WATER | SEWER | ELECTRICITY | GAS | NBN www.utilitymagazine.com.au Issue #3, August 2014

Engineering, Construction & Maintenance

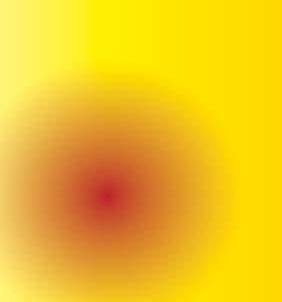

Nobody knows the importance of combining design innovation, high quality and value quite like the world‘s largest furniture retailer… which is why it awarded Canadian Solar to install 3.6MW solar capacity on its facilities in Australia. Canadian Solar is one of the world‘s largest and foremost solar power companies providing its

customers with high-quality products and total turn-key solar solutions that reduce complexities and installation cost. The seven solar projects will achieve the highest energy production values with considerable savings on electricity costs whilst contributing to energy independence and sustainability goals.

COMMERCIAL

Canadian Solar (Australia) Pty Ltd . 165 Cremorne Street . Richmond, VIC 3121 . Phone: 03 8609 1844

for you at www.canadiansolar.com/au

WE ARE BUILDING THE LARGEST

PV PROJECT IN AUSTRALIA

Contact Canadian Solar to discover a solution that works

Welcome to the third edition of Utility, the fastest growing magazine servicing the Australian utility sector. The response to the magazine continues to overwhelm us; and motivate us to continue bringing you content on the news, projects and issues that matter most to you.

As we move into the second half of the year, we move closer to what is traditionally a busy period for conferences across the utility sector, with events including WIOA in Bendigo from 3-4 September, Stormwater 2014 in Adelaide from 13-17 October, InterWater and All Energy Australia in Melbourne from 15-16 October, and APIA in Melbourne 18-21 October all sure to attract participants from the various sectors this magazine covers. I look forward to catching up with as many of our readers, contributors and advertisers as possible at these upcoming events.

Utility will of course be distributed at these events, so we’ve focused on delivering content in this edition that ties in with these areas of interest. We spoke to WIOA Chairman Jim Martin about his first year in the job; and we also feature a thought-provoking article from the Stormwater Industry Association regarding our management of urban run-off.

With the AEMO recently releasing a report forecasting a long-term downward trend in the use of electricity – with the

increasing use of renewables part of the cause for this – we’ve also opted to look at some of the large scale renewable energy projects that are happening across Australia, and the potential impacts these can have on the National Electricity Market.

Finally, I’m pleased to let you all know that since the last edition of Utility, we’ve recorded another milestone in the development of this magazine, with our first round of audit figures released by the Audited Media Association of Australia.

It has now been verified that Utility is directly mailed to 5,142 subscribers. Having this verification from the publishing industry’s independent auditing body is very important to me personally, as it assures our readers, contributors and advertisers that this magazine is being read by the people we say it is.

It’s a topic I feel strongly about; and I encourage our readers, contributors and advertisers to consider the magazines they work with – and be aware that being audited by the Audited Media Association of Australia is a basic benchmark any reputable magazine should have.

Chris Bland Publisher and Editor FROM THE EDITOR welcome August 2014 Monkey Media Enterprises ABN: 36 426 734 954 GPO Box 93, Melbourne VIC 3001 P: (03) 9440 5721 F: (03) 8456 6720 monkeymedia.com.au info@monkeymedia.com.au utilitymagazine.com.au info@utilitymagazine.com.au ISSN: 2203-2797 ISSUE 3 Published by Engineering, Construction & Maintenance WATER SEWER ELECTRICITY GAS NBN www.utilitymagazine.com.au Issue #3, August 2014 UTILITY MAGAZINE AUGUST 2014 PLUGGING IN TO RENEWABLES A NEW STANDARD ASSET MANAGEMENT WASTEWATER UNDER PRESSURE OF THE LOST TRIBAL WISDOM SCADA IN SL-RAT Demonstration NSW 2015 W austeck.com E info@austeck.com 835 mins TRANSMITTER RECEIVER BLOCKAGE Publisher and Editor Chris Bland Managing Editor Laura Harvey Editorial Assistant Michelle Goldsmith Marketing Consultant Cynthia Lim Design Sandy Noke 1

4 CONTENTS 14 25 34 67 74 72 RENEWABLES Plugging in to wind ...................... 14 The Australian Energy Market Operator has been investigating the potential to integrate excess energy generated by wind turbines around Australia into the National Electricity Market. The power of the grid 18 Challenges in grid integration .... 22 SCADA Relearning the lost tribal wisdom of SCADA 26 By Andrew West. Improved connection, increased capability ..................... 30 Secrets of good communication ............................ 32 ASSET MANAGEMENT A new standard in asset management 34 By Danielle Roche. Evolving imagery delivers real solutions................................ 38 Failure prediction of critical pipes and pipe leak management ................................ 42 PIPE AND CONDUIT Plastic pipe connects Australia ....................................... 67 JULIA JOHNS Project Engineer, City West Water ............................ 72 NBN Fibre and copper: connecting end users to the NBN ................. 74

IN UTILITIES

WOMEN

August 2014 ISSUE 3 5 46 48 57 WASTEWATER Jim Martin: water reform expert rewires 57 Bringing pressure sewer to small communities ...................... 60 Pressure sewer innovation 62 PIPE RELINING Sewage spill prevention strategies ...................................... 46 Innovation in gas pipeline rehabilitation ................................ 64 BILLING Customers see benefits of better data 48 The metering menu ..................... 50 CitiPower and Powercor 52 Cables connect increased capacity ...................... 54 In each issue Editor’s welcome .................................................. 1 A word from the ENA .......................................... 6 News briefs ........................................................... 8 Advertisers’ index .............................................. 80 Editorial schedule .............................................. 80 Utility magazine is bringing together experts on various fields to answer all your questions UTILITY IN PROFILE 78 52 70 STORMWATER Making linkages that matter ........ 70

A WORD FROM THE ENA

JOHN BRADLEY

CHIEF EXECUTIVE OFFICER – ENERGY NETWORKS ASSOCIATION

Australia’s energy sector is frequently described as being in a state of ‘transformation’ – a fact again highlighted by recent Australian Energy Market Operator forecasts that electricity use will decline by 1.1 per cent over the next three years.

Consumption trends and a rooftop solar PV market with an average annual growth rate of 24 per cent have brought significant change with the potential for more change to come – as consumers increase their use of embedded generation technologies and consider new options in battery storage, electric vehicles and demand side participation.

With this transformation in mind, current and future energy consumers have a central interest in a policy debate which will play out during 2014. The Australian Energy Market Commission is now consulting on a rule change proposal to expand competition in metering and related services. While the development of the electricity metering framework may sound like a dry topic, it could be the difference between ensuring our electricity system evolves, rather than spirals.

Advanced Metering Infrastructure, or Smart Meters, are a gateway to the long-term sustainability of the electricity system. As technology and energy markets develop rapidly, smart meters will benefit individual customers by providing practical information about energy use, permitting more efficient and rewarding tariff structures; and enabling participation in new markets, such as exporting energy to the grid through solar panels.

Importantly however, smart meters also provide a simple way to achieve benefits to all customers when used by network businesses as part of strategies to reduce or defer capital and operating expenditure through improved network planning, control and management. The whole of system benefits to consumers include improved

safety, greater access to power quality and outage information to reduce customer time off-supply, and improved outcomes for reliability performance.

Recent decisions by Energy Ministers to provide consumers with choice about their metering provider are welcomebut it is vital that the new framework also ensures networks can also employ and rollout these devices to provide benefits to all customers through more efficient and effective network operations.

The 2011 study of Victorian Advanced Meter Infrastructure found that the benefits derived from efficiencies in network operations was $733 million, or approximately 29 per cent of the total benefits – the largest category of smart meter benefits after avoided replacement and meter reading costs.

A new report commissioned by the Energy Networks Association on the potential benefits of smart metering infrastructure suggests that there may be a wider range of potential benefits from smart meters being realised since earlier studies were done.

The Energeia study submitted to the AEMC by the ENA highlights a number of previously unidentified additional benefits which may be achieved through advanced metering to the benefit of consumers.

Not all benefits will be achieved in all circumstances and each investment

will require its own business case, but the Energeia analysis highlights how network customers will be disadvantaged if the new metering framework stifles network access to smart meter services or does not fix antiquated rules preventing some networks from using smart meters today.

Energeia concludes in its Review of the Potential Network Benefits of Smart Metering that:

• The potential network benefits have been greater than initially anticipated in the original Victorian and national costbenefit assessments;

• Energeia’s indicative estimate is that the network derived benefits may be up to three times higher per annum than estimated by the most recent Victorian review in 2011;

• Benefits will vary significantly due to circumstances, and so it is critical that the metering framework fosters innovative applications of smart meters and the economic realisation of benefits as they emerge.

Importantly, it finds that as the penetration of smart meters in an area increases, the benefits to consumers also increases.

6

Illustration of Benefits Realisation by Smart Meter Penetration 100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% Smart Metering Penetration Capacity Power quality Reliability Potential Benefits per Year per Customer Continued on page 8

BOOST YOUR PRODUCTIVITY AND REDUCE RISK WITH THE LEADER IN UTILITY INSTALLATION SOLUTIONS

Available in a wide range of trailer and truck-mounted configurations to meet the needs of every operator.

When you need to meet the increasingly common requirement for non-destructive digging on your job sites it makes sense to choose Australia’s most trusted brand. vermeer.com.au/vacuum-excavators

Put the penetrating power of a proven, simple and reliable mole design to work—just add compressed air.

Vermeer piercing tools have been the mole of choice for over 20 year for a range of short-run installations, including electrical, fibre and telecom installations. vermeer.com.au/piercing-tools

Take the backache out of trench digging with the utility trencher range that has the power, capabilities and durability needed on Australian jobsites.

Our range of tracked and wheeled pedestrian and ride-on trenchers have every utility installation scenario covered. vermeer.com.au/pedestrian-trenchers

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the United States and / or other countries. © 2014 Vermeer Corporation. All Rights Reserved. WWW.VERMEER.COM.AU 1800 444 394

us at www.vermeer.com.au or free call 1800 620 720 for more information and to arrange an on-site demonstration. See for yourself how Vermeer’s range of utility installation products, backed by our Australia-wide dealership network, an make a positive impact on your productivity and profit.

UTILITY

Visit

VACUUM EXCAVATORS HOLE HAMMERTM PIERCING TOOLS

TRENCHERS

SELECT SOLUTIONS RECOGNISED AS ‘BEST EMPLOYER’

Utility and infrastructure service provider Select Solutions has been commended as a ‘Best Employer for 2014’ by global human resources company, Aon Hewitt. Select Solutions received the prestigious award with 15 other companies, chosen from 120 entries across Australia and New Zealand, for its positive employee engagement results, commitment to safety and employee communications.

ABOUT US

Edge Underground is a precision microtunnelling contractor that operates in Australia and the USA. With a focus on innovative technology and expertise, Edge Underground designs and enhances the performance of trenchless equipment.

OUR SERVICES

• Microtunnelling

• Pipe Jacking

• Thrust Boring

• Laser Tunnel Boring GUIDED BORING SPECIALISTS

Find out more about keyhole pipeline installation www.keyholepipeline.com.au

Select Solutions General Manager, John Kelso, was delighted with the recognition and the strong growth of the business since inception. “Since our establishment in 2009, Select Solutions has grown from 300 to nearly 900 employees who provide services to the utility and infrastructure sectors across Australia, and this recognition is a proud moment in what has been a monumental year for the company,” Mr Kelso said. “Select Solutions has been recognised as having outstanding employee engagement scores and delivering excellence in people management practices.

“Importantly, safety was our highest employee engagement driver, scoring 94 per cent, which is critical in the industries we service,” he said.

Continued from page 6

ENA supports a contestable metering framework which delivers real benefits to consumers, by providing individual customers with choice, but also allowing all customers to benefit from more efficient network management services.

The current policy proposes to create a gatekeeper of metering services, the Metering Coordinator (MC). While a customer would have the choice to appoint its own MC – for most people appointing an MC is something done when planning a 21st birthday party, so they are more likely to accept their retailer’s choice. The problem for all consumers is that the new MC would be able to charge the network business for smart metering services as an unregulated monopoly. That risks higher costs to all network customers. A policy framework so unbalanced may provide a real barrier to parties reaching agreements which underwrite significant investment in smart meters.

The need for transformation in Australia’s energy sector is urgent – approximately 70 per cent of Australia’s small customers still have their consumption read on accumulation basis and they are stuck with out-dated tariffs that do not reward cost-saving behaviour.

As the winds of change sweep the Australian energy sector, consumers can ill afford a delayed take-up of smart meters because we ‘didn’t get the rules right’.

* stuart@edgeunderground.co

( 0458 000 009

8

www.edgeunderground.co

KEY APPOINTMENTS AT MONKEY MEDIA

Two recent appointments at Monkey Media have boosted the company’s ability to provide niche marketing solutions to those in the utility sector.

Laura Harvey joins the team as Utility magazine’s Managing Editor. Laura has more than ten years of experience as a journalist and editor in the infrastructure and energy industries.

“When Utility launched I was incredibly impressed with its concept, design and content. I’m delighted to now be a part of the team and look forward to working with our industry stakeholders to continue to grow the magazine and its standing across our key utility sectors,” said Laura.

Laura joins Cynthia Lim, who is working with Monkey Media as a Marketing Consultant, drawing upon her years of experience in the water and wastewater industries to develop bespoke marketing solutions to meet the industry’s needs. Cynthia’s previous roles include Operations Manager of the Water Industry Operators Association of Australia, and Technical Sales Representative for ATMR.

Monkey Media Managing Director Chris Bland is thrilled with the new additions to the team. “Laura and Cynthia are integral to the growth of Monkey Media. Having worked with both Laura and Cynthia in various roles over the past ten years,

Relationships | Expertise | Solutions

I’m excited to bring this team together at Monkey Media to continue to produce the highest quality magazines and innovative marketing solutions for our clients,” said Chris.

“Together we have 30+ years of infrastructure and utility marketing experience to offer, and we look forward to sharing our expertise with our clients in the months and years to come.”

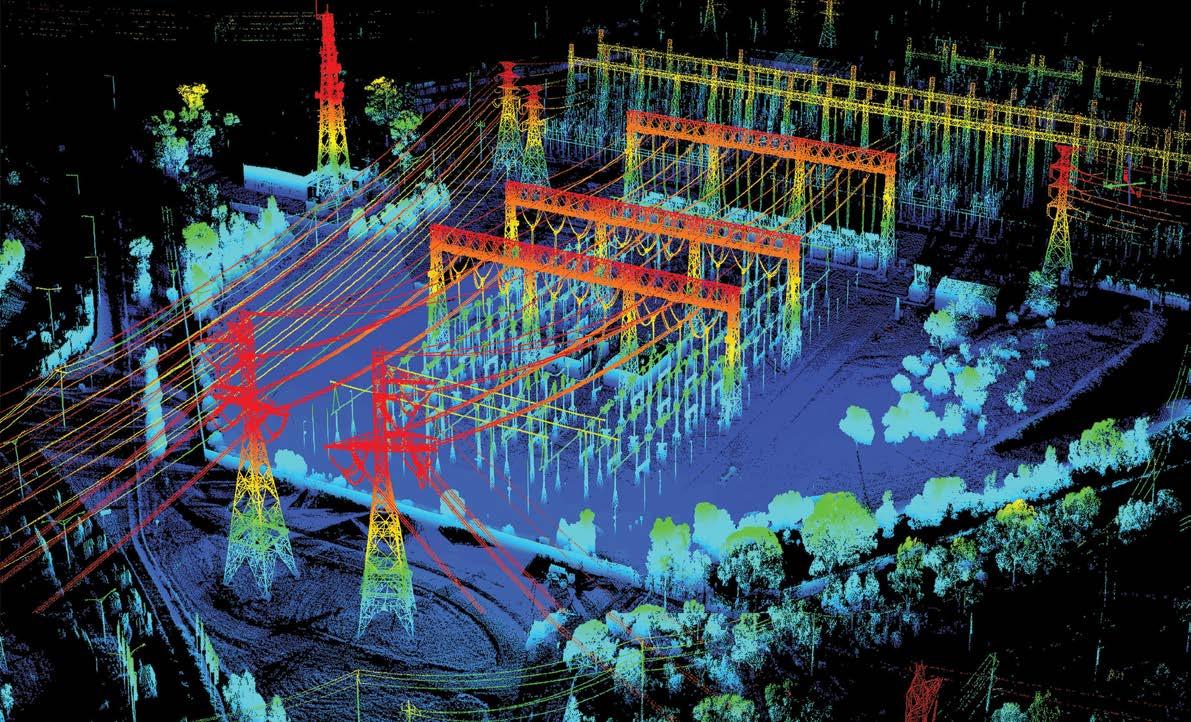

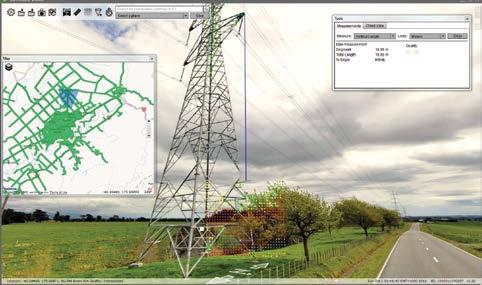

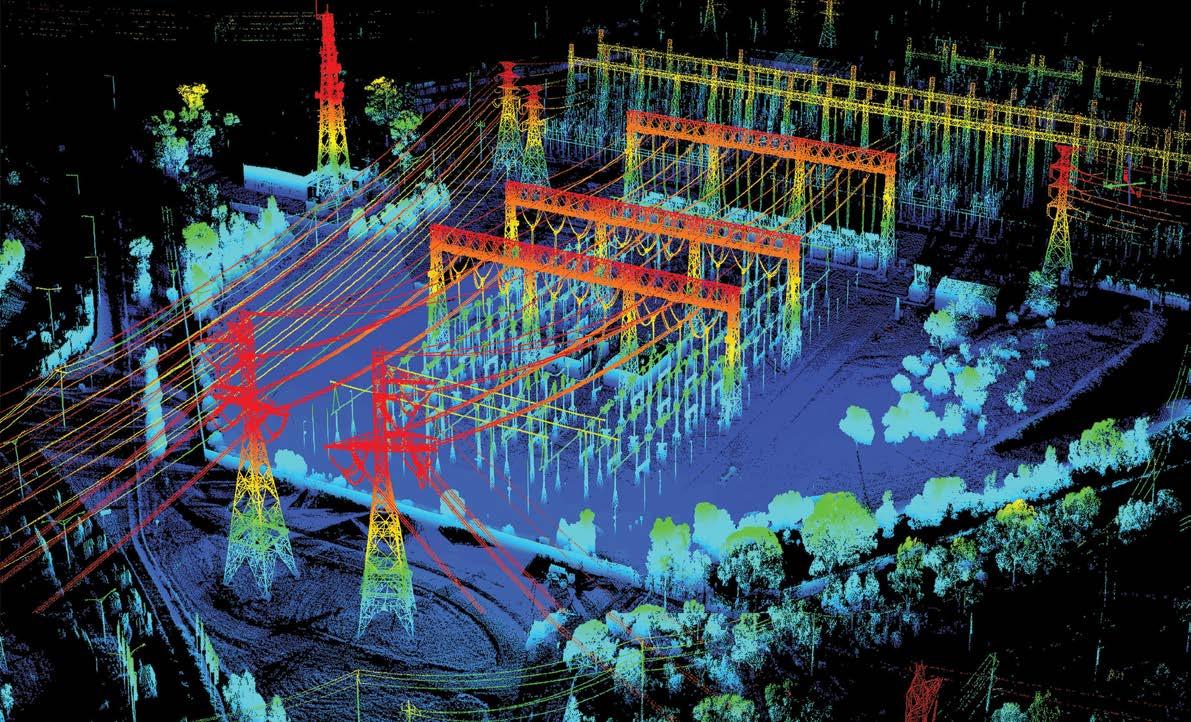

Environmental Consulting Solutions Hydrographic Technology

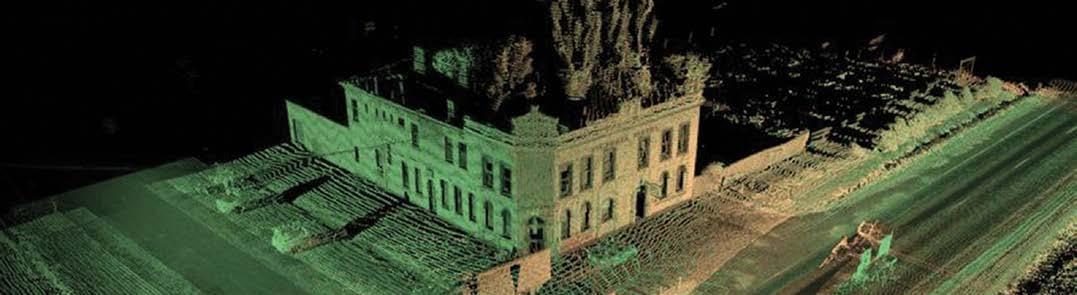

Our Infrastructure team remain at the cutting edge of solutions driven technology with the use of remote sensing boat technology to deliver hydrographic mapping.

Aerial Survey Solutions

Unmanned Aerial Vehicle (UAV) Mapping

We complement our traditional surveying services with aerial surveying using UAVs, delivering orthorectified imagery and digital elevation models in all common CAD and GIS formats.

Cutting Edge Technology

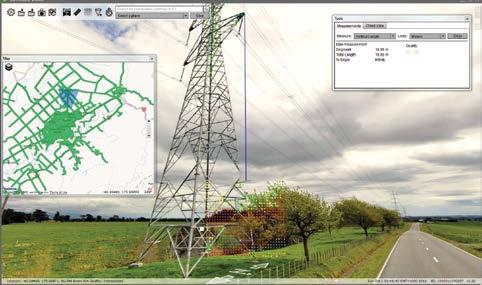

Vehicle Mounted LIDAR

This solution overcomes the challenges of mapping linear features to a high level of accuracy and is being used with great success as part of our service delivery on the NBN project.

Rapid Response Services

Terrestrial Scanning

Terrestrial scanning is our preferred method of survey for projects requiring a high level of accuracy. We can assist you with extracting information, or simply provide the point cloud to you directly. Our team of over 40 surveyors means that we can be on site, to most places in Melbourne, within 24 hours.

Our rapid response survey units use the latest in GPS, robotic total station and digital leveling technology to deliver acurate and cost effective solutions for a broad range of projects and market sectors. Visit our website to find out more.

www.taylorsds.com.au

Infrastructure

NEWS 9

QUU ANNOUNCES MAJOR 2014/15 PROJECTS

Queensland Urban Utilities has announced that it will be investing $292 million in water and sewerage assets throughout 2014/15.

The capital expenditure program will include 108 infrastructure projects across the company’s five service regions – Brisbane, Ipswich, Lockyer Valley, Scenic Rim and Somerset.

Queensland Urban Utilities CEO, Louise Dudley, said a key focus of the capital works program was building new infrastructure to cater for South-East Queensland’s population growth.

“It is important that we continue to plan and build for the future to ensure we have a sustainable water and

sewerage network for many years to come,” she said.

Ms Dudley also said a major priority in 2014/15 was replacing ageing infrastructure in Queensland Urban Utilities’ vast water and sewerage network.

“We have almost 9,000km of water mains and 9,200km of sewerage mains and the average age of the pipes in our network is between 20 and 50 years old,” she said.

“Under our rolling renewal programs, we will replace 29km of water mains and reline 24km of sewerage mains in 2014/15.”

MELBOURNE WATER AWARDS ALPHINGTON SEWER PROJECT CONTRACT

Melbourne Water has awarded Lend Lease a $36 million contract for the construction phase of the Alphington Sewer Project.

The project comprises the replacement of a section of the North Yarra Main Sewer between Coate Park and the Latrobe Golf Club in the suburb of Alphington, and an upgrade to a section of the Kew North Branch Sewer under the Yarra River to Willsmere Chandler Park. The two sections total 2.2km in length and service 85,000 homes.

Program Director of Capital Works

Mike Filby said the works would ensure the sewerage system could continue to deliver high-quality essential services to the northern suburbs.

COMDAIN COMMENCES SYDNEY WATER UPGRADES

Comdain Infrastructure has commenced its first mains renewal project under the Sydney Water Network & Facility Renewal Program (NFRP). NFRP Reticulation Renewal Package 7 sees Comdain crews working across the Sydney area focusing on the south-west and west of the city, as well as the Blue Mountains.

As part of Sydney Water’s ongoing program to replace unreliable network infrastructure, these reticulation renewals will see Comdain project manage the detailed design phase and the delivery phase of the renewal

of existing water mains. Conventional construction methods are used for these projects through open trench excavation, replacement pipe laying and full reinstatement.

Traffic management and local resident and stakeholder communications are paramount for this work. Comdain has engaged local service providers familiar with Sydney’s traffic control requirements, and has developed robust systems and methodologies for keeping residents informed throughout the duration of the works. Initial work site restoration is an important activity

SMART WATER METERS FOR WA REGION

Residents in the Pilbara are expected to save more than one billion litres of water each year after the installation of 4,260 smart water meters in homes.

WA Water Minister Mia Davies said the meters were now live and operational in the Karratha suburbs of Baynton West, Baynton East, Millars Well and East Bulgarra, as well as the towns of Roebourne, Point Samson and Wickham.

“More than 8,000 meters will be installed across the West Pilbara as part of the program,” Ms Davies said.

“The remaining 4,558 properties will have their smart water meters connected and operational within the next 12 months.”

The meters have been installed as part of the $4.735 million Pilbara Smart Water Meter Program, which is jointly funded by the Water Corporation and the Federal Government.

and part of community engagement ensuring that Comdain, on behalf of Sydney Water, leaves the work site in a safe, clean and functional state for later full reinstatement.

Comdain NSW State Operations Manager Tom Burns said, “Package 7 provides the catalyst for Comdain to demonstrate a robust, outcome-focused and diligent approach to project delivery through the implementation of a positive culture focused on exceptional safety, environmental, quality, community and compliance performance.”

10 NEWS sewer

water

EXHIBITION & CONFERENCE

THE WATER QUALITY, MONITORING & EFFICIENCY SHOW!

REGISTRATION NOW OPEN!

Inter-Water Australia is a free-to-delegate, businessto-business exhibition and conference that will focus on reducing the water footprint of industry, the public sector and the urban environment and will look at the role of technology in improving water quality and improving water efficiency.

● Free-to-attend exhibition

● Free-to-attend multi stream conference

● Free networking reception for all registered attendees

● Great value exhibition & sponsorship packages

Co-located with All-Energy Australia, Australian Sustainability conference and WasteExpo which attracted more than 6,500 participants in 2013!

To discuss exhibiting or sponsorship opportunities, please contact Jay Thorogood on 0488 228 882 or email Jay@inter-water.com.au

MELBOURNE CONVENTION & EXHIBITION CENTRE

15-16 OCTOBER 2014

www.inter-water.com.au ✆ 1 300 794 335 Media Partners Supporters Co-located with Sponsor Official charity IN PARTNERSHIP WITH

NBN

COMDAIN WINS MULTIPLE GAS ‘CITY GATES’

Comdain Infrastructure has been awarded six new gas ‘City Gate’ projects across metro and regional Victoria. With a total value of approximately $6.5 million, each of these six installations (for SP AusNet, APA Group and Multinet Gas) provides vital gas infrastructure upgrades to Victoria’s gas supply network.

The contracts are focussed on significant energy supply projects in

Victoria such as the Melbourne growth area of Werribee/Wyndham, and the Victorian Government’s Energy for the Regions Program. This program, which is to extend natural gas across regional and rural Victoria, identified a number of priority towns for gas, three of which (Avoca, Bannockburn and Winchelsea) will be undertaken by Comdain.

With a scope of work including detailed design and a substantial

NBN CO DETAILS INFRASTRUCTURE COMPETITION STRATEGY

In a hearing with the Senate Select Committee on the National Broadband Network, NBN Co CEO Bill Morrow and COO Greg Adcock revealed details about NBN Co’s plans for infrastructurebased competition with TPG, who is expanding its own fibre network.

They confirmed that NBN Co intends to begin the race to connect apartment buildings by using fibre-to-the-premises

(FTTP) technology (as opposed to the fibre-to-the-building technology being used by TPG and trialled by NBN Co) until their own FTTB product is ready. Mr Morrow said “We felt it was in the interest of the taxpayers and in the interest of NBN Co to offer a competitive response [to TPG’s plan]. We have outlined which areas we will do that in and we have said that we will do it by the

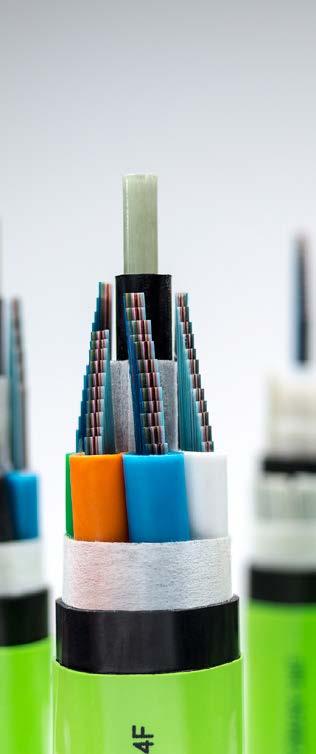

AUSGRID AWARDS $44M HIGH VOLTAGE CABLE CONTRACT

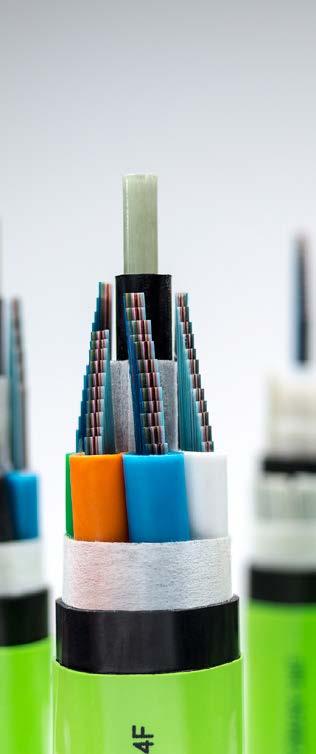

Ausgrid has awarded a contract worth approximately $44 million for 132kV underground high voltage cables to Prysmian Group.

These projects form part of Ausgrid’s network plans where existing cables and equipment, installed about 40 years ago, are being replaced in the Willoughby-Lindfield-Castle Cove area on Sydney’s North Shore, and the Engadine area, just south of Sydney. The contracts comprise design, manufacture, supply, civil works, installation, and testing of 132kV XLPE underground cables for both projects.

Production will involve multiple Prysmian locations: China will supply approximately 105km in total of 132 kV cable, China and the Netherlands will supply joints and outdoor terminations,

CLARIFICATION

and Prysmian Australia’s Liverpool and Dee Why plants will supply bonding and fibre-optic communications cables, respectively.

HORIZON POWER AWARDS EPCM CONTRACT

GHD has been selected to provide engineering, procurement and project management services for Horizon Power, Western Australia. As part of the agreement, a number of Horizon Power staff will be transferring to GHD.

Ian Shepherd, GHD’s CEO, said, “This appointment reflects our strengths in providing strategic engineering services for planning, development and operation of energy assets. GHD has extensive experience in helping deliver essential

component of off-site mechanical fabrication and instrumentation fit out in each gate, these projects will see Comdain’s Systems Group significantly involved. A development of Comdain’s existing fabrication workshop and electrical services team based in Epping, this group provides specialist mechanical, electrical, instrumentation and SCADA design, construction and maintenance expertise and service.

end of the financial year. The only product that we have available today is fibre-tothe-premise and that will be the product which we are offering.”

He added that while they are bringing forward their rollout to potentially profitable apartment buildings, they are not necessarily basing the selected locations on where TPG next plans to begin construction.

infrastructure for our clients and the community.

“Through seamless collaboration across our network, GHD professionals will assist Horizon Power to continue to provide safe and reliable power supplies for customers into the future.”

Horizon Power Managing Director Frank Tudor said, “The new outsourcing arrangement provides Horizon Power with increased flexibility when delivering major projects and is in keeping with our strategic principles of driving simplicity and scalability in our business. This step will deliver savings that will contribute to Horizon Power’s overall cost reduction goals. Horizon Power is pleased to have a company with the reputation and capability of GHD supporting our business.”

The May 2014 edition of Utility included an article titled ‘Lifting the lid on drain surveying technology’. Subsequently, we were made aware that this heading is similar to the trademarked tagline of Sewer Equipment Company of Australia (SECA). Utility magazine would like to make clear that any similarities with SECA’s slogan were inadvertent, and the companies and equipment featured in that article are not related to or supplied by SECA.

12 gas

electricity

NEWS

Promoting best practice in water management by building the knowledge, skills and networks of industry operators

All water industry personnel involved in the operation and maintenance of urban, rural and industrial water related infrastructure for the management, conveyance, treatment, discharge and reuse of water and trade wastes should attend this conference.

If you're an operator, manager, engineer, consultant, professional or someone who is working in the water industry or just has an interest in water, then this is a must attend event.

The Bendigo Exhibition Centre is located on Holmes Road, Bendigo

Email: info@wioa org.au

Phone: 03 5821 6744

Fax: 03 5821 6033

Web: www.wioa.org.au

Industry Operations Conference & Exhibitions

Water

your

in

management – sponsorship opportunities still available.

the

in the water

more information on sponsorship, www.wioa.org.au/2014conferences/sponsorship.htm Prime Sponsors epigen Media Sponsor

To view the conference program and find out how to register, visit www.wioa.org.au/2014conferences/vic.htm Position

company as a leader

water

Take advantage of the opportunity to align your company as a supporter of

leading non-profit organisation serving the needs of operators

industry. For

Organising association

Water Industry Operators Association of Australia PO Box 6012 Shepparton, Victoria 3632

Join us at the 77th Annual Victorian Water Industry Operations Conference & Exhibition

REGISTER NOW!

Bendigo Exhibition Centre

3 & 4 September 2014 VIC 3 4 Bendigo & September

14 RENEWABLES

PLUGGING IN TO WIND

Since 2012, the Australian Energy Market Operator has been investigating the potential to integrate excess energy generated by wind turbines around Australia into the National Electricity Market. AEMO has provided Utility with an update on the progress that has been made, and the challenges that lie ahead for the integration of large scale renewable energy into the grid.

In December 2012, the Australian Energy Market Operator (AEMO) published the National Transmission Network Development Plan (NTNDP), in order to facilitate the development of an efficient national electricity network that considers potential transmission and generation investments.

The plan focused on large-scale electricity generation and the main transmission networks that connect this generation to population and industrial centres. Across the

wide-ranging document, a number of forecasts and targets were set over a 25-year planning horizon, including a forecast of 8.88GW of new wind generation for the National Electricity Market (NEM) by 2020. This figure is in addition to the approximately 2.67GW already installed as of May 2013.

The NEM design incorporates several features which will assist in effectively managing the expected new wind generation forecast to connect to the national power system. Nevertheless,

integrating the level of new wind generation forecast will present challenges in operating the power system and the electricity market. These challenges are expected to arise first in South Australia and Tasmania, where forecast levels of wind generation are highest compared to demand.

Further challenges are expected to arise from technological innovations, including increased distributed generation such as rooftop photovoltaic (PV) panels; and from changing

15

RENEWABLES

consumer behaviour, contributing to a trend of declining electricity consumption from the power system.

CHALLENGES TO POWER SYSTEM OPERATION

Currently, it is forecast that there will be an additional 8.88GW of additional wind generation in the NEM by 2020, which will result in a total installed NEM wind generation capacity of around 11.5GW.

The key operational challenges in integrating this amount of wind generation into the NEM are:

• Power system inertia could be reduced, due to displacement of conventional synchronous generation, particularly in South Australia and Tasmania. This would make the control of power system frequency following contingency events more challenging in these areas. While power system frequency control in Victoria, New South Wales and Queensland would not be significantly affected, AEMO must make changes in Tasmania and South Australia to ensure ongoing control of power system frequency within required limits.

• Significant new wind generation can reduce existing interconnector transfer limits, particularly under conditions of low demand and high wind speeds when wind generation forms a large percentage of the generation mix.

• Early modelling indicates that, without action, up to 5,750GWh and 1,260GWh of the maximum potential wind generation energy in Victoria and South Australia respectively could be curtailed due to network limitations. This represents around 35 per cent and 15 per cent respectively of the energy potentially available from wind generation installed in these regions.

• Increasing levels of wind generation will reduce power system fault levels at some locations, which may lead to further limitations on the operation of wind generation and high voltage direct current (HVDC) links.

OPTIONS TO ADDRESS THESE CHALLENGES

AEMO could potentially manage these power system impacts with existing processes and systems. This could involve either using constraint equations in the central dispatch process to limit wind generation, or as a last resort, using market intervention through issuing directions to synchronous generators to ensure sufficient levels of power system inertia are maintained to allow adequate control of power system frequency.

A number of other options could be considered to assist integration of this generation. These would require changes to processes, systems and regulatory instruments. Some of these involve:

• Establishing new ancillary service requirements to provide services that allow adequate control of power system frequency under conditions of low power system inertia.

• Investing to install purpose-built synchronous condensers to maintain system inertia and power system fault levels.

• Investing to allow some existing generating units to operate either with reduced minimum load or as synchronous condensers. This would allow existing generation to maintain system inertia and power system fault levels during periods of high wind generation.

• Establishing new control schemes, or modifying existing schemes, to ensure adequate control of power system frequency under conditions of low power system inertia.

AEMO will investigate the likely costs and potential benefits of these options, as well as considering any other feasible options or proposals identified by other parties.

SHORT-TERM ACTIONS

AEMO is currently undertaking further work examining

16

RENEWABLES

the operation of the power system with increased levels of renewable energy generation, including wind and PV generation, with a particular focus on South Australia.

Some technical changes will be required to operational processes and systems in response to increasing levels of renewable energy in the NEM, such as changes in the calculation of contingency frequency control ancillary services requirements, to assist in maintaining system security.

However, to date AEMO has not identified a clear need for more substantial changes to AEMO systems or processes, or to existing market arrangements and design. The existing market design, and AEMO operational system and processes, already have a number of features that assist in the integration of renewables, such as five-minute dispatch, inclusion of large-scale renewable in the dispatch process, and accurate forecasting of wind generation output.

REVISIONS TO THE RET

LONGER-TERM ACTIONS

AEMO will improve its modelling of wind generation in its operational and planning tools and processes, to improve their accuracy with increasing levels of wind generation.

This raises broader questions about the challenges facing the power system, market, and regulatory framework due to the pace of technological innovation altering the supply mix, and changing consumer behaviour, particularly in response to high electricity prices.

At present, AEMO is continuing to follow up on recommendations around operational issues identified in its previous work, particularly in the South Australian and Tasmanian regions, and continues to work towards the outcomes required based on the 2020 RET targets.

At the time of printing, a decision had not been made on whether the Federal Government would retain, revise or abolish the 2020 RET instated by the previous Government. This decision may have implications on the wind target for 2020, however, every effort has been taken to ensure the information presented in this article is relevant and applicable, regardless of any changes to the RET.

17

The most channels Rugged Fully Integrated The best performance and productivity Interference protection and monitoring Lightest weight in class Best battery life An unbelievable price RENEWABLES

THE

IKEA has positioned itself as a global leader in the field of sustainability, and with a target of being completely energy independent by 2020, it’s hard to argue with their commitment to the cause. Recently, the Swedish furniture giant unveiled plans to generate solar power to run its Australian stores and warehouses – and potentially feed excess power back into the grid.

OF THE GRID POWER

18

RENEWABLES

GRID

The ambitious 2020 target is no small task, particularly when you consider the sheer size of the organisation – IKEA operates 303 stores in 26 countries and employs approximately 135,000 people.

In May, it was announced that IKEA Australia would work with Canadian Solar to install 3.6MW of solar photovoltaic (PV) panels on the roofs of seven IKEA sites across Victoria, New South Wales and Queensland. The panels will power the seven sites (a mix of stores and warehouses), and they are grid connected, so that any excess energy can be fed back into the National Electricity Market (NEM) for use where it is needed.

The PV panels to be installed will generate enough clean energy to offset approximately 4,000 tonnes of carbon dioxide annually, which will assist considerably in IKEA’s global energy independence goal.

IKEA Australia selected Canadian Solar after a competitive tender process, with a range of factors –including quality of the panels, price, and ability to integrate with the grid – key factors in the decision-making process.

IKEA Australia Sustainability Manager Richard Wilson said that following the tender process, the organisation felt comfortable that Canadian Solar was the company to provide a total turnkey solution on time, and in line with the various challenges that connecting a PV system of this size to the grid entails.

Shawn Qu, Chairman and Chief Executive Officer of Canadian Solar, agrees that the grid integration aspects of this particular project were challenging. “The IKEA project involved hefty undertakings of grid-connection negotiation,” he noted.

“Our organisation prides itself in not only producing the world’s best PV products, but also a dynamic expertisedriven projects team. Fully equipped with an advanced understanding of Australian grid codes, and backed by years of experience, our local team was able to effectively execute, despite the complexity of the projects.”

19

RENEWABLES

IKEA AUSTRALIA SUSTAINABILITY MANAGER RICHARD WILSON WITH SOME OF THE CANADIAN SOLAR PANELS.

Canadian Solar’s Australian Manager Daniel Ruoss echoed these sentiments. “IKEA Australia could see the work we had done on grid integration on previous projects, such as the Windsor Riverview Shopping Centre in New South Wales, and at the Mega Lifescience Factory in Pakenham, Victoria,” said Mr Ruoss. “Our experience in dealing with grid integration, which can be an often challenging process and speaking the same language as the DNSPs, was a critical part of what set us apart from our competitors.”

Installing solar systems onto the roofs of IKEA Australia’s stores and warehouses is a considerable undertaking, with each site having its own complexities and issues to consider. Canadian Solar’s product and installation offering fit well with IKEA’s vision for an efficient, reliable high quality product together with a competitive offer, expert knowledge and experience.

THE PANELS

The project is Canadian Solar’s largest commercial PV project rollout to date globally and emphasises the company’s ability to provide solutions that reduce the complexities and costs of solar system installation.

Canadian Solar’s professional engineering design was critical to the development of the project systems, which feature state-of-the-art products, such as the Quartech-Next Generation PV panels.

The Quartech PV panels have raised module efficiency to a new standard in the solar industry. They feature four busbar cell technology, which results in higher power output, higher system reliability, improved module conversion efficiency, reduced cell series resistance and reduced stress between cell interconnectors. Overall they offer excellent performance, superior reliability and enhanced value.

A UNIQUE OPPORTUNITY

The IKEA project presents the National Electricity Market, and Australia’s electricity generators, distributors and retailers with a unique opportunity.

“Some of our roofs have the capacity for significantly more panels, which could produce even more electricity, which could then be fed into the grid as a regular source of renewable energy,” said Mr Wilson.

It’s certainly a unique, and novel, way for businesses and utilities to capitalise on the real estate available on their roofs, particularly when their stores and warehouses are located close to points of the grid where security of supply can be an issue.

There’s no doubt that IKEA Australia is a leader in this area, both in Australia and globally, but there is a very real possibility that other companies may too follow its lead, and look into large scale solar projects as a means of powering their own operations, while also feeding excess energy into the grid.

Mr Wilson thinks there is certainly scope for utilities to consider whether the grid’s dimensions might need expanding. “We have to look at innovative solutions,” said Mr Wilson. “Hopefully IKEA can play a small part in bringing these ideas to the fore.”

THINKING BEYOND SOLAR

While the organisation may now have more than 550,000 solar panels in operation around the world, it has also invested heavily in wind turbines in order to meet their energy independence targets.

In 2013, IKEA globally committed to owning and operating 137 wind turbines around the world. In Northern Ireland for example, the electricity generated from the turbines directly powers a store, and in other parts of the world, electricity from the turbines is used to offset energy used by stores which are not completely run by solar power.

“Globally, IKEA has been investing in wind energy, most recently with a new wind facility in Illinois, US,” said Mr Wilson. “When it comes online in 2015 it will be our largest single renewable energy investment to date. The 49 turbines are expected to generate enough energy for 165 per cent of IKEA operations in the US.”

With such a strong wind market in Australia, and considering the fact that Australia has lofty targets of its own for wind generation by 2020 (see article on page 14), this could open

20 UTILITY • AUGUST 2014 WWW.UTILITYMAGAZINE.COM.AU

another potential generating opportunity for IKEA Australia.

MANAGING DEMAND

With such lofty targets for energy independence, IKEA Australia has also had to consider ways it can be efficient with the energy that it does use, to reduce the overall tally it must generate or offset.

Demand management has had a large role to play in this process. Globally the organisation has looked at the times at which certain functions are performed to ensure they are done so in an energy efficient manner – for example, car park cleaning at store locations across Australia now takes place in daylight hours, rather than overnight or early in the morning, when lights would be required for visibility.

The organisation has also ensured that for each store there is a thorough understanding of the building

“Installing solar systems on to the roofs of IKEA Australia’s stores and warehouses is a considerable undertaking, with each site having its own complexities and issues to consider.

management system, and steps that can be taken to ensure the efficient use of energy – for example, air conditioning is utilised at outside of peak demand times.

A BOLD VISION

Globally, IKEA has a long-term approach to sustainability, and Mr Wilson confirms the organisation is well on the way to reaching its lofty 2020 target.

“It’s an ambitious target, but at IKEA, we believe it’s possible to transform our business by creating the opportunity to reduce emissions and avoid rising energy costs. This means challenging the old ways and embracing the new, being bold and committed.”

21

challenges in GRI

Australian government agency ARENA has recently been investigating the opportunities to integrate renewable energy into the grid, and the challenges associated with this. Utility recently spoke to ARENA CEO Ivor Frischknecht about some of the challenges and opportunities presented by renewable grid integration.

The Australian Renewable Energy Agency (ARENA) was established by the Australian Government in 2012 to make renewable energy solutions more affordable, and increase the amount of renewable energy used in Australia. The organisation has a $2.5 billion budget to fund renewable energy projects, support research and development activities, and support activities to capture and share knowledge.

ARENA is supportive of all renewable energy technologies and projects

across the various stages of the innovation chain – from research in the laboratory to large scale technology projects.

An important focus for ARENA has been investigating ways to integrate renewable energy into the grid.

Currently, ARENA is investigating a new initiative that would focus on demonstration projects that address barriers to higher penetration of renewables in distribution networks, at both residential and commercial scale. It could also demonstrate the value and reliability of using embedded

energy resources – such as renewable generation, storage and demand management – as alternatives to upgrading ‘poles and wires’ network infrastructure.

“ARENA’s Board has identified integrating renewable energy in distribution networks as a major challenge and an opportunity for growth in the renewable energy sector,” said ARENA CEO Ivor Frischknecht.

“We are already funding several projects in this area and have been working with stakeholders to develop our priorities for future work.”

22 RENEWABLES

D INTEGRATION

WHY GRID INTEGRATION?

Due to the success of a range of renewable policy measures and accompanying cost reductions for technologies such as wind and solar photovoltaics (PV), renewables are reaching high penetration levels in a number of locations in Australia.

This distributed form and new source of energy generation presents an array of new matters for network and distribution operators to integrate into their business. These operators will benefit from improved forecasting for new generation types, technical standards, and balancing supply with demand to ensure that maximum benefit is derived from high renewable penetration.

According to Mr Frischknecht, technological change is fundamentally shifting the way Australian distribution networks are utilised. Increasingly, electricity consumers will produce electricity as well as consuming it. They will own or otherwise access distributed energy resources, especially rooftop solar, smart appliances and, potentially, energy storage. There will be greater opportunities for them to work with energy suppliers to manage their demand.

“Our stakeholders have told us that managing distributed renewable generation and other technologies is becoming increasingly important in distribution networks,” said Mr Frischknecht. “ARENA sees connecting

to the grid as an emerging issue to future deployment.”

The strong recent growth of distributed renewables – mostly solar PV – plays a major part in these changes. Approximately 95 per cent of Australia’s more than 3GW of solar PV is connected to a network. Last year solar PV penetration in regional Queensland reached almost 18 per cent, according to modelling recently undertaken for ARENA by ACIL Allen. In South Australia, SA Power Networks has projected PV penetration in their network to reach 60-80 per cent of premises over the next 15 years (refer to SA Power Networks Future Operating Model 2013-2018).

“While solar PV generation is valuable

23 RENEWABLES

in that it generates during the day when electricity demand is greater, it is also variable and doesn’t fit neatly with the network’s current reliability requirements. It also generates less during late afternoon/evening residential peak demand periods,” noted Mr Frischknecht. “Over time, as more electricity consumers install solar PV and battery storage costs come down, several stakeholders are concerned that the electricity grid will become an expensive back-up system for consumers who generate most of their electricity requirements on site.”

The transition to a new way of using electricity networks will have technical and economic challenges.

“As integrating renewables into the grid is a priority area, ARENA is undertaking activities to develop an evidence base that will be useful for the industry to navigate challenges - for example performance and reliability of a range of distributed technologies, pricing network services or engaging with consumers,” said Mr Frischknecht.

MAJOR PROJECTS

ARENA currently has a number of projects underway as a means to further investigate the integration of renewables into the grid.

Stocktake project

The ‘stocktake’ project will collate and publish information on the various trials and studies on integrating renewables into the grid that have been undertaken around Australia, as well as the most relevant international projects.

“This will bring together the existing knowledge, experience, gaps and issues into a single place,” said Mr Frischknecht. “This will be a valuable resource for the sector, as well as for ARENA to identify specific priorities for this area of work.

“ARENA has engaged Marchment Hill Consulting to deliver the project and has convened a small expert stakeholder reference group to guide the project, including members from network companies, retailers, research organisations and energy market bodies.”

ARENA will communicate the results through its website in a series of instalments scheduled during 2014, and will hold a series of workshops to update stakeholders on results and analysis and to seek feedback on how to make future results as valuable and user-friendly as possible.

DANCE project

The Dynamic Avoidable Network Cost Evaluation (DANCE) project has been developed by the Institute for Sustainable Futures, located at the University of Technology, Sydney with ARENA funding. ARENA is now looking at extending this project.

“The project aims to provide a national, annually updated, publicly accessible, online map of network constraints. This could help identify potentially avoidable network costs in transmission and distribution networks,” said Mr Frischknecht.

While much of the information required for this is already produced annually in some form in Distribution and Transmission Annual Planning Reports, the information provided can be difficult to access and interpret for those without specialised skills and knowledge, and is produced in different formats. The map could assist the sector in several ways such as helping to lift productivity of network capital assets and developing markets for distributed energy services.

Clean Energy Council project

The Clean Energy Council’s FutureProofing in Australia’s Electricity Distribution Industry project will focus on barriers to integrating renewables and related technologies in distribution networks.

ARENA’S FUNDING STATUS

It will engage a cross-industry steering committee.

“The project will explore the technical, knowledge, regulatory and economic challenges and consider solutions and the benefits of integrating renewable energy into distribution grids,” said Mr Frischknecht.

The project’s objectives are to:

• Identify key barriers that currently challenge the sustainable integration of renewable energy and demand management and what is needed for efficient resolutions both in the near and long term.

• Establish, coordinate and maintain relationships and transparent dialogue between key stakeholders.

• Ensure a holistic approach to the distribution network.

• Demonstrate the technical performance of existing and emerging renewable energy and demand management technologies and explore their value to the distribution network.

• Provide a set of recommendations and advocacy platforms to inform policy and regulation reform aimed at alleviating barriers to, and capturing the benefits of, the continued integration of renewable energy and demand management into distribution grids.

The project will also produce reports and hold stakeholder workshops starting around October 2014. The final reports are scheduled for May 2015.

The Government announced in the Commonwealth Budget 2014-15 that it intends to return almost $1.3 billion of ARENA’s uncommitted funding to consolidated revenue and incorporate its operations within the Department of Industry. However, the Australian Parliament will need to repeal the Australian Renewable Energy Agency (ARENA) Act 2011 for these changes to take effect. Until this occurs ARENA will continue its work progressing funding proposals and managing existing projects. Projects that already have a funding agreement with ARENA are not affected by 2014-15 Budget announcements.

24

RENEWABLES

DELIVERING MORE FOR LESS

The 2014 National SCADA Conference will cover the key operational and organisational challenges in developing a successful SCADA system.

Now in its 13th year, this established industry event is the one place where SCADA technicians and engineers can come together, swap stories, hear case studies of real life implementations and overcome the challenges posed in delivering essential services.

All organisations are seeking greater fiscal scrutiny and higher profits. SCADA operations, often classed as essential services, delivered over vast areas with multiple points of presence, do not lend themselves easily to budgetary restraint. SCADA professionals are charged with delivering essential services with maximum uptime, less budget and fewer staff, yet increased supply demanded from utilities.

This forms the theme to the conference, which is ‘Delivering more for less’. Great case studies and real life implementations will profile how other organisations have met this challenging remit to deliver essential services, with even greater constraints.

Speakers at the event will include:

• Andrew West, SCADA Communication Consultant and Chair, DNP Technical Committee;

• Graeme McClure, Engineering Lead, Smart Networks - Network Automation, SP AusNet;

• Dr Jason Smith, Assistant Director, CERT Australia;

• Ron Southworth, Director, Australian Operations, Lofty Perch;

• Dave Bowerman, Senior Principal / Manager Electrical & SCADA Engineering, Hunter Water Australia;

• Sean Murdoch, Manager, Control Systems Management and Support, Queensland Urban Utilities.

The conference is the annual meeting point for Australian SCADA technicians and engineers. It is the one place where this group can come together, to overcome the challenges posed.

For more information, including full program and event details, head to www.informa.com.au/ SCADAconference.

SCADAd Telemetryd IPWand DNP3bbbbb

We have the people with the experience you need to make it work on time and on budgetb

For over 26 years Cromarty has leveraged its intelligence to provide solutions in the areas of automation and controlz including instrumentationz electrical engineering and industrial information management. We have a staff of around 80z with offices in Melbournez Brisbanez Launcestonz Hobart and Devonport. Our SCADA and Telemetry solutions range from providing a simple single measurement to highly complex integrated automationz data visualization and reporting systems. At Cromarty we maintain and grow our relationships with our customers through best practicez technical expertisez ethical values and flexible solutions. We always offer a fair price for a great resultz and we want to be your go-to SCADA and Telemetry company.

SCADA & IT wwwbcromartybcombau LAUNCESTON DEVONPORT HOBART Operating since 1988 1300 365 136

25

THE LOST TRIBAL WIS RELEARNING

26 SCADA & IT

by Andrew West

DOM OF SCADA

As technology rapidly advances, SCADA and other data management systems are continuing to evolve to meet the needs of a modern utility sector. SCADA communications expert Andrew West provides his take on the current market for control systems, and provides insight into the road ahead for these technologies.

Most people reading this probably already have some idea about the differences between various kinds of control systems and system elements, such as distributed control systems (DCS), supervisory control and data acquisition (SCADA), programmable automatic controllers (PAC) and programmable logic controllers (PLC). But to others, those distinctions are not so clear.

For example: politicians and the journalists of the popular press have been trained to think of SCADA as being a general term for any kind of industrial control system (ICS). And even amongst engineers and technicians, the term SCADA means different things to different people. For some

it is the computer that sits on the factory manager’s desk and tells him how many widgets his plant made today. A more sophisticated version might also report other key performance indicators such as the cost to make each widget, and how this is affected by various factors.

Some will see SCADA as part of the factory automation system that lets the operators view and modify process parameters. Others will use the term to describe all the components of a network that monitor and operate a nationwide system such as the power grid, or a gas pipeline or a water or wastewater utility. Even within these groupings, each industry has its own unique requirements that

27

SCADA & IT

drive subtle (and sometimes not-sosubtle) distinctions in the systems that are designed to serve those requirements.

Each point of view is valid, and different. Whatever we think of as SCADA, that’s what it is. When we discuss our systems, it often happens that we use the same terms to describe different kinds of systems and functionalities, with the result that we often misunderstand each other.

Any conversation about SCADA should consider the distinguishing features that various products and systems have to offer. Don’t assume that any particular product or system supports the same requirements or offers the same functionality that may be familiar from your own work. SCADA systems span an enormous range of capabilities and have evolved to meet the distinct requirements of many different industries. Systems that are suitable for one application might not suit another, or they may provide the required functionality, but be unacceptably expensive. The nuances are sometimes subtle. It is rarely a case of one-size-fits-all. Vendors and end users should continue to remind themselves of this.

The history and evolution of various SCADA products is usually determined by their target application. Many master station devices that began as small factory automation human machine interfaces have grown into systems that are capable of supporting many

thousands of variables. The larger systems that managed large distributed networks have also become more powerful.

Nonetheless, many SCADA master stations are still compute-bound: SCADA is one of the few areas of computing technology where state-ofthe-art systems are still often limited by the performance of the hardware platforms on which they run.

The remote terminal units (RTU) of yesterday are now typically highlycapable devices that support multiple communication interfaces, perform automation processes and support distributed inputs and outputs. Many vendors now give their products different names in order to differentiate their perception of the device capability from the ‘data multiplexer’ that was the traditional RTU. Even so, as long as there is a need to monitor signals and control processes via a remote communication link, there will continue to be a device that does the job of an RTU, even if it is given a different name.

STANDARDS IN SCADA

The specific needs of SCADA systems have spurred the development of specific standards suited to the needs of those systems. Some of these are communication protocols (IEC 60870 and IEEE 1815 (DNP3) for example); some are in middleware and data modelling areas (CIM, IEC 61850 and OPC). Each meets specific needs and usually does not serve well in

applications far from its original targets.

SCADA depends on communication systems, and this is an area where standardisation is well established (e.g. interfaces), but evolution is causing rapid change, especially in areas of wireless technologies and broadband ethernetbased systems. Many of these changes are driven by the economics of internet adoption and mobile phone use, not the needs of critical infrastructure operators; so it is little wonder these technologies do not always suit the needs of SCADA.

Even for experienced professionals it takes considerable time and effort to learn the intricacies of different standards and products in order to make good design and implementation decisions. New factors such as cybersecurity continually bring change to the landscape; and this in particular will drive changes to traditional SCADA system maintenance and lifetime planning. There is no single solution or technology that seems to suit every application, although some seem to have wider utility than others.

BLURRED LINES

In the same way that there are a range of requirements and interpretations that fall under the umbrella of SCADA, the differences between SCADA and other kinds of control systems are often blurred. Specialist knowledge is needed to do SCADA well, and typically this is only found in companies that focus solely on SCADA.

For many years, SCADA products have been undervalued relative to equivalent control products from other areas. In this environment of low profit margins, little capital is available for ongoing product development. This has led to a decline in product quality and the demise of a number of vendor companies. Some other vendors have been subsumed into larger conglomerates. There is a tendency for design and manufacturing to be moved to low-cost countries with an attendant loss of expert domain knowledge.

Large companies that have SCADA as a small part of their portfolio typically do not appreciate the distinctive

28 SCADA & IT

nature of SCADA and merge SCADA into their mainstream product suite, almost invariably leading to a loss of functionality. There are a number of well-known control system companies that have products called RTUs that are just PLCs and have products labelled SCADA that are just DCS systems with some communication driver software. These products may be suitable for some applications, but many of them cannot provide the functionality that was, for example, commonly found in power industry SCADA in the 1980s and 1990s.

LEGISLATION AND TECHNOLOGY

The introduction of Restriction of Hazardous Substances Directive (RoHS) legislation in Europe has caused a shift in the materials used for electronic manufacturing. Nominally, control system devices are exempt from this legislation; but, practically, it is uneconomical to continue to use

RoHS-compliant products tend to have lower reliability and shorter service lives than products assembled from traditional materials. Systems installed today typically have orders-ofmagnitude more complexity than similar systems they are replacing. Sometimes this extra complexity arises from provision of additional functionality; sometimes it arises from the migration of hardware-based architectures to designs that are largely based on software. The 20 to 30-year ‘install and forget’ service lives typical of products produced in the last millennium are unlikely to be achieved today. Many end users have noted the decline in product quality in recent years that can be attributed to these kinds of changes.

MAKING SCADA SEXY

For the foreseeable future, systems will still need careful design and engineering in order to achieve reliable economic operation. Products

carefully. A knowledgeable user knows their system’s requirements and should specify the functionality they need – preferably in terms of outcomes rather than how they think it should be designed!

The future for the industry holds promise. The adoption of standards will assist the integration of a wider range of products and features. The new development centres are relearning the lost tribal wisdom of SCADA. Multinational conglomerates are learning that they need to make allowance for the special needs of SCADA systems. End users have realised that they cannot continue to de-skill and rely on outside suppliers to ‘own’ the design of their systems. Users and vendors have realised that many of their system experts are approaching retirement, and so are now introducing programs to induct a new cohort of engineers and technicians. The challenge will be to make control systems sexy enough to

29

SCADA & IT

IMPROVED CONNECTION, INCREASED CAPABILITY

When looking to improve the capabilities of its staff in the field, Tasmania’s Aurora Energy turned to Motion Computing for a proven, tablet-based solution.

Aurora Energy is a fully integrated energy and network business with complementary activities in telecommunications and energy-related technologies. With much of its business processes consisting of fieldwork including meter reading, pole and asset inspection and outage response, Aurora Energy was familiar with mobile computers, having used them in the field for some time.

However, due to the age of its mobile computers, Aurora re-evaluated its requirements in consideration of a bulk replacement strategy. Further, Aurora needed a platform to support its ‘Turn up once’ strategy.

Aurora’s field workforce is becoming more multi-skilled as demonstrated by ‘Turn up once’, and needed to be supported by technology solutions in alignment. As such, the utilisation of a feature rich mobile computing platform with an easy-touse, fully integrated set of features was critical.

Key requirements included:

• All aspect high visibility screen;

• Fast boot times;

• Camera;

• Barcode scanner;

• Increased durability for outdoor environment;

• SOE friendly;

• Easy to use form-factor.

Further, Aurora needed real-time access to back office asset information and intelligence in order to operate effectively and efficiently and was limited in its choices of a rugged mobility solution, due to the legacy of Windows-based applications that the business uses on a day-to-day basis.

THE MOTION SOLUTION

After investigating available tablets, Motion Computing was selected because of what it offered as a whole package – namely a rugged format, ease of use, weight, screen viewability and Windows compatibility.

Motion Computing’s sales partner to Aurora Energy, Intuit Technologies, then sourced the tablets and has worked with Aurora Energy’s Business Analyst Pat Luttrell, to integrate Motion F5 tablets into the business processes.

“Intuit Technologies continues to support our rollouts and provide ongoing assistance with the purchase of hardware

and accessories. We are currently working closely with Intuit to ensure that our fleet of Motion tablets is further leveraged and utilised in the business,” said Ms Luttrell.

“The capabilities of the Motion solution cater to Aurora’s needs, namely the ability to support more than 20 specialised applications used by the client,” said Intuit’s Nicola Cox.

“We were looking to give our field crews the ability to stay connected while out in the field, allowing them to readily access information and make informed decisions on the spot,” said Ms Luttrell.

“And the screen quality is also a major improvement, with the ‘view anywhere’ screen providing a display that is clear and crisp. It is easy to view in direct sunlight which is critical for our field crews,” she added.

“Beyond this, the ‘on-board’ camera is being used to capture images of faults and issues out in the field, with images being redlined/annotated and then sent back to the office for other staff to investigate. We are also looking into the use of the on-board GPS unit to geocode our photos,” she said.

With hardware characteristics specifically designed for durability in adverse environments, the tablet’s integrated handle makes it easy for field workers to carry; and its outdoor screen eliminates any worries about the sun’s glare impacting screen visibility.

THE RESULTS

The deployment of Motion’s F5 tablets has directly improved Aurora Energy’s productivity and has reduced penalty payouts due to jobs being dispatched and received without delay. This is via the direct connectivity with the network allowing for access to information whilst in remote sites, consequently saving on travel time and reducing site revisits.

“Motion tablets have allowed our staff to remain connected with the network, allowing for work packs to be sent and received immediately,” said Ms Luttrell. “The business can access the tablets while they are out in the field, allowing for updates and support to be performed remotely, eliminating the need for the tablet to return to base.”

30

SCADA & IT

Empower

Mobility tools from Motion Computing® extend productivity in the field for Work Order Automation, Inspections, or Inventory/Asset Management. Motion delivers rugged mobile Tablet PCs, carrying devices, in-vehicle solutions, connectivity and expertise to streamline field operations and save money.

With over a decade of experience in enabling computing while walking, standing, or in a vehicle, we have the expertise to get you up and running quickly and efficiently. Motion® has the tools mobile utility workers need to do the job anytime, anywhere.

With over a decade of experience in enabling computing while walking, standing, or in a vehicle, we have the expertise to get you up and running quickly and efficiently. Motion® has the tools mobile utility workers need to do the job anytime, anywhere.

www.MotionComputing.com I Info@MotionComputing.com I 1-866-MTABLET © 2014 Motion Computing, Inc. All rights reserved. Motion Computing and Motion are registered

of Motion Computing,

in the United States and/or other countries. Intel, the Intel logo, Centrino, Intel Core, Core inside and Atom are

or registered trademarks of Intel Corporation or its subsidiaries in the United States and other countries. All other

and registered

are the property of their respective owners.

MA k E M o BILE

wh E r E work MATTE rs

trademarks

Inc.

trademarks

trademarks

trademarks

Mobility tools from Motion Computing® extend productivity in the field for Work Order Automation, Inspections, or Inventory/Asset Management. Motion delivers rugged mobile Tablet PCs, carrying devices, in-vehicle solutions, connectivity and expertise to streamline field operations and save money. Empower your Field Workforce

work,

MAKE MOBILE WORK, WHERE WORK MATTERS

Motion Tablet PCs are powered by Intel® Core™ Processor Technology and Microsoft® Windows®

your Field Workforce

© 2014 Motion Computing, Inc. All rights reserved. Motion Computing and Motion are registered trademarks of Motion Computing, Inc. in the United States and/or other countries. Intel, the Intel logo, Centrino, Intel Core, Core inside and Atom are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United States and other countries. All other trademarks and registered trademarks are the property of their respective owners. Motion Tablet PCs are powered by Intel® Core™ Processor Technology and Microsoft® Windows® www.MotionComputing.com.au I Sales@MotionComputing.com.au I 1300 654 978

SECRETS OF GOOD COMMUNICATION

Gencom is the largest supplier of two-way communications solutions in NSW, employing over 50 staff and currently providing sales, service and engineering support for many radio communications and paging networks throughout NSW.

Gencom Two Way Radio began as a Newcastle-based company established in 1981 to provide a diverse range of radio communications products to government, mining, commerce and industry. Since that time, the company has experienced strong and sustained growth, with the acquisition of a number of companies and expansion.

Gencom acts as the prime delivery conduit for many large projects in the areas of coal seam gas, transport, power generation, electricity, water and gas, with local installation and support being provided by both Gencom and our local dealers where appropriate.

Gencom also offers the full range of data radio services to complement offerings in the voice radio market. Data radio services include point-to-point microwave links and SCADA radios. Gencom has significant expertise in telemetry and SCADA, wireless IP data, biometrics, collision avoidance, fatigue management solutions and alarm escalation solutions to provide a comprehensive suite of capabilities well beyond the traditional two way radio voice communications portfolio.

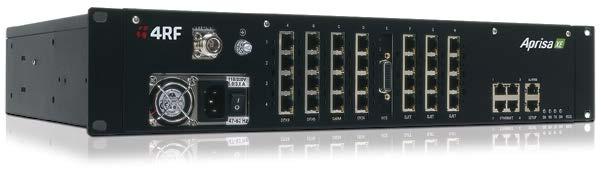

Gencom is the premium distributor for 4RF in Australia and has staff trained in the sales, installation, maintenance and operation of these advanced SCADA radios.

ABOUT 4RF

4RF are experts in radio communications and the organisation was founded in 1998 by industry experts with many years of experience in the telecommunications and microwave radio industry. 4RF is a global company

with customers in more than 130 countries, across multiple industries.

Design and manufacturing is based at 4RF’s headquarters in New Zealand, while sales, customer service and marketing are based in various parts of the world to meet the needs of our customers.

This allows 4RF to deliver an extreme focus on quality, resulting in technology and products that are renowned worldwide, backed up by unrivalled customer service and support, with local support delivered by Gencom in Australia.

WHY IS 4RF TECHNOLOGY SPECIAL?

4RF products are unique because they perform best in the real world, with reliability and cost effectiveness. Every element in the 4RF design is optimised for maximum performance, and rigorous attention to detail ensures that industryleading reliability is part of any Gencom and 4RF critical communications solution.

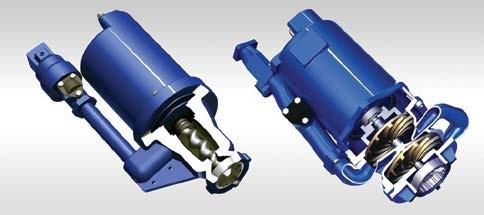

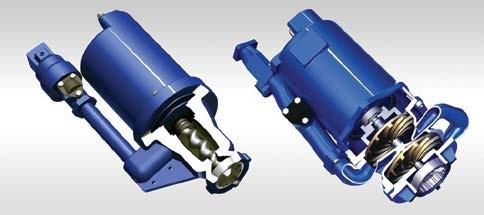

4RF’S PRODUCT PORTFOLIO

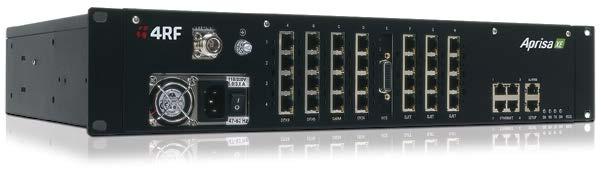

The Aprisa XE is a point-to-point wireless link that can reach up to 250km in a single hop, delivering carrier-class capacity of up to 65Mbit/s. It is available in a wide range of frequency bands from 300MHz to 2.5GHz, with channel sizes ranging from 25kHz to 14MHz, for maximum deployment flexibility. Its modular construction supports a range of easily configurable analogue and digital interface cards: E1/T1, 2 and 4-wire analogue, multiple data options and 10/100 Base-T Ethernet.

The Aprisa FE, SR and SR+ radios are point-to-multipoint radios for monitoring and control communications. Available in 136 and 174MHz and 400 to 470MHz licensed bands, it supports both serial and IP/Ethernet traffic, supporting a seamless transition from legacy communications to an IP-based world. Along with its superior RF for maximum traffic efficiency, the Aprisa FE, SR and SR+ embody industryleading cyber security measures.

32

APRISA FE PRODUCT

Partner solutions SCADA & IT

APRISA XE PRODUCT

A NEW STANDARD

ASSET MANAGEMENT IN

34 ASSET MANAGEMENT

STANDARD

ASSET MANAGEMENT

by Danielle Roche

by Danielle Roche

After almost five years of development, a new international standard for asset management has been released, providing a mechanism to deal with a number of the challenges facing utilities in Australia today.