ENDEAVOUR ENERGY IMPROVES PUBLIC SAFETY WITH ITS DIGITAL TWIN

SYDNEY WATER INSTALLS NEW IOT SENSORS IN MAJOR ROLLOUT

THE FUTURE OF WATER MANAGEMENT WITH URBAN UTILITIES’ NEW CEO

WATER SEWER ELECTRICITY GAS www.utilitymagazine.com.au Issue #38, May 2023

FROM THE EDITOR

It is with great excitement that I am writing this letter as the new editor of Utility Magazine, and I am delighted to be joining the exceptional team at Monkey Media.

My predecessors worked tirelessly to maintain Utility’s reputation as a respected industry platform for Australia’s utilities to share and learn alongside each other, and this is a legacy I hope to both preserve and build on. I am excited to immerse myself in the industry and I’d love to hear from you with any story ideas or industry insights.

Utility is and always has been a publication by the industry, for the industry, and our goal is to reflect the challenges and concerns facing Australia’s utilities, as well as celebrate their exceptional work and achievements and share the latest innovations. On this note, my contact details are below and I encourage you to get in touch if you’d like to discuss any potential articles, collaborations or news that you would like to see in future issues.

In this edition, we’ve collaborated with some of the industry’s key figures to bring you exciting contributions that cover the most important issues affecting Australia's utilities. Climate change, and subsequently the advancements in renewable technology are constantly shaping the way in which both the water sector and energy networks operate.

In this issue, we explore how water utilities are managing the challenges posed by unprecedented weather conditions, and how they are keeping services going amid devastating floods. While swift action in an emergency is essential, we’re seeing a lot of preventative measures being implemented across the country and Sydney Water is already underway on the large-scale deployment of IoT wastewater monitoring sensors.

Over in the energy sector, we’re also seeing new technology making exciting improvements to Australia’s energy networks. This issue covers Endeavour Energy’s new digital twin technology, and how it has allowed the utility to identify clearances between rising floodwaters and power lines remotely. We also take a deep dive into the major funding for trial sensors that will increase utilities' capacity to support renewable energy and improve the efficiency of existing transmission lines.

We’re honored to be partnering with some big industry events, with this issue of the magazine being distributed at WIOA Queensland, OzWater, Locate23 and Australia Wind Energy 2023, and I look forward to meeting some of you in person at these events over the next few months.

The team and I are working hard to deliver the insightful content that Utility is renowned for, and I can’t wait to learn more about the industry and bring my very best to each and every issue.

We hope you enjoy this edition.

Katie Livingston Editor

Drop Katie a line at katie.livingston@monkeymedia.net.au

free to call them on 03 9988 4950

Editor Katie Livingston Journalists Stephanie Nestor, Tayla Oates, Tess Macallan, Steph Barker Design Manager Alejandro Molano Senior Designer Luke Martin Designers Danielle Harris, Ozlem

Jacqueline Buckmaster National Media and Events Executives Rima Munafo,

Marketing Manager Radhika Sud Marketing Associates James Holgate,

Digital Marketing Assistants Natalie Ta,

Dawes Publisher Chris Bland GM Growth and Strategy Laura Harvey Managing Editor Jessica Dickers Published by Monkey Media Enterprises ABN: 36 426 734 954 C/- The Commons 36–38 Gipps St, Collingwood VIC 3066 P: (03) 9988 4950 monkeymedia.com.au info@monkeymedia.com.au utilitymagazine.com.au info@utilitymagazine.com.au ISSN: 2203-2797 welcome May 2023 ISSUE 38 1

let

know

–

Munur,

Brett Thompson

Jackson Barnes

Bella Predika, Rhys

or feel

to

them

what you think. Don't forget to follow Utility Magazine on social media

find us on LinkedIn, Twitter and YouTube.

Utility Magazine acknowledges Aboriginal Traditional Owners of Country throughout Australia and pays respect to their cultures and Elders past, present and emerging. Scan to subscribe to Utility magazine’s weekly newsletter – delivered to your inbox every Thursday morning. This document has been produced to international environmental management standard ISO14001 by a certified green printing company.

INDUSTRY INSIGHTS

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 2

METERS Toowoomba Council turns the tap on for smart water meters .......... 96 Smart Water Metering: business transformational, not just remote meter reading 98 ENERGY STORAGE The next generation of energy storage 100 FUTURE FUELS How research is creating new knowledge for the energy transition 102 How to get Australia back in the global hydrogen race ........... 106 MICROTUNNELLING Yarra Valley Water’s trenchless technology innovator explores critical innovations ..................... 108 88 96 102 WATER MANAGEMENT Procuring innovative water asset management technology 52 Sydney Water installs new IoT sensors in major rollout 54 Sydney Water is undertaking the first wastewater monitoring Internet of Things (IoT) deployment of its scale in Australia, which is saving hundreds of thousands of dollars per month in potential blockages. Everything you need to know about sodium hypochlorite in water treatment 56 Building trust, driving innovation, and delivering value in the water sector 58 Remote automation infrastructure transforms distributed water scheme ............ 62

MANAGEMENT New high-voltage transmission line powering SA’s Eyre Peninsula 42 Homes, businesses and communities across South Australia’s Eyre Peninsula now have a more secure power supply following the completion of Eyre Peninsula Link. Achieving renewable-first controls 44 WATER MANAGEMENT Keeping water services flowing amid rare river flood ................... 46 Water management: are utilities security guards or stewards? 50 VEGETATION MANAGEMENT Vegetation management that's ahead of the pack 88 The power of vegetation management in the Red Centre ............................. 90 Augment vegetation management with satellite imagery 94

CONTENTS SMART

DEMAND

The future of water management with Urban Utilities’ new CEO 26 Creating innovative solutions to mitigate flood damage ............. 30 Mitigating cybersecurity threats in water and wastewater 32 Coliban Water uses laser-guided tunnel bore for sewer installation 34 Think you know how to work near gas pipelines? Think again .................................... 36 The role of digital connectivity in Industry 4.0 38 Four practical ways to implement effective compliance programs .................. 40 46 42 26

SUSTAINABILITY

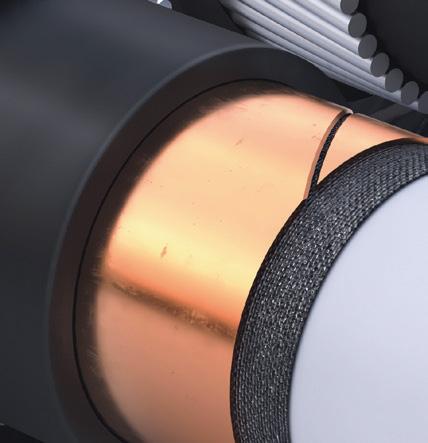

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 3 May 2023 ISSUE 38 In each issue Welcome from the Editor ������������������������������������������������������������������������������������������������������������� 1 A word from Energy Networks Australia ���������������������������������������������������������������������������������� 4 A word from WSAA ����������������������������������������������������������������������������������������������������������������������� 6 News briefs ������������������������������������������������������������������������������������������������������������������������������������ 8 Advertisers’ index ��������������������������������������������������������������������������������������������������������������������� 112 Editorial schedule ��������������������������������������������������������������������������������������������������������������������� 112 64 80 72 ENERGY NETWORKS Benefits and challenges of renewable transmission line sensors 64 The Australian Renewable Energy Agency (ARENA) is providing major funding to help New South Wales Transgrid and Infravision trial sensors that will increase capacity to support renewable energy and improve the efficiency of existing transmission lines. Virtual asset assessment: digital intelligence solving network challenges 66 Endeavour Energy pioneers innovation with its digital twin 68 Overcoming challenges in Port Melbourne network augmentation project 70 INSPECTION, CCTV & CONDITION ASSESSMENT How QLD’s largest sewer was upgraded while the city slept 80 Concrete solutions for Australia’s future pipelines 82 Aging infrastructure and rising sewerage temperatures pose increasing risks for corrosion of concrete sewerage pipes around the world. Failing pipes are a significant threat to utility operations, public health and the environment. However, there could soon be a solution. Professor in Structural Engineering at the University of South Australia STEM, Yan Zhuge, is leading a project focused on a self-healing concrete that could help prevent future pipelines from corroding. Boosting security for telecommunication assets .......... 84 Spacers assisting with corrosion management 86

Unitywater on a green path to achieve sustainability goals 72 With a growing population, a changing climate and the desire to improve the liveability of South East Queensland front of mind, Unitywater has harnessed the

of science, technology and

to implement key infrastructure projects that will help reduce the utility’s

Sustainable Infrastructure Solutions, Daniel Lambert,

of the projects and key

that the water utility is delivering. The equipment making vegetation management sustainable 74 Gippsland Water powers towards a 100 per cent renewable future 76 Increasing Australia’s digital capabilities and sustainability 78

power

Mother Nature

operating footprint. Unitywater Executive Manager

expands on some

milestones

A WORD FROM ENERGY NETWORKS AUSTRALIA

THE IMPORTANCE OF TRANSMISSION DEVELOPMENT ACROSS AUSTRALIA’S STATES

By Dominic Adams, GM Networks, Energy Networks Australia

If you follow the media’s updates of Australia’s energy sector, it would appear state governments all seem to be building their own transmission frameworks. Well, you’d be right. Each state has its own framework for getting transmission built in its jurisdiction. As they get on with delivering projects, there are a few important things to keep an eye out for. To understand how we got here, we need to go back.

Firstly, we need to talk about the problems with the old national framework, which will help us understand what the state frameworks have to do better.

Secondly, it’s important to talk about Australia’s constitutional history to understand why state governments care about transmission development. Then we will turn to the things to keep an eye out for as we develop new transmission frameworks.

THE OLD NATIONAL FRAMEWORK

In mid-2018 the energy industry collectively realised, with the release of AEMO’s first Integrated System Plan, that transmission was needed yesterday. The image shows the huge amount of transmission infrastructure, including interconnectors, that needs to be built to reach our decarbonisation objectives.

AEMO’s 2022 Integrated System Plan identifies an additional 10,000km of transmission lines are needed to support 120GW of large scale renewable energy and storage on the national interconnected energy system. The focus on transmission delivery was subsequently dialled up. It soon became clear that the national framework just wasn’t up to the job. There were three main issues:

1. It wasn’t designed to connect renewables – it could connect a big generator like a Snowy 2.0 but it couldn’t handle that coordination task with adding lots of smaller generators

2. It wasn’t designed for scale – it didn’t have wriggle room or financial pressure valves to allow a bit more cash-flow here or to accommodate a higher risk there. You need these mechanisms if you’re going to put in 10,000km of new transmission within a decade

3. It wasn’t designed for speed –projects were held up because the critical path was to go through all the regulatory approvals and then pick up the tools

Project EnergyConnect was a real-time case study. It needed the Clean Energy Finance Corporation support to deal with issue (2) and it needed government underwriting to deal with issue (3).

WHY STATE GOVERNMENTS CARE

Given the pace of the transition, the existing framework wasn’t going to deliver good outcomes for customers. The task ahead was, and still is, looking scary. So why is it state governments who seem to be leading the charge to deal with this? To answer this, we need

to go back to 1900 when the Australian Constitution was written. Back then:

• Sydney was four years away from electric streetlights

• Generators would shut down for Sundays

• The first high voltage transmission was 16 years away – for hydro in Tasmania

We can’t really blame them. In a federation like Australia, the buck stops with the states – as does the political and social imperative to keep the lights on. While the National Electricity Market formally commenced in 1998, interconnecting five east coast market jurisdictions, the more recent imperative to decarbonise our energy system, different state emissions reduction targets and system needs has led to a more bespoke state-bystate approach.

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 4

Consequently, all jurisdictions are moving with some urgency to bring the energy transition within their control. They are each going about it in different ways because their starting points are different – different market and ownership structures and in Victoria, different planning and investment rules. We often say of the transmission framework – both the physical system and the rules-based frameworks – that if you wanted to design what we need for the future you simply wouldn’t start where we are today.

NOTES FOR STATE FRAMEWORK DEVELOPERS

While each state is building its own framework to deliver much-needed new transmission, there are a few common issues and challenges that are worth keeping in mind:

Customers

There is only one reason we are on this journey. The challenge of managing the energy transition is a fine balance between environment, cost, and speed and it all comes back to the customer.

There is a big difference between working for customers and working with them. Building that trust and social licence requires transparency and genuine engagement. While transparency can sometimes meet its nemesis – confidentiality – it can pay significant dividends.

Risk allocation is critical

In the good old days when everything moved slowly, transmission businesses could arrive at a number through a regulatory process and back-to-back with a fixed price contract. It is not that simple anymore. Contractors should bear risks they can control, but they cannot control global supply chain costs and have limited ability to foresee all risks arising from greenfield projects. There are two options, to increase upfront prices or to share risks. How to solve this issue? See the first point.

This is a repeat game

There will be some mistakes, but the transition is not happening overnight, so we get to learn together. It is the mindset of listening to,

empathising, and partnering with your counterparties, whoever they are, that will get us through.

Workforce constraints need addressing

We have the capacity across the country to deliver about 700km of new transmission a year, which is not nearly enough. The silver lining is that we have an emerging talent pool of young apprentices, engineers and other skilled workers all keen to play their part in Australia’s energy transition. This is a once-in-a-lifetime transformation and we need to make this an attractive industry that looks after these future employees.

There are plenty more challenges to work through together and not all of them are known to us, given the rapid pace of the transition and the new technical and technological ground that is being broken. It is critical we continue to work together to share learnings and ensure the focus is always on the long-term interests of our customers.

UTILITY • MAY 2 023 WWW.UTILITYMAGAZINE.COM.AU 5 Unit 2 / 85 Heatherdale Road, Ringwood Vic 3134 PO Box 2500, North Ringwood Vic 3134 P: (03) 9872 4596 | F: (03) 9872 3293 | E: info@pezztrenchless.com.au | W: pezztrenchless.com.au Still the market leaders in laser guided microtunnelling Bore diameters from 325mm up to 2800mm Used for gravity sewers, water mains, storm water, gas and electrical conduits. Specialists in “free bore”, sleeve boring and pipe jacking in all sizes The Next Generation in Trenchless Technology

A WORD FROM WSAA

RESEARCH, DEVELOPMENT AND INNOVATION IN THE WATER SECTOR

The urban water industry is currently facing significant challenges, driven by the external factors of increased climate variability, aging infrastructure and constraints on our supply chain, human resources and capital availability, coupled with increasing customer expectations and upward pressures on interest rates and affordability.

In a post-COVID environment, communities have focused on creating resilient, well-functioning, digitallyconnected and liveable cities. Research, development and innovation (RD&I) provide a clear avenue to help address these challenges in ways that are lower cost, while delivering enhanced customer and community value.

To assist the sector, WSAA – alongside a focused leadership team – has formulated an integrated, national RD&I strategic approach. Called the RD&I Ecosystem, it is designed to streamline and enhance the delivery and uptake of RD&I offerings for the sector and position the sector well for the future.

In March 2023, WSAA released a strategy outlining the key elements for the RD&I Ecosystem and the five-year implementation plan for coordination and collaboration in RD&I across the water sector. The Strategy builds on the national research priorities agenda and is a core component of WSAA's national strategic program for the sector.

The purpose of the RD&I Strategy is to help the urban water industry develop, support and harness the RD&I potential from both within the sector and across other industries for value creation that supports thriving communities, optimises customer value, enhances the natural environment and delivers business resilience.

The RD&I ecosystem framework consists of seven elements:

• Leadership to drive an RD&I culture

• Knowledge to find what’s gone before and what’s happening now

• Opportunities to bring ideas, people and technology together

• Collaboration to work more easily with others and produce better results

• Pathways to explain clearly what happens next

• Application to provide guidance on implementation

• Communications and engagement to create awareness and drive participation

Each element includes an objective, key actions to take us there, and ways to measure improvement.

To read WSAA’s Strategy online, visit: www.wsaa.asn.au/publication/urban-water-industryresearch-development-and-innovation-strategy.

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU SECTION 6

IT DOESN’T JUST MEASURE VALUES. IT HAS VALUES. THE 6X ®. AVAILABLE NOW!

The VEGAPULS 6X: A radar level sensor that is not only technically perfect, it also takes the user into account. It’s easy to set up and at home in virtually any process or industrial environment. Made by a company that bases its decisions on values that are good for everybody.

VEGA. HOME OF VALUES.

www.vega.com/radar

$120M ALLOCATED FOR COMMUNITY BATTERIES

The Australian Renewable Energy Agency (ARENA) has announced $120 million in funding for the first round of the Community Batteries Funding Program.

The program aims to support the deployment of 342 community batteries across Australia to lower energy bills, cut emissions and reduce pressure on the electricity grid.

ARENA Chief Executive, Darren Miller, said community batteries represent the next step in optimising distributed energy resources in the electricity grid.

“Not everyone is able to install rooftop solar, but by storing electricity close to the point of consumer demand, we can reduce network costs and alleviate constraints in areas with high solar penetration. This will

ultimately reduce electricity costs for all consumers.” Mr Miller said.

ARENA is now seeking applications for up to $20 million in funding to deploy a minimum of five community batteries.

To be eligible for ARENA funding, each community battery must be between 50kW and 5MW in size and connected to the distribution network.

ARENA has allocated $120 million in funding for round one, split equally across two streams:

• Stream A: Distributed Network Service Providers (DNSP)

• Stream B: Applicants that are not DNSPs

Community batteries provide energy storage in the distribution network that can store excess solar energy for later use, putting downward pressure on

household electricity costs and easing pressure on the local electricity grid.

As part of the 2022/23 Federal Budget, the Government allocated $200 million for the Household Solar budget measure to deploy 400 community batteries across Australia.

ARENA was allocated $171 million of this funding to deliver at least 342 batteries, $120 million allocated to round one and the remaining funding allocated to a future round, based on learnings from this tranche.

The Department of Climate Change, Energy, the Environment and Water (DCCEEW) will deliver an initial 58 community batteries through the Business Grants Hub. This round is now closed, with DCCEEW now assessing applications.

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 8

NEWS No. 407319937 Key management Meter security seals Contact us for more information about our comprehensive range of key cabinets. Trackable Serial Numbering Expose Unauthorised Access

WINNER OF THE BEST TASTING TAP WATER IN VICTORIA COMPETITION

The winner of the 2023 Ixom Best Tasting Tap Water in Victoria competition was announced at the Water Industry Operators Association of Australia (WIOA) conference in Bendigo.

Watersure – Victorian Desalination Plant took home the title, after competing against the other two Grand Finalists for Victoria, Falls Creek Alpine Resort and North East Water –Benalla WTP.

Water samples were subjected to a blind taste test and rated according to the Water Tasting Wheel, which outlines some of the attributes that water professionals use when judging water such as colour, clarity, odour and taste.

This year’s Victorian judges included Utility Magazine’s new Editor, Katie Livingston; Warrick Green from Ixom; Doug Moorby, Manager Utilities at Narromine Shire, NSW; and Kyra Sunnex from NZ Tour Group.

Watersure will now go on to battle it out against the best from other states for the Australian title in November 2022.

The winner of the national competition will then represent Australia at the annual Berkeley Springs International Water Tasting Competition in West Virginia, USA.

WIOA Managing Director, George Wall, said the competition recognises and acknowledges the individuals and organisations that are stepping up,

some in very trying circumstances, to make sure their communities are supplied with safe drinking water every day.

“We want to use the competition to let people know the great work that is going on in local communities around Australia, and help to shape and secure Australia’s water future,” Mr Wall said.

Mr Wall also acknowledged Ixom’s support of the Best Tasting Tap Water competition.

“Thanks to Ixom’s unwavering commitment and support of the industry, we have been able to continue running the competition.”

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 9

NEWS

WA RESIDENTS TO RECEIVE STANDARD POWER SUPPLY ALLOCATION

The Western Australia State Government has announced an across-the-board power supply allocation will soon be in place for regional and metro areas across the South West Interconnection System (SWIS).

Western Australia Energy Minister, Bill Johnston, announced the standard power supply allocation and said it will meet the evolving energy needs of Western Australians.

“We’ve listened to the community and sought advice on how we can best serve the power supply demands of Western Australians now and in the future,” Mr Johnston said.

“I’m pleased to announce that we now have one equitable power supply allocation across the network – that means regardless of whether you live regionally or in the metro area, everyone will have the same standard supply.

“Western Power has successfully undertaken a trial to test this and ensure network infrastructure is built for increased rural loads.

“The comprehensive assessment used Advanced Meter Infrastructure data to verify that a standardised connection service can be applied across the network safely and reliably.

“The new standard demonstrates Western Power’s commitment to transforming the network to facilitate the growth of renewables and electrification.”

Western Power will now offer a standard connection service capacity of 63 amps for small-use, single-phase (240V) connections regardless of location, ensuring that all homes and businesses across the entire network have the same allocation.

The increase to regional supply followed Western Power’s trial, which successfully established that a standardised supply allocation could be managed in a safe and reliable way for community benefit.

The 24-week trial involved seven regional local government areas ensuring that a representative sample of a diverse range of rural customers with different energy needs was included.

The trial enabled the installation of a 63 amp-rated main switch circuit breaker for all new single-phase connections to the network, or when altering an existing electrical installation.

Data from 140,000 single-phase meters across the network was analysed to understand load demand and network usage in metro and rural areas, which proved that existing electrical infrastructure could accommodate increased rural load requirements.

The installation of a main switch circuit breaker is critical in providing overload protection for a household if its capacity is exceeded. It prevents more widespread outages and damage to equipment, ensuring that the whole community has safe and equitable access to power supply.

The one standard supply will enable greater electrification and uptake of renewables and aligns with state and national compliance frameworks including Australian standards.

Electrical contractors are required to assess household demand requirements when adding new circuits for property owners and apply for an upgraded supply allocation where necessary.

NEWS

10

Digital Transformation Without Compromise

Wireless IoT sensing for industrial processes from the benchmark for quality & reliability

Phone: +1300

965

email: AU.sushisensor@yokogawa.com website: www.yokogawa.com/au

558

THE LARGEST SOLAR FARM IN AUSTRALIA HAS FINISHED CONSTRUCTION

The Western Downs Green Power Hub in Queensland has reached the end of construction on the largest solar farm in Australia.

Totalling more than one million solar panels, the 400MW Western Downs Green Power Hub has the capacity to power the equivalent of 235,000 Queensland homes and is connected to the Queensland SuperGrid by a new 275kV line built by Powerlink.

Queensland Premier, Annastacia Palaszczuk, said, “Queensland is leading the charge with renewable power so it’s no surprise that the sunshine state is now home to the largest solar farm in the country.

“I’m pleased we can deliver clean, reliable and affordable energy to every Queenslander because we own our power lines and the majority of power generation,” Ms Palaszczuk said.

Located near Chinchilla, the Queensland Government’s publicly owned CleanCo Queensland has signed a power purchase agreement with owners Neoen for 80 per cent of the power generated at the site.

Deputy Queensland Premier, Steven Miles, said, “Queensland is building the infrastructure and delivering more clean, green power generation and more jobs.

“We are blazing a trail when it comes to green energy and the capacity this solar farm will be able to produce

WESTERN DOWNS GREEN POWER HUB IN QUEENSLAND.

is a testament to the Palaszczuk Government’s vision for Queensland.

“Our Energy and Jobs Plan means more opportunities for businesses, more skilled jobs and more growth, especially for our regional communities.”

The completion of panel installation will allow the final testing and commissioning phase of the project to begin to get it to full capacity.

Managing Director of Neoen Australia, Louis de Sambucy, said, “We are delighted to have completed the panel installation of the largest solar farm in Australia at Western Downs, and we’re excited about the strong contribution that this asset will make to Queensland’s rapidly accelerating energy transition.”

Construction of the project has also delivered a huge boost to Queensland’s regional economies, with an estimated $800 million in economic activity.

The solar farm is another major investment towards delivering 70 per cent renewable energy by 2032 under the Queensland Energy and Jobs Plan

Assistant Minister for Hydrogen Development and the 50 per cent Renewable Energy Target by 2030, Lance McCallum, said, “The renewable energy being generated is already supplying some of CleanCo’s biggest customers including Coles, BHP, and Westfield shopping centres.

“This is our Queensland Energy and Jobs Plan in action, delivering more jobs in more industries, affordable power, lower emissions, and stronger economic growth,” Mr McCallum said.

CleanCo CEO, Tom Metcalfe, said, “The renewable energy generated by the Western Downs Green Power Hub will supply some of CleanCo’s biggest customers including Coles and BHP.

“Projects like these complement CleanCo’s portfolio of fast ramping, flexible gas and hydro generators to provide our customers with 24/7 reliable clean energy.

“We are proud to support renewable energy projects like the Western Downs Green Power Hub that deliver great local employment opportunities and economic outcomes in regional Queensland.

“The renewable solar energy generated here in Queensland’s Western Downs will contribute to the longterm sustainability of Queensland industries and communities, helping them to thrive in a net zero future.”

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 12

NEWS

PROVIDED BY THE QUEENSLAND GOVERNMENT.

VIC WATER RECYCLING PLANT GETS GLOBAL RECOGNITION

South East Water’s Boneo Water Recycling Plant has been shortlisted for Water Reuse Project of the Year at the 2023 Global Water Awards, the only Australian project to be selected.

The project will compete against initiatives from the USA, Singapore and the Philippines at the 2023 Global Water Awards with winners announced at the Global Water Summit, held in Berlin in May 2023.

South East Water’s General Manager Liveable Water Solutions, Charlie Littlefair, said the global recognition for the Boneo upgrade shows that a sustainable approach to technology solutions provides benefits to customers, community and environment.

“This innovative upgrade of our Boneo plant will support the region’s growing community until 2050. We’ve increased its capacity to treat 50 per cent more wastewater, which provides a drought-proof source of high-quality recycled water for local farmers.

“It also supports peak sewage inflows in the area during the summer months and allows the connection of more

than 16,000 aging septic systems to sewer – a known cause of groundwater and waterway pollution in the region,” Mr Littlefair said.

In 2022, South East Water completed a $150 million upgrade of its Boneo Water Recycling Plant in a joint venture with John Holland, SUEZ and Beca (JHSB).

The upgrade transformed the Boneo Water Recycling Plant into a circular ecosystem, which reduces emissions and supports sustainable agriculture by making better use of the nutrient and energy rich by-products of the water recycling process.

The upgrade delivers a suite of innovative energy efficient technologies and biogas-driven combined heat and power (CHP), reducing the utility’s reliance on grid electricity by 30 to 40 per cent and contributing to a corporate emissions reduction target of 45 per cent by 2025.

The major upgrade is funded by a commitment South East Water made in its five-year Customer Commitment 2018–23 to stay ahead of challenges like population growth and climate change.

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 13

NEWS

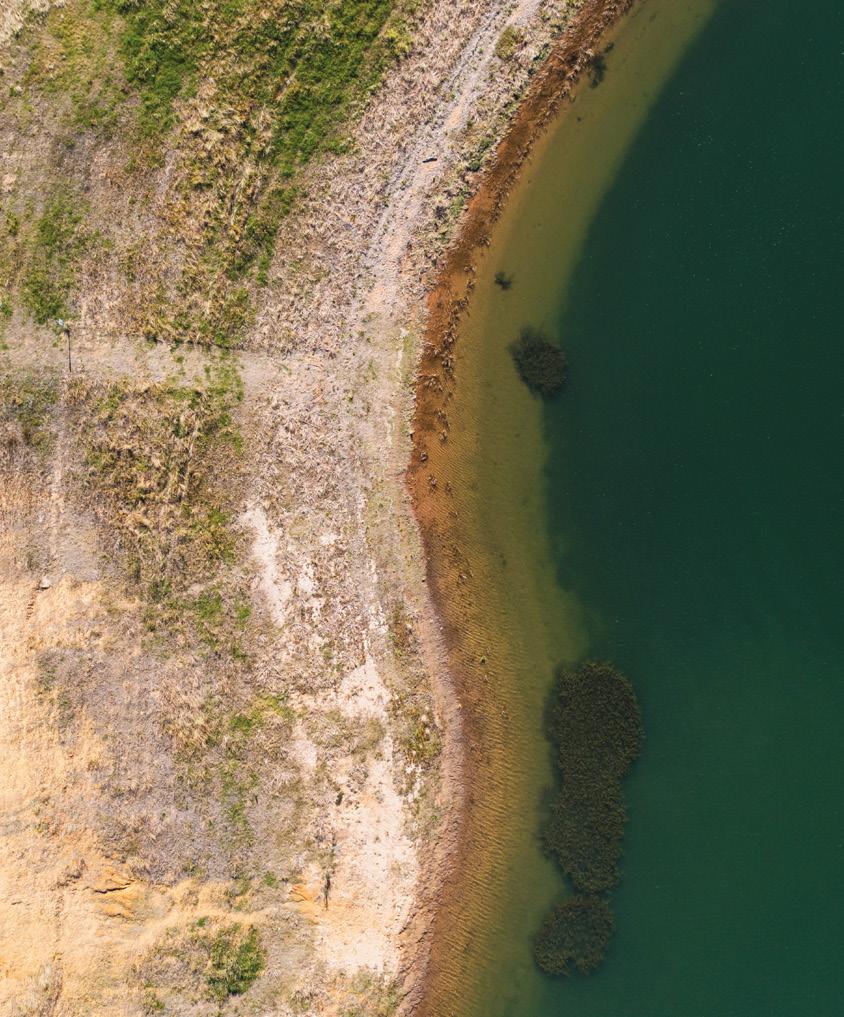

BONEO WATER RECYCLING PLANT – AERIAL VIEW OF UPGRADE. COURTESY OF SOUTH EAST WATER.

DRINKING WATER QUALITY REPORT PROVIDES INSIGHT TO NT’S WATER

The Drinking Water Quality Report 2022 details the water quality management system for the 91 locations Power and Water services across the Northern Territory, recognizing Power and Water’s commitment to providing safe, sustainable, and secure drinking water to all Territorians.

The annual report provides details about water quality management, including progress on delivering improvements to drinking water quality.

Over the past few years, Power and Water has developed and implemented a bespoke drinking water quality management system that aligns with industry best practice and responds to the Territory’s unique environments.

Power and Water’s Executive General Manager Water Services, Steven Porter, said, “Power and Water is committed to providing access to safe, sustainable and secure drinking

water to all Territorians, regardless of where they live.

“Power and Water’s passionate experts continually strive to improve water quality services across urban and remote communities, and that commitment was recognised with an Organisational Excellence Award at the 2022 NT Water Awards and as a finalist at the OzWater Awards.”

Power and Water has a central role in delivering the Northern Territory Government’s $28 million program to improve water quality and security in remote communities, including addressing the high levels of naturally occurring elements like uranium and nitrate in some communities’ drinking water.

“Construction of an ion-exchange water treatment plant in Laramba, about 200km west of Alice Springs, was completed in December 2022,” Mr Porter said.

“The plant, which will reduce the levels of uranium in the community’s water supply, is in the final stages of commissioning.”

Power and Water is also partnering with the University of New South Wales to trial membrane Capacitive Deionisation (mCDI) technology in Ali Curung to remove natural contaminants from groundwater.

View the annual Drinking Water Quality Report 2022 at www.powerwater.com.au.

Providing the highest confidence in level measurement in the most challenging conditions

● Easy installation and confidence in your data with the REFLECTTILT TM LED indicator

● Configure REFLECT™ with your application parameters using the secure browser-based Bluetooth® connection and user-definable range

● Accurate and repeatable FMCW radar technology for the most challenging conditions, even in the presence of dust, temperature changes, moisture, pressure and chemicals Contact us

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 14

NEWS

REFLECT™ Next Level Radar Introducing

For more

oceania@pulsarmeasurement.com PULSARMEASUREMENT.COM

for a quote today!

details, contact:

Work management software with people at the heart

Transform your utility’s workflow with powerful works management software

Xugo is a cloud-based solution that powers the compliance, control and vegetation management activities across your business.

With Xugo you can:

Access the insights needed to take actions, implement programs and meet your regulatory requirements

Create, manage, schedule and allocate work cases and tasks

Build your own forms and workflows

Visualise work progress

Capture complaints, incidents, and feedback directly from your customers and your teams

Store your complete collection of information relating to inspections, tasks, incidents, maintenance history, safety and environmental checks, investigations and analysis

Run and publish interactive reports

Engage with your mobile teams wherever you are via Xugo’s app in real-time

Scan to learn how Xugo makes utility regulatory compliance easy

Configurable to fit your requirements, and with an Australian-based team on hand to assist and enhance your workflow, Xugo delivers effciency benefits without disrupting your business model.

AUSTRALIA’S HYDROGEN INDUSTRY COULD GENERATE $40B BY 2040

Anew report from the National Energy Resources Australia (NERA) and Arup has revealed that Australia’s hydrogen industry has the potential to generate $40 billion in domestic GVA by 2040 and create tens of thousands of jobs per year by 2040.

The report, Powering Up: Seizing Australia’s Hydrogen Opportunity by 2040, is the first comprehensive analysis of Australia’s hydrogen supply chain and the hydrogen equipment, technology and services (HETS) opportunity from a national perspective, outlining crucial actions needed to support Australia’s future hydrogen economy.

The study builds on modelling developed by Arup for the yet-to-be-released National Hydrogen Infrastructure Assessment (NHIA) to consider one possible configuration of the hydrogen supply chain in 2040.

Key findings reveal an enormity of potential economic benefits for Australia, with the hydrogen industry capable

of generating nearly one per cent of national GVA and supporting 58,000–72,000 jobs by 2040, most of which would be created in regional areas.

By 2040, Australian hydrogen demand could soar to 9.5MMT, almost ten times the current global production, with 46 per cent designated for export markets. To meet this demand, massive infrastructure development will be needed, including a five-fold increase in Australia’s solar and wind capacity, thousands of electrolysers and compressors, and more than 5,000 hydrogen storage tanks. The required infrastructure investment is estimated to be between $340 –$420 billion, with an annual investment of $25–$30 billion between 2025 and 2040.

NERA CEO, Miranda Taylor, said realising the full potential hydrogen presents for Australia requires significant investment to foster local capabilities, job creation and decarbonisation efforts, particularly in regional areas.

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 16

tenders@lancogroup.com.au | www.lancogroup.com.au | 1300 1 LANCO (1300 152 626) Civil and Infrastructure Engineering | Project Management NEWS

“The hydrogen supply chain could drive Australia’s future economic growth and position the country to become a global leader in hydrogen. Our opportunity extends far beyond producing and exporting molecules. Rather, homegrown HETS businesses can offer cutting-edge technology and expertise across supply chain segments, such as hydrogen storage. But seizing this opportunity requires a robust local supply chain.

“The Powering Up report highlights the urgency of swift and strategic action to develop the strong hydrogen supply chain required, and provides actionable recommendations to help Australia take hold of its hydrogen opportunity, such as investing in regional capability, incentivising overseas manufacturers to onshore their capabilities, and securing annual infrastructure investment,” Ms Taylor said.

Ms Taylor emphasised that the report’s findings underscore the importance of strategic initiatives like the NERA-initiated hydrogen technology cluster network.

“The national network of 17 hydrogen clusters are pivotal in connecting emerging regional hydrogen industries in Australia, and promoting early HETS sector development, coordinated supply chains, and accessible entry points into hydrogen for local businesses. And, with 90 per cent of hydrogen industry jobs projected to be in regional areas, it is essential to develop local capabilities and supply chains to support this growth.

“As NERA’s tenure as Australia’s energy resources Industry Growth Centre concludes in July, we are transitioning the vital national leadership role for these regional networks to the Australian Hydrogen Council (AHC). This partnership allows AHC to build on existing momentum and continue to support the HETS sector’s crucial growth, connecting Australia’s emerging HETS supply chain and innovative businesses with major corporations at the forefront of hydrogen innovation,” Ms Taylor said.

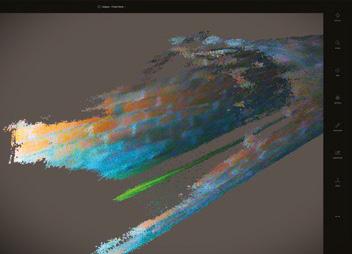

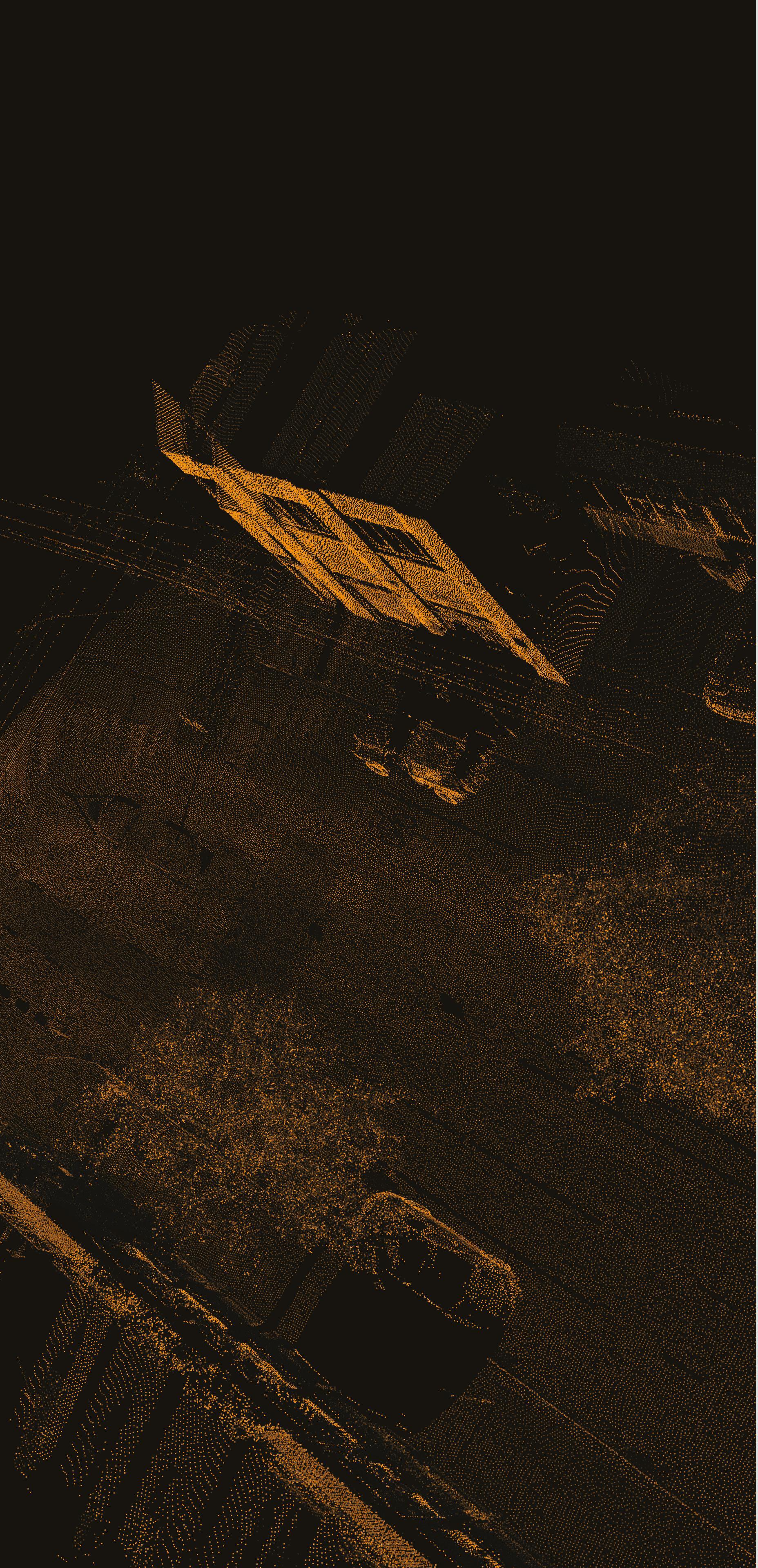

Introducing R.O.G.E.R, the Remotely Operated Ground Exploration Rover developed by UAM Tec for capturing high resolution data in non- ooded and partially ooded tunnel environments

PRODUCT

•4K UHD video and images

•HD dense Lidar & 360 degree pro ling Sonar

•HD PTZ camera and HD 360 degree camera

•PointVision®software : view & measure without lag

• Pr oprietary AI: image ltering, see below the waterline

•Advanced SLAM functionality: “Simultaneous Localisation and Mapping”

•Beta level AI for data mining of imagery and sensor data

•Client portal for interpretation and report generation

•Data can be delivered RAW and also in multiple formats

CAPABILITIES

•Can be tted with a range of arms and sensors to meet the precise survey needs of each client

•UAM Tec’s open architecture makes ROGER’s modularity exible and adaptable to mission requirements

•Manhole entries from 0.6 meters width and up

• Tunnels from 0.6 meters and up

•All shapes of tunnels

•Distance from 0 to 1KM

•Up to 400mm water submersion on base version

•All water types including low visibility environments.

Available now to help you understand the condition of your underground assets with greater accuracy than ever before. Get in touch for more imformation.

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 17

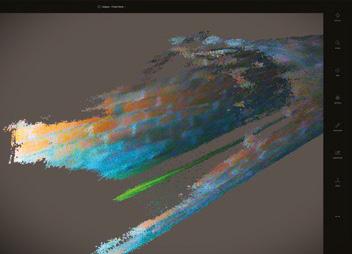

4K UHD 360 DEGREE VIDEO LiDAR - POINT CLOUD ZOOM FROM SAVED FILE

UAM Tec Headquarters Unit 5/ 11-15 Rocklea Drive Port Melbourne Victoria 3207, Australia Craig Smales 0408 837 066 sales@uamtec.com NEWS

MELBOURNE WATER’S WINNEKE TREATMENT PLANT POWERED BY NEW SOLAR FARM

Melbourne Water is making an effort to reduce carbon emissions while also increasing energy production for the Winneke Water Treatment Plant through the construction of the Winneke Solar Farm.

The 19,000 panel farm will deliver 12,400 MWh/annum, the equivalent of about 2,500 households’ yearly demand. All the energy produced will be used by the treatment plant and pumping stations. Any excess energy will be fed into the public grid for external use.

The total estimated carbon reduction is 12,000 TCO2-e/annum.

In an Australian first, Melbourne Water has utilised terrain tracking sensors for the solar farm’s construction. These sensors allowed the construction to occur on a slope, which otherwise would have required extensive earthworks, impacting financial viability.

By avoiding extensive earthworks, the panels were installed with minimal ground disturbance – a key restraining factor owing to water purity and soil runoff.

In order to maximise energy production in a limited area, the panels rotate on a pivoting bar which follows the movement of the sun. Additionally, the panels are bifacial, capable of generating energy from both sides of the panel.

This solar farm is an example of the Victorian Government’s commitment to decarbonisation and achieving a 50 per cent reduction of emissions by 2025, and net zero by 2030.

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 18

NEWS

FEDERAL GOVERNMENT WELCOMES RENEWABLE ENERGY STORAGE ROADMAP

The CSIRO has released its Renewable Energy Storage Roadmap, emphasising the need for major investment in storage technologies to meet the growing demand for cheaper renewable power.

Federal Minister for Science and Industry, Ed Husic, said the Government is pressing ahead with its ambitions to see domestic battery manufacturing capabilities ensure homes and businesses can access cheap and reliable renewable energy into the future.

“Large-scale uptake of battery storage and battery manufacturing will be vital in the nation’s transition to net zero and to Australia becoming a world leader in clean energy,” Mr Husic said.

“The Government recognises the pivotal role that cheap, widely available energy storage will need to play in the transition to renewable power. That’s why the Government is delivering the Australian Made Battery Plan, spearheaded by the development of Australia’s first National Battery Strategy.

“By 2030, the battery manufacturing industry has potential to be worth nearly $17 billion and create more than 61,000

jobs, according to the Charging Ahead report from the Future Battery Industries Cooperative Research Centre.

“As the CSIRO roadmap emphasises, we need a pipeline of projects using diverse technologies to unlock the full potential of our renewable energy resources.

“That means there’s a huge opportunity for new systems and technologies to be developed here to manage the production, storage and use of renewable energy.”

The Federal Government continues to implement other initiatives focused on bringing cheaper renewable energy to homes and businesses and meeting Australia’s international emissions obligations.

This includes reaching 82 per cent renewables in Australia’s energy grid by 2030, which will be achieved through our $20 billion Rewiring the Nation Fund through deals with states and territories, as well as unlocking around $10 billion of investment in clean dispatchable power through the Capacity Investment Scheme.

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 19

URD ELECTRICAL PILLARS +61 8 9378 1077 sales@rimco.net.au www.rimco.net.au ● Manufacturing Pillars in Australia for over 40 years ● Quality Assured to ISO 9001:2015 ● Pillars comply with AS/NZS 61439 ● Manufactured from proven, durable materials for Australian conditions ● Residential and Commercial applications. ● Minimal installation area required for Pillars ● Supplied Australia Wide NEWS

MCMENON AVERAGING PITOT TUBES

The MAPT is a multiport self-averaging flow meter with a design based on the classical pitot tube concept of fluid flow measurement.

The MAPT produces an averaged differential pressure (DP) signal proportional to the square of the flow rate. The DP output is normally piped to a Differential Pressure transmitter in order to generate an electrical signal proportional to the flow rate.

The outer impact tube has a number of pressure sensing holes facing upstream which are positioned at equal annular points in accordance with a log-linear distribution. The ‘total pressures’ developed at each upstream hole by sum of the impact

of the flowing medium and the static pressure are firstly averaged within the outer impact tube and then to a second order (and more accurately) averaged within the internal averaging tube. This pressure is represented at the head as the high pressure component of the DP output. The low pressure component is generated from a single sensing hole located on the downstream side of the outer impact tube, measuring static pressure.

The MAPT is an improvement on the round sensor design due to the unique profiled flats which are positioned

around the downstream hole in order to define the separation point at which the flow lines separate as the fluid passes around the outer impact tube. This feature creates a stable pressure area at the downstream pressure sensing hole, thereby maintaining a more constant flow coefficient at high velocities enabling a very wide range of flow measurement (turndown).

Options include the inclusion of a thermowell for temperature measurement of the measured product. INSTRUMENTATION

AMS have been suppliers of instrumentation and calibration equipment to all industries since 1973 representing some of the world’s leading manufacturers of the equipment in their field.

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 20

& CALIBRATION PTY LTD SPECIALISTS

www.ams-ic.com.au Flow Measurement Specialists

www.ams-ic.com.au sales@ams-ic.com.au

NEWS | Sponsored editorial

or visit our web site at www.ams-ic.com.au.

For further information contact AMS Instrumentation & Calibration Pty Ltd on 03-9017 8225, or Freecall (NZ) 0800 442 743, alternatively on e-mail: sales@ams-ic.com.au

DENSO AUSTRALIA OFFERS THE MOST COMPREHENSIVE TIME-PROVEN RANGE OF LONG-TERM CORROSION PROTECTION SOLUTIONS. THIS NOW INCLUDES THE NEXT GENERATION OF TRULY SURFACE TOLERANT, VISCO-ELASTIC COATING SYSTEMS WHICH DEMONSTRATE AMAZING ‘SELF-HEALING’ COATING CHARACTERISTICS IDEALLY SUITED TO THE WATER INDUSTRY AND WATER PIPELINES.

MORE THAN YOU THINK

77 – 95 National Boulevard Campbellfield Victoria 3061 AUSTRALIA

+61

FAX: +61

CORROSION PREVENTION

DID YOU KNOW?

www.densoaustralia.com.au

TEL:

(0) 3 9356 7600

(0) 3 9356 7699 EMAIL: denso@densoaustralia.com.au CONTACT YOUR LOCAL EXPERT NOW DENSO (AUSTRALIA) PTY LTD

THE TRUTHS AND MYTHS OF MULTI ARRAY GROUND PENETRATING RADAR FOR UTILITY DETECTION

Let’s remove all the marketing hype and look at the facts and benefits of multi array ground penetrating radar when used in large environments.

Amulti array ground penetrating radar is a GPR that has multiple antennas set close together. For instance, the Raptor 45 Cart has 8 channels, and the Raptor 45 Road system has 18 channels. There are some benefits to having many antennas close together, such as:

1. The array will see changes in direction of a service more clearly

2. It eliminates the need to scan multiple times reducing time in acquisition

3. An array can see voids easier, as it has a larger area to pass over showing irregularities below that a single or dual channel GPR would not show as clearly

4. Some array can move at legal speeds up to 110km in Australia, reducing locate times

Multi Array GPR does not eliminate other technologies used for locating underground services. Professional locate companies use many technologies like EMF and PWG, to name just a few. This avoids missing crucial services using just one technology.

Multi Array GPR’s are not immune to poor soils, and services can easily be missed no matter how good the array is. Good data quality relies on good soils.

Software is another important part of Multi Array systems. Having fancy videos showing 3D images doesn’t assist in getting info out to AutoCAD or 12D. Software should allow you to gather data quickly post-process, and then convert it to your preferred system or point cloud.

NEWS | Sponsored editorial

Build and Close Out Utilit y Construction Projects

Locusview's technology manages the entire utility infrastructure construction process from planning to execution and closeout. Faster, Safer, Smar ter

Faster Reconciliation

Backlog Reduction

2023 Locusview Inc. All rights reserved. | locusview.com/faster

90%

See How It Works 70% ©

INNOVATIVE NEW EXCAVATOR GPR TECHNOLOGY

RodRadar Australia has introduced the all-new, revolutionary Live Dig Radar (LDR) Excavate.

Fully integrated into an excavator bucket, the LDR Excavate brings RodRadar's unique high-resolution, ground-penetrating radar imaging into the operator's cabin during excavation and earthworks projects.

Available in three size configurations, the RodRadar LDR Excavate is compatible with most makes and models of excavator sized one to 18 tonnes.

The only solution of its kind worldwide, the Live Dig Radar provides real-time, precise data on the location of underground utility infrastructure, automatically and directly alerting the excavator's operator with simple-to-understand notifications.

The technology, although complex in scientific design, is simple to use; connect the LDR-integrated bucket to a compatible excavator, link the bucket to the supplied tablet which is mounted inside the operator cabin, then make sequential excavations into the earth to scan the ground below. As the bucket digs and makes contact with the ground, the built-in radar technology delivers highly accurate, real-time, easy-to-understand data to the tablet about underground utility locations and depths.

The technology’s aim is to provide holistic prevention of costly and unsafe utility damage, and exceptional improvement of project efficiency and productivity.

AVOIDING DANGEROUS AND COSTLY UTILITY STRIKES

Each year, underground infrastructure damage costs the global construction industry more than $150 billion AUD – including billions invested in less effective alleviation methods – with utility strikes during excavation, causing dozens of deaths and hundreds of injuries.

RodRadar Australia’s innovative Live Dig Radar is a dramatic improvement over current widespread excavation technologies and processes, overcoming their inherent limitations.

In February 2023, RodRadar Australia partnered with distributors ASV Sales & Service and STM Trucks & Machinery to conduct preliminary LDR Excavator Demonstration Days in Sydney and Newcastle. As part of each demonstration, utility services were buried underground in various earth compositions, and attendees were invited to find and unearth the utilities using the Live Dig Radar in-situ.

With more than 50 industry representatives in attendance – hailing from fields including construction, risk assessment, workplace health and safety, utility management and government – the LDR technology was met with extensive positive feedback.

A government agency representative in attendance said, “The accuracy of the radar was spot on. The LDR would work well in our operations and is exceptional new technology.”

In addition, Michael Owen from major construction body RTC Group, said, “[The LDR] would be very helpful for safety, and also a time saving device – and also looks to be easy to use.”

Furthermore, RodRadar’s Live Dig Radar is garnering exceptional acclaim on the global stage. Florida-based Haskell – a pioneering architecture, engineering and construction firm – has become the first contractor in the United States to deploy the technology.

Cutler Knupp, Managing Director of Haskell's innovation and venture capital arm, Dysruptek, said, "RodRadar's Live Dig Radar technology is a game changer. The accuracy has been impeccable, and it's already helping Haskell to identify subsurface conditions that we were not aware of before."

RodRadar Australia will roll out the new LDR Excavate nationwide throughout 2023.

24 UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU NEWS | Sponsored editorial

Visit www.rodradar.com.au for further information regarding the product, demonstration opportunities and stock availability.

TM

THE FUTURE OF WATER MANAGEMENT WITH URBAN UTILITIES’ NEW CEO

After more than three decades in the resources sector, Paul Arnold is now at the helm at one of Australia’s largest water service providers, Urban Utilities. Formerly the Chief Executive and Managing Director at Energy Resources of Australia based in the Northern Territory, Mr Arnold made the 2,200km journey back home to South East Queensland where he took up the role of Urban Utilities CEO in September last year.

Mr Arnold joined the organisation at a pivotal time as the water industry continues to respond to the challenges of climate change and population growth, and with less than a decade until Urban Utilities’ service region hosts the Olympic and Paralympic Games.

“This is undoubtedly one of the most exciting times to be part of the South East Queensland water industry,” Mr Arnold said.

“Our region has a lot to look forward to, including hosting the Olympic and Paralympic Games in 2032, but we’re also facing some pretty fundamental short and long-term challenges as a sector, which we need to work together to solve.”

As he forges ahead in his first year as Urban Utilities CEO, Mr Arnold has shared his vision for the role, what led him to make the change from natural resources to water and the key challenges and opportunities he’s observed for both Urban Utilities and the broader industry as utilities around Australia work to achieve a sustainable water future.

The future of water management drew Paul Arnold to the industry – here’s why Urban Utilities’ new CEO thinks now is the most exciting time to work in water.

FROM NATURAL RESOURCES TO WATER

Before joining the team at Urban Utilities, Mr Arnold spent 35 years in the resources and energy sectors, spanning operations, project development and execution, stakeholder relations, Indigenous engagement and business development.

This experience has helped him arrive in his leadership role at Urban Utilities with a unique perspective and clear priorities, accompanied by a deepseated curiosity to gain greater insight into the Australian water sector.

“One might ask how a mining engineer ended up running a water utility,” Mr Arnold said.

“Throughout my career in natural resources, I’ve been passionate about

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 26

INDUSTRY INSIGHTS

INDUSTRY INSIGHTS

the protection of the environment and the repair of country.

“One of the things that drew me to the water industry, and specifically to Urban Utilities, was its unwavering commitment to service and environmental leadership.

“Being born and first raised in central Queensland and then growing up in Brisbane from school age, I’m also thrilled to be working in a role that will help shape the future of water and enhance livability here in Queensland.”

PEOPLE, SAFETY AND WELLBEING

Before joining Energy Resources of Australia as CEO and Managing Director, Mr Arnold also held a variety of operations, commercial, business analysis and major project development roles with Rio Tinto and BHP, spending five years as a Director of the Queensland Resources Council.

“When I think about some of the learnings I’ve gathered over the years, the most obvious and important one that every industry should focus on is safety,” said Mr Arnold.

“Safety is a fundamental value in caring for our people and it’s a priority I have brought with me to the role as Urban Utilities CEO.

“What I’ve learnt about the water industry so far is that, like in mining, our people are often navigating the same high-risk activities as they complete

their essential work, such as working in tunnels and confined spaces, at height, with high-pressure equipment or beside mobile and heavy equipment.

“As a leader in this business, I know what an important role I can play to help ensure we have the best processes and support structures in place to look after our people’s mental and physical health.

“We also know that safe organisations are efficient and productive organisations, they go hand-in-hand.”

The connection to purpose of those in the water industry is something that has stood out to Mr Arnold since starting the role.

“At Urban Utilities we are committed to showing up in the moments that matter, and shaping the moments to come, and I have been continually impressed by the passion that is evident in the people I meet and work with every day,” he said.

“Regardless of their role, be it a contact centre operator, field worker, treatment plant operator or engineer, I see genuine care for our customers, community and country and a true passion to deliver our purpose of enriching quality of life.”

COLLABORATION AND PARTNERSHIPS KEY TO SOLUTIONS

Joining Urban Utilities amid the organisation’s ongoing recovery from

the February 2022 flood event means Mr Arnold understands all too well the increasing challenges for the water sector posed by climate change.

“Last year's floods are an example of how our industry is both planning for climate change and living with its impacts in real time,” he said.

"We’re thinking about the future impact of climate change on behalf of our customers.

“While this is most certainly a challenge, it’s also an opportunity for us to think about how we can deliver our services differently and make decisions now that will support our customers through the impacts of climate change.

“There’s also an important seat at the table in supporting government and the broader community in some of the decisions we have to make to protect ourselves from climate extremes.

“Another challenge for the industry is aging infrastructure. At Urban Utilities, we’re looking at ways we can get beyond age as the driver of asset performance, which means making use of emerging technologies and data analytics to improve both the way we maintain and rejuvenate our assets.”

Mr Arnold said the strong commitment to share best practice and learn from each other is a real positive for the water industry as it looks to meet common challenges.

“Since becoming Urban Utilities’ CEO, I’ve discovered that one of the defining features of this sector is its collective desire to drive sustainable water management. We share this common goal of doing our best for our customers and communities,” he said.

“Now more than ever, we need to collaborate and build our collective skills and knowledge so we’re best placed to achieve a resilient, secure and affordable water future.”

SHAPING AND GROWING OUR FUTURE

Urban Utilities has released its water leadership plan, Our Water Way, which outlines how the utility is preparing to meet the challenges of both climate change and population growth and ensure water security for generations to come.

“This is not just a local issue. Around Australia and the world, the way we use and look after water is

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 27

becoming more of a priority and we’re proud to play our part in supporting a secure water future for South East Queensland,” Mr Arnold said.

The Our Water Way plan outlines Urban Utilities' aim to reshape the water cycle from the traditional ‘catchment to sea model’ of water use, to a more circular model that manages water more sustainably.

“Water is at the heart of our much-loved lifestyle in South East Queensland. Our quality of life – our jobs, businesses and our communities – depend on it and that’s why we’re planning well ahead for the future,” Mr Arnold said.

“Our plan is about caring for the water we have today and creating the water we need for the future.

“Caring for the water we have today involves always using water efficiently in our homes and businesses and encouraging waterwise communities.

“Creating the water we need for the future is about grasping every opportunity to use our valuable and finite water resources more than once. To achieve this, we're focused on increasing our use of recycled water for

industry, agriculture and irrigation and keeping our water closer to home by treating and managing water nearer to where it’s used.

“Across our region, it also involves looking to other more resilient, climateindependent sources of water to help supplement our drinking water supplies, including desalination and purified recycled water, which can be produced in our region using the Western Corridor Recycled Water Scheme.

“We’re already exploring opportunities to design and build innovative and sustainable water and wastewater infrastructure for key Olympic and Paralympic precincts that will form part of our network to support activities such as cooling and greening.”

Urban Utilities last year announced its commitment to reach net zero greenhouse gas emissions by 2032, which will support the region to host a climate-positive Olympic and Paralympic Games.

To reach net zero, the utility plans to further improve energy efficiency, increase its renewable energy use, and invest in beneficial local offset projects.

BUILDING TRUST A KEY FOCUS

Mr Arnold said another priority he had identified for the role included further building trust with Urban Utilities' customers, communities and stakeholders.

“We’ve been entrusted with billions of dollars of assets by our communities,” he said.

“By providing safe and efficient water and wastewater services every day and by encouraging shared understanding, we will continue to build trust.

“As a water utility, we are stewards of the most precious natural resource our planet has, and I believe it’s important to bring our customers on the journey to support that shared understanding as we work towards a secure water future, together.

“I am relishing this opportunity to work with the passionate people at Urban Utilities and across the water sector as we ensure our communities continue to enjoy safe and reliable water and wastewater services every day and into the future, whatever the weather.”

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 28

INSIGHTS

INDUSTRY

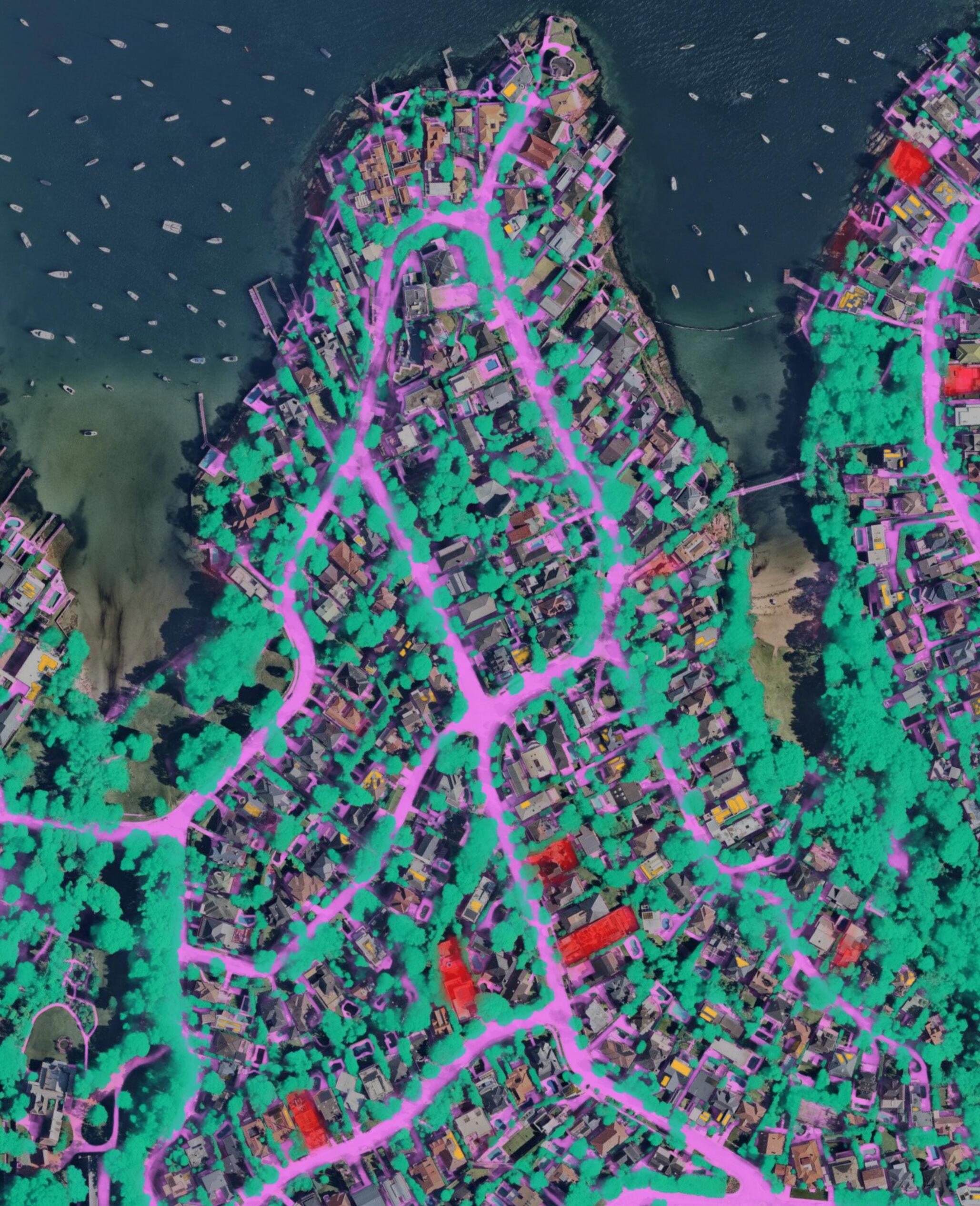

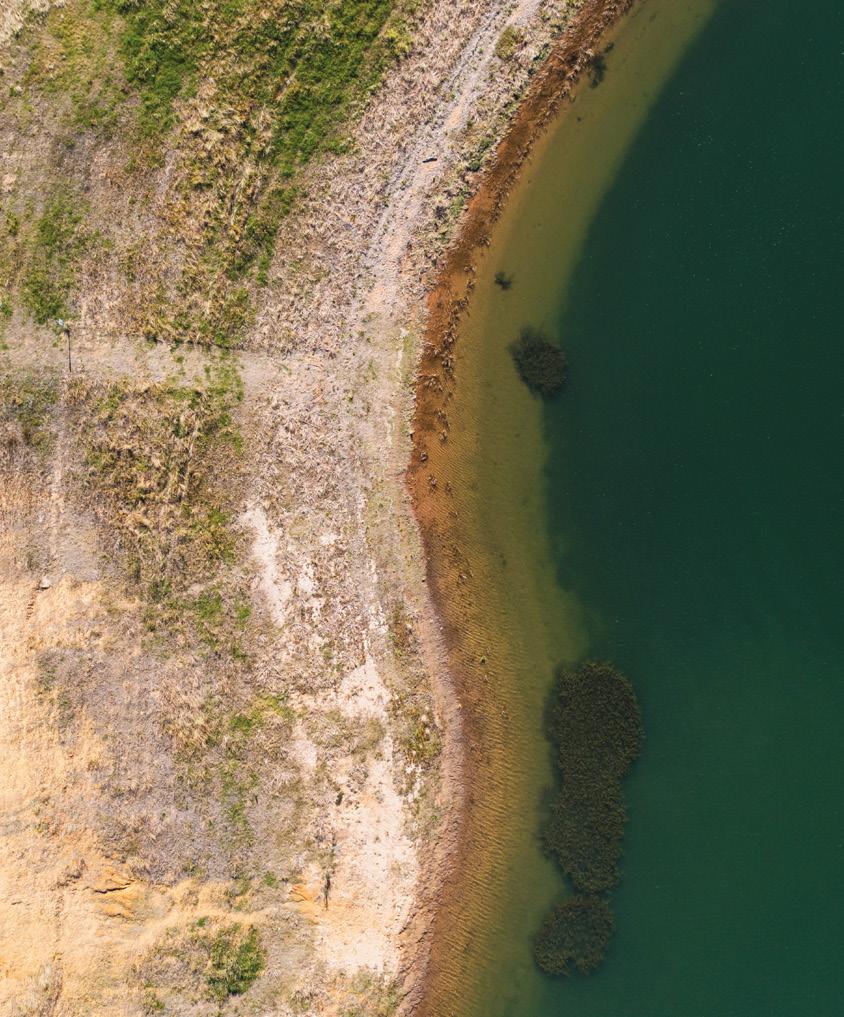

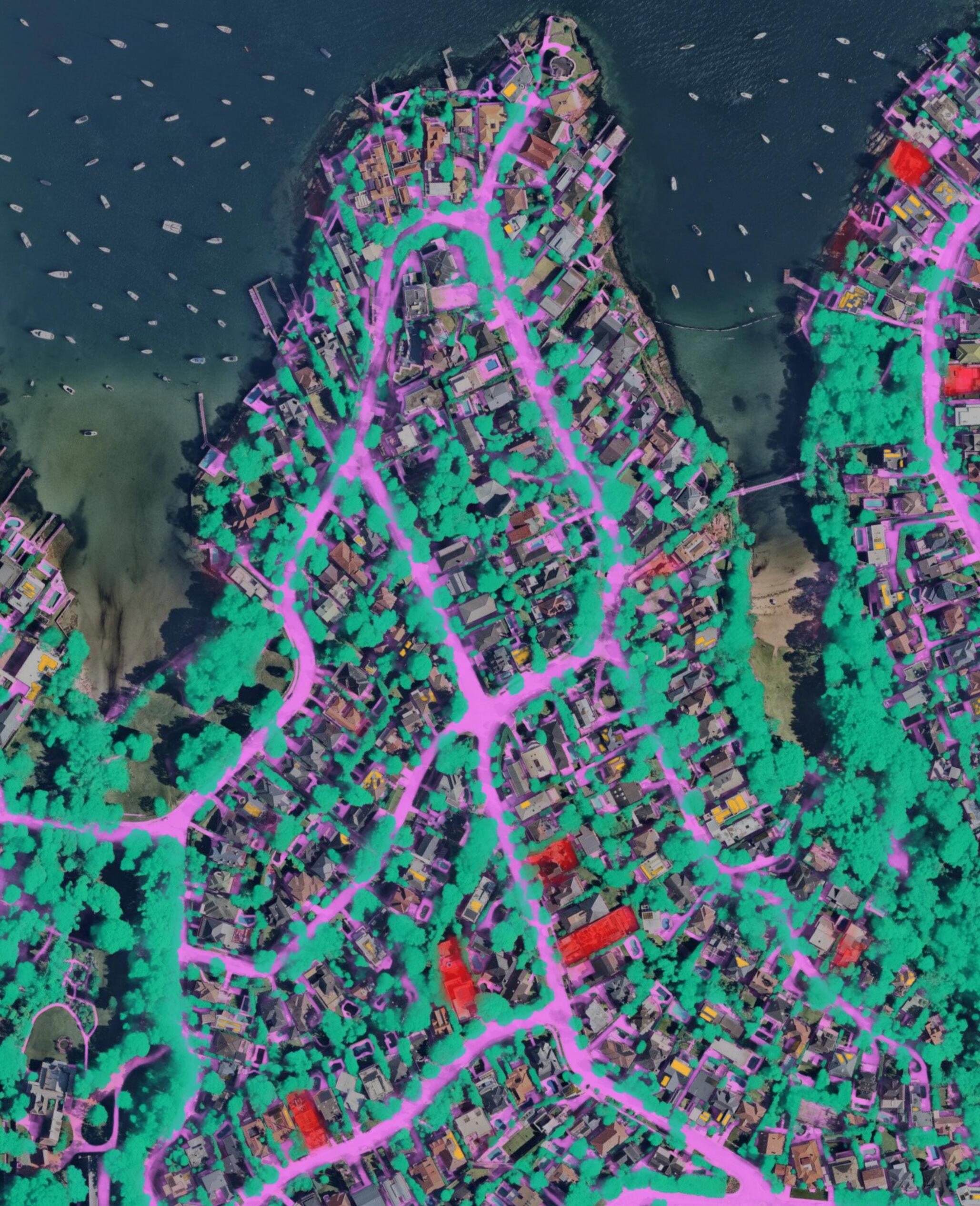

ENRICH YOUR DECISION MAKING WITH CURRENT LOCATION INTELLIGENCE

FOR MORE INFORMATION:

Scan here to email Myles from our business development team to discuss how Nearmap can enhance your workflow.

www.nearmap.com/industries/aerial-photography-utilities

93% of the Australian population captured

VAUCLUSE, NSW AU

SOLUTIONS TO MITIGATE CREATING INNOVATIVE FLOOD DAMAGE

Across Australia and the globe, EJ is relied upon to design, manufacture and distribute exceptional access solutions for vital infrastructure projects. These projects support the stormwater, wastewater and telecommunications networks necessary in modern society.

Each day, EJ solutions play a vital role in the development and maintenance of public and private infrastructure.

In early 2022, a series of floods hit South East Queensland and coastal New South Wales. Media reports estimate upwards of $2.5 billion in damages related to the floods. Businesses and residents impacted are still trying to rebuild over a year later.

A major rain or tidal event can overload your stormwater and sewer systems. The extreme pressure within the system often results in dislodged access covers. The result is a lifethreatening safety hazard for both motorists and pedestrians. These open pits are hidden if the area is submerged under even a small amount of flood water.

CREATING A SOLUTION

EJ has invented an access assembly designed to solve this problem. In everyday use, the MAESTROTM cover is secured shut by an engineered torsion bar design. Once subjected to a large back pressure surge, such as a flood, the cover will act as a relief valve allowing itself to hinge open.

Due to specially designed hinges, even when relieving pressure, the cover is retained in the frame, keeping the street safe and preventing accidents. Furthermore, once the pressure subsides, the MAESTROTM cover will simply close and lock safely under passing traffic.

The MAESTROTM product is already widely in use across New Zealand, with councils and governments embracing the resilient design. This investment in MAESTROTM products paid dividends in the recent flooding and cyclone hitting the North Island. After these events, while infrastructure was being assessed, cleaned up and sometimes rebuilt, the MAESTROTM products shut closed and went back to business as usual.

PROVIDING UNRIVALLED EXPERTISE

There is a comprehensive range at EJ including cast and fabricated products, which serve a vast range of industries such as construction, water distribution and telecom.

The EJ foundries and workshops around the world use the latest integrated technology and lean processes, and EJ has a century of experience in craftsmanship delivering quality products.

As a global presence, EJ draws from a wide range of expertise and resources, to provide users with access solutions that are specifically tailored to their unique requirements.

The EJ MAESTROTM cover is a testament to the EJ advantage. EJ has designed access solutions made to work for Australians, helping to keep the public safe and reducing damages during challenging times.

30 UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU INDUSTRY INSIGHTS | Sponsored editorial

EJ Advantage –

Visit ejco.com to learn more about the resilient

by EJ. QLD | 07 3216 5000 NSW | 02 9757 3862 VIC | 03 9792 5144 WA | 08 9209 2930 au.info@ejco.com

The

innovative solutions to upgrade stormwater and sewer systems with MAESTRO™ covers. Engineered to Perform.

designs

MITIGATING CYBERSECURITY THREATS IN WATER AND WASTEWATER

An increasing reliance on technology in water and wastewater infrastructure management has resulted in cybersecurity challenges becoming a significant concern in the sector, and one that must be addressed to ensure a safe and reliable water supply.

As more critical infrastructure is connected to the internet or accessible to staff, it is increasingly targeted by cybercriminals interested in breaching operational technology (OT) networks to lay the groundwork for future attacks.

A cyberattack on water and wastewater treatment facilities can temporarily stop operations and have huge consequences, not only for the water authority and the community it serves, but also the nation's overall economy.

RISKS FROM LEGACY TECHNOLOGIES AND INSIDER THREATS

Many water infrastructure systems still rely on outdated technology and managers are often under-resourced. Managers must invest in modernising and regularly upgrading their systems and can seek external assistance from cybersecurity experts.

Many employees are also unaware of cyberattack risks, while another threat is current or former employees with malicious intent. Water infrastructure systems are increasingly interconnected and often use third-party vendors and contractors, which makes them more vulnerable to cyberattacks.

RISK MITIGATION MEASURES

The specific mitigation measures each facility decides to implement will depend on its unique security risks. However, there are some key mitigation measures that most water infrastructure managers should implement as best practice:

Segmentation into zones: This should be practiced in every plant to help limit access to safety systems. For example, a demilitarised industrial zone (IDMZ) with firewalls and data brokers can securely segment the plantwide network from the enterprise network. Also, using virtual LANs (VLAN) and a layer-2 or layer-3 switch hierarchy can create functional sub-zones to establish smaller domains of trust and simplify security policy enforcement.

Physical access: Many organisations use RFID cards to control facility access, but physical access security should go further. Lock-in, block-out devices should be used to prevent the unauthorised removal of cables and to close unused or unnecessary ports. Control cabinets should also be locked to restrict walk-up and plug-in access to the industrial automation and control system devices.

Network-integrated safety and security: CIP Safety™ and CIP Security™ are extensions to the common industrial protocol (CIP), which is the application-layer protocol for EtherNet/IP™. CIP Safety allows safety devices to co-exist on the same EtherNet/IP network as standard devices and enables a safe shutdown during a denial-of-service attack. In addition, CIP Security incorporates data integrity and confidentiality into EtherNet/IP communications.

Asset and change management: Asset management software can automate the discovery of new assets and centrally track and manage configuration changes across an entire facility, including within safety systems. It can detect real-time malicious changes, log those activities and report them to key personnel. If unwanted changes are made, the software can access archived copies of a device program for fast recovery.

ENSURING SAFETY THROUGH SECURITY

The security landscape is ever-changing, so it’s important to partner with a company that is trustworthy to manage the constantly evolving risk. NHP works closely with Rockwell Automation and Claroty to provide comprehensive cybersecurity solutions beyond just network security, and its industrial security portfolio and services will help you assess, implement and maintain ICS security within operations and enable transformational technologies that rely on enterprise connectivity. Organisations that want to stay ahead of these risks must comply with the latest standards, conduct a comprehensive risk analysis and implement risk mitigation measures using the latest technologies.

For more information, contact NHP in Australia on 1300 647 647 or nhpsales@nhp.com.au or in New Zealand on 0800 647 647 or sales@nhp-nz.com.

literature.rockwellautomation.com/idc/groups/literature/documents/wp/safety-wp035_-en-p.pdf blog.cyble.com/2022/05/04/water-and-wastewater-treatment-facilities-vulnerable-to-cyber-attacks/

32 UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU INDUSTRY INSIGHTS | Sponsored editorial

Future proof your protection system with NHP ACB retrofitting

services

■ Increase system safety and reliability

■ Minimise production downtime

■ Reduce operational costs

NHP’s Services and Solutions team can customise solutions to suit specific requirements or work within your existing switchboard environment to provide a costeffective solution, engineered according to relevant Australian and New Zealand standards and recognised industrial practices. Find out more

nhp.com.au | nhpnz.co.nz

1300 NHP NHP | 0800 NHP NHP

nhpservice@nhp.com.au | sales@nhp-nz.com

USES LASER-GUIDED TUNNEL BORE FOR SEWER INSTALLATION COLIBAN WATER

Regional Victorian water authority, Coliban Water, has used a state-of-the-art laser-guided tunnel bore to install a new 507m section of sewer trunk main in White Hills, in suburban Bendigo.

The opportunity to use the tunnel bore was recommended by local contractor, R&R McClure, in its tender submission.

According to Coliban Water’s Manager of Infrastructure, Corey Bourne, they suggested using the laser-guided bore to ensure accuracy when installing the section of sewer trunk main on flatter areas of land.

“The laser-boring technique is similar to what is used in the Melbourne Metro Tunnel Project - only on a much smaller scale,” Mr Bourne said.

“While creating the micro-tunnel required for this project, the technology has proven successful and allowed us to constantly monitor and manoeuvre the machine for accuracy.

“One of the major benefits was the added control it gave our crews where there was little tolerance for vertical deviation.

“It also allowed us to avoid open trenching for this project, limiting disruption to local residents, roads, vegetation and natural habitat.”

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 34 INDUSTRY INSIGHTS

R&R McClure worked closely with subcontractor, S&Z Australia, and German company, Bohrtec, which developed the technology.

A Bohrtec expert visited Australia in February 2023 to train onsite crews about operating the bore. It was the first time the machine had been used in regional Victoria, after it was used once before on a Melbourne project.

Mr Bourne said the project team was able to keep abreast of the latest innovations, equipment and construction methodologies thanks to the use of new technology such as this.

“This has provided a great development and learning opportunity for Coliban Water staff and our contractors,” Mr Bourne said.

Having committed to improving environmental outcomes in its Environment and Sustainability Policy, Coliban Water continues to focus on its environmental management systems by adopting best available science and technical innovations.

“The added control and accuracy the bore made it a good choice for this project over other trenchless technologies,” Mr Bourne said.

WORKING TO OVERCOME CHALLENGES

While trenchless technology and the laser-guided bore have come with benefits, using the machine has not been without its challenges.

“This machine needed to sit in a pit, whereas other trenchless technology such as horizontal directional drills can sit on the surface,” Mr Bourne said.

“This means a larger pit was required on-site to house the machine while it drilled the micro-tunnel. In the future, there may not always be space available to do this.”

The machine’s German origins could add a further challenge for Australian crews.

“Any additional parts or attachments need to come from Germany,” Mr Bourne said.

“So, if there is a change on site, such as ground conditions, there could be delays.”

CATERING FOR BENDIGO’S GROWING POPULATION

The new sewer trunk main in White Hills replaces part of the aging East Bendigo sewer trunk main. It will improve the network’s capacity to carry sewage from the growing suburbs of Strathfieldsaye, Junortoun, parts of Strathdale and East Bendigo.

The new trunk main will accommodate greater flows and enable wastewater to be better distributed between two smaller mains that carry waste to the Bendigo Water Reclamation Plant in neighbouring Epsom.

Final work is currently being completed with the last connections being put in place. The project is one of a number Coliban Water is undertaking to cater for population growth in the Bendigo region.

The five-kilometre Epsom-Huntly Pipeline, due for completion in Autumn 2023, will increase water network capacity for Epsom and Huntly, north of Bendigo.

Phase One of works at the Bendigo Water Reclamation Plant are due to commence in 2024, while surveying work has commenced on a new pipeline to connect Golden Square with the growing suburbs of Maiden Gully and Marong.

UTILITY • MAY 2023 WWW.UTILITYMAGAZINE.COM.AU 35 INDUSTRY INSIGHTS

Visit connect.coliban.com.au for more information on Coliban Water’s projects.

THINK YOU KNOW HOW TO WORK NEAR GAS PIPELINES?

THINK AGAIN