Customer-Centric Is The Renewed Focus At Phoenix

Heat Treating

Customer-Centric Is The Renewed Focus At Phoenix

Heat Treating

In all walks of life, the most important advice you will ever be given about work is to work hard. For our society to succeed, there must be hard work, and there are ways to make hard work be smarter work, better work, and more successful and enjoyable work.

The common saying work smarter, not harder originated in the 1930s. Allen F. Morgenstern, an industrial engineer and the creator of the work simplification program, coined the term. The program’s intent was to increase the ability of people to produce more with less effort.

The phrase was later picked up by the cartoon character Scrooge McDuck, created in 1947 by Carl Banks. Scrooge McDuck always told his three nephews, Hewey, Dewey, and Louis, “Work smarter than the smarties and tougher than the toughies.”

When you work hard and smart, you fulfill a human need for achievement. Happiness does not come from idleness; it is work that brings us happiness. It is said well by, James M. Barrie: Playwright;“Labor, if it were not necessary for existence, would be indispensable for the happiness of man.”

Vince Lombardi, considered by many to be the greatest coach in football history, and recognized as one of the greatest coaches and leaders in the history of all American sports. once said, “The price of success is hard work, dedication to the job at hand, and the determination that whether we win or lose, we have applied the best of ourselves to the task at hand.”

A good work ethic is admired not only in sports but in all fields all over the world. Every coach in every sport admires the kind of athlete who comes to practice early, stays late, and works diligently the entire time. In fact, in a study of what college basketball coaches stated as critical in their players, every college coach agreed that what separated their best players from the others was work ethic. Some guys play basketball because they’re good at it, but the ones who thrive play because they love it. And they love the work.

The Office of Productivity and Technology (OPT) measures how efficiently the U.S. converts inputs into the outputs of goods and services. Measures of labor productivity compare the growth in output to the growth in hours worked and measures of total factor productivity (TFP), also known as multifactor productivity (MFP), compare growth in output to the growth in a combination of inputs that include labor, capital, energy, materials, and purchased services.

Data now shows that the U.S. workforce is not as productive as just a year ago — it seems people are not producing as much in the hours between clocking in and clocking out each day. In the end, this could have a profound effect on the country’s well-being, according to economists.

In the words of Margaret Thatcher, “Look at a day when you are supremely satisfied at the end. It’s not a day when you lounge around doing nothing; it’s when you’ve had everything to do, and you’ve done it.”

In closing, God bless our troops and I wish you continued hard and smart work, as well as success.

keep

manufacturers abreast of news and to supply a viable vendor source for the industry.

Circulation: The A2Z Manufacturing has compiled and maintains a master list of approximately 6500 people in the Rocky Mountain states actively engaged in the Precision Manufacturing Industry. It has an estimated pass on readership of more than 18,000 people.

Advertising Rates, deadlines and mechanical requirements furnished upon request or you can go to www.azManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

The Publisher assumes no responsibility for the con tents of any ad ver tise ment, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

JM

www.jmgrisleymachine.com

The versatile VMC lineup at DN Solutions is enough to get anyone excited.

The lineup of vertical machining centers at DN Solutions is versatile, compact and born to make incredible parts for as long as you need them to.

Get your ideal VMC, then get ready for the vertical leap. Talk to your local DN distributor or visit dn-solutions.com.

Colorado, Montana, Idaho and Wyoming

DEM: entry-level part producer

SVM: swift and strong

DNM: global bestseller

The lineup of vertical machining centers at DN Solutions is versatile, compact and born to make incredible parts for as long as you need them to.

BVM: premium powerhouse

Get your ideal VMC, then get ready for the vertical leap. Talk to your local DN distributor or visit dn-solutions.com.

√

√

√

MMT Name Change to Productivity Inc. Streamlines Communications and Processes and Strengthens Offerings

Productivity Inc. announced that MMT Productivity, formerly MMT, LLC and Moncktons Machine Tools, has officially changed its name to Productivity Inc. In 2015, Productivity joined forces with Moncktons Machines Tools to expand its presence into the Rocky Mountain region. In 2020, Moncktons Machine Tools took the name MMT Productivity, representing another step in the integration. And now, this name change is the final official step in the merger of two leading metalworking distributors.

Unifying under a single name better symbolizes Productivity’s

range of capabilities as a complete supplier of metalworking services and products. This allows the company to expand their territories and combine resources. Productivity now has an official presence in 12Productivity Inc has 5 locations serving 12 states states with five office locations. Although the MMT/Moncktons name is going away, customers will continue to experience the same on-time delivery, fast, responsive service, and dedication to excellence they depend on. It’s still the same company and people, just a new name and logo.

“When Productivity joined forces with Moncktons Machine Tools in 2015, it was a natural combination of two long-established distributors serving the metalworking industry,” stated Greg Buck,

We Specialize in Close Tolerance Precision Grinding and Small Parts Manufacturing Celebrating 28 Years In Business

Grinding Capabilities:

√ OD,ID Centerless Plunge and Thru Feed (OD Between Centers up to 72” L x OD Swing up to 24”) (ID - 9” depth x 10” LD)

√ Surface, Angled and Blanchard

√ Long Bar Grinding for Screw Machines

√ We grind all types of Industrial Blades

Announcing AS9100

Revision D Certification!

Grinding & Swiss Machining Capabilities:

√ CNC Universal Grinding Capabilities of 5” x 24”

√ We Have 4 Swiss Turning Centers with Diameter capabilities up to 32mm

√ CNC Circular Blade Grinding up to 20” Diameter

WE’RE GROWING! We Added a 2nd Supertech CNC Universal Grinder, We’ve Hired New Machinists and More!

President of Productivity Inc. “The name Moncktons in the Rockies was synonymous with machine tools, so it only made sense to partner with them to help expand our brand,” Greg added. “Once we were able to get Productivity’s name out there becoming one entity was the logical next step to streamline processes and resources.”

“Productivity is a top-notch, well-trusted machine tool company offering the highest degree of honesty, integrity and responsiveness,” said Mark Smith, Vice President & General Manager for the Rocky Mountain region. “We are happy and excited for this final step. While our name is changing, we are still the same people customers trust to support their metalworking needs.”

Over the next few months, Productivity Inc. will roll out rebranded collateral. Customers and vendors can expect email addresses and the corporate website address to be updated to productivity.com, and MMT social media accounts to now be under the Productivity name.

Since 1968, Productivity Inc., based in Plymouth, Minnesota, has been distributing a broad range of CNC metalworking

products and services. As a single source machine tool supplier, Productivity offers machine tools, tooling and accessories, machine repair, preventive maintenance, rotary and live tool repair, turnkey systems, robotics and automation and much more. In addition, their MachinesUsed.com division will sell your surplus equipment via its online auctions. Productivity services 12 states including Minnesota, North Dakota, South Dakota, Iowa, Nebraska, Wisconsin, Colorado, Utah, Idaho, Montana, New Mexico and Wyoming with five branch offices located in Plymouth, Cedar Rapids, Omaha, Denver, and Salt Lake City.

Though Rod Savage is fairly new to SCHUNK USA, he brings to customers throughout CO, ID, MT, UT, and WY years of both hands on and formal education in the industry. Rod

Continued page 10

is the perfect product when your business has a project or additional expenses. Simple application process and funds up to $250,000. Capital intended to grow your business.

up to $500,000 (without financial review) for your new or used equipment acquisitions. With 100%financing and terms up to 84 months, it allows you to reserve cash in your bank account.

is a graduate of Brigham Young University (BYU), with a combination degree in Manufacturing Engineering and Business Management. He additionally earned his Master of Science/ Masters of Business Administration (MBA) degrees from the University of Alabama.

Rod’s work experience includes engineering/engineering management positions at Parker Hannifin, Danaher, and The Aerostructures Corp. He has managed a team as a manufacturing manager at several fabrication and machine shops. More recently, Rod has supported customers in tooling sales, working at Walter USA, Ingersoll Cutting Tools and today, Rod supports customers as regional sales manager for SCHUNK USA.

SCHUNK opened its first production site outside Germany in Morrisville, North Carolina in 1996. Today, SCHUNK USA employs a total of 172 people in every area. At the facility, the team manufactures automation modules, hydraulic expansion toolholders and custom products on 85,000 square meters of production space.

Contact Rod at: 919-602-8294 or email him at: rod.savage@ us.schunk.com to see how he can best support your tooling needs.

During the Precision Machining Technology Show (PMTS) 2023, Mazak will showcase several models from its new SYNCREX Series of Swiss-style machines in booth 3053. Among them will be the SYNCREX 38/9 that accommodates bar stock up to 1.5” (38mm), and incorporates a removable guide bushing adapter that allows operators to preset guide bushings outside of the machine. The SYNCREX 38/9 is also convertible and can be quickly changed over to run in chucker mode for added part processing fl exibility.

Mazak’s SYNCREX Swiss-style Series encompasses models featuring seven, eight and nine-axis confi gurations and are optimized for precision high-production of small parts. SYNCREX “9X” models deliver added part processing fl exibility as they are capable of full 5-axis contouring while using the B-axis tool post.

Like all models in the series, the SYNCREX 38/9 is

Continued page 12

op�onsavailablefromLKMetrologyare availablewithALTERAC

integratedintoasinglemeasurement pla�orm

Trustworthytechnologyforprecise measurementatanaffordableprice!

Trustworthytechnologyforprecise measurementatanaffordableprice!

Trustworthytechnologyforprecise measurementatanaffordableprice!

Trustworthytechnologyforprecise measurementatanaffordableprice!

1963

2022 59 years

So�ware

AllCMMso�warepackagesand op�onsavailablefromLKMetrologyare availablewithALTERAC

Mul�-sensorTechnology

Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

sales.us@lkmetrology.com

measuringmachineisperfectwhenfloor spaceislimitedoronlyavailableata premium

CompactFootprint

IntegratedTech

IntegratedTech

op�onsavailablefromLKMetrologyare availablewithALTERAC

op�onsavailablefromLKMetrologyare availablewithALTERAC

So�ware

LKMetrology'sALTERACcoordinate measuringmachineisperfectwhenfloor spaceislimitedoronlyavailableata premium

Mul�-sensorTechnology

Mul�-sensorTechnology

AllCMMso�warepackagesand op�onsavailablefromLKMetrologyare availablewithALTERAC

IntegratedcontrollerandPCaretuckedaway undertheCMMgranitetable,withop�onal monitorandkeyboardarmavailable

IntegratedcontrollerandPCaretuckedaway undertheCMMgranitetable,withop�onal monitorandkeyboardarmavailable

www.LKmetrology.com

IntegratedTech

measuringmachineisperfectwhenfloor spaceislimitedoronlyavailableata premium Contactustodayat (810)263-6100 or sales.us@lkmetrology.com

Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

Mul�-sensorTechnology

Contactustodayat (810)263-6100 or sales.us@lkmetrology.com

IntegratedcontrollerandPCaretuckedaway undertheCMMgranitetable,withop�onal monitorandkeyboardarmavailable

Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

www.umw.com

Tollfree: 866-434-5679

Local: 801-364-5679

At Utah Metal Works, recycling industrial-related scrap metal is one of the things we do best. You simply won’t find more knowledgeable, capable partners for your scrap handling and recycling efforts anywhere. We are known in the industry for our honesty and integrity, and you can be sure you are always getting a competitive return along with superior service. We make it easy for you to cash in on non-ferrous metals from:

(MSSA) for fast and easy job setups along with the optional Mazak Dynamic Chip Control (MDCC) functionality. With Mazak’s intuitive and user friendly screens, the customer can quickly and easily touch off tools and prepare the machine for automatic cycle. Spending less time setting up the machine and more time in production.

Like all Mazak machine tools, SYNCREX machines are backed by Mazak’s comprehensive 2-year warranty, industryleading MPower complete customer care service and support program, and lifetime parts availability.

Stainless, titanium, Inconel, Hastelloy, Monel, cupronickel, aluminum;state-of-the-art metal analysis conducted on site; Mixed or contaminated items are accepted and sorted

a sliding headstock machine constructed on the Mazak High Damping Composite Casting (HDCC). This unique high rigidity base provides greater vibration damping characteristics, less thermal growth and greater part surface capabilities when compared to a cast iron base machine.

Mazak’s SYNCREX machines accommodate a maximum of 36 tools in a standard configuration: 20 static and 16 live. Mazak offers a full catalog of modular tool holders allowing their customers the tooling flexibility to meet their part requirements.

Additionally, Mazak offers an optional MT Tablet which creates a twin-screen system. The MT Tablet will allow the operator to work with offline programming systems (ESPRIT or AutoDesk-PartMaker) at the machine to help reduce set-up time and increase production.

Mazak SYNCREX machines sport the new MAZATROL SmoothSt and MAZATROL SmoothSt5 controls. Both controls feature the optional Mazak Swiss Setup Assist

From its humble roots on a college campus, Lux Precision Manufacturing (Lux) is a premiere manufacturing company that has a mission to re-energize American manufacturing. With the unique operating location on the campus of Grand Canyon University (GCU), Lux serves the medical device, aerospace, semiconductor, and defense industries with precision machined parts. Lux, however, has a unique business model that is re-energizing American manufacturing by introducing college students to precision manufacturing and giving them an opportunity for educational immersion in manufacturing.

In 2017, Weston Smith founded Lux out of a dorm room on the campus of Grand Canyon

Continued page 14

“Productivity is a top notch, well-trusted machine tool company offering the highest degree of honesty, integrity, and responsiveness. We are happy and excited for this final step. While our name is changing, we are still the same people customers trust to support their metalworking needs.”

Mark Smith Vice President and General Manager

Mark Smith Vice President and General Manager

We have added a number of improvements over the standard Fast Wire Edms including:

•Cutting capacity of 625 x 625 mm

•Panasonic AC Servo motors and drivers

•Hiwin Linear Guideways

•Build in Cad System

•Two filters

•Increased height side walls to reduce splashing

•View windows to see the wire progress

•Automatic spent wire spooler

•Optional build plate support fixture

•Optional Anti Electrolisis (AE)

A Denver aerospace company has successful contact with eight satellites launched for a new orbiting data network being built for the U.S. military’s Space Development Agency.

York Space Systems, a seven-year-old satellite manufacturer, is building 10 satellites for SDA, which is a rapidprocurement arm of the U.S. Space Force.

It’s a major milestone to contact the first eight of them for York.“This is an amazing first step in fulfilling the Space Development Agency’s vision for the Proliferated Warfighter Space Architecture, and we are proud to be in orbit in just over 2.5 years from contract award,” said Dirk Wallinger, CEO and co-founder of York. “We are excited to keep supporting SDA as they continue down the path to full system performance and are honored to be selected as their partner.”

The satellites launched April 2 on a SpaceX Falcon 9 rocket from Vandenberg Space Force Base, Florida. The rocket carried the eight York data network satellites into orbit and two SpaceX missiletracking satellites for SDA.

The York satellites are half of 20 that SDA contracted for the test phase — which SDA calls its Tranche 0 — of a laser-linked satellite data network it’s establishing for the U.S. military.

SDA contracted York Space Systems in 2020 for $94 million.

Lockheed Martin Space won a $187.5 million contract for another 10 satellites with about 54% of the work designing and building them expected to have been done in Colorado.

The satellites are the beginnings of what’s called a mesh network meant to improve communications from existing satellite systems upon which U.S. warfighters and military allies depend. The network is expected to eventually grow to involve hundreds of small satellites.

The SDA was originally established to speed up the U.S. military’s acquisition and development of fleets of small satellites.

Prior to the agency’s creation and its later folding into Space Force, U.S. military space acquisition favored traditional, large and capable satellites that took years to contract, build and place into orbit.

SDA aimed to be nimbler, speeding up the acquisition of small satellite networks.

“Through this launch, we’ve demonstrated that SDA can keep a schedule to deliver enhanced capabilities every two years,” said Derek Tournear, director of SDA.By

Women engineers and scientists from Hill Air Force Base, Utah, met with female high school students from NUAMES High School in Layton during a Science, Technology, Engineering and Math (STEM) event March 30, 2023.

This question-and-answer event is one of many that the Hill AFB WiSE, or Women in Science and Engineering, volunteers participate in to educate students about STEM careers available in the Air Force.

WiSE was started several years ago within Hill’s Stem Outreach program with the intent to generate interest for girls in STEM by providing them networking opportunities, career advancement education, and inspiration.

“Hill will never be able to have our mission critical STEM workforce of the future if we don’t get

more students in general interested in STEM, but with girls continuing to be such a small percentage of the STEM workforce, specific programs for girls are essential,” said Alison Sturgeon, 520th Software Engineering Group and Hill’s former STEM program manager.

Sturgeon said that studies show girls in particular need to see women role models who work in STEM-related career fields in order to see themselves there someday.

“Many students don’t know what they don’t know,” she said. “STEM outreach can spark interest and inform students at a young age encouraging them to choose a STEM pathway and consider an Air Force civilian career.”

Lockheed Martin Corp., Littleton, Colorado, has been awarded a $35,516,247 cost-plus-fixed-fee modification (P00049) to contract FA8823-21C-0001 for Space Based Infrared System contractor logistics support, product support, and integration contract evaluation. Work will be performed in Colorado at Peterson and Buckley Space Force Bases, Greeley Air National Guard Station, and Boulder, and is expected to be completed Nov. 30, 2025. Fiscal 2023 research, development, test and evaluation funds in the amount of $10,000,000 will be obligated at the time of award. Space Systems Command, Peterson Space Force Base, Colorado, is the contracting activity.

Arizona-based vehicle maker Nikola Corp. quietly purchased nearly 1,000 acres in the Phoenix metro at the end of September for $16.5 million, according to Maricopa County records.

According to the Arizona Corporation Commission, Corey Hessen and Omar Khayum, senior vice president and vice president of Canada-based TC Energy, respectively, are the managers of Phoenix Hydrogen Hub LLC. Oil and gas giant TC Energy partnered with Nikola last year to develop large-scale hydrogen production hubs across the U.S. and Canada.

completed February 25, 2024. Fiscal 2023 research, development, test, and evaluation (Navy) funds in the amount of $34,999,978 are obligated on this award. No funds will expire at the end of the fiscal year. This contract is awarded on a sole source basis under 10 U.S. Code 3204(a)(1), and was previously synopsized on the System for Award Management online portal. Strategic Systems Programs, Washington, D.C., is the contracting activity.

Nikola acquired the 920-acre site through Phoenix Hydrogen Hub LLC from Hardison Farms on Sept. 30, real estate database Vizzda shows. George Quinif of Peak Group LLC represented Nikola in the sale.

Vectrus System Corp., Colorado Springs, Colorado, was awarded a $73,872,000 modification (0001C3) to contract W52P1J-13-G-0027 for logistics support services. Work will be performed in Fayetteville, North Carolina, with an estimated completion date of April 1, 2024. Fiscal 2023 operation and maintenance, Army funds in the amount of $7,159,381 were obligated at the time of the award. U.S. Army Contracting Command, Rock Island Arsenal, Illinois, is the contracting activity. (Awarded March 30, 2023)

The massive site is located at 28702 W. Patterson Road in south Buckeye just west of State Route 85 near the Arizona Department of Corrections Lewis Prison, which is one of the largest prisons in the state and houses more than 4,400 inmates.

Nikola hasn’t confirmed, though, whether it plans to build a hydrogen production hub in Buckeye. Nikola said it has no comment about the Buckeye land sale or its plans for the property. The city of Buckeye said nothing has progressed with the company beyond negotiations.

The sale comes after Nikola made multiple announcements that it planned to break ground on a hydrogen production hub in Arizona. The company’s CEO said in August that Nikola would start construction on the new facility by the end of this year but did not disclose the location.

Lockheed Martin Space, Littleton, Colorado, is awarded a $34,999,978 cost-plus-incentive-fee contract modification (P00056) to a previously awarded contract (N0003019C0025) for the design, development, build and integration of equipment for missile flight test demonstrations and fielding. Work will be performed in Littleton, Colorado (74%); Cambridge, Massachusetts (14%); Simsbury, Connecticut (8%); Sunnyvale, California (3%); and Pittsfield, Massachusetts (1%). Work is expected to be

The automaker is currently producing battery electric vehicles and has produced several alpha prototypes of its fuel cell electric vehicles, which run on hydrogen. Nikola is planning to build out a hydrogen fueling network to support its vehicles. Its first three locations will be established in California.

In addition to the fueling stations, the

Bemsco Inc.,* Salt Lake City, Utah, has been awarded a maximum $29,655,660 firmfixed-price, indefinite-delivery/indefinitequantity contract for fixed landing gear. This was a competitive acquisition with two responses received. This is a threeyear contract with no option periods. The performance completion date is March 27, 2026. Using military service is Army. Type of appropriation is fiscal 2023 through 2026 Army working capital funds. The contracting activity is the Defense Logistics Agency Aviation, Redstone Arsenal, Alabama (SPRRA1-23-D-0017).

Lake, Utah, was awarded an $8,133,200 firm-fixedprice contract for overhaul of the dampener-flutter for Blackhawks. Bids were solicited via the internet with 12 received. Work locations and funding will be determined with each order, with an estimated completion date of Mar. 23, 2028. U.S. Army Contracting Command, Redstone Arsenal, Alabama, is the contracting activity (W58RGZ-23-D-0020).

Maytag Aircraft LLC, Colorado Springs, Colorado, has been awarded a maximum $12,355,098 firm�fixed�price contract for governmentowned, contractor-operated Alongside Aircraft Refueling services for U.S. Naval Support Activity Souda Bay, Greece. This was a competitive acquisition with three responses received. This is a four�year base contract with one five�year option period and one six-month option period. Location of performance is Greece, with a Nov. 30, 2027, performance completion date. Using military service is Navy. Type of appropriation is fiscal 2023 through 2027 defense working capital funds. The contracting activity is the Defense Logistics Agency Energy, Fort Belvoir, Virginia (SPE603-23-C-5004).

Raytheon, Aurora, Colorado, was awarded a $15,047,091 bilateral supplemental agreement modification (P00392) to previously awarded Next Generation Operational Control Segment (OCX) contract FA8807-10-C-0001 for additional development contractor support for OCX. This modification extends sustainment for the Block 0 Launch and Checkout System and certain other fielded components of OCX by nine

months. The location of performance is primarily Aurora, Colorado, and is expected to be completed by Dec. 1, 2023. Fiscal 2023 research, development, test, and evaluation funds in the amount of $15,047,091 are being obligated at the time of award. Total cumulative face value of the contract is $3,919,145,910. Space Systems Command, Los Angeles Air Force Base, El Segundo, California, is the contracting activity.

L3 Technologies Inc., Salt Lake City, Utah, has been awarded a $9,866,154 cost-plusfixed-fee contract modification (P00009) to the previously awarded Full Motion Video Extension and Unified Relay Task Order 7 (FA8726-21-F-0028) for a period of continued operations of Full Motion Video Extension & Unified Relay sites. The modification increases the total cumulative face value of the contract to $52,409,286. The location of performance is in the U.S. Central Command area of responsibility and is expected to be completed by Feb. 18, 2024. Fiscal 2023 operations and maintenance funds in the amount of $8,373,000 are being obligated at the time of award. Air Force Life Cycle Management Center, Hanscom Air Force Base, Massachusetts, is the contracting activity.

When it comes to workforce development, 5 years ago I felt like I was in a big island by myself, fortunately I found a great place to work and an owner that shares the same passion for machining as I do. We both see the need that our industry has and must develop the next generation of machinists. So I began going to job fairs at the high schools and started promoting CNC machining. As I was serving at a ACTE conference for the NUNTMA, I met Sandi Hemmert, and we began a collaboration that started to open some doors for me on my quest to bring my cause to the younger generation. As we toured Paramount with the top CTE people, invitations to come to the classrooms begun, I must say these are way more effective than job fairs. Subsequent field trips from classes, teachers and work-based learning counselors and my island started to have more people fighting for the same cause.

Developing a real apprenticeship program was not easy, who really has time to manage regulations when it comes to the underaged? Internships were pretty much limited for the same reasons and if kids can’t touch machines, they get bored and eventually leave. Add to this all the time and energy that it takes to train the unskilled.

In comes the Utah Manufacturers Association, Talent Ready Utah, K12 initiatives, the Utah State Department of Workforce Services; School Districts from Granite, Weber, Davis, Alpine, West Jordan and the Utah

Le gislature. Fighters like Peter Reed, Martin Moore, Melisa Stark, Rachelle Ackley, Megan Ware, Sandi Hemmert, Utah State Senator Ann Milner and State Representative Jefferson Moss and others that have come to help make the battle easier to win by passing House Bill 555 that addresses the liability issue that workers comp and Insurance companies want to avoid so hard with under aged apprentices. They also are handling all the dreaded paperwork that no shop owners have time or desire to manage. And the marketing campaign to promote this program will be handled by these soldiers as well. All is missing is your shop’s name in this list. Plenty of seats on this bus, come aboard!

Skills USA was another area that I started to be involved with, great cause to see how The Tech Colleges and some High schools were performing on the development of machining talent. The problem was that the technology had left behind the old manual coding standards that the contest was run on. It seemed

Established in 2010, the NUNTMA is a gathering place for machine shops in Northern Utah.

$25.00 Join

Thursday, May 11, 2023 6-8 pm

Dessert Sponsored by InPosition Technologies!

REGISTRATION REQUIRED FOR ALL EVENTS. VISIT: NUNTMA.ORG/UPCOMING-EVENTS

that contest was on life support for the last few years. After I pleaded with NIMS, the national association that runs Skills, to allow CNC and cam programming to play a bigger role on the contest, I was pleasantly surprised at how fast and well they responded to my pleas. So, I was hoping for better participation in 2023, but at the end of the registration period, the numbers were as low as in years past. We had to do something, with the backing of NUNTMA and State Skills USA, we agreed to allow other students to enter the competition under the NUNTMA umbrella. By reaching out to the unsung heroes at the CNC learning institutions, the instructors that care so much about developing CNC machinists, Wes Chambers at Bridgerland, Troy Winchester at Davis Tech, Kurt Jensen at Northridge High and Corey Bates at Mtech as well as Bret Holmes and Brent Smith at OWTC and SLCC. And Walla! We just run the most successful Skills contest the state has ever seen. Participation was an all-time high and

participants had a great time as they programmed, processed, test their knowledge and interview readiness.

Thanks to Broc Bryson from MSC and Steve Bowman from Stanley Black and Decker that made the prizes look like Xmas in March for the kids. And Mountainlands Tech for allowing such a fun contest be had and let the kids run the machines. Something that has been missing at previous contests. So where am I now?

My Island has a village now, full of soldiers, unsung heroes, amazing shops like Paramount, JD, Centric, Silencerco, Skydandee, Clean Machine, Leanwerks and Parker. Great vendors like Renishaw and Star Metal Fluids that will do anything to promote CNC machining. We need more shops and more schools to be involved, there is a lot of potential talent, but a few shops can’t support the flood gates that are opening with the new generation of apprentices and Skills competitors that the schools are providing.

So, in the words of the immortal Mr. Rogers: “Would you be my neighbor? Would you come to my village and help develop the next generation of CNC talent” We all are on this together, it does take a village but the reward can be amazing if we all work together on an united cause. The cause of keeping our country as the top manufacturing nation in the world.

Forget about the past and promises of other programs, this is for real, so many have worked so hard and tirelessly, don’t wait and see, get off the fence, come be part of something amazing. Support Skills USA and the CNC Apprentice Program. Nothing to lose but much to gain indeed!

and dedication to customer service are number one priorities. This type of expertise and dedication has fostered a reputation of excellence in the tooling and stamping industry.

Located in Tempe, Arizona, our 100,000 Sq. Ft. Facility contains state of the art equipment , with production capabilities ranging from simple geometries to complex forms with intricate details. Precision enjoys a world-class reputation supplying a variety of OEMs, managing their inventory levels, and making certain product quality and timely delivery are NEVER compromised.

“This is going to be one of the premier facilities in the world, certainly here in the state of Arizona, bringing thousands of good paying jobs that you can actually raise a family on and that do not require a

shipped to customers, said Jason Bagley, government affairs director for Intel Corp.’s U.S. Southwest region.

Maxar Technologies is close to completing a $6.4 billion deal selling the company to a large investment fund. The sale would take the aerospace company private and fund its growth.

private equity firm will pay $53 per share in cash to buy Maxar Technologies’ outstanding shares.

The fabs will support growing demand for Intel’s products and be a provider for Intel Foundry Services. The two fabs, when complete, will bring the total to six fabs on Intel’s existing Ocotillo campus.

Some regulatory approvals and closing conditions remain to be met. The deal is expected to close at the end of April or in early May, Jablonsky said.

“I almost can’t stress enough how important these wafers are to our economy,” Kelly said. “Semiconductor chips go in everything from cellphones, vacuum cleaners and cars to the most sophisticated fighter jets in the world.”

The Westminster-based company’s shareholders vote Wednesday afternoon and are expected to approve being acquired by Boston-based Advent International, a private equity investor.

Intel spokeswoman Linda Qian declined to disclose whether the company is on track for meeting its previously announced timeline for opening the fabs in 2024.

She said Intel is making a “tremendous amount of progress” on the fabs, which will be complete within three to five years from the initial groundbreaking date.

The pandemic exacerbated a global shortage of semiconductor chips, most of which are produced in Asia.

Maxar Technologies Inc. will remain on the same trajectory after becoming a portfolio business of the large investment fund, but the company will have more resources available to it, said CEO Dan Jablonsky.

Maxar Technologies builds satellites, collects images and earth observation data from orbit and increasingly turns the images, signals and data its satellites gather into usable information by applying artificial intelligence and virtual reality technologies to it.

The fabs will have more than 250,000 square feet of clean room space and will produce wafers, which are thin slices of semiconductor material used for fabrication of integrated circuits. Each wafer can hold hundreds or thousands of chips, depending on size.

“I think we are very aligned with Advent,” he said. ”They’ve got a lot of wherewithal to invest in the business.”

Maxar’s shareholder vote is scheduled to be completed after stock markets close this afternoon. The vote comes five days after the company revealed the deal has received the key regulatory authorization.

Intel will send the wafers to an assembly testing center where they’ll be cut via lasers into individual chips, packaged and

“We’re at a point now where we need to change the balance of the semiconductor industry supply,” Bagley said. “We are actively working on these two new factories here as part of that strategy to shift some of that production capacity back to the U.S. and back to Europe, so we have more of a fifty-fifty division between Asia, the U.S. and E.U. These efforts are critical to the ability of this country to continue to innovate and continue being a global leader in the semiconductor space.” By Amy

Prior to the 2018 transaction that pulled several space companies together to create Maxar, the business focused mainly on building commercial communications satellites and selling Earth imagery to businesses such as Google.

Edelen – Reporter, Phoenix Business JournalAdvent and Maxar reached an agreement on Dec. 15 on a deal in which the

But its biggest source of steady

revenue was from the federal government, which paid the company to supply Earth observation images and data that weren’t classified, which meant U.S. government agencies could freely share them with allies, non-governmental groups and others. Such shareable commercial satellite services have become a high priority for the U.S. Department of Defense and other nation’s governments in the year since Russia invaded Ukraine and the White House’s public sharing of satellite imagery bolstered the effort to contain Russia’s westward expansion.

Maxar has branched out in recent years to also win contracts from the U.S. military, which is exploring using Maxar-built virtual representations of realworld locations for training pilots, soldiers and others.

“We will prioritize Maxar’s commitment as a core provider to the U.S. defense and intelligence communities, and allies, while providing Maxar with the financial and operational support necessary to apply its technology and team members even more fully to the missions and programs of its government and commercial customers,” said David Mussafer, chairman and managing partner of Advent, in a statement issued when the deal was struck.By Greg Avery

– Denver Business Journal

– Denver Business Journal

Kai Kloepfer, the Gen Z founder of Broomfield-based Biofire, believes his new Smart Gun has the potential to improve public health in America by stemming the rise of gun violence.

As a Boulder high school student, Kloepfer was motivated by a local mass shooting to build a safer weapon. His concept for a handgun that could be unlocked only by its owner using his or her fingerprint landed Kloepfer on the Forbes 30 Under 30 list. His idea earned him a Thiel Fellowship and helped him raise more than $30 million in venture capital to pursue it.

A decade after he built his first model of a biometrically locked handgun for a high school science fair, Kloepfer’s Smart Gun launched for sale to the public Thursday. The 9mm handgun can be pre-ordered online, and the first guns are expected to ship by early 2024.

To pre-order, customers must pay a $149 deposit or about a tenth of the overall cost of $1,499. The gun is available only to people in the United States. Kloepfer and the engineers at Biofire interviewed thousands of gun owners and took the Smart Gun through hundreds of versions before arriving at the latest model. In a room inside Biofire’s Broomfield headquarters, past concept designs plaster three walls, and brightly colored models of previous versions are displayed floor to ceiling on the other.

We are an authorized distributor of genuine OEM parts from Flow, H2O Jet and KMT

From cutting heads, on/off valves, and orifices to ROCTEC nozzles and more, most parts are in stock, and ordering is fast and easy. Visit store.barton.com or call (800) 741-7756 to speak with a parts expert.

FREE SHIPPING EVERY DAY on qualifying online orders at store.barton.com

fall off in high temperatures. Both are common issues, said Essue. When the pins or seals fail they cannot be repaired, and replacing the entire part costs roughly $650.

Essue went to the 388th LSS Air Force Repair Enhancement Program shop here with the idea of creating magnetic covers, something he had seen tried and failed during his time as an F-22 maintainer. He thought it might work with the F-35. The AFREP shop here has a history of coming up with fixes for everything from broken F-22 maintenance equipment to new designs for missile silo button-covers.

After some trial and error, the AFREP shop finalized a design. Their new covers seal the ports with an O-ring, centered in a slightly oversized plastic triangle that is rubber-like, and flexible. The triangle is lined with 20 small magnets embedded around the edges. The covers are also interchangeable. They can be used on either side of any F-35, said Staff Sgt. Christopher O’Donnell, an AFREP technician, who along with Tech Sgt. Justin Platt, came up with the design.

BARTON INTERNATIONAL USA/Canada 800-741-7756

518-798-5462 • info@barton.com • barton.com • store.barton.com

BARTON is a trademark of BARTON Mines Corporation.

Two 388th Logistics Support Squadron maintainers are accelerating change by using their design skills to create sturdier covers for air data ports on F-35A Lightning IIs.

Their design protects a critical part of the aircraft and can be produced in-house, reducing the replacement cost of a failed part from more than $600 to under $50.

On either side of an F-35’s nose are small clusters of tiny holes. Behind them are sensors that collect in-flight data, like air pressure. After a sortie, when a jet is parked, those ports need to be covered.

“We have to keep out debris and moisture and anything that could obstruct those holes and keep the sensors from working properly,” said Master Sgt. Christopher Essue, 34th Fighter Generation Squadron production superintendent, “If those sensors fail, it could provide bad flight data and affect the avionics.”

The original data port covers from the manufacturer are mechanical, they lock into place with tiny quick-release pins. These pins are easily bent or broken, sometimes inside the aircraft. There are also a rubber seals that frequently fail or

The new covers were tested for three weeks in all weather conditions. Airmen and engineers also monitored other systems on the jet to ensure the covers and magnets would not cause any interference. They passed all tests with flying colors, Essue said.

O’Donnell and Platt are working to patent the design, which the Air Force will own. They are also sharing their success with other F-35 bases.“We’re printing for all three of our fighter generation squadrons. Other F-35 bases are purchasing the same equipment and we’re going to share the design files with them,” O’Donnell said. “In the next year and a half, every F-35 in the Air Force could be using these.” By Micah

GarbarinoL3Harris’ autonomy technology permits platforms to have a manned, remote and autonomous operation capability all on one vessel – providing significant benefits to the warfighter. Platform and payload autonomy plays a vital role in the future of naval operations that support Distributed Maritime Operations (DMO). The value to the warfighter stems from the multiple mission packages with the autonomous coordination between the various payloads, distributed platforms and manned assets. The addition of hull, mechanical and electrical (HM&E) autonomy, which allows control and routine operations of systems such that they can support extended operations at sea, adds increased

endurance and cost advantages.

L3Harris’ autonomous capabilities are designed to operate across multi-domains delivering advantages to operations in highly contested environments where manned operators are at risk.

L3Harris’ autonomous endurance vessels integrate state-of-the-art payloads that are being developed to detect and track the most challenging threats. L3Harris’ real-world maritime mission experience prove autonomy’s value in filling today’s operational gaps by decommissioned patrol and mine warfare craft.

The true offset, however, comes through the implementation of artificial intelligence and machine learning (AI/ML) to deliver the mission and situational awareness that maximizes the functionality, safe operating ability and effectiveness of autonomous platforms.

Autonomy is only as capable as the AI and ML that are created. Those vessels that employ AI/ML will evolve, to learn the right behaviors in real-time, to better suit the mission – whether that be transiting more safely, providing more effective kinetic delivery or providing better intelligence, surveillance and reconnaissance (ISR). L3Harris has teamed with the Navy’s best AI/ML providers to deliver this performance capability.

Autonomy takes many forms and can span from simple decision-

aid support to incredibly complex AI/ML algorithms that modify autonomous behavior in real-time. In the near term, autonomy’s value can fill today’s operational gaps in performing 3D activities. When assigned to an unmanned platform, these activities can often be performed at higher efficiencies, with significantly lower costs and less risk to human life than a traditionally manned platform.

AI/ML analytics will process the higher volumes of data needed to make better decisions as the computing power detects the anomalies that human operators cannot observe in real-time. Analytically recognizing trends and anomalies will help determine patterns of life that provide better decision-making through combat identification or adversarial intentions and warnings. Autonomous surface and subsurface vessels provide an affordable alternative for combating some of the common threat behaviors and tactics employed by maligned actors.

Additionally, L3Harris’ advanced computing power will enable high-speed reconnaissance and remote surveillance capabilities for unmanned platforms that frees up higher-end assets for other important mission sets.

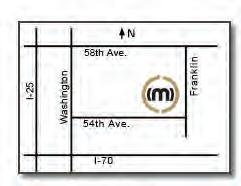

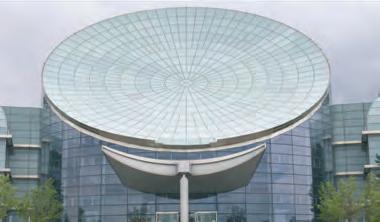

Becoming the most customer centric heat treater in the country is a lofty goal but one that Phoenix Heat Treating has its sights set on. Phoenix Heat Treating (PHT), located in the heart of Phoenix, Arizona, has served various industries since it opened in 1963. Originally established in a 700 square foot space, PHT has grown to two buildings totaling 43,000 SF on 4 acres of land. PHT also continues to expand their processing capabilities and their commitment to customer satisfaction.

PHT is a legacy of knowledge passed down from many generations, going back to the late 1800’s and the blacksmith trade. Charles Wesley Sr, was a Prussian Swordsmith. Charles immigrated to the U.S. in 1887 and opened his first heat treating facility in 1915 in Milwaukee, Wesley Steel Treating. He was also one of the founding members of the Metal Treating Institute. Charles’ grandson, Chuck Hushek, moved his family to Phoenix in 1957 and opened PHT in 1963. This year, the company is celebrating their 60th year of service in Phoenix and is run by its 2nd generation owner, Peter (Chuck’s son), and his son, Charlie Hushek. Heat treating is in their blood!

Not only does generational practical wisdom get utilized in their processing strategies, but Peter is also a degreed metallurgical engineer. It is estimated that less than 15% of commercial heat treaters have a metallurgist on staff. It is this combination of experience that has given Peter the nickname of Metal Whisperer. They have developed a reputation for being able to solve difficult processing scenarios and often receive parts from across the country from customers looking to achieve outcomes that they have otherwise been unable to achieve.

Charlie says that Pete understands metal from the inside out and it

makes perfect sense to him. Early on, Charlie didn’t plan to join the family business as a 5th generation heat treater. In fact, he studied construction management in college, and pursued this passion building hospital rooms after graduating from college. A couple of years later, Pete asked his son to join the business, and Charlie left construction management. He first worked 2nd shift unloading baskets from furnaces. Charlie moved from this arduous task to day shift; first in the shop, then in customer service, then into other departments, learning how Phoenix Heat Treating operated in every aspect of the business. Charlie moved into the General Manager position when the company lost their General Manager to Covid. Charlie was instrumental in the new ERP implementation, Pete says.

Charlie excels at a number of things, including communication with customers, suppliers and employees and a comfort level with adopting new technologies. “There is always a learning curve for family members working together but we seem to have found our stride and we actually enjoy working together. We have developed a respect for each other’s strengths,” said Charlie.

Phoenix Heat Treating has carved out a niche in the heat treat industry for doing the difficult orders but also for the wide variety of processes they are able to perform. Some of those processes include Vacuum, Aluminum, Carburizing, Carbonitriding, Mar-Quench, Austemper, Titanium, Cryogenics, Thermal Cycling, and Up-Hill quenching. PHT is also proud of their 18-month Nadcap Merit status and 24-month AC7004 quality certification. These approvals have afforded them the honor of processing work for Honeywell, Raytheon, GE, Pratt Whitney, Bell Helicopter, Rolls Royce, Lockheed Martin and Northrup Grumman to name a few. PHT also has a robust non-aerospace division which they call “PHT Precision.” This division services the unique needs of the tool and die, firearm and commercial industries. As Peter noted, “We pride ourselves on being the general store for heat treating. We can offer a little bit of everything to almost everyone.”.

Knowledge is just part of the equation – it’s how you use the knowledge and guard the knowledge that is equally as valuable. Phoenix Heat Treating has made tremendous investment into technology to leverage their years of experience. Every employee at PHT utilizes iPads to track, photograph, and record data on orders. Their company is filled with TV screen size monitors displaying live processing data, process recipes,

and production schedules. All orders at PHT are processed using a recipe, and the ERP system will block untrained personnel from completing tasks they are not qualified for.

“This advancement in technology has been the foundation to adding transparency to the supply chain”, noted Charlie, adding “Our customer portal allows customers to view certifications, shipping tickets, invoices, and real time job tracking, and none of this would have been possible without the digitalization that we went through”. When asked to elaborate Peter noted “Customers can see what operation parts are on in real time, the modern supply chain demands transparency and access to information quickly. We feel that our portal pulls us into the modern era and shares information that has not been seen by any other heat treater.”

Phoenix Heat Treating is indeed well on their way to being the most customer centric heat treater; not only in the west but also in the country. When asked what’s next, Peter and Charlie agreed that exploring new processes such as Hot Isostatic Press (HIP) to service the additive manufacturing industry and new technologies is a focus. Utilizing their generational knowledge, Peter’s practical engineering to solve customer challenges, a wide range of capabilities and approvals, leveraging technology, and a transparent supply chain; it’s clear to see that they are focused on providing customers the best possible experience.

To learn more about how Phoenix Heat Treating can support all of your heat treat needs, as well as specialized services, contact them at: phoenix-heattreating.com or call: 602-258-7751

www.westernstatesmetals.com

Science, technology, engineering and mathematics (STEM) educators will have the opportunity to make their voices heard at the 2023 Annual STEM Conference this August. The conference will take place on August 3-4 at Borah High School in Boise.

The first 200 educators to sign up to present or attend will receive free conference materials and resources from the State Department of Education. Presenters will also receive free registration to the conference. The deadline to apply to be a presenter is June 1, and all applicants will be notified by June 15 if the proposal is accepted. Presenters may make their presentations alone or with a co-presenter.

“Letting our educators lead the conversation on what is working for their students in

STEM puts our region’s true experts front and center,” Superintendent of Public Instruction Debbie Critchfield said. “I encourage any instructor who feels they have made a difference for their students in STEM to join us and share your experience at this year’s event.”

The conference is sponsored by the Idaho Council of Teachers of Mathematics, the Idaho Science Teaching Association and the Idaho Environmental Education Association, with support from the State Department of Education, and the Idaho STEM Action Center. Local presenters will be joined by this year’s conference keynote speakers Steve Spangler and Dr. Peter Liljedahl.

Spangler is a bestselling author, STEM educator and business leader. He has worked with educators at all levels to make STEM learning more connected and engaging in the 21st century classroom. Spangler’s in-person and virtual professional development workshops focus on inquiry-based le arning that highlights best practices for classroom teachers with research-guided strategies for engagement.

Liljedahl is a Professor of Mathematics Education at Simon Fraser University in Canada. He is a member of the executive of the British Columbia Mathematics Teacher Association and current president of the International Group for the Psychology of Mathematics Education. Liljedahl consults regularly with teachers, schools and school districts in both the United States and Canada on issues of teaching

and learning, thinking classrooms, assessment and numeracy.

Those interested in registering as an attendee can secure their place at the conference now by visiting https://www.idahoscienceteacherswix.org/conference.

Research on the best and worst states in which to start a small business rank Idaho among the best.

The most Idaho-friendly of these reports, released by Capital on Tap, ranks Idaho third best in the nation for small-business startups. The business credit card firm placed Florida on top, followed by Texas. Vermont came in as the worst, according to CoT.

While starting a business entails significant risks, “this research provides valuable insights when it comes to the business climate in different states to help new entrepreneurs in making informed decisions, and creating a favorable environment for their business,” said Damian Brychcy, COO at CoT, in a release.

They looked at factors including new firm survival rates, corporate tax rates and the number of entrepreneurs in each state to determine the viability of starting a small business.

CoT said Idaho has the eighth lowest labor cost nationwide, which is “a positive for a small business that may not have generated much cash flow to start.”

The study found Idaho has a new employer business actualization rate of 13.84 percent. That figure represents how many businesses become employers within the first

two years for every 100 business applications. Their report indicates Idaho startups create 6.1 jobs per 1,000 residents. Florida led the nation in this category, which indicates these businesses are viable enough to employ staff and improve local economies.

Other reports place Idaho lower on the ladder but still in the top five. WalletHub places Idaho at No. 5, behind Utah, Florida, Texas and Colorado. It made its comparisons based on business environment, access to resources and business costs, broken into 27 metrics all carrying each state’s weighted average. A score of 100 represents the most favorable conditions.

Idaho’s overall score was set at 55.88, compared with No.1 Utah at 59.91. However, the study said Idaho is No. 1 in the country for the average growth in the number of small businesses. Alaska, at the bottom of this study, came in with an overall score of 39.44.

NASA is just over a day away from launching its most comprehensive air-pollution monitoring instrument yet into orbit — a project years in the making and made possible by two Colorado companies.

The space agency’s TEMPO mission is slated to lift off from a Cape Canaveral, Florida launch pad. It’s putting a pollutiontracking instrument made by Boulder-based Ball Aerospace (NYSE: BLL) into orbit on a satellite made by Westminsterbased Maxar Technologies Inc.

The Ball-built payload, the size of a washing machine, will ride on a communications company’s large commercial satellite, lingering in an orbit that keeps the satellite over North America all day, allowing an unprecedented hourly collection of detailed air pollution data nationwide every day during daylight hours.

“We are very excited for this new capability for the United States and neighbors to the north and south,” said Dennis Nicks, director of payload engineering at Ball Aerospace.

The geostationary orbit will allow the host communications satellite, owned by Tyson’s Center, Virginia-based Intelsat S.A., to beam internet coverage to airlines flying across the continent while the TEMPO instrument tracks air pollutants — primarily nitrogen oxides, formaldehyde and ozone — anywhere between Mexico City and tar sands oil production areas of southern Canada.

The instrument will be able to measure atmospheric chemicals across areas as small as four square miles, offering nearly real-time understanding of air pollutants on a scale not possible with ground monitoring or coverage by existing satellites, said Karen St. Germain, director of NASA”s earth science’s division, which funded the project.

“The real unique difference is going to be that geostationary look,” she said, adding the four-square-mile resolution makes the data especially meaningful for public health uses. “With TEMPO, it’s down to more of a neighborhood scale.”

The TEMPO instrument, formally called the Tropospheric Emissions Monitoring of Pollution payload, was picked by NASA to be a tenant on larger satellite as a way to save money by avoiding the costs of having a larger satellite designed, built and large into geostationary orbit.

While most of the Intelsat’s satellite will be focused on providing internet services, the TEMPO air quality instrument will be collecting and beaming down data to scientific investigators at the Smithsonian Institute and Harvard University.

The air pollution data will be made available by NASA to public agencies and researchers and others.

The ride-along approach to getting TEMPO into orbit is a relatively rare arrangement, one only done a handful of times.

NASA contracted Ball Aerospace a decade ago to design and build the TEMPO pollution tracker, making it similar to an instrument the company made for a South Korean satellite studying air pollution over Asia.

Then, NASA hired Maxar, a major maker of satellites for communications companies and others, to find a host

satellite for TEMPO and integrate the instrument into it. The TEMPO instrument went into storage for nearly two years because no satellite company came forward willing to host it until Maxar and Intelsat worked out an arrangement.

Intelsat operates 56 geostationary satellites, many of them built by Maxar, that provide communications services internationally.

NASA’s costs to build TEMPO was about $90 million. Another $70 million was spent on designing and building it into the Intelsat satellite.

All told, NASA expects its total spending on TEMPO to be about $210 million, said Kevin Daugherty, TEMPO project manager, NASA’s Langley Research Center.

The initial TEMPO mission is funded to last 20 months. NASA expects to renew and fund TEMPO’s pollution monitoring after that for as many years as the instrument returns useful data, Daugherty said.

The Maxar-built Intelsat orbiter is designed to function for 15 years.

The satellite will launch atop a SpaceX Falcon 9 rocket. The Intelsat satellite, once in orbit, will take a few weeks to begin collect solar power and be commission.

The TEMPO instrument should be turned on by May and start going through calibrations allowing it to begin pollution monitoring in the fall.

NASA hopes it can succeed with other hosted payload missions in the future, a goal that has eluded the agency.

Companies typically spend several hundred million dollars on having large, long-lasting satellites built.

Fear of costly delays makes satellite operators hesitant to try to accommodate tenant payloads, said Jean Luc Froeliger, senior vice president of space systems at Intelsat.

But in this case, TEMPO was already built, and Intelsat’s longstanding relationship with Maxar made it comfortable the payload could be added to the satellite without changing the satellite’s timeline.

“The prime reason there haven’t been more opportunities is the schedule risk,” Froelinger said. “In this case, we didn’t have the schedule risk and it was a win-win.”By Greg Avery – Denver Business Journal

A question that I am often asked is “what are you seeing out there?”, which ultimately leads to a discussion about the economy from both a macro and micro perspective.

From my view (of financing manufacturing equipment all around the US), the larger companies are continuing to increase machining capacity with new machine orders, but the relatively smaller companies are showing increased hesitation in recent times. This is displayed in the accompanying graph (estimated figures for display purposes).

The bad: The majority economic indicators within the manufacturing market are pointing to some degree of a recessionary period that should be felt in late Q3/early Q4.

The good: This will be the most foreseen and anticipated recession in history. If we do enter a recessionary period, it should be relatively short term (versus a standard 18-month recession) and easy to weather. If we do not enter a recession, we will more than likely experience lack-luster production for that period.

The better: The forecast for late 2023 is positive and appears even stronger as we look at 2024.

The best: The US economy is extremely resilient and historically bounces back the year proceeding a recessionary period. We have the highest GPD in the world and manufacturing will always be a significant contributor.

Whether we enter a slow period or not, now is a great time to take advantage of Epic Finance’s 120-day payment deferral program. With this program, your first monthly payment isn’t due until 120 days after the equipment has been fully installed. This program, combined with our aggressive rates, speed of approval, and fearless customer service is what makes us your best option for all types of equipment financing.

Please feel free to reach out directly to discuss your goals and find out how Epic can help achieve them.

Chris Frans, CLFP; President chris@epicapprovals.com

Chris Frans, CLFP; President chris@epicapprovals.com

303-261-8200

Equipment and software investment growth cooled in the early months of 2023, resulting in the Equipment Leasing & Finance Foundation lowering its annual forecast for investment growth to 1.0%, according to the Q2 update to the 2023 Equipment Leasing & Finance U.S. Economic Outlook. The report also predicts sluggish economic growth in Q1 as the economy edges closer toward recession, which the Foundation continues to expect will begin during the second half of the year. Annualized economic growth is forecast to be 0.7% in 2023, largely driven by a solid jump-off point at the end of last year.

Nancy Pistorio, Foundation Chair, said, “Despite the U.S. economy ending 2022 with healthy growth and maintaining some momentum into early 2023, equipment and software investment softened to 2% annualized growth in Q4 and remains under pressure. The economy is still above water, but most indicators point to slowing growth, and many economists continue to expect a recession to begin later this year.

ACCESSORIES

Desert EDM Sales ____ 480-816-6300

Abrasive Products

Barton International ____ 800-741-7756

Chemtool Inc. _______ 815-957-4140

Bandsaw Blades

Roentgen USA _______ 847-787-0135

Bar Pullers

Accudyne Corp _______ 303-991-1500

Edge Technologies ______ 951-440-1574

Boring, Grooving, Milling, Turning Tools

Fullerton Tools ____ 989-799-4550

Ceramic Tools

NTK Cutting Tools ________ 425-365-3613

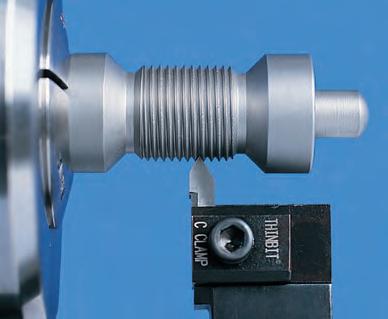

THINBIT __________ 888-THINBIT

Clamps & Grips

Hainbuch ________ 818-970-7874

SCHUNK _________ 919-602-8294

CNC Collet Chucks

Hainbuch ________ 818-970-7874

Royal Products _______ 800-645-4174

Sulli Tool & Supply ____ 714-863-6019

CNC Lathe Accessories

Von Ruden Manufacturing 763-682-0322

Collet Fixtures

Royal Products _______ 800-645-4174

Sulli Tool & Supply ____ 714-863-6019

Compressor Systems

Ingersoll Rand _____ 206-472-0826

Coolant Systems Chemtool _________ 815-957-4140

Chipblaster ________ 310-502-4184

MP Systems ________ 909-282-7463

Drills

Machine Tool & Cutter Grinding 435-512-4416

Dust Collectors, Filtration Equip.

Star Metal Fluids _____ 800-367-9966

EDM Materials & Supplies

Desert EDM Sales ____ 480-816-6300

EDM Network _______ 480-836-1782

EDM Perform. Access. ___ 800-336-2946

Global EDM Supply ____ 480-836-8330

Star Metal Fluids _____ 800-367-9966

EDM: Tooling Systems

Desert EDM Sales ____ 480-816-6300

EDM Perform. Access. ___ 800-336-2946

End Mills

Fullerton Tools ____ 989-799-4550

Machine Tool & Cutter Grinding 435-512-4416

Filtermist Mist Collectors

Royal Products _______ 800-645-4174

Gage Blocks

Starrett ___________ 949-382-4123

Garnet Abrasives

Barton International ____ 800-741-7756

Knives: Replacement Superior Grinding _____

Lifting & Material

____ 801-230-6794

Dormer Pramet ____ 720-837-3232

Industrial Supply __ 800-288-3838

SCHUNK ________ 919-602-8294

Sulli Tool & Supply ____ 714-863-6019

THINBIT __________ 888-THINBIT

Von Ruden Manufacturing 763-682-0322

Machine Tool Cool. Filtration

Chipblaster ________ 310-502-4184

Star Metal Fluids _____ 800-367-9966

Milling and Turning Products

Dormer Pramet _____ 801-230-6794

Dormer Pramet _____ 720-837-3232

Industrial Supply ___ 800-288-3838

Von Ruden Manufacturing 763-682-0322

Parts Washing Equipment

Star Metal Fluids _____ 800-367-9966

Power Tools

Ingersoll Rand _____ 206-472-0826

R8 Quick Change Tool System

Royal Products _______ 800-645-4174

Robot Accessories

SCHUNK _________ 919-602-8294

Rota-Rack Parts Accumulator

Royal Products _______ 800-645-4174

Solvents /Degreasing Agents

Castrol ___________ 800-894-7773

Hasco Oil__________562-595-8491

Star Metal Fluids _____ 800-367-9966

Spindles

GMN USA _________ 800-686-1679

Sulli Tool & Supply ____ 714-863-6019

Surface Plates

Starrett ___________ 949-382-4123

Toolholding

Hainbuch ________ 818-970-7874

Industr ial Supply ___ 800-288-3838

Tooling for Swiss Type Lathe

NTK Cutting Tools ________ 425-365-3613

Vices and Vice Jaws

Desert EDM Sales _____ 480-816-6300

Hainbuch ________ 818-970-7874

Sulli Tool & Supply ____ 714-863-6019

Waterjet Cutting Abrasives

Barton International ____ 800-741-7756

Workholding

Hainbuch ________ 818-970-7874

AUTOMATION

Acieta __________ 402-650-8132

DATRON _________ 480-826-3689

Bystronic Inc__ _______ 702-340-6964

Hainbuch ________ 818-970-7874

Fiero Automation _____ 303-431-3600

Automation Controls

Acieta __________ 402-650-8132

CALIBRATION SERVICES

Advanced Coord. Tech ___ 303-469-6161

Klontech Industrial Sales _ 480-948-1871

Total Qual. Syst. ______ 480-377-6422

GRINDING Grinding Machines

Moncktons Mach Tools _ 303-571-4933

Manual Lathes & Mills

AME, Inc. ________ 303-922-9266

Sharp Precision

Barcode Scanners

KEYENCE _____ _____720-614-9241

CMM Probes

Gage Lab Products_____ 801-716-2972

Innovative Measuring Systems 602-527-5488

Klontech Industrial Sales _ 480-948-1871

LK Metrology _______ 949-716-4440

Renishaw _________ 847-286-9953

Coordinate Measuring Mach.

Gage Lab Products_____ 801-716-2972

Innovative Measuring Systems 602-527-5488

Klontech Industrial Sales _ 480-948-1871

LK Metrology _______ 949-716-4440

Productivity _______ 303-571-4933

Renishaw _________ 847-286-9953

Selway Machine Tool __ 888-735-9290

Total Quality Systems ___ 720-338-2581

Zeiss Industrial Metrology _ 800-327-9735

Gauging Equipment

Gage Lab Products_____ 801-716-2972

Innovative Measuring Systems 602-527-5488

Klontech Industrial Sales480-948-1871

LK Metrology _______ 949-716-4440

Renishaw _________ 847-286-9953

Starrett ___________ 949-382-4123

Total Quality Systems ___ 720-338-2581

Laser Marking Systems

KEYENCE _____ _____720-614-9241

Measurement Systems

KEYENCE _____ _____720-614-9241

Starrett ___________ 949-382-4123

Metrology Instruments

Gage Lab Products_____ 801-716-2972

Innovative Measuring Systems 602-527-5488

KEYENCE _____ _____720-614-9241

Klontech Industrial Sales480-948-1871

LK Metrology _______ 949-716-4440

Renishaw _________ 847-286-9953

Starrett ___________ 949-382-4123

Total Quality Systems ___ 720-338-2581

Zeiss Industrial Metrology _ 800-327-9735

Microscopes

KEYENCE _____ _____720-614-9241

Optical Comparators

Gage Lab Products

Innovative Measuring Systems

Klontech Industrial Sales480-948-1871

LK Metrology

Renishaw _________

Renishaw

Total Quality Systems

Sensors: Contact & Optical

Zeiss Industrial Metrology

Video Measuring Systems

Gage Lab Products

Klontech Industrial Sales480-948-1871

Total Quality Systems

Horizon Carbide Tool

Utah Metal Works, Inc.

METALS & MATERIALS

AZ Tool Steel LLC

Coastal Metals

Erickson Metals

Laube Titanium

Olympic Metals

Ryerson _________

United Perform. Metals

Western States Metals

Affiliated Metals Olympic Metals

Garnet Abrasives

Barton International ____ 800-741-7756

Metals: Bar & Plate

AZ Tool Steel LLC ____ 480-784-1600

Coastal Metals ______ 800-811-7466

Ryerson __________ 303-227-6310

TW Metals ________ 800-203-8000

Mold Steel AZ Tool Steel LLC ____ 480-784-1600

Nickel Alloys AZ Tool Steel LLC ____ 480-784-1600

Ryerson _________ 303-227-6310

TW Metals ________ 800-203-8000

United Perform. Metals 317-946-0025

Plate-Precision Saw Cut

Erickson Metals _____ 877-543-6061

Pre-Honed Tube

Western States Metals _ 801-978-0562

Stainless Steel

AZ Tool Steel LLC ____ 480-784-1600

Coastal Metals ______ 800-811-7466

Olympic Metals _____ 303-286-9700

Ryerson __________ 303-227-6310

United Perform. Metals 317-946-0025 Steel

AZ Tool Steel LLC _______ 480-784-1600

Coastal Metals ______ 800-811-7466

Olympic Metals _____ 303-286-9700

Ryerson __________ 303-227-6310

Ryerson __________ 303-227-6310

United Perform. Metals 317-946-0025

Titanium

Laube Titanium___805-388-1050x124

METAL DISTRIBUTORS

Erickson Metals _____ 877-543-6061

Coastal Metals ______ 800-811-7466

Laube Titanium __ 805-388-1050x124

Olympic Metals _____ 303-286-9700

Ryerson __________ 303-227-6310

TW Metals _________ 800-203-8000

United Perform. Metals 317-946-0025

Western States Metals _ 801-978-0562

NEW MACHINERY

3D Metal/ Additive

Manufacturing Machines

Production Machine Tools _ 425-881-1200

Renishaw _________ 847-286-9953

CHIP CUTTING

CNC Drilling/Tapping

Methods West ______ 602-437-2220

CNC Mills

Action Machinery ______888-289-9100

AME, Inc. ________ 303-922-9266

DATRON _________ 480-826-3689

DMG Mori ________ 801-561-2001

Doosan _________ 973-618-2500

Hurco __________ 800-634-2416

J.M. Grisley _______ 801-486-7519

J.M. Grisley _______ 208-861-8991

KTR Machine ______ 623-202-7177

Methods West ______ 602-437-2220

Productivity _______ 303-571-4933

Romi Machine Tools LLC859-647-7566

Sharp Precision _____ 310-370-5990

Smith Machinery Co __ 801-263-6403

Tornos USA ________ 951-695-0342

Triad Machine _______ 303-424-0268

CNC Lathes

Action Machinery ______888-289-9100

AME, Inc. _________ 303-922-9266

DMG Mori__________801-561-2001

Doosan __________ 973-618-2500

Foothills Machinery ____ 303-466-3777

J.M. Grisley ________ 801-486-7519

J.M. Grisley ________ 208-861-8991

Hurco ___________ 800-634-2416

KTR Machine________623-202-7177

Methods West _______ 602-437-2220

Productivity_________303-571-4933

Smith Machinery Co ___ 801-263-6403

Triad Machine _______ 303-424-0268

CNC Swiss Turn Machines

Productivity ___ ____303-571-4933

Tornos USA ______ 951-695-0342

Triad Machine ______ 303-424-0268

______ 602-437-2220 Productivity _______ 303-571-4933

Rotary Surface Grinders

DCM Tech _________

Sawing Machines

Action Machinery

Multicam _________ 970-218-9046

Latitude Machinery ____ 602-517-7153

Production Machine Tools _ 425-881-1200

Band Saws

KNUTH Machine Tools ___ 847-415-3333

Ultimate Machinery ____ 480-966-2000

Bar Feeders

Edge Technologies _____ 951-440-1574

Bending

Bystronic Inc____ ____ 702-340-6964

Cold Saws

Fullerton Tools ____ 989-799-4550

KNUTH Machine Tools ___ 847-415-3333

CNC Punching Centers

Latitude Machinery ____ 602-517-7153

S&S Machinery Sales __ 602-368-8542

CNC Routers

Multicam _________ 970-218-9046

Drill Lines

Production Machine Tools _ 425-881-1200

Fiber Lasers

Budʼs Machine Tools ___ 385-271-6718

Multicam _________ 970-218-9046

Production Machine Tools _ 425-881-1200

Grinding Machines

DCM Tech ________ 800-533-5339

Latitude Machinery ____ 602-517-7153

KNUTH Machine Tools ___ 847-415-3333

KNUTH Ma

Multitool USA ______ 800-660-0880

Iron Workers

Action Machinery ______888-289-9100

Latitude Machinery ____ 602-517-7153

Production Machine Tools _ 425-881-1200

S&S Machinery Sales __ 602-368-8542

Laser Cutters

Action Machinery ______888-289-9100

Budʼs Machine Tools ___ 385-271-6718

Bystronic Inc__ ______ 702-340-6964

KNUTH Machine Tools ___ 847-415-3333

Latitude Machinery ____ 602-517-7153

MMT Productivty ____ 303-571-4933

Production Machine Tools _ 425-881-1200

S&S Machinery Sales __ 602-368-8542

Triad Machine ______ 303-424-0268

Magnetic Particle (NDT) Machines

DCM Tech _________ 800-533-5339

Pipe & Tube Benders/Notchers

Bystronic Inc__ ______ 702-340-6964

S&S Machinery Sales __ 602-368-8542

Plasma Cutters

Action Machinery ______888-289-9100

Bystronic Inc__ ______ 702-340-6964

KNUTH Machine Tools ___ 847-415-3333

Multicam _________ 970-218-9046

Production Machine Tools _ 425-881-1200

Press Brakes

Action Machinery ______888-289-9100

Bystronic Inc__ ______ 702-340-6964

Latitude Machinery ____ 602-517-7153

Production Machine Tools _ 425-881-1200

Fullerton Tools

Fullerton Tools

Latitude Machinery

Production Machine Tools

Shearing Machines

Action Machinery

Bystronic Inc__

Latitude Machinery

S&S Machinery Sales

Vacuum Tables

DATRON _________

OTHER ACCESSORIES

Grinding Accessories

Multitool USA ______ 800-660-0880

Tooling Systems

Desert EDM Sales _____ 480-816-6300

USA EDM Supply _____ 480-836-8330

PALLET SYSTEMS

Automatic Pallet Systems

Midaco __________ 847-593-8420

Automatic Door Opener Systems

Midaco __________ 847-593-8420

Manual Rotary Pallet Systems

Midaco __________ 847-593-8420

Robotic Part Loading Systems

Midaco __________ 847-593-8420

PLASTICS

Acrylics And Polycarbonates

Laird Plastics ______ 303-292-1687

Plastics: Fabrication

Laird Plastics ______ 303-292-1687

Graphics Materials

Laird Plastics ______ 303-292-1687

Mechanical/Engineering Material

Laird Plastics ______ 303-292-1687

ROBOTIC

Robotic

Business Forms/ Custom labels/Brochures

Pryntink __________

855-675-1444

Calibration Services

Advanced Coord. Tech __ 303-469-6161

Klontech Industrial ____ 480-948-1871

Quality Measurement Services970-413-2438

Western States Calibration 801-466-1700

Consultant,Operational Consultant, ISO

ABS Quality Evaluations702-371-7591

BMSC __________ 602-445-9400

MEP ___________801-863-7001

Contract Inspection