ENERGY STORAGE

PROJECT SUPPORTS

SMART GRID TRANSITION

URBAN AND RURAL COLLABORATION KEY TO SOLVING WATER

CHALLENGES

DIGITAL TECHNOLOGIES

CRUCIAL IN THE AGE OF SOCIAL DISTANCING

INDUSTRY

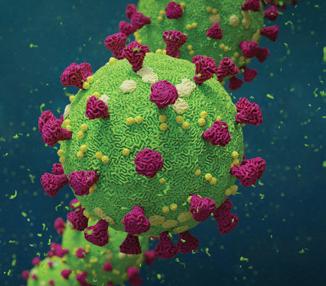

RESPONSE: COPING WITH COVID-19

ENERGY STORAGE

PROJECT SUPPORTS

SMART GRID TRANSITION

URBAN AND RURAL COLLABORATION KEY TO SOLVING WATER

CHALLENGES

DIGITAL TECHNOLOGIES

CRUCIAL IN THE AGE OF SOCIAL DISTANCING

INDUSTRY

RESPONSE: COPING WITH COVID-19

With a SMART Motor Control system and the help of our condition monitoring products, NHP and Rockwell Automation help you keep your plant floor running by detecting potential mechanical issues before they impact production.

For more information on our realtime protection modules, sensors, surveillance software and portable instruments, call NHP today.

he May 2020 edition of Utility has gone to print amidst an unprecedented backdrop of change – with previously unknown terms such as “social distancing” and “flattening the curve” now part of our everyday lexicon, highlighting the strange reality in which we currently exist.

The industry response has been nothing short of remarkable – both the energy and water sectors have been working tirelessly to ensure the reliable and efficient operation of essential services in these challenging times.

Utilities have also been quick to reassure customers that they have the necessary precautions in place to maintain supply while protecting the safety of employees and the community. Go to page 18 for a more detailed analysis of how COVID-19 is impacting the utility industry.

Across the world, COVID-19 is changing the way we live, work and communicate. As we remain, for now, physically distant from one another, digital technologies can at least help us stay socially connected.

Less than a week out from Utility’s flagship event, it became evident that an online conference was the only way forward for Digital Utilities 2020. It was a massive team effort to set up and test the Zoom tele-conferencing platform, adjust the program to reflect the new format and notify all delegates about the change of plan.

However, by embracing and adapting to the rapidly changing circumstances, Digital Utilities was able to create something of value for all participants and ensure conversations around the highly relevant topic of digital transformation could still take place. You can read more about how the event went in our wrap-up article on page 24.

Following the success of the Digital Utilities webinar, we will be hosting a series of virtual conferences on topics designed to assist the industry with the challenges ahead. The Disaster Management virtual conference will explore how Australia’s essential service providers have, and will continue to, manage the COVID-19 crisis, and what this means for future resilience operations.

The Smart Cities virtual conference will look at the essential skills and services the smart cities sector provides, and analyse the ways in which the sector will adapt and change as a result of COVID-19. This event is being delivered in conjunction with the Australian Smart Communities Association, the peak industry association in Australia for our rapidly developing digital, sharing and interconnected communities. To find out more about our different virtual conferences, please contact events@monkeymedia.net.au.

As Australians continue to face tight restrictions on all aspects of daily life, one of the key messages of hope is around unity and the idea that “we will get through this – together”.

Cameron FitzGerald, Managing Director of Southern Rural Water, iterates this message in our water management feature, emphasising that the urban and rural water sectors must work together to deliver a secure water supply, and identify opportunities to learn and grow from each other.

This edition also features ElectraNet’s Dalrymple Battery Energy Storage System (BESS), which won Energy Networks Australia’s 2019 Industry Innovation Award. The remarkable project is now in full commercial operation and is the first BESS in the National Electricity Market (NEM) to provide both regulated network reliability and security services alongside competitive market services.

The project has incorporated a knowledge sharing portal, which provides a significant amount of information to assist the entire utility industry in observing first-hand how the Dalrymple BESS is performing – another positive example of industry collaboration for the benefit of all. It is worth noting that some of the editorial in this edition predates the COVID-19 crisis, but there continues to be industry-wide consultation on pandemic response measures to ensure people, assets and security of supply are protected.

Thank you for your continued support of Utility – it is appreciated more than ever. If you’re working from home and haven’t updated your postal address, please get in touch and we can temporarily redirect your subscription.

Most importantly, stay safe.

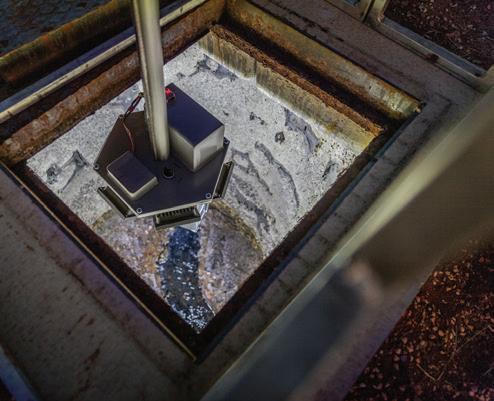

Afreak storm event in late January 2020 knocked six transmission towers to the ground and damaged a seventh just north of the town of Cressy in Western Victoria. This event caused an outage on the Moorabool to Mortlake and Moorabool to Haunted Gully transmission lines.

Supply to the Portland aluminium smelter was interrupted, and the Heywood interconnector between Victoria and South Australia was impacted, separating South Australia from the National Electricity Market.

Despite the damage, AusNet Services, the primary declared transmission system operator for Victoria, had temporary towers in place for the Moorabool to Mortlake line in just over two weeks of the incident occurring.

Considering transmission towers are significant structures designed to withstand extreme weather, what happened to cause the towers to collapse?

It was an extreme localised storm event late in the afternoon on Friday 31 January that caused the damage.

Winds in excess of 160km/hr (44m/s) created a hefty downdraft known as a downburst that is believed to have flattened six steel transmission towers completely transversal/perpendicular to the wind direction.

Significant damage to transmission equipment is a rare event, so the emergency reconstruction of seven towers and two 500kV lines is no mean feat.

AusNet Services organised operators to isolate and earth the lines, and immediately deployed local delivery partners who quickly reached the site in Cressy to assess the damage.

At the same time, AusNet Services worked closely with the Australian Energy Market Operator (AEMO) to restore supply to the Portland aluminium smelter on a contingency basis, utilising the services of Origin’s Mortlake Power Station.

Preliminary design works for the temporary reconstruction of the transmission towers were completed two days after the storm.

TransGrid, ElectraNet and Powerlink provided a conductor which helped accelerate the restoration process of the first line.

Three days after the storm event, materials for the temporary towers arrived on site ready for construction works to commence the following day.

The seven damaged towers each held double circuit 500kV lines along the Moorabool to Mortlake and Moorabool to Haunted Gully transmission lines.

The two sets of temporary towers that have been reconstructed are each designed to hold one of the two restored 500kV circuits. In the interests of restoring the lines as quickly as possible, one 500kV line was restored at a time, building temporary towers for each line. This process also helped ensure a more secure transition for the Portland aluminium smelter from its contingency arrangement.

The first line was repaired and re-energised by 17 February and the second line was back in service by 3 March.

More than 110 experts from AusNet Services’ delivery partners and interstate transmission peers helped with the construction of the temporary towers and removal of the fallen infrastructure.

The Bureau of Meteorology had predicted some storm activity on 31 January, but not the extreme weather that was experienced.

At the time of the storm, more than 500MW was being exported from SA to Victoria via Heywood. Seconds later the interconnector had reversed and was importing 500MW into SA until the Mortlake Power Station reduced generation.

The 1,000MW turn around caused wind and gas plants to trip or back off in SA. Grid-connected batteries provided a significant amount of frequency control ancillary services (FCAS). This response avoided a high-frequency collapse on the SA power system.

The Portland aluminium smelter tripped off initially but was brought back on to avoid the potlines solidifying, with supply for the Victorian facility provided by Origin’s Mortlake Power Station.

System improvements instituted post the 2016 event helped the grid to remain stable in SA, given the severity of the disruption. The FCAS services from grid-connected batteries were vital to this task.

There will no doubt be plenty of learnings to come, but through an industry combined effort that included AEMO, TransGrid, ElectraNet and Powerlink, AusNet Services and its delivery partners were able to provide a temporary solution in a very short timeframe.

IMAGE BY: AUSNET SERVICES.

IMAGE BY: AUSNET SERVICES.

Strengthen industrial cybersecurity without compromising efficiency.

As industrial devices become more connected through the Industrial Internet of Things (IIoT) there is not only great potential for businesses to optimise operations, there is also a significant challenge – cybersecurity. Moxa’s range of robust network devices meet the technical security requirements of the globally recognised IEC 62443 standard, which ensures your industrial control systems are well protected against network intrusions or attacks.

Connect with confidence.

Madison Technologies has been distributing Moxa’s reliable networking infrastructure Australia wide for more than 14 years. Our team is dedicated to ensuring our Moxa portfolio is fully supported with an extensive range held locally across our national supply chain, and a team of Moxa certificated sales and technical support engineers.

Although the short-term focus for society and water utilities is managing the COVID-19 pandemic, WSAA also retains a focus on long-term issues.

Ensuring all water supply options are on the table is a key focus for WSAA. In October 2019, we released our All Options on the Table report, which focuses on one option that is sometimes left off the table – purified recycled water for drinking. The report looks at insights and perspectives regarding community engagement, from places around the world where it has been considered and in most cases, adopted.

It includes ten lessons and global case studies, as well as recommended actions based on the learnings from these case studies. The report includes world-leading maps showing that purified recycled water for drinking has been adopted by 35 cities around the world, with more to come. That does not include the myriad cities all over the world where unacknowledged reuse has long occurred.

The report is not intended to identify purified recycled water for drinking as the way forward for specific locations but to go through key lessons learnt and consider how to have a conversation with the community should it be a future supply solution.

Some of the key findings on community education engagement include:

• It can be done – many towns in many countries have chosen it among other options as a safe and sustainable part of their water supply

• The three ‘t’s – time, trust and transparency – are crucial elements in engaging with any community

• Seeing is believing – there is immense value in running a demonstration project to showcase and prove the technology. As part of this, establish a visitor centre or experience so that people can see the systems in action, learn how it all works and ask any questions in a calm, fun learning environment. This could include tasting the water

• Wording and imagery are critical – words and images create perceptions and reactions, so it’s really important to choose these carefully

• News media coverage has a profound impact on public acceptance, and political support is essential

• Grassroots education and engagement can be more effective than high-profile marketing activity or ‘above the line’ presence

• General education around the urban water cycle and context will help prevent stigma and encourage acceptance

• Regulators play a powerful role

In August 2019, the Australian Infrastructure Audit 2019 report from Infrastructure Australia stated that “ensuring all options are on the table, and can be deployed when required, is likely to be essential for governments and operators to effectively and efficiently ensure secure supply over the long term”.

Later in 2019, WSAA asked nearly 10,000 Australians if they were interested in hearing about how the water industry

can purify water from a range of sources to drinking water quality or better – 57 per cent said they were interested in hearing more.

Our customer research in late 2017 found that acceptance of different drinking water sources varies across demographics and regions. It found higher acceptance levels in Perth and Brisbane which have both engaged in higher levels of public discussion around this area compared to other locations. Based on that, we found a correlation between communities engaging in public discussion and having purified water recognised as a viable option.

We have produced materials about visitor centres around the world, which are often part of a demonstration project. It would be valuable to see a demonstration project established in eastern Australia – as Water Corporation did in Perth while considering its Groundwater Replenishment Scheme.

WSAA also has a range of easy to use videos, animations, posters, expert testimonials and other resources. These will help any utility looking to start or continue the conversation with their community about purified recycled water for drinking.

The All Options on the Table report is available on WSAA’s website: https://www.wsaa.asn.au/publication/all-optionstable-lessons-journeys-others

For more information on this work, please contact Danielle Francis at WSAA: Danielle.francis@wsaa.asn.au

The Queensland NSW Interconnector (QNI) upgrade project will advance to the next stage after clearing a major review from the Australian Energy Regulator (AER).

The AER announced it had approved the Regulatory Investment Test for Transmission (RIT-T) on 30 March 2020. This determination supports the options assessment, costs and net benefits of the QNI project.

The $230 million QNI upgrade project, proposed by TransGrid and Powerlink, aims to increase transmission capacity between Queensland and New South Wales.

The AER has fast tracked its consideration to support the timely completion of the project. TransGrid expected that construction of the project would start in March 2020, with delivery and completion of inter-network testing expected by June 2022.

The project is expected to add an extra 60 cents to the transmission component of annual customer bills in New South Wales.

AER chair, Clare Savage, said the Liddell Power Station was scheduled to close in 2023, which would reduce the generation capacity in New South Wales.

“The proposed interconnector upgrade will allow more electricity to be exported from Queensland to New South Wales avoiding the need for costly new generation,” Ms Savage said.

The RIT-T is a cost benefit

assessment of the proposed interconnector. AER tested the reasonableness of TransGrid and Powerlink’s inputs and assumptions across a range of scenarios.

It found that the project was robust and would deliver a net economic benefit to Australian energy consumers.

“The investment is expected to deliver $170 million in net benefits to consumers and producers of electricity, and to support the ongoing energy market transition. The cumulative benefits are expected to exceed the investment cost within seven years,” Ms Savage said.

“We’re saying that the assessment by TransGrid and Powerlink stacks up and that consumers will get value for money from this investment.

“The proposed interconnector will help to address potential system security problems and alleviate upward pressure on wholesale electricity prices.”

TransGrid has separately applied to the AER to amend its existing revenue determination to recover the efficient costs of delivering the project. The AER will make a separate determination on this element in April 2020.

TransGrid’s Executive Manager of Works Delivery, Michael Gatt, said the company welcomed the AER’s determination.

“The QNI upgrade is important because it will increase the capacity to share electricity between Queensland and New South Wales, and reduce current and forecast network

constraints,” Mr Gatt said.

“It will ensure greater reliability of lowest cost electricity, as we enable more efficient sharing on the NEM and introduce more innovative technology to the system. The project is expected to provide net benefits of $170 million to electricity customers and producers.”

TransGrid is upgrading the 20-yearold transmission lines and three substations at Tamworth, Dumaresq and Armidale.

“It will allow 460MW more power to transfer into Queensland, and 190MW more into New South Wales and the ACT when it’s needed, and it will link customers to the National Energy Market.

TransGrid began working with Queensland transmission business Powerlink to initiate the RIT-T process in November 2018 and a number of network and non-network options were considered.

The project has been supported by the Australian and NSW Governments which have provided joint-underwriting to enable TransGrid to accelerate the delivery of the upgrade.

Mr Gatt said early works have commenced on the upgrade project which is expected to be delivered in September 2021.

“TransGrid is already working to deliver the upgrade, conducting environmental, geotechnical and site surveys, and engaging with communities along the existing transmission line corridor.”

The Water Services Association of Australia (WSAA) has announced a new partnership to launch an industry-leading Innovative Technology Program.

WSAA will partner with Isle Utilities and ThinkPlace to deliver the program for WSAA and its members.

The partnership offers a unique synergy between humancentred design and technology due diligence; visioning and co-design through to the identification and evaluation of leading-edge technology and innovation.

WSAA Executive Director, Adam Lovell, said, “Our partnership with Isle Utilities and ThinkPlace has been created following a global, competitive tender, and it seeks to facilitate collaboration, knowledge sharing, networking and cooperation in technology innovation across the entire WSAA membership.”

Managing Director of Isle Utilities (Asia-Pacific), Dr Michael Storey, said, “We look forward to delivering a seamless, endto-end experience for all WSAA members to define strategy, provide access to technology and innovation, and provide expertise to assist implementing these technologies.”

Isle is a leader in technology innovation and has developed a global ecosystem of 350 water users, including 200 leading water utilities, and more than 6,500 technology providers.

Global Partner of ThinkPlace, Dr Nina Terrey, said, “We are excited to partner with Isle Utilities and bring our design thinking approaches to driving positive impact in the water sector.”

Isle and ThinkPlace have a specialised team of 100 across Australia and New Zealand as well as a global team of 200 spanning six continents and 13 countries.

The CEO of Hydro Tasmania, Steve Davy, will step down when his contract ends in late 2020.

Steve Davy has been serving as the Chief Executive Officer of Hydro Tasmania for almost seven years, and has been with the business for over 15. Prior to being the CEO, Mr Davy was the Chief Commercial Officer, managing commercial operations that include supporting mainland retailing, contract and spot trading, major customer negotiations, supplier arrangements, and a range of operational activities.

Hydro Tasmania’s Chairman, Grant Every-Burns, announced Mr Davy’s resignation, and explained that Mr Davy had led the business through the energy supply challenge to being at the forefront of Australia’s renewable energy transition.

“Under Steve’s leadership, Hydro Tasmania has laid the groundwork for our future success as a business,

taking a bold vision for the role Tasmania can play in a renewable energy future and turning it into an actionable plan through the Battery of the Nation initiative.

“On behalf of the board, I thank him for his dedication, passion and hard work,” Mr Every-Burns said.

Mr Davy said he was proud of the achievements of the Hydro Tasmania team over the past 15 years, particularly the business’ support for the Tasmanian community.

“Now in its fourth year, our Community Grants Program has funded 20 projects throughout Tasmania, supporting everything from music, dance, historical preservation, healthy eating and mental health initiatives.

“Our new education program ‘Generation Hydro’ is now helping Tasmanian students learn about renewable energy and the opportunities for STEM careers here in Tasmania.

“I have great pride in the way our people responded to the energy supply

challenge, and I am also very proud of the work that has been done to identify and drive the opportunity for Tasmania to help Australia’s transition to a renewable energy future, and I will watch with interest as the Battery of the Nation vision and Tasmania’s recently announced 200 per cent renewable energy target become a reality.”

Hydro Tasmania has engaged executive search firm Heidrick & Struggles to assist in the recruitment of a new CEO.

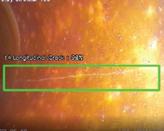

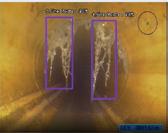

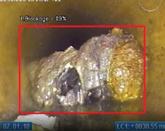

Trains the model to identify defect classifications.

Detect anomalies faster and fix infrastructure

sooner

Action insights more often

Streamline pipe asset management operations

More capacity for complex analytical tasks

Uses AI to review CCTV footage of pipes to identify cracks and anomalies.

Drafting and planning systems more accurately to achieve desired functions

Piping vibration, thermal and stress analysis

Sourcing more valuable engineering solutions

More thorough site inspections

Compliance with authority codes

Global application - applicable to any pipe material

Ability to apply expert classification and further train the model as the database builds

Concise classified defect report generated at completion of analysis

Generates a concise defect report to inform future maintenance plans or repair schedules.

Detect up to 15% more defects than a manual review

Contact us to find out how Pipe Ai can deliver better efficiencies within your organisation.

+61-7-3532 1300

enquiries@peakai.com.au

www.peakai.com.au

Longitudinal Crack Blockage Fine Roots

The Australian Energy Market Commission (AEMC) has published three milestone reports detailing its progress to deliver access reforms to Australia’s energy grid.

The reforms fall under the Coordination of Generation and Transmission Investment (COGATI) review.

Reforming the way generators access the grid remains critical to the future of the National Electricity Market (NEM) and represents the cheapest, fastest and fairest path towards a low-emissions energy sector.

AEMC’s access reforms are designed to integrate new technologies into the national grid in a way that’s reliable, secure and works in consumers’ best interests.

The reforms aim to rethink the NEM to develop price signals that will preference lowest cost and lowest emissions energy, keep power bills trending down and support transmission investment without repeating ‘gold plating’ mistakes of the past.

The three reports, which follow on from COAG Energy Council’s consideration of access reform at its meeting on 20 March, are:

• An update paper, which provides a recap of the case for change and updated key features of the model to address integration and congestion issues associated with the rapid transformation of Australia’s energy generation mix

• A technical blueprint for the access model that incorporates stakeholder feedback to date and will be used in further consultations during 2020

• A benchmarking study from NERA Economic Consulting on the benefits, costs and experiences of transmission access reform in other countries. The study estimates reform benefits that considerably outweigh the costs. NERA’s best estimate of the total benefits for consumers of the reforms is $387 million in savings per year – equivalent to two per cent off the cost of wholesale energy

AEMC Chair, John Pierce, said the Commission would, through the ESB’s market design process, continue to refine and develop the access reform model with stakeholders over the course of 2020.

“This will allow us to develop draft rules by the end of the year. While we have allowed extra time to further develop the detailed design for the model, what hasn’t changed is that this work was always, and will continue to be, integral to the Energy Security Board’s 2025 market redesign,” Mr Pierce said.

“This is because the transmission challenges facing the grid have a two-part solution. The first is actioning AEMO’s Integrated System Plan so that the right transmission is built and the second is implementing access reform so that the investments in that transmission are effective in the long term.

Through its innovative solutions, Veolia Water Technologies enables industry, local authorities and citizens to optimize their use of resources for more efficient, environmentally-friendly and socially responsible outcomes.

We understand the importance of increasing the value of water and we do so by supplying high quality water, treating and reusing wastewater, producing and/or recovering energy, extracting raw materials and capitalizing on valuable byproducts.

www.veoliawatertechnologies.com.au

“Both of these levers are fundamental to any market redesign because if you do the first and not the second, you pay billions to defer, not remove, current inefficiencies in the system. If we don’t tackle these issues holistically we also won’t keep power prices trending down – and we won’t realise the full emissions value of the renewable revolution.”

The access reforms rely on generators ‘doing their bit’ by improving the way they bid electricity into the market, making sure the cheapest, greenest energy gets dispatched most effectively. The result will be lower emissions and significant consumer cost savings.

In return, generators will receive better information on where to invest and more certainty on what profits they will make. For those more affected by the reform, the AEMC is proposing ways to help them through the transition, so everyone benefits in the long term.

“While these proposals are new for Australia, the changes we’re suggesting have been successfully in place for decades in many parts of the world including New Zealand, North America and Singapore,” Mr Pierce said.

“And they have shown significant benefits for consumers, as the benchmarking document we publish today shows.

“We are conscious though, that change must be managed carefully. This is why we have conducted an exhaustive

stakeholder engagement process around the reforms.”

Engagement to date includes:

• 151 written submissions on four consultation papers

• Six technical working group meetings

• Two public workshops

• More than 130 bilateral meetings and workshops with the ESB, AER, AEMO, consumers, Transmission Network Service Providers, incumbent and prospective generators, existing and prospective investors, government departments and other interested parties

“Our engagement will continue as we work together with our stakeholders on implementing these important reforms,” Mr Pierce said.

“Engaging with stakeholders in a considered way has always been fundamental to the way we work and will continue to be.”

Further detail on next steps for stakeholder engagement will be released shortly.

The AEMC has engaged NERA Economic Consulting to quantitatively model the reforms for the National Electricity Market. The results will inform the final access reform model blueprint.

•

•

•

Genex has signed a 30-year Energy Storage Services Agreement (ESSA) with EnergyAustralia for the 250MW Kidston Pumped Storage Hydro Project.

Key terms of the ESSA include:

• A term of up to 30 years, with an initial term of ten years and two options (at EnergyAustralia’s election) to extend for a further ten years each (Extension Options)

• Genex will provide the full operational dispatch rights for the K2-Hydro plant (including P&L responsibility) to EnergyAustralia in exchange for a fixed annual rental payment, escalating over the total term

• Following the expiry of the full 30-year term, and therefore conditional on the exercise of the Extension Options, EnergyAustralia shall have the right to acquire Genex’s shareholding in the project for a fixed cash payment

• The ESSA is subject to a number of conditions precedent, including achieving financial close for the project, which must be satisfied prior to the financial close sunset date of 31 December 2020

Genex remains deeply engaged with the other project stakeholders, including the Northern Australia Infrastructure Facility (NAIF) to complete the restructuring of the project financing on the basis of the agreed terms of the ESSA.

Genex CEO, James Harding, said, “Since November 2019, Genex has been actively working with all of its project stakeholders, including EnergyAustralia, NAIF and the Queensland Government, to complete the restructuring of the project financing for K2-Hydro and progress to financial close as quickly as possible.

“We have been extremely pleased with the support of our stakeholders and counterparties during this period and now believe, with today’s signing of the ESSA with EnergyAustralia, that we have the basis to move forward to financial close of the project.

“The K2-Hydro project will be the first pumped storage hydro project in the National Electricity Market in almost 40 years, and the first to be developed under private ownership.

“It will create over 500 jobs during construction and deliver significant economic benefits to Queensland through providing reliable generation for the grid and applying downward pressure on wholesale electricity prices.”

Seqwater’s Mount Crosby East Bank Water Treatment Plant, on Brisbane’s west, will undergo a filtration upgrade as part of a $35 million makeover to enhance water supply security for South East Queensland.

Natural Resources Minister, Dr Anthony Lynham, said the filtration upgrade would significantly improve the plant’s resilience to extreme weather events and climate change.

“The Mount Crosby water treatment plants, both East Bank and West Bank combined, are critical to the operation of the South East Queensland Water Grid and can provide up to half the region’s daily water supply,” Dr Lynham said.

The project, which is expected to take more than two and a half years to complete, will generate up to 100 jobs and deliver major improvements to the plant’s filter design and control.

“It will significantly improve the

plant’s ability to maintain water supply during extreme rain events and flooding to further improve the water supply security of our region,” Dr Lynham said.

Seqwater Chief Executive Officer, Neil Brennan, said the water grid would be used to supplement Brisbane’s water supply when the refurbishment works were being undertaken.

Mr Brennan said the work was being staged to ensure water supply was maintained, with six filters being taken offline at a time.

“Taking filters offline will result in reduced production at East Bank, with

the water grid and other treatment plants across the region helping to supplement supply to Brisbane and Ipswich during the project,” Mr Brennan said.

“This project will ensure that the East Bank can continue to supply safe and reliable drinking water to South East Queensland well into the future and be better equipped to deal with the impact of climate change.”

Filters play an essential role in the water treatment process, assisting with clarifying water prior to disinfection.

The upgrade work will help the plant be able to treat water with high levels of turbidity or sediment which can result from extreme rainfall events across the Wivenhoe catchment washing soil and debris into the creeks and waterways.

Water treated at the Mount Crosby water treatment plants comes from the Brisbane River, downstream from Wivenhoe Dam.

The Victorian Government has made the decision to remove the ban on onshore conventional gas exploration and production.

It introduced two bills to Parliament: one will enshrine Victoria’s fraccing ban into the state constitution, and the other allows for an orderly restart of the onshore conventional gas industry in the state. It will also introduce measures aimed at ensuring newly sourced gas within Victoria and state waters will be prioritised for domestic use.

In 2017, the Victorian Gas Program set about determining the potential for new onshore conventional gas discoveries and what would be the risks, benefits and impacts of allowing exploration and development.

The program has now delivered a large amount of work to answer these questions. The scientific studies have found there are likely to be onshore conventional gas resources in south-west Victoria and Gippsland.

The three years of studies has concluded that an onshore conventional gas industry would have no significant impact on farming because of the low risks to the environment or groundwater.

The gas program has shared the science with the community via more than 800 separate engagements.

Following the passage of the bill in Parliament,

the department will start working with industry and other stakeholders to amend the Petroleum Industry Regulations 2011

In line with the findings of the Victorian Gas Program, community engagement elements of onshore conventional gas projects will be strengthened.

In practical terms, the orderly restart will commence immediately with some specific milestones in place as the industry moves into gear from a standing start.

Onshore conventional gas development could potentially start from 2023-24 if industry makes a gas discovery, considers it commercially feasible to develop and secures the necessary regulatory approvals.

The Australian Energy Council (AEC) supported the Victorian Government’s decision. AEC Chief Executive, Sarah McNamara, said the decision was a sensible one supported by science.

“Ensuring reliable gas supplies into the future will help affordability for domestic, commercial and industrial customers,” Ms McNamara said.

“Readily available gas will also be an important, flexible backup fuel that is likely to help ensure the reliability of the state’s grid as older coal-fired power plants retire and more wind and solar generation comes into the system.”

As the fallout from the global COVID-19 pandemic continues to wreak havoc across the globe, Australian utilities have combined to tackle the challenges head-on. We take a look at the frontline response our essential service providers in the energy, water and telecommunications industries have rolled out in the immediate aftermath of the crisis.

The COVID-19 pandemic has rocked the global community to its core, wreaking a path of destruction across the world and prompting government responses not seen since World War II.

While economies globally have been battered and unemployment rates have skyrocketed, providers of essential services – like utilities – have found themselves run off their feet in a race to continue to meet customer needs, while maintaining new societal norms such as social distancing and working from home.

Here, we take a look at the steps the energy, water and telecommunications industries are taking to keep operating our essential services in these challenging times.

In the energy sector, federal and state governments have established a coordinated national approach to managing the impacts of COVID-19, fully supported by industry associations and energy utilities.

Federal Minister for Energy and Emissions Reduction, Angus Taylor, said the energy sector remains well-prepared to deal with the virus, and early action taken by governments and industry should ensure energy supplies for the coming months.

“One of my top priorities will always be to keep the lights on for Australian families and businesses,” Mr Taylor said.

“We also want to make sure that generators, retailers and networks are ready to support any customers who find themselves in difficulty due to the Coronavirus.

“The energy sector is good at responding to disruptions. The industry has well-established risk management, emergency management and business continuity plans, which are regularly tested and improved.”

A number of the state governments have announced payment freezes or subsidies for household and business energy bills.

The Western Australian Government has developed a $607 million stimulus package to freeze household fees and charges until at least 1 July 2021. The freeze will apply to the entire “household basket”, including electricity, water, motor vehicle charges, emergency services levy and public transport fares.

In New South Wales, a $30 million boost to the Energy Accounts Payments Assistance Scheme (which helps people experiencing a short-term financial crisis or emergency to pay their electricity or gas bill) has been announced.

Queensland meanwhile is giving sole traders, small and medium businesses a $500 rebate on their power bill for this year; and the Tasmanian Government has announced a $985 million stimulus package that will cap energy prices for 12 months and will waive the first quarterly bill after April 1 2020 for small business customers and community service organisations.

The Federal Government, through the Australian Energy Regulator (AER), has also set reasonable expectations of energy companies to protect householders and small business customers during the COVID-19 pandemic.

The AER’s Statement of Expectations sets out a range of measures, including:

• Waiving any disconnection, reconnection and/or contract break fees for small businesses which have gone into hibernation, along with daily supply charges to retailers, during any period of disconnection until at least 31 July 2020

• Offering all households and small businesses who indicate

they may be in financial stress a payment plan or hardship arrangement

• Not disconnecting customers who may be in financial stress, without their agreement before 31 July 2020 and potentially beyond

• Deferring referral of any customer to a debt collection agency for recovery actions, or credit default listing until at least 31 July 2020 and potentially beyond

• Minimising the frequency and duration of planned outages for critical works, and providing as much notice as possible to assist households and businesses to manage during any outage

The Australian Energy Council (AEC) confirmed that energy retailers stand ready to provide scalable, accessible and tailored assistance to all affected customers.

AEC Chief Executive, Sarah McNamara, also welcomed the AER’s recognition that the viability of energy businesses must be protected. Retailers often cannot control costs from other parts of the energy supply chain, such as wholesale power prices and distribution costs, that are charged to customers.

“For that reason, over the coming months, a whole-of-sector response is vital to achieve the best outcomes for customers. We look forward to working with the AER and other market bodies, governments and stakeholders on the best ways to share the risks and costs across the sector, and work through these expectations,” Ms McNamara said.

Commenting on the release of the Statement of Expectations, Energy Networks Australia CEO, Andrew Dillon, said networks were working to assist customers.

“Networks continue to discuss with governments, regulators and retailers about the best ways to support customers through this difficult period,” Mr Dillon said.

“Energy networks understand many households are also facing challenging circumstances. With many customers now

working from home, networks are doing what they can to minimise the impact of planned outages for critical work and to keep them as short as possible.

“Safely keeping the lights on and the gas flowing for the months to come is critically important, and networks are continuing to undertake critical works to keep energy supplies safe and reliable.”

Mr Dillon was also quick to point out that the industry has been working for some time now to start to prepare for the challenges this crisis will continue to present for a number of months.

Together with ENA, Ms McNamara confirmed that their members have been working to maintain the safety of their people, the security of the energy system and to support customers who are experiencing difficult circumstances.

“Safety is always our top priority. Energy companies have undertaken a range of measures in response to this pandemic to ensure its workforce, assets and energy supply are protected,” Ms McNamara said.

“There continues to be industry-wide consultation on pandemic preparations and necessary responses, with AEMO in regular discussions with generators, network and transmission companies and gas companies.”

Pandemic response measures underway include:

• Ensuring essential supplies, including the stockpiling of fuel supplies

• Reviewing any scheduled plant or network outages for maintenance and assessing the need and potential for rescheduling

• Further restricting access to control rooms and limiting access to areas required by critical staff

• Splitting of teams and establishment of multiple, separate teams

COVID-19: utilities unite to respond to the crisis

ENERGY COMPANIES ARE WORKING TIRELESSLY TO MAINTAIN NETWORKS AND ENSURE CONTINUITY OF SUPPLY DURING THE COVID-19 CRISIS.

• Rostering changes

• Non-contact and social distancing for shift changes

• Implementing new working arrangements, including having staff work remotely when feasible

• Monitoring of essential service providers

• Maintenance of personal protective equipment stocks

The ENA also moved to remind customers that part of keeping the lights on and gas flowing during these uncertain times is continuing to carry out scheduled maintenance works across our networks. Many utilities have reported frustration from customers having their services shut down during this challenging period; however Mr Dillon reminded customers that “there is a need to continue critical maintenance to protect lives, prevent damage to properties and keep the power on for the future”.

In the upstream energy sector, the Australian Petroleum Production & Exploration Association (APPEA) and Australian Pipelines and Gas Association (APGA) are both working with members, governments and energy users to ensure the delivery of essential gas supply to local customers.

APPEA Chief Executive, Andrew McConville, and AGPA Chief Executive Officer, Steve Davies, confirmed members were taking all steps necessary to ensure the production and delivery of gas supplies continued.

Mr Davies said the upstream and pipeline industries had robust operational integrity measures in place at all times, but were vigilant to the additional challenges posed by COVID-19.

“We are ensuring good information flows and open channels of communication as they are absolutely essential elements of the response in this rapidly changing situation,” Mr Davies said.

“We are continuously monitoring the situation and are taking appropriate precautions to ensure the energy we need in our homes, commerce and industry is delivered.”

The country’s energy utilities have been quick to reassure customers that they have the necessary precautions in place to maintain supply while protecting the safety of employees and the community.

Common themes in the response from energy utilities have been strict isolation protocols; limits on face-to-face interactions where possible; additional cleaning of sites and workplaces; additional personal protective equipment for staff; telephone contact with customers before crews arrive; and phone notification of future outages, rather than face-toface.

Other measures include increased infection control measures, ceased business-related international travel and teleconferences rather than face-to-face meetings where possible.

Most companies have also established separate locations, backups and staffing in critical service areas like control rooms; and have limited access to, and contact between, those teams to sustain customer operations in the event a case is confirmed.

Power companies have also noted that while it is too early to see a significant change or shift in demand for power supply due to COVID-19, it is likely we could see energy demand in commercial or industrial areas decrease, but a peak load in residential areas – similar to what we experience on an average weekend.

Contingency plans are underway across the country too, which includes a strong focus on completing urgent tasks on the network to ensure it is as resilient as possible in the event

of weather or other events that could happen in conjunction with the challenges COVID-19 presents.

AGL CEO, Brett Redman, reassured customers that there will be help for those in need as Australians face difficult financial times due to the Coronavirus outbreak.

In a letter to more than two million customers, Mr Redman acknowledged there are “difficult times ahead” for the country and urged any AGL customer experiencing difficulties paying their bill to get in touch.

“During the evolving COVID-19 pandemic, we want to reassure you that we are committed to supporting our people, customers and the community.”

EnergyAustralia has also reaffirmed its commitment to customers doing it tough during the Coronavirus pandemic in Australia.

Chief Customer Officer, Mark Collette, said that EnergyAustralia is already helping customers through this difficult period – but customers need a whole-ofindustry response.

“The COVID-19 situation is unlike anything we have seen or experienced before. We support the call by the AER for a whole-of-industry response to help households and businesses nation-wide get through this challenging time,” Mr Collette said.

“The AER has highlighted the need for network companies to support energy customers by waiving fees and extending payment terms; retailers alone cannot deliver what is needed to support customers.

“Our message to EnergyAustralia customers is this: If you're worried about not being able to pay your energy bill, reach out to us.”

Origin Energy has also reassured its customers that help is available for anyone impacted by COVID-19, and that it continues to take action to ensure access to reliable energy supply is maintained throughout the pandemic.

Origin CEO, Frank Calabria, said, “This is an unprecedented situation and we are focused on protecting the health and safety of our people and the communities in which we operate, while maintaining safe and reliable operations.

“We encourage any customers who are having trouble paying their bills to request a payment extension through our website or call us to discuss other types of support available.

“As a provider of an essential service, we plan extensively for these sorts of events and I’m proud of how our teams have responded and coordinated with industry to maintain reliable supply of power, natural gas and LPG to our millions of customers across the country.”

Leading energy infrastructure company Jemena has also taken significant steps to ensure the lights stay on and gas continues to flow to its more than 1.7 million customers during the COVID-19 pandemic.

“This is a dynamic and evolving scenario, and we have enacted our crisis management and pandemic response plans in response to the COVID-19 outbreak so we are able to maintain our operations while ensuring the safety of the community and our people,” Jemena Managing Director, Frank Tudor, said.

“At the same time, we are looking with a critical eye at our normal operating arrangements, so we can move beyond our standard approach to responding to hardship, noting the

extraordinary circumstances facing many Australian households and businesses.”

In the water industry, it’s a similar story as members of the industry come together to develop and provide a coordinated response to the crisis.

“Water utilities supply the most essential of essential services to our communities,” Adam Lovell, Executive Director of the Water Services Association of Australia (WSAA), said.

“Our drinking water remains high quality and safe to drink. In these unprecedented and challenging times, the industry is taking actions to ensure the continued safe supply of high-quality water and wastewater services in Australia and New Zealand.

“WSAA has held online meetings of its Customer and Leadership Committee and Utility Excellence Committee, which allowed members of the industry to discuss and share current actions in relation to COVID-19.”

Water utilities have been quick to assure customers their priority is delivering reliable water and sewerage services, and ensuring the safety and wellbeing of water industry employees.

Water authorities are establishing dedicated teams focused on the COVID-19 response, implementing measures to minimise risks to staff, and liaising with key government agencies on a daily basis to monitor and understand the health impact of COVID-19 as it develops.

Water utilities have also moved to shut down any public payment and processing facilities; and many have issued requests to customers to not approach staff in the midst of this crisis, to protect essential service workers as much as possible.

Unitywater Executive Manager Customer Delivery, Rhett Duncan, said, “We’re asking everyone to give us space so that our crews can do their job for the benefit of the broader community.

“Our crews work tirelessly to keep the water on for you. If our crews are in your street or your property is affected by our works, please phone us or visit our website rather than approaching them. They will keep their distance from you and we ask you to do the same.”

Other common measures being implemented by water utilities include:

• Activating pandemic response teams and business continuity plans

• Promoting and enforcing good hand hygiene practices

• Implementing mandatory social distancing measures

• Implementing work from home arrangements where possible, and isolating critical networks staff and teams to ensure the ongoing operation of water and wastewater networks

• Putting a stop to non-essential international and domestic travel

• Assessing customer hardship programs and developing a coordinated response for customers unable to pay their water bills.

Water utilities have also had to contend with increased wastewater network blockages, as users flush products outside of the “three P’s” down their toilets.

UTILITIES HAVE REQUESTED THAT CUSTOMERS DO NOT APPROACH CREWS WORKING ON NETWORKS DURING THE CRISIS.

Queensland Urban Utilities (QUU) RTL Trades General Manager, Mick Bradley, said the number of blocked drains his crews had attended to had skyrocketed since the toilet paper shortages.

“Usually we’re called out to around seven blockages a week, but at the moment we’re dealing with more than 20 a week,” he said.

“The majority of blocked drains are caused by people flushing wipes down the toilet and the costs can run into the thousands.”

SA Water’s General Manager of Customers, Strategy and Innovation, Anna Jackson, said SA Water is dealing with the same challenge.

“In the current situation we’re all in, we understand people are trying to conserve their toilet paper use and are perhaps starting to use another household item to clean up,” Ms Jackson said.

“Unfortunately, flushing things like tissues, paper towel, wet wipes or newspaper down the toilet can lead to problems for both you and our crews, because unlike toilet paper, which is deliberately designed to break down in around 30 seconds, these other items don’t disintegrate in the sewer system.

“Keeping the sewers healthy is a shared responsibility, so we’ll keep doing our part through ongoing sewer main cleaning and replacement programs, and using various technology to inspect the pipes and help predict where a fault may occur before it can impact the community.”

The telecommunications sector has also faced its own challenges in response to COVID-19, with significant growth in usage as customers driven indoors turn to streaming services, and the massive influx in home usage from employees working from home.

nbn co’s team of data scientists and network engineers have been studying data consumption patterns in other countries that have been significantly impacted by the pandemic in recent weeks. At the same time, the company’s engineering teams have been planning for, and strengthening the network to help meet residential data demand that will likely surge, based on overseas examples, at different times of the day and night.

nbn co is well-advanced with its contingency plans and will

incrementally increase its data capacity allocation to retailers to accommodate the expected growth in residential data demand. It is requesting that retailers place their forward orders for capacity in the normal way, and nbn co will increase capacity as required to meet demand.

The company is also planning to limit non-essential maintenance to minimise scheduled, planned outages in the weeks ahead to maintain network availability as much as possible.

nbn co Chief Executive Officer, Stephen Rue, said, “The NBN is part of Australia’s critical infrastructure, and the role of the network has never been more important than now and what we see unfolding over the weeks ahead. For many Australians, the NBN and other broadband and mobile networks will become the primary channel for work, study, entertainment, ordering food and maintaining contact with the outside world.

“As a telecommunications industry, we will work together to keep Australians connected and productive through this crisis. These are unprecedented times and we are already seeing a steady increase in demand on the NBN, and this is set to continue. In terms of the expected requests for additional capacity, we will work with the industry to find the best solution. Clearly we all need to play our part.

“We are in the fortunate position that more than 90 per cent of the national broadband network rollout has been delivered across the country, so the vast majority of Australians already have access to fast, reliable, secure broadband, which will serve them should they need or want to spend more time at home.”

Like all industries in Australia, utilities are grappling with a rapidly changing situation, with every day presenting different challenges to the day before.

The work already undertaken across our essential service industries has been exemplary and is something the industry should be incredibly proud of.

We wish all of our utility colleagues and stakeholders all the very best in the coming months as we continue to manage the impacts of this crisis.

50Hz to 480kHz Frequency Range

Large High-Contrast LCD Interface

Lightweight & Ergonomic

GPS & Data Logger Compatible

Remote Link Between TX & RX

84wH Lithium-Ion Batteries

12 Watts of Output Power

Constant Depth & Current

8 Locating Modes

www.rycominstruments.com

The COVID-19 pandemic has resulted in state-wide lockdowns, mass event cancellations and the closure of workplaces, as social distancing measures become key to slowing the spread of the disease. Despite the restrictions on travel and in-person meetings, the Digital Utilities event was able to connect utility leaders across the country by moving quickly to deliver a successful digital conference.

Hosting an event can be challenging at the best of times, and a global pandemic is an unprecedented situation for most event organisers. With the Coronavirus situation changing far more rapidly than anyone could have anticipated, on Friday 13 March it became clear that Digital Utilities 2020 could and should not go ahead as a live event.

In only three business days, the entire conference program was transferred to an online format, ensuring the safety of attendees by removing the need to travel and meet face-to-face in large numbers.

In the utility industry, embracing digital technologies and business models is vital for optimising asset management, improving network operations and keeping up with changing customer demands – as video conferencing and remote working becomes the new normal, Digital Utilities was able to create something of value for all participants and ensure conversations around the highly relevant topic of digital transformation could still take place.

From 19-20 March, over 130 delegates tuned in to watch the Zoom webinar live, with many others intending to watch the presentation recordings at their leisure. A lot of valuable information was exchanged and there was plenty of social interaction through the in-built Q&A and chat functions.

The support for the digital conference from speakers, sponsors, exhibitors and delegates was overwhelming, with many commenting how glad they were that the event still went ahead, with the majority of industry gatherings cancelled or postponed for the foreseeable future.

Bentley Systems – a global software development company with a portfolio of solutions that accelerate project delivery and improve asset performance –maintained its role as the Event Partner for a third year running, kicking off day one of the webinar with an informative presentation about digital twins.

John Da Mina, Regional Director ANZ at Bentley Systems, discussed the applications of digital twins for utilities, offering practical advice on how the technology’s immersive visualisation and analytics visibility can help achieve a deeper understanding of utility infrastructure assets.

In his presentation Using technology to highlight the risks overhead, Aaron Smith, HSE Business Partner & Community Safety Manager at Energy Queensland, discussed the lifesaving tool developed by the utility to improve safety around powerlines.

“Lookupandlive.com.au is an online mapping application that pinpoints the location of 178,000km of overhead powerlines and 1.7 million poles across Queensland,” Mr Smith said.

“At Energy Queensland, a team of community safety specialists has been collecting statistics on accidental powerline contacts for over ten years to better understand why these incidents are occurring and how they could be prevented. From the outcomes of the investigations a clear issue stands out – a distinct lack of planning and powerline awareness.

“The team has fostered a positive and proactive association within the community by building awareness of the dangers of accidental contact with powerlines. The Look Up and Live tool is an extension of this

Event Partner

Major Sponsors

Sponsors

and enables behaviour change by helping workers to adequately plan work and put effective controls in place, assisting businesses to keep their workers safe and be legislatively compliant.”

Natasha Ogonowski, Water Sensitive Cities Program Manager at Water Corporation, and Peter Condon, Data Science Team Leader at Western Power, both shared case studies that demonstrated the practical applications of digital technologies in real-world situations as part of the conference’s Technical Session.

Ms Ogonowski took delegates through Water Corporation’s H2OME study, which utilises the most advanced technology available to determine how much water Perth should be using to preserve the liveability, amenity and quality of life of its community.

“H2OME is a one-year mixed methods study followed by a four-year longitudinal study that will give Water Corporation the insights it needs to help secure our water future,” Ms Ogonowski said.

“The study of 2,500 households combines digital metering data with household data on fixtures, fittings and appliance efficiency, attitudes, demographics, billing, marketing and communications with big data sets comprising weather, spatial land and CSIRO photogrammetry data to understand the drivers of water use.”

Mr Condon explained how Western Power is improving operational response to incidents by embedding automated forecasts from its Short Term Operational Response Model (STORM) inside scheduling and dispatch processes,

resulting in faster response times, shorter outage duration and more efficient spending.

“By blending traditional engineering knowledge with geomorphological analysis and state-of-the-art machine learning, STORM forecasts more incident categories with higher spatial and temporal accuracy than was previously possible,” Mr Condon said.

Digital twins proved to be the hot topic for 2020, with AVEVA’s Strategic Account Manager – Water, Paul Banfield, delving into the major hurdles to success for utilities looking to implement the technology.

“The digital twin can predict the potential failures of its physical counterpart well before they happen and can suggest ways to prevent those failures – but there is a potential flaw,” Mr Banfield said.

“The digital twin can only be as good as the detailed data that it is built on, combined with the real-time data it gathers. It also requires accurate contextual information and real-life understanding of the system, area, units and rooms in which it exists. Only then can the twin represent the true ‘as-operated’ state that the business can trust.”

Matt Rennie, Oceania Power and Utilities Leader at EY, rounded off day one of the event with a forward-thinking presentation titled Not a time for perfection, exploring the challenges and opportunities present in the energy transition. Mr Rennie also highlighted the lack of action taken to make Australia the global vanguard of new energy, despite its abundance of natural resources.

“Voltaire once wrote that ‘perfection is the enemy of good’ – Australian energy policy has had neither. Over the past 15 years, as the early embers of technological and customer-driven change began to simmer through the industry, energy policy in Australia has veered from the reactive to the counterproductive,” Mr Rennie said.

“Time has now shifted against us, and Australia finds itself lined up as one of the first global countries to experience the energy transition, with grid parity for batteries expected in 2021 and EV/combustion engine parity in 2024.

“This is a time of challenge for our regulators and policymakers, which stand at the cusp of a maturity curve like never before. New funding compacts, new branches of cooperation and new approaches to attracting and retaining human capital are required. Will they meet the challenge? The energy transition depends on it.”

Lucia Cade, Chair at South East Water, commenced day two proceedings with her domestic keynote presentation

Digital transformation: the boardroom perspective

“Technology plays a vital role in enabling South East Water to bring value to its customers and community, so we are always thinking ahead and implementing new digital solutions in our network to help create a better world for our customers,” Ms Cade said.

Ms Cade focused on how South East Water is harnessing and inventing digital technologies to stay ahead of challenges like climate change and population growth to make its customers’ experience better and to provide fair and affordable services – all while minimising its impact on the environment.

This was followed by a panel discussion featuring Katherine Gee, Executive Manager of Customer and Community at Unitywater; Matt Grantham, Head of Strategy and Business Development at Billcap; Neil Horrocks, Director at the University of Queensland’s Centre for Energy Data Innovation; and Aaron Everingham, Country Manager Australia and New Zealand at Quadient.

This panel looked at the impact of digital transformation on people, exploring how utilities can create a digital culture and use data analytics to enhance service quality, lower costs, and preserve and deepen customer relationships.

This was followed by an individual presentation, Situational awareness and the operational twin, from Zoltan Borbas, Industry Consultant at Hexagon PPM, who discussed how utilities could transform unstructured information into a smart digital asset to visualise, build and manage structures and facilities of all complexities, ensuring safe and efficient operation throughout the entire lifecycle.

“Fusing the real world with the digital world is at our core,” Mr Borbas said.

Delegates also heard from Angela Lam, Manager Information Technology at Horizon Power; Paul Siemers, Manager – Digital Strategy, Architecture and Innovation, Information Technology at Melbourne Water; Michael Joffe, Energy and Utilities Industry Lead at Publicis Sapient Australia; Mark McCormack, Group Manager Digital Utility Program at South East Water; and Tyson Hackwood, Head of Growth at Monoova as part of a panel discussion focused on processes.

This panel explored how utilities can transition from legacy systems and manual operations to more streamlined digital processes, and the convergence of IT and OT as a critical component of digital transformation.

In her presentation, Your digital twin: what could possibly go wrong?, Anna Murray, Senior Account Director, Engineering, Construction and Infrastructure at IFS Australia, explained that the key to the success of your digital twin is to make sure that your processes are data driven rather than document driven.

“You don’t want all that hard won, critical asset data to sit in yet another silo of dark data. Structured asset information needs to flow directly into the systems used to build and manage it,” Ms Murray said.

“Without integrating your digital twins into existing enterprise solutions and processes, these transformational technologies will create data silos unto themselves and the organisation will struggle to achieve asset management efficiencies.”

Justin Parr-Davies, Partner & APJ Head of OT & IoT Security, Cybersecurity & Risk Services at Wipro then went on to talk about why a unified approach to IT and OT cybersecurity is critical to achieving cyber resilience in utilities as they take up the challenge of Industry 4.0.

“Industry 4.0 digital transformation programs require consideration of the digital processes, systems, machinery and objects that could be impacted with the convergence of IT, OT and IoT,” Mr Parr-Davies said.

“Industry 4.0 provides one of the greatest increases in cyber risk to business over the last 50 years and will directly impact utilities and other areas of critical infrastructure.”

The event ended with a session from independent technology consultancy, Isle Utilities, who went beyond the buzzwords to explore the real impact and strategic implementation of digital technologies. Delegates had the opportunity to meet a range of innovators and learn how emerging technologies can provide practical value to utility organisations.

The featured technologies included:

• Kieran Mackenzie, Founder/Chief Executive Officer at Presien, demonstrated Toolbox Spotter, an artificial intelligence computer vision system optimised for heavy industries

• Glyn Addicott, Operations Director at Hydraulic Analysis Group Limited, demonstrated VariSim, a dynamic, real-time pressure transient simulator for water networks

• Chad Moulden, Commercial Lead (Australia) at Open Energi, demonstrated Dynamic Demand 2.0, demandside response technology that reduces the cost of delivering and consuming power

• Matt Smith, Chief Executive Officer at MyPass Global, demonstrated MyPass, a digital workforce management platform that connects all of industry –workers, training organisations, service providers and end users

Major Sponsors, GHD Digital and DXC Technology, and Sponsors, BidEnergy and Amazon Web Services, are also helping accelerate digital transformation in the utility industry through their innovative product and service offerings.

Digital communications, video conferencing and remote working have fast become the new normal, and the two-day digital conference is just the beginning for Digital Utilities 2020

There will be a live Digital Utilities event later in the year once circumstances allow, where the winners of the 2020 Digital Utility Awards will be announced and celebrated.

Unfortunately, several speakers were not able to take part in the online conference because of the COVID-19 crisis – either due to illness or their involvement in coordinating emergency responses to ensure the delivery of essential services to all Australians.

These speakers will have the opportunity to participate in the live event so delegates can still benefit from their insights.

All delegates and supporters have also received an invitation to an exclusive online networking group, which will work actively to facilitate social networking between utility professionals until they can meet in the real world again.

This will help create a Digital Utilities community that will extend beyond the event and open up real communication possibilities in a more digitised world.

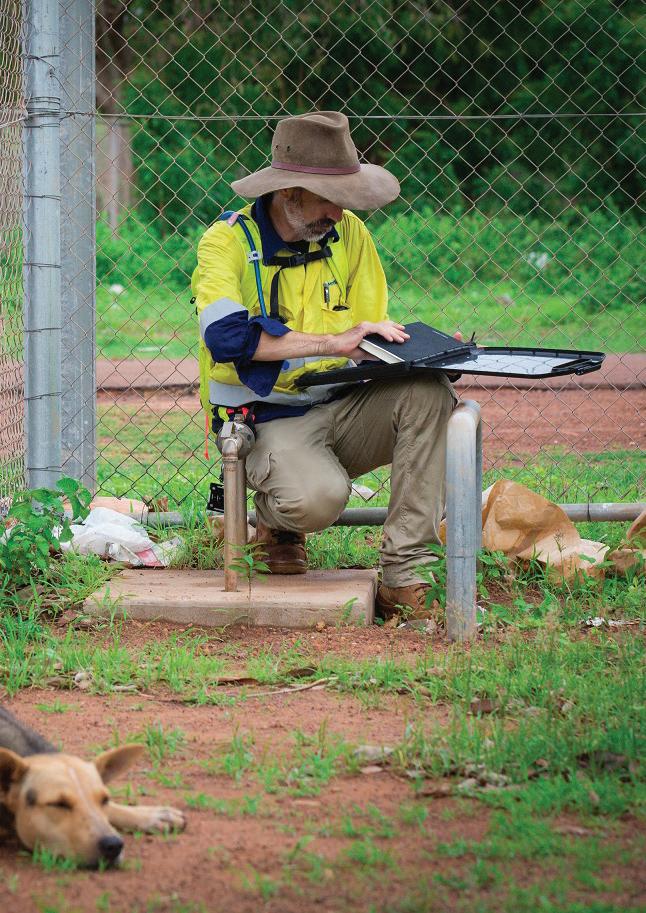

As Victoria experiences a rise in climate emergencies, population growth and threats to food security, it’s now more important than ever for the rural and urban water sectors to work together, says Cameron FitzGerald, Managing Director of Southern Rural Water.

Operating across 88,000km² of southern Victoria – a landmass greater than Ireland – Southern Rural Water services the needs of diverse customers via the regulation of access to surface water, groundwater and management of irrigation districts.

The utility’s operations support food and fibre production, contributing more than $14.2 billion to the Victorian economy each year. Its operations also power generators critical to the electricity grid operating across Australia’s southeastern seaboard, as well as providing raw water to a number of urban water authorities who transform this water into highquality drinking water for metropolitan customers.

According to Mr FitzGerald, excellence in water management requires a whole-of-sector approach, where the urban and rural sectors identify opportunities to learn and grow from each other.

“Drawing on my fifteen years’ experience in the urban sector, I see opportunities for the two parts of this industry to work better together,” Mr FitzGerald said.

“Drought response and climate emergencies are a significant part of this. How we manage irrigation water and how urban utilities manage water for cities and towns are fundamentally interlinked.

“When impacts of climate change take their toll, all communities face challenges in how they deliver water.

“Rather than making these challenges either rural or urban issues, we must shift our thinking and look to solve problems holistically.”

According to Mr FitzGerald, the urban and rural landscapes are not only linked through physical pipes and assets, but through customer expectations and the provision of services.

“From the CBD to the furthest tips of the state, customers want the same things. They want their utility to be easy to deal with and to demonstrate value for money,” Mr FitzGerald said.

“They want to know that the rules that apply to them are applied fairly to others, and that the rules won’t be changed without effective consultation.

“Most importantly, all customers require dependable water services that ensure the water gets to where it is needed, when it is needed.”

The impacts of climate change don’t discriminate. Whether a region is faced with increased average temperatures, low rainfall or flooding, the management of both rural and urban water is put to the test.

“We don’t need to look too far to see the impact that climate change is having on our customers. Last year, the Glenmaggie Weir failed to spill for the second year in a row – the first time this has happened in four decades,” Mr FitzGerald said.

“If there is less water, we as an industry have to get better at identifying opportunities to work together and to efficiently deliver the water we have.”

According to Mr FitzGerald, the water industry’s response to the current bushfire emergency is a strong example of what can be made possible when the sector works together.

“I was really pleased to see the industry stepping up to support the bushfire emergency and recovery efforts,” Mr FitzGerald said.

“At Southern Rural Water, our teams came together to assist in delivering critical water to livestock. We did this by opening up emergency supply points for farmers that took the pressure off main supplies.

“By doing this, we were able to meet an important community need while also supporting East Gippsland Water’s systems.

“It was a small contribution in terms of the overall response, but it demonstrates what can be achieved when our colleagues and the industry work as one.”

Southern Rural Water currently assists with climate emergencies, providing real-time information to the Bureau of Meteorology on local flood conditions, as well as using new technologies to enhance the value of the data it provides.

“The use of remote sensors and big data offers us all the opportunity to build better models and enhance the value we create not just for the Bureau, but for all stakeholders,” Mr FitzGerald said.

“Additionally, our ability to use the Bureau’s data analysis to drive our own decisions during climate emergencies will be critical to a successful emergency response.”

Southern Rural Water is looking to the future to plan how it can manage its assets, focusing on resilience in the long term for customers and communities.

“Over recent years, we’ve committed to an extensive modernisation program, ensuring the districts across our network are more efficient, reliable and resilient to a drier climate,” Mr FitzGerald said.

“For example, the Macalister Irrigation District, the largest irrigation district in southern Victoria, is undergoing an upgrade consisting of pipelining, channel automation and regulator upgrades.

“More than $92 million in works have been completed to provide 22,000 megalitres of water savings for irrigation use within the district.

“Investments of $30 million and $12.3 million into the Werribee and Bacchus Marsh Irrigation Districts have also been made to complete piping and modernisation.”

Mr FitzGerald knows that building a passionate, knowledgeable team and high-performing culture is vital in supporting collaboration across the sector.

“Southern Rural Water’s people bring our vision to life, and I believe that our success comes from being able to pool our wide range of expertise to collaborate and solve common problems,” Mr FitzGerald said.

“Great practices inside one irrigation district, for example, can be transferred to deliver better outcomes in others, and it’s really important to recognise and share these synergies.”

In recent months, Southern Rural Water’s senior leaders have also been involved in a significant leadership program focusing on self-awareness and equipping participants with individualised coaching to assist them on their leadership journey.

“With such a large area to manage, leading an inspired team spread across the state can be a challenge,” Mr FitzGerald said.

“There is no right way to build a great culture, but it does start with self-awareness and meeting people where they are on their journey, then encouraging them to explore their potential.

“As leaders, we must remember that it’s our people who are the ones delivering value to our customers. They are in the field installing, developing and managing our assets, and it’s critical that we are equipping them to thrive.”

The science, technology, engineering and mathematics (STEM) space is constantly evolving with the development of new systems, technology and practices, as well as an increasing ratio of women in the workplace. With this evolution set to impact the next generation of STEM professionals, it’s more important than ever for companies in the STEM space to partner with organisations and education providers to train, educate and inspire future professionals.

Aholistic approach to investing in future STEM professionals happens at all levels, from primary school students right through to university level and beyond. Pipeline repair, restoration and renewal provider, Interflow, is one of the companies leading the way when it comes to creating opportunities for young, innovative minds.

Saadia Ali, a Project Manager at Interflow in New Zealand, can trace her love of STEM back to her childhood. A love of building things, along with a flair for maths and physics, led her into engineering studies at university and on to a successful career in STEM.

Interflow is working alongside Engineering New Zealand on initiatives such as the Wonder Project, which is a free program for schools designed to get more young students excited about STEM subjects. For Ms Ali, this is an opportunity to pass on her passion for engineering.