11 minute read

DECADES OF EJECTION

Wastech’s Clearline trailers incorporate high tensile steel plates in the body, reducing tare weight and increasing payloads.

Decades of waste ejection

WITH 10 CLEARLINE WASTE TRAILERS DELIVERED AND NINE MORE ON THE WAY, A LONG-TIME INDUSTRY STALWART OUTLINES HIS 20-YEAR RELATIONSHIP WITH WASTECH ENGINEERING.

In 2017-2018, Victoria’s waste and resource recovery sector managed 12 per cent more material than the previous year, at over 14.4 million tonnes. The state achieved a 69 per cent diversion rate, recovering almost 10 million tonnes of material.

Despite high diversion rates, as with anywhere, Victoria still has to manage large volumes of waste that can’t be recycled. This reality is well known to council waste transfer station managers, with one such operator telling Waste Management Review that his transfer station moves 4500 tonnes of waste each month, equating to roughly 225 trailer loads.

The transfer station he runs, which was built in 1980, underwent a major refurbishment in 2000 with the intention of streamlining the delivery of essential waste management services to the Melbourne suburb’s residents.

Prior to the refurbishment, the council representative says the transfer station moved waste with

trucks and dog trailers, with a mechanical system moving small containers in and out of compactors.

While state-of-the-art when built, he explains that the process had become cumbersome and inefficient.

The transfer station’s compactors are now lifted off the ground, allowing semi-trailers to drive up for filling. To achieve effective movement rates, council put a tender out for new custom-built trailers to fit the compactors.

Through this, the council’s 20year relationship with Wastech Engineering was born, with a total of 10 trailers sold and nine more on the way.

“Wastech are the only ones building this type of trailer, and they have a very clean design with lots of space on the side for advertising recycling and other council programs,” the representative says.

Wastech’s Clearline rolled wall body design provides durability and integral strength to withstand the high compaction forces in waste transfer station applications. Built to withstand high piercing forces during compaction, the council’s trailers are used to manage green, hard and municipal solid waste.

The Wastech designed trailers incorporate high tensile steel plates in the body, reducing tare weight and increasing payloads.

Additionally, the smooth internal design, along with the hydraulic eject blade, safely and efficiently pushes waste loads out automatically.

While many councils now use this type of hydraulic eject blade system, the representative explains that he and Wastech lead the charge over 20 years ago.

“The reason for the change was the old system was falling apart, so we came up with this new concept. It allows us to transport 20 plus tonnes of waste per load, while providing ease of operation,” he says.

The representative adds that he had a lot of issues with the old containers, which had very large doors and required drivers to leave the hooktruck cabin for unloading.

“The ground in winter is very uneven and boggy, so we wanted to move away from that for safety reasons,” he says.

“Plus, when drivers have to get out to manually open the doors, it creates issues with injuries – when the wind catches a door of that weight it becomes like a sail.”

During the initial collaborative design process, the council representative requested that everything be hydraulically operated, meaning the ejection process can be completed from inside the cabin.

“Drivers just flick a switch and the waste is pushed out of the truck,” he says.

“This is much safer for our drivers and is also a quicker way to move a large amount of waste at any one time. Wastech’s trailers have effectively streamlined our process.”

Additionally, the representative highlights the trailer’s longevity, with his first set now in its 20th year.

“You won’t find any other council or transport business that’s still using 20-year-old trailers for this type of work,” he says.

“They’re well-made, have good design and have been very well maintained.”

Major repairs and refurbishments have been undertaken by Wastech, with maintenance done in-house at the council workshop.

While the trailers longevity is striking, the representative says they are now coming to the end of their life, which was the motivation behind ordering a set of nine new trailers from Wastech.

“Wastech do an outstanding job. If we have a problem – like a trailer goes down – they will fix it straight away,” he says.

“We can’t afford to have trailers off the road as any downtime makes it difficult to complete our tasks, so it’s very important for us to have that good working relationship with Wastech.”

Contact – Wastech Engineering

P 1800 465 465 P info@wastech.com.au W www.wastech.com.au

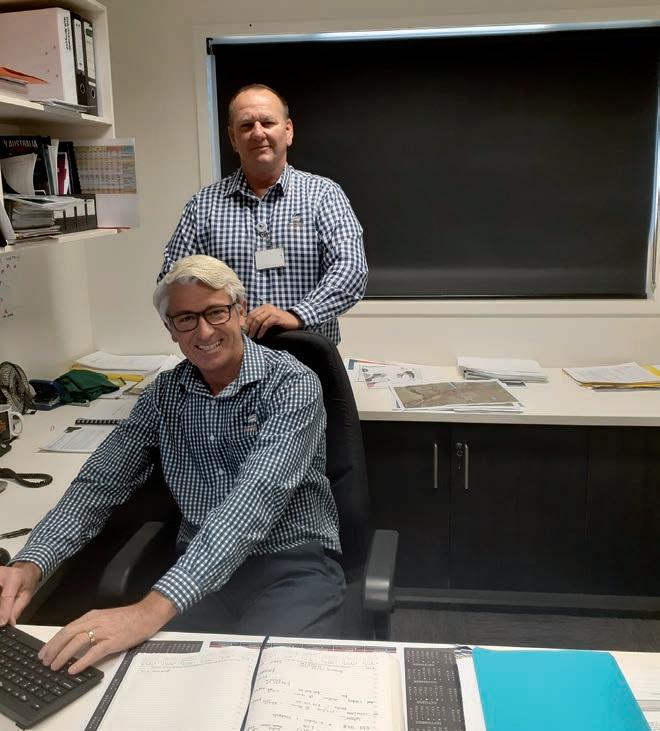

Wastech worked with a Melbourne council to develop a hydraulic transport solution for its waste transfer station.

Digital transition

AUSTRALASIAN WASTE AND RECYCLING EXPO PRODUCT MANAGER MELISSA CLENDINEN OUTLINES WHAT TO EXPECT FROM THE REIMAGINED ONLINE EVENT.

While COVID-19 and associated movement restrictions continues to disrupt traditional approaches to business and social interaction, the team behind the Australasian Waste and Recycling Expo (AWRE) is committed to providing an essential platform for the waste and resource recovery sector to grow.

After much consideration and consulting with industry, AWRE 2020 has been reimagined as an interactive online event.

Set to run 25-26 November, the online format is a first for AWRE, with the team dedicated to providing a platform for industry to connect, do business and navigate the transition to ‘COVID normal.’

Melissa Clendinen, AWRE Product Manager, says the AWRE team believes that making the transition

Attendees will have the opportunity to put questions to speakers via a live Q&A. to online will offer all attendees the opportunity to be involved in an environment where they feel safe.

“All of the AWRE partners have been extremely supportive from the outset as well, which made the decision to run a digital event over the existing two days of the show even easier and the obvious step to take,” she says.

AWRE’s traditional education program over the past 10 years has been a popular focus for visitors, with 54 per cent of 2019 attendees coming to attend the speaker series and 74 per cent of them walking away highly satisfied. According to Clendinen, the 2020 online event will be no different.

“The quality of all of our presentations is extremely high and it is great to have our association partners onboard to assist in the curation,” Clendinen says.

The event will be run with major partner the NSW EPA, with support from a number of key industry bodies including the National Waste and Recycling Industry Council, Waste Contractors and Recyclers Association, Australian Institute of Packaging, Australian Packaging Covenant Organisation, MRA Consulting Group and the Australia New Zealand Recycling Platform.

Kathy Giunta, NSW EPA Circular Economy Programs Director, says the authority is proud to continue its major partnership with AWRE, as it has done over the event’s 10-year history.

“In these changing times it is wise to go online and continue to provide the waste and recycling community with an accessible event,” she says.

MRA Consulting Group Managing Director Mike Ritchie will act as host over the two days, moderating 20 plus keynote speakers across 10 sessions.

NSW Environment Minister Matt Kean will open the event, providing attendees with an overview of the state’s 20-year waste strategy.

Featured sessions include a deep dive into the NSW Circular Economy Program, a discussion on trending topics such as waste-to-energy, e-waste and its development in the industry, the implementation of sustainable packaging guidelines, the Recycling Modernisation Fund, and an outline of the food waste and compostable guidelines. Additionally, AWRE will provide meeting hubs for attendees to network.

“Attendees will have the opportunity to put their questions to the speakers via a live Q&A – exactly as you would have at the traditional AWRE,” Clendinen says.

“We’re also very excited to introduce the inclusion of a live exhibition, product launches and technology and solutions

AWRE 2020 aims to provide visitors and exhibitors with an experience as close to a live exhibition as possible.

demonstrations over the two days.”

Exhibitors will be showcasing their solutions to the online audience through 15-minute sessions, with attendees able to book appointments to speak with the exhibitors firsthand.

AWRE 2020 aims to provide visitors and exhibitors with an experience as close to a live exhibition as possible, Clendinen says. She adds that registration for the event will be opening soon.

“We’re committed to bringing the industry a platform where they can re-connect and navigate the rapidly growing and changing landscape of waste and recycling,” she says. To register online go to awre.com.au

We are recruiting for tomorrow

To register your interest email memberservices@wriq.com.au

The role of reuse within the circular economy

SHIFTING OUR UNDERSTANDING OF CHARITABLE DONATIONS FROM RECYCLING TO REUSE WILL HELP EDUCATE CONSUMERS ON THE FUNDAMENTAL TENETS OF CIRCULARITY, WRITES OMER SOKER, CHARITABLE RECYCLING AUSTRALIA CEO.

Before we examine the role of reuse as a cornerstone of the circular economy, I have an admission.

I’m confused about the commonly accepted definitions of the words waste and recycling, and the limiting narratives this creates.

For example, if someone throws a brand new $2800 Louis Vuitton handbag into the red bin, is it waste?

What if they donate it to a charity shop or put it in a charity donation bin? Is this waste or is it a resource?

And then, when a lucky shopper buys it for $280 in an op shop, are they ‘recycling’, or is this actually ‘reuse’ in all its glory?

At Charitable Recycling Australia – where we champion the circular economy for a sustainable environment and an equitable society – we have a view on this.

Firstly, our credentials. We’ve been operating on circular economy principals for over a hundred years, since the first charity shop was opened in 1880 under the then progressive name of a recycling depot. Now, in 2020, our collective network of 3000 plus charity and social enterprise

Omer Soker, Charitable Recycling Australia CEO, says reuse creates up to 195 jobs per 10,000 tonnes of material.

retailers reuse 285 million products a year, divert 642,000 tonnes from landfill and generate $550 million in revenue to support the most vulnerable people in Australia. What we do, mostly, is reuse.

These 285 million products – clothes, toys and homewares – are simply reused again and again by different people to maximise the life of these precious resources.

75,000 tonnes of these resources are also exported to developing countries, where they are also reused – as the clothes, toys and homewares they are.

And yet, so many people define what we do in terms of waste or recycling. And that needs to change.

In our National Textiles Reuse Policy recommendations to the Federal Government, we’ve asked them to redefine donation behaviour to charities

Charitable Recycling Australia’s network of 3000 plus charity and social enterprise retailers generate $550 million in revenue to support the most vulnerable people in Australia.

as reuse instead of recycling. We’ve asked them to re-define donations to charity as a resource and not accept anyone suggesting this is waste.

Why? Because reuse is the cornerstone of any circular economy policy. And proper definitions of reuse and resources will help educate consumers and businesses on the fundamental tenets of circularity, just as defaulting from waste to recycling is simply an extension of limiting linear thinking. What you measure improves, so lets measure reuse and resources.

Doesn’t it make sense to reuse products over and over again to extract the maximum value out of them, before we then break them down to their constituent parts and recycle them?

Reuse also creates up to 195 jobs per 10,000 tonnes, which makes it up to twenty times as effective in job creation than recycling. Did I mention the half a billion reuse dollars raised towards social welfare programs?

Recycling is absolutely essential. We must create the infrastructure and end markets to make this a profitable business for all the smart companies out there creating technology solutions. Charities are 100 per cent supportive and ready to collaborate collectively on raw material, sorting and logistics capabilities.

We want to see more, better and cost-efficient recycling. All we’re asking is that reuse is prioritised first – so everyone gets the maximum value – before we invest to accelerate recycling at end-of-life. A perfect example of this is the Federal Government’s National Product Stewardship Investment Fund. It’s a brilliant and much needed initiative. However, if a product stewardship scheme misses the reuse opportunity by jumping straight to recycling, we all lose. Especially on products like clothes that can and should be reused.

That’s why we’ve launched our National Textiles Reuse Policy. To call for a government endorsed, multistakeholder policy to get clothes out of landfill – where the national resource recovery rate is 12 per cent – and into the charitable sector system where our resource recovery rates can reach 8090 per cent.

Charitable Recycling Australia is also investing directly in quality research and data-led recommendations. We have commissioned a major research project to identify the triple bottom line impact of the charitable reuse and recycling sector using clothes as a case study. In addition to this, we are the Partner Investigator in a Monash University led ARC Grant project to measure the benefits of charitable reuse in the circular economy, together with the Department of Environment and Science, Green Industries South Australia and Sustainability Victoria.

So, please let’s get clear on definitions, because language matters. And because the transition to a circular economy is driven by behaviour change. So, let’s change what we define and what we measure – and start talking reuse.