Engineering, Construction & Maintenance www.utilitymagazine.com.au Issue #21, February 2019 WATER SEWER ELECTRICITY GAS

ON THE DIGITAL TRANSFORMATION

TURNING

TAP A BIRD’S-EYE VIEW: HOW SEQWATER IS LEVERAGING DRONE TECHNOLOGY MANAGING BUSHFIRE RISKS WITH GEOSPATIAL ANALYSIS

THE ROCK DRILL FOR A RANGE OF CONDITIONS

The new D40x55DR S3 Navigator® horizontal directional drill helps deliver excellent productivity in a broad range of conditions, from hard, medium and soft rock to loamy dirt and clay. Dual rod technology delivers powerful down-hole cutting action and the flexibility to select the right tooling to match ground conditions. Help maximize jobsite productivity with multiple rod options, 40,000 lb (177.9 kN) of thrust and pullback and 5500 ft-lb (7457 Nm) of rotational torque. Demo it and experience the difference

TO

NEW D40X55DR S3 READY / VermeerAustralia VERMEER.COM.AU | 1300 VERMEER Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the United States and /or other countries. © 2019 Vermeer Equipment Holdings Pty Ltd. All Rights Reserved. Overseas model shown.

ROCK THE

AFROM THE EDITOR

ustralia’s future energy system, like many others around the world, is expected to look very different to the one currently in place.

This transformation is being driven not just by energy policy, but by broader trends in technology and digitisation, as well as consumer desire for security and lower costs of living.

To help drive this change, a WA Economics and Industry Standing Committee has been formed to investigate and report on the emergence and impact of microgrids and associated technologies, in both metropolitan and regional WA.

The committee is expected to report on the potential for microgrids (and associated technologies) to contribute to the provision of affordable, secure, reliable and sustainable energy supply and is due to table its findings by 28 March 2019.

Deloitte’s 2017 Innovation in Electricity Networks report recognised the state’s two network operators (Western Power and Horizon Power) as leaders in electricity network innovation.

In this edition of Utility, we have a piece from Horizon Power’s Technical Visionary, David Edwards, discussing the utility’s deployment of Australia’s first fully fledged Distributed Energy Resource Management System (DERMS) into three of its 38 regional microgrids, as it begins the next phase of its evolution as a manager of Advanced Microgrids.

Horizon Power isn’t the only utility embracing technological innovation either. Evoenergy, which operates and maintains the ACT electricity and gas network, is undertaking a Gas-Plus Smart Home Trial, which will gather gas consumption data from a number of different household appliances, and information on the home’s external and internal climate condition.

This trial highlights forward-thinking, change-embracing and innovative new systems for the collection of previously unseen data. Big data is one of the

major features in this edition of Utility, and in addition to Evoenergy’s exciting project, we also have an excellent article from Accenture on how data is key to winning over tech-savvy consumers who are demanding faster and more personalised services.

From a water perspective, South East Queensland bulk water provider, Seqwater, is discovering the benefits of drone technology, particularly in assisting with asset and water catchment management. Sydney Water also outlines the different technologies it is using to manage its networks, including artificial intelligence and advanced robotics.

Emerging technologies are one of the themes of our upcoming event, Digital Utilities 2019 , which is being held from 21-22 March in Melbourne.

The full program is now available and features a range of thought-leading presentations from some of Australia’s most innovative water and energy companies. The four targeted streams will provide opportunities for interesting and lively discussion around the key challenges and solutions related to digitisation, with some of the most respected figures in the industry sharing their insights.

Many utilities see the digital revolution as a threat to their business model, but massive opportunities await those ready for transformation, such as improved efficiency, lower costs and a more satisfied customer base.

At Digital Utilities 2019 , delegates will hear from the industry’s leaders — those who are taking the action required to turn their organisations into modern, dynamic utilities, equipped to provide customers with the services they expect, at the times they demand and at a price they are prepared to pay.

I look forward to seeing you at the event and celebrating the winners of the 2019 Digital Utility Awards together.

UTILITY • FEBRUARY 2019 February 2019

welcome

Charlotte Pordage

Published by Cover image highlights our feature on drones. Monkey Media Enterprises ABN: 36 426 734 954 PO Box 1763 Preston South VIC 3072 P: (03) 9988 4950 monkeymedia.com.au info@monkeymedia.com.au utilitymagazine.com.au info@utilitymagazine.com.au ISSN: 2203-2797 Engineering, Construction & Maintenance WATER SEWER ELECTRICITY GAS TURNING ON THE DIGITAL TRANSFORMATION TAP A BIRD’S-EYE VIEW: HOW SEQWATER IS LEVERAGING DRONE TECHNOLOGY MANAGING BUSHFIRE RISKS WITH GEOSPATIAL ANALYSIS 8,138 1 April – 30 September 2018 Editor Charlotte Pordage Assistant Editor Lauren 'LJ' Butler Journalists Elisa Iannunzio Daniel Johnson Senior Designer Alejandro Molano Designer Aileen Ng Business Development Manager Rima Munafo Marketing Assistant Helena Brace Melissa Charalambous Publisher Chris Bland Managing Editor Laura Harvey Operations Manager Kirsty Hutton Digital Marketing Manager

Penny

Editor

Sam

It’s the little things that Total Drain Cleaning S ervices does, that make the big things possible.

Drain and Pipe Cleaning with Vacuum Recovery and Wastewater Recycling

Vacuum Loading

Non Destructive Digging

Sewer and Stormwater Management

CCTV Pipeline Inspection

In Pipe Localised Patching, Robotics and Repairs

Clean up of Environmental Spills

Confined Space Entry

CULVERT CLEANING/WASTE WATER RECYCLING

GROSS POLLUTANT TRAP CLEANING

STRUCTURAL LOCALISED PATCHING

ROBOTICS AND REPAIRS

TANK CLEANING/WATER BLASTING

NON DESTRUCTIVE DIGGING

Total Drain Cleaning Services Pty Ltd

email: info@totaldraincleaning.com.au

phone: 1300 330 294

www.totaldraincleaning.com.au

CCTV PIPELINE INSPECTION

4 CONTENTS UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU 28 40 Australian energy providers get personal – data as a key enabler for customer experience ............ 20 Reading between the lines of largescale data 24 Boosting quality and productivity through digitisation 25 Data heating up opportunities for gas efficiency 26 SYDNEY WATER DISTRIBUTED GENERATION DRONES Technologies that are changing the way Sydney Water manages its networks ...................................... 46 DAMS The drought management measures stabilising NSW water supplies 62 Future-proofing dams for drought ................................... 64 Building a culture of security resilience 28 54 SWITCHGEAR Keeping the lights on for half a million Australians 40 Prevent your switchgear from overheating 42 SEWER REHABILITATION Co-digestion: the importance of pre-screening 52 Slip lining success for Williamstown main sewer 54 Effective planning key to successful sewer renewal 56 Instant seal achieved with the Link-Seal system exceeding all expectations 58 Overcoming tough conditions with groundbreaking technology ............ 60 Distributed Energy Resources lifting Australia closer to a cleaner, fairer and more efficient energy future 36 Working at height: aerial asset management in the water industry ....................................... 32 62 BIG DATA CYBER SECURITY 20 INTERVIEW Yarra Valley Water’s women in STEM 66

February 2019 ISSUE 21 5 UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU SOLAR 88 76 In each issue Welcome from the Editor ..................................................................................................................... 1 A word from Energy Networks Australia ........................................................................................... 6 A word from WSAA ............................................................................................................................... 8 News briefs .......................................................................................................................................... 10 Advertisers’ index .............................................................................................................................. 92 Editorial schedule .............................................................................................................................. 92 PUMPS, VALVES AND FILTERS Why wet prime pumps work 90 Harnessing solar energy to create clean fuels 70 Managing high PV generation ... 72 EMBEDDED NETWORKS Busting the biggest myths around embedded networks 74 MAPPING, GIS & SURVEYING Using geospatial analysis to mitigate bushfire risks 76 Protecting Melbourne waters from pathogens 80 Monitoring global water quality.. 82 UTILITY LOCATION The autonomous pipe and cable locator: are we there yet? 84 What lies beneath: updating AS 5488 86 Safety and productivity drive vacuum excavation solutions ... 88 70 91 The utility industry is regularly required to call on an enormous and varied range of specialists; from mapping, to drilling, to wastewater treatment, to asset management, to pipe relining, to pipeline integrity, to land access, to risk management, and the list goes on. To make the process a little easier, Utility is bringing together experts from various fields to answer your questions.

A WORD FROM ENERGY NETWORKS AUSTRALIA

ANDREW DILLON CHIEF EXECUTIVE OFFICER – ENERGY NETWORKS AUSTRALIA

The rise of solar PV in Australia has been blamed for high electricity voltage levels. While high penetration of solar does present challenges for networks, it is certainly not the only issue.

Voltage is a bit like pressure in a water pipe. It’s not surprising that voltage/pressure varies across different parts of the network, as the voltage at an individual house depends on its distance from the distribution substation or pole top transformer. Customers close to the substation or transformer will be supplied with voltages at the higher end of the allowable range to ensure customers further away can be supplied with voltage above the minimum allowed voltage — especially at peak times.

THE CHALLENGE OF SOLAR FOR NETWORKS

It is a priority for networks to keep pace with the increasing numbers of solar homeowners wanting to connect and export surplus energy back into the grid, but some of these customers occasionally find their inverters cut out due to higher voltages. Networks are being asked to rectify the situation, but it is difficult to manage the voltage variations caused by solar PV exports and at the same time cater for high demand at non-export peak times.

In locations where solar PV penetration levels are high, careful planning is undertaken and every connection request is carefully considered to take into account current network capacity limitations. In a small number of cases, limit exports on customer inverters are needed to ensure voltage variation remains within regulatory limits (i.e. 230V with allowances for an additional ten per cent and a reduction of six per cent).

To complicate matters further, some solar installations are exporting more than their inverter size (without agreement), which increases voltage rise within the network. There are also many thousands of solar PV connections that were installed before smart inverters were mandated, and therefore do not comply with the current Australian Standard AS 4777.

HOW ARE NETWORKS DEALING WITH EXCESS SOLAR PENETRATION?

When total customer capacity requirements on any particular feeder exceed the limit of the transformer, the traditional solution has been to upgrade the transformer. However, as we confront increasing solar PV connections across the system, this is an unacceptably costly solution

that is ultimately paid for by all customers, not just those with renewables connecting to the grid.

Smarter solutions are required, and the options include:

• Managing export limits – undertaking voltage impact assessments as part of the application process. In a small number of cases, limit exports are placed on customer inverters

• Network sensing and monitoring – networks have been applying to the Australian Energy Regulator to obtain approval to fund technology investment to provide better visibility of the distribution system, and tools that would make it easier for customers to export solar and use batteries, removing constraints where possible. This includes the possible installation of extra voltage controllers, sensors and systems to forecast and manage the low voltage network

• Smart meters – smart meters allow networks to build an analytics platform to investigate and respond to supply quality issues that may be caused by high penetration of solar on the low voltage network. While already rolled out to Victorians, accelerated roll out is needed in other jurisdictions

• Innovation – networks are undertaking a number of initiatives to better understand and plan for the expected growth in penetration of solar PV in the future using analytics, trials and smart inverters

• Forecasting and planning – networks conduct regular assessments to forecast potential growth of solar systems in certain locations and plan accordingly

• Voltage management – in areas where networks have identified voltage issues related to high penetration of solar PVs, networks try to adjust their voltage settings as much as currently practicable to manage the issue and enable the absorption of greater amounts of solar capacity

To better manage these voltage issues and integrate increasing levels of solar and storage into the system, Energy Networks Australia and the Australian Energy Market Operator (AEMO) are redesigning the management of distributed energy resources through the Open Energy Networks project. We look forward to sharing more information on this throughout 2019.

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU 6

P (08) 9725 4678 sales@kwikzip.com Contact us today to order Also available for order through Reece Civil stores. Is your pipe spacer compliant? KWIK-ZIP’S HDX SERIES CASING SPACERS COMPLY WITH WSAA PRODUCT SPEC #324 – CASING SPACERS; REFER WSAA PRODUCT APPRAISAL REPORT #1523 www.kwikzip.com

A WORD FROM WSAA

In early 2018, I visited New Zealand to discuss the WSAA submission to the New Zealand Department of Internal Affairs for its reform program — Three Waters Review. After working through some of the usual issues with Colin Crampton, who leads Wellington Water in the ‘coolest little capital’ in the world, Colin leant back in his chair and said, “Well, you know there’s something bigger, something more important than customer first.” Colin went on to talk to us about:

Te mana, e te mouri, o te wai

I’m hoping to give this statement justice, but it sums up the existential powerfulness and spirituality of water to the Maori people. Ki uta ki tai: from the mountains to the sea, the unbroken water cycle, a catchment-based approach that over the years we have ‘adjusted’ from a Western perspective. Colin is deeply passionate that the reform program in New Zealand captures these core Maori beliefs in their water planning and delivery.

This is a segue into a confronting and powerful trip I made to the Northern Territory for the opening of a new water treatment facility at Borroloola. The town of Borroloola, located on the McArthur River, about 1000km from Darwin near the Gulf of Carpentaria, has a population of around 1000 people. During the wet season it can be cut off from land access for many weeks at a time. The bore field raw water available has a low pH (around 4) and high dissolved CO2, terrible to treat

and terrible for pipes.

Power and Water Corporation has been working over an extended period of time to upgrade the water quality delivered to the town. It commissioned Suez to design and construct a compact water treatment facility resilient to the ravages of the brutal climate up there. Suez did a fantastic job designing the facility, building it in Darwin, semi-commissioning the plant, taking it apart again, and transporting it to Borroloola and reassembling on site.

What impressed me the most was the engagement program Power and Water Corporation pulled together, particularly with the local school. The project manager, Eric Vanweydeveld, spent at least 18 months talking to the school and the local community about the water quality issues and ways in which the community would view the facility as part of the ‘infrastructure’ of the town, something to protect.

Eric was recently awarded Gold in the Young Project Manager of the Year Awards. What he and Power and Water Corporation have delivered is very powerful — the water treatment kit is literally covered in artwork the local kids completed at school. The artwork mostly depicts water life from the local McArthur River. Given the site is unmanned for long periods of time, and with 13 months of no vandalism, it’s been a tremendous start.

Michael Thomson, Managing Director of Power and Water Corporation, is keen to see similar models of engagement rolled out across the many other remote indigenous communities it services (together with the Department of Housing). It was a valuable visit, the kids were super excited with yo-yos, handballs, water bottles and a quick site tour, which sadly contrasted against a population with large rates of suicide and unemployment.

The local Mabunji Aboriginal Resource Indigenous Corporation has just constructed a new crèche and other vital works around the town, services that support and add to the water treatment facility to help uplift

the health of the local community. As Maria, the local indigenous school teacher (beaming with pride as she wandered around looking at the artwork), said, “It’s one less thing to worry about, one more thing to be happy about.”

The WSAA Liveable Communities Committee has been looking closely at remote and indigenous services and we are very pleased to be partnering with University of Queensland, Griffith University and the Institute of Sustainable Future to scope out remote indigenous community needs for water and sanitation through a lens of values and equity. All of these partners have been involved in the past in co-designing water programs with indigenous communities to deliver services that make a tangible difference to the health and wellbeing of these communities.

This leads us to the United Nations Sustainable Development Goals and the commitment many WSAA members have made to achieving Goal six: Clean water and sanitation by 2030. In conjunction with the Australian Water Association and WaterAid, we are collaborating to make a difference in Australia, New Zealand and in Southeast Asia. I invite anyone to join the journey — as we work together with our indigenous communities here in Australia and embrace our own Te mana, e te mouri, o te wai

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU 8

CHILDREN

TREATMENT

OFFICIAL

AND WATER CORPORATION.

AT THE BORROLOOLA

PLANT

OPENING. POWER

AERIAL PHOTO OF BORROLOOLA TREATMENT PLANT. POWER AND WATER CORPORATION.

WSAA announces ROSS YOUNG SCHOLARSHIP

Following the passing of Ross Young, Water Services Association of Australia’s (WSAA's) Executive Director from 2003-2011, WSAA has established the Ross Young Scholarship for its Young Utility Leaders Program.

The scholarship is a way to ensure the contribution Ross made to WSAA and the broader urban water industry is appropriately remembered. Ross was a thought leader for the national water industry, particularly during the Millennium Drought and also with the advent of the National Water Initiative. He was a passionate supporter of

WSAA members and had one of the quickest wits you would find.

WSAA’s Young Utility Leader Personal Development Program is now in its second year with six candidates currently in positions. The Ross Young Scholarship will be attached to the program and will provide participants with the opportunity to pitch to the WSAA Board on their learnings and how they would invest $5000 for future personal development.

The current six program participants will be the inaugural candidates for the scholarship.

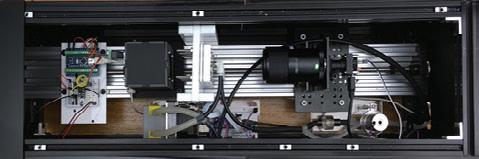

AUSTRALIA’S FIRST 100 PER CENT HYDROGEN

ATEST FACILITY

ustralia’s first test facility to trial 100 per cent hydrogen has been welcomed by the energy industry as it prepares for hydrogen use by appliances and in existing gas distribution networks.

Energy Networks Australia CEO, Andrew Dillon, who spoke at the launch of Evoenergy’s Hydrogen Test Facility in Canberra, said hydrogen offered the prospect of zero-emission energy supplies and energy storage capacity to back up renewable power, utilising existing gas networks.

“Hydrogen is carbon free and can be produced from excess renewable energy, for example during sunny and windy days when generation is high and demand is low,” Mr Dillon said.

“This offers a stable, carbon-free energy resource that can be stored for use on demand.

“We know from our work with the CSIRO on the 2018 National Hydrogen Roadmap that hydrogen represents significant and exciting opportunities for Australia, well beyond its potential as an export fuel.”

Evoenergy and the Canberra Institute of Technology partnered to build the Hydrogen Test Facility to understand how hydrogen gas could be used in the future to power homes using the existing natural gas network.

While many gas networks are embarking on hydrogen-related projects, the Evoenergy Hydrogen Test Facility will be the first in the country to test up to 100 per cent hydrogen in household appliances.

The use of hydrogen as a household energy resource aligns with the ‘green energy’ target set by the ACT Government to reduce emissions to zero by 2045.

The need to reduce carbon dioxide emissions has seen hydrogen plans developed throughout the world.

In Europe particularly, hydrogen is growing as an energy source and as a transport fuel, with the world’s first hydrogen passenger train now operating in Germany.

Hydrogen in Australia could eventually be used for domestic cooking, heating and hot water, for

powering passenger vehicles and even public transport.

“As the Gas Vision 2050 report has demonstrated, hydrogen’s scope is impressive, with potential to widen a customer’s power options, improve and increase renewable generation and even create a new energy export market,” Mr Dillon said.

“Perhaps best of all, the sophisticated, intricate infrastructure needed for hydrogen technology already exists for us in Australia — our natural gas networks.

“Most of Australia’s gas distribution networks are compatible with hydrogen and could deliver better outcomes for Australian households and businesses, the environment and the economy,” Mr Dillon said.

“I congratulate Evoenergy and its partners who are instrumental to the innovation this facility supports.”

10 NEWS UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU

THE FUTURE OF MELBOURNE’S SEWERAGE SYSTEM

Greater Melbourne’s sewerage network, which has been operational for over a century, is set to see sustainable change with the introduction of resource management and recovery to support the city into the future.

The Melbourne Sewerage Strategy — collaboratively developed by Melbourne Water, City West Water, South East Water, Western Water and Yarra Valley Water — highlights the current and future challenges and opportunities for the provision of sewerage services, and outlines how the sewerage system will be managed to enhance its contribution to public health and the environment, and affordable customer services.

Melbourne is facing a number of complex challenges over the next 50 years as population grows, climate

change takes effect and the pace of urban development accelerates. Technology advancements and customer expectations will play an important role in responding to these challenges.

Using an innovative approach, the strategy includes a framework for making ‘best for community’ decisions.

Melbourne Water General Manager, Integrated Planning, Chris Williams, said that the strategy is not an infrastructure plan, rather it provides a framework for the evolution of the features and functions of the sewerage system to serve the coming generations.

“Working together, we can ensure our sewerage system is well positioned to address the challenges and opportunities of the future, remaining a valued community asset that supports

Your business partner for engineering solutions

Since 1998.

“We don’t purely just design; we help our

a prosperous, liveable Melbourne,” Mr Williams said.

“With Melbourne’s population expected to more than double over the next 50 years, we need to think about the legacy we will leave future Melburnians. This strategy provides a roadmap for creating a resilient and adaptable system which will support the needs of a growing and changing community."

The strategy includes ambitious goals to support the 50-year vision for a liveable, thriving Melbourne, and describes the importance of evolving the sewerage system from one that is viewed as a waste disposal system into one which will play a critical role in sustainably managing resources such as nutrients, water and energy.

you give us an idea we can provide a efcient

P E Level 2, Suite 26/20 Enterprise Drive Bundoora Vic 3083 1300 1 L ANCO (52626) tenders@lancogroup com au lancogroup.com.au

customers realize their

Accredited consultant with Melbourne Water, Retail Water Corporations – Metropolitan and Regional Areas Quality ISO 9001 Environment Health & Safety AS 4801 ISO 14001 NEWS 11 UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU

goal, if

and efective engineering solution”

NORTHERN GAS PIPELINE COMPLETE

Jemena’s 622km Northern Gas Pipeline (NGP) has been completed, allowing the transport of gas from Northern Territory gas fields to Mount Isa in north-west Queensland.

The transported gas will be used as a crucial feedstock by local businesses — including Incitec Pivot Limited’s Phosphate Hill and Gibson Island Facilities, as well as mining and other commercial operations throughout Queensland’s north west.

Commercial operations were due to commence between 29 December 2018 and 10 January 2019.

Jemena’s Managing Director, Frank Tudor, said that around 80 per cent of the NGP’s capacity has been contracted; testament to the real need for additional gas across Australia’s east coast.

“Today we have taken a significant

step towards ensuring Australian homes and businesses have the gas they need, when they need it,” said Mr Tudor.

“I commend the Northern Territory Government for commissioning the NGP project in 2015 and am proud that the Territory is now well-placed to become the home of Australia’s gas industry alongside Queensland.

“We know that the Northern Territory has enough gas to meet Australia’s future supply needs for the next 200 years or more, and our pipeline is the crucial missing link that will connect this gas with Australian homes and businesses.”

Mr Tudor said Jemena was welladvanced in planning the expansion and extension of the Northern Gas Pipeline so that it further integrates with the east coast gas market.

“Provided gas is proven as

commercially viable in the Northern Territory, Jemena will be able to increase the NGP’s capacity from around 90TJs a day up to 700TJs a day. To put this in context, this is enough gas to meet the average daily gas needs of Sydney, Brisbane and Adelaide combined.

“The foundations we’ve laid in the Territory mean we will be able to complete this work at an expedited schedule while creating around 4000 jobs and investing approximately $3 to 4 billion.

“This investment is the answer to Australia’s future gas needs.”

KEEPING COSTS DOWN FOR CUSTOMERS

Mr Tudor said the NGP will help to lower gas prices for Australian homes and businesses.

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU 12 NEWS

“Jemena was awarded the right to build, own and operate the NGP following an extremely competitive tender process involving a number of other businesses. The strength of our submission was that it outlined the best — and most efficient — way to bring additional gas to market at the most competitive price for our customers.

“While at this stage the NGP principally supplies industrial customers, Jemena has a strong history of lowering its portion of household gas bills, and in 2018 announced that we were lowering distribution costs across the New South Wales Gas Network for the fifth year in a row.

“We are doing our part to ensure Australians have reliable and affordable energy by building new infrastructure, while also introducing efficiencies into our existing assets so as to continue to place downward pressure on prices.”

SUPPORTING LOCAL COMMUNITIES

As part of Jemena’s Local First policy, around 75 per cent of the more than 1100 jobs which were created throughout the construction, planning and commissioning phases of the NGP were filled by people from the regions surrounding the pipeline route.

Jemena extended this policy to its procurement processes with contracts worth more than $52 million being awarded to local businesses.

“We know when you employ local people and use local companies that the whole community benefits either directly, or from the flow on effects associated with greater

economic activity,” said Mr Tudor.

“Jemena would like to thank the people of the Northern Territory, especially those in the Barkly region, and also the people of the Mount Isa region for their interest in and support of us and the project over the past few years.

“Projects like the NGP are demonstrating the benchstrength of people and businesses from the Barkly and Mount Isa regions. I am very confident that these communities have a promising future as the opportunities associated with Australia’s gas industry continue to bear fruit.”

JEMENA NORTHERN DEVELOPMENT PROGRAM

As the NGP transitions into its operational phase, Jemena will continue to support the communities surrounding the pipeline route through the Jemena Northern Development Program.

“We’re really excited to have been welcomed as a member of the communities surrounding the NGP and are keen to continue to provide either direct financial or in-kind support to businesses and organisations which are making a real difference in regional Australia,” said Mr Tudor.

“As the project moves into its operational phase, we will also leverage the success of the NGP’s development program so we can offer local people an opportunity to participate in training that equips them with the skills they need to get a job either in the oil and gas industry or another industry of their choosing.”

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU

PUMP STATIONS • UP TO 3.6M DIAMETER • ENGINEERED TO 15M DEEP • SUPERIOR INTERNAL FINISH • SINGLE PIECE BASE SECTION • DESIGN AND CONSTRUCTION 02 6128 1000

www.qmaxpumping.com.au NEWS 13

BESPOKE PRECAST CONCRETE

sales@qmaxpumping.com.au

SA WATER'S SMART WATER NETWORK RECEIVES INTERNATIONAL PRIZE

Innovative smart water network technology used by SA Water has been recognised with the 2018 Customer Service Award at the Institute of Asset Management’s global awards in London.

The technology has already prevented around 30 water main breaks or leaks from impacting customers.

Competing with utilities from around the world, SA Water’s smart water network also claimed runner-up in the Project Achievement Award category.

SA Water’s Chief Executive, Roch Cheroux, said he was thrilled the team had been recognised for its pioneering adoption of smart technology for the benefit of customers.

“We are the first water utility in the world to implement a range of Internet of Things-enabled sensors at scale within a defined geographic area, and recognition like this award provides a platform to share the knowledge we’ve built and improve water network management practices,” Mr Cheroux said.

“Awards like this are a credit to our highly capable team, which developed this technology with our customers

in mind, along with smart technology solutions that will continue to expand to other parts of our network across SA.”

Implemented in a $4 million trial across Adelaide’s Central Business District, SA Water’s smart water network combines acoustic sensors, pressure and flow data, high-speed transient pressure sensors, smart meters and water quality sensors to identify potential leaks and trigger intervention before leaks or breaks escalate to impact customers or commuters.

Around 300 smart meters are also being installed at residences and businesses in Penneshaw, with a further 35 pressure sensors, 19 flow meters, 120 acoustic leak detection sensors and two water quality sensors currently rolling out across Athelstone, North Adelaide and Port Lincoln.

Following the success of the technology in its water network, SA Water has now expanded its program to wastewater, with around 185 level sensors, odour detection sensors and weather stations in its wastewater network in Gawler and Stonyfell.

“The combination of technology across both types of network, a

world-leading analytics platform and the expertise of our team will give us a more detailed view of our underground systems and how we can best manage them for the benefit of our customers,” Mr Cheroux said.

The award follows a number of other accolades for SA Water’s smart network in 2018, including two awards at the 2018 Australian Internet of Things Awards, a bronze prize at the International Water Association’s Project Innovation Awards, and title of 2018 Australian Digital Utility of the Year at the Digital Utility Awards.

A SOLAR TRADING TRIAL FOR CUSTOMERS

Anew peer-to-peer renewable energy trading trial in Western Australia is allowing a limited number of households with rooftop solar to trade excess energy with their neighbours.

About 40 residential properties across the City of Fremantle are taking part in the trial, which runs until June 2019.

The trial gives households the flexibility to determine how much they are willing to buy and sell solar energy for, and then make the purchase via a blockchain-enabled platform.

A fixed-use residential tariff and a new billing system has also been developed for the trial, allowing households to engage in discrete, time-based energy transactions.

The RENeW Nexus project is managed through Curtin University and is supported by the Australian Government through the Smart Cities and Suburbs Program.

The RENeW Nexus project includes the following partners: Curtin University, Murdoch University, City of Fremantle, Landcorp, Synergy, Western Power, Water Corporation, Power Ledger,

energyOS, CSIRO/Data 61 and CISCO.

WA State Energy Minister, Ben Wyatt, said, “The trial represents an innovative solution to virtual energy trading that may have implications for energy utilities working to balance energy supply and demand all over the world.

“These households are believed to be the first in the world to be taking part in an active, billed, peer-to-peer trading trial that allows them to effectively buy and sell solar energy generated by their rooftop system across the grid.”

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU

14 NEWS

SERVICE STREAM ACQUIRES COMDAIN INFRASTRUCTURE

Service Stream has entered into a binding agreement to acquire Comdain Infrastructure for $161.7 million.

Comdain Infrastructure is a major provider of integrated asset lifecycle services to Australia’s utility asset owners and operators. It’s a provider of engineering, design and construction, as well as operations and management of gas and water infrastructure services.

As part of the acquisition, Comdain Infrastructure’s Chairman, Tom Coen, has been invited to join the Service Stream Board as Non-Executive Director.

Peter Coen will remain in his role as head of Comdain Infrastructure’s operations to support ongoing growth, success and integration of the business, with Jim Gaha to remain in place as Chief Operations Officer to

support the transaction.

The acquisition is consistent with Service Stream’s strategy of diversifying and increasing annuity-style revenues, leading to a relatively even distribution of group revenues from the utility and telecommunications sectors.

Comdain Infrastructure operates across well-known utility markets and shares a familiar client base with Service Stream. This presents opportunities for expansion across additional areas, growing future service offerings and broadening the scope of works to cover other utility networks.

An integration plan has been designed to manage the transition and support the continued growth of Comdain Infrastructure, leveraging the learnings from the recent TechSafe integration process.

PLS-CADD

Design

Conductor

Underground

Fibre

Transformer

Testing

At the time of going to print, the acquisition had an expected completion date of either 2 January 2019, or 1 February 2019, upon satisfaction of conditions. Transaction costs of up to $2 million were expected to be incurred by Service Stream.

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU

NEWS 15

Lattice Towers

Steel Poles

powerline profiling

and install foundations

and

stringing

OPGW

cable

installation

optic cable installation

compounds

and commissioning WWW.FUTUREAU.COM.AU SALES@FUTUREAU.COM.AU +61 8 9417 4999

RECOGNISING THE BEST IN

ENERGY NETWORKS

REPRESENTATIVES FROM ESSENTIAL ENERGY

ACCEPT THE CUSTOMER ENGAGEMENT AWARD FROM ROSEMARY SINCLAIR.

Every year this gathering of network professionals is facilitated by Energy Networks Australia, the association representing and advocating for network businesses. The gathering takes place in the form of an Annual Dinner and Awards evening, last year staged in Canberra in November at the truly impressive and humbling Australian War Memorial.

The evening is a chance to gather and reflect on the year that was, network with colleagues, and make new industry connections.

But most importantly it’s a chance to acknowledge the incredible work that is happening right across the network industry. In total, three awards were handed out — recognising innovation in the sector, outstanding customer engagement and individual industry contribution.

In 2018, the awards were attended by Federal Energy Minister, Angus Taylor, along with a host of senior executives working for networks business around Australia.

RECOGNISING INNOVATION: THE KEY TO INDUSTRY GROWTH

Four finalists were recognised in the Innovation category:

• Essential Energy, for its Quality Assurance Lab

The critical role of energy networks in the lives of every Australian cannot be understated; and yet sometimes, outside the industry, it’s a case of out of sight, out of mind. For this reason, it’s so important that representatives from Australia’s energy network businesses gather each year to refect on the work they do, share their stories and recognise some of the industry’s best people and projects.

• Evoenergy, for its demand reduction program, incorporating the ACT Virtual Power Plant

• Jemena, for its demand response trial Power Chargers

• TasNetworks, for the CONSORT Bruny Island Battery Trial

After reviewing all of the projects, the judging panel deemed TasNetworks to be the winner of the Innovation Award for 2018. The trial helped 34 customers install solar generation and a battery on their homes to test the ability of distributed generation to be an alternative to a diesel generator during periods of peak holiday demand.

JENNIFER HARRIS FROM POWERLINK

ACCEPTS THE INDUSTRY CONTRIBUTION

AWARD FROM BEN WILSON FROM AUSTRALIAN GAS NETWORKS.

“The trial has shown how a modest number of residential PV and battery systems are able to provide a disproportionately large benefit to the grid,” said Energy Networks Australia Chief Executive Officer, Andrew Dillon. “Diesel usage is down by about 30 per cent, but more generally, the project delivers optimisation of distributed energy resources, which increases grid reliability."

TasNetworks Chief Executive Officer, Lance Balcombe said, “This project has demonstrated innovation across many facets of the energy sector. “It is a key step in our vision to be

ATTENDEES FROM A SESSION OF ESSENTIAL ENERGY’S AWARD-WINNING CUSTOMER AND STAKEHOLDER ENGAGEMENT PROGRAM.

NEWS 16 UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU

trusted by our customers to deliver today and create a better tomorrow.”

According to TasNetworks, customers were the key to the success of this solution. The project was founded on customer behaviour, which has been central to the project’s design and implementation.

In particular the concept of customer choice, overlaid with the technical requirements to manage a network problem, are embodied in the Network Aware Coordination (NAC) algorithm. This algorithm works in conjunction with the Reposit system to automatically and optimally coordinate the large number of batteries involved in the project.

The NAC algorithm, while developed prior to Energy Networks Australia’s Open Energy Networks consultation, actually foresaw many of the issues discussed in this paper, and in this way, the CONSORT Bruny Island Battery Trial is a ‘living laboratory’ to test these concepts.

Runner-up for the Industry Innovation Award was Jemena, for its Power Chargers demand response trial.

ENGAGING CUSTOMERS: MISSION CRITICAL

In a time where consumer trust towards the energy industry is lagging, it’s never been more important to actively engage with customers.

Five projects were named as finalists for the Energy Networks Australia and Energy Consumers Australia 2018 Consumer Engagement Award:

• Essential Energy, for its customer engagement regulatory proposal

• SA Power Networks, for its deep dive workshop program regarding its regulatory proposal

• TransGrid, for its Powering Sydney’s Future proposal

• The joint Victorian distribution businesses (CitiPower, Powercor, United Energy, Jemena and AusNet Services), for their joint consultation on Network Pricing Design, under which they committed to a joint approach to pricing for residential and small business customers until at least 2025

• Western Power, for its community

engagement during the evaluation and development of a microgrid for Kalbarri

Energy Consumers Australia CEO, Rosemary Sinclair, said the projects provided a snapshot of an industry sector that was increasingly recognising the value of engaging with consumers as partners to solve big challenges around affordability, trust and transformation.

Ultimately, the unanimous choice of the judging panel for the Consumer Engagement Award was Essential Energy.

Prior to submitting its proposal to the Australian Energy Regulator for building, operating and maintaining the electricity network over the period 2019–2024, and the proposed network charges, Essential Energy conducted an extensive customer and stakeholder engagement program, to share and gather information, insights and feedback and ensure that it could be confident its proposal reflected customer needs and expectations.

The engagement took place in four phases over more than two years, and ultimately delivered a true understanding of the priorities and expectations of customers.

“Rebuilding trust with consumers in the energy sector will take time and must come from the top,” said Ms Sinclair. “The leading businesses are entering into a new dialogue with consumers and taking responsibility for the issues they’re raising to deliver more affordable outcomes.

“Essential Energy showed they had proactively engaged with their consumers to better reflect their views and priorities and allow that to shape services,” she added.

The judges for the consumer engagement award compiled a report after the process and congratulated all businesses who had made an application for the award.

“We congratulate the change-makers — the businesses who have entered this year — and encourage these businesses to continue to be leaders.”

Western Power received a highly commended from the judges for its Kalbarri Microgrid project.

THE PATH FORWARD

The awards evening also provided the opportunity to recognise an individual for their personal, and substantial, contribution to the industry over several years.

In 2018, the Industry Contribution Award went to Powerlink’s General Manager Network Regulation, Jennifer Harris.

“This award recognises Jenny’s significant contribution to our industry and her clear focus on the customer driven transformation of our networks,” said Mr Dillon.

All three award winners gave attendees plenty to think about in terms of their own current and future contributions to the network industry; along with plenty of inspiration for how their businesses might be able to achieve innovation and customer excellence in 2019 and beyond.

17 NEWS UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU

THE TEAM FROM TASNETWORKS ACCEPTING THEIR NETWORK INNOVATION AWARD.

TURNING ON THE DIGITAL TRANSFORMATION TAP FOR UTILITIES

The digitisation of utilities is the greatest challenge currently facing the sector, with much to do to modernise existing networks, work practices and ways of interacting with customers. But it’s also an area of great excitement and opportunity for those utilities willing to be brave, and step boldly into a new paradigm.

Nigel Watson, Group Information Services Director at northern England’s Northumbrian Water, said that digitisation can provide many benefits for utilities, particularly in the areas of improving customer experience and operational resilience.

“We have been very careful to make sure that we complement our knowledge of the network with our machine learning initiatives,” Mr Watson said.

“We’re especially focused on ‘learning’ how to deliver a better and more personalised customer service, and are working hard on enabling greater resilience through better informed and more targeted maintenance and operational regimes.”

According to Mr Watson, utilities who ignore the movement toward digitisation risk missing the chance to eliminate inefficiencies — which can carry both regulatory and operational consequences.

“The regulators are keen to make sure that household bills are affordable,” Mr Watson said.

“I think that most organisations have historically implemented Six Sigma or Lean or some other program that has driven out an amount of inefficiency.

“Tapping into further savings is likely to require more digital customer and employee experiences.”

GETTING SERIOUS ABOUT PUTTING CUSTOMERS FIRST

With an array of new technologies primed to change the way that utilities do business and interact with customers, Wayne Pales, GM Technology Strategy at the Australian

Energy Market Operator (AEMO), believes that current energy operating models will require major revisions to be compatible with the grid of the future.

“The fact that our industry has created the term ‘behind the meter’ shows we have a very long way to go,” Mr Pales said.

“The phrase places the utility at the centre of the universe, with the consumer being ‘behind the meter’.

“The consumer is the centre of the universe, so we need to come up with terms that reflect that we are serious about putting the consumer first.”

An important step towards putting the consumer first is recognising the integral role that consumer-centric technologies, such as distributed energy resources (DER) and the connected home, will play in the grid of the future.

“In parallel to a distributed grid, we have aging power plants scheduled to close, and these closures may be accelerated if future governments get tough on emissions targets,” Mr Pales said.

“Given that the vast majority of people will invest in green technologies if it is financially beneficial for them to do so, tariff structures and demand-side programs are where I would focus my time to get the biggest ‘bang for buck’.”

LEARNING FROM THE INDUSTRY’S BEST

Both of these industry leaders will be speaking at Digital Utilities 2019 , a two-day event that provides delegates with the tools to use digital technologies to accelerate and transform their organisations.

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU

18 NEWS

An effective digital strategy can revolutionise all areas of the utility sector, and embracing new technologies and business models is vital for optimising asset management, improving network operations and keeping up with changing customer demands.

Digital Utilities provides a platform for utility leaders to share and discuss the challenges of digital transformation, and learn from those already seeing the benefits.

The expert speaker lineup features Managing Directors, Chief Information Officers and Heads of Digital at Australia’s major water and energy utilities, as well as digitisation experts and government representatives.

The full program is now available, and day one of the conference will see thought-leading presentations on:

• Becoming the world’s most digital water company

• Demand Response — crossing the chasm from pilots to operations

• Water utilities and emerging technologies: where’s the killer app?

• Lessons learned from large-scale transformation

• Digital transformation — we are doing it wrong

Day two takes this a step further and splits the conference into dedicated streams, so delegates can delve deeper into their chosen area of interest or specialty.

This year’s streams are:

• The connected customer — staying relevant in a changing world

• A new core — unleashing the digital potential in utility operations

• Innovation in electricity networks — building the grid of the future

• The smart water utility — improving water management

These streams will run as moderated panel sessions, with senior industry figures providing delegates with information specific to the digital challenges and solutions for that topic.

The conference is then rounded out with a Super Panel that brings back the speakers from across the two days to summarise some of the key discussions and answer any burning questions from attendees.

Digital Utilities is pleased to announce digital leader Bentley Systems as the Event Partner for 2019. Bentley's infrastructure asset management software is used around the world to aid utility projects, and their in-depth knowledge will be a fantastic resource for attendees.

EXHIBITION AND NETWORKING OPPORTUNITIES

In addition to the conference presentations and panel sessions, the event also features an exhibition where digital and technology related companies will be showcasing the latest innovations in the sector. Delegates will be able to find out about new and emerging technologies, and how to integrate digital solutions within their organisation.

The ability to establish meaningful connections is one of the main drivers behind conference attendance and

Digital Utilities offers access to senior decision makers from water and energy utilities across Australia.

There are multiple speed networking sessions designed to get conversations flowing and guarantee delegates introductions to colleagues within the industry. These formal sessions are in addition to the numerous opportunities to connect with other attendees during the lunches and breaks.

Delegates will also have the chance to mingle with senior leaders and experts from within the utility community at the Digital Utilities gala dinner on Thursday 21 March, where the winners of the 2019 Digital Utility Awards will be announced and celebrated.

The Digital Utility Awards recognise the utility industry’s greatest achievements in the digitisation of utility networks, processes and practices across Australia.

Six awards will be handed out in total, in the following categories:

• Digital Utility of the Year - Energy

• Digital Utility of the Year - Water

• Utility Innovator of the Year

• Young Digital Leader of the Year

• Best Customer Innovation

• Best Use of New Technology

Digital Utilities is hosted by Monkey Media, the publisher of Utility magazine. More than just a magazine, Utility brings the whole industry together through its integrated print, digital and event channels, inspiring utility professionals to learn and grow better together.

The conference programs are put together by Utility’s knowledgeable editorial team with a strong emphasis on providing useful information and creating genuine discussion around topical issues.

Digital Utilities is the premier event for anyone working with or for utilities, and grappling with the momentous impacts digital technologies are having on the industry.

The early bird gets the savings! Register before 18 February and enjoy 20 per cent off regular ticket prices. Visit www.digitalutilities.com.au for more information.

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU

NEWS 19

NIGEL WATSON

WAYNE PALES

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU BIG DATA 20

AUSTRALIAN ENERGY PROVIDERS GET PERSONAL– DATA AS A KEY ENABLER FOR CUSTOMER EXPERIENCE

With energy prices at a historic high, Australian energy retailers have struggled to gain and retain the trust of the consumer; an issue the Australian Government is currently addressing through industry consultation, along with new policy and regulation.

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU BIG DATA 21

Australian energy providers get personal – data as a key enabler for customer experience BIG

The Australian Competition and Consumer Commission’s (ACCC) recent retail electricity inquiry report highlighted the need to enhance the customer experience and lower costs, in a bid to restore consumer confidence.

The reality is customer expectations are shifting, and there is a new ‘normal’ in what is expected from the service provided by energy suppliers. Consumers are balking at one-size-fits-all approaches that create confusion, and increasingly, dissatisfaction. What was once considered an acceptable level of service is rapidly shifting and evolving, which is true for energy retailers and industries beyond.

To transform the customer experience, energy providers must focus not just on touch points but on ‘trust points’. Data is central to winning over tech-savvy consumers who are demanding faster and more personalised services.

Accenture’s New Energy Consumer research found that most consumers (92 per cent) would be more satisfied if their energy provider could personalise their overall customer experience. What’s more, 78 per cent would use more digital channels if this offered them a personalised experience. There is a clear demand for customers to learn more about their energy consumption and to directly manage usage over time, driving down cost and their environmental footprint.

A staggering 2.5 quintillion bytes of data is produced every day across the globe. In addition to providing businesses with information about consumer behaviour, this data is fuelling unprecedented opportunities for more sophisticated analytics to further understand their habits, and also anticipate future behaviour. Energy retailers should therefore fully leverage the vast amounts of customer data they hold to create a richer and more valuable experience, driving retention and trust.

Energy companies in Australia are already working to become more personalised retailers. AGL, for example, is using data platforms as a foundation for personalisation, exemplified through its Energy Insights feature, launched this year. Electricity customers across Queensland, Victoria and New South Wales have been given smart meters to provide greater insight into how energy is being used in their homes, breaking down consumption through categories such as heating, cooling and even home entertainment. This data is equipping customers with relevant information to make informed decisions about how they expend energy, and improving customer satisfaction.

Similarly, Origin Energy has made large strides in understanding the role data and analytics play in creating an improved customer proposition. Sandra Hogan, Head of

Analytics at Origin Energy, has revealed the provider’s plan to use data to create a targeted customer offering through a complete redesign of the framework used to analyse data to develop in-depth customer insights.

EMBRACING BIG DATA OPPORTUNITIES

Customer interactions such as these new innovations nurture trust by reinforcing the energy retailers’ image as helpful, efficient, proactive and reliable. To get there, energy providers must clearly define opportunities to build and rebuild consumer confidence.

This might include promoting new products and services, product comparison and purchase, or optimising the everyday user experience, through customer touch points such as issue resolution, regular payments and invoicing. Energy providers should develop their data strategy to ensure customers leave each interaction with a positive, trust-building impression.

However, despite the rising strategic importance of data, enterprises are still challenged in exploiting the full potential due to internal mis-alignments and conflicting priorities. Accenture has outlined five key characteristics for energy providers to embrace in order to be truly data driven in their pursuit of new value sources and building customer trust.

1. UNTAP NEW AND EXISTING DATA

Energy providers must tear down information silos and unlock ‘dark’ data, that is, data managed outside the knowledge of the IT department. Successful companies are harnessing real-time data streams (e.g. customer demand signals) with the Internet of Things (IoT). Companies like Origin and AGL are delivering data-led business strategies, such as product design, and leveraging new data science and digital methods such as intelligent automation.

2. CREATE NEW VALUE

Data should be viewed as a propeller to re-imagine the core business. Insights gained from internal and external data can lead to opportunities for new business models and customer services, and the transparency gained in enterprise operational efficiency and costs enable a relentless and on-going strive for efficiency and growth.

3. PLACE BUSINESS BEFORE TECH

Technology architecture must evolve to be in-line with business priorities. When it comes to unleashing the potential of data, it’s important that energy providers adopt value-driven approaches to prioritise analytics use across the enterprise.

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU 22

DATA

4. EMBRACE NEW CULTURE

Attitudes to data and technology must shift to reflect the new age of digital in customer service.

Energy providers need to start treating data as everybody’s business and as an enterprise wide asset. This can be achieved through championing an insights-driven culture, embracing new types of talent, and driving organisation-wide consensus across business and IT on the role and purpose of the data and analytics agenda.

5. OPERATE WITH NEW AGILITY

Energy providers should start embracing the ‘Do-Learn-Do’ approach without fear of failing.

Governance needs to be a daily agreement between stakeholders, with clear owners and responsibilities. The creation of blended ‘pod’ teams (including a mix of employees with business and technology skills) will help energy providers achieve agility.

ADAPTING TO CUSTOMER REQUIREMENTS

Australia’s energy system will be in a period of transition for many years to come, impacted by digital technology,

proliferation of DER, changing customer expectations and continued policy uncertainty. Energy retailers need to be acutely aware of how to adapt to customer requirements and the role that data will play to compete effectively.

As we transition to the future of far more personalised services, data presents a critical opportunity to empower consumers and providers alike. With the Consumer Data Right to be introduced to the electricity sector, providing customers with greater insights and trends on their usage data will lead to more informed decisions about energy consumption, as well as improved user experience.

Moving to a data insight-driven culture is a significant opportunity to generate new streams of revenue as energy retailers introduce more personalised and innovative product and service offerings.

Creating a meaningful energy consumer experience via personalised trust points won’t happen overnight and Australian providers must take deliberate steps to build a firm base of trust. Whether an energy retailer is seeking to be an innovator in the market or a trusted energy provider for its customers, data is — and will remain — a fundamental value lever in the new energy ecosystem.

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU

23

BIG DATA

This article was co-authored by Simon Mezger and Jeroen Wortel. Simon Mezger is Accenture’s Utilities Lead in Australia and Asia Pacific; Jeroen Wortel is a Senior Manager in Accenture’s Technology Strategy Practice.

Australian energy providers get personal – data as a key enabler for customer experience

READING BETWEEN THE LINES OF LARGE - SCALE DATA

Detecting leaks, infrastructure planning and accurate billing are the obvious benefts of smart meters and IoT sensors. But if you dive a little deeper into the data, there's a lot more that can be learnt by reading between the lines.

Some of the real value of big data comes when you stop looking at individual sensors or meters and start comparing relationships between different types of data.

Even more interesting is when machine intelligence can learn what the "normal" behaviour of a network is, and send out an alert when something changes. For example, in many tropical regions, high rainfall events can lead to wet weather overflows from the sewer. If a 40mm rainfall event is typically needed to trigger a sewer overflow, but in subsequent events, the amount required to trigger the overflow reduces to 30mm, then 20mm, this points to a change in the capacity of the sewer network.

For one North Queensland utility, this apparent pattern in decreasing performance led the team to go out and flush the pipe to discover that it had been blocked by building rubble. This type of monitoring of data becomes impossible to do manually when there are hundreds, or even thousands, of sensors in the network, and it is only achievable when using specialised software that can sort and analyse such large volumes of data.

This analysis gets even more complex when analysing data across multiple types of sensors. For example, when tracking the source of odour complaints, data from weather stations about wind speed and direction, H2S concentrations in the air, and flow and level data from the sewer network can provide the utility with the information required to identify the source and cause of the odours, and take corrective actions such as changing pumping patterns or dosing levels.

The nature of data analysis is changing. Scada systems tend to generate alerts when a single sensor moves out of a defined range, but IoT systems can generate data from thousands of sensors. It is only by applying big data tools and techniques that the real insights will be identified.

UTILITY • FEBRUARY 2019

24

DATA Utility Partner Solutions

BIG

BOOSTING QUALITY AND PRODUCTIVITY THROUGH DIGITISATION

Digitisation has an important fow-on efect for projects, impacting everything from safety to productivity. Novade’s Quality module, which is being used for Unitywater’s Kawana Sewage Treatment Plant Upgrade Project, ofers a unique solution that facilitates collaboration and improves productivity — all while capturing and delivering data in real time.

Novade’s Quality module is currently being used for defects management and equipment commissioning on Unitywater’s Kawana Sewage Treatment Plant Upgrade Project. This complex multidiscipline project includes civil, mechanical and electrical construction, as well as work on buildings, with multiple work fronts and teams involved. With so many components, a trusted digital management tool is integral to the successful identification and close out of defects on the project.

“Unitywater’s existing defect management solution wasn’t mobile-ready and didn’t allow the flexibility to manage a range of defect types. They need to be able to manage defects for a piece of equipment, as well as building and civil construction defects,” Novade’s Country Manager, Robert Zasadzki, said.

According to Mr Zasakzki, most systems are quite rigid in the way they deal with defects, and the reporting is not as detailed as it needs to be.

“What we’re offering is a solution which allows them to manage their ITP and ITC processes to quality control their principal contractor,” Mr Zasadzki said.

Delivering real-time data and access to construction verification forms, along with the added creation of a site diary, Mr Zasadzki said that the module is serving the project well. He puts this down to its ability to improve quality and facilitate asset handover.

IMPROVING QUALITY DURING CONSTRUCTION

Novade’s Quality module is part of an enterprise mobile platform, designed to manage quality and defects management. While there are numerous applications already in the market, Mr Zasadzki said that the Quality module has a distinct point of difference. It can easily scale to enterprise level while being flexible and fast to deploy.

“With Novade, data in the field is accessed and synchronised in real time. The data captured helps streamline site processes,” Mr Zasadzki said.

Novade works on all major mobile devices. If a user is offline, data will sync when an internet connection is next available. Users can get started with the app right away, and a project can be deployed in a short period of time.

The configuration of Unitywater’s modules were based on close collaboration with project managers, quality managers and the executive team.

The digital platform is used to improve quality during construction, and facilitate the commissioning and defect management process. Being highly configurable, Mr Zasadzki said that the module is ideal for companies trying to streamline processes and improve productivity.

During construction, Novade’s Quality module imposes a thorough quality inspection process in the field with digital forms. Digital checklists can be used for the entire lifecycle of the project, from excavation to handover, and a custom workflow can be deployed for each checklist.

With Novade, quality assurance personnel in the field can complete digital forms and checklists remotely with their mobile devices, and forms can be signed off digitally and archived for easy retrieval. This decreases the likelihood of losing documents, and means that management and project teams can track and monitor the status of all forms in real time using a standard web browser. This gives further oversight of the project, complimenting the work carried out by the field staff. Depending on the user’s role in the project, information is available at the right time in the right location.

FACILITATING ASSET HANDOVER

Inspection teams can easily complete inspections and lodge defect information with customisable digital checklists, and contractors can be given access to the system to enable the quick rectification of defects.

This streamlined system makes it possible for management and project teams to track the status of all inspections, with dashboards and reports automatically generated. This eliminates what could potentially be hours of work spent preparing reports.

By using standard definitions and digital forms, a user can analyse data, identify trends, draw correlations and ultimately improve quality on projects, all while reducing costs.

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU

25 BIG DATA Utility Partner Solutions

For more information on Novade’s Quality module visit: https://www.novade.net/ email anzsales@novde.net or call 0414956613.

DATA HEATING UP OPPORTUNITIES FOR GAS EFFICIENCY

At a time when driving down energy prices is high on the agenda, reliable data is more important than ever in developing new systems to maximise energy efciency. With little known about the quantity of gas required to power a house, a new family home on the ACT border could be the key to understanding gas efciency in the Canberra climate.

Evoenergy, which operates and maintains the ACT electricity and gas network, is currently working with the Toscan family whose home in Googong will be mainly powered by gas.

The Googong Gas-Plus Smart Home Trial — the first of its kind to be built and trialled in Australia — will gather real-time gas consumption data from several household appliances to understand usage patterns, appliance efficiency and the efficiency of gas in the Canberra climate in order to advance natural gas appliance and system solutions.

REAL-TIME DATA FROM REAL PEOPLE

Head of Gas at Evoenergy, William Yeap, said that Evoenergy was eager to be involved in the unique real-time trial.

“We know that every time you turn on gas or electric appliances, you’ll use energy. What we don’t know is how much it uses. When it’s minus five degrees, like in Canberra, and you try to heat up your house to 20 degrees, how much energy is needed?” Mr Yeap said.

“With energy prices being at the top of many people’s agenda, this is our chance to use real-time data to learn the real

cost of energy, with the aim of using these learnings to help people to manage their costs. This trial is unique in the way that it’s done using a real family, real appliances and a real climate.”

The family were selected for the trial after being recommended by the boutique builder who was building their home. Having met Evoenergy’s requirements and agreed to provide access to their data over a period of three years, the trial has only just begun, with the family moving into the house in November 2018. Data will be collected remotely and processed in collaboration with the Australian National University (ANU).

As the trial progresses, the Toscan family, and any other families who later build a gas-plus smart home, will have access to an energy management system and smartphone app where they can see the data on their appliances’ energy consumption.

“The family can see almost real-time consumption data of all the key appliances used in their home so they will be able to see, for example, the amount of gas used for their gas log fire and how much that changes when they adjust the temperature setting,” Mr Yeap said.

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU BIG DATA 26

“The smart home also has a weather station outside and inside, so it knows the barometers, wind, temperature and other factors.”

With access to the detailed data, the family will be able to understand how much money is involved in their consumption and adjust their appliance usage accordingly.

EFFICIENCY, EMISSIONS AND THE ENVIRONMENT

While the trial is heavily focused on improving affordability, gas efficiency also plays a significant role in reducing greenhouse gas emissions. Mr Yeap said that the trial is just one of the small steps needed in reducing emissions and becoming more gas efficient.

“Hopefully we will drive a community that’s a bit more educated, and collectively will do certain things – change certain appliances at home, change the way they operate to effectively use less energy,” Mr Yeap said.

“When you use less energy, it means you will need to buy less energy from the supplier that at certain times isn’t enough to meet demand. You will also expend less of your network. It’s just like a freeway, where if you have more cars on the road, you need to expand your freeway to accommodate more cars. The incremental cost of building a road and adding another lane next to it is much more expensive.

“If you can reduce the traffic, and find a better way of managing your energy, then the cost will go down without sacrificing the reliability of the assets. You’ll also reduce greenhouse emissions.”

This is just one of the innovative initiatives that Evoenergy is looking at across both its electricity and gas network to move to a renewable future and help people manage their energy more efficiently. Other initiatives include looking at the decarbonisation of the gas network, with a vision to one day see hydrogen become the primary gas source in the network.

Evoenergy also recently created a virtual power plant,

which brings over 400 members of the Canberra community together using excess stored energy from their solar battery systems which can be remotely dispatched back into the grid during periods of high electricity usage.

DATA SHARING

While three years is the minimum amount of time that Evoenergy wanted to take to conduct the trial, Mr Yeap said that 12 to 18 months’ worth of data will likely be enough for the company to start sharing its findings.

“We’re not going to wait until the end of three years to do something about it. I’m hoping that even once this coming summer and winter is finished, we’ll have the first set of data and that data set will only get richer as time goes on and more homes come online,” Mr Yeap said.

The data, which is collected remotely, will be put through a database such as a cloud system. Access will then be given to ANU, which will analyse the data and share the information with Evoenergy.

“It’s all part of how we educate Canberrans to manage their energy, but we also want to share the data with the broader industry,” Mr Yeap said.

“We’ll go to the Canberra community, the councils and other gas companies to let them know that ‘this is the result of this’. We can tell them that when Canberra is minus five degrees, you actually need this much energy to heat up the house, and if you reduce some of the settings, this is how much you can save.”

While the trial is currently on a very small scale, involving only one family, it will eventually require widespread involvement.

“It’s about data sharing and education. We’re not going to be able to do much without participation from essentially everyone in Canberra. When the next minus five or 40 degree day hits Canberra, then hopefully we will get people to be a bit more conscious of how to reduce consumption.”

BIG DATA 27

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU

UTILITY • FEBRUARY 2019 WWW.UTILITYMAGAZINE.COM.AU CYBER SECURITY 28

BUILDING A CULTURE OF SECURITY RESILIENCE

Trying to out-fox criminals is a demanding challenge, and while being open and transparent with security sounds counterintuitive, Jemena’s Operational Delivery Risk Manager, Justin Morghem, insists this type of collaboration and cooperation makes corporations and communities more resilient to crime.

Mr Morghem knows a thing or two about security.

With nearly 25 years in the intelligence industry, he has served on police forces in the UK and Australia, and worked with the coalition forces in Iraq, training the National Police. His career has taken him from a ‘Bobby on the beat’ to managing major incident rooms and operating in war-torn military zones.

“It’s not about being paranoid or jumping at shadows, but we have to acknowledge that we are operating in a particularly sensitive sector – energy. We have a duty to protect the nation’s energy networks and ensure communities, including our employees, are safe,” Mr Morghem said.

“Until recently, we, like many other companies, worked in isolation. Sharing news was thought to be a sign of weakness. But technology has changed the way we operate. It has opened the door to some negative changes, such as cyber-crime, hacking and data breaches, but it has also enabled real-time information, high performance soft and hardware and greater connectivity.

“Today, technology has encouraged greater openness and transparency and we find we regularly share information across different platforms with partners, which is a significant change in mindset.”

INDUSTRY SHARES, COMMUNITY BENEFITS

In a recent example of greater collaboration, Jemena installed new high-tech surveillance software at one facility and was so impressed by its connectivity that it recommended the system to other energy companies, some of them considered rivals.

This has enabled a compatible network of like-minded organisations, acting as eyes and ears not just for themselves, but for each other, and beyond.

Utility companies, infrastructure developers, transport organisations, governments, agencies and a whole gamut of critical infrastructure providers are increasingly becoming connected. As the net widens, the knowledge deepens and the resilience increases.

“The availability of critical infrastructure can no longer be considered in silos. We are all in the same fight against threats and criminality, so we are stronger by working together in an interlinked environment,” Mr Morghem said.

And Jemena has seen an important flow-on effect to the group at the heart of its activities – its customers.

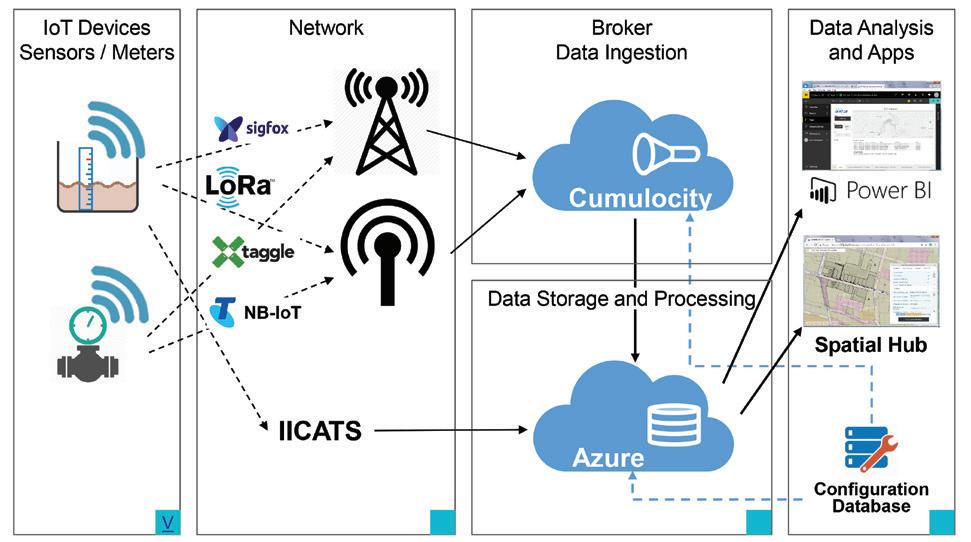

“We have had customers, who were initially hesitant about new security systems being installed on assets near their home, now thanking us, because criminals who had targeted the area have now moved on,” Mr Morghem said.