ISSUE 79 | JUNE 2023 THE OFFICIAL PUBLICATION OF THE AUSTRALASIAN SOCIETY FOR TRENCHLESS TECHNOLOGY ASTT welcomes familiar face | Interflow’s rising star in trenchless | Sneak peak into this year’s No-Dig Down Under | Adept Civil delivers on regional NSW greenfield project | Yarra Valley Water protects at risk maintenance holes ALMOST 30 YEARS IN THE MAKING Customer support key to Jeff Trackson’s decades-long relationship with Vermeer Australia

Scan to learn more!

ISSUE 79 JUNE 2023

A dealer relationship almost 30 years in the making thanks to incomparable service

sustainable solution when it comes to

NO-DIG

This magazine is the official journal of the Australasian Society for Trenchless Technology (ASTT) and is distributed to members and other interested parties throughout Australia and the Asia-

The publishers welcome editorial contributions from interested parties. However, neither the publishers nor the ASTT accept responsibility for the content of these contributions and the views contained therein are not necessarily the views of the publishers T. Neither the publishers nor the ASTT accept responsibility for any claims made by advertisers. All communications should be directed to the publishers.

Unless explicitly stated otherwise in writing, by providing editorial material to Prime Creative Media (PCM), including text and images, you are providing permission for that material to be subsequently used by PCM, whole or in part, edited or unchanged, alone or in combination with other material in any publication or format in print or online or howsoever distributed, whether produced by PCM and its agents and associates or another party to whom PCM has provided

Jeff Trackson shares his decades-long professional Page 18. Image: Vermeer Australia.

4 TRENCHLESS AUSTRALASIA JUNE 2023

Contents

COVER STORY

18

WESTERN AUSTRALIA WA Councillor Jiang Aizezi

14 Trenchless

sensitive locations 16

UNDER

joins the ASTT

technology, the

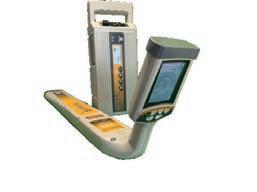

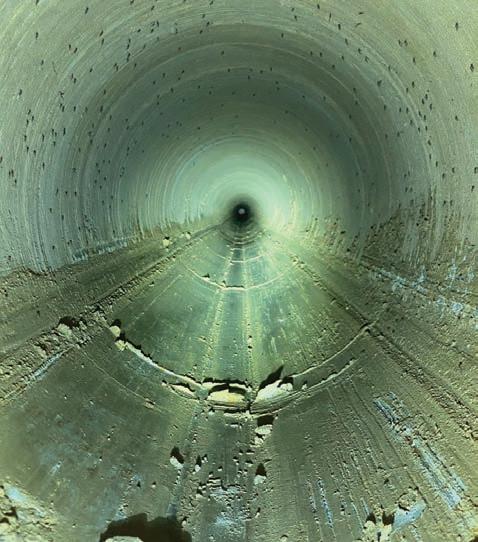

DOWN UNDER 2023 Innovation set for No-Dig Down Under 20 Exhibition Floorplan 22 Meet the 2023 sponsors 24 Bigger and better: more equipment than ever before 26 Four reasons why this year’s event is unmissable 28 WOMEN IN INDUSTRY Celebrating the women of SECA 30 Verena Reid, a rising star in the trenchless universe 32 MICROTUNELLING AdaptX technology key to challenging railway pipeline project 34 Pezzimenti Trenchless boasts microtunnelling capabilities 36 Adept Civil delivers on regional NSW greenfield development 38 VACUUM & HYDRO EXCAVATION How sustainability is leading the way for KAISER 40 REHAB & REPAIR Smart Lock: A key factor in BlueLine Drains’ completed project 42 Yarra Valley Water protects at risk manholes 44 UTILITY LOCATION Understanding EMF locators and the importance of training 46 CCTV Drain inspection cameras capable for the toughest projects 48 SPIRAL WOUND LINING Spiral wound lining for pipe maintenance 50 SLIPLINING kwik-ZIP: The go-to solution when it comes to trenchless 52 HDD Ditch what you’re doing and learn more about the Ditch Witch JT24 54 REGULARS Editor’s letter 6 From the President 8 From the ASTT Secretary 10 News in brief 12 ASTT corporate members 56 People on the move 58

Excellence in tunneling for water, wastewater and energy infrastructure.

With a focus on safety, innovation and collaborative delivery over the last 30 years, Rob Carr has achieved outstanding outcomes in water, wastewater and energy infrastructure projects in both Australia and overseas. Rob Carr is part of Soletanche Bachy a world leader in foundation and soil technologies and subsidiary of VINCI, a global player in construction across more than 100 countries. With outstanding capabilities to manage the complexities of any project, Rob Carr has the people, knowledge and experience to deliver success.

robcarr.com.au

CEO

John Murphy

COO

Christine Clancy christine.clancy@primecreative.com.au

MANAGING EDITOR

Molly Hancock molly.hancock@primecreative.com.au

EDITOR

Clemence Carayol

JOURNALIST

Vivien Topalovic

BUSINESS DEVELOPMENT

Nick Lovering nick.lovering@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey blake.storey@primecreative.com.au

DESIGNERS

Kerry Pert, Tom Anderson, Louis Romero

COPYRIGHT

Trenchless Australasia is owned by Prime Creative Media and published by John Murphy. All material in Trenchless Australasia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Trenchless Australasia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2021

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Drive, Docklands VIC 3008

Ph: +61 3 9690 8766 enquiries@primecreative.com.au http://www.primecreative.com.au

Sydney Office, Suite 303, 1-9 Chandos Street Saint Leonards NSW 2065, Australia Ph: (02) 9439 7227 Printed by:

Editor’s Letter

Clemence Carayol

As a woman in the industry, seeing women being put in the spotlight for the June edition of Trenchless Australasia is a bliss.

Here at Prime Creative Media, we acknowledge the exceptional women who have achieved success through their leadership, innovation and commitment to every sector we write about.

Prime Creative Media’s Women in Industry Awards recognises outstanding women from across a range of industrials sectors, for example those who work in mining, transport, manufacturing, engineering, logistics, bulk handling, waste management, rail and construction and infrastructure – all sectors that are traditionally male-dominated.

As I immersed myself in oil and gas, resources, and trenchless industries, which was extremely new to me a while ago, I couldn’t help but think that it was inherently masculine – which is partly true historically speaking.

I am beyond excited to see the ASTT introducing the category of Trenchless Woman of the Year for this years’ awards. More women are forging their career in this multi-faceted world. This edition is all about celebrating the rising stars of our industry and putting the spotlight on their skills and achievments.

communications managers or held managerial roles, and all were at the top of their games.

All have proven to me that I had been biased when I thought they were navigating in a world of men only, with women being the exceptions, the tick in a parity tab on an excel sheet somewhere.

Having women on board is a clear sign of intelligence. Inclusivity, which should be a given today, isn’t as popular as we think.

Having worked in numerous and diversified industries, most of them on the cultural and arty scope, the resource industry is among the ones which value women most.

The men in our industries have had the clear and indubitable intuition that women can be holding the same responsibilities and the same roles.

“Behind every great man, there’s a great woman” – this expression works the other way around too.

Happy reading!

Clemence Carayol Editor

clemence.carayol@primecreative.com.au

6 TRENCHLESS AUSTRALASIA JUNE 2023

Manark Printing 28 Dingley Ave Dandenong VIC 3175 Ph: (03) 9794 8337

We are a

Global Manufacturing Leader in CIPP Solutions

About Us

We are the world’s leading manufacturer and supplier of fiberglass reinforced liners for trenchless pipe rehabilitation, Cured-In-Place-Pipe (CIPP) solutions.

Why Choose Us?

We are reliable solution partners at all times, and commit ourselves to the highest future-proofed quality and to environmentally conscious conduct.

Our Service

Australia-Wide

Wherever you're based, we're ready to help.

Environmentally Conscious

Our activities are always resource-saving and environmentally conscious.

Globally Trusted

IMPREG CIPP liner systems for UV curing are used and trusted all over the world.

Our warehouses are fully stocked. Contact us today to secure your pipe rehabilitation project this summer. sales-apac@impreg.com

www.impreg.com

THE AUSTRALASIAN SOCIETY FOR TRENCHLESS TECHNOLOGY

ABN 43 893 870 966

18 Frinton Place

Greenwood, WA 6024

www.astt.com.au

jeffpace@astt.com.au

President: Ben Crosby

Secretary:Trevor Gosatti

Vice President: Blair Telfer

COUNCILLORS

Western Australia: Jiang Aizezi

Queensland: Ben Crosby

New South Wales: Sudipta Basu

Victoria:Ash Hamer

South Australia: Shaun Melville

New Zealand: Blair Telfer

Northern Territory: Vacant

Tasmania: Vacant

President’s Message

The last 12 months have been a successful period for the ASTT. Membership is healthy and it is seeing small, yet positive growth.

There was an exciting Quarry Day held in Brisbane in May, being hosted by the ATS where the ASTT had two members showcasing their equipment which I’m sure was well received.

This edition of Trenchless Australasia is themed “Women in Industry” and I’m sure you will enjoy reading the articles focused on our overachieving female collaborators in this male dominated industry as we pivot to a more inclusive approach. At the ASTT, we see infrastructure pivoting to ensure we as a society achieve parity in the coming decades which will positively affect the trenchless services, manufacturing and projects.

We are pleased to introduce the category of Trenchless Woman of the Year for this years’ ASTT Awards. Trenchless technology has traditionally been a male-dominated industry however we are seeing more incredible women take charge within the sector and feel it is appropriate to recognise them accordingly. I look forward to celebrating these outstanding women, along with other industry stalwarts, at the ASTT Awards Gala Dinner in September.

In the last year Council’s efforts have been noticed with the positive promotion of trenchless technology across our many touch points.

Most notably our promotion of trenchless technology is seen readily at the conference in 2022, which will continue at 2023’s conference. Coupled with this is our activity in forums, the Trenchless Australasia magazine, our integration with WSAA, our activity in the special interest groups, and our partnerships with AusJet and the ATS.

Another key change with the Council Structure is the resignation and retirement of Jeff Pace, having been our Security and

Treasurer since our incorporation in 1991! Jeff has been an amazing asset to the ASTT over the 30+ years and he will be sadly missed. He hands over to another long-term industry supporter in Trevor Gosatti who will slot into the role having worked in the ASTT for over 20 years as either a Councillor or as our President.

Planning for this year’s Brisbane Conference in September is going well. The theme this year is “Better Outcomes Through Trenchless” and it is this theme we plan to stimulate the conversation and influence the papers, the exhibitors and the panel discussion on improving the service industry with better design, better method selection and better delivery to conclude improved overall trenchless solutions.

Given that the conference is three months away it is again shaping up to be a huge success, with the exhibition space now sold out.

This year we are seeing more than normal change with our Council, and I will take this opportunity to thank our outgoing Council members in Justin Shepperd and Matthew Boyle who both have been instrumental in helping our industry and the ASTT; we appreciate their efforts. Both Justin’s and Matt’s careers are turning away from trenchless and we support their desire to resign from Council and we wish them the best in the future.

With the old comes the new, and we are very excited to welcome our new Councillors in Ash Hamer and Jiang Aizezi. We welcome both Ash and Jiang as they are formally appointed at the recent AGM. Ash and Jiang are passionate about trenchless technologies and we are looking forward to working with them in some of the new initiatives that we are rolling out in the near future.

Ben Crosby ASTT President

8 TRENCHLESS AUSTRALASIA JUNE 2023

STOP PAYING TOO MUCH FOR PLUGS & PACKERS Drainchem 5 Avian Street, Kunda Park, 4556, Qld sales@drainchem.com.au 0499 758 448 Australia’s largest range of inflatable and mechanical plugs in stock AQUATEQ high performance jetting nozzles from Sweden. Available from Drainchem

Secretary’s Corner June 2023

New Members

On behalf of the ASTT, I extend a warm welcome to the following new members:

Silver Corporate Members – Australia

• Membership upgraded from Individual to Corporate by Alex Tao from Ausinland Pty Ltd

• Andrew Bilton from SLB-M-I SWACO

David Dunstan from Dunstans

• James Pickup from Australian Pipeline Management Pty Ltd

• GCE Contractors Pty Ltd

Individual Members – Australia

• Samuel Pearce from SRG Global

• Nick Lewis from NAL Project Management Services Pty Ltd

Jeff Pace

My first action as the new ASTT Secretary is to recognise and acknowledge the tremendous efforts of the outgoing Secretary, Jeff Pace.

Jeff was the inaugural ASTT Secretary when the society commenced in 1991 and has performed the role of Secretary and Treasurer since that time being 32 years. He has overseen the progression of the society from its small beginnings to be an efficient, financially stable and leading representative. Jeff has overseen the society:

• Publish 78 Trenchless Australasia magazines in partnership with Prime Creative Media (and Pipeline Publications Australia).

• Host 14 Australasian exhibition & conferences (No-Dig Down Under).

• Host three international exhibition & conferences (in collaboration with the International Society of Trenchless Technology)

• Grow membership to over 300 members.

• Grow the society finances to be in a safe and prudent position ready to assist the industry.

• Complete prudent governance and

strategic planning arrangements for the society.

• Be regarded as one of the most stable and efficient trenchless societies in the world.

Jeff also significantly represented the ASTT in its membership with the International Society of Trenchless Technology (ISTT) serving as the Society’s ISTT contact for many years and serving as an ISTT executive sub-committee (board) member for six years. He also assisted on several ISTT sub-committees over the years.

At the recent Annual General Meeting of the Society, the ASTT Council nominated and approved Jeff Pace to become a Life Member of the ASTT in recognition of his service. Jeff becomes the society’s second Life Member, joining his friend, the late Menno Henneveld as Life Members of the ASTT.

It is planned to recognise and present his Life Membership Award at the Brisbane No-Dig Down Under in September. Having worked closely with Jeff over many years in my previous roles as WA Councillor and Chairman of the ASTT, I am very aware of the dedication and commitment Jeff applied to the role of Secretary and Treasurer of the ASTT. I hope to emulate that as I step into the position.

Jeff should be proud of the position he leaves the ASTT in upon his “retirement”, and we wish him well in future endeavours.

I look forward to serving the Council and great members of the society as the ASTT Secretary. I hope to make contact with many of you at the No-Dig Down Under later in Brisbane.

No-Dig Down Under 2023 Brisbane Planning for the No-Dig Down Under 2023 to be held in Brisbane from the 12 to 15 September 2023 is progressing well. The exhibition space is sold out and sponsorships for the events are nearly all

taken with the event still several months away. This shows the strong support the trenchless technology industry has in attending these events and the benefits that can be provided to all industry stakeholders. If you have interest in supporting the event please contact Nick Lovering (nick.lovering@primecreative. com.au) or visit nodigdownunder.com. The Organising Committee is now considering and finalising the conference papers and program to ensure another tremendous exhibition & conference is delivered to the industry, with great social events and networking. Make sure that you are part of it!

ASTT Strategic Plan

Post the recent ASTT Annual General Meeting, the ASTT Council devoted time to review and update the ASTT Strategic Plan. While many actions within the Strategic Plan have been completed, there are still many intended plans and actions to be considered and put in place to be completed. With the pandemic conditions a thing of the past, the Council can look ahead to action items with less restrictions and impediments. The Council is committed to complete and action the Strategic Plan for the benefit of the ASTT members and industry.

State of the Industry Report

The ASTT has commissioned a State of the Industry Report to be produced providing up to date information on the trenchless industry. The ASTT Council is anticipating this report to be available soon for consideration and then be able to be provided to members for their information and use in their businesses. The ASTT has previously produced State of the Industry reports for the benefit of members and is one of the many benefits of membership of the ASTT.

Trevor Gosatti ASTT Secretary

10 TRENCHLESS

JUNE 2023

AUSTRALASIA

CIVIL AND TRENCHLESS SOLUTIONS www.mtuckerandsons.com mail@mtuckerandsons.com | 03 9736 3439 20 Clancys Road, Mount Evelyn, VIC 3796 | PO Box 955, Lilydale, VIC 3140 CALL 03 9736 3439 Specialised Services: LATERAL REINSTATEMENT & ROBOTIC GRINDING CCTV INSPECTION, CONDITION ASSESSMENT & LASER PROFILING 100-2,000 mm (WSAA ACCREDITED) UV CURED MANHOLE/LATERAL SEALING & TOP HATS DRAIN CLEANING/NDD & VACUUM LOADING PIPE PATCH REPAIRS AMEX, QUICKLOCK, FIBREGLASS & SMARTLOCK UV PIPE RELINING DN 150-2,000 M. Tucker & Sons Pty Ltd (MTS), a specialised drainage infrastructure maintenance & trenchless rehabilitation provider established 1989. The organisation supplies a holistic service in the utilities and wastewater space, with technological, safety and environmental priorities as the driver of the company’s reputation for reliability and excellence.

supplying water pipelines to contribute to the development of Townsville City.

Infrastructure Services Committee Chairperson Kurt Rehbein says council awarded the tender for the supply of approximately 16.25km of raw water pipeline as part of upcoming enabling infrastructure works. “Iplex demonstrated the best value for money proposition for the project and has experience in delivering large diameter pipe, with a proven track record locally for their work on the Haughton Pipeline Duplication project,” says Rehbein.

A second tender has also been released for the raw water pipeline install in preparation for works to start mid-2023.

The raw water pipeline connects to the existing 900 mm Ross River pipeline at a point near the junction of Haberecht Road, Mountview Drive and Major Creek Road, Majors Creek, and finishes in the Lansdown precinct.

Construction of the raw water pipeline to the Lansdown Eco-Industrial Precinct will allow early proponents access to raw water by December 2024.

Michael Doyle, National Business Manager – infrastructure and assets at Iplex, says the company was proud to be involved in this large-scale project.

“This significant project will encourage new industry and advanced manufacturing to settle in Townsville, which will create jobs,” he says.

Greater Western Water’s renewal project hits next stage

Greater Western Water’s (GWW) contractor Jaydo Construction has commenced works on stage 2 of Melbourne’s Victoria Street Main Renewal project.

Construction began in April, with stage 2 involving replacing 1.8 km of water mains down Rathdowne Street and along the southern side of Victoria Street, between Exhibition Street and William Street. It involves around 1.8 km of pipes across North Melbourne, Carlton and the inner city being removed and replaced with a new, larger diameter pipe. This is to be installed via open trenching, with sliplining under key intersections, Jaydo Construction is the contractor for this work.

GWW General Manager for Growth and Infrastructure Amanda Smith says that ageing infrastructure is the main reason behind this work as the current water main is at least 140 years old.

“The upgrade will create more capacity in the system and help ensure the water supply remains clean and reliable for our customers across North Melbourne, Carlton and the inner city,” Smith says. “It will also prevent water network faults, reducing disruptions and improving customer experience of our services into the future.” The project is due for completion late 2023.

North East Link taking shape in Watsonia

200-metre-long tunnel boring machine (TBM) launch area.

Four giant piling rigs have been hard at work digging 379 holes since last October, with each hole being reinforced with a steel cage and filled with concrete.

becoming a solid launch area for our two massive TBM, forming the beginning of the North East Link Tunnels,” the team says.

The North East Link Program has completed piling works within its site on the east side of Greensborough Road, Watsonia, forming the structural foundations of the 40-metre deep,

“About 7400 cubic metres of concrete was used for the box piles alone (almost 19 elephants’ worth) and if you stacked each pile end to end, it would be almost 7.2 km long,” the North East Link Program team shared. Once a pile is set, each one is cut to the required height – then a concrete capping beam is poured, connecting all the piles together, adding more stability to the structure to allow major excavation.

“Now complete, this area is on its way to

The North East Link Tunnels will take 15,000 trucks off local roads every day and reduce travel times by up to 35 minutes. This will be made possible thanks to longer tunnels of 6.5 km to Watsonia, simpler interchanges at Lower Plenty Road and Manningham Road. It will also include five MCGs of parklands along Banyule Creek at Borlase Reserve, a new 2 km tree-lined boulevard for Greensborough Road, a 2 hectare Yarra Link green bridge over Bulleen Road, and three new wetlands along the Yarra River and Koonung Creek in Bulleen and Balwyn North.

FEATURE 12 TRENCHLESS AUSTRALASIA JUNE 2023 NEWS IN BRIEF

Iplex has partnered with Townsville City Council on the Townsville Lansdown eco-industrial project.

Jaydo Construction commenced works on stage 2 of Melbourne’s Victoria Street Main Renewal project.

With piling works complete, the structural foundations of Tunnel Boring Machine launch area is formed.

CREATING X-FACTOR OPTIONS FOR GROUNDBREAKING SUCCESS

optionxgroup.com.au

WHEN ACCURACY MATTERS

Edge Underground is a precision microtunnelling contractor that operates in Australia and the USA. With a focus on innovative technology and expertise, Edge Underground designs and enhances the performance of trenchless equipment. Full factory backing here in Australia means solutions can be created when they’re needed most.

OptionX Group and MTS offer product solutions for horizontal drilling technology. MTS machines suit a range of applications from the trenchless laying of supply and waste disposal lines, to pipe roofs and the expansion of pipeline routes. MTS machines purchased through OptionX Group are supported by our Australian team. That means spare parts, servicing and emergency repairs when you need it most. The quality expected from German engineering shines through in all MTS equipment. For more than twenty years, MTS has provided leading mircrotunnelling equipment that has been used around the world.

optionxgroup.com.au/mts

MICROTUNNELLING • PIPE JACKING • THRUST BORING • LASER TUNNEL BORING BOX CULVERT JACKING •

CANOPY TUBES

1300 522 533 | info@optionxgroup.com.au | optionxgroup.com.au

WA Councillor Jiang Aizezi joins the ASTT

My name is Jiang Aizezi (Aziz for short) and I’m very excited to join the Australasian Society for Trenchless Technology (ASTT) as the Western Australia Council representative.

I have been proudly working in the tunnelling and trenchless industry for more than 13 years, and been involved and contributed to the successful delivery of trenchless projects. These projects have involved diverse trenchless techniques including: microtunnelling, pipe jacking, auger boring, pilot boring, and horizontal directional drilling.

I’ve been active in the ASTT space since 2013 and have presented at a number of papers in the No-Dig Down Under Conference, organising or

presenting in ASTT technical sessions, and contributed to the ASTT design and construction short courses (on trenchless technology).

I relocated to WA just before the start of the COVID-19 pandemic in early 2020 after eight years around the east coast. Since then, I have continued my passion on actively promoting tunnelling and trenchless technology in the WA market. While the east coast was buzzing with major road and rail tunnelling works, which in turn created tremendous opportunities in the trenchless field, WA has not been so lucky.

After the completion of the challenging Forrestfield Airport Link Tunnel project, the outlook for another major tunnelling

project looked to be very dim.

However, a suit of major public transport projects initiated by Metronet have brought the trenchless market to a new height in WA with significant utility/service relocation works utilising trenchless techniques.

Notably, BP KWOL pipeline relocation project stands out as the largest trenchless relocations in the brownfield environment (arguably nationally as well) among these works. 12.5 km of DN300 pipeline was relocated where 11.5 km by HDD, with 12 drill shots varying between 500 m up to 1.4 km , and the depth up to 25 m; 2 DN700 microtunnell railway crossings and remainder open trenched.

Utility asset owners continue to show interest and invest on the trenchless technology. Some major microtunnelling works were awarded last year by Water Corporation, namely the Quins Main Sewer project and Balmont Water Main (BWM) project.

QMS involved 1931 m of DN1800 sewer main (1167 m via microtunnelling) while BWM involved DN1000 watermain by microtunnelling crossing a highway and busy operational passenger railway operated by a public transport authority.

The mining sector north of WA continues to engage trenchless specialist constructors for rail, road and river crossings as well.

Overall, we see a healthy growth on the WA trenchless market. With the continuous commitment on the state and federal level in the transport sector, we expect this growth will continue for the years to come.

Jiang Aizezi WA Councillor

UNDER WA 14 TRENCHLESS AUSTRALASIA JUNE 2023

L–R: Sean Melville, Sudipta Basu, Jeff Pace, Trevor Gosatti, Ben Crosby, Justin Shepherd, Ash Hamer, Blair Telfer and Jiang Aizezi at the recent ASTT AGM.

Australia-based operations with permanent local resources

Fully integrated with our global team at international headquarters

Multiple NASTT Project of the Year awards

Horizontal Directional Drilling

· Completed record breaking 4.7km long HDD

· 235 Intersect crossings completed since 2000

· 12 crossings completed over 3km since 2009

· Rigs available with push/pull capacity up to 815 tonne

· Pipe Installations up to 1.5m

· 26 projects completed in the US and Canada since 2010

· Foremost Direct Pipe Contractor

· Land-to-water outfalls

· Pipe Installations up to 1.5m

Direct Pipe

MichelsTrenchless.com.au

1300 464 243 Level 1 | 98 Murphy St | Wangaratta, VIC 3677 8,000 people strong founded in 17,000 pieces of equipment Pioneering HDD since 1988

TRENCHLESS INFRASTRUCTURE SOLUTIONS

Trenchless technology, the sustainable solution when it comes to sensitive locations

Whether it be a culturally sensitive site, a heritage location, or simply an ageing infrastructure, working around the inherent challenges that come with these worksites can sometimes require very special care. Trenchless technology is all about mastering and making the most out of every aspect of these locations.

Tenchless Australasia takes a deep dive into Western Australia and how certain projects are prime examples of the versatility of trenchless technologies.

HDPE pipeline renovation in Cape Lambert and Paraburdoo

The benefits of trenchless technology for pipeline rehabilitation in culturally sensitive areas during two installations for one of the world’s leading mining companies has been illustrated in Cape Lambert and Paraburdoo.

The benefits of Primus Line were recently proven during two Rio Tinto projects using

the technology in areas of cultural heritage sensitivity in Western Australia.

The first project took place near Cape Lambert and included the renovation of a 1500m long high-density polyethylene (HDPE) pipeline.

The second installation was in the outback near Paraburdoo where a 1000m of cementlined mild steel pipeline was rehabilitated. The liner comes pre-coiled on transport spools with a length up to 1000m or more and is inserted into the existing pipe.

Compared to traditional pipeline replacement, the carbon footprint in

construction is reduced by up to 90 per cent.

Trenchless methods are the perfect solution to overcome the challenges of pipeline works in areas of cultural significant importance and preserve them to traditional landowners, making sure that areas of cultural heritage sensitivity remain completely untouched.

Wastewater pipes refurbishment in the Merredin Shire

Merredin Shire’s authorised contractor Allpipe Technologies has commenced work to refurbish ageing wastewater pipes. This

UNDER WA 16 TRENCHLESS AUSTRALASIA JUNE 2023

Trenchless tech is big in Western Australia because of its versatility among others.

refurbishment work executed by Allpipe Technologies is set to be completed by late July 2023 and will take place across the town of Merredin.

Allpipe Technologies is working in both verges and/or roads, and in the boundary of private properties. Sewer relining uses trenchless technology to clean and refurbish existing wastewater pipes.

HDD boom in Fremantle

Recently Diversified has undertaken works with one of its long-time clients to replace the existing cast iron distribution network in Fremantle. The limestone rock ground conditions of this project presented several logistical challenges, but not insurmountable for Diversified with its newest Ditch Witch CEA machine – the AT32.

“The project involved 9000m of HDD installation and required a full turnkey solution. We undertook the installation of multiple HDPE conduits and manholes to house both fibre optic as well as earth grid network cables,” Diversified’s Managing Director, David Proctor says.

Released in 2022, the AT32 boasts increased drill pipe capacity, allowing 137.2m of all-terrain pipe or 182.9m of dirt pipe with reversible pipe box onboard,

boosting the productivity of any project.

It also features a patented ‘slide cartridge’ which provides back-up for the carriage rollers, allowing operators to complete a job without stopping to replace failed rollers. The drill’s 1200ft lbs of inner rotational torque allow for greater efficiency and better production in hard formations.

PST channels at Woodman Point

The Woodman Point Waste Water Treatment Plant in Munster, Perth, has experienced deterioration of the concrete structure around its channels due to a gas attack.

Fixing the damage was broken into two stages. McRobert Contracting Services (MCS) was brought in on the first stage of the project, which required the lining of a channel totalling 12 lineal metres.

The success of the first stage saw Woodman Point engaging MCS to continue the work on the second stage. This required work on a further 16 lineal metres of channel with similar damage and included both an ‘S’ bend and four launder channel entries on the PST channel.

MCS were called in to use its patented high-density polyethylene (HDPE) lining to restore the damaged infrastructure, which included the floors, walls, and roof of the

channel, up to the horizontal deck.

MCS used layers of 12mm HDPE striped to 25mm wide and fixed to the perimeter of the channel lining. The process allowed them to extend the lining, including pouring high strength grout behind the lining and existing concrete surfaces.

Twin crossings of Hume completed in Port Hedland

DJ MacCormick Contractors has completed the twin crossings of Humes 1000mm reinforced concrete jacking pipe in Port Hedland, Western Australia.

To complete the project, DJ MacCormick Contractors utilised the Iseki closed face slurry shield microtunnelling system. Ground conditions on site were in wet clay and at depths that ranged from 4m to 6m cover.

Of the six 1000mm drives completed, two drives of 46m were completed under Utah Road with an additional two drives of 152m under the BHP Rail also being completed. A further two drives of 80m under the FMG Rail line were also undertaken. A seventh drive of 1800mm was also completed 112.5m under the BHP Rail, located nearby the Iron Bridge mine site.

The total distance tunnelled for the project was approximately 668.5m.

UNDER WA JUNE 2023 TRENCHLESS AUSTRALASIA 17

A dealer relationship almost 30 years in the making thanks to incomparable service

Customer satisfaction is a key priority for any business, with customer loyalty a level above that. When it comes to customer loyalty, look no further than Jeff Trackson and his decades-long professional relationship with Vermeer Australia.

With his company, JR & LM Trackson Pty Ltd, specialising in directional drilling across the whole of Australia, Jeff bought his first Vermeer drill more than 26 years ago and since then has purchased 33 Vermeer drills, with the latest being the D100x140 S3. Plus, another 100plus pieces of ancillary equipment, including HDD locators, cable locators, mixing systems, cable ploughs, trenchers, recyclers, and more than 30 vacuum excavators.

For Jeff, his search for top quality, reliable equipment is what first led him to Vermeer Australia all those years ago. And just as important to Jeff as the equipment itself, is after sale care and service.

“I was looking for reliability, service and customer support,” he says.

Jeff says that alongside Vermeer Australia’s incomparable service and customer support is

COVER STORY 18 TRENCHLESS AUSTRALASIA JUNE 2023

Vermeer Australia Sales Manager Nigel Dobier and Jeff Trackson in 2012 at the

The delivery of the D100x140 S3 in Townsville earlier this year. L R: Greg Clayton, Vermeer Asia-Pacific, Paul Southey, Vermeer Australia, Linda and Jeff Trackson, Steve Batchelor, Vermeer Australia, and Jake Schulz and Chris Quabba, JR & LM Trackson Pty Ltd.

“A lot of the guys have been there just as long as I’ve been buying gear, so 20-plus years. I can ring Steve in Adelaide and he’ll help me get through the problems that we might have with the machine,” he says.

“They’re very good, and very knowledgeable in the machines that they sell. There are some good guys there that live and breathe Vermeer.”

It’s a sentiment that is echoed by Vermeer product specialist, Steve Batchelor. Batchelor has been working at the company for 30 years and first encountered Jeff early in his career. Since then, he has worked hard to maintain a close working relationship.

“I got to meet him when he was a very small operator. I’ve had a lot of out-in-the-field experience with him. And basically, we have a great relationship with him,” he says.

“Every time he bought a drill, I’ve been there with the installation to train them, and make sure that machine ran properly.”

Together, with the rest of the team at Vermeer, Batchelor has kept abreast of Jeff’s expanding business and has guided him through the various equipment groups to help him grow his business.

Another Vermeer Australia team member that has worked closely with Jeff for more than a decade is Sales Manager, Nigel Dobier.

“I’ve been at the company for 14 years, and I’ve known Jeff basically ever since I started in the spare parts department back in 2008,” Dobier says.

Dobier understands the importance of prioritising customer support and satisfaction, and taking a hands-on approach to customer service, working to uphold this across the various roles he’s held over the years.

“Jeff trusts our company overall, and I’ve been that person, among others, that he trusts. So, we’ve always maintained the relationship no matter what position I’ve been in,” he says.

“It’s been an important thing for us to ensure that Jeff stays comfortable with us. He knows that he can pick up the phone to me or others within our business, and he’s going to be looked after.”

“We’re going to keep his gear running and keep the pipe going into the ground,” Dobier says.

“Because that’s how he feeds his family, and the families that are employed by the Trackson Group of Companies. And that goes for all Vermeer customers.”

Jeff has extended a very special thank you to Peter Pullan, previous co-owner and current Executive Director of RDO Equipment Pty Ltd, for the personal advice and support he has provided him over the last 26 years.

For more information visit www.vermeeraustralia.com.au

COVER STORY JUNE 2023 TRENCHLESS AUSTRALASIA 19

Innovation set for No-Dig Down Under

With the theme of “Better outcomes through trenchless”, No-Dig Down

Under 2023 is set to be a mustattend event for all trenchless industry professionals.

No-Dig Down Under is the southern hemisphere’s only large-scale conference and exhibition dedicated to trenchless technology.

Organised in partnership with the Australasian Society for Trenchless Technology (ASTT), the conference has grown to become the second largest no-dig technology event in the world.

The technical program invites and encourages speakers from around Australia and the globe to present papers covering case studies, new and emerging technologies, challenging projects and environments, industry skills and training, risk management and more.

This year’s conference, sponsored by Rob Carr as platinum sponsor, Vermeer Australia as gold sponsor, Interflow, Rockpecker and Vivax Metrotech as silver sponsors, and Monitor Lifts

and STEP Oiltools as bronze sponsors, will be held at the Brisbane Convention and Exhibition Centre from 12-14 September.

Continuing Professional Development (CPD) hours can be claimed for attending the conference through Engineers Australia.

Tickets available now

Early bird tickets are now on sale for this year’s event until June 30, 2023.

Attendees can save up to $230 on each ticket, while ASTT members also receive further discounted tickets.

A full conference ticket includes the conference program, catering and all social functions including the Gala Dinner and ASTT Awards evening.

For all information about tickets, visit nodigdownunder.com/register

Scholarships on offer

Once again, the ASTT is offering 10 utility and council scholarships for attendance at No-Dig Down Under 2023.

The scholarships allow key members of Australasian utilities and councils to attend the conference with reduced costs and aim to attract more employees from these organisations to the event, increasing their knowledge of trenchless technology.

To be eligible, applicants must be a full-time employee of an Australian or New Zealand utility or council.

All applications will be judged on various criteria including employment position and job title, membership record with the ASTT, participation in previous No-Dig events, knowledge of the trenchless industry and career goals within the sector.

20 TRENCHLESS AUSTRALASIA JUNE 2023

No-Dig Down Under will be held at the Brisbane Convention and Exhibition Centre from 12-14 September.

A professional reference or testimonial from a colleague or industry contact must also be submitted.

Applications for ASTT utility and council scholarships close on Friday, 14 July 2023.

Training courses

Before the conference begins, a range of training courses will be available for attendees to build upon their knowledge of trenchless technologies.

Three courses will be featured at the 2023 event, with one focused on new installation methods, the second on horizontal directional drilling and the third on renovation of pipes by lining.

Registration for these one-day training courses is available from $515 for ASTT Members and $615 for non-members.

Members can also earn CPD points for the course attendance and completion.

ASTT Awards night

The prestigious ASTT awards are not to be missed, with the awards to be presented to the

winners at the ASTT Gala Dinner and Awards Evening on Thursday, 14 September.

Nominations can be made for the six awards, with nominations closing on Friday, 14 July 2023.

The award categories include: Rehabilitation Project of the Year

An award which recognises innovation and advancements across technology, environmental benefits and occupational health and safety benefits in rehabilitation projects.

New Installation Project of the Year

It recognises innovation, advancements in technology, environmental benefits and occupational health and safety benefits in new installation projects using trenchless technology.

New Technology: Machine, Tool, Material, System or Technique

Recognises a practical development of trenchless systems or equipment that results in benefits such as improved economy, accuracy, speed

of drive or replacement, ability to overcome difficult installations or similar.

Menno Henneveld Person of the Year

The award recognises an individual who has made major contributions to the trenchless industry in any area of activity. It will identify a contribution over and above the call of duty to grow, develop and promote the use of trenchless technology across Australasia.

Jeff Pace Young Person of the Year

This award recognises younger members of the Australasian trenchless community and the role they play in the growth of the industry.

Trenchless Woman of the Year

This new category recognises a woman who plays a leading role within the Australian trenchless technology industry who goes above and beyond their role within the sector.

ASTT President Ben Crosby says the ASTT was pleased to introduce this new category for this years’ awards.

“Trenchless technology has traditionally been a male-dominated industry, however we are seeing more and more incredible women take charge within the sector and feel it is appropriate to recognise them accordingly,” he says.

“I look forward to celebrating these outstanding women, along with other industry stalwarts, at the ASTT Awards Gala Dinner.”

For more information about this year’s No-Dig Down Under event, visit www. nodigdownunder.com

At L&D Micro Tunnelling we specialize in laser guided boring. Our Tunnel bore machines use a vacuum extraction system where all spoil is sucked into interceptor tanks for easy disposal with no mess. All our heads are hydraulically driven and guided by a high accuracy laser to achieve precision over long distances.

47a Brunel Road, Seaford, VIC 3198 | luke@ldmt.com.au | chris@ldmt.com.au | 0401 754 929 | www.ldmt.com.au Unrivalled reliability – Accuracy Guaranteed

•

•

• Specialists in free boring, sleeve boring and pipe jacking

Sizes ranging from 350mm > 600mm in most ground conditions

•

Drill up to 120 meters with a +/- 10mm tolerance

20 years experience in the drainage industry

This year’s conference theme is “Better outcomes through trenchless”.

No-Dig Floor Plan

22 TRENCHLESS AUSTRALASIA JUNE 2023

Stand No.Organisation

100Access Detection

30Acu-Tech Piping Systems

91Aqua Metro Service

28AT Boretec

44Aussie Trenchless Supplies

7 Austeck Pty Ltd

37 Australasian Society for Trenchless Technology

41Bamser

101Bellrock

78 Bohrtec

94Boss Attachments

92 Cangzhou Great Drill Bits Co.,Ltd

75 CDE

38CEA

14Channeline International Fiber Glass Manufacturing LLC

11CR Kennedy Survey Solutions

50DCS Manufacturing

102Denso Australia

49Derrick Corporation

96Detection Solutions

57 Digital Control Incorporated

13Drainchem

103Drainco Australasia

32ED. ZUBLIN AG

67 Empire Infrastructure

33ENVIROPACIFIC - SOLVE

97 F. Willich Australia

87 GCE Contractors

98Hebei GN Solids Control Co.,Ltd

55HERRENKNECHT

70 IMPREG (AUSTRALIA) PTY LTD

19IMS Robotics Australia Pty Ltd

8 Inrock International

Coffee Hub Interflow Pty Ltd

82Iplex Pipelines

95 JB Trenchless

63 KAISER Technology Pty Ltd

60KOR Equipment Solutions

45KRE Engineering Services

46kwik-ZIP Spacers

105Kynection

104Lateral Repairs

10Leica Geosystems (Hexagon)

3 MALA GPR AUSTRALIA

89Maxibor Australia

34MB Solutions Australia

Sponsors Exhibitors

99McBerns Innovative Solutions

35McRobert Contracting Services Pty Ltd

22Michels Trenchless Pty. Ltd.

88Monitor Lifts

18Mullane Trenchless

17No-Dig Depot

80Nuflow

77Nukote Coating Systems International

84OptionX Group

15PCTE-Industrial

90Pezzimenti Tunnelbore Pty Ltd

74 Pipe Core - Premium Pipe Relining Materials and Equipment

1 Pipe Couplings Australasia Pty Ltd

25Pipe Equipment Specialists

56Pipe Management Australia

76 Powell Industrial

4 Qenos

48Radiodetection

23RELINEEUROPE GmbH

26RIDGID Australia

59Rob Carr Pty Ltd

71Rockpecker Limited

54RSM Lining Supplies Global Pty Ltd

9 RTi Asia Pacific

72 SAERTEX multiCom®

2 Safety Shovel

36Schauenburg MAB Asia

39Sewer Equipment Company (Aust)

86Shore Hire

47 Smart Lock Group Pty Ltd

58Spiecapag Australia Trading As Hdi Lucas

42STEP Civil

64TRACTO Australia

53Trenchless Advisor

52Trenchless Sales

52 (cont.)Trenchless Sales

24a Trio-Vision

6 Tunnel24 GmbH

16UHI Machinery

27 Universal Corrosion Coatings

81USB-Australia

51Vermeer Australia

31Vertical Horizonz Australia

93 Vinidex Pty Ltd

40Vivax Metrotech AUS

24 Wuxi Lushun Drilling Tools Co. Ltd

25aZhangzhou Anyue Advanced Materials Technology Co.

JUNE 2023 TRENCHLESS AUSTRALASIA 23

Sponsors

Platinum Sponsor:

Gold Sponsor:

Australia

Silver Sponsors:

Bronze Sponsors:

Supported by: Media Partner: Charity Partner:

24 TRENCHLESS AUSTRALASIA JUNE 2023

Kaiser. Performance counts. THE GAME CHANGER FOR THE INDUSTRY. www.kaiser-technology.com.au Get in touch with our contact persons in Australia: Kristian Stamenkovic Roger Woods Area Sales Manager Service Manager +61 436 800 984 +61 482 524 737

Check out the range of equipment on display at this year’s No-Dig

No-Dig Down Under 2023 is the must-attend event for the trenchless industry, and with the theme of “Better outcomes through trenchless”, the equipment on show is set to be the best of new and emerging technologies.

Here’s a sneak peak of some of the equipment showcasing at this year’s conference.

The high-capacity system can also be utilised for cleaning of wet-wells, manholes, pits and culverts as well as for general cleaning and removal of any wet products.

“We are continuously striving to be at the fore front of design and user-friendly equipment for the Drain Cleaning and Hydro Excavation Industry,” the company says.

“There are exciting times ahead for this familyowned business with many positive changes being made that will benefit current and future cliental.”

Zealand,” the company says.

“We are also eager to share some new and innovative products in Gerotto, Falch, and Vanguard, whilst also having strong representation of Cappellotto, Schwarze and KEG. Come down and talk to a team that cares about you and your needs.”

Pipe Core

Pipe Core is showcasing various pieces of equipment at this year’s No-Dig Down Under including the Hächler Climbolino® E electric milling robot and Picote battery powered mini cleaner.

The Hächler Climbolino® E is a compact battery-powered milling robot which has been specifically developed for present-day conditions in sewer rehabilitation.

It features a powerful electric milling spindle, blending capabilities and multi-dimensional functionality – all with the benefits and technology of heavy milling machines.

Elsewhere, the Picote Mini Cleaner is a cordless battery-powered model that makes quick work of cleaning, descaling, root removal, cutting, reinstatements and coating in DN32-75 pipes.

It has a range of 16 m and also features an 8 mm shaft that allows working in smaller diameter pipes, multiple bends and p-traps as small as DN50.

DCS Manufacturing

The family-owned business, DCS Manufacturing, prides itself on being a local Australian-made manufacturer, based in Dandenong South.

This year at No-Dig Down Under, the company is showcasing its non-destructive digging unit (NDD) 8000 series hydro-excavation system.

CDE Group

The G:MAX has an integrated hopper for direct feeding, a split screen for separating products and a control panel on board.

The system be used to process a range of solid/ liquid wastes including road sweepings, gully waste, hydrovac waste and more.

The proven hydro-cyclone technology offers maximum grit recovery from wastewater –maximising product yield and minimising waste volumes to significantly reduce operational and disposal costs.

KOR

One of the leading industrial vacuum, non-destructive digging, dangerous goods, combination drain cleaning products, and industrial sweeper equipment companies, KOR, is exhibiting again at No-Dig Down Under this year, showcasing a multitude of equipment across its ranges.

“KOR are excited to be exhibiting again at No-Dig Down Under with increased capabilities within our national service centres including parts and accessories support and onsite mobile service vans across Victoria, New South Wales, Queensland, South Australia, and Hamilton New

Kaiser Technology Design, engineering, and manufacturing company Kaiser Technology is showcasing its Kaiser AquaStar III. The versatile vacuum and high-pressure jetting truck is capable of performing in sewer, stormwater, hydraulic, excavation, dry suction and industrial loading industries.

The system also has full recycling capabilities in both sewer and stormwater conditions.

Featuring Kaiser’s patented KWP liquid ring vacuum pump, a KDU pressure convertor water pump and single-stage RotoMax water recycling system, the AquaStar III has a payload of 7000 kg on Australian roads.

Other companies such as Rob Carr, KRE Engineering, IMS Robotics Australia, OptionX Group, SECA, Access Detection and RSM Lining Supplies will also be showcasing their innovative equipment at this year’s event.

26 TRENCHLESS AUSTRALASIA JUNE 2023

To learn more about the exhibitor’s showcasing at No-Dig Down Under 2023, visit www.nodigdownunder. com/exhibitor-list

The NDD 8000 series is a high-capacity hydro-excavation system.

The Picote Mini Cleaner is now available as a cordless, battery powered model.

The design of the Hächler Climbolino® E electric milling robot makes it the ideal tool for challenging construction sites and situations.

REPORT ANYWHERE, ANYTIME CLOUD-BASED COLLABORATION Talk to the experts 1800 028 584 or visit us online seca.com.au It takes a team to keep sewers flowing. WinCan Web is a cloud-based platform that lets you assign work and share inspections securely across your team. Results are available instantaneously, everywhere, through an app or browser—without the hassle of servers, offsite backups or email attachments.

Celebrating the women of SECA

In today’s rapidly evolving world, the achievements of women across various industries deserve recognition and admiration.

Within Sewer Equipment Company Australia (SECA), a dynamic and innovative organisation, a group of exceptional women are making their mark.

With their unique skills, dedication, and passion, these women are playing pivotal roles in driving the company’s success.

Trenchless Australasia takes a closer look at the remarkable women working at SECA, and the contributions they make every day.

Among the exceptional women at SECA, the influential presence of the female co-owner must be highlighted.

Nicola Enz Quealy is the co-owner and Strategic Programs Manager. She guides the company towards one big goal, excellence.

As a co-owner, Enz Quealy brings a wealth of experience, leadership, and a strong entrepreneurial spirit to the organisation.

Her vision and strategic direction has been instrumental in guiding the company’s growth and success.

Leesa Wright and Bernadette Bakulev are both Sales Support Coordinators and their skills empower the company from within.

Wright describes the trenchless industry as “helpful and inclusive”.

“Times have changed and it’s good to see women in trades,” she says.

As a woman in a male-dominated industry, Wright recommends others in the same case to “ask questions and don’t be shy to put yourself forward as a leader”.

Wright and Bakulev are the driving force behind the company’s sales operations.

With their exceptional communication skills and deep product knowledge, they effectively engage with customers, understand their requirements, and provide tailored solutions.

Their expertise ensures customer satisfaction fosters long-term relationships, and contributes to the company’s growth.

Sue Dawson, Key Accounts Manager, is all about nurturing strategic partnerships. Dawson plays a crucial role in maintaining and expanding SECA’s key customer relationships. All her working career has been in “the plumbing and trenchless industry”.

“I love every minute of it,” she says. “I have always found that the men I have worked with are happy to work alongside other hard workers, regardless of gender.”

Dawson says her biggest achievement was being the first female on road sales representative in the plumbing industry.

With her extensive experience and strategic mindset, she ensures that customer’s needs are met, expectations are exceeded, and partnerships are nurtured.

Dawson’s ability to understand market trends and identify opportunities has helped the company remain at the forefront of the industry.

Kristel Hudson, Marketing and Communications Lead knows the power of crafting a strong brand presence.

Hudson is responsible for creating and implementing effective marketing strategies.

“Being a woman in a male-dominated industry has certainly had its challenges, but it has also been incredibly empowering,” she says.

“I’ve used them as fuel to prove myself and showcase my abilities.

“Over time, I’ve gained respect and built strong relationships with my colleagues, and I’m proud to contribute to breaking down gender barriers.”

Hudson stumbled into the trenchless industry by chance seven years ago when she started as an administrative assistant and receptionist.

By working closely with accounts, she was able to progress and saw an opportunity to move into sales.

“I quickly became fascinated by the innovative technologies and solutions it offered, and gradually worked my way up to my current position as a marketing lead,” says Hudson.

Her creativity, analytical skills, and market insights has enabled her to develop compelling campaigns that highlight the company’s strengths and differentiate it from competitors.

Through her efforts, she enhances the brand’s visibility, increases market share, and drives business growth.

Hudson’s advice to other women looking to join the trenchless industry is to embrace their unique perspective and skills.

“Don’t be discouraged by the maledominated nature of the field; instead, let it motivate you to excel,” she says.

“Seek out mentorship and networking opportunities, and never underestimate the power of your voice. By staying true to yourself and continually learning and growing, you can make a remarkable impact in this industry and

WOMEN IN INDUSTRY 30 TRENCHLESS AUSTRALASIA JUNE 2023

L–R: Nicola Enz Quealy, Co-owner and Strategic Programs Manager and Jacqueline Alverez, People and Culture/Office Coordinator.

inspire others to follow in your footsteps.”

Office Coordinator knows how primordial it is to nurture a positive work environment.

detail and expertise in financial management.

As a result, Thi and Helen have ensured the company’s financial records are accurate and up to date.

Through their efforts, they contribute to SECA’s overall financial health and assist in making informed business decisions.

The women working at SECA play indispensable roles in various aspects of the organisation.

From driving sales and managing key accounts to crafting compelling marketing campaigns, and nurturing a positive work environment, these exceptional women are instrumental in the SECA’s success.

Their expertise, dedication, and commitment to excellence serve as an inspiration to their colleagues and contribute to SECA standing as

JUNE 2023

L–R: Helen Nguyen, Accounts Department, with Kristel Hudson, Marketing and Communications Lead.

Bernadette Bakulev, Sales Support Coordinator at SECA.

Sue Dawson, SECA Key Accounts Manager.

L–R: Sue Dawson, Kristel Hudson, Thi Nguyen, Nicola Enz Quealy and Leesa Wright.

Verena Reid, a rising star in the trenchless universe

Trenchless Australasia chats with Verena Reid, a nominee in the Women in Industry Awards under the Rising Star category, a 26-year-old who started her career at Interflow three years ago.

After joining Interflow as a cadet in 2020, today Verena Reid is a highly capable Project Engineer and is on track to becoming a leader within her field. She shares with us how navigating in a historically masculine industry can be, at times, challenging, but also rewarding.

Would you say the trenchless industry is more feminine or masculine?

Our industry feels masculine in my opinion. I still feel like we’ve gotten a lot better in the last few years, or decade, with trying to get more

women in the industry but it is still extremely male dominated, especially in the field.

How does it feel to be a nominee in the Women in Industry awards?

It feels fantastic to be nominated. I actually didn’t know that my team put me forward for a nomination until I heard about it. It feels really good, and the work that I do is being recognised in some capacity, especially within my team, in the office as well as on the field. I am really grateful for the nomination.

What drew you to this industry?

This interest in the trenchless industry goes back to my final years of university when I graduated at the end of 2021. I did a lot of work in my final year thesis around water sensitive urban design and focussed on a sustainability angle when it comes to the water industry. And from then on, I was just fascinated by the water industry.

I wanted to work in it and get to know what it’s all about. I’m so glad that I made the jump into this field and started being interested by it ever since I was an undergrad.

32 TRENCHLESS AUSTRALASIA JUNE 2023 WOMEN IN INDUSTRY

Verena with the team at WIOA in Bendigo.

Since you’ve been in the industry, how has your career evolved?

I started working with Interflow as an intern in 2020. Obviously, because it was during peak lockdown here in Victoria, it was quite hard to adjust, especially with working remotely all the time. But I started off in the estimating team, where I was doing a lot of bid management.

Then I got to learn all the ins and outs of the products that our company uses and how we fit within the wider industry as well. And from then on, I made a transition into sewer operations, where my current Project Engineer role is.

A few major milestones for me would be when I was still an undergrad, I managed a solar panel installation project at our depot to try and reduce emissions that we are outputting at our warehouse.

Among the most notable projects that I’ve delivered so far would have been delivering sewer main relining ahead of the Epsom Road sewer renewal project.

I also manage the sewer component of a Metropolitan water authority’s network renewals contract so that is my day to day, delivering reticulation sewer renewals.

on some big projects in the middle of the CBD at night, as well as all across the western suburbs. I love it and I am very proud of these achievements so far.

What is your main professional goal at the moment?

I would like to manage some larger projects in the near future. I manage small packages of work for reticulation sewers, however I’ve recently had the opportunity to branch out into larger civil construction projects. This has included construction of an Emergency Relief Structure for another major Victorian water authority.

What are the main challenges you have faced as a woman in trenchless so far?

I would say the adjustment to working in a male-dominated environment, especially on site. This adjustment has taken me a little while, but today I have strong relationships with the people in the field. I think that my people skills have really helped me out.

I know there’s huge differences between myself and some of my longer-serving colleagues when it comes to experience.

I still consider myself quite inexperienced as I’ve only been working for almost three years now.

However I’m talking to people everyday on site who have been working in the same industry or the same field for 20 years.

My way of overcoming this gap was to tell myself that everyday holds a lesson. And I am learning from the people I work with.

I think that means a lot to them as well, as someone is listening to them, and learning from them.

Everybody has a lot to offer in this industry and there’s always opportunities to learn. I would encourage anybody to just get out there and see what it’s like.

What advice would you give other women?

I would say don’t be scared. Just go for it. You’ll never know what it’s like until you actually start working there.

There’s plenty of things to learn. There’s plenty of things to do within this industry. And everybody’s role is so important. The best advice would be: get in there and give it a go.

And I think that you might really surprise yourself at the end of the day.

What could make the trenchless industry better for women?

I think maybe more education or more campaigning around the fact that we really need to encourage more women in the field. We have a lot to offer. And it shouldn’t just be a maledominated-industry.

We should definitely have a lot more women working in all sections of this industry. I think education around that would be key and to try and really change the stigma or the mentality that this industry is male dominated when it really does not have to be.

What are the lessons you’ve learnt so far? Sometimes you’ve got to get out of your comfort zone, as much as you possibly can.

For me it was hard to adjust at the start, but I think what really helped me out quickly is just really stepping out of my comfort zone – talking to as many different people as I could, and finding some really good mentors.

Mentorship has really helped me and the progression within my career and this industry in general.

Also, another piece of advice to anyone entering a new field or industry is to find a really good support network. And don’t be afraid of talking to as many different people as you can, people working in different roles, different operations, different projects.

When I just started at Interflow, I was quite nervous and very keen to get a foot in the door.

Almost immediately I was very pleasantly surprised, because in this industry, everybody is willing to help.

I really value the helpfulness and selflessness of my industry peers.

To see the 2023 award winners visit www.womeninindustry.com.au

JUNE 2023 TRENCHLESS AUSTRALASIA 33 WOMENININDUSTRY.COM.AU

Verena Reid is Project Engineer at Interflow and a nominee for the “Rising Star” category of the 2023 Women in Industry Awards.

AdaptX technology key to challenging railway pipeline project

A week to finish a challenging tunnelling project may seem like an impossible task for some. But for Edge Underground, this proved that there is nothing too daunting for the microtunnelling company.

Edge Underground was contracted for the project, which involved a 750 mm bore under an existing live railway line for 50 m. And on top of it all, the stakes were high.

Failure to complete the job before the Easter break could have had significant repercussions for the overall project by impacting the pipelaying crews.

The Edge Underground team was called in at late notice as the previous contractor was not progressing as anticipated. The company agreed

to assist and took on the tight timelines. Due to further project constraints, the initial mobilisation was delayed applying more pressure to an already tight program.

The project required the team to bore through 240 megapascals (MPa) of rock, a particularly difficult material to work with, and with the project’s tight deadlines and high stakes involved, there was no room for error.

Despite the pressure and unexpected challenges on-site, including other

subcontractors encroaching on its time, Edge Underground rose to the occasion.

As part of OptionX Group, Edge Underground has access to Bournedrill and its workshop, and has recently implemented new drill rods primarily designed for the AdaptX machine.

These rods, which could also fit the existing AXIS machines owned by Edge Underground, made the machines three to four times more capable than the original drill rods.

MICROTUNELLING 34 TRENCHLESS AUSTRALASIA JUNE 2023

The Edge Underground team pulled out all the stops to complete the job before Easter.

Founder of Edge Underground and CEO of OptionX Group, Stuart Harrison says a project of this nature wouldn’t have been possible just a few years ago.

“This was the sort of job that in the past, we would have allowed much more time for problems to come up,” Harrison says.

“But we had no time. The program was so tight that any problem would have meant we didn’t make the deadline.”

Harrison credits the success of this project to the modifications made to the AXIS machine, which included heavy-duty drill rods, geared reaming technology, and new rock reaming technology.

These modifications were originally developed and patented for OptionX Group’s AdaptX machine but were adapted to the existing AXIS machines with great success. The successful completion of this project is a testament to Edge Underground’s focus on operational efficiency and investment in advanced technology.

The innovations enabled the team to bore under a live railway line with tight deadlines and difficult material, while avoiding any disruption to the train schedule. The project has opened up new opportunities for Edge Underground, as it continues to take on difficult jobs.

With the support of OptionX Group and its ongoing investment in new technologies, Edge

Underground is ready to expand its capabilities and tackle whatever challenges come its way.

In the drilling, tunnelling, and boring industry, meeting tight deadlines is a significant challenge, often due to overcrowded programming, lack of support from suppliers, supply chain issues, and staffing problems.

However, Edge Underground has established measures to mitigate these issues and

THE GOLD STANDARD IN SEWER AND DRAINAGE POINT REHABILITATION.

ensure its projects are completed within the given timeframe.

Its recent success in the challenging railway pipeline project is a testament to its expertise and commitment to delivering exceptional results for its clients.

For more information visit www.optionxgroup.com.au

With Smart Lock, you can seal redundant lateral connections and repair cracked or damaged pipes in three easy steps, cured in only 30 minutes.

LOAD Smart Lock into position using the caddy

LOCK Smart lock into place with the intelligent ratchet system

LEAVE Cured in under 30 minutes so you can move to the next job

MICROTUNELLING

Smart Lock is the biggest advancement in point repair technology, in more than 15 years.

For more information visit smartlockgroup•com

The Edge Underground team has extensive experience working around live rail tracks.

Pezzimenti Trenchless boasts microtunnelling capabilities

Pezzimenti Trenchless continues to showcase its position as a leading trenchless specialist by completing works on two Victorian projects.

From tight residential streets, to managing households, pedestrians and traffic, the Mont Albert Level Crossing Removal and Korumburra Trunk Sewer projects were just some of the challenges Pezzimenti Trenchless faced.

Director Joe Pezzimenti tells Trenchless Australasia that while the project was completed by January 2023, and despite the above challenges, the team ensured the “works were executed diligently and efficiently”.

“We were working in a tight residential street, which meant we had to manage households, pedestrians and traffic,” he says.

“This also limited footwork, which suited our equipment.”

The scope of the Mont Albert Level Crossing Removal involved the installation of 245m of

the 324 mm OD Hobas GRP jacking pipes.

The Pezzimenti Trenchless method ensures all types of pipes are installed efficiently, with Hobas jacking pipes typically used for larger bores requiring continuous ground support.

For the Mont Albert Level Crossing Removal, as the railway was to be lowered at the location, a new sewer was required, which led to Harris Civil engaging Pezzimenti Trenchless to complete the pipe jacking works.

The lengths of the bores were 73m, 92m and 80m, installed at a depth from 5m to 8m through ground conditions of clay and siltstone.

Joe says for the Korumburra Trunk Sewer upgrade project for Harris Civil, Pezzimenti Trenchless was engaged by South Gippsland Water to complete various works.

MICROTUNELLING 36 TRENCHLESS AUSTRALASIA JUNE 2023

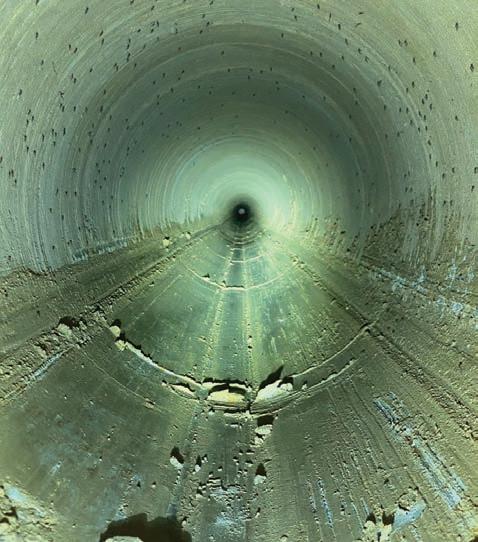

Pezzimenti Trenchless continues to be at the forefront of the trenchless industry through its laser-guided microtunnelling system.

Despite challenges in both projects, the Pezzimenti team completed the works diligently.

The overall project scope comprised of approximately 172m of 900m gravity sewer that required microtunnelling.

Pezzimenti Trenchless installed a 618mm OD Superlit GRP jacking pipe with the bores measuring 74m and 98m.

These were installed at a depth of 5m, through ground conditions of siltstone, which proved to be another challenge for the Pezzimenti team.

“The ground conditions of very hard siltstone were difficult to deal with, and ground water was encountered which required 24/7 dewatering,” Joe says.

“But we pride ourselves on maintaining the highest quality equipment and setting the standard for the industry when it comes to quality, care, and development.

“The dedication our team shows when it comes to completing a project, however big or small under any circumstance, in an efficient and effective manner, is why we’ve stood the test of time.”

It was through this dedication that enabled the Pezzimenti Trenchless team to complete the works within three weeks.

Since 1957, Pezzimenti Trenchless has positioned itself at the forefront of the trenchless industry through its laser-guided microtunnelling system.

MICROTUNELLING

rothenberger.com.au rico-gmbh.de/kempten/en/ RICO is part of the ROTHENBERGER Group. Innovative Inspection Technology. For 40 Years. RICO is one of the world’s leading companies in the field of mobile camera-based inspections since 1978. Interested in representing RICO in Australia? We are looking for State Distributors and Service Agents. Deal direct with the manufacturer. Email us to register your interest or for more information: sales-au@rothenberger.com For more information, visit www.pezztrenchless.com.au

The Pezzimenti method ensures all types of pipes are installed efficiently.

Adept Civil delivers on crucial regional NSW greenfield development project

Adept Civil Group has showcased its position as a leading civil engineering contractor by delivering microtunnelling on a greenfield development project in Albury, New South Wales.

In the northern area of Albury suburb Thurgoona, lies Brooklyn Fields Estate – a sprawling 210-hectare parcel of greenfield land. The estate consists of 118 hectares of residential zoned land, with construction of the first two stages complete and third stage ongoing.

In particular, the $2.75 million extension of the sewer network at the estate will assist in continuing a high level of wastewater service delivery to existing development throughout northeast Thurgoona, while preparing for future growth in the area.

As trenchless technology involves minimal surface disruption, it plays an important role in

greenfield developments, with many companies within the industry providing their expertise across these projects, including Adept Civil.

The company was engaged by Longford Civil to microtunnell 1100 m of 472 GRP, using a 500 mm forward clay cutting head which was required for the complex geology in the area.

Adept Civil Business Development Manager Quentin Powell says the company’s reputation and history of taking on challenging projects while staying committed to safety was crucial in securing the contract.

“At Adept, we’re always willing to collaborate with our clients to ensure projects are completed safely and diligently,” Powell says.

MICROTUNELLING 38 TRENCHLESS AUSTRALASIA JUNE 2023

Adept Civil continues to showcase its position as leading civil engineering contractor.

Adept Civil’s reputation of taking on challenging projects while staying committed to safety helped secure the contract.

Longford Civil and Albury City Council meant we were right for the job.”

He says the Brooklyn Fields Estate project, located in NSW, came with its own set of challenges.

“The location of the trunk sewer main which began at the northern end of Kerr Road, crossing Woolshed Creek and travelling southwest adjacent to the Woolshed Creek alignment was challenging to work with,” Powell says.

Despite the challenges faced during the installation, the Adept team completed the job successfully using the company’s Vermeer Axis GB812 laser-guided boring system.

“The Axis boring system’s precise grade drilling capabilities and the vacuum extraction

Powell says.

Specialising in water and sewerage drainage pipelines, pump stations and associated services, Adept Civil has earned its reputation as a leading civil engineering contractor by delivering quality projects on time and within budget.

The contractor makes safety a priority on every project it works on, and it is currently working towards a goal of zero workplace injuries through its in-house training and careful site management strategies.

The company also has a strong focus on environmental management through its philosophies of education,

communication, continual improvement, and company involvement.

By working with these philosophies, Adept Civil aims to minimise pollution created during any works and continuously monitors its impacts on the environment through audits, reports, and inspections.

» Quality and collaborative HDD design and construct services

» Expertise to advise at the right time in the project delivery cycle

» Gas, water and sewer, rail, road, power, telecommunications, mining, residential development, renewables and hydrogen

» Maxi-rigs capable of long and wide diameter bores in hard rock and difficult conditions

» Building a future we all look forward to

JUNE 2023 TRENCHLESS AUSTRALASIA 39

02 4966 5583 www.maxibor.com.au admin@maxibor.com.au Follow us on LinkedIn, Facebook & Twitter

AUSTRALIA’S LEADING HDD SPECIALIST

To learn more about Adept Civil Group, visit www.adeptcivilgroup.com.au

Maxibor is using its design and construct expertise to deliver better project outcomes to asset owners and principal contractors alike

Adept Civil was contracted by Longford Civil to microtunnell 1100 m of 472 GRP, using a 500 mm forward clay cutting head.

Despite the challenges faced during the installation Adept Civil completed the job successfully.

How sustainability is leading the way for KAISER

One of the leading vehicle manufacturers, KAISER is making waves in Australia through its sewer cleaning vehicles and sustainability initiatives.