WATER SEWER ELECTRICITY GAS Engineering, Construction & Maintenance www.utilitymagazine.com.au Issue #32, November 2021

UPGRADING CORRODED POWER POLES ON THE SPOT STAYING LIVE Tracking COVID-19 IN WASTEWATER HOW ENERGY RETAILERS ARE KEEPING UP WITH THE COMPETITION

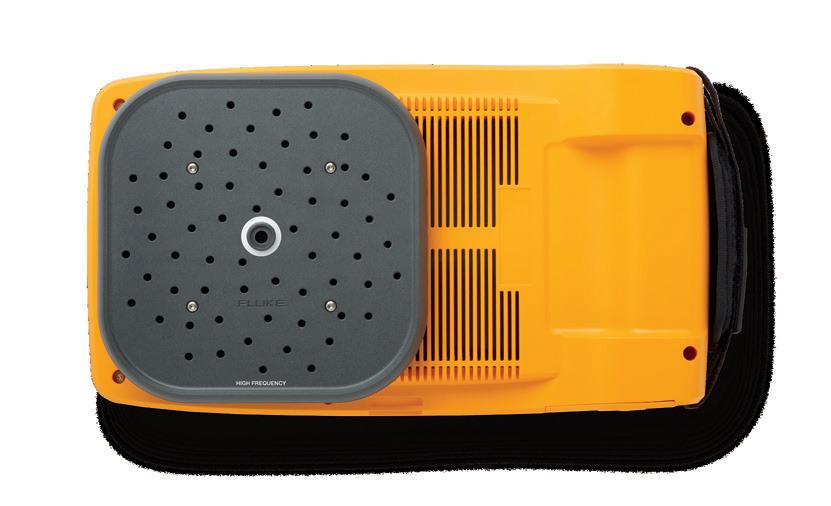

Fluke ii910 Precision Acoustic Imager

Quickly, easily, and safely monitor your equipment for partial discharge.

Partial discharge is a very serious issue that you would be like to be able to monitor quickly and easily. Whether you are inspecting insulators, transformers, switch gears or high voltage power lines you need to be sure that you can spot problems quickly and early. Partial discharge that goes unchecked can cause blackouts, fires, explosions, or even death from arc flashes. In addition, there is a significant monetary risk of downtime. Finally, a better way to safely detect partial discharge and prevent downtime before it occurs.

Learn more: fluke.co/ii910u11

FROM THE EDITOR

I’m very excited to be writing this letter as the new editor of Utility, and introducing you to this wonderful edition of the magazine. I’ve stepped into the editor’s role after spending the last few years editing Utility’s sister publication, Infrastructure. I’ve worked across all of our magazines over the last six years and it’s been fantastic moving back into the utility space.

a wider look at different aspects of utility safety, among others.

info@monkeymedia.com.au

utilitymagazine.com.au

info@utilitymagazine.com.au

ISSN: 2203-2797

My predecessor Charlotte did a great job building Utility into what it is today – a respected industry voice for Australia’s utilities – and I hope to continue this legacy. With that in mind, I’d love to hear from you. Utility exists to give you that latest news, updates and thought-leading content on the issues that impact your day-to-day working lives.

Our aim is to have your challenges, concerns, opportunities, achievements and innovations reflected in every issue, so I encourage you to get in touch if you would like to pitch a potential story idea, discuss a future collaboration, or talk about some of the biggest industry issues you want to see in the pages of this magazine. My contact details are at the bottom of this page.

My team and I have jumped straight into this bumper issue to cover features including the biggest renewable projects underway around the country, an in-depth look into the role utilities have been playing over the last year detecting COVID-19 in wastewater, the innovation and product expansion happening in the retail and billing side of the industry, and

Some of the biggest issues I’m seeing in the utility industry revolve around the increasing need for our assets to be more sustainable as we move towards a net zero future, as well as the digitisation of the sector and the implementation and growth of new technologies. It all boils down to a commitment to deliver sustainable, reliable and affordable water and energy.

It would be remiss of me not to mention the biggest challenge that has been playing out over the globe for the last two years, COVID-19. Australia is collectively tired. Here in Melbourne, this edition of the magazine was made in lockdown number six – earning the city the title of longest lockdown in the world, with Sydney also joining us with strict lockdowns and restrictions.

It’s hard and people are over it, but utilities, as an essential industry, have continued to ensure the lights stay on and the water is running. When the country has to deal with something as unprecedented and unpredictable as a pandemic, it’s imperative that everything continues to function, and I think it’s fair to say all of our utilities have been doing a tremendous job. The Utility team and I can’t wait to further delve into the industry and continue to bring you the latest information, and we hope you enjoy this edition.

Jessica Dickers Editor

UTILITY • NOVEMBER 2021 Editor Jessica Dickers Assistant Editor April Shepherd Journalists Annabelle Powell Lauren DeLorenzo Design Manager Alejandro Molano Designers Jacqueline Buckmaster Danielle Harris Luke Martin Business Development Managers Rima Munafo Brett Thompson Marketing Manager Radhika Sud Publisher Chris Bland Managing Editor Laura Harvey Published by Cover image highlights our article on Power and Water's innovative pole replacement program. www.mcrobertcontracting.com.au office.admin@mcrobert.com.au and walls with PVC for 100% gas tight lining Patented technology ✓ MANHOLE REFURBISHMENT AFTER BEFORE Assess structural integrity asset Detailed interactive report with 3D modelling ✓ 3D LASER SCANNING AND ASSET INSPECTION UTILITY MAGAZINE NOVEMBER 2021 UPGRADING CORRODED POWER POLES ON THE SPOT STAYING LIVE Tracking COVID-19 IN WASTEWATER HOW ENERGY RETAILERS ARE KEEPING UP WITH THE COMPETITION WATER SEWER ELECTRICITY GAS Engineering, Construction & Maintenance www.utilitymagazine.com.au Issue #32, November 2021 Monkey Media Enterprises ABN: 36 426 734 954 C/- The Commons 36–38 Gipps St, Collingwood VIC 3066

monkeymedia.com.au

P: (03) 9988 4950

welcome November 2021 ISSUE 32 1

Drop me a line at jessica.dickers@monkeymedia.net.au or feel free to call me on 03 9988 4950 to let me know what you think. Don't forget to follow Utility magazine on social media - find us on LinkedIn, Twitter and YouTube.

What are the benefits of selecting a microtunneling contractor with versatile equipment?

When it comes to microtunnelling, there are a number of challenges that can derail a project, costing time and money. That's why choosing a contractor with versatile equipment is important, as it increases the likelihood that your project will successfully be completed on time and on budget.

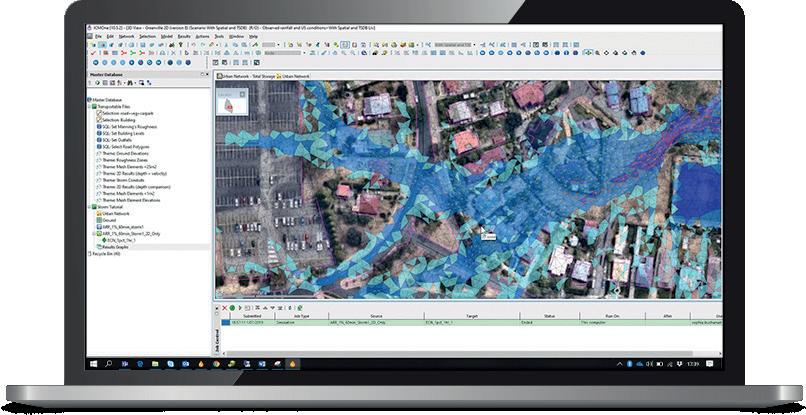

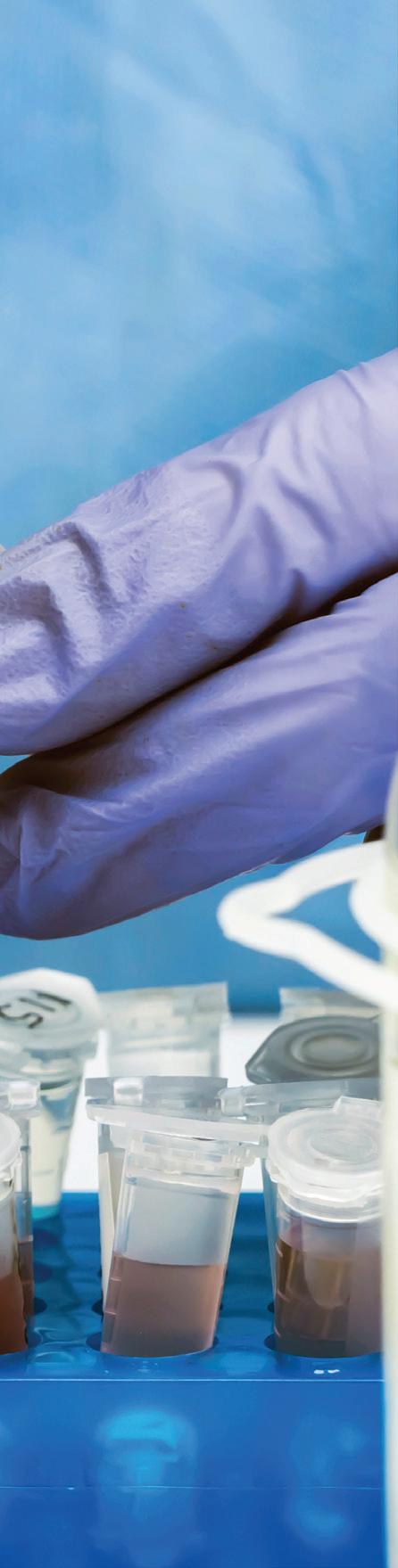

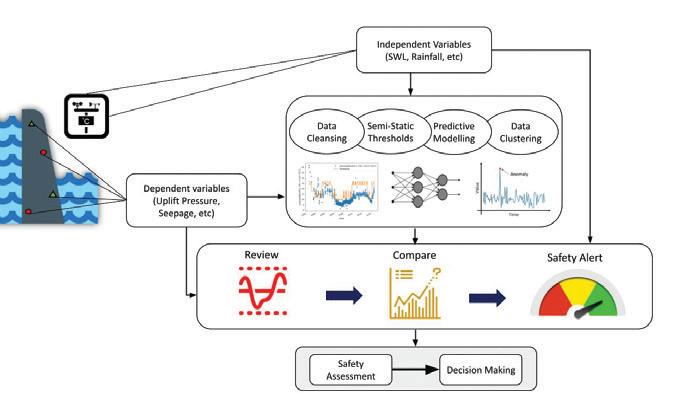

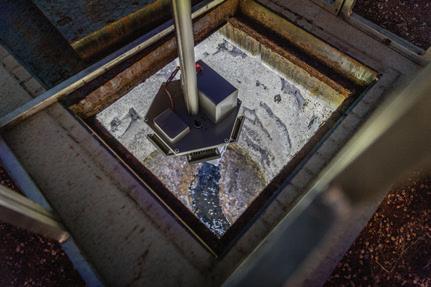

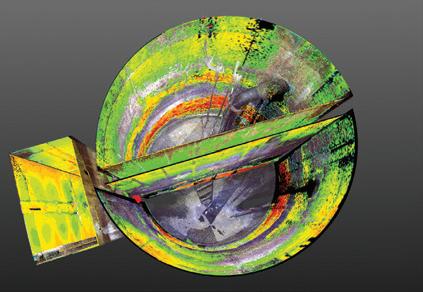

2 CONTENTS Renewables at a Glance: Australia's biggest up-and-coming projects 20 Reusing biosolids in the wastewater sector 24 Minding the citizen-utility gap 26 Economical water treatment through blending 28 LAND ACCESS A renewable energy future requires licence to operate ........ 30 Building a Digital Flood Twin of Tasmania 32 Wastewater sampling: utilities collaborating to track COVID-19 34 New technology transforms resiliency readiness 38 Implementing a cyber security plan to protect water and wastewater infrastructure .......... 40 CORROSION Engineering innovation ramps up rusted pole replacement program 42 Charting a path for utility digital transformation 46 Meeting 5-minute settlement regulatory requirements 47 A new billing system for Australian water utilities 48 Expanded product offerings: the future of energy retail? 50 With traditional revenue sources dwindling and energy retailers now competing for fewer customers, many companies have repositioned themselves as customer solutions providers, expanding their products to include insurance or telecommunications services. HORIZONTAL DIRECTIONAL DRILLING Albany to Denmark pipeline secures Denmark's water future 76 How HDD supports infrastructure asset resilience 80 Celebrating 85 years of innovation 82 DAMS Reimagining dam safety management 84 Water level and pressure instruments to meet all applications 88 84 82 50 34 24 90 UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU

RETAIL, BILLING AND CRM

RENEWABLES DISASTER MANAGEMENT

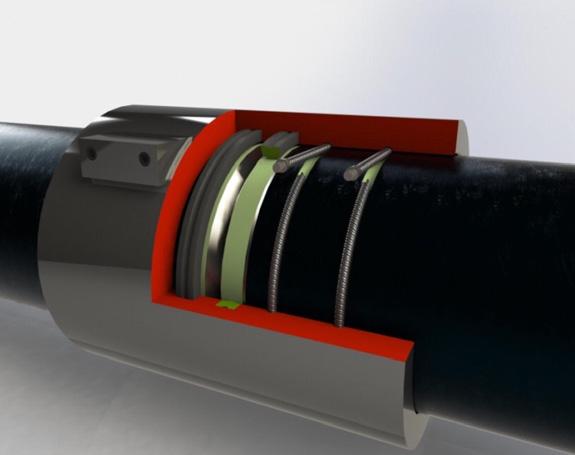

November 2021 ISSUE 32 3 74 In each issue Welcome from the Editor ������������������������������������������������������������������������������������������������������������� 1 A word from Energy Networks Australia ���������������������������������������������������������������������������������� 4 A word from WSAA ����������������������������������������������������������������������������������������������������������������������� 6 News briefs ������������������������������������������������������������������������������������������������������������������������������������ 8 Advertisers’ index ���������������������������������������������������������������������������������������������������������������������� 92 Editorial schedule ���������������������������������������������������������������������������������������������������������������������� 92 QLD-NSW Interconnector boosting reactive power and grid stability 54 Powering up Perth: the Western Power Hay to Milligan Project 58 The invisible threat you can now see ........................................ 60 Boost productivity with PowerFlex 6000T medium voltage drives ... 62 Listen up: TasWater’s active leakage management technology ............ 64 In a bid to address water losses in the network, TasWater has implemented active leakage management, featuring technology that listens for leaks that may not be visible to the naked eye. Manage water assets during a crisis by leveraging smart devices 66 Industrial reverse osmosis ......... 68 Essential Energy’s new digital and training safety initiatives 70 Inspiring confidence and improving process safety 72 Technology reducing costs for pump maintenance and downtime for water utilities 74 58 64 UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU TRANSFORMERS AND SUBSTATIONS LEAK DETECTION SAFETY

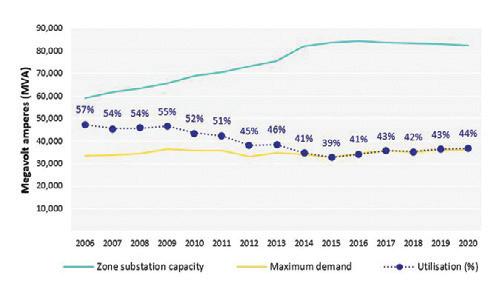

IS IT TIME TO RETIRE NETWORK UTILISATION MEASURES?

BY CHRIS GILBERT, SENIOR ECONOMIC ADVISER, ENERGY NETWORKS AUSTRALIA

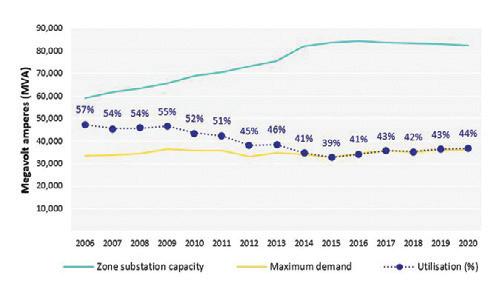

How do you measure success? As the pathway to a two-way energy system becomes more well-trodden, yard sticks that measure how well networks utilise their assets need to change. The relevance of utilisation measures is under question – as they don’t show what they claim to anymore.

Utilisation measures have been referred to by various energy policy and regulatory bodies, as well as public agencies throughout the years, in different contexts.

At its most fundamental, network utilisation measures how well a network’s assets have been used to meet maximum demand and have been used as a signpost as to whether network investments are delivering value for customers.

The most common utilisation measure is calculated as the very unpleasant phrase ‘non–coincident summated raw system annual maximum demand’. In English this means the peak of each zone substation’s highest demand, at different times across the year without normalisation for temperature, divided by the total capacity of all zone substations on a network.

TIMES HAVE CHANGED

Network utilisation was traditionally very stable in a one-way system prior to the introduction of heightened state reliability targets. Overzealous reliability targets, in some cases, drove additional network investment to mitigate against potential disaster on the electricity network’s most demanding days. These investments coincidentally resulted in some minimally used capacity and a reduction in measures of network utilisation.

In the years since, old state-based reliability targets have been wound back and distributed energy resources (DER) such as solar PV and battery uptake, have continued to surge. The measure of network utilisation has crept upwards as zone-substation capacity declined and distributors adapted

to invest in new areas where it was needed most, like highly populated areas and those with high DER.

As DER continues to become a staple in the electricity system, its continued uptake is muddying the waters on what network utilisation measures actually show.

WHAT DO UTILISATION MEASURES ACTUALLY SHOW?

Customers are demanding increased ability to export solar and connect their DER, creating local demand for network usage that may require additional network investment to facilitate. While DER might create network congestion at the local level, it can also result in a reduction in the overall demand requirement at the zone substation level.

This reduction in demand can have the effect of reducing utilisation measures, while also requiring additional investment in network reinforcement, raising questions about what these measures represent in a two-way energy system.

Whether fortunate or by design, utilisation measures most often cited are related to peak demand on each zone substation. This traditionally occurs in the evening when DER output is low and its impact on reducing utilisation is less severe, but still exists.

In today’s electricity system, customers are showing strong preferences for DER uptake and distributors are rightly targeting investment to enable these preferences. Is it sensible then, that enabling customer preferences might be having unintended negative impacts on measures often associated with network performance?

This conundrum raises an interesting question about the usefulness of utilisation measures in a high-DER future, and whether we should be looking at alternatives.

CAN WE DO BETTER?

Discussing utilisation measures in the context of network performance may have made sense when we had single direction transmission ‘highways’ and large baseload generation centres, but much less so in a high-DER world with scattered, non-synchronous generation centres.

Network regulation in Australia doesn’t directly draw on utilisation measures for benchmarking or productivity assessment, and rightly so. It’s probably time to consider retiring utilisation measures and shifting focus to measures that have more meaning to customers in practice.

4 UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU A WORD FROM ENERGY NETWORKS AUSTRALIA

FIGURE 1 – NETWORK UTILISATION OF ELECTRICITY DISTRIBUTION NETWORKS. SOURCE: AER STATE OF THE ENERGY MARKET 2021, P. 168

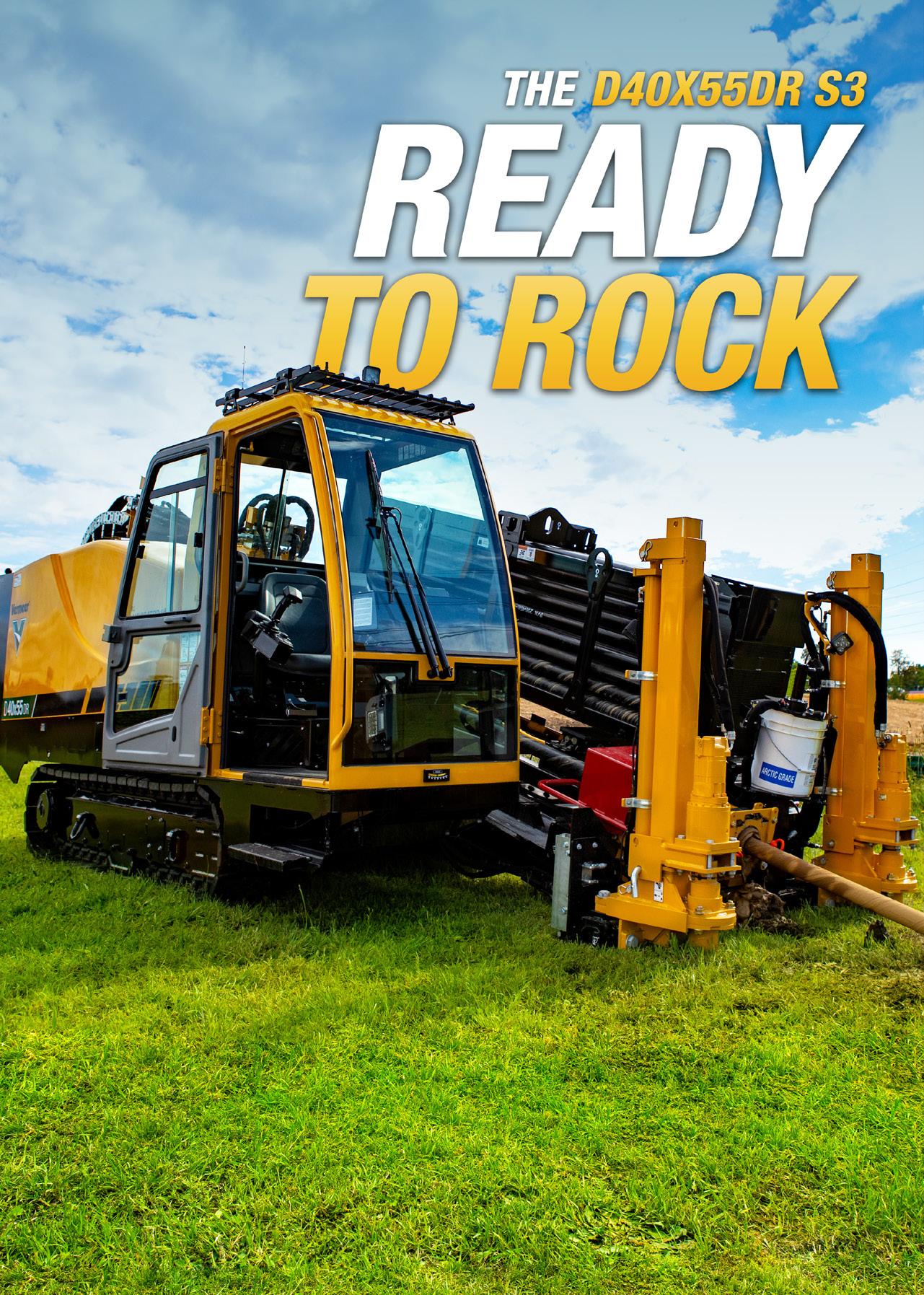

THE ROCK DRILL FOR A RANGE OF CONDITIONS

The D40x55DR S3 Navigator® horizontal directional drill helps deliver excellent productivity in a broad range of conditions, from hard, medium and soft rock. Dual rod technology delivers powerful down-hole drilling action and the flexibility to select the right tooling to match ground conditions. Maximise jobsite productivity with 40,000 lb (177.9 kN) of thrust and pullback and 5500 ft-lb (7457 Nm) of rotational torque. Demo the D40X55DR S3 and experience the difference.

VERMEERAUSTRALIA.COM.AU | 1300 VERMEER

/ VermeerAustralia

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the United States and /or other countries. © 2021 RDO Equipment Pty Ltd (trading as Vermeer Australia). All Rights Reserved.

A WORD FROM WSAA

FLUSHABLE PRODUCTS STANDARD TO HELP CLEAN UP MESS

After a couple of years of work, Standards Australia has released the Draft Standard, DR AS/NZS 5328 Flushable Products, for public comment.

The draft Australian/New Zealand Standard defines the criteria for material suitable for toilet flushing, along with appropriate labelling requirements.

The Draft Standard has been developed by a technical committee including manufacturers, water utilities, peak bodies and consumer groups.

Wastewater systems are key to protecting public health and the environment, however when any blockage occurs, there is a risk that wastewater may spill from the system and create public health and environmental risks, along with otherwise unnecessary costs to water utilities and customers.

WSAA and the urban water industry in Australia and New Zealand have been concerned about the contribution of wet wipes products to pipe blockages for some time. The issue became even more serious during the COVID-19

pandemic, with utilities reporting increases in blockages of between 20 and 60 per cent at the height of the pandemic last year, as people flushed materials never intended to go down the toilet, like paper towel and wet wipes.

The Draft Standard will provide manufacturers with clear specifications and sets out methods for testing whether products are suitable for toilet flushing and compatible with wastewater systems and the environment. It also includes guidelines for manufacturers to clearly label products to better inform customers whether or not their products are suitable for toilet flushing.

If a product meets the Standard, and is therefore suitable for flushing, the packaging can display a “flushable” symbol. Packaging for non-flushable products that have a potential to be flushed, should clearly indicate that the product should not be disposed of via the toilet. The new labelling could be on products as early as mid-2022.

The Draft Standard, DR AS/NZS 5328 Flushable Products is available

for public comment for nine weeks until 1 November 2021. The public consultation period allows any parties concerned with the application of the proposed Standard to review the Draft and submit their comments. The Draft Standard can be altered during this time.

It is not an Australian/New Zealand Standard until finally issued by Standards Australia/Standards New Zealand. The Standard will be voluntary, however we will be encouraging manufacturers of products to comply with the Standard, including labelling requirements.

Everyone is encouraged to comment, in particular water utilities and councils, manufacturers, industry bodies and consumer advocacy groups. To comment you must register on the Standards Australia website. Once you have logged in, DR AS/NZS 5328:2021, Flushable Products can be found on the Standards Australia Connect Portal. Public comments must be submitted using Standards Australia’s template to be accepted.

To review the Draft Standard and comment please go to: www.standards.org.au/news/flushable-products-colon-public-commenting-stage.

Or for more information, please contact Dr Greg Ryan, WSAA’s Director Business Excellence, at greg.ryan@wsaa.asn.au.

6 UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU

more than just maps

MONITOR UTILITY ASSETS FROM THE COMFORT OF YOUR DESK

• Manage your infrastructure reliably with frequent captures

• Respond efficiently to maintenance requests

• Monitor vegetation around critical assets

• Measure confidently with high spatial accuracy

• Flexible access via web-application or your own GIS

• Overlay rich cadastre and building insights

metromap.com.au

Scan to access free trial

MAJOR WATER UTILITY CEO TO STEP DOWN AFTER A DECADE

Urban Utilities has announced its CEO, Louise Dudley, will be resigning in August 2022, following ten successful years transforming the company into one of the world’s leading water authorities.

Urban Utilities Chair, Bronwyn Morris, said Ms Dudley was recognised as an exemplary leader in the water industry, serving on several Australian and international peak bodies.

“Next year will mark a decade as CEO for Louise and I’d like to acknowledge the outstanding contribution she has made in the transformation of Urban Utilities into an innovative, customer-focused organisation,” Ms Morris said.

“We’re pleased Louise will continue as CEO for another 12 months to oversee the delivery of a number of strategic projects and priorities and ensure a seamless transition to her successor.

“We remain excited for the future and look forward to building on our organisation’s strong foundations and

continuing to deliver for our customers and community.”

Ms Dudley was instrumental in the formation of Urban Utilities in 2010, which involved the merger of five local council water businesses to establish one of Australia’s largest water utilities.

“I’m extremely proud of the team that we have at Urban Utilities. Together, we have created a highperforming culture with a strong focus on customer service, enhancing our community and environment, and improving the wellbeing and safety of our employees,” Ms Dudley said.

After leaving Urban Utilities, Ms Dudley is looking forward to new professional opportunities including taking on board and advisory roles.

She is passionate about the water industry and will continue to serve as President of the Australian Water Association and as a Director of WaterAid and WaterStart Nevada.

The process to select Urban Utilities' next CEO will commence within October 2021.

SYDNEY WATER REVEALS NEW CHAIR

Sydney Water Corporations’ new Chair has been announced, replacing the outgoing Bruce Morgan, who will step down on 30 September 2021.

Prominent Australian businessman, Grant King AM, is the new Chair of Sydney Water Corporation. Mr King was appointed as a non-executive director of Sydney Water on 9 June before taking the reins of Chair on 1 October.

Mr King said he was delighted to be taking on the new role at such a pivotal time for Greater Sydney and paid tribute to the leadership of his predecessor.

“Bruce has made a significant contribution to Sydney Water over the past decade and in that time helped to successfully steer the business

and indeed Greater Sydney, through successive droughts, floods and more recently COVID,” Mr King said.

“Sydney Water has a key role to play in the future development of Greater Sydney, particularly in terms of resilience and liveability.”

Mr King is also the Chair of the Climate Change Authority, HSBC Bank of Australia, CWP Renewables, GreenCollar, Areventa and Melanoma Institute of Australia, a Non-Executive Director of the Origin Foundation, Great Barrier Foundation, O’Connell Street Associates and a member of the University of NSW Foundation.

He also holds a position as Professor of Energy Economics and is Chair of the Energy Institute at the University of NSW.

“I’m delighted to carry on Bruce’s legacy and look forward to working with the Board and the highly committed people of Sydney Water to create a better life for the citizens of Greater Sydney,” Mr King said.

UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU 8 NEWS

UNITED ENERGY’S WORLD-FIRST POLE-MOUNTED BATTERY to transform renewable integration

The Australian Renewable Energy Agency (ARENA), on behalf of the Australian Government, has announced $4 million in funding for United Energy to trial the use of pole-mounted batteries to operate as virtual power plants, supporting more rooftop solar and demand management services.

The first of its kind in Australia, the $10.98 million project will see 40 custom-built batteries manufactured and mounted to electricity poles across United Energy’s distribution network.

The batteries will operate as a virtual power plant (VPP), helping to manage peak demand across the low voltage distribution network in South Eastern Melbourne and the Mornington Peninsula, and increasing hosting capacity for rooftop solar.

Each of the 30kW batteries will be capable of providing at least two hours of storage and will be installed at strategic locations across the network.

The batteries will be manufactured locally by Thycon in Melbourne’s north and mirror the design of existing distribution transformers that are already mounted to poles across United Energy’s network in Melbourne’s bayside area.

In addition to reducing stress on distribution transformers in times of peak demand, the batteries will also be able to regulate voltage and increase the hosting capacity of solar PV in the local grid, providing benefits to all customers.

United Energy has signed a deal with Simply Energy for the market trading rights of the VPP. When the batteries are not required by United Energy, Simply Energy will operate them to provide wholesale power and frequency control ancillary services.

The project follows a successful pilot by United Energy that saw two battery units installed in early 2020 in the Melbourne suburbs of Black Rock and Highett to demonstrate the feasibility of pole-mounted technology.

CUSTOM CABLE SEALS harcor.com.au Master Security Licence No. 407319937 Custom cable seals can be used to indicate the valve’s position and what flows through the valve. Ask about our fantastic pricing on nitrile & latex gloves email sales@harcor.com.au for more information UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU 9 NEWS

JEMENA ANNOUNCES AUSTRALIAN-FIRST GREEN FINANCE FRAMEWORK

Jemena is releasing an Australian-first sustainable finance framework, to satisfy investor demand for more sustainable investment options.

The Green Finance Framework was developed in collaboration with global investment banks HSBC and ING, and is believed to be the first of its kind to be delivered by a traditional energy company operating in Australia.

The Green Finance Framework follows Jemena announcing its ambition to achieve net zero emissions by 2050, and will see the business use funds raised from green instruments such as bonds, loans, and promissory notes to finance and/or refinance projects, which will have a positive impact on the environment.

The framework applies to companies within the State Grid Singapore Power Australia Assets (SGSP Australia Assets) Group, including Jemena and engineering, project management, operations and maintenance services company, Zinfra.

Jemena’s Chief Financial Officer, David Gillespie, said the framework reflects the Group’s contribution to the United Nations Sustainable Development Goals, particularly goal seven – affordable and clean energy –and goal 13 – climate action.

“This is a natural evolution of our Group’s Sustainability Strategy which focuses on supporting the development of new technologies as part of the energy transition,” Mr Gillespie said.

“Our Green Finance Framework gives confidence to investors that

they are backing projects which will make a difference in lowering carbon emissions, while also helping to create the energy system of the future.”

Net proceeds of green instruments issued by Jemena will be used to fund projects in four major categories: renewable energy, energy efficiency, clean transport, and climate adaptation.

Administration of the framework will be subject to external review, and will be reported annually as part of the Group’s annual reporting process.

10 Call now 1800 816 830 Truck

Systems AUSTRALIAN MADE enviroline.net.au Practical, powerful, safe, efficient and reliable truck jetting range from Enviroline. 2 YEAR WARRANTY AUSTRALIA WIDE SERVICE PROUDLY AUSTRALIAN MADE Ranger T100 267LPM@ 2250PSI 180m x 1” I.D Jetting hose Ranger T80 160LPM@ 2600PSI 180m x ¾” I.D Jetting hose UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU NEWS

Jetting

WSAA calls for quick action on IA water recommendations

The Water Services Association of Australia (WSAA) has responded to reforms posed in Infrastructure Australia’s 2021 Infrastructure Australia Plan, joining the Productivity Commission in calling for a renewed and modernised National Water Initiative and calling on all governments to progress water-related recommendations from the Plan.

WSAA has welcomed the release of the Plan, which outlines a 15-year roadmap to improve the resilience and sustainability of essential infrastructure, including urban water.

The 2021 Plan responds to the 180 infrastructure challenges and opportunities identified in Infrastructure Australia’s 2019 Australian Infrastructure Audit, and sets out detailed recommendations to deliver better infrastructure for all Australians.

The 2021 Plan includes waste and social infrastructure for the first time, alongside energy, transport, telecommunications, and water.

It also focuses on three cross-cutting key themes: Place (Cities, Regions, Rural and Remote Areas, and Northern Australia), Sustainability and Resilience, and the Infrastructure Industry.

The water-related plans focus on creating resilient, secure and quality water supplies available for all Australians, to create attractive, liveable and resilient communities.

The Plan also acknowledges the need for consistent and reliable water and wastewater services in remote communities.

The WSAA said that, after Australia experienced two of the worst droughts recorded in recent history, they believe it is time to update the national water plan.

Key water-related takeaways from the Plan are:

• Consistent approaches to measuring water security risk to significantly improve governance of Australia’s water resources, supporting transparent and reliable decisionmaking that addresses the needs of local communities

• Stronger planning processes enabled by water security information to support better health and environmental outcomes, with reduced frequency and intensity of water shortages, enhancing community sustainability and unlocking social benefits

• Implementing a consistent approach to assessing water needs and measuring water security risk to help ensure regional, remote and rural communities have comparable levels of quality and access to services

• Prioritising water investments based on more accurate assessment of water security risk to improve the reliability of services that support economic productivity for both communities and businesses; in the long-term, this can improve affordability by reducing expenditure on reactive activities and improving efficiency.

Innovative Water Solutions

Through its innovative solutions, Veolia Water Technologies enables industry, local authorities and citizens to optimize their use of resources for more efficient, environmentally-friendly and socially responsible outcomes.

We understand the importance of increasing the value of water and we do so by supplying high quality water, treating and reusing wastewater, producing and/or recovering energy, extracting raw materials and capitalizing on valuable byproducts.

www.veoliawatertechnologies.com.au

UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU 11 NEWS

WATER TECHNOLOGIES

© Veolia Photo Library

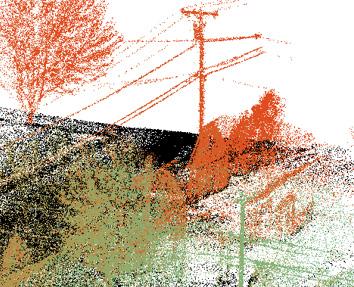

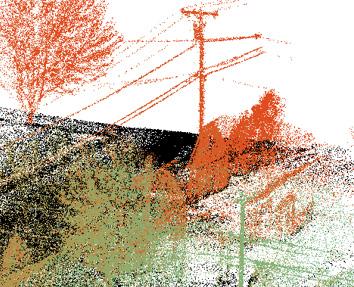

POWERCOR TRIALS NEW DRONE TECH ON BALLARAT POWER NETWORK

The Ballarat region has acted as a testbed for Powercor’s new drone technology, which is able to inspect powerlines promptly and in great detail.

Remotely-piloted drones have inspected more than 30km of powerlines around Ross Creek, Cambrian Hill, Napoleons and parts of Buninyong in recent weeks.

The work is in addition to Powercor’s ongoing program of asset inspections, which are also being conducted by crews in vehicles, on foot and by helicopter.

A specialist team is trialling the Matrice 300 RTK – a powerful industrial drone platform with an advanced flight controller system, six-directional sensing, real-time video transmission, thermal imaging and obstacledetection systems.

This follows a trial of a similar technology in the Otways in September 2020, with results from the new Ballarat trial to inform whether the technology is suitable for inclusion in Powercor’s continuous inspection program.

Powercor Head of Network Asset Management, John Mifsud, said the drone inspections had covered a large area, with high definition cameras used to capture the condition of powerlines quickly and easily.

Mr Mifsud said the area south of Ballarat was chosen due to its topography and environmental factors, as well as network characteristics that make the location a good trial site.

The drone trials also complemented extensive foot patrols in the area in early 2021, following reliability issues over summer for customers south of Ballarat.

“This trial is about finding new ways to keep our network operating safely and reliably,” Mr Mifsud said.

“While these drones won’t replace our existing inspection methods, we’re looking at whether they have a permanent role in our program in the future.”

Powercor manages its network of almost 90,000km of powerline and 588,000 poles through a rigorous inspection and maintenance program, on top of a network-wide vegetation management program clearing trees and shrubs well away from powerlines.

UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU P E Level 2, Suite 26/20 Enterprise Drive Bundoora, Vic, 3083 1300 1 L ANCO (52626) tenders@lancogroup com au lancogroup.com.au Your business partner for engineering solutions Since 1998. “We don’t purely just design; we help our customers realize their goal, if you give us an idea we can provide a efficient and effective engineering solution” Accredited consultant with Melbourne Water, Retail Water Corporations – Metropolitan and Regional Areas Corporate Profile Insurance Category Level of Cover $ Professional Indemnity $10 million Public Liability $20 million Work Cover n/a A list of applicable insurances includes: Name of Entity: Lanco Group Pty Ltd ABN: 27 160 328 478 Company Address: University Hill Business Park South Level 2, Suite 26/20 Enterprise Drive Bundoora, Vic, 3083 Company Structure: Private Company Quality ISO 9001 Environment Health & Safety AS 4801 ISO 14001 2 NEWS

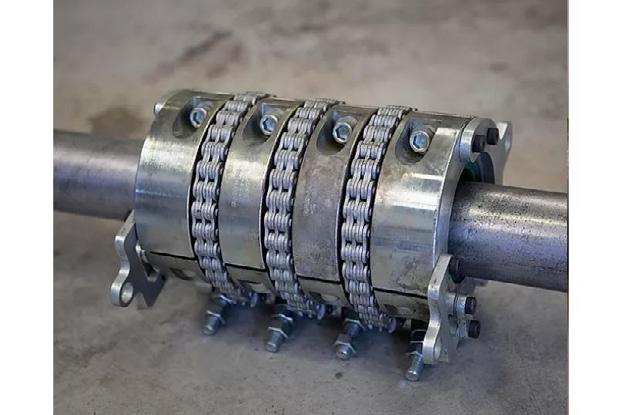

SRJ Technologies Asset Protection Range 1 3 0 0 7 9 4 0 9 6 w w w . p s s s a . c o m . a u s a l e s @ p s s s a . c o m . a u PSSS also offers..... Proudly Presents..... Construct ; Maintain ; Preserve Your Pipeline Assets HDPE Tooling & Machinery Pipeline Pigs & Pigging Equipment Pipe Cutting & Bevelling HDPE Butt Fusion

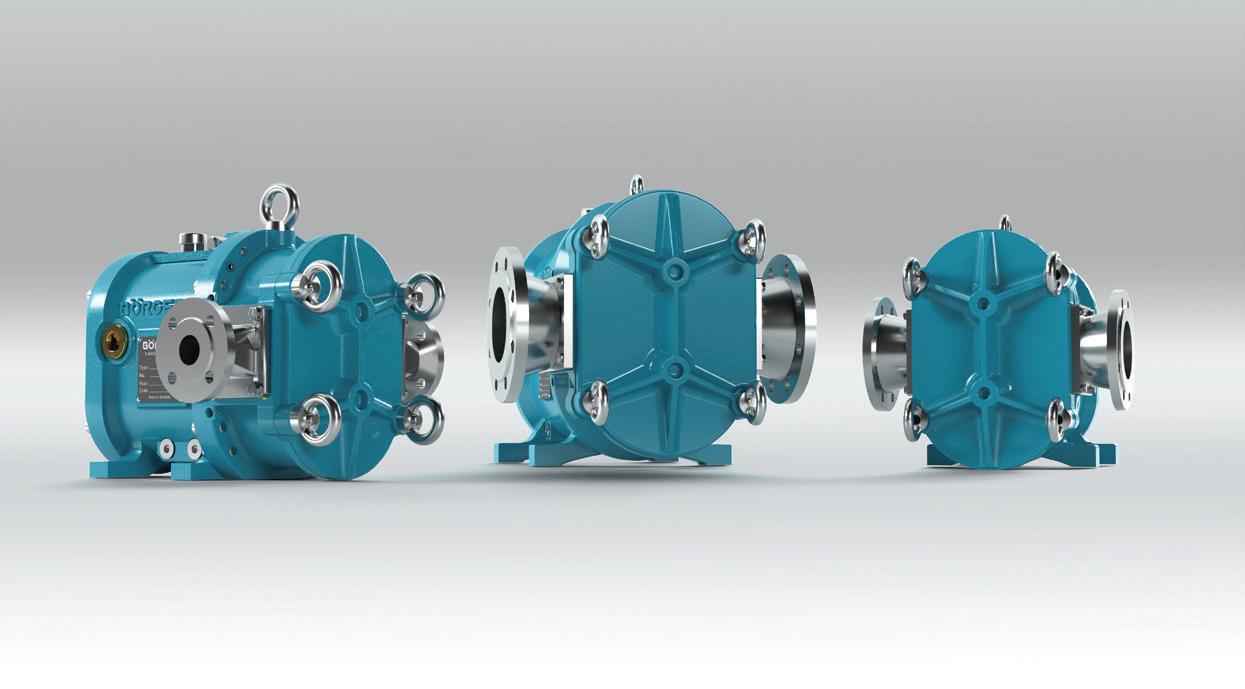

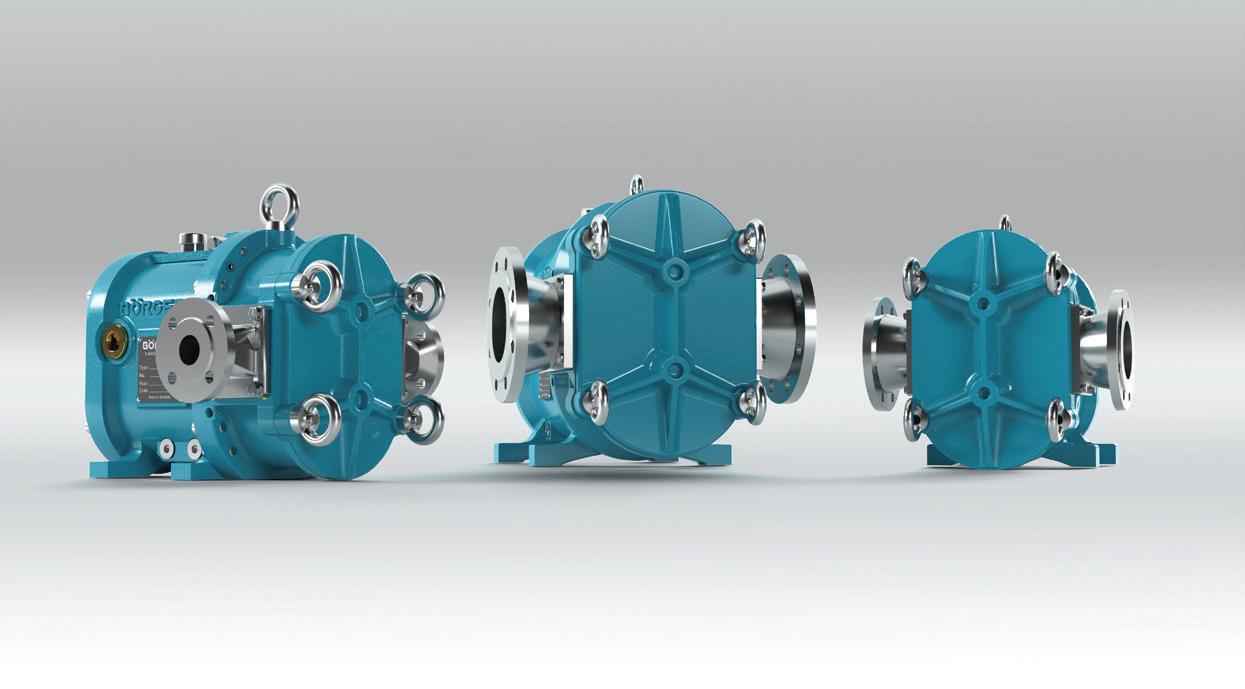

NEW HIGH-TECH ROTARY LOBE PUMPS

Boerger has surprised the world of pumps with a new generation of its BLUEline rotary lobe pumps, the BLUEline Nova, with the high-tech pump available in six sizes and with flow rates of up to 110 m3/h. The German manufacturer promises not only excellent volumetric efficiency but also maximum choice of sealing systems.

Boerger is well-known for its high-quality rotary lobe pumps with flow rates of up to 1,450 m³/h. Presenting the new generation of its BLUEline rotary lobe pumps, Alois Börger, Managing Director of Boerger, said, “The development of the BLUEline Nova has benefited from our 30 years of experience in pump manufacturing. With the help of computer flow simulations and physical test bench hours, we were able to improve the pumps even further.”

Mr Börger said the rotors and casing were made for one another. This newly developed one-piece DIUS rotor ensures an almost pulsation-free pumping at pressures of up to 12 bar, while the wide sealing surfaces of the screw-profile rotor prevents backflow of the medium.

“Boerger has also modified the pump chamber to utilise the dual-lobe rotor to its full potential. The geometry of the inlets and outlets, as well as the wrap angle of the casing, were particularly optimised. We were able to considerably improve the volumetric efficiency of the pump. To this end, we have adjusted the pump chamber to the rotor geometry in a flow-optimised design,” Mr Börger said.

The BLUEline Nova comes in two variants: with or without protection plates and liners. In its clean version, protection plates and liners are not required. The pump with minimum dead space can be cleaned according to the hygiene

procedures, CIP (Cleaning-In-Place) and SIP (Sterilisation-InPlace).

In its tough version, the pump is equipped with protection plates and liners for pumping abrasive media containing solids. With a new innovative fastening system, the ‘tough’ version of the Nova pump ensures the best volumetric efficiency ever achieved in a rotary lobe pump. In case of wear, the protection plates and liners will be replaced quickly and easily due to its MIP® design (Maintenance in Place).

The large seal chamber of the BLUEline Nova provides space for different sealing systems, therefore ensuring connection of external supply systems is possible, and without issues. Different motors can also be selected for driving the BLUEline Nova rotary lobe pump. Upon request, the drive can be directly flanged to the pump and, due to the elimination of the coupling, the unit is now even more compact. In addition, this version does not require a base frame.

Like all Boerger pumps, the BLUEline Nova rotary lobe pumps can be manufactured according to the European ATEX guidelines for use in potentially explosive atmospheres. An API-676-compliant design, production according to the FDA regulations, or a technically tight pump design according to the German TA Luft requirements, round off the various options for versatile applications.

For more information, please visit www.newblueline.com.

UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU 14 NEWS | Sponsored editorial

FLOW OPTIMIZATION SECOND TO NONE

THE NEW BLUELINE NOVA ROTARY LOBE PUMP

The BLUEline Nova sets new standards in pump technology. With or without protection plates and liners – the BLUEline Nova achieves unrivaled volumetric efficiencies.

Made for one another – the newly developed DIUS rotors in combination with the flow-optimized pump chamber ensure perfectly smooth running at pressures of up to 12 bar.

MADE TO LAST

EXCELLENCE –

www.newblueline.com NOVA BLUEline

Boerger Pumps Asia Pte Ltd • 16 Boon Lay Way #01–48 Tradehub 21 • Singapore 609965 • P: +65 6562 9540 • asia@boerger.com

THE KINLEY ESTATE OUTFALL SEWER

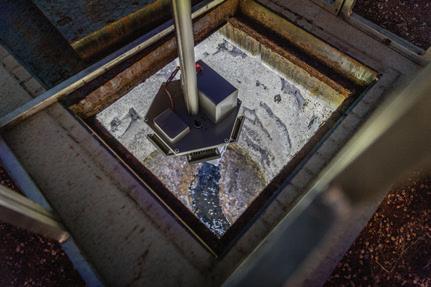

Fulton Hogan’s outfall sewer project in Melbourne’s Kinley Estate overcame several challenges in ground conditions and traffic flow disruption thanks to Pezzimenti Trenchless’ laser guided microtunnelling techniques.

Open cut was not an option for this project due to possible disruption to traffic and residents. The project required full traffic flow during microtunnelling, including residents having access to their properties, and traffic both ways was enabled during the project due to its minimal footprint. Fulton Hogan also had a limited permit to work on the road which meant a very tight program.

Other challenges included groundwater, needing to maintain the very flat grade, and a transition in ground conditions from clay to siltstone, which required a change in

cutters. Pezzimenti also had to drill into the existing sewer line and stop drilling just 300mm away from the existing pipeline.

INNOVATIVE PROJECT SOLUTIONS

In order to overcome these challenging conditions, the project used a laser guided microtunnelling technique. This was due to the depth of the outfall sewer and because the location required the sewer line to be designed along Hull Road in Lilydale and into the existing sewer.

Microtunnelling of 350m of 345mm

OD Clover GRP pipe took place along and crossing Hull Road, into the subdivision, with bore lengths of 50m, 94m, 117m and 89m, and tunneling through ground conditions such as clay and siltstone.

All bores and pipes were installed within a three week window, with depths ranging from 4.5m deep to over 7m in depth, with a design grade of 1:300. Pezzimenti’s experience, expertise and state-of-the-art laser-guided microtunnelling system helped ensure the project was a major success.

UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU 16

DELIVERING

NEWS | Sponsored editorial Unit 2 / 85 Heatherdale Road, Ringwood Vic 3134 PO Box 2500, North Ringwood Vic 3134 P: (03) 9872 4596 | F: (03) 9872 3293 | E: info@pezztrenchless.com.au Still the market leaders in laser guided microtunnelling Bore diameters from 325mm up to 2800mm Used for gravity sewers, water mains, storm water, gas and electrical conduits. Specialists in “free bore”, sleeve boring and pipe jacking in all sizes The Next Generation in Trenchless Technology

iota.net.au

The IoT platform, fit-for-water.

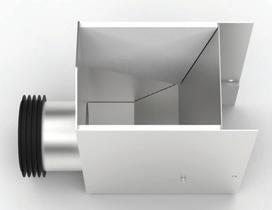

TECHNOLOGY GIVING UNDERPERFORMING SEWERS A SECOND CHANCE

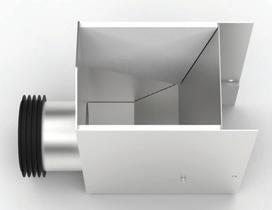

In areas that have a large quantity of restaurants, fats, oils and greases (FOG) are an ongoing issue to be dealt with, and if left to worsen, can create an underperforming sewer catchment that requires costly surcharging and maintenance.

That’s where the FLUSHER II and its cutting edge technology can help, providing a super simple solution, designed to maintain the serviceability of underperforming sewer catchments.

The FLUSHER II is a unique patented flush generating flap valve, that is designed for cleaning and maintaining drains and sewers.

FLUSHER II reduces effluent for a short period at a predetermined hydraulic head, then an automated gate releases a high-volume, lowpressure column of effluent through the catchment network, scouring and mobilising sediment downstream,

which will prevent future silt build up and FOG blockages.

THE SAFER WAY TO CLEAN SEWERS

The FLUSHER II upstream velocity, which will encounter significant increases, can be controlled by adjusting the equipment, ensuring the right effect can be achieved easily.

By storing and then suddenly releasing the natural flow present in drains and sewers, the FLUSHER II generates an enhanced hydraulic flush energy.

This energised flush action repeats continually, without the need for

A passive gate device for controlling and maximising hydraulic flow in sewers

• Reduces operational costs

– No more water jet sewer cleaning

– No more Silt & Debris removal

– Less surcharge & blockages

• Installed in Maintenance Holes

– Easy to install

– Easy to maintain

– For DN150 to DN450 sewer pipes

• Resistant to rag jamming and blocking

• Inherently “fail safe” during storms

• Data Logger and Telemetry Module

– Know what’s happening and when

power, jetting costs, or a hefty carbon footprint.

In comparison to the sewer cleaning method of water jetting, the FLUSHER II can be a much safer alternative, as there is no physical work needed after installation, and because it eliminates generation and release of contaminated water droplets and aerosol.

FLUSHER II is designed for optimal benefit in problem areas and keeps maintenance costs down.

enquiries@aussietrenchless.com

www.aussietrenchless.com

UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU 18

NEWS | Sponsored editorial

FLUSHER II +61 418 691 989

2229 Australia

6/58 Box Road, Taren Point NSW

more about

To find out

the FLUSHER II, visit www.aussietrenchless.com

PROVIDING SOLUTIONS FOR:

• Municipal Sewage Treatment

• Commercial & Industrial Estates

• Government Projects

• Residential Developments

• Urban Subdivisions

• Resorts & Caravan Parks

• Mining Accommodation

• Airports & Infrastructure

• Service Stations

• Defence Assets

1800 057 771 | truewateraustralia.com

SEWAGE & WASTEWATER SPECIALISTS

• DESIGN • MANUFACTURE • INSTALLATION • MANAGEMENT

us about our CONNECTmi® and TELEmi® products for dynamic real time Asset and Management.Monitoring

CONSULTANCY

Ask

RENEWABLES AT A GLANCE:

AUSTRALIA'S BIGGEST UP-AND-COMING PROJECTS

by April Shepherd, Journalist, Utility Magazine

by April Shepherd, Journalist, Utility Magazine

As the impacts of climate change worsen and put Australia's energy future under the microscope, renewables are set to play a significant part in the country’s pathway to a low-emissions future. Utility has collated Australia's most ambitious renewable projects across batteries, bioenergy, solar, wind and hydro, to reveal how the country is making the most of its abundant resources.

As the effects of climate change start to unfold in real-time, Australia is investing in the renewable energy industry.

Australia’s growth of renewable uptake is almost double the global average, with renewable electricity generation doubling over the last decade, and 21 per cent of the country’s total electricity generation coming from renewables in 2019.

The uptake has been driven by solar and wind, with rooftop solar growing a massive 25 per cent in 2019, and largescale solar growing rapidly; contributing to two per cent of all generation in Australia.

According to a recent International Renewable Energy Agency (IRENA) report, Renewable Capacity Statistics 2021, Oceania’s renewable growth rate was the highest in the world, boasting a 18.5 per cent rise – in comparison,

Europe had a six per cent rate and Asia 15 per cent.

Renewable energy uptake will play a significant role in the transition of the National Electricity Market (NEM) to creating sustainable, clean and reliable energy.

BIG BATTERY POWER

Big batteries are playing a crucial role in the transition to renewable energy, by acting as the ‘power banks’ of the energy world.

Traditionally, coal, gas and hydro energy have provided the grid with stability, using frequency control and inertia. Inertia is supplied by energy sources that have large rotating rotors, acting as a defence for service disruptions, because if the power source wanes, the rotor will keep spinning.

However, as these types of energy suppliers reduce in the grid, so does the grid’s back-up storage.

Battery Energy Storage Systems (BESS) provide a backup supply for renewable energy sources, overcoming the problem of intermittent supply when it is not sunny or windy. When conditions for renewables are ideal, BESS can store excess power created for use when conditions are not as good, or when service is in demand.

THE VICTORIAN BIG BATTERY

The Victorian Big Battery – a 300MW battery the size of a football field in Geelong – began in 2019 and is set to be one of the biggest batteries in the world.

The project is a collaboration between French renewables company Neoen and Tesla Megapack technology – a modular system that is high-density

UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU

20 RENEWABLES

and designed for grid-scale commercial projects, allowing the project to be installed quickly.

The Tesla battery Megapacks are pre-assembled with battery modules, bi-directional inverters, a thermal management system, controls and an AC main breaker, in the one enclosure.

The project’s timeline:

• 2019-2020: Development stages, involving meeting landowners, choosing a site, designing and gaining government submission approval and ensuring the battery has a grid connection agreement and suitable finance

• 2021: Construction stage (estimated to take around ten months), received the battery equipment during May, June and into August, construction including building, testing accreditation, grid connection and storing and discharging electricity, with both 180 MVA 220/33kV transformers energised

• 30 July 2021: During initial testing a megapack caught fire, but the site was electrically isolated and emergency services called

• 2 August 2021: Megapack doors removed for temperature check and the site was declared under control. Investigators state that the cause was most likely a leak within a cooling system in a megapack

• 29 September 2021: Reenergisation testing set to recommence after investigations by experts from Victoria state groups concludes

• End of 2021: (to be officially confirmed) Operations to begin, estimated to be active for 20 or more years

The project aims to boost renewable capacity in Victoria, in line with the state’s targets of 40 per cent renewables by 2025 and 50 per cent by 2030.

The battery also acquired a grid-services contract with AEMO, unlocking 250MW peak capacity for the Victoria-NSW Interconnector, and partnering with AusNet, who will provide the connection for the battery.

BIOENERGY

Bioenergy, or energy from waste, is a form of renewable energy that generates energy from converting biomass into heat, biogas, liquid fuels and electricity.

Biomass resources are organic and come from forestry, agriculture or waste streams that are available on a renewable basis – the process often creating byproducts that can be used in other ways, such as biomassbased concrete.

Biomass conversion technologies include combustion, gasification, transesterification, pyrolysis, anaerobic digestion and fermentation, or linked to biorefining processing. The benefits of bioenergy include reduced emissions, waste disposal, and improved air quality.

• 2019: Construction underway

• 2020: Major foundations and civil components completed and the mechanical erection of boiler steelwork well-advanced, installing combustion grates for the two boiler lines (part of technology supplied by Keppel Seghers)

• 2021: Project is moving into its critical stage of boiler water wall installation; prefabricated elements that contain water and steam piping to receive heat from the waste combustion process

• 2022: The project was originally set to be completed by the end of 2021, but has been re-forecast to be finished by the second half of 2022

THE KWINANA WASTE-TOENERGY PROJECT

The waste-to-energy (WtE) project in Kwinana, an industrial hub located 40km south of Perth, is an emerging waste facility.

The waste-to-energy project will use Keppel Seghers (the environmental technology arm of Keppel Corporation) moving grate technology to thermally treat waste and convert the energy recovered from the process into steam, producing electricity.

Some materials will be recovered in the process, such as metallic objects, which will be recycled, and other materials will be reused in construction.

The project’s timeline:

• 2018: The project received financial closure in October with Avertas Energy

The project will be the first wasteto-energy facility on a utility-scale in Australia, aiming to divert around 25 per cent of Perth’s rubbish (postrecycling) to landfill sites.

The waste-to-energy project is aiming to export 36MW of energy to the local grid on a yearly basis, which could power 50,000 houses.

The project will avoid 400,000 tonnes of carbon dioxide being emitted yearly, similar to taking 85,000 cars off the road.

SOLAR POWER

Solar energy is Australia's most popular and well-known renewable power source as it is accessible and abundant. It is easy to think of solar as the country’s face of renewables.

Solar energy is a relatively simple process compared to other

UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU

21 RENEWABLES

renewables; solar panels convert sunlight into direct current electricity and solar inverters convert this electricity to alternating current power. If a household or business has its own rooftop solar panels, it can run off this power, and even sell electricity to the grid.

THE AUSTRALIA-ASIA POWER LINK (AAPOWERLINK)

The AAPowerLink will build the world’s largest solar farm and world's biggest battery storage facility, located in the Northern Territory. The AAPowerLink plans to deliver a 5,000km transmission system to not only supply Darwin with competitively priced renewable electricity, but Singapore and Asian markets as well. Energy will be generated by a 14GW solar farm with 33GWh battery energy storage, located near Elliott, in the Northern Territory. Energy generated at this facility will be transmitted 800km to Darwin and then 4,200km via undersea high voltage direct current (HVDC) transmission networks to Singapore.

The project timeline:

• June 2019: Project announced

• July 2019: Project awarded granted Major Project Status by Federal and NT Governments

• January 2021: Northern Territory Government and Sun Cable sign the Project Development Agreement (PDA)

• August 2021: Proprietary optimisation software for the entire AAPowerLink system, including the Singapore and Darwin electricity markets is developed, completed the 750km Australian section of the subsea survey, and appointed PwC as Project Advisory Partner

• October 2023: Financial close and construction to begin

• 2027: Commercial operations to commence

The AAPowerLink project is valued at over $30 billion, and will include 3,750km of HVDC submarine cables, 14,000 MW of solar arrays, 3GW of dispatchable electricity, and aims to supply up to 15 per cent of Singapore’s total electricity needs.

WIND

Alongside solar, wind is one of the most well-known sources of renewable energy, with the use of wind energy beginning in Australia in 1987.

Wind power is one of the cheapest forms of energy to produce, and now makes up eight per cent of all electricity generated in Australia (as of 2019) and 35 per cent of all renewable energy in the country, with the Australian Clean Energy Council (AEC) stating that there is approximately 6,279MW of installed wind power capacity in Australia.

The Federal Government has also recently passed new legislation, The Offshore Electricity Infrastructure Bill 2021, to establish a framework for the construction, operation, maintenance and decommissioning of offshore electricity transmission and generation projects.

The legislation is set to support a wave of investment in offshore electricity generation and transmission projects, including offshore wind farms – boosting opportunities for renewables.

RYE PARK WIND FARM

Set to be the biggest wind farm ever built in NSW, Rye Park Wind Farm will be located near the small southern tablelands town of Rye Park, near Yass.

The Tilt Renewables project reached financial close in August 2021 and will

be located on a ridgeline positioned at a right angle to the prevailing wind, providing optimal wind conditions. The farm will be connected to the NEM through Transgrid's 330kV Yass to Gullen Range Line, by building a new 330kV connecting substation.

The project timeline:

• December 2020: Tilt Renewables announces that the offtake agreement with Newcrest Mining for the supply of electricity and green products for a 15 year period from the Rye Park Wind Farm has been finalised

• August 2021: Project reaches financial close

• End of 2021: Construction to commence

• 2023: Operational (to be officially confirmed)

The project will create around 250 jobs during construction and a further ten long-term jobs during operation, with plans to be operational not long after the Liddell Power Station closes in 2023, according to Tilt Renewables Chief Executive Officer, Geoff Dutaillis.

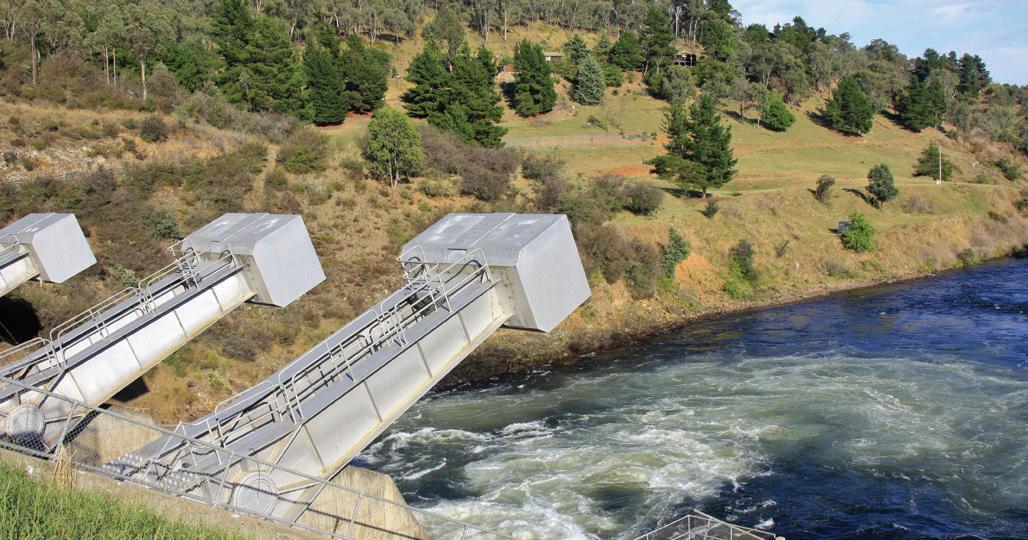

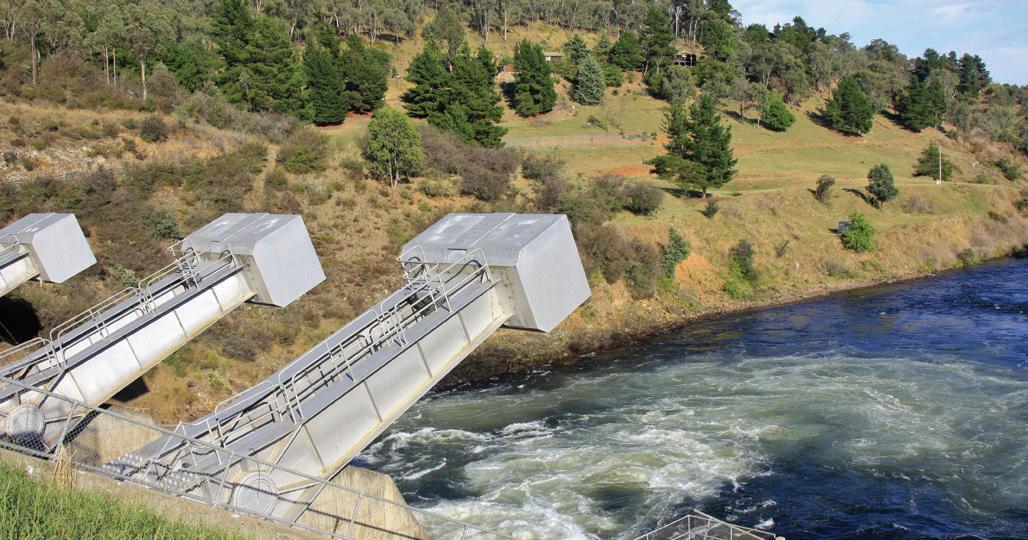

HYDROPOWER

Hydropower, or hydroelectric power, is one of the oldest forms of renewable energy, using the natural flow of water and converting this movement into electricity.

UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU

22 RENEWABLES

Hydropower has been used for thousands of years, typically using the techniques of hydroelectricity and Pumped Hydro Energy Storage (PHES) for generation and storage.

Hydroelectricity typically involves reservoirs or dams, where water can pass through a generator, called a turbine, setting the blades into motion and turning this motion into energy.

PHES can store large amounts of electricity for a long time, and focuses on storage of energy and reliability for consumers. It does this by using excess energy, possibly from a renewable source such as wind, to pump water from lower dams to higher ones, storing energy in the upper reservoir (much like a battery).

This energy can then be released, creating hydroelectricity at any time, which is critical to ensure power reliability and avoiding blackouts.

SNOWY 2.0

Snowy 2.0 is a pumped hydro expansion of the original Snowy Scheme, completed in 1974, and the largest committed renewable energy project in Australia.

Located on the Snowy Mountain Scheme in NSW, in the Kosciuszko National Park, the 2,000MW expansion will link the two existing dams on the mountain; Tantangara and Talbingo, with 27km of tunnels, whilst also building an underground power station one kilometre beneath the mountains.

The new power station has turbines that are reversible, meaning that the water can be pumped back to the top dam, reusing it to create reliable clean energy on-demand. This is especially important as solar and wind electricity increases and large scale storage, like Snowy 2.0 will be required.

The project will supply 350,000MW hours of large-scale storage, enough to power 500,000 homes at once and be able to deliver electricity to the grid within ninety seconds.

The project timeline:

• 2017: Snowy 2.0 announced, feasibility study commenced and publicly released, geotechnical investigation program began

• 2018: Snowy 2.0 declared a Critical State Significant Infrastructure by the NSW Government, final investment decisions (FID) made and final FID report released

• 2019: Exploratory works approved, principal contractor

Future Generation Joint Venture appointed, construction begins with early works underway at Lobs Hole

• 2020: Construction progresses with concrete tunnel segments underway and permanent bridges and tunnel portals in the works, first tunnel boring machine (TBM) arrives on-site

• 2021: Construction continues, TBM called ‘Lady Eileen Hudson’ set to begin excavation

• 2025: First power generated expected

• 2026: Project expected to be completed

The project is partly funded by the Federal Government, who have committed $1.38 billion, with Snowy Hydro to fund the remaining.

Snowy 2.0 aims to help Australia convert its grid to low-emission and renewable energy, whilst creating reliable energy for major cities Melbourne and Sydney.

Ambitious projects like Snowy 2.0, show what Australia's future of embracing renewable energy can look like, providing a solution to one of the biggest hurdles the country has faced when reducing coal energy in the grid; reliability.

These projects will ensure that the country's future low-emission grid has enough storage to support Australia through any disruptions and adverse weather events.

With Australia boasting some of the largest renewable projects in the world, and the potential for offshore renewable generation given the go-ahead, the country's renewables future is bright.

UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU

23 RENEWABLES

REUSING BIOSOLIDS IN THE WASTEWATER SECTOR

24 RENEWABLES

South East Water is involved in a new wastewater management project to transform leftover biosolids headed for landfill into reusable products for farmers.

Developed by RMIT University and the first of its kind in Australia, the innovative technology uses a process called pyrolysis, whereby high temperatures destroy pathogens and microplastics in biosolids to create biochar – a carbonrich form of charcoal for use by farmers and the wider agriculture industry to improve soil health.

Currently around 30 per cent of the world’s biosolids resource is stockpiled or sent to landfill, creating an environmental challenge.

The Biosolids to Biochar project is a circular approach to wastewater management, with the new technology having the potential to eliminate landfill waste across the water industry.

South East Water is helping to deliver the Biosolids to Biochar project in partnership with RMIT University, Intelligent Water Networks and Greater Western Water, with the technology currently in trial at the Melton Recycled Water Plant in Melbourne.

WORKING WITH OTHER INDUSTRIES

Steve McGhie MP, Member for Melton representing Acting Minister for Water Richard Wynne, recently toured Greater Western Water’s Melton Recycled Water Plant for a first-hand demonstration of the new technology.

“This collaboration will enable the water industry to find alternative markets for biosolids, reducing waste going to landfill and allowing 100 per cent of products to be reused or recycled,” Mr McGhie said.

“By creating a safe product with a steady supply stream, we’re also providing our farmers and the wider

agriculture industry a product which is completely natural and can improve soil health and fertility. This project is incredibly exciting for both industries and I can’t wait to see the outcome of the trial.”

Mr McGhie said this project is an excellent example of like-minded organisations working together with a shared commitment to sustainable solutions.

“By reusing and adding value to biosolids, we recover local resources, reduce landfill and create renewable energy to reduce our greenhouse gas emissions,” he said.

South East Water's Managing Director, Lara Olsen, said that supporting these kinds of innovative emerging technologies is an important part of South East Water’s commitment towards reduced emissions and a circular economy approach towards wastewater.

“The disposal of biosolids is a challenge across the water industry. South East Water is continually looking for ways we can work with others to create innovative solutions to protect our environment and to help our customers and community.

“This technology is important as it can be scaled to any size, making it a possible solution for both urban and regional water utilities” Ms Olsen said.

TRANSITIONING TO A CIRCULAR ECONOMY

Associate Professor, Kalpit Shah, Deputy Director (Academic) of the ARC Training Centre for Transformation of Australia’s Biosolids Resource, RMIT University, said that developing new ways to squeeze the full value

from waste resources is critical in our transition to a circular economy. He said the Training Centre is thrilled this Australian-first technology has reached full trial stage.

“At the heart of RMIT research are our strong partnerships with industry, and we hope this collaborative trial will enable us to accelerate the translation of our innovation into new homegrown technologies that advance sustainability and make a real impact in water and agriculture,” Professor Shah said.

Maree Lang, Managing Director Greater Western Water said that she is delighted that Greater Western Water is also a part of this project.

“With a growing customer base and one of the largest service regions in Victoria, it’s so important that we find ways to add even more value to the work that we do. This project is an excellent example of like-minded organisations working together with a shared commitment to sustainable solutions,” Ms Lang said.

“By reusing and adding value to biosolids, we recover local resources, reduce landfill and create renewable energy to reduce our greenhouse gas emissions.”

Dean Barnett, Program Director, Intelligent Water Networks (IWN), said IWN is also excited to be part of this innovative technology trial – turning a waste product into a usable resource, which meets its objective of a circular economy for its members and the broader water industry.

The next stage of the trial will involve scaling up the technology, with a dedicated unit in place at a Water Recycling Plant (WRP) over a longer period of time.

UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU

25 RENEWABLES

MINDING THE CITIZEN-UTILITY GAP

When it comes to sustainability, how often do citizens feel connected, obliged or responsible?

Not so long ago, sustainability was seen by many as a peripheral ‘green’ issue, hardly central to our lives. However, that mindset has been changing. Increasingly, people, communities, businesses and governments are choosing to address and adapt to a range of disruptive forces which are now bringing the impacts of mankind’s effect on our planet’s delicate ecosystem to the fore. This is where utilities and policymakers can make a difference and forge deep, empowering relationships with citizens.

At the helm of the sustainability movement are citizens. The traditional views of one-way delivery of services are transforming to a different form of relationship based on engagement and empowerment, bringing both of the key players in the race to net zero, from backstage to front and centre. Utilities are finding new ways to connect and collaborate to better manage precious resources.

At Smart Energy Water (SEW) we make the case for a fully integrated sustainability model through new digital tools to help address the citizen experience gap.

CITIZEN EDUCATION A PRECURSOR TO ENGAGEMENT

Raising awareness and sensitizing citizens around the sustainable development goals remains a critical precursor to their engagement and collective participation. As primary agents of their own development and wellbeing, the engagement and participation of citizens and communitylevel actors is invaluable and can be leveraged for greater action, monitoring, and impact. To save energy and water, utilities need to build on awareness and identify programs meant to promote truly sustainable outcomes. With digital tools and smart platforms enabling two-way communication, citizens can start to feel motivated and encouraged to co-innovate.

ENGAGING CITIZENS ON THEIR OWN TERMS

Engaging citizens as primary change agents enables the development of communities and makes these citizens,

their communities and cities, ‘smart’ across a range of factors. Utilities and governments are starting to encourage ownership of goals, connect citizens with actionable insights for their everyday living, and empower them to hold their governments and utilities accountable to their responsibilities and obligations.

Now, to better manage energy and water, utilities can engage citizens with personalized one-to-one conversations, consistent omni-channel experience, self-service through mobile and web, and get smarter with AI-powered conversational bots and analytics. The utility experience can morph into an everyday ‘living’ experience with people managing their homes, offices, vehicles etc.

EMPOWERING CITIZENS ANYTIME ANYWHERE

Digital is the backbone for the modern-day citizen experience, with smart cities, e-mobility, smart homes and beyond. With intelligent technologies, it has become easier to perfect self-service and communication, in addition to simplifying utilities’ work.

By embracing cloud, AI/ML, mobility, advanced analytics etc. utility providers are set to easily become more resilient and adaptive. The agile innovation comes with leveraging the digital-first approach, vitally important to stay relevant in the current ecosystem. These systemic changes empower the citizens to do more, saving energy and water proactively.

We have begun these journeys with Australian and New Zealand utilities. We’re bringing innovation that’s helping utilities leverage digital tools to transform its customer experience, empowering connected citizen journeys. Utilities are finding it cost and time effective to uplift and execute their engagement strategy by adopting SEW’s Smart Customer Mobile (SCM®) digital CX platform.

It has provided them with an easy and secure way to manage accounts, track usage, get real-time notifications, collect payments, reward sustainable behaviour, support capital works and connections processes, and enable rich personalised experiences for different customer segments. The intuitive UI/UX, offered on mobile apps and the web along with comprehensive prebuilt use-cases, have helped utilities elevate the experiences of both the utility personnel and end consumers.

About Smart Energy Water Smart Energy Water, with its innovative and industry-leading cloud platforms, delivers the best Digital Customer Experiences (CX) and Workforce Experiences (WX), powered by AI, ML, and IoT Analytics to the global energy and water providers. For more information, please visit www.sew.ai.

UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU 26

RENEWABLES | Sponsored editorial

Engage. Empower. Educate.

Engage. Empower. Educate.

Connecting People with Energy and Water Providers

Connecting People with Energy and Water Providers

Powered by AI/ML/IoT

Powered by AI/ML/IoT

Meet Smart Energy Water

Meet Smart Energy Water

Smart Energy Water with its innovative and industry-leading cloud platforms aim to deliver the best Digital Customer Experiences (CX) and Mobile Workforce Experiences (WX), powered by AI, ML and IoT Analytics (IX) to global energy and water providers . We partner with utilities to deliver solutions that are easy-to-use, integrate seamlessly with utility systems, and help build a strong technology foundation that allows utilities to become future-ready, by harnessing the power of digital technologies.

Smart Energy Water with its innovative and industry-leading cloud platforms aim to deliver the best Digital Customer Experiences (CX) and Mobile Workforce Experiences (WX), powered by AI, ML and IoT Analytics (IX) to global energy and water providers . We partner with utilities to deliver solutions that are easy-to-use, integrate seamlessly with utility systems, and help build a strong technology foundation that allows utilities to become future-ready, by harnessing the power of digital technologies.

Our Products

Our Products

Our innovative platforms help our utility clients engage and empower customers, reduce cost to serve, enable business growth and drive operational excellence.

Our innovative platforms help our utility clients engage and empower customers, reduce cost to serve, enable business growth and drive operational excellence.

#1 Digital Customer Experience (CX) Platform (SCM )

(SCM )

#1 Digital Customer Experience (CX) Platform

• Energy Efficiency & Water Conservation

• Energy Efficiency & Water Conservation

• Billing & Payments

• Billing & Payments

• Outages & Service Requests

• Outages & Service Requests

• Electric Vehicle & Smart Home

• Electric Vehicle & Smart Home

• Usage & Comparison

• Usage & Comparison

• Preference & Notification Centre

• Preference & Notification Centre

• Advanced CRM & Marketing Cloud

• Advanced CRM & Marketing Cloud

• Smart Messaging & Chatbots

• Smart Messaging & Chatbots

• AI powered Customer Service

• AI powered Customer Service

#1 Digital Workforce Experience (WX) Platform

#1 Digital Workforce Experience (WX) Platform

• Work Order Mgmt.

• Work Order Mgmt.

• Auto Scheduling & Dispatching

• Auto Scheduling & Dispatching

• Assets & Inventory Mgmt.

• Assets & Inventory Mgmt.

• Training & Learning Mgmt.

• Training & Learning Mgmt.

• Online & Offline mode

• Online & Offline mode

• Safety & Compliance

• Safety & Compliance

• Damage Assessment

• Damage Assessment

• Operational AI & Analytics

• Operational AI & Analytics

• GPS Route Tracking & Optimization

• GPS Route Tracking & Optimization

#1 Leader in Customer Experience Solutions for Utilities

#1 Leader in Customer Experience Solutions for Utilities

Want to know more about our platforms? Our industry experts are here to help.

Want to know more about our platforms? Our industry experts are here to help.

Write to us at info@sew.ai

Write to us at info@sew.ai

AI/ML/IoT Analytics (IX) Platform

AI/ML/IoT Analytics (IX) Platform

• AI powered Customer insights

• AI powered Customer insights

• Energy & Water Analytics

• Energy & Water Analytics

• AI / IoT driven Use Cases

• AI / IoT driven Use Cases

• Programs & Rebates Mgmt.

• Programs & Rebates Mgmt.

• Peak Load Mgmt.

• Peak Load Mgmt.

• Complaints & Violations

• Complaints & Violations

• Leakages & Flow Analysis

• Leakages & Flow Analysis

• Micro Customer Segmentation

• Micro Customer Segmentation

• District Metering Analysis

• District Metering Analysis

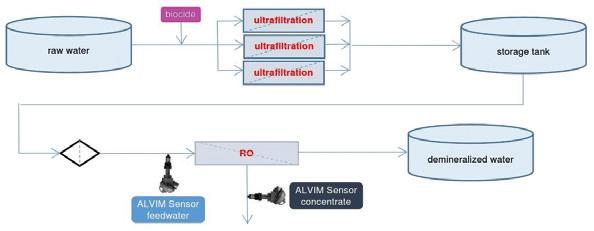

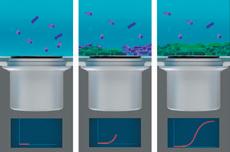

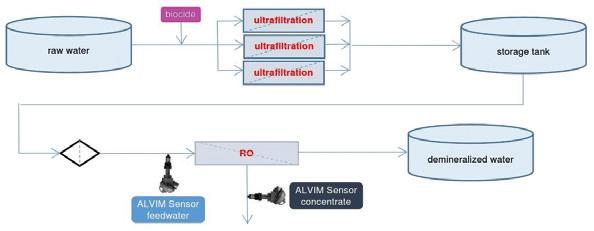

ECONOMICAL WATER TREATMENT THROUGH BLENDING

Water conducts and controls industrial processes in industries such as manufacturing and energy generation as well as in heating, ventilation and air-conditioning applications. Before it can be used, it has to be processed appropriately. One technique that is often used consists of blending raw water with processed water until the required quality is achieved, directly in the end user’s plant.

Two basic techniques are used for blending: proportional regulation and qualitative regulation. The type of treatment required determines which technique is best suited in any given case. This depends on the industry and the application concerned. Cooling towers and plant for ventilation technology (AC re-cooling) often require that the degree of hardness, the electrical conductivity, or the sulphate and chloride content be reduced. For irrigation systems in plant cultivation, the salt content is an important factor that needs to be measured to prevent substrate salinisation.

THE WATER TREATMENT TECHNIQUE DETERMINES

THE BLENDING PRINCIPLE

Where reverse osmosis is used to extract salts from water, what results is pure water known as the permeate, and because relatively few ions remain, it conducts practically no electricity. The salt content of blended water can then be determined very accurately by means of a conductivity measurement.

On the other hand, if an ion exchanger is used, knowing the conductivity is of no help because ions are simply ‘exchanged’, the conductivity remains almost the same. In such cases an alternative is needed – if possible, this may be simple proportional blending.

To produce blended water with a particular degree of hardness, both techniques require the raw water quality to remain essentially constant. However, if the raw water

hardness varies, then a combination of proportional regulation and qualitative regulation is needed.

In all cases, the regulation must be carried out exactly and rapidly, and even where boundary conditions change (e.g. variable flow rates), the quality of the blended water must meet the requirements as closely as possible to ensure constant production conditions.

A PRACTICAL BLENDING SOLUTION

Whether the raw water quality is constant or varies –modified blending principles are used. Therefore, the most practical solution consists of stand-alone operation that saves the plant operator from having to intervene in existing plant processes.

Bürkert Fluid Control Systems supply modular blending units that can deal with practically all usage scenarios that may arise. This is where the user profits from a broad product portfolio of components that are designed to work perfectly with each other. Analogue and digital interfaces are available if communication with the process is required.

FAST, ON-SITE INSTALLATION

The pre-assembled module with two infeed connectors and a blended water connector only has to be integrated into the existing water supply, or integrated into the water treatment plant as a pre-wired component solution. The values for the required quality or the blending proportions are pre-set, so the blending unit can be put into operation immediately.

RENEWABLES UTILITY • NOVEMBER 2021 WWW.UTILITYMAGAZINE.COM.AU 28

Industrial water prefer to partner with Bürkert

Using digital technology, Bürkert’s positioners and process controllers have pushed through the barriers of traditional solutions. These positioners are available for linear as well as quarter turn valves (and other pneumatic devices).

Request a quote

Type 8805

Consists of a quarter turn valve (ball or butterfly) and a pneumatic rotary actuator. Accurate end position setting, high flow values, high medium pressures and long lifecycle for reliability.

A RENEWABLE ENERGY FUTURE REQUIRES LICENCE TO OPERATE

by Kate Healey, Transmission Advocate, RE-Alliance

There’s been much talk of the role Renewable Energy Zones will play in Australia’s energy future. But before we can plan and build this critical infrastructure, there is a critical need to work with regional landowners to gain land access and ensure that the critical licence to operate is achieved.

LAND ACCESS

30

Renewable Energy Zones (REZs) will be the power stations of the future. Distributed over a region, solar, wind, pumped hydro and battery projects will collectively become the equivalent of conventional power plants, a reliable source of power that will feed into the National Electricity Market (NEM).

There is keen interest from investors and renewable energy developers to develop new projects in REZs. Recently, the NSW Government opened EOIs for renewable investors wanting to join the New England Renewable Energy Zone, set to host 8GW in total when complete. They received a massive 34GW of project proposals from over 80 proponents.

In light of the IPCC’s recent report, the urgent need for the successful roll out of the REZs has never been clearer. So with State Governments and renewable energy proponents onside, what is causing delay?

THREE BARRIERS TO OVERCOME

To carry the power to our homes, schools and workplaces, we need to build clean energy transmission lines that will connect the REZs to the existing grid. In its 2020 Integrated System Plan (ISP), the Australian Energy Market Operator (AEMO) identified 18 transmission projects worth billions of dollars to “plug in” REZs and transition our grid. So how can we expedite the roll out of this crucial new infrastructure?

There are three hurdles we must overcome.

The first hurdle is the regulatory arrangements for transmission lines. The Regulatory Investment Test for Transmission (RIT-T) is a cost benefit analysis which only includes energy market costs and benefits. It does not include the social or environmental costs borne by local communities. An ongoing problem is the failure of governments to agree to include climate change within the National Electricity Objective which governs the RIT-T.

The RIT-T process takes several years to approve a new project and slows down the pace of the urgent transmission roll out. Frustrated with the length of the process, the NSW and Victorian governments have passed legislation that will allow them to develop their own regulatory investment test in place of the RIT-T. If federal regulators want to retain their role in grid approval, they will need to hurry to outdo the states in developing a system fit for the task ahead.

The second hurdle is cost. Many of the ISP’s 18 projects will cost upwards of a billion dollars, in some cases several billion dollars. Current arrangements see the cost of new transmission lines recovered from all energy consumers through our energy bills. Another option, proposed by Craig Memery of the Public Interest Advocacy Centre (PIAC), is that renewable energy developers who benefit from new transmission lines should shoulder a portion of the cost. Government funding can and should also play a role.

State and Federal governments, as well as the Clean Energy Finance Corporation, have all recently committed hundreds of millions to support the planning and delivery of transmission projects.

The third hurdle is social licence. It's a tall order for farmers and landholders to accept large transmission towers being proposed on their properties. Landholders have little negotiating power in determining route-selection processes. Existing easement payments for landholders are one-off, unlike the annual payments received by wind turbine hosts, which can often be in the tens of thousands of dollars annually, and can be a meaningful droughtproofing mechanism for farmers living through increasingly unpredictable seasons.

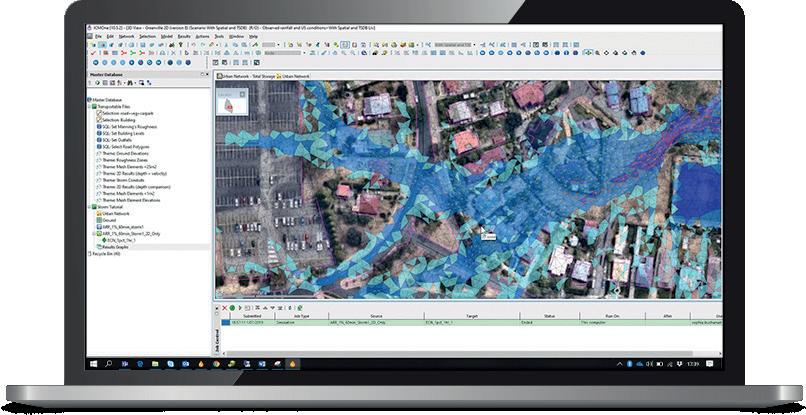

COMMUNITY CONSULTATION AND ENGAGEMENT