal combustion engine currently under development as a strong contender for the future. Having a 15-litre ICE running on hydrogen and virtually eliminating CO2 emissions has advantages over other carbon reduction technologies for heavy truck operations.

The familiarity of internal combustion is a big plus: There’s no reinventing the wheel, rather the base diesel engine is adapted for an alternative fuel, greatly simplifying the installation of the 15-litre platform into an existing truck.

This year, around 20 new Kenworths with Cummins X15 power will be put into service – a far cry from the days when Les and Judy wondered if they could afford to put one new truck on the road a year!

“We have a very good relationship with Cummins,” he says. “We get good support from Cummins nationwide and we pay a lot of attention to our own preventive maintenance and trend analysis.”

While future power sources are a focus at Blenners, higher productivity vehicles, operating under PBS guidelines, are in the spotlight too, with the number of 38-pallet B-doubles in the fleet steadily increasing, with close to 20 in service at the time of writing.

Replacing 34-pallet B-doubles, the new bigger capacity units feature a quad-axle lead trailer and operate at 73 tonnes over a length of 28.1 metres,

with 16 pallet spaces in the lead trailer and 22 in the second.

Three PBS A-doubles, operating at a gross weight of 91 tonnes over a length of 30 metres, are also proving their value, running from far north Queensland to Derrimut in Melbourne. Three more A-doubles will be put into service in 2023 on this freight route.

Blennerhassett’s involvement in the banana industry hasn’t accrued just through his trucking business. Before he and Judy ventured into trucking in 1988, their roots were in farming –bananas and sugarcane. “The reason

we bought a truck in 1988 – a Kenworth T650 – was to cart our own bananas to market,” he recalls.

The business has grown on the back of customer service – understanding the needs of farmers and providing the flexibility that has encouraged a strong relationship with Blenners Transport as a family company. “As our customers have grown, we’ve grown with them,” he explains.

Blenners’ continuation as a family company long term also seems

assured with Les and Judy’s two sons involved in the business, Roger as Brisbane manager and Ben as Tully manager.

The company operates eight depots in Queensland – Cairns, Mareeba, Tully, Innisfail, Townsville, Mackay, Rockhampton and Brisbane – and offers storage and warehouse services for freezer, chiller and dry freight at its Brisbane, Townsville and Cairns facilities. Construction of a new $12 million facility in Cairns is about to begin while a new Rockhampton depot will follow in 2024.

n the world of truck leasing and rental, September is the when most of the new truck purchases take place, in the lead up to the busiest time of the year, the period heading into Christmas. For Penske Truck Leasing, this means a number of MAN TG3 models arriving in Australia.

“We’re really excited about the MAN TG3s coming through, I’ve always been a big fan of MAN, and their 10 litre and 13 litre products. They have done very well for us in rental and lease,” says Adrian Beach, General Manager Penske Truck Leasing. “They’ve been super durable and we understand the maintenance costs.

“I’ve always kind of thought that they were a little utilitarian and didn’t have much of a wow factor to them, but these new TG3s, they get everything we love about the TG2s, same engine and driveline, but it’s such a nicer cab and they really took into account what drivers want, and they smoothed out the ride with the front suspension, and I can’t wait to get them in traffic and see them with Penske Truck Rental decals on.

“In a lot of ways we’re kind of the demo program for the dealership. In the past, the dealership would have to buy a couple themselves and hold them on their books and register them and eventually try to sell them as a used truck. Now the dealership can

rent a truck from us to give it to one of their retail customers.”

Penske Truck Leasing puts telematics in its trucks and can provide fuel economy data. The Penske Truck Leasing team try to help increase MAN market share by being a customer, buying them and getting them on the road, but also helping their dealership sales teams, by using them as demos or support units.

In the last year and a half, because of the supply issues, the Penske rental business has been booming. Adrian estimates the business gets an extra 10 or 15 per cent utilisation bump from people who’ve ordered a truck, but they’re going to have to wait a year or so for it to actually arrive.

“One thing that dealership sales teams and the national fleet sales team has been able to do, is say, they know they’re looking at other brands, but if they get the order, they can get a rental next week,” says Adrian. “At least you’re moving freight. There have been a couple of times when their customers contract starts and their customer took so long to make a decision that they had to drop some of the bidders out because they wouldn’t be able to supply on time.

“I think we’ll get a bump when we get these TG3s into the rental fleet, because there may be a lot of current MAN customers who want to try one of these before they make a commitment to it. I think that’s a way we’re going to get some growth with the leased product line, because even if there

are people who like the truck, they like how it looks, but they’re asking about resale and maintenance. We can answer all those questions by holding the residual position and building the maintenance into the lease payment.”

Trucks with the Penske Lease stripes which we see on the road are the trucks on rental terms. However, over the past couple of years, Penske Truck Leasing has really grown its fully maintained operating lease fleet, which will either be plain white or in the customer’s livery. Customers on these longer term deals can customise the trucks and get different configurations like 8x4 rigids, or fitted with hydraulics.

The length of the leases can vary widely from the operator with a two or three year contract to fill or one which needs the truck as long as possible to handle a specialist task.

“Sometimes we have customers that say, they’ve got a two year contract or a three year contract, who are less concerned about the monthly payment, and more concerned about if the customer doesn’t renew that contract. Then they just hand these, four or five trucks back to us and they’re done.

“There is quite a wide spectrum of the way that people want their operational lease to work. That’s another way we fit in well with the dealership, so with the rental fleet there, they can try one and use a rental truck as a kind of a demo, they can rent one to fill in for an accident, downtime or peak seasonal needs.

“If they want to do something long term, we can do a fully maintained operating lease, or if they just want to buy it like they may have in the past they can get the positive experience from the

rental fleet and then feel comfortable purchasing right from the dealership.”

When it was started, the Penske Truck Leasing business was rental only. It didn’t really go to market with fully maintained operating leases until around 2017. Although the fully maintained business made a little bit of progress, when COVID hit, problems like limited travel and in-person meetings meant that progress with leasing slowed for a couple of years.

In the post-COVID period that side of the business has grown to over 30 lease customers, most of them in Brisbane. There has been more growth in the last 18 months than there was in the previous five years.

“Customers have changed in how they want to use their capital,” says Adrian. “There’s a few customers that we’ve signed recently who haven’t gotten their trucks where, internally, the various departments and divisions in the company are competing for capital. In that case, the fleet may need to show what kind of return they can get on this investment. It’s difficult for the fleet guy showed a return.

“A couple of customers are looking to just use someone else’s capital for the rolling stock because they need a new printing press or a new plastic injection moulding machine or they want to build a new shed, elsewhere in the business. They can do something a little more productive with their money.

“I can’t tell you how many smaller fleet customers I’ve talked to who lease their depot but have always purchased their trucks. Own the real estate, lease the trucks. It’s a more effective use of capital, whether it’s a smaller company, like a four truck fleet with a little depot, or a company that actually manufactures something.”

Taking the latest Scania out for a test with top horsepower and the extended cabin, the question Tim Giles is asking is, is bigger necessarily better? The answer is a bit more complicated than you would think.

There is something about a big banger. Just the sound of the numbers, ‘770hp’ sets off a little flurry of excitement. Whereas, the statement that the rear wall of a truck cabin has been extended back 270mm does not have the same visceral effect.

However, at the end of the trip from Sydney, down to Melbourne, it was probably the dimension which seemed to be more important than the other magic number.

The question has to be just how the Scania 770hp engine performs in those functions for which we need as much power as possible. Climbing the grade up Aeroplane in a fully loaded B-double is one of those times where the driver can expect something special from the big banger. As it happens, the number which impressed on the grade wasn’t the 770, but the 3700Nm (2729 ft lb) of torque which makes this truck an unrelenting climber.

As the truck gets onto any grade at all, it is the fact that just about every time it comes up behind a similarly fully loaded B-double, you indicate, pull out and cruise on by. The rest of the time there’s no difference, everyone is limited to 100 km/h. On

the climb the truck is running at 86 km/h at 1600rpm in 10th gear.

The cruise control is connected with the topographical data which is available on board and the kind of anticipation this system adds to the mix can be felt just before the top of a rise, or at the foot of an upgrade. The system also uses the eco-roll when it sees an opportunity.

With this much power it is possible to really down speed the engine and at 100 km/h the engine is ticking over at 1250rpm. With the revs that low you are saving fuel, but you do have a V8 770hp engine which is going to be more thirsty, it’s a matter of getting the balance right between the two and playing those two factors off against each other. It’s the old equation of matching power output and rear axle diff ratio, and it is about a sweet spot.

This is a continual dynamic and often simply a matter of opinion. An engine with around 600 hp will probably give you a similar performance with better fuel economy, but it is such a fine balance and there is room for a wide set of opinions on the topic. Fleets vary widely, reckoning on a sweet spot for B-double all of the way from the

mid 500s to the mid 600s, in terms of horsepower.

The other factor here is emphasised by the fact this truck has the number 770 emblazoned down the side, suggesting it’s all about marketing, but it’s not a vanity project. Scania know that there will be people who will buy this truck because it’s got 770hp, and why not? Perhaps the truck maker should go into the business of selling very expensive 770 stickers to put on the doors of more frugal trucks?

One of the strengths of the Scania brand over the years has been the driving environment. The feeling inside the cabin is always relaxed and quiet. The R model cabin doesn’t have a flat floor floor, but we are close enough with this design and similar ones from other brands, to be satisfied with this kind of layout. In this instance the small step up does mean the dirt etc, which gets into the cabin on the drivers feet does not end up all over the floor and remains in the footwell.

Scania is always ultra conservative and hasn’t gone down the route of having the screen in front of the

driver as one big electronic screen. There’s a relatively small screen which has got all the data the driver needs. Then there’s an analog speedometer, and in the middle of it is a digital speedometer and odometer. Around this are the usual analog dials the driver needs.

The basic shape for the curved dash has changed little since the old Scania 3 Series, but what’s on there has changed and it’s still ergonomically correct. Anything that a driver actually needs to touch on a regular basis is within touching range.

The number of buttons on the top of the driver’s door still holds the record, with 16 by my count. This is because the light controls also live there, in an easily viewable position.

This cabin has got the high roof with a lot of big lockers in it, three at the front and three in the back up to the ceiling height. Underneath there’s the larger than usual bed, you wouldn’t think 270mm would make so much difference. It just adds the sensation of space, you don’t feel

was based on a persistent demand from several markets, notably Australia. Known as the CR23 cab variant, the larger cabin is produced by Scania’s subsidiary Laxå Special Vehicles, which also builds its other speciality vehicles like fire engines.

The extra room means the bed which can be pulled out to one metre wide, now no longer needs to be retracted to move the seats back into their driving position. Scania reckon the adaptation represents an increase of more than 13 per cent in internal cabin dimension.

Australia’s love of the big cabin is demonstrated by the fact that this bigger cabin is selling more in Australia than in any other truck market in the world.

The other ‘Scania’ aspect is the nice little touches in the design. The small desk which folds out in front of the passenger seat which is well designed and neat. The pedal on the inboard side of the seats releases them, so you can slide them as far forward or backwards as you can, freeing up some space. The sun

at 100 km/h heading south down the Hume Highway in the constant ascent and descent countryside there are minimal occasions when the service brakes needed to be used.

The topographical mapping in the cruise control system means the truck knows when the up and down grades are coming up and is prepared for them. There is a tendency to bring in the retardation, first engine brake and then retarder, as the truck overruns the set speed. There is enough there to hold the B-double back on all of the downgrades and keep the overspeed inside the two km/h limit set.

The first service brake application was in the evening heading south out of Sydney, slowing down to park up for the night at the servo in Yass.

The effectiveness and accuracy of the topographical mapping was illustrated on the relatively flat roads passing Euroa. This country is generally flat and there are mild ups and downs as the truck drives along on cruise control.

As one of the flat sections started

build up pace until it was back at 100km/h. Then it just brought the engine back in and the revs rose back up to 1200.

At the start of the rise the engine was at 1200rpm, as it was trying to climb up the slight grade and then coasted slower over the top of the hill, but allowed the slight descent to get its acceleration back up to cruising speed. Even when running at 500rpm you are using some fuel, but you’re using considerably less fuel at idle than at 1200.

The eco-roll tended to be holding on for really long periods on some of these roads. There was a period of several minutes on another section of road, just a slight downhill, going at 100km/h at the top and it just took everything off and it remained like that for quite a while until it hit the bottom at this very slight slope. From the driver’s seat it was not clear

which section was downhill and which was flat. But the truck knew.

At the end of the trip, the run down the Hume felt like a walk in the park. The truck had taken away a lot of the hard work from the driver and the experience of the drive enabled me to trust the automated systems more, as I realised how smart it was without my interference. I could have intervened more and may have shaved seconds off the trip time, but I am certain I would not have done the trip using less fuel.

At the end of the day this is a truck with the most power available and the top torque on the Australian truck market. It does feel like it’s doing it easy, and a lot of the time it is. When it does need to dig in, at the foot of a grade at 60 tonnes for example, it does, and delivers a smooth ride, while only

being overtaken by unladen trucks.

The fact that the number 770 is emblazoned down the side of the cab in very large numerals tells you this truck is being sold on that figure. These numbers come at a price, but it is a price that some people are willing to pay, whether it is for kudos, or driver retention.

Surprisingly, there was no indication anywhere on the cabin to tell passing trucks this has the bigger cabin. In fact its size is disguised by the aerofoils which sprout from the rear of the standard cab. Because of this, the 270mm bulge in the rear of the cabin wall is hidden by the aero kit, talk about hiding your light under a bushel!

From my point of view, as a truck driver for well over 40 years, if you were trying to sell this truck to me, the 770 wouldn’t hook me in, but the wider bunk would be much more likely to get me over the line.

“770HP’ SETS OFF A LITTLE FLURRY OF EXCITEMENT.”

Evolved, refined, technologically advanced, the award-winning K220 takes the driver experience to the Next Level.

KENWORTH.COM.AU/K220

The Kenworth K220 was awarded the 2023 Truck of the Year Australasia award, but how was it designed and developed? PowerTorque spoke to some of the team behind its design.

Designing a new truck model is a large, long and complicated task, over a period of years. After the Kenworth K220 was presented with the ToYA award earlier this year, Tim Giles sat down with two of the Paccar design and engineering team, Brad May, Paccar Australia Chief Engineer and Ross Cureton, Director of Product Planning, Paccar Australia to drill down into just what went into the creation of the final truck.

“The initiation of a project comes from a number of factors. In the K220’s case it started with the fact there was new technology available to include in the design, and an update was needed to keep our models aligned – in terms of technology, comfort and powertrain, says Brad.

“The K200 was very successful, but you can’t keep selling the same thing forever,” says Ross. “Customers’ requirements also change. You can’t wait until the customers say ‘no, I’m not buying that anymore.’ Now that didn’t happen with K200s because they’re so versatile and productive that people

keep buying them, and making a living with them.

“You have to look at what do people value now as opposed to what they valued back in 2008, when we developed the last one, and has that moved? And of course it has.”

The planning process started in early 2019. Paccar did its most extensive tour of customers around the country, gathering their input. A lot of time and energy was spent finding out and getting an understanding of what the customers wanted, working out where their preferences had changed.

The design team went on a tour of sorts that year, meeting with a wide range of customers at their sites to get their initial thoughts on what they would like to have seen in a new model. In May 2021, the team brought the customers to the Kenworth development centre and showed them the product and asked whether the designers hit the mark., The customers whose input had been requested got to physically interact with something and tell the design team what they thought of it.

There was also new technology Kenworth needed to put into the truck. A new platform needed to be designed into the truck to enable advanced safety and other items to be included in the design.

The K220 team created a platform with which Kenworth could access the latest technology. As time evolves, the systems get better, the software gets more advanced and the hardware which drives the software gets more capable.

“It’s just greater depth of quality in executing those things that the K220 enables,” says Brad. “From a compliance point of view, it doesn’t make a difference, but as far as offering the very best and the latest of everything, that’s probably the main part of the K220 story, the electrical architecture.”

At the start of the program the team didn’t know that AEBS would become standard. Even the date for mandating Euro 6 was uncertain at that point.

“We knew the Cummins X15 Euro 6 engine was coming, but there was a separate project to validate them and

or operator can choose to have the traditional dials and instrumentation on that screen, which was previously shown on the analogue version. However, it has the capability to display contextual information, which can’t be shown in an analogue way, which the operator may decide they need in five years’ time.

“Just because you can doesn’t mean to say you should,” says Brad. “You have to think about what problem you’re solving and what opportunity are you creating. Looking at the Australian market, at things like driver availability and the need to help them improve their performance, it’s been a great asset if you can have a driver interface that helps customers deal with that.”

The real meat of the design process took place during the long hard shutdowns that Melbourne suffered during the pandemic. Engineers used to rubbing shoulders each day and bouncing ideas around the office had to try and replicate that teamwork via online discussions with just a computer screen to talk to.

Luckily the teams have been working together for years and the relationships with the vital component suppliers are also long term. This enabled the collaborative environment needed in a situation like this to

develop on the K220 project.

“Some of the things we found in our discussions with customers sharpened our focus, so when we talk about the new cab suspension we’ve developed for the truck, that was something that evolved during the development of the truck,” says Ross. “So we included it and it’s locally manufactured and designed by us to suit our roads and our requirements, with input from customers and tested by us as well.”

That cab suspension is in a ‘controlled’ release at the moment, in certain applications. It’s getting some experience in the real world.

“The customers who buy the trucks are the main stakeholder, but we certainly have plenty of opportunity to bring in the rest of the stakeholders as we develop products,” says Ross. “It was tricky because the factory was working throughout COVID.”

More than 100 people are working in engineering, but the core project development teams are much smaller than that. Engineers with highly specialised knowledge from the local team, and increasingly, from the broader Paccar engineering team are brought in just when the team needs to access that expertise. Those specialists can be anywhere in the world,

sometimes writing specific code for a truck they will probably never see.

“It certainly has changed a lot about the way we design new products now. We’ve got many engineers here now who spend their working days outside the normal daylight hours of Australia, because they’re connecting with people in all parts of the world.”

The engineering team at Bayswater has demonstrated its skills and is so capable and respected that they are now the first people outside of Holland to be designing and changing DAF trucks.

“DAF in Holland are very capable engineers that understandably closely monitor the changes we need to make for Australia,” says Ross. “Now we have this local team that is doing exactly that, enhancing the product. That’s something to be proud of, a group that’s so recognised and respected globally they can participate in global projects.”

The Paccar operation in Bayswater typically hires somewhere between 10 and 30 new engineers as graduates every year. They will then spend a lot of time working in the business and around the different departments, in manufacturing, in service, sales, engineering, many different roles to build a bedrock of understanding of the market and the products. Only then will they be let loose on designing the product.

“We understand that there’s a lot of equity in the current product and you have to change it carefully” says Ross. “What do you want to keep? What do you not want us to alter? That’s a big part of the conversation we have with customers, because we think we know, but sometimes, it’s surprising the daily things that they feel strongly about.

“When we started the project, we had just finished releasing the T610, then the T410 and the T360. Nothing is entirely in a bubble, what did we learn from that product, that process? The dash is a different method and construction than what we’ve done previously, and there was of a lot of concern and interest about how we did that.

“I remember Brad coming to me and saying, ‘I’ve had a customer say to me, when can I have that dash in a cab over?’. You watch people’s perceptions change and then I heard the same thing.

“You have to get to the heart of what they mean with a request like that. Perhaps it turns out they mean the air conditioner is fantastic in that one, and that’s what they’re really asking for. So you start to tease out what the customer does value, and it’s great when you hear the customers essentially saying ‘you hit the nail on the head, when can I have more of what you just did?’”

One of the important selling points of the Kenworth K220 is its powertrain and two major components in this vital aspect of the truck come from the Cummins stable, the engine and the drive axles.

In the last ten years the Kenworth and Cummins brands have become almost synonymous. Most Kenworth trucks coming down the line at the Bayswater plant will have the distinctive red engine under the bonnet. At the same time, the majority of those trucks will also be fitted with the Cummins Meritor rear end.

In the Kenworth K220, the red engine comes in two variants, the X15 Performance Series and the X15 Efficiency Series, with one offering flexibility and the other improved fuel efficiency.

The Cummins X15 Performance Series is designed for flexibility and the ability to work effectively with both manual and automated transmissions. It is suitable for, vocational, heavy-haul and line-haul applications.

Ratings on offer go from 525hp to 625 hp and there’s 2050 lb-ft of torque available at 1000RPM, this gives the truck excellent application flexibility. Working at high masses and in difficult tasks this engine has the durability and reliability that provides peace of mind for truck operators.