TECHNOLOGY BEHIND STATS’ TEMPORARY LINE PLUGGING SOLUTION – page 22

X marks the spot for Mipela 46

Harnessing the power of AI 106

overview 26 ISSUE 199 | SEPTEMBER 2023

APGA Convention

Plugged in

ALL ABOARD THE PIG TRAIN › Line cleaning and scraping › Batching › Hydrostatic fill › 360 degree coverage › Magnetic ferrous material removal Our Exclusive Global Partner www.pipetek.com.au Taddam: 0432 666 917 taddam@pipetek.com.au Myles: 0417 707 729 myles@pipetek.com.au CLEAN YOUR PIPELINE WITH FEWER PIG RUNS Achieve optimal cleaning results while saving time and money by running multiple cleaning elements at the one time.

Introducing the SafeVac Lifting Systems™ SV400: the Perfect Marriage of Safety and Productivity.

Austrack’s SafeVac SV400 delivers improved lifting capacity and visibility in vacuum lifting. Featuring a large in-cabin control screen which improves operator control and overall safety, it is also equipped with extensive data logging capabilities.

Timed sequence dual action joystick buttons improve productivity, reduce operator fatigue and improve safety, and the machine’s vacuum latch/release valve means instantaneous vacuum latch/release. The SV400 is also equipped with a reserve vacuum tank with non-return valve assembly at the spreader bar, ensuring the pipe will not release even in a catastrophic destruction of the main vac line. The machine also features an over rotation warning to prevent pipe from colliding with the cabin.

All of these features combine to deliver more for less:

• More Productivity

• More Safety Features

• More Lifting Capacity

• And Less Stress for your Project

26 Cul ya S t, P ink en ba, Q LD 400 8 +61 419 170 29 7 sa l es @ austrackequ i pment . com .au www. a us trac k eq ui pme nt.com.au NEED A LIFT? LOOK NO FURTHER Introducing the SafeVac Lifting Systems™ SV400: the Perfect Marriage of Safety and Productivity. 26 Cul ya S t, P ink en ba, Q LD 400 8 +61 419 170 29 7 sa l es @ austrackequ i pment com .au www. a us trac k eq ui pme nt.com.au NEED A LIFT? LOOK NO FURTHER

the SafeVac Lifting Systems™ SV400: the Perfect Marriage of Safety and Productivity. NEED A LIFT?

Introducing

LOOK

FURTHER

NO

CONTENTS 4 The Australian Pipeliner | September 2023 22 STATS

ImagecourtesyofSTATSGroup. EXECUTIVE REPORTS President's Message 8 APGA MEMBER Q&A A story no bloke should ignore 12 POLICY Gas and energy policy 14 FUTURE FUELS Event focuses on the future of pipelines in Australia, US and Europe 16 PIPELINES IN NEW ZEALAND Significant contracts awarded 18 WOMEN’S PIPELINE FORUM Emerging leaders showcase Australian talent at global hydrogen conference 20 COVER STORY The right tool for hot tapping and line stopping 22 APGA CONVENTION Sponsors 24 Unleashing the power of industry insights 26 Unlocking career advancement 28 Exhibitors list 30 Exhibition floorplan 32 Conference program 34 Star in the shutdown containers constellation 42 kwik-ZIP puts mark on WORM 44 X marks the spot 46 Keeping natural gas an option 48 FlexSteel pipe rehabilitating aging infrastructure 50 Ten years of AJ Stack Solutions 52 Lifting safety to new levels 54 A match made in HDD heaven 56 A one-stop shop solution 58 The ideal solution for isolating gas distribution pipelines 60 Setting sight on growth 62 A partnership 24 years in the making 64 Optimising throughput and pipeline performance 66 A recipe for success 68 Handling the pressure: cleaning and testing results from Pipe Tek 70 A leader in supply chain services 72 Combating modern slavery through procurement 74 Nacap’s RAP journey 76 REHAB & REPAIR Finding the right corrosion inhibitor 78 Belzona composite repair system for pipes 80 Versatile tool in pipe rehabilitation 82 ENGINEERING SERVICES A trusted partner in pipeline infrastructure projects 84 PIPELINE CONSTRUCTION Building an Empire 86 Durable safeguarding solutions 88 Pipeline projects keep flowing to PPH 90 Industry recognised pipeline specialist 92 Pipeline protection served on a plate 94 Design better with Vertex G4Plant 96 A reliable pipeline specialist 98 HYDROGEN Empowering the future with hydrogen 100 PE PIPELINES Saving time and money where it matters 102 Plastic – the material of choice for pipes 104 HDD Harnessing the power of AI 106 REGULARS Members & memos 10 APGA members 108 People on the Move 110

Group's BISEP is a temporary line plugging tool that ensures the safety and reliability of pipelines.

TRACTO.COM/GRUNDODRILL The GRUNDODRILL ACS300 is the most powerful HDD rock drilling rig in its class setting new standards: - Intuitive operating concept - Maximum automation - Remote-controlled drilling - 30 tonnes of pulling and thrust force - Large drill rod magazine with automatic rod handling - Peak power & performance for drilling in all geologies To find out more, please get in touch. info-au@tracto.com T + 61 7 3420 5455 THE PREMIER LEAGUE OF ROCK DRILLING GRUNDODRILL ACS300 See us at: NODIG DOWN UNDER BRISBANE 12. - 14.09. 2023 BOOTH 64

CEO John Murphy

COO

Christine Clancy christine.clancy@primecreative.com.au

MANAGING EDITOR

Molly Hancock molly.hancock@primecreative.com.au

EDITORIAL

Clemence Carayol clemence.carayol@primecreative.com.au

Vivien Topalovic vivien.topalovic@primecreative.com.au

BUSINESS DEVELOPMENT MANAGER

Nick Lovering nick.lovering@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey blake.storey@primecreative.com.au

DESIGNERS

Kerry Pert, Louis Romero

COPYRIGHT

The Australian Pipeliner is owned by Prime Creative Media and published by John Murphy. All material in The Australian Pipeliner is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in The Australian Pipeliner are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2021

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Printed by: Manark Printing 28 Dingley Ave Dandenong VIC 3175 Ph: (03) 9794 8337

Maximise

brand awareness by connecting with thousands of industry professionals

The Australian Pipeliner brand comprises: a quarterly magazine, a news website, a fortnightly e-newsletter, multiple social media platforms, an annual industry directory and an annual pipelines wallchart. Book an advertising and editorial package to gain access to our exclusive audience.

3,300+

magazine subscribers

16,500+ e-newsletter subscribers

Want to find out more?

20,000+ website views each month

13,700+ social media followers

Head Office 379 Docklands Drive, Docklands VIC 3008 Ph: +61 3 9690 8766

The Australian Pipelines and Gas Association’s (APGA) vision is to lead the sustainable growth in pipeline infrastructure for Australasia’s energy. APGA is a non-profit organisation formed to represent the interests of its members involved in: the ownership, operation, maintenance, design, engineering, supply and construction of pipelines, platforms and all other structures used in or in connection with the drilling for, extraction and transmission of hydrocarbons, solids, slurries and similar substances both onshore and offshore. As a single voice representing the collective interests of its members, APGA is dedicated to encouraging the extension and development of the industry.

The Australian Pipeliner is the official journal of the Australian Pipelines and Gas Association (APGA) and is distributed to members without charge and circulated to interested organisations throughout Australia and overseas. It is also available on subscription. The publishers welcome editorial contributions from interested parties. However, neither the publishers nor APGA accept responsibility for the content of these contributions and the views contained therein are not necessarily the views of the publishers or APGA. Neither the publishers nor APGA accept responsibility for any claims made by advertisers. All communications should be directed to the publishers.

6 PUBLISHER

our

to discuss how you can grow your

The

Contact

business development team

business with

Australian Pipeliner. Call 0414 217 190 or email nick.lovering@primecreative.com.au

Sydney

Office Suite 303, 1-9 Chandos Street Saint Leonards NSW 2065 Ph: (02) 9439 7227 enquiries@primecreative.com.au www.primecreative.com.au

The Australian Pipeliner | September 2023

WE BRING ENERGY TO ITS DESTINATION

TURNKEY ENERGY INFRASTRUCTURE SOLUTION PROVIDER

CAPABILITIES

Pipelines

Renewables

Defence Facilities

Power CSG Gathering

nacap.com.au

+61 3 8848 1888 (Melbourne, Head Office)

+61 7 3328 8800 (Brisbane)

+61 7 3029 1111 (Brisbane, PNG Project Office)

+61 2 6884 7878 (Dubbo)

+675 321 1001 (Port Moresby)

◊ TRANSMISSION PIPELINES

◊ CSG GATHERING AND WELLHEAD CONNECTIONS

◊ ABOVE GROUND AND BURIED FACILITITY

◊ REFINERY FACILITIES INCLUDING BROWNFIELD SITES

INTEGRITY TEAM WORK

STRIVE TO BE BETTER

President’s Message

I’ve liked being President. It’s different from being a Director, and different again to being a member. It’s a position that you feel honoured to have as you drive the strategy forward, representing all the members that make up this great Association. Don’t get me wrong, you all made me work hard… (some more than others!), but to see us go headfirst against a narrative with a negative discourse on our industry and to pull out of COVID-19 to get our swagger on again at events, has been a big responsibility… with lots of fun.

You have a great Board and Secretariat. Above all, we are a great family… so don’t let me down. Let’s blow this Perth Convention up!

Now down to dos & don’ts. Do make new contacts, do listen to the speakers, do have an open mind, do chat to the exhibitors and do eat & drink and be merry. Don’t go to bed early, don’t miss out on the fancy dress, don’t let the YPF’ers lead you astray at 3:00am in the morning and just don’t miss out. If you do, you’ll regret it.

In this special conference edition, it is exciting to look at the program for this year and see many interesting topics. There are some good case studies on projects completed this year, safety lessons and new to the agenda are Young Pipeliners and Advocacy panels. We continue the discussion and be real to what we are doing to decarbonise, the governance in procurement, and approaches to construction.

As I write this, there are 48 exhibitors, and we thank them for their continued support. The gratitude we can extend is to walk the exhibition hall and see the latest on offer.

In August, APGA hosted the inaugural ESG (Environment, Social Governance) Forum. A day that brought to the industry another piece of our sustainability jigsaw puzzle. ESG is a framework encapsulating many things, but relevant for our industry, it captures those activities we’ve been implementing such as community engagement, environment, safety and human resources. There are also emerging ESG factors that are, and will, impact our industry including carbon emissions, modern slavery and sustainable procurement. I am excited as President, to have opened this dialogue as an industry. ESG as a business alone contributes a small piece, but as an industry coming together, we can really shift the needle in this space. It’s certainly about

collaboration and partnering, just like safety was 50 years ago, and with time it will make our industry more sustainable financially and champion our social licence to operate.

In this edition, you’ll find a personal story of a person I have been fortunate to meet over the last four months, Chis Croylon. Chris bares his soul on a medical issue which was brought about because of the dedication to his job. Completely unavoidable, but then ignored the warning signs. Having spent time with him, he is passionate about this industry and so he has built up the courage to tell his story so others can learn. Please read.

We also say goodbye to one of our Directors, Wendy Oldham, who has been on the APGA Board since 2016. Notably, Wendy was Treasurer for a good many of these years and led us from the red to the black. As she heads to retirement, we wish her all the very best and hope life finds her pots of gold.

As this is my last President’s address, I’d like to thank everyone for having trust in their voting of me and appointing me as APGA’s first female President. It is a badge I will always wear with honour and appreciate the friendship and support over the last two years. I’ll see you at the bar.

ABN: 29 098 754 324

APGA Secretariat Registered Office: 7 National Circuit, Barton ACT 2600 (PO Box 5416, Kingston ACT 2604)

T: +61 2 6273 0577

E: apga@apga.org.au

W: www.apga.org.au

Chief Executive Officer

Steve Davies

Corporate Services Manager

Michelle Wickson

National Policy Manager

Jordan McCollum

Communications Manager

Lawrence Shelton

Engagement Manager

Gayle Burns

Membership Officer

Katy Spence

Events Coordinator

Matthew Freeborough

Policy Manager

Catriona Rafael

Government Relations Manager

Paul Purcell

Reference

1. ‘New Energy Outlook Australia’, Bloomberg Finance May 2023

EXECUTIVE REPORTS 8

DONNA MCDOWALL APGA PRESIDENT

The Australian Pipeliner | September 2023

The leading innovator supplying cutting-edge integrity solutions. Together we can ensure sustainable decision-making. Our combination of advanced inspection systems and expert consultants delivers a comprehensive understanding of asset safety, lifetime, and performance.

Comprehensive Asset Integrity Management

www.rosen-group.com

Pioneer pipeline project complete

TasWater’s $5 million pipeline project to deliver safe and reliable drinking water to the residents of Pioneer, Tasmania is now complete.

Water now flows from TasWater’s extended Ringarooma Valley Water Scheme which services other towns in the region.

As part of the works, a new reticulated network has been installed through Pioneer as well as an extension of the water main from Winnaleah.

TasWater acting chief executive officer Tony Willmott said the new works will have a significant impact on the residents of Pioneer. “I’ve met with residents several times over the

years, and I know what a difference this will make to them,” Willmott said.

“We’re committed to delivering high-quality

Surat Basin to provide much needed gas supply

This agreement with Senex is an important step forward in supplying reliable, affordable energy to retail and business customers in the future.

Senex and EnergyAustralia have signed a conditional agreement for the supply of 24 petajoules (PJ) of natural gas from January

2025 from Senex’s proposed Atlas expansion in Queensland’s Surat Basin. While the Australian Competition and

potential shortfalls in New South Wales and Victoria.

“Senex’s $1 billion investment to boost gas supply for Australia’s east coast is exactly the type of project required to address supply concerns,” said Senex chief executive officer Ian Davies. EnergyAustralia trading and transition executive Ross Edwards concurred, saying this agreement with Senex was an important step forward in supplying reliable, affordable energy to retail and business customers in the future.

The new gas deal between Senex and EnergyAustralia is conditional only on the timely recommencement of Senex’s Atlas expansion which was put on hold in

APA completes first stage construction on east coast gas grid

APA Group has completed construction on the first stage of its east coast grid expansion to boost gas security and reliability. The company first made the decision in 2021 to invest in a 25 per cent expansion of the grid, to deliver more capacity to customers.

“The first stage of our East Coast Grid expansion is now complete, with the second stage under construction and expected to be complete in readiness for the growing winter demand in 2024,” APA Group chief executive officer and managing director Adam Watson said.

Over the next few weeks, construction is expected to complete on the South West

“When completed, these projects will further enhance system capacity, reliability and

backing in and backing up renewables,” Watson said.

10 The Australian Pipeliner | September 2023 MEMBERS & MEMOS

A new reticulated network has been installed through Pioneer as well as an extension of the water main from Winnaleah.

The new gas deal between Senex and EnergyAustralia is conditional only on the timely recommencement of Senex’s Atlas expansion.

APA Group has completed construction on the first stage of its east coast grid expansion.

Major water main work begins at Monarto

Major work in Monarto has started, with more than 7000m of new water main being laid in the area over the next 12 months.

The work is part of SA Water’s $3.9 million investment in upgrading capacity within the local water network.

The project also includes an upgrade to SA Water’s pump station in White Hill, along with construction of a new chlorine booster station. SA Water’s senior manager of capital delivery Peter Seltsikas said the new upgrades along Monarto Road, and areas of Monarto Safari Park will support further business and residential growth.

“As our regions develop and grow, it’s our role to invest in evolving our infrastructure’s capacity to keep them in step with the changing demands from businesses and households,” Seltsikas said.

First pipes arrive for Fitzroy-to-Gladstone Pipeline

The first pipes for the $983 million Fitzroy-to-Gladstone Pipeline arrived in Rockhampton, signalling that preparations are well underway for the start of construction.

Water Minister and Member for Gladstone Glenn Butcher said the 117km pipeline will deliver long-term water security to the Gladstone region to support more job creating industries.

“The funding locked in as part of the Big Build is proof of the Palaszczuk Government’s commitment to central Queenslanders,” he said.

“The Bradfield panel recommended investing in the use of water closer to where it falls as well as developing Regional Water Grids, and we are doing just that.”

The pipeline will have the capacity to transport 30 gigalitres per annum from the Fitzroy River to Gladstone.

The pipeline will run from the Lower Fitzroy River in Rockhampton and connect to Gladstone Area Water Board’s existing water network at Yarwun, providing long-term water security to Gladstone’s industry and will support ongoing economic development in the region.

11 The Australian Pipeliner | September 2022 MEMBERS & MEMOS

Defence and Infrastructure, Asset Remedia�on & Corrosion Mi�ga�on Solu�ons ww w.cceng.com.au Australasia’s foremost corrosion prevention and protection solution providers W: www.eptec.com.au P: 08 6174 4303 E: eptec@eptec.com.au

The project also includes an upgrade to SA Water’s pump station in White Hill.

The pipeline will run from the Lower Fitzroy River in Rockhampton and connect to Gladstone Area Water Board’s existing water network at Yarwun.

A story no bloke should ignore

Chris Corlyon’s life turned upside down when he was diagnosed with a rare condition. This is his story, plus a few tips on how to avoid being in the same position.

Many will know Chris Corlyon as “that welding guy” who’s been piping industry for years and just loves to talk about, well, welding.

But what people probably didn’t know is that for past 11 years the resident welding expert ignored a medical issue which, unfortunately, has come home to roost and forced him to dramatically change his lifestyle to manage his illness – for the rest of his life.

The question on everyone’s mind is, of course, what’s Corlyon got?

The answer is an ailment many wouldn’t have heard of: atonic bladder. This is a condition that means his bladder muscle doesn’t do what it’s supposed to do, which is primarily to squeeze out pee to empty his bladder when full.

According to Corlyon, he started to notice the health issue when things like taking longer to pee and peeing less stared to occur, followed by signs of infection.

But Corlyon believed it would just go away.

“Basically, I was your typical bloke who thought there was no need to see a doctor,” he said.

“Over the years it got progressively worse, to the extent that I could only pee just a little bit at a time, regardless of how much I drank.

“But, in my head, I thought, ‘Nah I’ll be right, there’s no need for a doctor’.

“A little further down the track, the missus forced me to go to the doctor and he gave me the bad news, I had an atonic bladder, and because I’d left it for so long I needed to be on a handful of tablets every day, immediately.

“It wasn’t a good day, and unfortunately it didn’t get any better for me, as the medication he prescribed was more a preventive measure and I’d simply left it way too late.”

Corlyon ended up having to take eight weeks off work and needed an operation to address the issue.

“But unfortunately the op didn’t work either because, again, I’d let it go for too long and it had got gradually worse,” he said.

“In late-2020, after several more problems, I was working in the Cooper Basin and noticed myself progressively getting sicker and sicker and on my return home I got off the plane and went straight to the emergency unit.”

Corlyon was admitted for two weeks due to the infections throughout his body.

“The doctors monitored me, but things went

from bad to worse and I ended up losing my natural function to take a pee,” he said.

“The complication with not being able to pee, is you either have a catheter leg bag, or a hole in your stomach with a pipe and valve, to enable you take a leak.”

Corlyon’s options weren’t pretty, and both were uncomfortable.

“Take a quick moment to imagine having a bag of pee resting on your leg with a permanent catheter jammed into it, or the alternative, a permanent open wound in your gut and changing a pee pipe every five to six weeks,” he said.

In the end, Corlyon opted for the hole in the stomach with a pipe and valve, not because he liked the option, but he had now become resistant to most antibiotics, so this method was deemed the safest.

With all of this going on, coupled with the prospect of losing his career and livelihood, Corlyon spiralled into a dark hole.

“It wasn’t a great place to be, but while I was unlucky in the health stakes, the good news is I won the lottery in the support stakes,” he said.

Despite a huge amount of support from colleagues, friends and family, it initially wasn’t

easy for Corlyon to open up about the issue.

“I couldn’t even talk to family members about it as I felt embarrassed and ashamed that a grown bloke like me couldn’t deal with it,” he said. “So to be talking about it here is quite an achievement for me.

“I see telling my story as part of my recovery process, but I also see it as an opportunity to get a health message out to my work mates, in the hope it doesn’t become an issue for them.

Corlyon’s story can serve as an example and encourage anyone affected by such a condition to not delay visiting their GP.

“My message to all the MPK blokes out there, and to our MPK ladies with husbands and partners, don’t turn a blind eye to health issues and get to a doctor much earlier,” he said.

“Please don’t think, ‘Oh, I’ll just have that pee later’, which ends up being at the end of a 12hour shift. Because I can tell you now, that was the root cause of my problem.

“I don’t mind being Exhibit A if it means someone doesn’t end up with a lifetime medical condition like I have now.

“The moral of the story is look after yourself as life can change very quickly, and sometimes it’s not for the better.”

12 The Australian Pipeliner | September 2023

APGA Q&A Y CM MY CY CMY K

Chris Corlyon is battling with a rare condition.

“I don’t mind being Exhibit A if it means someone doesn’t end up with a lifetime medical condition like I have now.”

Gas and energy policy

By Jordan McCollum, National Policy Manager, APGA

Victoria’s new gas connection ban – politics is winning against physics and prices at the cost of future energy consumers. But why would the Victorian Government pursue the misleading narrative of electrification being cheaper for households than renewable gas?

Energy markets are typically governed by the three Ps – physics, prices, and politics. Physics can’t be broken; prices drive customer choice within the boundaries of physics; and politics help or hinder efficient market outcomes.

In the case of the Victorian ban on new gas connections, the politics of climate urgency have forced an unnecessary and backward step in spite of physics and prices – and it will be Victorian households that pay a much higher price for energy. But how does this happen, and why?

After three studies concluded households need to be urgently electrified and new gas connections banned, it may seem that the political choice to ban new household gas connections was based on physics and prices. However, a closer look shows that it could be the other way around.

The first signs of political motivations were in the Victorian Gas Substitution Roadmap (VGSR). Despite modelling predicting 35 to 70 per cent of future gas use decarbonisation being best achieved through renewable gas uptake, the Victorian Government continued to push for household electrification.

Ironically, this seemingly popular move is anything but. By all indications, through multiple surveys, the majority of Victorians are against the move, and Labor voters feel the most aggrieved.

In fact, two in three Victorian Labor voters are in favour of using renewable gases in the home.

Nonetheless subsequent VGSR fact sheets showed the pro-electrification case was based on heroically low electric appliance cost estimates, inclusive of electric appliance rebates. The Victorian Government’s $14,500 electric appliance replacement cost assumption would come as a surprise to anyone who has undertaken home renovations in 2023.

The Victorian Government stands by this number despite acknowledging the 2022 Frontier Economics study Cost of switching from gas to electric appliances in the home. This study found real world electrification costs for existing households of between $14,000 and $42,000. Considering VGSR quoted bill savings of $1,110 per annum, it would only take electrification costs of $22,500 before electrified households would be paying more in combined energy and appliance costs.

The Grattan Institute’s recent Getting Off Gas

study called for a ban on new residential gas connections. This report chose to continue using artificially low appliance cost figures in its study despite referencing the abovementioned Frontier Economics study for other purposes.

The Grattan Institute justified its gas ban on analysis showing electrified household gas demand having a net present value of -$169 to $13,908 compared to renewable gas uptake. It is likely that they would have come to the opposite conclusion had Grattan considered Frontier Economics’ realworld appliance cost data with its median electrification cost of $28,000.

Alongside artificially low appliance costs, unachievably high emissions reduction targets can also skew decarbonisation pathway choices. This is seen in the work of the Independent Expert Panel for the Victorian 2035 emissions reduction target which recommended Victoria significantly step up the ambition, urgency and scope of actions to electrify homes and buildings and to electrify or deploy alternatives in other sectors.

This may only be necessary due to the Panel’s recommendation of an 80 per cent emissions reduction target by 2035 – a move they acknowledge as being among the most ambitious in the world and puts Victoria ahead in the global race to net zero emissions.

It is clear that, in setting one of the highest emissions reduction targets in the world, the Victorian community will have to bear the cost of faster emissions reduction in contrast to their global equals. But who could the Victorian Government convince to do more – and pay more – than necessary for the energy transition?

In the VGSR, the Victorian Government identifies public education as one of its actions. In this action, the government states that it will target households in winter noting that they can free up significant gas demand at peak time by educating them that using reverse cycle air conditioning to heat

homes will help them save on household energy bills.

If its analysis does not stack up, why would the Victorian Government want to convince its citizens through an education program to spend their hard-earned cash – in the midst of a cost-ofliving crisis – on a more costly gas use decarbonisation pathway?

Victorian businesses and industries take emissions reduction advice from energy experts. They have the ability to undertake their own analysis. The Victorian Government knows the broader business community will not pay more to decarbonise quicker than their peers if it is irrational to do so.

The only sector left to bear the economic burden – the cost – of the state’s world-leading emissions reduction targets is the residential sector.

Could it be that Victorian households will have to bear the cost burden of the government’s high decarbonisation targets rather than the state’s taxpaying businesses and industries?

If so, this would allow business and industrial gas customers to delay taking action on emissions reduction options that cost less per emissions reduced than household electrification.

There is a better way. All gas users – be they household, business or industrial – can access lower cost gas use decarbonisation if governments enable a domestic renewable gas industry.

The gas industry knows this because the physics of a gas-based energy system can deliver firm, reliable renewable energy at lower prices compared to a firm and reliable electricity-based renewable energy system – and no level of political imposition can change that.

The other states get this reality. Every other Australian state that has commented on the Victorian ban have dismissed such a move because physics and prices should always trump politics.

We can only hope the Victorian Government has the same realisation.

14 POLICY The Australian Pipeliner | September 2023

“It is clear that, in setting one of the highest emissions reduction targets in the world, the Victorian community will have to bear the cost of faster emissions reduction in contrast to their global equals.”

DISCOVER AMLD is an open-air fixed path Mid-lR Tunable Diode Laser Absorption Spectroscopy (TDLAS). Resolution is in the part per billion (ppb) range for both methane and ethane. Ethane detection aids in determining whether a detection is pipeline gas or naturally occurring biogas.

DISCOVER AMLD consists of a detector, GPS , anemometer and proprietary software loaded onto the vehicle's computer/tablet. The system is portable between vehicles, and robust, utilising the latest in wireless technology.

SPECIFICATIONS

..................................

• Gases Detected -Simultaneous detection of methane and ethane

• Sensor Technology - Open-air fixed path Mid-lR TDLAS

• Sensitivity & Resolution - Methane: < 100 PPB at 10 Hz, < 30 PPB at 1 Hz, Ethane: < 15 PPB at 10 Hz, < 5 PPB at 1 Hz

• Selectivity -No cross-sensitivity to humidity, other hydrocarbons or industrial gases

• Response Time - Sample frequency of 100 Hz, data update rate of 10 Hz

• Accuracy -±10% of reading for methane/ethane in natural gas

• Calibration - Field calibration using self-test with a natural gas calibration cellGPS - GNSS-INS system at 10 Hz, < 1 m accuracy, inertial navigation

• Battery & Display - All sensors powered with rechargeable batteries (8-10 hr life), Rugged Windows 10 vehicle mounted tablet with HD display

• Data & Connections -Robust Bluetooth 5 (BLE), Full suite cloud based Leak Survey Analytics (LSA)

• User Interface & Reports - Simple intuitive and graphics rich touch screen operation: Real-time leak detection, Post-processed leak detection and leak localization, Leak survey coverage area, Emission quantification, Operation While Driving, Hands off voice alerts, instructions and commands

The Emerging Fuels Symposium 2023 – the future of pipelines in Australia, US and Europe

Australia’s pipeline engineering experts met their counterparts from the US and Europe in Florida to share the technical knowledge that is unlocking the future of pipelines as new fuels move to large scale deployment.

The US and Europe already have biomethane networks and hydrogen infrastructure that in Australia are still only at the development stage, but much of our technology innovation is matching or leading the world. I must acknowledge the hard work and technical leadership of all the Australian’s who made the trip, including three of Future Fuels CRC’s PhD students. The range of research was impressive, with so much compelling work coming from Australia:

Amrita Kambo, University of Queensland highlighted the role of safety as the most important factor the public considers, based on their latest research.

Jeremy Harris and I shared the enormous potential for future energy pipelines, using Future Fuels CRC’s own focused technoeconomic research work as well as Net Zero Australia’s economic modelling as a demonstration. As soon as any form of production at scale occurs or long duration energy storage is required, then pipelines become very advantageous, with long pipelines allowing significant linepack with minimal pressure cycling.

Craig Clarke, GHD and Bradley Davis, University of Wollongong outlined the progress of the Parmelia Gas Pipeline hydrogen conversion, with the testing to date showing that the existing pipeline steel could deliver satisfactory performance to provide a safe operating envelope with 10-year maximum inline re-inspection intervals.

Josh Wickham, GPA detailed Australia’s world-leading work on our Hydrogen Pipeline Code of Practice. This document is the first step in a journey to incorporate hydrogen ultimately into the existing AS2885 series standard, and brings together a comprehensive list of issues, knowledge and existing gaps into one reference material. It was widely discussed that all regions in the world are rapidly moving to codifying hydrogen, but this work puts Australia ahead of others at this stage.

Nolene Byrne and Sebastian Espinosa of Deakin University presented on the response of polyethylene and other polymer pipelines to hydrogen, including the effect on elastomer seals’ performance. Also from Deakin, Bob Varela covered how varying the CP current in response to rain can increase the local pH and prevent corrosion, creating new opportunities to better protect steel in-ground pipelines.

From the University of Adelaide, Douglas Proud highlighted the existing limit of noncombustible gases in natural gas and its future relevance for biomethane. And Peter Ashman presented on their wide-ranging research into the limits of hydrogen blends in existing gas appliances.

My highlights from the international presentations

Bill Caram from the US Pipeline Safety Trust delivered the opening presentation, imploring the industry to consider a safe energy transition and insuring we do not regress on pipeline safety. He highlighted that industry must be prepared to share and engage even more with the public. Bill also noted that the US’s massive IRA energy incentives appear to be ahead of regulation and the industry must take this opportunity to act strongly on safety in every step it takes.

An array of interesting and positive results from several testing locations working on small scale laboratory testing of tensile samples of steels in hydrogen atmospheres. This included work from Sandia in the US, Australia, Gasunie and several other locations in Europe.

Anders Johnson’s review of underground gas storage emphasised the potential for hydrogen storage which allows low-cost, large-scale storage, reinforcing the need to quantify the business cases that are competitive for underground storage and prioritise and action the research needs ahead of further commercialisation.

While in the USA for the Symposium, the

team and I got to catch up with some of the key contacts in future fuels. We saw the fast growth of biomethane in California’s gas networks, the potential conversion of LA’s Scattergood 830MW gas power station to hydrogen, large operational hydrogen powered bus fleets and liquid hydrogen already being rolled out to refuelling stations across Los Angeles. It gives us all a view of what’s possible in Australia.

Many thanks to all the Australian team and to our hosts the US’s Pipeline Research Council International (PRCI), Australian Pipeline & Gas Association (APGA), the European Gas Research Group (GERG) and the European Pipeline Research Group (EPRG). These interactions are vital. By sharing technical knowledge across the globe we can create a safer, faster and more reliable future for the pipeline industry.

DAVID NORMAN CEO, FUTURE FUELS CRC

16 The Australian Pipeliner | September 2023

FUTURE FUELS CRC

Significant New Zealand pipeline contracts awarded

While the past 12 months have seen difficult challenges for the pipeline industry in New Zealand, various companies have received significant pipeline infrastructure contracts.

Australian engineering services company Verbrec was awarded the contract for the Wharf Line Replacement at Mount Maunganui in Tauranga, New Zealand.

Similarly in June 2023, the company was also awarded the Broadlands Biogas Upgrade design for First Renewables Limited (FRL), as part of the Firstgas Group.

Leading global supplier of pipeline intervention solution, STATS Group, allowed for the safe replacement of an ESD valve onshore at the Production Station in New Zealand.

In water pipelines, Wellington Water and Watercare reached significant milestones on projects such as the Kaitoke Pipe Bridge and Dunkirk Road wastewater upgrade.

Verbrec secures significant NZ projects

Numerous projects will be completed by Verbrec’s Engineering Services division in New Zealand, which provides innovative engineering and project delivery solutions to clients through its technical specialties, including digital industry, power, process plant, pipelines, and asset management.

The Wharf Line Replacement scope of work includes multi-discipline engineering design, pipe stress analysis, pipe support and foundation design, SMS validation workshops and third-party consultations.

For the Broadlands Biogas Upgrade, the

team will carry out the detailed design engineering contract for the balance of the plant.

This also includes linking the biogas upgrading unit and RTO with Firstgas metering to enable it to be safely injected into the gas transmission system.

The company will also complete engineering design to upgrade three Firstgas transmission facilities to be able facilitate biomethane injection.

“We are delighted to be able to work together with Firstgas in their support of their development of New Zealand’s first large-scale biogas upgrading facility at Ecogas’ Organics Processing Facility in Reporoa,” Verbrec NZ General Manager Peter May said.

Both contracts are an important step for Verbrec in the company’s strategy to diversify its New Zealand client base.

Tecno Plug finds success in New Zealand

STATS Group provided double block and bleed isolation of a 12-inch gas pipeline while at an operating pressure of 72 barG.

To undertake this operation safely and efficiently, STATS Group proposed the use of a remotely operated Tecno Plug.

A STATS Group isolation technician visited the production station prior to the activities and carried out a site survey to gather critical information, completed a noise survey and aided with the selection of the tool configuration.

The Tecno Plug was configured in a fourmodule arrangement with a full factory acceptance test (FAT) performed in a purposebuilt test-fixture.

On location, the Tecno Plug was hydraulically set to activate the locks and dual seals.

The dual seals of the Tecno Plug were then independently tested with full pipeline pressure in the correct direction to confirm leak-tight isolation, which allowed the pipeline to be bled down to ambient from the platform launcher to the rear of the Tecno Plug.

With the isolation in place and double block and bleed isolation verified, the valve replacement workscope was safely conducted.

Kaitoke Pipe Bridge

In early 2023, Wellington Water completed works on the southern bridge foundation of its Kaitoke Pipe Bridge upgrade.

Works began on a bridge replacement to ensure the supply of safe drinking water continued for the Wellington region.

Greater Wellington councillor Ros Connelly said she was pleased to see work get underway on an important project for the security of the water network.

“This impressive bridge will support a vital pipeline that supplies almost 50 per cent of the Wellington region’s raw water,” she said.

“The current pipe bridge is ageing and in need of replacement. I’m delighted the new bridge will not only secure our water supply but be a place where we can come to admire a magnificent landscape.”

Dunkirk Wastewater upgrade

Stage one of the Dunkirk Road wastewater upgrade progressed well with four storage tanks underground and the gravity main over halfway complete.

The $52 million joint project between Watercare and Kāinga Ora is set to reduce wastewater overflows and cater for population growth in the Panmure area in New Zealand.

The gravity main, which travels between the wastewater pump station and Johnson Reserve, has had significant progress.

Four storage tanks have also been installed, which was a significant milestone for stage one of the project.

“Each of the 24-metre-long storage tanks weighed 5.3 tonnes each and had to be individually lifted in and placed six metres down into the underground structure to perfectly align with the manholes and inlet pipes managing flows received via the gravity main,” Project Manager Jason Salmon said.

“For me, this was the most significant achievement in the project as we safely installed the storage tanks in two days rather than the four, we anticipated, enabling us to maintain good momentum on the project.”

With these significant milestones now reached, Watercare estimates that stage one of the project is on track to meet its completion in October next year.

18 The Australian Pipeliner | September 2023

REGION REVIEW – NEW ZEALAND

Australian engineering services company Verbrec was awarded significant contracts in New Zealand.

GAS

COMPRESSION & PIPELINE FACILITIES SOLUTIONS

MULTIDISCIPLINE TURNKEY PROJECT SOLUTIONS

GAS COMPRESSION

GAS PROCESSING

PIPELINE FACILITIES

METERING AND OFFTAKE FACILITIES

SKID AND WORKSHOP FABRICATION

info@alltypeengineering.com.au

www.alltypeengineering.com.au

Emerging leaders showcase Australian talent at global hydrogen conference

By Caitlin Grant, Graduate

Energy Consultant, Advisian

Some 11,000 global leaders from the energy industry, across government, research, and private sectors,

new technologies through decarbonisation, electrification, and circularisation. Hydrogen is considered a key player in the energy transition with multiple projects in Australia approaching final investment decision (FID).

A developing concern discussed at the summit was the skills shortage throughout the entire hydrogen supply chain. This has led to the key concern of how to effectively assemble the teams required to bring ambitious projects to life.

We need to have the expertise on hand now at all levels, with a deliberate focus on equity and inclusion from the start. Engineers, researchers, business developers and policymakers are required to deliver successful projects and bring down costs of electrolysers, storage systems and hydrogen-fed engines and processes.

FEmaleena and Caitlin. These women received scholarships from the Australian Gas Industry Trust (AGIT) to attend the summit, with support from their companies, who regard each of them as rising stars in a rapidly changing industry.

Carina Nixon Project Engineer, GPA Engineering

Carina Nixon joined GPA in 2019 as an undergraduate and has proven herself to be an outstanding engineer in her contribution to GPA projects including the Bulwer Island ENEOS Direct MCH® Demonstration Plant. Nixon’s excellence both in the engineering field and as an ambassador for women in the engineering industry made her a standout applicant to receive the scholarship.

Parul Tangri Operations Manager, Ausnet Services

Joining AusNet as an engineer more than four years ago, Parul Tangri has been actively involved in feasibility studies, collaborating with industry peers and exploring new technologies to support the energy transition.

At the summit, Tangri networked with global industry experts, gained invaluable insights into emerging technologies and business models, and developed new partnerships that will ultimately drive innovation and growth for AusNet to stay

Emaleena Baker Strategic Advisor, AGIG

Emaleena Baker’s strategic vision and innovative thinking has guided AGIG since she joined in March 2022. Baker has helped position AGIG to pave the way for renewable hydrogen in Australia. Gaining a global perspective at the conference has both deepened Baker’s appreciation for the sector and reinforced the work she is doing in Australia as part of AGIG.

Caitlin Grant Graduate Energy Consultant, Advisian

Caitlin Grant joined Advisian in February 2022 and has experience in a variety of engineering advisory services including feasibility studies and options analysis, which has provided her with a solid foundation to tackle the challenges of decarbonising the chemicals and fuels industries. The Summit was a formative career experience where Grant extended her network and gained insights into hydrogen developments on a global scale.

Time for change

A shift in the gas industry is fast approaching with increasing social and environmental pressures. There is no silver bullet when it comes to achieving net zero. It will require leveraging a mix of existing and

We need to plan for the expertise of the future by offering hydrogen training to gas fitters, plumbers, plant operators, truck and bus drivers, and mechanics. We need to inspire the next generation from an early age, through educational programs for school children, visible role models and ongoing engagement. We need to build partnerships with diverse groups and institutions to draw from a wide pool.

Due to the synergies between the natural gas and hydrogen sectors, upskilling those already in the gas and pipeline industry will also be an important step as the industry transitions to net zero. Giving the next generation of pipeliners the rare opportunity to attend national and global conferences, which are nominally reserved for more senior leaders, enables our emerging leaders to appreciate decision making at a higher level and be empowered to rise to the challenge of changing the industry.

The Women’s Pipeline Forum was established with the purpose of promoting collaboration, contribution, and development of women in the pipeline industry – a key part of ensuring a just transition to net zero.

These topics and more will be discussed at the APGA Convention in Perth in October.

Members of the WPF are able to access discounted conference registration and are encouraged to attend the WPF event on Sunday 15 October.

For more information contact wpf@apga.org.au

20 The Australian Pipeliner | September 2023

APGA CONVENTION

Emerging leaders from the Australian gas industry at the World Hydrogen Summit 2023. From L-R Parul Tangri, Caitlin Grant, Carina Nixon and Emaleena Baker.

BOOTH NUMBER 14

The right tool for hot tapping and line stopping

ipeline hot tapping and line stopping are critical techniques to ensure the safety and reliability of pipelines.

One of the primary benefits of these techniques is the ability to minimise downtime and maintain product flow. Shutting down a pipeline for maintenance or repair can be a time-consuming and costly process, and can result in significant product losses, adverse environmental effects, and

Hot tapping and line stopping allows operators to perform necessary work while the product is still flowing, reducing the requirement to depressurise, vent and purge large

STATS’ BISEP is a temporary line plugging tool available in 3–56 inches and pressures up to

Achieved using patented and DNV-type approved technology, the BISEP provides a failsafe double block and bleed isolation deployed through a single hot tap penetration, without the need for additional hot tapped bleed or

The solution offers safety advantages over traditional line stop technologies, with the hydraulically activated dual seals providing leak-

The dual seal isolation barrier is confirmed once each seal is independently tested with full pipeline pressure in the correct direction and the pressure between the seals is vented, creating a

The zero-energy zone between the seals is monitored throughout the work scope, confirming the isolation integrity with zero leakage which increases worksite safety.

The BISEP provides a fail-safe isolation as the seals are activated and maintained by two independent mechanisms, hydraulic activation and pressure differential across the seals provided by the pipeline pressure. The differential pressure maintains self-energisation of the seals, ensuring isolation integrity independent of the hydraulic

The BISEP can be configured with an integrated bypass through the launcher, which ensures no interruption to flow, maintaining production throughout the maintenance activities.

The fact it is installed into the pipeline unset allows deployment into a flowing pipeline, resulting in no interruption to production and

APGA 2023 Annual Convention & Exhibition

12” class 600 extended reach hot tap tie-in, Queensland.

This configuration includes many of the benefits of the standard BISEP; however, the addition of an integrated bypass reduces the work area and number of fittings required, reducing project costs and timescales.

Reducing venting and flaring

Pipeline operators face challenges associated with eliminating greenhouse gas emissions during pipeline maintenance and facility upgrades.

STATS’ double block and bleed pipeline isolation technology reduces carbon emissions by minimising the length of pipeline that needs to be depressurised during repair and maintenance work. This prevents entire pipelines being depressurised, thereby avoiding the need to discharge significant quantities of greenhouse gases into the atmosphere.

With investment in carbon capture and storage and hydrogen accelerating, there is a growing focus on how existing infrastructure can be repurposed. This makes isolation and intervention technology to isolate critical energy pipelines safely and efficiently for repair, maintenance and modifications is increasingly important.

STATS Group's double block and bleed isolation technology is already proven to provide high integrity isolation in both hydrogen and high-pressure liquid CO2 pipelines.

STATS strives to drive higher levels of safety to the energy industry while supporting the transition to a low-carbon future.

For more information visit www.statsgroup.com

23 The Australian Pipeliner | September 2023

“Achieved using patented and DNV-type approved technology, the BISEP provides a fail-safe double block and bleed isolation deployed through a single hot tap penetration, without the need for additional hot tapped bleed or vent ports.”

14” Fittings manufactured for Western Australia.

BISEP® Seal Test Sequence.

HOST SPONSORS

2023 APGA Annual Convention & Exhibition

SPONSORS

14–17 October 2023

PERTH Convention & Exhibition Centre

MAJOR SPONSORS CONVENTION SPONSORS

POWER OF THE PRESENT F FORCE OF THE FUTURE

2023 APGA Annual Convention& Exhibition 14–17 October 2023 PERTH Convention & Exhibition Centre POWER OF THE PRESENT F FORCE OF THE FUTURE WWW.APGACONVENTION.COM TICKETSon SALE

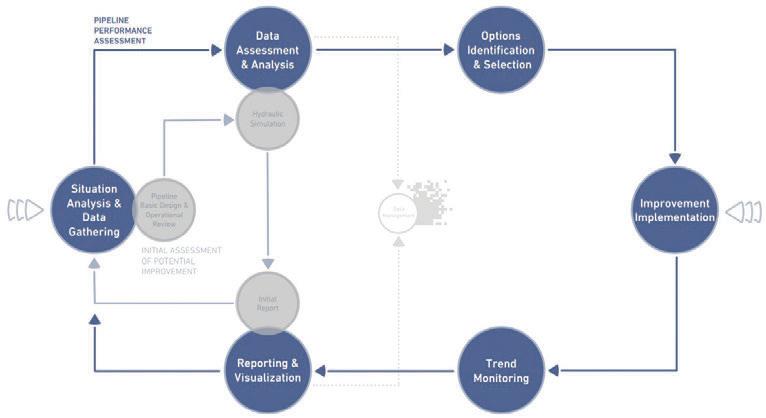

Unleashing the power of industry insights

Attending conventions has become an integral part of career development, and the APGA Convention shines with benefits for professionals seeking growth and success.

Bconvention experience and eagerly downloading all of the industry information on hand, attendees of the APGA Convention can gain unparalleled knowledge, spark inspiration, and pave the way for remarkable professional achievements.

Embracing expertise and connections

A unique opportunity to interact with industry experts and thought leaders lies at the heart of the APGA Convention.

Over the course of two days, attendees have the opportunity to engage directly with luminaries who have made significant contributions to their respective fields. These interactions enable professionals to tap into a wealth of wisdom, gather insights, and gain a fresh perspective on their industry.

By actively participating in sessions, panel discussions, and Q&A sessions, attendees can build valuable connections and forge relationships with influential individuals who can become mentors, collaborators, or even future employers.

Staying informed about the latest industry developments is vital for professional success, and the APGA Convention offers a condensed and focused learning experience that is designed to surpass traditional methods of knowledge acquisition.

concentrated dose of industry information. From joining enlightening keynote speeches to participating in specialised workshops and seminars, professionals can swiftly acquire new skills, discover best practices, and identify emerging opportunities.

This accelerated knowledge transfer helps to ensure attendees can promptly apply what they have learnt, gaining a competitive edge in their respective fields.

Igniting inspiration

The APGA Convention is a hub of inspiration and innovation. The vibrant atmosphere, brimming with passionate professionals, cultivates an environment primed for creativity.

In being surrounded by like-minded individuals sharing their experiences and success stories, attendees can be stimulated to think beyond traditional boundaries. The exchange of ideas and the exposure to diverse perspectives can also spark inspiration and ignite the imagination.

Professionals who embrace the convention experience often find themselves infused with fresh ideas that can revolutionise their work and propel their careers forward.

Amplified networking

Beyond the acquisition of industry insights, the

networking opportunity.

Being immersed in the convention allows professionals to engage in focused and intentional networking. By actively seeking out like-minded individuals, joining networking events, and participating in informal discussions, attendees can expand their professional network. And these connections hold the potential for collaborations, job prospects, mentorship opportunities and even long-term friendships.

The immersive nature of the convention environment amplifies the chances of forging meaningful connections within a short span of time.

Diving into the APGA Convention and taking in all the information available can be a gamechanger for professional growth.

The convention serves as a gateway to expert knowledge, inspiring ideas, and invaluable networking opportunities. Fully embracing the experience allows professionals to gain direct access to industry experts, stay up-to-date with the latest trends, accelerate their learning process, ignite their creativity, and expand their network exponentially.

The APGA Convention has the power to transform careers and pave the way for success. It may be the catalyst that propels you to new heights in your professional journey.

26

The Australian Pipeliner | September 2023 APGA 2023 Annual Convention & Exhibition

The annual convention and exhibition will be held at the at the Perth Convention and Exhibition Centre from 14–17 October.

Anthony Wells Project Manager phone +61 434 728 980 email anthony.wells@qube.com.au Your complete pipeline logistics partner

Unlocking career advancement –The power of the APGA Convention

In today's fast-paced world, professionals are constantly seeking opportunities to enhance their careers and stay ahead in their respective industries. While technological advancements and online networking platforms have revolutionised the way we connect, there is still something unique and invaluable about attending conventions. Among these, the APGA Convention stands out as a premier event that offers a multitude of benefits, empowering individuals to forge meaningful connections and catapult their careers to new heights.

conventions provide an immersive environment for learning and self-improvement. These enhanced skills can translate into improved job performance, increased job satisfaction, and even promotions.

Industry insights and trends

Staying up to date with industry trends is crucial for career success. The APGA Convention offers a unique opportunity to gain firsthand knowledge of emerging technologies, market shifts, and industry breakthroughs. Attendees can attend keynote speeches, panel discussions, and specialised sessions dedicated to exploring the latest developments within their field. Such exposure allows professionals to stay ahead of the curve, make informed decisions, and contribute to their organisations' growth and success.

Inspiring and motivational environment

Networking opportunities

One of the most compelling reasons to attend the APGA Convention is the unparalleled networking opportunities it presents. Interacting face-to-face with like-minded professionals, industry leaders, and potential mentors can open doors that would otherwise remain closed. The convention acts as a hub, bringing together experts from various backgrounds and allowing attendees to tap into a vast pool of knowledge and experience. Conversations over coffee breaks, panel discussions, and workshops can lead to valuable connections that may prove instrumental in future collaborations, job prospects, or even business ventures.

Learning from industry experts

The APGA Convention offers a treasure trove of knowledge through its line-up of renowned speakers and thought leaders. Attending insightful sessions and discussions led by

industry experts provides an unparalleled opportunity for professional growth. Participants can gain insights into the latest trends, innovations, and best practices relevant to their field. Moreover, the convention offers a platform for thought-provoking discussions, where attendees can challenge their assumptions, broaden their perspectives, and gain a competitive edge in their careers.

Personal development and skill enhancement

Conventions such as the APGA Convention are not just about professional networking; they are also platforms for personal growth and skill enhancement. The diverse range of discussions, seminars, and interactive sessions available allows attendees to expand their skill sets and acquire new competencies. Whether it's honing industry skills, learning new techniques, or developing effective environmental, social and governance communication strategies,

Conventions like the APGA one serve as catalysts for inspiration and motivation. The electric atmosphere, filled with like-minded individuals passionate about their respective industries, fosters a sense of camaraderie and shared purpose. Engaging with successful professionals who have overcome challenges and achieved great heights can ignite the spark within attendees, encouraging them to push their boundaries and reach for new goals. The positive energy and contagious enthusiasm at the convention can leave a lasting impact, re-energising professionals to approach their careers with renewed vigour.

The Convention stands as a beacon of opportunity, offering a wealth of benefits to professionals seeking to elevate their careers. From networking with industry leaders to acquiring new skills and staying abreast of industry trends, attending conventions is a powerful tool for career advancement. By embracing the transformative power of conventions like the APGA Convention, professionals can unlock new avenues, broaden their horizons, and pave the way for a brighter future. So pack your business cards, and get ready to embark on a journey that could transform your career trajectory forever.

28 The Australian Pipeliner | September 2023

APGA 2023 Annual Convention & Exhibition

The APGA Convention stands as a beacon of opportunity, offering a wealth of benefits to professionals seeking to elevate their careers.

PE ISOLATION has changed for the better.

Part of the comprehensive gas distribution systems offering from TDW, the revolutionary POLYSTOPP® Quick Connect system makes it easy to safely perform tapping, plugging and branching on polyethylene (PE) pipelines — faster than other methods of isolating and using significantly less excavation space.

One person lift. | For 4-inch through 8-inch pipelines. Pressure rated to 10 bar (150 psi). | Covers multiple standard dimension ratios. 2-inch bypass capable. | Plugging or branching fittings available.

SAFE. QUICK. RELIABLE.

How much faster is it? Watch the speed comparison video:

©2023 T.D. Williamson

Exhibitor list

30 The Australian Pipeliner | September 2023

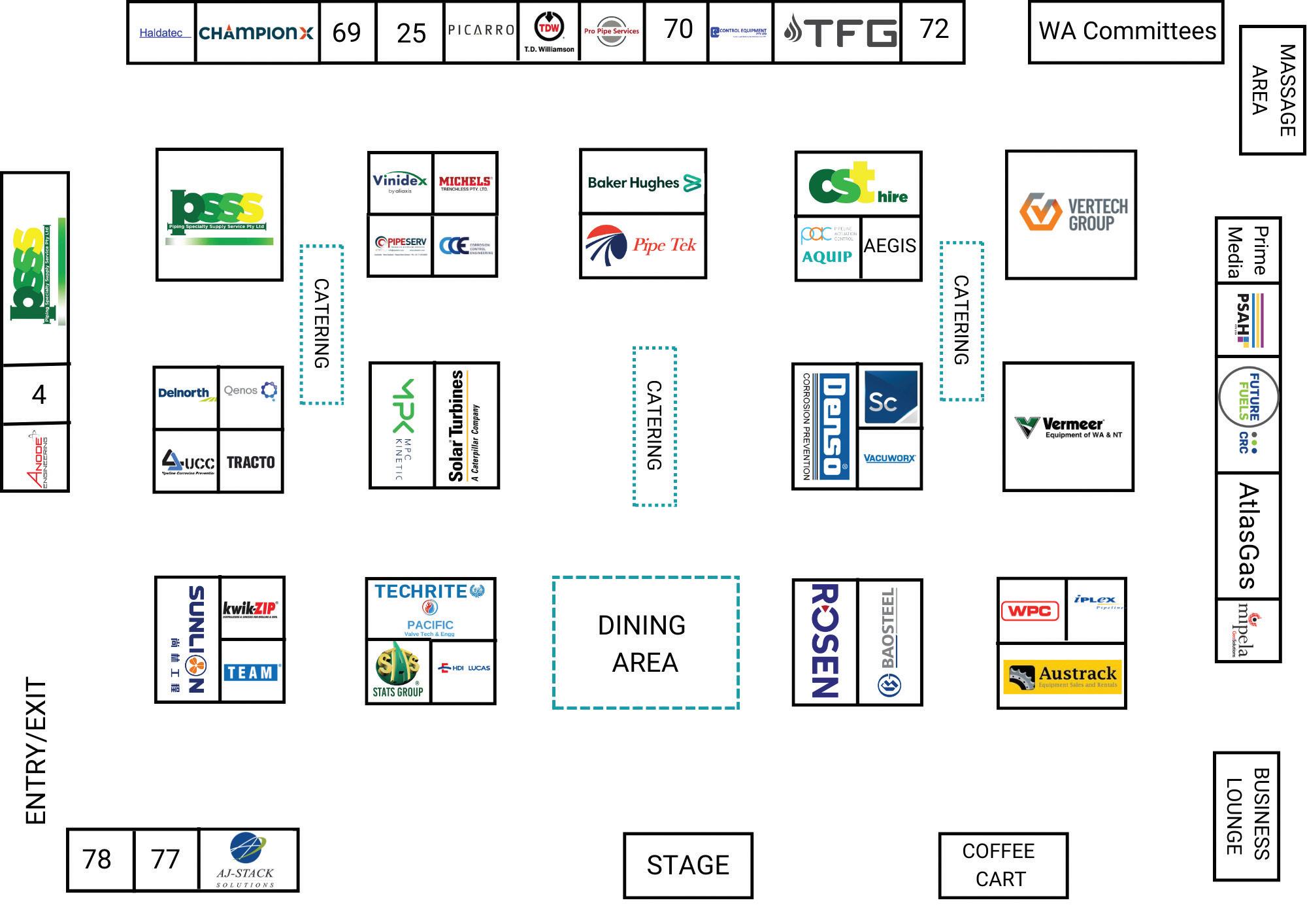

Stand Exhibitor 33 Aegis 75 & 76 AJ Stack Solutions 5 Anode Engineering 51 & 52 AtlasGas Pty Ltd 60 & 61 Austrack Equipment Sales and Rentals 54 & 55 Baker Hughes 39 & 41 Bao Australia Pty Ltd 7 & 8 ChampionX 29 Control Equipment Pty Ltd 21 Corrosion Control Engineering 31 & 32 DEATON ENTERPRISES PTY LTD trading as CSThire 10 Delnorth 36 & 38 Denso (Australia) Pty Ltd 78 FlexSteel 49 & 50 Future Fuels CRC 6 Haldatec Pty Ltd 13 Hdi Lucas 58 Iplex Australia 62 kwik-ZIP Spacers 23 Michels Trenchless Pty Ltd 53 Mipela GeoSolutions 18 & 20 MPC Kinetic 34 PAC & Aquip Systems 16 Pacific Valve Tech and Engineering Pty Ltd Stand Exhibitor 26 Picarro 56 & 57 Pipe Tek 22 PipeServ 1,2,3 & Equipment Piping Specialty Supply Service 47 Prime Creative Media 28 Pro Pipe Services 48 PSAH Pty Ltd 9 Qenos 40 & 42 ROSEN Australia Pty. Ltd 35 Scape Consulting 17 & 19 Solar Turbines 14 STATS Group 63 & 65 SUNLION METALS ENGINEERING 27 T.D. Williamson 64 TEAM 15 Techrite Controls Australia Pty Ltd 30 & 71 TFG Group 11 TRACTO AUSTRALIA 12 Universal Corrosion Coatings 37 Vacuworx 44, 45, 46, 47 Vermeer 73 Vertech Group Pty Ltd 24 Vinidex 59 Western Process Controls APGA 2023 Annual Convention & Exhibition

R YOUR PIPELINE PARTNER OF CHOICE Solving Australia’s Water Challenges Over 80 years’ experience Supply and service excellence Infrastructure project expertise CONTACT US IPLEX.COM.AU IPLEX PIPELINES CIVIL 13 10 86

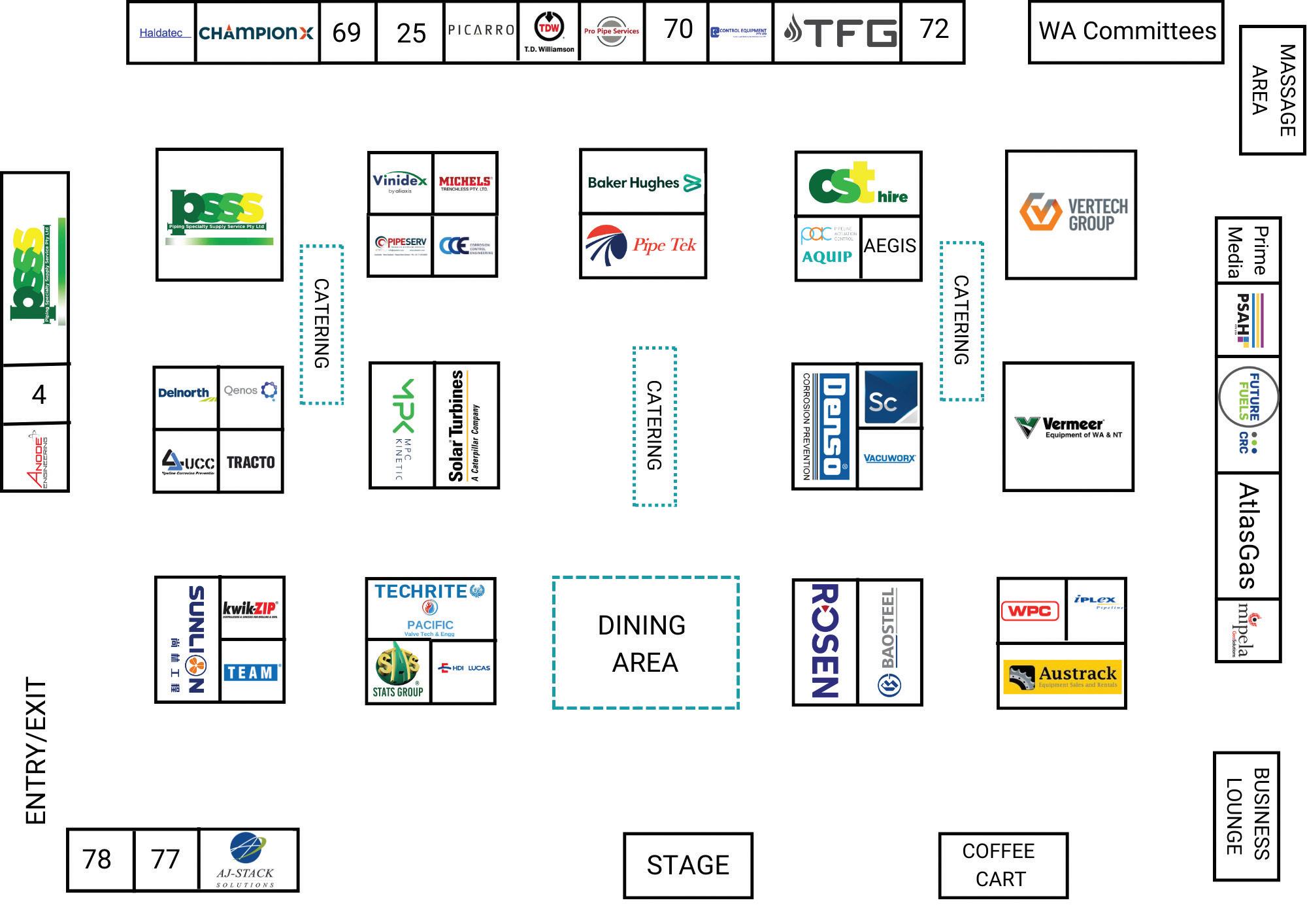

32 The Australian Pipeliner | September 2023

2023

FLOORPLAN

APGA

Annual Convention & Exhibition

33 The Australian Pipeliner | September 2023

2023 APGA Annual Convention program

Day 1: Saturday 14 October 2023

07:00 – 13:00

17:30 – 18:30

19:00 – 22:00

Vermeer Golf Classic

Golf Classic 18-hole competition, Maylands Public Golf Course

WA Young Pipeliners Forum Social Function

Bells Functions

Welcome Reception

Art Gallery of Western Australia (AGWA), Perth Cultural Centre

Day 2: Sunday 15 October 2023

10:30 – 14:30

15:00 – 17:00

18:00 – 19:30

19:30 – 23:00

23:00 – 00:00

Sunday Get Together

Bathers Beach House, Freemantle

Women in Pipelines Function

Perth Convention and Exhibition Centre

Exhibition Opening

Perth Convention and Exhibition Centre

Opening Dinner

Perth Convention and Exhibition Centre

Happy Hour

Metro Bar & Bistro, Adina Hotel

34 The Australian Pipeliner | September 2023 APGA 2023 Annual Convention

& Exhibition

VISIT US AT ... Safe, Reliable Pipeline Solutions • Hot Tapping • Line Isolation & Bypass • Pipe Cutting • Commissioning • Decommissioning • Equipment Maintenance • Training Maintenance & repairs: • Natural Gas • Steam • Water • Chemical • Hydrocarbons An Australian Owned Company, Australian Based Technicians E: info@propipeservices.com P: (03) 9330 4016 A: 49 Lambeck Drive, Tullamarine, Vic 3043 W: www.propipeservices.com

Day 3: Monday 16 October 2023

08:00

08:30

08:50

09:10

09:55

10:25

11:00

11:45

12:15

14:00

14:25

14:45

15:05

15:25

15:50

16:15

16:35

16:55

17:20

19:00 – 23:00

Arrival & Registration

Perth Convention and Exhibition Centre

Convention Opening Day 1

Donna McDowall, President, Australian Pipelines and Gas Association

Welcome to Country

Opening Address

Milton Catelin, Secretary General, IGU

State of the Industry

A discussion between Donna McDowall, President, APGA and Steve Davies, Chief Executive Officer, APGA

APGA Awards Presentation

Recognition and presentation of the prestigious 2023 APGA awards

Morning Tea – Exhibition Hall

Leaders Panel

A leaders panel, comprising industry CEOs, will engage in discussion on industry topics and provide insight into the future of pipelines and gas

Keynote Speaker: Michelle Cowan

Michelle Cowan, a trailblazer in breaking down barriers for women in business and sport, is an engaging and empowering speaker, known for her energetic and inspirational approach to empowering women to achieve their goals

Lunch – Exhibition Hall

Keynote Speaker: David Norman Chief Executive Officer, Future Fuels CRC

Harnessing Decades of International Pipeline Research Collaboration to Support the Development of our Future Energy Grid

Klaas van Alphen, APA

Learning Lessons from the North West Shelf and other Gas Projects to Support the Delivery of Excellence for Australian Hydrogen Projects

Thomas Jackson, GPA Engineering

Hydrogen Pipeline: Technical Challenges

Robin Gordon, Microalloying

Afternoon Tea – Exhibition Hall

Surviving the Storm – Gas Pipeline Emergency Management in NZ

Ryan Phipps, First Gas

ILI Validations – What are they good for? An Operators Perspective

Gary Brown, Exxon Mobil

Balancing Compliance with Practicality in Emergency Response

Daisy So, APA Group

Drone ROW Survey (TBC)

Andrew Bambridge, Tas Gas

Convention Close Day 1

Recap of the day’s activities and highlights of the evening’s social events

Fancy Dress Dinner

Optus Stadium, Perth

36 The Australian Pipeliner | September 2023 APGA 2023 Annual

&

Convention

Exhibition

Pollard’s Sawdust Supplies has been a trusted national supplier of graded and bagged sawdust and wood shavings products for over 50 years. The pipeline construction industry has been entrusting our business to provide support for their pipe assets for many decades.

Pollard’s PACK TUFF bags are:

• The perfect pipeline bedding solution

• Lightweight – up to 80% lighter than equivalent sandbags

• Eco-friendly from sustainable sources

• Chemical free

• 3 sizes to suit all pipe diameters

• Won’t explode or balloon under pressure

DELIVER AUSTRALIA WIDE

Day 4: Tuesday 17 October 2023

08:00

08:50

09:00

09:45

10:05

10:25

10:45

11:05

Arrival & Registration

Perth Convention and Exhibition Centre

Convention Opening Day 2

Welcome and Acknowledgement

Young Pipeliners Panel Discussion

Hosted by Carina Nixon with Jeanette Rose (AGIG), Matt Nash (PAC), Sam Galofaro (Veris), Mikayla Rousham (APA), Dan Schneke (ROSEN)

Gender diversity in pipelines

Carol Bond, RMIT

People of the Present, Looking after our Future

Elizabeth Wheeler, APA

Organisational Accident Prevention, School of Property, Construction and Project Management

Prof Jan Hayes, Modester Chawirah, Enscope

Putting Stakeholders at the Heart of Transformation – so no-one is left behind. The Human Side of Energy Transition

Louise Pogmore, KPMG

Morning Tea – Exhibition Hall

Post Morning Tea sessions will be split across the Main Auditorium and the Breakout room. Please note the location of the presentation you wish to attend.

Main Auditorium

11:35

Green Gas: The Economic Regulation Challenge – How can we change regulatory culture to remove barriers to a green gas pathway

James Turnley, JT Economics

Meeting Rooms 1&2

New Approach to HDPE Pipe Fusion

Sergio Arellano, McElroy Australia

11:55

CO2 Transmission Pipelines for Carbon Capture, Utilisation and Storage; Recommendations of Overcoming the Challenges

Marzieh Amanababi, GPA Engineering

The role of green HDD for pipeline construction

Andrea Fluck, Herrenknecht

12:15

12:35

12:55

The Role of Biomethane in Australia’s Net Zero Emissions Future

Jarrod Irving, AGIG

Requalifying existing gas pipelines for hydrogen service

Jason Amiri, Nacap

An Approach to Weld Design on Hydrogen Service.

Luke Ludwig, CRC Evans

The effect of accurate HDD pilot drilling on pulling forces, pipe stress and hydrogen safety

Hans Blok, Brownline Australia Pty Ltd

Australian Hydrogen Centre Statewide Feasibility Studies, Owen Sharpe, AGIG

Kewdale White Oil Pipeline

John Stuart Robertson, Spiecapag

38 The Australian Pipeliner | September 2023 2023

SUCCESS IN WATER TRANSPORTATION STARTS WITH THE RIGHT PIPELINE

Achieving excellence in the water industry is your number one priority. Helping you get there is ours. Steel Mains’ manufactures high quality steel pipelines but what makes us a leader is the partnerships we develop with our customers. By understanding your business needs, we are able to provide agile solutions and service. Which means you can focus all your energy on achieving success, while we deliver it.

Through our cutting edge corrosion systems, our Sintakote Steel Pipeline System® has an enviable 150 years’ service life. Choose Steel Mains, the leader in pipeline manufacturing for your next pipeline project.

www.steelmains.com

13:15

14:15

14:35

14:55

15:15

15:30

16:15

16:35

16:55

17:15

19:00-23:00

23:00-00:00

Lunch – Exhibition Hall

Ensuring Safe Isolation of Plants and Equipment in Piping Industry: All Isolation Methods and Related Technologies.

Charly Ribeiro, ONIS Line Blind

By Data, Be Driven: Improving Decision Making in the Safety Management Process.

Simon Braun, Rosen Group

Researching the Aggressive Internal Corrosion of CO2 Pipelines. Tom Seeber, Atteris.

Afternoon Tea – Exhibition Hall

Policy and Advocacy Panel

Jordan McCollum (APGA – Chair), Paul Purcell (APGA), Ian Israelsohn (Jemena), Liz McNamara (APA), Cathryn McArthur (AGIG)

Environmental Excellence at Ironbridge, Daniel Bromley, Consultant

Western Outer Ring Main

TBA, Spiecapag

Challenges and Solution of Northern Goldfield Interconnect Pipeline

Daniel Wallace, APA Group and Mark McLeod, Nacap

Convention Close Day 2

Recap of the day’s activities and highlights of the evenings social events

APGA Annual Gala Dinner

Perth Convention and Exhibition Centre

Happy Hour

Metro Bar & Bistro, Adina Hotel

Please be aware that errors may occur as changes can happen after the program has gone to print.

40 The Australian Pipeliner | September 2023 APGA 2023 Annual

Convention & Exhibition

• First to move the vacuum reservoir from the excavator stick to the counterweight

• First to use the excavator hydraulics to power the vacuum pump

• First to remove radio remote control

• First to introduce dedicated excavator operator controls

• First to introduce 360˚ rotation

• First to develop an in-trench pipe assembly apparatus

• First to develop an hydraulically assisted multiple o ring jointed pipe assembly tool

• First to develop a remote controlled in pipe inspection tool

• First to develop a VacLift that will only release a pipe when the pipe is on a solid surface

• First to increase the range of diameters able to be handled by each pipe shoe

• First to develop a fully adjustable attachment pickup.

We know the industry better than anyone, talk to us about all your pipeline plant hire needs first.

ONE CALL - PROBLEM SOLVED 1300 367 046 PIPELINEPLANTHIRE.COM.AU

BOOTH NUMBER 1,2,3 & Equipment

Star in the shutdown containers constellation

Piping Specialty Supply Service (PSSS) is aptly named, as evidenced by the company’s extensive range of shutdown containers.

PSSS is known for its ability to supply customer-focused and flexible solutions. These shutdown containers are the perfect example packed with… well… everything and more.

For example, the containers can house any tool for flange management and bolting, such as torque wrenches, tensioners, flange facers, spreaders, aligners, and nut splitters.

But that’s not all. The containers can also contain pipe-cutting and bevelling machinery such as clamshells, oxy/ascet machines and end prep such as line up and reforming clamps for welding.

Hiring PSSS’ shutdown containers also enables industry professionals to have their hot tapping machines, hot bolting clamps, repair clamps, weld neck testers, and line up and reforming clamps at their fingertips.

They offer deep and secure shelving options and a work bench with vice, as well as wallmounted documentation storage. All equipment comes certified and calibrated with document packs ready for QA.

Wcontainer? According to PSSS, it’s all about versatility and selection.

PSSS is truly every specialist’s one-stop-shop for their next shutdown, with years of experience

to the oil and gas, energy and chemical sectors. The company has propelled itself as an industry leader and knows what is needed to get the job done.

PSSS can further add value to the project with a complete range of poisoned pipeline execution (PPE), blast and coating machinery, tooling and consumables.

PSSS’ containers really are like a portable workshop, with optional lighting allowing users to work and store at the same time and place. For more information visit psssa.com.au

42 The Australian Pipeliner | September 2023

APGA 2023 Annual

PSSS’ shutdown containers are versatile and can house all kinds of equipment.

Convention & Exhibition

The containers can house any tool in the flange management and bolting sector.

The containers can also contain pipecutting and bevelling machinery.

Construction with Integrity EST 2016 Focusing on end to end steel and HDPE construction. Our goal is to stay nimble and complete works where a more focused or unique approach is required. TALK TO JOEL ROGERS & KIRSTY SWIFT AT THE APGA CONVENTION 0400 620 790 Email: joelrogers@rogersenergyservices.com.au Web: www.rogersenergyservices.com.au COMPLETE PIPELINE CONSTRUCTION

BOOTH NUMBER 62

kwik-ZIP puts mark on WORM

Texisting pipelines at Plumpton in Melbourne’s west and Wollert in the north.

Several different kwik-ZIP spacers - HDX38’s, HDX-125 and HDXT-63’s - were utilised on different cased crossings along the pipeline route.

The pipeline will address a key capacity constraint in the Victorian Transmission System (VTS) by providing a new high-pressure connection between existing sources of natural gas supply in Victoria.

Addressing this missing link will deliver improved network reliability by increasing the amount of gas that can be stored for times of peak demand.

It will also ensure sufficient volumes of gas can be moved where it is needed most.

Importantly, without the project being delivered, the Australian Energy Market Operator (AEMO) has forecast that parts of Victoria may soon face natural gas supply shortages by 2023.

The

will be

44

pipeline

constructed from highstrength steel line pipe with an external epoxy

APGA 2023 Annual Convention & Exhibition

protective coating would not be damaged during

Without the project being delivered, the Australian Energy Market Operator has forecast that parts of Victoria may soon face natural gas supply shortages by 2023.

The pipeline will be constructed from highstrength steel line pipe with an external epoxy coating and be buried for its entire length to a minimum depth of 900 millimetres.

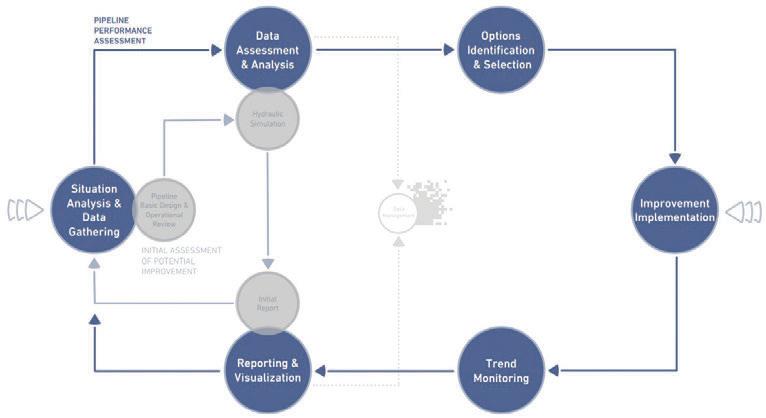

the pipe wouldn’t make contact with the enveloper during and after installation.