Published

Publisher

Chief

Managing

Editor

Business Development Manager

Client

Design

Art

Design

www.RailExpress.com.au

The

From east to west, it’s an exciting period for passenger rail network projects across the country.

In Western Australia, Perth’s $1.86 billion METRONET Forrestfield-Airport Link is all but complete, set to begin operations this month.

Jointly funded by the Australian and Western Australian Governments, it will be the first passenger rail line that runs directly to Perth Airport. Along the way it will deliver three new train stations, increasing public transport options for Perth’s eastern suburbs and foothills area.

Domestic and international tourism will be boosted by the improved access between the city and Perth Airport, and new residential and commercial opportunities will be created around the new stations.

It’s anticipated an average of 20,000 passenger trips will be made each day on the new rail line in its first year of service, increasing to 29,000 by 2032.

It’s all part of the ambitious public transport revamp initiated by the State Government, with another 13 projects planned or underway.

Adding to this transformation is the the resumption of railcar manufacturing in WA, with the first set of trains to be made locally for 30 years now being tested on the tracks.

By 2029, it is anticipated that 246 new C-series railcars will be locally built, spearheaded by the expertise of rolling stock specialist Alstom.

Meanwhile, on the other side of Australia, the Queensland government is preparing to roll out the world-class European Train Control System (ETCS) on its network.

With the groundbreaking Cross River Rail system well into construction and a raft of other significant projects in the SE Queensland rail pipeline, a number of trains are being tested with the world-class digital signalling technology.

In essence, ETCS allows the train to know its location precisely, which in turn allows trains to safely be scheduled to travel closer together.

Continuous information is relayed between the Rail Management Centre and locomotives via trackside equipment, which will be crucial for safe travel within Cross River Rail’s tunnels, where this digital technology will be relied upon rather than conventional trackside

signalling equipment such as coloured lights. It’s the next step in the modernisation of train operations, and other states are sure to keep an eye on how it performs to determine if it could be applied to their respective transport grids.

This edition of Rail Express looks at the progress of the initiatives in each state: we feature Alstom’s involvement in the manufacture of the railcars for WA, while also focusing on how ECTS is fast becoming a reality in the Sunshine State.

Of course, all the sophisticated and advanced rolling stock in the world count for nothing if the tracks they travel on are not built or maintained to necessary standards.

That’s where plant and equipment specialists are valued. They bring a wealth of the latest innovations and apparatus to the industry, and help ensure the highest quality work can be carried out within the rail environments.

Inside, we showcase a listing of some of the best plant and equipment dealers and suppliers in the country, and also take an extended glimpse into the operations of some of the businesses.

The types of products are varied and many: track rail transporters, overhead wiring units, tamping machines, clip inserters, spike pullers, ballast regulators, excavators, down to basic welding devices and power engines.

There is bound to be information on innovations and services which can help successfully deliver cost-effective solutions across a broad spectrum of projects, from large complex programs to narrow working maintenance windows.

Elsewhere, read about Siemens’ transformational cloud-based digital interlocking system, which enables all the interlocking operations of any railway system to be managed digitally from the one spot.

More rail sector staff are profiled in the Workforce section, and our industry partners continue to inform us with the latest updates from their respective organisations.

We also welcome Dr Hermione Parsons as the new executive officer for the Australian Logistics Council, who contributes her first column this issue.

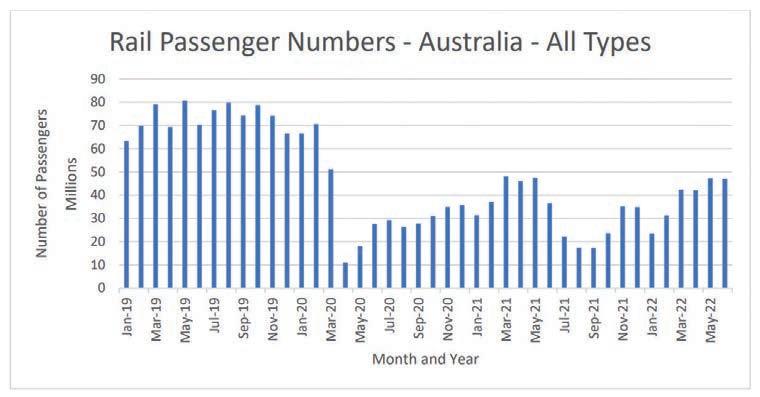

Rail passengers have risen again in the second quarter of 2022, but patronage remains 38.1 per cent below pre-pandemic levels.

National patronage increased by 39.19 million passengers or 40.4 per cent for the period from March–June 2022 compared to the previous quarter, but figures were still below pre-pandemic levels.

The urban rail network saw the largest increase in passengers, with a 41.5 per cent increase, which equated to an additional 32.59 million passenger journeys during the quarter.

Australasian Railway Association chief executive officer Caroline Wilkie said rising inflation and increasing petrol prices meant there had never been a better time to return to public transport.

“Public transport offers an affordable, convenient and sustainable option, making it a great choice as we all navigate the rising cost of living,” she said.

“Rail has traditionally been the most popular transport mode for commuters and will be an essential part of ensuring the sustainable growth of our cities.

“Our passenger operators continue to support safe, accessible and convenient transport options for the community and it is important we welcome more people back to rail as the weather warms up.”

How rail patronage fared since 2019.

All jurisdictions recorded increases in passenger numbers during the quarter, although June’s national figures were down compared to May as some had increased work-from-home arrangements in response to winter COVID concerns.

NSW and the ACT recorded the biggest rise, with patronage up 48.4 per cent or 22,761,782 passengers.

Victoria saw a 34.1 per cent or 10,611,520 increase in passengers, and Queensland patronage rose 48.1 per cent or 3,550,529 passengers.

South Australia’s passenger numbers also grew 27 per cent or 738,723 passengers, while Western Australia saw a 15.1 per cent or 1,336,552 increase in passengers during the quarter.

Patronage in New Zealand increased by 62.8 per cent or 1,840,042 passengers during the quarter. The quarter was 27.5 per cent down from the same time last year and 48.5 per cent below pre-COVID levels.

Increasing patronage was recorded against all rail modes, with urban rail having the greatest rise in numbers.

The first cohort of students has successfully graduated from the Inland Rail Skills Academy (IRSA) Foundation Course.

In addition to developing skills in construction, students have accessed training in financial literacy, digital literacy, literacy, numeracy, and career preparation skills.

The successful graduates can now apply for positions working on the Inland Rail project with various contractors, or graduates can also take their studies further by undertaking a Certificate II in Rail Infrastructure – some graduates have already registered for this – or in infrastructure and resource qualifications.

Of the first 11 graduates from the program, five have fully completed a Certificate II in Construction, providing options for a range of careers. The remaining students have completed with competencies or partqualifications.

has funded the Foundation Course as part of its commitment to ensuring local and local First Nations people make the most of the employment opportunities on Inland Rail.

Inland Rail Director of Health, Safety and Environment, Steve Jones, said the graduation of the first students from the IRSA Foundation

developing skills and resources which will contribute to regional sustainability and prosperity,” he said.

The Victorian opposition says it will axe the government’s $35 billion Suburban Rail Loop project if it wins the November state election.

Liberals leader Matthew Guy vowed instead to use the money for Victoria’s health system, which he says has been plagued by years of mismanagement and neglect.

He said the SRL was the most expensive yet least scrutinised project in Australia’s history.

As a first step, Guy has promised to put the stretch from Cheltenham to Box Hill in Melbourne’s east on ice.

“This November, Victorians face a clear choice. A choice between immediately rebuilding Victoria’s broken health system or a train line in 13 years’ time,” he said.

Early works worth about $2.3 billion were already budgeted for and signed off on for the rail loop, so the opposition wouldn’t rip up those contracts, he said.

“When the state can afford it, we might be able to build it but the key point is, what’s the priority now – you can’t do both,” he said.

“You can’t go and borrow tens of billions of dollars and rebuild the health service.”

In reply, Victorian Premier Dan Andrews said the opposition’s plan would cut 24,000 jobs.

“The Liberals will cut the SRL, meaning Cheltenham, Clayton, Monash, Glen Waverley, Burwood and Box Hill would never get the brand new train stations that are currently in early works,” he said.

“He will walk away from a train to Monash University, to Doncaster, to Deakin and La Trobe University, there will be no orbital rail to connect Melbourne’s suburbs.

“Just like Melbourne needed a city loop all those years ago – with discussions beginning in 1929 and construction completed in 1981 – our growing city now needs an orbital rail loop to give effect to the vision laid out in Plan Melbourne.

“The SRL – to be built in partnership with the Federal Government – is not just a rail line, it’s a network that connects Victoria’s fastest growing centres of jobs, tertiary education, major hospital and research centres and the airport.”

Andrews said Guy also threatened to scrap the state’s Big Build Program that currently supports 50,000 workers. He said level crossing removals, road upgrades and train line works would all be at risk under the Liberals.

“He’s walking away from the transport connections that these projects deliver, the jobs they offer and the wages that support Victorian families,” he said.

The 90km orbital SRL line will improve travel efficiency for more than 80 per cent of Melburnians.

scathing of the threat.

executive Adrian Dwyer said Victoria had to work hard to shed the baggage of ripping up the East West Link contract, but the speculation on the SRL risked the re-emergence of the “big dollars, no diggers” approach to infrastructure.

“This is infrastructure policy in Dire Straits, it’s Money for Nothing,” he said.

“Certainty is crucial in infrastructure, with major projects spanning a decade, and programs often multiple decades; we can’t afford to signal to global markets that every election will see the map re-drawn.

“International bidders are lining up for major infrastructure bids in Australia at this very moment, it could be incredibly damaging to send a signal to board rooms in Madrid and Rome and Kuala Lumpur that the Victorian infrastructure pipeline is a moving feast.

“Cancelling the existing SRL contracts now will be double the cost of cancelling the East West Link and deliver exactly the same amount of infrastructure – zero.”

Australasian Railways Association chief executive officer Caroline Wilkie said the construction and delivery of the SRL would create a long-term pipeline of work, generate thousands of local jobs and help train the next generation of skilled workers in Victoria.

“The rail industry needs certainty to attract and retain skilled workers to support the successful delivery of transformational projects like the SRL,” she said.

“Having a clear pipeline of upcoming projects is vital, particularly with the significant number of major infrastructure projects underway or planned across the country.

“Stopping a key project like this when early works have already started would set a

worrying precedent that could see industry and Victoria’s skilled workers look to other states in

transformational project for Victoria’s public transport system, which will deliver enormous social, environmental and jobs creation benefits for all Victorians.

“Once complete, the 90km orbital rail line is projected to improve travel efficiency for more than 80 per cent of Melburnians,” she said.

“This will take 600,000 cars off the road each day and slash travel times for the people of Melbourne and its regional centres, making it easier for them to get to work, education and essential services.”

Meanwhile, Monash University said it supported the current SRL project, which it had been working on with the Victorian Government, and viewed it as the best possible solution for the Monash community, its partners in the Monash Technology Precinct and broader South East community.

In a statement, it said it had been advocating for and promised by various governments (both state and federal) an efficient and effective public transport rail network since the University was established in the 1960s.

As part of SRL East, a new station at Monash will connect more people to Melbourne’s largest employment and innovation hub outside the CBD – providing students, employees and visitors with a direct train connection to the area for the first time.

The university said as the largest employment node outside of the CBD, the Monash Precinct was one of Victoria’s most important ‘engines’ of innovation, employment generation and skills development. Currently, 30,500 people are employed in the region and this is forecast to grow to 162,000 by 2056.

Victoria

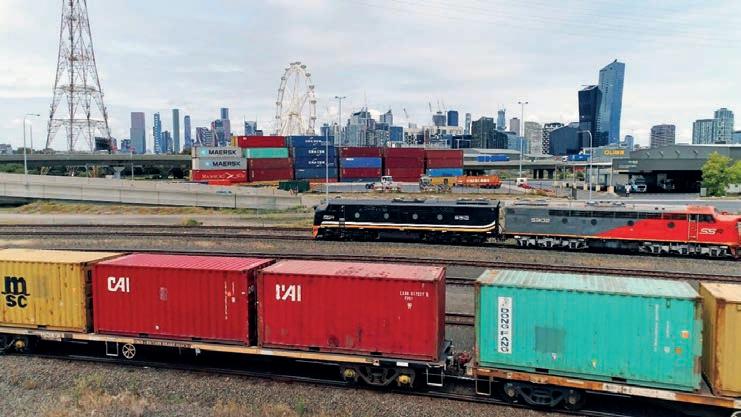

Works to move more freight onto rail and take more trucks off local roads in Melbourne’s south-east have progressed, as part of the Port Rail Shuttle Network (PRSN) project.

Crews have completed laying the track of a new rail connection, enabling freight to be transported more efficiently from Dandenong South to the Port of Melbourne.

The connection – known as a spur line –will also link the Cranbourne line to a new intermodal freight terminal to be constructed

delivered as part of the PRSN, this will result in lower transport costs for businesses and take thousands of trucks off arterial and suburban roads.

The Australian Government is contributing $38 million towards this project and the Victorian Government $20 million.

Direct rail connections will be provided from the Port of Melbourne to major freight hubs in metropolitan Melbourne in the south-east, north and west.

while construction at the Austrak terminal in Somerton is scheduled to take place later this year.

Once complete, PRSN will slash truck movements on suburban roads by up to 175,000 trips each year and cut freight transport costs by up to 10 per cent.

The work at Dandenong South is being delivered by the Level Crossing Removal Project as part of the $1 billion Cranbourne Line Upgrade.

Passengers on the Cranbourne line are also benefiting from completed track duplication, which has increased train services to every 10 minutes in the morning peak.

Federal Infrastructure, Transport and Regional Development minister Catherine King said the Port Rail Shuttle Network would not only enhance the strategic importance of freight and logistics operators, but also deliver efficiencies and cost-savings for businesses.

The Port Rail Shuttle Network will enhance the strategic importance of freight and logistics operators.

“The Australian Governent’s $38 million investment in this project will enable producers and operators to transport their product more efficiently, boost the economy and reduce congestion on the road network,” she said.

Metro Trains recently recruited its 500th female driver – a first in Australia – as part of an ongoing push by the Victorian Government to boost the number of women working in transport.

Women now make up 37 percent of the nearly 1400 qualified and trainee train drivers, the biggest pool in Metro Trains’ history.

In 2009, there were just 26 women driving trains for Metro. But a recent Metro Trains’ recruitment drive was made up of 84 per cent women.

Women are traditionally under-represented in the transport and transport construction industry. The Government has committed $6.25 million to its Women in Transport Program, which aims to increase the number of women working across transport by 30 per cent by the end of 2024, the number of women in senior roles in the public sector to 50 per cent and the private transport sector to 30 per cent.

The program includes 21 initiatives to attract and retain women in the transport

sector, including training programs for women heavy vehicle drivers, diesel mechanics scholarships, a leadership development scholarship program and an engineering pathway program for female refugee and asylum seekers.

The strategy involves public and private entities – the Department of Transpot, Major Transport infrastructure Authority and major transport project organisers, VicTrack, MTM, Yarra Tram, V/Line and bus operators.

In the year ending December 2021, up to 2000 more women joined the transport industry compared to June 2019 – including an increase of more than 1200 women in senior leadership positions across the public sector and transport operators.

Metro has been endorsed by global jobs network Work180 as an employer of choice for women. It screens employers against a set of criteria that demonstrates that the organisation is committed to diversity, equality and inclusion.

Women now make up 37 per cent of the train drivers for Metro Trains.

Metro chief executive officer Raymond O’Flaherty said train driving was an important job opportunity offering flexibility and career progression and urged people interested in finding out more to do so.

“We want our team to reflect the community that we serve. This means committing to a more diverse and inclusive workplace,” he said.

It’s all systems go for Perth’s $1.86 billion METRONET Forrestfield-Airport Link, which began operations on October 9.

The METRONET Forrestfield-Airport Link, now known as the Airport Line, is jointly funded by the Australian and Western Australian Governments, and is the first passenger rail line to Perth Airport.

The project delivered three new train stations at Redcliffe, Airport Central and High Wycombe, increasing public transport options for Perth’s eastern suburbs and foothills area.

This will support domestic and international tourism by improving access between the city and Perth Airport, and create new residential and commercial opportunities around Redcliffe and High Wycombe Stations.

It’s anticipated an average of 20,000 passenger trips will be made each day on the new rail line in its first year of service, increasing to 29,000 by 2032.

The Airport Line will be supported by an enhanced bus network connecting surrounding suburbs to the new train stations, adding an additional 26 new buses to the network, as well as approximately 1.7 million annual bus service kilometres to the Transperth network.

Prime Minister Anthony Albanese said the Federal Government was partnering with the WA Government to deliver billions of dollars

of upgrades and improvements to road and rail projects around the state, creating and supporting thousands of local jobs.

“As a former Infrastructure Minister, I know how important access to affordable and accessible public transport is and I’m really pleased this important METRONET project will start operating later this year,” he said.

“I look forward to visiting Perth and riding on the new Forrestfield-Airport Link later this year.”

WA Transport, Planning and Ports minister Rita Saffioti said the Forrestfield-Airport

Link had been one of the biggest and most complex public transport infrastructure projects the state had ever undertaken, including the delivery of an 8.5 kilometre rail tunnel that travels underneath the Swan River.

“We expect in the first year of service, we will see around 20,000 passenger movements everyday on the rail line, which will increase public transport options for Perth’s eastern suburbs and foothills area, as well as for visitors and residents going to and from the airport,” she said.

Arc Infrastructure’s Mid West Track and Structures teams recently completed the rebuild of ‘Sandy Curve’, a section of track approaching the town of Walkaway in Western Australia, and replaced the ageing Walkaway Bridge over a five-day shutdown.

‘Sandy Curve’ and the Walkaway Bridge are located on the Millendon Junction to Narngulu rail line, which is used to transport grain through the Mid West.

The team worked on a tight schedule to carry out the works and ensure the 730 metre section of track and bridge could reopen to customers as quickly as possible.

Located within the bounds of an Aboriginal Heritage area, the bridge works had required special approvals from the Yamatji Southern Regional Corporation as

well as the Department of Planning, Lands and Heritage. Works were conducted in two phases, and required a significant number of large machinery.

Phase one preliminary works commenced prior to the shutdown, and included earth works and equipment mobilisation.

With the approvals and pre-works complete, the shutdown and work on phase two got underway. The works included removal and repairs to the track and the bridge installation.

Regional Lead Mid West Trevor Blackmore said the work was made possible through organisation and teamwork.

“To have zero incidents and injuries with the amount of large plant operating in such a confined area is a credit to all involved,” he said.

Queensland

With the Cross River Rail project charging ahead to completion, the Queensland Government recently released its blueprint for how the South East Queensland rail network would be transformed as a result.

Transport and Main Roads Minister Mark Bailey said the SE Queensland Rail Connect plan showed just how trains would move when Cross River Rail opened.

“The Government has been carefully and progressively making the sorts of investments in rail that will completely transform the way we travel throughout the South East of this state,” he said.

“In 2025, the first underground rail system in the state’s history will be built paving the way for faster, more frequent services, but we aren’t just building Cross River Rail, we’re building a brand new network.

“This network will be a change for Queenslanders, but it will open the door for future investment and timesaving timetable changes to help Queenslanders get home sooner and safer.

“The rail connect plan is headlined by projects like the Beerburrum to Nambour and Kuraby to Beenleigh track duplications, Gold Coast Light Rail stage three, station upgrades across all of Queensland, plus the manufacture of 65 brand new trains in Maryborough.

“Bringing all of these projects together is a new modern signalling system and implementation of state-of-the-art platform screen doors for underground stations, a world leading technology used on the subway networks of Europe and Singapore, which will allow us to run more services, more often, all while improving safety.”

Bailey said the new plan would open up new public transport opportunities for many residents and visitors to SE Queensland by establishing a new three-sector network.

Sector One will create a north-south spine connecting the northern and southern regions through the Cross River Rail tunnel from Varsity Lakes and Beenleigh to Redcliffe Peninsula and Nambour.

Sector Two will comprise services from Rosewood, Ipswich and Springfield through Central to Doomben, the Airport and Shorncliffe, while Sector Three will operate from Ferny Grove through Central and Southbank to Cleveland.

All trains will run through Roma Street either through the existing station or the new below ground Cross River Rail station.

“This will be a big change for some

The rail connect network is split into three sectors.

customers, but presents many opportunities especially when considering the sheer level of investment and good jobs that will be supported,” Bailey said.

“Cross River Rail is already supporting more than 1700 Queensland subcontractors and will support 7700 jobs over the life of the project, while the Queensland-made Train Manufacturing Program and rollout of the European Train Control System will support thousands of jobs over the life of the programs.

“There’s nothing that helps Queenslanders tackle the cost of living more than having a strong pipeline of work on Queensland soil.”

Bailey said the rail transformation underway across Queensland would deliver for all commuters.

“More than 80,000 people migrated to Queensland in the past two years, and this investment shows we are at full throttle, planning, building and delivering a world-class rail network for the state,” he said.

“Our rail revolution is all about building for growth and providing a legacy of infrastructure for generations of Queenslanders to come.

“The new network we build now will be the network Queensland kids and Olympic-goers will remember.

“Our four-year road and transport plan includes $7.154 billion in funding towards this ambitious near $20 billion pipeline and we’re proud to be investing in the network at record levels. On top of this, the Government is fully funding the $5.4 billion Cross River Rail project.

“The pipeline includes major projects like this, as well as those in the planning phase

like the Direct Sunshine Coast line (formerly CAMCOS), Springfield to Ipswich and Salisbury to Beaudesert.”

Queensland’s rail pipeline includes:

• $5.4 billion Cross River Rail

• $7.1 billion Queensland Train Manufacturing Program (including Ormeau stabling and maintenance facility)

• $2.6 billion Logan and Gold Coast Faster Rail Project to upgrade tracks and stations between Kuraby and Beenleigh

• $1.2 billion Gold Coast Light Rail stage three

• $764.3 million European Train Control System rollout

• $275.7 million for Automatic Train Operation and Platform Screen Door fitment on New Generation Rollingstock

• $550.8 million Beerburrum to Nambour upgrade (stage 1)

• Over $500 million South East Queensland Station Accessibility Upgrades Program

• $360 million Park n Ride upgrade program

• $374.1 million European Train Control System train fitment

• $20 million Salisbury to Beaudesert business case

• $15 million Brisbane to Toowoomba passenger rail business case

• $6 million Direct Sunshine Coast line planning study

• $2.5 million Springfield to Ipswich rail corridor study

• $371.1 million smar t ticketing.

To view the plan, visit https://www.tmr.qld.gov.au/ About-us/Corporate-information/Publications/

Ipswich/Rosewood and Springfield train line customers are now able to use credit cards and smart devices to take the train as the rollout of the Queensland Government’s $371 million Smart Ticketing project ramps up.

Once fully rolled out, the system will cover the largest geographical area of any ticketing system in the world, and be able to adapt to future growth and technology.

The system will allow commuters to tap onto buses, trains, trams and Translinksupported ferries using contactless debit and credit cards, smartphones and smart watches.

Full fare paying customers travelling between Rosewood and Central, and Springfield and Central, can tap on at the start and off at the end of their journey using Smart Ticketing equipment with Visa, Mastercard or American Express contactless debit or credit cards, or smart devices such as phones and watches.

The program also recognised Queensland’s First Nations’ history.

The Smart Ticketing readers and gates are colourfully wrapped in the iconic First Nation’s Connecting Thread artwork, and include larger, brighter and clearer screens, sounds and messages – making it easier for users to stay on top of their taps.

Member for Mount Ommaney Jess Pugh said the progressive testing and trial periods made sure customers had the best experience possible when transitioning to the new system.

“Queensland’s iconic go card has been used to pay for transport for about 16 years so the new system will be a big shake up to how people plan, catch and pay for services, not just here in Brisbane but right across the state,” she said.

“We’re focused on giving Queenslanders a new product that is fit for purpose and easy to use, so it’s important we take this time to progressively trial the system.

“With each tap, we are moving Queensland into the future.”

Customers can only pay for their journey, and if they are travelling with family or friends, everyone will need to use their own contactless debit or credit card or smart device to tap on and tap off.

South Wales

The final track has officially been laid on the NSW Government’s flagship public transport development, the Sydney Metro City and Southwest project.

Premier Dominic Perrottet and Minister for Transport, Veterans and Western Sydney David Elliott visited Martin Place Station and secured the final piece of track into place, marking the completion of trackwork in the 15.5 kilometre twin tunnels between Chatswood and Sydenham.

Perrottet said the project would slash travel times for commuters and transform the way

beneath the CBD at Martin Place, Pitt Street Waterloo and Barangaroo,” he said.

Elliott said the new metro railway line would have a target capacity of 40,000 customers per hour, similar to other metro systems worldwide.

“Sydney Metro trains will make history as we complete the first railway crossing deep below Sydney Harbour, with the trip between Victoria Cross in the city’s north to Barangaroo a fast three-minute journey,” he said.

“Furthermore, this has been a boost for the economy and local jobs with more than 5000 people currently working on the City

Station has seen all platform screen doors installed on station platforms and finishes are now underway.

A new 65m-long pedestrian link tunnel is also complete. It will provide the public with all-weather access to areas and alternative transport connections around the station and also link directly to Hunter Street and to the future Sydney Metro Hunter Street Station.

The two new commercial buildings at the station – a 39-storey building above the northern entrance to the station and a 28-storey office building above the southern entrance –are rising rapidly, reaching a new level every one to two weeks.

More than 40,000 cubic metres of concrete – enough to fill more than 16 Olympic swimming pools – was used to embed about 45,000 sleepers which supported 62km of Australian steel rails with a combined weight of about 4000t.

Now track laying is complete, workers are using railway wagons, fitted with large cable drums, to roll out the hundreds of kilometres of high voltage power cables needed to energise the driverless metro trains.

Workers rolling out the high voltage power cables needed to energise the driverless metro trains.

Connection of the new Sydney Metro City and Southwest Line with the existing Metro North West Line will occur later this year, ready for train testing to start along the new alignment in 2023 ahead of passenger services starting in 2024.

New South Wales Premier Dominic Perrottet has handed down an angry ultimatum to the Rail, Tram and Bus Union over its campaign of industrial strikes which continued to cripple the Sydney rail transport system.

The last straw came a month ago when Sydney ground to a halt once again, after 70 per cent of the city’s train fleet did not run because of more stopwork action.

To compound matters, bus drivers walked off the job in a separate protest, which led to a heavy backlog on the roads due to the higherthan-usual traffic congestion.

Trains were forced to operate to a reduced timetable for majority of the network, as negotiations over a new enterprise agreement fail to achieve resolution.

As well, the RTBU separately wants

the government to agree to make safety amendments to a fleet of intercity trains.

The Waratah, Millennium, and OSCAR trains were affected, while RTBU members said they would consider refusing to run services if they believe trains did not meet a minimum maintenance or cleanliness standard.

Perrottet said he had enough.

“I will not have our city grind to a halt, our people inconvenienced anymore by the actions of a union movement that belongs back in the 1970s,” he said.

“I have instructed the Transport Minister to finalise all negotiations with the RTBU. That will then go to a vote.

“If there is any further industrial action until that enterprise agreement has been voted on, we immediately seek to terminate the current

agreement and we will remove the new InterCity fleet from that agreement.

“We’ll have the new agreement arbitrated by the Fair Work Commission and that will be resolved in that manner.”

RTBU NSW branch secretary Alex Claassens said while the NSW Government had agreed to rectify the safety issues on the new fleet, the union needed to “see the complete package and commitment in writing and discuss it with members before any action can be called off”.

“This isn’t the first time the NSW Government has promised it will fix the safety issues. Rail workers and commuters have been burnt too many times to believe what one Minister in one meeting says,” he said.

As Rail Express went to print, there was still no breakthrough in the impasse.

The NSW Government’s historic Rail Trails Bill has passed through Parliament, empowering regional communities to convert disused rail corridors into walking and riding tracks.

The Transport Administration Amendment (Rail Trails) Bill 2022 alters the Transport Administration Act 1988 to provide a streamlined process that may enable regional rail trails where and when the community wants them.

Cities and Active Transport minister Rob Stokes said the Bill unlocks opportunities for communities and fixes outdated and onerous legislation that required a change to the Act for each rail trail.

“This bill will allow regional councils to transform these spaces into treasured public places. Projects that are consistent with the Rail Trail Framework and have broad community support will now be able to proceed,” he said.

“We know that active transport options are great for our wellbeing, our environment and give locals and visitors a way to explore the beauty that regional NSW has to offer, free of charge.”

Regional Transport and Roads minister Sam Farraway said an improved process to authorise the use of non-operational rail lines for rail trails and related tourism uses will benefit rural communities and economies, without compromising on biosecurity or ongoing viability.

“The Government’s approach makes the process for rail trail development more

rigorous and transparent; this is not a green light for all disused rail corridors to become a rail trail,” he said.

“State-funded pilot projects have proved popular and beneficial — the first completed rail trail between Tumbarumba and Rosewood saw spend in the local economy increase 20 per cent following its opening in mid-2020.

“The $4.9 million project has had over 15,000 visits so far and welcome economic stimulus from this has flowed to Snowy Valley businesses.

“We’ve also invested $7.8 million in the Northern Rivers Rail Trail, which is expected to create an extra 200 jobs and attract 82,000 visitors each year in and around the Tweed communities of Murwillumbah to Crabbes Creek.”

All rail trails would be created under a lease agreement of up to 30 years with the local council.

The agreement allows the Minister to

terminate the lease should the corridor be required for a future transport use.

However, the move continues to anger the Northern Railways Defenders Forum, which has been steadfastly against the legislation.

Spokesmen Siri Gamage and Mathew Tierney said as the country faced higher fuel prices, and with a need to commit to climate change targets, it is the wrong time to be alienating railway lines from their original purposes.

“We are not against rail trails per se, just ones that can be done by ministerial fiat, despite the real opportunities that we are currently exploring,” they said.

“Let’s instead see a full review of the non-used but still open railway lines to see what purposes they can and should be put to as functional railway lines.

“These rail lines need to be incorporated into short, medium and long-term transport planning for the restoration of an efficient and effective non-metropolitan rail alternative.”

The largest project in the New South Wales Fixing Country Rail Program is officially complete.

Regional Transport and Roads minister Sam Farraway said 174 kilometres of rail between Junee and Griffith have been replaced, while a $11.7 million project is about to get under way near Coolamon to further reduce rail bottlenecks on the line.

“Fixing Country Rail is a $400 million program unlocking the economic potential of regional NSW,” he said. “Our regional freight task in NSW is expected to increase by 17 per cent to 311 million tonnes by 2036, which is why improving our supply chain network, whether it be rail or roads, is so important.

“The Junee to Griffith upgrade allows heavier freight trains to use the track, and adds capacity for those trains to travel at higher speeds, making journeys more efficient for freight trains transporting goods and produce from farms in the Riverina across the state, Australia and overseas.”

The project to extend the Coolamon Siding will help alleviate bottlenecks and congestion on the single line track between Junee and Griffith, where currently there are limited opportunities for freight trains to load and unload off the main line.

“It will allow access for modern freight trains up to 1500 metres long to exit the

main line, letting passenger and other freight services pass while the train is loading or unloading,” Farraway said.

“The Riverina is the largest agricultural producer in regional NSW, and this rail upgrade will increase bulk grain loading capability for freight trains.”

Member for Cootamundra Steph Cooke said the Coolamon project would support around 30 jobs during construction.

“The Riverina Murray region makes the largest regional contribution to agricultural production across NSW, accounting for almost 13 per cent of produce across the state,” she said.

In the dead of night, a train slowly makes it way between two suburban stations on Brisbane’s Shorncliffe line.

When the suburban multiple unit (SMU) – a stalwart of the QR’s Citytrain fleet – reaches Sandgate station, it sits at the platform for a while as hi-vis-clad workers conduct their checks.

It then makes its way just as slowly back to Shorncliffe station.

The same train repeats the same pattern over eight nights, completing 50 runs in total between the same two stations.

To the untrained eye, the monotonous back and forth might not seem like anything special at all.

But to those involved, the exercise was a huge milestone in modernising Queensland’s

rail network through the introduction of worldclass European Train Control System (ETCS) digital signalling technology.

The train in question – an SMU276 – is the first-of-class of a number of SMUs being fitted out with ETCS technology.

The vital work is being delivered through the Cross River Rail project – the new 10.2 kilometre rail line from Dutton Park to Bowen Hills, which includes 5.9km of twin tunnels under the Brisbane River and CBD.

As Cross River Rail Delivery Authority chief executive officer Graeme Newton points out, the significance of the testing underway on that stretch of track between Shorncliffe and Sandgate throughout July and August could not be overstated.

“While Brisbane slept, the future was

arriving,” he said. “For the first time, an ETCSequipped train was tested in Level 2, or under ‘full supervision’, on the Queensland Rail network – a huge step in our state becoming the first to use an ETCS Level 2 system on a passenger network anywhere in Australia.”

Full supervision means ETCS was fully connected using both operational lineside and onboard signalling equipment, without relying on existing signalling conventions such as red or green lights on the side of the track.

Newton said trains had previously been tested in Level 0, where drivers onboard ETCS-equipped trains had to adhere to existing signalling conventions, but this new phase provided a wealth of new information.

“The team confirmed the onboard and trackside equipment were communicating

With Cross River Rail well into construction and a raft of other significant projects in the South Eastern Queensland rail network pipeline, the rollout of the world-class European Train Control System (ETCS) has never been more important.The console of an ETCS-equipped train.

with each other, and Queensland Rail’s Rail Management Centre, as expected,” he said.

“A number of minor issues were picked up during the testing and are being analysed further – which is the whole point of testing to begin with.

“This testing is continuing over coming months between Sandgate and Shorncliffe, and this will allow us to update the system and ensure any issues are resolved.”

Newton, like so many others involved in the project, is excited by what this new technology will bring.

“ETCS allows the train to know its location precisely, which in turn allows trains to safely be scheduled to travel closer together,” he said.

“Continuous information is relayed between the Rail Management Centre and trains via trackside equipment.

“This is crucial for the safe operation of trains within Cross River Rail’s tunnels, where this digital technology will be relied upon rather than conventional trackside signalling equipment such as coloured lights.”

Queensland Rail’s Head of SEQ, Scott Riedel, said the benefits would extend to the wider network.

“ETCS is the next step in the modernisation of our network,” he said.

“It will lead to improved network performance, increased network capacity and improved timetables.

“In fact, as part of the ETCS project, our Rail Management Centre at Bowen Hills will be modernised with a new rail traffic management system to move trains around the network with greater efficiency and updated train planning systems.”

Riedel believes one of the biggest ways ETCS will increase safety is by providing an engineering control for signals passed at danger (SPADs) on the network.

About 200 people are helping to make ETCS a reality in Queensland.

This includes at a specialised facility at Redbank, where the fleet of SMUs are being fitted out with ETCS equipment and undergoing testing; the Systems Integration Lab at Eagle Farm, where software is tested in a lab setting before it’s tested on the track; and along the Shorncliffe line, where trackside equipment including radio masts are being installed.

Newton said the various partners involved in ETCS works – the Delivery Authority, Queensland Rail, Hitachi Rail and the

Department of Transport and Main Roads – recently moved to a new alliance-style contract to deliver the project.

“The new alliance, known as Sequence, ensures close collaboration between the key partners, and is really the most effective model for delivering this game-changing project,” he said.

“ETCS is a complex project which has critical deadlines to provide signalling and other technology for Cross River Rail’s tunnels and to integrate with the existing Queensland Rail network.

“This model, which is successfully used on many large infrastructure projects with complex requirements, gives us the best chance for success.”

Newton said Shorncliffe line testing remains the team’s key focus for the time being.

“Testing is a complex, extensive process which needs to be carried out at night and on weekends, when revenue services aren’t running,” he said.

“We want to make sure we get this right, which is why ETCS will be rolled out in several stages, starting with the rigorous testing program on the Shorncliffe line, where construction work is already well advanced.

“All parts of the new signalling system will be progressively tested, including equipment installed on and along the track, onboard test trains and within the Rail Management Centre.”

Newton said focus would then shift to the design requirements and installation for Cross River Rail’s tunnels, which will rely on the new signalling technology to safely operate.

“This will ensure there is enough time for testing and commissioning and integration with other parts of the project before the twin tunnels open to services,” he said.

But with ETCS to deliver benefits beyond the transformational Cross River Rail project, exactly where the technology is rolled out next will depend on a number of factors, including network requirements, capacity and the asset life of existing signalling systems across the network.

The rollout of the new technology comes on the precipice of a huge investment in rail infrastructure in the state.

Cross River Rail is already well advanced, with tunnels and caverns excavated and new underground stations taking shape.

But prompting the introduction of ETCS and adding a second river crossing at the core of the rail network, Cross River Rail provides the capacity to increase train services as the population grows.

And with the Brisbane Olympic and Paralympic Games on the horizon, the megaproject also acts as a fix at the core of the network that makes a number of rail improvements across the whole of SEQ more viable.

It’s an opportunity not lost on Queensland’s Transport and Main Roads minister Mark Bailey.

“We’re not just building Cross River Rail, we’re building a new network,” he said.

“Our latest budget delivered a $6 billion pipeline of rail projects over the forward estimates, over and above Cross River Rail.

“These include Beerburrum to Nambour Stage One and Kuraby to Beenleigh (also known as Logan and Gold Coast Faster Rail) and Gold Coast light rail stage three.

“We’re building new or upgrading more than 30 stations across all of Queensland to improve accessibility to the network, and manufacturing 65 new train sets in Maryborough.

“That’s trains built in Queensland, by Queenslanders for Queenslanders.”

And at the heart of all of it is the ETCS.

“Bringing all these projects together is the rollout of ETCS technology – the world-leading system used across much of Europe, which will allow us to run more services, more often, all while improving safety,” Bailey said.

“This world-class technology is what will help us provide world-class public transport to service a world-class event during Brisbane 2032.

“It will also help provide the kind of public transport network the growing south east corner needs and deserves.”

So while that lonely train in the middle of

the night might be what ETCS looks like on the surface, the reality of what it will provide, and what it will enable, is so much more.

Like the Cross River Rail project itself, ETCS is just the beginning of Queensland’s rail revolution.

Welcome to the 2022 Rail Express Plant and Equipment Showcase, a useful resource highlighting the capabilities of some of the major plant and equipment suppliers to Australia and New Zealand’s railway construction and railway maintenance industries.

The showcase, over the next six pages, is an essential industry resource, demonstrating the skills and expertise of businesses involved in the sector.

Affective Rail www.affectiverail.com.au peter@affective.com.au(02) 4227 6222

Affective Rail www. affectiverail.com.au phil@affective.com.au0412573016

Allworks (WA) Pty Ltd www.allworks.com.au info@allworks.com.au(08) 9303 4368•

Alpha Rail www.alpharail.co.nz mark@alpharail.co.nz+64277785898•

Autech Rail Australia Pty Ltd www.autechrail.com.au a.bibby@autechrail.com.au0473598259

Bexon Crane Rail www.bexon.com.au bexon@bexon.com.au (02) 9522 9437

Diesel Traction Group www.dtg.co.nz secretary@dtg.co.nz

E Rail Trans Pty Ltd www.erailtrans.com sales@erailtrans.com(02) 8880 7661

Engineered Solutions Asia Pacific P/Lwww.esap.net.au/ xipengj@esap.net.au0409281159

Engineering Supplies www.engineeringsupplies.com.au/ jeremy@engsup.com.au0437919313

Ironcore Transformers Pty. Ltd., www.ironcore.com.au info@ironcore.com.au(03) 9480 6044

Laing O’Rourke www.laingorourke.com/ rbarker@laingorourke. com.au 0419564747 • • •

Liebherr-Australia www.liebherr.com.au elle.nguyen@liebherr.com(02) 9852 1866•

Loram www.loram.com.au enquiriespty@loram. com.au 1800 059 955

Luke Penrith Arts & Designs www.lukepenrithartsanddesigns. com/ admin@ lukepenrithartsanddesigns. com 0419220635

Lyons Machine Hire Pty Ltd rhonstud@bigpond.net.au0418187475

Martinus www.Martinus.com.au billie.stanic@martinus. com.au 0424274963

McLeod Rail www.mcleodrail.com.au admin@mcleodrail.com.au(03) 9687 3955•

Civil Pty Ltd www.newbridgecivil.com.au markr@newbridgecivil. com.au

www.pandrol.com salesaus@pandrol.com(02) 9852 2500

Rail Services www.railtrain.com.au/service-list/ rmc-track-and-civil/

3557 6054

•

Affective Rail www.affectiverail.com.au peter@affective.com.au(02) 4227 6222

Affective Rail www.affectiverail.com.au phil@affective.com.au0412573016

Allworks www.allworks.com.au info@allworks.com.au(08) 9303 4368•

Allworks (WA) Pty Ltd www.allworks.com.au info@allworks.com.au(08) 9303 4368

Alpha Rail www.alpharail.co.nz mark@alpharail.co.nz+64277785898•

Autech Rail Australia Pty Ltd www.autechrail.com.au a.bibby@autechrail.com.au0473598259

CRRC Australia Pty Ltd www.CRRCGC.CC yangbin1818@gmail.com0488043786

Diesel Traction Group www.dtg.co.nz secretary@dtg.co.nz

Engineering Supplies www.engineeringsupplies.com.au/ jeremy@engsup.com.au0437919313

Freightquip www.freightquip.com andrew.steel@freightquip. com 0413156708

Keltbray International Pty Limited www.keltbray.com/ mark.thomas@ keltbrayinternational.com 0448802804 •

Kennards Hire www.kennards.com.au brettharvey@kennards. com.au 0428026670 •

Laing O’Rourke www.laingorourke.com/ rbarker@laingorourke. com.au 0419564747 •

Liebherr-Australia www.liebherr.com.au elle.nguyen@liebherr.com(02) 9852 1866

Loram www.loram.com.au enquiriespty@loram. com.au 1800 059 955

Lyons Machine Hire Pty Ltd rhonstud@bigpond.net.au0418187475

Martinus www.Martinus.com.au billie.stanic@martinus. com.au 0424274963

MATISA www.matisa.com.au steven.johnson@matisa. com.au 0429153530

Melvelle Equipment www.melvelle.com.au sales@melvelle.com.au(02) 4951 5244•

Melvelle Equipment Corp Pty Ltdwww.melvelle.com.au sales@melvelle.com.au(02) 49515244

Pandrol www.pandrol.com salesaus@pandrol.com(02) 9852 2500•

Rail Equipment Australia www.railequipmentaustralia.com.au sales@ railequipmentaustralia. com.au

Schaffler Consulting www.schaeffler.com/en/divisionsproducts/consulting/ bernard.schaffler01@ gmail.com

TechPlas Extrusions www.TechPlas.com.au Enquiries@techplas.com.au(02) 9636 6755

THEE group www.theegroups.com.au jthompson@theegroups. com.au

Titan Rail www.titanrail.co.nz steve@titanrail.co.nz+64277045527 webbair pty ltd www.webbair.com.au chris@webbair.com.au0419568976

• •

Affective Rail www.affectiverail.com.au peter@affective.com.au (02) 4227 6222

Allworks www.allworks.com.au info@allworks.com.au (08) 9303 4368

Allworks (WA) Pty Ltd www.allworks.com.au info@allworks.com.au (08) 9303 4368

Alpha Rail www.alpharail.co.nz mark@alpharail.co.nz +64277785898

Bexon Crane Rail www.bexon.com.au bexon@bexon.com.au (02) 9522 9437

Calgraphics www.calgraphics.com.au/ wayne@calgraphics.com.au0400549216

CRRC Australia Pty Ltd www.CRRCGC.CC yangbin1818@gmail.com0488043786

Diesel Traction Group www.dtg.co.nz secretary@dtg.co.nz

Engineered Solutions Asia Pacific P/Lwww.esap.net.au/ xipengj@esap.net.au 0409281159

Engineering Supplies www.engineeringsupplies.com.au/ jeremy@engsup.com.au 0437919313

Ironcore Transformers Pty. Ltd., www.ironcore.com.au info@ironcore.com.au 0394806044

JU Design Pty Ltd www.judesign.com.au jill@judesign.com.au 0400123852

Keltbray International Pty Limited www.keltbray.com/ mark.thomas@ keltbrayinternational.com 0448802804

Kennards Hire www.kennards.com.au brettharvey@kennards.com.au0428026670

Laing O’Rourke www.laingorourke.com/ rbarker@laingorourke.com.au0419564747

• Loram www.loram.com.au enquiriespty@loram.com.au1800 059 955

Lyons Machine Hire Pty Ltd rhonstud@bigpond.net.au0418187475

Martinus www.Martinus.com.au billie.stanic@martinus.com.au0424274963

• MATISA www.matisa.com.au steven.johnson@matisa.com.au0429153530

McLeod Rail www.mcleodrail.com.au admin@mcleodrail.com.au(03) 9687 3955

Melvelle Equipment www.melvelle.com.au sales@melvelle.com.au (02) 4951 5244

Melvelle Equipment Corp Pty Ltdwww.melvelle.com.au sales@melvelle.com.au (02) 4951 5244

Newbridge Civil Pty Ltd www.newbridgecivil.com.au markr@newbridgecivil.com.au0487431571

www.pandrol.com

and-civil/

In the rail industry, wheeled excavators are most commonly used for classic earthmoving work. The mobility of such wheeled machines is a great advantage over those with tracked undercarriages as they are not restricted from hard stand areas of concrete and asphalt.

Across Australia, Liebherr’s A 922 and A 924 Rail Litronic excavators are employed in various rail infrastructure building and maintenance jobs.

The 120 kW/163 HP engine of the A 922 Rail Litronic ensures it achieves high working speeds with the Litronic’s renowned fluid equipment movement. The A 922 Rail is suitable for use on railway tracks and for road construction, and is fast thanks to the mobile undercarriage.

The innovative hydraulic concept of the model consists of a Liebherr variable displacement double pump with independent control circuits. High-performance, hydraulic attachments can thus be operated independently of the working and travel movements of the railroad excavator.

The heavy ballast was also redesigned to yield the best bearing load values with improved weight distribution and a more compact rear dimension of 2000mm.

The A 922’s unique double cab featuring standard rollover protective structure (ROPS) and a modern interior design offers the best conditions for comfortable, productive and safe operation. To improve productivity by up to 30 per cent, the rail road excavators can be fitted with a fully hydraulic quick coupling system developed by Liebherr.

The A 924 Rail Litronic model combines strong performance with a high level of economy.

Running on a 120kW/163HP at 1900rpm machine engine, it delivers higher working speeds and smooth operation. The powerful D924 diesel engine is environmentally friendly thanks to its reduced fuel consumption and emissions..

Combining power and dynamic properties, this all-rounder machine is the efficient solution for safe use on all rail projects as well as construction sites which require stable power, strength, and

precision to deliver higher productivity and mobile flexibility.

Both the A 922 and A 924 are designed with the operator in mind. The double cab provides user friendliness and comfort, with vision of the working area supported by a generous use of glass as well as rear and side cameras as standard and ensuring safe operation at all times.

The touchscreen colour display as well as the other control elements on the console and the comfort operator’s seat are ideally and ergonomically coordinated with each other, forming a perfect unit. The service-oriented design of the Liebherr excavators guarantees short maintenance times and minimises the associated costs.

The excavators play a big part in works run by the Anric Group, an acknowledged industry leader in Hi Rail technology, rail construction, civil works and plant hire.

With projects across NSW, the business has been delivering cost-efficient and innovative civil and rail business practices for more than 40 years.

As Anric Group operations manager Anthony Spinozzi tells Rail Express, the only way to deliver superior results is through providing clients with international best practices combined with a reputable, driven and highly skilled team, backed by the best equipment.

And that includes the Liebherr rail excavators.

“We’re involved in a lot of maintenance works and construction projects, and we deliberately chose those machines for their efficiency and turnkey capabilities,” he said.

“The machines have many strong performance features in them apart from just lifting and handling. Traditionally a rail machine in Australia is piecemealed together, so that means users would have to purchase an OEM standard vehicle, and then have them accessorised, for example going to a

specialist to bolt on or fabricate the rail gear for that vehicle.

“And there are several other things to get done to a vehicle. The Liebherr rail-specific machines have everything on them already.”

Spinozzi said that also meant users were only dealing with one company if there were any problems or issues.

Anric bought the first Liebherr machine around 2018, and was so impressed it acquired a second one six months later. Now the fleet has expanded to six, all being used on a weekly basis on various projects around Sydney.

This includes carrying out work for Systems Connect, an unincorporated joint venture between CIMIC companies CPB Contractors and UGL Engineering, as well as the Sydenham to Bankstown Metro project, aimed at converting the 13.5km T3 line to metro standard. The group has also been contracted to build the line-wide work to convert excavated tunnels into a working railway for Sydney Metro City & Southwest.

Spinozzi said the company was more than satisfied with the actual performance of the Liebherr rail excavators.

“The excavating power is exceptional, the lifting system is smooth and runs well, as does the console computer system,” he said. “For example, it’s quite fast in recognising and calculating excavation numbers and putting the weights in so that the operator can tell quickly what’s happening to the machine and how much he’s got on it.

“Characteristics like the orientation of the machine is all on the screen for display, so you can definitely accurately see what position it’s in, making it safer for lifting purposes. They’re also inexpensive compared to other products in the market that do the same thing.”

In essence, Spinozzi said the Liebherr rail excavators were well put together machines with minimal problems.

more information, visit www.liebherr.com.au

Digging, excavating and shovelling are the main tasks of the excavator, and Liebherr offers the optimum machine for every job.The Liebherr excavators at work for Anric.

With a full range of capabilities for keeping the country’s lines in top shape, Melvelle Equipment has grown rapidly and now enjoys growing support from its domestic and international customer base.

Such is its global reach that the company was last month invited to InnoTrains 2022, the international trade fair for transport technology, held in Berlin.

Chief executive officer Andrew Melvelle visited various international suppliers as well as supported Rail Products UK, which unveiled its new hybrid Mobile Elevated Work Platform (MEWP) with a 450kg basket capacity.

Melvelle Equipment is a secondgeneration, Australian-owned family business manufacturing rail track maintenance equipment, geotechnical drilling rigs, portable hydraulic equipment and hand tools.

Established in 1982, it was renamed when the second generation purchased the company in 2007, with manufacturing facilities located in Newcastle, Australia.

Led by Andrew, the team makes it a point to “listen to its customers” and continually develops new products to add to its expanding product range, offering design, manufacturing, hire and service services.

“Our products are practical in nature, easily maintained, robust in design, and give outstanding performance,” he said.

The range is seemingly endless: dedicated work equipment, grinders, shears, drills, clippers, drivers and hand tools of all types are available.

The design team focuses on providing robust solutions that solve technical problems that customers face.

“The team is comprised of qualified mechanical engineers and dedicated drafting staff,” Andrew said.

“Using 3D CAD software AutoDesk Inventor, our team are able to generate a fully functioning virtual product.

“Once the designs are approved and tested, new products are manufactured in our facility in Newcastle.”

Melvelle Equipment is proud of its Trackpack system, powered by a complete hydraulic unit with boom arm, designed to allow the use of multiple hydraulic work heads without the need for numerous power supplies.

“A quick change boom allows an easy change over from one head to another, with adjustable counterbalance positioning so the weight on the operator handles never exceeds 3-5kg,” Andrew said.

“It can be coupled with multiple hydraulic work-heads and powered by battery, diesel or petrol engines. All electric start machines have a night light option. All work heads come with emergency stops and hydraulic hose covers as standard.”

As a rail equipment specialist, Melvelle has developed a battery-powered unit which can be coupled with any of the Trackpack work heads to remove or install various trackfastening systems.

These include clip inserters and removers, spike pullers and drivers, and wood borers.

Andrew said the system can operate all day quietly, is fume-free and can be quickly assembled and disassembled.

“Added to our electric series of products is our innovative battery-operated inspection/

transportation and storage frame or supplied complete for rapid deployment at stations or railway access points.”

Melvelle Equipment also distributes various products, including the Rail Products

UK MEWPs, Knox Kershaw ballast regulators, Permaquip track equipment, Abtus measuring instruments, Sola track gauges, Rotabroach rail drills, Husqvarna rail saws, Atlas Copco tampers, Enerpac track jacks and tensors, Yanmarpowered products and Honda engines.

The company services equipment at its premises or is available to attend on-site.

Melvelle Equipment is celebrating its 40th anniversary of serving the railway industry from its Maryland manufacturing facility in New South Wales.The Melvelle Equipment team with battery-operated inspection trolleys. The Trackpack system E-clipping/ unclipping work head in use.

The future of mobility in our globally networked world calls for seamless, sustainable, reliable, and secure mobility solutions. We’re leveraging the benefits of digitalization, engineering excellence, and our entrepreneurial spirit to master this challenge. Trusted by our partners, we’re pioneering transportation, moving people sustainably and seamlessly from the first mile to the last. And we always go the extra mile to help transport services all over the globe move beyond the expected.

With more than 2000 jobs completed to the highest levels over seven years, Affective Rail is one of the leading privately-owned rail construction, maintenance and contracting companies in Australia.

With a highly experienced management team and workforce, it has successfully delivered cost-effective solutions across a broad spectrum of projects, from large complex closedowns to narrow working maintenance windows.

One of the main reasons for the NSWbased company’s success is its link with the Scotland-based McCulloch Group, an international rail plant and innovation business that specialises in rail handling and rail logistics, enabling Affective Rail use of a unique range of market-leading machines and equipment that are innovating the rail industry worldwide.

The patented rail handling and movement equipment is streamlining rail track maintenance and construction projects across Australia – improving safety, creating efficiencies, and reducing costs.

Affective Rail’s Mitchell Stewart tells Rail Express that the company prides itself on

having a dedicated team of machine operators and staff that have been mentored and certified by the McCulloch Group’s in-house training team.

“Our operators undertake regular training for variety of real-world situations plus classroom sessions to reinforce the machine safety systems, maintenance and capabilities,” he said.

“To maintain our high standards all of our machine operators are required to undergo periodical recertification.”

One of the standout items is the Trac Rail Transposer (TRT), the safest and most versatile rail handling machine for rail infrastructure.

The TRT can remove and install all profiles of rail and any gauge of track under live overheard line equipment (OLE).

“Just a pair of TRTs can be used to move lengths of rail up to 220 metres as well as transport, remove and install associated steel work, like switches and crossings,” Stewart said.

The TRT is a tracked machine which is powered by a Tier 4-compliant diesel engine, allowing a hydraulic system to move and handle rails and track furniture.

The list of Australian operators which employ the TRT is impressive, and includes

Sydney Trains, Transport for NSW, Sydney Metro Networks, ARTC, and Queensland Rail. When the many features are considered, it’s not hard to understand why.

TRTs are ideal for use on both single line and multiple track layouts, can easily cross multiple tracks, can operate in confined spaces such as tunnels and bridges.

They remove, transpose, move and install rail in a safe controlled manner by remote control, creating both cost and time efficiencies when compared to alternative methods, and in the process removes the vast majority of risks associated with people and plant separation on-site.

The units can also be stored lineside to reduce the need for demobilisation.

“They can handle all different types of rail regardless of track gauge,” Stewart said.

“They can access the rail infrastructure from access points as small as 1800mm in width and can travel unloaded on embankments and restricted access areas up to an angle of 45º.”

The McCulloch Group has transformed the way in which infrastructure projects are carried out

The McCulloch panel lifter removes and replaces rail panels swiftly and safely.

Affective Rail is working with Scottish innovators to help change the face of track-building projects in Australia.

TRTs are ideal for use on both single line and multiple track layouts.

globally and is celebrating its 30th anniversary this year.

McCulloch Group chief executive officer David Girdler said the company was delighted to work with its clients across the globe over the past few years to bring its innovative plant to rail infrastructure.

“In Australia it has been encouraging to see the appetite for our equipment, to such a degree that we have invested in sending our own Billy Jordan to be on the ground supporting our clients as they roll out the ‘McCulloch way’ here in Australasia,” he said.

“From the way in which our kit looks, its size and footprint as well as its impressive operational output – our plant is truly disrupting the industry in its own quirky way.

“I would encourage anyone keen to learn how our equipment can support projects with their resource requirements and improving their safety measurements to connect with us via social media, visit our website or indeed reach out to Billy directly”.

Stewart said there was a wide range of complimentary accessories for the TRT, which reduce the number of additional tools and equipment required on site.

“For example, with the use of supplied foam ramps, the TRTs can cross all types of rail track, and they can be adapted to undertake additional activities using attachments such as lifting cranes, ploughs and rail saws,” he said.

• Recovery engine

This enables completion of the task and recovery of the vehicle from track locations.

• Plough

This clears most ballast from either side o the track, on the sleeper ends.

• Hydraulic tools

These are versatile front-mounted connectors that power various hydraulic tools such as rail saws.

• Mounted jib

The jib attachment allows safe lifting of track furniture up to 990kg in live OLE areas.

• Switches and crossings

These unique handling heads can move switches and crossings safely, from access to install.

• Rail saw

This is a zero-emission, hydraulic, long arm saw designed to allow full use in a standing position, reducing fatigue and the risk of back injury.

removes and replaces rail panels swiftly and safely.

Using remote control technology, it creates an instant exclusion zone which eliminates any handling issues and keeps the work team safe while panels are removed and replaced.

The speed at which it works makes it a more efficient and faster process, an important element to consider on projects with limited possession timescales.

“The McCulloch Group designed and developed the lifter system and has been using this system successfully within the UK for nine years,” Stewart said.

The Panel Lifter revolutionises the method of removing and placing rail panels swiftly and safely with greater efficiency in comparison to all other methods.

It has an 18 tonne lifting capacity, and even when fully loaded, can turn in any direction whilst in motion.

The variable track width allows access and use in narrow environments such as bridges, tunnels, platforms and cuttings, and is ideal to be used for removing and installing panels on a single line.

The compact size and manoeuvrability enables easy transportation, rapid deployment and demobilisation.

“A panel lifter system of two machines can be used to move panel lengths of up to 30m long. More machines can be added to move longer panels,” Stewart said.

For more information on Affective Rail, visit: www.affectiverail.com.au

For more information on McCulloch Group,

Just a pair of TRTs can be used to move lengths of rail up to 220 metres.

In the space of just two years, rail manufacturing has returned to Western Australia, almost three decades after the last locally made trains rolled on the tracks.

The new C-Series railcars will be delivered over an eight-year period as part of a contract that global rolling stock manufacturer Alstom has secured with the Public Transport Authority of WA (PTA).

Under the contract, Alstom will be responsible for the design, supply, manufacturing, testing and commissioning of 41 six-car electric (EMU) and two three-car diesel (DMU) trains, plus 20 years maintenance of the EMU trains and maintenance support services for the DMU trains.

The new railcars will run along the Joondalup and Mandurah lines, two of the busiest services on the Perth network: and looking towards the future, there is a possibility

for additional lines as the WA Government carries out its plans to overhaul the METRONET public transport rail system.

The forecast is that by 2029, there will be up to 246 new C-series railcars locally built at the Bellevue manufacturing facility to service Perth’s growing train network.

The first six-car set completed high-voltage testing recently and will now move to the Nowergup Depot in September.

Here the set will undergo extensive dynamic validation testing period which is the last step before revenue service carrying its 103,000 daily passengers.

Alstom’s Project Director for the METRONET railcar procurement project, Fabrice Ponti, tells Rail Express that it has been quite a remarkable achievement to get to this stage.

“When the contract was signed in 2019, there was no rail industry in WA. Two and a

collaboratively to realise the WA Government’s vision to return railway manufacturing back to the state.”

Indeed, Alstom has a proven ability to localise its operations right across the globe, including Australia.

“Alstom has the expertise and experience to setup a new manufacturing facility, through extensive transfer of technology from its

Trains are being made locally in Perth once again, led by the expertise of rolling stock specialists Alstom.The first C-Series railcar rolls out onto the tracks.

“In parallel, the Government delivered the infrastructure for the project, the magnificent, modern, world-class facility in Perth at Bellevue, which was handed over to us in May 2021.

“We then fitted out and equipped the site with the jigs and tools needed, implemented our processes to the latest global standards and international best practices”.

The site is now fully operational and will be for the duration of the project.

The production employees are equipped with iPads, which they use on the job for production processes, record progress, report problems and access documentation.

This technology enables staff to apply Alstom’s AOS – Advanced Operations System – which connects all the functions around the shopfloor, whether they are part of the supply chains, industrial quality or methods teams.

“Alstom is operating in the digital world and this is well and truly implemented in Bellevue,” Ponti said.

The other important aspect of the contract is that the railcars will have at least 50 per cent WA local content, in a commitment to supporting local jobs, and boosting the state’s rolling stock supply chain, jobs, and skills development.

“This means building the trains locally and involving local suppliers that make and deliver components of the trains,” Ponti said.

The local components, materials and services are varied and many, large and small, such as bogie frames, battery boxes, passenger seats, air conditioning systems, and a whole range of metallic parts.

In the process, Alstom is also supporting the further development of the skillsets of the local supply chain.

“By using local suppliers, we help increase their range of competencies and qualifications, as the Rail Industry works with specific standards and requirements,” Ponti said.

“There was a significant piece of work around assessing the supply chain base in WA and the technical capabilities of the various suppliers.

“We then support these local companies throughout the duration of product development and production in order to ensure they deliver the product that we need.”

Ponti said training of the employees within the project has always been a priority.

“From the very beginning, even before we had a component or anything really in Bellevue, we set up a virtual reality room on site,” he said.

This was to ensure employees could start being trained for their specific roles in this 3D environment.

“We developed a competency matrix which covers every single staff working on the project,” Ponti said.

“It is used to define the extensive training period that every new employee goes through, from general training about the company to task-specific trainings like gluing, torque tightening or cable crimping. The competency of every team member makes the quality of the product in the end.”

Attracting trainees and apprentices is another priority.

“As part of our local employment initiative, we are also working with the North Metropolitan TAFE, East Perth, on a preemployment program for Indigenous people,” Ponti said.

“They will serve their apprenticeship on the project, with the view to continue their career with Alstom after they complete their apprenticeship.

“We expect eight to 10 Aboriginal apprentices by the end of 2022.”

The first C-Series trains are expected to roll into passenger service in late 2023.

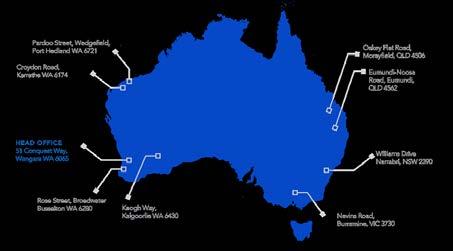

Throw a dart on a map of Western Australia, and chances are high it will land on an area that bears the footprint of Allworks WA.

The ubiquitous provider of dry and wet hire equipment and personnel for the civil and rail industry is so well-regarded in the state that its client list reads like a definitive guide of the prominent names in the rail sector: for example, John Holland, Laing O’Rourke, Aurizon, Arc Infrastructure, and WA’s Public Transport Authority (PTA), just to name a few.

The family-owned business, with Angelo Sarich and wife Robin at the helm, has been operating since 1999, with its key staff each having more than 30 years of experience in rail and civil works.

“Our vision statement of ‘On Track, On Time’ drives and guides our well-equipped organisation to operate in a dynamic environment, offering our customers with solutions to ensure project timing and budgets are maintained within their expectations,” Sarich said.

“While our office is based in Wangara in WA, we also have depots in Port Hedland and Kalgoorlie, and we also cover programs and projects throughout Victoria, Queensland and New South Wales.”

Sarich said Allworks has demonstrated the ability to produce efficient, consistent

providing civil, rail and plant hire services throughout Australia.

“Despite variable demands and requirements, we have a proven track record of providing the right plant and equipment and the right operators,” he said.

“The pillar of our success to date can be attributed to our industry alliances and relationships which we have developed over the past 20 years.”

With a fleet of more than 300 machines and vehicles, Allworks has the ability to provide to any location mine-spec wet and dry hire equipment, as well as rail-specific items such as Hitachi hirail excavators, tamper heads and sleeper layers on excavators, and Volvo L120 oaders.

“We understand the requirements of modern rail services and our customers both current and future,” Sarich said.