West Coast Edition For: WA, OR, and CA Vol. 12, No. 6 DEC / JAN ‘22-’23 Cover Story Pages 20-21 a2zMFG.com Precise Components Made to Specification, Faster, More Precise, to ISO-9001 Standards!

GROOVING THREADING PARTING BORING TURNING FACE GROOVING CUSTOM TOOLING FORM TOOLING MILL TOOLING Follow us on: 888-THINBIT | WWW.THINBIT.COM

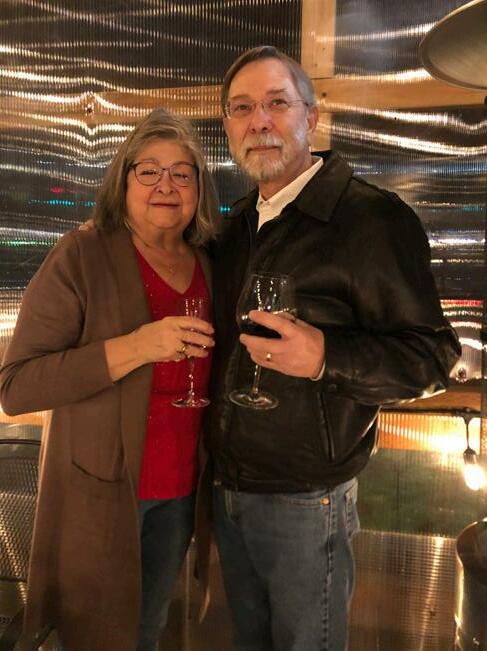

If it’s one thing the pandemic taught us, is that life is too short.We find ourselves in a position where we want more time with our people; the wife, friends, kids, and grandkids. Americans are looking for non-traditional jobs in the work place and for more flex and freedom to live their moments free from the 8-hour workday.

With manufacturers facing a skills gap that could result in 2.1 million unfilled jobs by 2030, retaining qualified and effective employees is critical. But how do manufacturing leaders keep great employees on staff?

The main reasons that employees remain at a company are enjoyment of the work (83%) and stability/job security (79%). Other contributors to satisfaction include the family friendliness of the employer and the way the job fits into their lifestyles outside of work.

•Feeling good: Employees who felt valued by their companies had significant more motivation and job satisfaction.

•Nearly all workers who said they felt valued by their employers (97%) described themselves as highly motivated and satisfied with their jobs. Nearly as many (96%) would recommend their company to others as a good place to work.

•Meanwhile, among employees who did not feel valued by their employers, those numbers dropped to 45% and 25%, respectively.

•Fair treatment:Workers who felt that their employers treated them fairly were also less likely to be stressed out on a typical workday (at only 16%). But among workers who said they were treated unfairly, 68% felt stressed on a regular basis.

Securing a college degree is traditionally seen as the surest way to obtain a good-paying job. Statistics also bear out the fact that the best opportunities await those with higher education. Anyone can look up the numbers and confirm this workplace reality. In 2018, for example, 83% of the United States population between the ages of 25 and 64 with a bachelor’s degree or higher were employed. Meanwhile, among the civilian population in the same age group with high school as their highest educational attainment, only 68.8% were in the labor force (Ma et al., 2019).

Despite the staggering difference between the employment status of college degree holders and non-college-educated workers, the unemployment rate for the latter has been steadily decreasing in the past nine years. According to the U.S. Bureau of Labor Statistics, the unemployment rate for individual’s age 25 or older who have a high school diploma had gone down to 3.7% in 2019 from 10.3% in 2010. A major driving force behind the decrease in the unemployment rate of non-degree holders is the growing number of companies that recognize the value of experience and hands-on skills instead of just focusing on educational attainment, especially if there are good character and professional references.

I encourage you all to look at the ways we do business as open mindedly as possible. This is how we should all staff our businesses and continue to grow.

Thank you all for your continued support of our regional manufacturing magazines!

Merry Christmas and Happy Prosperous New Year!

Kim Carpenter

Western Sintering Compressing Powdered Metal to Perfection, Sintering, and Finished Machining.

Announcements/Releases ................... 6-14

Feature Articles ........................... 1,10, 20-21 Buyers Guide Equipment Services ..... 32-38 Buyers Guide Processes ...................... 39-45 Card Gallery ........................................ 32-45

Index Of Advertisers ............................... 46

Editorial .................................. Throughout

Published by: A2Z Manufacturing West Coast

PUBLISHERS/EDITORS

Kim Carpenter & Linda Daly Kim@A2ZManufacturing.com

Mail Address: 1538 E. La Vieve Ln. Tempe AZ 85284

Telephone: (480) 773-3239 Website: www.A2ZManufacturing.com E-mail:Kim@A2ZManufacturing.com

CONTRIBUTORS

Linda Daly, Eugene Wirth, Stephen Hannemann, Hugh Taylor

Published bi-monthly to keep precision manufacturers abreast of news, contracts, trends, and to supply a viable supplier source for the industry.

Circulation: A2Z Manufacturing West Coast maintains a master list of over 14,000 decision makers consisting of fortune 1000 companies, small manufacturing companies, engineering firms, DOD & Scientific Lab facilities, machine shops, fab-shops, and secondary source businesses. It has an estimated pass on readership of more than 25,000 people. The majority of our readers are based in CA, OR, WA area!

Advertising Rates have remained the same since 1999, deadlines and mechanical requirements furnished on our website at: www.a2zManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

Cover

A2Z MANUFACTURING WEST COAST • 4 • DEC - JAN ‘22-’23

Editor’s

Corner

Boeing Gets Needed Max Extension Added To Spending Bill

The Boeing Renton factory rolled out the first 737 Max 10, the largest jet in its Max family of aircraft, in November 2019.

By Daniel McCoy

By Daniel McCoy

The Boeing Co. appears set for a year-end reprieve through Congress

that will allow it to certify its newest 737 MAX jets without costly changes.

According to a report from the Seattle Times, legislators early Tuesday agreed on a spending bill that included an amendment to the certification process that Boeing (NYSE: BA) has lobbied hard for throughout the second half of the year.

Tucked into the 4,155-page, $1.7 billion omnibus spending bill —

which also prevents a government shutdown with expected final approval before midnight on Friday — is a provision that allows the Federal Aviation Administration to give the manufacturer a pass on a Dec. 27 certification deadline that has loomed over the coming MAX 10 and MAX 7 narrow-body jets.

Boeing had previously raised the possibility of canceling one or both aircraft programs without an extension, an outcome that would have a substantial impact on future production work in Wichita.

Locally based Spirit AeroSystems Inc. (NYSE: SPR) builds the complete fuselage and other components on the existing MAX 8 and MAX 9 models, helping make the 737 the most important individual aircraft program to the Wichita economy.

Spirit is the city’s largest employer, with around 11,000 local workers.

Boeing said at the end of the third quarter that it had orders for around 600 MAX 10s and around 250 MAX 7s in its firm backlog.

The previous deadline stemmed from the Aircraft Safety and Certification Reform Act passed in 2020 in the wake of deadly MAX crashes in 2018 and 2019. That legislation set new cockpit-alerting equipment requirements for jets certified past the end of 2022.

Those crashes of two 737 MAX 8 aircraft just five months apart killed all 346 people aboard the jets and led to a 20-month safety grounding of the jet.

A2Z MANUFACTURING WEST COAST • 5 • DEC - JAN ‘22-’23

Announcements & Releases

Name Change From Allied Tool & Die Co., LLC To Atd Precision Manufacturing LLC

Hello Everyone, I am excited to announce the name change to ATD Precision Manufacturing effective January 1, 2023.

The company was founded 72 years ago by the Jordan family as a provider of tools, dies, and jigs for the aerospace industry. The original company name matched the output of the business.

In 1984 when ownership passed from the first to the second generation the focus of the company shifted to piece production and contract manufacturing. In the decades since, the capabilities of the company have grown to encompass both sheet metal fabrication and CNC machining.

In 2015 the third generation took ownership, and it was clear that both customers and vendors did not understand the breadth of our operations. Should we keep the name known for decades or change because it no longer communicates what we do?

At trade shows people invariably come up to us looking for tooling to be made or to sell us die components. We tell them “We can make tooling, but we would use it to make and sell parts. We haven’t sold a die set to a customer in over 15 years.” This begets the real question of how many people don’t approach us because of our name when we could be the vendor, customer, or partner they are looking for. ATD Precision Manufacturing is a name that truly represents what we do. Sheet Metal Fabrication and CNC machining of parts for the aerospace and related industries.

The management team and ownership of the company continues to be the same. The tax ID and bank accounts are also all staying the same. We are very proud of our workforce, culture, and the quality parts produced that have long made us a great company to associate with.

Change summary effective January 1, 2023:

New name: ATD Precision Manufacturing LLC

New website: atdpmfg.com (please check it out to learn more about us)

New email suffix: all employee emails will have the suffix @alliedtool. com change to @atdpmfg.com.

Regards, Bill Jordan CEO (3rd generation)

Star Metal Fluids Adds A New Sales Professionnal To Their Already Great Arsenal

We are excited to announce the addition of Lucas Cassil to the Star Metal Fluids team! Lucas has been hired on as an Account Manager for our Utah branch and will support accounts located between Salt Lake City and Gunnison.

Lucas is a Utah native and enjoys mountain biking and baseball.

Please feel free to reach out and help us welcome Lucas to the industry at: l_cassil@metalfluids.com.

Epic Finance – Focusing on the Buyer AND Seller

Epic Finance (Golden, CO) is taking a modern approach to the machine tool financing industry. Led by Chris Frans, CLFP (President), Epic’s goal is to provide the most optimal customer service to both the customer and the distributor or OEM that is selling the equipment, all while providing aggressively low rates.

Chris Frans has been in the equipment finance industry for a decade and has provided financing to thousands of customers around the US. He has a great understanding of the manufacturing industry, the equipment, and what is needed to meet each individual customer’s needs.

Please reach out to Chris with any financing inquiries that you might have. Email him at: chris@epicapprovals.com.

A2Z MANUFACTURING WEST COAST • 6 • DEC - JAN ‘22-’23

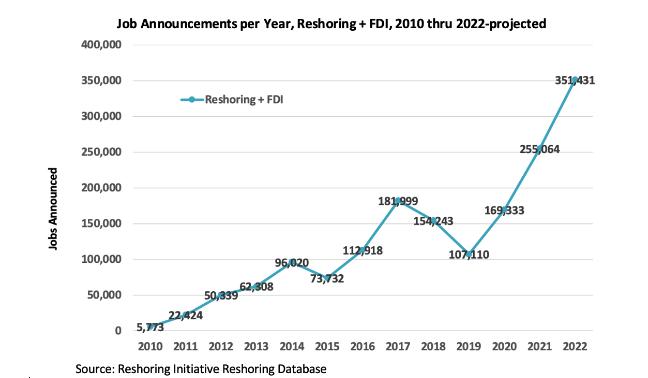

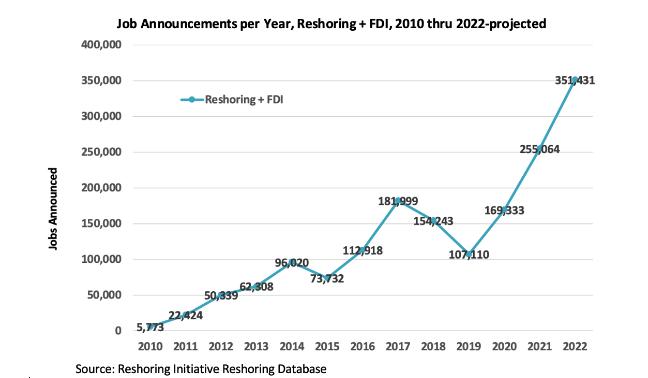

Reshoring and FDI Set New Quarterly Record, on Track for A Record-Breaking 350K Jobs per Year

Q3 data is in, and it shows reshoring + FDI job announcements were at the highest rate ever recorded, about 15% above Q1 2022, the previous record. 4Q 2022 looks strong enough to reach a 2022 total of 350,000+ jobs. Top takeaways:

Projected 350k reshoring jobs announced for 2022.

EV battery investments make Electrical Equipment the top industry.

Private and federal entities are investing in skilled workforce, addressing one of the leading barriers to success.

With the Inflation Reduction Act, Chips Act and Infrastructure Bill, the U.S. Government is finally getting started on an industrial policy. A more comprehensive plan is needed.

investments, a 25% lower USD and retention of immediate expensing of capital investments.

“The current actions and momentum are a great start. A true industrial policy would accelerate the trend and increase U.S. manufacturing by 40%, 5 million jobs. Reshoring will reduce the trade and budget deficits and make the U.S. safer, more self-reliant and resilient,” said Harry Moser, Founder and President of the Reshoring Initiative.

Alt Text Read more at Reshoring Initiative 2022 Q3 Data Report: Reshoring and FDI on Track for Another RecordBreakingYear: 350K Jobs.

About the Report

The Reshoring Initiative’s 2022 Q3 Data Report contains data on U.S. reshoring and FDI by companies that have shifted production or sourcing from offshore to the United States. The report includes projections and analysis for 2022 full year and beyond.

“We publish this data semiannually to show companies that their peers are successfully reshoring and that they should reevaluate their sourcing and siting decisions,” said Harry Moser, founder and president of the Reshoring Initiative. “With 5 million manufacturing jobs still offshore, as measured by our $1.1 trillion/year goods trade deficit, there is potential for much more growth. We also call on the administration and Congress to enact policy changes to make the United States competitive again.”

About the Reshoring Initiative

In 2021 the private and federal push for domestic supply of essential goods propelled reshoring and foreign direct investment (FDI) job announcements to a record high. Projections from Reshoring Initiative 2022 Q3 data show reshoring and FDI continuing these gains.The current 2022 projection of jobs announced is around 350,000 - another record, up from 260,000 in 2021. If the projection is achieved, 2022 will bring the total jobs announced since 2010 to over 1.6 million.

Supply chain gaps and the need for greater self-sufficiency set the stage for the current upward trend in reshoring.The risks of Taiwan-China conflict or China voluntarily decoupling are focusing those concerns. Destabilizing geo-political and climate forces have brought to light our vulnerabilities and the need to address them. The White House responded with the Inflation Reduction Act, Chips Act and Infrastructure Bill, offering some direction and financial security to the companies and industries intent on filling the gaps. These government actions are necessary in the short run but are not sufficient since the U.S. non competitive cost structure is not being improved. A true industrial policy would level the cost playing field via comprehensive actions such as massive skilled workforce

A 55-year manufacturing industry veteran and retired President of GF Machining Solutions, Harry Moser founded the Reshoring Initiative to move lost jobs back to the U.S. For his efforts with the Reshoring Initiative, he was named to the Industry Week and Association for Manufacturing Excellence (AME) Halls of Fame. Additional information on the Reshoring Initiative and its many sponsoring associations and companies is available at www.reshorenow.org. The Reshoring Initiative provides the media with custom analyses of specific regions or industries. Contact Harry Moser to inquire.

A2Z MANUFACTURING WEST COAST • 7 • DEC - JAN ‘22-’23

MEDIA CONTACTS: Harry

President Reshoring Initiative®

or dgs Marketing Engineers® Chuck

Director

bates@dgsmarketing.com

Moser

847.867.1144 Harry.Moser@reshorenow.org

Bates, Public Relations

317.813.2230

The Shape Of Things To Come: How Innovation Defines The Next Chapter In GE History

Tomas Kellner

Tomas Kellner

Starting with Thomas Edison, “for almost 130 years, GE has leveraged its DNA of innovation to build a world that works — solving the biggest challenges through our technological expertise, leadership and global reach,” Larry Culp, GE chairman and CEO, told investors. “Operating each of these businesses as independent companies will enable them to

realize their full potential, driving longterm growth and value for all stakeholders.”

What does that future look like? GE engineers and scientists are already working on it. It could have planes powered by sustainable aviation fuel and hybrid and electric engines, precision diagnosis and treatments aided by cloud-enabled software solutions and AI-powered medical devices, and a digital grid that will seamlessly integrate electricity from many sources and protect itself and heal quickly after a storm.

GE says the plan to separate the companies will help speed up the process. “We have a responsibility to move with speed to shape the future of flight, advance precision health and lead the energy transition,” Culp said.

GE Healthcare, the first business set to leave the GE fold, in early 2023, is a good example. It is blending the physical and digital worlds to improve diagnostics and help make precision healthcare commonplace. “With four million installations worldwide, serving more than one billion patients and executing more than two billion procedures per year, GE is at the nexus of key care pathways,” Culp said.

Since March 2020, some 65 of the hospitals in Oregon — approximately 90% of the state’s beds — used an early version of the system to help maximize the state’s major lifesaving resources, including ICUs, ventilators, and negative-pressure beds.That system corralled 4.2 million data points per day from the state’s hospital networks, updating once every five minutes with fresh intelligence about admissions, patient movements, nursing flows, ventilator usage and bed requests.

But Oregon and GE aren’t finished. By the end of this year, through a strategic partnership with Apprise Health Insights, the data and analytics subsidiary of the Oregon Association of Hospitals and Health Systems, an expanded version of the system is expected to cover a wider range of information: emergency department, advanced ventilators and life support systems.

The statewide expansion, the first in the nation, is being funded in part by a federal grant provided by the Office of the Assistant Secretary for Preparedness and Response and the U.S. Department of Health & Human Services to Oregon’s hospital association. “Our system is designed to scale regionally, nationally and beyond if needed with the appropriate

A2Z MANUFACTURING WEST COAST • 8 • DEC - JAN ‘22-’23

CNC AND MANUAL MACHINERY SINCE 1979 New - Used -Appraisals - Auctions Our Showroom At: 3305 Edison Way, Fremont, CA 94538 Is Open Monday - Friday From 8am To 5pm BOB KROHA ROB KROHA CONTACT US TODAY: 510-249-1000, PERMACH.COM

controls in place,” says Jeff Terry, who leads the Clinical Command Centers unit at GE Healthcare.

These capacity systems are just one example of how GE‘s command center software platform is helping caregivers orchestrate daily care.

This was the third healthcare deal announced since Culp became GE chairman and CEO, following the acquisitions of Zionexa and Prismatic Sensors, which developed Deep Silicon detectors for photon counting computed tomography (CT).

Photon counting CT is poised to further improve the clinical capabilities of traditional CT, including the visualization of minute details of organ structures, improved tissue characterization, more accurate material density measurement and lower radiation dose.

Zionexa is a privately held French and U.S. company developing innovative PET (positron emission tomography) tracers used in the diagnosis of cancer and neurological diseases.

Then there’s the tectonic shift underway in where care is delivered, with patients increasingly routed to the lowest acuity setting possible, aiming to improve hospital capacity, productivity and outcomes. This further distributes already fragmented patient data, leading healthcare payers and providers to place more importance on the integration of clinical data to simplify and standardize how care is delivered.

Addressing this need, GE Healthcare’s Edison Digital Health Platform aggregates clinical data from various sources, including clinical devices, allowing Edison applications to generate insights by applying advanced analytics and AI across the care continuum of screening, diagnosis, therapy and monitoring of disease.These Edison applications range from analyzing high-res brain scans or a stroke, and detecting cancers, to helping doctors predict which patients should be prioritized.

tomorrow, delivering on the future of healthcare is about enabling precision health: integrated, efficient and highly personalized care,” Culp said. “Making this a reality requires merging clinical medicine and data science by applying advanced analytics and AI across every possible point of the patient journey. GE is one of the few companies with the reach, capabilities and relationships to do this.”

The second business GE plans to spin off, in early 2024, will be a combination of GE Power, GE Renewable Energy and GE Digital. Culp says that the new company “will play a critical role in solving the trilemma of affordable, reliable and sustainable energy. This business possesses a unique offering, with some of the world’s most powerful wind turbines and most efficient gas turbines as well as technology to modernize and digitize the grid. And the energy transition represents the largest

A2Z MANUFACTURING WEST COAST • 9 • DEC - JAN ‘22-’23

“Today and

opportunity

digital with vertical solutions in grid and power D o os a n M a c h i n e To o l s i s n ow The lineup of ver tic al machining center s at DN Solutions is ver satile, compac t and born to make incredible par t s for as long as you need them to Get your ideal VMC , then get ready for the ver tic al leap. Talk to your loc al DN dis tributor or visit dn-solutions com DEM: entr y-level par t producer S VM: swif t and s trong DNM: global best seller BVM: premium powerhouse MILL S & THRILL S The versatile VMC lineup at DN Solutions is enough to get anyone excited. www.ellisontechnologies.com | SALES (866) 567-2580 SERVICE (800) 994-0146 PARTS (888) 207-2787 Continued P age 10

for

generation.”

Some of those offerings are already here. GE’s Haliade-X offshore wind turbine was engineered to evolve with demand, and evolve it has. The initial model produced 12 megawatts — and even at that level, a single rotation of the machine’s blades could generate enough power to supply the equivalent of one U.K. household for two days. But when GE Renewable Energy engineers tested a Haliade-X prototype, they found it could be improved to produce 13 MW. Now an even more powerful version will be rated at 14 MW — and this machine was selected for Dogger Bank C, the 1.2-gigawatt third phase of the U.K.’s Dogger Bank wind farm. The Haliade-X will also power Vineyard Wind, an 800-MW farm off the coast of Massachusetts.

GE is also helping utilities bring more renewables online. For more than a century, the electrical grid was a one-way street, with current traveling from power plants to consumers. But two decades into the 21st century, it’s rapidly becoming more like a busy highway, with lots of on-ramps and off-ramps.The rise of the renewables age, with tech like rooftop solar, storage batteries and electric vehicles, is adding a new layer of complexity for grid operators.

Vera Silva, chief

technology officer of GE Renewable Energy’s Grid Solutions unit, says utilities must “operate the grid like a Swiss clock” — and that her business is there to help: “If you think about the transition toward decarbonization, how do you convert that ambitious goal, in a way that keeps the grid rock-solid all the time but deals with this rate of change?”

The answer is innovative hardware in combination with digital technology. That’s why Silva’s business is working to solve the challenge in partnership with GE Digital, GE’s software and analytics arm. During everyday operations, the grid generates a mammoth amount of data that can be mined for insights. Past outages and weather data, for instance, can help locate future spots of vulnerability during a storm — so utilities are prepared to speed up repairs and minimize downtime. The ultimate goal? An autonomous grid that can not only fix but predict problems on its own. “Our vision is that we will provide the technologies that enable the grid to continue to be highly reliable, but also resilient — so that it actually becomes even better-performing, more energy-efficient and renewables-centric,” said Patrick Byrne, GE senior vice president and CEO of GE Digital and the onshore unit of GE Renewable Energy. “That’s a tremendous technology opportunity and challenge for us to take [on].”

GE’s innovative gas turbines are helping, too. With its recent wildfires, California is no stranger to the effects of climate change. As the state transitions to more renewable energy, it is getting help from GE Gas Power’s aeroderivative gas turbines. These turbines are modified jet engines, they run on natural gas and they can generate power on demand within minutes. “We are helping the state of California meet its renewables and carbon targets, while providing reliability to the electrical system

A2Z MANUFACTURING WEST COAST • 10 • DEC - JAN ‘22-’23

when renewable resources are not sufficient to meet the state’s electricity demand,” said Eric Gray, Americas CEO at GE Gas Power.

GE has the largest installed fleet of gas turbines in the world, which — through the pathways provided by pre-combustion lower-carbon fuels, including hydrogen and post-combustion carbon capture — can play a meaningful role in combating climate change beginning immediately. In early July, New York State decided to bring green hydrogen into the state’s portfolio of sustainable energy solutions — and GE is helping the state to make it happen.This fall, the Brentwood Power Station on Long Island began a demonstration project to test the feasibility of running on a blend of natural gas and carbon-free green hydrogen, which uses renewable electricity to split water molecules and produce oxygen and hydrogen.

GE Gas Power, whose combustion turbine powers the station, is providing the blending technology and helping execute the project. And this GE unit already has a leadership role in the use of hydrogen in gas turbines. GE turbines have logged more than eight million operating hours running on blends of hydrogen, and power facilities that will go online in Ohio and Australia will use blends of hydrogen and natural gas. Hydrogen could help remove millions of tons of CO2 from the atmosphere by the end of the decade.

In October, the Air Transport Action Group declared the aviation industry’s commitment to a goal of net-zero carbon emissions by 2050. The group’s members include GE Aviation, which invested $1.8 billion in 2020 in aviation research and development, including new advanced materials and technologies that can help cut fuel consumption and even enable hybrid electric design. In June, CFM International, a 50-50 joint company between GE and Safran Aircraft Engines, announced the launch of the Revolutionary Innovation for Sustainable Engines (RISE) Program to demonstrate advanced technologies for the next generation of engines, which could ultimately lead to engines that would use 20% less fuel and produce 20% fewer CO2 emissions than the most efficient jet engines built today. “This technology development program demonstrates the commitment GE and Safran share for achieving ambitious goals for a more

sustainable future,” says Travis Harper, GE product manager on the CFM RISE Program.

Another opportunity involves SAF. By switching from petroleum to SAF, the aviation industry could reduce its carbon contribution from fuel by up to 80%, factoring in the entire life cycle of the fuel. One person who knows a lot about this task is Gurhan Andac, who as GE Aviation’s engineering leader for aviation fuels and additives is working on biofuels and synthetic fuels for engines. “Sustainable fuel is not a research project that we are doing on the side,” Andac says. “It is happening. We are flying today with SAF blends.”

“Stepping back, at GE, we’ve always had immense pride in building a world that works,” Culp said. “The momentum we have built puts us in a position of strength to take this exciting next step in GE’s transformation, enabling each of our businesses realize their full potential.”

A2Z MANUFACTURING WEST COAST • 11 • DEC - JAN ‘22-’23

Flatline Fabrication Inc. THERE’S NO JOB WE CAN’T TACKLE, NO MATERIAL TOO TOUGH!!! Laser cutting – Forming – Certified Welding – Finishing – Kitting & Flat Pack, Full Assembly & Installation Contact us today 503-477 7566, www.flatlinefabrication.com Production and Custom Fabrication WE MAKE MAGIC!

Your partner for innovative manufacturing

California Tool Targets the Aerospace Industry with Diamond Coated Cutting Tools

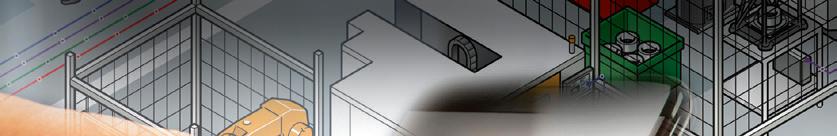

California Tool is reaping the benefits of technology with a robotic loader that uses ANCA software to incorporate different diameters and collet sizes, reducing the need for individual setups.

California Tool has been making custom carbide cutting tools that are specifically designed for their customers’ needs for over 30 years. Cutting tools come in many different shapes and sizes, but you can also have the same tool with many different geometrical features, including hook, helix, and clearance angles.That is why California Tool has remained outside of the catalogue market, a strategy that has born them great success.

Jordan Armitage, Manufacturing Manager at California Tool and Cutter said: “We make high performance cutting tools made to print, and we also

offer regrinding services. The main market that we service is aerospace, we do tailor to automotive cutting tools and medical cutting tools.” “We’re not trying to compete with catalogue companies, we are trying to diversify and operate as a high end, high performance house that can grind anything that you can dream of.We also understand it is vital for our customers to have their request turned around quickly. A lot of companies will say they can do it, but they take 16 weeks to make it. We’re looking to doing it in six days, it’s a huge difference.”

“Our regrinding services, although small in scope and hyper-focused, are a cost-effective way for the customer to extend the life of a tool. For some of our customers their tools have a lot of intricacy. There is tribal knowledge that is built in to these cutting tools, and it’s taken a long time to develop what works for the customer. From our end we need to regrind the cutting tools to a high level of complexity to meet the demands of our customers intricate geometries. We have an in-house CAD system that enables us to generate prints. We can reverse engineer some of their prints, or we can make custom-tailored tools to their process.”

“What I see personally as a fantastic opportunity in the industry are diamond coated cutting tools. A diamond coated tool will offer longevity, repeatability and predictability. That means customers will know exactly how long the cutting tool will last and they can predict their machine process based on that. With the materials being used to build airplanes today, the manufacturing process uses a significant amount of carbon fibre, and you need diamond coated tools to cut it.”

A2Z MANUFACTURING WEST COAST • 12 • DEC - JAN ‘22-’23 The factory of the future, today Smart. Connected. Data-driven. 4.0—whatever mission you choose, Renishaw is your source for achieving the highest level of precision and productivity in your manufacturing environment. From industrial metrology hardware to smartphone apps and interfaces, our automated and intelligent process control technologies collect data and respond in real time to keep your factory at its peak. The day to optimize your process, reduce costs, and increase throughput, is today! www.renishaw.com usa@renishaw.com Renishaw Inc., West Dundee, IL 60118 © 2022 Renishaw Inc. All rights reserved.

SmartAdHalfPageA2ZJuly2022.indd 1 10/19/22 11:27 AM

“There’s a specific kind of grade of carbide required to make the diamond coated tools and we stock all that in-house to enable us to move quickly on our customer inquiries. We manufacture any cutting tool to specification and send it out for diamond coating.”

Technology gives a marketing edge

“I would say that California Tool is keen to invest in the latest and greatest technology and we have banked on ANCA to be able to bring the latest and greatest to our doorstep.”

“Our facilities are an important aspect of how we market ourselves as a lot of our customers want to come in and vet us, they want to see our production floor. I believe that this collaboration that we have between Zoller and ANCA is just a fantastic way to showcase how we make cutting tools.”

Getting diameters down to the millionths

“A lot of the cutting tools that are coming in nowadays are very complex. The Zoller Genius and the whole team at Zoller have really helped us as a business to be more repetitive and to be more competitive in the marketplace because we’re able to give customers exactly what they’re asking for, with diameters down to the millionths and with cutting geometries that are plus or minus one degree.”

Software to automate manufacturing

“The ANCA machines have everything that a grinding house needs and you can even get beyond that. There’s just so much to the software that a lot of people don’t even tap into. The RoboMate software for example, allows you to incorporate all different kinds of diameters and even collet sizes. It makes it easy for the guys to be able to set up jobs -- we’re constantly doing setup so to be able to scramble between all our different setups and still use a robot is pretty fantastic. I think that speaks volumes to the software that’s involved.”

For further information, please contact: Russell Riddiford

President, ANCA Machine Tools Russell.Riddiford@anca.com 248-926-4466

Johanna Boland

PR and Communications Manager, ANCA M: +61 407799779

Johanna.Boland@anca.com

Jordan Armitage

Owner, California Tool jordan@caltoolgrind.com 909-595-1334

* Prototyping * 5 Axis Machining * Design Consulting * 3D Printing * Low-Limited Production womodesigns.com Call Today: 253 735-6707 info@womodesigns.com A2Z MANUFACTURING WEST COAST • 13 • DEC - JAN ‘22-’23

New Technology Functions for the SINUMERIK ONE CNC Simplify Operation and Increase Productivity

• Y-turning and Advanced Rapid Movement for greater machine tool productivity, up to 10% faster machining

• Reduced Dynamic Mode reduces wear and increases availability

• End-to-end keyboard and machine control panel portfolio from 15 to 24 inches

With the new system software SINUMERIK V6.20, there are new technology functions for SINUMERIK ONE that simplify machine tool operation, reduce machine wear and increase manufacturing productivity. With these developments, Siemens is demonstrating how the powerful SINUMERIK control system can be optimally used for digital transformation in a highly productive, flexible and modular way.

With the new Y-turning function, SINUMERIK ONE can be used for machines that turn from the Y-axis, enabling up to 3-times the feed rate, resulting in increased productivity. New tool types were created for this purpose and all turning functionalities and cycles were adapted for these tools.

The Advanced Rapid Movement function is also one of the innovations in this new technology. It enables time-optimized movement, which means faster movements take place between machining operations. The part program does not require a change. Overall, machining can be up to 10% faster. The function can be implemented in tandem with the machine builder.

With Reduced Dynamic Mode, there is now a CNC function that actually reduces wear on the machine and increases its availability. The Numerical Control Kernel (NCK) function enables the machine tool builder to automatically transfer the machine to reduced operation, if the axis becomes too warm.When the temp stabilizes, the machine can be returned to full load. In this way, the Reduced Dynamic Mode enables individual operation of machines in motion.

A2Z MANUFACTURING WEST COAST • 14 • DEC - JAN ‘22-’23

In the area of hardware, there are additional new innovations for the SINUMERIK ONE that are designed to simplify operation. The new keyboards and Machine Control Panels (MCPs) are now available from 15 to 24 inches to match the HMI design — and SIMATIC Industrial Thin Clients (ITCs) and industrial PCs are being launched at IMTS 2022 with increased performance and a resolution up to 1920 x 1080 pixels.

The new MCPs are also integrated in the digital twin of SINUMERIK ONE (Create and Run MyVirtual Machine), so that the appearance and operation correspond to the real CNC in every respect. In addition, the digital twin of SINUMERIK ONE has been equipped with new features that simplify engineering and work preparation. Examples of the many innovations include: the 3D option offers support for a second channel. In addition, each tool can be assigned an individual color, so that the ablated surfaces are color-coded, depending on the tool used. The integration of the STEP format is an important new feature, especially for complex geometries of the clamping in a turning operation. Collision detection now also offers extensive functionalities such as the display of all collided bodies, NC program line and more, so the cause of collisions can be quickly investigated and rectified.

Background information on SINUMERIK ONE

SINUMERIK ONE plays a central role in the transformation of machine tools in the age of Industry 4.0, outperforming previous generations of controllers in terms of PLC and CNC performance in machine operation, cutting speed, data capture and processing power. With its integrated

SIMATIC S7-1500F PLC, it offers up to 10 times faster PLC cycle times. With the SIMATIC S7-1500F PLC, SINUMERIK ONE is now fully integrated into the Siemens TIA Portal engineering framework, enabling standardization of all engineering tasks for operators of larger plants. SINUMERIK ONE is fully compatible with the previous SINUMERIK 840D sl controller generation in terms of programming and operation. This makes the changeover to SINUMERIK ONE more seamless.

With SINUMERIK ONE, Siemens offers CNC technology that easily creates and works with digital twins of machine tools. Work preparation and engineering departments can also benefit from the digital twin. Siemens offers a comprehensive user interface for SINUMERIK ONE that enables convenient, flexible and efficient operation of machine tools across all machining technologies.

Siemens will accelerate digitalization for a sustainable tomorrow by demonstrating how the enormous potential for optimized machine tools can be utilized, owing to the improvements in its digital native CNC platform, SINUMERIK ONE.

Siemens John Meyer (847) 952-4158 john.meyer@siemens.com

A2Z MANUFACTURING WEST COAST • 15 • DEC - JAN ‘22-’23

Faraday Future Says It Will Start Production Of Its Luxury Electric Car In March

2023

Faraday Future recently appointed leadership includes (from left) Matthias Ayd, global senior vice president product execution; Xuefeng Chen, global CEO; and Yun Han, chief accounting officer and interim chief financial officer.

Faraday Future recently appointed leadership includes (from left) Matthias Ayd, global senior vice president product execution; Xuefeng Chen, global CEO; and Yun Han, chief accounting officer and interim chief financial officer.

Faraday Future Intelligent Electric Inc. said it plans to start production of its FF 91 Futurist luxury electric car at the end of March 2023.

The company, which delayed production of the FF 91 earlier this year, said the vehicle is slated to come off the assembly line in early April, with deliveries before the end of April.

Faraday (Nasdaq: FFIE) said the schedule of production is subject to the timely availability of $150 million to $170 million of additional funding and stockholder approval of an authorized share increase. The company said it recently received a $30 million binding letter of intent draft from a current investor, which will go before the board for approval.

Faraday also said it continues to make progress with testing and validating the FF 91 Futurist through its Product and Technology Generation 2.0 program, which included significant upgrades of systems and core components in both the vehicle and the advanced core area consisting of internet, autonomous driving and intelligence technology.

The company previously said it completed the construction and equipment installation in vehicle assembly areas, marking six of the seven milestones that Faraday laid out in late 2021 to mark its manufacturing achievements toward the start of production, which is the seventh milestone.

“The management team at FF is committed to executing the next milestones and I’m energized by the commitment of the team,” Global Chief Executive Xuefeng Chen said in a statement. “We will utilize our capital in a disciplined manner that is focused on bringing the best product to market.”

Faraday said the FF 91 Futurist features an industry-leading 1,050 horsepower, an EPA-certified range of 381 miles, zero-to-60 mph in 2.27 seconds and a unique rear intelligent internet system.

A2Z MANUFACTURING WEST COAST • 16 • DEC - JAN ‘22-’23

We are a fullservice job shop, providing asmuch or aslittle projectinvolvement as required – from tooland die design to finishing and assembly.

Qu ali t y, Reliabili tyand Service

Precision aluminum and zincdie casting, machining and finishing. tvtdiecast.com ▼ 800 280 2278 ISO 9001:2008 Certified

Rocket Lab Sets First U.s. Rocket Launch — How To Watch

By I-Chun Chen

Rocket Lab USA Inc. is ready to launch its first Electron mission from Virginia.

“Electron is on the pad and ready to fly, but with NASA & the FAA working to close out final documentation required for launch, we’re now targeting no earlier than Sunday December 18 for our first mission from Wallops,” the company tweeted.

The mission will be Rocket Lab’s first liftoff from Launch Complex 2 at Virginia Space’s Mid-Atlantic Regional Spaceport within NASA’s Wallops Flight Facility, developed to support Electron missions from the U.S. for government and commercial customers.

The company said the launch window was set following recent progress by NASA in certifying its Autonomous Flight Termination Unit software, which is required to enable Electron launches from Virginia.

Launch Complex 2 supplements Rocket Lab’s existing site, Launch Complex 1 in New Zealand, from which 31 Electron missions have already launched.

“This extensive launch heritage already makes Electron the most frequently launched small orbital rocket globally, and now with two launch complexes combined, Rocket Lab can support more than 130 launch opportunities every year, delivering unmatched flexibility for rapid, responsive launch for government and commercial satellite operators,” Rocket Lab said on its website.

The launch pad and production complex for Rocket Lab’s large reusable Neutron launch vehicle will also be at the Mid-Atlantic Regional Spaceport.

The mission, dubbed “Virginia Is for Launch Lovers,” will deploy three satellites for radio frequency geospatial analytics provider HawkEye 360.

Rocket Lab plans to live stream the launch on its website.

A2Z MANUFACTURING WEST COAST • 17 • DEC - JAN ‘22-’23 (800) 481-6271 www.pmplating.com We Are The Noble Partner With The Personal Touch! Precious Metals Plating Co., Inc + Gold Plating + Silver Plating + Nickel Plating + Electroless Nickel Plating + Tin Plating + Heat Treat With Plate + Nadcap Approved Processes + Boeing Approved Processes + Expedited Turnaround + X-ray Fluorescence Thickness Verification + In-House Laboratory With Atomic Absorption (AA) + Expanded Capacity In Vibratory Plating

By Mary Serreze

The modification to an existing contract, announced Wednesday by the Pentagon, will support production of advanced ballistic missile subs at GDEB’s shipyards in Groton, Connecticut; North Kingstown, Rhode Island and Newport News, Virginia.

Two 560-foot Columbia class submarines — an item identified as a top procurement priority by the Navy — are already under construction by Electric Boat. The Navy plans to buy 12 such ships from the defense contractor through 2035. The company says it will deliver the lead ship in 2027.The advanced vessels will replace the Navy’s 14 Ohio class submarines as they are retired.

The Navy estimates that the first Columbia class ship will cost $15.3 billion in 2022 dollars, with subsequent ships averaging $7.4 billion each. The total cost for a dozen submarines would be $96.7 billion, which includes appropriations of $15.5 billion from 2017 to 2022.

The Congressional Budget Office has come up with estimates that are 9% greater than the Navy’s. The CBO estimates that the first Columbia class submarine would cost $16 billion, with subsequent ships costing $8.8 billion each for a total program cost of $105 billion.

Kevin Graney, the Electric Boat president, said Thursday that strategic investments in processes, procurement strategy, and industrial capacity will reduce risk and ensure that the ships are delivered on time.

“Advance procurement of long lead time materials and component

A2Z MANUFACTURING WEST COAST • 18 • DEC - JAN ‘22-’23 WWW.NORTHSOUTHMACHINERY.COM | (800) 460-9014 | CA • OR • WA • AZ • NV LEAN. MEAN. 100% GREEN! • 100% Electric Precision Press Brake • 110 US Tons x 10.2’ • EC10 Touch Screen Control (EC20 Optional) • CNC X-Axis, R-Axis, Y1/Y2-Axis • Manual Z1/Z2-Axis (CNC Optional) • Mechanical Tool Clamping (Hydraulic Optional) • Tool Lighting on Front • 2x Front Support Arms • 2x Backgauge Stops • Installation & Training Included SAFANDARLEY E-BRAKE STANDARD FEATURES:

Electric Boat Gains $5.1B Navy Contract To Build 5 Columbia-Class Submarines A rendering of the Columbia class submarine that General Dynamics Electric Boat will deliver to the U.S. Navy.

General Dynamics Electric Boat has been awarded another $5.1 billion to build five Columbia class nuclear submarines for the U.S. Navy.

construction is critical to the program, and the strategic investments in the development and expansion of the Submarine Industrial Base will help stabilize and grow the supply chain, which increases manufacturing capacity, reduces risk and ultimately drives timely delivery of submarines to the Navy,” Graney said in a statement.

The news comes as significant federal legislation promises to boost the nation’s defense spending. U.S. Sen. Jack Reed, chair of the Armed Services Committee, said last Wednesday that the $857.9 billion National Defense Authorization Act would provide $14.7 billion to support submarine production by General Dynamics.

Textron Aviation Ceo Joins High-Profile Industry Committee For

2023

By Daniel McCoy

By Daniel McCoy

Ron Draper, CEO of Textron Aviation, is joining the executive committee of the General Aviation Manufacturers Association next year.

The leader of Wichita’s largest general aviation company will help guide the General Aviation Manufacturers Association in 2023.

Ron Draper, CEO of Textron Aviation, was this week announced as one of the members of GAMA’s 13-person leadership team for its executive committee next year.

Those members were elected by the association’s board of directors at its fall meeting.

According to a press release from GAMA, which includes the full list of committee members, Draper will serve as chair of the flight operations policy committee. While Draper has been on GAMA’s board since 2020, this will be his first role on the executive committee.

Draper has been CEO of the local Textron Inc. (NYSE:TXT) division since 2018.

Textron Aviation employs around 10,000 people in Wichita, where it builds Beechcraft and Cessna aircraft.

Another committee member of note to local industry observers is David Coleal. Now CEO of supply chain management firm Incora, Coleal is best-known in Wichita for his time with Bombardier and Spirit AeroSystems Inc.

Coleal led Bombardier’s local Learjet facility from 2008 to 2011, followed by four years as an executive at Spirit (NYSE: SPR) and a return to Bombardier in Canada until 2020.

A2Z MANUFACTURING WEST COAST • 19 • DEC - JAN ‘22-’23

Western

Sintering Automation of

Metal Components

at Their Finest!

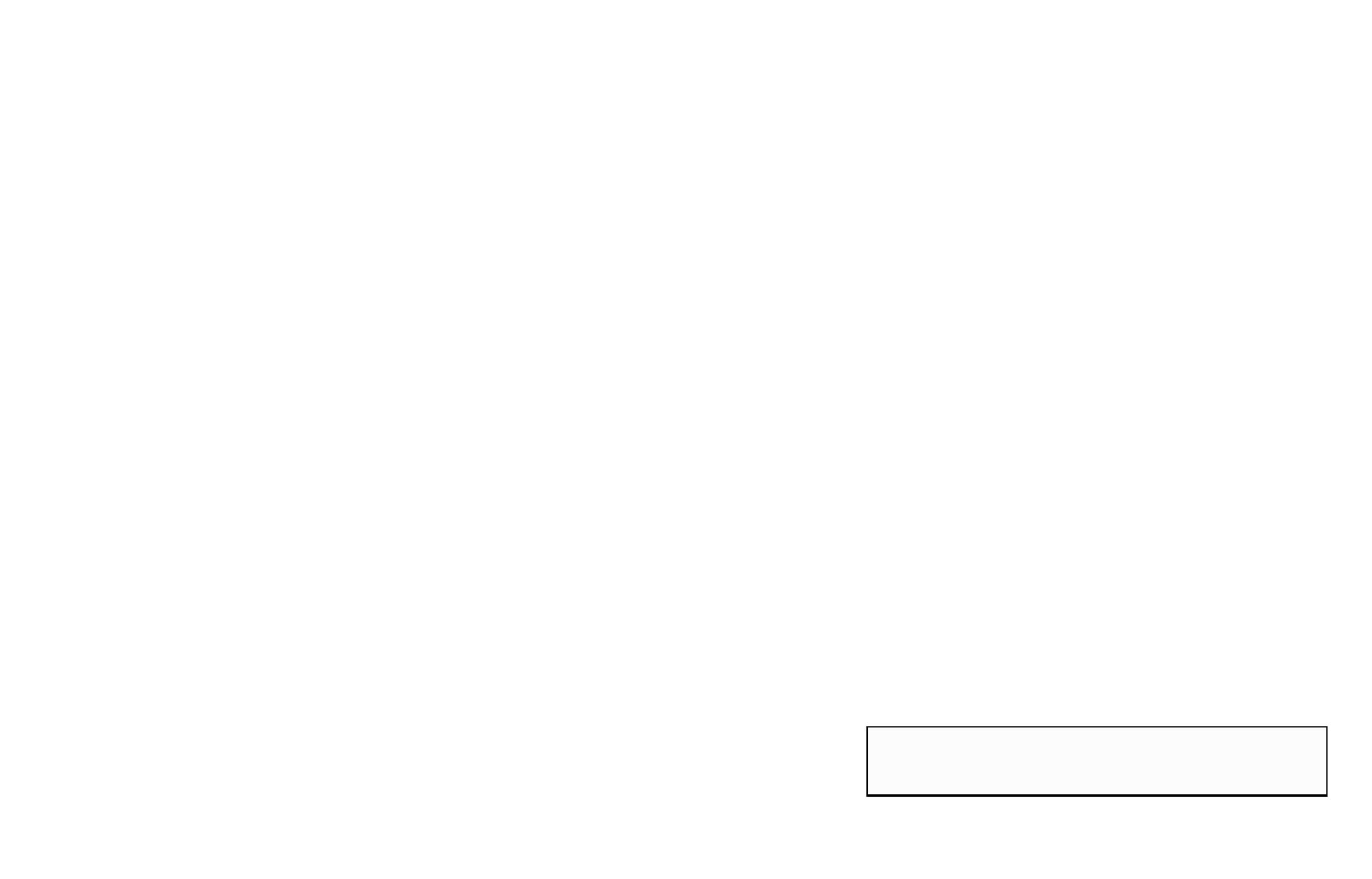

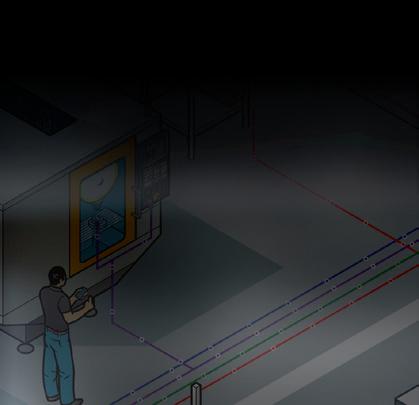

When you want to compete in manufacturing, the first thing you must do is figure out how to automate your processes.

Repeatable processing of any kind needs the help of robotics that are programmed to do the mundane tasks humans tire of. Initially the human sets up the job, programs the robot, proves the process and perfects it. Then, it’s time to turn it over to the one that never tires, never needs breaks, never goes to the bathroom, doesn’t call in sick, doesn’t go on vacations, and will run through the night until you show back up in the morning, rested and ready to start another project. That’s right, it’s our buddy the never tiring robot.

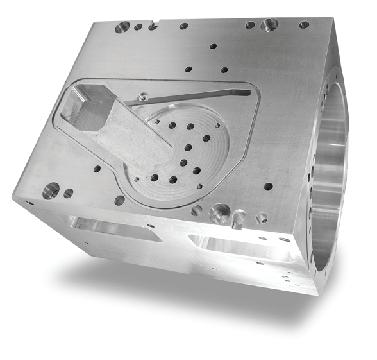

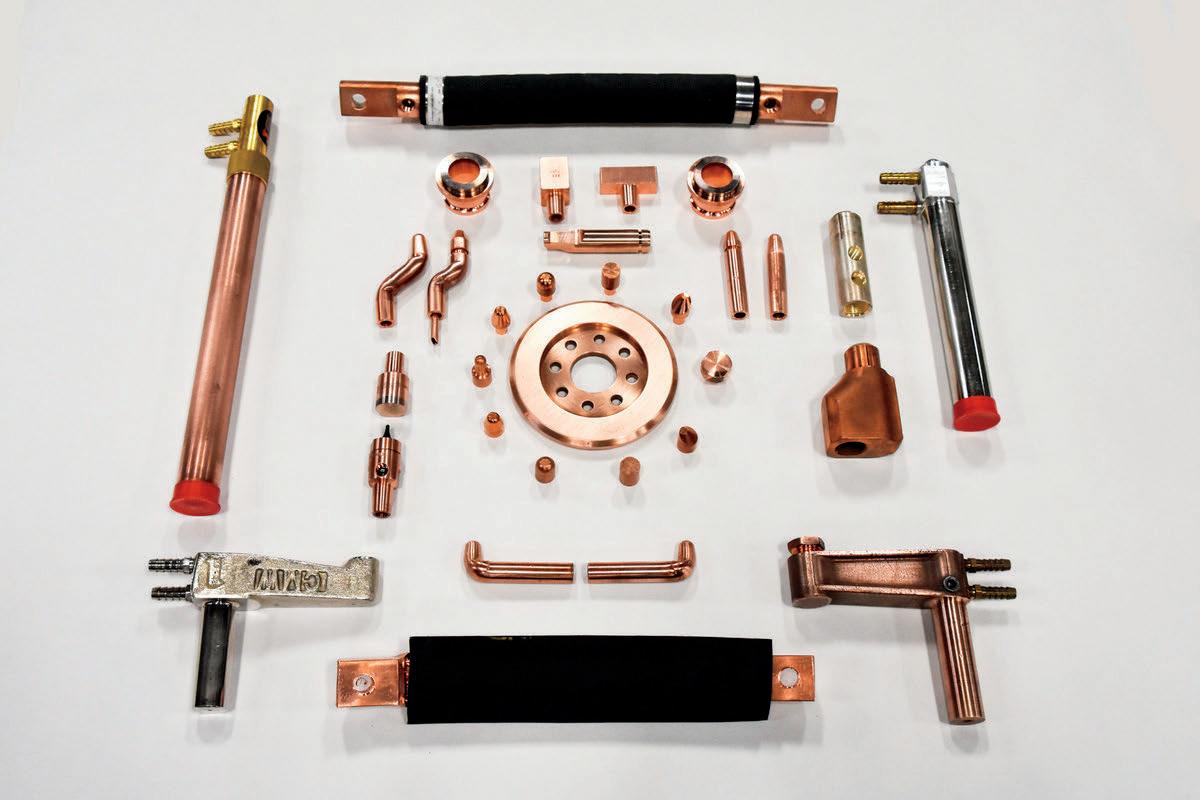

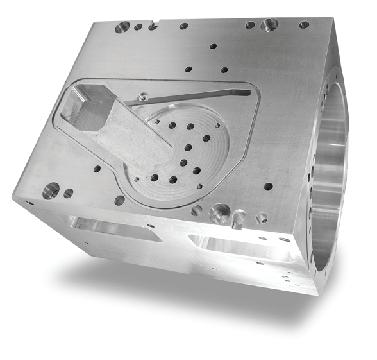

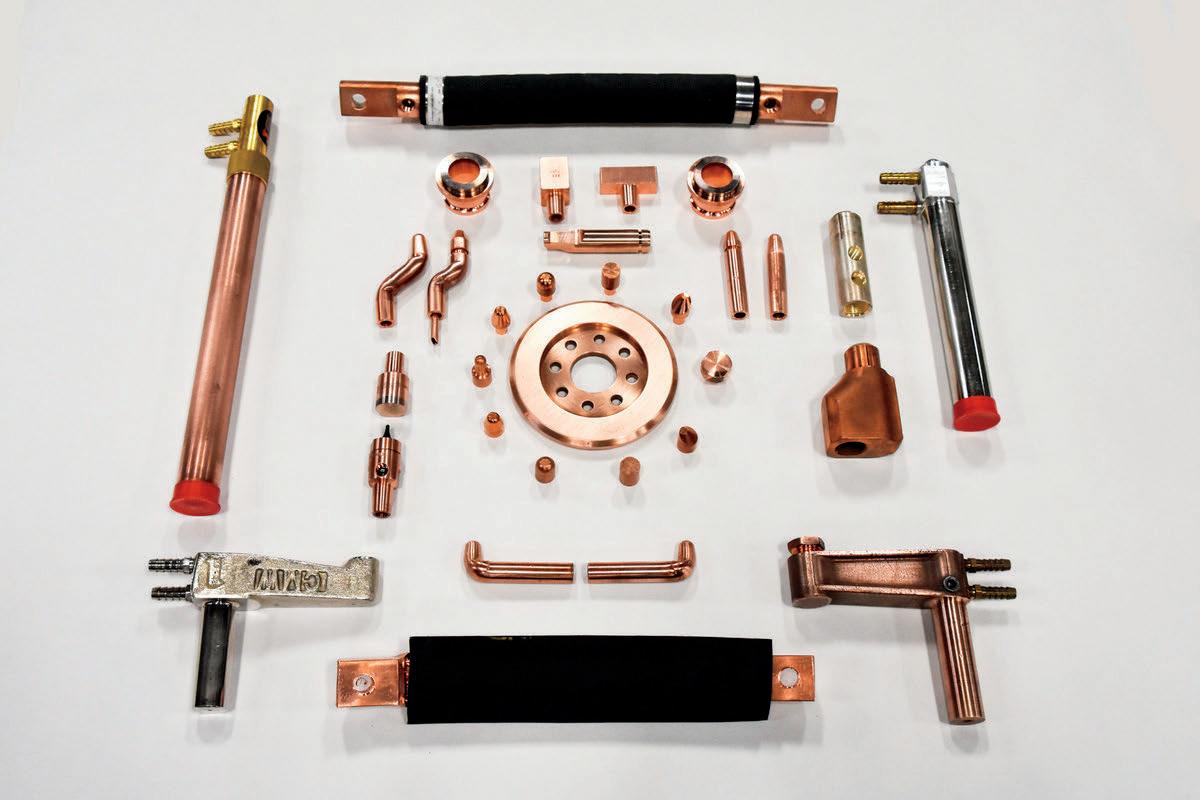

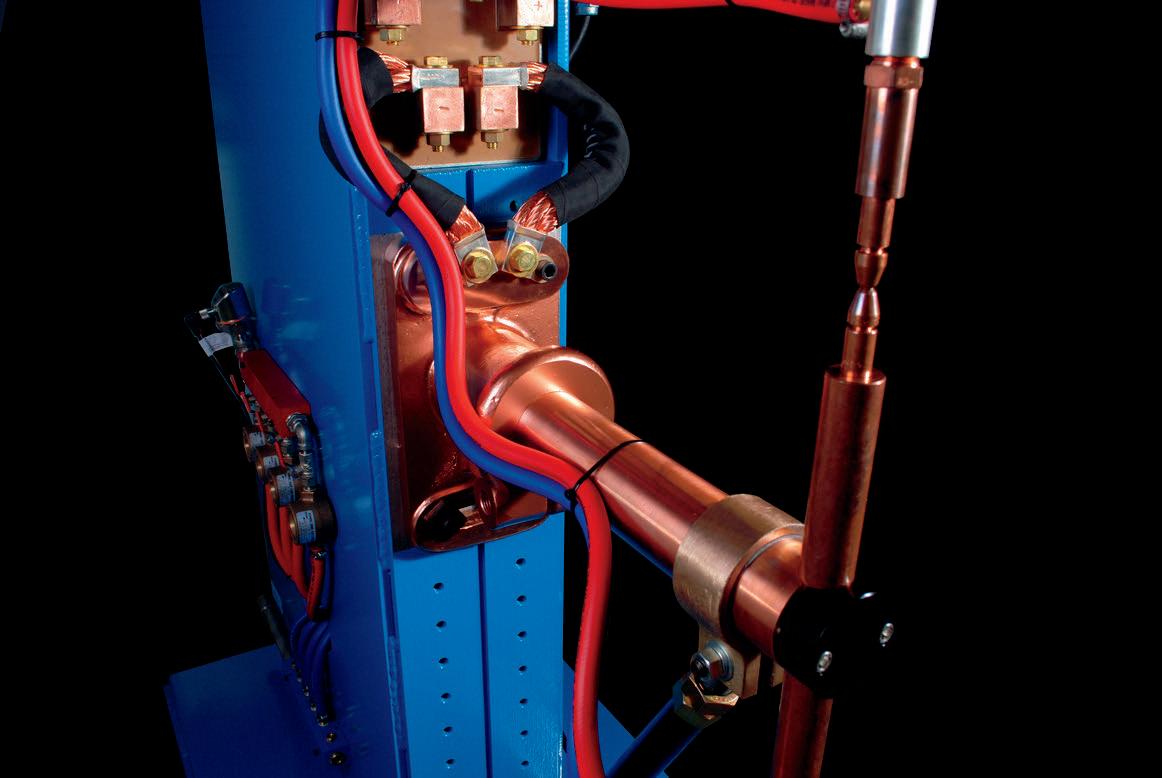

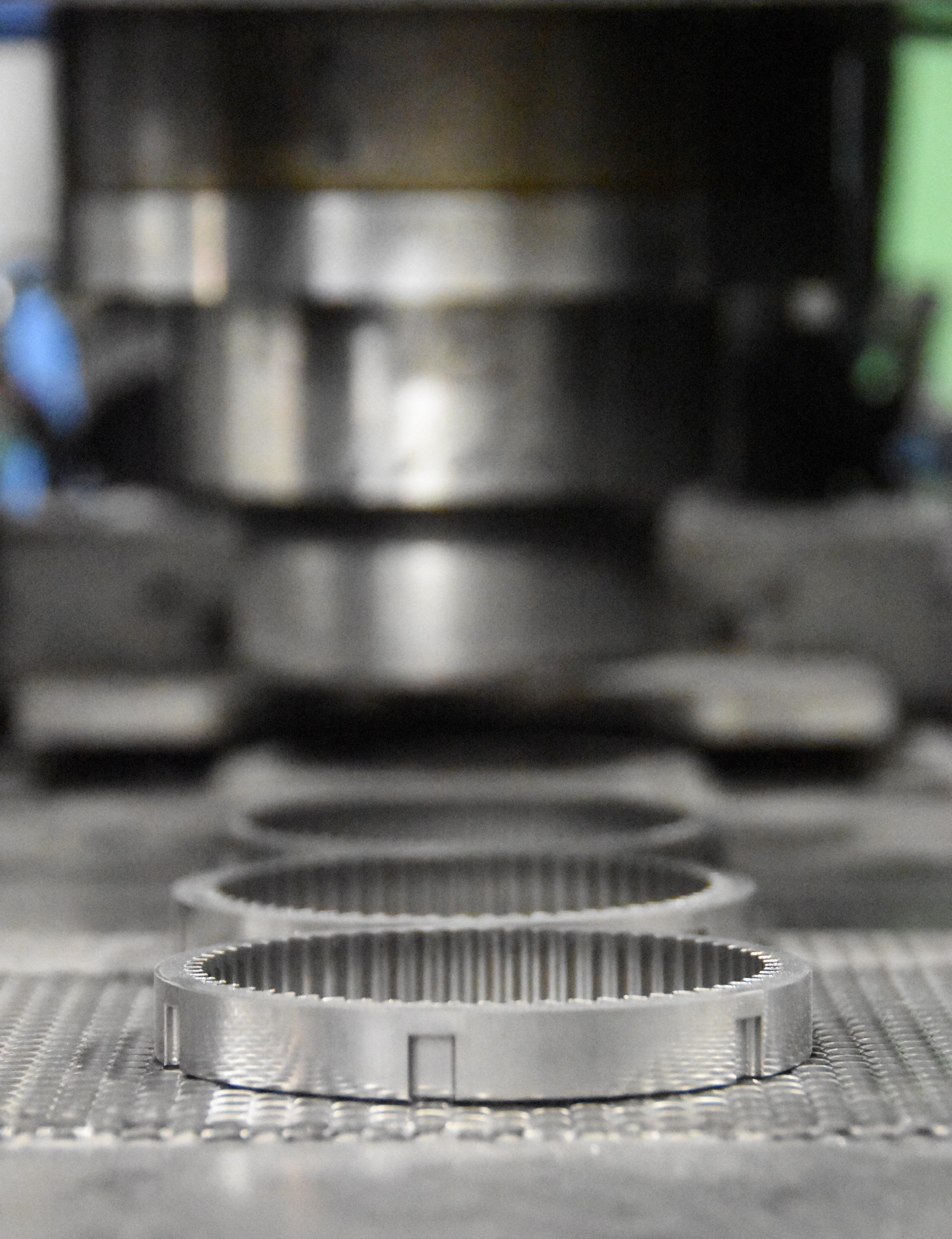

Western Sintering Company (WSC) excels at problem solving, engineering, and offering their customers solutions that helps them fill their customers’ supply chain with repeatable quality product every time. Instead of hogging out a part from a hunk of raw metal, WSC furnishes a pure powder metal solution, and engineers a tool molding process that forms a metal powder solution.The metal powder is pressed with many tons of force to a calculated density, pressed with tons of force to a near net shape, prior to heating it up to the highest in sintering temperatures to allow the powder metal to bond together and meld to a finished part. Yes, their expert engineers create a process that allows a near perfect part for their machine shop to CNC program what we call a ‘Kiss’ in the industry, that takes the pressed sintered part to final processing that is pressed quickly, uniformly, consistently, and faster than most forms of manufacturing, including 3D manufacturing.

It’s hard to find qualified humans in manufacturing. Bringing on robotics has transformed Western Sintering.. Fast is good! But, haste does not make waste in WSC’s engineering process. Once the process is perfected with tooling, the right density, the perfect heat processing, then the process has to be formulated into the robot’s realm, one that continues to

be monitored by WSC’s team. The more steps that can be automated, the more possible problems or inconsistencies are ruled out, and complete perfection is inherent.

WSC started out the old fashion way many years ago. Founder, John Rector started out at the age of 26 leading a dozen tool and die makers at the DuPont plant in Kansas City forming 16mm cannon cartridges for the war. John received his first major promotion because he could compute square roots in his head. DuPont sent him to the ‘Manhattan Project’, a secret weapons project in the eastern Washington desert to

A2Z MANUFACTURING WEST COAST • 20 • DEC - JAN ‘22-’23 A2Z MANUFACTURING WEST COAST • 24 • FEB - MAR ‘20

perfect his work and processes. John designed a process to sinter aluminum boron that was control rod material for the historic B reactor. John envisioned that rather than machining parts the common way from raw solid material, he could press powder with tons of pressure into a form and take it to the ovens to heat it to a molded, net, almost perfect shape and density. Once molded these metals or pucks could be minutely machined into a perfect part quickly and uniformly.

Companies have utilized WSC for this unique process for years and as production moved to thousands; it was imperative to automate the process. Jeff Wood, President of WSC and Dave Morasch, Vice President of WSC worked together to create an automated process that could be tracked, improved, and moved to a production scale of manufacturing. Since robotics and pressing metal aren’t widely implemented this management team sent two of their expert team to the Fanuc factory. Once trained, WSC was able to take the automated pressed puck from the 200 ton press machine to sintering trays and be placed in position for the heating process. When you are dealing with thousands of parts this is a Godsend for the operating staff as the mundane process can be taxing and not to mention a boring feat for humans.

As an ISO9001 company, WSC maintains an expertise in many varieties of metals from alloy steel, stainless steel, copper, brass, nickel silver (white brass), bronze, aluminum, and many others.WSC aligns approved outside processing partners to plate the parts to a component that once quality checked by their team, is packaged carefully and shipped to the customers for a finished part that is ready to arrive on time at their customers’ production line.

It sounds easy. But when you are working with powdered metal, precision molds, 200 plus tons of pressure, handling, heat treating or sintering it is a delicate game of making sure your process for ms the solid mass that is placed in a perfect atmosphere that yields the perfect end result, once a solid piece of particles that are deposited in the right density for melding in the sintering process. Wow!

WSC has maintained their quality service by continuing to add state of the art processing, from 200-ton compacting press machines, 17 zone sintering controlled furnaces, to now robotics that aid in handling

the pressed parts off the presses.This all adds to the goal of WSC to move the production of their customers parts into a perfect state of production that will allow no human error, and aid in the production of finished parts that meet their customers production schedules of higher volume parts, on time. If you are looking for an excellent choice for production where precision is required, look nowhere else but, Western Sintering Company.

For more information on Western Sintering Inc., WSC and how they can automate your processes contact Dave Morasch at 509-375-3096, www.westernsintering.com

A2Z MANUFACTURING WEST COAST • 21 • DEC - JAN ‘22-’23 A2Z MANUFACTURING WEST COAST • 25 • FEB - MAR ‘20

At Gigafactory Near Austin, Filings Show

By Cody Baird

Construction is expected to begin on a new project at 1 Tesla Road in the coming days, according to a Dec. 20 filing with the Texas Department of Licensing and Regulation.

And plans filed with the city of Austin further indicate Tesla (Nasdaq: TSLA) has its eye on developing land it owns west of SH-130, including the construction of a wastewater interceptor.

Tesla did not respond to requests for comment. But these public filings show how the company, now the largest manufacturer in Central Texas, is laying the groundwork for continued growth at the site, which sources said already employs about 10,000 people.

The scope of work for the latest construction on the gigafactory is for “ground up and complete interior finish out of the [electric vehicle] manufacturing facility.”The filing gives a Dec. 27 start date for construction, with an estimated completion of March 13.

The 174,979-square-foot project carries an estimated cost of $58 million. No design firm was listed; instead, that portion of the TDLR filing simply names “Giga Texas.”

Are you ready to implement or upgrade your Quality Management System to the new ISO 9001:2015 or AS9100D / ISO 9001:2015 Standard, AS9110C or AS9120B?

Special Packages available, take advantage of 20 plus years’ experience implementing and auditing quality management systems for commercial and aerospace companies!

Bretta Kelly, President and Owner of BMSC, LLC www.businessmsc.com has proven, copy written templates for ISO 9001:2015, AS9100D / ISO 9001:2015, AS9110C / ISO 9001:2015 and AS9120B / ISO 9001:2015 Standards with more than 30 companies upgraded and certified with zero to one finding results to date in their upgrade audits!

Packages Available:

Complete Electronic QMS System/Templates and 4 hours consulting – Manual, Policy, System Procedures, Work Instruction / Flow charts for some processes, internal audit program, management review program (including forms), competency / training program, objectives training template, risk training and how to document a corrective action training PowerPoint’s - $3,500

Complete Electronic QMS System/Templates and online webinar of how to complete –Manual, Policy, System Procedures, Work Instruction / Flow charts for some processes, internal audit program, management review program (including forms), competency / training program, objectives training template, risk training and how to document a corrective action training PowerPoint’s - $2,500

Do you need Quality Management System Software? Bretta Kelly is also President of CIS WWSG, LLC and is now offering the $3,500 Templates for FREE with purchase of CIS Software! www.cissoftware.com. CIS Software costs $5,000 upfront (one time) and $385/month license and server fees for UNLIMITED users, request a demo today!

Testimonial from BMSC Clients featured in the A2Z Manufacturing Magazine who have taken advantage of the BMSC Templates for successful upgrades:

Bretta, I wanted to email you and let you know that because of the help of yourself and Debbie we completed our audit to the new revision with no findings! :) We very much appreciate all of the help that you both did for us and will recommend your company to anyone looking to get certified. Your system really makes it easy for companies like ours to stay organized and compliant to the guidelines. Kristie McKee, Gibbs Precision Machine

In late October, Tesla submitted to the city of Austin a site plan for a logistics yard and associated parking lots at 11901 1/2 Tesla Road, west of the SH-130 toll road.The so-calledWest Support Facility would be built on a site of a little less than 239 acres, according to the site plan, although it was not clear how much of that acreage would be occupied by the project.

Colorado River Project LLC, a shell company tied to Tesla, owns the 1,699-acre gigafactory site, plus about 666 acres across two lots directly west of SH-130.

The final proposed project from Tesla is for construction of a wastewater interceptor at 2205 1/2 S. SH-130, according to a Dec. 19 site plan application.

That speaks to the infrastructure needs of large projects such as the sprawling gigafactory. An interceptor sewer is a major sewer line that receives wastewater flows from wastewater collectors and transports it to a treatment facility, according to the Environmental Protection Agency.

Construction began on Tesla’s gigafactory in 2020 and is seemingly unending.

This summer, Tesla filed a site plan for a Production Support Area on 68 acres at 12601 Tesla Road. In June, the company filed a site plan application for above-ground piping and underground plumbing for 500,000 square feet of space, and in February filed a site plan application for Project Cathode, a 36-acre project potentially related to battery manufacturing.

A2Z MANUFACTURING WEST COAST • 22 • DEC - JAN ‘22-’23

www.techfin.net Tech Financial has been providing best-in-class financing to the Machine Tool Industry across the USA and Canada for over 20 years! We are committed to providing: •Hassle-Free Equipment Financing •Fast Approval Process •Flexible Financing Structures and Terms •Unmatched Industry Knowledge Isaac Leman, CLFP 541-360-1318 isaacl@techfin.net Kobe Knaak 414-213-2261 kobek@techfin.net Contact our sales team today so we can help you get the equipment you need, when you need it Sara Charlton, MBA 262-844-7571 sara@techfin.net Tesla To Add More Infrastructure

www.TJSNOW.com (423) 894-6234 RESISTANCE WELDING ONE-SPOT-SHOP MACHINERY CONSUMABLES SERVICE + REPAIR TRAINING

Contracts

Woodward HRT, Santa Clarita, California, is awarded a $27,170,000 delivery order (N00383-23-F-YN03) under previously awarded basic ordering agreement N00383-21-G-YN01 for the repair of 418 components of the drive unit used in support of the V-22 aircraft hydraulic system. All work will be performed in Santa Clarita, California, and is expected to be completed by August 2024, with no option periods. Working capital (Navy) funds in the amount of $20,377,500 will be obligated at the time of award and funds will not expire at the end of the current fiscal year. One company was solicited for this non-competitive requirement pursuant to the authority set forth in 10 U.S. Code 2304 (c)(1), with one offer received. Naval Supply Systems Command Weapon Systems Support, Philadelphia, Pennsylvania, is the contracting activity.

Boeing Space, El Segundo, California, has been awarded a $36,689,916 launch and missions’ operations modification (P00143) to contract FA8808-10-C-0001 for Wideband Global Satellite Communications (WGS). The contract modification is for the implementation of launch and mission operations for WGS Space Vehicle 11. Work will be performed in El Segundo, California, and is expected to be completed Oct. 31, 2025. Fiscal 2023 Space Force procurement funds in the full amount is being obligated at the time of award. Total cumulative face value of the contract is $2,616,221,284. Space Systems Command, Los Angeles Air Force Base, California, is the contracting activity.

Mercury Mission Systems LLC, Torrance, California, is awarded an $18,391,509 firm-fixed-price modification (P0001) to a previously awarded contract N0001922C0038.This modification exercises an option to procure 35 data transfer units, 15 Secret Serial Advanced Technology Attachment Encryption Module cables, 157 High Definition Video Recorders (HDVR), and 72 HDVR data transfer devices for retrofit on F/A-18C-F aircraft in support of Small Business Innovation Research Phase III topic N102-0129 titled, “Automatic Real-Time, Reconfigurable Interface Generalization Hardware Multiprotocol Data Recorder.” Work will be performed in Torrance, California, and is expected to be completed in March 2025. Fiscal 2023 aircraft procurement (Navy) funds in the amount of $11,691,669; fiscal 2022 aircraft procurement (Navy) funds in the amount of $2,996,712; and Foreign Military Sales funds in the amount of $3,703,128 will be obligated at the time of award, none of which will expire at the end of the current fiscal year.The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

Raytheon Technologies Corp., Pratt and Whitney Military Engines, East Hartford, Connecticut, is awarded a not-to-exceed $511,589,719 modification (P00025) to a previously awarded cost-plus-incentive-fee, cost-plus-fixed-fee, cost reimbursable, and fixed-price incentive (firm target) undefinitized contract (N0001921C0011). This modification provides for F135 propulsion system annual sustainment including recurring sustainment support, program management, financial and administrative activities, propulsion integration, replenishment spare part buys, engineering support, material management, configuration

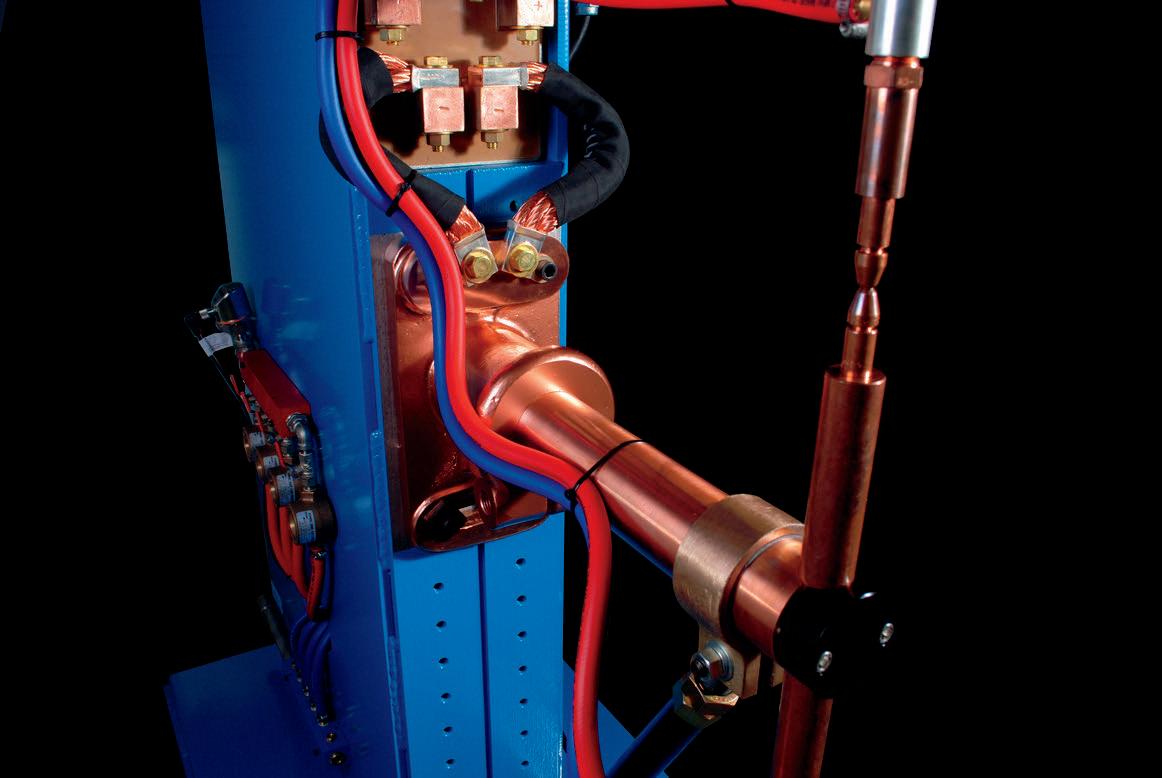

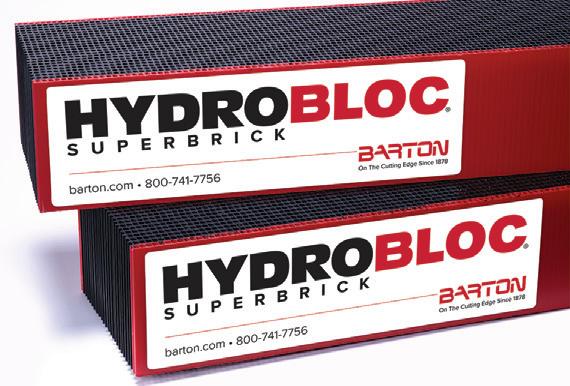

A2Z MANUFACTURING WEST COAST • 24 • DEC - JAN ‘22-’23 OIL MIST AND SMOKE IN YOUR SHOP? Low-Cost, Highly Efficient Mist and Smoke Collectors Designed Specifically for the Metalworking Industry www.mistcollectors.com 1-800-645-4174 BARTON INTERNATIONAL USA/Canada 800-741-7756 518-798-5462 • info@barton.com • barton.com • store.barton.com The BARTON logo and our brands are registered trademarks of BARTON Mines Corporation. Experience cleaner, quieter cutting and produce better-looking parts with HYDROBLOC Superbricks. Their flat, even, honeycomb surface keeps parts from falling into the tank and drains water away to minimize splash back. The laminated highdensity polyethylene layers are welded and screwed together for unrivaled durability. • Cleaner Cutting • Recyclable • Quieter Operation • Better-Looking Parts Learn more at barton.com/hydrobloc Upgrade Your Waterjet with HYDROBLOC®

Department of Defense (DoD) Awards

management, product management support, software sustainment, security management, joint technical data updates, support equipment management, depot level maintenance and repair for all fielded propulsion systems at the F-35 production sites and operational locations, as well as training. These efforts are in support of the F-35 Lightning II aircraft for the Air Force, Marine Corps, Navy, non-U.S. Department of Defense (DOD) participants, and Foreign Military Sales (FMS) customers. Work will be performed in East Hartford, Connecticut (40%); Oklahoma City, Oklahoma (21%); Indianapolis, Indiana (12%); Windsor Locks, Connecticut (6%); West Palm Beach, Florida (6%); Brekstad, Norway (4%); Leeuwarden, Netherlands (3%); Iwakuni, Japan (3%);Williamtown, Australia (2%); Cameri, Italy (1%); Marham, United Kingdom (1%); and Fort Worth, Texas (1%), and is expected to be completed in May 2023. Fiscal 2023 operation and maintenance (Air Force) funds in the amount of $38,863,770; fiscal 2023 operation and maintenance (Marine Corps) funds in the amount of $25,890,796; fiscal 2023 operation and maintenance (Navy) funds in the amount of $8,315,050; non-U.S. DOD participant funds in the amount of $23,125,291; and FMS funds in the amount of $12,102,937 will be obligated at time of award, $73,069,616 of which will expire at the end of the current fiscal year. The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity. Rolls-Royce Corp., Indianapolis, Indiana, is awarded a $228,092,989 firmfixed-price, indefinite-delivery/indefinite-quantity contract.This contract provides for sustaining engineering and logistics support services for the KC-130J aircraft propulsion system for the Navy, Marine Corps, and

Nammo Defense Systems Inc., Mesa, Arizona, was awarded a $498,092,926 firm-fixed-price contract for the full rate production of M72 Light Assault Weapon variants and components for shoulderlaunched munitions training systems. Bids were solicited via the internet with one received. Work locations and funding will be determined with each order, with an estimated completion date of Dec. 19, 2026. U.S. Army Contracting Command, Newark, New Jersey, is the contracting activity.

Foreign Military Sales customers.Work will be performed in Indianapolis, Indiana (92.8%); Iwakuni, Japan (1.6%); Kuwait City, Kuwait (1.6%); Cherry Point, North Carolina (1%); Miramar, California (1%); Kaneohe, Hawaii (1%); and Fort Worth, Texas (1%), and is expected to be completed in November 2027. No funds will be obligated at the time of award; funds will be obligated on individual orders as they are issued. This contract was not competitively procured pursuant to 10 U.S. Code 2304 (c)(1).The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity (N0001923D0014).

Raytheon Co., Tucson, Arizona, is awarded a $55,121,826 costplus-fixed-fee modification to a previously awarded contract (N0002421C5434) for engineering and technical services in support of the Evolved Seasparrow Missile and NATO Seasparrow Missile Sys-tems programs. This contract combines purchases for the U.S. govern-ment (99%); and the governments of Japan and United Arab Emirates (1%) under the Foreign Military Sales (FMS) program. Work will be performed in Tucson, Arizona (82%); Portsmouth, Rhode Island (17%); Andover, Massachusetts (less than 1%); San Jose, California (less than 1%); Aranjuez, Spain (less than 1%); Brisbane, Australia (less than 1%); and Koropi Attica, Greece (less than 1%). Work is expected to be com-pleted by December 2022. The Naval Sea Systems Command, Wash-ington, D.C., is the contracting activity.

Honeywell International Inc., Phoenix, Arizona, is awarded a $22,467,124 cost-plus-fixed-fee contract for the development, build and demonstration of the Compact Rubidium Extended

GE Aviation Systems LLC, Sterling,Virginia, is awarded a $157,183,240 firm-fixed-price indefinite-delivery/indefinite-quantity contract. This contract provides for propeller engineering reliability and logistics support for the KC-130J R391 propeller system utilized by the Navy, Marine Corps, and Foreign Military Sales customers. Work will be performed in Sterling, Virginia (31.18%); Iwakuni, Japan (13.95%); Cherry Point, North Carolina (13.95%); Miramar, California (13.95%); Gloucester, United Kingdom (8.85%); Fort Worth, Texas (8.63%); Kaneohe, Hawaii (5.18%); Kuwait City, Kuwait (2.59%); and various locations within the continental U.S. (1.72%), and is expected to be completed in November 2026. No funds will be obligated at the time of award; funds will be obligated on individual orders as they are issued. This contract was not competitively procured pursuant to 10 U.S. Code 2304 (c)(1).The Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity (N0001923D0013).

Stability Timing (CREST) — a ruggedized atomic clock module with a unique combina-tion of performance and size, weight and power, capable of the abso-lute accuracy of a commercial cesium beam clock in a VPX-card-like form-factor. The CREST module will be designed to provide uninter-rupted Global Positioning System (GPS)-quality timing holdover in challenging military environments. Work will be performed in Phoenix, Arizona, with an expected completion date of Dec. 21, 2026. This contract was competitively procured under long range broad agency announcement (BAA) N00014-21-S-B001. The Office of Naval Research, Arlington, Virginia, is the contracting activity).

The Boeing Co., Mesa, Arizona, was awarded a $239,590,243 cost-plus-fixed-fee contract for the Apache Improved Turbine Engine Inte-gration Phase II. Bids were solicited via the internet with one received. Work will be performed in Mesa, Arizona, with an estimated comple-tion date of Dec. 31, 2026. Fiscal 2021 and 2022 research, develop-ment, test and evaluation, Army funds in the amount of $18,000,000 were obligated at the time of the award. U.S. Army Contracting Com-mand, Redstone Arsenal, Alabama,

A2Z MANUFACTURING WEST COAST • 25 • DEC - JAN ‘22-’23 A2Z MANUFACTURING SW • 44 • March / April 2022

is the contracting activity. A Heat-Treating Company OFFERING Salt Bath Nitride-MELONITE®- Per AMS2753 D • GASEOUS CARBURIZING • GASEOUS NITRIDING • VACUUM HEAT TREATING • HEAT TREATING • NORMALIZING, ANNEALING, HARDENING, COLD TREATMENT STRESS RELIEVING, PRECIPITATION Serving the Aerospace/Aircraft, Military, and Commercial Industries Other Services; For More Info: Contact Tim Johnston; 602-272-3714; tjohnston@cttaz.com CONTROLLED THERMAL TECHNOLOGY (CTT) AND TS WEST 2617 West Cypress Street Phoenix AZ 602-272-3714

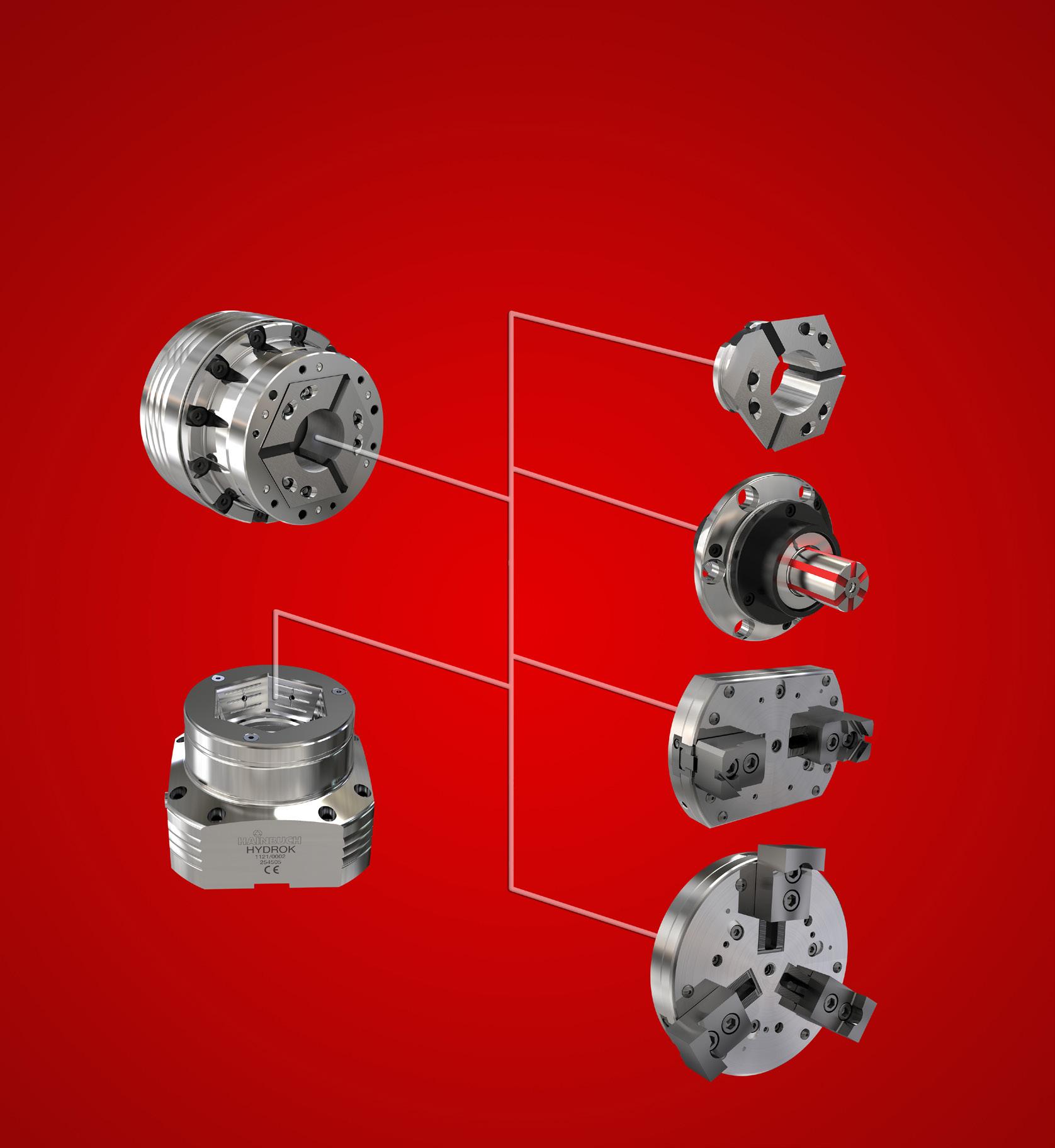

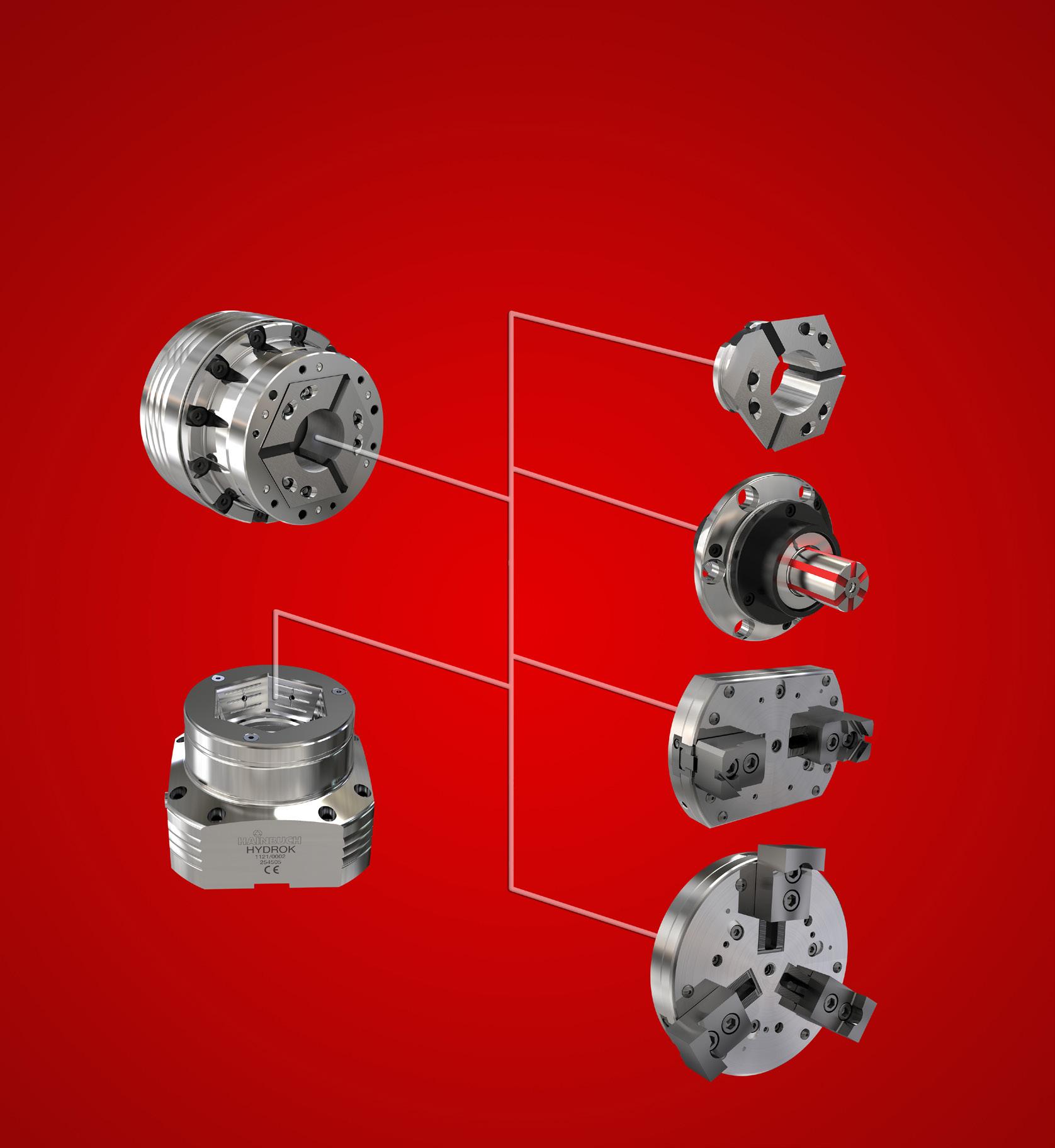

Adapting to New Possibilities

n Change from O.D. to I.D. to jaw clamping in < 2 minutes

n Use the same adaptations on your HAINBUCH turning or stationary chucks

Vertuelab Hires PSU’s Juan Barraza For New Innovation Role

By Malia Spencer

Portland startup veteran Juan Barraza joins VertueLab in a newly created role as director of innovation and entrepreneurship.

Juan Barraza, a fixture in the Portland startup community, is joining VertueLab in a newly created role as director of innovation and entrepreneurship.

VertueLab is a nonprofit that supports startups fighting climate change. It started in 2007 as Oregon BEST, a statewide center of excellence to support cleantech startups. It became VertueLab in 2018 and launched a climate impact fund. It also runs the Cascadia CleanTech accelerator hosts events and helps founders navigate the federal grant process.

In his new role, Barraza will lead the nonprofit’s suite of entrepreneur support programs including growing the Cascadia accelerator and expanding the support and resource network for the founders the organization works with.

“VertueLab allows me to learn a part of the ecosystem I am not familiar with — how to interact with federal and state dollars to secure funding for hardware and difficult-to-fund ventures” said Barraza.

Want more Portland startup and innovation news? Sign-up for The Beat delivered to your inbox twice weekly

He comes to VertueLab after spending seven years at Portland State University in the Center for Entrepreneurship in various leadership roles, including director. A new director of the center was recently named. He is a past board member of Oregon Entrepreneurs Network and current board member for Oregon RAIN and Rural Development Initiatives Inc.

Barraza also is an entrepreneur himself, having founded and run VDO Interpreters, a video service providing interpreters in health care from 2009 to 2015. He is co-founder of the group Latinx Founders and an organizer of the event Pitch Latinx.

“We’re so excited to have Juan join the VertueLab team. Juan has a strong and proven track record of supporting innovators and entrepreneurs in our region and his experience and networks in both the startup and university ecosystems will be a tremendous asset for us,” said David Kenney, president and executive director of VertueLab in a written statement.

Barraza said he found himself interested in a new career challenge after taking stock of his work during the Covid-19 pandemic.

A2Z MANUFACTURING WEST COAST • 26 • DEC - JAN ‘22-’23

1.800.281.5734 Germantown, WI USA www.hainbuchamerica.com

and

are available in

configurations

n Keep the basic clamping device mounted on the machine Chucks

adaptations

round or hexagonal

“I started wondering what could be next in professional development and the things I want to do,” he said, adding that he is still bullish on the work at PSU and programs like InventOR. “My foray into VC with Vamos Ventures (where he was a scout) and the accelerator for Latinx Founders, for me it was a moment of realization (that) I was looking for something else to continue that development.”

Announcements & Releases Continued

from outside North America to North America. Reshoring includes work that is produced either in-house or outsourced. A complete definition of “reshoring” is available here. Applications must be submitted by June 30. To view award details and enter to win, visit this webpage.

Aerojet Rocketdyne To Sell For $4.7

Billion

materials and services to the industry.

in Canoga Park, California; Camden, Arkansas; West Palm Beach and Orlando, Florida; Huntsville, Alabama; Orange, Virginia; Redmond, Washington; Stennis Space Center, Mississippi; Jonesborough,Tennessee; and Carlstadt, New Jersey.

L3Harris CEO and Chair Christopher E. Kubasik said the acquisition will combine the talents of more than 50,000 employees to “drive continuous process improvement, enhance business operations and elevate the performance of this crucial national asset.”

“From 2010 to 2020, more than one million jobs were announced as coming to the United States from offshore. This is a tremendous achievement, and we seek to motivate and honor the companies that have made reshoring a reality,” said Harry Moser, founder and president of the Reshoring Initiative.

By Isabel Sami

By acquiring the El Segundo, California-based company, L3Harris (NYSE: LHX) is bulking up its aerospace and defense industrial base and scientific innovation by investing in advanced missile technologies, hypersonics and more. The merged companies will provide enhanced business operations and continued delivery of essential capabilities for the Department of Defense.

The Association For Manufacturing Technology (AMT) represents U.S. builders and distributors of manufacturing technology – the advanced machinery, devices and digital equipment that U.S. manufacturing relies on to be productive, innovative, and competitive.

“We’ve heard the DoD leadership loud and clear: They want highquality, innovative and cost-effective solutions to meet both current and emerging threats, and they’re relying upon a strong, competitive industrial base to deliver those solutions,” Kubasik said in a news release.

Questions about the National Metalworking Reshoring Award can be directed to Harry Moser at 847-867-1144 or harry.moser@ reshorenow.org. For more information on AMT’s efforts on reshoring and supply chain efforts, visit IMTS.com/supplychain.

This isn’t the first piece of acquisition news regarding Aerojet (NYSE: AJRD). In December 2020, aerospace and defense corporation Lockheed Martin announced its intention to buy the company for $4.4 billion. Before the acquisition could close earlier this year, Lockheed Martin abandoned the deal when the Federal Trade Commission sued to block the sale in January 2022, claiming the acquisition would give Lockheed an unjust ability to deny other defense contractors access to components needed to build competing missiles, provided by Aerojet. Aerojet Rocketdyne generates approximately $2.3 billion in annual revenue, operating primarily out of advanced manufacturing facilities

Aerojet Rocketdyne President and CEO Eileen P. Drake said the agreement will accelerate innovation for national security propulsion solutions, as well as increase value for shareholders. She added that joining L3Harris represents the natural next phase of Aerojet’s evolution.

The Reshoring Initiative, founded in early 2010, helps manufacturers realize that local production, in some cases, reduces their total cost of ownership of purchased parts and tooling. The Initiative also trains suppliers how to sell against lower-priced offshore competitors.

PMA, an inaugural sponsor of the National Reshoring Award, is the full-service trade association representing the North American metalforming industry — the industry that creates precision metal products using stamping, fabricating, spinning, slide forming and roll forming technologies, and other value-added processes. Its

NTMA is the voice for the precision manufacturing and tool and die industries in the United States. Backed by nearly 1,300 member companies, representing more than $30 billion in sales, NTMA provides an array of benefits to members and the industry including advocacy in Washington, training and education programs and networking events nationwide.

“As part of L3Harris, we will bring our advanced technologies together with their substantial expertise and resources to accelerate our shared purpose: enabling the defense of our nation and space exploration,” Drake said. “This is an exciting new chapter for Aerojet Rocketdyne and our over 5,200 dedicated team members, providing them with additional opportunities, and we look forward to working closely with L3Harris to complete this transaction.”

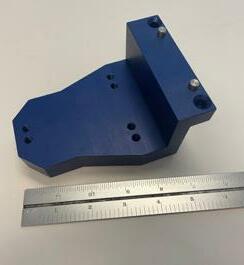

The Benefits Of Worki ng With P4Swiss / Lindel CNC Machining