LOUISE DUDLEY REFLECTS ON 10 YEARS AS A UTILITY CEO

MAINTAINING SYSTEM STRENGTH IN THE RENEWABLES TRANSITION

SMARTER MAINS MANAGEMENT PUTS LEAKS ON DOWNWARD TREND

Engineering, Construction & Maintenance WATER SEWER ELECTRICITY GAS www.utilitymagazine.com.au Issue #34, May 2022

SIMPLIFY SITE MANAGEMENT WITH AERIAL IMAGERY

• Manage your infrastructure reliably with frequent captures

• Respond efficiently to maintenance requests

• Monitor vegetation around critical assets

• Measure confidently with high spatial accuracy

Scan to access free trial

• Flexible access via web-application or your own GIS

• Overlay rich cadastre and building insights

metromap.com.au

In April, the Intergovernmental Panel of Climate Change (IPCC) released the third instalment of its Sixth Assessment Report and urged that its ‘now or never’ to take prompt action to cut greenhouse gas emissions.

The report makes it clear that we are running out of time to act on climate change, and Australia has already seen some of the consequences of this in 2022 with a range of disaster events, including the recent devastating floods.

This is the most important issue we’re facing globally, and it's clear that the utility industry has a large role to play.

As we cover exciting project developments and industry innovations in this edition of the magazine, we do so with a sustainability lens, to highlight what Australia's water and energy sectors can be doing now and in the future to reduce emissions and manage assets more sustainably.

This issue has features on water management, energy networks, storage, future fuels, condition assessment and more.

In the water industry, we’re looking at the utilities around the country that are implementing initiatives to reduce emissions; how one utility is reducing its water main breaks and leaks using smarter management; how we can make water work in Northern Australia, and how sector collaboration is changing the game.

Over in energy, we explore distributed energy resources giving customers control, how Australia’s big batteries and transmission networks are supporting the renewables transition, and infrastructure resilience.

These themes will also be on display at Utility magazine’s upcoming Digital Utilities virtual conference, running from 21-23 June.

Digital Utilities features three unique conferences that will dive deep into how we can create efficient and secure future grids and engage customers in the new digital era. These conferences include: Future Grids on 21 June, Engaging Customers on 22 June, and Cyber Security on 23 June.

The event provides delegates with genuine learning opportunities from some of the best and brightest minds across Australia including water and energy utility CEOs, CIOs and digital teams. Find out more on page 24 or visit www.digitalutilities.com.au to register for free.

Utility is also excited to be a media partner for several in-person events this year including OzWater and Locate22 in May and WIOA Victoria in June. We love supporting these industry conferences and having the opportunity to chat with our readers about the industry issues that they are passionate about. Don’t hesitate to come find us at these events and have a chat.

Jessica Dickers Editor

UTILITY • MAY 2022 Editor Jessica Dickers Journalists April Shepherd Annabelle Powell Lauren DeLorenzo Christopher Allan Mikayla Bridge Design Manager Alejandro Molano Designers Luke Martin Danielle Harris Jacqueline Buckmaster National Media and Events Executives Rima Munafo Brett Thompson Jacob Trad Marketing Manager Radhika Sud Marketing Associate Andie James Digital Marketing Assistants James Holgate Jackson Barnes Publisher Chris Bland Managing Editor Laura Harvey Published by Cover image highlights our feature on Inspection, CCTV & Condition Assessment and SA Water's water mains condition assessment strategy. Engineering, Construction & Maintenance WATER SEWER ELECTRICITY GAS www.utilitymagazine.com.au Issue #34, May 2022 LOUISE DUDLEY REFLECTS ON 10 YEARS AS A UTILITY CEO MAINTAINING SYSTEM STRENGTH IN THE RENEWABLES TRANSITION SMARTER MAINS MANAGEMENT PUTS LEAKS ON DOWNWARD TREND Monkey Media Enterprises ABN: 36 426 734 954 C/- The Commons 36–38 Gipps St, Collingwood VIC 3066

(03)

4950

utilitymagazine.com.au

welcome May 2022 ISSUE 34 1

me a line at jessica.dickers@monkeymedia.net.au or feel free to

me on

to let me know what you think. Don't forget to follow Utility magazine on social media - find us on LinkedIn, Twitter and YouTube.

P:

9988

monkeymedia.com.au info@monkeymedia.com.au

info@utilitymagazine.com.au ISSN: 2203-2797

Drop

call

03 9988 4950

FROM THE EDITOR

INDUSTRY INSIGHT

WATER MANAGEMENT

ever before. But the industry focus remains the same, utilities are committed to providing the community with safe water now and into the future, while dealing with these challenges, managing water quality and water availability and keeping costs down. With these same goals, it’s critical that utilities around the country collaborate with each other as well as with different sectors and educational institutions, to share insights and solutions.

How can strong principal and subcontractor partnerships increase the chance of success on a microtunnelling project?

Too often on construction sites – when unexpected situations occur or a different way of doing things to reduce risk and improve project outcomes are suggested – it can become a case of principal contractor versus subcontractor. When this occurs, it creates an environment that is not conducive to performance.

2

STORAGE Australia’s big batteries: new storage to match the rise of renewables 84 Battery storage systems are vital assets for stabilising energy generation during the national energy transition, and a robust stock of storage assets might serve as the best insurance policy for any network powered by renewables.

CONTENTS ENERGY

Success factors for Australia’s hydrogen export industry 88 78 84 28 26 90 UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU

FUTURE FUELS

Collaboration in the water sector: more voices means better ideas 26 Water utilities around Australia face similar challenges – population growth, more frequent weather events, drought and climate change means there’s

pressure on our water storages

The end of an era: Louise Dudley reflects on leading Urban Utilities for the last decade 28 AI in the water sector: Safer, faster, better 32 Creating Australia’s best tasting tap water ......................... 34 Every year WIOA’s IXOM Best Tasting Tap Water Competitions celebrate the

water

year,

Casino

Treatment Plant

Australia’s best tasting

Why use a duckbill valve? 38 Making water work in Northern Australia 40 Helping water companies prevent wastewater spills 42 Athens upgrades its pressure management with regulating valves ................ 44 DEMAND MANAGEMENT Using distributed energy resources to give customers control 46 INSPECTION, CCTV & CONDITION ASSESSMENT Smart mains management puts SA Water breaks on downward trend 78 Sewer blockage rates slashed thanks to million dollar campaign 80 VEGETATION MANAGEMENT Trialling new technology to keep power networks safe ............82

more

than

work undertaken by

professionals who work hard behind the scenes for their communities to deliver high-quality drinking water across Australia. Earlier this

the water produced at the

Water

was named

tap water.

It seems astonishing that two years after we were shocked by the unprecedented awe and impact of the Black Summer fires, we stand again humbled by the power of mother nature, this time due to the ongoing tragic flooding events in South

It’s promising to see that around Australia, more and more organisations like city councils are pledging ambitious emission reduction targets – but what does the journey to zero emissions look like at the scale of our major utilities?

May 2022 ISSUE 34 3 In each issue Welcome from the Editor ������������������������������������������������������������������������������������������������������������� 1 A word from Energy Networks Australia ���������������������������������������������������������������������������������� 4 A word from WSAA ����������������������������������������������������������������������������������������������������������������������� 6 News briefs ������������������������������������������������������������������������������������������������������������������������������������ 8 Advertisers’ index ���������������������������������������������������������������������������������������������������������������������� 92 Editorial schedule ���������������������������������������������������������������������������������������������������������������������� 92 50 74 UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU ENERGY NETWORKS HORIZONTAL DIRECTIONAL DRILLING (HDD) 68 SUSTAINABILITY Supporting the energy industry in the renewables transition 50 A trusted partner for a major Australian infrastructure electricity project 54 Power quality that delivers cost savings and efficiency gains 56 Transmission’s importance to energy transformation –a Victorian perspective 58 Connect, protect and optimise your fleet 64 SMART METERS Does your water data flow like your H2O? 66 Vermeer HDD a fab addition for Irrifab ......................... 74 Powerful pumps – the heart of HDD maxi-rig spreads 76 It’s common to think of HDD drilling spreads in terms of rig size, but the true workhorse of the spread is in fact the mud pump – a high efficiency positive displacement piston pump. Without these pumps, the drilling fluid cannot be pumped into the bore to either jet

or

the

and the

don’t just need resilient infrastructure, but infrastructure for resilience 68

drill

motor drill,

bore would not have any stability,

cuttings would not be removed from the bore. We

and Northern

Wales. Australian water utilities on the right track for zero emissions 72

East Queensland

New South

AVOIDING THE HOUSE that Jack built

by Dor Son Tan

Derived from the children’s nursery rhyme, ‘The house that Jack built’ usually describes something that is badly designed or patchworked together without an overall result being considered. As we adapt our energy grid to prepare for a net zero future, it is imperative that networks, system architects and everyone in between, ensure our planning is well considered rather than patchworked together or else we risk ending up with a house that Jack built.

WHAT IS A SYSTEM?

A good analogy of a system is one of a house. In a house there are different systems like plumbing (water and sewage), wiring (electrical) and heating (gas). All these systems don’t directly interact with one another, but they do work together to provide a service. For example, all three systems are probably needed at various points to cook dinner.

What most people don’t think about is how these systems work and interact, because they already exist and they work, why change or think about them? But what if the systems in your house were rapidly changing and no one really knew what they would look like in the future? I bet you would start to pay a bit more attention if you needed to buy a new heater that runs on hydrogen or if you couldn’t flush your toilets after 5pm because the sewage system was congested.

This also highlights something that’s very human. We naturally focus on fixing symptoms and not causes. For example, if we see a leaky tap we

¹ https://gridarchitecture.pnnl.gov/

replace a washer, but what if the actual cause was very high-water pressure from the mains?

Now apply this concept to something like the electricity system during a once-in-a-century transition.

WHAT IS SYSTEMS ARCHITECTURE AND WHY IS IT IMPORTANT?

According to the Pacific Northwest National Laboratory (PNNL), systems architecture1 is a way of thinking about how a group of systems or a ‘system of systems’ behaves, what it can and can’t do, and how these different things work together as a whole. This framework is particularly useful to complex machines like the electricity grid.

Without getting too technical, it breaks up a very complex problem like the electricity grid in transformation by viewing it through different lenses in a managed and holistic way.

What it doesn’t do is provide quick and easy answers that turn out to be costly mistakes in the long term. It also doesn’t provide individual solutions to specific problems.

Even with these mental tools and frameworks, this is hard, hard work. But if something is hard, it’s probably

² https://www.csiro.au/en/research/technology-space/energy/g-pst-research-roadmap

a good indication that it’s worth doing. I can think of nothing more important for the prosperity of Australia (and the world) than adapting our energy system for the future – so much depends on it economically, socially and environmentally.

CSIRO/AEMO GLOBAL POWER SYSTEM TRANSFORMATION (G-PST)

CSIRO and the Australian Energy Market Operator (AEMO) are doing their bit to move the industry’s thinking forward to meet the many pragmatic and technical problems appearing now. Networks, as well as AEMO, are feeling the bow wave of challenges that the energy transition is presenting through things like minimum demand, lack of transmission infrastructure to connect variable renewable energy (VRE), lack of distributed energy resources (DER) visibility and the added disruption of climate change, to name a few.

This broad program of research questions2 cover many valuable topics such as how we operate a system with few to no synchronous machines, how to restore the system after blackouts, ensure system stability with DER and of course power system architecture.

CSIRO and AEMO are to be commended for this work, and networks are eager to help to ensure this transition delivers safe, secure, and reliable clean energy at the lowest possible cost to customers.

I leave you with a simple question: if you want to build a house, would you start with a pencil or a shovel?

4 A WORD FROM ENERGY NETWORKS AUSTRALIA

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU

FIGURE 1. PNNL GRID ARCHITECTURE DISCIPLINES

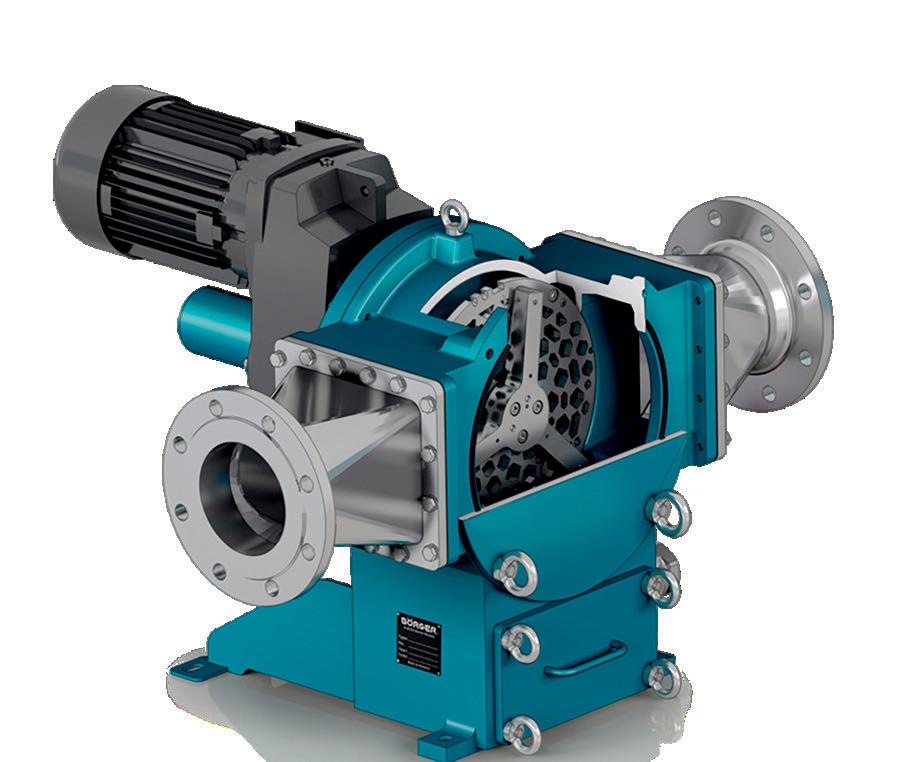

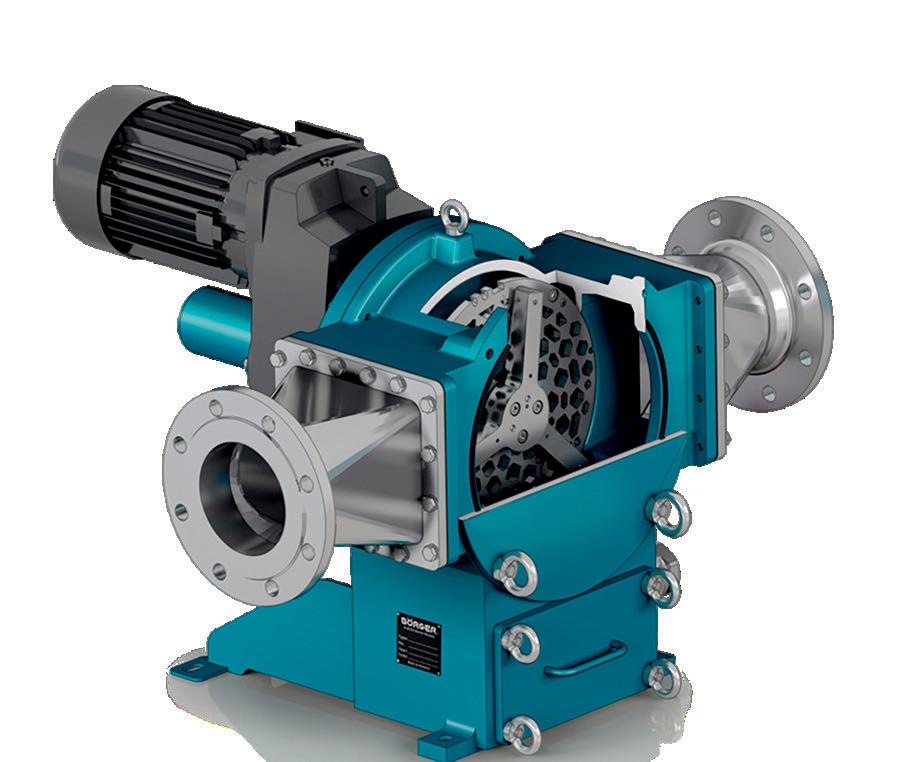

EXCELLENCE – MADE TO LAST

WE DELIVER SOLUTIONS

Mobile, stationary or submerged – Börger configures and builds each rotary lobe pump in line with the requirements of the specific application.

The application options of Börger pumps have expanded with the new B BLUEline Nova rotary lobe pump. The BLUEline Nova pump ensures the best efficiency even with high pressures. Börger pumps are available in 25 pump sizes with flow rates between 1 – 1,440 m³/h.

THE MOST EFFICENT WAY OF PUMPING

Further to this, Börger also offers three different macerators - providing efficient chopping operations and capabilities, ensuring downstream machines and pumps to perform smoothly.

www.boerger.com Boerger Pumps Asia Pte Ltd • 16 Boon Lay Way #01–48 Tradehub 21 • Singapore 609965 • P: +65 6562 9540 • asia@boerger.com

A WORD FROM WSAA

WATER FUELLING THE PATH TO A HYDROGEN FUTURE

A hydrogen revolution is gathering pace and the world is fast pivoting towards new, non-fossil-fuel dependent energy sources. In 2021, over 30 countries have released versions of hydrogen roadmaps, and the hydrogen industry has announced more than 400 hydrogen projects globally. What does this mean for urban water? Does the industry know enough to participate and what unknowns are holding us back?

Last December, we released a paper that outlines the basics of hydrogen for the urban water industry, answers some of the key emerging questions, and points to questions that warrant exploration in the years ahead.

The Australian government has identified clean hydrogen as one of Australia’s five pathways towards decarbonisation. Australia’s vision for a hydrogen future, articulated in the National Hydrogen Strategy (COAG, 2019), highlights that Australia has the resources and the experience to take advantage of increasing global momentum for clean hydrogen, and make it our next energy export. These sentiments are echoed by the International Energy Agency and the World Energy Council, both identifying Australia as a potential hydrogen production powerhouse.

The viability of participating in the hydrogen economy for a water utility is dependent on several factors. There are generally three major attributes for success:

1. Participation needs to be shaped around an identified challenge or opportunity

2. Site attributes need to be favourable

3. Access to suitably skilled partners is key

The focus and development of green hydrogen is a relatively new concept to the urban water industry. The opportunity for green hydrogen has caught the attention of policymakers worldwide as it is likely to be a game changer in the transition to renewable energy and decarbonisation. It is also the type of hydrogen of most interest to the water industry. Various water utilities are considering or trialling new processes, and forming cross industry partnerships for further exploration. This time of discovery provides a unique opportunity for our industry to be able to proactively engage and create awareness about the crucial role we have to play in supporting a sustainable hydrogen economy.

A number of different projects are already testing the opportunities for urban water industry innovation and participation, including the Hazer trial on Water Corporation land in Western Australia; using biosolids for gasification at Logan in Queensland; and the Australian Gas Industry Group and Engie producing hydrogen at the North East Water treatment plant in Wodonga to inject into a gas supply main. Jemena and Sydney Water are producing biomethane for supply into the gas distribution system, and Yarra Valley Water are investigating a hydrogen hub at Aurora.

6

The water requirements for early hydrogen projects may be small, but the demand for water of a suitable quality will grow significantly if projects achieve their planned scale.

Utilities also have treatment plant sites that not only produce recycled water, but may also be able to accommodate production facilities such as electrolysers. These sites may be advantageously placed close to transport, industry and potential users of the hydrogen produced. Hydrogen could have many future uses: to power cars, whether through direct fuelling or fuel-cell batteries; for stationary power or heat generation used for customer properties and/or industrial processes; and blending into the existing gas distribution network as a greener energy source substitute.

There is also a growing strategic synergy between customer and internal expectations for the water industry to adopt circular economy approaches to make full use of all the resources at our disposal. This includes harnessing all elements of the water cycle such as using recycled wastewater and also stormwater for productive purposes.

There are other aspects that water utilities should start considering as the hydrogen revolution gathers momentum, to be prepared for potential opportunities or demands that may arise. Utilities will already be considering how best to meet their own emissions reduction commitments, and may find a Marginal Abatement Cost Curve a useful tool to explore the contribution hydrogen could make. Utilities may also have the capacity to produce surplus renewable energy. Even if they do not participate directly in producing hydrogen, they may be able to offer this resource as a valuable input into hydrogen production by others. As some water utilities

consider how they might be called upon to support or participate in the hydrogen economy, and others strive to involve themselves in this exciting new field, there are many important aspects to consider.

Underpinning all of it is making sure that as an industry, we engage proactively and robustly with our stakeholders, regulators, customers and governments, and explore our potential role as a partner for the hydrogen economy of the future, and ensure the sustainability of water supply for our customers and communities. The call is for policy makers and players within the hydrogen industry to recognise the crucial role of the urban water industry and to ensure early engagement on new projects and proposals.

In exploring hydrogen production, the water industry is stepping outside its comfort zone. We certainly have the willingness and resources to be able to partner and create valuable products in tomorrow’s hydrogen economy. However, the commercial aspects – like bringing new products to market, setting prices, skills and capabilities required – are relatively unfamiliar areas for our industry. As such, there is a road ahead to explore how individual water utilities can best make inroads into the emerging hydrogen economy. Given the pressures on the oil and gas industries to rapidly decarbonise their activities and exploit emerging market opportunities, they are likely to be key partners and potential customers for the water industry in fostering the hydrogen economy of tomorrow.

The urban water industry is willing to take on the opportunity the hydrogen economy provides. The reputation of the industry in leading on sustainable commitments and securing customer trust, places water utilities as key brokers in facilitating transactions for mutually beneficial partnerships. No single industry can implement the required change, but our industry can utilise the collaborative nature we have fostered in driving the change that is needed.

WSAA has produced a paper looking at the role of the water industry in the hydrogen revolution. To read the paper and case studies go to: https://www.wsaa.asn.au/publication/water-fueling-path-hydrogen-futurerole-urban-water-industry-australia-and-new-zealands

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 7

UNITYWATER APPOINTS NEW CHIEF EXECUTIVE OFFICER

Water and sewerage services provider Unitywater has appointed its new Chief Executive Officer.

Unitywater has appointed Anna Jackson to the role, who comes from state government-owned SA Water, where most recently she was General Manager Customer and Commercial.

Ms Jackson has also held executive roles responsible for business strategy, water security and quality, innovation, customer engagement, and environmental and social governance.

Ms Jackson will join Unitywater in July 2022 when she finalises her commitments at SA Water.

Unitywater Chairman, Michael Arnett, said Ms Jackson’s skills, experience and personal values were an ideal fit for Unitywater’s strategy, vision and culture.

“Anna has a well-earned reputation for developing businesses that deliver excellent customer service and

environmental performance while making a real difference in the communities where they operate,” Mr Arnett said.

“Anna joins us at an exciting time for Unitywater as we meet the water and sewerage needs of a growing population across Moreton Bay, the Sunshine Coast and Noosa.

“Anna is an outstanding talent and I’m looking forward to working with her as we continue to build a modern, highquality water and sewerage services provider.”

Prior to SA Water, Ms Jackson held senior business development and corporate affairs roles with global consulting and engineering firm Tetra Tech International Development, aerospace and defence company Raytheon, and in Federal and State government.

Ms Jackson is a member of the Australian Government’s Australian Water Partnership Advisory Committee and the Water Services Association of Australia’s Liveable Communities Committee and a supporter of WaterAid.

8

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU

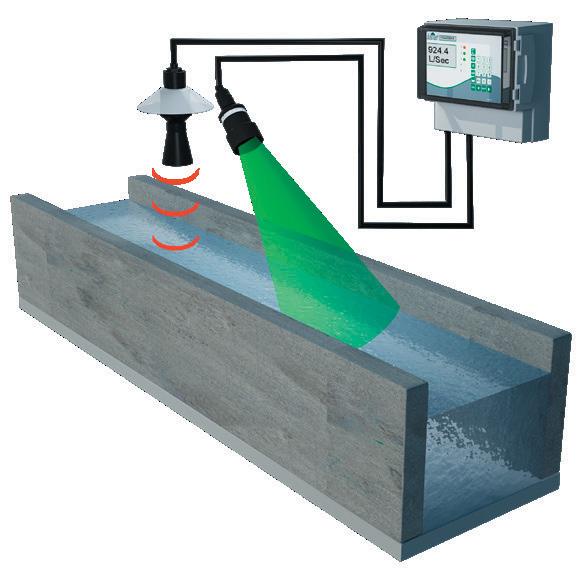

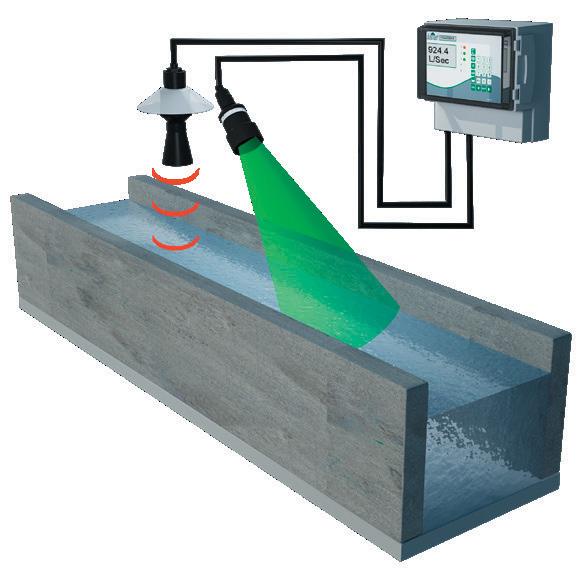

AMS have been suppliers of instrumentation and calibration equipment to all industries since 1973 representing some of the world’s leading manufacturers of the equipment in their field. www.ams-ic.com.au Flow Measurement Specialists www.ams-ic.com.au sales@ams-ic.com.au NEWS

INSTRUMENTATION & CALIBRATION PTY LTD SPECIALISTS

The IoT platform, fit-for-water. iotaservices.com.au

The Federal Government has announced the 202223 Budget, investing $2.4 billion in new initiatives under the industry, energy and emissions reduction portfolio, and investing in water infrastructure and security.

The Federal Government has invested in water infrastructure through the National Water Grid Fund, which is receiving an additional investment of $6.9 billion through the Budget.

The new investments include:

• $5.4 billion for Hells Gates Dam, subject to the completion of the final stage of the business case and regulatory approvals

• $600 million for Paradise Dam Improvement

• Up to $433 million for Dungowan Dam and Pipeline, subject to the finalisation of the business case and approval processes

The Federal Government has also locked in $483 million to build Urannah Dam, pending demonstration of value for money and sufficient public benefit for investment. The Budget has also committed millions to keeping rivers and wetlands, and surrounding communities, healthy.

The On-farm Emergency Water Infrastructure Rebate Scheme is also being extended, to help farmers install infrastructure like pumps, tanks, dams and bores through a rebate of up to 25 per cent on eligible projects, up to the value of $25,000.

ENERGY INVESTMENT TAKING THE ‘TECHNOLOGY NOT TAXES’ ROAD

The Budget includes $2.4 billion of new initiatives under the industry, energy and emissions reduction portfolio, which are expected to support 4,800 jobs.

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 10

& Velocity measurement Continuous Biofilm Monitoring Sample Biofilm growth signal over time LEVEL METERS BIOFILM ANALYSER ANALYTICAL CONTROLLERS PROCESS INSTRUMENTS PULSAR • Lightweight, compact design • No interruption to service • ATEX Ex mb Zones 1 & 2 approval • Minimal installation costs • Maintenance-free • RS485 Modbus • IP68 • Non-contacting • Cost-effective • Ultrasonic Transmitters and Controllers • Point Level Switches • Sludge Level Systems • Wireless Systems • Early detection of Bacterial Growth on surfaces • Monitoring & optimisation of sanitation requirements. NEW TURBIDITY MONITOR BINTECH SYSTEMS WATER SOLUTIONS 1300 363 163 sales@bintech.com.au www.bintech.com.au NEWS FEDERAL

ENERGY SECURITY, WATER INFRASTRUCTURE IN FOCUS

BUDGET 2022-23:

Energy investments include:

• $300 million to support low emissions LNG and clean hydrogen production at Darwin, together with associated carbon capture and storage infrastructure

• $247.1 million to support increased private sector investment in low emissions technologies including hydrogen, the continued development of a hydrogen Guarantee of Origin scheme

• $200 million to increase onshore processing and value-add of iron ore exports, to support low emissions steel production in Indo-Pacific customer countries like Japan and Korea

• $200 million to enhance Australia’s supply chain security through new low emissions manufacturing facilities (using hydrogen and hydrogen-derivatives like ammonia, as well as carbon capture utilisation and storage) in the Pilbara region

• $148.6 million to support more investment in affordable and reliable power, including the development of community microgrid projects in regional and rural Australia

• $100 million to de-risk private sector investment in firm generation and grid infrastructure to increase system strength and capacity in the Pilbara region

• $100 million to support pre-Final Investment Decision activities and early works to make the Port of Newcastle ‘hydrogen ready’

• $50.3 million to accelerate the development of priority gas infrastructure projects consistent with the Future Gas Infrastructure Investment Framework and support investment in carbon capture and storage pipeline infrastructure

Excellence in flow & level measurement.

FLOW, LEVEL , PUMP CONTROL VOLUME , & SLUDGE BLANKET

• Contacting & non-contacting measurement options

• Full, partially filled pipes, and open channel flow measurement

• Ultrasonic and radar technology

• Process measurement made simple

• Customer-centric

• Award winning service

For Australian sales & technical support, contact our local team or use our virtual Partner Locator to find the nearest Pulsar Authorized Distribution Partner

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 11

OCEANIA@PULSARMEASUREMENT.COM +61 ( 0 ) 428 692 274

NEWS

TWO NEW BATTERY PROJECTS FOR NSW IN ENERGY PARTNERSHIP

In a new partnership, EnergyAustralia and Edify Energy (Edify) are developing two new battery storage projects to secure reliable electricity supply for customers in New South Wales and boost renewables in the energy sector.

EnergyAustralia and Edify Energy are partnering together on two long-term battery storage services agreements for a combined 90MW/180MWh in Darlington Point, New South Wales.

Under the agreements, EnergyAustralia will have market control of two of the three independent, but co-located projects – the Riverina (65MW/130MWh) and

Darlington Point (25MW/50MWh), for at least ten years.

Edify Energy is a leading developer in renewable energy generation and storage projects, and will oversee the project’s deployment and construction, which utilises Tesla Megapacks.

Due for completion during the summer of 2023/24 and developed on traditional lands of Wiradjuri Country, the Darlington Point and Riverina Battery Energy Storage Systems have the potential to power more than 46,000 homes for two hours of peak demand before being recharged.

Construction will commence later this year on the lithium-ion battery

projects, which will bring flexible, dispatchable capacity to the New South Wales market and complement the significant volume of renewable generation in the region.

EnergyAustralia and Edify first came together in 2017 with the offtake agreement for the Gannawarra Solar Farm in Victoria and then again in 2018 to successfully deliver the 25MW/50MWh Gannawarra Energy Storage System (GESS).

Developed by Edify, EnergyAustralia holds the rights to charge and dispatch GESS’ energy into the National Electricity Market.

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 12

EW0019-DIEHL-ADVERT-FA.indd 1 29/3/22 1:31 pm NEWS

Easy transportation Simple implementation Operator and equipment safety 1300 FMT FMT (368 368) Melbourne 1/53-57 Rimfire Drive Hallam VIC 3803 Brisbane 2/5 Percy Drive Brendale QLD 4500 Perth 3/48 Hardey Road Belmont WA 6104 The water supply operator’s kit H2O WATER KIT

AUSTRALIAN-FIRST TRIAL FOR ROBOT-DELIVERED TRENCHLESS TECHNOLOGY

In an Australian-first, Urban Utilities has trialled new robot-delivered trenchless technology which makes water main renewal more efficient, benefitting customers and the environment.

The state-of-the-art Resiline technology sprays a rapid-curing lining inside the pipe, relining it underground and removing the need for a traditional ‘lift and lay’ pipe excavation.

Urban Utilities completed the trial with project partners Downer, WSP and Wilsons Pipeline Solutions, rehabilitating a 90m section of underground pipe in Somerset in South East Queensland.

Urban Utilities’ maintenance innovation lead, Senthil Kumar, said the state-of-the-art Resiline technology sprayed a rapid-curing lining inside the pipe, relining it underground and removing the need for a traditional ‘lift and lay’ pipe excavation.

“With this new trenchless technology, works that would have traditionally taken weeks can be completed in just a few days,” Mr Kumar said.

“This helps reduce our overall carbon footprint and can make essential works more cost efficient.

“The technology also has great potential to benefit our customers, particularly those in busy CBD or popular community areas, by allowing us to upgrade vital infrastructure underground without a need to excavate large sections of footpaths or roads.”

Urban Utilities’ water program manager, Jonathan Farrell, said Urban Utilities would investigate how the technology could be used as part of its existing pipeline renewal program following the successful trial.

“We’re responsible for maintaining a network of 9,000km of water pipes that supply water to more than 1.5 million people across South East Queensland and we’re always looking at ways we can improve outcomes for our environment and our customers,” Mr Farrell said.

“This technology is a great example of Urban Utilities’ commitment to innovation and we’re proud to be part of this Australian-first trial.”

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 14

No. 407319937 Key management Meter security seals Contact us for more information about our comprehensive range of key cabinets. Trackable Serial Numbering Expose Unauthorised Access NEWS

Solving for the aftermath. Before the aftermath.

Smart grid technology, intelligent devices and an industrial IoT network to connect it all. Not only is this the best way to prepare your grid for a storm, but it’s the best way to bounce back afterward. Reduce outage minutes, restore service efficiently and recover quickly. We can’t predict the weather. But we can be ready for it.

More intelligence. More possibilities.

Itr on.com/possibilities

© Copyright 2021 Itron. All rights reserved. Itron and the Itron logo are registered trademarks of Itron, Inc.

NORTHERN TERRITORY PROGRESSES WORLD’S LARGEST RENEWABLE ENERGY SYSTEM

The Northern Territory Government is set to introduce legislation to support what is expected to be the largest and most technologically advanced renewable energy transmission system in the world.

The $30 billion Sun Cable AustraliaAsia PowerLink (AAPowerLink) project includes the world’s largest solar farm and battery in the Barkly region, plus a converter site and transition facilities at Murrumujuk, near Gunn Point.

The Solar Project (Australia-Asia Power Link) (Special Provisions) Bill 2022 will provide certainty that key commitments in the Territory’s Project Development Agreement with Sun Cable will be met.

The legislation will clarify and streamline existing processes, increase project certainty, and support Sun Cable to secure project financing.

Sun Cable Founder and CEO, David Griffin, said, “Sun Cable appreciates the ongoing support for the AAPowerLink from the Northern Territory Government.

“The introduction of the Solar Project Bill 2022 is a manifestation of our common desire to drive investment in the Territory. This bill provides certainty that key commitments from the Project Development Agreement will be met.”

With an expected life span of more than 70 years, the Northern Territory Government sees the project as integral to the Territory’s future.

NT Chief Minister, Michael Gunner, said, “The AAPowerLink will be built here in the Territory. It will be a major economic driver, and it will put the Territory on the international map when it comes to renewables.

“The legislation provides certainty for the project, and facilitates its implementation which will create over 1,750 jobs during construction and 350 ongoing positions as part of operations.”

It has been awarded Major Project Status by the Federal and Territory Governments.

The NT Government and Sun Cable have also signed a Project Development Agreement to facilitate the project.

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 16

tenders@lancogroup.com.au | www.lancogroup.com.au | 1300 1 LANCO (1300 152 626) Civil and Infrastructure Engineering | Project Management NEWS

SA WATER BEGINS KANGAROO ISLAND DESALINATION PLANT CONSTRUCTION

SA Water, alongside major construction partners John Holland and Guidera O’Connor, has begun construction of Kangaroo Island’s new seawater desalination plant, which will improve drinking water reliability for the region.

SA Water and partners have begun setting up equipment, fencing and temporary site huts, as well as ground preparation at the Penneshaw site.

The project will also support the local economy and provide greater bushfire resilience.

More than $64 million is being invested in the project, with the new 2ML a day capacity plant to supplement the smaller existing nearby desalination facility and Middle River Reservoir.

SA Water’s General Manager of Sustainable Infrastructure, Amanda Lewry, said this work is happening in parallel with the continuing installation of a pipeline to connect customers in four local communities to the new desalination facility and water supply network.

“Close to 12 of a total 50km of large underground water main has been laid, and this pipe – along with smaller reticulation mains – will deliver water to more than a

thousand residents in American River, Baudin Beach, Island Beach and Sapphiretown,” Ms Lewry said.

“These communities currently rely on private rainwater tanks or water carters for their drinking water, with the new desalination plant and water network providing access to a safe, reliable and climate-independent supply of drinking water.

“Fire plugs will also be strategically placed along the pipes, enabling fire authorities and water carters for the first time, direct access to water via our infrastructure in these areas, to fill or refill.”

SA Water’s development application for the desalination plant was informed by detailed marine and land assessments, with the site at the corner of Hog Bay Road and Williams Walkers Way determined as the most suitable, based on a range of criteria.

The independent State Commission Assessment Panel’s review and assessment process opened the application for public consultation and considered feedback, with conditions set to ensure areas such as road safety and environmental management are managed in accordance with regulations and community expectations.

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 17

NEWS Innovative Water Solutions Through its innovative solutions, Veolia Water Technologies enables industry, local authorities and citizens to optimize their use of resources for more efficient, environmentally-friendly and socially responsible outcomes. We understand the importance of increasing the value of water and we do so by supplying high quality water, treating and reusing wastewater, producing and/or recovering energy, extracting raw materials and capitalizing on valuable byproducts. www.veoliawatertechnologies.com.au WATER TECHNOLOGIES

© Veolia Photo Library

MAJOR AUSTRALIAN-FIRST OFFSHORE WIND FARMS

The Victorian Government has committed to delivering Australia’s first offshore wind farms, announcing major energy targets around offshore projects.

The policy, set out in the Victorian Offshore Wind Policy Directions Paper, includes procuring projects that will generate at least 2GW of offshore wind online by 2032 –enough to power 1.5 million homes – creating thousands of jobs in the process.

The first power from offshore wind is expected as soon as 2028, following a competitive process, and targets of 4GW have been set for 2035 and 9GW for 2040.

Victorian Premier, Daniel Andrews, said, “Today, Victoria has the lowest power prices in five years and the greatest annual increase in renewable energy of any state, ever.

“We’re not just talking about transitioning to clean energy, we’re actually delivering it – along with thousands of jobs in one of the world’s fastest growing industries and cheaper bills for millions of households.”

Victorian Minister for Energy, Environment and Climate Change, Lily D’Ambrosio, said, “Victoria’s offshore wind

resources are officially open for business, but the real work starts now.

“We know it will take years to plan and develop the first tranche of wind projects in Australia, due to their complexity, scale, regulatory and infrastructure requirements – and we’re ready to start that journey today.”

Studies show the state has the potential to support an enormous 13GW of capacity from coastal regions by 2050 –five times the state’s current renewable energy generation.

At 13GW, these offshore wind projects would generate up to 6,100 jobs in the development and construction phase and in ongoing operational jobs.

In November 2021, Victoria pledged approximately $40 million under the Energy Innovation Fund to fund feasibility studies and pre-construction development for three major offshore wind proposals: Star of the South, Macquarie Group and Flotation Energy.

Together, those three projects could generate 4.7GW of new capacity, power around 3.6 million homes and bring more than $18 billion in new investment to Victoria.

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 18

Unit 2 / 85 Heatherdale Road, Ringwood Vic 3134 PO Box 2500, North Ringwood Vic 3134 P: (03) 9872 4596 | F: (03) 9872 3293 | E: info@pezztrenchless.com.au Still the market leaders in laser guided microtunnelling Bore diameters from 325mm up to 2800mm Used for gravity sewers, water mains, storm water, gas and electrical conduits. Specialists in “free bore”, sleeve boring and pipe jacking in all sizes The Next Generation in Trenchless Technology NEWS

PROVIDING SOLUTIONS FOR:

• Municipal Sewage Treatment

• Commercial & Industrial Estates

• Government Projects

• Residential Developments

• Urban Subdivisions

• Resorts & Caravan Parks

• Mining Accommodation

• Airports & Infrastructure

• Service Stations

• Defence Assets

1800 057 771 | truewateraustralia.com

SEWAGE & WASTEWATER SPECIALISTS

• DESIGN • MANUFACTURE • INSTALLATION • MANAGEMENT

us about our CONNECTmi® and TELEmi® products for dynamic real time Asset and Management.Monitoring

CONSULTANCY

Ask

NEW RESERVOIR TO BOOST WATER STORAGE CAPACITY FOR TAS REGION

Anew reservoir is being built in Rosebery in Tasmania, as part of a program to boost water reliability for TasWater’s regional customers.

TasWater Capital Delivery Office (CDO) Project Manager, Nathan Toomer, said the new reservoir will significantly increase Rosebery’s water storage capacity.

“The new tank we are constructing will be able to store approximately 1,200 kilolitres of water,” Mr Toomer said.

“It is being built next to the existing reservoir which will continue to be used for the town’s water supply.

“This will help increase water security for the Rosebery region well into the future.

“This will be particularly important for the community during periods where demand increases such as hot summer

days or in the event of a bushfire when firefighters need to access our supplies for their essential work.”

Construction of the new Rosebery reservoir was commenced by Fulton Hogan as the main contractor late last year, with the works expected to be wrapped up this winter.

Once complete, the old reservoir will be drained, undergo maintenance and will then be refilled and brought back online to service the town alongside the new reservoir.

This project is part of TasWater’s commitment to providing additional water storage for communities across Tasmania.

This upgrade is one project in a program of reservoir upgrades across the state that includes Tunbridge, Triabunna and Coles Bay.

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 20

NEWS 1800 816 830 enviroline.net.au THE WATER JETTING SPECIALISTS Talk to the experts! For all your drain maintenance equipment needs

AUSTRALIA’S WATER INDUSTRY IS OUR CAPABILITY

Benefitting from over 140 years of experience, we partner closely with our clients to ensure that secure and innovative pipeline projects are developed to their full potential. We work with pipeline designers by providing in-depth design analysis support, leading to reliable solutions with our unique Sintakote Steel Pipeline Systems. All the hallmarks of an established Australian manufacturing business you can trust with your next pipeline project.

www.steelmains.com ®

CLARITY IN ONE TECHNOLOGY SOLUTION

Connecting Australia’s water sector to smarter, real time data – in one place

KPMG Water Central, powered by the intelligent software platform Arwin, connects all your data sources to create a crystal-clear view of your business in real-time.

It enables you and your team to visualise your entire water asset ecosystem, make more informed decisions, and ultimately helps deliver better staff productivity and customer experience.

KPMG Water Central uses advanced analytics and data visualisation to help you anticipate future events and predict potential operational threats.

Geospatial visualisations give you context on outages alerts and predicted failures, showing the real-time impact of events and helping you respond with speed.

Built in collaboration with the water sector using industry data sets, KPMG Water Central provides a unique opportunity for the Australian water sector to benefit from shared insights, improvements and new use cases – reducing the overall industry spend and cost to deliver benefits.

NEWS | Sponsored editorial Find out more on how KPMG Water Central can help your business enhance the value of your customer, workforce and asset data. Please visit KPMG.com/au/WaterCentral 22 UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU

1300 062 064 | polymaster.com.au 25 YEAR DESIGN LIFE

our range

See

DIGITAL UTILITIES IS BACK FOR 2022!

Utility Magazine is thrilled to announce the return of the Digital Utilities virtual conference for 2022, running from 21–23 June.

Digital Utilities is the landmark virtual event for the Australian utility sector, and consists of three unique conferences that will dive deep into how we can create efficient and secure future grids and engage customers in the new digital era.

The event provides delegates with genuine learning opportunities from some of the best and brightest minds across Australia.

Digital Utilities brings together water and energy utility CEOs, CIOs and digital teams to exchange information. As travel remains uncertain, the virtual event allows delegates to connect online and keep up-to-date with the latest trends and developments in digitisation.

The three Digital Utilities conferences for 2022 include:

FUTURE GRIDS – 21 JUNE

In this conference, we’ll look at the evolution of energy and water networks, as we begin to integrate new technologies and new directional flows into our existing grids. We’ll look at the challenges and opportunities; and hear case studies from utilities who have cracked the code of making their networks work for them in the new, connected world.

ENGAGING CUSTOMERS – 22 JUNE

This conference will focus on the changing needs and expectations of customers when engaging with utilities. We’ll look at how other industries engage with customers; and analyse the way that this is shifting expectations for utilities. We’ll also explore some of the latest data, technologies and insights when it comes to managing customer experience and reducing churn.

CYBER SECURITY – 23 JUNE

Our final conference will take a deep dive into cyber security, exploring the challenges utilities face in keeping their digital networks secure. We’ll look at some of the latest technologies and thinking when it comes to keeping assets safe; and we’ll also take a look at global cases where things have gone wrong – and drill down to the key learnings to be taken from these events.

This event is being delivered by Monkey Media, trade publisher of Utility magazine, as well as Energy, Infrastructure, Council and Pump Industry magazines.

It will be a must-see for anyone working in Australia’s utility industry.

Registration is free, please visit www.digitalutilities.com.au to secure your spot.

A limited number of sponsorship opportunities are also available for companies looking to work with Digital Utilities and reach the Australian utilities sector. Visit www.digitalutilities.com.au for more information.

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 24

NEWS

21–23 June 2022

Three virtual conferences:

• Future Grids – 21 June

• Engaging Customers – 22 June

• Cyber Security – 23 June

Creating efficient and secure future grids and engaging customers in the new digital era.

REGISTRATION IS FREE!

to

at www.digitalutilities.com.au

2022 Brought

you by Register

COLLABORATION IN THE WATER SECTOR: more voices means better ideas

Water utilities around Australia face similar challenges – population growth, more frequent weather events, drought and climate change means there’s more pressure on our water storages than ever before. But the industry focus remains the same, utilities are committed to providing the community with safe water now and into the future, while dealing with these challenges, managing water quality and water availability and keeping costs down. With these same goals, it’s critical that utilities around the country collaborate with each other as well as with different sectors and educational institutions, to share insights and solutions.

Lara Olsen, Managing Director of South East Water, believes the water industry is the most collaborative sector in the country, especially compared to other industries she’s worked in, such as energy.

“We have the same goals, so the only way you really achieve them is when you work at scale and go with the best ideas rather than trying to do everything in your own organisation,” she said.

In addition to providing water, sewerage and recycled water services to 1.91 million people across Melbourne per year, South East Water is focused on developing new technologies to solve some of these water challenges, which are then tested in their network.

For instance, it’s recently achieved this with Sotto and Lentic, two technologies that its engineers conceived, developed and manufactured for market.

Embedded within digital meters, these technologies help locate leaks early before they impact the community, helping save water and additional water usage charges.

Ms Olsen said sharing these insights and collaborating with other organisations has been a key part of these projects having the biggest impact in the sector as possible.

“If you're just looking to solve a problem for your particular situation then you miss some of the best ideas and the chance for it to have a much greater impact than it otherwise could, and I think that comes from collaboration right from the start,” Ms Olsen said.

“The more voices you have around the table, asking questions and suggesting ideas, the better the technology or solution that you will get. That includes customers as well.”

APPROACHING COLLABORATION WITH STAKEHOLDERS

It can be hard to know what the best approach is when it comes to collaboration; who to partner with and why, what people, projects and technologies should be involved, and what are the best outcomes.

Ms Olsen said the approach can be different based on what you’re trying to achieve.

“There's certainly some projects which we've initiated and led, and then other projects where we are a project partner, learning from others and looking to see what they're doing. I think that's an important characteristic – there is not just one set organisation that looks to lead, it's a sharing of that role as well.”

One example of this is South East Water’s Biosolids to Biochar project, a partnership with RMIT University, Intelligent Water Networks and Greater Western Water. RMIT was developing a technology to transform biosolids – a waste product from sewage treatment – into something beneficial for the agriculture industry such as soil fertiliser.

“This was a project that focuses on what we could do with those biosolids and how we make the treatment of them more energy efficient. How do we keep the great parts of the biosolids in terms of nutrients but remove the contaminants, and come up with a solution that not only works for us, but also for the broader water industry.

“It's been a great example of working with universities in terms of

26

INDUSTRY INSIGHT

the expertise that they bring, working with our research and development team and industry partners in determining how technology works in practice at the treatment plant, and confirming what is then needed to take the technology to the next stage,” Ms Olsen said.

The Biosolids to Biochar project is now at the demonstration plant stage with a trial at the Greater Western Water Melton recycled water plant recently finishing, and plans to expand further, as it can be implemented in small and large plants, both locally and overseas.

The project also won the R&D Excellence Award at the Australian Water Association’s Victorian (VIC) Water Awards in March 2022.

This drive to develop proven solutions for common industry challenges also extends to housing developments and how these are built in the future to minimise water

and energy use. The construction industry can be a great source of collaboration to create solutions that improve communities and the way they function.

The Aquarevo project, a collaboration with South East Water, Villawood Properties and Melbourne University, is a community in south-eastern Melbourne built with three sources of water; drinking, recycled, and rainwater. Homes are integrated with technologies ranging from a rain-tohot-water system, through to remote pressure sewer monitoring, and intelligent rainwater tanks.

“By using the rainwater tanks and the hot water systems, on average, homes have been able to save about 45 per cent of their drinking water. We've been working with Melbourne University and La Trobe University to trial a range of different technologies around smart tanks as well,” Ms Olsen said.

SOLUTIONS FOR FUTURE INDUSTRY CHALLENGES

While it’s great to be able to get different internal teams involved and working with other utilities and organisations on innovative projects, Ms Olsen said the main benefit of collaboration is the difference these projects will have for future generations.

“Often when people think of a water utility, they think about turning on the tap, but for us, we're trying to think about our role in helping communities be the best they can be and protecting our environment,” Ms Olsen said.

“It's not just about what comes out of the tap, sometimes it's about working with energy companies, universities, other water corporations and building developers. This is what we need to be thinking about now if we are going to enhance what our environment or community looks like in ten or 20 years.”

27

INDUSTRY INSIGHT

by April Shepherd, Journalist, Utility magazine

by April Shepherd, Journalist, Utility magazine

CEO of Urban Utilities, Louise Dudley, is finishing up her ten year tenure at the leading water utility in August, following her transformative stint at the helm. Utility talked to Ms Dudley about her role’s biggest challenges, encouraging women to enter the sector, championing inclusivity and the industry’s innovation evolution.

28

WATER MANAGEMENT

The end of an era:

LOUISE DUDLEY REFLECTS ON LEADING URBAN UTILITIES FOR THE LAST DECADE

Ms Dudley is finishing her ten year long tenure at the helm of one of the nation’s largest water distributor-retailers and what has become, largely thanks to her guidance, a trailblazer in the Australian utility industry.

Urban Utilities delivers drinking water, recycled water and sewerage services to more than 1.4 million people in South East Queensland, with a large focus on sustainability and collaboration in the sector.

Ms Dudley first entered the water industry in 2007, working for the Brisbane City Council's retail water business in the role of Executive Manager.

“I was part of the team that facilitated Australia’s largest ever water sector transition and merger transaction, which ultimately resulted in the formation of Urban Utilities. I took on the role of CFO and, two years later, was appointed CEO,” Ms Dudley said.

“Fourteen years on, the industry is more innovative, sustainable and customer-centric than ever. It’s been a pleasure to be part of its evolution.”

LESSONS LEARNT: IT’S ABOUT THE PEOPLE, NOT THE PIPES

Ms Dudley said that, despite Urban Utilities undoubtedly being an infrastructure-heavy business, she has learnt that the real investment needs to be in people, “In a nutshell: it’s about the people, not the pipes”.

“They are the ones who are working together to deliver the outcomes for our customers and communities, and really determine the reputation of the business,” Ms Dudley said.

Ms Dudley said that during her time as CEO she found that a healthy and balanced workplace culture couldn’t be bought or cultivated overnight, but takes a huge amount of time and effort – and trial and error – to see results.

“It’s so important that each and every team member feels connected to our purpose (enriching the quality of life) and understands how their role contributes to our strategic direction and overall success.

“If people are purpose-driven and feel engaged, enabled and rewarded, they will do their best work and be more likely to go above and beyond to provide top quality products and services to our customers and communities,” Ms Dudley said.

THE CAREER-DEFINING PROJECTS

Throughout the past decade, Ms Dudley has worked on hundreds of projects, but one that stands out as a highlight was successfully establishing Urban Utilities as an entity in 2010, and maintaining continuity of service throughout the process.

“It was a $4.3 billion transaction that merged five water and sewerage businesses into Australia’s fourthlargest distributor–retailer. It’s not

often you get the opportunity to get in at the ground floor and grow with an organisation, so it’s been a real privilege,” Ms Dudley said.

She said that the change in company culture and championing inclusivity have also been some of her most proud initiatives.

“Diversity really lifts the overall performance of an organisation – not just diversity of gender but diversity of thought, experience, background and ethnicity, which is why implementing a Diversity and Inclusion Strategy was always high on my agenda.

“Since we started measuring Employee Effectiveness in 2014, our score has increased by 58 per cent, which is a testament to the ongoing investment and commitment.”

A DECADE OF CHALLENGES

A decade tenure doesn’t come without its fair share of challenges, with the period of water reform in the early 2000s one of the biggest challenges faced by not only Urban Utilities, but the entire South East Queensland water industry.

“Initially, Urban Utilities was going to be a retail business, with a separate water distribution business to service the entire region. But in mid-2009, the model changed, and the combined distributor-retailer model was adopted,” Ms Dudley said.

“It was unclear whether Urban Utilities would continue in this form,

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 29

WATER MANAGEMENT

which led to feelings of uncertainty and instability right across the industry. In turn, it became difficult to attract and retain staff, which was an additional stressor at the time.

“On top of that, we had the challenge of merging five individual, and very differently run, entities in a short time frame. We were dealing with a melting pot of cultures, values and personalities, so a lot of work was required to become one cohesive team, working towards a shared purpose.

EMBRACING INNOVATION TO BOOST THE CUSTOMER EXPERIENCE

The past decade has seen a new innovative shift in asset management, with more choice bringing a heightened focus on improving customer experience and championing sustainability.

Ms Dudley said the water industry has undertaken a transformational shift from being asset-centric to customer-centric.

If merging five unique entities wasn’t challenging enough, not long after Ms Dudley began her time at Urban Utilities, the state faced some of the deadliest floods it had ever seen.

Queensland suffered catastrophic floods in January 2011, which according to Ms Dudley profoundly impacted Urban Utilities.

Not only was 60 per cent of the utility’s infrastructure extensively damaged, but the natural disaster left Urban Utilities with a property damage bill in excess of $100 million.

“Not two years later, the region was, again, ravaged by flood water.

Whilst this period was devastating for the business, we used our learnings to develop a robust Flood Resilience Program, which really paid dividends earlier this year when parts of our service territory were flooded for the third time in 11 years. Thankfully, we were able to recover our critical assets much faster.”

“Soon after becoming CEO, I made it my business to personally engage with each and every employee, to hear their questions and concerns and to ensure they felt connected with Urban Utilities’ newly created purpose and vision.”

“Once upon a time, a burst water main may only have been addressed in terms of the fastest, most costeffective way to repair the pipe. Now, we look at it through a customer-impact lens and ask questions like: Who relies on that pipe? How will losing water affect them? What can we do to minimise disruption?”

Ms Dudley said that Urban Utilities has taken great strides in becoming a customer-focused organisation, using specialised teams that understand and attend to the unique requirements of different customers; and using data and insights to provide personalised services.

“The industry has also collectively embraced an innovation mindset and is now thinking outside the traditional solutions to deliver greener, smarter services that are more reliable and affordable for customers.

“We have also evolved from being primarily a service delivery industry

to one that is a key player in our region’s growth and prosperity – one that enhances the liveability of its communities and creates a meaningful impact on society.”

Urban Utilities' reputation in the industry is synonymous with innovation, with the Urban Utilities’ Innovation Program delivering operational efficiencies and improving safety, customer and environmental outcomes.

In Urban Utilities' Research and Development Program, future areas of innovation are discovered, working with the industry and research partners to find smarter ways of operating.

“The success of the Urban Utilities’ Innovation Program was really cemented when we made Australia’s Most Innovative Companies List in 2015 and again in 2018. Also in 2018, we were named one of the Leading Utilities of the World, which is a network of some of the world’s most innovative water utilities.”

WOMEN IN THE INDUSTRY: THE CEO CHAIR IS FOR EVERYONE

Ms Dudley’s career is notable for many reasons, one of which is her work to not only normalise, but encourage women in senior leadership positions in the water industry, saying that to attract women to the water industry, it’s important they have strong and successful role models to guide and inspire them.

“Sometimes people are surprised when I tell them I’m a CEO, and even more surprised that I’m the CEO of a utility, because neither are roles traditionally held by a woman,” Ms Dudley said.

“To overcome this stereotype, we need to change the perception that CEO roles are held exclusively by men.”

Ms Dudley said that leading by example is the key to attracting more women to industries that are historically male-dominated, and fostering the right culture to retain women; such as promoting work/life balance through a range of flexible and supportive work options and access to various leave.

“The fewer hurdles there are for women to progress their careers, the more likely it is that the industry retains quality talent.

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 30

WATER MANAGEMENT

“If young women don’t see examples of female chemists, engineers, treatment plant operators or CEOs, they are less likely to imagine or pursue those career paths for themselves.

“Thankfully, there are organisations around now that are committed to connecting young women with mentors in STEM-based industries, and Urban Utilities is proud to be involved.”

Ms Dudley said it is not only critical to address the gender imbalance in the industry, but also focus on fostering a culture of diversity and inclusion; where an individual’s contribution, knowledge, skills and experience is valued and recognised.

THE FUTURE IS BRIGHT: UTILITIES BUILDING LIVABLE COMMUNITIES

Ms Dudley said she is excited to see what the future holds and how water utilities will play a greater role in shaping the livability of Australia's communities.

“I’m also looking forward to seeing water utilities become embedded in the early stages of the community planning process, along with the State Government, regulators, councils and

developers, and for these stakeholders to consider us an essential partner in creating liveable communities.”

Ms Dudley believes this will also involve engaging with customers to codesign sustainable blue/green spaces that suit the needs of both current and future generations.

To those just starting out in their water utility career, Ms Dudley recommends networking with likeminded people, as it’s a great way to share ideas, raise your profile and increase your confidence.

“Also find a mentor whom you respect and admire. Ask to accompany them to industry functions or sit in on meetings as an observer. Ask them questions and brainstorm ideas. There’s always something new to be learnt.

“And take risks! Don’t underestimate your abilities. If you’re offered an opportunity, grab it with both hands and see where it takes you.”

THE NEXT JOURNEY

Ms Dudley is finishing up her tenure as CEO in August 2022, with plans to continue serving on the AWA and WaterAid boards, and is looking forward to taking on additional board roles if they may arise.

“I’m also passionate about leadership and creating high-performing teams, and plan to coach executives and board members in the areas of conversational intelligence and psychological safety.

“From a personal perspective, I’m keen to tap into my artistic side, maybe take a few art classes and see if I have any hidden talent! I also plan to fulfil my long-held ambition to learn French.”

As for her legacy, some might think it hard to choose just one after looking at the extent of innovation Ms Dudley has brought to the industry throughout the past ten years.

“It’s Urban Utilities’ Innovation Program and innovation culture that I see as being the legacy I’ll leave. Innovation is a personal passion of mine, so being able to watch the program go from strength to strength and see it attract global attention has been one of the most rewarding parts of my role as CEO,” Ms Dudley said.

“What started as a small-scale internal initiative is now a multi-faceted, multi-million-dollar program that’s delivering widespread economic, social and environmental value.”

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 31

WATER MANAGEMENT

AI IN THE WATER SECTOR: SAFER, FASTER, BETTER

Once considered a threat to people’s jobs, automation is enabling many in the water sector to leave mundane tasks behind and focus on high value work.

Engineering graduates and other specialists are often employed to sit in front of video screens for weeks on end to watch footage from drone-mounted cameras being driven through pipes. The purpose? To assess where pipe maintenance needs to be carried out.

But no engineer wants to spend their days in front of a screen watching videos of the inside of a pipe. Fortunately, technology offers a smart solution for this.

WHAT A DIFFERENCE DATA MAKES

Technology fuelled by artificial intelligence (AI) is driving change in the water sector. Once considered a threat to people’s jobs, such technology is now helping people do more of what they want to do, while meeting increasingly high expectations.

For example, councils and water authorities have extensive kilometres of underground pipelines for wastewater, stormwater and water.

“Many of these pipes are approaching the end of their life and they need to be renewed,” John Phillips, Business Development Manager at Interflow, a leader in pipeline infrastructure, said.

“Digging them up to replace them all would be extremely expensive and would disrupt communities.”

How then does a water manager assess where the work needs to be done?

Previously it has been undertaken by sending a camera through the pipes and relying on an operator to conduct an accurate analysis.

“By the time they engage a contractor to do the upgrade work, often the footage is very old,” Mr Phillips said.

“Things could be completely different by the time we go to do the job.”

That’s where a neat, AI-based solution comes to the fore.

THE FUTURE OF WATER MANAGEMENT IS HERE

A faster, more accurate solution is now being utilised by leading councils and authorities. It’s one that removes repetitive and low-value work and liberates engineers and others to do the higher-value tasks that keep communities’ infrastructure running smoothly.

“The analysis of the condition of the pipes can all be done by machine,” John Weaver, Contracts Manager at Interflow, said.

Instead of camera footage being analysed by humans, it is analysed by an AI engine that has been trained on tens of thousands of hours of similar footage.

“It categorises every individual issue found and provides an immediate, realtime report of the entire pipe network,” Mr Weaver said.

“A recommended capital works program, complete with anticipated costs, comes with the analysis. This means the council or water authority can work that program into their budget over the next four or five years.”

The transformative effect of AI is making condition assessment reports and asset maps faster, more objective and more consistent. Wherever such technology is introduced it removes often mundane and repetitive work and frees engineers and other staff to perform higher-value tasks.

In the current environment in which the war for talent has become very real, anything that can be done to make work more engaging and relevant is welcome.

32 UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU

WATER MANAGEMENT | Sponsored editorial

AI in the water sector: We’re using AI to work safer, faster, better

CREATING AUSTRALIA’S

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 34

WATER MANAGEMENT THE WATER PROCESSING TEAM AT RICHMOND VALLEY COUNCIL.

best tasting tap water

Every year WIOA’s IXOM Best Tasting Tap Water Competitions celebrate the work undertaken by water professionals who work hard behind the scenes for their communities to deliver high-quality drinking water across Australia. Earlier this year, the water produced at the Casino Water Treatment Plant was named Australia’s best tasting tap water.

It takes a little less than two hours for Casino’s Water Treatment Plant to turn the water from Casino’s Richmond River into Australia’s best tasting tap water.

Operated by a three-person team in the northern New South Wales town of 11,000 residents, the plant supplies between six to ten megalitres of water daily, which took out the IXOM Best Tasting Tap water competition title this year.

The process is not without challenges, and Richmond Valley Council Operations Coordinator Water and Sewer, Sandeep Chugh, said the process starts more than three kilometres away at the river.

“We are at the mercy of the catchment –it is considered high risk,” he said.

“It’s an uncontrolled water source; there can be blue-green algae issues, animal carcasses and other natural elements in the river, quite a lot of things to deal with.”

With many controlled town water sources measuring under 200 nephelometric turbidity units (NTU), a measurement of suspended particles in the water, often the Richmond River would present levels of more than 1000 NTU.

“But this plant absolutely loves it,” Mr Chugh said.

“At the river, stainless steel mesh screens out many larger solids in the water before being pumped towards the treatment plant.

“We have the capacity at the raw water pump station to dose powder activated carbon for blue-green algae and taste and odour issues.

“We use potassium permanganate for manganese issues when they arise at the raw water pump station, and those two dosing points are separated by 500m.

“The water then passes to the head of works, where aluminium sulphate and polymer are added to bind the sediment together in the floc basins and then drops into sedimentation tanks before passing through the main filters.

“So, we have coagulation, flocculation, sedimentation – and then filtration.

“We like the sedimentation tanks to do all the hard work, removing the majority (of solids) there, giving an easy run for the filters.”

Appropriate levels of chlorine and fluoride are added after final filtration before travelling to three of four reservoirs, which supply the town.

At each point in the process, pumps feed a sample of the water to the laboratory, monitored by manual and automated analysis.

Each point in the process has a turbidity analyser which will trigger an alarm at a level of turbidity and a failsafe to shut the raw water pumps and treatment plant down, preventing poor water from being sent to the reservoir when the plant is unattended.

“There is also a lot of visual work done by looking at what is coming into the lab and the tanks,” Mr Chugh said. “And that comes back to experience and knowing what to look for.”

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 35

WATER MANAGEMENT

Mr Chugh said the plant’s design had changed little since commissioned in 1986 and, despite the challenges of its source water, had stood the test of time.

“There have been changes in the chemical dosing and the addition of variable speed drives to pumps,” he said.

“There has also been a big leap forward in SCADA and the level of automation at the plant, however, further work is being undertaken to bring the plant in line with the industry best practice.”

The process of creating the clean drinking-water source had constantly evolved, Mr Chugh said, pointing

to powder-activated carbon treatment introduced permanently in the past 12 months and working with enhanced coagulation to improve what was already a successful process.

“When we work with normal coagulation, it likes a pH range of six and a half to seven, so that’s what we’ll run at the head of works,” he said.

“When you go to enhanced coagulation, which is good for removing organic carbons, we’ll run a pH range of 5.5 to 6.

“We’re deliberating driving that pH down to remove those organic carbons with aluminium sulphate dosing.

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 36

WATER MANAGEMENT

AERIAL VIEW OF THE CASINO WATER TREATMENT PLANT.

“The benefit is you’re using a lot less chlorine, and it’s the chlorine and by-products which gives you an unpleasant taste around town.”

With recent floods further challenging the source water quality for the plant, Mr Chugh said they would use the experience to create new procedures for the future to ensure the town continued to receive the highquality of water from the tap.

Mr Chugh said while the water quality was a boon for the town, it was also an essential part of local industry.

“The Casino Food Co-op takes more than a third of the water we produce, and it must be top quality because as a meatworks it has health requirements to meet, and strict exporting demands,” he said.

Mr Chugh said he and the team were proud to have the best tasting tap water in Australia.

“To have the best drinking water in Australia, though? It’s pretty amazing. Considering the challenges we have, it is really amazing.”

UTILITY • MAY 2022 WWW.UTILITYMAGAZINE.COM.AU 37

MANAGEMENT

THE WATER PRODUCED AT CASINO.

WATER

TESTING

Why use a DUCKBILL VALVE?

Check valves are used in all stormwater and wastewater systems. They allow the forward flow of fluids before closing to prevent backflow conditions. These valves come in a variety of diameters and designs including swing, ball, diaphragm and duckbill check valves. They are simply designed, passive devices that rely on flow velocity and pressure to open and close without any manual or automated assistance.

For hundreds of years, towns, cities, farmers, and homeowners have been concerned with stopping rising rivers, ocean tides and even rainwater from infiltrating their premises in the event of reverse flow.

Millions of dollars are spent every year attempting to prevent back flows; and even more money is spent in reclamation and clean up after major floods, levy failures and ocean headwall damage.

For many years the accepted valve was the traditional style flap gate, which was always problematic from rusted hinges, warped disks, jammed open gates; to even the complete gate being removed by theft. Hence, the duckbill check valve was invented, and the rest is history.

The duckbill check valve is a flexible sleeve shaped like a duck’s beak. It allows forward flow of water with positive head differential pressure which progressively opens the valve as flow increases. Duckbill check valves consistently provide the tightest seal for preventing backflow. The flexible elastomer material can compress tightly around trapped solids if necessary. Its ability to resist ocean waves, freezing temperatures and scorching heat makes the valve one of the most specified valves on the planet.

Duckbill valves offer a wide range of benefits over standard valves in water and wastewater operations. We take a closer look at the compelling reasons to take advantage of the benefits duckbill valves provide.