STAYING ON TOP OF THE SAND PIT

Holcim Australia’s Grantville Quarry stays on top of the competition, thanks to a partnership with Delta Rent.

ENSURING COMPLIANCE

Steve Franklin, founder of Eltirus, details the remarkable results that can emerge when operators plan, do, check and act.

HEAVY DUTY MACHINES FOR HEAVY DUTY QUARRIES

WA Limestone wanted a rock breaker with some “meat on the bones” to handle its hard rock quarry in Onslow.

18 34 40 OFFICIAL JOURNAL OF THE INSTITUTE OF QUARRYING AUSTRALIA AUGUST 2023

Call us today on 1300 566 287 to find out more. Upgrade your fleet with Komatsu iSite Equipped on all HD405-8 and HD605-8 Dump Trucks Komatsu iSite provides production visualisations and real-time overviews of machine movement and production to allow you greater control. Komatsu iSite functionality is only available with an active subscription. For more information, visit www.komatsu.com.au/innovation/smart-construction/komatsu-isite

IN THIS ISSUE

FEATURES

20 ADAPTING TO A CHANGING WORKPLACE

Komatsu Australia explains how the company is improving outcomes.

24 EVOLUTION OF EXCELLENCE

Volvo Construction Equipment has launched the 56-tonne L350H2 loader.

26 QUARRY EXPANSION ON TRACK WITH ASTEC

Hopkins Brothers’ quarry expansion is on track as part of the company’s plan.

28 ENSURE BELTS CAN HANDLE

A TOUR OF DUTY

STAYING ON TOP OF THE SAND PIT

Grantville Quarry stays on top of the competition, thanks to a partnership with Delta Rent.

34

ENSURE COMPLIANCE

Steve Franklin, founder of Eltirus, details the remarkable results that can emerge when quarry operators plan, do, check and act.

40

HEAVY DUTY MACHINES FOR HEAVY DUTY QUARRIES

WA Limestone wanted a rock breaker with some “meat on the bones” to handle its hard rock.

50

RUBBER AND ASPHALT DO MIX

Quarry explores how crumb rubber asphalt is being used across NSW.

Martin Engineering recommends some key considerations to ensure your site gets the most out of the conveyor belt.

32 ALL COVERED

Kinder Australia is helping quarries protect one of their expensive assets.

38 PILE UP THE BENEFITS OF STOCKPILERS

New industry thinking has highlighted the value of local manufacturing.

42 BORAL GETS MORE WITH THE XMOR BUCKET

Andrew Rankin explains how a new bucket is boosting productivity.

44 A FORWARD-THINKING CRUSHER

A vertical shaft impact crusher with European sophistication has been a hit.

46 INSITU’S END-TO-END CORPORATE ADVISORY AND REAL ESTATE DELIVERS

Insitu Advisory and Real Estate’s experience and knowledge comes to the fore with quarries.

48 MANUFACTURING LOCAL MEASUREMENT

Tecweigh’s latest conveyer belt scales are designed for the quarry industry.

52 WHEN YOU NEED IT, WHERE YOU NEED IT

Oli Vibrators Australia is fully stocked and on standby to assist quarries.

COVER ADVERTISER: Holcim Australia’s Grantville Quarry utilises two articulated dump trucks and two frontloaders to stay on top of the competition, thanks to a partnership with Delta Rent..

Quarry August 2023 3 18 AUGUST 2023 www.quarrymagazine.com QUARRY Holcim Australia’s Grantville Quarry stays on top the competition, thanks to partnership with Delta Rent. Steve Franklin, founder Eltirus, details the remarkable results that can emerge when operators plan, do, 18 34 40 OFFICIALJOURNALOFTHEINSTITUTEOFQUARRYINGAUSTRALIA AUGUST2023

AUGUST

VOLUME

ISSUE

2023

33,

8

06 FROM THE EDITOR 08 FROM THE PRESIDENT 10 NEWS THIS MONTH 16 PRODUCT FOCUS 54 IQA NEWS 56 IQA MEMBER 60 GEOLOGY TALK EVERY MONTH

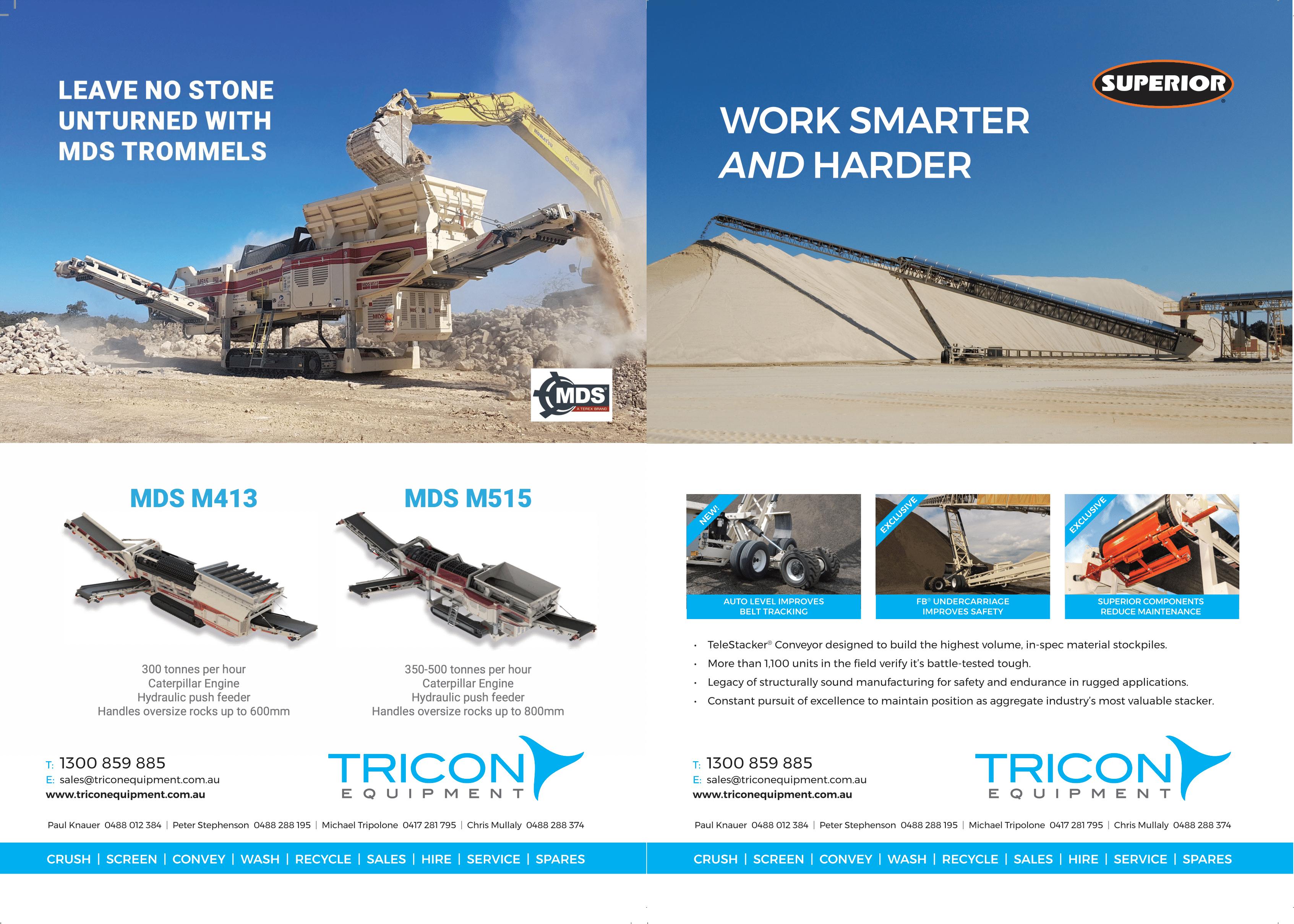

2022 LIPPMANN L300C CONE CRUSHER

The Lippmann 300c is a heavy duty cone crusher with an innovative material flow that maximizes capacity and throughput while delivering a consistently high quality product. POA

Heavy duty 20x6 screen box, Cat C7.1 engine, hopper extensions, apron feeder, full radio remote control function

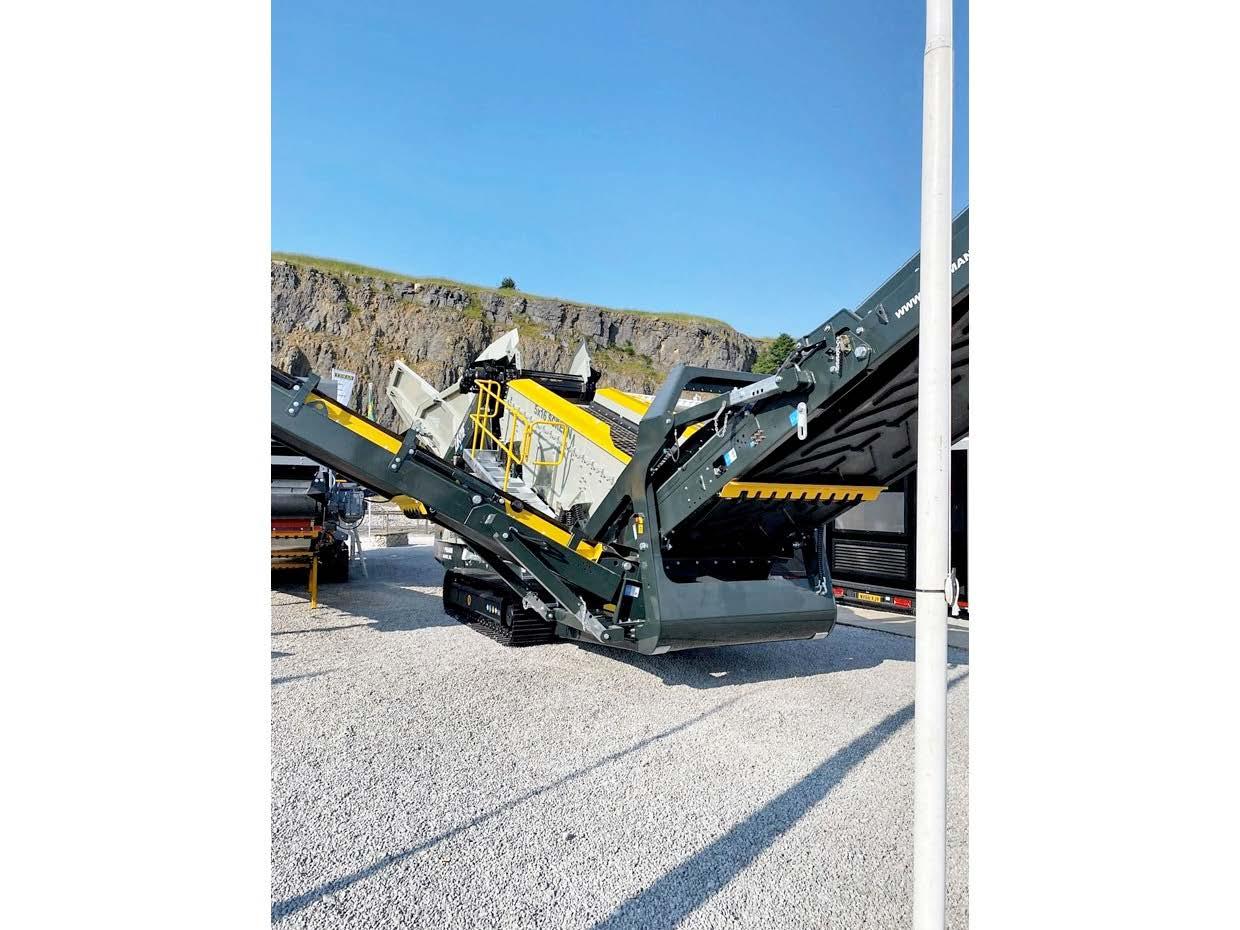

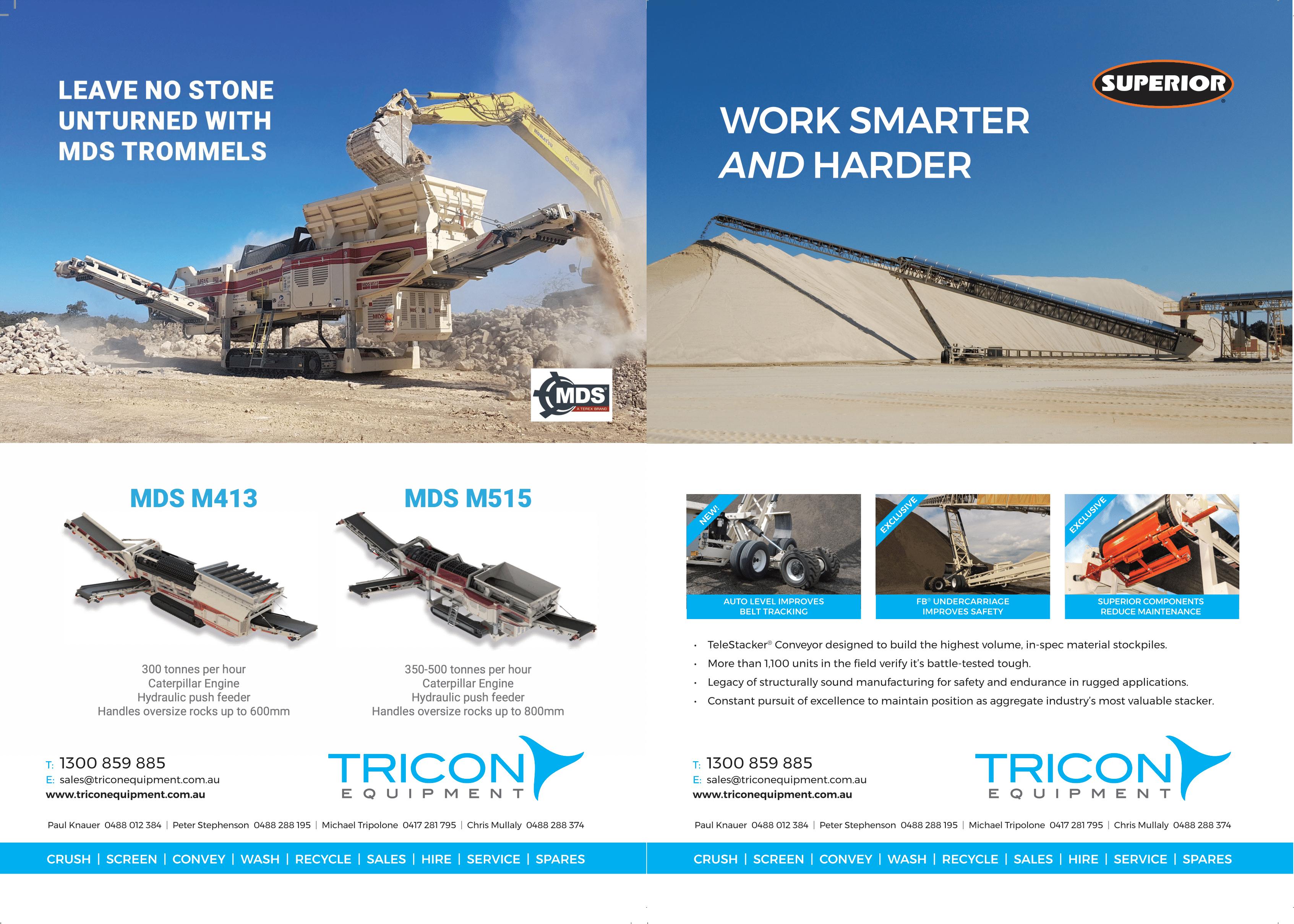

TEREX M515 HEAVY DUTY ROCK TROMMEL

New & Used units available throughout Australia, Tricon is Australia’s only authorised Terex MDS distributor.

LIPPMANN

&

MOBILE SCREENS

Lippmann LS range, 22x6 and 20x5 triple deck finishing screens now available, POA

LIPPMANN L620R 20x6 SCALPER

LS520

LS622

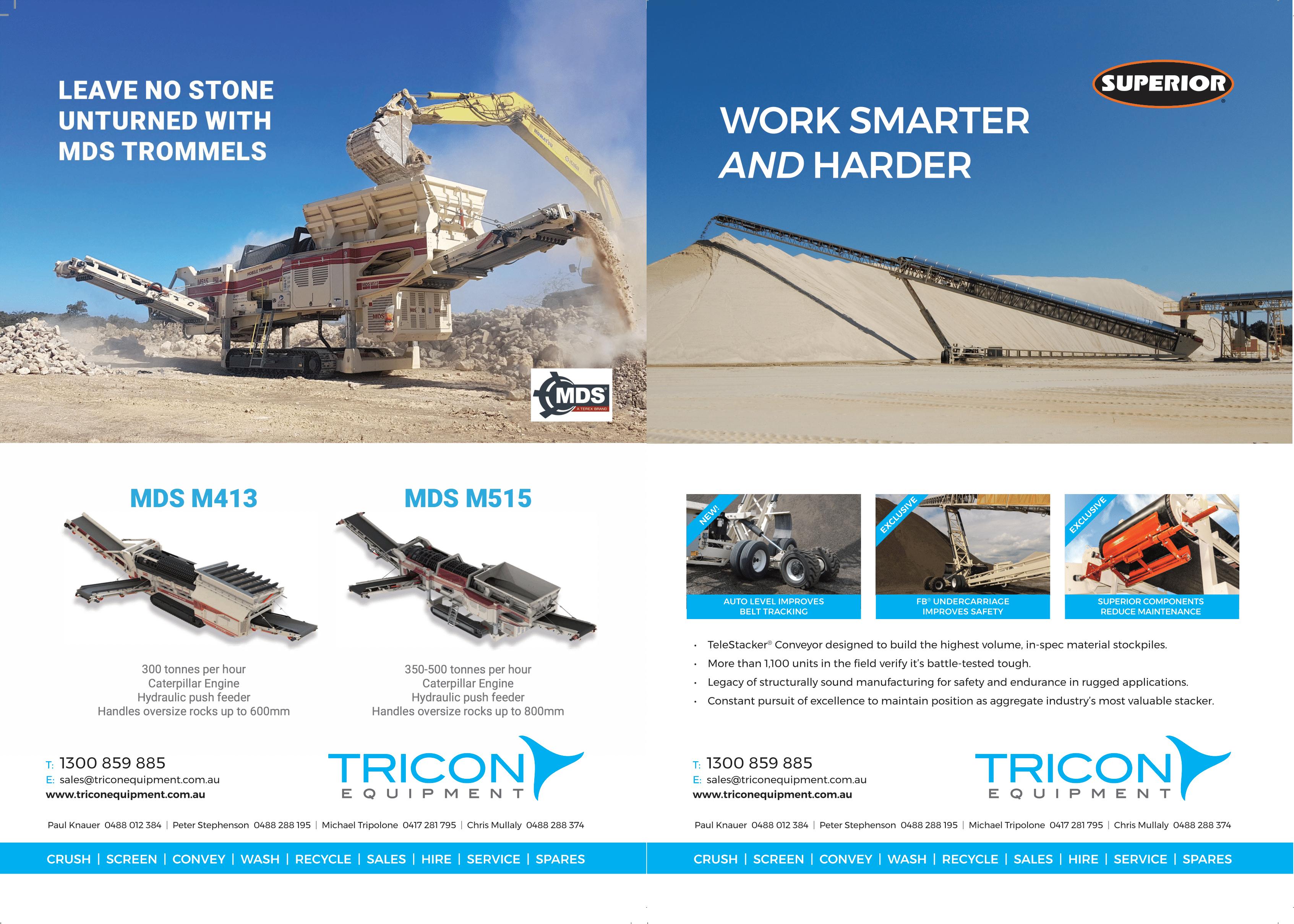

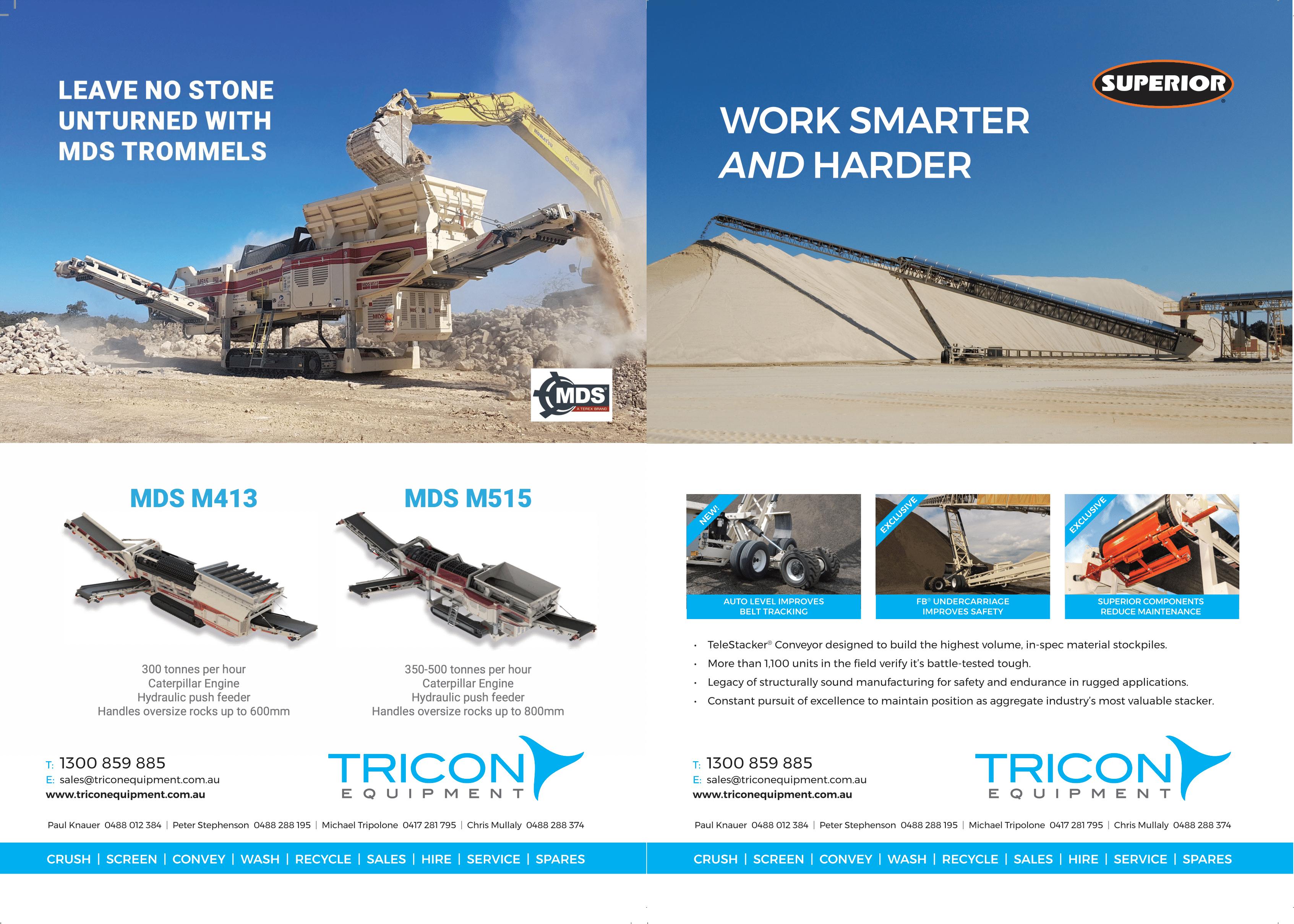

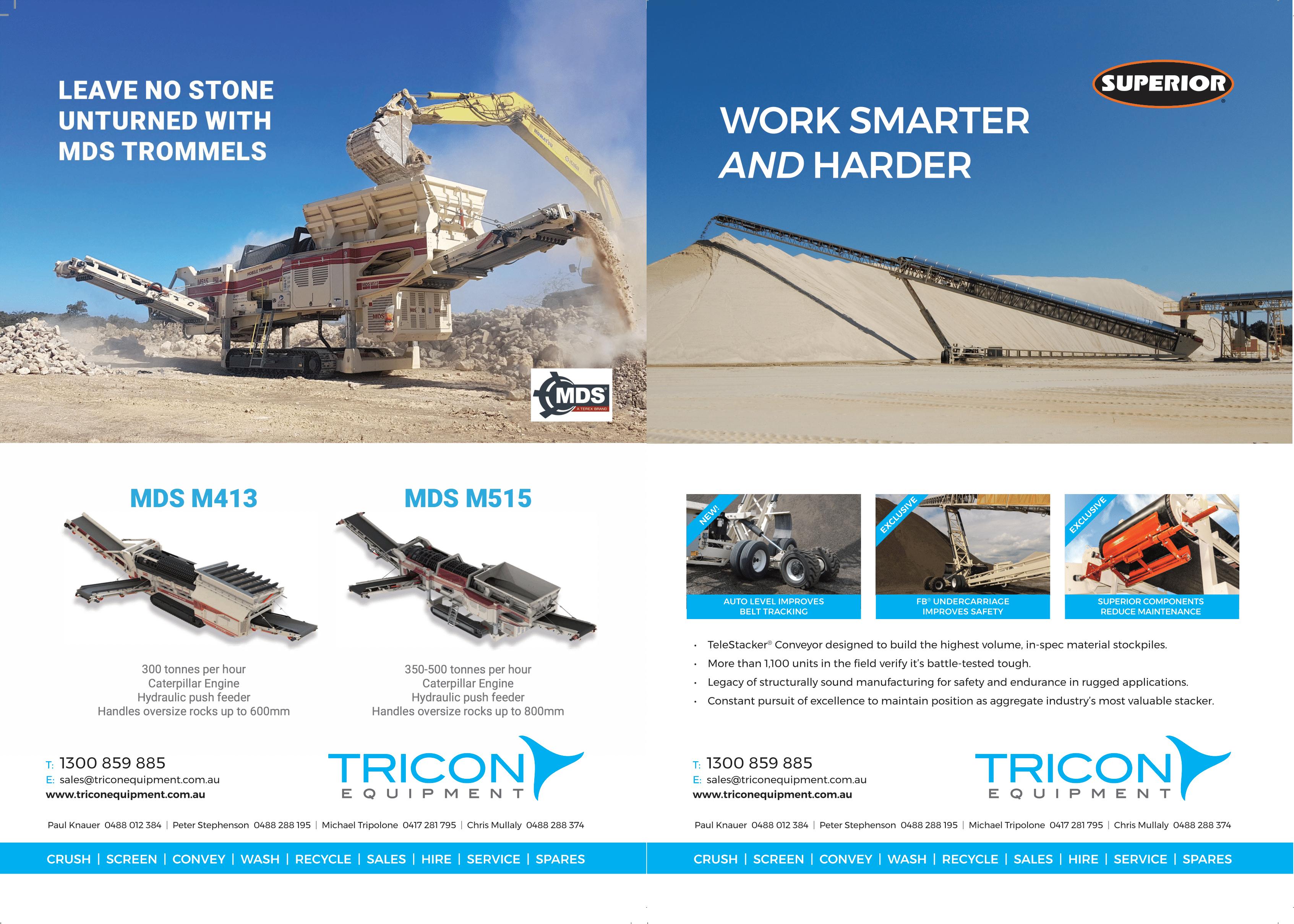

SUPERIOR TSSA 150' TELESTACKER

New Superior Telestackers in stock, 1000TPH, 46m, AS3000 electrics, AS4324 structure, auto stockpile, radio remote control. POA

SUPERIOR ALLIANCE LOW WATER WASHER

Wash your natural, manufactured or recycled sands with a greatly reduced water demand. POA

SUPERIOR TSSA 130' TELESTACKER

TSSA 130’ telestackers back in stock, 1000TPH, AS3000 electrics, AS4324 structure, auto stockpile, radio remote control. POA

SUPERIOR

SUPERIOR GUARDIAN 6203

Superior Guardian 6203 20x6 horizontal screen boxes now available Australia wide (ex QLD & NSW) POA

RAZERTAIL TRUCK UNLOADER

RAZERTAIL TRUCK UNLOADER

RUBBER HITS THE ROAD

Infrastructure is the order of the day around Australia, as local, state, and federal governments invest billions into building, expanding, and maintaining key roads.

These projects have a voracious hunger for construction materials, requiring millions of tonnes of concrete and asphalt. However, governments of all levels are seeking sustainable solutions for these materials.

One such solution is crumb rubber. Made from end-of-life rubber products, like the tyres used on quarry equipment, the highly refined rubber can be used for road surfacing.

It’s an excellent example of how we can recycle and repurpose materials that were once seen as waste, and incorporate them into new applications.

Key players in the industry like Boral have embraced the material, supplying it to local councils for use in a range of asphalt mixes. The company has been involved in a recent year-long project, supplying thousands of tonnes of the asphalt mix to pave across local council streets.

The performance of each asphalt mix will be monitored in a range

of applications and conditions to measure the benefits, and to generate comprehensive data on the use of recycled rubber-based treatments.

It is part of Boral’s efforts to decarbonise and to process recyclable materials, like construction waste, that would have otherwise been destined for landfill.

As sustainability initiatives grow and develop, it is likely there will be significant uptake of new recycled materials. The industry is well positioned to support these burgeoning material developments as more organisations help to build the “circular economy”.

In this edition of Quarry we are highlighting the businesses that have embraced sustainability and recycling. It has been great to hear about how quarries are getting involved and supporting this important work.

In the next issue, we will be focusing on earthmoving and ground engagement equipment. If you would like to get involved, please get in touch.

Paul Hayes Managing Editor

“THESE PROJECTS HAVE A VORACIOUS HUNGER FOR CONSTRUCTION MATERIALS, REQUIRING MILLIONS OF TONNES OF CONCRETE AND ASPHALT. HOWEVER, GOVERNMENTS OF ALL LEVELS ARE SEEKING SUSTAINABLE SOLUTIONS FOR THESE MATERIALS.”

Published by:

379 Docklands Drive Melbourne VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

Chief Executive Officer

John Murphy john.murphy@primecreative.com.au

Managing Editor Paul Hayes paul.hayes@primecreative.com.au

Assistant Editor

William Arnott william.arnott@primecreative.com.au

Journalist

Adam Daunt adam.daunt@primecreative.com.au

Business Development Manager Les Ilyefalvy les.ilyefalvy@primecreative.com.au

Client Success Co-ordinator

Janine Clements janine.clements@primecreative.com.au

Design Production Manager Michelle Weston michelle.weston@primecreative.com.au

Art Director

Blake Storey

Graphic Design

Kerry Pert, Tom Anderson, Louis Romero, Cat Zappia

Cover photography

Delta Rent and Ned Meldrum

Photography Subscriptions

T: 03 9690 8766 subscriptions@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published. © Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

6 Quarry August 2023 EDITORIAL

Strong. On their own or together.

THE MOBICAT MC 110 EVO2 AND MOBICONE MCO 90 EVO2

110

TEAM PLAYERS THAT WORK TOGETHER INTELLIGENTLY AND STRENGTHEN EACH OTHER. In linked plant combinations, the MOBICAT MC 110 EVO2 jaw crusher and the MOBICONE MCO 90 EVO2 cone crusher really flex their muscles. SPECTIVE makes both plants easy and intuitive to operate. Also, an advanced drive concept ensures greater effi ciency with lower consumption. Maximum throughput is achieved thanks to the material fl ow concept coordinated via line coupling across both crushing stages. Go for the perfect team!

www.wirtgen-group.com/kleemann

A WIRTGEN GROUP COMPANY

MC

EVO2

WIRTGEN AUSTRALIA PTY LTD · National Ben Lefroy +61 448 030 420 · WA Greg Lewis +61 448 033 441 · QLD/NT Adam Lane +61 459 031 778 · NSW Linn Smith + 61 418 276 649 · VIC/SA/TAS Kyle Fredericks +61 447 539 302 · sales.australia@wirtgen-group.com · www.wirtgengroup.com/australia

MCO 90 EVO2

PLANNING AHEAD

It is always a busy time of year through these winter months and that is also true at the IQA where we have had several exciting developments.

We have announced a significant addition to the IQA team with Clare Murray coming on board as chief executive officer.

Clare will be focusing on meeting our branches, suppliers, and the industry to discuss and implement our new strategic plan and deliver projects to meet our objectives.

Clare takes over from Kylie Fahey, who has left an indelible mark on the organisation in her time with us and we thank her for her contribution.

The new strategic plan was endorsed at our April 23 meeting with members to receive further communication about the initiative in the coming months.

With this plan, we are aiming to support industry participants with compliance and regulation, foster stronger industry connectivity and build a diverse and skilled industry workforce.

We conducted extensive research and an external review with industry stakeholders and our members in designing the strategic plan.

The strategic priorities address the key facets the industry raised through consultation and the IQA is wellpositioned to address these both now and into the future.

These strategic priorities cement our intention as an organisation to provide the best education and opportunities to our members and

people engaged with the extractive and associated industries.

We managed to reach a significant milestone in the financial year with more than 1600 members which was our highest ever recorded number.

Our members have been and always will be at the heart of everything we do as an organisation. I would like to take this opportunity to thank you all for your support which has helped make the IQA a wonderful community.

With memberships due for the 2024 financial year, we encourage all current members and anyone who has thought about joining to sign up to be part of our organisation.

Our industry needs its members involved. I encourage you to join your local committee and/or enable your staff to get involved. Committees offer a fantastic insight into the industry and help develop our emerging leaders.”

Our branches have delivered a full suite of events already which have focused on improving network opportunities and educational events with more to come later this year.

By joining your local branch and committee you will be able to access these opportunities which will provide you with a terrific insight to become an emerging leader in our industry.

Duncan Harris President Institute of Quarrying Australia

www.quarry.com.au

The IQA’s Strategic Plan 2020 to 2025 embodies the following vision, values and strategic priorities:

Vision:

Educating and connecting the extractive and associated industries.

Values:

• A safe and sustainable environment.

• Diversity and inclusion.

• Working development skills, careers and life-long learning.

• Networking, connection, trust and communication.

Strategic Priorities:

• Maximise outcomes for industry through education and sustainable practise.

• Increase our relevance.

• A high performing and sustainable organisation.

IQA Contacts:

Phone: 02 9484 0577

Email: admin@quarry.com.au

Chief Executive Officer

Clare Murray

Deputy President

Sarah Bellman

Company Secretary

Rod Lester

For all education, member and branch enquires please email: admin@quarry.com.au.

8 Quarry August 2023

The Institute of Quarrying Australia

PRESIDENT’S REPORT

Educating and connecting our extractive industry

“WITH THIS PLAN, WE ARE AIMING TO SUPPORT INDUSTRY PARTICIPANTS WITH COMPLIANCE AND REGULATION, FOSTER STRONGER INDUSTRY CONNECTIVITY AND BUILD A DIVERSE AND SKILLED INDUSTRY WORKFORCE.”

Sustainability improvement services

There are three specific areas where CO2 emissions can be reduced in a quarry operation. We work with sites to help them identify the opportunities for improvement, implement them and monitor the results, resulting in reduced emissions and lower cost per tonne. Talk to us about how we can help you meet your sustainability targets.

+61 7 2139 5924 • L2, 127 George Street Brisbane Q 4000 Australia • eltirus.com KNOW WHAT’S IN THE GROUND | EXTRACT IT SUSTAINABLY | ENSURE COMPLIANCE

NZ QUARRY CONFERENCE BRINGS INDUSTRY TOGETHER

Some of the brightest minds in quarrying visited New Zealand to discuss the major topics facing the industry.

Queenstown and Christchurch hosted the events including the firstever meeting of the NZ of the Global Aggregates Information Network.

The events had industry leaders visit from across the globe.

AQA chief executive Wayne Scott said the conference was an exciting opportunity for the industry.

“They face the same issues as New Zealand quarries – getting

quarries consented, dealing with neighbours, meeting increasing sustainability requirements – and achieving recognition when many exceed those requirements,” Scott said.

“We all also face the realities of climate change.

“One consequence of more frequent, more savage floods and rising sea levels is that people need ready access to quarry materials to rebuild and make their homes and roads more resilient.”

“You can’t get those materials

TO THE CITY’S REBUILD.

if you face years of delay to get a new quarry consented or an existing one approved.”

The issues discussed at the Queenstown GAIN meeting will flow on into the annual QuarryNZ conference.

Around 600 people were estimated to have attended, including some GAIN representatives.

It is the first QuarryNZ conference in Christchurch since the 2010–11 earthquakes and marks the industry’s contribution to the city’s rebuild.

MCLANAHAN FINALISES DIEFENBACH ACQUISITION

McLanahan Corporation announced it has finalised the acquisition of Diefenbach, which was announced in February 2023.

Diefenbach, a leading manufacturer of filter presses and thickeners based in Medolago, Italy, has been designing and manufacturing liquid-solid separation equipment since 1907.

With thousands of installations around the globe, Diefenbach provides solutions for filtration and dewatering applications in a wide range of industries, including chemicals manufacturing, food and beverage processing, aggregates, mining, battery recycling, PET recycling, wastewater treatment and many more.

McLanahan and Diefenbach have been working on projects together since 2013. This new partnership will

allow McLanahan to better serve its customers around the world, offering a more comprehensive solution to water recycling and tailings management to help customers meet ever-changing processing requirements and to help contribute to sustainable materials processing practices as part of the circular economy.

“As the focus on sustainability and creating a circular economy within the materials processing industry continues to grow, the need for water recycling and tailings management is more important than ever,” said Cory Jenson, EVP – sales and business development at McLanahan.

“This acquisition complements McLanahan’s existing line of tailings and water management solutions and allows us to offer more competitive solutions.”

Diefenbach will continue to operate as an independent brand in the marketplace and continue to support its customers globally. For the aggregate industry, Diefenbach is partnering with Eagle.

Iron Works, another brand in the McLanahan family of companies, provides a proven line of filter presses and thickeners to EIW customers who are looking to purchase a complete tailings management and water recycling solution from one vendor.

Headquartered in Hollidaysburg, Pennsylvania, United States, the McLanahan Corporation offers more than 188 years of experience in providing processing solutions to a variety of materials handling industries, including quarrying.

10 Quarry August 2023 NEWS

IT IS THE FIRST QUARRYNZ CONFERENCE IN CHRISTCHURCH SINCE THE 2010/11 EARTHQUAKES AND MARKS

THE INDUSTRY’S CONTRIBUTION

AQA CEO Wayne Scott.

LEADERS IN LOADING.

The New Volvo L350H Wheel Loader

Built to take on the toughest of jobs, the new Volvo L350H wheel loader arrives on the back of decades of innovation, revolutionising operations and streamlining productivity. It’s advanced features such as Volvo OptiShift technology ensures smooth gear shifting, and reduced fuel consumption and downtime.

Experience the future of quarrying with the Volvo L350H and unlock new levels of performance, efficiency, and reliability.

Contact your local branch for more information

YOUR PARTNERS IN PRODUCTIVITY

CJD.COM.AU 1300 139 804

CONSTRUCTING THE FUTURE

The Inside Construction Expo 2023 is shaping up to be Melbourne’s leading event for the construction and infrastructure sector.

Hosted by Prime Creative Media, the Expo will act as a forum to discuss key challenges rising in the construction sector, and what can be done to address them.

Such challenges that have affected the key sector include skilled labour shortages and supply chain disruptions, forcing these areas to adapt and evolve to keep up with the booming national infrastructure pipeline. Additionally, safety and digital transformation in the construction industry will be discussed.

The Inside Construction Expo 2023 will have a conference program featuring over 100 speakers across multiple stages, and an exhibition showcasing the latest in construction equipment and technology.

The primary aim of the Inside Construction Expo 2023 is to help attendees understand key solutions to the mentioned challenges that have arisen in the sector.

“Inside Construction Expo was created to fill the apparent gap in events targeted at major commercial and civil projects,” Prime Creative Media show director Lauren Winterbottom said.

“With such a large investment in infrastructure, we’re seeing the best in new

industry developments – from safety to technology – rolled out before our eyes.”

From engineering to sustainability, the Expo will offer diverse perspectives and experiences which will contribute to answering the industry’s toughest questions.

“Throughout the conference, attendees can expect to hear from executive-level representatives from Australia’s major constructors and suppliers, alongside research and education bodies and government figures,” Winterbottom said.

One of the key speakers will be Teagan Dowler, the director and founder of the BCW – which offers services to support organisations at all stages of diversity and inclusion maturity.

Dowler has over 15 years’ experience in the heavy industries with a focus on diversity and inclusion, as well as cultural change and coaching. She has also been the STS Consulting project and capability manager for 12 years.

Recently, Dowler won Mentor of the Year at the 2023 Women in Industry Awards, an event hosted by Prime Creative Media that recognises outstanding women from across male-dominated industries.

Winterbottom said it is pleasing to partner with industry associations and peak bodies to bring the Inside Construction Expo to life. Of course, the event would not be possible

without the support of a wide range of sponsors – one being Wurth Australia.

Wurth Australia, a subsidiary of Wurth Group, is a specialist in assembly and fastening materials for the Australian marketplace. It focuses on the quarry, automotive, cargo, metal, wood, mining, and construction industries.

Position Partners will also be a proud sponsor of the conference. It is provider of intelligent positioning solutions for surveying, quarrying, mining and building activities.

It also focuses on the distribution and support of intelligent positioning solutions for specifically geospatial, construction and mining projects.

Winterbottom said that the event is already seeing great success through media coverage.

“In the lead up to the event, over 19 industry-leading publications continue to extensively cover the latest in Expo news reaching more than 80,000 decision makers across multiple sectors,” Winterbottom said.

The Inside Construction Expo 2023 promises to be a must-attend event for industry members across the construction and major infrastructure sectors. •

The expo will be held from September 20–21 at the Melbourne Convention and Exhibition Centre. Visit insideconstructionexpo.com.au to learn more.

12 Quarry August 2023 EVENTS

The Inside Construction Expo 2023 will be held at the Melbourne Convention and Exhibition Centre.

KOBELCO XD SERIES

The new XD Series is engineered for the most demanding applications. Built on Kobelco’s rock-solid reputation for quality and reliability, these extreme duty machines feature a rugged machine body with comprehensive additional reinforcement where it matters most. These machines take strength and durability to an all new level – delivering increased performance across even the harshest work sites. Built for power. Built for reliability. Built to last. The new Kobelco XD Series.

kobelco.com.au | 1300 562 352 @kobelcoaustralia

WINNERS OF THE WOMEN IN INDUSTRY AWARDS ANNOUNCED

The winners of the 2023 Women in Industry Awards have been revealed. The awards recognise outstanding women from across a range of industrials sectors, including in mining, transport, manufacturing, engineering, logistics, bulk handling, waste management, rail and construction and infrastructure.

The 2023 Women in Industry Awards were held at Aerial South Wharf in Melbourne.

THE 2023 WINNERS: BUSINESS DEVELOPMENT SUCCESS OF THE YEAR

Stefanie Frawley from TMX Global.

Stefanie successfully identified a gap in the offerings available to TMX customers, and introduced a new Portfolio Management option. As a result, Stefanie has grown her team from one to seven employees, servicing more than 14 clients in this new offering, and increased revenue from her team by 1000 per cent in the past two years.

INDUSTRY ADVOCACY AWARD

Jemma Walshe from Fulton Hogan.

Jemma advocates to ensure time, energy and resources are dedicated to making a difference to the communities that Fulton Hogan works within and has been critical to the establishment and roll out of a number of positive community engagement outcomes.

MENTOR OF THE YEAR

Teagan Dowler from The BCW.

Teagan has dedicated her career to supporting women in industry. Running online coaching sessions and a career development program, she is tireless in

her passion for celebrating, supporting, and developing females in industry and has positively impacted the careers of thousands of women in Australia and abroad.

SAFETY ADVOCACY AWARD –SPONSORED BY KOMATSU

Giselle Phillips from Fredon QLD.

Giselle has been instrumental in pioneering change within the Fredon QLD business; driving the use of technology to streamline the compliance of training and competencies, as well as being proactive in delivering mental health and well-being initiatives.

RISING STAR OF THE YEAR –SPONSORED BY ATLAS COPCO

Sophia Kurianski from Jinolo.

In 2021, Sophia founded Jinolo, a 3D collaboration start-up that helps industrial design and engineering teams save time and money when working on designs with external clients and suppliers. Jinolo has already garnered significant attention, with manufacturing, design, and engineering teams using Sophia’s software to collaborate on 3D files.

EXCELLENCE IN TRANSPORT

Coralie Chapman from Humes Concrete Products.

Coralie has always had a passion for promoting the various roles in the transport and logistics industry as well as safety around heavy vehicles. She is passionate about encouraging women to choose transport as a career path and strongly advocates for diversity and inclusion for people pursuing “non-traditional” careers.

14 Quarry August 2023 EVENTS

The awards recognise outstanding women across several sectors.

The 2023 Women in Industry Awards were held at Aerial South Wharf in Melbourne.

Elsa Antunes from James Cook University.

Elsa graduated her PhD in chemical engineering in 2018 and in the five years since has shown ambitious leadership and innovation in the engineering sector. She has been promoted to Senior Lecturer, received over $1 million in grants and is instrumental in creating collaborations with industry and government across a range of topics.

EXCELLENCE IN MANUFACTURING –SPONSORED BY PACCAR AUSTRALIA

Kristi Riordan from Harvest B.

Kristi founded Harvest B. in 2020 to help address global protein needs and sustainability concerns in our food system. With capital support from Woolworth’s venture fund, W23, she has since opened Harvest B’s first factory and a dedicated lab facility to enable rapid cycles of R&D to commercial production.

EXCELLENCE IN CONSTRUCTION – SPONSORED BY NAWIC

Trudy Grimshaw from Department of Finance, Western Australia.

Trudy found her passion for construction through a winding road of career choices. Currently the Senior Project Director on the Bunbury Hospital Redevelopment, Trudy in all respects demonstrates how women can take a leading role in the construction industry.

EXCELLENCE IN MINING – SPONSORED BY WEIR MINERALS

Ashara Moore from BHP.

Ashara commenced her career as a Site Engineer, working on projects Australia-wide. Her ultimate goal is to encourage people from all backgrounds to be involved in the resources sector. Ashara firmly believes that mining can be done better –and is determined to be a part of the solution.

WOMAN OF THE YEAR – SPONSORED BY FULTON HOGAN

Giselle Phillips from Fredon QLD.

•

KEEP YOUR DUST DOWN

Most fugitive material from conveyors like dust and spillage is generated at load zones and transfer points.

Spillage and dust in a conveyor system result in accelerated wear of components, belt misalignment and belt damage.

The ESS 2000 Skirting System is a cost-effective solution to spillage issues.

The ESS 2000 Series Skirting System is;

• Easy to install

• Easy to maintain

• Suitable for high loads

• Suitable for harsh environments

• Easily adjustable for a linger sealing life

Installing ESS 2000 Series Skirting Systems can prevent material loss from the conveyor load zone.

With ESS Service crews, correct application and maintenance, spillage-free conveyor load zones are a reality.

PH: 1800 074 446 www.esseng.com.au

ENGINEERING SERVICES & SUPPLIES PTY LTD

PRODUCT FOCUS

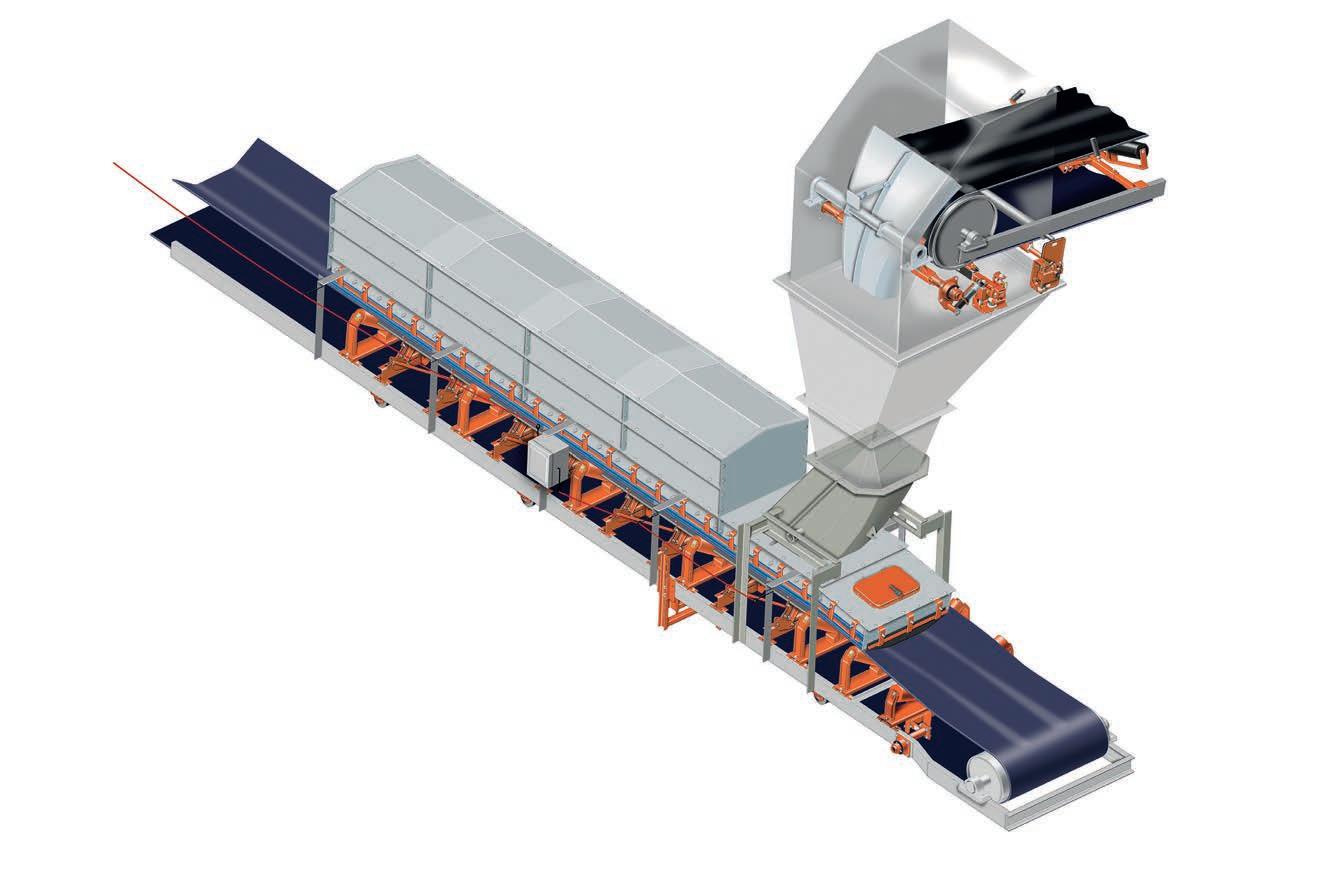

TRICON PROVIDES PREMIUM PUGMILLS

Pugmills play a crucial role in the production process by efficiently mixing and blending the necessary materials.

They are used to blend various aggregates together to create a consistent and well-graded mixture. Aggregates such as crushed stone, gravel, sand, or recycled materials like reclaimed asphalt pavement (RAP) are fed into the pugmill.

Pugmills allow for the addition of binding agents to the aggregates. These binding agents can include cement, lime, or bitumen emulsion. The binding agent is introduced into the pugmill and thoroughly mixed with the aggregates to ensure proper adhesion and strength.

They also help in controlling the moisture content of the roadbase material. Water is added to the pugmill in precise amounts to achieve the desired moisture level. This is crucial for proper compaction and workability of the roadbase.

The rotating shaft with blades or paddles inside the pugmill thoroughly mixes and blends the aggregates, binding agents, and water. The continuous mixing action ensures a uniform distribution of materials, resulting in a consistent roadbase mixture.

Pugmills can de-air the roadbase mixture, removing excess air voids and improving the density and compaction characteristics of the material. This is achieved by subjecting the mixture to kneading and compression forces as it passes through the pugmill.

The mixed and processed roadbase material is extruded from the pugmill through a discharge opening or conveyor belt. The pugmill allows for precise control over the output rate, ensuring a consistent supply of roadbase for construction purposes.

By incorporating a pugmill into the roadbase production process, the mixing, blending, and homogenisation of materials are efficiently achieved, resulting in a high-quality and durable roadbase material ready for use in road construction or other civil engineering applications.

Tricon Equipment supplies a broad range of pugmills, including the Tricon Phoenix Track Mounted Pugmill, the Lippmann LS-Series Triple Deck High Energy Screeners, and the Superior TeleStacker Conveyor.

For more information, visit triconequipment.com.au

FIRST CHOICE IN HIGH HEAD PUMPING

The H range of Selwood pumps offer maximum performance and efficiency for high head, high pressure dewatering. These pumps offer total heads up to 158 metres, and flows up to 260 litres per second, Selprime automatic self-priming and emission compliant engines, making them ideal for high head and high-pressure applications with the added bonus of being simple to operate and maintain.

The Selprime priming method is a unique Selwood auto-priming pump that utilises a water tolerant diaphragm air pump. The design is environmentally friendly and has none of the problems of oil vapour emissions and oil emulsification associated with other priming systems.

The Selwood range of auto priming pumps are the market leader and are available in Australia from Toolkwip Pumps.

For more information visit toolkwippumps.com.au or call the Toolkwip team 03 8805 0500

16 Quarry August 2023

NATIONWIDE BRANCHES . NATIONWIDE BRANCHES . NATIONWIDE SERVICING . NATIONWIDE SERVICING . 1800 655 860 | WWW.SMARTTECHAUSTRALIA.COM.A U PERTH. BRISBANE. SYDNEY. MELBOURNE. TASMANIA . ALBURY. DARWIN. TOWNSVILLE .

STAYING ON TOP OF THE SAND PIT

Holcim Australia’s Grantville Quarry utilises two articulated dump trucks and two frontloaders to stay on top of the competition, thanks to a partnership with Delta Rent.

The Grantville Quarry, which is a joint venture between Holcim and Boral, has relied on rented machines from Delta Rent for more than a decade, to ensure it can meet demanding workloads. The quarry supplies Holcim and Boral internally with sand for manufacturing concrete.

Holcim Australia’s Grantville Quarry site supervisor Ron Walker said with the operation being a joint venture, using machinery from Delta on-site provided access to the latest machines without significant up front investment.

Delta’s rental division, established in 2005, offers short, medium, and long-term flexible rental plans to help any site or project-specific requirement. The heavy plant hire division operates across Australia with offices in Melbourne, Sydney, Brisbane and Adelaide.

“As we operate a joint venture between Boral and Holcim we tend not to own our equipment/machinery,” Walker said.

“So, we partner with Delta Rent –giving our employees access to the latest state-of-the-art reliable machines.

This is imperative as our operation is reasonably high hours for a rental.”

Holcim’s Grantville site, located around 90 minutes from Melbourne, needed machines that could handle the clay track around the site in the wet and sodden tracks in the Victorian winter.

Delta Rent, which has one of the largest rental fleets in Australia, supplied the Victorian operation with two articulated dump trucks and two front-wheel loaders.

The articulated dump trucks are designed for off-road sites which require heavy-duty usage, predictive gear selection, downhill speed control and a high payload capability.

Walker said it was crucial Delta Rent was able to match the needs of the site with machines in its fleet.

“They run through pretty hard conditions in winter and all our tracks are clay, which can become quite wet. Despite the weather conditions, we still need to operate as much as we can,” Walker said.

“Delta Rent provides us with very reliable trucks, along with superior comfort for the operators.”

One of the key features the front end wheel loaders offer is a large capacity of 7.1 cubic metres, allowing 11.5 per cent more material to be loaded than previous models. This enables the road trucks to be loaded and sent out faster, increasing the site’s efficiency.

Delta Rent Account Manager Andrew Hagan said the company focused on the customer’s needs, with a rental and service based model that customers can rely on to help operations run smoothly.

In the case of the articulated hauler, its ability to handle “wet and uneven terrain very well” became a major factor given Holcim’s Grantville site, according to Hagan.

“The turnaround time to get trucks in and loaded was definitely seen as a benefit because they didn’t want trucks lining up at the gate, you just want them out.”

“Fuel burn was also a critical factor to the operation to lower production costs.”

“The support and 24–7 service Delta Rent provides is reliable, consistent, and gives our customers comfort knowing they can access immediate help when they need it,” he said.

18 Quarry August 2023 SAND

Holcim Grantville has two L260Hs on-site and has been impressed with its handling of on-site conditions.

Delta Rent provides maintenance on the high-risk and capital-intensive machines to ease pressures for workers on-site.

The support system minimises unexpected maintenance and associated downtime.

“We rely on Delta’s after-hours service, so when something breaks down and we need it repaired pretty quickly, they’re onto it immediately,” Walker said.

“I manage the gear and liaise with Delta to do all the repairs and upkeep of the trucks. They’re usually pretty prompt getting out and getting the gear repaired as quickly as they can, which works for us because if the machine isn’t running, it is downtime for us and loss of production.”

Walker, who has spent around 40 years in the industry, really appreciates the level of service and quality of the machines.

“They’ve always been a good company to deal with, and they’re very good at keeping their gear on the move,” Walker said.

“Knowing Delta Rent is there helps us maintain focus on our core business.” •

For more information visit deltagroup.com.au

Quarry August 2023 19

Holcim Grantville has two AG45s on site which are made for the conditions and driving the clay tracks.

The Volvo L260H’s larger bucket capacity improves efficiency.

ADAPTING TO A CHANGING WORKPLACE

Quarry sat down with Komatsu Australia’s Colin Shaw to learn how the company is improving outcomes for employees from all walks of life.

Many companies, including those in the quarrying sector, are attempting to reconfigure their workplaces to be more flexible in the wake of the “great resignation”.

Around one-third of mothers were planning to or were already in the process or had scaled back and exited their jobs in 2021 during the pandemic according to Seramount.

Research from McKinsey from around the same time showed that parents were more likely to leave the workforce than non-parents. As part of the research, many parents were dealing with exhaustion from juggling their work and home commitments.

Colin Shaw, Komatsu Australiua’s executive general manager of people and strategy, told Quarry the company recognised the impact that happy and healthy families have “If we can make it easier for our people to balance work with having children and raising their families, then, of course, we should,” he said.

“It means our people are happier and it means we’re able to keep those incredible employees who might otherwise feel they need to step out of the workforce to pursue their personal goals. It’s a win-win.”

Komatsu changed its paid parental scheme to ensure its workers could better handle these commitments.

The new families at Komatsu program replaced the company’s paid parental leave scheme and is designed to provide benefits and support to all types of families.

Key elements of the program include 16 weeks of paid leave for the primary carer of a new baby, plus four weeks of bonding leave for the secondary carer; plus, special paid leave for our people who experience miscarriage or stillbirth.

The company has also developed a structured return to work program to make it easier to come back into a role, and provides ongoing access to flexible work arrangements.

“We’re really proud of this comprehensive program which really is about our people’s wellbeing,” Shaw said.

EMPOWERING EMPLOYEES

Komatsu Australia has won several awards for its HR focus and the positive experience its people enjoy at work. Most recently, it was named in the 2023 AFR BOSS Best Places to Work List.

“Komatsu Australia is always proud to be recognised for our commitment to creating an environment that empowers employees to grow, excel and achieve their personal and professional goals. We really do believe that a supportive and positive work environment is critical to our success,” Shaw said.

Australia’s gender equality scorecard, created by the Australian Workplace Gender Equality Agency (WGEA), revealed the mining and resources sector maintained a 14 per cent wage gap between male and female employees.

20 Quarry August 2023 WORKPLACES

WGEA director Mary Wooldridge has previously said the pay gap can be due to three main factors including systemic bias, women’s career progression being disrupted due to parenting and caregiving, and differences in pay for female and maledominated industries.

Mining and quarrying have for been a largely male-dominated industry. The Mining for Talent study conducted by Women in Mining (Wim) UK and PwC estimated women make up just eight per cent of board positions in the top 100 mining companies worldwide and 5-10 per cent of the mining industry depending on the country.

One of the key reasons which have been commonly identified is women a lack pathways into the male-dominated industry.

Komatsu has developed its awardwinning Say Again? Program which aims to address workplace sexism and includes training programs to improve outcomes for its female workers.

Shaw said the company had taken an innovative approach to getting more diversity into its ranks.

“We are always looking for opportunities to highlight the benefits diversity can bring to our organisation and address the barriers that may hold us back,” Shaw said.

“We’re doing very well in our entry-level roles, with goals of 30 to 50 per cent women, compared with an industry benchmark which is less than a third of that.”

The company’s approach is that age and gender don’t hinder the employee.

Almost half the current Western Australian apprentices are women.

The company selects apprentices based on potential, not age. A few years ago Komatsu had a 47-year-old apprentice, and in the current intake there are apprentices in their 30s.

“We’re also making inroads on increasing female representation further up the corporate ladder, by thinking more openly about what the key skills are in some of our leadership roles, to enable us to recruit from a wider pool of applicants,” Shaw said.

THE WORLDWIDE LEADER IN VIBRATION TECHNOLOGY

Designed for industrial sectors INDUSTRIAL VIBRATORS

OLI is the world’s top selling manufacturer of electric and pneumatic vibrators. The high level of customer service, guaranteed by 18 trading subsidiaries worldwide, and long-lasting and performing products make us always ahead.

Our vibrators are designed for industrial applications in all sectors, from the most extreme environments such as quarries, mines and foundries to the food and pharmaceutical.

OLI Vibrators Pty Ltd. 7 Jellico Drive, Scoresby Vic 3179, Australia - Phone: +61 3 9764 9988 - Mail: info@olivibrators.com.au - www.olivibrators.com.au

Komatsu has delivered several programs designed to help its employees balance work and home life.

TRAINING WORKERS FOR THE FUTURE

To help ensure its apprentices are given the best shot at their careers, Komatsu takes apprentices from all walks of life through its training academy.

“That means, for instance, that we don’t just look to people with a technical background – which typically means men in our industry – for roles where the key skills are around communication,” Shaw said.

The Komatsu training academy gives apprentices continued training and upskilling to help build the employees of the future for the quarrying industry.

“A big focus of the academy is upskilling people in their current roles, whether that be in leadership and management, operator skill proficiency development or customised technical training,” Shaw said.

“We offer a mix of fully accredited courses and modules, along with purpose-designed operator, technical and management training.”

Komatsu Australia recently doubled its annual training investment to $12 million.

The company’s apprentice development system is focused on the way apprentices are trained in the industry. The program received won the silver award for the large employer of the year and the employing Australian apprentice categories at the National Training Awards in 2022.

“The way our system is designed means that by the time our apprentices complete

level that would take about another year of experience for apprentices trained in conventional programs. It really supercharges our apprentices’ careers and helps them reach their potential,” Shaw said.

through the Komatsu training academy, which has two purpose-built education centres, located in Brisbane and Perth, giving the company a presence on both the east and west coast.

The facilities are designed for hands-on training in the quarrying and mining industry as well as construction to help students gain practical skills.

Students use several simulators with the help of expert instructors to gain experience across a range of machines from utility machines to heavy excavators.

The company currently has over 300 apprentices in training on the west coast and more than 200 on the east coast and plans to build the total to over 600 in the coming year.

“Flexibility for us isn’t just about how you structure a workday, it’s about how you think about what makes a good apprentice, or a good mechanic, or any other role,” Colin said.

“We want our people to feel truly valued, to see real rewards for their commitment and to be able to achieve their goals both in and outside of work.

“We want people to feel like they can bring their whole selves to work.” •

For more information visit komatsu.com.au

22 Quarry August 2023 WORKPLACES

The company has a well-recognised and regarded training program for all apprentices.

Komatsu was nominated as part of the 2023 AFR BOSS Best Places to Work List.

IMS DI ST RI BU TOR

r

Papua N

and South East Asia

IMS have produced another high quality Pugmill Blender to their range of Mobile Track and Modular Electric Pugmill and Blenders. The new PM1200-20TB Track Pugmill-Blender offers twin feed hoppers with separate feed conveyors, both fitted with belt scales for independent blending of the raw material, single or twin powder hoppers offering the ability two blend two powders at once or separately along with the option to

The twin feed hoppers have a large variation in belt speed and with the front of hooper adjustable flow gates and PLC control offers accurate blending, the feed hoppers are five meters long holding 10m3 each with the option of removing the dividing wall making a single 20m3 hopper. The pughead is 50% longer than the top selling single feed hopper

IMS-PM1050-16TB track pugmill to ensure well blended material, with the option of two different augur designs to suit different raw material characteristics along with two water spray bars. The hydraulic drive train is powered by a Cat C7 Motor.

CR USHE

R & SCREEN SA L ES PTY LTD

for Aust

alia,

ew Guine a

Specialist Manufacturers of Quarry, Mining & Recycling Equipment Irish Manufacturing Services Ltd | www.ims-ltd.ie

John Andersen +61(0)42 4 181 056 | Chri s Won g +61(0)42 4 18 0 860 info@crusherscreen .c om | ww w.crusherscreen .c om | Unit 4, 181 Sandy Creek Road Yatala QLD 4207 Crusher an d Scree n Sale s PT Y Lt d | ABN: 5 5 15 0 60 0 418 Gol d Coast QLD 4 220 | PO Box 14 4 Southport QL D 4215

EVOLUTION OF EXCELLENCE

Building on the success of its predecessor, Volvo Construction Equipment has launched its updated 56-tonne L350H2 loader, with a host of upgrades to increase productivity, fuel efficiency and profitability.

The L350H2 is designed to handle the demanding tasks in quarrying, construction mining and other challenging environments, and represents Volvo’s commitment to providing eco-friendly solutions in the heavy machinery sector.

Hayden Grant, national product manager at CJD Equipment, Volvo CE’s national distributor, said the big difference between this L350H2 compared to the existing one is the new drivetrain, new transmission, and new axles.

“Over the years Volvo have built on their experience and worked closely with customers to improve these machines,” Grant said.

“Now, in 2023, Volvo have introduced exciting new features that have made it our flagship loader. These upgrades make it even more efficient and productive.”

ENHANCED PERFORMANCE

With its robust construction and lifting capacities, the L350H2 is built to tackle heavy loads with ease. A highly notable improvement on the L350H2 wheel loader is that it boasts a more responsive hydraulics system featuring new lift and tilt cylinders, and an increased hydraulic working pressure for up to 10 per cent faster work cycles and higher productivity.

Volvo hydraulics are manufactured using high quality components, designed specifically for machines like the L350H2, to deliver superior precision and machine functionality.

At the heart of the Volvo hydraulic system is the load-sensing technology, which continuously monitors and adjusts the hydraulic flow and pressure according to the load requirements. This dynamic system ensures that power is distributed precisely where it is needed, resulting in efficient operation and reduced energy consumption.

“The L350H2 is the ideal production loader for all applications, from load and carry to moving quarried material,” Grant said. “Its ability to move tonnes per hour, with more tonnes per litre of fuel burnt make it a fantastic piece of machinery in terms of efficiency and sustainability.”

With the additional on-board weighing option, operators can know the current load in the bucket and exactly how much has been unloaded for the current task, whether that be loading a truck or stockpiling.

EASY OPERATION

Operators can rely on fast cycle times thanks to the updated driveline, featuring new Volvo axels and all new Volvo transmission. These updates enable the third generation of

24 Quarry August 2023 SUSTAINABILITY

The L350H2 is built to tackle heavy loads with ease.

The L350H2 boasts a more responsive hydraulics system.

Volvo hydraulics are manufactured using high quality components.

Volvo Opti-Shift with lock-up converter and Reverse-By-Breaking technology.

Volvo’s new Opti-shift transmission offers smooth shifting with automatic lock-up in second, third and fourth gear, dramatically reducing fuel consumption and environmental impact while maintaining productivity and operator comfort.

In load and haul applications, it’s common for operators to use the gear shifter to change between reverse and forward without applying the breaks. Deceleration is handled by the torque converter in such cases, resulting in energy loss and places a lot of strain on the converter due to heat transfer. Volvo’s Reverse-by-Breaking (RBB) function recognises the speed, direction and throttle position and applies the service

brake to slow the machine, saving fuel and reducing converter wear.

Already found on the Volvo L110H and L260H, this new Opti-Shift technology integrates the RBB function and the lockup function in transmission to boost fuel efficiency by up to 15 per cent.

With its advanced technology and intelligent features, the Volvo L350H2 not only enhances productivity but also prioritises operator safety and comfort. From heavy lifting to delicate operations, the L350H2 delivers outstanding performance, reliability, and control, making it a top choice for quarry, mining, and other demanding applications.

Volvo Construction Equipment is well known as one of the world’s best

manufacturers of high-quality, and technologically advanced equipment – and CJD Equipment have been proudly offering their products to the Australian market for close to half a century.

Together, CJD Equipment and Volvo CE provide a range of premium machinery suited to Australia’s unique industry requirements to deliver a range of productivity, fuel efficiency and safety solutions for a highly productive operation. CJD Equipment has an extensive national support network in place to ensure you are well supported, no matter where or when. •

For more information contact your local CJD branch on 1300 139 804 or visit cjd.com.au

InSitu Real Estate is an affiliated company of Providing end-to-end real estate solutions for the specialised property sector InSitu Real Estate is a boutique agency providing real estate services to the extractive industry, mining, concrete & asphalt, waste & resource management, industrial and infrastructure markets. For enquiries contact Todd Clark Director Licensee in Charge +61 (0) 424 165 077 todd@insiturealestate.com Suite 303, 17 Wurrook Circuit Caringbah, NSW 2229 www.insiturealestate.com linkedin.com/company/insitu-real-estate

Operators can rely on fast cycle times.

Deceleration is handled by the torque converter.

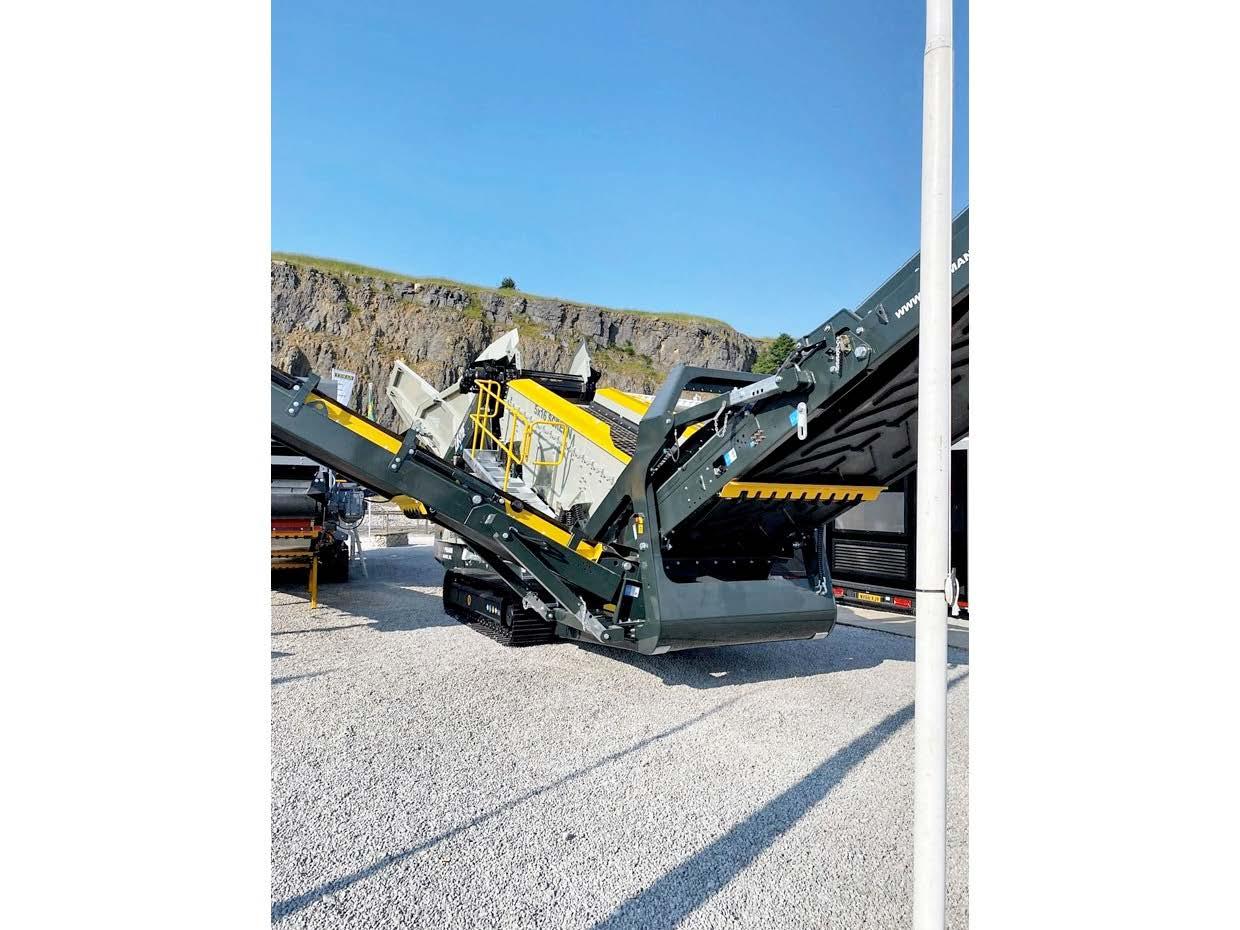

QUARRY EXPANSION ON TRACK WITH ASTEC

Hopkins Brothers’ Midgee quarry expansion is on track as the company looks to cement itself as a major aggregates supplier in Queensland.

The Queensland quarry has been working behind the scenes with Astec Australia and Scope Engineering to increase the site’s capacity to match the needs of the infrastructure construction industry.

The current Midgee pit, 10 kilometres south of Rockhampton, can produce up to a million tonnes of hard rock quarry products a year, but Hopkins Brothers is aiming to double that output after the modernisation is complete.

The new fixed crushing and screening plant has been custom-designed by Astec to integrate with the existing plant and deliver a high degree of automation in the new operation.

The suite of Astec machinery in the new circuit includes a vibrating grizzly feeder, horizontal heavy-duty scalping screen, two Kodiak K350+ Cone Crushers, four 6203-32LP Horizontal Screens and a 3500EVT Vertical Shaft Impactor.

Astec Australia’s senior account manager Shaun Quinn said the project has extended its relationship with Hopkins Brothers.

“We’ve been working closely with the Hopkins family for a decade,” Quinn said, “and the strength of that relationship is evident in

the amount of Astec equipment going into this expansion project – nine pieces in all.”

The new plant will enable Hopkins Brothers to produce high-quality alternative sources of

concrete aggregates, sealing aggregates and road base, and the company will offer those materials at competitive rates to the local infrastructure construction industry.

26 Quarry August 2023 CRUSHERS

Hopkins Brothers has enlisted the help of Astec Australia and Scope Engineering to complete the project.

The addition of the new crushing and screening plant is expected to double the output of the existing site.

sector and aligns with where we see ourselves in the coming years.”

Scope Engineering integrated Hopkins’ specifications and Astec’s equipment to ensure the plant design worked with the topography of the site.

is on track to be completed by December.

“We’re coming to the final stages of the build,” Hoseason-Smith said, “and we’re extremely pleased with the progress.

“We’ve got the right people working on the right jobs, which makes all the difference.”

“Astec’s aim is always to help our customers succeed and with this new plant at Midgee, Hopkins Brothers will continue to do that.” •

For more information visit astecindustries.com

Quarry August 2023 27

BELT FEEDERS CONVEYER BELT SCALES

The expansion works are expected to be complete by December.

WEIGH

for Quarry and Mine installations

Stainless Steel construction for Harshest Environments. Throughput up to 1,000 TPH For Belt Widths between 450mm and 2,000 mm accuracies of +-0.5% for a single idler and +-0.25% for a dual idler Contact Tecweigh Website www.tecweigh.com.au Email sales@tecweigh.com.au Phone 03 9775 0266 CUSTOM ENGINEERED WEIGHTOMETERS & WEIGHING SOLUTIONS Manufacturer of conveyer belt scales (weightometers) and weigh belt feeders all manufactured in australia

Mild Steel Powder Coated

and

ENSURE BELTS CAN HANDLE A

TOUR OF DUTY

As one of the leading designers and manufacturers of belt conveyor accessories, Martin Engineering recommends some key considerations to ensure your site gets the most out of the conveyor belt’s lifespan.

With constant exposure to raw and abrasive materials and harsh weather conditions, few parts wear faster in the quarrying industry than conveyor belts.

Due to the duress of these punishing conditions, most sites have experienced critical failures with conveyor belts, commonly from splice failure, piercing damage or chronic issues including mistracking and frozen idlers.

In some circumstances, damage can strike from a one-off event like tramp metals or oversized lumps impacting the belt from the material flow stream. Often these events can lead to immediate shutdowns for repairs, project delays, and missed deadlines.

Given the significant cost of downtime and lost production on-site, knowing how to avoid conveyor belt wear and extend its performance and life is vital.

While belt cleaners can wear the conveyor belt, they do so at a much lower rate than loading practices do.

Belt wear during loading generally occurs

over a significant period from abrasive raw materials impacting the belt. Components, like seized idlers from fouling and improperly tensioned belt cleaners, can further contribute to wear. Combined, these factors can create a two-fold dilemma with impact damage and frictional wear.

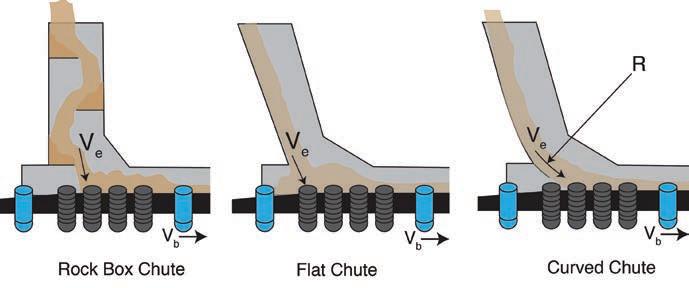

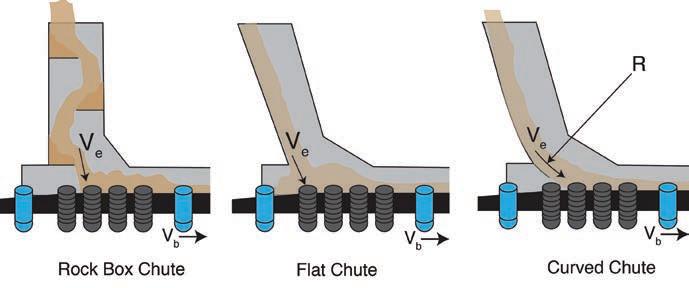

To reduce loading wear, sites should consider adopting a curved chute design. Curved chutes allow the material’s stream velocity to closely match the speed of the belt.

Compared to a flat chute, a curved chute will deliver a reduced impact velocity even if the basic discharge angles are similar. The benefits of a well-designed chute can be enhanced by paying significant attention to the selection of liners.

Flat chutes can create greater impacts depending on the drop heights which takes a constant toll on the belt and creates fugitive materials like dust and spillage.

Martin Engineering’s Todd Swinderman recommends viewing wear liners as ‘sacrificial components’ and spending more time improving chute design

with lower friction liners to make them easier and quicker to change.

Improved design can be achieved by utilising discrete element modelling (DEM).

DEM has provided the quarrying industry with a valuable tool for verifying and optimising chute designs as well as predicting conveyor belt wear life.

Since idler and pulley fouling lead to significant belt wear on the unprotected return side, eliminating fugitive materials as much as practical can benefit a company seeking to extend its conveyor belt life.

The US Mine Safety and Health Administration estimates that 85 per cent of all conveyor problems – including wear –come from fugitive materials.

Spillage, dust and carryback in the discharge zone can build up and encapsulate the belt, contributing to belt and conveyor wear, which is why Martin Engineering recommends undertaking adequate belt cleaning.

In severe cases of damaged belting with divots, cracking and skirtboard grooves, the company suggests employing a wash box

28 Quarry August 2023 CONVEYORS

using water sprayers along with mechanical scrapers or rotating brush cleaners.

A belt cleaning station can keep a belt, which is in good condition and professionally maintained, in good condition and limit carryback to within 10100 g/m2.

While it is a common expectation that a conveyor belt can be cleaned with an efficiency approaching 100 per cent, even a brand-new belt has macro and micro defects that make cleaning close to 100 per cent practically impossible.

These imperfections can result in as much as 60 g/m2 of carryback passing a belt cleaner station with a new belt. When the belt surface is damaged, the amount of carryback that can be shielded from belt

cleaning in scratches and gouges can be even more significant, on the order of 100 to 200 g/m2.

The Conveyor Equipment Manufacturers Association established a system for rating the difficulty of the belt cleaning application and for desired levels of carryback exiting a cleaning station in its seventh edition of Belt Conveyors for Bulk Materials.

This aids users in specifying belt cleaning performance, rather than making decisions based on brand preference or price alone.

With these solutions in mind, companies can extend the life of conveyor belts across the work site which will have significant follow-on effects, like reduced downtime and optimising the value of a major cost element. •

Quarry July 2023 29

Innovative cleaner design reduces belt wear and eliminates the need for re-tensioning.

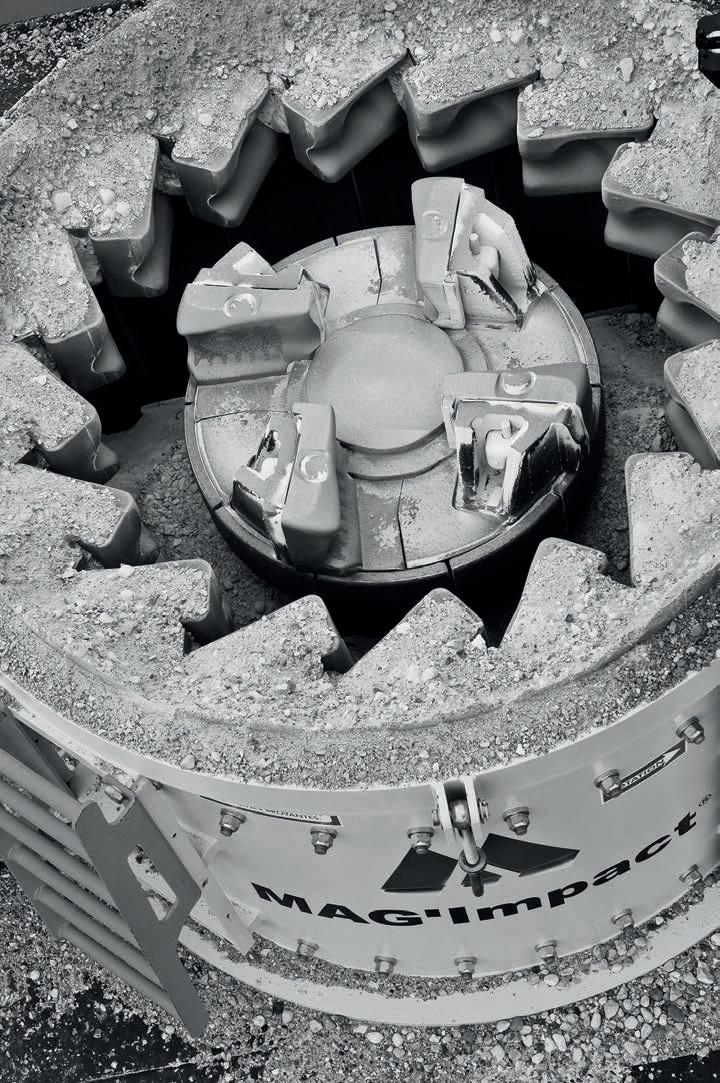

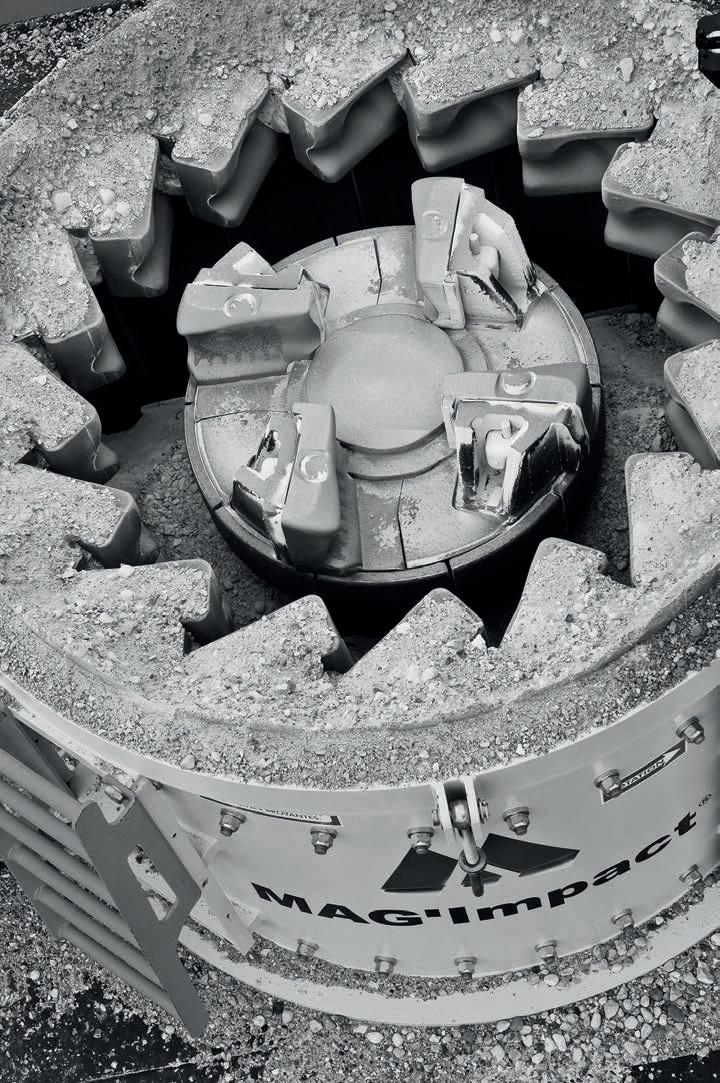

Optimise your production by reducing wear part change out frequency We offer the longest lasting wear solutions for all your impactor applications www.magotteaux.com Contact us! +61 8 6316 2400 info.asia@magotteaux.com Our innovative solutions in ceramic or mono-metal options: Blow bars Liners Impact plates Walls Impellers & Anvils

Properly positioned and tensioned primary and secondary cleaners mitigate belt wear issues commonly associated with cleaners.

UNBEATABLE NEXT GEN MOBILE RANGE IN AUSTRALIA NOW FT200 Mobile Cone Plant GT205 Mobile Screen Plant GT206 Mobile Screen Plant

Unmatched Strength from Rock to Road

Customer-focussed innovation has been Astec’s hallmark for 50 years.

Our Next Generation tracked jaw plants, tracked cone plants and tracked screening plants launch another era of industry-leading design.

The tradition continues.

BUILT TO CONNECT

enquires.australia@astecindustries.com astecindustries.com

1300 278 322

GT2612V Mobile HF Screen Plant

FT300 Mobile Cone Plant

GT125 Mobile Jaw Plant

ALL COVERED

Kinder Australia is helping quarries protect one of their expensive assets – conveyor belts.

The Australian sun is relentless, with some of the highest levels of ultraviolet (UV) radiation in the world.

According to the Cancer Council, the UV radiation is strong enough to cause sunburn in as little as 11 minutes on a fine summer day.

For people, avoiding the damaging rays can be as simple as “slip, slop, slap,” but the same can’t be said about conveyors.

Usually located outside conveyors need to bear the brunt of the elements. Conveyor belts – which are usually the most expensive part of the conveyor – are susceptible to UV and heat. It can cause cracking, or delamination of the top cover, significantly shortening the equipment’s life.

Sean Kinder, business development manager at Kinder Australia, told Quarry that to avoid costly downtime and repairs, quarries can cover up and protect their conveyors with the K-AllShelter.

“K-AllShelter Conveyor Covers have been designed to provide complete and reliable coverage of the conveyor,” he said.

“K-AllShelter Conveyor Belt Covers are manufactured using a wide range of

optional materials and engineered as a waterproof, durable barrier.”

It’s not just the sun and heat that can disrupt a quarrying operation. Rain, hail, and sleet can alter the consistency and quality of the conveyed materials.

Kinder points to the example of a concrete plant that needs to keep its moisture levels consistent to maintain the relevant specification. Heavy rains would make this impossible, pausing critical production time.

Rain can also create downstream production issues, including screen blinding and clogging issues. Moist materials can also cause hang up in chutes, blocking material flow and creating a spillage risk. In extreme scenarios, the wind and rain could even wash the material off the belt.

Kinder said the K-AllShelter can be custom made to suit all belt widths and models.

“It depends on what you’re trying to do – are you just looking to keep the product dry, or are you looking to protect it from the wind? Is the cover being used as a guard? Are you looking to reduce dust?” he said.

“We can change the shape of the cover to fit almost any application. Our team will

visit the site and inspect the conveyor, taking measurements and acquiring drawings. From there, we can create a digital model before beginning the manufacturing process.”

“When it is installed, we can also paint the cover to fit with the rest of the environment. If it’s in a more arid area, we can help it blend into the surrounding colours.”

The conveyor belt covers can be designed and manufactured using a wide range of high-performance materials including galvanised steel, pre-lacquered steel, stainless steel and aluminium and fibre reinforced polyester.

Covering the conveyor is also beneficial to operators from a safety perfective. Moving parts are covered effectively, and dust is contained safely within the covers. It features a patented double lock/hinge system, which allows access from either side of the conveyor. Service props and struts also come in varying designs, shapes, and sizes. These handy tools allow operators to gain access inside the cover to conduct routine maintenance.

Service props are fully adjustable systems that hold up the conveyor belt cover safely and

32 Quarry August 2023 CONVEYORS

K-Allshelter successfully installed.

securely so that any maintenance inside the covers can be easily performed.

Kinder has had positive feedback.

“The sites that have generally ordered a sample to be installed on one conveyor have come back to have them installed on others,” he said.

“The sites are comfortable using them and they can see the value the protection brings.”

The K-AllShellter also feature a dust-tight seal that prevents dust from escaping the conveyor. This also prevents dust from entering the conveyor system and causing damage to the components.

Kinder said eliminating spillage and dust is vital for the company, and one of the reasons it is focusing on the K-AllShelter.

“We are always looking for ways to cut down on the amount of labour our customers need to do. Eliminating spillage means there is less time spent cleaning around the conveyors, and more time focused on tasks that add value.” •

Extreme wind flipping conveyor belt.

Extreme wind flipping conveyor belt.

For more information visit kinder.com.au ONETRAK - 1300 727 520 WWW.ONETRAK.COM.AU CONTACT@ONETRAK.COM.AU SALES • SERVICE • PARTS • RENTAL 9 Helles Avenue, Moorebank NSW 2170 NEW BRANCH NOW OPEN MOOREBANK NEW SOUTH WALES

ENSURE COMPLIANCE

Steve Franklin, founder of Eltirus, details the remarkable results that can emerge when quarry operators plan, do, check and act.

What would you think of a professional sporting competition that played teams against each other and only measured their results financially and didn’t let the players into how things worked out? Seems like this would be an odd way to manage things and yet this is all too common in business. Perhaps it is time to take another look?

PRODUCTIVITY IMPROVEMENT

One of the discussions we see in the financial press is the lack of productivity improvement that is currently occurring in Australia. For some reason, this does not appear to be as important to business as it has been in the past. The stark reality

however is that as wages and costs go up, productivity must go up with it.

At Eltirus, we have a very strong focus on productivity improvement, and we see that those of our clients who wholeheartedly embrace this approach prosper and gain accordingly and those who want to stick to more traditional methods don’t.

The reality is that digitalisation and increasingly Artificial Intelligence are game changers. At the very least, they enable better decisions making, but how do we maximise the value of these technological advances –what frameworks are needed?

HOW DO WE IMPROVE SOMETHING?

The primary way you improve anything is

through Statistical Quality Analysis and there is a good chance that I have lost you right there – statistics was certainly not my favourite maths subject, and you would be well within your rights to ask, “what does this have to do with my quarry”?

Back in the 1920s, an American called Walter Shewart made two very important observations:

• Data have no meaning apart from their context.

• Data contain both signal and noise. To be able to extract information, one must separate the signal from the noise within the data.

These observations became the Shewart cycle, the Plan-Do-Check-Act (PDCA) cycle.

34 Quarry August 2023 SUSTAINABILITY

This cycle is incredibly powerful – you plan what you are going to do, put the plan in action, check that the results are as expected and modify what you are doing based on the results – something that you are probably more than familiar with doing.

WHAT DOES IT MEAN IN PRACTICE?

If we look at the PDCA cycle, we see that it is easy to Do. These are the actions that we take every day in the quarry to get the job done. We can also Check the outcomes, lab tests being a good example of where we Check and then Act as needed.

But interestingly in many parts of our business, we don’t have a Plan to Check against. For example, one of the ways to reduce CO2 emissions is to reduce the amount of fleet idling time. To achieve this, you would have to have a Plan (or target) and some way to Check the results against achieved against the plan (a system to record equipment idling time). Without a Plan or the ability to Check the plan, your results are going to be at best, hit and miss.

HOW DOES THIS APPLY TO QUARRY PLANNING?

Some years ago, we put in place a system we call a Quarry Operating Plan (more commonly known at a QOP). This system is now in place on quarries across the region and interestingly is regularly sought out by

auditors and regulators.

The reason we came up with this system was that we regularly saw life of quarry plans on office walls that were at best, ‘pretty pictures’. When we checked with quarry management, they generally had no idea of how they were going to achieve the plan displayed. The reasons for this were many, but revolved around the fact that first, it wasn’t broken down into ‘bite sized pieces’ and second, there was no way that it could be translated into the field (through lack of survey).

In the mining world, this progression from long term (>5 years) to medium term (1-5 years) to short term planning is fairly well understood and is often conducted by separate teams. Further, there is a continual reconciliation process conducted to ensure that the three different planning horizons (long, medium, and short) align for the best result against the geology, recovery and market requirements.

If this sounds a little over the top, I can think of many examples from over the years where a quarry manager had made a decision that looked great in the short term but was disastrous to the overall business due to material being sterilised, ramp access dug out or stripping requirements not being fully understood.

One of the reasons that these teams are often separated is to ensure a critical eye is run over the process from multiple angles.

It is also important the overall strategy for the quarry is reflected in the quarry budget. Where there is a well thought through plan for the site, this can feed into the budgeting process to ensure that senior management will have an accurate view of what material is available for sale and when and what capital will be needed for development. A budget that is not built up in conjunction and aligned with an effective quarry plan is not easy to understand, nor will it result in the best possible outcome.

Having an agreed upon short term plan that is operating in alignment with the overall longand medium-term plan is the first part of the Plan-Do-Check-Act cycle.

CHECKING THE PLAN

If you have a robust plan that all stakeholders are aware of and have signed off on, the next step is to check planned results vs. actual results.

This process of reconciliation helps to identify whether the plan was followed or not and if not, why. This would include what material was extracted and from where and with what quality.

Variance could have been because of the material quality not matching what was expected (indicating a lack of geological knowledge), a change in sales balance or maybe the quarry was flooded (perhaps through poor stormwater management).

PROACTIVE TODAY PRODUCTIVE TOMORROW visit us at kinder.com.au

Whatever the reason was, a well thought through plan that is reconciled against actuals will ensure that senior management can be confident the site is on track (or not) and gain insight into what has occurred (both good and bad) and the confidence in what changes need to be made.

ACTING ON THE PLAN

In the lead up to the Sydney Olympics I was running a very large quarry in the greater Sydney region, and we were continually sold out. My focus was on increasing productivity and output in any way that I could.

One of the things that I was most focussed on was crushing and screening performance. Working with an excellent lab manager, we focused on increasing concrete aggregate throughput and yield and had some huge improvement in both through adopting a Plan-Do-Check-Act approach.

One of the things were working on was how could pull as much of the bottom end of the 14mm into the 10mm and the top end of it up into the 20mm and improve the shape (without running the Barmac).

The approach we took was to create a detailed plan of the whole process and record the settings and configuration on this sheet, run a test on yield improvement and then from this adjust the plant accordingly.

This worked most of the time, but occasionally we found very unexpected results that perplexed us and so our Check didn’t result in an effective Act. Not being one to let things go, I did a lot of investigation into why we didn’t get the result that we had planned. Invariably, it was because some ‘bright spark’ had decided to make a change to the process that we didn’t know about. Crusher settings were not adhered to, different size screen meshes were used ‘because that was what we had’, resulting in unexplained variations.

Once we understood this problem, we went back to ensuring that the configuration plan (we called it a plant configurator) was better communicated and that everyone knew that there was no ‘freelancing’ on how things were setup and run. This approach can be used in many, many ways.

As a final example – on this same site, I

was curious as to the level of the stockyard floor. No-one could tell me what the design height of the floor was. Given we were sold out, the area was easily accessible, and I brought in a backhoe with the narrowest trenching bucket to dig test pits across the floor.

Imagine my surprise when we found over the years the stockpile floor had continued to increase to the point where there was some 2m of material left behind. In short, there was no Plan for the stockpile floor height and over time, the Do (stockpiling and loading out of those stockpiles) had resulted in an accumulation of lost material. Without a Check process (no survey of the floor level), there was no opportunity to Act, (recover the lost material). Digging the test holes gave us the Check (the depth of lost material) that we needed, and we then could Act (push it up with a dozer and re-screen for sale).

Have a Plan, Do it, Check the actual results and compare how they relate to the Plan –from there you can Act with certainty – the results can be quite remarkable. •

For more information visit eltirus.com

36 Quarry August 2023 SUSTAINABILITY

Strength and sustainability combined

United. Inspired. Smart and Green Series

Our battery-electric range is now known as the Smart and Green series, or to put it short: SG. Equipped with Rig Control System, RCS, and ready for smart functionality such as automation and remote control. With the Smart and Green series, our ambition is to create the world’s greenest machines – so you can produce metals and minerals in the most sustainable way possible.

epiroc.com/en-au

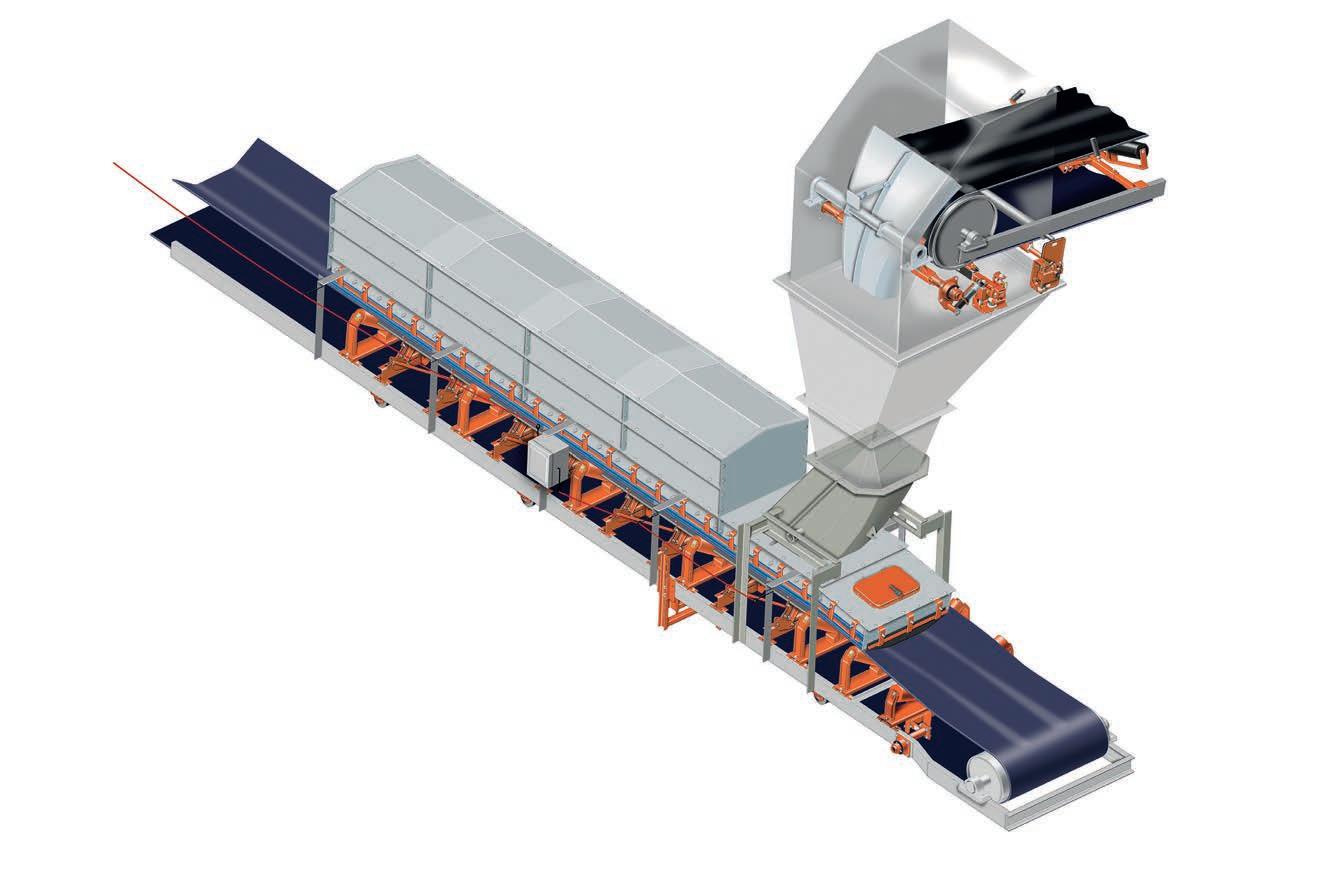

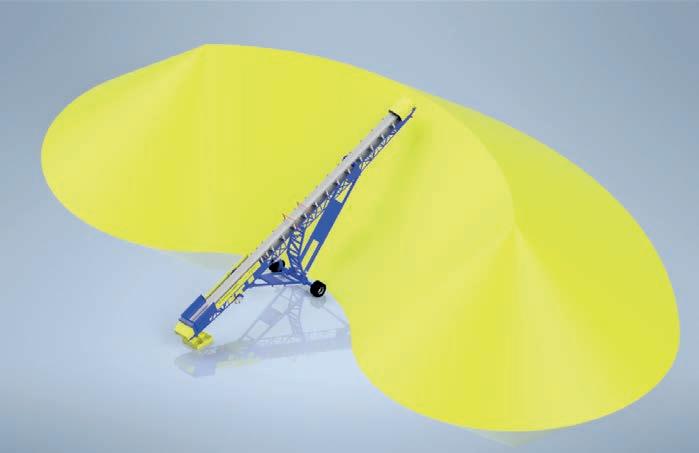

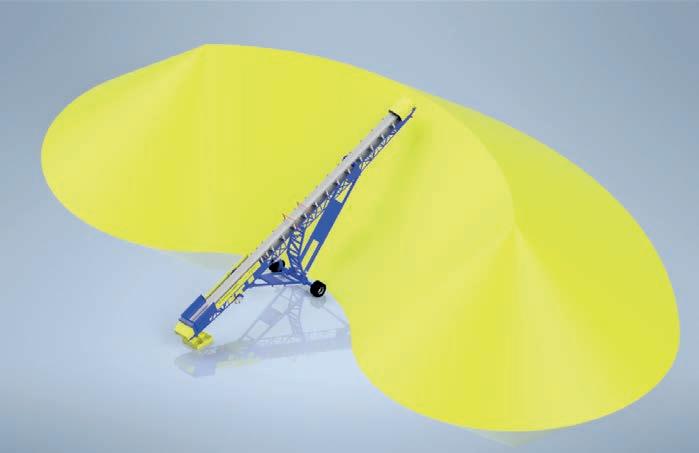

PILE UP THE BENEFITS OF STOCKPILERS

New industry thinking has highlighted the value of locally manufactured stockpilers as a convenient and flexible addition to the quarry site.

Stockpilers can perform a range of jobs, from moving materials away from machinery or piling up to 40,000 tonnes of material without having to move the conveyor.

This is especially true in the quarrying and extractive industry where operations need to be able to move materials to specific areas or be able to move up to 450 tonnes an hour.

The stockpilers can offer a clean separation of materials on site as well as the flexibility to suit tailored plant operations which is why Precisionscreen’s Jonny McMurtry said customers had shown an increasing interest in the product.

“We’re getting more and more competitive with manufacturing our conveyors and finding new ways to manufacture them so

our biggest strength is that we can tailor to customers’ needs,” he said.

“We can add options, we can take parts away if needed, we can offer a more tailored solution based on what the customer needs and the materials that they are looking to produce.”

When it comes to imported stockpilers, the convenience can come with headaches.

Imported loaders can lead to expensive ongoing costs, some of which can be initially unforeseen by businesses.

There can be shipping costs and extended wait times if supply chain issues occur on top of ongoing costs like diesel, maintenance, and repairs. Additionally, loaders need a person to operate so the cost of labour and other associated costs need to be factored.

All these factors can increase project budgets, and timelines and in some cases lead to downtime.

Precisionscreen’s stockpilers, which are built and designed in Brisbane, can reduce several of the associated costs of imported machinery by being by Australians for Australian conditions.

Compared with imported loaders and products, the Queensland company’s designs are made to endure the harsh Australian conditions.

This includes fitting out stockpilers with triple-sealed bearings, heavy-duty channelled frames, and high-depth poly rollers with deeper inset bearings to handle, the harsh and dusty environment of quarry worksites.

McMurtry said with nearly four decades in Australia and an experienced team, Precisionscreen’s knowledge of local conditions is important .

“That is probably the beautiful part of what we offer because our stockpilers are designed and manufactured in Brisbane and in Australia, we can offer options to suit your needs,” he said.

“There are options for stockpilers and loaders from overseas, but we have plenty of customisable options available on our stockpilers.”

Many quarry sites are found in remote areas which means if a machine does not match exact specifications, waiting for replacements or alterations can take considerable time.

This is where Precisionscreen’s tailored approach, which has been used by companies from more than 15 countries

38 Quarry August 2023 STOCKPILERS

Stockpilers have plenty of benefits to offer the Australian quarrying site.