The triple bottom line of HDD 54 Digital quality assurance 46

ADAPTS INFRASTRUCTURE

RENEWABLE GAS TRANSMISSION

28 Keeping fugitive emissions at bay 34 ISSUE 197 | MAY 2023

The path to net zero OPERATOR

FOR

- page

WE KNOW PRESSURE › Pipeline integrity › Pigging services › NATA pressure testing › Inline inspection › Live line dig ups › Leak detection › CCTV inspection › HDD construction Our Exclusive Global Partner www.pipetek.com.au Taddam: 0432 666 917 taddam@pipetek.com.au Myles: 0417 707 729 myles@pipetek.com.au

ATCO is adapting its infrastructure vital for WA’s net-zero journey through renewable gases. ImagecourtesyofATCO.

CONTENTS 4 The Australian Pipeliner | May 2023 28

EXECUTIVE REPORTS CEO’s Message 4 POLICY Why a renewable gas target is critical to gas use decarbonisation 12 APGA MEMBER Q&A APA Group Head of Hydrogen and Future Fuels, Klaas Van Alphen 14 FUTURE FUELS Pipeliners have everything to gain from a net zero Australia 18 PIPELINES IN WESTERN AUSTRALIA Significant infrastructure developments in WA 20 WOMEN’S PIPELINE FORUM Reinforcing gender stereotypes 22 HYDROGEN & EMISSIONS REDUCTION Inspection solutions and their role in pipeline repurposing 24 A crucial step on the net-zero path 28 Future Pipe and Empire Infrastructure partnership committed to reducing carbon emissions 30 Defying heat, remoteness and sensitive environments 32 Keeping fugitive emissions at bay 34 Silver lining as STATS Group marks 25th anniversary 36 Could hydrogen microgrids replace diesel generators in remote areas? 38 PIPELINE CONSTRUCTION Pollard’s Pack Tuff for pipeline projects 40 Lift up the design game with Vertex G4Plant 42 A kwik solution 44 Digital quality assurance 46 The EZIpit is always the easy decision 48 ROTHENBERGER’s ROWELD leads charge on pipe welding systems 50 REHAB & REPAIR Pro Pipe Services completes one of the largest high-pressure isolation in Australia 52 TRENCHLESS TECHNOLOGY The triple bottom line benefits of trenchless technology 54 TRACTO strengthens Prime Drilling partnership, delivers new machines 56 PIGGING & ILI One-of-a-kind pipeline pigs collaboration 58 Pipe Tek and Enduro partnership making invaluable impact 60 CATHODIC PROTECTION The wonders of temporary flange coatings 62 REGULARS Members & memos 10 APGA members 64 People on the Move 66

COO

Christine Clancy christine.clancy@primecreative.com.au

MANAGING EDITOR

Molly Hancock molly.hancock@primecreative.com.au

EDITORIAL

Clemence Carayol clemence.carayol@primecreative.com.au

Vivien Topalovic vivien.topalovic@primecreative.com.au

BUSINESS DEVELOPMENT

Nick Lovering nick.lovering@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR Blake Storey blake.storey@primecreative.com.au

DESIGNERS

Kerry Pert, Louis Romero

COPYRIGHT

The Australian Pipeliner is owned by Prime Creative Media and published by John Murphy. All material in The Australian Pipeliner is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in The Australian Pipeliner are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2021

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Maximise brand awareness by connecting with thousands of industry professionals

The Australian Pipeliner brand comprises: a quarterly magazine, a news website, a fortnightly e-newsletter, multiple social media platforms, an annual industry directory and an annual pipelines wallchart. Book an advertising and editorial package to gain access to our exclusive audience.

3,300+

magazine subscribers

16,500+ e-newsletter subscribers

Want to find out more?

13,700+ social media followers

Head Office 379 Docklands Drive, Docklands VIC 3008 Ph: +61 3 9690 8766

Office Suite 303, 1-9 Chandos Street Saint Leonards NSW 2065 Ph: (02) 9439 7227 enquiries@primecreative.com.au www.primecreative.com.au

The Australian Pipelines and Gas Association’s (APGA) vision is to lead the sustainable growth in pipeline infrastructure for Australasia’s energy. APGA is a non-profit organisation formed to represent the interests of its members involved in: the ownership, operation, maintenance, design, engineering, supply and construction of pipelines, platforms and all other structures used in or in connection with the drilling for, extraction and transmission of hydrocarbons, solids, slurries and similar substances both onshore and offshore. As a single voice representing the collective interests of its members, APGA is dedicated to encouraging the extension and development of the industry.

The Australian Pipeliner | May 2023

6 PUBLISHER

our business

team to discuss how you can grow your business with The Australian

email

Contact

development

Pipeliner. Call 0414 217 190 or

nick.lovering@primecreative.com.au

20,000+ website views each month

Printed by: Manark Printing 28 Dingley Ave Dandenong VIC 3175 Ph: (03) 9794 8337 Sydney

CEO John Murphy

The Australian Pipeliner is the official journal of the Australian Pipelines and Gas Association (APGA) and is distributed to members without charge and circulated to interested organisations throughout Australia and overseas. It is also available on subscription. The publishers welcome editorial contributions from interested parties. However, neither the publishers nor APGA accept responsibility for the content of these contributions and the views contained therein are not necessarily the views of the publishers or APGA. Neither the publishers nor APGA accept responsibility for any claims made by advertisers. All communications should be directed to the publishers.

As the leading innovator, we continue to supply our customers with the technology, methods, and consultancy to make the best integrity management decisions for their assets. No matter what the future holds, renewable hydrogen as a flexible energy carrier plays a vital role in moving the industry further; we want to make sure you are ready.

Fit for the Future. Ready for Hydrogen.

www.rosen-group.com

Chief Executive Officer’s report

As you may have noticed, the gas industry has been making headlines recently due to significant government activity that has impacted gas markets and the pipeline industry. The government has made interjections with the intent to determine outcomes through gas price caps and an increased scope of powers for the Australia Energy Market Operator (AEMO). These developments have all played out heavily in the media and are the likes of which we have not seen since the 1970s.

In response to these changes, our advocacy program and policy team has been working tirelessly to ensure the voice of the industry is heard. We have introduced several new narratives into the conversation, most recently focusing on the “cost of electrification” for the everyday person. Independent modelling from the parliamentary Budget Office has revealed that the cost of electrifying a suburb in Canberra would be an average of $26,000 per home to switch from gas to electricity. Through a few simple calculations, we were able to put a total cost of electrification in a region upwards of $130 billion, which is a total much higher than what has been estimated to date. This interjection resulted in much-needed debate on the cost of electrification and its impact on the gas industry, as well as a few days of media coverage for the APGA.

Our policy team has also been working relentlessly to inject commentary on the opportunity renewable gas provides to meet emissions targets and direct conversation around proposed changes to the industry. We have provided commentary on key topics including the safeguard mechanism, Australian domestic gas security mechanism, and state-based policy in Tasmania, New South Wales, and South Australia. You can have a look at the submission section of the website and see that we have made 24 submissions to the end of April in 2023

already. This is an unprecedented level of activity from governments across the country and I am sure that you are all experiencing the effects of this in some way, shape or form in your own organisations.

It is great that APGA has the capacity to match this level of activity and be a bigger part of the public conversation this year. I can see from the feedback that members are noticing. The additional resources APGA’s Owner Members have put into the enhanced advocacy program is the reason we have been able to keep the pace and make more of a difference. The work we are doing is critical to ensuring the role of gas and gas infrastructure in delivering a decarbonised future is understood, accepted and supported across Australia.

At APGA, we are committed to our 2050 vision and support a net-zero future for Australia. Within that, we believe that a multipronged approach to emissions reduction is necessary. As such, we are actively advocating for the introduction of a renewable gas target. Renewable gases, such as hydrogen and biomethane, represent a real, technically viable approach to lowest-cost energy decarbonisation in Australia. We see renewable gases playing a critical role in decarbonising gas use for both wholesale and retail customers. All that is needed now is a plan to deliver the integrated energy system of the future that delivers decarbonised liquid, gas and electricity to the country. I can write it in a single sentence but it is a huge task.

The theme of this edition of The Australian Pipeliner is as important as ever in our industry, with a focus on future fuels and emissions reduction. We believe that it is crucial to continue this theme throughout the year at the APGA, with a particular focus on the future of the industry and the role that renewable gases play. As such, we would like to extend an invitation to you to attend this year's APGA Convention and Exhibition in Perth in October.

ABN: 29 098 754 324

APGA Secretariat Registered Office: 7 National Circuit, Barton ACT 2600 (PO Box 5416, Kingston ACT 2604) T: +61 2 6273 0577

E: apga@apga.org.au

W: www.apga.org.au

Chief Executive Officer

Steve Davies

Corporate Services Manager

Michelle Wickson

National Policy Manager

Jordan McCollum

Communications Manager

Lawrence Shelton

Engagement Manager

Dean Bennett

Membership Officer

Katy Spence Events Coordinator

Matthew Freeborough

Policy Manager

Catriona Rafael

Government Relations Manager

Paul Purcell

Early bird is open now! We believe that this is an excellent opportunity to learn more about the industry, network with like-minded individuals, and stay up-to-date on the latest trends and developments, and how you can play a role in the future of the industry.

I hope to see you all there.

STEVE DAVIES CHIEF EXECUTIVE OFFICER

C M Y CM MY CY CMY K

Central Highlands Water invests $15 million in Daylesford water supply pipeline

Central Highlands Water’s announcement of a $15 million investment in Daylesford’s longterm water supply security is a welcome boost for the region’s future growth and climate resilience.

According to Central Highlands Water‘s (CHW) chair Angeleen Jenkins, the new 14-kilometre water pipeline will provide enhanced security of water supply within the region and will future-proof the water needs of the service area against the impacts of climate change.

“As part of the operations of the asset when complete CHW has committed to 100 per cent use of renewable energy by 2025,” she said.

“This major capital investment in Daylesford’s water reserves will support long-term prosperity, growth and development within the region.”

CHW will continue working with the Hepburn Shire Council and relevant cultural, environmental and community

stakeholders regarding the planning and delivery of this project.

“We appreciate the ongoing collaboration and support shown by all involved and we look forward to securing the region’s water future together,” Jenkins said.

Hepburn Shire Council mayor Brian Hood welcomed this collaboration.

“Securing water for the future through the delivery of this valuable infrastructure is important for local residents, businesses and tourism as well as for the next generation of our water users,” he said.

When needed, it will be able deliver more than 300 million additional litres per annum of supplementary raw water for the community. This means during periods of dry climate and drought, the pipeline will complement Daylesford’s two existing major surface water supplies, the Wombat and Bullarto Reservoirs. The underground 400mm diameter raw water pipeline will extend from Blampied, connecting to the Goldfields Superpipe, and

utilising existing power easements and road reserves where possible.

The end connection for the pipeline will be at the Daylesford Water Treatment Plant.

The successful contractor for this significant project is S & R Construction and Engineering. The development of the water pipeline will be undertaken in three stages, with commencement of pipeline construction work to begin in early 2023 and with the expected completion of works in the second half of 2024.

Oil and gas industry urge NSW to consider energy challenges as priority

Repeated recent warnings from independent authorities like the Australian Competition and Consumer Commission (ACCC) and the Australian Energy Market Operator (AEMO) regarding the NSW energy strategy are not to be ignored any longer if forecast shortfalls are to be avoided.

Australia’s oil and gas industry has urged the incoming New South Wales Labor Government to recognise the crucial role of natural gas in the state’s cleaner energy future and enable investment in new supply to avoid forecast shortfalls and put downward pressure on prices.

The Australian Petroleum Production & Exploration Association (APPEA) congratulated Premier-Elect Chris Minns for winning the support of NSW voters at the recent state election.

APPEA Chief Executive Samantha McCulloch however was adamant: NSW needs to listen to ACCC and AEMO’s repeated warnings.

“The oil and gas industry congratulates Chris Minns on his victory and urges his new team to consider the serious and immediate energy challenges as a matter of priority,” McCulloch said.

“New South Wales is a big gas user but has left its own reserves in the ground and outsourced its energy security, exacerbating the cost-of-living pressures on NSW households and businesses.

“Bans and regulatory uncertainty have made new supply investment very difficult and left users paying $2/GJ extra when gas is transported from Queensland, often over untapped NSW reserves.”

McCulloch outlined that the new government needed to recognise the key role of natural gas in a cleaner energy future as identified by international and national energy authorities and echoed by the Prime Minister.

“The state needs to provide a clear strategy to promote investment in new supply in order to help avoid forecast shortfalls in the east coast energy market and put downward pressure on prices,” she explained.

“This could include fast-tracking new supply options like the long-delayed Narrabri Gas Project, which could supply enough natural gas to meet up to half of the state’s gas demand.”

McCulloch said states which have put in place investment-friendly environments benefited greatly – with better energy security, cheaper energy, emissions reductions and substantial economic benefits.

“Queensland, for example, forecasts $7 billion in gas royalties in coming years to build hospitals and roads while over 30,000 jobs are supported by its CSG and LNG developments,” she said.

“New South Wales, meanwhile, is missing out on the public revenue and jobs that local gas production provides while risking the lights going out.”

10 The Australian Pipeliner | May 2023 MEMBERS & MEMOS

Australia’s oil and gas industry has urged the incoming NSW Labor Government to recognise the crucial role of natural gas in the state’s cleaner energy future.

CHW will continue working with the Hepburn Shire Council regarding the planning and delivery of this project.

Jemena opts for renewable electricity and organic waste

Jemena is investing in demonstration projects that will generate biomethane sourced from gases released by organic waste and hydrogen made by using electricity to split water into hydrogen and oxygen.

In a recent video, “Renewable gas – from pipe dream to pipe line”, Jemena’s commitment towards a cleaner energy future is reinforced. Jemena’s customers are committed in reducing their emissions, that is why the company is investing in projects that demonstrate that renewable gas “is a viable way to help Australia meet its net zero emission targets.”

“However, at Jemena, they are exploring how renewable electricity and organic waste can provide renewable gas for their customers.”

In the video, the Jemena team explains how “gas plays an important role in firming the

energy system and generating electricity when base load power stations and renewables like solar and wind aren’t available”.

“Our customers tell us they love gas – it’s fast, flexible, reliable and has provided energy to our homes and economy for many decades.”

With its demonstration projects, Jemena is exploring how to use hydrogen and oxygen to reduce carbon emissions in the gas network in the coming decades, and to look at the potential for its customers to use renewable gas in their homes, businesses, and manufacturing. “By using renewable gas in existing gas infrastructure, it will help keep energy affordable for our customers in the long run,” shares the Jemena team.

The Australian Pipelines and Gas Association (APGA) applauded Jemena for thinking

Coliban Water’s new pipeline to improve local water supply

Residents in Epsom and Huntly will be able to benefit from improvements this autumn with Coliban Water finalising its new pipeline project.

With residential areas in Epsom and Huntly in regional Victoria continuing to grow, the performance of the local water supply is primordial.

Design work for the pipeline started in 2021 and construction commenced in May 2022, and is set to be finalised in the coming months, as final trenching is underway near Station Street and ground boring is being finalised across several short sections of the new pipeline. The new pipeline, which will run from Howard Street in Epsom to Gungurru Road in Huntly, is one of the largest water supply pipeline projects installed in our region in recent years.

“We are aware some customers have been experiencing water pressure issues, particularly on hot days and at peak times when more water is used to run air conditioners, water gardens and keep cool,” said the Coliban Water team.

“We work closely with Council and land developers to plan for population changes in our region to ensure we provide adequate

outside the box when it comes to renewable energy and producing biomethane.

“When it comes to renewable energy, most people think of solar panels and wind turbines” shared the AGPA team.

water services.”

According to Coliban Waters, operating from this autumn, the benefits of the pipeline will be immediate.

However, local residents can expect to notice a real difference from next summer, when increased demand for water typically adds to low-pressure issues.

11 The Australian Pipeliner | May 2023 MEMBERS & MEMOS AUSTRALASIA’S LEADING CATHODIC PROTECTION & CORROSION SPECIALIST Sydney I Melbourne I Brisbane I Perth Adelaide I Townsville I New Plymouth Engineering • Field Services • Products Our Experience Delivers Solutions www.cceng.com.au

The new pipeline is one of the largest water supply pipeline projects installed in our region in recent years.

With its demonstration projects, Jemena is exploring how to use hydrogen and oxygen to reduce carbon emissions in the gas network in the coming decades.

Why a renewable gas target is critical to gas use decarbonisation

By Jordan McCollum, National Policy Manager, APGA

As advocates for the transition to renewable gases, we often talk about the ability to reach net zero gas in Australia by 2050. But what does reaching net zero gas actually mean?

achieving net zero, and 2025 can be considered as a reasonable point in time to start targeted renewable gas development. The application of a diffusion of innovation curve between 2025 and 2050 can be seen in Figure 4. By following this renewable gas uptake trajectory, rather than a straight line or some other form of trajectory, diffusion of innovation theory suggests Australia should deliver net zero gas by 2050.

Now that we know that this is the trajectory that the renewable gas industry must meet to achieve net zero gas by 2050, the question that remains is – how do we get on this trajectory?

Having come leaps and bounds in researching the production, transport, storage and utilisation of renewable gases like hydrogen and biomethane, we know that we have the tools necessary to achieve a net zero gas system domestically in Australia. However, the path ahead of us is still a little less clear.

Luckily, renewable gases aren’t the first new technology to embark on a gradual takeover of an existing market. Thanks to the experience of the motor vehicle, the internet, smart phones and even renewable electricity before them, the pathway of renewable gases to transition Australia’s gas supply chain to net zero gas isn’t as murky as one may think.

Like new technologies in the past, renewable gases are anticipated to follow what is referred to as diffusion of innovation theory. The theory observes that most new technologies will follow, at least approximately, a normal distribution s-curve when taking over an incumbent market –referred to as the diffusion of innovation curve. Approximations of the diffusion of innovation curve have been seen across most new technologies which have developed across the past century. With 20 per cent adoption by 2020 under the Renewable Energy Target (RET), this positions the renewable electricity industry on the curve to achieve net zero for the existing electricity market by 2050 (Figure 3). Whether by accident or design, targeting 20 per cent

uptake played a role in putting renewable electricity firmly on the trajectory to full market takeover. The 20 per cent mark is well above the combined innovators (first 2.5 per cent of uptake) and early adopters (next 13.5 per cent of uptake). By ensuring uptake enters the early majority portion of the diffusion of innovation curve, the RET ensured that renewable electricity uptake would continue even after the target had been met.

Renewable gas advocates can take advantage of this knowledge to plan out the renewable gas diffusion of innovation curve required to achieve net zero gas by 2050. As per the electricity sector, targeting 90 per cent renewable gas production by 2050 will be considered equivalent to

This is why a renewable gas target is so critical to gas use decarbonisation in Australia. A renewable gas target of 3.5 per cent by 2030 and 20 per cent by 2035 can ensure that renewable gas deployment develops beyond the innovators and early adopters phases of the diffusion of innovation curve prior to 2035. By doing to, renewable gas deployment will be on a trajectory which aligns with net zero gas by 2050.

By observing how new technologies diffuse into existing markets and how the RET ensured that this occurred in a timely manner, we have the opportunity to ensure that renewable gas deployment doesn’t follow the diffusion of innovation curve, but that a renewable gas target is set to align with achieving net zero by 2050.

For more information visit www.apga.org.au

12 POLICY

The Australian Pipeliner | May 2023

Figure 2: Diffusion of innovation curve examples.

Figure 4: Renewable gas diffusion of innovation curve.

Figure 1: Diffusion of innovation curve.

Figure 3: Renewable electricity diffusion of innovation curve.

ELECTRIC DRILLING FOR LOW EMISSIONS

Higher efficiency and optimized environmental protection: the HK300TE HDD rig from Herrenknecht has a newly developed electric drive that is more efficient than hydraulic drives. The electric drive is more quiet and produces fewer emissions, which reduces the impact on the environment.

www.herrenknecht.com/hdd

NEW HDD RIG HK300TE

From the Netherlands to APA Group's leading man in hydrogen and future fuels

So, tell us a little about yourself?

As the Head of Hydrogen and Future Fuels at APA Group, I am responsible for delivery of APA’s strategic hydrogen and future fuels projects. My role involves looking into the future at the transportation and storage infrastructure requirements necessary to support future fuels such as hydrogen and biogas.

One of the key projects I have been leading is focused on the potential conversion of the southern section of the Parmelia Gas Pipeline in Western Australia, from natural gas to hydrogen service. This involves addressing various

technical challenges to ensure a safe and efficient conversion process.

This is a key project in APA’s Pathfinder Program, which is focused on helping unlock the energy solutions of the future – and would make the Parmelia Gas Pipeline Australia’s first, 100 per cent hydrogen-ready transmission pipeline.

Some background on how you landed your new role?

I was born and raised in the Netherlands and came to Australia in 2009 to work as a program manager at the Global Carbon Capture and

Storage Institute in Canberra. I spent four years there, focusing on various aspects of carbon capture, transportation, utilisation, and storage technologies.

After that, I moved to Wollongong to work as the Research Manager for the Energy Pipelines Cooperative Research Centre (EPRCRC). It was during this time that I became involved with the APGA Research and Standards Committee. Toward the end of my time at the Energy Pipeline CRC, I coordinated a bid for the Future Fuels CRC and served as the Research and Innovation manager for that new industry-led research centre after it received

14

APGA Q&A

The Australian Pipeliner | May 2023

In this month’s APGA Q&A, the spotlight is on APA Group’s Head of Hydrogen and Future Fuels, Klaas Van Alphen.

its funding in 2019.

After nearly a decade of managing R&D projects on behalf of industry I jumped the fence and joined the corporate world in July 2022. It's been a great opportunity to move beyond research, and actually work on projects that are looking to utilise the technologies and concepts we've always been studying in the lab. Given the strong climate ambitions in Australia and across the globe, I believe this is the right time to be on the side of developers and owners of the net zero energy infrastructure required in the energy transition.

You've gone from a very theoretical position to a very practical position, can you elaborate?

Yes and no. Even though my previous roles were primarily research oriented, I have been managing research on behalf of industry, particularly the energy pipeline industry. So, there was always a practical and applied element to it as well. The research projects I managed, sometimes 50+ at one time, were largely aimed at improving industry standards and delivering research outputs that could be adopted by industry. Research projects ranged from future proofing Australian gas distribution networks by testing the long-term effects of hydrogen on the plastic materials in that network, to better understanding organisational causes of major incidents in our sector. It is fair to say that most of the research led to improved safety outcomes of our (future) gas industry.

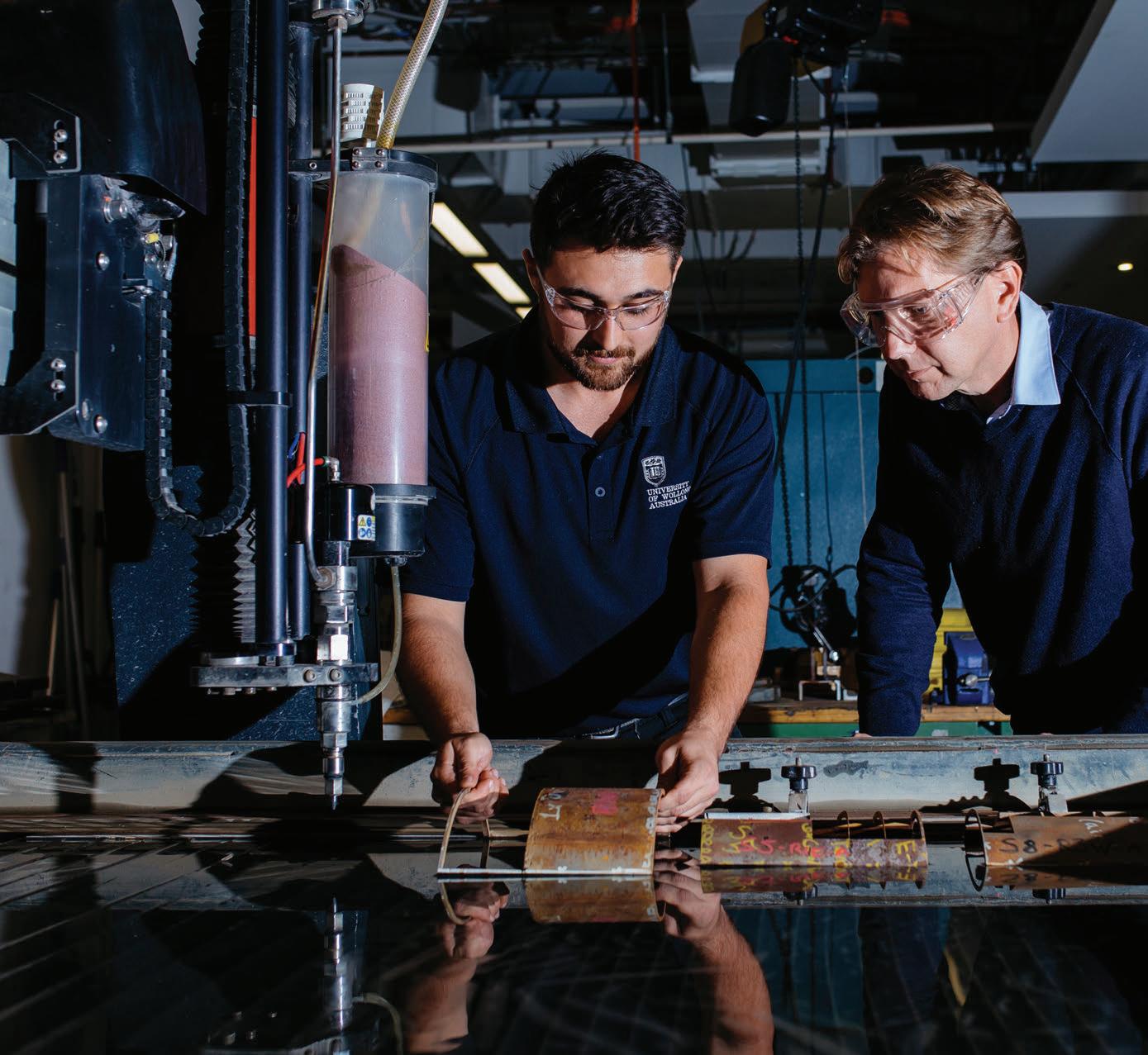

You say you had early engagement with the Research and Standards Committee at the University of Wollongong?

That's right. The APGA Research and Standards Committee is the largest industry funder of the research conducted by cooperative research organisations such as the Energy Pipeline CRC and its successor, the Future Fuels CRC. As a result, the committee guides and directs the research to ensure that it addresses the needs and challenges of the industry now and into the future.

In my previous role, I was responsible for listening to the industry's opportunities, challenges and issues, and translating them into research projects aimed at developing solutions to realise the opportunities and resolve the issues. Now, in my current role, I am on the other side of the equation, seeking out research bodies to help solve my own challenges. But regardless of which side I am on, the goal is always to drive innovation and progress the wider industry, with an emphasis on safety, efficiency, and sustainability.

Tell us a bit more about your involvement in the APGA RSC and how you sort of came to it and what your future ambitions are for the committee?

Well, I was recently appointed as the chair of the RSC, which is a great honour for me. I understand that the past chairs of the RSC have set high standards, and I hope to live up to those expectations. There are some big shoes to fill.

In the past, I was more concerned with informing the RSC, briefing them on the latest research. However, my new role as the chair requires me to oversee the committee's work looking at the interface between standards and research, as well as strengthening important international relations. Using research and relationships to inform standards and ensuring the

safety of our pipeline assets in Australia.

Included in that is also doing both long-term strategic researche looking at what's over the horizon, as well addressing the issues and opportunities we face today. We need research to make our projects run efficiently and safely today, but also need to undertake research now to be ready for the projects of the future.

It might be quite exciting to be able to be in a position to kick off research projects that might have an influence in five, 10 years?

It is, but it is as important to have a mix between technical research that provides quick solutions to current issues and more strategic research that looks towards the future. For example, when the Future Fuels CRC was established in 2019, hydrogen was not yet a widely recognised industry opportunity. Now, the industry is pleased to have the CRC in place to provide answers to important technical and engineering questions, such as whether our pipelines can transport hydrogen at high transmission pressures and if our current gas customers can use it without major modifications to their equipment. At the same time, the CRC is working to develop new codes and standards for designing and operating hydrogen pipelines. The RSC plays a crucial role in ensuring that our current standards are up-to-date and informed by the latest science, while also anticipating and preparing for new fuels that may be transported through pipelines in the future, with a focus on safety.

You mentioned safety a few times is that a big part of the research going for it or is that just a part of research as a whole?

Maintaining our technical standards to ensure the safety of our people working in our industry as well as the customers and communities that interact with our pipeline assets has always been a significant focus of the APGA RSC.

With roughly 50 companies contributing funding to research, the research done is typically for the benefit of the entire industry, rather than just individual companies. It is essential to have sound technical standards in place that people can design and operate assets to, and investing in research to improve safety is a worthy cause. As the industry transitions into new fuels, it is crucial to ensure a safe transition because even a single incident could set back the entire industry or development for years. While research that benefits commercial interests or allows projects to run more efficiently is also important, safety should always be a top priority. This includes managing existing assets safely and looking into the future with pipeline infrastructure.

APGA Q&A The Australian Pipeliner | May 2023 15

APA Group’s Head of Hydrogen and Future Fuels, Klaas Van Alphen.

What is the committee like when people inside the committee how is it organised? How do the people work together within the committee?

I believe around 50 companies have signed up to the RSC, and we usually have around 30-35 people representing their companies attending our meetings three times a year. While we do offer a hybrid option, I strongly encourage people to attend in person as there is a very open and collaborative spirit within the committee. It's a great opportunity to meet colleagues and friends, and for operators, constructors, consultants, suppliers, and others to come together and discuss their issues. We discuss whether these issues can be resolved through Standards or if research is required, and these discussions often lead to new research topics and programs moving forward.

Our meetings always include a ‘lessons learned’ or sharing session where people share their experiences since the last meeting. Even if the topic is not directly related to your area of expertise, it's still fascinating to hear what others are doing for the industry and what issues they may face.

Through the RSC, as well as our current research with the Future Fuels CRC, we have established a strong reputation for the Australian pipeline research and standards community with our counterparts in North America and Europe.

I frequently have late-night and earlymorning calls with colleagues from the European Pipeline Research Group (EPRG) and Pipeline Research Council International (PRCI), where we share our findings and keep up with the latest research and standards development happening overseas. It's important for the Australian industry to tap into these international linkages and access the research being done in other parts of the world. By joining the RSC, companies do not only gain access to the world leading research undertaken by our Australian research partners, but also gain benefit from those valuable international connections.

Is there any exciting innovation coming out of North America or Europe at this point that might be beneficial to us?

It's interesting because you would think that in the future fuels space we are potentially lagging a bit behind overseas developments. However, this is not the case. When it comes to our knowledge and focus on pipeline assets, particularly in terms of hydrogen pipeline design and operations, some companies in North America are actually looking at us and

what we're doing as opposed to the other way around. We always look to complement the research done overseas to best utilise our research dollars.

We have been leading the way in this area through our work with the Future Fuels CRC, and through APA’s Parmelia Gas Pipeline hydrogen conversion project that I mentioned earlier. Our engineers and scientists are doing some amazing work in material science, organisational safety and pipeline design engineering.

While we do look at Europe, North America and other parts of the world for innovations and new thinking, we recognise that their scale and resources are different from ours. I’m sometimes a bit jealous of the resources they have available to do things. However, because we are so well connected, we are able to leverage their work and we often share our findings with them. Overall, I am impressed by the level of collaboration and the sharing of knowledge between different regions.

Anything locally that you are excited about coming out of the RSC?

I know we spoke about innovation, but I'll bring it back a bit and talk about codification and Standards. One thing I'm really excited about is what we've done with the industry membership, working collaboratively with the research community and the state-based technical regulators, in developing a Hydrogen Pipeline Code of Practice, which is what I would call an interim standard that allows those involved in designing new or repurposing existing pipelines for hydrogen service to have sound guidance to support those designs and eventually the operations of those assets. This is a big gap now as it doesn't exist in Australia. So, for that to come out, and I expect it to come out by the middle of this year, is going to be a key milestone and key output of Future Fuel CRC and the APGA Research and Standards Committee.

The Hydrogen CoP is an amalgamation of the research and industry knowledge sharing undertaken to date and bringing it all together in a code of practice.

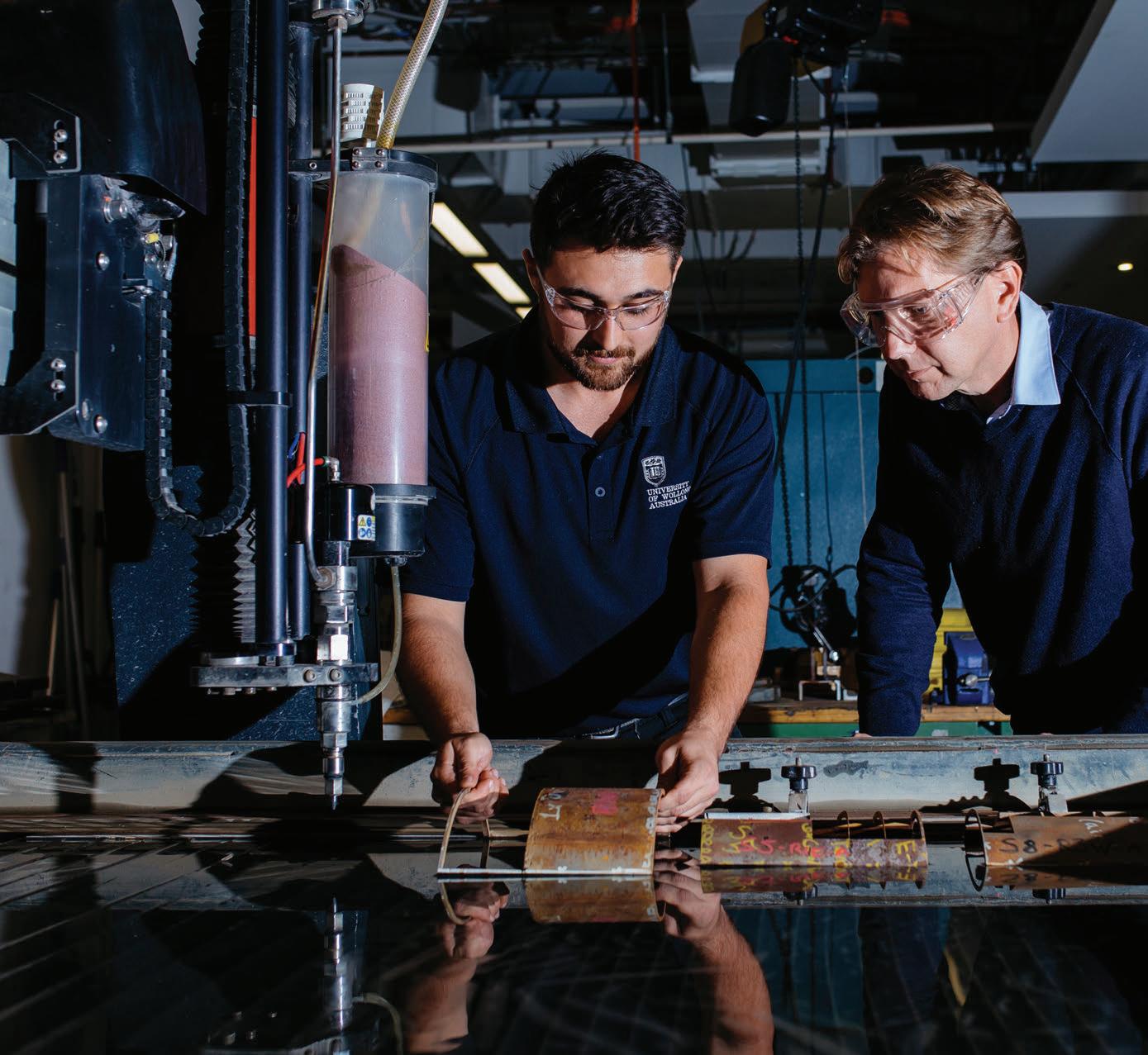

In addition to the anticipated code of practice, the RSC and Future Fuels CRC have already made a major contribution by building a test lab at the University of Wollongong. It allows us to test pipeline materials in a hydrogen environment at pipeline pressures, contributing to new pipeline design or asset conversion. Having that testing capability in Australia is a major win for the industry.

More with a focus on the distribution assets, Deakin University has set up a similar system

that allows for testing of plastics (or PE pipes) for use with hydrogen. I think that's key, having the research capability available at a number of Australian world-class universities to support the industry across a wide range of topics, not just the new energy transition fluids like hydrogen, ammonia and carbon dioxide, but also to support our existing natural gas system.

I could go on about all the good research that has been done, like novel corrosion monitoring approaches, innovation in pipeline surveillance techniques, mechanical damage assessments, and many other exciting things, but the short of it is that there is a long history of really good research that was guided and used by APGA RSC members.

What would you say to someone who wants to join a committee so whether it'd be the Research and Standards Committee or one of the other committees within the APGA?

It's always best to try things out for yourself and that goes for every APGA committee. It is a great way to contribute to the industry and gain relationships and new knowledge that will benefit your business.

My main involvement has been with the RSC, and one of the benefits of participating in the RSC is not only being up-to-date with the latest developments in Standards and research, but also the networking opportunities it provides. Although not all the research and knowledge may be relevant to your company, there are always some valuable insights that you can gain from participating in the RSC. It is also a great way for new entrants in the industry to learn. Additionally, being part of a collaborative community that is at the heart of new research and standardisation is something to be proud of and is important to be a part of.

What’s on the agenda for you in your new role?

That is a good question. Look, I've just started in my role and only had one meeting as chair, but there are a few things on the horizon that I am excited about.

One of my goals is to improve communication and integration between the RSC and other APGA committees. To strengthen the ties between research teams and standards committees, as they sometimes diverge. Additionally, I want to ensure that everyone in the RSC gets the value they seek from the committee. There are a lot of opportunities to strengthen what the RSC already has, and I plan to develop a forwardlooking research program that goes beyond the term of the Future Fuels CRC.

16 The Australian Pipeliner | May 2023 APGA Q&A

E: info@propipeservices.com P: (03) 9330 4016 A: 49 Lambeck Drive, Tullamarine, Vic 3043 www.propipeservices.com Safe, Reliable Pipeline Solutions •Hot Tapping •Line Isolation & Bypass •Pipe Cutting •Commissioning •Decommissioning • Equipment Maintenance •Training Maintenance & repairs: •Natural Gas •Steam •Water •Chemical •Hydrocarbons

Pipeliners have everything to gain from a net zero Australia

By David Norman, CEO of Future Fuels Cooperative Research Centre

By David Norman, CEO of Future Fuels Cooperative Research Centre

May marks a milestone with the launch of a major techno-economic study of how a net-zero Australia could look. Titled the Net Zero Australia Study, and led by the Universities of Melbourne, Queensland, Princeton and the Nous Group Consultancy, we at Future Fuels CRC have sponsored the study alongside APA Group and Worley. Included is a diverse advisory group to achieve its aim of being rigorous, granular, evidence-driven, technology-neutral and nonpolitical.

The study is designed to look at how a true net-zero emission Australia would operate based on a series of potential scenarios. It does not make judgements of which scenario is more desirable, achievable or likely. It lets each of us decide that for ourselves. But what it does do is illustrate the scale, complexity and cost of the net zero challenge, the implications of key choices, and the potential impacts of making those choices across society, the economy and the environment.

The study is a ground-breaking piece of modelling, showing how large-scale variable renewable energy (VRE) could transform our country, both for domestic and exports markets. The model was provided with the option of building either hydrogen pipelines from VRE aggregation nodes to port and demand locations or building only electricity transmission instead.

The model chose to build primarily hydrogen pipelines between the VRE nodes and ports, with hydrogen being produced in electrolysis facilities at VRE aggregation nodes before being piped to the port, and electricity lines being run in parallel to support the electricity requirements of other new industrial infrastructure, such as desalination plants and ammonia facilities.

All core scenarios involve the construction of very substantial hydrogen pipelines by 2060, with a need for 292 to 600 GW of hydrogen transmission pipelines. These pipelines are chosen by the model as the least cost means of moving the enormous quantity of clean energy from inland solar and wind locations, where the model choses to convert the renewable electricity to hydrogen at the earliest possible opportunity and then utilise the cheaper means of transmission of clean molecules by pipeline to port locations. This outcome is very consistent with separate modelling work released by the APGA, of the economics of pipelines versus powerlines and again demonstrates the commercial advantage of moving molecules versus moving electrons in such situations.

Depending on the individual scenario, that’s 10,000 to 15,000 kms of large diameter hydrogen transmission pipelines to service these export regions, plus water pipelines to carry the required desalinated water in the opposite direction. Separately the modelling study

illustrates the requirement for 16,000 to 20,000 kms of carbon dioxide pipelines to support the carbon capture, utilisation and storage (CCUS) needed to make net zero possible.

All this capacity will need storage to balance VRE supply and demand from both domestic and export customers. Depending on the scenario, between 20 and 60 TWh of hydrogen storage will be needed. That’s equivalent to over 200PJ of gaseous fuel storage.

All of this creates an enormous opportunity for the pipeline industry to innovate and support the transition to net zero across Australia.

There are countless other conclusions and insights available from the ground-breaking work. I encourage you to delve into this study in depth and find the opportunities for your business.

You can find the full study plus all the methods, data and the seventeen downscaling reports which provide granular results on employment, capital deployment, renewable and non-renewable resources at www. netzeroaustralia.net.au

You can find out more about our research at futurefuelscrc.com and the Net Zero Australia study at netzeroaustralia.net.au

18 FUTURE FUELS CRC

The Australian Pipeliner | May 2023

A new study by three major universities shows the scale of hydrogen, carbon dioxide and water pipelines needed to achieve net zero. Australian pipeliners have everything to gain from the opportunities that decarbonisation will bring.

The Net Zero Australia Study explores how large-scale variable renewable energy could transform Australia.

SEWER MAINTENANCE & INSPECTION STRUCTURES

The EZIpit® is your easy-to-use modular plastic maintenance structure solution. Available in a range of sizes, Iplex’s EZIpit® range can provide a complete offering for your gravity sewer project.

TOUGH AND DURABLE

Proven performance in Australian sewers

FAST,

Lightweight components for ease of handling

SPECIFIED WITH CONFIDENCE

WSAA Appraised to WSA137

The EZIpit® Chamber is accepted by Sydney Water

Are you aware of the new design rules for maintenance chambers used in the Sydney Water’s sewer network?

Sydney Water now accepts the use of the EZIpit® 600 Maintenance Chamber for gravity sewer networks provided the system has been designed and constructed in compliance with the requirements in WSA – 02 Sewer Code of Australia, Sydney Water Edition VA2017 and EPS500.

If you would like to learn more about the EZIpit®, request a presentation, or download the EZIpit® Technical Guide, please scan the QR code below or visit uqr.to/ezipit.

TM

DN425 Maintenance Shaft DN600 Maintenance Chamber DN1000 Maintenance Hole

SAFE AND EASY TO INTALL

SPEAK WITH OUR SALES TEAM SCAN THE QR CODE TO LEARN MORE 13 10 86 IPLEX.COM.AU IPLEX PIPELINES

Significant infrastructure developments in WA

Over the last 12 months, Western Australia has seen many infrastructure developments crucial in developing future growth for the region.

WA state Development Minister Roger Cook says providing the land for projects including hydrogen, ammonia and green iron ore would help transform the two sites into globally competitive, multi-product industrial precincts.

“The projects across the two SIAs will deliver a range of projects including ammonia, green iron ore, and hydrogen,” he says.

“From job creation to growing the local advanced manufacturing industry and servicing international markets, we will see the economic benefits of these land allocations and these projects flow through the WA economy over time.”

Santos delivers more domestic gas to WA

Strike Energy received multiple key regulatory approvals regarding the Walyering gas field development via the Part V works approvals, Pipeline License and now the Environmental Plan which will support construction and commissioning operations.

In investment news, Mandurah’s largest Water Resource Recovery Facility (WRRF) received a $37 million investment aimed to cater for future growth in the region. Similarly, the WA government announced that it had earmarked land in the Pilbara region for mainly hydrogen projects.

Elsewhere, Australian oil and gas exploration and production company Santos entered into a new gas supply agreement with the Walyering joint venture (JV) in the Perth Basin.

In celebration of an important milestone, the Goldfields Water Supply Scheme pipeline marked its 120th anniversary, underlining its significant contribution to the development of Western Australia.

Strike receives approvals for Walyering gas field development

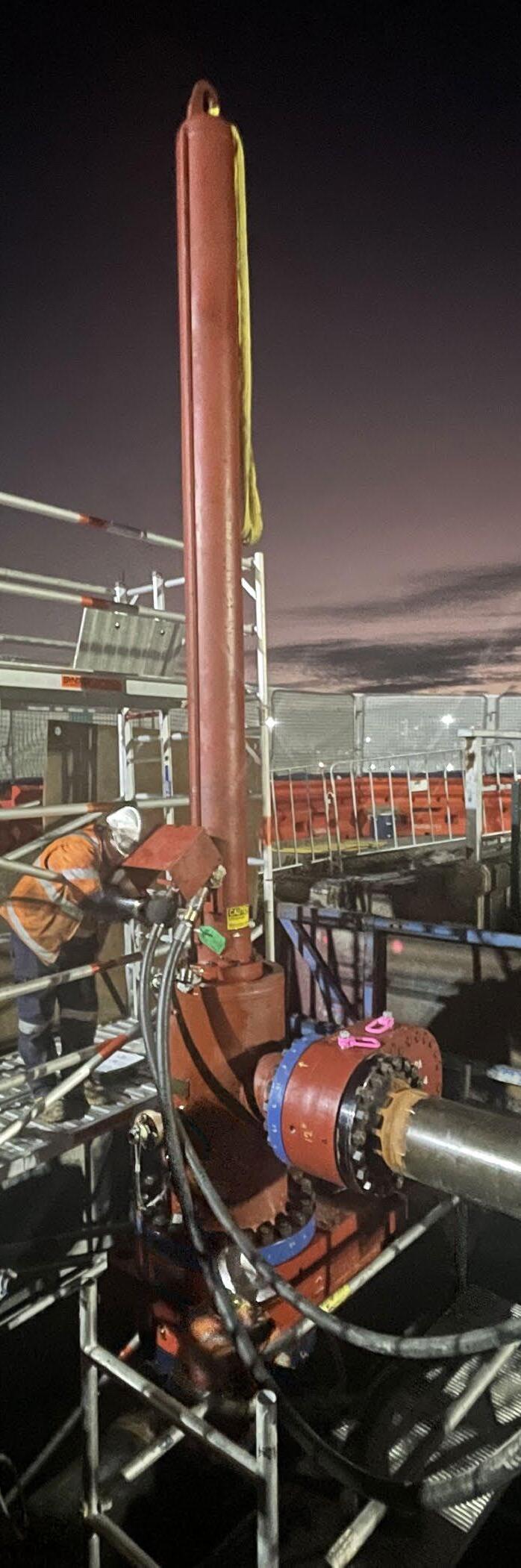

The facility, which will be the closest source of gas to the major southwest gas market and powered purely by solar and battery storage, enables Walyering to have one of the lowest emissions intensities for current WA domestic gas supplies.

Construction and commissioning is estimated to take approximately six weeks with production operations to follow on completion of pipeline connection.

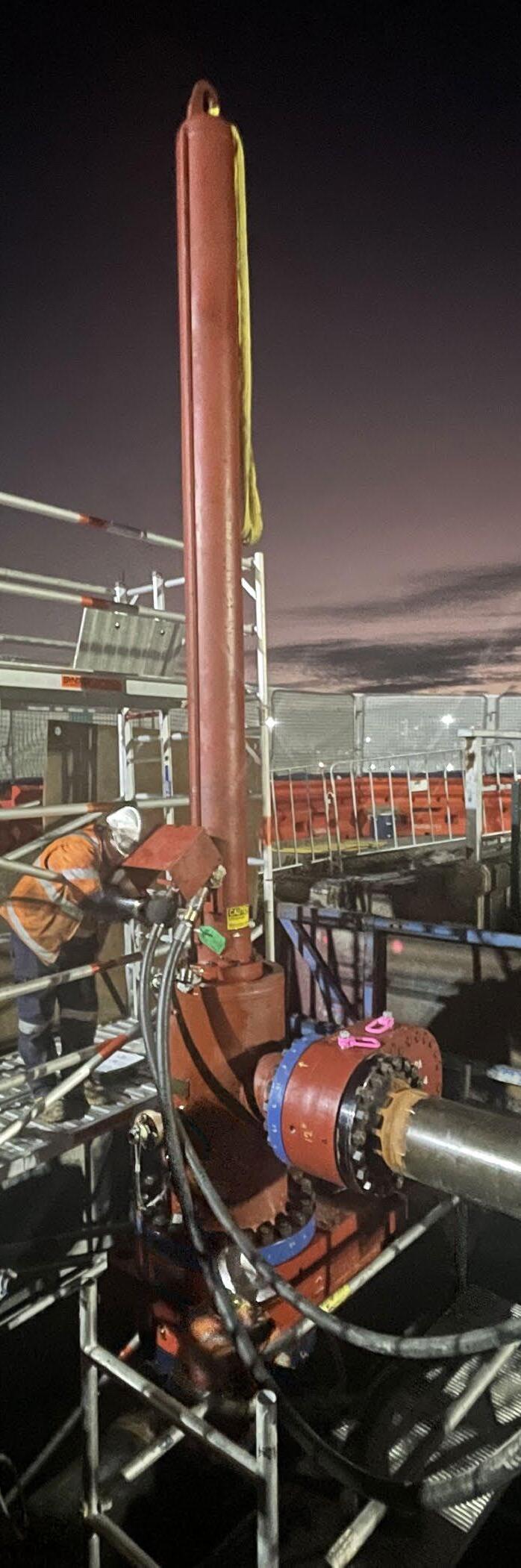

The workover rig is currently on Walyering-5 before moving to Walyering-6 to install the production completions.

Mandurah WRRF gets $37 million investment

Water Corporation’s Gordon Road WRRF treats wastewater from tens of thousands of homes and businesses in Mandurah, North Mandurah, Barragup, Yunderup, and West Murray.

Water Minister Simone McQurk says that the McGowan Government is committed to ensuring that water and wastewater services keep pace with the growing demand across the region.

“We live in a booming State with a strong job market, thriving economy and an enviable lifestyle, that will see our population continue to grow. Nowhere is that more evident than in Peel,” he says.

“Water Corporation’s upgrades to the Gordon Road Water Resource Recovery Facility will ensure the community continues to receive a safe and reliable wastewater service well into the future.”

The project is expected to be completed in late2024 and create 100 jobs during construction.

WA dishes out land for $70 billion green megaprojects

The WA government announced in early January 2023 that it had earmarked land for seven projects collectively valued at $70 billion at two heavy industrial estates near the Pilbara coastal towns of Port Hedland and Onslow.

BP, POSCO, Fortescue, Alinta Energy and UK firm Tees Valley Lithium were allocated land at the 4000-hectare Boodarie strategic industrial area (SIA) south of Port Hedland where most of Australia’s iron ore exports are loaded. Similarly, Equus Energy (a subsidiary of Western Gas) and Fortescue Future Industries were allocated land in the Ashburton SIA.

Santos will purchase a total of 36.5 petajoules of gas from the Walyering field over five years, commencing in the first half of 2023.

Santos Managing Director and Chief Executive Officer Kevin Gallagher says Santos continues to support Western Australian industry through the delivery of competitively priced domestic natural gas.

“We are delighted to sign this agreement with the Walyering joint venture and bring this gas to market in a timely manner, reinforcing our position as WA’s biggest supplier of domestic gas,” Gallagher says.

Golden Pipeline celebrates 120 years of service

The heritage listed scheme, commonly known as the Golden or Goldfields Pipeline, officially opened at Mount Charlotte, Kalgoorlie, on 24 January 1903, pumping fresh water 566 km east from Mundaring Weir to the Eastern Goldfields.

Water Minister Simone McGurk says that the iconic pipeline is the only reason people in the Goldfields get fresh water every day and how Kalgoorlie-Boulder and Coolgardie survived as towns through the gold rush and beyond.

“The scheme will evolve over the next 50 years, as sections of the above-ground pipework reach the end of their service life, to improve the reliability of the scheme, while also supporting population and economic growth well into the future.”

The brainchild of WA’s first Engineer-in-Chief CY O’Connor, the pipeline had a focus on delivering a reliable water supply to the arid Goldfields. It is considered one of Australia’s greatest engineering achievements and was the world’s longest overland pipeline at completion.

20

The Australian Pipeliner | May 2023

PIPELINES IN WESTERN AUSTRALIA

The Western Australian government announced in early January 2023 that it had earmarked land for seven projects.

www.densoaustralia.com.au 77 – 95 National Boulevard Campbellfield Victoria 3061 AUSTRALIA TEL: +61 (0) 3 9356 7600 FAX: +61 (0) 3 9356 7699 EMAIL: denso@densoaustralia.com.au CONTACT YOUR LOCAL EXPERT NOW DENSO (AUSTRALIA) PTY LTD CORROSION PREVENTION DO YOU NEED PROTECTION? DENSO AUSTRALIA OFFERS THE MOST ADVANCED HEAVY-DUTY ABRASION RESISTANT OUTERWRAP DESIGNED FOR THE HARSHEST ENVIRONMENTAL CONDITIONS AND HDD APPLICATIONS

Reinforcing gender stereotypes

By Margaret Gayen on behalf of the APGA

Advocacy Committee

Women are irrational. Men pay on dates. Girls are just naturally better at caring. Boys like cars. Most of us would agree that the first two of these statements are problematic, but how many of us would casually accept the last two?

All of these ideas are stereotypes: widely held, generalising ideas that create expectations of people by their “category”. Gender stereotypes in particular are frequently applied because gender is one of the first traits we recognise, and one we

always remember.

Stereotyping directly affects our lives: evidence shows that gender stereotyping in the workplace impacts access to training, promotions, pay rises, networking opportunities, mentoring, flexible work, and parental leave, among others1.

The thinking is insidious. Managers apply stereotypes to their team without meaning to. Recruiters apply them to job applicants. Team members apply them to other team members, and individuals apply them to themselves. You have probably seen, applied, or experienced stereotyping without noticing.

Most gender stereotypes derive from the historic division of labour; however, beyond the physical birthing and feeding of children by women, the reason for that division of labour is unclear. In today’s Australia, we recognise that women can do historically male activities, and can do them well. We also recognise that men can do historically female activities, and can do them well.

So why do these stereotypes continue?

There is a persistent belief in our society that women are “better” at historically female activities (caretaking, domestic work), while men are “better” at historically male activities (competitive, protective work). But this is selffulfilling: believing that women are better than men at caring supports a view that childcare responsibilities should fall exclusively on

22

The Australian Pipeliner | May 2023

WOMEN’S PIPELINE FORUM

WPF

Gender stereotypes in particular are frequently applied because gender is one of the first traits we recognise.

Margaret Gayen from APGA WPF says stereotyping directly affects our lives: evidence shows that gender stereotyping in the workplace impacts access.

women. It also suggests that men aren’t good at caring, which implies that fathers should not be primary carers. When these beliefs are used to justify division of labour, it becomes true: anyone with more experience at childcare will become better at it. Someone who has never performed childcare is unlikely to be good at it. In this case, it is not the genetic characteristics of the person, but the education and opportunity the person was afforded that created a skill divide.

These are also messages that we are internalising. As Paula Stone Williams said: “the more you’re treated as if you don’t know what you’re talking about, the more you begin to question whether you do, in fact, know what you’re talking about”.

Tell someone they can’t show emotion or display a caring attitude, and they will try not to let themself do so. Doubt their ability to perform domestic work, and they will lose confidence and interest in doing it.

Similarly, if we question a person’s logical thinking, scientific ability, or leadership skills, they will question their own ability in those areas. If we limit a person’s access to suitable facilities, or suitable clothing, or safe and accepting working environments, they will

not feel like they belong there.

Are we creating the stereotype of the “unemotional” man, the “stoic” and “uncaring” man, simply by expecting it? Are we enforcing the stereotype of the “less confident” woman, the “emotional” woman, the “non-technical” woman, simply by believing it?

Cordelia Fine investigates “essential differences” between sexes in her book “The Delusions of Gender”1. She shows that there is very little unbiased scientific backing to any of the well-known gender differences. However, there is proof that once supposed gender differences become known, they help to create those differences. Fine explains, “when the environment makes gender salient, we start to think of ourselves in terms of our gender and stereotypes, and social expectations become more prominent in the mind. This can change self-perception, alter interests, debilitate or enhance ability, and trigger unintentional discrimination. In other words, the social context influences who you are, how you think and what you do. And these thoughts, attitudes and behaviours of yours, in turn become part of the social context”.

So not only are stereotypes limiting access to education and opportunity, and imposing

Save Design Time and Costs

Using Vertex G4Plant makes design work easier and faster. Plan effectively with parametric components. Access our extensive pipe, profile and component libraries that come standard in G4Plant or customise the components to suit your needs.

Vertex G4Plant is a compatible software for plant, equipment, PI -diagram and instrumentation design, providing certainty for high-speed design.

The speed of plant design and modelling in Vertex G4Plant software is based on powerful special functions in different areas for most plant design requirements together with all the functionality of Vertex G4 mechanical design software

This allows you to quickly design even large facilities and related equipment and structures.

Vertex G4Plant contains several special functions in the following areas:

• piping

• isometrics

• support

• ducts

• steel structures and platforms

• structural analysis (FEA)

• visualisation

• animation

• collision inspections

• 2D drawings

• part lists

• and several other features

boundaries on our behaviour, but we are also affected by the preconceptions of the people around us to the extent that we internalise it – and unconsciously behave according to the expected social identity of our gender. In this way, stereotypes which may originally have been unfounded are reinforced again and again, exacerbating gender inequalities that would not exist without those stereotypes.

To break this cycle, we must work to challenge gender stereotypes. We must promote equality of respect, education, and opportunity. We must constantly question our assumptions. We must allow ourselves, and the people around us, the opportunity to develop skills, abilities, and possibilities free from imagined limitations.

Wouldn’t it be freeing to do what you are good at in the way you are good at it?

REFERENCES

1 Gayen, M., Nixon, C. (2022) Creating cultural Change to Support Gender Equality in Engineering”. APGA. https:// www.apga.org.au/sites/default/files/uploaded-content/ website-content/creating_cultural_change_to_support_ gender_equality_in_engineering_and_in_the_oil_gas_and_ pipeline_industry.pdf

2 Fine, C. (2010). Delusions of Gender: the Real Science Behind Sex Differences. London: Icon.

WOMEN’S PIPELINE FORUM

VertexG4@vertexaustralia.com www.vertexaustralia.com 9/17 Middle Street, Cleveland, QLD 4163 PO Box 797 Cleveland, QLD 4163 (07) 3286 5845 / 0448 294 376 Contact us to hear more about automating design processes using Vertex 3D CAD Software Solutions

Inspection solutions and their role in pipeline repurposing

Achieving ambitious climate policy goals will require significant investments in energy efficiency, renewables, new low-carbon technologies, and grid infrastructure. It will also necessitate the close integration of the electricity and gas sectors and their respective infrastructures. A decarbonised Europe will be based on an interplay between renewable electricity and renewable and low-carbon gases in an integrated energy system, all aimed at transporting, storing, and supplying all sectors with green energy to deliver a reliable and affordable transition to climate neutrality.

Anumber of studies have shown that the existing gas infrastructure and knowledge can support the transition to net zero in the most efficient manner. As the energy transition advances, the valuable pipeline system will provide efficient transportation and

storage capacity for renewable energy in the form of molecular energy carriers, making the energy system more flexible and resilient. [1].

Energy systems

Over the past decades, energy systems around

the world have grown to connect supply and demand. Countries and companies have built electrical power transmission lines and pipelines for oil and gas to enable economic growth and prosperity. With this growth, consumption of fossil fuels, and therefore greenhouse gas

24 The Australian Pipeliner | May 2023

HYDROGEN & EMISSIONS REDUCTION

Figure 1: Sector coupling principle with different forms of energy in pipeline transport.

emissions, has increased. The current carbonbased energy system is undergoing profound changes driven by increased concerns over the longevity and security of fossil energy. Countries all around the world are looking for ways to transform their energy systems. Initiatives like the European Hydrogen Backbone illustrate the efforts to transform current European energy systems in order to lower their greenhouse gas emissions.[2].

Pipelines play a major role in the transformation of the energy system because of their ability to safely transport energy over long distances and act as storage at the same time. Compared to electrical power lines, pipelines can carry more energy and are directly connected to existing storage infrastructure, such as caverns. This integrated setup enables countries like Germany to integrate imported energy via pipeline from sources with lower energy production costs. Especially in light of international climate control goals, the high energy density and the established and partly global transport infrastructure (e.g., pipeline connections from Scandinavia or the Mediterranean or new terminals to import LNG from overseas), it can be assumed that a global market for CO2 neutral gases (and

fuels) will develop.[3].

A transformed energy landscape with significantly lower emissions will be based on the sector coupling principle, providing greater flexibility to the energy system so that decarbonisation can be achieved in a more costeffective way.[4]. Figure 1 illustrates the different sources of energy on the left; the right side highlights the different forms of energy that could be transported by pipeline (including carbon sequestration).

With more focus on the pipelines in the energy sector, it can be seen that the energy is transported in different carriers, such as hydrogen, ammonia, oxygen and/or biomethane. These carriers are called future fuels. Purpose-built pipeline networks transporting these products are already in use today but in a significantly smaller volume than will be needed in the future. [2].

The potential exists that low-carbon gases and their associated products can reliably and efficiently be transported, stored, and distributed in our global existing and newly built pipeline network. Pipelines will also be used to facilitate carbon capture, utilisation, and storage (CCUS) projects by transporting carbon dioxide safely from emission locations to permanent storage or

end use locations. The transportation of these fuels through pipelines will require general as well as specific integrity threats and damage mechanisms to be considered to ensure safe and efficient operation. These challenges can only be managed with a comprehensive integrity management system. [5].

Inspection technologies and necessary changes for future fuels

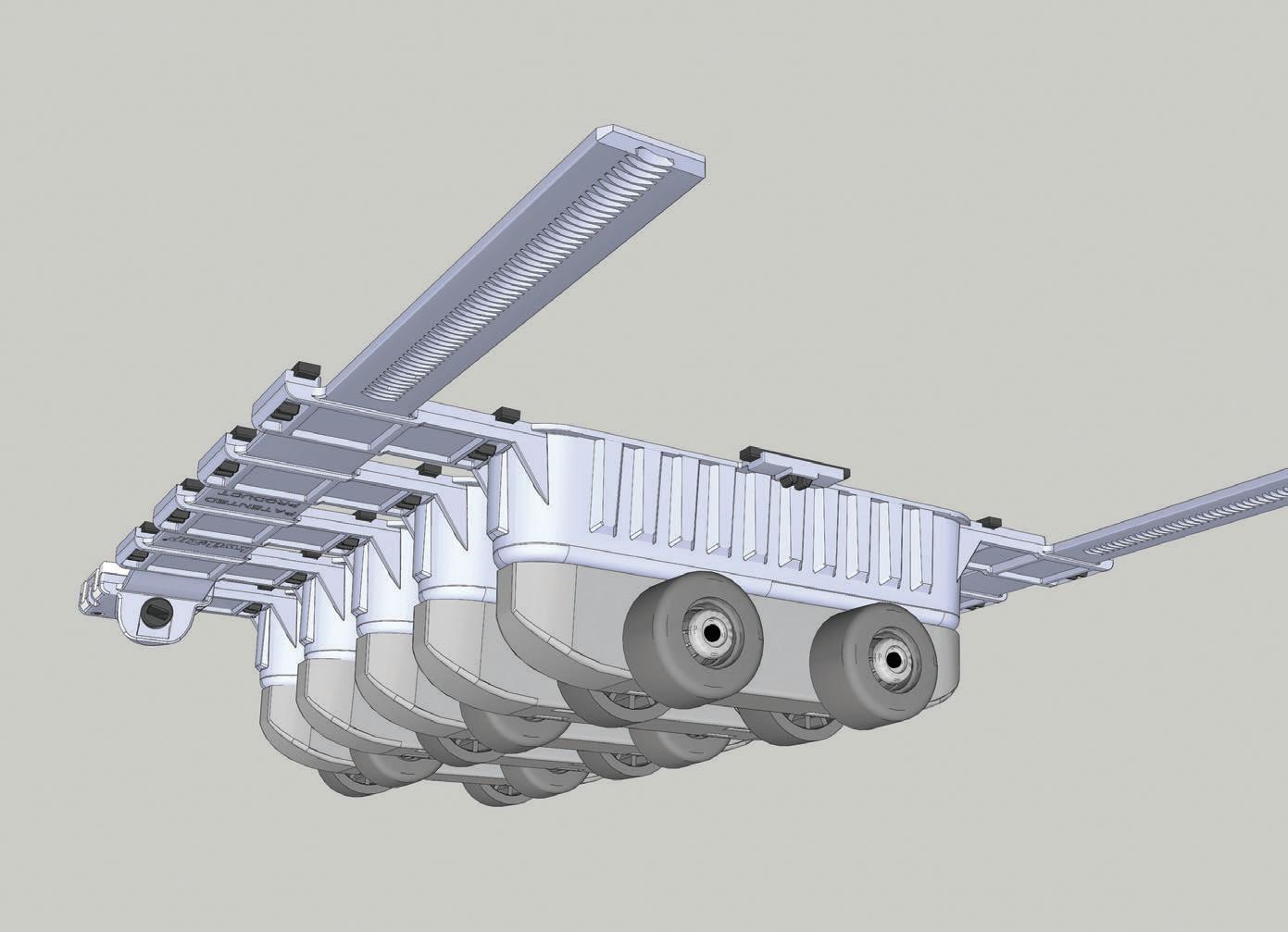

In-line inspection (ILI) technology can be of significant value in repurposing activities, as it is highly utilised in today’s pipeline integrity management. The support of integrity decisions with measurement data has improved over the last decades, and technological developments in other industries (telecommunication, defense, IT, etc.) will further enhance these capabilities. ILI tools can be classified by integrity threat type or technology principle; widely used principles are mechanical calipers, magnetics, eddy current, ultrasound and electromagnetic acoustics. Knowing the integrity threats for pipelines related to hydrogen or other future fuels, ROSEN acknowledges that different kinds of ILI technologies can support the integrity management of such pipelines. Those ILI technologies could be technologies for the detection of, for example, deformations, mapping or corrosion. Technologies could also include those particularly applicable to future fuels, such as those for the determination of material properties or the detection of cracks and crack-like anomalies in gas pipelines. [5].

Today’s diagnostic ILI portfolio delivers solutions from simple cleaning applications to high-resolution crack detection services to understand feature populations and deliver data

25 The Australian Pipeliner | May 2023

HYDROGEN & EMISSIONS REDUCTION

Figure 2: Exemplary operational limit diagram to evaluate tool run behavior based on simulations for a single specific tool.

Table 1: Applications and technologies.

ROSEN is creating solutions to adapt its fleet of inspection tools, getting them ready for future fuels.

for integrity decisions. It is important that all these applications are also available in future fuel assets. Table 1 summarises the applications and technologies available. ROSEN is creating solutions to adapt its fleet of inspection tools, getting them ready for future fuels. Initial inspections in smaller-diameter product lines for hydrogen, ammonia and carbon dioxide have already been conducted [5], and the lessons learned and use of the solutions in larger diameters and longer pipelines are under development.

The main outcome of these development efforts are solutions for safe and successful inspections in future fuel pipelines. Independent of the technologies, the three main working areas are material compatibility, operational success and safety.

The inspection tools need to withstand the environment, which can be very different compared to oil and natural gas. Products like ammonia, carbon dioxide and hydrogen pose specific challenges for the materials comprising

the inspection tools, and intense upfront testing and an understanding of deterioration processes are key for inspection vendors to deliver highquality services. ROSEN is utilising its own hydrogen laboratory to execute material testing on all components used to build tools within the ILI portfolio.

Another key aspect of ILI is the ability to gather a high-quality dataset under the harsh conditions in pipelines. Speed control valves as well as low-flow/low-pressure setups enable a constant flow velocity without speed excursions or tool stops. [6]. The lower density of hydrogen compared to natural gas will increase bypass rates while also changing the behaviour of existing speed control implementations. Tool run simulations are a standard deliverable for proper inspection preparation, and these simulations have now been extended to also allow simulations to understand the tool dynamics in a hydrogen environment. Besides tool friction properties in the specific pipeline, the dynamic behaviour of ILI tools in gas

pipelines also depends on the density and compressibility of the fluid. In order to classify the behaviour of tools in different pressures, velocities and fluids, operational limits diagrams as shown in Figure 2 can be used.

In order to generate the diagrams, several simulations of the specific ILI tool in a pipeline are performed at different pressures and the results evaluated. Based on availability, bypass information from a pump test in water is integrated to specify a minimum gas velocity for future inspections.

The safety requirements for the operation of ILI solutions may change with the introduction of hydrogen into pipeline networks. Existing ATEX certificates might need to be updated to ensure proper consideration of the lighter hydrogen in on-site safety procedures. ROSEN is covering this aspect in current developments to implement a suitable solution for customers worldwide.

The damage mechanism of hydrogen embrittlement, and therefore the potential initiation or propagation of cracks in pipeline steel, is one of the big uncertainties in repurposing activities. Understanding the population of planar flaws is as critical to estimating remaining life as it is to making proper investment decisions. Table 1 shows ultrasound, electromagnetic acoustic transducer and eddy current as possible technologies to detect cracking in pipelines. Cracking (internal SCC) is also a potential threat for both CO2 and ammonia pipelines, meaning crack detection technologies are likely to be required for most future fuel pipelines.

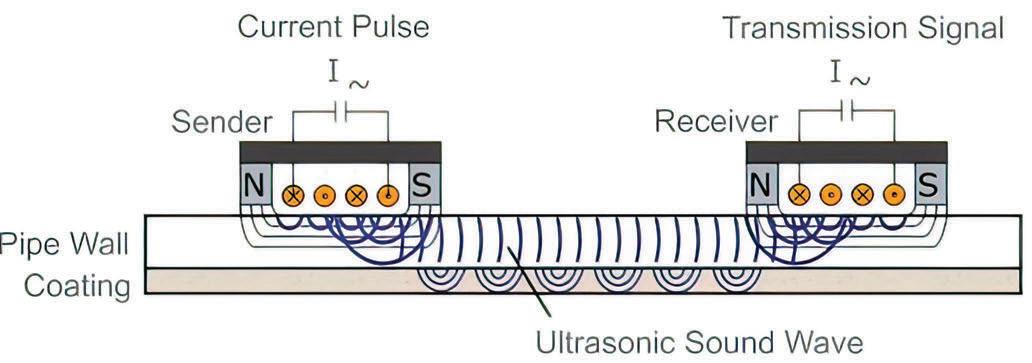

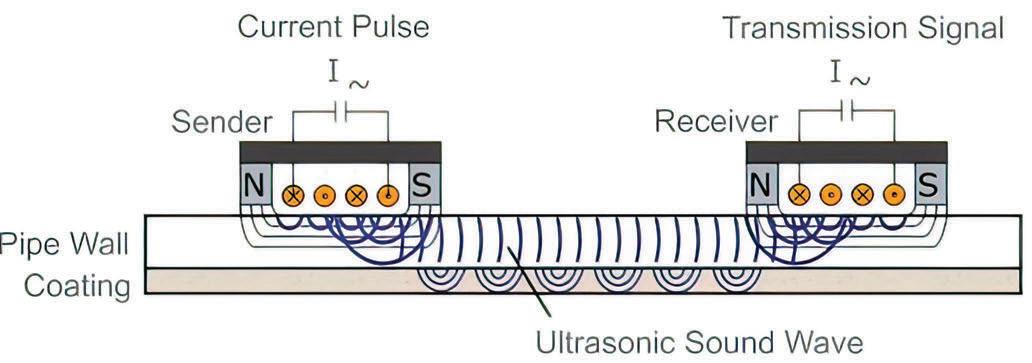

There are different implementations of ultrasound technology available; one of special interest for non-liquid (hydrogen or CO2) pipelines is electro-magnetic acoustic transducer (EMAT) technology. Mainly utilised in natural

26 The Australian Pipeliner | May 2023 HYDROGEN & EMISSIONS REDUCTION

Figure 3: EMAT principle.

Pipelines play a major role in the transformation of the energy system.

gas pipelines to assist in the management of stress-corrosion cracking and long seam integrity, EMAT has a significant advantage over conventional ultrasound: it does not require a liquid couplant, meaning it can be run in a gas line without the need for liquid batching. There are several generations of inspection tools available, with the latest implementations showing signification improvements in circumferential resolution and sensitivity. The technology allows for the detection, identification, and sizing of axial planar flaws, which can be helpful when inservice inspections in hydrogen or CO2 pipelines are required, or repurposing activities are executed in natural gas pipelines without the need to include a liquid batch.

Figure 3 illustrates the EMAT principle. EMAT induces an acoustic wave by generating an eddy current and magnetic flux field in the pipe. An additional benefit of EMAT is that it can give information about the external coating condition, which can be valuable when assessing external integrity threats. More information about the technology can be found in [7] and [8]. Figure 4 shows the latest

implementation of the technology in a larger diameter. These inspection tools are equipped with speed control units to ensure a proper velocity profile and thus adequate data quality.

Conclusion

There are three main challenges to overcome when it comes to inspection solutions for future fuel pipelines. Safe on-site operation depends on updated processes for the people and machinery involved. Furthermore, existing concepts for explosion protection (ATEX) may be upgraded to include the lighter hydrogen. Materials and components used on in-line inspection tools can be tested in a laboratory environment to characterise their durability and adapt them if necessary. High-quality datasets depend on proper tool run behaviour and sensor-to-wall contact. Simulations can support these assessments to understand fluid dynamics in future fuel pipelines before executing the inspections.

REFERENCES

[1] Siemens Energy, "Power-to-X: The crucial business on the way to a carbon-free world," 2021.

For more information visit rosen-group.com

[2] R. van Rossum, J. Jaro, G. La Guardia, A. Wang, L. Kuehnen and M. Overgaag, "European Hydrogen Backbone," Guidehouse, Utrecht, 2022.

[3] D. Bothe, M. Janssen, S. van der Poel, T. Eich, T. Bongers, J. Kellermann, L. Lueck, H. Chan, M. Ahltert, C. A. Quinteros Borras, M. Corneille and M. Kuhn, "Der Wert der Gasinfrastruktur in Deutschland," Frontier Economics, 2017.

[4] Frontier Economics, "Potentials of sector coupling for decarbonisation," European Union, Luxemburg, 2019.

[5] N. Gallon, M. Humbert and M. Tewes, "Energy Transition And The Impact On Pipeline Integrity," Pipeline Technology Journal, 2022.

[6] J. Becker, C. Richards, G. Sundag and R. Wittig, "Improving Data Collection With In-Line Inspection in Low-Pressure Gas Distribution Networks," in International Pipeline Conference, Calgary, 2020.

[7] R. Kania, K. Myden, R. Weber and S. Klein, "Validation of EMAT ILI Technology for Gas Pipeline Crack Inspection: A Case Study for 20″," in 9th Pipeline Technology Conference, 2014.

[8] M. Tomar, T. Fore, M. Baumeister, C. Yoxall and T. Beuker, "Graded EMAT Performance Specification Validated in Blind Test," in International Pipeline Conference, Calgary, 2016.

27 The Australian Pipeliner | May 2023 HYDROGEN & EMISSIONS REDUCTION

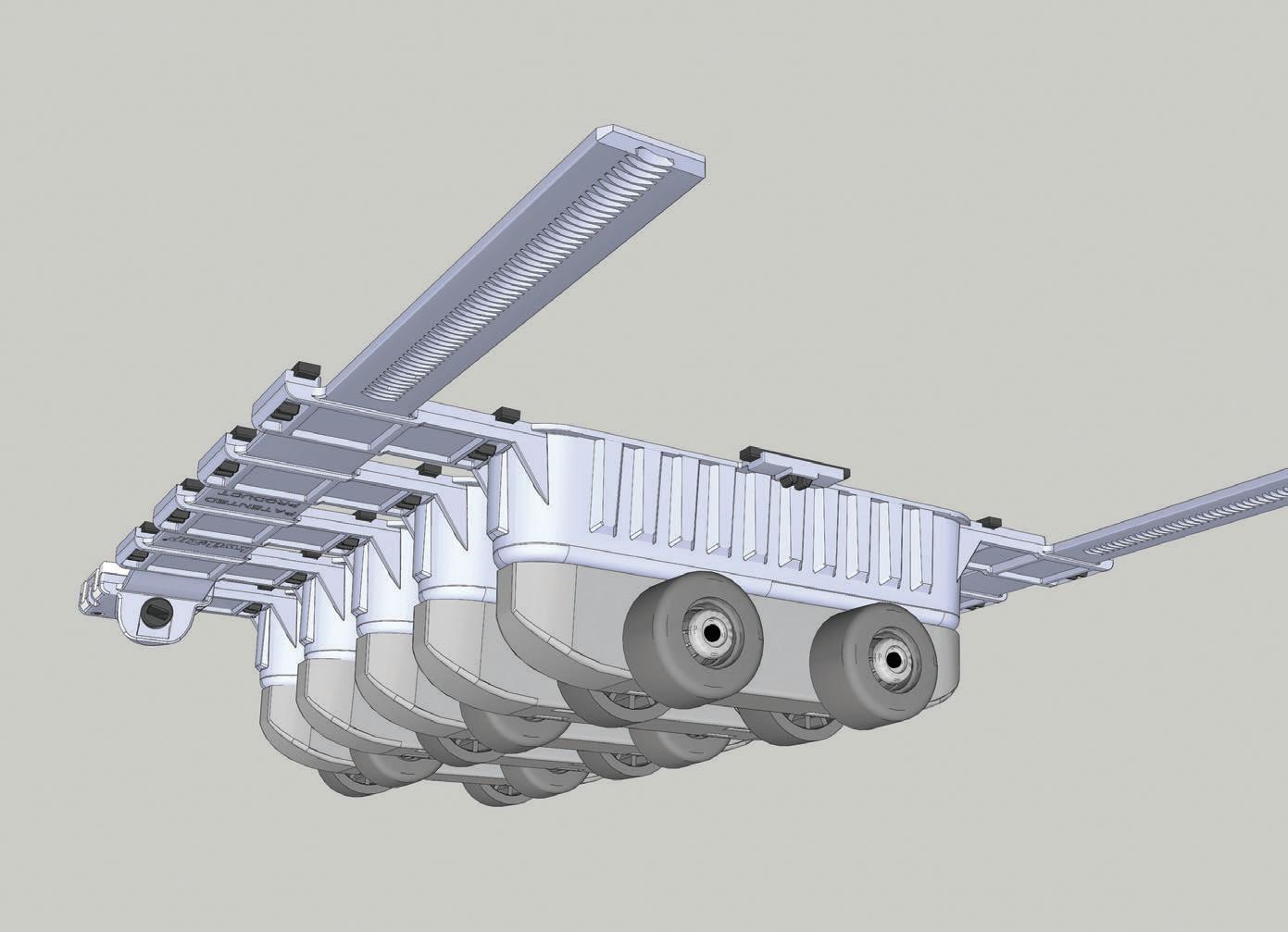

Figure 4: RoCD EMAT-C inspection tool.

A crucial step on the net-zero path

As Australia works towards net-zero by 2050, a pertinent question is how to innovate existing infrastructure traversing suburbs, towns and regions around the country that have been delivering the energy requirements of households and businesses for decades.

In many industries, changes in technology has created new ways of operating and businesses have accepted the transition which has led to the development of new, more sustainable assets.

Within the energy industry, one company is viewing its pipeline infrastructure, that has serviced Western Australian households and businesses for more than three decades, as part of the solution in the transition to net zero and long-term sustainability.

ATCO owns and operates more than 14,000 km of pipeline within Western Australia which has been providing natural gas to around 800,000 homes and businesses across the Perth greater metropolitan area, as well as Geraldton, Kalgoorlie, Bunbury, Busselton and Albany in the regions.

According to ATCO Gas General Manager Renewable Fuels, Jim Richardson, the company’s 14,500 km of pipeline buried under Perth’s

greater metropolitan area is a significant investment that can be leveraged to be part of Australia’s emissions reduction targets.

“We don’t necessarily need to build new infrastructure to play a part in reducing emissions, but rather we can innovate and adapt existing infrastructure,” Richardson says.

“Through our existing network, ATCO has the opportunity to repurpose the infrastructure to provide customers renewable energy and help reduce their carbon footprint.

“With renewable and lower emissions gases blended into our natural gas network, the infrastructure can indeed play an important role as a critical and integrated part of a cost-effective sustainable energy future.”

Repurposing its network for the transition to blended renewable gas has been part of ATCO’s plans for a number of years.

In 2019, with the support of the Australian Renewable Energy Agency (ARENA), ATCO began testing the introduction of renewable hydrogen into its network at its world-class Clean Energy Innovation Hub in the Perth suburb of Jandakot.

“At our Clean Energy Innovation Hub, ATCO has been supporting Western Australia’s transition

to renewable energy through our clean energy testing facilities, our pilot Hydrogen Blending project, and using Hydrogen to power parts of our Jandakot operations through an on-site fuel cell,” Richardson says.

“With our pilot hydrogen blending project, we started blending small proportions of hydrogen with natural gas on-site at our Jandakot depot in blends of up to 10 per cent.

“This research is proving the reliability and safety of the blending process for the network and use within commercial and household settings.”

To transition from testing on-site to a functional pilot project ATCO worked extensively with WA’s Department of Mines, Industry Regulation and Safety (DMIRS) to develop in depth safety procedures that could validate and verify the project while ensuring all users would be safe.

The procedures cover system specification, identifiable risks, the regulations, codes and requirements that would govern the project, how ATCO would comply with each of those requirements, while also prescribing the continued proof and verifications reported for the life of the project.

28 The Australian Pipeliner | May 2023

HYDROGEN & EMISSIONS REDUCTION

ATCO is adapting its infrastructure vital for Western Australia’s net-zero journey through renewable gases.

ATCO’s connection to the local distribution network where renewable H2 can be blended in to the gas.

From the close collaboration with DMIRS and its support, ATCO was able to successfully launch its hydrogen blending pilot project in December 2022.

“ATCO began the blending project mixing a two per cent renewable hydrogen blend with natural gas into around 2700 customers’ homes of a discrete section of the distribution network within the City of Cockburn – Glen Iris, Treeby and Calleya estate neighbourhoods,” Richardson says.

“This project is providing valuable insights into how our existing gas distribution infrastructure can continue to benefit customers through renewable gases as part of the future energy mix.

“ATCO will continue building on the pilot project’s success and finding solutions to reduce carbon emissions through renewable energy.”

Building towards net-zero

In addition to its pilot Hydrogen Blending Project, ATCO is also working towards a 30 per cent reduction of Scope 1 and 2 emissions by 2030.

A primary metric of ATCO Scope 1 emissions reduction for the gas distribution network is unaccounted-for gases (UAFG), which is the difference between the measured quantity of gas entering the gas distribution system from various supply points and the gas delivered to customers.

“One of the key aspects of our net-zero journey is how we reduce our own carbon

emissions and help support our customers on this path,” Richardson says.

“We work very hard to make sure every molecule of energy that we transport through our network gets to where it needs to be.