S&Z Australia General Manager Jim Pound

UNDER VICTORIA

Conservation and expansion hand-in-hand in Victoria

SAFETY

Veolia is the vanguard for safety SECA expands offerings from inhouse training centre

HDD

Mitigating climate change risk with insurance TRACTO hosts Australasian contingent at Europe’s largest construction event

Prime Drilling: Putting the customer first M Tucker & Sons turns worksite waste into valuable resource

Vacuum excavator becomes tool of choice in council fleets

Pace Drilling partners with horizontal drill specialists Ditch Witch CEA Michels’ mission ensures its people return home safely each day Anti-corrosion measures tailor-made for every solution

Sewer cleaning just got easier Smart Lock makes short work of sewer drain repair in Hong Kong NordiTube offers safe solutions for asbestos cement water pipes

Ageing pressure pipelines come to life with Primus Line’s innovative trenchless technology

18 20 22 24 26 28 30 32 34 36 38 40 42 44 46 48

Rob Carr invaluable on South Melbourne sewer project kwik-ZIP HDX-90s support Quickway’s trenchless water main installation Fighting against the elements: Pre-planning for success in Townsville

SOFTWARE

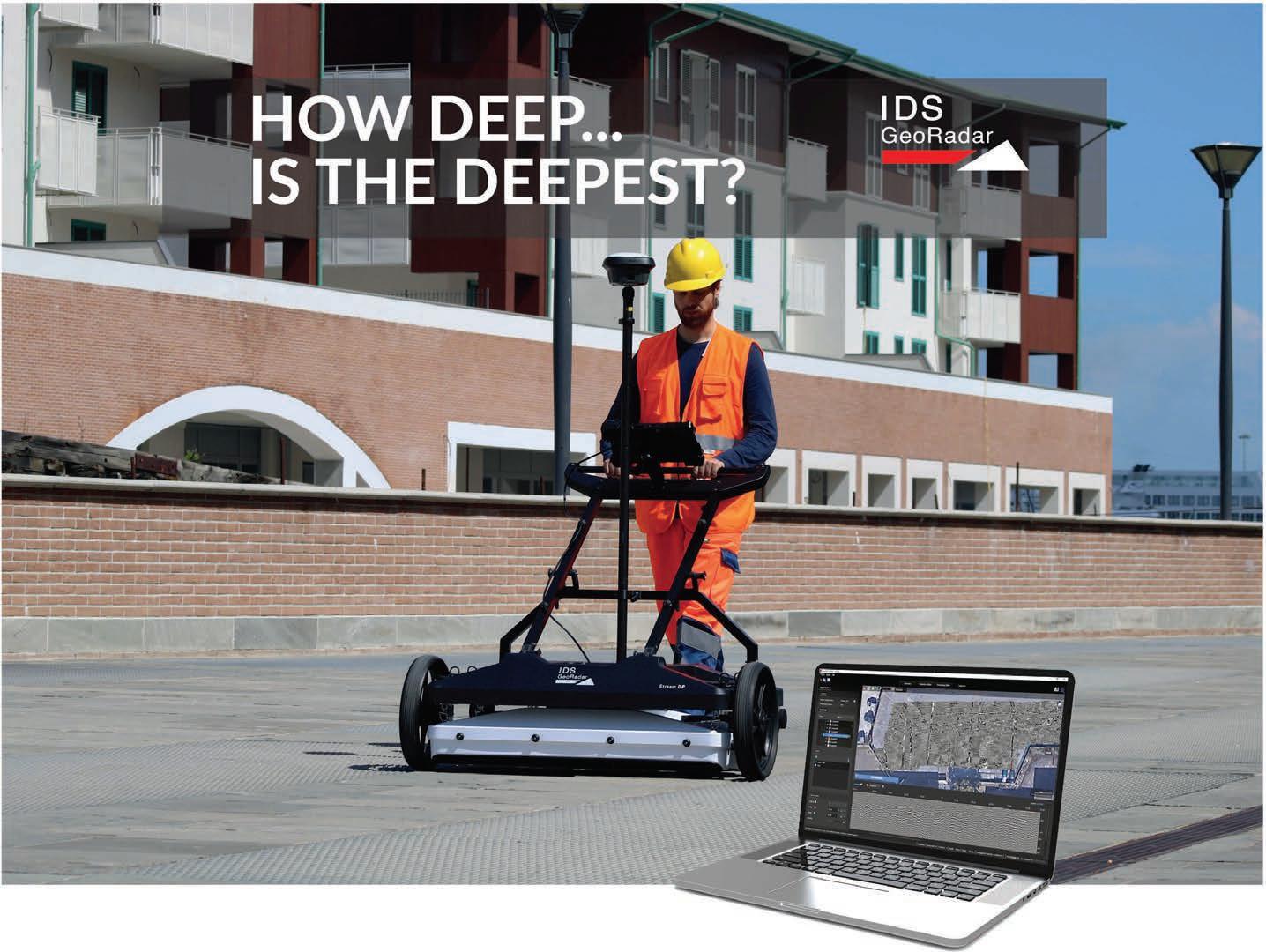

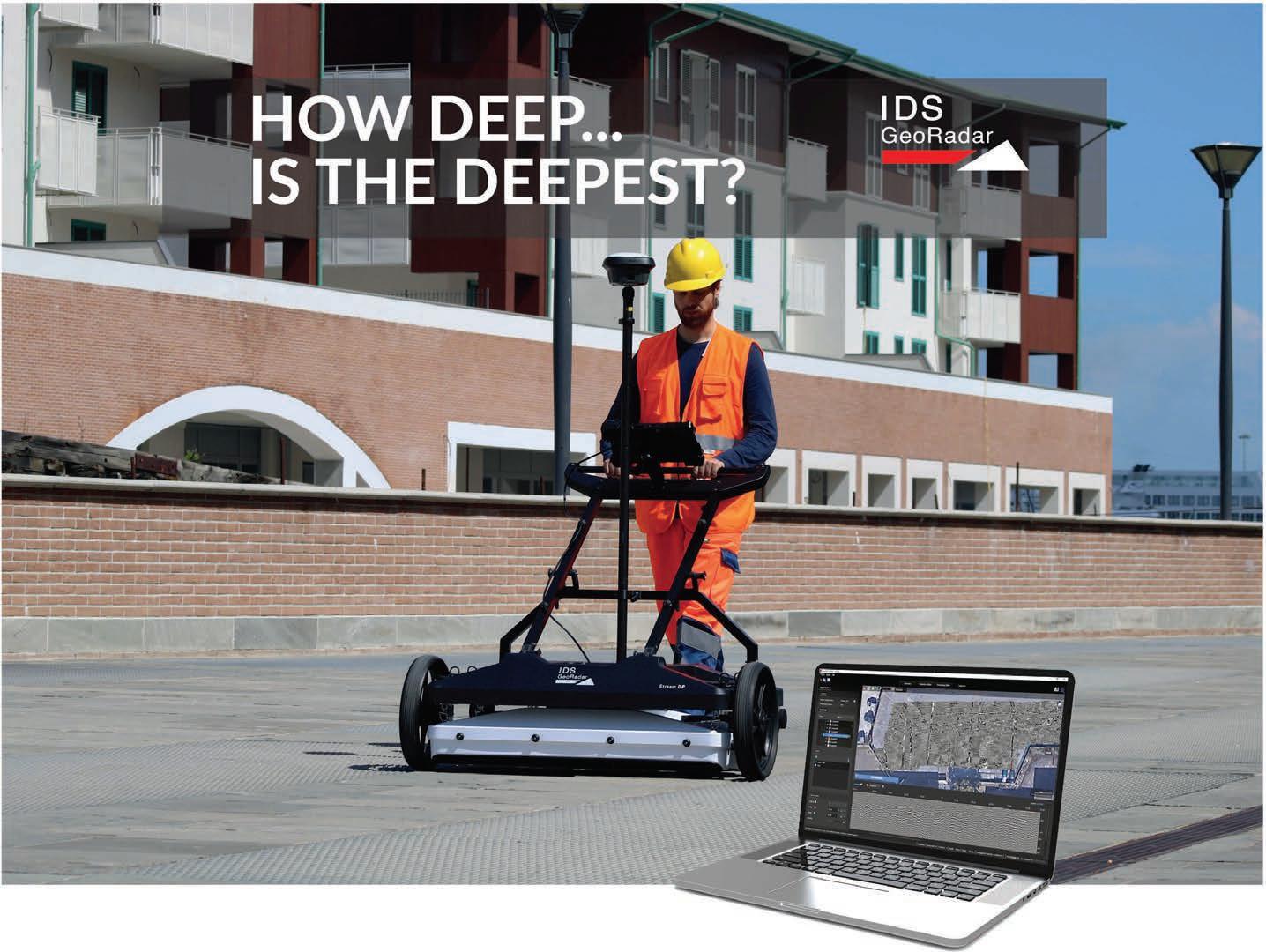

Stream DP with EsT technology: Bringing GPR performance to the deepest level

Aussie Trenchless has the future of pipe rehabilitation solutions sorted iMPREG celebrates international success in the UK EVENTS

No-Dig Down Under 2023

REGULARS

Editor’s Letter From the President From the ASTT Secretary News in brief ASTT Corporate Members People on the Move

50 52 54 56 58 60 62 8 10 12 14 64 66

This magazine is the official journal of the Australasian Society for Trenchless Technology (ASTT) and is distributed to members and other interested parties throughout Australia and the Asia-Pacific. It is also available on subscription.

The publishers welcome editorial contributions from interested parties. However, neither the publishers nor the ASTT accept responsibility for the content of these contributions and the views contained therein are not necessarily the views of the publishers or the ASTT. Neither the publishers nor the ASTT accept responsibility for any claims made by advertisers. All communications should be directed to the publishers.

Unless explicitly stated otherwise in writing, by providing editorial material to Prime Creative Media (PCM), including text and images, you are providing permission for that material to be subsequently used by PCM, whole or in part, edited or unchanged, alone or in combination with other material in any publication or format in print or online or howsoever distributed, whether produced by PCM and its agents and associates or another party to whom PCM has provided permission.

Cover image

Left: Mt Cole Pipeline. Image source: Interflow.

With a focus on safety, innovation and collaborative delivery over the last 30 years, Rob Carr has achieved outstanding outcomes in water, wastewater and energy infrastructure projects in both Australia and overseas. Rob Carr is part of Soletanche Bachy a world leader in foundation and soil technologies and subsidiary of VINCI, a global player in construction across more than 100 countries. With outstanding capabilities to manage the complexities of any project, Rob Carr has the people, knowledge and experience to deliver success.

CEO

COO

Christine Clancy

christine.clancy@primecreative.com.au

MANAGING EDITOR

Molly Hancock molly.hancock@primecreative.com.au

EDITORIAL

Christian Alphonso, Jenna May

Nick Lovering nick.lovering@primecreative.com.au

Michelle Weston michelle.weston@primecreative.com.au

Blake Storey blake.storey@primecreative.com.au

Kerry Pert, Tom Anderson, Louis Romero

Trenchless Australasia is owned by Prime Creative Media and published by John Murphy. All material in Trenchless Australasia is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Trenchless Australasia are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2021

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office 379 Docklands Drive, Docklands VIC 3008 Ph: +61 3 9690 8766 enquiries@primecreative.com.au http://www.primecreative.com.au

Sydney Office Suite 303, 1-9 Chandos Street Saint Leonards NSW 2065, Australia Ph: (02) 9439 7227

Welcome to the last edition of Trenchless Australasia for 2022. What an achievement it is for many to make it through these last 12 months. From completing major projects to surviving another year of COVID-19, and rebuilding following the effects of the recent floods, 2022 has been another challenging year for the industry.

However, the trenchless sector has come out stronger and more versatile, by enhancing its technology and networking back in person to create better solutions for the challenges faced.

This year was also one of firsts ‒ both personally and the magazine itself. My first edition as editor, attending my first No-Dig Down Under convention, and the magazine shifting from four to six editions a year for the first time.

In the spirit of firsts, Trenchless Australasia has introduced a new regular column tracking new appointments in Australia and New Zealand’s trenchless industries.

‘People on the Move’ will be published in every print edition of the magazine, celebrating the people who make the industry what it is. The column gives companies the opportunity to introduce new team members to the Trenchless Australasia’s audience and position them as a point of contact for their business.

Hodnett, and Veolia’s Jason Climo. To read more about their roles and ambitions, check out the People on the Move feature on page 66.

This edition also highlights the safety and training work being done in the industry. While trenchless technology and methodologies are still considered a niche segment of the construction industry, significant work is being done by stakeholders to ensure the benefits of no-dig methods are becoming mainstream, and importantly completed in a safe and sustainable way.

In addition to this theme, other unique features in this edition include Horizontal Directional Drilling, Rehabilitation and Repair, Microtunnelling, Software and Technology, and Relining.

Jim Pound also shares his thoughts on the industry for the Trenchless Pioneers feature, stating that if the industry continues to grow at the same rate it has in the past 20 years, that he is excited to imagine what may be possible.

The team from Trenchless Australasia thank you for your support during 2022, and wish everyone a happy and safe Christmas and New Year. We look forward to joining you again in 2023.

Happy Reading!

Printed by: Manark Printing 28 Dingley Ave Dandenong VIC 3175 Ph: (03) 9794 8337

In this edition we celebrate and welcome kwik-ZIP’s Phil Micallef, PSSS’ Michael

Molly Hancock Editor

molly.hancock@primecreative.com.au

THE AUSTRALASIAN SOCIETY FOR TRENCHLESS TECHNOLOGY

ABN 43 893 870 966 18 Frinton Place Greenwood, WA 6024 www.astt.com.au jeffpace@astt.com.au

President: Ben Crosby

Secretary: Jeff Pace

Vice President: Blair Telfer

Western Australia: Trevor Gosatti

Queensland: Ben Crosby

New South Wales: Matthew Boyle

Victoria: Justin Shepherd

South Australia: Shaun Melville

New Zealand: Blair Telfer

Northern Territory: Vacant

Tasmania: Vacant

Sudipta Basu

As 2022 draws to a close it enables us at the ASTT and as an industry to reflect on the year that was.

In summary the society continues to work on the following key initiatives to benefit the industry and the membership:

• The roll out of our Strategic Action Plan

• The finalisation of our Liner Design Specification

• The delivery of the Trenchless Technical Stream at Water New Zealand October, 2022

• The finalisation of the Liner Design Training Package

• The continuation of the updates to our NASTT licenced training packages

• The compilation of the report: The State of the Industry (Trenchless)

• The partnership with AusJet

• The partnership with WSAA (Water Services Association of Australia).

All these initiatives are designed to deploy the membership resources to benefit the industry and the membership in one way or another. A reminder to our members; if there is something that you feel we, as the peak trenchless body, should be working on, please reach out and contact either myself or your local Councillor.

As we draw 2022 to a close and we look to 2023, we are excited to plan another NoDig Down Under Conference in Brisbane in September 2023.

The conference planning is well underway, and it will be full of the elements that keeps bringing you back, plus some new exciting initiatives to keep us relevant in our industry.

I encourage you to be creative in the exhibitions that you are planning, and we would really encourage you to showcase your new products and services in the exhibition hall.

I also implore you to celebrate your successes, challenges, and developments in the technical portion of the conference. We had a great technical and case study paper presentation at No-Dig in Sydney 2022 and we’d love to see more in Brisbane 2023.

Thank you to our sponsors and exhibitors for continuing to believe in the vision of No-Dig Down Under and supporting the event through the challenges that the COVID-19 years continued to present.

As we turn into 2023 we all hope that the pandemic is behind us and we can get on with our professional and personal lives. I look forward to seeing you at No-Dig Down Under 2023 in Brisbane.

As Australia’s only dedicated exhibition and conference for trenchless technology, this event is incredibly important for our industry.

2022 has seen us get back to face-to-face technical forums which has proven to be a good way to network and showcase new developments and updates in our industry.

We also saw the ASTT partner with the Australian Tunnelling Society, resulting in two good and informative site visits being conducted and live streamed around Australia and New Zealand.

We hope to see more of these opportunities in 2023 in and around the No-Dig Down Under Conference.

Ben Crosby ASTT President

Gold Corporate Members – Australia

Ben Hayes from Herrenknecht AG

Silver Corporate Members – Australia

Glenn Hayes from DCS Manufacturing

Silver Corporate Members – New Zealand

Asset Owners – Australia

Asset Owners – New Zealand

Individual Members – Australia

Lachlan Rankin from Julconix

Andrew Lukas from AJ Lucas Services

Jiang Aizezi from Downer

All Papers from the Sydney Conference can now be downloaded by members of the ASTT. Refer: https://astt.wildapricot. org/NDDU-Conference-Papers

The ASTT has now formerly established its 2023 National Conference and Exhibition organising committee that will be working feverishly on your behalf to ensure that the Brisbane Conference will be a resounding success. Exhibition sales are now available and you are interested in exhibiting, please contact: nick.lovering@ primecreative.com.au. More information is also available on the event website, refer: https://nodigdownunder.com/

Thank you to all members who participated in our recent members survey. The survey covered the key areas of the ASTT membership offer being communication, membership benefits, education, industry standards and promotion of trenchless technology. The results from this year’s survey were compared with the previous surveys conducted in 2019 and 2021.

The key findings from this year’s survey:

• The level of communication the members receive from the ASTT was

seen as sufficient by the large majority of members. The quality of this communication was rated as very good.

• The quality of the trenchless magazine and ASTT website are rated as very good.

• The level of satisfaction with the quality of the ASTT events is high albeit there are some suggestions for improving member attendance and engagement.

• There is an appetite for the ASTT to do more promotion of trenchless technology and capabil-ity in the market.

• There were several suggestions for areas where the ASTT could further develop new industry guidelines, standards, and specifications.

• The Net Promotor Score (NPS) from the 2022 survey was plus 8. This is a slight decline from the 2021 NPS result of plus 12.

The results and feedback from the survey will be reviewed by the ASTT Council.

The ASTT is pleased to advise that we have accepted the Australasian High Pressure Water Jetting Association and the Australasian Drain Cleaning and Vacuum Association as reciprocal members. They now join the Australian Tunnelling Society. Refer: https://www.astt.com.au/ reciprocal-members/

In early December, the majority of the membership will be receiving your Tax Invoices for the 2023 membership renewals through our Wild Apricot new automated database system. Your membership fees will be emailed out to you, and these fees will be due to be paid on or before January 1, 2023. All members are now encouraged to use either PayPal or direct debit to pay your fees. The ASTT will still accept cheques as has been the practices in the past. When making your payment, can you please either ensure that your company name or invoice number is included as a reference. Members from New Zealand, please note that the

amounts shown on your invoices are shown in Australian dollars.

Also, as we now have several new membership categories, any member can request a change of membership category prior to payment of their fees. Members are encouraged to request the changes preferably as soon as you receive your tax invoice. For detailed information of what the benefits are for all categories, please refer to the following - https://www.astt. com.au/member-benefits/

The ASTT has acquired limited numbers of the NASTT publications as listed under which are now being offered to members and non-members. These publications are intended to provide contractors, engineers, and utility owners with an overview of many of the various trenchless methods. All NASTT publications were peer-reviewed by volunteer industry professionals to ensure that they offer generic and non-commercial information. These publications were funded solely by NASTT as part of its educational outreach program. If you would like a copy, email: simon.coburn@primecreative.com.au .

A reminder to all members to review the information listed about you and your company on the ASTT website. To view, go to the Members Directory area of the ASTT website, refer https://astt.wildapricot. org/directory. If any changes are required, you can either do the changes yourself or you can send the changes to me and I will amend for you.

In closing, may I also take this opportunity to offer all of you on behalf of the ASTT, a very merry Christmas and a happy and safe New Year.

Jeff Pace ASTT Secretary secretary@astt.com.au

Watercare is set to begin laying down the foundations for a new $20 million wastewater pipe network to reduce wastewater overflows and cater for growth in Rosedale and its surrounding suburbs.

Alongside the $21.5 million Mairangi Bay Pump Station, the new wastewater pipeline will increase the wastewater transmission capacity and reduce wet-weather overflows in the East Coast Bays area.

The construction of the 1.75 km pipeline is one of the many key infrastructure projects that Watercare currently have in the works in the Rosedale and Mairangi Bay areas.

Although it plans to carry out much of the work in Windsor Park and Centurion Reserves, Watercare acknowledged that people may experience disruptions along Apollo Drive and Centurion Drive such as reduced on-street parking, lane widths, speed limits and pedestrian detours.

practical knowledge on utilising trenchless technologies in sustainable industry projects.

Water New Zealand’s 2022 Conference and Expo brought together some of the most insightful speakers in the water industry last week to share their ideas and vision for the future of sustainability in the industry. The Australasian Society for Trenchless technologies (ASTT) delivered a stream in collaboration with Water NZ.

The series focused on the innovations present in existing projects, from the massive northern interceptor pipeline to the relocation of curved alignment tunnel in Mt Eden.

Operators in the water and wastewater industry were given the opportunity to connect and collaborate, helping to form Whanaungatanga – or, ‘close connections or kinship’ – within the industry to allow innovations to thrive.

Local Government Minister Nanaia Mahuta’s keynote address called on all operators within the industry, saying that the time to make a change is now.

“The current changes and reform present us with the opportunity to be aspirational about how we want key services to be delivered in the future,” Mahuta says.

The microtunnelling specialist won the award in the $5 to $10 million category for its Gnangara Branch Sewer section 2 project, located in Western Australia.

The project, undertaken on behalf of client Water Corporation, involved installing a new pressure main to an existing sewer section.

The company’s expertise in microtunnelling saw overcame a number of challenges for the project, including in-ground infrastructure and a limited time frame.

Teams completed four drives reaching a total 500 metres of microtunnelling, and managed to construct a DN1000 glass reinforced plastic, 259-metre microtunnel in 10 days.

The Gnangara project was automatically nominated following Rob Carr’s win at the CCF WA Awards in September.

Managing director Damien Maitre received the award on behalf of the company.

The TBM is an earth pressure balance machine, meaning it can stabilise the earth it excavates to reduce impact on the surface.

It has a 7.15 m diameter, weighs 910 tonnes and is 7.15 meters in length.

Now that the tunnels are completed, crews will begin work fitting them out with everything they will need for use:

• 16 km of rails

• 816 km of signal cables

• 247 km of low voltage cables

• 74 km of cable containment

• 86 km of traction cables.

Tunnelling works for Auckland’s CRL have been completed with the final breakthrough of the tunnel boring machine (TBM) at Te Waihorotiu Station (Aotea) on 14 September.

Over the duration of the project, the TBM bored a total of 3.2 km of tunnels, placed over 2000 segment rings and removed more than 260,000 tonnes of spoil.

The Dame Whina Cooper is now in the process of being lifted out. Despite being custom built for the CRL project, pieces of the equipment will be returned to Germany where manufacturers Herrenknecht AG will repurpose them for future machines.

The 75 tonne cutter head was removed last week, while the shield is being dismantled into six pieces that will each be crane-lifted above ground for removal.

DJ Mac

have achieved yet another

success on one of its longest single drives for non-man entry to date.

DJ Mac Cormick Contractors has undertaken one of the longest single drives for an 800 mm diameter closed face slurry shield micro tunnelling project, with no-man entry available for installing intermediate jacking stations or slurry pumps.

The project was completed on behalf of the city of Swan, located in the eastern metropolitan region of Perth in Western Australia. The drive length for a main drain was 234 m and due to the high level of traffic, community use and business trading work was only able to be undertaken over the Monday to Friday traditional work week.

Launch and receival shafts were constructed utilising Ground Support Systems (Aust) shoring and associated safety equipment, which included certified structural KPA ratings for all the shoring.

Temp designs were certified by structural engineer & undertaken for thrust block, entrance wall and concrete pad.

DJ Mac Cormick Contractors had previously undertaken the previous stage back in 2019.

The works in this stage involved several high complexity traffic MGE plans staged to ensure continual flow traffic through locality in order to minimise disruption to businesses as well as the broader community and residents.

Ground conditions ranged from stiff clay to running sand. Underground streams encountered throughout the project also meant working on river sands and river stone cobbles during the drive length. All works were undertaken within 20 mm tolerance over drive.

Upon completion of the drive, various tie in works and open cut drainage excavations including the construction of drainage manholes and side entry pits were required. This included the construction and maintenance of connections to existing drainage structures.

CCTV inspection of all lines was also required for this stage of the project, with a quality insurance pack and drawings provided upon completion.

DJ Mac Cormick Contractors undertakes tunnelling for diameters from

150 mm to 2500 mm diameter with its a fleet of Iseki & Herrenknecht closed face tunnel boring machines (TBM).

The company boasts a variety of TBM cutting wheels to suit soft, mixed and rock ground conditions in varying ground conditions, both wet and dry, to fit the needs of the Australian people and its landscape country wide.

The company has the capacity to complete drives up to 1 km utilising intermediate jacking stations and intermediate jacking units to run another four stations from within pipelines or intermediate slurry pumps in which pipe diameter is 1500 mm or greater.

For these sizes and more, the company has TBM’s with the ability to change cutters from within where required along the drive length. Not only that, but also DJ Mac Cormick Contractors has rock cutting wheels suitable for 200 MPA rock.

With offices in Perth, Adelaide, Sydney, Melbourne, Brisbane and Townsville, DJ Mac Cormick Contractors is able to provide expertise to its clients throughout Australia.

Further information or enquiries to info@djmaccormickcontractors.com.au

In a bid to celebrate the achievements and growth of the trenchless industry and the ASTT, Trenchless will be running a new question and answer segment. In this edition, the Trenchless Pioneer is Jim Pound, the General Manager of S&Z Australia. This is his story.

IThe trenchless industry provides methods that allow infrastructure to be delivered safely with minimum impact on the environment and the community.

How did you become involved in the trenchless industry?

My initial exposure to trenchless was in the early 1990s when working as a plumber. I engaged the services of a pipe bursting company to replace a very deep sewer in Ardeer. Since then, I have worked with several companies including suppliers and trenchless specialist companies. These companies exposed me to various trenchless technologies such as slip lining, pipe cracking, pipe bursting, fold and form pipe lining, HDD and microtunelling.

What is a standout trenchless project or milestone you have been involved in? Our involvement in a large project in the NSW Mountains which required us to deliver over 6 km of communication and power through extremely hard rock in a remote and challenging environment is a project that we are extremely proud of. Working day and night in snow and rain to deliver the project

within the necessary time frame, requires great dedication from our staff and we are extremely grateful for their commitment.

What is the best part of trenchless technology? And how has it evolved since you first became part of the industry? Trenchless technology is always evolving. New techniques and improvements to current methods see the industry continually growing and improving. Most companies within trenchless technology are prepared to share experiences to help improve the industry and there is good collaboration within the various companies even if they may compete at times.

Which form of trenchless technology do you think has had the most transformation and why?

Tunnel boring continues to evolve and appears to be becoming a preferred method of trenchless technology due to the advancements in techniques which see longer lengths and larger sizes achievable.

Where do you see the trenchless industry in the next 10-20 years?

If the industry continues to grow at the same rate it has in the past 20 years, I am excited to imagine what may be possible. I

expect the opportunity to reduce emissions and minimise impact on the environment and provide safer work practices will see projects that would normally be delivered by traditional open trench methods be replaced by trenchless technologies.

With trenchless technology having a strong ability to reduce the impact on the environment, what more do you believe the industry needs to do in order to further reduce emissions and the impact on the environment?

The industry should lobby water authorities and other utilities to educate them of the benefits trenchless technologies provide to the environment. The equipment manufactures should continue to invest in technology to investigate alternate power sources for plant and equipment.

How has the industry progressed in being more diverse?

When I commenced in the industry there were no women in the trenchless space. Over the years we have witnessed more women become involved and prove to be extremely valuable contributors to the industry. S&Z Australia welcomes and encourages women to apply for any position we have available.

Experience a maximized asset detection in underground surveys with a superior productivity and versatility.

Stream DP is the revolutionary multichannel GPR array solution for real-time 3D mapping of underground utilities overturning the state-of-the-art in underground surveys. Stream DP by IDS GeoRadar features the new radical Equalized scrambled Technology - EsT that brings underground assets detection to the next level: the deepest one.

IDS GeoRadar offers a full range of non-intrusive utility detection and mapping products which exploit the most advanced ground penetrating radar technologies and methodologies.

www.idsgeoradar.com

PART OF HEXAGON

PART OF HEXAGON

As regional utilities make moves to fortify and expand their networks around the state, trenchless operators are overcoming challenging geology and preserving environments with expertise.

Sewer Network in Dandenong Ranges

Yarra Valley Water is installing 91 kms of a reticulated pressure sewer network in the Dandenong Ranges. The geological make-up of the ranges, as well as a number of hard-to-access areas, has necessitated the use of trenchless technologies

For many years, development of the Dandenong Ranges has been held back by lack of access to a sewerage network. Homes in the area rely on septic systems that require property owners to manage their own wastewater. Some of these older systems discharge grey water directly into storm water drains, impacting delicate ecosystems and waterways. The new sewerage network will allow the local community to modernise while still preserving the delicate environment.

The project faces several challenges. Delivery partners Interflow, Melbourne Pipelines and

Pressure Sewer Services Australia (PSSA) are installing DN 50 to DN 90 polyethylene pipe around existing services, dense and protected vegetation, narrow roads, steep hills, and a community going about their daily lives.

Shem Macdonald, construction manager for Melbourne Pipelines, talks about some of the challenges their drillers have encountered.

“We’ve gone from friable red soils in Monbulk to hard ground, boulders and cobbles higher up in the hills. The drillers’ experience and expertise are needed to determine how we deal with each ground type: do we knock floaters out the way, grind through them or cut our losses and stop to excavate and remove them?” said MacDonald.

“We’re also relying on proving pot-holes and excavations to provide a better idea of ground conditions so we can make more informed decisions on our own drill rig

selection, positioning and set-up, and using B&M Infrastructure’s pneumatic drill rig for exceptionally hard ground.”

The narrow lanes, dense vegetation and limited space mean contractors are using small water trucks, vac trucks and excavators to reduce their footprint. Site dumpers transport materials, equipment and longer hoses to the drill truck, offering more flexibility with drill truck set-up.

“We have a variety of trenchless options for property connections such as horizontal directional drilling, a piercing tool, hydro borer and bed borer,” says MacDonald.

HDD protecting native wildlife in Gippsland Water and wastewater in Warragul and Drouin are getting an upgrade as part of the western ring main project.

The towns include two of the most rapidly growing populations in the Gippsland region, prompting the company to keep ahead of this growth by constructing a new 4.3 km water main.

Warragul has only a single main running through the centre of town, says Gippsland Water’s project engineer for the new pipeline, David Suter. The new water main will provide

much needed redundancy to the Warragul system.

Horizontal directional drilling (HDD) has been chosen to complete the project, as the area is home to some important native species including the Giant Gippsland Earthworm, Warragul Burrowing Crayfish and Strzelecki Gums.

Running the pipeline along already disturbed areas such as the roadside, combined with the use of HDD, will enable operators to keep the impact on these species to a minimum, as well as reduce the cultural heritage and potential artefacts of the area’s Traditional Owners.

The pipeline will assist development in the south-west growth corridor of Warragul, while serving double duty by increasing the volume and security of water supplies for the town of Drouin.

Works on the pipeline are expected to be completed in late 2023, with further work possible in the future to extend it to the south basin, in line with potential urban development.

Progress towards Melbourne’s suburban rail loop (SRL) is rolling ahead with the announcement of the shortlisted firms vying to build the massive project.

Three joint ventures, all global industry leaders, have been shortlisted for the tunnelling contracts for what is being called a ‘city-shaping’ project in Melbourne’s eastern suburbs:

Metro and the Caulfield to Dandenong level crossing removal

• John Holland and Gamuda (Australia)

Branch: With extensive experience, these have been responsible for a number of projects in Melbourne – Melbourne’s metro tunnel and city loo – as well as abroad

• Webuild and GS Engineering and Construction Australia: Well known globally, these have worked on the North East Link tunnels, as well as projects in Asia and the Middle East.

SRL CEO Frankie Carroll was encouraged by the interest in the project.

“This competitive process has been a massive vote of confidence in Suburban Rail Loop – with construction giants from around the world vying to partner with us to deliver this city-shaping project,” said Carroll.

The project is well on track with the first contract to be awarded next year for twin tunnels between Cheltenham and Glen Waverley.

Initial works on SRL have already begun in Clayton and major works have been given the green light due to an extensive Environmental Effects Statement.

Jacinta Allan, the Minister for Suburban Rail Loop spoke indicated the project could generate up to 8000 local jobs, creating opportunities for professional growth.

• CPB Contractors, Ghella and Acciona Construction Australia: These companies bring with them a wealth of experience in tunnelling and transport infrastructure. Past projects include Brisbane’s Cross River Rail, Sydney

For more information visit www.trenchless-australasia.com

“SRL East is a project Victoria needs… this is an exciting day as we move closer to the start of tunnelling,” said Allan. At L&D Micro Tunnelling we specialize in laser guided boring. Our Tunnel bore machines use a vacuum extraction system where all spoil is sucked into interceptor tanks for easy disposal with no mess. All our heads are hydraulically driven and guided by a high accuracy laser to achieve precision over long distances.

Veolia claims few companies have had as much of an influence on safety standards for high pressure water jetting than it has.

In 2021, Veolia began developing a series of guidelines and safety measures collectively called its high-risk management standards (HRMS).

The impact of the HRMS is being seen in Veolia’s operations around the world. In Queensland, the company performs maintenance and operation work on water and sewage assets, looking after all elements of the transport network – the pipes – that keep water and wastewater going where it needs to.

Daniel Faccio is a senior asset engineer for Veolia’s Queensland branch. His work involves customer service and keeps him close to Veolia’s teams on the job. Having been with Veolia for almost a decade, Faccio has seen how the company’s approach to safety has taken shape in its workforce, but also on the industry as a whole.

Faccio says that decades of evidence from work in the field shows that the safest work environments are also the most productive. “Safety is at the forefront of everything we do,” says Faccio. “If the guidelines are

well-structured, then the work is safe, and you then get the highest benefit of productivity out of that outcome. That drives us, because keeping our people safe also guarantees the best outcome for our clients,” he says.

While there are challenges involved with high pressure water jetting (HPWJ), it is still utilised by Veolia as one of the safest methods for cleaning underground assets like sewer pipes and storm water lines. It is an effective way to remove tree roots, sediment, and other blockages from these assets.

Before the advent of water jetting, crews would have to manually pull through chains or steel cables with discs that would remove blockages. These traditional methods had a long list of heightened risks to work crews, especially when combined with the sheer level of manual handling required to complete them.

“Water jetting makes the cleaning of sewers less labour intensive, it is actually safer for the crews to waterjet then manually pull the traditional discs with tensile cables

or plumbing rods. Combining jetting with a vacuum system just adds another level of safety,” says Faccio.

He explains that most of the risk with water jetting comes from the nozzle. Without the appropriate safety measures, there is a risk that the pressure from the hose will whip the nozzle out of the maintenance hole, which can cause property damage, injury, and even death.

This is where Veolia’s HRMS comes in to mitigate those risks. The company fastidiously assessed all the potential causes of harm across the industry to develop these standards and holds to them without compromise.

“The HRMS is basically Veolia’s Bible,” says Faccio. “Our people know we don’t compromise on safety.”

Veolia’s entire fleet of trucks – equipment ranging in value from $200,000 to $1.5 million – are equipped with the highest level of safety equipment. The safety measures cover everything from engineered controls on the equipment, like pressure safety valves, to the

highest quality personal protective equipment (PPE).

The company has introduced a mechanism called a hold to activate on the HPWJ controllers on every one of its trucks. If it is released while the equipment is being operated, the entire water pump systems shuts down – minimising the risk of a loose nozzle causing damage.

“We actually managed to get the industry to incorporate the hold to activate feature into all the new trucks, and we’ve retrofitted it into our entire older fleet as well,” says Faccio.

To get things changed, Veolia has had to challenge the status quo. One such instance was in the standard use of whip checks – a piece of equipment designed to restrain a hose, but not to its full extent. With a whip check in place, hoses can still buck up to a metre at incredibly high speeds.

“Once again, we’ve gone through and retrofitted all of our trucks with a hose stocking – which actually restrains the hose and stops it from whipping out in the event of a connection failure,” says Faccio.

He says that the industry assumption was that whip checks would be suitable, but Veolia upgrading its fleet with hose stockings has raised the bar across the industry.

“You can’t downplay the significance of that step. It’s a huge safety advantage to the industry,” Faccio says.

The right equipment is incredibly important, but even the best pieces run the

rigorously pressure tests all its hoses as part of its standard procedure. If a hose does break, it gets repaired and tested again to make sure it is fit for use with the minimum possible risk of rupturing.

Veolia’s relationship with the industry has demonstrated a far-reaching interest in improving safety measure.

The company worked with an Australian supplier to make anti-withdrawal devices – a kind of customised maintenance hole lid –available to the whole industry. Once again,

Originally, the commonly held industry opinion was that asbestos was safe if it was wet, as in HPWJ work. In teaming with regulators to test the air quality at work sites, Veolia found below-detectable levels of asbestos in the air.

To address this, Veolia modified its safe work method statements (SWMS, or “swims”) to control for the unique risks posed by asbestos pipes, as well as introducing an asbestos management plan for all work.

Veolia didn’t have to raise the bar in the way it did. Safety is now well-known as a strong driver of value. The capital expenditure is offset by increased productivity in the field and less downtime from equipment failures or injury to personnel, increasing value for

More importantly, Faccio says that keeping workers safe is always the right thing to do.

“We weren’t willing to go along with the industry norm when it came to delivery in the field, so we took it upon ourselves to put further practical safety controls in place to make sure the risks were removed.”

Veolia continues to work towards a safer industry, often driving change at significant cost. There is no doubt that the cost is worth it, both for the company and for the industry as it grows to meet safety requirements, and solutions. Developments for which Veolia is at

“Ultimately, we want everyone to get home in the same condition they arrived to work in,”

SECA has expanded the training it can provide from its training centre.

SECA is one of Australia’s leading suppliers of equipment for the cleaning, testing, inspection and rehabilitation of pipes, sewers, and drains. As well as providing cuttingedge equipment to operators in rehabilitation and asset management, the company also provides nationally recognised training courses based in its warehouse at the head office in Sydney’s southwest.

With warehouses opened in other cities around Australia, SECA is also able to offer its training from its other warehouses in Brisbane and Melbourne, ensuring that operators around the country are equipped with the knowledge they need to operate safely across a variety of skillsets.

By reducing risk of harm to people, and damage to equipment, training is one of the most powerful ways that industry bodies can ensure incident-free execution of work and efficient delivery of projects – meeting deadlines and budgets.

SECA provides high-quality training across a variety of equipment and worksite operations that will equip attendees with a working knowledge of health and safety practices. From the operation of industrial drain cleaning systems to the CCTV courses for conduit inspection software and codes, SECA has operators covered.

Commencing in February 2023, this course is designed for anyone who intends to work with Class B high pressure water pumps for either surface cleaning or the cleaning of pipelines. It covers water jetting equipment and how to operate it safely, the dangers of HPWJ, safe work practices and associated law, work permits and emergency response practices. The course produces an operator that requires supervision, but is more than capable of carrying out high pressure water jet work.

For personnel with more experience and knowledge of HPWJ, the Operate a High-

SECA’s facility has purpose-built working pipes for training.

SECA’s provides nationally recognised training courses.

Pressure Water Jetting System course, which also includes organising work permits, reading and interpreting plans, and emergency and rescue practices is the right course. The safe work and emergency practices included in the course equip attendees with the necessary qualifications to supervise HPWJ operations in the field.

The Operate a Drain Cleaning course provides drain cleaning operators with the necessary knowledge to supervise a drain cleaning operation and how to be responsible for a crew of drain cleaning workers. It covers indepth knowledge of industrial drain cleaning operations, managing worksites, safe work practices and associated law, and emergency and rescue practices.

(RTO 91255). By utilising trainers who are chosen for their in-depth knowledge of equipment and procedures and substantial personal experience in the field, the knowledge gained from attending these training courses is sure to have a lasting impact on work crews’ capabilities.

Training is essential when it comes to mitigating the risks associated with work in the field, which is why accredited training courses are typically required before personnel are able to undertake such work.

Well-trained work crews are invaluable when working in the constantly evolving trenchless industry. New technologies, equipment and procedures are appearing constantly, and it pays to keep operators informed of best practices to keep up.

the field SECA provides training through Asset Training

For more information visit, www.seca.com.au

Horizontal directional drilling (HDD) is seen as one of the higher risk areas in the infrastructure sector. Climate change is further increasing this risk as extreme weather events become more frequent. As Chief Executive Officer for a leading HDD design and construction provider, Maxibor’s Rodney O’Meley highlights the key factors in understanding contract works and equipment insurance policies to ensure adequate cover is in place in this changing risk environment.

“Simply put, a business can go broke if it doesn’t. One major unforeseen event can stop a business in its tracks, leaving owners and staff without livelihoods, clients without a delivered project and other stakeholders unpaid,” says Maxibor CEO Rodney O’Meley.

It is just not about having insurance. Operators must know what their insurance policy covers and for how much. A simple certificate of currency explains very little – it is the extent of cover contained in the insurance schedule and policy wording that tells the real story.

O’Meley says it is those HDD providers, with appropriate insurance covers in place, that asset owners and principal contractors should be seeking out to undertake HDD works if they are genuinely serious about mitigating their risk.

In the HDD world, the main risks are covered under contract works, equipment, public liability, professional indemnity and workers compensation insurance policies.

Understanding which HDD risks are covered by these policies and the extent and nature of necessary cover requires alignment of knowledge between HDD engineering, operational, commercial and financial people from the business, as well as the insurance broker and the underwriter.

“If you do not understand what you are insuring and for how much you are just gambling that you will be covered,” O’Meley says.

He says insurance policies are lengthy documents, rarely visited except in the event of a claim. They are accompanied by a policy schedule which often refers to a policy section rather than providing specific detail of what the cover represents.

It can take years of experience to understand what the wording in the policies and schedules

actually means, what events or losses are excluded, and how the policy applies to scenarios which are likely to impact a business.

“Most learnings are unfortunately gained through the experience of claims but by then it is often too late to ensure you are adequately covered or covered at all,” says O’Meley.

Contract works covers damage to HDD works and materials under the insured party’s care, custody and control during a project.

It is one of the more complex areas of insurance, but it can be a lifesaver for a business when an unforeseen event occurs.

Claims for loss or damage commonly emanate from events beyond the control of the contractor, including earthquake, landslide, subsidence, collapse, storm, rainwater, flood, tsunami or cyclone.

• Contract value limit – the insurer will require a contract value limit to be set under the policy. This limit cannot be set with certainty especially in a growing business or where variations, such as extra overs for rock, come into play.

“If you win a contract in excess of the set policy limit, or have variations causing the contract value to exceed the limit, ensure that you

notify your broker with a view to achieving agreement for coverage by the underwriter (at no additional cost),” says O’Meley.

Bore diameter limit – underwriters struggle providing cover over 500 mm, let alone in excess of one meter diameter bores.

“This is where you need the underwriter to have a good feel for the risk associated with the specific project and your business overall so that cover can be readily provided,” says O’Meley. “You also need to know whether your insurer has the capacity to insure larger diameter bores because finding an underwriter with the wording to allow it can be exceedingly difficult.”

• Free issue materials – even if materials supply is not part of a works contract, if the materials are in the operator’s care and custody, works contracts can contain clauses making the materials the operator’s responsibility until installed.

“This means you are at risk for loss or damage. Ensure you have cover for free issue materials and up to a value of the materials under your care and custody,” says O’Meley.

• Above 26th parallel exclusion – insurers do not like the cyclone areas of Australia. If working above Gladstone, Alice Springs or Exmouth, operators need to ensure that this exclusion does not apply to them.

“If not, it’s a matter of going there at your own risk,” he says.

• Flood – drilling under rivers and low-lying areas will always have the risk of flood attached to them.

O’Meley says that it is necessary to ensure that a policy covers flood events and that that there is an effective flood risk management plan in place for the project.

“Also watch the 72 hour rule – if the flood extends over this timeframe then it can become more than one event triggering extra deductibles,” he says.

• Principal contractor project contract works policies – in cases where the principal contractor has in place contract works

insurance, which covers the work of its subcontractors, operators should not automatically assume they are adequately covered.

“Know what that policy covers and, in particular, what the deductible is. A $250 k deductible set for a tier 1 contractor is not especially useful in providing cover for a smaller subcontractor,” says O’Meley.

• Ground conditions – the extended La Niña event has made ground conditions less stable and caused the build-up of underground water levels. This can impact on HDD operations either directly or, where nearby other contractors’ works have water problems, “flow through” onto an operator’s HDD bores.

“In these instances, it’s about knowing not only your policy cover, but those of the other contractors on the project,” he says.

Equipment policies cover sudden and unforeseen physical loss or damage to the insured equipment. Policies also provide ancillary benefits such a financial protection for loss of revenue and increased cost of working.

Factors to watch out for include:

• Insured value – getting insured values close to a current market value, particularly on higher value equipment that is critical to the business, is essential.

“Having an agreed value under your policy is preferable on the proviso that it is at, or near, market value,” says O’Meley.

In the event of a total loss, having an agreed value will expedite the claims process as valuers will not become involved in the claim settlement process.

• Partial loss - in the event of a partial loss the insurer may compare the market value to the insured value. If there has been under insurance, then they may have a clause in the policy which allows a proportional reduction in the claim to allow for under insurance.

• Valuations – it is good practice to have current valuations of key equipment, especially in the present market where there is the impact of inflation, plus supply shortages, creating alltime high values for used equipment.

• Financial protection – this cover is for consequential loss that occurs if the equipment suffers damage during a flood event. The policy will set both the maximum amount and period of cover. If policies have reference to the average revenue derived over the last year by the individual item

of equipment, that amount will be low if utilisation has been low i.e., the benefit of this cover will be limited. In the case of the numerous recent eastern state floods, it can be up to three months before works can recommence.

• Tooling – equipment policies will not generally cover tooling such as drill pipes, collars, rock bits, reamers, core barrels, stabilisers, logging equipment and casings while in the bore hole.

“In case of flood, make sure you get them out before the waters arrive,” says O’Meley

Maxibor is fortunate that it has been able to establish, over time, exceptionally good working relationships with its insurance broker Luke McMahon of Bespoke Insurance Group.

McMahon has provided a truly knowledgeable and professional link into the underwriters, enabling the full spectrum of Maxibor’s insurance policies to provide good coverage of the business.

The company’s go-to valuer, Tony Taylor of Blue Gum Asset Advisory, has also helped ensure the value of its equipment has been at or near market value in a volatile market space.

The Maxibor team can be contacted at www.maxibor.com.au

In October, TRACTO Australia hosted a group of contractors and partners from Australia and New Zealand at one of the world’s largest construction events in Munich, Germany. The group of almost 20 people made the pilgrimage to Bauma 22, and were in attendance to see the manufacturer’s launch of its latest horizontal directional drilling (HDD) machine, the GRUNDODRILL ACS300.

Bauma is the one of the world’s leading trade shows for construction equipment and machinery. This year the event boasted approximately 3200 exhibitors from 60 countries, while nearly 500,000 visitors from more than 200 countries descended on Munich, half of which travelled internationally to get to the event.

TRACTO Australia, led by Managing Director Jeff Rose and Sales Manager Daniel Toms, hosted a number of contractors and partners from Australia and New Zealand who had travelled over for the event.

Rose says the trip was an opportunity to further develop the relationships the Australian subsidiary has with its clients.

TRACTO’s most important event anywhere in the world,” he says.

“First and foremost, it was exciting to have some of our key partners from Australia and New Zealand here to see the event, and the launch of the machine in person.

“However, it was also an opportunity for us to further develop those relationships, ensuring we have a deep understanding of their needs, enabling us to determine how best to support them and the unique challenges they face.

“We also had key members of our engineering and design team, and service and support at the opportunity to speak directly with the people who

know the whole range of TRACTO machines better than anyone.”

During the course of Bauma, the manufacturer hosted a several networking events on its stand, giving the Australasian delegation an opportunity to learn more about the machines and also form relationships with TRACTO’s international team.

As the local agent for fellow German manufacturer Prime Drilling, the event also enabled the visitors to learn more about Prime’s range of HDD machines as well as the company’s wider team.

The new GRUNDODRILL ACS300, which was launched at Bauma, exemplifies TRACTO’s commitment to providing the HDD industry with intelligent, no-dig solutions for intact infrastructure projects.

The most powerful rock drilling rig in its class, the newest addition to the GRUNDORILL range is equipped with the largest possible engine, powering a large drill rod magazine and designed to the latest concepts in HDD operations.

The ACS in the machine’s name stands for ‘all condition system’, reflecting the ACS300’s ability to drill in all geologies, up to and including solid rock.

The rig is loaded with features to guarantee success on the job and comfort for the

operator: from a vibration-cushioned cabin with automatic air conditioning and electrical swivelling mechanism, to stabilisers that enable perfect alignment and positioning and an anchoring system that is perfect for anchoring it on the job site.

A hydraulic loading crane allows for the selfsufficient handling of additional drill rod boxes, single rods and accessories.

The rig combines significantly increased

functions identified for the best daily use on a jobsite.

This diversity in application comes down to the use of the highest quality materials, granting the machine maximum reliability and diverse application.

The GRUNDODRILL ACS300 will be available for Australian operators in 2023.

In addition to the ACS300, TRACTO also

exhibited a prototype of the company’s first electric drill, the JCS130 E.

According to the manufacturer, the continued development of the prototype is an opportunity to supply the trenchless solutions in a new and sustainable society.

Prime Drilling has earned a reputation as a supplier of high-precision horizontal directional drilling equipment not only in Australia but across the world. Its drilling rigs are made from the highest quality materials, and developed and designed to be robust, reliable, and low maintenance.

made hardy, reliable rigs that have boasted lifespans of at least 40 years – the equivalent of approximately 40,000 hours of use.

“With the bigger rigs, our customers have very specific needs. They’ll come to us with a long wish-list and our designers work very hard to meet those demands,” says Kiesow.

Prime Drilling’s PD 45/19 CU is a consistent best-seller from its range of compact equipment. The machine demonstrates great efficiency and a small footprint, setting the standard for other compact rigs in the HDD industry.

It was designed with specific attention to optimising weight and size, keeping the cost of transport and set-up to a bare minimum. Its 205 kilowatts of power and 19,000 Nm of torque makes the PD 45 the rig of choice for customers who need guaranteed fast, economic, and uncomplicated operation.

a notable name in the global horizontal directional drilling (HDD) industry.

Prime Drilling began as a manufacturer of custom built and designed HDD rigs, allowing the company to showcase its ongoing commitment to meeting the specific needs of its customer base.

As Prime Drilling demonstrated that hard work and reliability makes the company shine, the satisfaction of its customers ensured that it could grow alongside operators in the HDD industry.

International Sales and Service Director, Ralf Kiesow, has watched Prime Drilling grow since he started with the company 18 years ago.

“Over time, as our reputation and our expertise grew, there became more of a demand for bigger machines,” says Kiesow.

He explains that there was a point in Prime Drilling’s history where it realised that it could

to meet those industry needs.

“From that realisation, we figured out that we could produce a standard model for this unit that could then be customised to suit the needs of specific clients,” says Kiesow.

Kiesow says a number of Prime Drilling’s products are gold standard and range from smaller compact units to the huge 150-tonne rigs that the company manufactures.

The longevity of the manufacturer is due in part to the careful consideration that is made with regards to the availability of parts for its customisable rigs. By making its machinery compatible with a range of globally available standard parts, Prime Drilling ensures that clients can easy acquire replacements without the challenges usually involved in repairing custom rigs. The need to replace parts on Prime Drilling’s machines is not as common as operators think. The manufacturer has

Its CAT 7.1 ACERT motor features the latest emission standards and adjustable cooling systems, minimising fuel consumption and further optimising efficiency, while its feed and pull back functions for the hydraulic power rotary head are carefully driven by an internal rack and pinion feed system.

Prime Drilling has grown steadily in small, deliberate steps. According to Kiesow, part of the reason for this is that the company has been sure that it is doing everything it can within its capabilities before expanding. The company also makes sure it’s investing in the right people.

“We’re very happy with the people we have,” says Kiesow. “Most of our people have been there since day one. Our people love what they’re doing; they live and breathe HDD.”

With its expertise in the HDD industry, and the focus on getting each step of its operations right, Prime Drilling has earned its place as a global manufacturer.

For more information visit www.prime-drilling.de/en

Packers: Drainchem now offer high quality pipe packers with or without bypass that are flexible for ease of installation. These high quality packers are available to suit pipe sizes 25mm up to 2000mm in diameter.

TopHat Packers: Drainchem have also introduced packers that allow the installation of top hats to laterals from mains and are available in 100x100mm, 150x100mm and 150x150mm.

Cone plugs: Also new to the Drainchem range are inflatable Cone plugs to suit multiple pipe diameters chloroprene and Aramid fabric reinforced with vulcanized rubber. The Cone plugs fold down much smaller than a traditional rubber plug and this enables ease of access into pipes and manholes. Pillow plugs: Another exciting product is the Inflatable pillow plugs. Ideal for larger pipes. These are flat like a matt and can be rolled up to help installation into the pipe. Available in sizes 600-100mm up to 1800-2800mm

Civil and trenchless drainage specialist M Tucker & Sons is expanding its services it can offer customers and tackling no-dig waste at the same time.

In the trenchless industry, it’s well known that no-dig drilling (NDD) and horizontal directional drilling (HDD) are the methods of choice on projects that aim to minimise disruption and impact on communities and the environment.

The waste produced by these operations is one thing that has been consistently overlooked.

M Tucker & Sons is now set up to take what most operators consider waste and is transforming it into a useable product that can be used to give back to the community –concrete.

Disposal of waste from NDD and HDD isn’t free. There is a price associated with its collection, as well as fees at the landfill and the cost of trucking it to be thrown away.

Beyond that, there is an environmental cost. In a world where operators are becoming increasingly aware of sustainable practices, reusing waste products is as good as it gets.

When the company owner Mark Tucker

came up with the idea, the focus was on landfill diversion. While NDD and HDD waste contains vegetation and other contaminants, it also contains all the crushed rock, sand and silt that can be repurposed.

By taking the waste product from work sites to the plant that the company set up at its headquarters in Mount Evelyn, east of Melbourne, the company is able to save money by refining it into concrete that could be transported back to the worksite. The product can be used to construct pits for construction projects, or even for pouredconcrete furniture, planter boxes, and community pathways.

“The goal is to team up with major construction projects to help them meet their sustainability goals, and to keep costs down. Manufacturing concrete also means we don’t have to buy quarry products, which reduces the carbon footprint of a project even further,” says Tucker.

The company is using the concrete on its own work sites, but Tucker says there is more than enough that can be used by one company.

The process

M Tucker & Sons is able to utilise waste not only from NDD and HDD projects, but also storm water waste, excavated material and waste pulled from gutters by local councils.

The waste-turned-resource comes in under an EPA licence where it is registered, stored, and then tested to determine its contents.

Once that’s done, the material pushed through a CDE G:MAX wet recycling system where it is treated and separated into real waste (plant matter and rubbish) and useable material – clean stone, sand and water.

Rocks are then sized so they can be used in different forms of concrete.

“We understand what we have. We have the data to show that we’re manufacturing structural concrete,” says Tucker.

An added benefit is the company doesn’t have to introduce water to the cleaning process. The water from the mud that comes in as waste is treated with special polymers and chemicals that help the solids settle during the cleaning process and can be collected and reused.

With increasing amounts of water

being generated, M Tucker & Sons is now undertaking studies to determine how excess water can be made safe to use as part of the concrete itself, further increasing the amount of recycled material used, which is already 70 per cent.

Able to meet all needs

Tucker says that the entire operation is scalable, allowing the company to increase the amount of waste it processes, or

concrete it generates.

“If the project is big enough, we can set up on a temporary footprint, put a dewatering system there and create the product, the concrete, on site,” Tucker says.

He says that, especially with the prevalence of no-dig options in urban areas with a lot of foot traffic, he would like to see concrete paths underfoot that came from the invisible projects that, despite best efforts, do have some impact on the community.

“It’s how we can give something back,” says Tucker.

Equipped with undeniable proof of the viability of its process, M Tucker & Sons can help industry operators across the civil and construction industry ensure the sustainability of their operations.

Vacuum excavators are the often unsung hero of the trenchless technology world, quickly and effectively moving soil when needed so that horizontal directional drilling can take place. But now, local governments across Australia and New Zealand are discovering a multitude of uses for vacuum excavators.

For the uninitiated, vacuum excavation, pressure water with an air vacuum, vacuum COMPACT FOOTPRINT. LOW NOISE. COMMON CONTROLS. From small but mighty clay and dirt drills, to large bore rock drills, Vermeer drill rigs are famous Australia wide. And now, with common controls, it’s easy for operators to transition from dirt to dual-rod rock drilling. Every Vermeer HDD Drill is about capability, productivity and profit. Get on board.

Talk to the leader in HDD today and visit your local Vermeer Australia branch.

inefficient methods of working.

“In Australia and New Zealand, communities are becoming less tolerant of works that impinge on their daily lives. They expect local governments and contractors to utilise construction methods that reduce the area required to carry out any works,” says Jeff Lawson, Vermeer Australia’s General Manager

footings for poles, signs and fence posts has become common.

One task that is often a challenge for councils is digging up and replacing existing utility poles that have either been damaged or exceeded their useful life. Using an excavator or backhoe to dig up the poles without disrupting surrounding utilities can present a difficult challenge. The

Ditch Witch CEA is helping New South Wales horizontal drilling company Pace Drilling with a range of construction challenges.

Founded in 2004, Pace Drilling has grown to be one of the most respected and reliable horizontal directional drilling (HDD) specialists in New South Wales.

With a track record of cost-effective and quality methods, as well as continually meeting the challenges each construction job requires, Pace Drilling has the expertise and equipment to get the job done.

Pace Drilling has worked on a multitude of projects involving different conditions and challenges including motorway crossings, river crossings, rail corridor crossings and suburban street works.

Aaron Pace, Pace Drilling Primary Driller, has worked in the family business for over a

following bore designs. These skills are ones that I’ve built over several years and I’ve been fortunate enough to have been able to learn from the founder and father of the company, Simon Pace.”

Pace Drilling initially used a relatively small drill rig, which was rated at 20,000 pounds of pullback and was not rock capable, in 2004. Subsequently, the company was limited to completing smaller bores to a maximum distance of 100 m.

Over the years the business has been able to upgrade to newer and more capable equipment. Now the company operates with two drill rigs – the Ditch Witch AT30 and AT60 – both of which are all-terrain machines

Park stage 3 upgrade on behalf of Georgiou, the Nepean Hospital Underbore, and the M4 Motorway Crossing.

The AT60 drill rig is well suited for much larger projects. Pace Drilling is currently completing bores of up to 450 m in length, with their drill, and are capable of larger diameter bores pending ground conditions. Pace Drilling has used the AT60 on projects such as the Western Sydney Airport upgrade on behalf of Sydney Water and Quickway’s Sydney Metro West 33Kv Underbore Crossing.

Optimised for industry-leading performance and productivity when drilling in hard rock conditions, the Ditch Witch AT30 is designed with an advanced version of the proven Ditch Witch all terrain drilling system.

The updated, two-pipe system boosts power to the bit—33 per cent more torque than the competition. The drill leverages the next-generation features of the JT40 model so operators get increased jobsite cycle times, improved durability, and greater control.

“The power enabling works for the Sydney Metro located in Rozelle on behalf of Quickway stands out as an especially proud moment for the team,” says Pace. “The works were completed across Victoria Road and were a dual bore, with each bore being large in diameter and containing multiple electrical

Pace Drilling has been working with Ditch Witch CEA for over 16 years, having purchased its first drill rig in 2007. Since then, Ditch Witch CEA has proved its dedication to delivering the highest level of product support

Employing factory-trained sales and service specialists who are dedicated to supporting clients and all machinery requirements, Ditch Witch CEA is equipped with the expertise and knowledge to help businesses like Pace Drilling develop a strong reputation in the industry.

“Ditch Witch CEA is always willing to provide on-site service whenever called upon to ensure completion of the project is at a high safety standard,” says Pace. “CEA has proved

that we always have their support as a Ditch Witch owner; all the way from the dealership to parts and service.

both powerful and reliable, providing cutting edge technology. The capability to drill and steer in hard rock has assisted us over the years to achieve many successful bores.”

Pace Drilling is accustomed to putting in the hard work and dedication needed to provide

records are meticulously kept. It seems like a little thing, but that attention to detail is key.”

Looking to the future, it seems the only way to go is up – the company has been awarded

several projects with clients including the Botany Duplication project and the South Erskine Zone Substation.

These projects are yet another exciting chance for Pace Drilling to flex its expertise and prove that this family owned and operated company is not to be underestimated.

“In the future, I see Pace Drilling keeping our high work standard and ethic by achieving our clients’ needs within budget and as safely as possible,” says Pace.

“As a company, Pace Drilling is aiming to continue becoming more sustainable and environmentally friendly. With new and innovative technologies arising and evolving, Pace Drilling is always trying to stay ahead of the trend when it comes testing these new technologies to help reduce our carbon footprint.”

Supporting the company during this exciting time, Ditch Witch CEA is committed to continuing to provide Pace Drilling with expert advice on what equipment best suits the company’s needs and ensuring each piece of machinery is of the highest quality.

For more information visit www.ditchwitchcea.com.au.

Safety is critical to the success of an energy construction project. More importantly, it is the basis of a strong energy construction company. Michels Trenchless, part of the Michels family of companies, demonstrates its commitment to safety by using it as a framework of its first core value: Safety is the cornerstone of our culture.

Michels has expanded its international footprint to Australia, selectively specialising in technically challenging trenchless installations in Australia. This is to ensure customers are provided with reliable, unobtrusive service in metropolitan and remote areas. The team consists of Wangaratta-based project management, HSE and field staff supported by industry experts at its international headquarters in Brownsville, WI, USA.

Founded in the Midwestern United States in 1959 as a regional natural gas distribution company, Michels quickly expanded its services to meet the evolving needs of established and new customers. In 1988, Michels entered the horizontal directional drilling (HDD) market, offering a safe, environmentally sound way to install utility lines in areas where traditional open-trench construction would not be practical or feasible.

Keeping with Michlels’s spirit for innovation, the trenchless team has grown and advanced with the industry. By building a reputation for completing some of the world’s most challenging, significant installations, Michels has expanded the capabilities of its team and custom designed and fabricated equipment. The company has completed more than 225 pilothole intersect HDD projects and drills in excess

is being completed, it is backed by Michels’s extensive programs focused on ensuring the safety of everyone who works on its projects. Michels’s Stop Work Promise asks everyone to make a promise to their families, friends and co-workers to stop or not perform any work or action that is or appears to be unsafe without fear of repercussion, whether on the job or in their personal lives.

Michels’s mission is to ensure its people return home safely each day. Projects are supported by a team of nearly 200 trained HSE professionals, including those in Australia, who work with field crews to ensure safety by providing training,

Michels is honored to have been recognised by the national awards programs for the results of its safety culture.

In 2022 and 2021, Michels Canada was named the Gold Winner for Canada’s Best Health & Safety Culture in the Canada’s Safest Employers Awards program. Michels was also honored to receive the 2021 Distribution Contractors Association Arthur T. Everham Safety Award (first place), the 2021 ASDC Outstanding Safety Award, and the 2021 ASA Chicago Bronze Safety Award, among others.

For more information visit www.michels.us

Denso Australia offers the complete range of corrosion prevention technologies to its customers. Its systems are made for individual anti-corrosion and sealing troubleshooting, as well as being

Denso Australia, a subsidiary of Winn and Coales International, was founded in London in 1883 and is one of the leaders in corrosion prevention and sealing technology. The Denso range of products has been used successfully for close to 100 years and has a proven track record with verifiable case histories.

The Denso range comprises a variety of specialised pipeline, structural and marine protection systems. The company offers concrete and tank coatings, including tapes, brush and spray-applied liquid coatings, abrasion resistant outer-wraps, mastics, primers, and sealants based on materials such as petrolatum, butyl rubber, bitumen, plastics and epoxy resins.

Systems are tailor-made for individual anti-corrosion and sealing problems developed with the realities of an on-site application in mind. The company’s extensive product range is suitable for use in a wide range of highly corrosive environments and operating temperatures.

Denso’s Protal 7700™ is a state-of-the-art, solvent-free high-build epoxy. The Protal 7700 is an environmentally friendly, fast cure coating

that exhibits superior adhesion, gouge, and impact resistance, as well as excellent cathodic disbondment, flexibility properties and abrasion resistant characteristics.

The company’s Denso Bore-Wrap™ is an abrasion resistant outer-wrap (ARO), with outstanding performance against impact, gouge, abrasion, and fracture. The Denso Bore-Wrap creates a superior

sacrificial outer laminate layer, which protects both pre-approved field joint coatings and mainline coatings. This includes: liquid epoxy coatings, heat shrink sleeves, 3LPE, 3LPP and FBE coatings— from damage during pipeline installations, in difficult terrain or by means of trenchless installation methods, such as directional drilling, horizontal directional drilling (HDD) or boring.

It is easily applied in the field; there is no mixing required. It is simply wrapped

over the existing pipeline coating and cured with water.

Due to its flexibility and exceptional level of mechanical protection, Denso Bore-Wrap minimises the need for costly spot repairs or re-pulling pipe due to damage.

In May 2021, Winn & Coales International acquired the global business of Viscotaq™, including Amcorr Products & Services.

Amcorr Products & Services, based in San Antonio, USA, is the formulators and manufacturer of the viscoelastic and self-healing protective coating and sealing technology known in the marketplace as Viscotaq. The patented Viscotaq product range is used for corrosion prevention and sealing applications on vital infrastructure across a broad range of sectors.

The acquisition of Amcorr has since been a major stepping stone for Denso, as the Viscotaq product line enhances and complements Denso’s existing range of coatings. Denso is now able to offer the complete range of corrosion prevention technologies to customers.

For more information go to www.densoaustralia.com.au

Drainchem is the provider of StoneAge Tools’ cutting-edge nozzle range – the Magnum series.

StoneAge Tools, the makers of one of the world’s best sewer jetting tools, have developed a high-spec nozzle range called the Magnum series.

The series showcases a number of key features including:

• ½-inch to 1-1/4-inch inlet options.

• Suitable for recycled water.

• Increased service life of 1600 hours between seal change.

• Suitable for 150-900 mm pipe (depending on pump capacity).

• Operating pressures from 83-345 bar.

• Operating flows from 50– 450 lpm.

• Reduces toilet blow outs.

• Increased pulling power and cleaning power.

The Warthog Magnum Switcher head is two powerful tools in one. The most significant design change from the classic model is that the Switcher has two sets of jets that operate independently.

One set of jets has one forward and several rear jets (the number of which depends on flow and pressure of the operator’s jetter) and is used to jet up the line, punch through the blockage and reach the upstream manhole.

This angle change increases the thrust or pull of the nozzle when jetting up the pipe, allowing operators to reduce flow and pressure while jetting up the pipe. Doing so reduces the likelihood of breaking a water seal at the house or blowing the toilet.

If the grade is very steep or a very long run, then increasing the pump speed will deliver

much more power.