ISSUE 78 | APRIL 2023 THE OFFICIAL PUBLICATION OF THE AUSTRALASIAN SOCIETY FOR TRENCHLESS TECHNOLOGY The challenges of maintaining coastal sewer infrastructure | Drain inspection cameras available for distribution in Australia | OptionX Group strikes deal with MTS Microtunnelling Systems | Progress is in the pipeline GOING UNDERGROUND Rob Carr launches MTBM under Brisbane for Breakfast Creek Trunk Sewer Main Upgrade

Progres s is in the pipeline: we’re shifting the dial towards a more inclusive water industry

Your next career move could be just around the corner. Scan to learn more about working at Interflow.

This magazine is the official journal of the Australasian Society for Trenchless Technology (ASTT) and is distributed to members and other interested parties throughout Australia and the Asia-Pacific. It is also available on subscription.

The publishers welcome editorial contributions from interested parties. However, neither the publishers nor the ASTT accept responsibility for the content of these contributions and the views contained therein are not necessarily the views of the publishers or the ASTT. Neither the publishers nor the ASTT accept responsibility for any claims made by advertisers. All communications should be directed to the publishers.

Unless explicitly stated otherwise in writing, by providing editorial material to Prime Creative Media (PCM), including text and images, you are providing permission for that material to be subsequently used by PCM, whole or in part, edited or unchanged, alone or in combination with other material in any publication or format in print or online or howsoever distributed, whether produced by PCM and its agents and associates or another party to whom PCM has provided permission.

Cover image Left: Rob Carr has commenced construction of a new 1 km long wastewater pipe running under the heart of Brisbane, Queensland for Urban Utilities - Page 20. Image: Rob Carr.

Contents

78 APRIL 2023 COVER STORY Rob Carr begins construction of important Brisbane sewer in $45m Urban Utilities project 20 UNDER SOUTH AUSTRALIA South Australia hits every curveball 16 Wrapping up the challenges in SA 18 UTILITY PROJECTS The unique challenges of maintaining coastal sewer infrastructure 22 EMISSIONS REDUCTION The drive to thrive 24 Future Pipe Industries’ ongoing commitment to reducing carbon emissions 26 SAERTEX-LINER® MULTI saves 1 million kg of CO2 emissions 28 Closing the recycling loop 30 M axibor at the forefront for climate transition 32 RELINING IMPREG continues to invest in Australian and NZ market 34 Spin me right round, right round 36 Trenchless contractor puts maintenance hole relining system through its paces 38 SLIPLINING Focus on pipe protection 40 INSPECTION & CONDITION ASSEESSMENT Drain inspection cameras available for distribution in Australia 42 SECA has final say on CCTV equipment 44 Remote reading of conduits and pipes 46 MICROTUNNELLING OptionX Group strikes deal with MTS Microtunnelling Systems 48 WOMEN IN INDUSTRY Progress is in the pipeline: shifting the dial towards a more inclusive industry 50 DRAIN CLEANING How to clean large diameter pipes full of water and debris 52 HDD Directionally drilling down, down, down 54 Guiding through technology 56 GRUNDODRILL 28N overcomes challenges during Queensland installation 58 The triple bottom line benefits of trenchless technology 60 REGULARS Editor’s Letter 6 From the President 8 From the ASTT Secretary 10 News in brief 12 Events 62 ASTT Corporate Members 64 People on the Move 66

ISSUE

Excellence in tunneling for water, wastewater and energy infrastructure.

With a focus on safety, innovation and collaborative delivery over the last 30 years, Rob Carr has achieved outstanding outcomes in water, wastewater and energy infrastructure projects in both Australia and overseas. Rob Carr is part of Soletanche Bachy a world leader in foundation and soil technologies and subsidiary of VINCI, a global player in construction across more than 100 countries. With outstanding capabilities to manage the complexities of any project, Rob Carr has the people, knowledge and experience to deliver success.

robcarr.com.au

CEO

John Murphy

COO

Christine Clancy christine.clancy@primecreative.com.au

MANAGING EDITOR

Molly Hancock molly.hancock@primecreative.com.au

EDITOR

Clemence Carayol

BUSINESS DEVELOPMENT

Nick Lovering nick.lovering@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey blake.storey@primecreative.com.au

DESIGNERS

Kerry Pert, Tom Anderson, Louis Romero

COPYRIGHT

Trenchless Australasia is owned by Prime Creative Media and published by John Murphy. All material in Trenchless Australasia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Trenchless Australasia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2021

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Drive, Docklands VIC 3008

Ph: +61 3 9690 8766 enquiries@primecreative.com.au http://www.primecreative.com.au

Sydney Office Suite 303, 1-9 Chandos Street

Saint Leonards NSW 2065, Australia

Ph: (02) 9439 7227

Editor’s letter

Clemence Carayol

Welcome to this autumn edition of Trenchless Australasia

As an editor, it is the first time I have worked on a publication revolving around oil, gas, and energies, and thanks to Trenchless Australasia and its team, I have learnt so much.

I have learnt about who are the industry leaders in this very special industry.

I have also learnt how important and broad it is: trenchless technology has been used on what matters most in everyone’s life, such as water, wastewater, energy and communications infrastructures for decades now.

As I was finalising the pages of this edition of Trenchless Australasia, I immersed myself in what made this industry so unique as I learnt more about it every day.

It has been truly humbling to learn about all the distinct elements that compose the Australia and New Zealand’s trenchless technology industry, and how this industry is truly the backbone of our every day’s life.

Learning so many new terminologies has been fulfilling – HDD, microtunnelling, pipe jacking, pipe ramming have become part of my everyday language.

For this edition, we will focus on emission reduction, a topic that has become more and more prominent in the past decade.

Since emissions come mainly from energy combustion, it’s only normal that the very same industry should play a role in reducing these emissions.

This theme is also in line with this year’s No-Dig Down Under 2023 conference, as the event’s motto this year is “better outcomes through trenchless.”

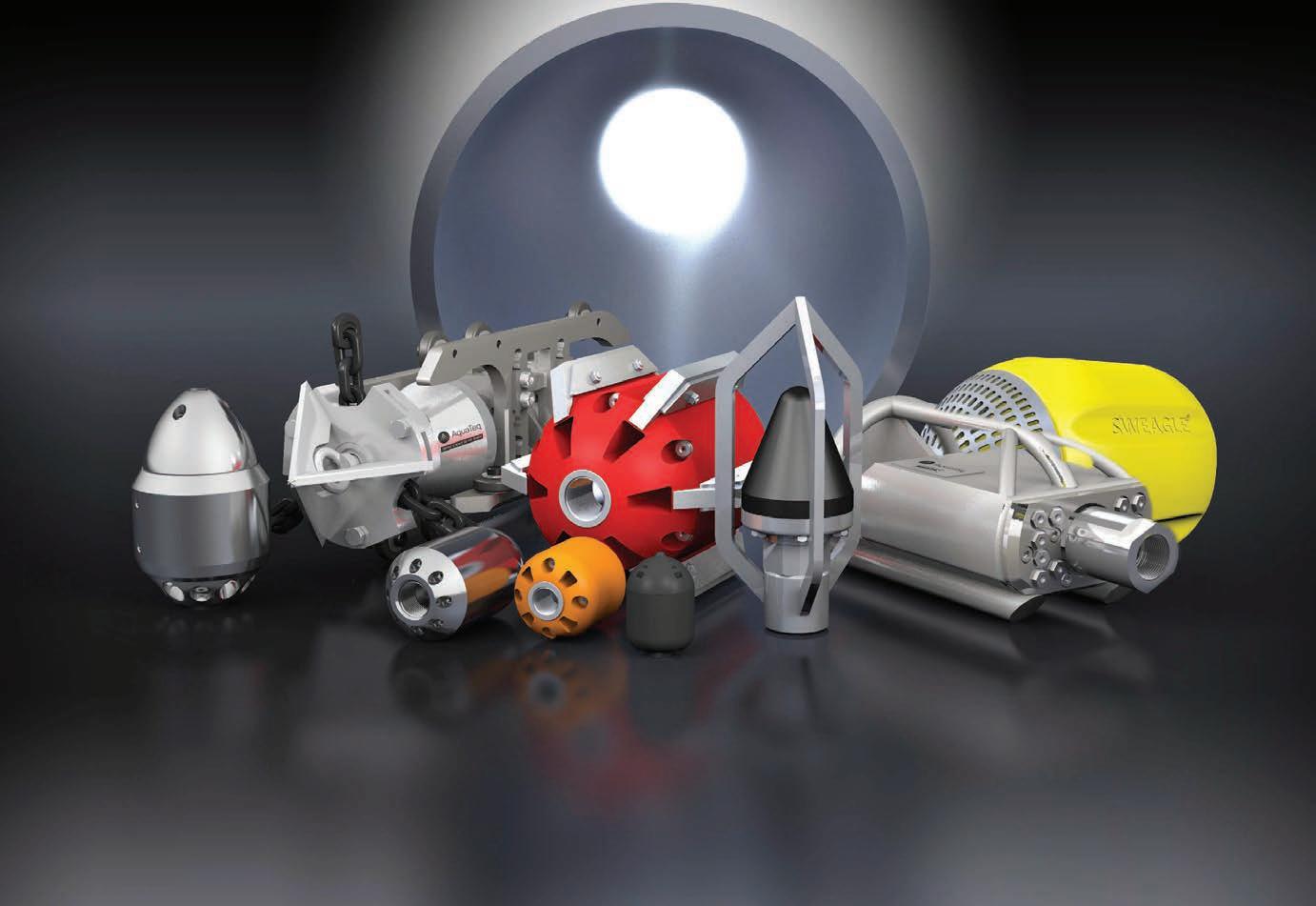

offer 10 utility and council scholarships for attendance at No-Dig Down Under 2023.

Three training sessions organised by the ASTT will focus on new installations good practices, whereas the second will be all about horizontal directional drilling, while the third will be pipelining orientated.

How to be more sustainable is crucial, and this is also at the very core of Pipe Core’s interest when it comes to making trenchless pipeline rehabilitation more sustainable.

Hence why the company has added SAERTEX-LINER UPgreen to its portfolio, a technology which impressively, since its launch two years ago, has enabled savings of one million kilograms of CO2, which our readers will be able to learn more about as they turn the pages of this magazine.

Reducing emissions is also very much at the heart of Empire Infrastructure’s philosophy. This edition of Trenchless Australasia highlights a Future Pipe Industries’ range of projects, distributed by Empire Infrastructure.

Future Pipe Industries has a comprehensive environmental, health and safety management program and all manufacturing units are committed to the group environmental and safety policy.

This product range is also equally committed to reducing our environmental impact. As with safety goals, each manufacturing facility has environmental initiatives focused on responsible use of energy and water and on waste reduction.

Printed by: Manark Printing 28 Dingley Ave Dandenong VIC 3175 Ph: (03) 9794 8337

This encompasses better environmental outcomes, from less wildlife disturbance and pollution, but also better community outcomes, from reduced disruption to essential roads and services as well as better financial outcomes, from lower costs for major projects.

I hope that, as you turn the pages of Trenchless Australasia, you will find as much pleasure reading it as we had while we were writing the magazine.

Happy reading!

Clemence Carayol Editor clemence.carayol@primecreative.com.au

6 TRENCHLESS AUSTRALASIA APRIL 2023

NEW ESRI ARCGIS INTEGRATION FOR SUPERIOR PIPELINE INSPECTION DATA Connects directly with GIS Eliminate human error with direct data transfer Easily locate critical infrastructure FASTER, ACCURATE, VISUAL Report with confidence. Visit us online seca.com.au

THE AUSTRALASIAN SOCIETY FOR TRENCHLESS TECHNOLOGY

ABN 43 893 870 966

18 Frinton Place

Greenwood, WA 6024

www.astt.com.au

jeffpace@astt.com.au

President: Ben Crosby

Secretary: Jeff Pace

Vice President: Blair Telfer

COUNCILLORS

Western Australia: Trevor Gosatti

Queensland: Ben Crosby

New South Wales: Matthew Boyle

Victoria: Justin Shepherd

South Australia: Shaun Melville

New Zealand: Blair Telfer

Northern Territory: Vacant

Tasmania: Vacant

INTERIM REPRESENTATIVES

Sudipta Basu

President’s Message

With a full quarter of 2023 down, I hope you can reflect on the start of the year being a rewarding and a positive one. To date, 2023 has been a good one for the ASTT and currently we are planning for our Annual General Meeting; of which you are invited to. Details are communicated on our website.

This edition of Trenchless Australasia is themed “trenchless going green” and I’m sure you will enjoy reading the articles focused on our overarching infrastructure industry as we pivot to a green and renewable approach. At the ASTT we see infrastructure pivoting to ensure we achieve net zero in the coming decades which will positively affect the buoyancy of our trenchless products, services, manufacturing and projects.

This year we are seeing more than normal change with our Council, and I will take this opportunity to thank our outgoing Council members in Justin Shepherd and Matthew Boyle. Both Justin and Matt have been instrumental in helping our industry and the ASTT and we appreciate their efforts. Both Justin’s and Matt’s careers are turning away from trenchless, and we support their desire to resign from Council and we wish them the best in the future. With the old comes the new, and we are very excited to welcome our new Councillors in Ash Hamer and Jiang Aizezi. We welcome both Ash and Jiang as they are formally appointed at the AGM in April 2023. Ash and Jiang are passionate about trenchless, and we are looking forward to working with them in some of the new initiatives that we are rolling out in the near future.

Another key change with the Council Structure is the resignation and retirement of Jeff Pace, having been our Security and Treasurer since our incorporation in 1991! Jeff has been an amazing asset to the ASTT over the 30 plus years and he will be sadly missed. We wish Jeff well in his “full retirement” decision that has been on his mind for a few years now. More recognition for Jeff’s amazing commitment to the ASTT and our industry will follow. Jeff hands over to another longterm industry supporter in Trevor Gosatti, and fortunately Trevor will slot into the role having worked in the ASTT for over 20 years as either

a Councillor or as our President.

The Conference theme this year is “Better Outcomes Through Trenchless”, and it is this theme we plan to stimulate the conversation and influence the papers, the exhibitors, and the panel discussion on improving the service industry with better design, better method selection and better overall solutions.

Given that the Conference is five months away, it is again shaping up to be a huge success. With over 95 per cent of the exhibition space sold there is little time to ponder, we’d love to see you showcase your services and products at No-Dig Down Under 2023.

A special thanks goes to our consistent and new supporters of the conference:

Platinum – Rob Carr

Gold – Vermeer

Silver – Rockpecker and Interflow. Successful conferences wouldn’t be possible without the commitment of these companies and all those others that take a booth, commit their time and effort to tell us all about their products and services. We appreciate your input which make our conferences a success. Council will continue to work through the allimportant key actions during 2023:

• The annual ASTT AGM

• The roll out of our Strategic Action Plan

• The finalisation of our Liner Design Specification

• The finalisation of the Liner Design Training Package

• The continuation of the updates to our NASTT licenced training packages

• The compilation of the report: The State of the Industry (Trenchless)

• The partnership with AusJet

• The partnership with WSAA.

All these initiatives are designed to deploy the membership resources to benefit the industry and the membership in one way or another. A reminder to our members; if there is something that you feel we as the peak trenchless body should be working on, please reach out and contact either myself or your local Councillor.

Ben Crosby ASTT President

8 TRENCHLESS AUSTRALASIA APRIL 2023

Future Pipe Industries and Empire Infrastructure: working together to deliver water and energy to Australasia in the most efficient and sustainable way

Empire Infrastructure is now supplying Future Pipe Industries’ (FPI) range of composite pipe systems to pipeline and trenchless projects throughout Australasia.

Established in 1984, and with a current workforce of over 3300, FPI has a reputation for delivering engineering excellence and a commitment to creating value for its customers. Across the globe, Future Pipe has successfully supplied more than 190,000 km of pipe and fittings.

FPI has operations and manufacturing facilities around the world, including one strategically located in Australasia which greatly reduces supply chain emissions. FPI is a company that is driven by its purpose: to work together to deliver water and energy to the world in the most efficient and sustainable way.

Contact Empire Infrastructure for more information about FPI’s sustainable pipe products or to obtain a copy of the Future Pipe Environmental Product Declaration.

info@empire.team | 1300 116 664 www.empireinfrastructure.com.au

Secretary’s Corner April 2023

New Members

On behalf of the ASTT, I extend a warm welcome to the following new members.

Gold Corporate Members – New Zealand

Philip McFarlane from WSP New Zealand Ltd.

Silver Corporate Members – USA

Jed Sheckler from Vector Magnetics.

Silver Corporate Members - New Zealand

David Smythe from Smythe Contractors Ltd upgraded from Individual to Silver Corporate.

Asset Owners – Australia

Phillip Bowley from Bowley Plumbing Services Pty Ltd.

Jasmine Stefanac from EnviroPacific - SOLVE.

Individual Members – Australia

Dino Everts from CPB Contractors.

Alex Tao from Ausinland Pty Ltd.

Jonathan Farrell from Credo Environmental Engineering.

ASTT AGM

Notice is hereby given that the 31st combined Council and Annual General Meeting will be held in the Mornington Boardroom at Prime Creative Media offices located at 379 Docklands Drive, Dock-lands, Melbourne on Thursday April 27, 2023, commencing at 9am.

All members are welcome to attend.

ASTT Council Nominations

The call for nominations to Council was e-mailed to all ASTT Members on 5 January 2023. The same notice was also published by PCM on the Trenchless Australasia website on 12 January 2023 also it was mentioned in the e-news dated 19 January 2023.

The results are as follows and will be ratified at the next AGM on April 27, 2023..

Councillor Changes

As can be seen from the table, we have a new WA Councillor namely Jiang Aizezi. Jiang is the Area Manager – TCL Utilities and Tunnels. Also, we also have a new Victorian Councillor namely Ash Hamer. Ash is the Manager Major Project with Yarra Valley Water.

Western Australia

Jiang Aizezi Tasmania Vacant

New South Wales

Sudipta Basu Victoria Ash Hamer

Queensland Ben Crosby New Zealand

South Australia

Shaun Melville

Blair Telfer

Northern Territory Vacant

New Secretary/Treasurer for the ASTT This is my last Secretaries Corner report. After much deliberation, I have decided to throw in the towel and officially retire from my position as your ASTT Secretary/ Treasurer effective from April 27, 2023 It has certainly been an amazing ride throughout these past 32 years. We have come a long way since our beginning back in 1991. Although no longer with us, I would like to especially thank Menno Henneveld for having the vision to come up with the idea to create a society and giving me the op-portunity to fulfill this task and continue to manage it for all of you. His legacy lives on. I would also like to thank you the members for allowing me to represent you all over this period. It was an honour to work alongside you all and learn all the amazing advancement that trenchless technology has realised over this long period.

We the ASTT have accomplished a tremendous amount over this time and are now recognized as one of the most efficient societies of all the other Affiliated societies worldwide.

We continue to produce world class International and National conferences and exhibitions that are the envy of the world. This is partly due to the team at Prime Creative Media (PCM) who ensure we get the best out of these shows and also have fun at the same time. PCM also now produce our Trenchless Australasia magazine a task I was so pleased to hand over in 2004 as I found it extremely difficult to produce our modest newsletters for a circulation of 200.

I will miss the time I had being involved with the ISTT as your representative, however I will not miss the 11pm regular

meetings that the ISTT has. It goes without saying that there will be a gap in my life due to not catching up with all the ASTT and affiliated society members both locally and overseas at the conferences. I will also miss the daily checking of emails that has kept me busy every day since email was introduced.

And finally I can announce prior to the AGM that you will have a new Secretary/Treasurer namely Trevor Gosatti, effective from April 27, 2023. I wish Trevor all the best and I am confident he will not dissappoint you all. I want to wish the ASTT Councillors and you the members, both past and present, all the best, and who knows, you might see me at times pop up at some of our events.

Trenchless Australasia Magazines now online Following several requests from the members and providing yet another benefit to members, I can now confirm that past editions of Trenchless Australasia from June 2020 to date can now be downloaded directly from the ASTT members only area of our website.

Refer to the new heading shown as MAGAZINES at astt.wildapricot.org/ Magazines.

No-Dig Down Under 2023 Brisbane

At the time of writing this in mid March, there were only a few stands left which once again con-firms that the trenchless industry totally supports the ASTT. If you are interested in getting in before it is too late, then please contact Nick Lovering at nick.lovering@primecreative.com.au. More infor-mation is also available on the event website, refer: nodigdownunder.com/ A reminder that our next National Conference and Exhibition will be held over September 12 to 15, 2023 at the Brisbane Convention and Exhibition Centre. This year the organising committee is considering having some site visits possibly starting the day after the conference. Early Bird delegate registrations are now available online as well as the Awards nominations.

Jeff Pace ASTT Secretary

10 TRENCHLESS

2023

AUSTRALASIA APRIL

M. TUCKER & SONS CIVIL AND TRENCHLESS SOLUTIONS www.mtuckerandsons.com mail@mtuckerandsons.com | 03 9736 3439 20 Clancys Road, Mount Evelyn, VIC, 3796 PO Box 955, Lilydale, VIC, 3140 CALL 03 9736 3439 Specialised Services: M. Tucker & Sons is a proud family run company, specialising in drainage maintenance and pipeline rehabilitation CCTV INSPECTION, CONDITION ASSESSMENT & LASER PROFILING 100-2,000 mm (WSAA ACCREDITED) LATERAL REINSTATEMENT & ROBOTIC GRINDING UV CURED MANHOLE/LATERAL SEALING & TOP HATS DRAIN CLEANING/NDD & VACUUM LOADING PIPE PATCH REPAIRS AMEX, QUICKLOCK, FIBREGLASS & SMARTLOCK UV PIPE RELINING 150-1,500 mm

Innovative product protecting trenchless contractors from costly and dangerous asset strikes

Conceived specifically for the trenchless and civil construction industries, The Safety Shovel simultaneously detects metal and power under the ground, preventing harmful asset strikes before they happen.

The Safety Shovel is designed to be used as a supportive tool to protect workers from harmful events, resulting from asset strikes.

Although best endeavours are deployed to prevent infrastructure strikes, records that are inaccurate deliver risk that cannot be minimised without advanced tooling. The Safety Shovel provides a functional real time detection tool to protect workers by simultaneously detecting metal objects and electrical cables (EMF) under the ground.

With alignment to Australian excavation standards, The Safety Shovel allows workers to operate within the exclusion zone and detect materials and cables that – if damaged – would result in a major Occupational Health, Safety & Environmental OHSE event or asset strike.

Typical assets detected include, water and gas pipes, communications cables, as well as live power cables.

The Safety Shovel compliments the efforts of Before You Dig and alerts excavation teams of potential danger before they happen.

Trenchless industry celebrates International Women’s Day

The trenchless industry has come together to celebrate the women who help keep the industry running.

International Women’s Day (IWD) 2023 is an opportunity for companies to foreground the hard work and dedication of their female employees, and the trenchless industry has answered the call. From suppliers like Vermeer and SECA to inspection service providers like VAPAR and training companies like DBYD Certification – no-dig operators have announced their support and encouragement for women in the industry.

In a Linkedin post Kristel Hudson, SECA’s Marketing and Coms lead, said that operators must acknowledge the challenges and obstacles that women still face today.

“This day is a reminder of the resilience and strength that women possess, and how we have continued to break down barriers and pave the way for future generations,” she said.

“To my female colleagues, you are an inspiration to me and those around you. You have shown incredible strength, perseverance, and dedication to your work, family and friendships and I am proud to work alongside you.”

IWD 2023’s theme is ‘Embrace Equity’.

Vermeer manager supports Leukaemia Foundation with World’s Greatest Shave

One of Vermeer Australia’s Area Manager’s, Tristan Jackson did the World’s Greatest Shave and raised $7,637 for the Leukaemia Foundation.

The money raised was in support of the Leukaemia Foundation, which offers expert support, funds leading-edge research and campaigns to make change for Australians facing blood cancer.

“To say I am overwhelmed by the support from everyone, is an understatement. I am truly in awe of the generosity that people have shown, and how together we can make a difference,” said Jackson.

“Thank you to everyone, who donated, helped

and supported me in raising such a significant amount for the Leukaemia Foundation by doing the World’s Greatest Shave.”

Jackson proceeded then to thank Vermeer, RDO Equipment and L&M Trenchless – among others – for their support.

The organisation’s first World’s Greatest Shave dates back to the late nineties, when the challenge was then named Shave for a Cure. This year, World’s Greatest Shave is hitting its 25th milestone, making it one of Australia’s longest running and most iconic fundraising events.

Over the last quarter-century, more than 2 million Aussies have taken part – with an estimated 39,000 kilograms of hair removed. Be like Jackson, “be brave and shave”, as the Leukaemia Foundation’s motto says.

FEATURE 12 TRENCHLESS AUSTRALASIA APRIL 2023 NEWS IN BRIEF

The Safety Shovel simultaneously detects metal and power under the ground, preventing harmful asset strikes before they happen.

Vermeer Australia’s manager Tristan Jackson shaving his head for the World’s Greatest Shave to support the Leukaemia Foundation.

International Women’s Day 2023 is an opportunity for companies to foreground the hard work and dedication of their female employees.

WHEN ACCURACY MATTERS

Edge Underground is a precision microtunnelling contractor that operates in Australia and the USA. With a focus on innovative technology and expertise, Edge Underground designs and enhances the performance of trenchless equipment. Full factory backing here in Australia means solutions can be created when they’re needed most. MICROTUNNELLING

PART OF THE

BUILDING BETTER UNDERGROUND OPTIONS

optionxgroup.com.au optionxgroup.com.au

• PIPE

• LASER

JACKING THRUST BORING

TUNNEL BORING BOX CULVERT JACKING • CANOPY TUBES

Merredin Shire Council authorises wastewater pipes refurbishment

Merredin Shire’s authorised contractor Allpipe Technologies will soon commence work to refurbish ageing wastewater pipes.

This refurbishment work executed by Allpipe Technologies is set to commence in mid-March 2023 and completed by late July 2023 and will take place across the town of Merredin. Allpipe Technologies will be working in both verges and/or roads, and also in the boundary of private properties. Sewer relining uses trenchless technology to clean and refurbish existing wastewater pipes.

It reduces the likelihood of blockages and extends the life of this important infrastructure by at least 30 years.

Residents and businesses may notice more activity in the area, noise from generators and vehicles and temporary odour. Traffic management will be in place to direct vehicles, cyclists and pedestrians safely around the work area. Night works may occasionally be required and access to property might be requested, and in both cases, the shire will notify impacted residents in advance.

Primus Line® flies the flag

for

trenchless solutions in sensitive locations

Primus Line has illustrated the benefits of trenchless technology for pipeline rehabilitation in culturally sensitive areas during two installations for one of the world’s leading mining companies.

Trenchless methods, such as Primus Line, are the perfect solution to overcome the challenges of pipeline works in areas of cultural significant importance and preserve them to traditional landowners.

The benefits of Primus Line was recently proven during two Rio Tinto projects using the technology in areas of cultural heritage sensitivity in Western Australia.

The first project took place near Cape Lambert and included the renovation of a 1500 m long high-density polyethylene (HDPE) pipeline. The second installation was in the outback near Paraburdoo where a 1000 m of cement-lined mild steel pipeline was rehabilitated.

Primus Line is a flexible, safe and reliable pipeline relining technology that reduces earth movements to a minimum, usually only requiring two small construction pits at the beginning and the end of the pipeline section to be rehabilitated.

Thus, the areas of cultural heritage sensitivity remain completely untouched.

The liner comes pre-coiled on transport spools with a length up to 1000

FEATURE 14

NEWS IN BRIEF

The refurbishment work executed by Allpipe Technologies is set to commence in mid-March 2023 and will take place across the town of Merredin.

Primus Line being used during two Rio Tinto projects.

ALWAYS ONE TURN AHEAD

GRUNDODRILL ACS130

ROCK DRILLING HDD RIG

The GRUNDODRILL ACS130 from TRACTO is setting standards in HDD: From the finest silts to impossibly hard rock, the ACS130 works where others give up.

- Fully automatic operating and rod loading modes

- Maximum power output and reaming speeds

- Full remote drilling

- Dependable power transmission

- Flushing capacity of 320 l/min

- Minimum working width of just 1.91 m

To find out more, please get in touch. info-au@tracto.com

T + 61 7 3420 5455

TRACTO.COM/GRUNDODRILL

South Australia hits every curveball

Trenchless operators in South Australia have been assisting in flood relief and expanding infrastructure ahead of a potential game-changing innovation in the world of wastewater pipe corrosion prevention.

In service to people

SA Water and Interflow’s efforts to support flooded towns and communities throughout Australia in 2022 haven’t ceased.

After heavy rain in Queensland, New South Wales and Victoria caused exceptional flooding late last year in several towns along the length of the Murray River in Southern Australia, SA Water and Interflow’s help towards the impacted communities continue.

With the water only now starting to recede in the last few weeks, this help is more than necessary today.

Located 84 kilometres east of Adelaide lies the historic town of Mannum, on the west bank of the river, where a number of properties became inundated with floodwaters.

“Some of these low-lying properties feed into the common wastewater main, and if nothing was done the river could have freely flowed into the wastewater network, inundating pump stations and impacting SA WaterCorp’s ability to provide wastewater services to some of their local customers,” shared the Interflow team.

“Early on in the event, SA Water put several actions in place to help mitigate this

challenge, including calling on some of its contract partners, such as Interflow.”

Interflow welcomed its ongoing collaboration with SA Water to support local communities.

“Working consistently over three weeks, together with SA Water, we isolated required properties from the local wastewater network, through patching and sealing, and continue to work with the utility now, gradually restoring services as the floodwaters recede,” said the Interflow team.

“We’re proud of the SA Water and Interflow teams’ quick response through the floods, and for supporting the local communities.”

Healthy expansion

SA Water is investing $155 million in a water main management program that is affecting its extensive network.

The utility has begun works to replace 55 metres of water mains in Mount Barker, around the heritage SteamRanger tracks.

In order to minimise the environmental and community impacts of the work, the utility company has decided to use horizontal directional drilling (HDD) at a depth of 2.4 metres underneath Mount Barker’s heritage SteamRanger tracks.

The section of pipe being replaced is critical to the water service in Mt Barker and surrounds.

Amanda Lewry, SA Water’s General Manager of Sustainable Infrastructure said that HDD is considered to be safer and more efficient for the project.

“These works are part of our efforts to continually improve water services for our customers, with this section of pipe critical to transporting water to residents and businesses in and around Mount Barker,” she said.

“Together with our contractors, we’re committed to minimising any impacts to the community during the works, such as dust or noise caused by the use of heavy machinery and increased vehicle movement in and out of our worksite.”

Work will be timed for periods in which the SteamRanger is not operating.

Bright future

Researchers from The University of South Australia and the University of Queensland have developed self-healing concrete that may use waste to mitigate corrosion in Australia’s sewer pipes.

Professor Yan Zhuge, Professor of Structural Engineering from the University of South

UNDER SA 16 TRENCHLESS AUSTRALASIA APRIL 2023

South Australia is in a growth mindset with trenchless operating leading the way.

Australia, is leading the trial of a an innovative solution for dealing with the corrosion of concrete pipes.

Developed alongside researchers from the University of Queensland, the trial will use pipes that are manufactured from concrete that contains microcapsules filled with a mix of alum sludge and calcium hydroxide, which are added in the final step of mixing the concrete.

The microcapsules have a pH-sensitive shell that will respond to acidic buildup by breaking own and releasing the contents, which act as healing agents and makes the concrete highly resistant to microbially-induced corrosion.

The capsules have a pH-sensitive shell so that they can respond when the pH of the pipes reaches a certain point – a change caused by the corrosive acid from sulphur-oxidising bacteria in wastewater.

“This technology will not only extend the lifetime of concrete structures, saving the Australian economy more than $1 billion, but it will promote a circular economy as well by reusing sludge that would normally end up in landfill,” Zhuge said.

This reuse of waste will be essential to the carbon-neutral aspirations of many industry operators.

“Mainland Australia alone has about 400 drinking water treatment plants, with a single site annually generating up to 2000 tonnes of treated water sludge,” said Zhuge. “Most of that is disposed of in landfill, costing more than $6 million each year, as well as causing severe environmental issues.”

By utilising waste product from wastewater treatment plants in the sludge, the research has the potential to generate a circular economy – an essential element as all industries attempt to decrease their carbon footprint as much as possible.

At L&D Micro Tunnelling we specialize in laser guided boring. Our Tunnel bore machines use a vacuum extraction system where all spoil is sucked into interceptor tanks for easy disposal with no mess. All our heads are hydraulically driven and guided by a high accuracy laser to achieve precision over long distances.

UNDER SA APRIL 2023 TRENCHLESS AUSTRALASIA 17

47a Brunel Road, Seaford, VIC 3198 | luke@ldmt.com.au | chris@ldmt.com.au | 0401 754 929 | www.ldmt.com.au Unrivalled reliability – Accuracy Guaranteed • Specialists in free boring, sleeve boring and pipe jacking • Sizes ranging from 350mm > 600mm in most ground conditions • Drill up to 120 meters with a +/- 10mm tolerance

20 years experience in the drainage industry

•

The field joints for the DN250 FBE coated pipeline were prepared to SA 2.5 (abrasive blast clean) prior to the contractor applying Protal 7700™ (rapid cure, high build epoxy) as the Field Joint Coating (FJC) at a nominal Dry Film Thickness (DFT) of 1000 microns via airless spray guns from 1000ml cartridges.

Following the inspection for both the mainline coating and field joint coating, Denso BoreWrap™ was applied on site in a two-layer system to protect against the abrasion, impact, gouging and shearing impacts which are to be expected

Wrapping up the challenges in SA

In December 2022, Denso Australia completed the supply of a project involving the protection of 400 lineal metres of DN250 mild steel pipeline in Bolivar, South Australia.

when undertaking Horizontal Directional Drilling (HDD) installations.

Denso Bore-Wrap™ is designed to protect the underlying corrosion system and work efficiently with the cathodic protection system as it is a nonshielding Abrasion Resistant Outerwrap (ARO).

The ease of application for both the Protal & Bore-Wrap products contributed greatly to cost savings in labour and QA. In addition, the successful application of these products has assured that both the client’s asset as well as the corrosion coating are protected long-term through the rigours of the HDD installation.

Denso (Australia), is a subsidiary of Winn & Coales International and specialise in the manufacture and supply of corrosion and chemical resistant coatings and linings for the long-term protection of steel, concrete and timber surfaces in the toughest corrosive environments.

The company is at the forefront of innovative corrosion prevention technology and has a focus on developing an extensive range of custom solutions to meet the specific needs of different industries.

Denso’s full range of products are manufactured to comply with the strict quality standards. The products are designed for

longevity, with corrosion prevention solutions that can offer up to 30-plus years of maintenance free service.

For more information go to www.densoaustralia.com.au

UNDER SA 18 TRENCHLESS AUSTRALASIA APRIL 2023

Denso Bore-Wrap ready for installing.

Denso Bore-Wrap following successful HDD pull-back.

Contractors applying the Denso Bore-Wrap™ System.

Rob Carr begins construction of important Brisbane sewer in $45m Urban Utilities project

Microtunnelling contractor, Rob Carr, has commenced construction of a new 1 km long wastewater pipe running under the heart of Brisbane, Queensland. The Urban Utilities project is part of a major infrastructure upgrade to cater for population growth in the city’s north, which is expected to increase by 37,000 over the next 30 years.

An Australian Bureau of Statistics report based on data from 2019-2020, found greater Brisbane’s population was growing faster than anywhere else in the country, at a rate of 1.9 per cent per year, and its popular northern suburbs are booming. Urban Utilities is responsible for providing reliable water and wastewater services for the growing city, with the utility servicing more than 1.6 million customers across Brisbane, Ipswich, Scenic Rim, Somerset and Lockyer Valley local council areas in South East Queensland.

To cater for the expected 37,000 additional people in the north Brisbane region who will be relying on the utility’s services over the next 30 years, Urban Utilities is investing $45 million to upgrade the area’s essential wastewater network, by building the Breakfast Creek Trunk Sewer Main Upgrade. Stretching from Bowen Hills to Windsor, the 1 km long and 1.8 m internal diameter pipeline will be one of the largest in the utility’s 9000 km wastewater network, transporting up to 400 L of wastewater per second once complete.

Urban Utilities spokesperson Michelle Cull says the project is a key aspect of the organisation’s plans to support population growth in the region.

“We plan well ahead for the future and the population in this catchment area on Brisbane’s northside is expected to grow by around 40 per cent over the next three decades,” she says.

“That means a lot more toilets flushing, washing machines running and showers being used, so it’s important we continue to invest in essential infrastructure for our growing community. The new sewer will run beneath some of Brisbane’s busiest roads, including the Inner City Bypass, and will transport the wastewater from thousands of homes and businesses to our Luggage Point Resource Recovery Centre, where it’s treated.”

Construction of the sewer will utilise microtunnelling, with Rob Carr contracted by Urban Utilities’ delivery partner Fulton Hogan Utilities to complete the trenchless design and construction, taking place at depths of up to 14 m, around four storeys, below ground.

“By using this state-of-the-art technology,

we’re able to carry out this significant upgrade while minimising impacts on traffic, customers and the community,” says Cull.

“The project is a feat of engineering and it’s a far cry from the traditional tunnelling methods used by miners to build the city’s largest and oldest sewer pipe – the S1 Main Sewer – in 1915.”

Rob Carr general manager Angelo Soumboulidis says the company was contracted for the project after working closely with Fulton Hogan Utilities on a design which leveraged innovation.

“We have a strong reputation as a leader and innovator in the industry with a proven track record of delivering high-quality work,” he says.

“Working closely with our client, Fulton Hogan Utilities, our innovative final design solution minimised disruption to the surrounding community and limited environmental impact.

“Our commitment to providing innovative solutions to our clients’ needs and our dedication to delivering exceptional customer service were also key factors in our selection for this project.”

Rob Carr is using a 29 t Herrenknecht microtunnel boring machine (MTBM) named Leila Perry after the granddaughter of George Edmonstone, a politician who made significant contributions to Brisbane in the late 1800s. The family has also gifted the land where construction of the project is taking place.

The 29 t MTBM is also one-of-a-kind, having been transformed into a colourful work of art created by a local high school student. The design is inspired by Brisbane, representing the city’s iconic jacaranda trees, the Brisbane River and Story Bridge.

On 13 March, the MTBM was lowered into the launch shaft in Perry Park, on the corner of Folkstone St and Edmonstone Rd in Bowen Hills, beginning its journey west towards Windsor. The machine will pass underneath the Inner City Bypass before reaching a retrieval shaft adjacent to the Airport Link northbound entry ramp and Lutwyche Road intersection where it will be recovered.

The MTBM will tunnel through Brisbane tuff rock up to 150 MPa traversing an innovative alignment, and will use pipejacking to install 334 lengths of reinforced concrete pipe which will form the new sewer main as it progresses.

COVER STORY 20 TRENCHLESS AUSTRALASIA APRIL 2023

The Rob Carr crew onsite at the Breakfast Creek Trunk Sewer Main Upgrade.

Rob Carr project manager Thierry Candito says the contractor is excited to be contributing to such an important project, ensuring the growing city of Brisbane can continue to enjoy essential services now and into the future.

“This project is very interesting and challenging,” he says.

“The pipejacking operation is only one part of the project. We have many activities happening in parallel that we need to plan and coordinate carefully.”

To be ready for the MTBM launch, Rob Carr first had to excavate and complete an underpinned segmental shaft up to 15 m deep. In parallel, the company started construction of the first stage of connecting the tunnel with Urban Utilities’ existing S1 sewer.

While this work was ongoing, the contractor also installed a 10 t portal crane on the surface, which will provide logistical support for deliveries to site and lower jacking pipe to the foot of the shaft. The company is also concurrently constructing the receival shaft using the caisson sinking technique.

Once the MBTM completes its journey to Windsor, Rob Carr will undertake high density polyethylene welding of the pipe joints, while also carrying out the second stage of the S1 tunnel connection. Once this has been completed, Rob Carr will move onto constructing maintenance holes at either end of

the pipeline alignment.

Candito says the experience and knowledge of Rob Carr in delivering complex projects will help them to meet three of the key challenging aspects of the installation, including the MTBM passing under a live rail crossing.

“We are working closely with our client Fulton Hogan Utilities and Queensland Rail for this operation, and are implementing a 24/7 rail monitoring system,” he says.

“We have selected the optimum location to set up a theodolite that will continuously check target prisms installed along the rail. Through a cloud-based website, we will be able to monitor the rails in real time while the MTBM operates underneath.

“With this live input, we will be able to better manage the operation of the machine.”

The MTBM will also travel underneath

a creek in the area and Rob Carr is working with Fulton Hogan Utilities to finalise the parameters and a process for executing this important section of the alignment.

“We have completed additional boreholes and a geotechnical investigation to have the most accurate data along the tunnel alignment,” says Candito.

“We have completed an MTBM face pressure analysis with the data received and are now reviewing it with third parties to ensure it is satisfactory. We also plan to stop the machine prior the creek, complete cutter head maintenance and check machine’s system, allowing us to mitigate risks of a breakdown or maintenance while traveling below the waterway.

“Finally, the last challenge is our people, who are the ones making this project a reality. We need to ensure they are working in the best environment possible and give them the opportunity to continue to grow throughout the project and keep them safe.”

Soumboulidis says the project is an opportunity for the company to once again illustrate its expertise in microtunnelling and trenchless pipeline construction.

“The project is incredibly important to Rob Carr as it represents our commitment to providing innovative and cost-effective solutions that meet our clients’ needs,” he says.

“We are able to showcase our expertise in microtunnelling and complex civil works, delivering efficient solutions, whilst simultaneously minimising our environmental impact.”

Construction of the project is expected to take 18 months and be completed in 2024.

For more information visit www.robcarr.com.au

COVER STORY APRIL 2023 TRENCHLESS AUSTRALASIA 21

The local high school student whose colourful design was selected for the MTBM with her mother.

The launch shaft in Perry Park.

Rob Carr is using a 29 t Herrenknecht microtunnel boring machine.

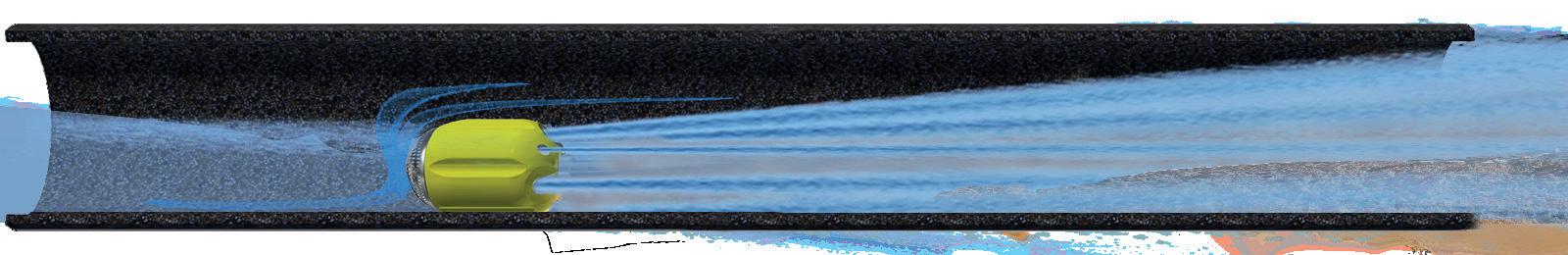

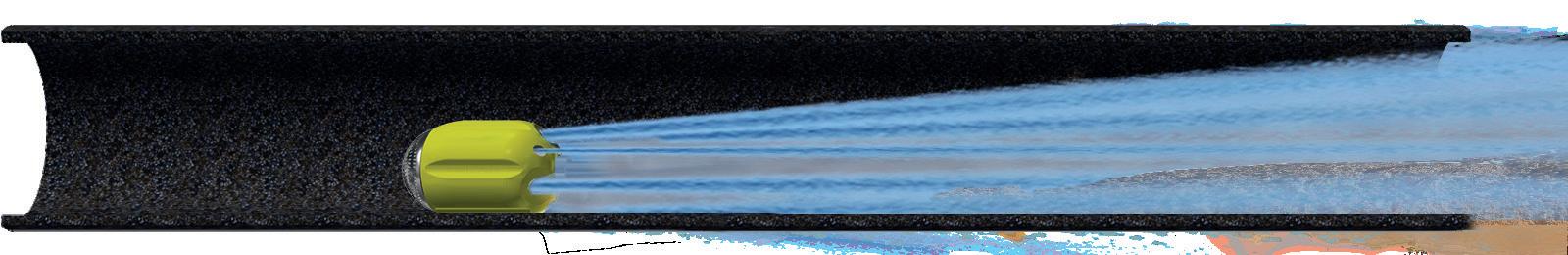

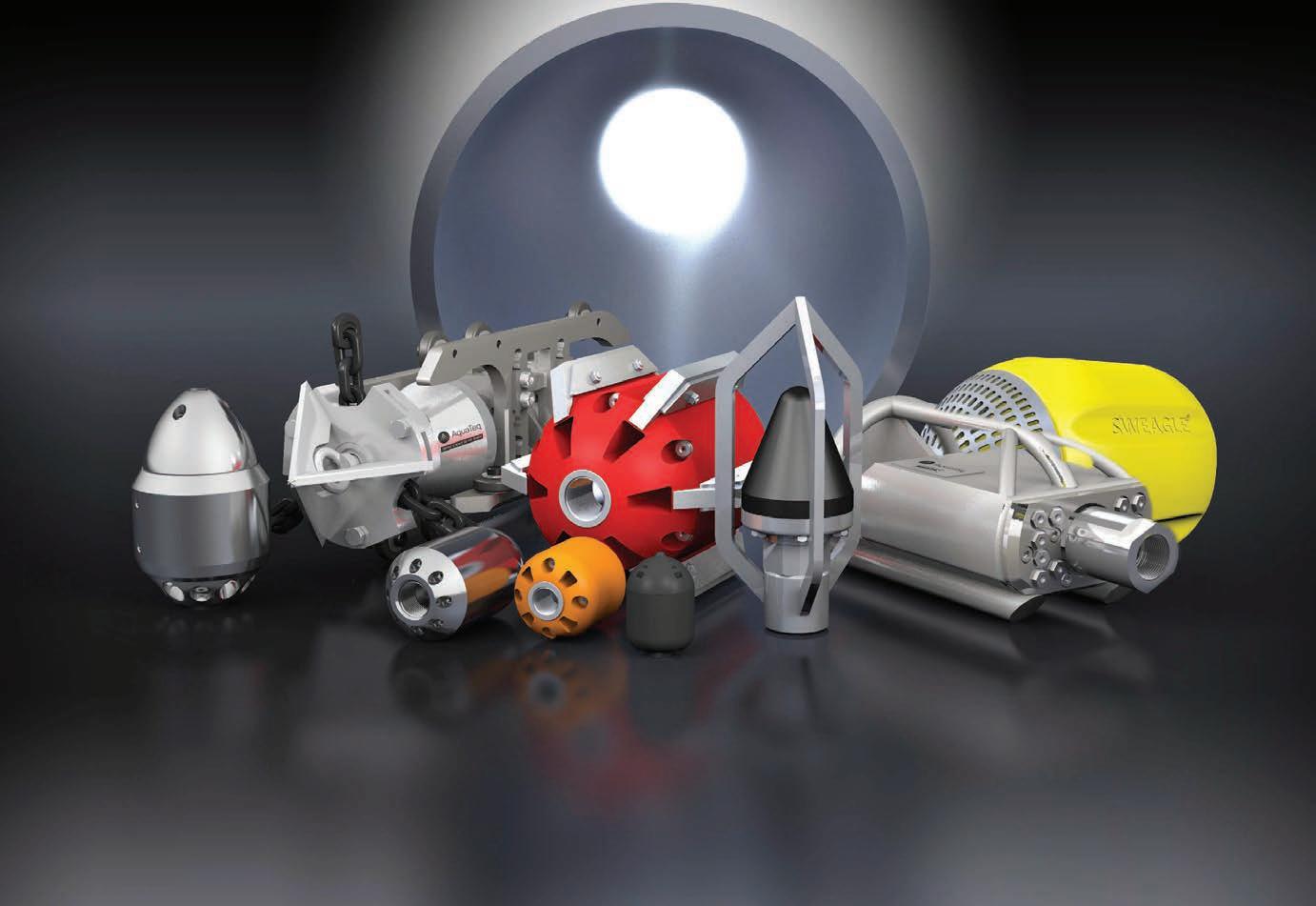

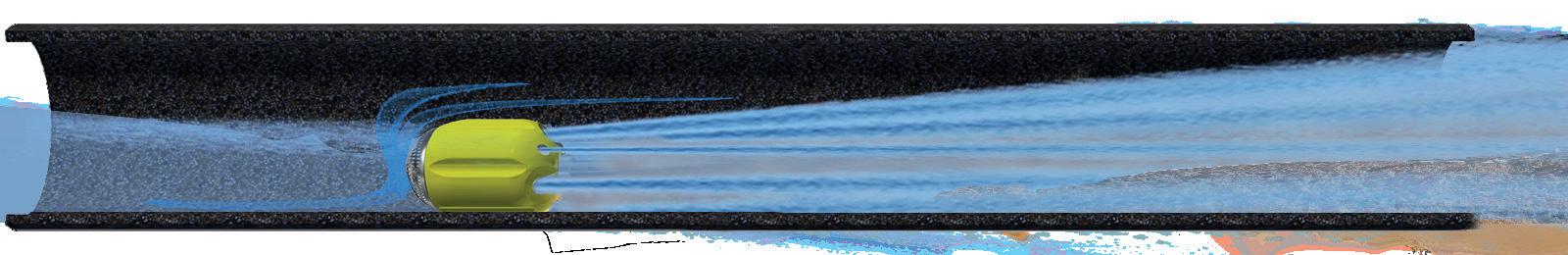

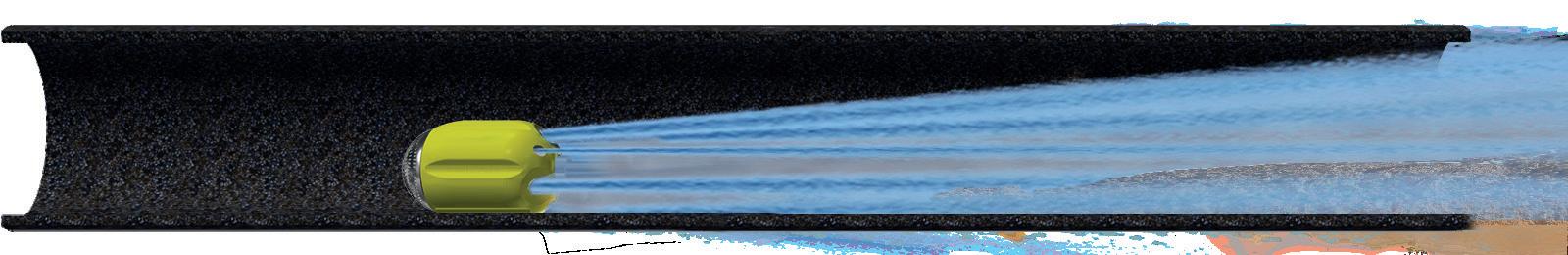

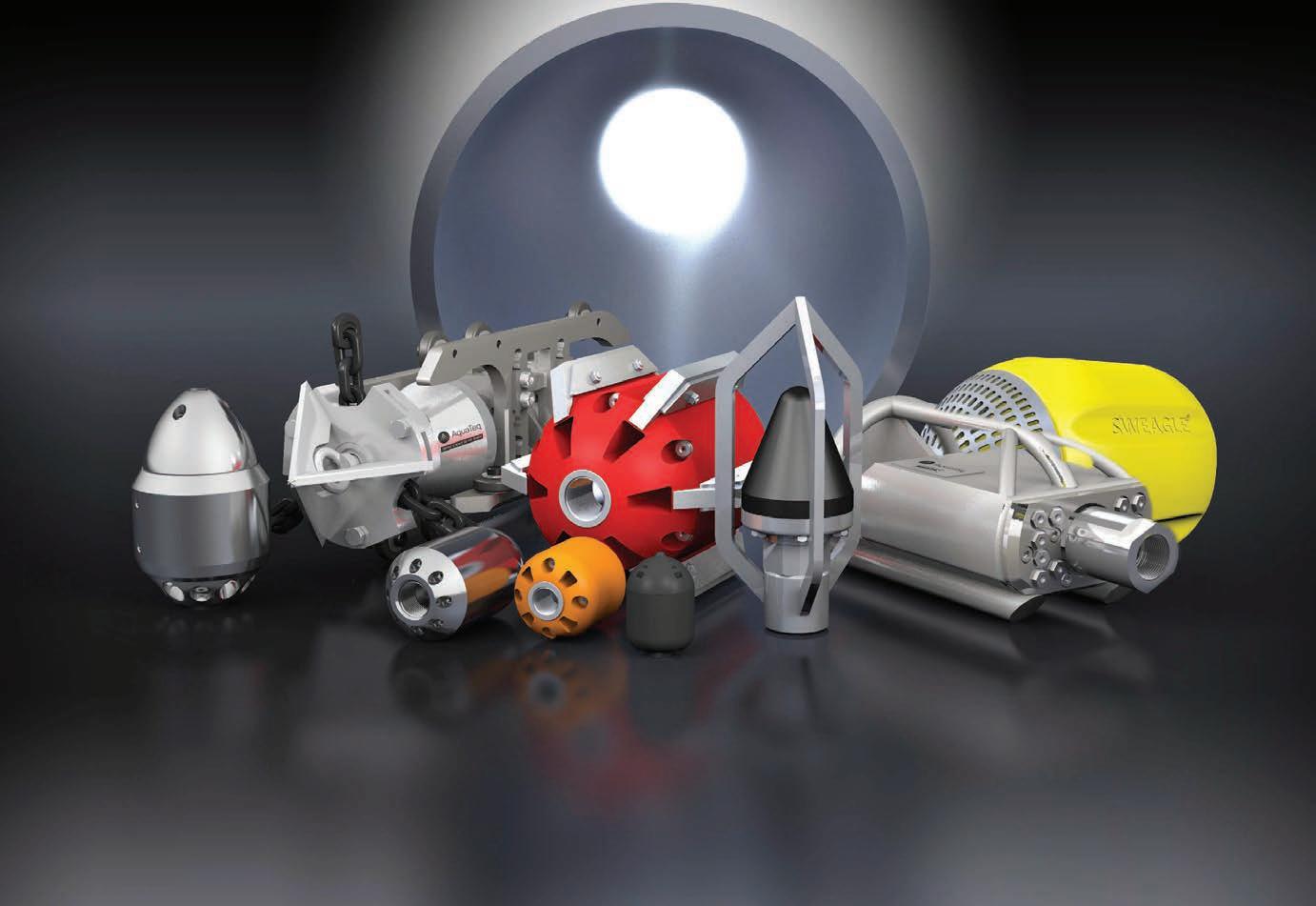

The unique challenges of maintaining coastal sewer infrastructure

Due to its location on the east coast of Australia, Central Coast Council’s sewer network experiences a range of challenges that differ from inland asset owners.

Jamie Loader is the Central Coast Council’s Director Water and Sewer, overlooking the entire reticulated system – including 2600 kilometres of sewer mains, 320 pump stations and eight treatment plants.

Loader tells Trenchless Australasia that it can be hard to identify minor issues, meaning that sometimes faults are only seen when there is a system failure.

“There’s a range of things that will contribute to damaging the sewer network,” says Loader. “Anything from ageing infrastructure, tree

root intrusion, cross connections from private properties where they’ve connected their sewer in the storm water, either deliberately or unknowingly.”

“Even just movement within the soil can sometimes dislodge pipe connections.”

Unique to coastal regions, however, is the ingress of salt water – which speeds up corrosion of water assets.

“Flooding is also more frequent in coastal areas – storm surges and sea-levels rising can contribute to infiltration,” Loader says.

The combination of a number of ecologically sensitive locations in the area and the dense urban population along the coast means that, when leaks do happen, the impact can be exaggerated compared to less complex urban environments, with public health being at the forefront.

Late in 2022, the combination of these various pressures on the system resulted in Terrigal Beach – in the southeast of the council’s jurisdiction – receiving a poor water quality rating, partially due to

UTILITY PROJECTS 22 TRENCHLESS AUSTRALASIA APRIL 2023

sewer infiltration. In response, the council commenced a massive relining program to mitigate the sewer outflow that was contributing to pollution in the area.

Since the pollution at Terrigal Beach was identified, Central Coast Council has relined over 125 kms of sewer mains. Contractors working on this effort are using spiral-wound liner on most of the system. Larger pipes, however, have required cured-inplace pipe (CIP)

“We have another 93 km to replace in the next five years – 25 km of which will be done in this financial year,” says Loader. “Plus, we’ve got about 1000 kms of vulnerable material – sewer gravity mains that will be assessed for relining.”

Asset management on this kind of scale required by the council’s network is an ongoing task.

“It’s kind of like painting the Harbour Bridge. By the time you’ve inspected the whole network, it’s time to go back to the start,” Loader says.

To stay proactive in its asset management activities, the council combines the services of a dedicated, full time CCTV inspection crew with more reactive, issue-specific operators that respond to specific blocks or leaks as they occur in the network.

The whole operation is organised through a kind of triage system. The council has all the data regarding different parts of the sewer

network – the age of the pipes, time since last inspection, condition, pipe material. This information is assessed so that the council knows where best to deploy its resources.

“We’re currently developing the Water and Sewer Master Plan,” says Loader.

“We’re analysing the network assessing the brownfield areas that aren’t connected to it and determining if and how they should be.”

Loader says Central Coast Council has been identified as a growth council.

“We have a lot of developer-led infrastructure being installed so Council’s role is to ensure that our trunk mains and treatment plants are suitably sized to accommodate the increased population,” he says.

UTILITY PROJECTS APRIL 2023 TRENCHLESS AUSTRALASIA 23

Central Coast Council has been identified as a growth council.

Central Coast Council has relined over 125 kms of sewer mains.

The drive to thrive

Aqua Metro is a proudly Australianowned organisation with world-class capabilities. Its absolute commitment to people, community and the environment is combined with a lean, agile structure, ensuring that it can effectively respond to its client’s needs. Aqua Metro is an integrated service provider offering turn-key solutions in the utility sector. It has significant capability and experience in the design and construction of water and wastewater treatment plants, pump stations, dam construction, water and sewer rehabilitation works, water main maintenance works, pipeline works and program management. Our staff are highly skilled and experienced, with a demonstrated track record of delivering services in long-term partnerships for our key customers.

Under the optimistic leadership of Chief Executive Officer Manish Pancholi, Aqua Metro is becoming a significant player in the utility market. Servicing the water industry and becoming a leader in the utility sector is more than just about the numbers.

“It’s all about the purpose, who we are and what we stand for. At Aqua Metro, our purpose is to create a sustainable organisation supporting health and wellbeing of our people, creating opportunities to deliver social value and provide quality services to our customers,” Pancholi says.

“Our people are our greatest asset, and they make the organisation it is today. We strive to create a healthy culture and sustain an enabling environment for our people to learn, grow, achieve and thrive. We have 21 different nationalities working at Aqua Metro, and we want all our

people to feel equally welcome, valued, respected and included in our organisation. I believe that strength in our team, healthy culture and the ability to lead with purpose makes us a great partner for our customers,” he says.

“I feel immense gratitude for the support and partnership of our incredible customers. We work collaboratively with our clients to identify their needs and develop innovative and efficient solutions. We exist to help achieve customer goals.”

“We are poised for growth and setting the right course with the right people and group of customers. There’s great momentum as we are looking to diversify our customer base and offerings further, and I am optimistic about the future of our people and Aqua Metro,” says Pancholi.

Thinking sustainably for the long-term future

As part of its footprint, Aqua Metro looks at sustainability holistically. Sustainability is a fundamental part of its philosophy and covers every aspect of the business.

“The effort we put into creating a sustainable organisation is all about what is best for the business in the future. It’s forward-looking so that the organisation remains relevant in the coming years,” says Pancholi.

A vital part of this thinking is taking a broader position on what sustainability means. It’s not just about carbon emissions and being a green organisation. For Aqua Metro, it’s about being diverse and inclusive of maximising opportunities for people.

“We are creating an inclusive organisation

that gives people opportunities to shine, improve productivity and efficiency and support better decision-making.”

That element of inclusion, diversity and cultural richness brings different ideas together, fosters innovation and empowers people providing a great opportunity to achieve our sustainability goals,” Pancholi says.

Putting people first fundamental to Aqua Metro

Iliana Dimitriadis is the Head of People and Culture at Aqua Metro. She has taken a leading role in creating inclusive and diverse culture.

“More than ever, the last three years have made people assess what is important professionally and personally. We have seen a shift in expectations of what people expect from their

EMISSIONS REDUCTION 24 TRENCHLESS AUSTRALASIA APRIL 2023

Aqua Metro CEO Manish Pancholi.

“It’s all about the purpose, who we are and what we strive for. At Aqua Metro, our purpose is to create a sustainableorganisation supporting health and wellbeing of our people, creating opportunities to deliver social value and provide quality services to our customers.”

employers. From my perspective, employers need to change their focus to providing a safe workplace and professional development and what it takes to look after the ‘whole’ person. I am incredibly proud of our inclusive and diverse culture and the focus on the well-being of all our people.

When you have leaders who lead with empathy, you always make decisions that are in the best interest of your people,” says Dimitriadis.

local businesses,” says Bartle. “We do this predominantly through our customer-first mindset by co-delivering and co-designing our strategies to align with our customer’s views and values. As a business and organisation, we could not do this without listening to and learning from our customers.”

Bartle highlights the importance of Aqua Metro leaving a community legacy for those that come after those currently within the organisation.

“Aqua Metro are delivering works in the construction industry. It goes further than that because we are in people’s neighbourhoods and backyards. We want to make sure that when we deliver our works, we leave something long-lasting that will benefit the community,” says Bartle.

For more information, visit www.aquametro.com.au

Rosie Bartle, Aqua Metro’s Marketing and Communications Coordinator, has incorporated putting people first into every aspect of her work.

“It’s not just our internal teams for whom putting people first is standard practice. It’s how we communicate, impact our communities, and collaborate with our

EMISSIONS REDUCTION APRIL 2023 TRENCHLESS AUSTRALASIA 25

The team at Aqua Metro.

Future Pipe Industries’ ongoing commitment to reducing carbon emissions

Future Pipe Industries is committed to ensuring minimal impact on the environment throughout its manufacturing process. The company’s commitment to reducing emissions is undeniable and its latest recent Environmental Product Declaration (EPD) is a testimony to the brand’s commitment to sustainability. Future pipes workforce includes more that 3300 staff. Globally there has been more than 190,000 metres of Future Pipe products installed.

Designing, manufacturing and supplying composite piping systems, Future Pipe Industries services the industrial, oil and gas, water and marine, offshore, as well as trenchless sectors.

The company’s jacking pipes for instance, solely for trenchless applications is – just like all other Future Pipe Industries productsmade from glass fibre reinforcements that are embedded in cured thermosetting resin.

Environmental protection is one of the main pillars of the company’s corporate purpose, as it is an integral part of the business strategy and ranks equally with other company objectives, in the form of a comprehensive environmental, health and safety management program.

Director of Sales and Operations at Empire Infrastructure Aaron Mackley, says Future Pipe Industries stated purpose is “to deliver water and energy to the world in the most efficient and sustainable way”.

“Our Corporate Purpose is rooted in the knowledge that by conducting our business operations responsibly we will create shared value for all stakeholders,” says Mackley.

“From Future Pipe’s Corporate Purpose through to the actions we take every day, we recognize sustainability is a business imperative which needs to take place at both a strategic and

operational level.”

As with safety goals, each manufacturing facility has environmental initiatives focused on responsible use of energy and water and on waste reduction.

Through its most recent Environmental Product Declaration, Future Pipe Industries has proven how eco-friendly glass reinforced polymer pipe can be. The declaration was peer reviewed by the IVL Swedish Environmental Research Institute Secretariat of the International EPD® System.

This environmental product declaration comprises the full life cycle of glass reinforced polymer, which is a composite material that consists of a polymer matrix and glass fibres.

The polymer matrix is typically an epoxy, vinylester or polyester thermosetting resin.

The resin brings the environmental and chemical resistance to the product, while the glass fibres add strength to the composite material.

With their material selection and advanced processes, Future Pipe is able to deliver composite piping systems to projects which span petrochemical, desalination, sea water intake systems, brine lines, water transmission, waste water treatment, sewer and drainage and topside piping as just a few examples.

The nature of our business means that we need to understand and carefully manage our impact on the environment. We also have a major responsibility and opportunity to convert the world’s pipe systems to the longer term, more environmentally friendly composite pipe.

Mackley says Future Pipe Industries’ products tick many boxes, as they are very long lasting and less energy is required to produce composite pipes, making them environmentally friendly and sustainable.

“They are durable, cost effective and efficient, as well as versatile,” he says.

All manufacturing sites operate under a certified quality (ISO 9001), environmental (ISO 14001) and health and safety (ISO 45001) management system.

Future Pipe products are sold though Empire Infrastructure in Australia.

For more information, visit www.empireinfrastructure.com.au or contact Empire Infrastructure per mail: admin@empire.team or phone: 1300 116664.

26 TRENCHLESS AUSTRALASIA APRIL 2023 EMISSIONS REDUCTION

Advatages of FPI GRP/GRE products.

We are a

Global Manufacturing Leader in CIPP Solutions

About Us

We are the world’s leading manufacturer and supplier of fiberglass reinforced liners for trenchless pipe rehabilitation, Cured-In-Place-Pipe (CIPP) solutions.

Why Choose Us?

We are reliable solution partners at all times, and commit ourselves to the highest future-proofed quality and to environmentally conscious conduct.

Our Service

Australia-Wide

Wherever you're based, we're ready to help.

Environmentally Conscious

Our activities are always resource-saving and environmentally conscious.

Globally Trusted

IMPREG CIPP liner systems for UV curing are used and trusted all over the world.

Our warehouses are fully stocked. Contact us today to secure your pipe rehabilitation project this summer. sales-apac@impreg.com

www.impreg.com

SAERTEX-LINER® MULTI saves

1 million kg of CO2 emissions

SAERTEX multiCom® GmbH are firmly commited to significantly reduce the CO2 footprint of its MULTI S+ Liners by using unsaturated polyester resins, aiming to make trenchless pipeline rehabilitation more sustainable.

Together with its strategic partner Scott Bader, SAERTEX multiCom are able to utilise a more climate-friendly manufacturing process for its resin systems.

Impressively, since implementing this change, savings of 1 million kilograms of CO2 within a single year have become possible. This corresponds to the CO2 footprint of 2717 flights from Frankfurt-am-Main to New York.

“The new SAERTEX-LINER UPgreen technology has enabled us to reach our target and, together with our customers, we have taken another step towards greater sustainability,” says SAERTEX multiCom Director Sales Europe, Africa and Southern Africa, Stephan Raab.

The environmentally-friendly conversion to the UP resin system does not affect the products’ technical characteristics and corresponds with all product approvals that exist around the globe.

“We focused from the very beginning on

sustainable orientation of our entire sector encourage and motivate us to take further steps,” says Kai Diecks, Global Managing Director at SAERTEX multiCom.

Motivated by these results, customers are returning time and time again to use SAERTEX multiCom products as a sustainable rehabilitation option for supply and wastewater pipes, with huge growth seen in recent years via Pipe Core, SAERTEX multiCom’s distributor

with such impressive material characteristics for the trenchless rehabilitation of municipal wastewater pipes and pressure lines and has a worldwide proven record of over 100,000 installations.

Pipe Core customer, Raad Al-Karbouli, Director and General Manager of NZ Lining chooses SAERTEX-LINER MULTI when he tackles the rehabilitation of wastewater and stormwater pipes as “it is the most efficient, flexible and sustainable choice on the market”.

On one project in 2022, over 5 tons of CO2 emissions were saved.

Furthermore, Neil Kermeen, Managing Director at Rangedale Group also favours the products for his jobs rehabilitating critically damaged underground infrastructure in Australia.

“With a business model focused on no-dig methods of rehabilitation, we were pleased to see the positive steps SAERTEX multiCom has taken with the support of Pipe Core to reduce their carbon footprint,” he says.

On a recent project between September 2022 and April 2023, SAERTEX-LINER achieved a reduction of 7 tons of CO2 for Rangedale Rehabilitation & Renewals.

Initial measures to determine the CO2 footprint and introduce an environmental management system for certification to the international DIN EN ISO 14001 environmental management standard have already been implemented.

“We are consequently working on a comprehensive sustainability strategy for

EMISSIONS REDUCTION 28 TRENCHLESS AUSTRALASIA APRIL 2023

From the Fiber to the Liner, SAERTEX-LINER involves a complete in-house production process in Saerbeck, Germany. Photo Credit: SAERTEX multiCom® GmbH.

achieving the structured implementation of sustainable corporate development. This will help us make our products and processes more environmentally friendly, while at the same time supporting our customers during tender processes,” explains Kai Diecks.

According to Pipe Core Manager Sergej Fast, the outstanding results of this key innovation pertains to sustainability in the pipeline industry.

Fast is pleased to report a massive saving of over 34 tons of CO2 emissions during the production of SAERTEX-LINERs in 2022.

is already in itself more sustainable than opencut construction, producing less odor, noise and dirt,” says Fast.

“However, SAERTEX multiCom’s climatefriendly manufacturing process for their UPresin system is a further step towards reducing carbon emissions.

“We are pleased to see sustainability embedded into SAERTEX multiCom’s corporate strategy, with a particular focus on protecting natural resources and developing innovative rehabiliation solutions with low environmental impacts.”

Katharina Helming, Business Development

Manager at SAERTEX multiCom says how important emission reduction is for the company.

“With so many Australian and New Zealand Pipe Core customers now engaged in trenchless rehabilitation projects using SAERTEXLINERs, we are excited to be working towards further CO2 savings and being transparent about the positive role customers are playing to reduce carbon emissions,” she says.

EMISSIONS REDUCTION APRIL 2023 TRENCHLESS AUSTRALASIA 29

“Rehabilitation using trenchless technology

more

Photo Credit: SAERTEX multiCom® GmbH.

For

information www.pipecore.com.au/saertex

Photo Credit: SAERTEX multiCom® GmbH.

Closing the recycling loop

Angar Environmental is a recycling company that is playing a significant role in keeping construction waste out of landfills by repurposing it back into the industry,” Operations Manager Pat Gough explains.

“With our facility in Keilor East operating at full capacity, Angar Environmental produces 35,000 cubic metres per annum of recycled materials, with 60 per cent of it being returned to the industry for dedicated reuse.”

“We specialise in recycling non-destructive digging (NDD)/drilling slurries and sludges, and runs a roll on/roll off waste management system across a broad range of projects throughout Victoria.”

What sets Angar Environmental apart from its competitors is its commitment to building a cleaner future for the environment. The clean-fill recycling plant processes large ballast used for access roads and free stand areas, quarter minus and 10 to 25 mm aggregates used in the plumbing and drainage industries. Fine soils and clay are used for capping and blending and as bedding under porous soils to retain moisture and give commercial productivity to farming acreage. The remaining water is put through a two-stage filtering and recycling system and used for plant processing, vehicle, and free-stand wash down, eliminating the operation’s need for domestic water. The converted end products are 100 per cent recyclable.

Angar’s depots located in Altona, Keilor East, Dandenong, and Epping are strategically placed to service a large range of projects, providing an excellent disposal location for current and upcoming projects planned for Melbourne. The company has slurry bins scattered around the state with horizontal directional (HDD) drillers, providing services to several projects across Victoria, including the Westgate Tunnel Project, Shepparton Rail line upgrade, Gippsland line upgrade, and several level crossing removals.

“Our company’s growth has been impressive, from three employees on start-up to now employing 26 people and processing up to 150 tonnes of NDD waste per shift,” Director Andrew McIntosh says.

“Angar Environmental has plans to grow its

EMISSIONS

30 TRENCHLESS AUSTRALASIA APRIL 2023

REDUCTION

It was 2015 when Angar Environmental Services saw a gap in the non-destructive digging industry to recycle and repurpose current clean slurry waste that was going into landfill.

Angar has depots located in Altona, Keilor East, Dandenong, and Epping.

Angar’s mission is to help play a part in eliminating construction waste and repurpose it back into the industry to help build a cleaner future.

Angar’s roll on/roll off bin system.

larger range of materials in the future. The company also sees the merit and opportunity to work with similar recycling groups within the industry to optimise the reuse of materials.”

“Our success is built on serviceability and customer relations. We are committed to being flexible with our clients’ needs and requirements, and our slurry bins and hook trucks on site have proven to increase client’s productivity, reducing the CoR risks and obligations,” Gough says.

“Our overall mission is to help play a part in eliminating construction waste by repurposing the materials back into the industry, as Angar Environmental is focused on building a cleaner future for the environment.”

Angar Environmental’s innovative full recycling process of clean mud slurry waste is a significant step forward for the construction industry. “Our commitment is to build a cleaner future for the environment by repurposing materials back into the industry,” McIntosh says.

“As we continue to expand our operations and collaborate with other recycling groups, we continue towards a greener and more sustainable future for all of us,” Gough says.

THE GOLD STANDARD IN SEWER

DRAINAGE POINT REHABILITATION.

With Smart Lock, you can seal redundant lateral connections and repair cracked or damaged pipes in three easy steps, cured in only 30 minutes.

LOAD Smart Lock into position using the caddy

LOCK Smart lock into place with the intelligent ratchet system

LEAVE Cured in under 30 minutes so you can move to the next job

Smart Lock is the biggest advancement in point repair technology, in more than 15 years.

AND

For more information visit smartlockgroup•com For more information, visit www.angar.com.au

The transfer of mud slurry from a hydro excavation unit to the Angar mud bins onsite, allows for the hydro excavation units and operators to remain on site.

Angar Environmental has plans to grow its clean-fill recycling plant to facilitate a much larger range of materials in the future.

Maxibor breaks through climate transition challenges

As the civil construction sector is going through the post–pandemic recovery stage, it needs to manage other challenges, namely climate transition, labour shortages, supply chain disruptions and inflation. Maxibor CEO Rodney O’Meley shares his insights on the impact of these challenges on the horizontal directional drilling industry and how Maxibor is addressing them so that clients and other project stakeholders’ expectations continue to be met.

O’Meley is adamant: the horizontal directional drilling (HDD) industry must play a big role in the climate transition process.

“Maxibor has been at the forefront in Australia for some time now as we have espoused the important contribution the HDD industry can make to mitigating the impact of increasing frequency and impact of fire, wind, flood, inundation, sea level rise, subsidence, drought and rain rivers and rain bombs,” he says.

“It is ever more important that the diffusion of new knowledge and better practice around HDD is promoted across the infrastructure sector as the impact of climate change is accelerating much faster than expected and becoming even more extreme.

“The Maxibor cooperative and knowledge sharing approach across the trenchless industry is the way we can build a future we all look forward to.”

The company’s status in the HDD industry allows it to self-perform most projects with its highly experienced drillers and crews. The volume of HDD work now and in the pipeline is however placing significant pressure on resources in Maxibor and across the HDD industry.

“Maxibor is needing to work smarter and more productively to help overcome the scarcity of labour resources,” says O’Meley.

“It is also supplementing its existing resources through both subcontracting and assembling project teams from the body of contract HDD workers in Australia and abroad.”

Maxibor has already been able to improve its productivity in several ways.

It’s the case for when it comes to continuing the push for early involvement in the design of projects utilising the better practice knowledge that exists inside Maxibor and its wider network of design engineering and other advisors. This expedites project start times and minimises delays through the delivery stage.

The company has also improved the enhancement of in-field technology for daily reporting, data gathering, security and site inspections (drones) along with application of advances in design engineering, business development and operational management technology. The digital dividend is time and money saved and more informed decision making.

Maxibor extended one of its Vermeer 100x120 rigs to enable it to use the longer 9.1 metre drill rods providing maxi-rig drill rod capability without increasing the set-up area.

The company also focuses on the individuals who are part of the brand’s DNA; Maxibor focusses on on-going people skill development as part of a life-long learning approach, and creating a more agile workforce and increased role flexibility within the company.

Maxibor has implemented a successful subcontractor model.

“Clients are very happy as Maxibor maintains its full involvement in the important early design and scoping stages of the works,” says O’Meley.

“Subcontractors are happy as they have access

to a ready pipeline of work without the hassles of business development, commercial negotiations, dealing with the client on delivery matters and preparation and collection of payment claims.”

This approach, combined with on-going HDD project management through Maxibor’s experienced and knowledgeable project managers, ensures works are delivered safely, with quality and on schedule.

“Our clients know that Maxibor will be there at all the key phases of the project and are happy in dealing with an HDD provider who knows how to work cooperatively and share knowledge across the supply chain to get projects delivered,” he says.

“Subcontractors are happy as Maxibor effectively takes away their pain points and allows them to move to the next Maxibor provided project without the concern or cost of all the areas which Maxibor’s very experienced design engineering and HDD project management team very capably handle.”

The company already has numerous subcontractors working under this model, and there is growing interest from others looking to reduce the pain.

“Subcontractors are also appreciating the support Maxibor provides them through access to equipment, friendly cash flow and support for them to develop and grow in their own right,” says O’Meley.

According to David Turner, Maxibor’s National Business Development Manager, its reputation and network across the Australian and international HDD world is due to its numerous skilled HDD drillers and crew members who can be readily assembled for those special projects requiring added and experienced resources to undertake delivery of the works.

“The ability of Maxibor to be able to bring together a very experienced additional team at relatively short notice is helping Maxibor to participate in even more major maxi-rig projects,” says Turner.

“Clients are very impressed when you can turn up with such experienced heads in your HDD project team.”

Supply chain disruption has been one of the major side effects of the global health and political upheaval in the past few years. This has particularly impacted the supply of specialised equipment into the civil construction sector.

32

EMISSIONS

Maxibor Extended Vermeer 100x120 drill rig.

REDUCTION

Maxibor is overcoming this situation through improved supply chain management processes as the company is constantly working with suppliers to ensure that supply of materials and other services into projects is able to be aligned with the construction schedule.

Strong supplier relationships developed over many years is being leveraged to ensure project needs are met in these difficult times.

Maxibor is also working closely with international supply chain experts such as Alex Tao from AusInland, who can better connect Maxibor with overseas sources of equipment not readily available to the Australian market.

This is increasing Maxibor’s knowledge of the latest technology and innovation in the underground installation industry and opening wider opportunities of participation in the market.

One of the other challenges the HDD industry has to navigate through is inflation.

It is an increasingly significant factor in the pricing of projects, as the time from initial quote for a project to actual delivery now very much matters given the underlying rate of inflation.

O’Meley says the civil construction sector has been particularly impacted by increases in fuel, equipment costs, interest rates and insurances.

While the average wage growth rate at around 3.8 per cent is lagging inflation, it is expected to escalate further in 2023, especially in the

civil construction sector where job vacancies are very high.

The wage growth rate for the sector is likely to be above the expected 4.5 per cent average for Australia by the end of 2023, even if the headline inflation rate falls.