DIGITAL TWINS FOR ADVANCED ASSET MANAGEMENT

TECHNOLOGY TRIALS

ADDRESS WATER INDUSTRY CHALLENGES

ADDRESS WATER INDUSTRY CHALLENGES

Quickly, easily, and safely monitor your equipment for partial discharge.

Partial discharge is a very serious issue that you would be like to be able to monitor quickly and easily. Whether you are inspecting insulators, transformers, switch gears or high voltage power lines you need to be sure that you can spot problems quickly and early. Partial discharge that goes unchecked can cause blackouts, fires, explosions, or even death from arc flashes. In addition, there is a significant monetary risk of downtime. Finally, a better way to safely detect partial discharge and prevent downtime before it occurs.

Learn more:

While most of the net-zero targets have been focused on reducing emissions from electricity use, attention has also turned to what leadership in reducing emissions from gas use looks like.

In June, the Clean Energy Finance Corporation made its first hydrogen-related commitment, investing in innovative electrolyser production technology developed by the University of Wollongong, which has the potential to boost Australia’s clean hydrogen industry by bringing down production costs.

As the largest gas distributor in New South Wales and the owner of some of Australia’s most important gas transmission pipelines, Jemena is well-placed to initiate the transition to renewable gas and a more sustainable energy future.

In this edition, we’ll be looking at the key projects Jemena is undertaking to better understand the interaction between renewable gases, such as hydrogen and biomethane, and existing gas infrastructure.

Finding the right scalable technology is also crucial for the water industry to meet its challenges.

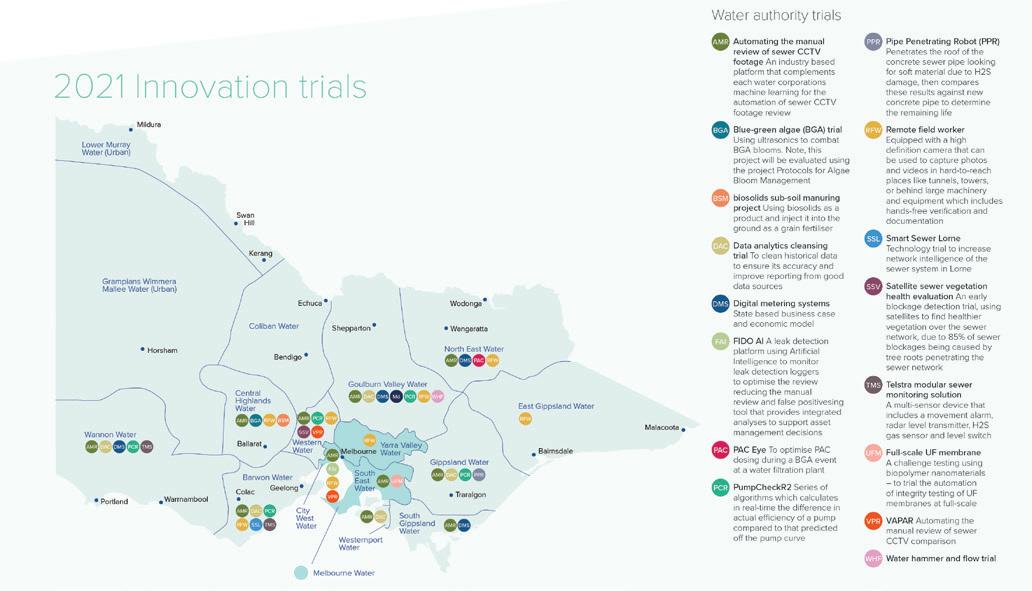

In Victoria, this is where Intelligent Water Networks (IWN) comes in. It represents 16 Victorian water corporations, acting as a collective safe sandpit for testing and trialling technology.

IWN’s trials assess whether technology can solve common problems, drive business efficiencies and achieve better customer outcomes. With IWN’s ten-year anniversary passing quietly in the blur of 2020, we thought it was about time for an update on IWN’s eight programs and what they are currently focusing on.

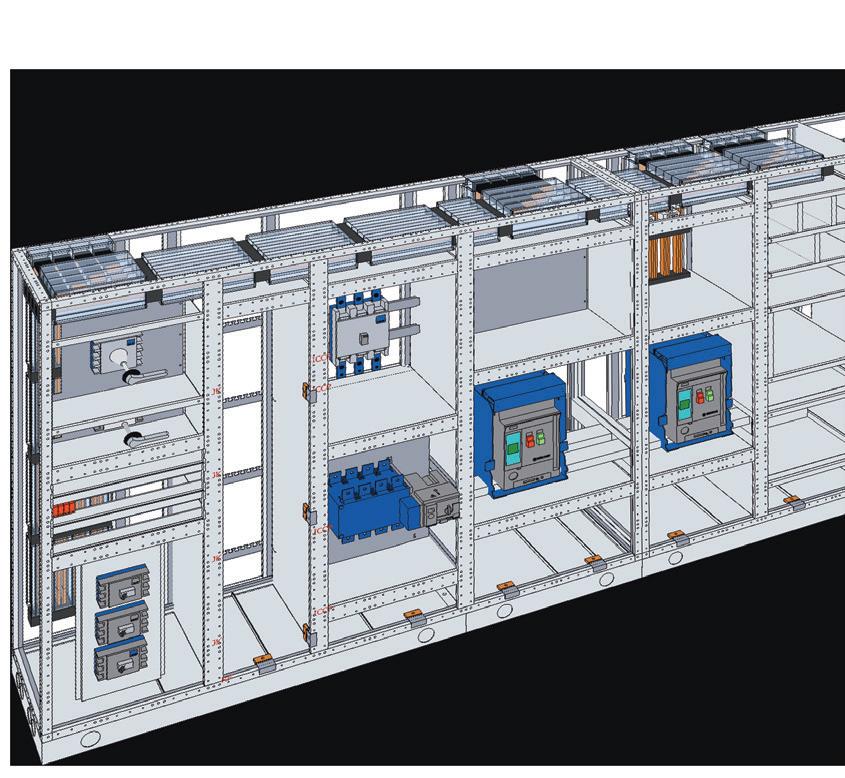

Angelo Fiumara, Digital Asset Integration Manager at Essential Energy, has contributed an excellent article on how the utility is utilising a digital twin to uplift its asset management and operational practices, unlocking ways of working not previously possible.

Essential Energy manages one of the largest and most geographically dispersed distribution networks in the world. By

building a digital model of the network and its surroundings, the utility has access to new insights that better inform the asset decision-making process, because assets can be accurately modelled to replicate how they will perform in reality and interact with the real world.

I also have my own announcement to make: I am moving on from Monkey Media and this is my last edition of Utility as Editor. My colleague Jessica Dickers will be taking the reins and will be your main contact moving forward.

Jess is Monkey Media’s Senior Editor and currently looks after Utility’s sister publication, Infrastructure magazine. She has been with the company for six years and has worked across all the magazine brands, including previously on Utility, so she’s the perfect person to continue Utility’s reputation for high-quality, engaging content.

On a personal level, I’ve met so many wonderful people during my time as Utility Editor and I’ve loved being part of such a passionate community – one that is committed to delivering affordable, reliable and sustainable water and energy services to Australians everywhere.

It’s been a pleasure working with you all and thank you for making the past three years so rewarding and enjoyable. No matter what I do in the future, I’ll always look fondly on my time spearheading Australia’s only dedicated utility magazine and cementing its role as a consistent voice for the industry.

Change is simultaneously terrifying and exhilarating which is what makes it important – it keeps us fresh, energised and on our toes. While I’m sad to be leaving Utility and Monkey Media, I’m looking forward to this next chapter of my career and seeing where it takes me.

For those interested in keeping in touch, you can connect with me on LinkedIn at www.linkedin.com/in/charlottepordage. Otherwise, please welcome Jess as the new custodian of Utility – you can direct all enquiries to jessica.dickers@monkeymedia. com.au.

As

Australia’s recycling and resource recovery sector is undergoing major transformation, driven by global market pressures. A new Clean Energy Finance Corporation (CEFC) report has identified an upside to this upheaval: a potential investment pipeline worth billions of dollars.

temperatures continue to rise, and the number of extreme heat days each year increases, keeping cool is more important than ever. In Australia and worldwide, our cities are particularly affected by hot weather, with severe public health, liveability, environmental and economic consequences. Adopting innovative smart irrigation can significantly and cost-effectively cool urban spaces, mitigating the effects of heatwaves while also saving water.

RBy Dr Dennis Van Puyvelde, Head of Gas, Energy Networks Australia

RBy Dr Dennis Van Puyvelde, Head of Gas, Energy Networks Australia

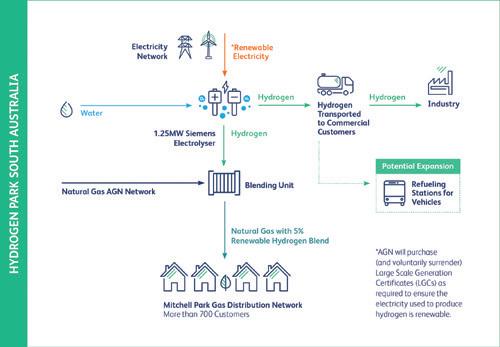

esidents of Mitchell Park in Adelaide’s south-west are living in the future, today. In May, Australian Gas Networks launched its Hydrogen Park SA project, a hydrogen blending initiative that demonstrates hydrogen use in Australia is not some far away fantasy, but a reality.

Australia is on a pathway to decarbonise its gas sector to help meet our nation’s emission reduction commitments. A key part of this journey is to demonstrate the role of hydrogen for homes, businesses and industry. The logical steps are to start with renewable gas blends in networks, then to demonstrate 100 per cent renewable gas in dedicated towns or regions and ultimately to convert all existing networks to 100 per cent renewable gas.

The Hydrogen Park – South Australia (HyP SA) project started blending five per cent hydrogen into the residential gas network. This major step is demonstrating the supply of renewable hydrogen to 700 homes and subsequent stages may include providing hydrogen to industry or for refueling hydrogen vehicles.

There are global examples of blending renewable gases such as biomethane and hydrogen into the gas grid. Demonstrations of up to 20 per cent hydrogen have been successfully carried out in France and the UK. A demonstration of 100 per cent in the Scottish town of Levenmouth shows how renewable hydrogen and hydrogen appliances can be used to provide heating services to homes.

The Australian projects build on this international experience and address local issues such as different operating pressures of the gas network, different energy content of the natural gas and different appliances. Shortly to follow will be more renewable gas projects increasing in scale, application and hydrogen blends. These are important stages to work through to minimise the impacts and disruptions to customers when converting to renewable gas.

There are a range of different hydrogen production processes. The cleanest form is to use renewable electricity to produce hydrogen through electrolysis. The energy required in the HyP SA project will be generated by wind and solar power, so the whole process will be renewable.

A few weeks ago, the City of Yarra in Victoria pledged to switch its buildings from natural gas to renewable electricity by 2030. This pledge aims to reduce greenhouse gas emissions. Unfortunately, switching from gas to electricity comes with many challenges and increases the overall cost of reaching zero emissions.

Recent regulation-driven electricity price increases in the ACT, off the back of a 133 per cent hike in the Territory’s large-scale feed-in tariff, offer a cautionary tale about an electrification bias.

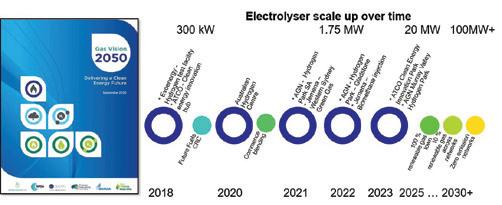

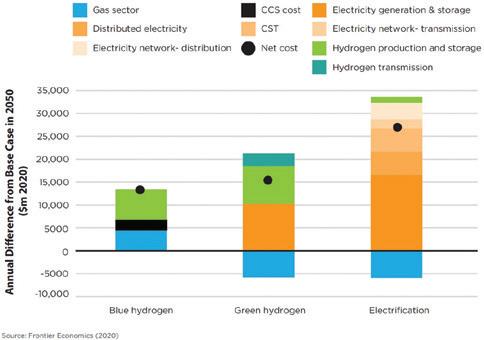

Decarbonisation costs (Source: Gas Vision 2050: Delivering a Clean Energy Future, Nov 2020)

The use of renewable gas is a cheaper option that should be on the table. It ensures efficient investment in energy infrastructure, manages seasonal and daily peaks, and creates benefits to other sectors such as transport and power generation. Most importantly, many customers prefer to use gas over electricity for cooking and heating.

Australia’s gas infrastructure businesses are demonstrating the most economically efficient way to achieve zero emissions by blending renewable gas into networks. Hydrogen is here today, and it has a big role to play for Australia to meet its Paris Agreement on climate change. You could say it is a primary element to do so!

This year, WSAA has formed significant partnerships to progress conversations and collaboration in the digital space. In March, WSAA and Internet of Things Alliance Australia (IoTAA) signed a Memorandum of Understanding (MoU) and officially launched the collaboratively developed Digital Reference Framework

In April, WSAA formed a MoU with BIM4Water, a UKbased cross-industry group, with a mission to lead the digital transformation of the water sector through better information management. Both partnerships see the advancement of conversations and knowledge sharing to benefit the urban water industry and its customers.

In addition, WSAA also re-confirmed its ongoing relationship with the Victorian Intelligent Water Networks (IWN), producing a leadership video on digital asset management around the Victorian Digital Asset Strategy (VDAS).

The collaboration with the IoTAA has seen the development of a Digital Reference Framework. This framework is designed to facilitate simpler and more direct conversations about digital technology both within the business and with suppliers – resulting in quicker, more informed and more effective adoption of new technology.

Its use should simplify the understanding of digital systems, improve clarity, and streamline digital procurement. The Internet of Things proposes significant opportunities for the water sector. Through collaborations such as this one with IoTAA, it is hoped we can provide tools and insights that will benefit not only the sector, but also our customers and the Australian economy.

A new collaborative opportunity is now being explored through the development of the IoT Water Hub. The initial concept is for an industry partnership IoT system of real-time monitoring and control to help the delivery of a secure water future, increased diversity of supply, enhanced ecosystems and engaged communities.

WSAA has been working with the founding members, South East Water, Melbourne Water, Monash University and Melbourne University, together with the IoTAA and IWN, to broaden industry participation. This initiative offers a unique opportunity for collaboration between several key water sector groups and the private sector in a way that will enhance the uptake of innovative IoT solutions.

The MoU with BIM4Water in the UK will facilitate mutual sharing and collaboration. Both WSAA and BIM4Water believe there is value in partnering and, where appropriate, developing Australian groups to mirror those in BIM4Water. The first collaborative initiative between the organisations has been to develop a mirror group for the UK Water Industry Classification and Hierarchy Standardisation group.

The intent is to accelerate the development of an international asset naming convention for water utility assets based on UK classification standard, Uniclass. Completion of this naming standard would enhance the ability of water utilities to manage their digital asset information and communicate with other sectors.

WSAA will develop these partnerships further as the industry continues the journey of digital transformation. For more information please contact Dr Greg Ryan, WSAA’s Director Business Excellence, on greg.ryan@wsaa.asn.au

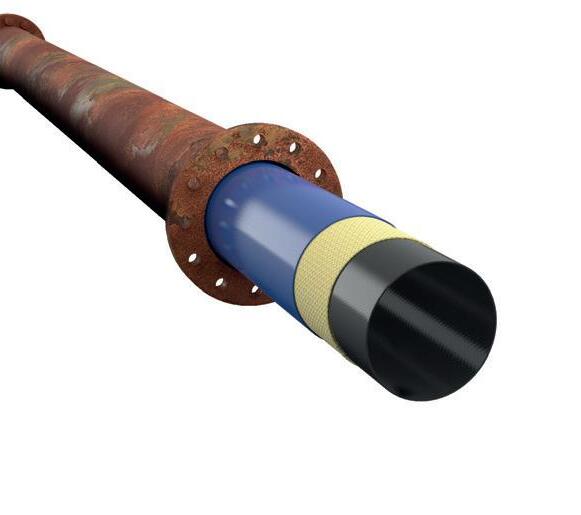

DENSO BORE-WRAP

FIELD-APPLIED ABRASION RESISTANT OUTERWRAP (ARO)

SUITABLE FOR: Field Joint Coatings | Mainline Coatings | Shrink Sleeves Trenchless Installation | Directional Drilling | HDD and Boring

DENSO® are leaders in corrosion prevention and sealing technology. With over 135 years’ service to industry, our mainline field joint coating solutions offer reliable and cost effective protection for buried pipelines worldwide.

United Kingdom, UAE & India

USA & Canada

Australia & New Zealand Republic of South Africa

www.denso.net

www.densona.com

www.densoaustralia.com.au

www.denso.co.za

TransGrid will invest $1.8 billion to build Australia’s biggest electricity interconnector, Project EnergyConnect, which is expected to save NSW customers $180 million a year, and create 1,500 new construction jobs in regional NSW.

The TransGrid announcement coincided with the Australian Energy Regulator (AER) handing down its determination on capital expenditure for the project, approving $2.28 billion to deliver the project efficiently, including $457.4 million for ElectraNet to construct the South Australian section of the project.

Project EnergyConnect (PEC), a vital piece of energy infrastructure, will span more than 900km.

TransGrid CEO, Paul Italiano, said the company’s investment would deliver the major NSW section of PEC from Wagga Wagga in the state’s south to the South Australian border.

“PEC is a transformational energy project which will provide net benefits of up to $11.9 billion and save NSW customers $180 million a year, or $64 annually on an average household bill,” Mr Italiano said.

“PEC will be Australia’s biggest electricity interconnector built to date in the National Electricity Market (NEM) and it will help to accelerate Australia’s energy transition by connecting customers with more renewable generation.

“PEC will also help to abate an estimated one million tonnes of carbon emissions each year, contributing significantly to meeting Australia’s climate change targets.

“Regional NSW will benefit from the creation of 1,500 construction jobs and an injection of more than $250 million in direct project expenditure.

“The project will also contribute a further $4 billion in economic activity for NSW.”

Mr Italiano thanked the South Australian Government for its support for the project, the Federal Government for the support it has provided via an underwriting agreement with South Australia and through the Clean Energy Finance Corporation (CEFC), and project delivery partner, ElectraNet, for the essential role it has played to advance the project through the regulatory process.

The ElectraNet Board will review the determination by the AER and consider its final investment decision on the project shortly.

ElectraNet also welcomes the TransGrid Board’s final investment decision to proceed with the NSW section of the project.

ElectraNet Chief Executive, Steve Masters, said, “The AER and TransGrid decisions are a significant milestone for PEC, which is a project of national significance and a priority project for the national electricity grid.”

The TransGrid Board’s investment decision came after it was able to partially resolve financeability issues for PEC, which challenged delivery of major regulated transmission projects in the NEM.

This has been achieved via an agreement between TransGrid and the CEFC on the issue of an innovative $295 million hybrid debt instrument.

“The agreement with the CEFC has been essential to the board’s final investment decision today and we are thankful to the corporation for working with us to progress this important project,” Mr Italiano said.

The CEFC investment, on behalf of the Federal Government, has been made via an innovative subordinated note instrument which has contributed to the crowding in of further private sector debt to this critical project.

CEFC CEO, Ian Learmonth, said, “It is significant that the largest single investment the CEFC has made since we began investing will help deliver more renewable energy to Australian consumers by adding such a substantial piece of infrastructure to our electricity grid.

“We are proud that CEFC finance is supporting this important investment in the grid.”

The CEFC commitment is a significant first step in the delivery of the Australian Energy Market Operator’s (AEMO) 2020 Integrated System Plan (ISP).

The CEFC investment will see TransGrid build the NSW portion of the new 330kV interconnector connecting

Using OsmoFume to protect your wood poles from internal decay provides benefits to your utility infrastructure through added resiliency and extended asset life.

OsmoFume meets the rigorous performance and toxicity criteria established by the Australian Pesticides and Veterinary Medicines Authority (APVMA Reg. No. 88348/120987).

First dazomet-based wood pole fumigant commercially available in Australia. Dazomet provides superior long-term benefits when compared to a diffusible rod.

Proprietary, stick design provides a controlled dose and sufficient space for a copper accelerant, like Hollow Heart CB Wood Preservative (APVMA Reg. No. 90556/129272). ®

the energy grids of NSW and SA, with an additional link to North West Victoria. ElectraNet is constructing the SA portion of PEC.

Clean Energy Council Chief Executive, Kane Thornton, said that PEC is a really exciting and necessary project that will help build a 21stcentury electricity network.

“A lack of transmission investment is now one of the most critical challenges facing the Australian energy system. This is stifling new generation investment, constraining existing generation and resulting in increased energy security and reliability risks as well as higher power prices,” Mr Thornton said.

“While it’s great to see Project EnergyConnect progress to this stage, the time taken to navigate the regulatory framework and the need for the CEFC to play a crucial role in financing is a stark reminder of the flaws inherent in the current regulatory environment.

“The pace of change in the energy transition warrants a major overhaul of the regulatory process for transmission,

particularly in light of the implications and importance to push ahead with the remaining transmission projects identified in the AEMO’s ISP.”

Energy Networks Australia (ENA) CEO, Andrew Dillon, echoed Mr Thornton’s concerns regarding the current regulatory framework.

“This commitment from the CEFC of a $295 million hybrid instrument has enabled TransGrid to manage financeability issues that threatened its capacity to proceed,” Mr Dillon said.

“The CEFC support is very welcome, but if the regulatory regime was delivering reasonable returns for major projects like this, it wouldn’t have been necessary.’’

AEMO forecasts that PEC will unlock as much as 1,800MW of renewable energy generation across Renewable Energy Zones, including approximately 800MW in SA, 400MW in NSW and 600MW in Victoria.

Importantly for energy consumers, PEC is expected to deliver estimated annual energy savings of about $100 to SA households and $60 to NSW householders. Businesses can also

expect higher savings, proportional to their energy use.

The enhanced grid is expected to drive competition in the wholesale electricity market by connecting more low-cost generation to the grid. Its location near identified renewable energy zones will support grid connection for future renewable energy projects as well as enable SA to increase the export of its renewable energy production into the national market.

By creating a second point of connection between SA and the NEM, the PEC will significantly reduce the risk of the SA grid being “islanded” or disconnected from the NEM.

Victoria’s Alcoa Portland aluminium smelter will also indirectly benefit from PEC, with an alternate interconnector from SA to the rest of the NEM enabling critical maintenance to be performed at the nearby Heywood interconnector.

Work on Project EnergyConnect is expected to commence by the end of 2021.

The Best Municipal Water for 2021 at the Berkely Springs International Water Tasting Event in West Virginia has come from a small regional town in Tasmania, which was once deemed unsafe for consumption.

The award went to Rossarden Water Treatment Plant in Tasmania’s Northern Midlands.

The global event judged water from five continents, 14 countries and 19 US states.

Significantly, this is the first time water from Australia has won the prestigious award, which is a major coup for the nation and the state.

TasWater Acting CEO, Juliet Mercer, said the international award was a testament to the hard work that went into the organisation’s 24glasses Regional Towns Water Supply Program, which resulted in the removal of all public health alerts on Tasmanian drinking water.

“Just over three years ago, Rossarden was under a Do Not Consume notice,” Ms Mercer said.

“A safe, clean and reliable water supply underpins the health and well-being of our communities, which was the driving motivation behind the 24glasses program.

“The program saw public health alerts removed from 29 Tasmanian towns and drinking water systems through the installation of 17 new water treatment plants, 16 reservoirs and more than 70km of new trunk mains.

“Seeing a town where so recently you could not even drink the water, now recognised as having the best drinking water in the world is an incredible result and is a great source of pride to TasWater.

“This global recognition reinforces that the standard of treatment processes we have implemented is truly world class.”

The Rossarden Water Treatment Plant is run in partnership with water utility services provider TRILITY, which built and designed the facility as part of TasWater’s 24glasses Regional Towns Water Supply Program Work Package One in 2018.

TRILITY Managing Director, Francois Gouws, said it was a great honour for Rossarden to take out the Best Municipal Water for 2021 in the world, against some high-calibre competition.

“This makes us very proud of our team of dedicated operators at TRILITY who put in a lot of work each week at these sites to ensure we are providing the community with great tasting, safe and reliable drinking water, which is leaps and bounds ahead of what they previously had access to in Rossarden,” Mr Gouws said.

The Water Industry Operators Association (WIOA) Chief Operations Officer, Craig Mathisen, said WIOA conducted taste tests across Australia before the top drops were decided to represent the country.

“This celebrates our unsung heroes – the water operators and their crews who, despite the impacts of COVID-19 and before that drought, fires and floods, ensure we have water which is essential to keep us alive,” Mr Mathisen said.

“Our members, including TasWater and TRILITY, work diligently to deliver high-quality drinking water to their communities.”

Tasmanian Minister for Finance, Michael Ferguson, congratulated TasWater on its success in transforming Rossarden’s water supply, with the achievement testament to the benefits of TasWater’s focus on removing public health alerts.

“Without investment in water infrastructure, the Rossarden area would still be facing a Do Not Consume notice,” Mr Ferguson said.

“The State Government’s $200 million much-needed capital injected into TasWater will accelerate its capital works program, allowing more Tasmanian households to benefit from modernised infrastructure over the next decade, just like the residents of Rossarden have.”

The international recognition acknowledges that TasWater is delivering great tasting, safe and reliable drinking water to Tasmanians at a world-class standard.

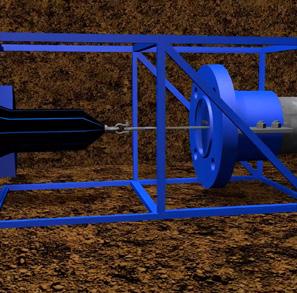

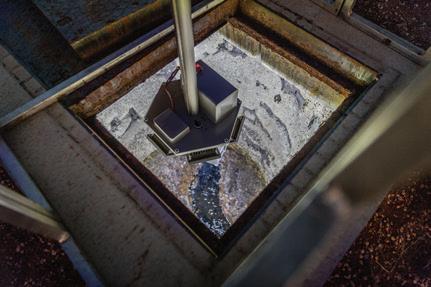

Industry legend Aurelio Pezzimenti, who invented the first prototype of a vacuum extraction microtunnelling system in his father’s garage, has passed away.

Aurelio Pezzimenti is the inventor of the world’s first microtunnelling system using vacuum power as the means to transport the spoil from the cutting chamber to the surface.

Thanks to Aurelio’s invention, the trenchless technology technique of microtunnelling was introduced into Australia, literally changing the way pipes would be installed forever.

In 1986, Aurelio and his brother Gilbert started Pezzimenti Laserbore, which was founded as a manufacturing company and commissioned and trialled the country’s first laser guided microtunnelling system in major sewerage projects around Melbourne.

After seeing how the rest of the world had embraced trenchless techniques, Pezzimenti Laserbore

became a founding corporate member of the Australian Society Trenchless Technology (ASTT).

Aurelio has continuously improved the capability of the system so that diameters up to 3m in material as hard as basalt can be tunnelled. In 2013, Aurelio was awarded ASTT Person of the Year for his dedication to developing an accurate, rapid and reliable microtunnelling system.

Pezzimenti Laserbore continues to focus on the design and manufacture of microtunnelling systems, with Aurelio founding Pezzimenti Tunnelbore, which operates in New South Wales, Queensland, the Northern Territory and Western Australia, as the contracting arm for the group.

Born in Italy, raised in Australia, gifted with a creative mind and the courage to pursue his vision, Aurelio Pezzimenti will be remembered as a true pioneer of trenchless technology in Australia.

Link-Seal offer hundreds of solutions to seal pipe penetrations ranging in size from 10mm to 3 6 meters diameter

Link-Seal are suitable for most types of pipes including PVC, HDPE, Copper and Steel

Resistant to water, oil, gas, aggressive chemicals and fire

Projex Group helps calculate the right Link-Seal size and model for your application

your leading source of news for the local government sector

Council has been developed to keep you up-to-date with all of the latest news, discussions, innovation and projects in the local government sector.

Council is fully integrated across print and online, featuring a website updated daily with the latest industry news, a weekly e-newsletter delivered direct to your inbox, and a quarterly magazine that can be read in print and online.

Published by industry publishing experts Monkey Media, Council will arm community decision-makers with the critical information they need to deliver a better future for cities, towns and suburbs all over Australia.

HEAD TO THE WEBSITE TODAY to sign up for the FREE WEEKLY NEWSLETTER!

www.councilmagazine.com.au

info@councilmagazine.com.au

Anew Board of Directors for Greater Western Water (GWW) commenced on 1 July 2021.

The GWW Board includes new directors and previous City West Water and Western Water directors, to ensure fair representation at a board level of both organisations, plus a mix of required skills.

The inaugural Chair will be David Middleton, who has been Chair of City West Water for the past six years and brings a depth of experience in the water sector.

The new GWW Board includes Western Water Directors Llewellyn Prain, Claire Filson and Liza McDonald, and City West Water Board Directors Bruce Cohen and Tania Fryer.

New members to the board include Matthew Burns, a proud Taungurung man and CEO of Taungurung Land & Waters Council, Efim Tkatchew, an experienced chief financial officer, and Linda White, a skilled lawyer with extensive board expertise.

In June, Maree Lang was announced as the inaugural Managing Director of GWW.

In welcoming the new GWW Board, Ms Lang paid tribute to those who have served on the Western Water and City West Water boards.

“I would like to acknowledge the outgoing directors of Western Water and City West Water for their contribution and commitment to the water sector,” Ms Lang said.

“In particular, I thank Andrew Cairns for his significant contribution as the Western Water Chair.

“I look forward to working with the new GWW Board. This team of highly qualified, dedicated directors will guide Greater Western Water through its early phases from 1 July 2021 and represent the diverse community of which they are a part.”

The selection process was overseen by an independent selection panel, chaired by former CEO of the Victorian Bushfire Reconstruction and Recovery Authority, Ben Hubbard.

Greater Western Water’s formation follows work by the Victorian Government, City West Water, Western Water and Melbourne Water to identify the best way to cater for population growth in the region and deliver high-quality, affordable water services.

Through its innovative solutions, Veolia Water Technologies enables industry, local authorities and citizens to optimize their use of resources for more efficient, environmentally-friendly and socially responsible outcomes.

We understand the importance of increasing the value of water and we do so by supplying high quality water, treating and reusing wastewater, producing and/or recovering energy, extracting raw materials and capitalizing on valuable byproducts.

www.veoliawatertechnologies.com.au

© Veolia Photo LibraryPower Your Decisions with a Dynamic Digital Twin.

Info360.com is a SaaS platform that enables real-world water management workflows using the scalability and accessibility of the cloud.

To learn more contact an Innovyze water expert today.

+61 (0) 7 5506 5700

sales-asiapac@innovyze.com

Finding the right scalable technology is crucial for the water industry to meet its challenges. Here’s how Intelligent Water Networks helps with this in Victoria.

Water corporations face common challenges –aging infrastructure, changing climates and population growth. But with daily operational demands, it’s not easy to dedicate time and resources to find scalable technology to solve these challenges and provide better outcomes for corporations and customers.

In Victoria, this is where Intelligent Water Networks (IWN) comes in. It represents 16 Victorian water corporations, acting as a collective safe sandpit for testing and trialling technology. IWN’s trials assess whether technology can solve common problems, drive business efficiencies and achieve better customer outcomes.

It also runs Champions – a two-year leadership program –to develop tomorrow’s leaders for the water industry through professional development, coaching and mentoring.

With IWN’s ten-year anniversary passing quietly in the blur of 2020, it’s time for an update. Here is a glimpse of IWN’s eight programs and what they are focusing on at the moment.

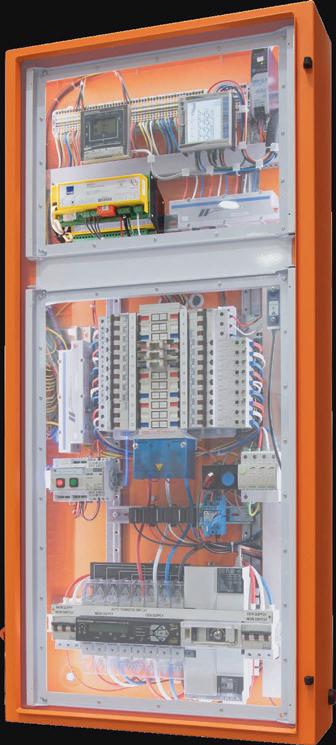

This program helps water corporations manage assets effectively and optimise performance with better tools and technologies.

It is currently working on a PumpCheckR2 trial with five water corporations to optimise pump station operational expenses. It is also trialling remote level sensor technology to collect height data and levels from streams, intermediate bulk containers, reservoirs and potable water tanks without having to attend a remote site.

This program assesses and runs projects to manage the pressing issue of biosolids.

It is working on a pilot plant to turn biosolids into biochar, which is a significant trial in partnership with RMIT and South East Water. The pilot is being held at a Western Water treatment plant. If successful, it will provide a pathway for the industry to turn waste into a usable, value-add product.

IWN’s unique role in trialling technology on behalf of the Victorian water industry also means it is well positioned to share information and introduce new innovations to the sector.

To this end, the program manages an annual conference, a popular monthly webinar series and other initiatives. It aims to not only share IWN’s work but to foster more collaboration and knowledge sharing across the industry.

Good decisions depend on good data and that’s what this program is about. It looks into technologies designed to better manage and analyse data, so water corporations can make cost-effective asset decisions.

At the moment, this program is working closely with ten Victorian water corporations on an automated sewer CCTV footage trial with the potential to reduce the manual review of this footage by about 85 per cent. If successful, the program will consider artificial intelligence options related to the trial’s findings.

This is IWN’s newest program. It aims to share knowledge and resources to support digital metering adoption across Victoria.

The team is working on a 2021 water industry State of Play report, showing where each Victorian water corporation is on their digital metering journey. It is also developing a state-based business case template and economic model for all IWN member water corporations to use and share their learnings.

As the name suggests, this program investigates new and emerging technologies on behalf of the Victorian water industry, avoiding risk and expense that might otherwise put individual corporations off trying these innovations.

One of its most successful trials to date is underway –using augmented reality headsets to support field workers. The headset connects into Zoom or Microsoft Teams so support staff in the office or elsewhere can see what the field worker sees and send them information. The field worker receives information and records data through the headset, hands free.

This technology was especially useful during 2020, allowing site commissioning to continue despite COVID restrictions. It has also worked well for inductions to high-risk sites and safety audits in remote locations.

This program focuses on developing a shared understanding of how the industry can reduce emissions, optimise energy usage and work together towards zero emissions.

At the moment, the team is looking at fugitive wastewater emissions, working with the Water Services Association of Australia (WSAA) on a report detailing measurement and reporting methods, process innovations and optimisation methods. This will be available for water corporations to inform work on mitigating fugitive wastewater emissions.

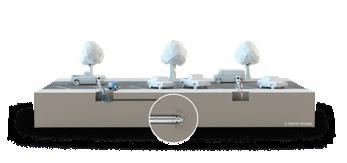

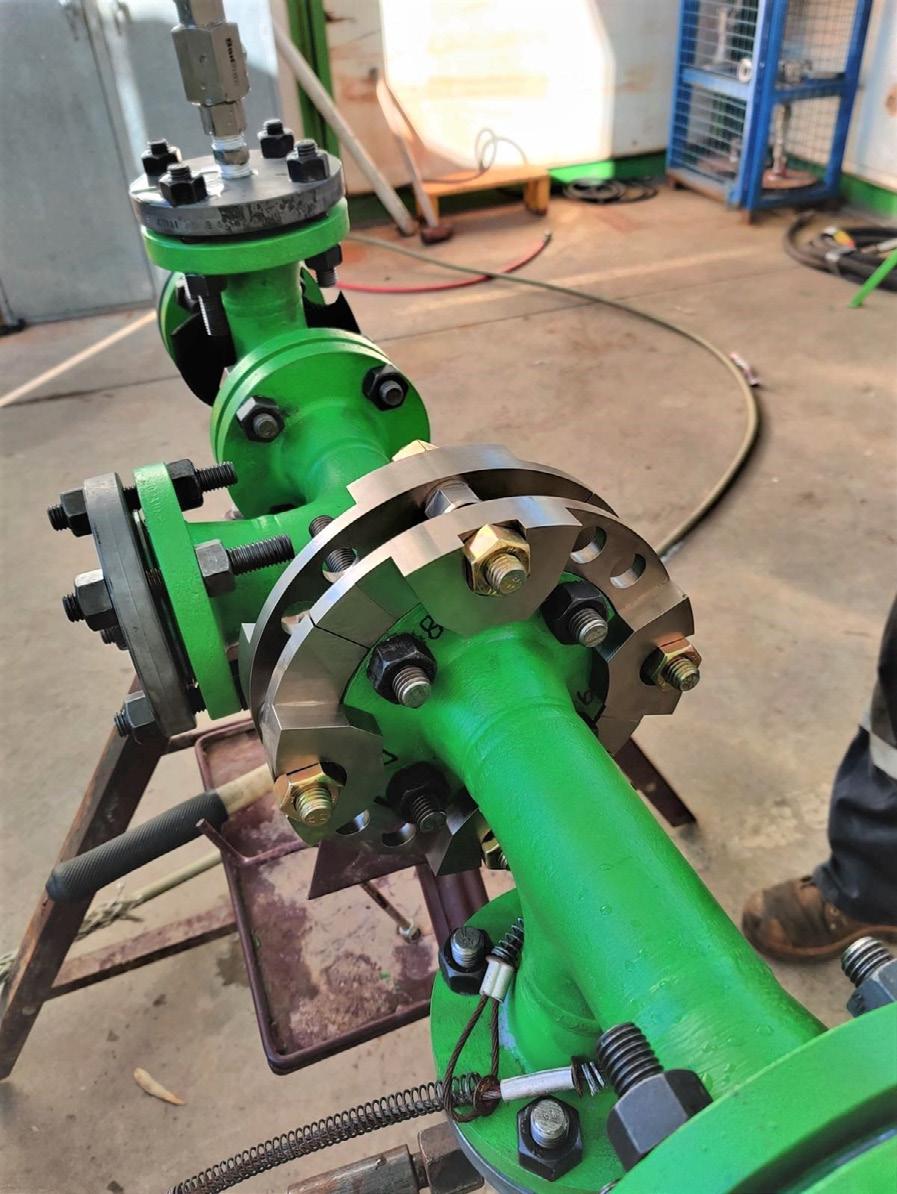

This program investigates new technologies to refine pipe replacement, reduce costs and minimise service interruptions.

It is currently testing a modular sewer monitoring solution that monitors levels, flow and hydrogen sulfide. The trial aims to provide information to the water corporation so they can detect issues early and deal with them proactively, reducing customer impacts.

IWN is a membership-based organisation, driven by the industry and the hard work of its Executive Group, Champions, Program Managers, deputies and working group members who all have jobs at water corporations.

To find out more about IWN’s programs, head to its website at iwn.org.au where you’ll find an interactive map showing the technology trials currently underway across Victoria.

There are strict standards placed on the quality of water used for drinking and food production, and water with a high iron concentration can cause major issues including cloudiness and impaired taste. It’s therefore critically important that a treatment plant’s iron removal system is checked continuously – a process that can demand a great deal of time and resources.

An excessively high iron concentration in water can cause long-term sedimentation of iron particles in pipes and valves, which leads to a reddish discolouration of water. An iron concentration of 0.5 mg/l can be tasted by humans, but the actual limit value is 0.2 mg/l. If this limit value is exceeded, it needs to be dealt with immediately to prevent adverse effects.

In conventional systems, iron removal is achieved using oxygen or chemical dosing. Iron dissolved in water is oxidised and precipitates as metal hydroxide, and then filtered out with quartz sand.

When it comes to the monitoring process, one turbidity sensor is used for each individual filter. However, monitoring individual sensors requires a large amount of time and personnel, as it is carried out randomly for each individual filter line with the laboratory or handheld photometer.

A turbidity sensor does not show if the iron removal process is running successfully or if it is working with the optimum amount of oxygen or chemical dosage.

In traditional plants, the filter load must be monitored at all times and each individual filter checked, so it is difficult to find the optimal backwash time. Each individual sensor must also be cleaned and calibrated regularly, making the entire process time-consuming and not cost-effective to the plant’s operation.

With any laborious and expensive process in the water sector, utilities are turning to automation to reduce manual monitoring and costs. Automated sensors are highly beneficial for iron content because it is something that must be observed constantly to prevent the limit value being exceeded.

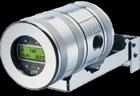

Bürkert’s MS06 flow injection analysis (FIA) sensor cube for iron content and online analysis system is helping to automate the process of controlling iron content and turbidity in raw water. The MS06 sensor cube uses state-of-the-art flow injection analysis to quickly detect excessive iron values in process water, monitor the load status of filters and react accordingly – with just one sensor able to monitor multiple filters.

It analyses the iron content in cycles, operates fully automatically and has extremely compact dimensions. Its flow injection analysis requires only a few reagents, making it economical, and the barcode-based reagent detection prevents misidentification.

It works by using high-precision microfluidic components. A sample is taken from the flowing medium, and a reagent is added. Then the sample and reagent are pumped through the system and mixed – the reaction forming a specific dye. The iron content is then determined through the photometric analysis of this dye.

In addition to the iron sensor, you can integrate sensors for pH, chlorine, chlorine dioxide, ORP, conductivity and turbidity, and in combination with Bürkert water sampling, just one sensor unit – consisting of the aforesaid sensors – can monitor up to eight sample water lines.

For more information, visit www.burkert.com/en.

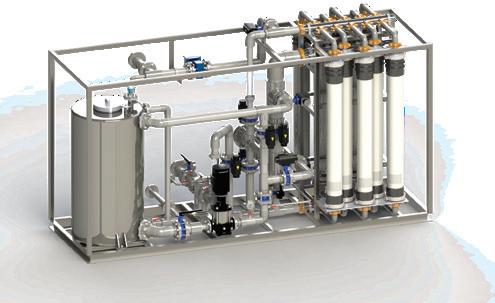

Introducing the FILTEC UF 2/10D Membrane Skid – a pressurised ultrafiltration water treatment solution to help you make water safer in a cost-effective way.

Suitable for drinking water, process water and treated wastewater, this modular plug-and-play system provides an economic solution to many water treatment applications.

Based on the Suez ZeeWeed 1500 Membrane, the FILTEC UF 2/10D is delivered as either a skid-mounted package or containerised solution and provides you with a range of engineered filtration systems.

The FILTEC UF 2/10D also delivers an absolute barrier of 0.02 micron, screening out viruses and making it a true ultra-filter, and includes fully automated operations for

filtration, backpulse, scour aeration and automatic membrane integrity testing. Further features and benefits of the FILTEC UF 2/10D include:

• Adaptable to a wide range of flow rates from 2 to 10L/s (7 to 36m3/hr)

• Capable of receiving ground and surface water of up to 100 NTU with suitable pre-screen

• Fully automated backwash system

• Designed to meet New Zealand DWSNZ and Australian Drinking Water guidelines

For more information on the FILTEC UF 2/10D, contact Alan Tan on +61 413 844 308 or visit filtecinternational.com.au.

FILTEC is committed to making communities safer with advanced water and wastewater treatment.

With one point of accountability, FILTEC’s team of skilled engineers and in-house design experts can oversee large multidisciplinary projects end to end. Their fully integrated capabilities are backed with 25 years in the industry and a world-class service team.

FILTEC. Leading the way in advanced engineered systems and cost-effective solutions to water and wastewater problems.

Barwon Water recently joined with the Birregurra community to celebrate the success of the first phases of the Birregurra Sustainable Communities – Water project, which has so far saved more than 11 million litres of water a year through leak detection and water efficiency.

The Barwon Water water efficiency team was in Birregurra on 21 May for an event at the Community Hall to thank the township and in particular a group of 39 property owners who signed up to be dedicated “Water Savers”.

The group actively tracked their household water usage and learnt how to be more water efficient inside and outside their homes.

Barwon Water General Manager Customers and Community, Jo Murdoch, said the Birregurra Sustainable Communities – Water project started last summer with the installation of 400 digital meters at residences and businesses in the town.

The meters helped identify 36 leaks and Barwon Water is working with property owners to have them fixed, so far saving an equivalent of about six Olympic-sized swimming pools.

At the same time, a new Water Savers group started actively tracking their household water use and learnt how to be more water efficient inside and outside their homes via ongoing engagement with Barwon Water.

“We were absolutely thrilled with the enthusiasm of our Water Savers who responded to the information about their water use positively and proactively, leading over time to average daily savings of about 40L per person compared to the rest of the Birregurra community,” Ms Murdoch said.

Some great examples included one household that reduced daily water consumption from 1,749L to 209L as the project progressed and another who brought their use down from about 1,200L to under 200L a day in the last week of the 12-week project.

Ms Murdoch thanked the Birregurra community for partnering with Barwon Water on the unique place-based approach to water saving. She also acknowledged members of Birregurra Community Group, Birregurra Sustainability, the Friends of the Barwon and Colac Otway Shire for championing the project.

“I’d like to extend particular thanks to our Water Savers Group who really embraced the Birregurra Sustainable Communities – Water project’s focus on behaviour change, leak detection and repair, and water efficiency measures,” Ms Murdoch said.

“Part of the Water Savers Group's success was making it fun and building on the strong local connections that regional communities enjoy.

“Participants enjoyed being able to view data about their water use online, through their own personalised MyH2O Dashboard, at any time of the day or night. A bit of friendly competition developed between participants to see who could save the most water.

“We also invited Birregurra customers to share their best water saving tip during the month of March to be in the running to win a great prize.

“Soon we will be supporting the Birregurra community to participate in a ‘Living Laboratory’ concept, which will incorporate short exercises and trialling new water efficient products to help us determine the amount of water that can be saved for both indoor and outdoor activities; think shorter showers, garden irrigation techniques and rainwater tank to toilet or garden set-ups.

“This place-based approach to water efficiency and water saving shows what’s possible when council, community, business and school leaders partner with the local water corporation to save our precious resource.”

Other highlights of the project to date have included a free WaterAssist Home program to help fix water leaks, a Water Hero program with the Birregurra Primary School, exploring opportunities with businesses for using Class C recycled water and water efficiency tips and information.

Most leaks are easily fixed, but even a small water leak of 5L per hour can add up quickly over time.

If not detected and repaired, this can result in water losses of 840L per week or 43,680L per year and an extra $90 on a customer’s water bill annually.

Ms Murdoch said that customers in Birregurra with leaks were booked into Barwon Water’s free WaterAssist Home program.

“The program includes a home water use assessment and a reliable, affordable plumbing service to repair or replace inefficient water fittings valued at $360,” Ms Murdoch said.

“Offering customers the support they needed to save water has led to significant water savings.”

In the first month of the digital meters being installed, some customers identified as having leaks turned out to be businesses with high water use, but Ms Murdoch said Barwon Water was making support available to them too.

“To help support our non-residential customers, our Business Water Grants are now available for businesses connected to drinking water,” Ms Murdoch said.

“Grants can be used for projects that improve water efficiency and/or achieve permanent water savings through substitution of drinking water, recycling of wastewater or other water efficiency improvements.”

The Birregurra Sustainable Communities – Water project is also exploring with the community opportunities to increase recycled water use for non-drinking purposes from its water reclamation plant.

Ms Murdoch said that Barwon Water is leaving no stone unturned to make better use of resources, reduce pressure on the potable supply and improve regional prosperity.

“Digital meters will likely play an important role in the future of water security and it’s important for us to explore new, innovative ways to help save and prolong our precious drinking water supplies.”

For further details on the Birregurra Sustainable Communities – Water project, visit www.yoursay.barwonwater.vic.gov.au/birregurra.

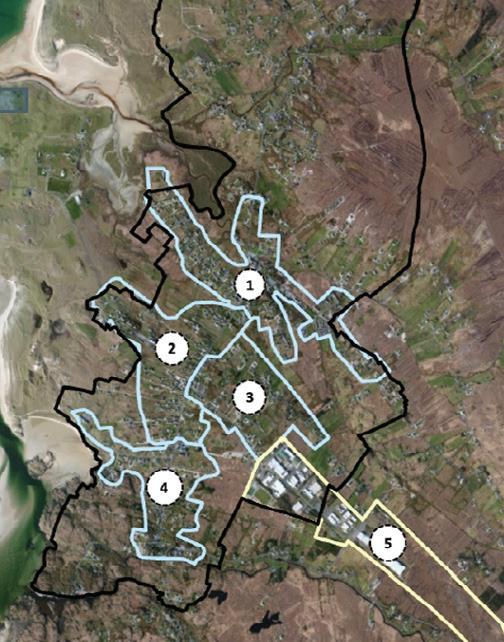

Acommitment to deliver a sewerage system in Gweedore, Co Donegal, was given as part of the Water Services Investment program in 2013 –predating the formation of Irish Water. Failure to address this and provide a collection system and associated treatment facility for Gweedore would have resulted in Ireland being prosecuted for non-compliance with Urban Wastewater Directive (UWWD).

Due to topography, ground conditions and the nature of the development, a conventional gravity collection system was impractical from an economic and technical perspective. Deep excavation in both rock and bog would present significant construction challenges and introduce a high level of program and cost uncertainty.

Maintaining pipeline integrity in these ground conditions is extremely difficult; and would pose risk of pipe settlement and water ingress with potential significant impacts on ongoing operational costs. All of the above, in conjunction with the complex land ownership patterns in the area, would also have precluded the connection of many properties to the network.

As such a challenge was issued, to identify a practical and implementable solution that could resolve the issue and was economically viable.

Mark O’Callaghan, Business Lead – Innovation, Standards and Technology at Irish Water, said, “We want to provide the highest quality service to our customers. The low pressure sewer system will allow delivery of a comprehensive collection system in Gweedore that was simply not practicable using a conventional drainage solution.”

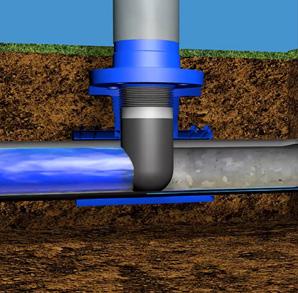

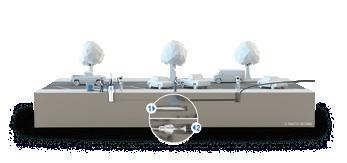

A utility-to-utility conversation between Irish Water and South East Water, facilitated by Iota, highlighted details of South East Water’s PeninsulaEco (PenEco) project – globally the single biggest smart low pressure sewer scheme.

The benefits achieved by this project captured the interest of Irish Water’s executive team who saw it as a novel way to meet the challenges of the Gweedore Scheme, whilst also having the potential to address:

• Servicing of dispersed properties on the periphery of existing networks

• Where conventional networks are not considered viable

• Providing a very effective system that could be deployed to service dispersed communities and properties

Eamon Casey, Technical Director at Iota, said, “We have a culture within Iota – and more widely throughout our parent company, South East Water – to share learnings, insights and technology with our industry peers.

“Details of the PenEco pressure sewer system were highlighted and the alternative sewering method, along with the near real-time monitoring and control capabilities of OneBox®, posed a potential solution to many of the challenges being faced by Irish Water.”

Mr O’Callaghan added, “The proposed project in Gweedore hadn’t progressed any further than the feasibility stage at that point, due to the very difficult terrain and the prohibitive cost of a gravity sewer system.

“The option of a smart low pressure sewer, similar to the PenEco installation, opened up an opportunity for us that we hadn’t investigated previously. We also saw the attractiveness of having a smart system that could be remotely controlled and managed.”

Irish Water engaged Nicolas O’Dwyer (NOD) Consulting Engineers to provide design and project management services on its capital delivery program, which included the Gweedore sewerage system.

NOD engaged Iota to deliver the detailed hydraulic design of a smart pressure sewer scheme for the township of Gweedore consisting of approximately 700 individual connections.

Residents in many rural areas in Ireland, like many other countries, rely on individual septic tank systems to provide treatment of wastewater. Gweedore is such a place located in a truly scenic area of County Donegal and characterised by dispersed development, along either side of a regional road. The surface geology of the area is dominated by blanket bog overlying shallow granite with protruding rock, and sands in the coastal area leading to a high water table. Not great territory for effective wastewater treatment with septic tanks, as was indicated by emerging water quality issues in the adjacent bay.

John Flavin, Associate Director at Nicolas O’Dwyer, said, “We saw the appeal of Iota’s smart pressure system, not only due to its simplicity and cost-effectiveness, but also because of cost estimates for a gravity sewer solution that proved uneconomic due to the difficult ground conditions.”

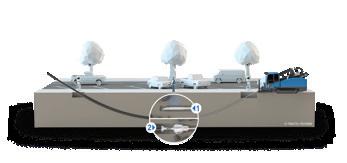

Iota designed the smart hydraulic sewer network based on South East Water’s learnings from the PenEco project, which is monitored and controlled by OneBox®

The feasibility study confirmed the appropriateness of a smart low pressure sewer for the project. Environment One Corporation (E/One) was awarded a tender to install and connect the initial 700 grinder pump units in Gweedore.

Amongst the benefits recognised by Irish Water in deploying E/One’s pumps with Iota OneBox® control system were:

• The capacity to identify and address issues before they impacted customer service

• Infiltration alarms through monitoring of run time

• Controlled flushing of the network to prevent solids deposition

• The ability to balance flows to treatment facilities

All of which have potential to impact favourably on both capital and operational costs, whilst ensuring a quality service to Irish Water customers and good environmental outcomes.

Derek Lachut, Director of Engineering at Environment One Corporation, said, “Irish Water wanted to maximise the functionality of the system. E/One’s industry-leading reliability and ruggedness coupled with OneBox® for command, control and communication will drive extreme customer satisfaction and ensure success of the scheme. The E/One and Iota solution is set to deliver this.”

The solution, which provides remote monitoring and control of individual sites and the network as a whole, will support Irish Water to provide a better customer experience; reduce operational expenditure by reducing the need for

emergency on-site maintenance outside normal working hours; and avoid the risk of spills into the environment through near-real time alarms.

Irish Water expects to realise a reduction in the project capital expenditure due to an optimised network. It is designed to manage flows and utilise individual units across the network as additional storage capacity in high flow events, for example after power outages or storm events. This ultimately allows for smaller diameter pipes throughout the system.

“Further capital savings are realised through reduced construction costs due to shallow trenches or trenchless installations and no requirement for major pump stations,” Mr Lachut continued.

The Gweedore project has now commenced, with the first 42 homes and two commercial properties in the rollout due to be completed in the coming months.

In 2014, True Water designed and installed the Kubota Sewage Treatment Plant (STP) for the Toowoomba Wellcamp Airport and Business Park, the largest private infrastructure project in Australia. With the increasing capacity of the airport and the ongoing development of the business park, True Water has been asked to facilitate the expansion of the sewage treatment system.

As part of the initial site-specific design, True Water included the ability to stage the expansion of the wastewater facility in line with the future growth of the project. The infrastructure was designed to treat the sewage and wastewater generated by the large-scale industrial community as it continues to expand.

This is possible due to the scalable nature of the Kubota STP – additional modular systems can be added with minimal disturbance to the facility and with no impact on the daily operational function.

The expanded system will have the ability to manage wastewater flows of up to 250kL/day. The treated water is then gravity fed to a treated water (effluent) tank prior to transfer to an agricultural irrigation scheme.

Durability, reliability and longevity were key project objectives. The Kubota STP employs biological treatment to manage the highly variable flows and concentrations generated by the business park. The biological moving bed biofilm reactor (MBBR) process utilises a gravity flow path to provide high-quality treatment even during power outages.

Being located next to the airport it was important to provide a compact and unobtrusive system. The below ground installation ensures no odour and minimal visual impact, while improving the infrastructure lifecycle.

The airport was completed by Wagners Corporation in 19 months and is designed to cater for large jets up to the size of a Boeing 747, facilitating the movement of the largest

freight aircraft in and out of the region. The capacity of the airport has continued to expand, particularly in its role as a major inland freight hub and the home of Australia’s first QANTAS Pilot Academy.

Wellcamp Business Park is a highly attractive business destination with wide landscaped streets, parklands and firstclass presentation of buildings. The business park has also seen immense growth, including multiple large workshops and factories, a major milk processing plant, RSPCA depot and micro breweries.

Throughout this time, the Kubota STP installed by True Water has continued to operate at a high level. True Water has continued to work closely with Wagners to ensure the ongoing compliance of the sewage treatment infrastructure at Wellcamp. Due to the high-quality Japanese treatment technology utilised by the plant, the system has maintained a very high level of treatment.

The simplicity of the Kubota MBBR STP ensures continued low overheads and easy to manage operation and management of the infrastructure. True Waters maintenance team service the system regularly and coordinate with Wagners to keep all components looking like new and running at their optimum.

PROVIDING SOLUTIONS FOR:

• Municipal Sewage Treatment

• Commercial & Industrial Estates

• Government Projects

• Residential Developments

• Urban Subdivisions

• Resorts & Caravan Parks

• Mining Accommodation

• Airports & Infrastructure

• Service Stations

• Defence Assets

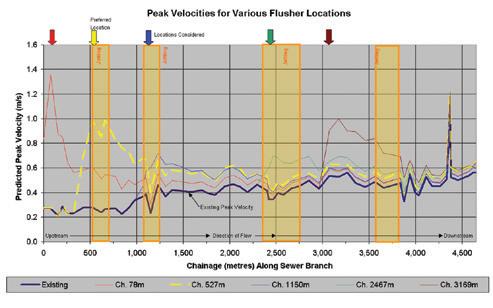

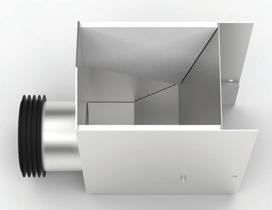

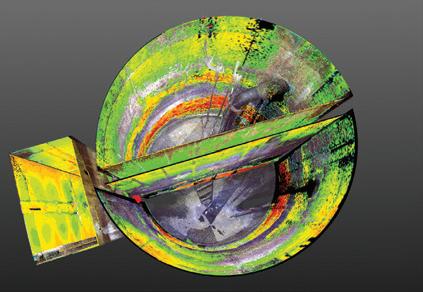

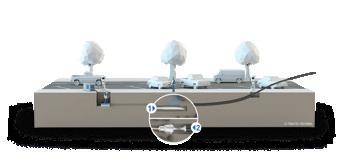

The Flusher is an innovative system that utilises the potential energy from the flow within the sewer to clean it. This outline is extracted from a case study undertaken by Atkins Global to assess the effectiveness of the Flusher units theoretically, using infoWorks CS.

The Flusher units have been simulated in InfoWorks CS using the Real Time Control (RTC) functionality. The assessment has been undertaken on an example 225 sewer prone to siltation at four separate locations. The sewers where silt occurs have been laid at gradients of less than 1 in 300, while the average gradient of the whole branch is approximately 1 in 120. The study investigated the effects of locating the Flusher unit at five locations in the system and assessing the results.

Under a dry weather flow, the greatest increase in velocity occurs immediately upstream of the Flusher unit and within the first 500m downstream. However, the units are responsible for an increase in peak velocity for up to 4km downstream. Furthermore, the increased velocity would be repeated for every operation of the Flusher unit which could typically be more than 50 times per day depending on the characteristics of the catchment.

It was predicted that the Flusher will operate approximately 64 times in a day under dry weather flow conditions, therefore improving flow conditions by eliminating silt build ups.

A passive gate device for controlling and maximising hydraulic flow in sewers

• Reduces operational costs

– No more water jet sewer cleaning

– No more Silt & Debris removal

– Less surcharge & blockages

• Installed in Maintenance Holes

– Easy to install

– Easy to maintain

– For DN150 to DN450 sewer pipes

• Resistant to rag jamming and blocking

• Inherently “fail safe” during storms

• Data Logger and Telemetry Module

– Know what’s happening and when

The steps in assessing the benefits of a Flusher:

• Review historic and ongoing jet cleaning costs

• Undertake a hydraulic performance assessment of the location

• Consider the effectiveness of various Flusher locations

• Assess potential upstream surcharge risks

• Evaluate downstream benefits

• Develop a monitoring plan

A cost-benefit analysis can be completed once the above information has been sourced, assessed and evaluated.

+61 418 691 989

6/58 Box Road, Taren Point NSW 2229 Australia

enquiries@aussietrenchless.com

www.aussietrenchless.com

WTW IQ Sensor Net digital monitoring system for water and wastewater combines many innovative features to provide you flexibility, reliability and durability in continuous monitoring. It is designed and built to last, providing you with many benefits and guaranteeing the quality you choose today will remain long into the future.

Our innovative digital Plug & Play system is suitable for installations of all sizes, making connecting and hot-swapping a breeze. What’s more, the network flexibility of our modular system means you will save on equipment, cable, and installation costs.

The IQ Sensor Net is available with controllers suitable for one, all the way up to 20 sensors, and is easy to install, operate and maintain. Providing a wide range of measuring parameters for both water and wastewater, the IQ Sensor Net offers multiple output options including 4-20mA, Modbus, Profibus, and EthernetIP - as well as an optional built-in web-server for remote access.

Rugged, reliable, and requiring low maintenance, the WTW IQ Sensor Net is the perfect solution to your water quality measuring needs.

Industry leader in pipeline infrastructure, Interflow, is excited to announce the launch of RediFlow®, an advanced Pressure Water Main Renewal System that takes efficiency to the next level.

As thousands of kilometres of asbestos cement pipes reach the end of their service life across Australia and New Zealand each year, asset owners are seeking low impact, affordable ways to renew their water infrastructure.

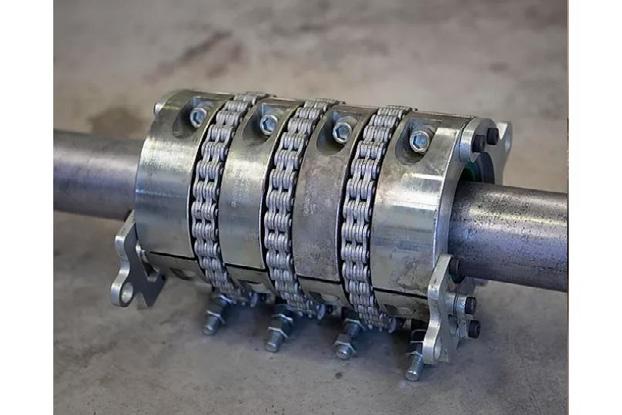

A company that continues to push the boundaries of pipeline innovation in pursuit of meeting its customers’ water infrastructure needs is Interflow. Working with researchers, specialists and engineers, the organisation has developed a game-changing water main renewal system called RediFlow® . This methodology combines exclusive Titeflow® H112 and patented Infrastop® technologies into one synergistic process, providing an ‘all-inone’ package for renewing ageing water main pipelines.

Traditional shutdowns using network valves are disruptive, impacting hundreds of customers at any one time. Rediflow’s Infrastop component can greatly reduce the number of impacted homes by isolating only those pipeline sections specific to the works being delivered.

Infrastop® is a temporary under-pressure fitting that immediately stops flow within a watermain. It only requires a small excavation and can be rapidly installed and operated within 90-minutes, without interrupting supply to consumers upstream.

With Infrastop® in place, Interflow’s Titeflow process then installs a new tight fit HDPE pipe into the host pipe. This snug-fitting technology uses H112, an internationally recognised, high quality, high strength PE100 compliant resin that is specifically designed for pipe applications.

The Titeflow pipe is towed under tension through a static die, reducing its diameter and allowing it to pass through the host pipe. Once it is in place, the pulling load can be released. The liner pipe increases in diameter, fitting tightly inside the host pipe.

The liner is then connected to the main, new service tappings are installed, and the Infrastop® plugs are removed, leaving the offtake in place and the community’s water supply ready to use.” Learn

RediFlow ®: changing the game for water mains

Learn

Enviroline has been manufacturing market-leading drain cleaning equipment for the past 15 years, and the SEWERJETT™ T80 truck mounted jetting system has been stealing the show in recent months.

With so many utilities, councils and contractors looking for a safe

and efficient way to keep sewer and stormwater assets maintained, Enviroline decided to develop the perfect water jetting system.

After extensive market research, Enviroline discovered that the industry is looking for a safer, more efficient and sustainable solution.

Fitted with the cutting-edge control system, these trucks are amongst the safest units on the market with many standout features such as hose burst detection which detects a burst and shuts the unit down within 500 milliseconds in the event of a failure.

Operation is also made more efficient and simplistic with the automatic flow and pressure regulator, allowing the operator to precisely preselect a water flow or pressure.

Remote diagnostic is now also possible, allowing Enviroline engineers to remotely log onto any truck to quickly diagnose or troubleshoot. Software updates can also be sent over the network, keeping the units up to date into the future.

Enviroline has chosen the popular Isuzu FRR110-260 fitted with the 2500 series Alison Automatic gearbox as its chassis of choice. The Isuzu platform has proven to be extremely reliable with outstanding backup Australia wide.

Enviroline has been working with Interflow to continually advance the safety and efficiency of its fleet and decided the SEWERJETT T80-160 jetting truck best suited these requirements.

Stormwater is rainwater that runs off impervious or saturated surfaces in the urban environment, such as roofs, roads and pavements, and green spaces. In an undeveloped environment, natural vegetation allows for rainwater to infiltrate soils, allowing for transpiration by vegetation and evaporation into the atmosphere. The concrete jungles of Australia's cities generate enormous volumes of stormwater, which has significant environmental consequences for the waterways that receive it. Stormwater harvesting can also help save hundreds of millions of litres of drinking water each year by providing an alternative water supply and play an essential role in the development of thriving green spaces for community use.

Stormwater can carry pollutants including litter, soil, organic matter, grease, oil and metals collected from roads and properties, and fertilisers from gardens, with stormwater run-off cited as the primary cause of urban waterway degradation.

In addition to negatively impacting stream ecosystem health, altered flow regimes and poor water quality as a result of stormwater run-off can render urban waterway restoration efforts largely ineffective.

It’s also important to note that when excess water falls on impervious surfaces, it runs rapidly rather than soaking gradually into the earth. This can cause flooding, erosion and infrastructure damage if not managed properly.

While stormwater clearly harms the environment, it is also a resource that is not being utilised to its full potential.

Stormwater has a range of non-potable applications in urban environments, including toilet flushing, garden watering, car washing, industrial uses, open space irrigation, ornamental water features, fire fighting, environmental flow provision and groundwater recharge.

With appropriate treatment, stormwater can also provide a supplementary potable water supply; however, there are a number of barriers that significantly limit the potable use of stormwater in Australia and overseas, the most important being:

• Limited understanding of the hazards of utilising urban stormwater as an alternate water source. In particular, there are very few datasets that have quantified the levels of pathogens and chemicals of concern to human health in stormwater

• Minimal knowledge on pathogen and chemical removal in low-energy and affordable stormwater treatment systems that are based on the principles of water sensitive urban design

• Non-existent validation procedures for these types of stormwater treatment systems

The traditional model of stormwater management aims to drain urban run-off as quickly as possible with the help of channels and pipes, which only increases peak flows and the costs of stormwater management.

New technologies for stormwater management have been in existence since the 1970s and include detention and retention basins, permeable surfaces, infiltration trenches, surface and subsurface groundwater recharge, and other control measures.

A number of utilities and councils are trialling innovative technologies and adopting local stormwater management projects, which offer the opportunity to improve the health of the surrounding waterways while providing secondary benefits to communities, such as increasing water security and reducing peak summer temperatures.

Melbourne Water is one utility working with stakeholders and the community to minimise the negative impacts of stormwater and improve the habitat, ecology and amenity of local waterways.

Dandenong Creek is one example, with long-term investigations showing that the primary stressor on the creek’s health was pollution from nearby industrial areas and residential stormwater run-off.

Rather than undertake a conventional sewer upgrade to manage the risk of overflows into the creek, Melbourne Water worked with the EPA to investigate alternative ways to improve water quality and deliver measurable on-ground benefits.

The Enhancing Our Dandenong Creek project was designed to improve amenity and liveability, reduce stormwater pollution, create habitats for native fish, and manage the impact of non-compliant wet weather sewage outflows into the creek.

The pilot program identified the real opportunities to establish programs, new monitoring technologies and a way of working together that over time, will ultimately improve water quality, and protect ecosystem health and public health and safety.

The pilot project ran from 2013 to 2018, and saw $15 million invested over five years in significant works, including:

• Revitalising 12 billabongs and wetlands along the creek corridor

• Removing 830m of drainage pipe to ‘daylight’ and naturalise the creek

• Planting more than 69,000 plants in billabongs, wetlands and the naturalised section of the creek

• Conducting live pollution monitoring at 32 sites with data loggers

• Constructing 20 fish habitats, including breeding areas

• A fish stocking program and reintroduction of two threatened fish species

Now in its second phase, the project demonstrates an innovative and collaborative approach to meeting sewage containment obligations – creating an opportunity to do things differently and achieve greater outcomes for the community.

This commitment to working with the community was recognised at the 2019 Stormwater Victoria awards, with the water provider a joint winner of the Excellence in Research and Innovation category for the Enhancing Our Dandenong Creek project.

The Stormwater Victoria honour capped off a series of accolades for the project, which also won two national Australian Water Association awards in 2019.

Melbourne Water also claimed the 2019 Stormwater Victoria award for Excellence in Strategic and Master Planning for the Chain of Ponds Collaboration – Transforming the Moonee Ponds Creek Through Collective Action – a project that is breaking new ground in how Melbourne Water delivers waterway management.

The Moonee Ponds Creek catchment is one of Melbourne’s most urbanised and modified creek systems. Significant issues persist across the catchment, including poor water quality, introduced species, habitat fragmentation, minimal expansion of the creek corridor through land acquisition, limited linkages to other open spaces, poor stormwater management, litter, restricted public access and movement, poor urban design outcomes, and fragmented management and decision-making.

Rather than sole organisations trying to implement another plan for a creek, this collaboration has established a new partnership model between organisations and community to drive change in a catchment which supports a healthier waterway.

In October 2018, a historic agreement to help transform the Moonee Ponds Creek was signed by 15 organisations to commit to the Chain of Ponds Collaboration and work together in finding lasting solutions for the catchment, which will transform the Moonee Ponds Creek into an iconic waterway for Melbourne that provides high social and environmental benefits.

The organisations who signed the Memorandum of Understanding include the City of Melbourne, City of Moonee Valley, Hume City Council, Moreland City Council, City West Water, Yarra Valley Water, the Victorian Planning Authority, Parks Victoria, Conservation Volunteers Australia, Kensington Association Living Colour Studio, Moonee Valley Bicycle User Group, Friends of Moonee Ponds Creek and Friends of Upper Moonee Ponds Creek.

The project recognises opportunities within the broader creek catchment (offline) and those which operate more directly on water within the creek itself (online).

Offline initiatives operate on stormwater within the broader creek catchment which can have an impact on the health and operation of the creek. Strategies to manage stormwater runoff and quality prior to the water entering the creek itself include:

• Catchment Scale – through water harvesting and wetland opportunities

• Street Scale – canopy trees, permeable surfaces and raingardens

• Lot Scale – water tanks and permeable surfaces

Online initiatives manage water quality and flows once the water has entered the creek. These ideas operate directly on the physical form and function of the creek itself and include:

• Flow control and water aeration – through weirs, rifle choke points and channel materials

• Creek profile – through terracing, benching utilising different materials for increased community connection and ecology outcomes

• Landform – utilising adjacent landform in order to detain water before it enters the creek, to recharge water tables, improve soil condition and provide landscape opportunities to increase social connection and habitat value of the landscape

While individual options can be pursued in isolation, the potential for significant improvements in creek health is only achieved when multiple options across both the catchment (offline) and the creek (online) are considered in unison.

The collection, treatment, storage and use of stormwater is referred to as stormwater harvesting.

The regional city of Orange – located approximately 260km west of Sydney in the Central West of New South Wales – has been able to demonstrate that despite the lack of existing regulation or guidance, stormwater can be harvested and used safely for potable supplies.

Water supply in Orange was provided by two water storages which captured runoff from predominantly rural catchments. While Orange has a relatively high annual rainfall compared to surrounding areas, its location at the top of the catchment limits the volume of water that can be captured.

By late 2007, the city’s water storages were below 40 per cent and significant resources were directed to reduce water consumption. By August 2008, the combined water storage level reached 26.7 per cent and dropped to its lowest level of 23 per cent in May 2010. It was therefore critical that alternative water supplies were identified and used to augment the city’s water supply.

Piped stormwater flows from over half of the Orange City urban area originally drained to Blackmans Swamp Creek downstream of Suma Park Dam, with the remaining urban areas draining to Ploughmans Creek.

A detailed hydrological model showed that 15 to 30 per cent of the city’s annual water needs could potentially be gained through stormwater harvesting from Blackmans Swamp Creek.

The Blackmans Swamp Creek stormwater harvesting solution was also economically viable due to:

• The close proximity of Blackmans Creek Swamp to Suma Park Dam

• The availability of key infrastructure including road access, power and an existing pipeline between the creek and Suma Park Dam

• The very high level of treatment provided by Council’s water treatment plant which already treats the raw water from Suma Park Dam including the use of ozone treatment and biologically activated carbon filtration

• The regularity of flows in Blackmans Swamp Creek (average of 53 rainfall events a year which can be harvested)

The Blackmans Swamp Creek stormwater harvesting scheme involves some catchment pretreatment – via two large Gross Pollutant Traps – before flows are harvested from the rock and gabion weir and transferred to a 230ML holding dam. The stormwater is then treated in batch ponds to meet target water quality criteria before being piped into Suma Park Dam to be treated with the other stored water for potable supply.

Following the success of the Blackmans Swamp Creek stormwater harvesting scheme it was expanded to include the Ploughmans Creek stormwater harvesting project. This project involved the retrofit of four stormwater treatment wetlands into existing urban areas before flows are harvested and transferred to the holding dam already used for the Blackmans Swamp Creek stormwater harvesting scheme.

The combined average harvesting potential of both of these projects is 1,350ML/year with 850ML provided by Blackmans Swamp Creek and up to 500ML provided by

Ploughmans Creek. This equates to approximately 25 per cent of Orange’s annual unrestricted water demand.

The Blackmans Swamp Creek and Ploughmans Creek stormwater harvesting to potable schemes received permanent approval in April 2015, almost seven years after the Blackmans Swamp Creek stormwater harvesting scheme was first approved under emergency authorisation.

Since the construction of the Blackmans Swamp Creek and Ploughmans Creek stormwater harvesting schemes, the council has also been investigating the best use of its stormwater through the use of a dual pipe plumbing system.

Dual pipe systems are becoming more common in new residential developments across Australia to reduce the consumption of drinking water and make the most of all water sources.

The dual pipe systems have been included in all houses built in the Ploughmans Valley and North Orange area since 2005 and since December 2017, have been allowing residents to use stormwater collected from the city’s wetlands and stormwater harvesting schemes to irrigate their gardens and flush their toilets.

As part of its Integrated Water Management program, City West Water [now Greater Western Water] is also working with its customers and community to develop impactful projects that promote sustainable water management and reduce demand on drinking water supplies.

Owned by the Victorian Government, City West Water provides drinking water, trade waste and recycled water services to Melbourne's CBD, inner and western suburbs.

During 2018, the utility launched round one of its Stormwater Harvesting Partnering Fund. City West Water co-funded several projects during this round which included:

• Melbourne Olympic Park, Melbourne

• Woodlands Park, Essendon

• Balmoral Park, Derrimut

• Melbourne Ballpark, Altona

• Arndell Park, Truganina

• Edinburgh Gardens, Fitzroy

These projects will supply up to 108 million litres of stormwater per year for irrigation of sports grounds and public open spaces.

In October 2020, City West Water launched round two of its Stormwater Harvesting Partnering Fund, kicking off with the Dempster Park Stormwater Harvesting Scheme in Sunshine North. This project will save an additional 11 million litres of drinking water by capturing, treating and reusing stormwater to irrigate Dempster Park and surrounds.

In December 2020, City West Water’s Stormwater Harvesting Partnering Fund won top honours in the government category at the Premier’s Sustainability Awards

– Victoria’s most highly recognised annual sustainability awards program.

The award recognised the utility’s work with project partners and the community to deliver innovative stormwater harvesting initiatives that increase green spaces across Melbourne’s west while future-proofing water supply.