Engineering, Construction & Maintenance www.utilitymagazine.com.au Issue #18, May 2018 WATER SEWER ELECTRICITY GAS MAKING

DROP

WITH BETTER WATER MANAGEMENT FIND OUT

EVERY

COUNT

THE WINNERS OF THE DIGITAL UTILITY AWARDS GETTING ‘BEHIND THE GRID’ WITH BLOCKCHAIN ENERGY STORAGE: REWIRING THE ELECTRICITY NETWORK

Its 24,000 lb of thrust and pullback and 3000 ft-lb of rotational torque equals a 20% and 36% increase over its predecessor, the venerable D20x22 Series II—yet length and width has only increased by 20cm and 6cm respectively.

Noise level at operator’s ear of 78.7 dB(A) makes the D10x15 S3 jobsite and operator friendly, while familiar controls and the new DigiTrack® Aurora™ display offers ease of use and unmatched feedback.

See your Vermeer team to learn more.

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the United States and / or other countries. © 2018 Vermeer Australia. All Rights Reserved. D23X30

GET EQUIPPED. / VermeerAustralia

| 1300 VERMEER

| 1800 195 558 (WA & NT) D23X30 NAVIGATOR® S3

NAVIGATOR ® S3.

WWW.VERMEER.COM.AU

WWW.VERMEERWA.COM.AU

THE ULTIMATE STREET MACHINE THE VERMEER D23X30 NAVIGATOR® S3 BRINGS NEW LEVELS OF SPEED AND POWER TO URBAN JOBSITES.

RFROM THE PUBLISHER

ight now, the South African city of Cape Town is enduring the worst water crisis to face a modern city. Severe water restrictions have been put in place and water tariffs have also been increased in an effort to reduce consumption. Fortunately, this is not a reality we have to consider quite yet, but Australia too is facing unprecedented challenges in managing its water resources.

With the majority of Australia’s water users concentrated around its capital cities, one of the ways in which these challenges could be mitigated is through a national reform of the urban water industry. Reforming Urban Water: A national pathway for change, a report released by Infrastructure Australia and supported by WSAA, highlights key sector vulnerabilities and suggests fundamental changes to the governance and regulation of Australia's urban water markets.

The power sector is also facing upheaval as current technology and consumer trends transform the electricity network and reshape it from the ground up. Regulatory innovation is essential to make the most of the technological opportunities available and reduce long-term network costs, with demand management being a central component of this.

The results of ARENA’s study into virtual power stations 2.0 have the potential to overcome the high and fluctuating voltages associated with some renewable generation which can exceed the capacity of distribution networks. Blockchain may be the industry’s current favourite buzzword but a two-year trial currently underway in Fremantle could demonstrate real-world applications of the distributed ledger technology within the utility space.

The digitisation of utilities is the greatest challenge currently facing the

sector with much to do to modernise existing networks, work practices and ways of interacting with customers. Recognising the momentous impacts that digital technologies are having on the industry, Utility hosted the two day conference Digital Utilities 2018 in Melbourne in April, which featured expert speakers and delegates from Australia’s major water and energy utilities.

We had a great response to the event and enjoyed some fascinating discussions across both days of the conference. One of the highlights of the event was the spectacular Gala Dinner and Awards Ceremony – find out who the well-deserved winners of the inaugural Digital Utility Awards were on page 22.

Not being one for complacency, we’ve already set the date for Utility’s next event, Asset Management for Critical Infrastructure 2018, which will be held in Sydney on 12–13 September. The two-day conference will bring together the best of the utility and infrastructure industries to discuss the latest news and techniques in the sector and explore practical applications that can improve the way assets are managed, with streams that include rail, corrosion and trenchless technologies.

If you’re involved in asset management for a utility or other critical infrastructure provider and would like to attend, you can register at assetmanagementevent. com.au.

With such vast changes creating new cultures of disruption and innovation across both the water and energy sectors, I’m excited to see how utilities respond to these changes, and look forward to discussing this with some of you at Asset Management for Critical Infrastructure in September.

welcome 1 UTILITY • MAY 2018 ISSUE 18 May 2018

Chris Bland Publisher Published by Cover image highlights our feature on urban water reform. Publisher Chris Bland Acting Editor Charlotte Pordage Managing Editor Laura Harvey Senior Associate Editor Jessica Dickers Associate Editor Lauren Cella Journalists Elisa Iannunzio Nicole Valicek Kirsty Hutton Marketing Director Amanda Kennedy Marketing Associate Sam Penny Marketing Assistants Rima Munafo Katie Chancellor Helena Brace Production and Customer Service Titian Bartlau Senior Designer Alejandro Molano Designer Jacqui Abela Monkey Media Enterprises ABN: 36 426 734 954 PO Box 1763 Preston South VIC 3072 P: (03) 9988 4950 monkeymedia.com.au info@monkeymedia.com.au utilitymagazine.com.au info@utilitymagazine.com.au ISSN: 2203-2797 Engineering, Construction & Maintenance www.utilitymagazine.com.au Issue #18, May 2018 UTILITY MAGAZINE MAY 2018 WATER SEWER ELECTRICITY GAS MAKING EVERY DROP COUNT WITH BETTER WATER MANAGEMENT FIND OUT THE WINNERS OF THE DIGITAL UTILITY AWARDS GETTING ‘BEHIND THE GRID’ WITH BLOCKCHAIN ENERGY STORAGE: REWIRING THE ELECTRICITY NETWORK 8,807 1 April – 30 September 2017

Bulk Liquid Transport

Bulk Liquid Transport

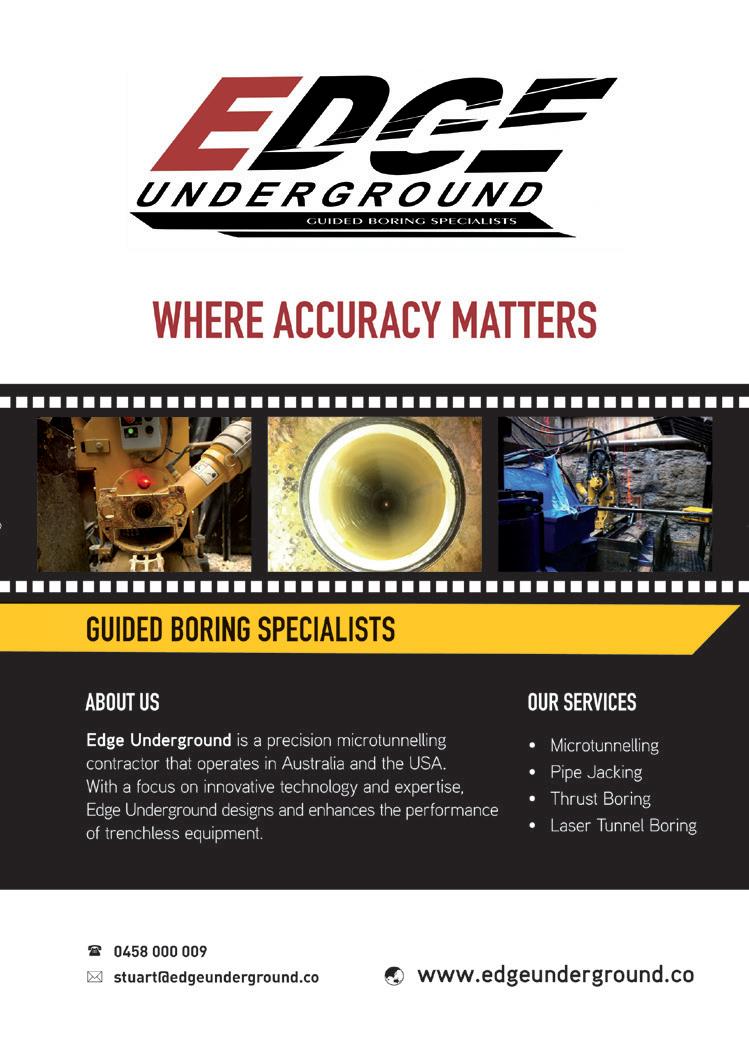

4 CONTENTS UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU 24 50 WATER MANAGEMENT The call for national urban water reform .......................................... 24 Digital efficiency key to combating water challenges ......................... 28 Raising the roof on sustainable water supply 30 Experts assemble: simplifying turbidity readings 32 Blueprint to aid water conservation during tough times 34 Infrastructure upgrade for the Nyngan to Cobar water supply pipeline 36 Visualising data in the water and sewerage industry ...................... 38 DEMAND MANAGEMENT The blockchain effect .................. 50 ENERGY NETWORKS Regulatory innovation: an oxymoron or future necessity? .. 54 Intelligent Motor Control supporting connected enterprises................................... 58 Virtual Power Station 2.0: a network game-changer 60 The transition to a Distribution System Operator 62 VEGETATION MANAGEMENT Our approach to vegetation management ............................... 86 Bigger options – bigger productivity gains 88 SCADA everywhere – the benefits of LPWAN communications to SCADA managers 40 Next-generation urban drainage keeping cities safe 41 An industry leader in plumbing .. 42 Chlorination on demand 43 WASTEWATER MANAGEMENT Groundwater replenishment for Perth 44 Alternative approach to maintenance 48 IRRIGATION A secure water supply for Tasmania’s Southern Highlands 92 MICROTUNNELLING Rob Carr finishes strong on its largest project to date 96 Minimising disruptions and maximising accuracy with microtunnelling 98 72 88 92 ORGANISATIONAL RESILIENCE Organisational resilience: what it means for the utility sector 90 90

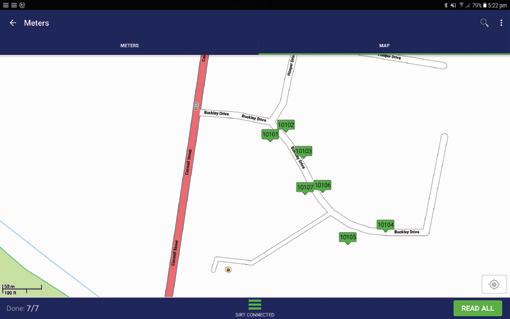

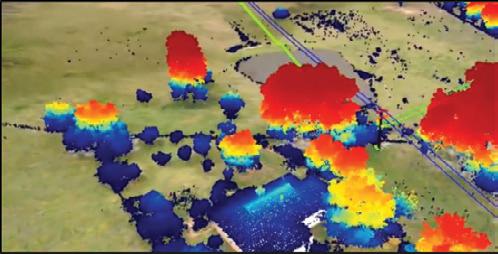

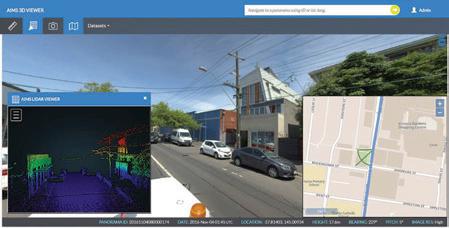

May 2018 ISSUE 17 5 UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU 64 SMART METERS Ten million meters: Australian Smart meter designer EDMI celebrates 40 years of precision, reliability and innovation 64 Smart meter trials continue to unearth new ideas 66 Taking the pain out of moving to smart meters 70 74 80 STORAGE Looking beyond lithium-ion in energy storage ............................ 74 Battery storage boosts remote island power station ................... 78 INSPECTION New pole inspection technology provides new perspective .......... 80 Utilising 3D imagery for more accurate asset assessment ........ 84 In each issue Welcome from the Publisher ......................... 1 A word from Energy Networks Australia .... 6 A word from WSAA ........................................ 8 News briefs .................................................... 10 Advertisers’ index ...................................... 104 Editorial schedule ...................................... 104 EVENTS Register today for Energy Networks 2018 – Vision Critical 100 MOBILITY Data collaboration for a truly mobile workforce supply chain ............... 72 100 72 102

i

The utility industry is regularly required to call on an enormous and varied range of specialists; from mapping, to drilling, to wastewater treatment, to asset management, to pipe relining, to pipeline integrity, to land access, to risk management, and the list goes on. To make the process a little easier, Utility is bringing together experts from various fields to answer your questions.

A WORD FROM ENERGY NETWORKS AUSTRALIA

ANDREW DILLON CHIEF EXECUTIVE OFFICER – ENERGY NETWORKS AUSTRALIA

There’s no such thing as green electrons or brown ones. Your TV and fridge run just the same on solar power from Queensland, wind power from SA, hydropower from Tasmania or coal power from the Hunter Valley. Interstate sharing of electricity makes power cheaper and more reliable.

Regrettably, since the system blackout event in South Australia in September 2016, state governments across our National Electricity Market (NEM), which covers everywhere except Western Australia and the Northern Territory, have adopted isolationist “my state first” energy policies.

While it’s human nature to look after your own in a time of crisis, continuing this trend will result in more expensive and less reliable energy supply for all, and more costly emissions reductions.

The 2017-2018 summer has demonstrated that the solutions to the major energy challenges we face will only be found in a collaborative approach.

Analysis by the CSIRO for the Electricity Network Transformation Roadmap clearly demonstrates that there will continue to be geographic differences in the generation mix between and within states. This ebb and flow of generation capacity across the country was one of the key reasons for establishing the NEM in the first place.

South Australia leads the world in intermittent generation –wind and solar – and the adoption of cutting edge technology, such as the 100 megawatt Tesla battery at Hornsdale. However, it is unsurprising that when SA demand is high but wind output is low, they rely on electrons from Victoria via the Heywood interconnector.

This is not policy failure; it’s exactly how a connected, national system should work. As our generation mix inevitably changes, each state attempting to install enough gas turbines and mega batteries to ensure they have sufficient home-grown supply every hour of every day of the year would come at a significant extra cost for Australian homes and businesses.

The NEM has been described as the world’s biggest machine. We will all be worse off if we have wind farm after wind farm unable to connect to this machine due to capacity constraints. It will be an inefficient and costly outcome if network congestion means solar generators large and small are blocked from injecting into the grid.

For this reason, we desperately need the Integrated System Plan, currently being developed by the Australian Energy Market Operator, to deliver on its name.

The only electricity future that makes sense for Australia is a more connected future.

The theme of the Energy Networks 2018 conference and exhibition is “Vision Critical”, and without a doubt, the national conversation on the future of the energy grid is nothing short of critical.

Energy Networks 2018 will put the summer that was under the microscope for a detailed look at how the energy sector performed. After a year of intense interest in the gas and electricity sector, what have we learned, what have we achieved and, most importantly, what must come next?

Our international keynote speaker, Miranda Ballentine from the Rocky Mountain Institute, will share insights on key trends for the future of the energy system and strategies for shaping a resilient and sustainable energy grid together with customers.

Energy Networks 2018 will also take a deep dive into the customer experience with Citysmart’s Reduce your Juice platform. This revolutionary behaviour change program, built on digital gamification and research insights, will demonstrate how Australian consumers use, think about and spend on electricity.

With international and domestic leaders in innovation, technology, asset management, consumer engagement and regulation, this will be the preeminent conference of the year, focused on the challenges facing the future of energy networks.

Australia’s energy sector faces huge challenges. Some are saying the NEM is broken – but a Brexit-style approach in which states disconnect certainly won’t work. We need long-term planning, based on what customers really value, to inform strategic policy and timely investments. The best results can only come from us all working together.

I extend a personal invitation to you to join us in Sydney in June for what will be an unmissable two days of world-class knowledge sharing, invaluable networking opportunities and open, accessible discussion.

The need for collaboration and shared expertise has never been more critical for our sector. This year’s Energy Networks conference may be the springboard from which the next big idea is generated and I urge you to be a part of it. Register

UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU 6

for Energy Networks 2018 at www.energynetworks2018.com.au

about the 'Reduce your Juice' game at www.reduceyourjuice.com.au/energy18.

and find out more

A WORD FROM WSAA

ADAM LOVELL EXECUTIVE DIRECTOR – WATER SERVICES ASSOCIATION OF AUSTRALIA

Earlier this year I spent a few days in the UK attending a high-quality water customer conference through Utility Week and meeting our collaborators including WaterUK, UKWIR, Consumer Council for Water and Isle Utilities. The conference had some great takeaways including the Trust Equation. Familiarity + Favourability = Trust is the Trust Equation.

While customer satisfaction and trust has been increasing for water services – in fact most essential services in the UK – there is an emerging and worrying trend that might see those trust figures slip. That trend relates to another measure called “customer effort” which is creeping upwards (sounds pretty much self-explanatory). Many of the utilities are using the equation familiarity + favourability = trust as a black box type framework that seems to work. They break that down further: favourability is based on both value for money and customer service. Excellence will be the new norm.

Undoubtedly a major theme emanating from all the speakers at the conference, including John Russell from OFWAT and “it’s not ok to be ok” from Jo Causen from the Institute for Customer Service. It is clear that stakeholders, regulators and customers are raising the bar to new levels as the water businesses prepare to lodge their submissions for Price Review 2019 (PR19). Excellence, brilliance, moments of difference were

words and phrases sprinkled heavily through the presentations from the UK utilities. Expectations of service are driven by everyday experiences – not by customers comparing utilities from across the country. Leadership.

Interesting to note, there seems to be a growing trend for a super General Manager type role at utilities. Certainly combining customer and operational responsibilities is the new norm, but a growing trend of combining the human resource role in that single General Manager space. Jo Causen talked about some significant work clearly linking customer satisfaction and trust with deep employee engagement. Louise Beardmore from United Utilities was a really impressive leader and speaker who is covering all three roles. “Channels by choice’ not ‘digital by default”.

Sarah Bentley from Severn Trent talked about utilities being available anytime, anywhere, through any device. The message from all the speakers was that funnelling customers through only digital channels was not the right direction. There was a great question from the audience – what about the silent majority? No different to here in Australia and New Zealand, how do you engage the customers who persistently won’t engage for a variety of reasons. Louise Beardmore provided a great response: “create the moments of difference, create WOWs” which is a reference to

the WOW awards website where huge emphasis is placed on live customer feedback. Do something with street works, create an opportunity to be seen creating community value as well as minimising service disruption. Vulnerable customers.

Across the board, stakeholders, regulators and utilities were all talking about approaches to assisting vulnerable customers, with some programs similar but not the same as say the Yarra Valley Water “Thriving Communities” initiative. Net Promoter Score.

The NPS is being used widely, although with some trepidation. Many utilities are disappointed with scores below +50. OFWAT will be trialling the use of NPS within their CMeX framework in PR19

I also took the opportunity to meet our key collaborators in the UK. We are developing a collaboration with Tony Smith, CEO at the Consumer Council for Water, on leading edge customer engagement, picking up some of the experiences and lessons learnt from WSAA members, and comparing that with the UK water utilities, particularly after they submit their proposals under PR19 later this year. It was evident that the UK water utilities are continuously undertaking engagement with their customers – not just when a price submission is required. As Louise Beardmore said, “be curious, constantly”.

UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU

8

P (08) 9725 4678 sales@kwikzip.com Contact us today to order Also available for order through Reece Civil stores. Is your pipe spacer compliant? KWIK-ZIP’S HDX SERIES CASING SPACERS COMPLY WITH WSAA PRODUCT SPEC #324 – CASING SPACERS; REFER WSAA PRODUCT APPRAISAL REPORT #1523 www.kwikzip.com

SCIENTISTS DEVELOP REVOLUTIONARY FILTER TO IMPROVE DRINKING WATER QUALITY

Aworld-first, graphene-based, laboratory-scale filter that can remove more than 99 per cent of the ubiquitous natural organic matter left behind during conventional treatment of drinking water could soon be used in conventional plants.

The research collaboration between University of NSW (UNSW) scientists and Sydney Water has demonstrated the success of the approach in laboratory tests on filtered water from the Nepean Water Filtration Plant in Western Sydney, and is working to scale up the new technology.

The project is led by Dr Rakesh Joshi of the UNSW School of Materials Science and Engineering, in collaboration with Professor Veena Sahajwalla and Professor Vicki Chen of UNSW, and Dr Heriberto Bustamante of Sydney Water.

could be converted into an alternative new option that could in the future be retrofitted in conventional water treatment plants.”

Sydney Water supplies clean water to about 4.8 million people in Sydney, the Illawarra and the Blue Mountains. These natural organic matter contaminants can affect the performance of direct filtration plants, reducing their capacity after heavy rain.

“The most common methods used at present to remove organic matter from water supplies include the application of chemical coagulants,” Dr Bustamante said.

“However, these existing treatments are only partly effective, particularly as the concentration of natural organic matter is increasing.”

“Our advance is to use filters based on graphene – an extremely thin form of carbon. No other filtration method has come close to removing 99 per cent of natural organic matter from water at low pressure,” Dr Joshi said.

“Our results indicate that graphene-based membranes

Dr Joshi said the new treatment system is made by converting naturally occurring graphite into graphene oxide membranes that allow high water flow at atmospheric pressure, while removing virtually all of the organic matter. The UNSW team is upgrading the experimental rig to construct a small pilot plant that could be tested in the field.

10 UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU NEWS NETWORK SERVICES

UNSW's Dr Rakesh Joshi (far left) and team members hand over water free of natural organic matter to Sydney Water's Dr Heriberto Bustamante (far right).

KIDSTON SOLAR STAGE TWO GETS DEVELOPMENT APPROVAL

The Etheridge Shire Council has given development approval (DA) for stage two of the Kidston solar project (K2-Solar).

The DA is for a maximum of 270MW but Genex has the potential to build K2-Solar in stages to match energy off-take and energy transfer capabilities. This represents a significant milestone for the K2 projects.

As with Kidston solar stage one (KS1), K2-Solar will benefit from being located within the highest solar radiation zone in Australia.

Genex continues to advance the Early Contractor Involvement (ECI) process toward agreeing full fixed price Engineering, Procurement and Construction (EPC) wrap contracts with UGL for K2-Solar and with McConnell Dowell/ John Holland Joint Venture (JV) for K2-Hydro.

EPC contracts are expected to be finalised by the end of June 2018.

As part of the ECI process for K2-Hydro, the JV has selected ANDRITZ, an international tier-one supplier and global leader in hydraulic power generation, as the preferred electromechanical equipment supplier.

Managing Director of Genex Power, Michael Addison, said, “After several months of detailed market engagement, we are now in negotiations in regards to securing debt funding

for our Kidston stage two projects with a select group of partners.

“Genex’s main focus remains on progressing the Kidston stage two projects to financial close in calendar year 2018. Concurrently, Genex continues to consider further renewable opportunities to broaden its project pipeline, as the company evolves into a broader renewable energy generation and storage developer.”

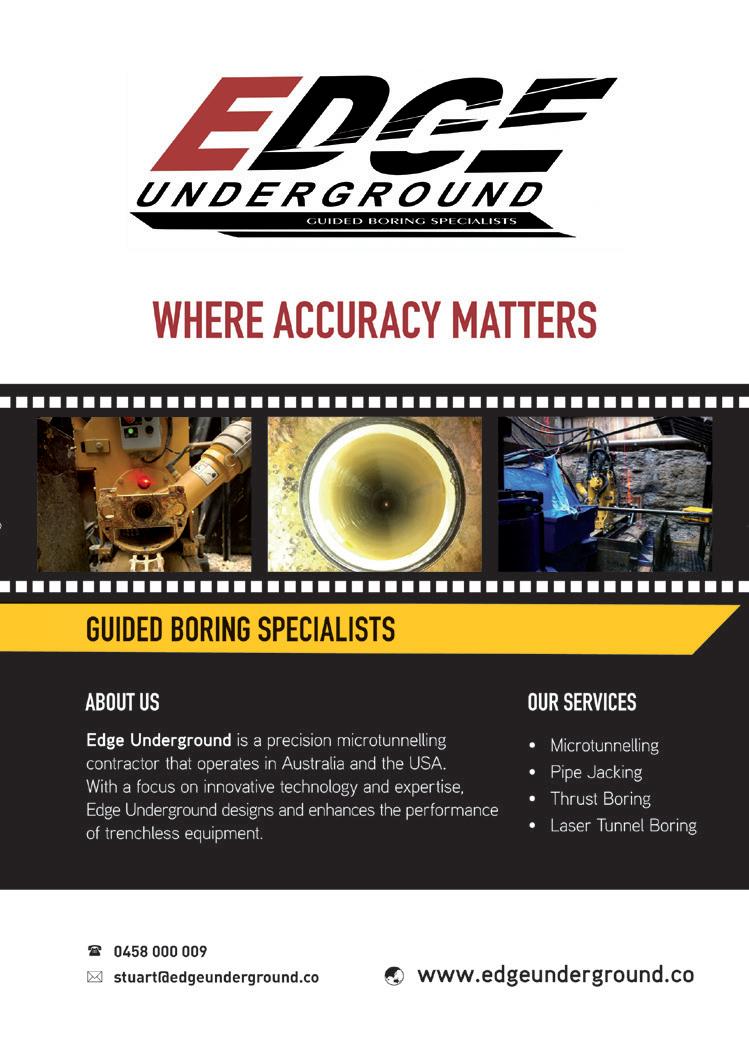

The Federal Government, through the Australian Renewable Energy Agency (ARENA), has provided $8.9 million in funding to support the construction of Genex’s KS1 Project, and up to $9 million in funding to support the development of K2-Solar and K2-Hydro.

The Queensland Government has continued to support the development of the Kidston Renewable Energy Hub, providing a 20-year revenue support deed for KS1 through the Solar 150 Program, and designating the Hub as ‘Critical Infrastructure’ to the state.

UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU 11 NEWS

Australia’s most advanced HDD contractor... AHD Delivers, every time • Experienced staff • The latest equipment • Technologically innovative T: (03) 9439 93 73 W: www.ahdtrenchless.com.au

MILESTONE FOR MELBOURNE SEWER PROJECT

ATunnel Boring Machine (TMB) is working its way under Spencer Street in Melbourne’s CBD, marking a major milestone on one of City West Water’s sewer upgrades.

Project Delivery Manager City West Water, Kate Houlden, said the installation of the tunnel borer is an exciting ‘next step’ for the Spencer Street Sewer Upgrade project.

“With population growth set to increase by 14,000 apartments within the Spencer Street sewer catchment, tunnelling works to increase its capacity are vital.

“Our TBM – owned by Bothar Boring – has made its journey from its last project in Lismore, NSW, and is now beginning its next journey under Spencer Street.

“Weighing in at an impressive 25 tonnes, our TBM is about four times as heavy as a Tyrannosaurus Rex.

“The borer is nine metres and is made up of three sections – cutter head, power pack and telescopic sections – which have been lowered into the 12m-deep launch shaft in stages.

“The sections were delivered one day at a time, with our crews working hard to ensure that each was installed safely, on time and with precision.”

The Tunnel Boring Machine is now making its way from Lonsdale Street towards the 7.5m deep retrieval shaft

that will be constructed at Flinders Lane.

Ms Houlden said the borer works quite quickly, with 6-8m of pipe being installed every 12 hours for the next several months.

“The total length of the bore will be just over 590m with a bore diameter of 1.5m.

“On completion our TBM will be pulled out of the retrieval shaft at Flinders Lane and transported to another project location for reuse.”

UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU NEWS 12 NSW Ph: 02 8197 2825 WA Ph: 08 9201 0948 QLD Ph: 07 3333 2825 SA Ph: 03 9017 8225 Head Office: Unit 20, 51 Kalman Drv Boronia VIC 3155 Ph: 03 9017 8225 Fax: 03 9729 9604 www.ams-ic.com.au sales@ams-ic.com.au AMS Instrumentation & Calibration Pty Ltd Analytical Process Division Oxygen Analysers, Thermal Conductivity Analysers, NDIR Analysers, Multigas Analysers, OEM Analysers U.V Absorption Conductivity pH / ORP Colour Industrial Water Analysers and Liquid Analytical Products (pH, Conductivity, ORP, Dissolved Oxygen, etc) Oxygen Analysers, Relative Humidity Sensors and Meters, Dewpoint Measurement

How do I make the most of the web, SEO, social media and content marketing to reach my customers? Visit www.monkeymedia.com.au and sign up to our newsletter to get free marketing tips for companies in the Utility industry www. .com.au publishers of Engineering, Construction & Maintenance

8MW VIRTUAL POWER PLANT FOR ADELAIDE

The Australian Renewable Energy Agency (ARENA) has announced $7.7 million in funding for Simply Energy to build a second virtual power plant across Adelaide.

The $23 million project will deliver Tesla Powerwall 2 home batteries to up to 1200 Adelaide households, representing six megawatts of residential energy storage.

A further two megawatts of demand response capacity will be deployed across ten commercial businesses.

The virtual power plant is expected to be up and running by the end of 2019.

A virtual power plant is a centrallymanaged network of battery systems installed behind-the-meter that can be collectively controlled to deliver benefits to households, energy retailers and the local network.

Individual customers will benefit from reduced power costs as they are able to increase the amount of rooftop solar power they consume by storing the solar-generated energy and using it later when they would otherwise be consuming power from the grid.

The battery systems are also able to provide backup power in the event of an outage.

The three-year trial will give South Australia Power Networks (SAPN) greater visibility of behind-the-meter battery storage and access to those batteries as distributed energy resources that can be used to address local network constraints and manage demand.

Simply Energy’s virtual power plant will be the second in South Australia after ARENA previously provided $5 million in funding to AGL to establish a virtual power plant of 1000 households and businesses across Adelaide.

ARENA CEO, Ivor Frischknecht, said this project will build on the AGL VPP.

“We think consumer energy resources have a huge role to play in Australia’s energy future, but we are still figuring out how we can orchestrate rooftop solar and home batteries to feed back into the grid. This is technically hard to do, which is why these pilot projects are so important,” Mr Frischknecht said.

“This is a potential model for how distributed energy resources can be operated at large scale in the future to help reduce energy prices."

Simply Energy CEO, Carly Wishart, said Adelaide households will be able to participate in the trial, which will see the home battery system delivered at a subsidised price.

“Simply Energy is proud to be able to deliver this innovative solution that helps our customers reduce their energy costs while also providing additional energy security in South Australia,” Ms Wishart said.

“We will work closely with South Australian Power Networks to give both networks and the market operator greater visibility of behind-the-meter batteries and the ability to use batteries to manage demand and manage network constraints, reducing network costs.

“It’s a win-win because our customers are getting better value from their renewable energy solution and the network will have more electricity sources from which to draw, which in turn improves reliability, particularly at times of peak demand.”

Consultants Marchment Hill and Flex are also involved in the Simply Energy consortium developing and managing the project.

UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU NEWS 14

FUNDING FOR NEW EAST COAST GAS SUPPLY

The Australian Government will provide $26 million in funding from its Gas Acceleration Program (GAP) for four new projects to boost the supply of gas in the East Coast market.

Minister for Resources and Northern Australia, Matt Canavan, said the projects would supply an extra 12.4 petajoules of new gas to the East Coast market by 30 June 2020 and an extra 27.6 petajoules over five years.

Mr Canavan said this extra supply would help safeguard Australia’s future gas security.

“Gas is vital to Australia’s energy security as a fuel, as a feedstock for industry, and as a source of energy generation,” Mr Canavan said.

“We must continue to invest in the gas sector to ensure a secure, reliable and affordable gas supply. Bringing more gas to market will help Australian businesses remain competitive, create more jobs and reduce cost of living pressures on all Australians.

“While Australian Government measures like the Australian Domestic Gas Security Mechanism and the Prime Minister’s agreement with LNG exporters in October 2017 have helped to address domestic gas supply in the short term, the only way to provide gas security into the future is by increasing the supply of gas through increased development.

“SWEP [Utilising Verge

“We can access our plentiful gas resources in a responsible and balanced way, using the best available science. I encourage all states and territories with limitations on gas projects to rethink their blanket bans.

“The GAP is fast tracking projects with the best prospects of bringing significant new gas volumes to target markets by mid-2020.”

The funded projects include:

• The Kincora Gas Acceleration Project, Armour Energy (Surat Basin), will receive a $6 million grant towards a $16.1 million project

• A $6 million grant towards a $14.3 million project for the Greater Meridian Domestic Gas Acceleration Project, Westside Corporation

• A $6 million grant for Beach Energy (Adelaide Energy) for a $22.6 million project to construct a new Katnook Gas Processing Facility

• A $6 million grant for a $16.3 million project by Tri-Star Fairfields

“The GAP is a significant component of the Australian Government’s $90 million investment in gas security, reliability and affordability for Australian gas users,” Mr Canavan said.

products] has helped schools avoid losses of over 4 billion litres of water”

16 UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU Making IoT work for you 13 000 VERGE vergesolutions.com.au

could you be saving?

million data points collected 45 years of instrumentation expertise

years of Internet of Things (IoT) experience Measuring and monitoring daily Flow | Level | Temperature | Water Quality | Rainfall Increasing e ciency, by saving Water | Time | Money Executive Director Policy, Governance and Legislation Victorian Government - 3rd August 2017

What

275

8

IoT

NEWS

ASSET MANAGEMENT FOR CRITICAL INFRASTRUCTURE CONFERENCE IS BACK IN 2018

Following the success of last year’s event, the Asset Management for Critical Infrastructure Conference is returning for another year, running from 12-13 September in Sydney. Its return will include the addition of an exhibition, new focused panel streams and in-depth discussions with a new lineup of industry experts.

Asset Management for Critical Infrastructure 2018 will bring together leading experts across the utility and infrastructure sectors for two days of thoughtleading discussion around the most pressing issues in asset management.

Last year’s conference was attended by infrastructure asset owners, senior figures within the utility sector, and others working in the asset management space, which gave delegates the opportunity to network with the industry’s best.

WHAT’S NEW FOR 2018?

The 2018 conference will include the addition of an exhibition, which will see leading asset management, technology, utility and infrastructure companies highlighting some of the newest products and innovations in the sector.

The conference is created by Monkey Media, who publish Utility and Infrastructure magazines, so the content itself is the highest priority - the event takes the issues covered in the magazines and brings them to a live and interactive format.

The lineup of speakers will include senior figures from Australia’s water and power utilities, as well as infrastructure asset owners, and representatives from government and key industry bodies.

While the two days will explore asset management challenges and solutions, technologies and processes across utilities and infrastructure, there will also now be targeted streams to suit your exact area of interest and specialty.

This year will feature dedicated streams, including:

• Rail

• Corrosion

• Trenchless

This is in addition to presentations and industry panels covering the asset management journeys of Australia’s major water and energy utilities.

WHAT TO EXPECT AT ASSET MANAGEMENT FOR CRITICAL INFRASTRUCTURE ?

While managers of critical infrastructure, such as water supply, electricity generation and transport, have more tools available than ever before to manage these assets, the amount of public scrutiny has never been higher.

This event is a chance for anyone working in the asset management space, or for a utility, to explore practical applications that can help improve the way assets are managed. The aim is for delegates to leave the event with new ideas or perspective that they can then implement in their organisation.

NEWS UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU 17

It’s also a chance for asset managers to learn what they need to do to keep up with the rate of change occurring in the sector, and get advice from colleagues in related or complementary sectors. Sometimes all it takes is to see what someone else is doing to spark an idea or innovation.

This year, you can expect presentations and panel discussions on topics such as:

• Big data and data analytics

• Updates to asset management standards

• How new technologies are being implementeddrones, VR/AR

• Are utilities using the Internet of Things (IoT) to their best advantage

• Predictive maintenance

• Balancing the construction of new assets with maintaining existing assets

• Asset management best practices

• And so much more!

18 UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU NEWS

Asset Management for Critical Infrastructure will run from 12–13 September in Sydney. Full program and speaker lineup to be released shortly. Visit assetmanagementevent.com.au for updates or to submit an enquiry

Asset Management for Critical Infrastructure Conference is back in 2018

Things have never been better.

For more than 30 years we have delivered reliable and innovative simulation software for network hydraulics and water quality in the Australian and New Zealand water industry. We’re now stronger than ever with a larger

THE UTILITY INDUSTRY’S BEST SHARE THEIR DIGITAL TRANSFORMATION JOURNEY

Representatives from Australia’s major water and energy utilities gathered in Melbourne in April to discuss the impact of digital disruption on the utility sector and learn how to embrace emerging technologies and be fearless in the face of innovation.

Digital Utilities 2018 was held from 19-20 April at the Pullman Hotel in Albert Park, Melbourne, providing members of the utility community with an opportunity to learn from the industry’s best, network with clients and colleagues, and discover the latest digital tools and technologies needed to accelerate and transform their organisations.

Bentley Systems - a global software development company that supports the professional needs of those responsible for creating and managing the world’s critical infrastructure, was the event partner - and ABB - a pioneering technology leader in electrification products, robotics and motion, industrial automation and power grids - was the event major sponsor.

The expert speaker lineup was spearheaded by two keynotes - Stuart Hartley, Sector Leader - Power and Utilities APAC, EY; and Susan Heath, Chief Information Officer, Queensland Urban Utilities.

Mr Hartley’s keynote presentation, Are we at the tipping point to digitally reimagining the future utility?, kicked off day one of the conference.

According to Mr Hartley, technological disruption is moving so fast that many utilities are struggling to prioritise the right investments and deal with new risks such as new competitors, cyber security and shifting demand patterns.

Despite the uncertainty surrounding these changes, Mr Hartley said there’s never been a more exciting time for the utilities sector to adopt technology to transform energy services.

“Innovation around renewables, battery storage, electric vehicles,

as well as advances in niche digital innovation, including artificial intelligence, IoT (internet of things) and mobility, create unprecedented opportunities to capture new revenues and drive productivity.”

Susan Heath’s keynote presentation Queensland Urban Utilities’ digital transformation journey provided the opening for day two of the conference.

According to Ms Heath, having an Innovation Program encourages staff to contribute bold, new ideas to improve business operations, and supports the integration of new digital transformation initiatives.

“This appetite for exploring new digital opportunities has led to an involvement in the hack community, which has seen bright minds in our community develop technologyfocused solutions to challenges facing the water and wastewater industry,” Ms Heath said.

Ms Heath also highlighted the use of technology to foster a more digitally enabled workforce and the importance of data and real-time information in establishing more predictive operations.

UTILITIES EXPLORE THE BENEFITS OF DIGITISATION

The keynote presentations were supported by a number of speakers who are already taking the action required to transform their organisations into truly digital utilities.

Luke Skinner, Head of Network Technologies at Citipower and Powercor, talked about how smart meters are allowing Victorian network businesses to use artificial intelligence and analytics to support the transforming electricity grid.

“Victoria's foresight in rolling out the technology almost a decade ago has provided distribution businesses with better insights into what's happening on the network and support grid stability,” Mr Skinner said.

“This technology has allowed CitiPower and Powercor to devise demand response initiatives that have pushed innovation boundaries and helped reduce pressure on the grid.”

Brock Tunnicliffe, Customer Compliance Officer at City West Water explained how virtual reality presents an exciting opportunity for the water industry to enhance and augment the

DIGITAL UTILITIES 20

way it plans and designs new assets and undertakes staff training.

“By using 3D CAD models, operators and field workers who may not be able to read complex plans effectively, can now visually audit and inspect plans in a virtual environment, providing an effective methodology at finding defects and hazards present in the design stage of a project,” Mr Tunnicliffe said.

Brett Millington, Flagship Program Director at Intelligent Water Networks, discussed the importance of finding better ways to manage and integrate data, so as to assist water corporations in making sensible and cost-effective asset investment and business decisions.

“Big data and analytics have become a real focus that can improve customer service, business processes, asset management and field operations, making water corporations efficient ‘digital utilities’.”

PANEL DISCUSSIONS STIMULATE DEBATE

The second day of Digital Utilities 2018 featured four panel sessions, split into morning and afternoon streams. At the end of each session, delegates had the opportunity to ask questions, which led to some lively discussions on the topics.

The stream, Using digital technologies to improve customer relationships, featured Toby Evans, Senior Manager of Digital Transformation at SA Water; Paul Loftus, Head of Customer Sales at Powershop; and Cate Hilliard, Manager, IT Capital Portfolio at SA Power Networks sharing their insights into better ways of managing customer

relationships and shaping digitisation around the needs of the customer.

During the other morning stream, delegates heard from Helen Millicer, President at the Alternative Technology Association; Mottel Gestetner, Business Development and Transactions at ARENA; and Joshua Lowndes, Asset Management Engineer at Pacific Hydro for a panel session titled The role of renewables in our digital future.

This panel explored the role that new generation technologies, such as solar, battery storage, pumped hydro etc, will play for utilities in the future and the importance of digital technologies in the transition to a low carbon future.

With the significant amount of data now being collected thanks to new digital technologies, the afternoon stream Achieving cyber security resilience in a digital environment was a key point of interest for many delegates.

Ian McKenzie, General Manager, IT Operations at Jemena; Sven Bluemmel, Victorian Information Commissioner, and Jarrod Loidl, Cybersecurity and Technology Risk Leader at Rapid7, discussed how utilities can ensure their data is only used to benefit themselves and their customers, as well as how to build high-performing security teams and a security culture within an organisation.

Delegates also spoke highly of the Modernising the network for the digital age stream, comprised of Frank Tudor, Managing Director at Horizon Power; Joe Locandro, Chief Digital and Technology Officer at the Australian Energy Market Operator; Peter Tickler,

Digital Innovation and Advisory Leader at ERM Power; and Andrew Fraser, Network Innovation Team Leader at TasNetworks.

During this session, the panelists considered the role of the grid for digital energy utilities, how to achieve network stability, effective investment in disruptive technologies, and data driven decision-making and asset management.

The Super Panel, featuring seven key speakers from across the two days, wrapped up the conference and offered a ‘big picture’ view of all the topics covered.

FORGING INDUSTRY CONNECTIONS

Digital Utilities 2018 allowed delegates several opportunities to network and get to know other members of the utility community.

Multiple speed networking sessions provided delegates with introductions to colleagues and other industry professionals. These formal sessions were in addition to the numerous opportunities to connect with other attendees during the networking lunches, tea breaks and drinks.

Exhibitors from digital and technology related companies were also on hand to showcase the latest innovations in the sector and were able to provide delegates with advice on how to integrate digital solutions within their organisation.

One of the main highlights of the event was the Gala Dinner and Awards Ceremony honouring the winners of the inaugural Digital Utility Awards Many delegates arrived at the Grand Ballroom to enjoy an evening of fun and celebration - find out who received the top prizes, along with photos from the night, over the page.

The inaugural Digital Utilities 2018 was an engaging event and delegates were left with plenty of tools and advice to move their organisations into the digital age. The second annual Digital Utilities event will be held again in the first half of 2019 - keep reading Utility in print and online so you can stay up to date with all the details as they are announced.

DIGITAL UTILITIES 21

WINNERS OF THE 2018 DIGITAL UTILITY AWARDS ANNOUNCED

The Digital Utility Awards were launched as a way to gather some of the best ideas when it comes to the digitisation of utilities – and the best implementation of these ideas – so that all of the industry can benefit from some of the impressive changes that are being made.

The awards recognise the utility industry’s greatest achievements in the digitisation of utility networks, processes and practices across Australia.

The inaugural Digital Utility Awards were presented on 19 April 2018 at a gala dinner and awards ceremony that was held as part of Digital Utilities 2018

The two-day event, which took place at the Pullman Hotel in Albert Park, Melbourne, was attended by senior leaders and experts from within the utility community.

All award applicants were required to submit their entries by 23 February, with the shortlist announced on 13 March.

The final judging panel was comprised of Water Services Association of Australia Executive Director, Adam Lovell; Energy Networks Australia CEO, Andrew Dillon; and PwC Australia's Energy Utilities and Mining Leader, Mark Coughlin.

BEST CUSTOMER INNOVATION

In recognition of the best digital innovation focused on improving customer outcomes.

Finalists:

AGL for its digital reporting service, Energy Insights, which provides customers with a detailed breakdown of their energy usage per home appliance category.

ERM Power for its digital platform, STEP Online, which gives customers the ability to manage the timing and volume risks associated with contracting in the electricity market.

SA Power Networks for its Customer Communication Applications (CCA), which are a set of online customer self-service tools that enable customers to locate and understand why outages are occurring.

TasNetworks for its Voice of the Customer Program, comprising the Customer Connections Portal, EmPOWERing You Trial, virtual reality software and a variety of advanced network technologies.

WINNER: TasNetworks

DIGITAL UTILITIES 22

UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU

BEST USE OF NEW TECHNOLOGY

In recognition of the best new technology in place across a utility network.

Finalists:

Essential Energy for its use of drone technology to perform network inspection, condition assessment and vegetation management.

Horizon Power for its Horizon Power app, which allows regional and remote customers to monitor and control their energy bills.

Isle Utilities for its digital platform, Isle CATwizard, which provides a review of condition assessment technologies available worldwide, with a vast range of searchable parameters.

SA Power Networks for its Machine Learning Algorithm (MLA) to convert and migrateCAD Drawings through an automated process.

SA Water for its Smart Networks project, which uses pressure and acoustic leakage sensors and smart meters to improve service delivery, reduce service disruptions and better manage assets.

Water Corporation for its use of virtual reality tool ‘Holodeck’ in Safety in Design operability workshops, which enables the operator to walk around the proposed asset as if it was a built environment and better identify safety hazards.

WINNER: SA Power Networks

DIGITAL UTILITY OF THE YEAR

Awarded to the utility showcasing the best use and implementation of digital technologies, tools and processes across their organisation.

Finalists:

Horizon Power

Melbourne Water

Powerlink

Queensland

SA Power Networks

SA Water

South East Water

WINNERS: Horizon Power and SA Water

UTILITY INNOVATOR OF THE YEAR

Awarded to the individual making the single biggest contribution to the digitisation of the utility sector.

WINNER: Frank Tudor, Managing Director, Horizon Power

DIGITAL UTILITIES 23 UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU

The call for NATIONAL URBAN WATER REFORM

The extensive network of water infrastructure that delivers services to more than 20 million people nationally is under increasing pressure due to population growth, climate change, growing customer and community expectations, and aging infrastructure. Infrastructure Australia has called on Australia’s governments and utilities to make fundamental changes to the governance and regulation of Australia's urban water markets.

UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU

24 WATER MANAGEMENT

In December 2017, Infrastructure Australia released its report Reforming Urban Water: A national pathway for change to address the mounting challenges in the urban water industry and provide a case for a national reform while outlining the potential costs of inaction.

Water Services Association of Australia (WSAA) Executive Director, Adam Lovell, said WSAA welcomes the report as it has the long-term interest of customers in mind.

“WSAA supports the calls from Infrastructure Australia for a new national urban water reform plan and an independent national urban water reform body. It is good to see the strong and growing consensus around urban water reform that has developed between governments, water utilities and the private sector.

“While the industry is well regarded across the world and has made significant gains in efficiency and customer focus, WSAA agrees with Infrastructure Australia that the institutional environment in which the industry operates needs to evolve if it is to meet the challenges of the future,” Mr Lovell said.

VULNERABILITY IN THE SECTOR

Infrastructure Australia has highlighted the Millennium Drought of 1997–2012, the most severe Australian drought on record, as exposing a number of vulnerabilities in the sector.

The response to the drought saw a return to major supply-side and led to over $11 billion of investment (in today’s dollars) to augment supply through desalination plants. Because of this, the urban water sector emerged from the Millennium Drought with a resilient, high-quality and diversified supply.

However, the supply challenges faced and crisis-based response from governments during that time raised questions about whether decisionmaking processes, policy settings and institutional arrangements were delivering the most efficient and effective outcomes for the community.

Infrastructure Australia Chief Executive, Philip Davies, said, “If Australians want continued access to safe, reliable and affordable water in the future, we need to begin a staged approach to reforming the sector now — starting with a new national urban water reform plan.

“Now is the time for governments to get on with the job of bringing urban water policy, regulation and governance up to speed so that it can meet the changing needs of Australians in the twenty-first century.”

CONSEQUENCES OF INACTION

Factors such as climate variability and aging infrastructure could put upward pressure on the costs of delivering water services. In order to better gauge the potential impact these challenges have on affordability, Infrastructure Australia commissioned modelling to offer accurate projections on what the future of household water bills may look like.

The analysis found that without appropriate action, a typical residential water and sewerage bill could rise by around $600 in today’s money over the next ten years. By 2040, the average bill could be as high as $2553 in real terms — more than double what it is today.

Mr Lovell said that while WSAA hasn’t seen the detail behind the modelling of future price rises, it does know that substantial capital investment will be required to meet the water and wastewater needs of Australia’s growing cities, and this will ultimately be funded by customers.

“WSAA agrees that unless a new reform program is effectively implemented, customers could be exposed to rising bills in the coming years,” Mr Lovell said.

“We do know categorically that price spikes, caused by a number of factors, including political expediency, poor planning or adverse environmental or external shocks, cause customers distress and lower trust and satisfaction scores.

“We are seeing growing numbers of vulnerable customers who are more acutely exposed to any price increases. Programs such as the Thriving Communities Partnership are working across sectors (banking, energy and others) to reduce the pain and hardship experienced by these customers.”

The report states that for many families, growth in bills of this scale could cause significant hardship, ‘In the context of slow wage growth and rising cost of living pressures, including increasing bills across other forms of infrastructure, it is imperative that the urban water sector ensures services remain affordable’.

Infrastructure Australia suggests short-term measures such as running down legacy assets will do nothing to address long-term affordability of urban water services. "Instead, utilities – with the support of governments and regulators – should look to forward-thinking, efficiency enhancing solutions to service delivery and network management. Advances in technologies, processes and analysis can help utilities to extract more value from existing assets, which can lead to better services at lower costs," the report said.

25 UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU WATER MANAGEMENT

The call for national urban water reform

THE PATHWAY FORWARD

The report suggests that in order to reduce the challenges faced, the urban water industry should move away from a sector where governments balance roles as owner, regulator and policymaker, into a more sophisticated, well-regulated, responsive sector with stronger links between supply and demand, and clearer signals for efficient investment.

Infrastructure Australia has condensed its 12 recommendations into a three stage approach to reforming urban water.

Stage one

The first stage is for the Australian Government to establish a national reform pathway by the end of 2018, including agreeing to a new national urban water reform plan, establishing an independent national reform body and using incentive payments to drive reforms.

This national agreement should follow four national objectives outlined in the report:

• A focus on the long-term interests of users

• Efficiency and affordability

• Independence, transparency and accountability

• Security and resilience

Infrastructure Australia also called for an independent national champion of urban water reform. A body that would provide support to jurisdictions through their separate reform efforts, guide public discussions about urban water and call out instances where reforms are not being progressed as planned.

The report states that "the key to unlocking reforms across other states and territories is to examine what has worked, what may have been less successful, and how these can be applied across the country in a way that maximises benefits for customers and taxpayers".

Stage two

The second stage is to rollout nationally consistent reforms over the next five years. This includes refinements to regulation and governance in each state and territory, improvements to long-term planning and pricing frameworks, and enhanced collaboration between regulators.

Under this stage, regional outcomes should be prioritised to ensure customers outside major cities also benefit from progress in urban water delivery. Private participation should be encouraged where there is potential for it to improve services and reduce costs.

Stage three

The final stage is to consider further reforms over time, such as moving to a national regulator and privatising urban water assets.

The report suggests moving to a national regulator and privatising urban water assets could provide substantial benefits to customers if implemented in the right way—but it is important to recognise that the sector needs to be reformed first.

Mr Lovell said that while it welcomes the report, WSAA does not agree with all the recommendations.

“For example, we have not argued for national regulation, however we support minimum standards for state regulation. Minimum standards would help prevent fraying at the edges of the governance, institutional and regulatory settings that are not consistent with the long-term interest of customers.

“In relation to private ownership, WSAA considers this a matter for individual government shareholders to consider on a case by case basis. WSAA, in its submission to the Productivity Commission’s Draft Report on National Water Reform calls for the Commonwealth and states to negotiate a new National Water Agreement to progress urban water reform.”

Infrastructure Australia has stressed that it is essential to take action before future challenges, such as another major drought or failing assets, prevent clear thinking on efficient, long-term solutions.

26 UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU

WATER MANAGEMENT

FILTEC ADDS EQUIPMENT SALES AND SERVICE TO ITS AUSTRALIAN PROJECT BUSINESS

Filtec has a long and outstanding reputation in New Zealand for providing specialist water treatment equipment and service to its municipal and industrial customers.

Since arriving in Australia in 2015, Filtec International has completed several substantial water treatment projects across a variety of applications.

In addition to our water and wastewater treatment project work we are pleased to announce the arrival of our equipment sales and service division into the Australian market.

Supported by our long-term partners Trojan, SUEZ, 3M, SATI and HACH we offer a large range of equipment solutions including package UV, UF, MF, RO, chlorination, hi flow cartridge filtration, analysers, self-cleaning screens and polymer dosing systems.

Filtec would also be pleased to discuss your ongoing plant service needs.

For further information on Filtec’s skills and capabilities for your water treatment equipment and service needs, please contact Alan Tan on 0413 844 308 or alan.tan@filtec.co.nz. You can also visit www.filtec.co.nz.

•

•

27 WATER MANAGEMENT

TROJAN UV SWIFT SC UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU Utility Partner Solutions New Compact OSEC® L electrolyser

sodium hypochlorite on-site and on-demand Plug & Play with pre-engineered hydrogen ventilation system Applications

Creating

Drinking water - remote chlorination stations

Commercial aquatics / pools / spas and theme parks

Industrial process water and cooling towers

Healthcare, Nursing Homes and Institutional facilities

Agricultural and irrigation - water reuse Key benefits

No hazardous chemicals required

Up to 400g/h chlorine equivalent

50% smaller footprint than other on-site generators

Colour touch screen operation

Certified to NSF/ANSI 61 Drinking Water Standard www.evoqua.com Ph 1300 661 809 sales.au@evoqua.com OSEC L Australien.indd 1 06.03.2018 09:02:16

•

•

•

•

•

•

•

•

TO COMBATING WATER CHALLENGES DIGITAL EFFICIENCY KEY

Australia’s booming population growth has created a need for new water infrastructure and increased maintenance on existing assets to cater for the growing demand. With so many projects underway it’s essential that they are managed efficiently at all levels and that contractors are competent and compliant with a variety of legislative and safety requirements.

With such a high number of water infrastructure projects geographically spread across Australia, there are a greater variety of contractors engaged to complete the maintenance and project work which requires more effective real-time systems that will add value and increase efficiency.

This means utilities and contractors need to know who’s doing what (and where) and what work is planned, to ensure projects run on-time. Additionally safety legislation is a major consideration, have all risks been identified and managed? Are workers able to simply report incidents?

In its recent report Reforming Urban Water: A national pathway, Infrastructure Australia outlined ‘Meeting the needs of a growing population’ as one of the main challenges facing the urban water sector.

The report, released in late 2017, said that to deal with population growth and the strain it’s causing on current water infrastructure, water services must take advantage of ‘shifts in technology and processes’.

The report states that technology can be an enabler of change in urban water and that “greater access to real-time information could hold benefits for customers and suppliers".

It’s this ‘real-time information’ that helps manage projects when there are many different contractors and moving pieces. For contractors and utilities to have access to realtime information they must have digitised systems in place, as paper-based systems don’t provide vision, efficiency or accurate communication.

DIGITAL SYSTEMS INCREASE EFFICIENCY

Digitising paper-based processes helps support collaboration and communication across projects; create efficiencies across an organisation as it removes manual admin tasks; and allows for projects to have auto-generated real-time notifications which supports asset management.

FiNAO is a solutions provider that works with organisations to digitise their paper-based forms and processes by creating an online system offering automatically generated notifications, automated workflow and real-time reporting.

FiNAO Director, Terry Down, said the main thing contractors are looking for in water infrastructure projects is to know what’s happening where and in real-time, so they can make informed decisions based on relevant data. Relevant data can include contract variations or types of defects. This real-time reporting feature (on relevant data) is a point of difference of FiNAO’s systems.

“Traditionally, through paper-based systems, there were delays in getting information to the right people, but our online management systems ensure users at all levels are getting the relevant information that they need in real-time,” Mr Down said.

“This allows for real-time planning so clients know what’s going on right now on their sites and they can plan more efficiently for this afternoon, this evening, tomorrow, the next day and so on. Using our systems allows them to measure progress, as well as reduce supervisor admin time by around 60 per cent, as they now only need to enter data once.

Supervisors can then spend more time doing the jobs they need to, rather than menial admin tasks.

28 WATER MANAGEMENT UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU Utility Partner Solutions

“The other challenge that we’re helping to combat is ensuring contractors and supervisors are competent and compliant the whole time. Previously, if someone became noncompliant there could have been a lag between the expiry of certification, insurances or tickets without knowing. Now they know in advance and can make appropriate decisions.”

Not digitising operations runs the risk of having outdated and incorrect information on projects which can cause a variety of problems. Real-time reporting makes projects more efficient, which in turn supports the overwhelming number of water infrastructure developments and maintenance projects across the country.

“As soon as you generate a report or download data and distribute within an organisation, it can become outof-date. Whereas, if you send people an email with a link to the appropriate data or report, when they click it they get the real-time information. Data can change rapidly and organisations need to have the latest information to make informed decisions,” Mr Down said.

PLANNING STAFF RESOURCES AND UNLOCKING VALUE

A fully automated system helps organisations unlock more value from their assets and projects by generating automated notifications and reminders when, for example, maintenance is required, based on the data entered and specific business and/or organisational requirements. This can ultimately lead to better services and more efficient resources at lower costs.

FiNAO’s online management systems are different because they are off-the-shelf solutions that can be customised to specific business requirements. Organisations can create a system that is directly tailored to their specific needs. A FiNAO system is scalable and flexible, and can grow and adapt as the business develops and needs change.

“Our systems are able to generate reminders for maintenance and services in real-time so asset managers don’t have to be continually checking spreadsheets and manual systems – it’s a completely automated process from start to finish.

“It also allows you to get the right resources involved at the right time and ensures they are available. Based on current requirements and/or work planned, you can assess what resource is required in the future months. Even with high risk and/or specialised work, you know what compliant resource you have so you can then plan and schedule that work around resource availability.

“For example, we have created systems for Sydney Water that plan specific resource activities over the next three months based on current requirements. So when a manager asks, ‘What resources do I need for these activities over the next three months?’ they can see exactly what they’ve got planned out (based on current FTE), which allows them to better plan ahead for managing assets, resources for the work that needs to be done,” Mr Down said.

FiNAO has two major systems in place at Sydney Water: the Delivery Management data portal and the SWConnect system.

Sydney Water’s Delivery Management team delivers most of Sydney Water’s capital investment program so they have to ensure projects are delivered safely, on time and within budget, and with minimal impact on the community and environment. To do this, the team needs to manage hundreds of project sites. The Delivery Management data portal custom system allows Sydney Water to on-board hundreds of staff and projects and using the system, work is allocated and managed as part of a collaborative contracting model.

The online system tracks and manages the progress of multiple construction projects (of various values) in line with GC21 contract conditions utilising accredited management systems compliant with ISO 9001 - 14001/AS4801 and Australian Federal Government Safety Commission accreditation scheme.

“Whether you’re a big company like Sydney Water or you’re just trying to meet your legislation and safety requirements, you need to be able to effectively collaborate and communicate with your people. Our systems allow this at all levels, so businesses can explain what’s going on, particularly to people like the unions and the board. Digitisation allows this to happen very quickly.”

If your business is keen to explore the gamechanging opportunities for digitisation within your organisation, FiNAO is offering Utility readers with a complimentary consulting session. For more information on how FiNAO can create an online management system with real-time reporting for you, head to finaomanagementsystems.com.au or contact Terry Down at terry@finao.com.au or 0413 481 070.

WATER MANAGEMENT 29 UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU Utility Partner Solutions

Raising the roof on

SUSTAINABLE WATER SUPPLY

Many townships and cities around Australia are experiencing dwindling water resources. Wannon Water’s roof water harvesting project is a leading example of integrated water management, using water from household roofs to supplement existing water supplies and support more liveable and sustainable cities.

WANNON WATER'S BRANCH MANAGER ASSET PLANNING

WANNON WATER'S BRANCH MANAGER ASSET PLANNING

Wannon Water is an urban water supply corporation serving the south west of Victoria, including the provincial centre of Warrnambool, a fast growing city facing increasing water demand.

The Warrnambool Roof Water Harvesting Project is a leading example of water-sensitive urban design that is sustainable, cost effective and environmentally friendly.

It promotes the use of an alternative water source to help meet the challenges of adapting to climate change without imposing unreasonable requirements on developers.

The project ‘taps’ a new water catchment by capturing water from rooftops in new residential or industrial subdivisions that would otherwise be lost to run-off. This water is then directed for treatment to supplement the urban water supply.

The harvesting of roof water in urban environments has the combined effect of contributing to the city’s water resources, plus reducing the severity of rainfall events on the natural creeks and waterways in the catchment.

The award-winning scheme, which won the 'Infrastructure Project Innovation Award' at the Australian Water Association’s Victorian Water Awards in December 2017, is a partnership between developers, Wannon Water and the Warrnambool City Council, and is also supported by the Australian and State Governments.

The core aim of the project is to address a number of the detrimental factors associated with urban development by:

• Utilising the available water in the urban environment - within that urban environment - rather than placing further pressure on rivers and groundwater sources

• Reducing the volume that causes a detrimental impact on the streams downstream of urban development

• Avoiding the need to transport water from up to 100km away

• Deferring the need to augment water supply systems to transport ever-increasing volumes of water over long distances

• Addressing the water quality concerns of accessing the roof water run-off

• Reducing the carbon footprint of the water supply system

WATER MANAGEMENT

PETER WILSON AT BRIERLY BASIN

ACHIEVING INNOVATIVE OUTCOMES IN THE WATER CYCLE

Stage one of the Warrnambool Roof Water Harvesting project was launched in the city’s Russells Creek residential growth corridor, at the corner of Whites Road and Aberline Road, in 2011.

The $3.8 million project involved a dedicated pipe network comprising around 2km of trunk mains and more than 2km of smaller collection pipes installed within the new subdivision.

Water from 180 new houses is transported through the pipes to Brierly Basin where it is mixed with other raw water and then treated at the Warrnambool Water Treatment Plant, supplementing the city’s regular drinking water supply.

Property owners still have the option of collecting rain water for their own use such as in gardens. They can install a tank to collect the water and direct any overflow to the scheme. Alternatively they can have no tank and direct all their roof water to the scheme.

The project has a range of social benefits including:

• Sustainable housing - Connection to the roof water harvesting system satisfies the water conservation/ reuse objective of the six star house energy rating requirement. Home owners can meet the water conservation requirements without additional costs. They also save around $5000 by avoiding the need for water-tank-to-toilet and garden tap systems (this can still be installed if the owners wish)

• Public health and safety - When compared to private water tanks or recycled water options, this concept is superior in that the risk of cross-connections or poor tank water quality is removed

• Liveable cities and amenity – More backyard space is available for other uses if water tanks do not need to be installed or attached to houses. Other amenities in the subdivision are not compromised, as more than half the urban stormwater volume is still available for Water Sensitive Urban Design initiatives such as wetlands

• Lower water bills - A water supply system that provides water without pumping and is assessed as the lowest augmentation cost for water will result in lower prices overall. Better quality water provided from roofs rather than rivers also has lower treatment costs

A LONG-TERM STRATEGY FOR FUTURE GROWTH

The scheme will progressively expand as development occurs across the north-eastern area over the next 25 years. Eventually, roofs on 3000 new homes will form an urban catchment and contribute around 471 megalitres of water a year to supplement Warrnambool’s urban supply.

The project is also expanding to the Gateway Business Park in Horne Road, East Warrnambool.

Wannon Water has worked with the developers to design the industrial estate’s pipe network and pumping station.

Roof water will be collected from sheds built during stage one of the development and piped to the existing Dales Road raw water storage basins. It will be transferred to Brierly Basin and then to the Warrnambool Water Treatment Plant where it will supplement the city’s regular urban supply.

Due to the large roof areas and the flat land in the estate, each industrial site will require above-ground tanks allowing the flow entering the basins to be regulated. The scheme requires a designated buffer volume, dependent on the roof area, but property owners still have the option of installing a larger tank and reserving the extra volume for their own use.

The pipe works are planned for completion in the 2017/18 financial year and, when fully developed, this stage is expected to harvest 25 megalitres per year.

31 WATER MANAGEMENT UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU Utility Partner Solutions

Experts assemble:

SIMPLIFYING TURBIDITY READINGS

The common issues operators face using a turbidimeter include instrument maintenance, bubbles in the sample and exposure to chemicals. To find a solution to these challenges, Lovibond® Tintometer® assembled a team of globally recognised turbidity and process instrumentation experts who have created a user-inspired secure system with significantly reduced complexity.

The process of turbidity monitoring is necessary under the Australian Drinking Water Guidelines to ensure that filtration is optimal and produces safe drinking water. Turbidimeters are used to review short-term performance of filtration as well as monitoring their long-term effectiveness over months and years under a full range of challenges.

The turbidimeter has evolved slowly over its life span with the process remaining largely unchanged and complex. Operators encounter the same problems including excessive instrument maintenance to ensure read accuracy, bubbles in the sample compromising the turbidity reading and the handling and exposure of chemicals in the standards. These issues, if not controlled, can affect the accuracy of

the turbidimeter creating false data.

With these issues in mind, the team of experts produced a solution that carefully considers every aspect of process turbidity workflowfrom installation and setup; daily measurement and control; routine procedures such as calibration, verification and maintenance; to data collection and management.

USER-INSPIRED DESIGN

Unlike traditional turbidmeters, the PTV Series requires little maintenance. Focused on simplicity, the PTV series eliminates the need to change light sources regularly and has a thoughtful, easy to clean design.

The body has been optimally designed to provide faster response to turbidity spikes due to its low volume flow; the optimal flow rate of the

instrument is 40 to 80ml per minute. This uses far less water which, over the lifetime of the instrument, translates to over three million litres of water saved per instrument versus competitive instruments.

THE SMARTER WAY TO CONTROL

The PTV 1000 and PTV 2000 allow two ways for operators to interact with the instrument. They have the option to use the integrated touchscreen interface on the unit itself that is able to perform all functions. Or operators can interact with an unlimited number of turbidity sensors using an app installed on a smartphone or tablet. The AquaLXP app eliminates the need for dedicated controllers for each instrument which allows for maximum flexibility with changing regulatory requirements and operator needs. A record of every reading, calibration, verification, cleaning or other maintenance performed over the lifetime of the sensor is automatically logged into the instrument history. The AquaLXP app makes it easy to extract and analyse data such as upper and lower control limits and percent compliance over a selected time frame which can be viewed as a table or graph.

For added security, the app is password protected and only operators within a certain physical proximity of the PTV sensor can connect to it assuring data integrity.

With the PTV series ability to easily interface, export and analyse data, getting accurate turbidity readings has never been easier.

32 WATER MANAGEMENT UTILITY • MAY 2018 WWW.UTILITYMAGAZINE.COM.AU Utility Partner Solutions

Save time, money and water with the Lovibond® PTV Process Turbidimeter Series.

• • Smart interface

• • Simplified and streamlined processes

• • Innovative low maintenance design

• • Unsurpassed accuracy for low-level effluent measurement

• • Regulatory compliant

The development of the PTV Series considered every aspect of the process turbidity workflow. With no light bulbs to change, an easy to clean design and safe calibration procedures, it’s not hard to see the benefits. Call: 1300 735 295 Email: infowaterAU@thermofisher.com

Find out more at thermofisher.com.au/Lovibond-PTV

© 2018 Thermo Fisher Scientific Inc. All rights reserved. Trademarks used are owned as indicated on thermofisher.co.nz/trademarks. 1520987715

User inspired design Lovibond ® PTV Process Turbidimeters