® AUSTRALASIA’S TRAILER INDUSTRY RESOURCE FEBRU ARY 2023 SHOWCASING THE VERY BEST AUSTRALASIAN TRAILER AND BODY TECHNOLOGY ISSN 1838-2312 9 771838231003 01 FEBRUARY 2023 $10.00 TRAILER BUILDER MOVING FLOOR NEWS IMAGE REFLECTS A BRAND IMAGE REFLECTS A BRAND Pure water in motion Pure water in motion WORLD MAP ECONOMY INDUSTRY INNOVATORS

PUBLISHER

John Murphy john.murphy@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

JOURNALISTS

William Craske william.craske@primecreative.com.au

Peter White peter.white@primecreative.com.au

Anjali Behl anjali.behl@primecreative.com.au

ADVERTISING

Con Zarocostas: 0422 222 822 conzarocostas@primecreative.com.au

Ashley Blachford: 0425 699 819 ashley.blachford@primecreative.com.au

DESIGN

Daz Woolley/Tom Anderson

ART DIRECTOR

Blake Storey

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia

SUBSCRIPTIONS

03 9690 8766 subscriptions@primecreative.com.au

Trailer Magazine is available by subscription from the publisher.

Annual rates: AUS $99.00 (inc GST). For overseas subscriptions, airmail postage should be added to the subscription rate. The right of refusal is reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Trailer Magazine is owned by Prime Creative and published by John Murphy.

All material in Trailer Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material.

While every effort has been made to ensure the accuracy of information Prime Creative will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Trailer Magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

The illustrious path

A newly established Net Zero Unit will work across government and industry to help achieve net zero emissions and improve the resilience of transport networks and supply chains.

Led by Ian Porter, it will support the cross-portfolio Net Zero Taskforce that will advise the Government on ensuring regional Australians benefit from Australia’s transformation to a renewable energy superpower.

Porter brings significant experience in climate change, energy and sustainability policy as well as working across government, public service, consulting and the not-for-profit sector –including heading up program delivery for Climateworks.

This builds on initiatives already underway across the portfolio, including creating a Jet Zero Council to promote sustainable aviation fuels in this country and consulting on fuel efficiency standards for light vehicles to support the National Electric Vehicle Strategy.

It also forms part of the Government’s commitment to reduce greenhouse gas emissions by 43 per cent below 2005 levels by 2030 and achieve net zero emissions by 2050.

The unit aims to advance the Government’s emissions commitments by connecting government agencies, industry and climate experts to translate the latest research into action, while ensuring climate expertise is embedded into policies and investments.

Minister Catherine King said to achieve Net Zero by 2050 will require concerted action to drive emissions lower across the transport sector. She noted an increase in the uptake of electric vehicles.

Climateworks reported that state and territory governments have an implied combined zero emission vehicle sales target of 46 per cent by 2030.

King also mentioned consideration towards fuel efficiency and promoting

other technologies is helping to achieve Net Zero.

However, we would also need international cooperation, though, to realise tremendous change especially when it comes to shipping. And then there’s the annual average spending on physical assets which one report estimated to be in the ballpark of nine trillion dollars to achieve the 2050 target.

So, how is Australia going on the decarbonisation front?

In terms of overall emissions reduction targets, according to Climateworks, the Federal Government’s commitment to reduce 2030 emissions to 43 per cent below 2005 levels and achieve net zero emissions by 2050, brings it in step with 2021’s states and territories’ targets (with an implied 37–42 per cent reduction below 2005 emissions by 2030, and all committed to net zero).

Outside of transport, other key areas such as land emissions also need attention which would come in the form of incentives and plans for a

From the Editor’s desk

Officially endorsed by the VTA www.trailermag.com.au

4 Trailer Magazine FEBRUARY 23

AAA TRAILERS Jeffrey 0414 671 969 - Jeffrey@aaatrailers.com.au www.aaatrailers.com.au - 02 9188 3222 - 159 Walker St, Helensburgh, NSW 2508 Neil 0418 880 077 – sale1@aaatrailers.com.au – Perth WA TOP QUALITY AND FIT FOR PURPOSE WITH A FOCUS ON SAFETY AND RELIABILITY. DROP DECK TANKERS EXTENDABLE CURTAIN SIDE DROP DECK B DOUBLE CURTAIN SIDE STRAIGHT SIDE TIPPER WIDENER

February 2023

The latest news and industry developments.

22 Economy

Changing demographics in Australia’s workforce is a growing concern for thriving industries and workshops.

26 Trailer builder

Seventy years in business is a milestone Tieman

Tankers is unconditionally proud of, and recently delivering its 6,000th tanker to bulk spring water supplier Black Mount, is one that will remain in the history books of both companies for a long time to come.

32 Moving floor

See the latest innovation from KEITH W

34 Trailer building materials/components

These are the suppliers that keep Australia’s heavy vehicles operating safer and more productive.

58 Special report

E-commerce demands to lead innovation in supply chain in 2023.

64 World map

TSE Trailer Engineering has experienced tremendous growth in Germany.

66 Fleet of the month

Global Product Supply Management runs its own transport division, making it a rare industry presence given its line of work.

68 Industry Innovators

Russell Baxter wanted to become a mining engineer before entering the transport industry. His career, however, took a different path.

70 What’s on

Upcoming shows and field days.

6 Trailer Magazine FEBRUARY 23

26 54 30 40 44 58

RUNNING GEAR FOR ALL APPLICATIONS AND ENVIRONMENTS FUWA K-HITCH www.khitch.com.au MELBOURNE 13-21 Bliss Court Derrimut VIC 3030 p: 03 9369 0000 f: 03 9369 0100 melb@khitch.com.au PERTH 77B Kurnall Road Welshpool WA 6106 p: 08 9350 6470 f: 08 9350 6570 perth@khitch.com.au BRISBANE 41 Moreton Street Heathwood QLD 4110 p: 07 3372 2223 f: 07 3372 1022 qld@khitch.com.au FOR ALL YOUR EQUIPMENT AND OE SPARE PART REQUIREMENTS, YOU CAN TRUST KHITCH

Silk has eye on organic growth, larger footprint in FY2023

Silk Logistics reports revenue growth across all service lines in the current financial year.

Despite significant challenges of the Covid pandemic, global supply chain issues and labour shortages, Silk Logistics Holdings has achieved outperformance against all metrics in FY2022.

The company has reported revenue of $394.7 million, which is a 22 per cent growth over FY2021.

Compared to the previous financial year it has also reported underlying earnings growth of 16.2 per cent, underlying NPAT growth of 45 per cent, and underlying free cashflow improvement of 37.5 per cent.

Silk has seen revenue growth across all service lines in FY2022, maintained its margins in challenging industry and market conditions, seen expansion into e-commerce, increased its warehouse occupancy, seen rapid growth in distribution revenue, and an ongoing growth in container volumes.

It has reported new annualised business wins of $46.6 million, renewed customer contracts worth $27.6 million, and recurring contracted revenue of $186.9 million.

The company has seen some key acquisitions in the past year, and it now has 47 operational sites strategically located in all major Australian capital cities.

“We remain focused on organic growth opportunities and are building a longterm strategic pipeline to support the development of new facilities,” said Brendan Boyd, Managing Director & CEO of Silk Logistics Holdings.

“This includes the Kemps Creek site, on which Silk purpose-built warehouses will come online from FY2025, enabling the establishment of a new hub in New South Wales, and creating increased warehouse capacity at reduced operating costs.

“Over FY2023 and FY2024 we expect to add over 115,000 square metres of new capacity, allowing us to further drive organic growth. Our five-year plan features a series of time horizons over which we will continue to strengthen our core service offer, grow our share of wallet and fill gaps in our capabilities. We have new sites and capacity coming online in the near term, in New South Wales, Queensland and Western Australia, that will aid our geographic expansion where we will seek to deploy bespoke technology and automation solutions.

“In September 2022, we acquired Fremantle Freight & Storage Group, a leading Western Australian Port Logistics provider. This acquisition fulfils one of the primary growth targets flagged in our Prospectus and enables us to better service our blue-chip customer base on a national level. We have an exciting pipeline of acquisition targets and expect to continue to expand our service and

geographic coverage in the year ahead.”

The near-term focus of the company is on the further integration of 101Warehousing and Fremantle Freight and Storage, implementing new customer sites and developing technology including robotic solutions where appropriate. Its Corporate Development team is also actively seeking further acquisitions.

Silk was recently awarded the ‘Business Services Growth Company of the Year’ for 2022 by the Australian Growth Company Awards.

“This award is testimony to the success of The Silk Way and our performance in FY2022 and should give all shareholders comfort that the Board and management team of Silk Logistics Holdings are delivering,” said Boyd.

Subject to no material adverse change in current economic conditions (including in respect of Silk’s market, customers, suppliers and resources), Silk expects to grow revenue and underlying earnings in FY2023.

8 Trailer Magazine FEBRUARY 23 News

SAF-HOLLAND (Aust.) Pty. Ltd

ABN: 79004371215 | Sales: 1300 131 613 Email: sales@safholland.com.au

www.safholland.com.au SAF-HOLLAND (Aust.) Pty. Ltd Ph: (61-3) 9971 7900 Fax: (61-3) 9743 6763 SAF-HOLLAND (Aust.) QLD Ph: (61-7) 3375 7033 Fax: (61-7) 3375 7044 SAF-HOLLAND (Aust.) WA Ph: (61-8) 9353 1720 Fax: (61-8) 9353 1730 SAF-HOLLAND (Aust.) NSW Ph: (61-2) 9672 1950 Fax: (61-2) 9672 1994 Specify SAF- HOLLAND INTRADISC & INTRADRUM.

+

anchor

SAF INTRA

warranty on

absorber & pivot bushes *WHICH EVER OCCURS FIRST OFF-ROAD WARRANTY 3 YEARS / 500,000KM*

+ Frame bracket symmetry – no shocker bracing needed

SAF drum brake with quick release spherical

+ No Ubolts + More uptime + Low maintenance + Patented composite rotor + Long life disc brake technology

1 MILLION KM OR 6 YEARS* On-road

bearings, shock

www.safholland.com.au

Kimberley communities receive flood support from Centurion

Transport and logistics company, Centurion, carried vital supplies by road and barge to Fitzroy Crossing and surrounding communities in East Kimberley last month.

Major road access to the region remained impassable from recordbreaking flooding.

Damage to the Fitzroy River bridge, the only sealed road linking Broome with the rest of the Kimberley and Northern Territory, will require extensive repairs.

Three fully loaded B-doubles

Additionally, Centurion worked with the Department of Fire and Emergency Services, Coles Group and Woolworths Supermarkets over the weekend to mobilise its emergency barge service to deliver essential items to affected communities.

The standby service is activated from Dampier and used to transport trailers into Broome in the West Kimberley if the town finds itself suffering from extended isolation due to floodwaters.

Centurion loaded five fully stocked

ensuring ongoing supply of much needed groceries.

Centurion CEO, Justin Cardaci, said the company was doing everything it could to support affected communities.

“We’re in constant contact with Main Roads through relationships that were established when the rail line between WA and the eastern states was washed out last year,” said Cardaci said.

“We came together quickly to ensure vital food supplies got through, proving that industry and government can work together at times like these to ensure communities are looked after and get the supplies they need.”

It will be weeks before the region’s major highways are safe to re-open and damage to road infrastructure will take some time to repair.

Cardaci said the massive and complex logistical exercise will go on for some time.

“There is a surprising and devastating amount of water in the area, and we’re seeing the benefits of the forward planning we had in place to be able to quickly move supplies to the region,” he said.

“Whether its by road or sea, our priority is ensuring we get what’s needed to the area, and we’ll continue operating frequent alternate routes to keep the shelves stocked.”

He has extensive product and application knowledge along with a commitment to customer service excellence.

“This role will see Shane working closely with fleets and assisting with product specification to maximise productivity and safety along with the introduction of new innovative JOST products,” said JOST Australia.

“Shane will also play a key role in helping fleets with training requirements, from driver training to maintenance and

workshop training, to ensure maximum benefit for our customers fitting JOST products.”

10 Trailer Magazine FEBRUARY 23 News

Vawdrey Victoria Ph: (03) 9797 3700 Vawdrey New South Wales Ph: (02) 9421 6444 Vawdrey Queensland Ph: (07) 3273 6156 Vawdrey Western Australia Mob: 0448 901 126 Vawdrey South Australia Mob: 0447 343 579 SUCCESS THROUGH VERSATILITY vawdrey.com.au

The flexibility that Vawdrey provides with their service and trailers is second to none. They are great to deal with and always deliver on time – we stand by their products. EXODAS TRANSPORT MANAGING DIRECTOR, Brett Tynan.

ALRTA supports targeted changes to horse transport standards

ALRTA supports targeted changes to horse transport standards

The Australian Livestock and Rural Transporters’ Association (ALRTA) has submitted its response to a consultation regulation impact statement proposing changes to horse transport standards.

The proposals were recently considered by ALRTA’s National Driver and Animal Welfare Committee, and its submission is supportive of targeted changes to the horse transport standards.

This will mean new legislation and new or modified rules specified in the Australian Animal Welfare Standards and Guidelines – Land Transport of Livestock 2012 as it applies to horses.

The standards provide a basis for developing and implementing consistent legislation and enforcement across Australia, and provide guidance for all people responsible for livestock during transport.

ALRTA supports new standards requiring:

• a written record of last access to water;

• a transporter to manage welfare risks and take corrective actions due to heat stress;

• horses with poor body conditions score (0 or one) not to be transported without vet advice;

• foals with unhealed umbilical stumps not to be transported except to foster mares;

• transporters to ensure horses have sufficient space to maintain a comfortable

standing position and balance (instead of adhering to loading density tables);

• a prohibition on transporting horses in multi-deck trailers (except where only the lower deck is used and there is sufficient vertical clearance);

• a prohibition on transporting mixed loads of handled and unhandled horses; and

• removal of hind shoes where horses are travelling to slaughter.

In a statement, ALRTA has strongly opposed a proposal to move from a

Vale Frederick John (Ned) Amezdroz

An energetic and dynamic leader in the road transport industry, Frederick John (Ned) Amezdroz, has passed away.

Amezdroz joined the family transport business, Amezdroz & Menzies, aged 17, where he toiled for the remainder of his 57-year working life.

With his brother Bill, Amezdroz took over business in 1961, helping build it into one of Victoria’s leading carriers.

The company continued to grow and became Amezdroz and Sons in 1984. Following several strategic acquisitions, rapid expansion ensued resulting in a

group rebrand to Wettenhalls in 2004.

“He was instrumental in advocating for change within the Victorian transport industry, as a member of the Executive of the then Victorian Road Transport Association, which he served for 20 years,” the Victorian Transport Association said in a statement.

“Recognition of Ned’s outstanding service to the transport industry came in 2005 when he was admitted to the National Road Transport Hall of Fame.

“Away from business, Ned was a pillar of his local communities in Colac,

24-hour time off water limit to a 12-hour journey time limit.

“This proposal is inconsistent with standards for all other species and introduces unacceptable operational / regulatory risks,” it said.

“We have however supported a reduction in the time of water limit to 15 hours to align with BFM fatigue rules.”

ALRTA expects a decision regulatory impact statement on the refined proposal to be released in 2023.

Werribee and Geelong, through his charitable deeds, volunteer work and tireless community involvement.

“He was involved in numerous local organisations, volunteering with Rotary International, where his service was recognised with a Paul Harris Fellowship. Ned and his beloved wife Audrey also served on the Foundation Board of Mambourin Enterprises in Werribee, supporting people with disabilities.

“Our sincere sympathies to all who knew and interacted with Ned.”

News

12 Trailer Magazine FEBRUARY 23

Access to mental health support can be challenging for members of our blue collar industry and it shouldn’t be that way. Scully

RSV is on a mission with TIACS as an Alliance Partner, to not only spread the word about mental health support but showcase a great organisation in TIACS who are making it free.

Over 13,000 clients have been supported with over 10,000+ hours of conversations about mental health, since June 2020.

Find out how you can spread the conversations and make a real difference to our community. NEED A YARN? Call or text TIACS on 0488 846 988 Mon-Fri 8am-10pm AEST to speak with a counsellor. 1800 728 559 www.scullyrsv.com.au info@scullyrsv.com.au NEW & USED SALES SHORT & LONG TERM HIRE UTES, TRUCKS & TRAILERS

Wimmera Highway works to improve road train access

Two new junctions to be delivered on the Wimmera Highway nwear Naracoorte, South Australia, are expected to improve road safety and freight productivity.

The construction of two new junctions on the Wimmera Highway will help freight vehicles up to 36.5 metres in length (Performance-Based Standards 3A road trains) better access local businesses including the Teys Australia Naracoorte Facility and the Qube Hynam Depot. These two new junctions, with work expected to commence Monday 9 January, will provide sheltered right-turn lanes into both businesses.

The project will also include a dedicated left-turn deceleration lane into Teys Australia, new asphalt, line-marking, LED lighting, safety barrier installation and upgraded drainage.

Completion of this project is expected in mid-2023, weather permitting.

Works will be undertaken Monday to Friday between 7am and 5.30pm and

Saturday 7am to 3:30pm. Some work may be required outside of these hours.

To safely facilitate these works, the highway will be intermittently reduced to a single lane of traffic, with speed restrictions and temporary traffic lights in place to control the direction of traffic.

Outside of working hours the highway will re-open to two lanes of traffic (one in each direction) with speed restrictions in place.

Road users are asked to please plan ahead, expect delays, allow extra travel time and take extra care when workers are on site. Observe speed limits, lane restrictions and traffic controllers when travelling through the area.

The contract for these works has been awarded to South Australian company Bardavcol and will support approximately 25 full-time-equivalent jobs over the construction period.

The works form part of the $14.6 million Rural Roads Package — Naracoorte

Roundabouts project, which is jointly funded on an 80:20 basis by the Australian and South Australian governments.

“The two new junctions on the Wimmera Highway will be a great win for all road users, particularly freight operators with larger vehicles, who will have better access to local businesses such as Teys Australia and the Qube Hynam Depot,” said SA Minister for Infrastructure and Transport, Tom Koutsantonis.

“Other upgrades as part of the project include new asphalt and line-marking, improved lighting and the installation of safety barriers, which will all contribute towards making Wimmera Highway safer and smoother for all road users.

“Congratulations to Bardavcol on winning the contract for these works, which underlines our commitment to supporting employment for South Australians.

“We thank the community for their cooperation and patience while these important works are undertaken.”

News

14 Trailer Magazine FEBRUARY 23

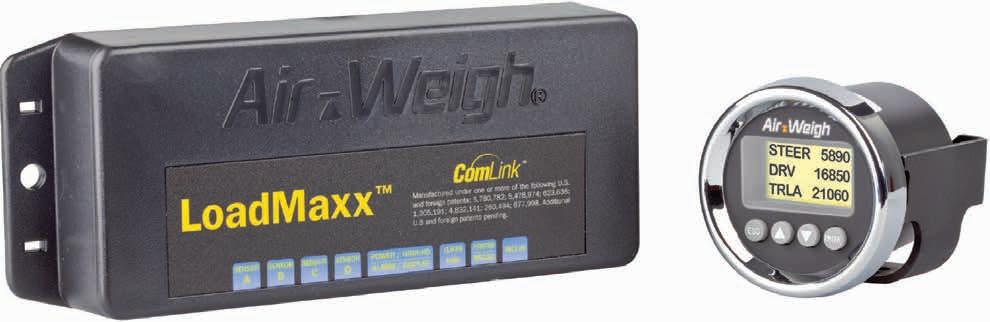

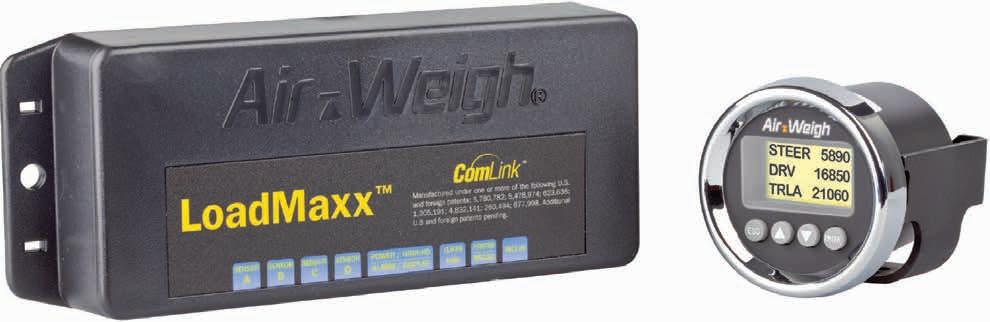

Approved for use with all TCA approved telematics devices, for Smart OBM and IAP-M

• 3 year limited warranty

• No maunual pairing of the system needed, no extra cost or need for a third party phone or tablet, system connects automatically with no driver input required, turn the key and go.

• Smart OBM and IAP-M ready today, with whatever telematics you have in your fleet.

E-Mail: info@e-max.com.au P: 1300 850 575

www.air-weigh.com.au

•

Bridge funding to improve freight in NSW

The Australian Government is investing over $39 million towards 18 projects under the Bridges Renewable Program, as part of its ongoing commitment of $85 million each year.

As part of the program, the Albanese Government will be contributing $3.5 million towards the replacement of the Watergums Creek Bridge in Wonboyn, New South Wales.

The existing single-lane bridge will be replaced with a two-lane concrete structure, and will be co-funded by the Bega Valley Shire Council to provide a total project cost of $4.5 million.

The new bridge will be higher than the 100-year flood level and will be capable of carrying heavy forestry vehicles.

Minister for Regional Development, Local Government and Territories, and member for Eden-Monaro, Kristy McBain, said the Bridges Renewable Program improves freight through local communities.

“These projects will support local communities and holiday makers to travel in greater safety and assist businesses to deliver and receive their products and services more efficiently,” she said.

“I know this upgrade will be welcomed by the Wonboyn community and our forestry industry who depend upon this bridge for the daily commute to work, or to move freight or stock for their business.”

The Bridges Renewable Program provides funding to fix issues with bridges no longer fit for purpose, and often involves the replacement of historic single-lane timber bridges with doublelane, modern concrete structures.

WA launches infrastructurespecific initiative

The Western Australian Government has launched the Resources Community Investment Initiative which will facilitate investment in iconic state infrastructure projects and community and social initiatives across WA.

Established with founding partners, Rio Tinto, BHP, Hancock Prospecting, Roy Hill, Atlas Iron, Woodside Energy, Chevron Australia and Mineral Resources, the initiative provides a State Government-backed platform for direct contribution to iconic infrastructure and social projects.

The initial commitments total $750 million, with $250 million from Rio Tinto, $250 million from BHP, $100 million from Hancock Prospecting, Roy Hill and Atlas Iron, $50 million from Woodside Energy, $50 million from Chevron Australia and $50 million from Mineral and Resources.

The initiative will also extend to include transformational projects across WA, enabling companies to contribute to achieving long-term social and economic outcomes in each region.

WA Premier, Mark McGowan, said the strength of WA’s economy has placed it in a good position.

“We are proud that the partnership between our government and the resources sector enables us to continue to help make our state an even better place to live,” he said.

“I commend the efforts of Rio Tinto, BHP, Hancock Prospecting, Roy Hill, Atlas Iron, Woodside Energy, Chevron Australia and Mineral Resources as foundation partners of the initiative and acknowledge their leadership in contributing to our state in this capacity, which will have lasting benefits for generations.

“I am confident that other resources companies across WA will join this worthwhile initiative and look forward to seeing some iconic state projects delivered.”

Each company involved will decide the projects they wish to nominate funding to, and individual project agreements will be established with agreed project milestones.

An advisory committee comprising of an independent chair as well as government and industry representatives will be convened to oversee the initiative.

16 Trailer Magazine FEBRUARY 23 News

Ask us about LocAl® at the Brisbane Truck Show

Cleaner, Greener. Lower-carbon aluminium for your projects.

Choosing lower-carbon aluminium in your next project can reduce the embodied energy of your aluminium products by up to 75%* LocAl® Green (8kg CO2e/1kg AL) and LocAl® SuperGreen (4kg CO2e/1kg AL) are the responsible choice for a locally extruded, lower-carbon option in your next project.

FOR MORE INFORMATION VISIT lowcarbonaluminium.com.au POWERED BY

* When compared with global average CO2e for primary aluminium production, Scope 1 and Scope 2 ex smelter.

Approved QLD coal mines to boost economy

Two steelmaking coal mine projects in Central Queensland have been approved, with construction work set to begin in early 2023 and coal production to begin within six months.

Futura Resources’ Fairhill and Wilton projects are located adjacent to one another and are about 50km north east of Emerald.

Its coal will be processed using existing infrastructure at the nearby GregoryCrinum mine.

Queensland Resources Minister, Scott Stewart, said the approval was a big boost for the regional workforce and economy.

“This investment is a strong vote of confidence in the Queensland resources sector and our state’s large deposits of

high-quality steelmaking coal,” he said.

“These projects are in the heart of the Bowen Basin and will benefit from the existing infrastructure in place from nearby mines.

“At their peak, these two mines will produce more than three million tonnes per year of steelmaking coal, which will be processed then transported by rail to the Port of Gladstone and exported to key international markets.

“This means from Emerald to Gladstone, regional communities will benefit from job opportunities and the economic flow-on effects of these projects.”

Both mines have an initial 10-year proposed lifespan, but according to the Queensland Government, it could be

expanded to more than 20 years with continued exploration.

Futura Resources CEO, Ben Dunlop, said coal continues to play a big role in steelmaking and energy mix.

“We see ourselves as a sustainable, low environmental footprint producer utilising nearby existing infrastructure, including coal processing facilities which will be 50 per cent powered by renewable energy by end of 2023,” he said.

“We believe these projects are well positioned to meet future market demand for high quality steelmaking coal and we will be supporting the people and communities of Central Queensland by using local suppliers and contractors where possible.”

Mark Nelson retires: Tieman Tankers

Tieman Tankers wishes Mark Nelson the very best for his retirement.

“Forty-eight years of service with one company is truly an amazing achievement and supported by his wife Wendy we thank Mark for his loyalty and dedication,” Tieman Tankers said in a statement.

“Mark started with Tieman in 1975 as a sheet metal apprentice and has worked in many senior roles over many years.

“He has been integral to the company’s success and in introducing new and innovative Tieman tankers around Australia, New Zealand and PNG.

“He has developed relationships with Tieman employees, customers and suppliers that will always be remembered and appreciated by his strong work ethics and willingness to share his wealth of knowledge.”

Image credit: IngeBlessas / Shutterstock.com

18 Trailer Magazine FEBRUARY 23 News

ACT Government increases funding for road repairs

The Australian Capital Territory Government will significantly increase maintenance funding to $153 million over the next four years, in a new strategic maintenance program to repair and preserve Canberra’s roads for a generation.

The program has been developed based on research undertaken by the Australian Road Research Board (ARRB) to support a new, strategic approach to maintenance, which will support freight movements and improve safety and ACT’s liveability.

The research-led approach aims to extend the life of Canberra’s existing high-quality roads through proactive resealing, while undertaking more rehabilitation work including using an up to 150 per cent increase in asphalting.

Minister for Transport and City Services, Chris Steel, said the new road maintenance program represents a 52 per cent increase in expenditure on road maintenance.

“This maintenance program is evidencebased and will have a greater focus road rehabilitation and use of asphalt, as well

as ensuring that we continue our focus on preventative resealing,” he said.

“With the annual road resurfacing program now underway, this new maintenance program will extend the life of Canberra’s roads by 20 years through additional resealing measures adopted across our rolling roads program.

“And investing now will reduce road maintenance costs in the long term.”

Increased investment in Canberra’s annual road maintenance program will now see resurfacing of the network grow by 268,000 square metres a year to cover an area of 1.26 million square metres resurfaced per year going forward, concentrating on arterial and collector roads.

Steel said the challenging climate, heavier vehicles and greater than anticipated ACT population growth had accelerated road degradation and the likelihood of defects such as potholes.

“It’s no secret that roads across southeastern Australia have taken an absolute battering over the past few years with constant La Nina weather cycles,” he said.

“Since 2020, Canberra has continued

to experience heavy and frequent rain events.

“In October, we experienced Canberra’s wettest month since records began, with more than 2,800 pothole repairs undertaken across the Territory in that month alone.

“This long term program will see smoother, more resilient roads, that result in safer travel and better drivability, meaning Canberra drivers will save on fuel and vehicle maintenance.”

ARRB CEO, Michael Caltabiano, said the ACT Government isn’t taking any shortcuts in the project.

“Our research looked at the condition of the ACT’s roads, and the investment and treatments required to ensure that they are well-maintained over the coming decades,” he said.

“Based on our research, the ACT Government has chosen the highest cost and highest quality option which will deliver good road conditions in Canberra over the years ahead.”

The new funding includes funding under the Australian Government’s Local Roads and Community Infrastructure Program.

NSW advances in fully sealed highway network

A decade-long project to completely seal 153 kilometres of the Silver City Highway in New South Wales has been achieved.

Minister for Regional Transport and Roads, Sam Farraway, said NSW is now one step closer to a fully sealed highway network.

“The completion of construction and sealing on the Silver City Highway is an incredible milestone for people living in the Far West of NSW, not to mention the many freight operators and tourists who use the road every year,” he said.

“The NSW Government is building the infrastructure that matters to make daily life easier for regional communities and our $195 million investment to seal this vitally important highway is just one example of how we’re doing that.”

Farraway said the Highway is a vital north-south connection between Victoria and Queensland, with sections closed for up to 70 days a year due to poor weather.

“A sealed highway not only means quicker, safer journeys for all road users but will also mean it can stay open

more often when the region experiences extreme weather.

“Sealing the Cobb Highway remains the final piece in the puzzle for a fully-sealed highway network, which is due to be completed mid-2023.”

The NSW Government is providing $145 million to seal and upgrade the existing unsealed sections on the Cobb and Silver City Highways in Western NSW.

All remaining sections of the Silver City Highway have been completed, and 10.9 kilometres remains to be sealed on the Cobb Highway.

www.trailermag.com.au 19

Livestock partnership delivers new code of practice for managing effluent

The National Heavy Vehicle Regulator (NHVR) has registered a new national code of practice developed in partnership with the Australian Livestock and Rural Transporters Association (ALRTA) to reduce the hazards and risks associated with effluent spillage during the transport of livestock.

NHVR CEO, Sal Petroccitto, said the Managing Effluent in the Livestock Supply Chain Code of Practice had been specifically developed by industry for industry, but would have farreaching benefits for all road users and communities.

“The ‘Effluent Code’ is a practical guide that helps livestock transporters and other

parties in the livestock supply chain meet their primary duty and other obligations under the Heavy Vehicle National Law (HVNL) when managing livestock effluent during road transport,” said Petroccitto.

“It combines industry knowledge and experience in suggesting measures to minimise effluent loss that can be implemented at each stage of a land transport journey – from preparing livestock for transit to unloading – without impacting animal welfare.

“I’d like to congratulate ALRTA and the other parties involved for addressing this difficult issue and helping make the livestock transport task safer for all road users.”

ALRTA President, Scott McDonald, said ALRTA had worked with a wide range of stakeholders – including livestock producers, transport operators and drivers, vehicle manufacturers, agents, saleyards, feedlot managers, processors, regulators, animal welfare advocates, government agencies and the community – to develop a code that was both practical and workable.

“Historically livestock transport drivers have been left solely responsible for managing livestock effluent in transit,” said McDonald.

“This code is a game changer because it makes it clear that Chain of Responsibility applies to off-road parties in the livestock supply chain, and articulates the measures they can take to minimise the risk of effluent accumulation and spillage.

“This is a supply chain problem that requires a supply chain solution.

“While the Effluent Code will help to improve road safety, it will also improve animal welfare outcomes, mitigate biosecurity threats and contribute to the sustainability of the livestock industry.”

The NHVR is currently working with stakeholders to develop further industry codes of practice and welcomes enquiries and suggestions about other new codes.

Major NSW truck wash re-opens

A major truck wash on the Kamilaroi Highway capable of accommodating vehicles as large as road trains and B-triples has officially re-opened.

Located at the Gunnedah Regional Saleyards in New South Wales, the $1.8 million drive-through facility was funded by Regional NSW, Restart NSW Fixing Country Truck Washes Program and Gunnedah Shire Council as part of the Saleyards’ $14 million redevelopment.

The truck wash was designed following consultation with operators and industry organisations, and its realignment and modification now allows more trucks to move forward into the wash bays and exit

from the same direction.

Minister for Regional Transport and Roads, Sam Farraway, said the project highlighted the important role truck washes play in vehicle productivity and maintenance.

“The upgraded truck wash facility at Gunnedah Regional Saleyards will provide access for all truck operators, including livestock carriers, and has capacity to cater for modern road trains as well,” he said.

“The new truck wash means drivers no longer need to reverse their vehicle to access and use the facility, creating a safer and more efficient wash-down process.

“Truck washes are essential to reducing the spread of weeds and disease across NSW and I’m pleased to see the new facility opened.”

Gunnedah Shire Mayor, Jamie Chaffey, said the completion of the truck wash was great news for the livestock industry.

“It’s fantastic to see this new facility now made available to livestock transporters who rely on truck washes to clean their vehicles,” he said.

“Since the introduction of road trains into this region, it’s great to see that transporters now have the ability to wash their vehicles, no matter the size.”

News

Image credit: Serge Goujon / Shutterstock.com 20 Trailer Magazine FEBRUARY 23

NSW world-class intermodal hub officially opens

The new Riverina Intermodal Freight and Logistics (RIFL) Hub in Wagga Wagga is officially open, increasing New South Wales’ freight efficiency and strengthening its supply chain network.

The new RIFL Hub will connect in with the $292.2 million, 60-hectare Bomen Industrial Precinct, supported by the NSW Government’s Growing Regional Economies Program.

Minister for Regional Transport and Roads, Sam Farraway, said the RIFL is positioned to become a dynamic operations centre for freight operators.

“The 4.9 kilometre rail siding will be a game changer for the rail freight industry, allowing for longer trains with the capacity

to securely load and unload without holding up other services,” he said.

“These trains can carry loads the equivalent of 134 semi-trailer trucks, reducing the number of rigs on Riverina roads and allowing freight to move efficiently across the state.

“We know the Riverina and Murray accounts for 12 per cent of the state’s agricultural output and are important contributors to our economy. That’s why we are improving freight linkages to secure a brighter future for our state.”

Wagga Wagga City Council Mayor, Dallas Tout, said the project will benefit the region as a whole.

“It will prove a catalyst for freight

movements by all parties to be rethought in relation to form of delivery and structure,” he said.

“A once in a generation opportunity.” Visy Logistics will carry out operations at the RIFL Hub as an open access terminal and provide logistics solutions and services to businesses across the Riverina.

Lee Schmelich from Visy Logistics said Visy was proud to partner with the NSW Government and Wagga Wagga City Council on the project.

“The RiFL will turbocharge local agriculture and industry by making it easier to get local products from the Riverina to customers across the country and the world,” he said.

Leadership update at Australia Post

Siobhan McKenn is now the Chair of the Australia Post Board for a term of three years.

McKenna brings commercial, strategic, digital and technology experience to the role from her many years in the media, communications and telecommunications industries.

McKenna is currently Chair of Foxtel Group, an Independent Non-Executive Director of Amcil Limited and the Managing Partner at Illyria Pty Ltd. She has served on several company boards including Woolworths Group Limited and Nova Entertainment, and was a partner of McKinsey & Company. Ms McKenna has previous public service experience as a Commissioner of the Australian Productivity Commission and Chair of NBN Co Limited.

McKenna’s knowledge, leadership and experience will help support Australia Post as it modernises and adapts to meet shifting consumer demand. The Government looks forward to working with her in her new role.

The Government also acknowledges the service of Lucio Di Bartolomeo as Chair, who stepped down at the conclusion of his term on 21 November 2022.

Di Bartolomeo has had an extensive corporate career and led the Board in supporting Australia Post to continue to deliver postal services through the

challenges and parcels boom of the Covid-19 pandemic.

The Government thanks Di Bartolomeo – along with Ms Andrea Staines OAM for acting as Chair in the interim – for their stewardship of one of Australia’s most cherished public institutions.

“Australia Post has always been a driver of economic activity for small businesses and continues to deliver essential services to all Australians, particularly in regional, rural and remote Australia,” said Minister for Finance, Katy Gallagher.

“I welcome the appointment of Ms McKenna and thank Mr Di Bartolomeo for his years of service to Australia Post.”

Minister for Communications, Michelle Rowland, said: “Australia Post forms an important part of Australian society, supporting communities, businesses, and our economy, and we are committed to ensuring it continues to deliver for every Australian.

“The appointment of Ms McKenna and her extensive experience in corporate governance will help support this treasured national institution in achieving these important outcomes. I acknowledge Mr Di Bartolomeo’s service and wish him well.

“The Government looks forward to working with Ms McKenna and the senior leadership team at Australia Post.”

/

www.trailermag.com.au 21

Image credit: Jackson Stock Photography

Shutterstock.com

Is mass immigration the solution to Australia’s skills shortages?

Following the disruptions of Covid-19, Australia is seeing a period of changing demographics in workforces across the country. With a large reduction in immigrant workers, a wave of skills shortages has also reached Australian borders.

The Australian Council of Trade Unions (ACTU) released its Skilling the Nation: Addressing Australia’s skills and migration needs now and into the future report earlier last year, which criticised the former Coalition Government’s lack of management between skilled migration and the Vocational Education and Training (VET) system.

ACTU explained that during the Covid pandemic approximately 500,000

temporary migrant workers left Australia. Now that the country is rebuilding its economy, many businesses are claiming an urgent need for gaps in the workforce to be filled by short-term migrant numbers.

The report called for the reinvigoration of Australia’s TAFE by guaranteeing a minimum of 70 per cent public funding, as well as “repairing almost a decade of damage to our apprenticeship system”.

Following this, the 2022 Jobs & Skills Summit saw the Federal Government devise a clear plan which will aim to address skills shortages and strengthen the migration system. This includes its immediate actions, areas for further work, and complementary existing commitments.

Immediate actions

The Government will:

• I ncrease the permanent Migration Program planning level to 195,000 to help ease widespread, critical skills shortages

• Provide $36.1 million in additional funding to accelerate visa processing and resolve the visa backlog

• I ncrease the duration of post study work rights by allowing two additional years of stay for recent graduates with select degrees in areas of verified skills shortages to strengthen the pipeline of skilled labour in Australia, informed by advice from a working group

• E xtend the relaxation of work restrictions for student and training visa

Changing demographics in Australia’s workforce is a growing concern for thriving industries and workshops, and a shortage of skills following Covid-19 has seen many organisations calling for a change.

22 Trailer Magazine FEBRUARY 23 XXX Economy

holders until 30 June 2023 to help ease skills and labour shortages

• W iden the remit of the National Housing Infrastructure Facility, making up to $575 million available to invest in social and affordable housing. The funding can be used to partner with other tiers of government and social housing providers, and to attract private capital including from superannuation funds

Areas for further work

The Government will conduct a review of the purpose, structure and objectives of Australia’s migration system to ensure it meets the challenges of the coming decade.

The Government will also progress work to:

• A ssess the effectiveness of the skilled migration occupation lists

• E xpand pathways to permanent residency for temporary skilled sponsored workers

• Raise the Temporary Skilled Migration Income Threshold (TSMIT) following broad engagement on equitably setting the threshold and pathway for adjustment

• Reform the current labour market testing process following consultation with unions and business

• B ring forward a package of reforms to address migration worker exploitation during 2023

• E xamine the potential for industry sponsorship of skilled migrants

• Embed a role for Jobs and Skills

Australia’s analysis of skill shortages in setting priorities of the skilled migration program

• Consider policies to address regional labour shortages and how to improve small business access to skilled migration All levels of government will work together to ensure infrastructure, housing and social services are wellplanned to meet the needs of a growing population

Complementary existing commitments

• I mplement the recommendations of the Migrant Workers’ Taskforce to tackle migrant worker exploitation

• Encourage more migration from our region by reforming the Pacific Australia

Labour Mobility scheme and creating a new Pacific engagement visa

• Under the one-year National Skills Agreement the Government is providing (unmatched) $50 million to modernise TAFE technology infrastructure and $24 million to support vulnerable students to be successful

According to ACTU, evidence suggests that although Australia’s borders have now reopened, migrant workers are not returning in large numbers. The reason, it said, is due to the poor treatment many migrant workers have experienced in Australia which has incurred significant reputational damage.

“This includes the lack of support for temporary migrants during the Covid-19 pandemic and the growing and systemic problem of migrant worker exploitation, both of which have damaged Australia’s international reputation and made us a less desirable destination for migrant workers,” the report read.

“In addition, the temporary nature of many visas, the visa processing backlog for skilled migrant workers, long wait times for applications for permanency and to bring family members to Australia has led to extensive delays and lives lived in limbo. All of this makes Australia a less attractive place to settle.”

Interest rate December 2022 GDP growth rate September 2022 Unemployment rate October 2022 3.2% 5.9% 3.4% Australian Consumer Confidence 0 5 -5 -10 -20 10 15 20 10 10 6 5 0 1 12 13 16 3 -12 Jan 2022 Apr 2022 Jul 2022 Oct 2021 7 www.trailermag.com.au 23

ACTU dismissed the idea of an urgent need to restart temporary migration, labelling it as a “short-sighted outlook” that will not deliver the skills-based needed over the long term. Instead, it explained that the causes of the problem go much deeper, which include:

• The shift from an immigration system based on permanent migration, where previous generations of migrant workers brought their families and built lives in Australia, to a system based on temporary, employer-sponsored migration, where workers are on insecure short-term visas, in many cases tied to their employer

• A decade of stagnant wages

• A n overreliance by particular industries and employers, including the public sector, on migrant workers to fill skills gaps instead of investing in developing a local workforce

• A failure to address the structural issues that are driving local workers out of industries, such as low pay and insecure work

• A failure to develop career paths and develop workers to take on higherskilled roles within their industry

• The undervaluation of jobs traditionally done by women, for example jobs in the care economy

• Lack of industry planning and an adhoc approach to migration and skills development

• A decade of underfunding, cuts and marginalisation of TAFE, which has exacerbated skills gaps

• A lack of protection and a safety net for temporary migrant workers which leave them highly vulnerable to exploitation. Many industries and organisations believe mass immigration is the solution to fixing Australia’s skills shortages, while others say changing its current working conditions and increasing wellbeing in the workforce could accommodate the change in demographics.

Industry initiative, Healthy Heads in Trucks & Sheds, addressed the latter last November by making its information on looking after wellbeing more accessible and easily understood for different

cultural groups working across the industry.

This involved launching its industrytailored wellbeing resources translated into eight of the most commonly spoken languages other than English in the Australian road transport, warehousing and logistics sector. The information included in all English as Second Language (EASeL) resources derives from the Healthy Heads Workforce Handbooks, which is now available in English, Hindi, Punjabi, Arabic, Filipino, Vietnamese, Mandarin, Cantonese and Sinhalese.

HHTS CEO, Naomi Frauenfelder, said stigma around mental health in this sector is a key risk factor and barrier for helpseeking.

“In developing this project, our ambition was the ensure that the information within the EASeL resources was not only more accessible from a language perspective, but, also through the simplicity of messaging,” she said.

“To achieve this, we created a set of positive messages, that call out some of

The National Skills Commission’s 2022 Skills Priority List found shortages in 286 occupations in 2022, compared to 153 occupations in 2021. These included nurses, software programmers, aged care workers, construction managers and childcare workers.

XXX 24 Trailer Magazine FEBRUARY 23 Economy

the key actions we can take to keep our wellbeing in check, including exercise, eating well, getting good quality sleep, cleanliness and drinking water.”

The project was funded by the National Heavy Vehicle Regulator’s (NHVR) Heavy Vehicle Safety Initiative, in partnership with the Federal Government.

NHVR CEO, Sal Petroccitto, said providing greater access to mental health resources was particularly

important as the transport industry approached the busiest time of the year.

“I am extremely pleased to see a dedicated project that focuses on inclusion and provides more people in the heavy vehicle industry with access to important information to help them maintain positive health and wellbeing,” he said.

“I encourage everyone in the sector to use the EASeL resources developed by HHTS and prioritise their mental health

and wellbeing this holiday season.”

The National Skills Commission’s 2022 Skills Priority List found shortages in 286 occupations last year, compared to 153 occupations in 2021. These included nurses, software programmers, aged care workers, construction managers and child care workers. With the Federal Government’s initiatives backed by industries and organisations nation-wide, the 2023 Skills Priority List could show a very different figure this year.

NEW 50MM TRAILER COUPLING BY HYVA Automatic Trailer Coupling designed for the Australian market Key safety device design within the main body for optimum protection Coupling and jack knife sensors available High load rating and vertical load rating Geared handle for ease of opening a first for the Australian market Cast and sealed top mechanism housing for greater protection giving the Hyva unit a longer life Individual guide funnel with automatic re centre function for easy repair Darren Stocks P: 07 3288 2688 E: d.stocks@hyva.com A: 51 Lower Cross St Goodna QLD 4300 W: www.hyva.com

Tieman and Black Mount Spring Water, two family brands in sync

Seventy years in business is a milestone Tieman Tankers is unconditionally proud of, and recently delivering its 6,000th tanker to bulk spring water supplier Black Mount , is one that will remain in the history books of both companies for a long time to come.

Tieman Tankers was founded in 1953 by Neil Tieman, and while he sadly passed away in October 2021 at the age of 95, his respected legacy lives on behind the Tieman brand.

A loyal companion to Tieman Tankers since its beginning in 1993, Black Mount is a well-known bulk spring water supplier based in Millbrook, Victoria, established by Brian Carey. His son, Tim Carey, now guides the company with more than 50 prime movers towing single tri-axle trailers, 19m and 20m combinations right up to 26m and 30m A-double combinations throughout Victoria, New South Wales, Queensland, South Australia and Western Australia – hand in hand with Tieman Tankers.

“The opportunity came up to supply water from our farm to one of the bottlers down in Melbourne,” Tim says. “At the time, bottled water was a very small industry and Dad recognised the potential. From the very start of the industry here in Australia we’ve supplied the water from our farm in a Tieman tanker that we purchased from Neil Tieman 30 years ago.”

Black Mount has always invested in dedicated spring water tankers of the highest standard to reflect the company’s quality in spring water. This philosophy, thanks to Tim’s father, has kept the business by Tieman’s side since it commenced operations.

“We’ve always held the Tieman product in our highest regard, and we keep coming back to Tieman because of the long-term relationship we have,” Tim says.

“We’re really grateful for the relationship that has got our business to where it is today.

“The second tanker we acquired from Tieman was a 26m B-double combination that still carts spring water to our customers today. That reflects the longevity and quality of a Tieman tanker, as we still have the trailer from the initial start of the relationship today.”

Tieman Tankers recently delivered its 6,000th tanker, a Performance-Based Standards (PBS) 20m B-double to Black Mount. Neil’s son, and Tieman Director, Colin Tieman, says it was a special achievement due to the long-lasting relationship between both families.

26 Trailer Magazine FEBRUARY 23 XXX Trailer builder

milestone tanker was made at Neil’s funeral, where Tim and Colin agreed that it would be a great way to tribute Neil and the everlasting bond between both companies.

“I was speaking to Colin at Neil’s wake, and I mentioned that we were approaching a milestone of 30 years and 50 Kenworth trucks,” Tim says. “Following a day of stories of how Neil started the Tieman business and how my father started the Black Mount business,

holds a payload of 42,500 litres and displays a quality finish that reflects Neil’s commitment to detail and Black Mount’s premium service offered to its customers. The combination is fitted with Hendrickson Intraax AA250 airbag suspension, MAXXT22 disc brakes, HXL7 bearings and a Tyremaax tyre inflation system that is proving to keep tyre wear even – hence increasing the life of the tyres. It also features a polished s/s steel barrel with electro polished rings, polished s/s mudguards and mirror finish s/s bumper bars.

The trailer is being towed by Tim’s 50th Kenworth purchased early 2022 and the combination will be located at Black Mount’s farm in Black Hill, Millbrook. From there, it will service its customers everyday – travelling between Metropolitan Melbourne and Black Mount’s various water sources located in the Yarra Ranges, the Macedon Ranges and the Central Highlands of Victoria. Tim says the trailer is the pride of his fleet.

“The 20m PBS combination has been a great unit throughout our fleet,” he says. “We ordered this one specifically to run from our Millbrook depot where we started 30 years ago. It looks terrific and it pulls really well. It did its first load in November, and the driver couldn’t have had better things to say about it.”

Combined with its PBS design innovation, there is little surprise why Tieman is a preferred supplier to so many fleets and contractors around Australia, New Zealand and Papua New Guinea.

“Our

6000th tanker is a reflection of the pride and skill taught and handed

Contact Tieman Tankers 180 Northbourne Road Campbellfield VIC 3061 Ph: 03 9469 6700 Web: www.tieman.com.au

Tieman 42,500-litre PBS 20m B-double.

L-R Black Mount CEO, Tim Carey, and Black Mount founders Kate Carey and Brian Carey.

www.trailermag.com.au 27

Tieman`s 6000th tanker.

RCT makes a special delivery with Vawdrey

Ron Crouch Transport , based in New South Wales, has taken delivery of a brand-new B-double from Vawdrey which will travel around the country promoting a message the transport industry holds very close to heart.

Ron Crouch Transport (RCT) specialises in general freight, Dangerous Goods (DG), warehousing and third-party logistics. The company was established in 1978 by Ronald and Beverly Crouch, with the family’s third generation now having key roles in the business.

RCT has expanded its operations during the last 44 years and now has a fleet of 40 trucks and 90 trailers, complemented by its six warehouses which service small rural customers to large multinationals.

For almost half of its existence, the family company has placed its trust in Vawdrey to provide quality trailers for its applications, and Executive Director, Geoff Crouch, says he hasn’t been let down once.

“I’ve been dealing with Vawdrey

personally for 25 years and I have never had any issues,” he says. “It’s always been run on the basis of mutual respect and ensuring that the high values and ethics of our companies are upheld for mutual benefit.”

RCT’s latest addition from Vawdrey is a B-double dedicated to Healthy Heads in Trucks & Sheds (HTTS) by promoting its values on the curtains. The B-double will travel across the state as well as to all major cities along the eastern seaboard and most regional areas.

HTTS is a non-profit organisation for mental health in Australia’s road transport, warehousing and logistics industries. It was founded in August 2020 in response to the poor state of mental health and wellbeing

across road transport warehouses during the Covid-19 pandemic, and it has continued to improve outcomes drastically in areas relating to psychological safety and physical wellbeing.

Some of its most recent efforts include offering discounts on healthier meals at BP service stations, commencing a Nutrition Pilot Program to encourage longer-term healthy eating among truck drivers and launching industry-tailored resources translated into eight of the most commonly spoken languages other than English in workshops.

Due to commitments like these which aim to better the transport and logistics industry, Geoff says it is an honour to promote HHTS’ values alongside Vawdrey.

28 Trailer Magazine FEBRUARY 23 XXX Trailer builder

“I’ve been a very strong supporter of HHTS from the very beginning,” he says. “It’s an initiative that I passionately believe in, and I am determined to provide whatever assistance I can to get the message out there – that there is assistance for members of the Australian logistics industry for people that don’t have optimal mental health and wellbeing.

“Anything that I can do to get the message out there is worthwhile. I firmly believe in the initiatives that HHTS developed, and that over the course of time they will make a massive benefit to the mental health and wellbeing to thousands of people.”

Geoff explains that the purchase of the B-double was part of his plan to replace some older vehicles in the fleet while increasing its size by four units in preparation for planned growth over the next 12 months. Due to Vawdrey’s reputation for reliability, Geoff knew it was the right path to take.

“It’s a product with the highest quality

possible, and it stacks up perfectly on our business analysis proposition,” he says. “We’ve always been hugely impressed by the Vawdrey product. With its quality and attention to detail, the value for money is unmatched.”

In June last year Vawdrey announced that it had established a partnership with HHTS, and as part of this agreement, it would add a Healthy Heads sticker to each of its new trailers to promote the organisation’s key message. As a result, this decision has attracted the attention of many fleets such as RCT which support what Healthy Heads stands for.

HHTS CEO, Naomi Frauenfelder, says the culture and vision at Vawdrey led it to partnering with HHTS.

“Having such a well-known and respected Australian business like Vawdrey come on board is super important to us,” she says. “It means we can continue to delivery on our key target ambitions.

“Like many businesses in our sector,

Vawdrey would have seen the impact of the pandemic on trucking operators as well as drivers and logistics companies, so they’re looking for an opportunity to meaningfully contribute to the lives of people working in the sector and other businesses.”

Geoff and the team at RCT are very happy with their latest purchase. And, with the help of Vawdrey and HHTS, it hopes to spread awareness on mental health and wellbeing in the workforce.

“This trailer is a very special one to us,” Geoff says. “We’re glad to be able to dedicate it to the amazing work that HHTS does: Improving the mental health and wellbeing of every single member of our incredible industry.”

Contact Vawdrey Australia 1-53 Quantum Close Dandenong South, VIC 3175 Ph: 03 9797 3700 Web: www.vawdrey.com.au

www.trailermag.com.au 29

Ron Crouch Transport Executive Director, Geoff Crouch.

Tough without compromise

Part of Chris’s Body Builders’ (CBB) Hardox product range, the Lumiere is a lightweight option for bulk carriers to get the resilience of the Hardox product while reducing tare weight.

The tipper body uses a formed side to increase capacity while reducing tare weight to ensure they are operating an efficient bulk transport solution.

For CBB CEO, Chris Debono, it’s

important that operators get every kilogram possible onboard.

“I think it’s a really good option for somebody who’s in the market for tare weight sensitive equipment but wants to have a bit of versatility in what their fleet can achieve,” he says. “It makes the fleet coordinator or owner operator a little bit more versatile. The traditional Hardox product is quite heavy, and this prohibits it from being used in tare weight sensitive applications. By using the Lumiere range you get that same toughness as the Hardox, but you don’t have to compromise on tare weight.”

Lumiere enables a reduction in fuel usage while giving better payloads and requiring less maintenance over an aluminium product.

It’s just a tougher solution, something that’s bulletproof that you can put into a variety of different situations and have one unit that will do them all.

The increased strength in the bodies design allows less material to achieve the same strength in the body. With the addition of wear plates in the body’s walls and the Lumiere’s signature curved sides, operators can achieve better payloads

30 Trailer Magazine FEBRUARY 23 XXX Trailer

Chris’s Body Builders’ Lumiere range is built to last, and with a combination of strength and weight saving innovations using the well-known Hardox range of materials, every opportunity could become the next job.

builder

Customers lucky enough to have experienced the Lumiere firsthand say it’s great to have a steel product which can be used across a different variety of fields that aluminium bodies wouldn’t dare go.

can be customised to suit a range of applications to suit every individual need. Ph:

AIR BRAKE FITTINGS

D.O.T / S.A.E

STANDARDS

BIGGEST range and stockist of Metric / Imperial Push to Connect and Compression Style D.O.T Air Brake Fittings

CONFORMITY TO:

DOT - DEPARTMENT OF TRANSPORT

DOT PUSH TO CONNECT FITTINGS

Huge range available. Approved to meet: Australian Design Rules ADR-38/05 DOT FMVSS 571.106, SAE J2494/3, SAE J1131 blanking plugs.

FULL RANGE OF BRASS & STEEL FITTINGS

All brass fittings are designed to suit North American and European Truck & Trailer Air Brake systems.

24HR EMERGENCY AIR BRAKE SOLUTIONS

BREAK DOWN & GLOVE BOX KITS

Including both metric and imperial joiners, tees and blanking plugs.

Break Down Kit

Metric & Imperial Tubing

Part# GPKT-6264-01

Glove Box Kit

Imperial Tubing

Part# GPKT-6264-02

Glove Box Kit

Metric Tubing

Part# GPKT-6264-03

QUICKLY IDENTIFY & ACCESS YOUR FITTINGS!

FITTING MASTER

STORAGE SYSTEMS

Mobile Fitting Stand

Part# GPRK-DOT-068

Versatile mobile storage unit perfect for the workshop or shop floor.

Fitting Cabinet

Part# GPFC-DOT-30

Lockable cabinet with perspex door.

03 9311 6124

www.chrisbodybuilders.com.au UNCOMPROMISING PERFORMANCE

Web:

CONFORMANCE

GP TRUCK PRODUCTS available from Truck & Trailer parts outlets Australia wide. Compliant Standards: ADR-38/05 & DOT Phone +61 3 9580 1811 sales@gptruckproducts.com.au www.gptruckproducts.com.au

Waste hauling efficiencies covered

Efficiency and safety are always top considerations when purchasing equipment in the solid waste and recycling sectors, which is why moving floors have become such a popular choice in the industry.

Moving floor trailers unload horizontally, with a series of hydraulically driven floor slats that ‘walk’ material out the rear of the trailer. This allows them to safely unload on uneven ground and during windy conditions, resulting in a much larger area at the landfill at which they can unload.

As a result, trailers equipped with moving floors can offer flexibility in unloading while eliminating the safety risk posed by traditional tipper trailers.

Building on this concept, KEITH Walking Floor systems have been designed for

durability in the waste and recycling industries and can easily handle high volume loads.

KEITH’s Walking Floor systems have been used in the waste industry since the early 1980s, with the unloaders gaining popularity for their safety features.

Zyggy Reinoga of KEITH Walking Floor Australia explains that its revolutionary product allows operators to unlock a level of efficiency unreached in other applications by taking full advantage of several benefits over tipping trailers.

“When the landfill is busy, trailers can position themselves closer to each other without compromising safety, which helps with operating efficiencies,” he says. “It isn’t unusual for trailers to handle six to eight loads per day. So, the wear and tear

the floors need to be able to absorb is substantial.”

Another area in which operators can benefit from versatility is how the trailer is loaded. Depending on the type of floor slat installed in the trailer, trailers can be top-loaded or compactor loaded. Zyggy explains that slats such as the J-MAX profile can also expand the types of materials that can be unloaded.

“A slat like KEITH’s steel J-MAX slat holds up well to compactors,” he says. “Because it is made from high strength steel, you can expect a longer slat life over our standard aluminium profiles.”

In addition to Municipal Solid Waste (MSW), trailers can unload products as diverse as wood waste, gravel and glass.

“Glass is a product that can be tricky to

With the capability to efficiently unload a wide range of products at nearly any location, increasing productivity is a breeze with KEITH Walking Floor systems.

XXX 32 Trailer Magazine FEBRUARY 23 Moving floor

Fast fact

The slats from KEITH Walking Floor are available in a wide range of profiles and thicknesses to address different applications and unloading needs. Whether you are transporting high moisture loads that require leakproof and leak resistant options, or abrasive materials such as asphalt, sand, scrap, glass or fly ash, or need backhauling options for bulk materials, pallets or bales, or simply need standard or high-impact flooring for top loading applications, KEITH Walking Floor has the right solution.

unload using standard aluminium flooring, and most operators use a slip sheet for the occasional load of crushed glass,” Zyggy says. “The steel slat is better suited for handling recycled glass, with no slip sheep needed to protect the floor.”

According to Zyggy, a versatile floor slat can also contribute to the financial bottom line.

“Customers tell us that in addition to giving them more choices for backhaul options, the trailers quickly pay for themselves because they are able to haul larger volumes,” he says. “Worker safety

is a major concern for the industry and the horizontal unloading of a moving floor system not only prevents toppling over like a tipper trailer, but also eliminates the risk of hitting overhead utility lines or trees during unloading.”

KEITH has spent the past 50 years designing a trailer unloading system aimed at providing customers the lowest cost of ownership of any moving floor on the market. By requiring very little maintenance and being engineered to make servicing as simple as possible, it’s a resource unbeaten in the transport industry.

Contact KEITH Walking Floor

Factory 2/11-15 Mario Place

Hallam VIC 3803

Ph: 0404 041 883

Web: www.keithwalkingfloor.com

HYVA set to launch new 50mm drawbar couplings

In less than two months Australia and New Zealand are set to see the arrival and launch of the Hyva JK51-C9 50mm automatic trailer drawbar coupling. This will be a breath of fresh air to the industry as the first coupling in a long time to be designed for Australian and New Zealand conditions and upgraded performance in mind. Having an exceptional D-Value of 330kn gives the new Hyva coupling the highest rating available in Australia and New Zealand.

The coupling is set to hit the market in March this year.

Discussing the new couplings Darren Stocks, Hyva Pacific’s National Manager for tipping solutions and truck and trailer components, said the Hyva couplings have been undergoing real-world trials in Australia on various combinations including

truck & dogs, A-doubles, AB-triples and standard road train combinations with outstanding performance and wear results.

With a standard bolt pattern and a host of innovative ideas the New Hyva JK51-C9 couplings will give performance and driver acceptance a new benchmark.

Two built-in safety security devices and a third external security device for ultimate protection from unplanned disconnection. Other design elements include:

• A compact auto balanced centering funnel system;

• rotating coupling pin to reduce wear, compared to non-rotating pin this extends the service life by 50-70 per cent;

• frontal crash damage prevention with a full cast top box with reinforced rhino horn front section for added strength;

• funnel locking system so opening of the

The innovative towing solution with a smart and compact design has gone through rigorous testing in Australia

34 Trailer Magazine FEBRUARY 23 XXX Trailer building materials/components

WASTE

MOLASSES

TALLOW

BITUMEN

CHEMICAL

PREMIUM STAINLESS STEEL FINISH

UP TO 61.25T GROSS COMBINATION MASS

DESIGNED FOR EASY MAINTENANCE

TRUSTED EXPERIENCE

CUSTOMISED ENGINEERING

WATER

DRY BULK

OIL

AVIATION

Reliable sources

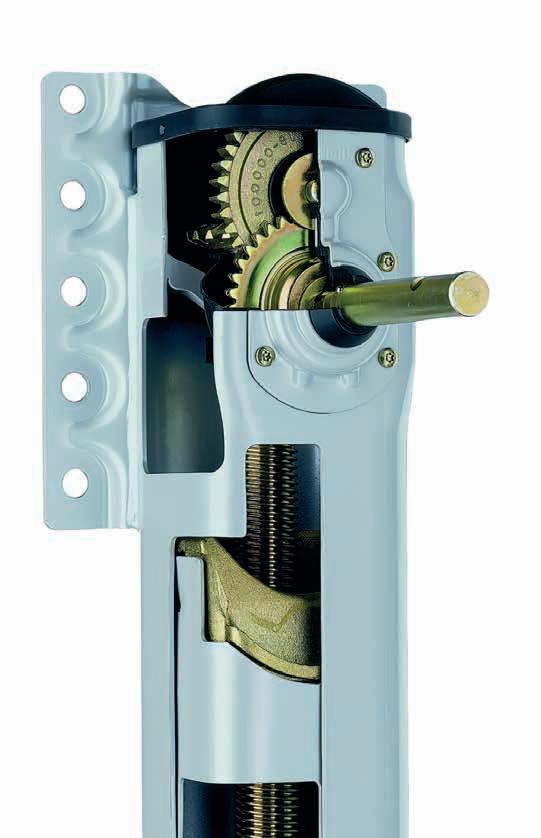

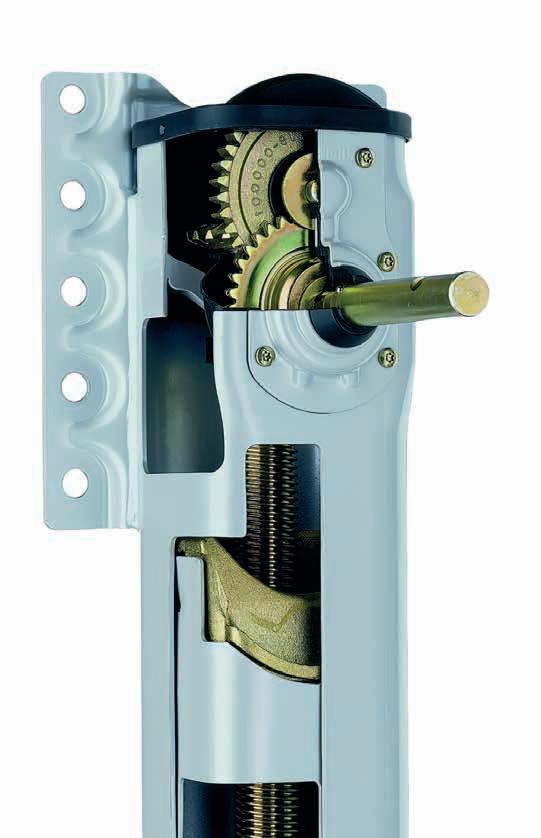

Based in Western Australia, Bruce Rock Engineering has been using JOST’s wide range of products for more than 25 years. The trailer builder turned to JOST after experiencing reliability and durability issues in harsh 24/7 operating conditions with a competitor’s landing legs, and it hasn’t looked back since.

Bruce Rock Engineering (BRE) has established itself as a superior trailer manufacturer and supplier in Australia with quality applications for any request. Because of this commitment, BRE has proven its ability to deliver innovative solutions across the transport, mining, agriculture, construction and retail industries.

The BRE heavy vehicle manufacturing process is carried out completely inhouse to ensure 100 per cent quality control, including the use of SSAB steel products along with JOST’s fifth wheels, kingpins and landing legs.

Prior to its first purchase with JOST, BRE had been using landing legs from an international competitor in the market. However, once establishing that JOST had surpassed it in every possible way, the company made the wise decision to apply JOST’s products to its combinations for the unforeseeable future.

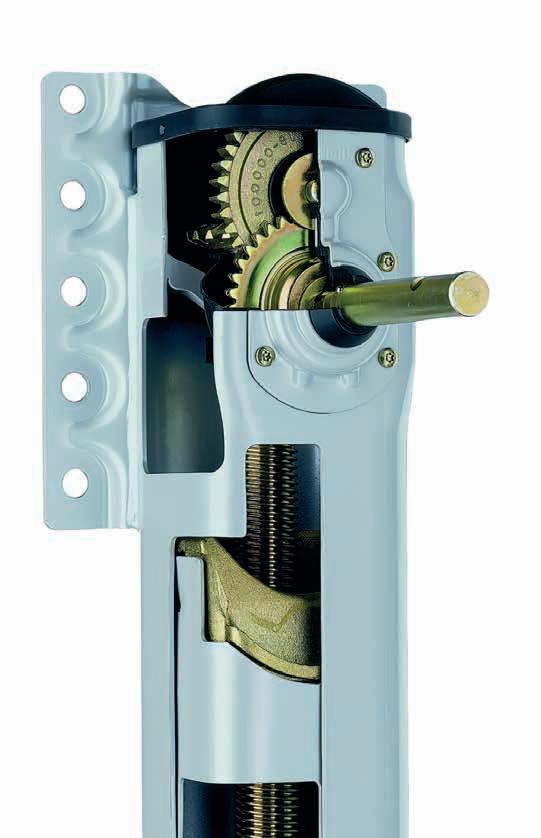

“We were using a Chinese

competitor’s leg for a long time previously, but it had reliability issues with gearbox gear selection and a few other issues there,” says BRE Managing Director, Damion Verhoogt. “We always knew that the Modul legs were a good product, but they were more expensive than what we had been using. We made the call that the price difference was not worth the headaches that we were getting with what we were using previously.”

BRE trailers operate in remote areas all over Australia, so the reliability of components and landing legs fitted require the highest standard of durability. The design of JOST’s Modul Leg comes into play in this field as it provides multiple options in regard to backing plates, leg travel and interchangeable foot options.

With such a compact design, trailer builders like BRE can obtain unmatched flexibility with mounting on the chassis which results in maximum ground

38 Trailer Magazine FEBRUARY 23 XXX Trailer building materials/components

Fast fact

JOST’s CA Modul Landing Leg is available in aluminium for trailer manufacturers looking for additional weight savings. The CA Modul is also available with two-sided operation and special crank and has continuous back plate for high variability during installation.

clearance without losing stroke.

Being corrosion resistant, the Modul is ideal for Australian conditions with first class pre-treatment and powder coating. And, being engineered in Europe with extensive life cycle tests, drop tests and bending tests, consistency is delivered with every leg manufactured.

“You just don’t have problems with the JOST ones, that’s why we changed,”

Damion says. “They’re definitely much more operator-friendly, they provide a smoother operation and they have better gear ratios.”

The design of the Modul delivers significant gain in stroke whilst keeping a large overlap, ensuring support and strength. With minimal parts, the Modul’s patented internal gearbox design delivers ultimate durability and reliability alongside a user-friendly crank speed within 15mm of travel per crank turn.

In addition to its exceptional quality, JOST offers its renowned aftersales support nationally with an unmatched promise. With the support of its distribution network, it guarantees the replacement of legs if required.

“JOST gives us really good support,” Damion says. “They’ve got a great range of products for a series of different applications. They’re amazing quality and their product gives us very little problems.”

Contact JOST Australia

Ph: 1800 811 487

Web: www.jostaustralia.com.au

www.trailermag.com.au 39

Superchrome takes wheels from tired to tough

For more that 20 years Superchrome has been setting the standard in chroming truck wheels and has a well-earned reputation as the industry leader in aluminium wheel chroming. This reputation backed by exceptional customer service and product support. One of the most common conversations customers have with Superchrome is the economics of purchasing brand new chromed wheels versus re-chroming their old wheels.