Water management

Mining unites in quest for water in droughtstricken land

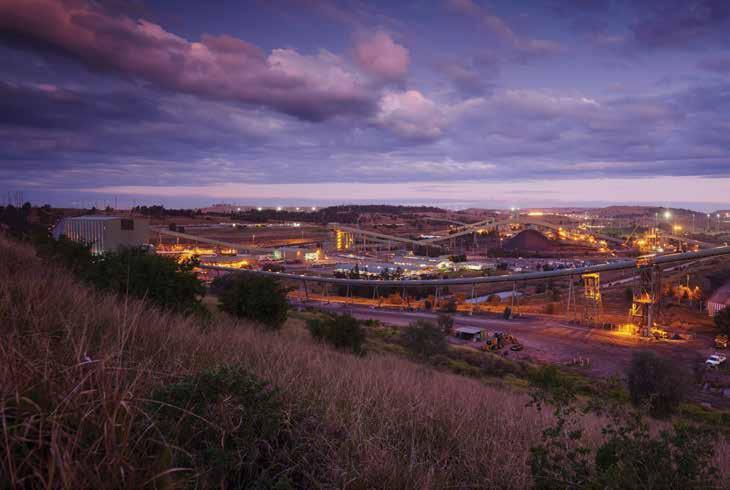

MINING COMPANIES SUCH AS WHITEHAVEN COAL, BHP AND NEWCREST MINING ARE FINDING WAYS TO ENSURE MINES AREN’T DRY IN PRODUCTION LIKE THE LAND HAS BECOME. SAFE TO WORK REPORTS.

A

ll hands are on deck across Australia when it comes to the threats posed by drought – it is unfortunately an enduring feature of the country’s landscape. Mining operations have to compete with other users such as agriculture and towns for water. Without it, valuable minerals such as coal and iron ore cannot be extracted out of the ground. Water is also core to the transport of ore and waste, separation of minerals, cooling systems around power generation,

suppression of dust and washing equipment, according to CSIRO. While the impact on farmers is well-understood, water supply is also crucial for mining operations, according to New South Wales Minerals Council chief executive Stephen Galilee. “Mines support thousands of jobs in regional areas and the security of water supply for mining operations can have major implications for regional economies,” Galilee tells Safe to Work in a statement. Whitehaven Coal’s Maules Creek mine in the Gunnedah Basin is one

SAFETOWORK 42 JAN-FEB 2020

mining operation that has been hit by drought conditions persisting in north west New South Wales. “I am only too aware of the fact this is truly a land of droughts and flooding rains, but the drought conditions we have observed across much of New South Wales have been especially challenging and are arguably the worst since the Federation Drought at the turn of the last century,” Whitehaven chairman Mark Vaile, speaking at the company’s 2019 annual general meeting, says. The company’s Maules Creek mine relies on a high security water