Save time, money and ensure the quality of your assets by choosing an experienced partner who can manage and respond quickly to all your pipeline integrity needs.

› Pigging

› Inline Inspection

› Live line dig ups

› NDT, including verification by phased array

› Leak detection

› Welding and field joint coating repair

› NATA pressure testing up to 70,000 kPa

› Flexible set-ups for remote and limited footprint locations

› Fast emergency response

Taddam: 0432 666 917 taddam@pipetek.com.au

Myles: 0417 707 729 myles@pipetek.com.au

Nacap’s recent 580km major gas pipeline project for APA Group in Western Australia, the Northern Gold elds Interconnect Pipeline. ImagesuppliedbyNacap.

CEO

John Murphy COO

Christine Clancy christine.clancy@primecreative.com.au

MANAGING EDITOR

Molly Hancock molly.hancock@primecreative.com.au

EDITOR

Clemence Carayol clemence.carayol@primecreative.com.au

JOURNALIST

Vivien Topalovic vivien.topalovic@primecreative.com.au

BUSINESS DEVELOPMENT MANAGER

Jake Niehus jacob.niehus@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey blake.storey@primecreative.com.au

DESIGNERS

Kerry Pert

COPYRIGHT

The Australian Pipeliner is owned by Prime Creative Media and published by John Murphy. All material in The Australian Pipeliner is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in The Australian Pipeliner are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated. © Copyright Prime Creative Media, 2021

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Printed by: The Precision Group

83-89 Freight Drive, Somerton VIC 3062

Ph: (03) 9490 1500

The Australian Pipeliner brand comprises: a quarterly magazine, a news website, a fortnightly e-newsletter, multiple social media platforms, an annual industry directory and an annual pipelines wallchart. Book an advertising and editorial package to gain access to our exclusive audience.

3,300+

20,000+ website views each month

13,700+ social media followers magazine subscribers

16,500+ e-newsletter subscribers

Want to find out more?

Contact our business development team to discuss how you can grow your business with The Australian Pipeliner. Call 0466 929 675 or email jacob.niehus@primecreative.com.au

Head Office 379 Docklands Drive, Docklands VIC 3008 Ph: (03) 9690 8766

Sydney Office Suite 303, 1-9 Chandos Street, Saint Leonards NSW 2065 Ph: (02) 9439 7227

enquiries@primecreative.com.au www.primecreative.com.au

The Australian Pipelines and Gas Association’s (APGA) vision is to lead the sustainable growth in pipeline infrastructure for Australasia’s energy. APGA is a non-profit organisation formed to represent the interests of its members involved in: the ownership, operation, maintenance, design, engineering, supply and construction of pipelines, platforms and all other structures used in or in connection with the drilling for, extraction and transmission of hydrocarbons, solids, slurries and similar substances both onshore and offshore. As a single voice representing the collective interests of its members, APGA is dedicated to encouraging the extension and development of the industry.

The Australian Pipeliner is the official journal of the Australian Pipelines and Gas Association (APGA) and is distributed to members without charge and circulated to interested organisations throughout Australia and overseas. It is also available on subscription. The publishers welcome editorial contributions from interested parties. However, neither the publishers nor APGA accept responsibility for the content of these contributions and the views contained therein are not necessarily the views of the publishers or APGA. Neither the publishers nor APGA accept responsibility for any claims made by advertisers. All communications should be directed to the publishers.

Abletech Underground is recognised as a trusted leader in providing industry solutions for a wide range of sectors and industry projects.

Abletech Underground brings a wealth of experience and capabilities to the energy sector, approaching each pipeline project with the utmost e ciency. We have the ability to mobilise Australia-wide, understanding individual site requirements. We ensure our clients’ needs are met while establishing long-term professional relationships founded on personalised service, reliability, and e ciency.

Abletech Underground has unmatched expertise gained from our extensive involvement with a multitude of challenging large-scale projects. Our highly skilled team, up-to-date industry accreditations, state-of-the-art equipment, industry leadership, ISO certifications, and attention to detail.

Welcome to the latest edition of e Australian Pipeliner. e year has started rmly with well-attended networking evenings, golf days, and a series of technical seminars and symposiums, with events stretching from New Plymouth in New Zealand to Perth. In particular, I wanted to mention the mini-seminars held as part of the networking evenings. is is a new initiative designed to provide both excellent networking opportunities and valuable insights through informative seminar sessions. I encourage you to attend the next one, and if you have something that you would like to share, the mini-seminar is a great format to do it in. It has been great catching up with many industry participants with signi cant ongoing projects nationwide.

Also occurring in the first part of the year was the Australian Domestic Gas Outlook Conference in Sydney. Again, it was wellattended, with several keynote presentations from many APGA members, including our Chief Executive Officer, Steve Davies, and National Policy Manager, Jordan McCollum. A key theme of this conference was unlocking potential gas supply opportunities. While we have seen a positive shift in the public debate, with the role of gas in the energy transition becoming more widely understood and accepted, it needs to translate into releasing the potential of our domestic supply. This reinforces our need to engage with policymakers, regulators, and stakeholders to advocate for policies that support new opportunities.

The infrastructure of our industry plays a crucial role in Australia's energy mix, in its use for electricity generation, heating, industrial processes, and as a feedstock for various industries. Our Future Fuels CRC (FFCRC) focuses on technologies, systems, and markets while supporting social acceptance, public safety, and supply security. This edition of the magazine features the critical work that the FFCRC have been completing and a focus on collaborating with industry partners, research institutions, and government agencies to develop and deploy innovative technologies for emission reduction.

Recognising the strategic importance of fostering international collaboration and addressing the future of gas infrastructure, APGA has awarded five scholarships to Young Pipeline Professionals and Women in Pipelines members to facilitate their attendance at the Emerging Fuels Symposium in Greece in May 2024. The Emerging Fuels Symposium, a new initiative highly relevant to the global industry, is an opportunity to discuss and exchange insights on emerging trends.

During the past few years, several longdistance, cross-country pipelines have been delivered in Western Australia, which is our regional focus for this edition. With several projects underway and future development planned, it is a timely review. Future projects for water supply, desalination, gas pipelines to power generation, and hydrogen and alternative fuel initiatives headline the future opportunities in the 'pipeline'.

T: +61 2 6273 0577

E: apga@apga.org.au

W: www.apga.org.au

The Secretariat has been working hard to prepare for our Annual Convention in Adelaide from 12 to 15 of October 2024 at the convention centre. Adelaide always puts on a great show when we visit each time. Registrations are now open, and event program details can be found on our website. As our flagship event, it facilitates knowledge exchange through comprehensive business sessions, while the planned social gatherings foster extensive networking opportunities. An important part of the Convention is the Annual award presentations. APGA presents awards to individuals and companies in recognition of their services to the nation’s pipeline industry. There are six annual awards with nominations currently open. I encourage all members to put found their nominations which are also open now.

Stay safe and I look forward to seeing you at the next event.

JOHN STUART-ROBERTSON APGA PRESIDENT

JOHN STUART-ROBERTSON APGA PRESIDENT

Chief Executive Officer

Steve Davies

Corporate Services Manager

Michelle Wickson

National Policy Manager

Jordan McCollum

Communications Manager

Lawrence Shelton

Engagement Manager

Gayle Burns

Membership Officer

Katy Spence

Policy Manager

Catriona Rafael

Government Relations Manager

Paul Purcell

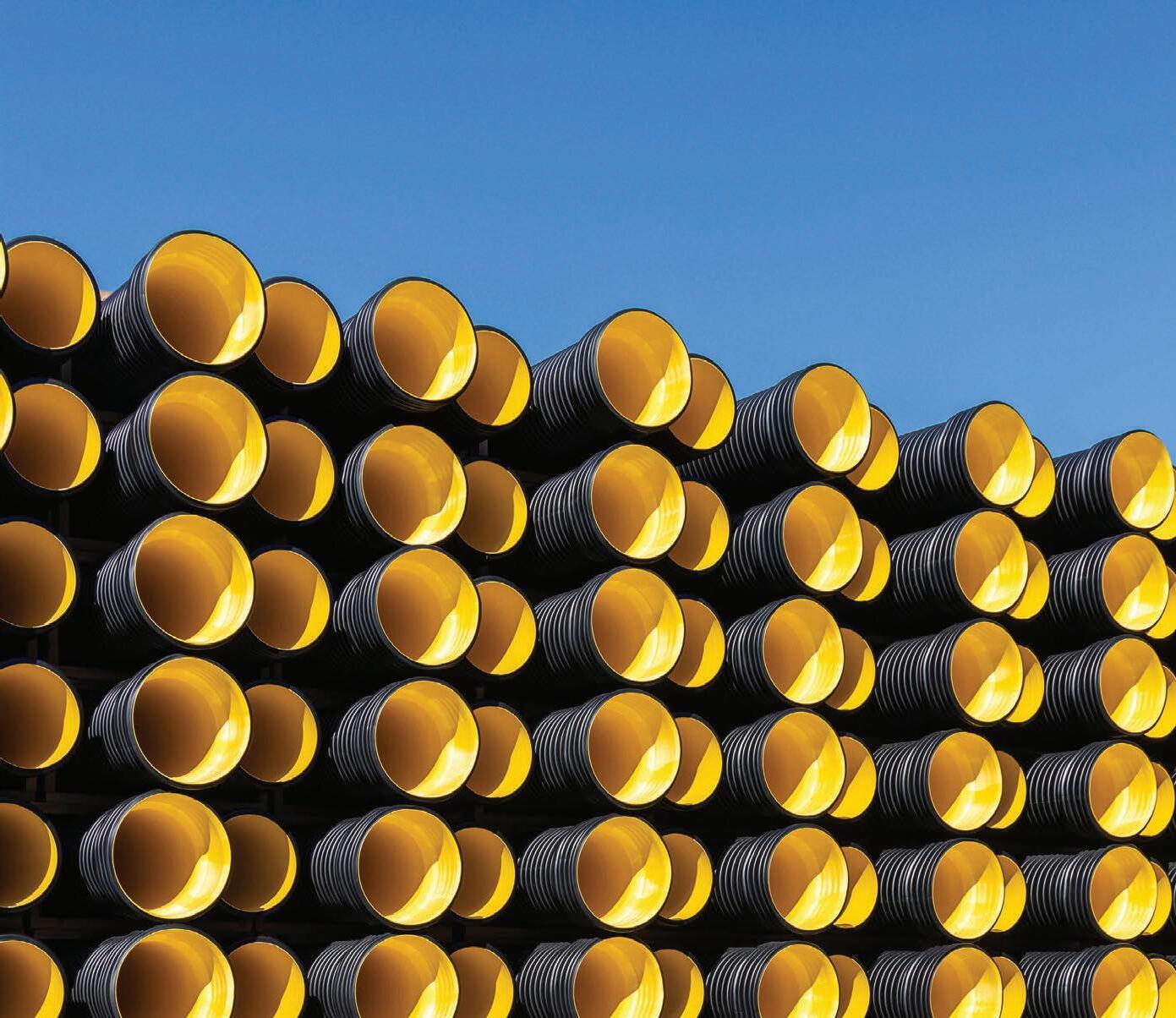

Lightweight

BlackMAX

Even those who don’t keep much of an eye on energy policy will likely have come across the phrase ‛Supercharged Integrated System Plan (ISP)’ throughout 2023. APGA National Policy Manager Jordan McCollum has deciphered the plan and its grey areas.

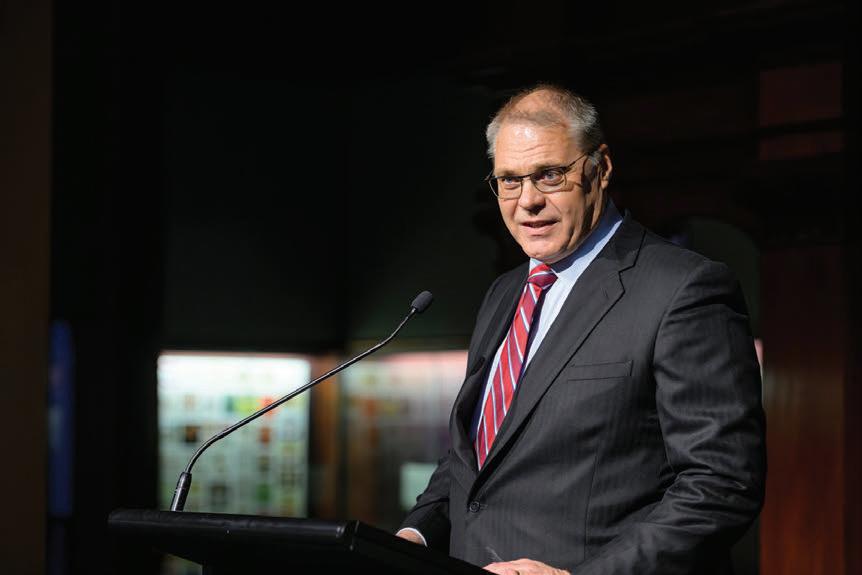

APGA National Policy Manager Jordan McCollum

The Supercharged Integrated System Plan (ISP) was heralded as the solution to all energy system planning woes, delivering much needed integration of electricity and gas system planning. But the product may in fact be more super- op than supercharged.

A recently published Energy Ministers’ response to a Department of Climate Change, Energy, the Environment and Water (DCCEEW) review into the ISP shows that the nal recommendations around a supercharged ISP fall far short of their potential.

e review into supercharging Australian Energy Market Operator (AEMO) ISP forecasting responsibilities started with much promise for gas customers. e Terms of Reference (ToR) for the review talks about energy, not just electricity, focusing on the ISP as a ‘whole-of-system plan’. e ‘increasing interrelationship between gas and electricity’ is centre to the ToR which noted that ‘there is considerable uncertainty about potential transition pathways’. e ToR went on to state that a ‘Supercharged’ ISP is expected to be an integrated transition plan for the National Electricity Market (NEM) and the East Coast Gas Market (including hydrogen and renewable gases as the industries develop) that considers the generation, storage, transmission and distribution requirements to maintain a ordable and reliable energy for all consumers as Australia transitions to net zero emissions.

Statements such as ‘the NEM and the East Coast Gas Market and a ordable and reliable energy for all consumers’ implied that a Supercharged ISP would genuinely consider all energy supply chain options – including renewable electricity and renewable gas options – when considering least cost energy supply through the net zero transition for todays’ energy customers, gas and electric alike.

A Supercharged ISP combining analysis of electricity and gas consumption and supply chains would have the potential to drive so much progress for decarbonisation in Australia. Renewable gases could be considered alongside renewable electricity as a viable decarbonisation option for gas customers. Cheaper gas and

Cheaper gas and hydrogen energy storage options could drastically reduce the burden of higher-cost deep electricity storage development from the ISP – or even remove the burden of costly consumer energy storage, noting that available gas storage dwarfs the quantity of electricity storage the AEMO’s ISP identi es consumers will need to nance themselves to decarbonise their households.

And all this reducing the need for Australia gas customers to pay for more expensive electric appliances during a cost-of-living crisis to decarbonise their households as well.

Alas, this window into a possible Supercharged ISP utopia provided by the ToR was too good to be true.

e rst red ags arose through initial industry consultation. Only part way into the review and the white ag had already been raised at even attempting to model gas and electricity customers side by side, walking away from any intent to support gas consumers ‘maintain a ordable and reliable energy for all consumers as Australia transitions to net zero emissions’ as stated in the ToR.

is was initially said to be due to the impossibility of modelling electricity and gas customers side by side – something proven possible through the Future Fuels CRC and other analysis. It was later made clearer that AEMO would not be provided any additional federal funding to

A Supercharged would have the potential to drive so much progress for decarbonisation in Australia.

supply costs for Gas Power Generation (GPG) are better understood. In a return to DCCEEW’s obsession with optimising gas infrastructure costs (around 1 per cent of GPG generation costs), initial suggestions included AEMO producing a plan for gas infrastructure investments – a suggestion in complete opposition to the contract carriage form of market seen in the gas pipeline industry.

Luckily, this proposal has been scaled back to simply expanding cost analysis to existing and potential pipeline costs. But this is as far as the so-called Supercharged ISP recommendations seem to go.

GPG cost analysis recommendation aside, most recommendations within the ECMC paper come in a benign “consider more analysis here” form. ese rarely go beyond the extent of analysis which AEMO could choose to perform today - far from delivering what is required to ‘maintain a ordable and reliable energy for all consumers as Australia transitions to net zero emissions’.

Had DCCEEW recommendations delivered to the ISP Review ToR, the Supercharged ISP could have been so much more. Instead, gas customers continue to be left behind by government policy which won’t even attempt to analyse their least cost decarbonisation pathway.

Gas customers simply deserve better. Supercharged ISP? More like super- op.

The Remote Tecno Plug ® provides fail-safe double block and monitored isolation of pressurised pipelines while the system remains live and at operating pressure.

As Australia prepares for future fuels including hydrogen, Future Fuels CRC researches the details that will make this transition a success.

Across the Australian industry’s research programs there are many research projects focussed on unlocking the speci c details that will make future fuels a reality.

Applications of hydrogen that involve combustion need to consider ame visibility. Being able to visually assess a ame has implications for operations and safety in any industrial, commercial or residential application. A pure hydrogen ame produces less visible light than a natural gas ame, yet in practice they are not invisible and salts and dust in the air often give the ame an orange colour. Our research is now identifying the limiting conditions which in uence hydrogen ame visibility under real-world conditions, and to what extent the environmental aspects a ect this visibility. is research is nding the variables that impact ame colour and which combination of variables leads to the best outcome for ame colour for aesthetic and safety purposes.

Ammonia transmission

Ammonia has great potential as a renewable energy carrier and fertiliser both within Australia and for export. is means we could soon see ammonia transmission pipelines in Australia, rather than the current ones that exist within industrial facilities. However, there is a lack of compiled data on risks and consequences for cross-country ammonia pipelines. Our research team is now reviewing

ammonia toxicity and dispersion behaviour and how this relates it to acceptable limits for human and environmental exposure. e project team are reviewing regulations and legislation for the design of ammonia pipelines to prevent leaks and ruptures and minimise consequences using e ective mitigation strategies. Research has a huge role to play in the reduction of risk for this new industry, helping to de ne the vital details such as location relative to population, isolation valve spacing and automation, leak detection requirements and emergency response processes.

Plastic distribution networks could have a major role to play in the future distribution of hydrogen. In plastics networks squeezing the pipe to temporarily close it is a routine operation, but the current use of re-rounding clamps to extend the lifetime of a pipe with a squeeze o is not completely understood. e mechanism by which the clamp extends the life is not well understood nor is the extension of life the clamp provides. Certain variables including the age of the pipe and the type of clamp need to be better understood. Deakin University’s research team is now assessing available clamp methods and associated life expectancy to help industry better understand this issue in detail.

to hydrogen and future fuels. e RMIT research team have been working to evaluate di erent professional learning experiences for safety. ey are already holding training workshops with pipeline engineers from March to May 2025 that use a serious game called Planet Pipeline to put pipeline engineers into real-life situations to develop their decision-making skills. Engineers will play the serious game in small groups with a debrief and replays encouraged to test alternative outcomes.

e game covers three scenarios:

• Making design and operating choices to manage the threat of third-party damage to a pipeline.

• Make design choices regarding oods and work with a landowner who doesn’t want a pipeline running through their agricultural land.

• Exploring decisions on defects in an operational pipeline that requires a welded repair.

e results from these workshops will inform professional learning modules that the APGA plan to deliver to develop excellence in engineering professional practice.

All of these research projects are available to our industry participants on our website at futurefuelscrc.com along with our webinars and events, and Future Fuels CRC looks forward to sharing more of our research to enable hydrogen and biomethane in Australia.

Women in Pipeline Forum (WPF) hosted a site visit to the Jemena Malabar injection plant, o ering a tangible glimpse into one of the opportunities future fuels presents. e project demonstrates the process of upgrading biogas produced by Sydney Water to biomethane for injection into the gas network.

Lunn caught up with one of the attendees, APA Future Fuels analyst Vaish Kala, within the Path nder team, for her thoughts on the site visit, her role and how future fuels are already changing the industry.

What did you like about the Malabar plant? It was great to see how biomethane is already playing a role in decarbonising the gas network. It’s really inspiring to see an end result of concepts that are always talked about.

What’s your team role within future fuels?

e role of the team is to ensure the possible medium to long term future directions of the

might be next and why current focus areas may need new direction.

What’s your role within the team?

I initially joined the team as Future Energy Graduate and later returned as a Hydrogen and Future Fuels Analyst, having completed my graduate program. My current role centres on project development and delivery. It’s a fascinating blend of commercial acumen, technical expertise, and stakeholder engagement.

Although, I believe one of the crucial components for our team is to ‘bring people along the journey both within our organisation and externally - be it from a knowledge sharing perspective or a social license forefront.’

What excites you about working in future fuels?

e sector itself is transforming while grappling with the need to balance energy security, a ordability and reliability. It provides

been amazing.

e importance of showing what’s already happening with clean energy within the industry cannot be underestimated. rough site visits and events spotlighting projects, we can engage both industry insiders and external stakeholders in this journey. By actively involving young people in these initiatives, they o er a rsthand glimpse into the future of the industry, inspiring them and providing avenues for their involvement in shaping tomorrow's energy landscape.

Two site visits are being hosted in May 2024 by the Young Pipeliners Forum and APGA to two di erent projects, both contributing to the changing energy mix. ese are Hydrogen Park in South Australia (AGIG) and the Kurri Kurri Lateral Pipeline Project in Newcastle (APA). I’m looking forward to hearing from everyone attending these events and hosting events throughout the year.

The most e ective method to maintain and improve safety and reliability of pipeline ball valves is routine lubrication using a proven valve lubricant along with a preventative maintenance scheme will ensure optimum valve operation.

The DSI range of lubricants, sealant and flush are being used throughout the Pipeline industry in all states within Australia.

All ACC’s DSI products are supplied by a company that is a leader in the manufacture of lubricant since 1968.

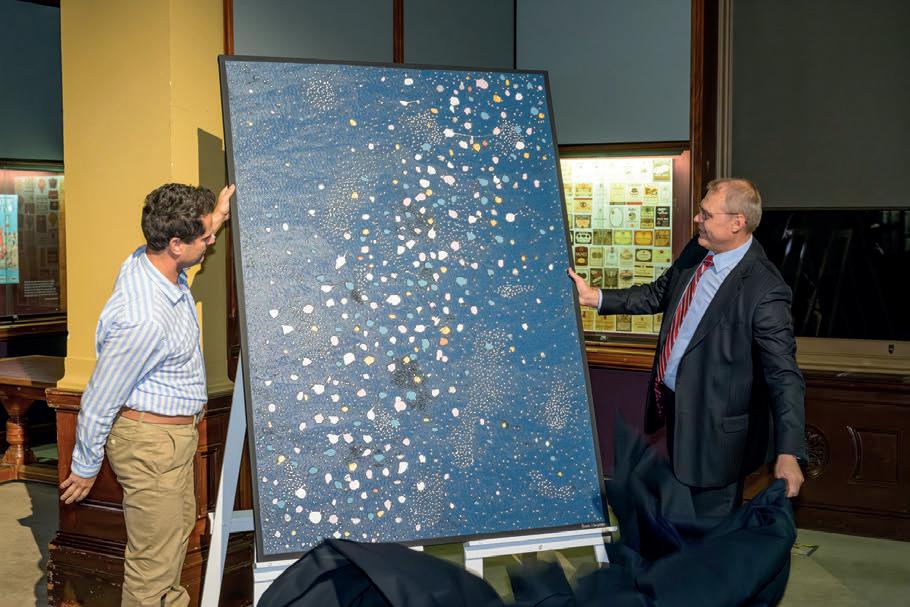

Explore the company's recent project history in pictures.

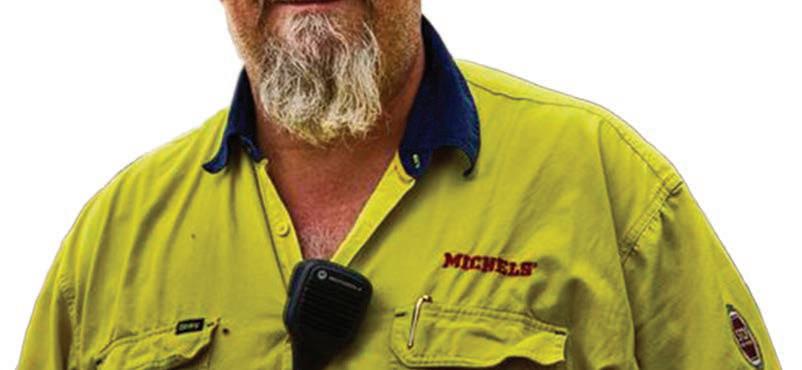

Nacap has long been at the forefront of the pipeline industry for many decades. Today, it is recognised as a versatile energy infrastructure contractor, encompassing a wide range of projects ranging from complex transmission pipelines to wind farms and infrastructure in defence, water and mining across Australia, Papua New Guinea, and South East Asia.

Nacap President Matthew O'Connell emphasised the company's remarkable legacy and steadfast dedication.

“As a specialist energy solutions provider, Nacap is underpinned by a commitment to delivering our clients safe, reliable and robust solutions for powering communities,” he said.

“Our team is renowned as much for our capacity to form professional, mutually bene cial long-term partnerships as we are for our values: integrity, teamwork, and striving to be better.”

e company’s expertise spans the oil and gas, power transmission, renewable energy, defence, mining, and water sectors, encompassing everything from pioneering power generation solutions to major pipelines and networks.

e company also provides civil construction for complex infrastructure projects.

Nacap stands as a respected energy contractor within the Australian, Papua New Guinea and South East Asian pipeline industry, catering to major asset owners and prominent multinational organisations in sectors like liqui ed natural gas, oil, gas, water, and mining.

e company’s commitment to

innovation, safety, and excellence paves the way for a promising future.

And as the team looks ahead, Nacap is unwavering in its dedication to investing in the energy transition, with a vision to build a better, more sustainable future for all.

O’Connell rea rmed Nacap’s commitment to investing in new innovations and technology:

"We continuously re ne and enhance our resource strategies to ensure the highest standards of quality and safety,” he said. "Our aim is to e ciently and reliably deliver resources while contributing to the global transition towards sustainable energy for a better future.”

Nacap respects cultural heritages and works cooperatively with landowners to deliver successful outcomes for projects.

“Social license is integral to every facet of our operations,” O’Connell said.

“Our deep-rooted commitment to respecting both people and the land is evident in our longstanding support for First Nations Australian participation and reconciliation.

“Our genuine concern for the welfare of our communities, and our proactive approach to pioneering tomorrow’s energy infrastructure today.”

O’Connell said he has always taken an immense pride in the Nacap team who bring the company’s values to life, and who are the backbone of its success.

One of Nacap’s recent project for Jemena/Zinfra, Port Kembla Gas Pipeline. Nacap successfully delivered an ECI scope to de-risk and optimise, followed by the construction scope. Project located in Wollongong NSW.

company

In a commitment to harnessing renewable energy sources, Nacap’s comprehensive services encompass the cutting-edge construction of wind farms, battery storage solutions, and the advancement of thermal energy systems.

Nacap’s recent 580km major gas pipeline project for APA in Western Australia, Northern Gold elds Interconnect Pipeline.

Nacap delivers complete program of gathering network infrastructure with expertise including access tracks, civil well sites, gas and water pipeline gathering networks in Australia and PNG.

Another recent gas pipeline project in Moomba for Santos. The project included close collaboration with Santos and their engineering team to support construction optimisation and delivery timelines.

Nacap’s recent gas pipeline project for Beach Energy, Enterprise gas pipeline in South-West Victoria including the construction of gas and mono-ethelyene glycole pipelines.

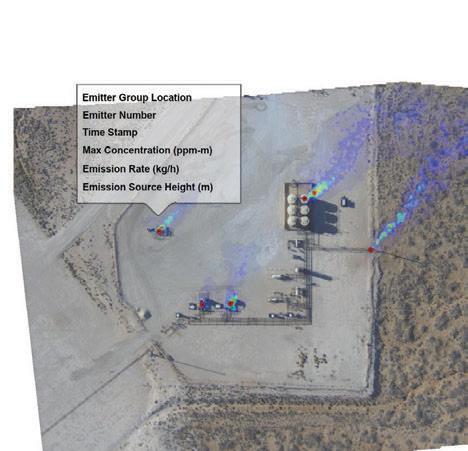

Discover how Bridger Photonics’ new technologies enables navigation of emissions reduction challenges.

At the core of Australasia's oil and gas industry lies a critical task: the reduction of methane emissions across the entire value chain.

Emission reductions are important due to the strong global warming potential of methane, and oil and gas resources present accessible mitigation opportunities to assist.

From remote gas elds to extensive pipeline networks and liqui ed natural gas (LNG) facilities, every part of the industry is committed to confronting this challenge head-on. Balancing energy demands with emission reduction goals is a complex task, and operators across the globe face similar challenges.

One such way that has emerged to help operators face this challenge is a growing eld of emissions detection technology.

e eld of emissions detection has experienced rapid advancements in technology in recent years, growing beyond hand-held cameras and site visits to state-of-the-art sensors ying over sites that help operators more e ciently reduce methane emissions.

Challenges for emissions reduction across various parts of the oil and gas industry vary, and each sector faces its own unique challenges.

Production facilities are spread across a wide

geographic area, are intermingled with other methane sources, consist of many di erent types of equipment and various potential leak sources on each facility.

Until recently, it has been di cult to e ciently detect and attribute methane emissions to a speci c equipment type and from individual sources. Plumes that are lumped together as one from technologies with inadequate resolution may be misleading, creating the illusion of a single, larger leak, when several smaller leaks are present.

Adequate localisation and attribution of emissions to distinguish from nearby sources, along with the proper emission rate detection sensitivity (i.e. the leak size that is consistently detected by a technology), are key elements to gaining meaningful information about production site leaks.

Pipeline infrastructure covers tens of thousands of kilometres, can go across land owned by a third-party or through a shared right-of-way, can run below roadways, waterways, and other obstacles. Additionally, the access and ability to survey the entirety of an operator’s pipeline infrastructure combined with the proximity to cities, homes, or other civilian areas has historically made scanning for leaks di cult.

Popular emissions reporting frameworks like

Oil and Gas Methane Partnership 2.0 (OGMP 2.0) require transparency and accountability in reduction e orts. Additionally, Bridger Photonics continues to see regulations evolve locally and across the globe, requiring highaccuracy top-down measurements, all underscoring the need for reliable and accurate data.

Despite these challenges, innovative solutions that have been rigorously vetted on other continents by oil and gas multi-nationals o er promising avenues for enhancing emissions monitoring and mitigation e orts.

Innovation has always been the driving force behind progress, and this adage holds true for emissions detection. roughout North and South America, Bridger Photonics’ aerial Gas Mapping LiDAR™ (GML) technology has been widely adopted as the market leader for emissions detection across the entire natural gas value chain.

Household names like Chevron, ExxonMobil, Cheniere, and Phillips 66 have adopted the technology, along with dozens of mid-sized and smaller operators, many after trialing several technologies.

Chevron’s Americas president of Exploration and Production Bruce Niemeyer described the

company’s experience using aerial GML technology as a “gamechanger”.

“It can nd leaks that are 10 times smaller than other commercial providers are capable of spotting,” Niemeyer said.

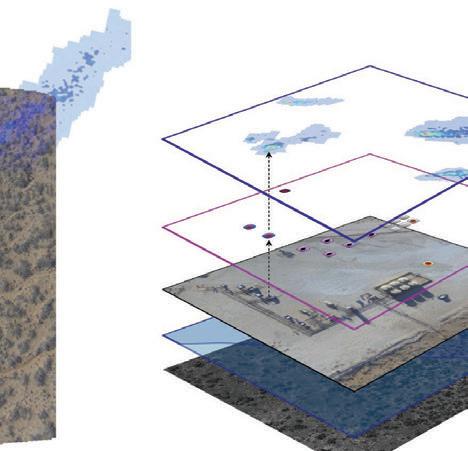

GML sensors are deployed on small aircraft - xed-wing or rotary-wing - and scan hundreds of production sites, or hundreds of kilometres of pipeline in a single day.

Gathering lines, gas processing plants, and LNG facilities can also be monitored with unprecedented speed and accuracy. Companies whose assets span the value chain can utilise a single technology to unify their data collection and analysis.

e laser mapping techniques used by GML pinpoint leak sources down to the equipmentlevel, so crews can go directly to a detected leak without the need to search around a facility, thereby reducing both vehicle and foot tra c, and utilising personnel resources more e ciently.

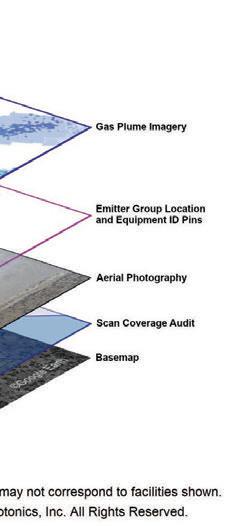

Aerial photography captured during the scans o ers valuable context for understanding

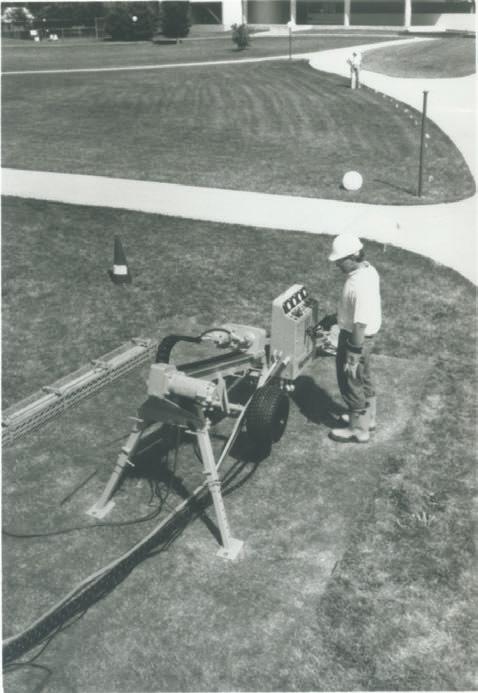

Gas Mapping LiDAR sensors are attached to small aircrafts and scan hundreds of production facilities or hundreds of kilometres of pipeline per day.

activities at the facility. Emission rate quanti cation helps repair crews prioritise based on the relative size of emissions. GML's easy-tounderstand maps and data allow crews to clearly see the sources - without any doubt.

Having the most accurate information available becomes crucial for e ective emissions reduction, baselining, and reconciliation. e integration of advanced technologies like GML, capable of providing comprehensive and accurate emission data at scale, becomes increasingly vital for operators striving to reduce emissions, meet regulatory requirements, and adhere to reporting frameworks like OGMP 2.0.

e oil and gas industry in Australasia is facing the monumental task of reducing methane emissions across every facet of the value chain. Amid this challenge lies an opportunity to utilise market-proven innovative technologies that have been widely validated and adopted on other continents by industry-leading operators.

GML is exceptionally positioned to support Australia’s unique oil and gas industry, from remote infrastructure crossing harsh environments, to its most complex facilities where safety is paramount. By deploying advanced technologies like GML, the industry can scan vast expanses of production sites and pipelines with unprecedented speed and accuracy, pinpointing emission sources down to the equipment level.

is strategic utilisation of innovative solutions not only enhances operational e ciency but also reinforces the industry's commitment to emissions reduction.

With lessons learned and technologies re ned through global implementation, the time is ripe for embracing these advancements and ushering in a new era of emissions reduction in the region.

With Bridger Photonics slated to begin scans in Australia this autumn, the industry is well poised to bene t from cutting-edge tools and expertise in methane emissions detection and reduction.

Heath Services and Bureau Veritas Australia are together working with Australian gas suppliers to discover a true measure of fugitive emission losses, utilising state of the art equipment to directly measure samples and report via innovative new software for improved analysis.

Currently, for Australian providers, committing to e Oil & Gas Methane Partnership 2.0 (OGMP 2.0) framework is voluntary.

e OGMP 2.0 is the United Nations Environment Program’s agship oil and gas reporting and mitigation program.

It is the only comprehensive, measurement-based reporting framework for the oil and gas industry that improves the accuracy and transparency of methane emissions reporting, according to the United Nations, and is key to prioritising methane mitigation actions in the sector.

However the European Union (EU) proposes to introduce new legislation, and the rest of the world is likely to follow.

is new mandatory EU legislation proposed by the European Commission applies a time based OGMP 2.0 framework. is includes providing direction to oil and gas producers on monitoring and reporting, mitigation obligations, leak detection repair, venting and aring requirements.

Legislation requires that by 2027 all external oil and gas importers must also abide by the same regulations as EU producers.

Leading Australian exporters are anticipating the implementation of comparable regulations and

Large incompatible datasets from diverse origins produce complexities where amassed data is di cult to compare.

Leading methane emissions reduction strategies are incorporating digital platforms, understanding that creating a harmonised approach for global emission calculations removes variances originating in local regulatory frameworks.

Bureau Veritas is a recognised world leader in quantifying greenhouse gas emissions and providing unbiased third-party compliant emission reporting.

Bureau Veritas is working with Australian clients to combine the data that Heath are collecting, the multiple levels of the OGMP 2.0 reporting framework, and the Australia’s National Greenhouse and Energy Reporting Scheme.

e unique BV EmissionView dashboard combines multiple reporting schemes into one easy

Safe and Effective Solutions for Rapid Pipe Testing & Repairs

Confidently test open-end pipe, pipelines & pressure vessels without welding, and isolate & test flange-to-pipe weld connections with GripTight Test & Isolation plugs from Curtiss-Wright.

• Patented gripper design for increased safety in high-pressure applications

• Eliminates welded end cap procedures for testing pipe spools & piping systems

• Test flange-to-pipe welds without pressurizing entire systems

• Isolate & monitor upstream pressure and vapors during hot work

• Standard pressure ratings up to 15,000 PsiG (1034 BarG)

• ASME PCC-2 Type I, III & IV testing devices

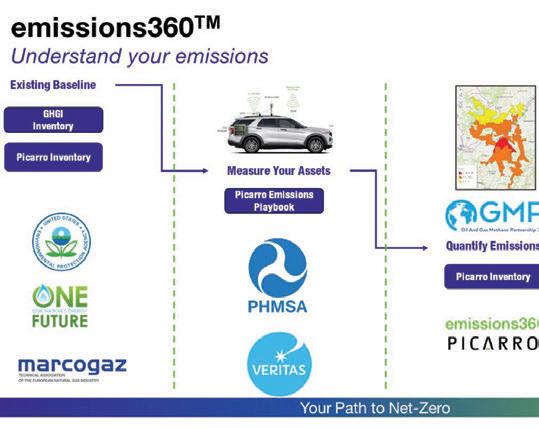

As the world grapples with the urgent need to reduce methane emissions, the role of gas networks cannot be overlooked. Picarro delivers a breakthrough solution with emissions360.

Through a measurement-informed emission inventory (MIEI), gas network operators can gain detailed insights into their emissions, helping them take an informed and proactive approach toward net zero goals.

Picarro's emissions360 platform provides reliable, data-driven insights into methane emissions across a gas network, enabling operators to identify, quantify, and reduce their environmental impact.

is platform o ers an advanced, scalable, and easy-to-use solution for managing emissions data.

Traditional inventory methods – which have been in place since the 1990s - often underestimate the actual emissions, primarily due to the reliance on generalized emission factors and lack of granularity.

On the other hand, an MIEI provides a comprehensive and accurate representation of a gas operator's emissions, identifying speci c areas of high emissions and opportunities for targeted mitigation.

e emissions360 platform takes emission management to another level. It analyses methane concentration data, wind data, and natural gas infrastructure data to locate, quantify, and visualise methane emissions.

With this tool, operators can identify leaks faster and prioritise their repair, helping them keep their networks safe, e cient, and environmentally compliant.

In the current regulatory landscape, having a clear understanding of one's emission inventory isn't just good for the environment; it is also good for business.

Regulators, environmental groups, and investors are increasingly demanding greater transparency and responsibility in emission management.

Gas networks across Australia have a critical role to play in reducing the country's methane emissions.

e value of a comprehensive, accurate emission inventory cannot be overstated.

With tools like Picarro’s emissions360, gas operators can maintain the integrity of their networks while taking a signi cant step toward a cleaner, more sustainable future.

The

e value of a Measurement-Informed Emission Inventory is immense. It empowers gas operators to transition from a reactive to a proactive approach in emission management. rough Picarro’s emissions360 platform, operators can gain precise, actionable insights that will help them improve safety, optimise operations, and signi cantly reduce their environmental footprint.

In the current era of energy transition, the demand for more sustainable and e cient energy solutions is paramount.

As natural gas operators navigate this evolving landscape, the key to long-term viability lies in aligning with emissions reduction, risk management, and ongoing value delivery.

Picarro, at the forefront of leak management and emissions reduction, enables operators to revolutionise their approach to risk management.

Its enterprise solution provides the necessary balance to e ectively lower emissions, optimise asset management, and cut costs, ensuring operators meet their goals within a uni ed framework.

In any gas network, a handful of critical leaks can signi cantly impact system risk, emissions, and public perception. With Picarro technology and analytics, operators can collect emissions data across the entire network, quantify emissions ow rates with unprecedented e ciency, and prioritise critical leaks.

is transformative approach provides operators with the most e ective tools to proactively manage leaks using a risk-based strategy, and embrace a structured, planned methodology.

It enables operators to holistically manage system risk as regulations evolve, and continuously assess and improve their gas system health and performance.

As the transformative force in gas distribution, Picarro delivers impactful, immediate enterprise value.

Collaborating with leading operators, its database of direct measurements and analytics set the industry’s benchmark.

Emergency and temporary liquid transfers require robust and reliable equipment that is also sustainable. In an attempt to help protect the planet and people, Crusader Hose challenges the usage of single-use high density polyethylene poly pipe for pipelines.

Moving water or fuel from A to B requires e cient and safe execution for storage, distribution, acquisition, or transportation.

When planning temporary pipelines, beyond turning to familiar rigid systems, what is often overlooked is whether it best supports sustainability objectives in reducing singleuse plastics.

Crusader Hose, a manufacturer of lay at hose suitable for high-volume and high-pressure pumping applications, believes its reusable exible lay at pipeline solutions o er more environmental support than rigid poly.

Crusader Hose is an Australian company that has been manufacturing exible lay at hose for over 38 years and has gained a strong reputation for reliability, trust, and excellence.

It has strong connections with the mining, pump, and drilling industries as well as with the Australian Defence Force (ADF).

Crusader Hose Managing Director Francois Steverlynck said the company’s approach was unparalleled in the industry.

“For example, not only is our Waterlord lay at hose strong and robust, capable of withstanding pumping at 2000 kilopascals, we are con dent our lay at hose solution ticks many boxes when

build supports on uneven ground, their exible

exible pipelines require far fewer trucks to transport the same length of rigid pipe. Fewer trucks on the road equals reduced CO2 emissions and cost savings.

Being easily reusable is a major rehabilitation bene t over poly pipe. When exible lay at pipelines are no longer needed, they can be easily retrieved with the reel systems.

ese pipelines can be either redeployed to their new location or stored for future projects. If managed properly, abandoned lay at hose lying around waiting to be dismantled and removed from the site will be non-existent in principle.

e reel systems also greatly reduce the need for manual handling and are key to the lay at hose system.

e most sought-after models are the Hamersley, Argyle, and Timor. Each system has its features and capabilities to satisfy a large range of demands.

Customised models have also been designed for several large-scale projects with the ADF, Taiwanese government, and South Korean Navy. eir large-diameter high-pressure Waterlord hose can pump up to 500 litres per second. With

up to 200m of lay at wound onto interchangeable reels, their reel systems can deploy pipelines in hours versus the days it would take to lay similar-length high density polyethylene (HDPE) pipelines.

With over 350 established mines across Australia, the Waterlord dewatering system may prove an advantage to many.

“Crusader Hose has worked with many mines from WA to Queensland and have supplied many hundreds of kilometres of lay at hose,” Steverlynck said.

“Our manufacturing and engineering expertise allows us to support this essential industry and other industries, too.”

Considering the critical elements of agility and speed, the ADF have been using Crusader Hose Petroline lay at hose and reel systems for over two decades.

Refuelling helicopters and fuel debunking need reliable and e cient systems.

With tested and tagged hose tted with couplings that won’t blow o under

pressure, the vital fuel supplies can be replenished with quick pipeline deployment up to 30km long. After the transfer, the reel system retrieves the pipeline until it is needed again.

Although lay at hose have been around for decades and proved itself a coste ective and eco-friendly solution, moving away from a rigid pipe system to using lay at requires con dence in Crusader Hose’s capability.

“For those water engineers who doubt the bene ts, bear in mind that the military also uses our hose for fuel pumping across seas and beaches,” Steverlynck said.

“We have created an extra dewatering option for the mining industry with our quality hose.”

Steverlynck said he was calling on the water management experts to consider all aspects of using exible lay at hose and reel systems, including transportation, handling, installing and rehabilitation costs, when planning liquid transfer systems.

The Australian Pipeliner sat down with Global Pipeline Equipment's (GPE) Matt Dridan to discuss how companies, such as GPE and Pipeline Plant Hire, are optimising project delivery through matching equipment selection with requirements.

GDridan is adamant; ‘one size ts all’ doesn’t apply when it comes to nding the right equipment and machinery for a speci c project.

Can a project achieve desired production with a smaller machine, less transport cost, fuel burn, and hire cost?

e advantages of using vacuum lifts over conventional lifting equipment, such as cranes and slings, are common knowledge now.

Vacuum lifts are one clear case of not just a major improvement to productivity, but also a massive improvement in risk aversion to both personnel and product.

What is less obvious, are the advantages of one vaclift setup over another.

What are the main considerations for a project to contemplate when selecting a vacuum lift?

e tare weight, or unladen weight, of both the host machine and the vacuum lift attachment.

is is a very important point to consider. Not only do you have the additional hire costs of an oversize machine, but there is also the additional transport, fuel, and serving costs to consider.

Especially when some projects require multiple freight movements over the course of the job. Pipeline Plant Hire (PPH) has dedicated both many years, and great expense to maximise the e ciency in these areas.

consider. is is animportant consideration, especially when working in remote locations.

e last thing a project wants is a bunch of trucks lined up, waiting to be unloaded, because of some over complicated gadget spitting the dummy. e secret to any great design is simplicity. e more layers of electronics and sensors, the more potential problems they create.

And you then need to have especially quali ed service people on hand to rectify the matter. is is not exactly an option in remote areas, and often with limited comms.

Again, simplicity in design is what has underpinned PPH’s long standing success in

supplying vacuum lifts to the pipeline industry.

Finally, take into account the experience. e importance of selecting the correct equipment for lifting operations, cannot be overstated.

ere are many considerations involved when selecting vacuum lifting equipment, including: product static and dynamic exibility, protective coating texture, and mechanical seal assembly forces required.

PPH has a long-standing reputation in his area. We have been supplying this technology since well before the mining boom. And our record in this area speaks for itself. Trial and error in lifting equipment, is not an option.

Do you have example of a project answering this criteria in mind?

For more than a decade major pipeline projects in Australia have been safely completed using PPH vacuum lifts.

is has included Queensland projects: Australia Paci c LNG, Gladstone LNG and Queensland Curtis LNG. ey were successfully completed using our vacuum lifting technologies, whereas existing alternatives at the time would have cost upwards of 30 per cent more, in both transport and hire costs.

PPH was able to use its 36t and 47t machines, coupled with our integrated vacuum lifting systems, to provide the heavy pipe handling solution. On top of this, our PL1500 quick-hitch vacuum lifts provide an e cient method of pipe handling on smaller projects by utilising the projects’ own diggers as host machines.

Horizontal Directional Drilling

• Multiple NASTT Project of the Year awards

• Australia-based operations with local resources

• Extensive experience with intersects and long crossings

• Successful 4.7km HDD under waterway

Direct Pipe

• Foremost Direct Pipe Contractor

• Outfalls and shore approaches

• Pipe Installations up to 1.5m

• Completed first of multiple 2,250m HDD’s with 590m elevation change

Longest HDD intersect completed in Australia

Record breaking HDD for combined elevation change and length

In the dynamic landscape of stormwater management, Iplex is breaking new ground with larger BlackMAX® stormwater pipes hitting the market.

Designed to exceed industry standards and set new benchmarks in quality and performance, BlackMAX stands as a testament to engineering excellence.

Iplex Technical Product Manager, Michael Lancuba reinforced the quality and performance .

“Our BlackMAX pipes are renowned for their durability and e ciency, and we are happy to announce that they are now available to order in larger diameters, including DN750, DN900, DN1000, and DN1200,” he said.

“ is expansion represents a signi cant leap forward in engineering possibilities, o ering engineers and industry leaders exibility in designing and implementing stormwater systems.”

e product is now available to order in larger diameters, doubling the range of what was previously available, making it the stormwater solution that makes sense.

“With our new expanded range of larger diameters and a commitment to excellence, BlackMAX is the de nitive choice for futureproo ng infrastructure projects and ensuring long-term success in stormwater management,” Lancuba said.

BlackMAX encompasses many features:

• An enhanced capacity and performance: e introduction of larger diameters means increased stormwater carrying capacity. is may translate to improved system performance, reduced risk of ooding, and better resilience against heavy rainfall events, crucial factors in ensuring e ective stormwater management.

• A greater design exibility: With a wider range of diameters to choose from, engineers have more options for designing tailored stormwater solutions. e versatility of BlackMAX allows for e cient customisation to meet speci c project requirements, whether it is for urban drainage, industrial sites, or infrastructure developments.

• Streamlined installations: e larger diameter BlackMAX pipes streamline the installation process by reducing the number of joints and ttings required. is not only simpli es construction but also minimises potential points of failure, leading to more robust and reliable stormwater systems.

• Cost-e ective solutions: Despite the increased capacity, BlackMAX remains a cost-e ective choice for stormwater infrastructure. Its

lightweight yet durable construction contributes to lower transportation and installation costs while ensuring long-term performance and minimal maintenance expenses.

“We are working every week with forward looking customers who are choosing plastic pipe options, and we are proud to be able to give our customers a larger range when it comes to sizes,” Lancuba said.

“We know polypropylene pipes o er several advantages over conventional pipes, especially in certain applications and environments.”

BlackMAX is crafted from structured wall polypropylene, and all Iplex pipes and ttings are meticulously engineered to withstand the rigors of non-pressurised gravity drainage systems. e result is a durable, e cient, and sustainable solution that stands the test of time.

Ensuring durable stormwater management pipes is crucial for infrastructure longevity.

BlackMAX o ers enduring stormwater solutions for future generations, with a service life of over 100 years when designed and installed in accordance with the relevant standards and manufacturers advice.

Requiring minimal maintenance compared to

conventional pipes, the pipes are less prone to scaling, rusting, and other issues that can a ect the performance of pipes. is product requires less energy to transport, contributing to sustainability goals.

BlackMAX bene ts from the material’s durability and high sti ness, making it structurally robust while maintaining lightweight properties.

It o ers superior hydraulic capacity, facilitating e cient ow and minimising the risk of deposit formation. is is especially bene cial for stormwater management systems where e cient water ow is crucial.

BlackMAX also o ers exibility and ease of installation across a range of environments. ey are available in a wide range of sizes and ttings, enabling swift and adaptable design con gurations for e cient stormwater drainage solutions.

ey are signi cantly lighter than conventional pipes, making them easier to handle, transport, and install.

is can result in reduced labour costs and faster and safer installation times and with rising

concerns surrounding the health and wellness of Australian construction workers, BlackMAX puts safety rst.

e lightweight nature of BlackMAX pipes means fewer hazards posed during transport and on-site movement, reducing the potential risk of accidents and injuries.

For more information, visit iplex.com.au

With more than 85 years of experience, Iplex is one of the original Australian manufacturers of large bore, twin-wall polypropylene pipes. e company’s technical engineers o er expert guidance and support for project success, ensuring reliability and professional support for stakeholders.

» Quality and collaborative HDD design and construct services

» Expertise to advise at the right time in the project delivery cycle

» Gas, water and sewer, rail, road, power, telecommunications, mining, residential development, renewables and hydrogen

» Maxi-rigs capable of long and wide diameter bores in hard rock and difficult conditions

» Building a future we all look forward to

Contracting company Rob Carr turned to kwik-ZIP for its project in Gosnells, Western Australia, and used its spacers to facilitate the slip-lining of a wastewater pressure main.

kwik-ZIP’s DNA is made up of versatility, simple installation and ease of use for contractors.

And it was because of these traits that contracting company Rob Carr turned to kwikZIP for its project in Gosnells, Western Australia.

e kwik-ZIP HDXT-103 spacers were installed to facilitate the slip-lining of a mild steel cement mortar lined (MSCL) wastewater pressure main into a RC Jacking pipe, running under a rail line for the Gosnells Main Pumping Station Wastewater Pressure Main Realignment project.

Rob Carr Project Manager Marie Piette saluted kwik-ZIP and its innovative spacers.

“ e MSCL pipes insertion is making good progress despite a challenging environment, with production e ciency notably enhanced by the simplicity of installation of the kwik-Zip spacers,” Piette said.

e simple and e cient installation process did not require any special tools or any requirement to pre-wrap the pipe.

kwik-ZIP spacers have no metal parts and are made from the company’s engineered thermoplastic blend with high exural strength, high temperature resistance, low co-e cient of

friction, abrasion resistance and outstanding chemical resistance.

With integrated rubber grip pads under collars to prevent slippage, kwik-ZIP spacers load sharing suspension system allows heavy loads to be shared across multiple runners.

is reduces point loading and increases the overall load capacity of the spacer.

kwik-ZIP’s series of spacers caters to a range of carrier and casing pipe size combinations. It also provides contractors and installers exibility to deal with project alterations.

In Australia, kwik-ZIP’s HDXT and HDX Series spacers have been successfully appraised by the Water Services Association of Australia (WSAA) against the requirements of WSAA product speci cation number PS-324 (casing spacers).

e WSA PS-324 product speci cation prescribes casings spacer requirements for correct protection of carrier pipes when installed inside casings.

kwik-ZIP’s rm presence in the industry has come about through years of hard work. e company was established in 2000, following the development of the industry’s rst patented nonmetallic plastic bow spring centralisers.

Since then, kwik-ZIP spacers have been making waves in the industry, and the company has been producing and marketing centraliser and spacer products for wider use.

Over the years, the kwik-ZIP team has developed and been awarded patents on various other centraliser and spacer products for applications in many industries, from production drilling to trenchless pipeline installations.

Today, kwik-ZIP manufactures and supplies a centraliser and spacer system for a wide range of industry sectors including production well drilling, trenchless pipelines, horizontal directional drilling, ground engineering and the general civil and construction markets.

Like all of its products, the HDX/HDXT spacer system series are aligned with the kwikZIP’s ethos to provide simple, cost-e ective, and high-quality solutions.

“kwik-ZIP is proud to be supplying products to such a well-respected Australian business in Rob Carr,” kwik-ZIP General Manager Paul Je reys said.

“Rob Carr is considered one of the pioneers in microtunnelling in Australia and a leader in utilities infrastructure construction.”

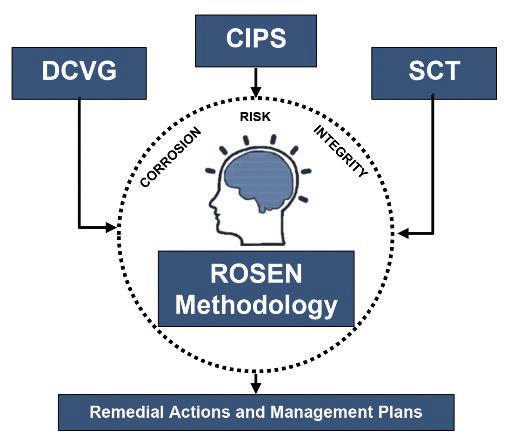

With our team of thought leaders specialized in emerging fuels, we serve as your capable partner in advancing your path through the energy transition. Four decades of experience in pipeline integrity management, own testing capabilities and a unique data pool are the basis for unparalleled integrity and risk assessments for the seamless integration of emerging fuels into your asset base. Choose ROSEN for the technology and competence needed to navigate the challenges of tomorrow’s energy landscape. www.rosen-group.com/hydrogen

When it comes to safeguarding oil and gas infrastructure, ACC Corporate leads the charge with tailored pipeline maintenance services.

Building on its foundations rst formed in 1992, ACC Corporate’s product range has grown to encompass valve service products, grease injection pumps and valve ttings.

For over 30 years, ACC Corporate has catered for the o shore market, providing lubricants, sealant, grease ttings and grease injection pumps for pipeline operators.

rough this extensive experience, the company has proven that regular lubrication of pipeline valves will allow the valves to function correctly.

One speci c product that has proved popular among pipeline operators is the grease gun, which is available as hydraulic foot-operated and air operated.

e ACC hydraulic foot-operated grease injection fun is an easy-to-operate and lightweight unit that provides an extremely fast discharge rate.

e product is ideal for situations where compressed air is not available and comes complete with an aluminium frame, a 10,000PSI hydraulic pump and a ‘J’ or ‘K’ grease stick barrel.

A versatile unit, the pump works well in o shore and onshore projects and is recommended for eld, plant, and platform applications.

e air operated grease gun is also lightweight and provides ease to operators with its fast discharge rate.

is pump also comes with an aluminium frame, a 10,000PSI hydraulic pump, a ‘J’ or ‘K’ grease stick barrel and a carrying case.

Also recommended for o shore and onshore projects, the air operated grease gun is designed to pump standard and special materials including lubricants, sealants, packing and cleaners.

on pipelines and wellheads, with many Australian pipeline service companies using both products.

As the company has evolved its product o ering, so too has its ability to provide personnel to conduct on-site valve maintenance.

ACC Corporate technicians can ease pipeline operators minds by conducting integrity checks.

Each ACC technician has training to identify faults and provide solutions to ensure the pipeline valves are fully functional.

is includes testing of valve seats and cycling operations.

To assist in the maintenance of the pipeline valves, ACC Corporate has several products perfect for the job.

e company’s range of valve ush, lubricants

and sealing qualities for pipeline ball valves.

With a focus on providing e cient support services for its customers, ACC also provides a 24/7 phone service for eld technicians to discuss any speci c issue and seek assistance from ACC personnel.

Expanding on this, ACC Corporate prioritises safety and implements various initiatives to minimise risks.

ese include utilising an online integrated management system to log risks and improvements, implementing online health and safety e-learning modules, electing a Health and Safety Representative to be the voice of its workers, a drug and alcohol testing program and safety refreshers at all sta meetings.

With its number one goal to meet client objectives, the company follows strict quality and conformance checks on all projects and follows recommended guidelines.

roughout its journey over the last 30 years, ACC Corporate has developed its highly experienced team of professionals to ensure the e ective development and management of its products and services.

e company prides itself on its fast response to demands and ability to adapt its o erings to comply with the various complexity of di erent client requirements.

When it comes to providing hot tapping and line isolation services in the Australian pipeline industry, Pro Pipe Services provides customers with unparalleled service excellence.

Pro Pipe Services’ Director Joe Buttigieg is con dent all of his customers have a 100 per cent success rate thanks to the work the company provides.

Since its inception in 2018 into the pipeline industry, Pro Pipe Services has prided itself on the quality of its service excellence it upholds.

“Our strength is the rsthand knowledge our team has in the pipeline industry,” Buttigieg said.

“While we have a small workforce, all our sta have had numerous years working in the industry.”

Buttigieg said that the company’s strength lies in being an Australian-owned company, and having locally based technicians.

“ is means we understand the requirements of our customers,” he said.

“Our customers can be rest assured knowing that all our eld sta and technicians are trained to the highest Australian standards and competencies.”

He also noted that having a local base means the company can react to its customers’ needs as quickly as possible, without the need to rely on technicians from abroad.

A testament to this is the substantial growth Pro Pipe Services has encountered since its inception.

“Originally, our operational service was in Victoria only, however, we are now constantly executing hot tapping, line Isolation and pipeline services right across Australia - from the east coast to the west coast, on shore and o shore,” Buttigieg said.

“While natural gas pipelines are the predominant product we work on, we have also executed work on hydrocarbons, water and other pipeline products.”

Recently, Pro Pipe Services completed two 34-inch (DN850) high pressure hot tap and line isolations for the installation of two new line valves for a major project.

e project was executed in a remote part of Australia, so logistically it was tough.

Moving equipment of that size to a remote location provided its challenges due to ooding and road closures. However, the job was completed on time, safely and awlessly.

e company backed that job up the following week by undertaking a 20-inch (DN500) isolation for a major pipeline project in Victoria.

Pro Pipe Services conducts hot tapping and line isolation services almost on a daily basis.

Based in Victoria, Pro Pipe Services executes hot tapping, line isolation and pipeline services across Australia.

Whether it’s a high-pressure gas pipeline or lowpressure water line, on steel or polyethylene, Pro Pipe Services has the knowledge and experience to execute any job. No job is too big or small.

When it comes to providing hot tapping and line isolation services, the company uses proven technology that has stood the test of time.

T.D Williamson’s (TDW) hot tap and STOPPLE® has been designed, engineered, and successfully operated for many decades.

“By using TDW’s hot tap and line isolation equipment, we know that we can achieve a seal that can provide the customer with a safe environment to perform alterations, tie-ins or

abandonment of existing infrastructure, whether it be for a modi cation or repair of a pipeline,” Buttigieg said.

“ e channel partnership between Pro Pipe Services and TDW, means we can access more equipment, engineering, and products for our customers.”

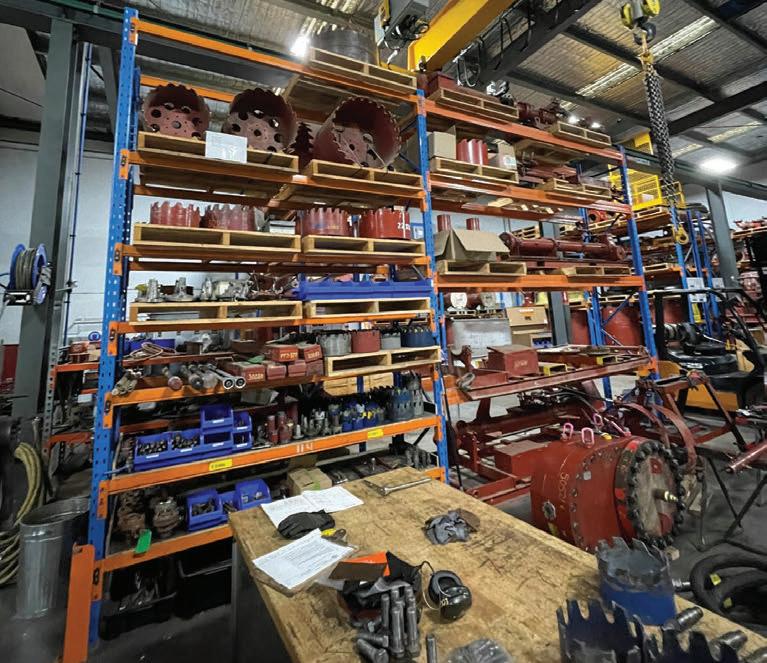

Based in Tullamarine, Victoria, Pro Pipe Services operates out of a state-of-the-art workshop, fully equipped with all the tools, fully maintained equipment, and parts to execute any service job.

“We are very proud of our facility in Victoria,” Buttigieg said. “Working out of Victoria provides us with the exibility to ship equipment to all parts of the country.”

Buttigieg said that by working out of its facility means it can ensure all equipment is fully maintained and stored right here in Australia and ready to ship at a moment's notice.

Pro Pipe Services not only provides hot tapping and line isolation services, but it also equipped to do pipe cutting, commissioning, decommissioning, equipment maintenance on all types of pipeline equipment, and training.

Process control Quality Innovation Customer service

We specialise in applying our induction technology to solve seemingly intractable problems.

Induction bending of pipe up to DN900, wall thicknesses up to 100mm.

Carbon steels, stainless steels, clad pipe and other exotic alloys

High X grade bends

Compound bends

Helix bends

Custom OD mandrels

Structural steel section bending

Fully customizable bend geometry

Other specialist heating applications

Onsite induction bending (large diameter high volume projects)

Cold eld bending machines also available for hire (up to DN1200)

Through its Pack Tu bags, Pollard’s Sawdust Supplies provides customers with an economical and reliable solution.

Pollard’s Sawdust Supplies provides a reliable solution for pipeline bedding, and its Pack Tu bags are supplied with timely service and competitive pricing.

Since 1968, Pollard’s Sawdust Supplies has processed, packaged and distributed wood shavings and sawdust across Australia.

e company’s primary material is sustainably sourced Australian softwood and hardwood bres, and its eco-friendly products are biodegradable and chemical free.

Pollard’s Pack Tu bags are both durable and uncompromising, essential factors in facilitating multiple re-uses in the heavy-duty pipeline industry.

Light, yet hard-wearing and resilient, the Pack Tu bags are an ideal solution for protecting assets, not only on-site but also during transportation of the pipes and for storage in laydown yards.

point of di erence of the product.

hammering,” he said.

take a great deal of rough handling and tossing about on job sites.”

term storage, for reliable transport applications, and supporting pipes up o the ground.

explode under the weight of the pipe. e largest

sawdust.com.au

and this allows for easier manoeuvrability and lowers risk from an occupational health and safety perspective.

Providing a exible service, Pollard’s freight its Pack Tu bags across Australia with pallets arriving on-site stretch-wrapped and weatherproof.

e bags have been used on numerous projects around the country involving companies such as McConnell Dowell, Steel Mains, MPC Kinetic, Spiecapag, John Holland, and Nacap. ese projects include the Victorian Desalination Plant, Northern Gas Pipeline, Lake Way Gas Pipeline and currently the Fitzroy to Gladstone Pipeline in Queensland. Pack Tu bags were also used on the Wentworth to Broken Hill Pipeline, for which Pollard’s provided 25,000 bags.

In addition to the Pack Tu bags, the company supplies a number of other hard and softwood products Australia wide. ese include a variety of chemical free and graded sawdust products which can be used for a range of applications in addition to pipe bedding, such as animal bedding, absorbing oil and chemical spills, horticultural applications, and as a composite component for a multitude of end products.

Pollard’s pride themselves on providing quality Australian sawdust and wood shavings products which is why their customers keep coming back.

The Tritan 560 is the newest member of McElroy’s pipe fusion lineup and is set to arrive in Australia soon.

The Tritan 560 combines features of three of McElroy’s most innovative machines; the rugged portability and technology of the TracStar iSeries, the bottom-loading capabilities of the Talon 2000, and the Acrobat QuikFit carriage’s ability to meet the pipe where it lays on the job.

With those innovations in mind, McElroy designed a machine that rethinks the fusion jobsite with an eye for e ciency and worker safety.

e Tritan’s bottom-loading carriage sets it apart from the other equipment in McElroy’s fusion lineup, along with its full 360-degree rotation and a boom that can raise, extend, and curl the carriage to approach and load pipe.

With the Tritan, there’s no need to top-load pipe into the machine, and the machine operator is able to safely and easily position the Tritan using the DataLogger® tablet, which allows them better visibility to ensure there’s nothing – and no one – in the way of the machine.

“Because the design of the Tritan allows so much freedom of movement, wireless controls were developed so the operator can move wherever is needed for the best visibility,” McElroy Product Innovation Manager Mike Pacheco said.

e Tritan o ers a removable carriage that can operate in a two one two or three and one con guration, in both a top-loading or bottom-

loading setup for maximum exibility in the eld.

In con ned spaces or in-ditch applications, the carriage can be loaded directly onto the pipe from above, minimising the amount of excavation required under the pipe.

To take the e ciency improvements a step further, the Tritan 560 aids in pipe positioning, allowing for more exibility and increased performance and productivity.

With the same rugged, dual rubber tracks found on McElroy TracStar machines, the Tritan o ers all-terrain mobility to easily travel across a variety of terrains and can be driven directly to and from the pipe itself.

By building o the legacy and design of multiple McElroy units, the Tritan minimises the amount of time spent between fusions while also letting the machine work in tight areas.

In addition to its other revolutionary functions and features, the Tritan includes a hydraulically powered generator to supply voltage to its heater.

Rather than energising and de-energising the heater to control its temperature, this new approach varies the motor’s speed to raise and lower voltage. For operators and contractors, that means less fuel consumption and an overall reduction in engine noise.

Many operators are familiar with using the DataLogger 7 as a wireless control for the TracStar iSeries. e Tritan 560’s design takes that functionality a step further, with the DataLogger

7 poised to fully, wirelessly operate the vehicle as its primary interface.

e Tritan’s controls work seamlessly through the DataLogger, including its basic function controls, the bottom-loading carriage, rotation, and boom.

e DataLogger is a staple of the fusion industry, allowing contractors and operators to capture, store, and share fusion data.

In the years since its release, the DataLogger has proven itself an invaluable tool for operators, managers, and inspectors due to its ability to document all aspects of the fusion process from start to nish, including metrics like GPS and operator identi cation for each joint fused, anywhere in the world.

DataLogger integration also allows users to take full advantage of McElroy’s Vault, a powerful cloud-based tool to collect, store, analyse, and share joint reports and project information.

Its easy-to-use interface also allows for the recording of each fusion’s GPS location, machine, and operator information, along with joint data.

“As contractors begin to receive and use their Tritan 560 machines, we’re excited to see how they apply the Tritan’s functionality to real-world applications,” McElroy President and CEO Chip McElroy said.

“ e Tritan 560 builds o the success of our existing lineup, and we can’t wait to see this latest machine add to that legacy.”

Gippsland Water has completed two major projects to provide local communities with water security. The Australian Pipeliner takes a look at the two projects helping increase water supply and improve sewer system capacity.

Securing water and ensuring sewer systems are optimal for the future is vital, and no one knows this quite like Gippsland Water.

e utility’s new pipeline is delivering more water to Drouin via the Moe-Warragul interconnect, creating a second source for the quickly expanding Victorian town.

Gippsland Water Senior Project Delivery Lead David Peake said this project had been crucial for the communities in the region.

“ e Warragul western ring main is a large diameter transfer main that loops through a largely undeveloped area to the west and south of Warragul. e project has allowed for future development between the Warragul and Drouin townships,” he said.

“Hydraulic modelling has also shown that the addition of the Warragul western ring main balances the pressure and ow characteristics of the Warragul water supply system, which signi cantly decreases the reliance on pre-existing large diameter assets in the township.”

According to Peake, Warragul, Drouin, and surrounding towns have developed signi cantly in the last decade and the western ring main is part of Gippsland Water’s work to proactively manage the region's growing water and wastewater needs.

e main was constructed using horizontal

drilling (HDD) methods, which was selected to minimise the impact of the project on native ora and fauna, including the Warragul Burrowing Cray sh and Giant Gippsland

“ e main extends for about 4.3km and consists of a 0.7km of DN450 PVC-M PN16 pipe section which was constructed via open trenching. 3.1km of DN560 PE100 PN 16 pipe was installed using trenchless (HDD) methods and 0.5km of DN560 PE100 PN16 was also constructed via open trenching,” Peake said.

“ e project was largely bored rather than open trenched to minimise the impacts to the natural environment.”

e new pipeline travels in a north-westerly direction through road reserves from Butlers Track to the railway crossing on Lardners Track.

It has also provided an alternative supply to the town of Warragul that can be used during maintenance or emergency work, avoiding interruptions to customers’ water supply.

According to Gippsland Water, Warragul and Drouin are two of the fastest growing towns in the region, and understand that building water and wastewater infrastructure is vital to keep ahead of the growth – and the Warragul western

directional Earthworm habitats.ring main project is an essential part of this work.

e pipeline will assist development in the south-west growth corridor of Warragul. It will also increase the volume and security of water supplies for Drouin.

e water main will be constructed around existing urban areas to provide an additional main to supply water to Drouin, with further extensions of the pipeline planned in the future, in line with local urban development.

roughout the process, Gippsland Water has actively worked to protect environmental and cultural heritage values, with environmental assessments completed for the Giant Gippsland Earthworm, Warragul Burrowing Cray sh and Strzelecki Gums.

e utility is committed to protecting environmental and cultural heritage values as the project continues, as well as making sure the works cause minimal disruption to the local species by using underground boring and keeping the route along previously disturbed areas of road.

Gippsland Water is working with Traditional Owners to protect cultural heritage and any artefacts found.

Community consultation and engagement was also inherent to the project, as Gippsland Water engaged with residents and stakeholders while planning for this work, including consulting

As local communities’ demographics are booming, these projects were needed for a continued water security.

residents along the pipe route.

Gippsland Water has also started works to increase the Warragul’s north-east region’s sewer system capacity starting this year.

e project, for which a $7 million contract was awarded late last year, involves upgrading a 1.5km section of existing sewer main by installing a new larger pipeline.

Gippsland Water Managing Director Sarah Cumming said the new sewer main was an important upgrade and would help prepare for Warragul’s future.

“We always look ahead and plan for the future to determine what services our customers will need and when,” she said.

e new pipeline will transfer all wastewater from homes and businesses in Warragul’s northeast future boundary to the town’s wastewater treatment plant.

Construction will begin within the boundaries of the Warragul wastewater treatment plant before progressing in a northerly direction towards Stoddarts Road.

“It’s essential for our network to be able to withstand pressures like population growth, rainfall variability and climate change,” Cumming said.

“ e existing sewer main was built in 1971, when there were fewer homes and businesses in the area, but it is now nearing capacity.

“Upgrades like this one also bene t the environment by reducing the risk of spills and main failures.”

Construction will begin in the coming weeks, with tra c management in place on roads at various times during construction.

e project is on track to be completed in mid 2025.

Rädlinger primus line GmbH sat down with The Australian Pipeliner to discuss the environmental bene ts of trenchless technology.

Climate change and reducing emissions appear to be the buzz words not only in ltrating the pipeline industry currently, but the minds of politicians, business leaders and the public, according to Rädlinger primus line GmbH.