Two years after joining forces, Smith Machinery Company and Action Machinery offer customers best in class Sales and Service for CNC Metal Cutting and Fabrication solutions.

Two years after joining forces, Smith Machinery Company and Action Machinery offer customers best in class Sales and Service for CNC Metal Cutting and Fabrication solutions.

“If you want loyalty, get a dog!”

I’ve been a Southwest Airlines customer since as long as I can remember. Through their loyalty program, I can check bags free (well actually everyone can do this), I can board early as an ‘A List’, I get a good boarding position without having to check in 24 hours prior to departure, and I can even select a Companion who flies free with me any time we fly together. This last perk is only available because I use their credit card to charge all of my printing costs!

And so, for the last 2 decades, while traveling domestically I been loyal to my airline. During and after Covid, however, my loyalty airline cancelled direct services to some of the cities I fly to.

Their service also went downhill. Delayed connecting flights had me change my travel to new airlines, including American Airlines, Delta, and Alaska Airlines.

I had a ‘Wow’ event the first time I traveled on a non-Southwest flight. While I boarded, I was handed earplugs, as was everyone who wanted one. My flight had complimentary Wi-Fi, movies were also no charge, and there were even USB ports at every seat. I no longer had to worry about using my phone, in particular, because prior, I knew I would need it for my GPS, and I didn’t want it to go dead.

I loved my new airlines! Once I made the decision to switch to these new airlines (each beneficial for specific cities I was traveling to), I signed up for their Airlines credit cards. This quickly gave me elite status, as I used it to pay for printing. It also meant I wouldn’t have a bag charge, just like Southwest. My point is this. In business, and in our personal lives, we make a vendor/ supplier selection and we stay with it for years, and often we don’t go back to competitors to price check, to determine if turnaround times are better, to see if they have newer offierings, or in general if there are new advantages to this supplier.

We likely miss out, as I did for years believing Southwest was the best airline for me.

I am not suggesting that you undo relationships you have had with your suppliers. What I am recommending is that you re-evaluate suppliers on a regular basis. Your business is the most important thing for you to worry about, outside of your personal life. It is imperative that you regularly look for providers who are helping your business to succeed.

This also applies to services such as communications, travel, contract labor, business and medical insurance, and other suppliers who help you keep your business humming. These costs have escalated in 2023, far beyond increases we were accustomed to seeing.

On another note, there has never been a more critical time in the lives of manufacturing owners to automate. You can read about companies in this issue that are using automation to remain competitive. “There’s a lot of automation that can happen that isn’t a replacement of humans, but of mind-numbing behavior.” ~ Stewart Butterfield.

Celebrating Two Years As A Merged Entity: Offering Best In Class Sales and Service....For CNC Machining AND Precision Fabrication

Published

manufacturers abreast of news and to supply a viable vendor source for the industry.

Circulation: The A2Z Manufacturing has compiled and maintains a master list of approximately 6500 people in the Rocky Mountain states actively engaged in the Precision Manufacturing Industry. It has an estimated pass on readership of more than 18,000 people.

Advertising Rates, deadlines and mechanical requirements furnished upon request or you can go to www.azManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

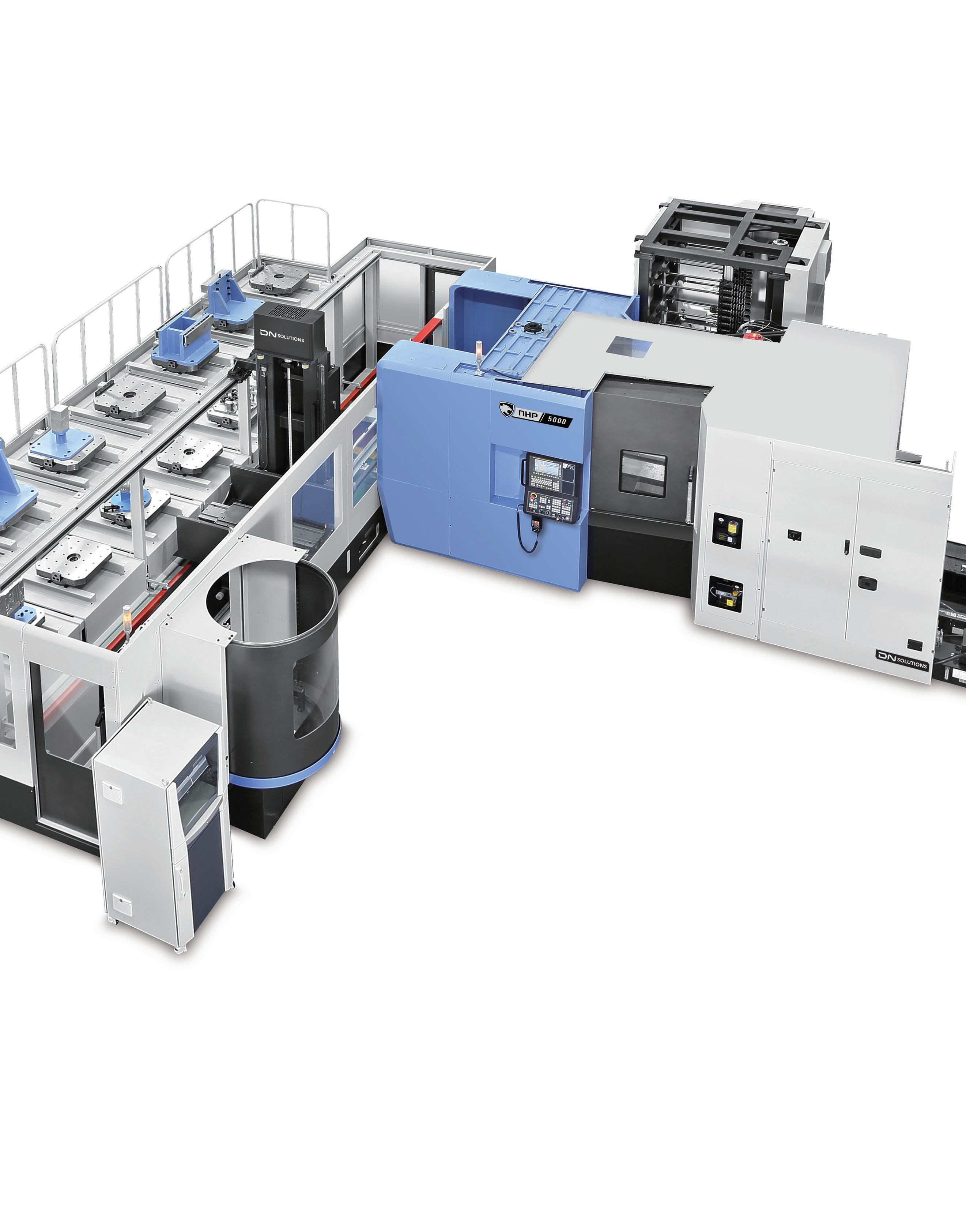

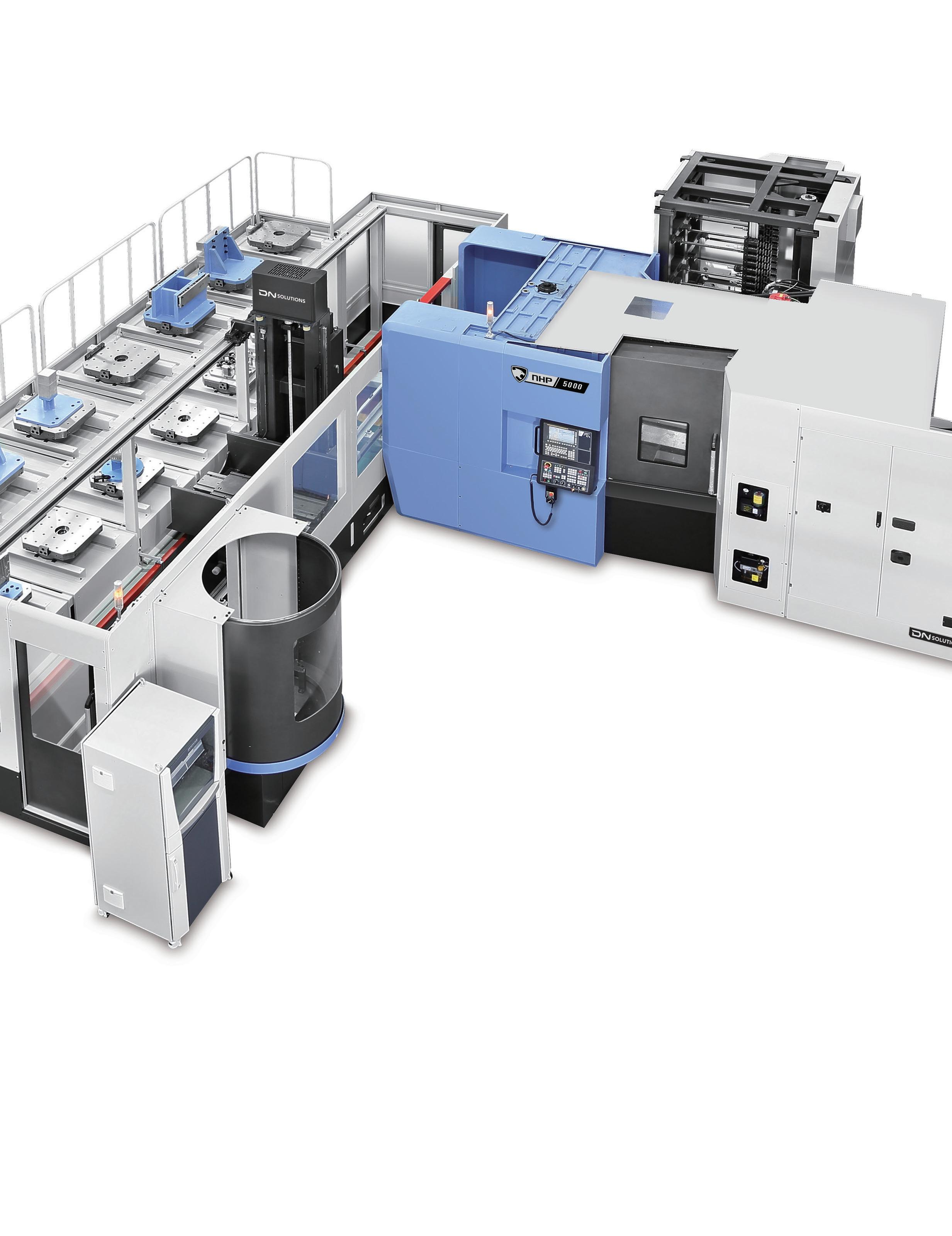

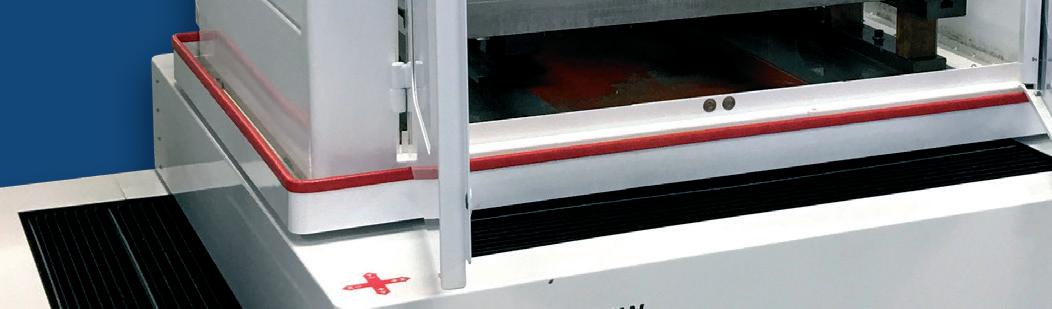

Nothing is sweeter than the sound of a spindle making chips, especially when it’s the high-performance spindle found on one of our NHP Series of Compact Horizontal Machining Centers. These workhorses can handle whatever you throw at them, and are always asking for more.

That’s where our Linear Pallet System (LPS) comes in. It feeds the NHP around the clock, which leaves nothing but pallets upon pallets of precise, ready-to-ship parts. And if floor space is a concern, the Rotary Pallet System (RPS) will fit right in.

√ Are You Ready To Simplify Your ISO9001 and/or Your AS9100 System? We Can Help With Do-It-Yourself Templates all the way to Full Implementation Services.

√ Working Remotely? Now is the time to implement Continuous Improvement Software (CIS) and have transparency in your Business Management System! Are you ready to get help Maintaining your QMS (Internal Audits Management Reviews)?

√ Need Help Maintaining Your Internal Audits or Management Reviews?

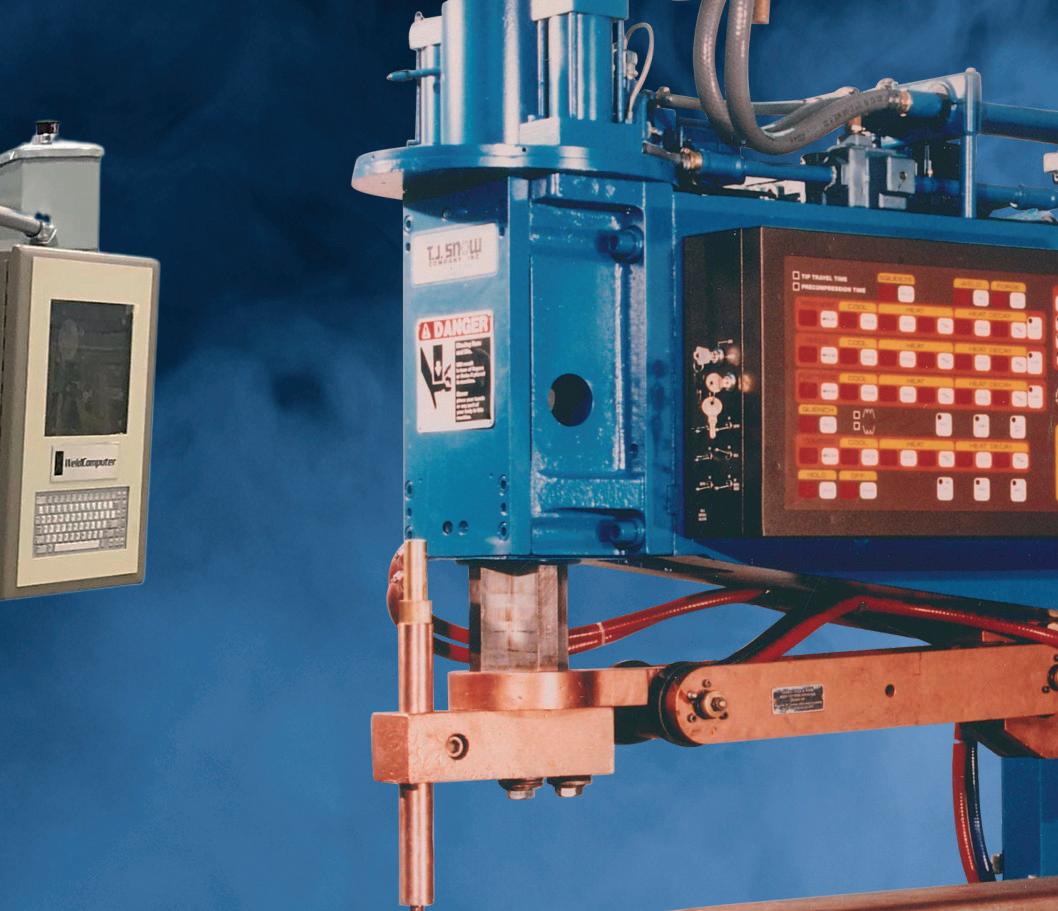

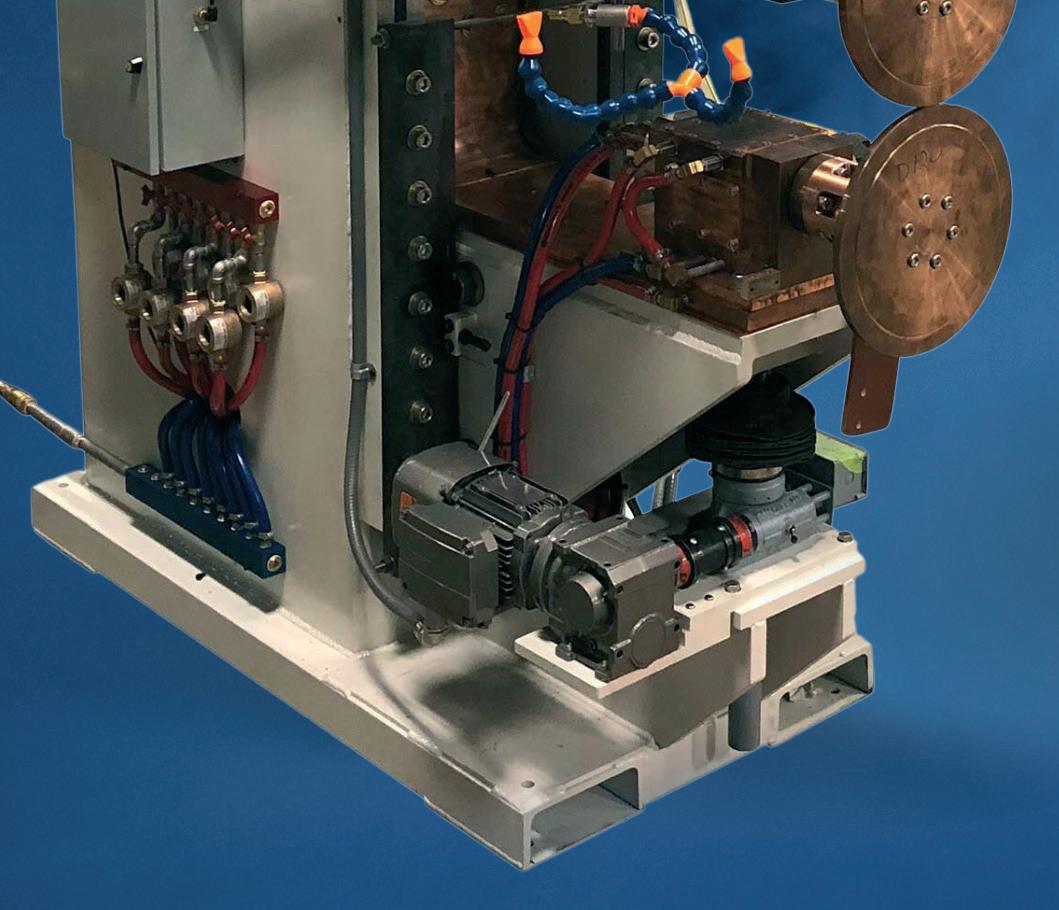

control, which must be remote-mounted on a wall or pedestal.

To facilitate a full range of motion, TECNA portable spot welding guns can be matched to a properly-sized TECNA spring balancer.

TECNA stationary spot welders include rocker arm and vertical press-type machines of various KVA ratings.

T. J. Snow Company of Chattanooga, Tennessee is the largest stocking distributor of TECNA portable and stationary resistance spot welders in the U. S.

Made in Italy, the value-priced TECNA product line includes a complete range of machines for spot and projection welding.

The small models of TECNA spot welders have become increasingly popular in recent years because Miller Electric obsoleted its line of 10 and 20 KVA machines that were popular with sheet metal shops.

TECNA portable gun-style spot welders are unique because the programmable welder control is built into the gun’s handle. Other brands of portable spot welders require a separate

One of the most popular TECNA welders is the Model 6128N, a versatile 160 KVA press-type combination projection and spot welder with a Mid Frequency Direct Current (MFDC) power supply.

The welder is equipped with a sophisticated Model TE-700 control, which includes Constant Current and a Dynamic Mode which allows the weld schedule to adjust on the fl y.

To make the selection of the ideal TECNA welder easy, T. J. Snow Company invites customers to send samples for welding in its lab.

Trustworthytechnologyforprecise measurementatanaffordableprice!

We Specialize in Close Tolerance Precision Grinding and Small Parts Manufacturing Celebrating 28 Years In Business Grinding Capabilities:

√ OD,ID Centerless Plunge and Thru Feed (OD Between Centers up to 72” L x OD Swing up to 24”) (ID - 9” depth x 10” LD)

√ Surface, Angled and Blanchard

√ Long Bar Grinding for Screw Machines

√ We grind all types of Industrial Blades

Announcing AS9100

Revision D Certification!

WE’RE GROWING! We Added a 2nd Supertech CNC Universal Grinder, We’ve Hired New Machinists and More!

Platinum Registration Achieves ISO 13485:2016 Accreditation to Certify Quality Management Systems for Medical Device Companies

This accreditation enables Platinum to issue ISO 13485:2016 certificates to clients whose quality management system meets the requirements set out by the ANAB and demonstrates its ability to provide medical devices and related services that consistently meet customer and applicable regulatory requirements.

“With a rapidly growing medical device industry, the demand for ISO 13485 certification is expanding exponentially,” explained the President of Platinum Registration, Kerri Williams. “Having this ANAB accreditation affords our clients the advantage they need when bidding on jobs in an increasingly competitive market,” she continued. “I don’t see this industry diminishing anytime soon. For our clients’ customers, ISO 13485 certification gives them the peace of mind knowing that they’re hiring a company that is demonstrating best-practice in terms of their quality management system, and that’s a powerful tool,” she stated.

Williams goes on to say that the industries seeking ISO 13485 certification range from manufacturers of non-active medical devices like metal components to active implantable devices as well as service providers such as medical record management companies who deal mostly with software.

“We are thrilled to be able to offer ISO 13485 certification services to those organizations that provide products or services to the medical industry. With our skilled auditors, Platinum is wellpositioned to meet the needs of our clients,” stated Williams.

So�ware

LKMetrology'sALTERACcoordinate measuringmachineisperfectwhenfloor spaceislimitedoronlyavailableata premium

About Platinum Registration

IntegratedcontrollerandPCaretuckedaway undertheCMMgranitetable,withop�onal monitorandkeyboardarmavailable

AllCMMso�warepackagesand op�onsavailablefromLKMetrologyare availablewithALTERAC

Mul�-sensorTechnology

Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

So�ware

ALTERAC

Trustworthytechnologyforprecise measurementatanaffordableprice!

1963 2022 59 years

Mul�-sensorTechnology

Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

measuringmachineisperfectwhenfloor spaceislimitedoronlyavailableata premium

CompactFootprint

LKMetrology'sALTERACcoordinate measuringmachineisperfectwhenfloor spaceislimitedoronlyavailableata premium

IntegratedcontrollerandPCaretuckedaway undertheCMMgranitetable,withop�onal monitorandkeyboardarmavailable

IntegratedcontrollerandPCaretuckedaway undertheCMMgranitetable,withop�onal monitorandkeyboardarmavailable

IntegratedTech

Contactustodayat

op�onsavailablefromLKMetrologyare availablewithALTERAC

Mul�-sensorTechnology

Mul�-sensorTechnology

AllCMMso�warepackagesand op�onsavailablefromLKMetrologyare availablewithALTERAC

Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

Mul�-sensorTechnology

IntegratedcontrollerandPCaretuckedaway undertheCMMgranitetable,withop�onal monitorandkeyboardarmavailable

(810)263-6100 or

(810)263-6100 or sales.us@lkmetrology.com

Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

www.LKmetrology.com

service and manufacturing organizations across multiple industries in North America and Canada. Platinum’s audits ensure that clients conform to international and national standards, assuring customer satisfaction and positioning them for growth in the marketplace.

http://www.platinumregistration.com

Established by the International Organization for Standardization, ISO 13485 is recognized as the worldwide standard for quality management systems and practices for the medical devices and related services. The standards body provide requirements, guidance, and tools for companies and organizations who want to ensure that their products and services consistently meet customer’s and regulatory requirements.

https://www.iso.org/standard/59752.html

Since the Inflation Reduction Act (IRA) passed one year ago, U.S. solar and storage companies have announced over $100 billion in private sector investments, helping bolster the American economy, according to new analysis released today by the Solar Energy Industries Association (SEIA).

Solar and storage manufacturing is now surging in the United States, as 51 solar manufacturing facilities have been announced or expanded in the last year.

“The unprecedented surge in demand for American-made clean energy is a clear sign that the clean energy incentives enacted last year by Congress are working,” said SEIA president and CEO Abigail Ross Hopper. “This law is a shining example of how good federal policy can help spur innovation and private investment in communities that need it most. We are unleashing abundant clean energy that is creating jobs and capable of delivering affordable, reliable power to every home and business in this country.”

By 2026, the U.S. will have over 17 times its current manufacturing capacity across modules, cells, wafers, ingots, and inverters when these announced factories are in operation, which is enough to supply a majority of solar projects expected to be built in the U.S.

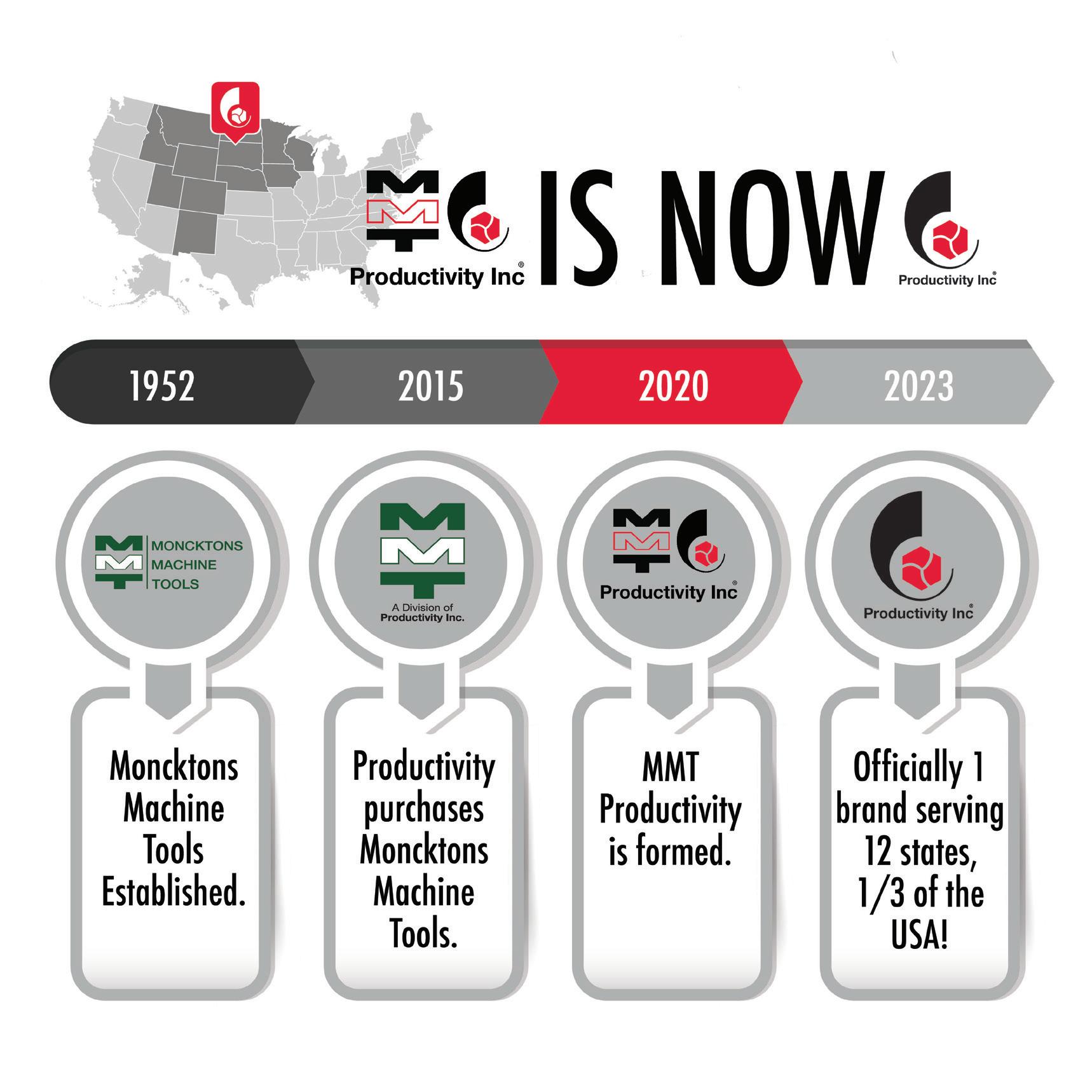

“Productivity is a top notch, well-trusted machine tool company offering the highest degree of honesty, integrity, and responsiveness. We are happy and excited for this final step. While our name is changing, we are still the same people customers trust to support their metalworking needs.”

Mark Smith

Vice President and General Manager

Mark Smith

Vice President and General Manager

We help our clients grow business by independently validating their management systems for conformance to national and international standards, helping to ensure the best business practices.

Platinum is pleased to announce our ISO 13485 accreditation!

Platinum is an ANAB-accredited certification body focused on affordable certification with personalized service.

Call or email for your customized quote.

Platinum Registration, Inc.

Passionate ▪ Professional ▪ Precise

Phone: 303-639-9001

Website: www.platinumregistration.com

E-mail: info@platinumregistration.com

Again in August

The Equipment Leasing & Finance Foundation (the Foundation) releases the August 2023 Monthly Confidence Index for the Equipment Finance Industry (MCI-EFI) . The index reports a qualitative assessment of both the prevailing business conditions and expectations for the future as reported by key executives from the $1 trillion equipment finance sector. Overall, confidence in the equipment finance market is 50.4, an increase from the July index of 46.4.

When asked about the outlook for the future, MCI-EFI survey respondent Dave Fate, CEO, Stonebriar Commercial Finance, said, “In spite of significant turmoil in the U.S. banking sector, including multiple downgrades and warnings from the rating agencies, as well as unprecedented interest rate increases over the past year, the equipment leasing and finance industry continues to persevere. Secured equipment loans and leases continue to outperform every other asset class. I would expect our industry to continue to deploy much-needed capital—which serves as a catalyst for the U.S. economy—across a diverse set of industries across the credit spectrum. Stonebriar continues to thrive in this environment with year-to-date originations through July 31 of $1.26 billion, up 28% year over year.”

The overall MCI-EFI is 50.4, an increase from the July index of 46.4. When asked to assess their business conditions over the next four months, 3.6% of the executives responding said they believe business conditions will

improve over the next four months, a decrease from 7.7% in July. 89.3% believe business conditions will remain the same over the next four months, up from 65.4% the previous month.

10.7% of the survey respondents believe demand for leases and loans to fund capital expenditures (capex) will increase over the next four months, an increase from 7.7% in July. 78.6% believe demand will “remain the same” during the same four-month time period, an increase from 69.2% the previous month.

7.1% of the respondents expect more access to capital to fund equipment acquisitions over the next four months, down from 7.7% in July. 78.6% of executives indicate they expect the “same” access to capital to fund business, up from 76.9% last month. 14.3% expect “less” access to capital, down from 15.4% the previous month.

Corps of Engineers, European District, is the contracting activity (W912GB-23-C-0005).

www.umw.com

Tollfree: 866-434-5679

Local: 801-364-5679

At Utah Metal Works, recycling industrial-related scrap metal is one of the things we do best. You simply won’t find more knowledgeable, capable partners for your scrap handling and recycling efforts anywhere. We are known in the industry for our honesty and integrity, and you can be sure you are always getting a competitive return along with superior service. We make it easy for you to cash in on non-ferrous metals from:

Industrial/Manufacturing Scrap

• Punchings

• Solids of any metals

• Turnings and borings

• Skeleton plate

• Machine Shop/Fabricator

• Solids of any size or type

Aircraft/High Temperature Alloy Scrap

Stainless, titanium, Inconel, Hastelloy, Monel, cupronickel, aluminum;state-of-the-art metal analysis conducted on site; Mixed or contaminated items are accepted and sorted

L3Harris Corp., Colorado Springs, Colorado, has been awarded a $22,342,133 cost-plus-fixed-fee modification (PZ0135) to previously awarded contract FA881919-C-0002 for continued support, sustainment, infrastructure, and delivery for three systems. Work will be performed at Colorado Springs, Colorado, and is expected to be completed by Jan. 31, 2024. Fiscal 2023 operation and maintenance funds in the amount of $24,671,502 are being obligated at time of award. Space Systems Command, Los Angeles Air Force Base, California, is the contracting activity. (Awarded August 4, 2023)

Bryan Ashush JV, Colorado Springs, Colorado, was awarded a $35,889,240 firmfixed-price contract for the construction of a life-support area. Bids were solicited via the internet with five received. Work will be performed in Israel, with an estimated completion date of Aug. 30, 2026. Fiscal 2023 military construction, Army funds in the amount of $35,889,240 were obligated at the time of the award. U.S. Army

Sierra Space Corp., Broomfield, Colorado, has been awarded a $22,605,083 firm-fixed-price contract for the maturation of the Advanced Upper Stage Engine (VR35K-A). This contract provides for leveraging the test data from the first Phase III Small Business Innovation Research component and integrated breadboard engine test to develop flight-weight engine component designs. Work will be performed at Broomfield, Colorado, and is expected to be completed by Oct. 25, 2025. The contract was a sole-source acquisition. Fiscal 2022 research, development, test and evaluation funds in the amount of $20,512,596 are being obligated at time of award. The Air Force Test Center, Edwards Air Force Base, California, is the contracting activity (FA9300-23-6015).

HHI Corp., Ogden, Utah, was awarded a $73,581,115 firmfixed-price contract for roof repairs. Bids were solicited via the internet with one received. Work will be performed in Layton, Utah, with an estimated completion date of July 27, 2025. Fiscal 2010 military construction, Army funds in the amount of $73,581,115 were obligated at the time of the award. U.S. Army Corps of Engineers, Sacramento, California, is the contracting activity (W91238-23-C-0021).

Silicon Technologies Inc., Midvale, Utah, was awarded a ceiling of $41,983,055, a cost-plus-fixed-fee contract for an advanced analog & mixed signal rad hard microelectronics design and manufacturing

Continued next page

project. This contract provides for improvement to access and efficiency to the back end of the line complementary electron beam lithography capabilities that enable lower cost development of advanced analog electronics for programs with high-mix and low-volume integrated circuit requirements. Work will be performed in Salt Lake City, Utah, and is expected to be completed by March 20, 2028. This contract was a competitive acquisition and one offer was received. Fiscal 2023 research and development funds in the amount of $2,630,445 are being obligated at the time of award. The Air Force Research Lab Space Technology Branch, Kirtland Air Force Base, New Mexico, is the contracting activity (FA9453-23-C-A036).

Vectrus Systems Corp., Colorado Springs, Colorado, is awarded $7,663,827 for an indefinite-delivery/indefinitequantity modification to previously awarded contract N62470-20-D-0004. This modification provides for the exercise of Option Number Two for base operating support services at U.S. Naval Support Facility Deveselu. Work will be performed in Deveselu, Romania, and the option period is from August 2023 to July 2024. After award of this option, the total cumulative contract value will be $37,739,278. Fiscal 2023 operation and maintenance (Navy) funds in the amount of $7,343,320 will be obligated at time of award and will expire at the end of the current fiscal year.

Naval Facilities Engineering Systems Command Europe Africa Central, Naples, Italy, is

the contracting activity.

Creative Times Dayschool LLC,* Ogden, Utah, was awarded a $27,547,246 firmfixed-price contract for construction of a composite aircraft antenna calibration facility. Bids were solicited via the internet with two received. Work will be performed in Layton, Utah, with an estimated completion date of Aug. 5, 2025. Fiscal 2019 military construction, Army funds in the amount of $27,547,246 were obligated at the time of the award. U.S. Army Corps of Engineers, Sacramento, California, is the contracting activity (W91238-23-C-0011).

HHI Corp., Ogden, Utah, was awarded a $30,569,428 firm-fixed-price contract to construct an aircraft maintenance unit. Bids were solicited via the internet with three received. Work will be performed at Luke Air Force Base, Arizona, with an estimated completion date of Sept. 4, 2025. Fiscal 2023 military construction, defense-wide funds in the amount of $30,569,428 were obligated at the time of the award. U.S. Army Corps of Engineers, Los Angeles, California, is the contracting activity (W912PL-23-C-0016).

We set containers for:

• Machine, welding & fab shops • Manufacturing facilities

• Demolition projects • One-time clean-ups

• Containers: 1 to 60 yards • Flatbed, cargo trailers, rolloffs

• Small boxes on wheels • Locking Lids • Leakproof boxes

Top prices paid for:

• Aluminum • Copper • Brass • Stainless • Steel/Iron

• Alloys • Lead & more

Convenient drive-in recycling:

• Easy acces from I-25, I-70 and Commerce City

• Fully paved • Se Habla Espanol ~

A trio of Colorado companies’ space projects won funding from a $150 million NASA program meant to boost cutting-edge technologies considered close to having commercial applications.

NASA’s Space Technology Mission Directorate chose 11 projects for “tipping point” grants to technologies ranging from in-orbit construction, 3-D printing of space habitats to rocket technologies and making solar panels from moon dirt.

The idea is to fuel technologies NASA hopes will help sustain human presence on the Moon. Denver-area companies winning grants were some of the biggest space companies in the area and a lesser-known manufacturer.

The tipping point grants target projects for which larger companies are expected to ultimately fund at least 25% of the technology’s development. For companies with fewer than 500 employees, that figure drops to 10% minimum of company funding. The grants are spread over terms as long as four years and disperse funds based on project milestones being hit, NASA said.

The biggest of the grants won by a Colorado company was $25 million awarded to United Launch Alliance, a Centennial-based space launch company that handles most of the U.S. military’s satellite and spacecraft launches. The company proposed an inflatable heat shield it’s making to protect rocket engines during re-entry in the Earth’s atmosphere for

one of the tipping point grants.

Jefferson County-based Lockheed Martin Space won a $9.1 million grant for a method the company proposes to join items in space. The project is an experiment to join items using equipment that will be delivered to the International Space Station and set up for the project. The idea is to test assembling items in orbit and the integrity-inspecting systems needed to ensure the structure is sound, the company said.

Another company, Denver-based Big Metal Additive, won a $5.4 million grant to work on improving the cost and availability of in-space habitats using additive manufacturing, or what’s more commonly known as 3-D printing using metals.

Another project, which received the largest grant, is a project of Kent, Washington-based Blue Origin that’s developing machinery to make solar panels from 99.9% pure silicon refined on the lunar surface from moon dirt, what’s known as regolith. The technology holds the promise of one day being able to build solar power sources “in situ” at moon bases.

“Can you help us with supply chain logistics?”

“Can you provide safety and compliance training?”

“We need a distributor partner in the Intermountain West.”

“We are looking for help with managing our inventory.”

“Our distributor needs to be uniquely integrated with our business.”

“Our inventory needs are specific, timesensitive and cost-driven.”

Industrial Supply delivers results. Our vast inventory and integrated supply solutions have made us the trusted source for the products and services customers demand — when and where they're needed. Visit indsupply.com to learn how we can help your business run at peak efficiency.

Expect the Expected.

We’ve been saying “We can do that,” since 1916.

Arizona-based vehicle maker Nikola Corp. quietly purchased nearly 1,000 acres in the Phoenix metro at the end of September for $16.5 million, according to Maricopa County records.

The largest communications satellite ever fielded launched into orbit last month culminating years of construction by a Colorado company and unlocking growth for another area business.

A SpaceX Falcon Heavy rocket blasted off with the Jupiter 3 satellite overnight last month. By the end of the weekend, the satellite owner, Hughes, a subsidiary of Douglas County-based EchoStar Corp., was communicating with the satellite to start a monthslong setup process.

The massive site is located at 28702 W. Patterson Road in south Buckeye just west of State Route 85 near the Arizona Department of Corrections Lewis Prison, which is one of the largest prisons in the state and houses more than 4,400 inmates.

The satellite, which cost hundreds of millions of dollars to build and launch, is designed to provide 500 gigabits of beamed internet capacity to spots across the Western Hemisphere.

The sale comes after Nikola made multiple announcements that it planned to break ground on a hydrogen production hub in Arizona. The company’s CEO said in August that Nikola would start construction on the new facility by the end of this year but did not disclose the location.

Westminster-based Maxar Technologies built the Jupiter 3 satellite for Hughes, the fifth satellite Maxar has made for the company.

Satellite internet service is the biggest service sold by EchoStar’s Hughes subsidiary, based in Germantown, Maryland. Satellite internet is primarily used by people in areas where faster terrestrial broadband and telecom networks don’t offer high-speed service.

The Jupiter 3 satellite is expected to allow HughesNet Broadband to add to its customer base for the first time in years.

The company’s existing, less-powerful satellites are maxed out and had no more internet capacity to offer.

According to the Arizona Corporation Commission, Corey Hessen and Omar Khayum, senior vice president and vice president of Canada-based TC Energy, respectively, are the managers of Phoenix Hydrogen Hub LLC. Oil and gas giant TC Energy partnered with Nikola last year to develop large-scale hydrogen production hubs across the U.S. and Canada.

Within hours of Jupiter 3’s deployment, Maxar confirmed the satellite’s solar arrays — as long as a 10-story building is tall — had unfolded and begun collecting the sun’s rays for electrical power.

Nikola hasn’t confirmed, though, whether it plans to build a hydrogen production hub in Buckeye. Nikola said it has no comment about the Buckeye land sale or its plans for the property. The city of Buckeye said nothing has progressed with the company beyond negotiations.

The satellite will propel itself over several weeks to a higher orbit 22,236 miles above the Earth then undergo extensive testing before entering service and adding 500 gigabits of internet capacity to what Hughes offers across the hemisphere.

Jupiter 3 is key to the service’s return to growth, Hughes says.

The automaker is currently producing battery electric vehicles and has produced several alpha prototypes of its fuel cell electric vehicles, which run on hydrogen. Nikola is planning to build out a hydrogen fueling network to support its vehicles. Its first three locations will be established in California.

In addition to the fueling stations, the

The HughesNet service has been limited by maxed-out exiting satellites as the company waited for the Jupiter 3 satellite to enter service near the end of the year.

By Greg Avery – Denver Business Journal

Ball Corp. is selling its aerospace manufacturing and technology business to defense giant BAE Systems in a $5.6 billion deal announced.

The Westminster-based company, maker of aluminum beverage cans, auctioned the business over the spring and ultimately reached an agreement on a sale for cash with Farnborough, Englandbased BAE Systems Plc.

The Ball Aerospace division employs 5,250 people, the largest concentrations of which are in Boulder and at the Ball Corp. headquarters campus in Westminster and Broomfield.

“Since 1956, generations of dedicated Ball Aerospace colleagues have transformed a business of humble beginnings into a thriving enterprise offering innovative capabilities in a world that needs rapid, scalable technology solutions,” said Daniel Fisher, Ball chairman and CEO, in a transaction announcement. “The complementary cultural fit of Ball Aerospace and BAE Systems and their combined position as a pure-play aerospace and technologies company will leverage Ball’s recent investments in talent and facilities located across the country and centered in Boulder, Broomfield and Westminster, Colorado, to provide a multi-dimensional platform for vital national defense, intelligence, and science hardware, software, and space-based assets.”

The transaction, pending regulatory and shareholder approval, is expected to close in the first half of 2024.Ball expects to net $4.5 billion cash after taxes, proceeds that will allow the company to accelerate its shareholder dividend payments and stock buybacks, the company said.

It said buying the high-quality Ball business was both strategically and financially compelling, and it will complement BAE Systems’ work in the U.S. on electronic warfare and advanced military command and control technologies.“The proposed acquisition of Ball Aerospace is a unique opportunity to add a high-quality, fastgrowing technology-focused business with significant capabilities to our core business that is performing strongly and well positioned for sustained growth,” said Charles Woodburn, CEO of BAE Systems, in a statement. “It’s rare that a business of this quality, scale and complementary capabilities, with strong growth prospects and a close fit to our strategy, becomes available.”By

Greg Avery –Denver Business Journal

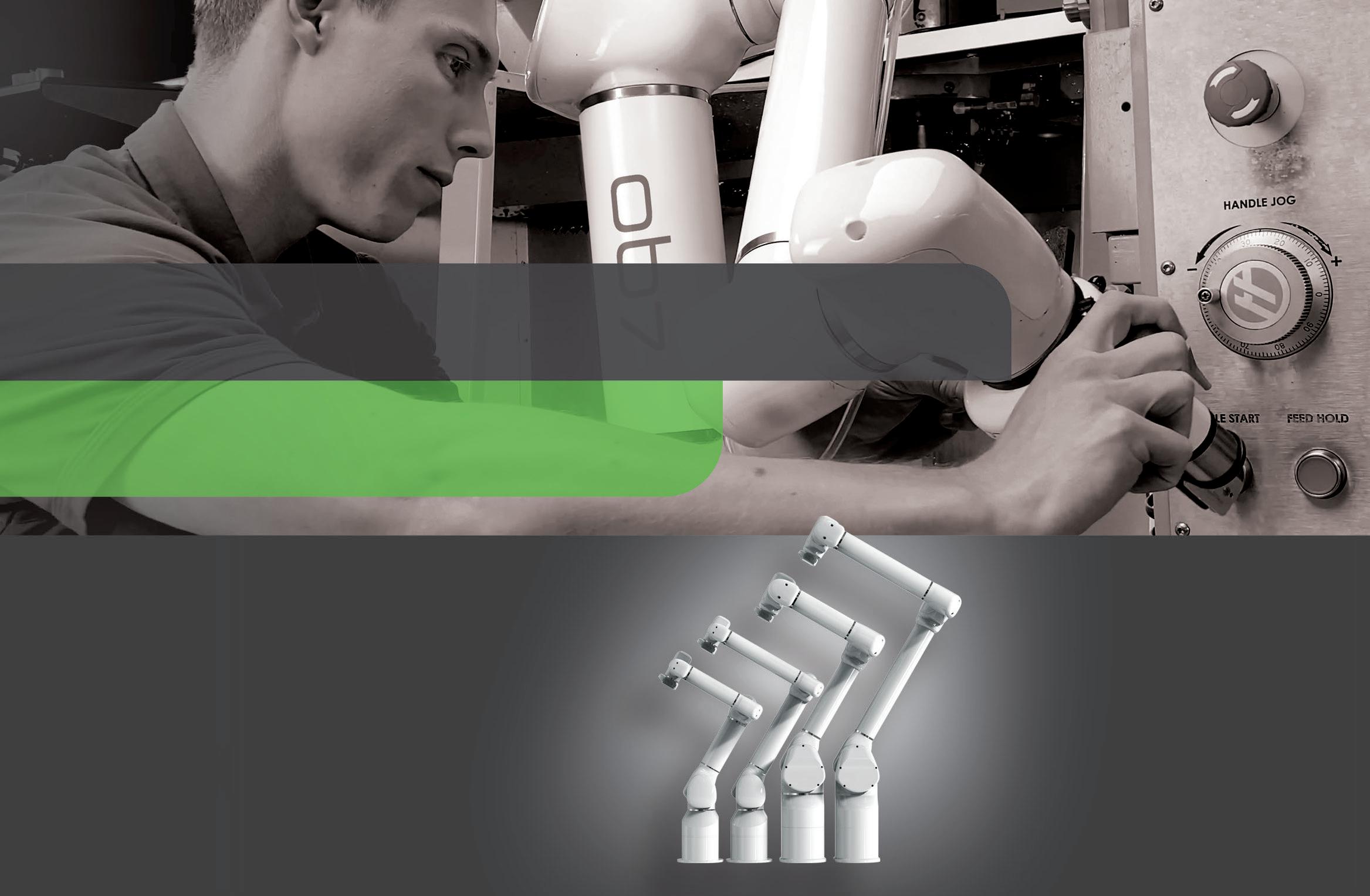

Easily automate CNC loading and unloading. Run 24/7 ‘lights out’. Reduce scrap. Let skilled machinists focus on skilled work. And win more bids.

Add robot productivity more affordably than you might think. No robot experience required.

Ongoing efforts by the U.S. manufacturing industry to develop the workforce of tomorrow received a significant boost with the announcement by the U.S. Department of Labor of $183.8 million in workforce development grants to help create and promote partnerships among educational institutions, companies and trade associations. The grants, together with the Labor Department’s announcement of plans to award an additional $100 million in grants to further promote apprenticeships, were applauded today by the National Tooling and Machining Association (NTMA) and the Precision Metalforming Association (PMA).

“There will be an estimated two million vacant manufacturing jobs by 2025 and the industry cannot close this gap on its own,” said PMA President David Klotz. “The federal programs announced today mean that the government is listening to our message that, for manufacturing to continue to drive the U.S. economy, this country must invest in helping manufacturers attract and train the next generation of workers. We encourage Congress to provide funding to expand these types of programs.”

“NTMA and its chapters have made workforce development a top priority issue for more than a decade and these grants will help our efforts to close the skills gap in our industry. We applaud the Trump administration for continuing to make manufacturing and closing the skills gap top priorities”, said NTMA Interim President Doug DeRose.

The Labor Department also made public a Notice of Proposed Rulemaking

to establish a process for the Department to advance the development of industry-recognized apprenticeship programs (IRAPs) that would enable manufacturing associations and others to apply to the federal government to obtain the ability to certify apprenticeships themselves.

NTMA through its National Tooling and Machining Association Foundation and PMA through the Precision Metalforming Association Educational Foundation have spent millions of dollars over the years supporting workforce development programs and providing grants throughout the United States to attract, train and retain workers in the manufacturing industry. The associations look forward to working with local partners and national stakeholders such as the National Institute for Metalworking Skills to promote manufacturing careers, train American workers and develop a next generation of manufacturers.

“WE

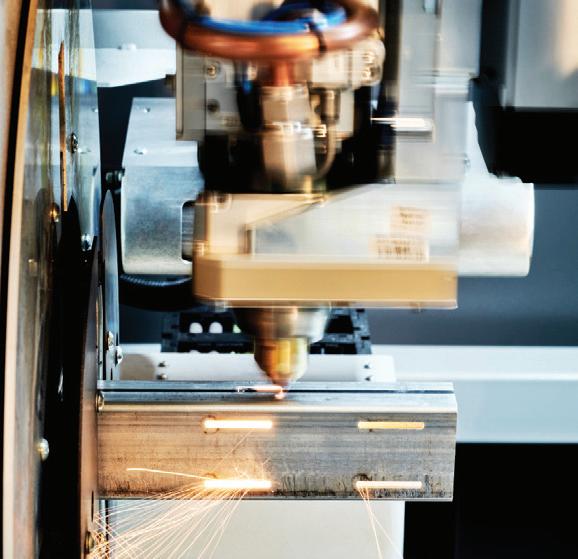

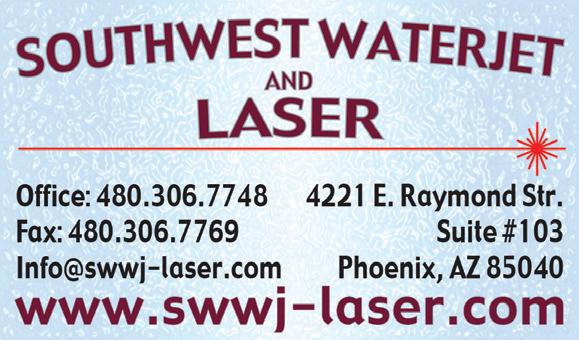

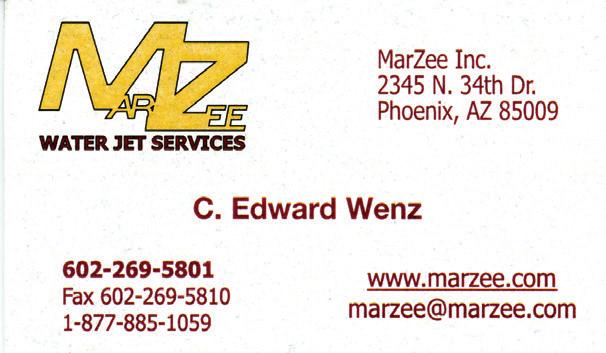

Marzee Inc., an ISO 9001 Certified company renowned for their waterjet cutting (they have 5 waterjets), now has one of the fastest laser cutting machines in the Valley.

Ed Wenz, owner of the company, says, “The Eagle iNspire 2040 Fiber Laser Cutting System is our 2nd laser cutting machine, and it offers a 20kW laser source, unmatched 6G acceleration, a rigid composite base, a lightweight carbon fiber bridge, and a 9 to 12 second pallet changer. What’s more, the iNspire fiber laser machine has its own patented best-in-class eVa Laser Cutting Head and it operates with the brand’s premium software technologies like CatLine, Fast Line, MixLine, CutEye, and Drop&Cut. With cutting speeds up to 5,906” per minute, top positioning speed of 13,780” per minute, acceleration of nearly 6G, and fiber laser power of 1 to 20 kW, the iNspire series are the fastest and most efficient laser machines in the world.”

He continues, “We’ve been offering precision waterjet cutting since we opened for business in 1997. While waterjet cutting is ideal for a wide variety of applications and materials, including thicker parts (1”), laser cutting is a superior solution for incredibly fast cutting of stainless steel and aluminum up to 1” thickness.” On a particular job, Ed says that it would take 50 hours to cut on the waterjet and today is cut on the iNspire fiber laser machine in 8 hours. Ed is pictured with 1” parts cut by the water jet machine.

“We love this machine”, Ed says. Not only can it run 24x7, but it is also a highly intelligent machine. It tells us when it needs service, provides a cutting head with automatic focusing and it offers a super-fast pallet changer, to be coming in the end of year. For many jobs, we can use the Eagle Inspire to reduce costs for our customers.

Today, Marzee specializes in production and prototype cutting, serving

a number of industries, including aerospace, architecture, defense, machine shops, and environmental design. They provide one of Arizona’s largest cutting windows of 80” by 250” and cutting 13” plus thick. In addition to waterjet cutting and laser cutting, they offer forming with their Accurpress 12’ x 250 ton press brake to serve their clients’ needs.

Marzee has its own internally designed online quoting system that facilities ordering. Ed says, “We even have a button for those who aren’t sure if their parts need to be waterjet cut, laser cut or formed. Many of our customers are simplifying their order process with our system.”

Marzee can cut parts as small as 1” x 2” and they can cut parts as large as 20’ just as well. In fact, when it comes to doors, elevators, railings, structural, and anything else in architectural metal work, Marzee can provide value added engineering to save time and money.

Marzee is a family-owned and operated business, with 3 generations of Wenz family members having worked at the business, and their team includes over a dozen employees. Ed says, “When I hire someone, you’re not a number, you are an integral team member.” Marzee is always looking for new team members who are hardworking with an attention to detail.

Located in Phoenix, AZ, MarZee is the industry leader for Waterjet, Forming, and Laser cutting with their CNC-controlled state of the art machines. For more information on how they can support you, call: 602-269-5801 or visit marzee.com

We have added a number of improvements over the standard Fast Wire Edms including:

• Cutting capacity of 625 x 625 mm

• Panasonic AC Servo motors and drivers

• Hiwin Linear Guideways

• Build in Cad System

• Two filters

• Increased height side walls to reduce splashing

• View windows to see the wire progress

• Automatic spent wire spooler

• Optional build plate support fixture

• Optional Anti Electrolisis (AE)

“Everything

Four sizes available:

• 400x320x410mm H

• 630x500x625mm H

• 1000x800x1050mm H

• Horizontal Model 1000x1000x1000mm

www.edmnetwork.com

lbs. of garnet eliminating the need to handle individual bags of abrasive.

• Saves time and labor

• Increases worker safety

• Minimizes clogs

• Reduces waste

Interested in learning more?

Call 800-741-7756 or email info@barton.com

A Colorado manufacturer is expanding its footprint to Kentucky following its latest acquisition. CoorsTek Inc., a manufacturer of technical ceramics used for semiconductor, automotive, aerospace and medical parts, acquired competitor Avon Protection’s Lexington, Kentucky, assets and facility last month.

This 100,000-square-foot Kentucky facility was primarily used by Avon, a British manufacturing company, to produce body armor and aircraft armor. CoorsTek took over the lease for the facility and plans to continue making similar products.

“Our aerospace and defense market has been a strategic growth opportunity for us,” said Steve Brazil, CoorsTek’s vice president of operations Americas East. “When we heard that the Avon facility was available for potential purchase that was very appealing to CoorsTek. We competed against this facility, historically, for large government contracts, so it really helps to complement our portfolio and the way that we manufacture armor today.”

CoorsTek CEO Timothy Coors said in a statement that the company has invested more than $50 million into its defense industry portfolio over the past two years. This includes work at its Benton, Arkansas, facility, which makes advanced body armor and aircraft armor. Established in 1910 by the founders of Coors Brewery, CoorsTek works directly with government entities and businesses that contract with government organizations to supply them with its products.

Millennials’ technology expectations have been shaped by smartphones, Facebook and digital media – in other words, by easy and ubiquitous connectivity. It’s not surprising, then, that traditional manufacturing systems can seem as retro as waiting for dial-up internet to connect. And that’s bad for the manufacturing sector, because its skills gap is looming large.

CoorsTek now has 16 locations across the U.S., including seven in Colorado. It also has facilities in Canada, Mexico, Japan, Thailand, South Korea, China, the Netherlands, Germany, Sweden, the Czech Republic and the U.K.

A joint study by the Manufacturing Institute and Deloitte Consulting projects a surge of nearly 3.5 million open manufacturing jobs created over the next decade. Some of the empty slots will come by way of retiring baby boomers, while others are related to new positions created as a result of natural business growth, the report found.What the report also predicts: As conditions stand now, 2 million of those jobs will go unfulfilled. In other words, the need for the manufacturing sector to appeal to Millennials – the generation typically defined as those born between 1981 and 1997 – is both critical and a very tall order.

In addition to acquiring the Kentucky facility and its operations, the 40 Avon employees who worked there joined the CoorsTek team. CoorsTek said it plans to hire more people for this location in the future. This facility can accommodate more than 150 employees, Brazil said.

CoorsTek, which ranked No. 7 on the DBJ’s 2023 list of Denver-area manufacturing firms, has more than 5,000 global employees, with 1,064 based in the Golden area. The company plans to move its global headquarters from its current location in Golden to a new mixed-used development in town.

Indeed, manufacturing still has a negative image among younger generations, experts say. In a 2015 public perception of manufacturing study, also by The Manufacturing Institute and Deloitte, respondents ages 19 to 33 ranked manufacturing as their lowest preference in terms of potential career choices.

Manufacturing’s image problem is complex and in, some aspects, based on false assumptions. But one real obstacle is that some manufacturing systems can seem antiquated, and it’s an issue that many manufacturers

Two years after joining forces, Smith Machinery Company and Action Machinery offer customers best in class Sales and Service for CNC Metal Cutting and Fabrication solutions.

Safan, Accurpress, Omax, and many others.

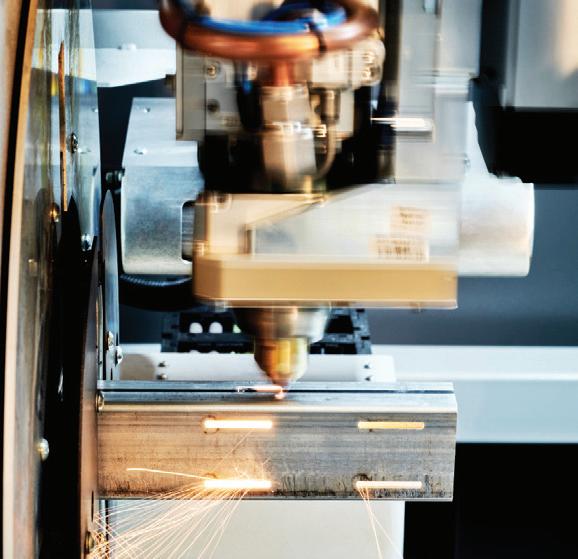

When 4th generation owner Clark Smith of Smith Machinery made the decision to retire, Action Machinery was the ideal choice to acquire the successful business. Smith Machinery’s premier line of metal cutting machines included the Mazak line.

Smith Machinery and Action Machinery combined their expertise in metal cutting and fabrication solutions in 2021 to greater serve the Rocky Mountain Region. Two years later, Smith Machinery and Action Machinery offer a comprehensive product offering that includes some of the best known industry leading technology brands in both the Utah and Colorado markets.

For over 60 years Smith Machinery has provided Utah and surrounding states with industry leading metal cutting machine tools. They have been the Mazak distributor for over 45 years, providing customers with state-of-the-art equipment.

Action Machinery was founded in Colorado in 1982 and has been under the ownership of Randy Breitenbach since 1994. The company has carried both metal cutting and fabrication lines, including their premier Mazak line for nearly 20 years.

In 2003, Action Machinery expanded into Utah as a dealer of fabrication equipment. Randy hired Tom Weaver, a degreed Manufacturing Engineer with experience in manufacturing to develop the Utah market. In 2005, Tom became partner and manager of the division. Over the years Randy and Tom have expanded their line of products to include industry-leading solutions from Mazak Optonics,

“Action Machinery’s Colorado division had nearly 20 years of experience with the Mazak metal cutting line, and we knew that we could leverage this expertise with the addition of Smith Machinery in Utah,” Tom says. “In essence, we were taking the business model that was working well for Action Machinery in Colorado of offering both metal cutting and fabrication machinery and duplicating this in Utah with the acquisition of Smith Machinery.”

Two years after the acquisition, Tom says, “It has been a smooth transition for our customers because we still have sales teams focused on each market. The Action Machinery sales team remains focused on the fabrication market and the Smith Machinery team on the metal cutting market. Both teams carry a high level of experience in their fields yet work together when customers need a solution outside of their area of expertise.”

What customers appreciate with Action Machinery/ Smith Machinery are two active, hands-on owners in Randy and Tom. “In addition to running the businesses, we also are managing our own group of customers so we know what real challenges our customers face in today’s market,” Tom says, adding that he and Randy believe strong relationships with their customers is key to the long term success.

There are other changes Smith Machinery has undergone under the guidance of Action Machinery. Over the two years, Smith Machinery has a new look, complete with an updated logo and website. This, along with Action Machinery’s push to streamline customer

• Mazak has 3 locally based service technicians to assist customers.

Lucas says, “I can tell you that customers who have embraced automation with Mazak machine tools are the shops that are growing and are less impacted by the labor shortage.“

Action and Smith Machinery customers will always hear a friendly voice on the other end of the line when they call during business hours. The office is staffed with knowledgeable customer service representatives to help respond to their needs.

The Smith Machinery sales team focuses on metal cutting solutions and consists of 3 experienced salespeople. Lucas Harwood, covers Salt Lake City and south to St. George, Utah. Lucas has over 30 years of experience in machining. Lex McCormick is another Smith Machinery sales team member. Lex covers Utah from Salt Lake City north to the Idaho border. Cody Eck is based in Idaho and covers the Idaho and Montana markets for Smith and Action. In addition, Smith Machinery has a full time Application Engineer, Jason Oliver, to assist customers with training and application support.

Action Machinery’s sales team focuses on the fabrication market. Utah office owner, Tom, covers Salt Lake City north to the Idaho border. Charles Sorensen covers Salt Lake City south to St. George. Charles joined the team in 2012. In addition, Action Machinery has two full-time service techs, Lloyd Nolan and Ty Boyce, to support their customers.

Lucas was a journeyman machinist who made the transition to sales with Smith Machinery in 2019. He says, “I really enjoy helping our customers understand the importance of automation, because I saw what it did to the machine shop I worked for previously. We had a turret lathe we were using to build 30-40 similar parts. When we made the jump to a Mazak J200 INTEGREX, we went from 4-8 hour set ups to 5-10 minute setups per part. Our run time went down by 30-40%, and we increased our tooling efficiency. It was an ‘Aha’ moment in our shop, and I just want this to happen for all my customers.”

He adds, for those who ask, “Why Mazak,” they already recognize the Mazak brand as a premier metal cutting tool line, but there are some things they may not know:

• Mazak has a complete line of CNC machine solutions, including their EZ line, which is designed as an entry level, cost effective solution.

• Mazak continually develops the latest technological advancements into their machines. They have been an industry leader in multi-axis (5 axis) machining and are also developing solutions for additive manufacturing.

• Mazak manufactures machines in Japan and in their U.S. plant in Florence, KY. Spare parts and spindles for U.S. and Japanese built machines are stocked at the Florence plant for quick delivery to customers.

Action Machinery, in conjunction with Smith Machinery, can help your manufacturing business grow while increasing profitability. Contact them at (801) 263-6403. You can also visit smithmachinetools.com and action-machinery.com

service processes by moving to a paperless system has created an overall better experience for both companies’ customers.Mazak HCN-5000 Horizontal Machining Center Purchased Through Smith Machinery Safan Electric Press Brake Mazak OPTIPLEX NEO Laser Mazak Integrex i-200ST Mazak VC EZ20 Vertical Mill

THE NORTHERN UTAH CHAPTER OF THE NATIONAL TOOLING & MACHINING ASSOCIATION

Established in 2010, the NUNTMA is a gathering place for machine shops in Northern Utah.

Where: Stonebridge Golf Course

4415 Links Dr, West Valley City, UT 84120

To ensure that the tournament surpasses your expectations, we kindly request your participation in a brief RSVP survey. Please take a moment to click on the following link to access the RSVP survey: https://www.surveymonkey.com/r/NJ6PWZD

REGISTRATION REQUIRED FOR ALL EVENTS. VISIT: NUNTMA.ORG/UPCOMING-EVENTS

The ribbon-cutting ceremony for the freshly constructed Morton Buildings manufacturing plant was held Tuesday, inviting local officials, business owners and community members to participate in guided tours of the facility at 1990 Boeing Ave. next to the Pocatello Regional Airport.

Illinois-based Morton Buildings designs, manufactures and constructs residential, commercial, equestrian and farm buildings throughout the nation, priding itself on what they call a “post-frame construction method” that allows for maximum flexibility and strength. Construction on the Pocatello plant began in December 2021.

Centennial-based Boom Supersonic has named a veteran of aerospace giant Boeing to lead work on the engines for the faster-than-sound jetliner it plans to build in Greensboro, North Carolina. Boom announced in December it’s developing an engine with a team that includes Florida Turbine Technologies,

GE Additive, and StandardAero, rather than have the extensive work needed to make a new engine done by an outside company. Aviation industry analysts said it was an unusual but bold move.

Boom executives said it’s a chance to start fresh with design and manufacturing techniques enabling much more in-air time than most existing jetliner engines, with a stated goal of 25% more on-wing time and 10% less operating cost, all helping make Overture cost-effective for airline customers.

Powell, according to Boom, was with Boeing for 38 years, including four years as engineering propulsion leader for the Dreamliner 787-8 and -9, where he was responsible for design, development, test, build, and business management. He also managed teams for craft such as the KC-46 tanker and joint strike fighter, and most recently was propulsion integrated product team leader for the B-52J engine replacement program. By David Hill – Denver Business Journal

A Colorado-born space company recently got more reason to grow locally. Sierra Space Corp. received approval for up to $7.05 million in performance-based job growth tax credits over an eight-year period.

Sierra currently employs 1,800 people including 1,200 in Colorado. New jobs will include roles in production, support and management. The company maintains office space in Broomfield and an engineering location in the Highlands Ranch area that is focused on developing the Orbital Reef space stations they’ve partnered with Amazon founder Jeff Bezos’ Blue Origin to develop for launch in 2028.

Identified only as “Project Tycho” in the EDC’s project description, Sierra produces space systems and components while engaging in hundreds of missions.

The company will need to create at least 20 new jobs before the tax credits are issued. The project is contingent upon proximity to available talent, supply chain and incentive support.

Along with Sierra, the EDC approved tax incentive proposals for four other unidentified companies during the July 20 meeting, including:

Project Blanc: A solar company headquartered in Switzerland with facilities in Germany and the United States is considering expansion to El Paso County. The EDC approved the company’s request for up to $4.94 million in performance-based job growth incentive tax credits over an eight-year period.

The company expects to create 380 new jobs at an average annual wage of $77,842.

The jobs will include project managers, operators, facility managers, process engineers and maintenance personnel. Project Blanc must create or maintain at least 20 new jobs before the credits are issued.

Project Bullseye: A womenowned aerospace and defense engineering company based in Colorado Springs got unanimous approval from the EDC for $7.5 million in performance-based job growth incentive tax credits. The incentive will be used to create up to 620 new jobs at a minimum average annual wage of $60,151.

Supporting the Colorado Office of Economic Development & International Trade, the EDC develops incentive packages to assist existing business expansions and encourage company relocations to grow jobs in all regions of the state.

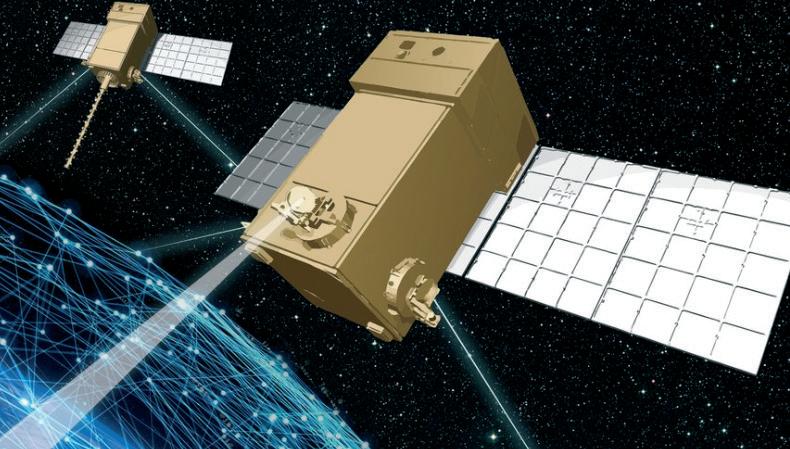

Lockheed Martin Space has opened a new factory at its headquarters campus in Jefferson County in preparation for making hundreds of orbiters for the U.S. military. The company retrofitted part of an existing building to establish a 20,000-square-foot small-satellite production facility able to churn out 180 satellites or more annually.

The factory later this year will start making 42 of the washing machine-sized satellites Lockheed Martin Space is under contract to produce for the Space Development Agency. Those satellites are slated be launched in 2024.

The six production lines that Lockheed can activate in the new factory aren’t limited to the Space Force agency’s satellites. It’s designed to handle a variety of designs as Lockheed Martin Space seeks to win business building small-satellites for other military and private-sector, commercial projects.

“This facility is all about having different programs,” said Kevin Huttenhoff, senior manager of space data transport for Lockheed Martin Space. “It’s multi-purpose and designed for that opportunity.”

The space industry giant has historically made largescale satellites for the U.S. military and other federal agencies, including the modernized fleet of GPS III satellites and the latest advanced weather models used by the National Weather Service. Those satellites can be the size of school buses, host many different instruments and take years to build before they’re launched to fly in far-away geostationary orbits for up to 15 years. Smaller satellites have become more capable in recent years, giving rise to demand from the U.S. military and commercial companies for fleets of dozens or hundreds of satellites that fly in low-Earth orbit a few hundred miles above the planet for about five years.

The Space Development Agency was formed by the

Pentagon to pioneer rapid procurement of smallsatellite fleets for the military.

Lockheed Martin Space won contracts to build 10 satellites for the SDA’s Tranche 0 wave of test satellites. Those have been built and are expected to launch this year.

Last year, Lockheed Martin Space won a $700 million contract to build 42 of the satellites in SDA’s Tranche 1 series.

The company is using satellite bodies made by partner company Terran Orbital. Lockheed Martin Space brings the bodies to its factory for assembly and integration of the satellite’s instruments and then tests them to ensure they’re ready for the rigors of being launched and exposed to intense temperatures and radiation.

Lockheed Martin Space started creating the new small-satellite production facility after it won the SDA contract. It laid out the facility using augmented reality tools and other design technology to optimize the flow of production, Huttenhoff said.

That’s very different from the high-bay cleanrooms used for large satellites, which are made one at a time. “This is designed with more of a production-line mindset as you’d see in the automotive or aviation industries,” said Chris Winslett, program director for Lockheed Martin Space’s SDA Transport Layer projects.

SDA began soliciting company proposals for making an even larger round of small satellites known as Tranche 2. The SDA plans to select three contract winners to produce models for that tranche this fall.

The new factory would be where the company builds Tranche 2 satellites if it is selected.

A unique feature of the facility is that it can run classified, military satellite production in parts of the facility and meet security requirements there while having other production lines not “compartmentalized” and able to simultaneously produce unclassified models, Winslett said.

Lockheed Martin Space is still sorting out which staff and how many will be dedicated to working in the facility.

Denver-based York Space Systems, which has focused exclusively on high-volume, small-satellite production, also won SDA contracts to build Tranche 0 and Tranche 1 satellites. By Greg Avery – Denver Business Journal

Abrasive Products

Barton International ____ 800-741-7756

Chemtool Inc. _______ 815-957-4140

Balancing Machines

HAIMER ________ 503-726-8202

Bandsaw Blades

Roentgen USA _______ 847-787-0135

Bar Pullers

Accudyne Corp _______ 303-991-1500

Edge Technologies ______

951-440-1574

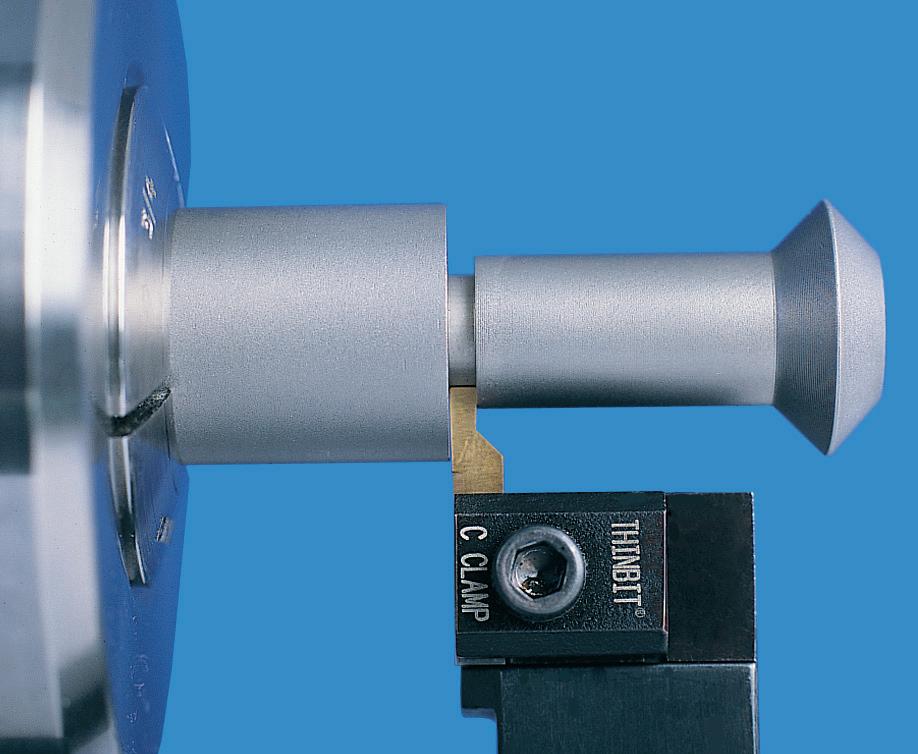

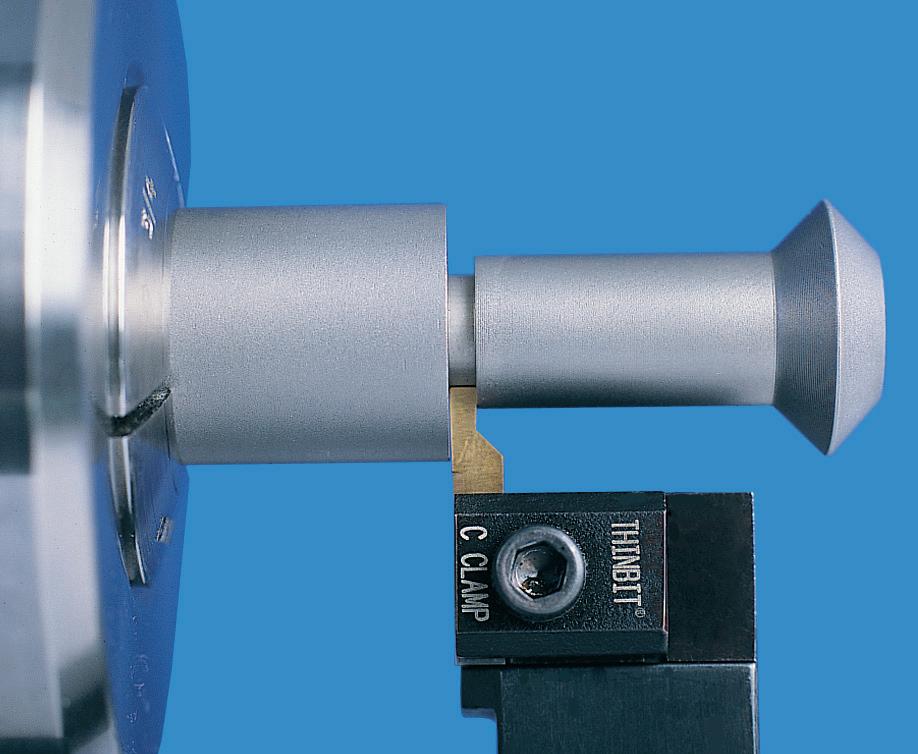

Boring, Grooving, Milling, Turning Tools

Fullerton Tools ____ 989-799-4550

Ceramic Tools

THINBIT __________ 888-THINBIT

Clamps & Grips

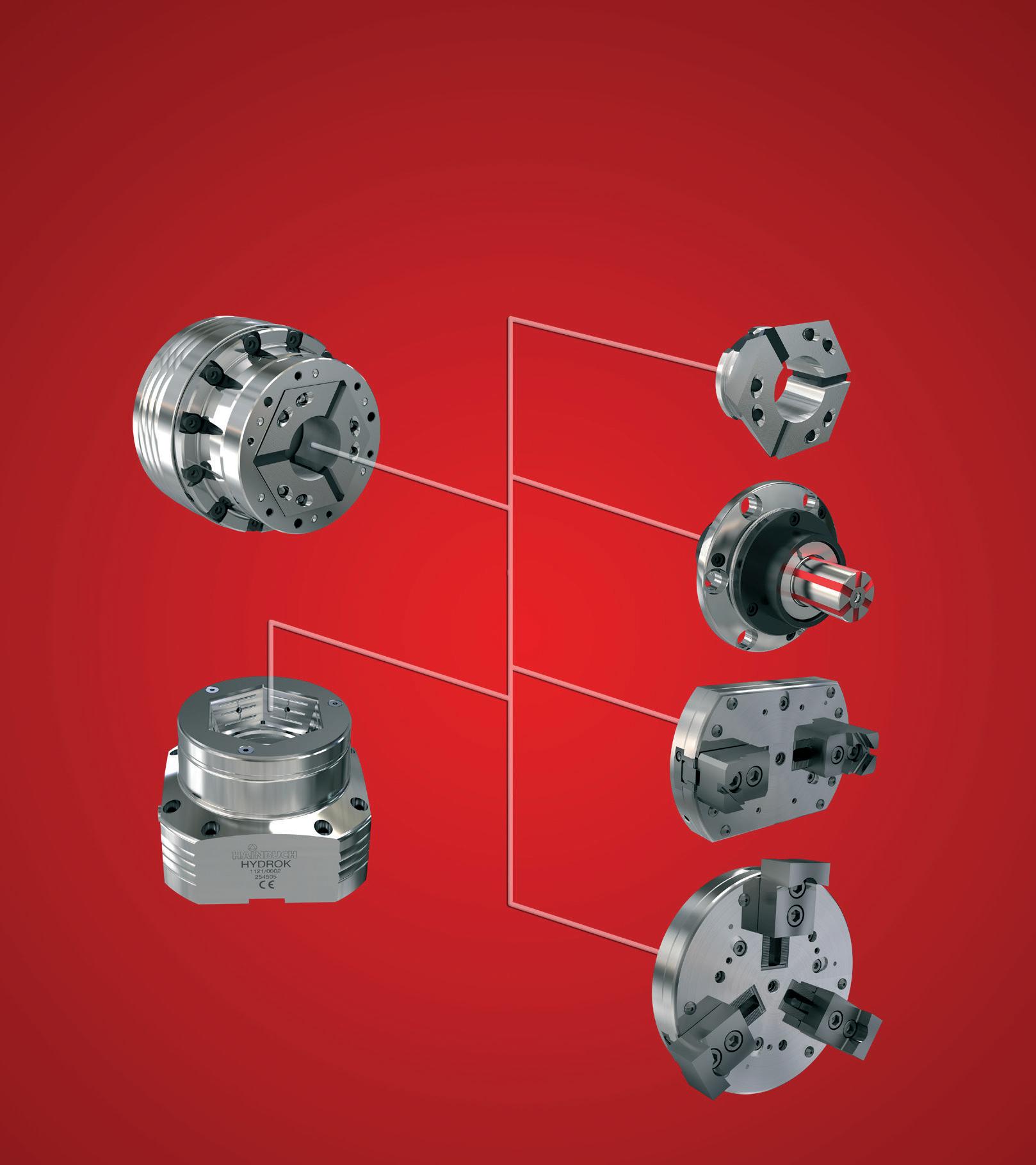

Hainbuch ________ 818-970-7874

SCHUNK _________ 919-602-8294

CNC Collet Chucks

Hainbuch ________ 818-970-7874

Royal Products _______ 800-645-4174

Sulli Tool & Supply ____ 714-863-6019

Collet Fixtures

Royal Products _______ 800-645-4174

Sulli Tool & Supply ____ 714-863-6019

Compressor Systems

Ingersoll Rand _____ 206-472-0826

Coolant Systems Chemtool _________ 815-957-4140

Chipblaster ________ 310-502-4184

MP Systems ________ 909-282-7463

Qualichem, Inc. ______ 480-320-0308

Star Metal Fluids _____ 800-367-9966

Coolant Chillers

Chipblaster ________ 310-502-4184

MP Systems ________ 909-282-7463

Custom Tools

Fullerton Tools ____ 989-799-4550

Machine Tool & Cutter Grinding 435-512-4416

EDM: Tooling Systems

THINBIT __________ 888-THINBIT

Cutting Fluids & Oils

Chemtool _________ 815-957-4140

Chipblaster ________ 310-502-4184

Qualichem, Inc. ______ 480-320-0308

Star Metal Fluids _____ 800-367-9966

Cutting Tools

Dormer Pramet _____ 801-230-6794

Fullerton Tools ____ 989-799-4550

HAIMER ________ 503-726-8202

Horizon Carbide Tool __ 480-968-0957

Industrial Supply 800-288-3838

Tool & Cutter Grinding 435-512-4416 NTK Cutting Tools ________ 425-365-3613 SCHUNK _________ 919-452-4535

THINBIT __________ 888-THINBIT Drilling/ Threading Tools Industrial Supply ___ 800-288-3838

Industrial Supply __ 800-288-3838

SCHUNK ________ 919-602-8294

Sulli Tool & Supply ____ 714-863-6019

THINBIT __________ 888-THINBIT

Von Ruden Manufacturing 763-682-0322

Machine Tool Cool. Filtration Chipblaster ________ 310-502-4184

Star Metal Fluids _____ 800-367-9966

Milling and Turning Products

Dormer Pramet _____ 801-230-6794

Dormer Pramet _____ 720-837-3232

Industrial Supply ___ 800-288-3838

Von Ruden Manufacturing 763-682-0322

Parts Washing Equipment

Star Metal Fluids _____ 800-367-9966

Power Tools

Ingersoll Rand _____ 206-472-0826

R8 Quick Change Tool System

Royal Products _______ 800-645-4174

Retention Knobs

T.J. Davies ________ 440-248-5510

Robot Accessories

SCHUNK _________ 919-602-8294

Rota-Rack Parts Accumulator

Royal Products _______ 800-645-4174

Shrink Fit Machines

HAIMER ________ 503-726-8202

Solvents /Degreasing Agents

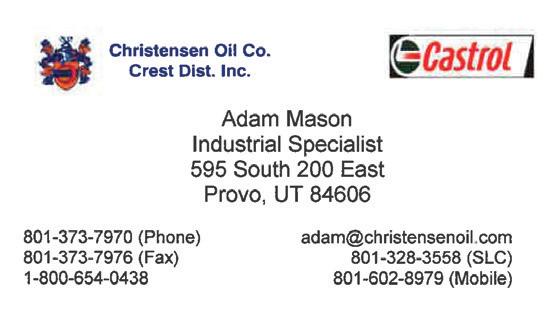

Castrol ___________ 800-894-7773

Hasco Oil __________ 562-595-8491

Star Metal Fluids _____ 800-367-9966 Spindles

GMN USA _________ 800-686-1679

Sulli Tool & Supply ____ 714-863-6019

Surface Plates

Starrett ___________ 949-382-4123

Toolholding

HAIMER ________ 503-726-8202

Hainbuch ________ 818-970-7874

Industrial Supply ___ 800-288-3838

Tooling for Swiss Type Lathe

NTK Cutting Tools ________ 425-365-3613

Vices and Vice Jaws

Desert EDM Sales _____ 480-816-6300

Hainbuch ________ 818-970-7874

Sulli Tool & Supply ____ 714-863-6019

Waterjet Cutting Abrasives

Barton International ____ 800-741-7756

Workholding

Hainbuch ________ 818-970-7874

AUTOMATION

Acieta __________ 402-650-8132

DATRON _________ 480-826-3689

Saw Replacement Parts Rocky Mountain Saw Blades_303-761-3000

INSPECTION EQUIP

Advanced Coord. Tech ___ 303-469-6161

Gage Lab Products_____ 801-716-2972

Hexagon _________ 303-859-7159

Innovative Measuring Systems

Klontech Indust. Sales ___ 480-948-1871

LK Metrology _______ 949-716-4440

Productivity Inc. ____ 303-571-4933

Renishaw _________ 847-286-9953

Total Qual. Syst. ______ 480-377-6422

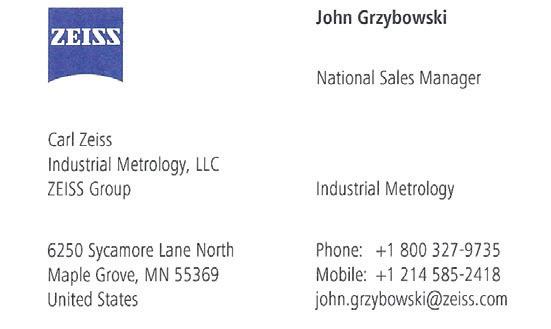

Zeiss Industrial Metrology _ 800-327-9735

Barcode Scanners

KEYENCE _____ _____720-614-9241

CMM Probes

Gage Lab Products_____ 801-716-2972

Hexagon _________

LK Metrology_______ 949-716-4440

Productivity _______ 303-571-4933

Renishaw _________ 847-286-9953

Selway Machine Tool __ 888-735-9290

Total Quality Systems ___ 720-338-2581

Zeiss Industrial Metrology _ 800-327-9735

Gauging Equipment

Gage Lab Products_____ 801-716-2972

Innovative Measuring Systems 602-527-5488

Klontech Industrial Sales 480-948-1871

LK Metrology _______ 949-716-4440

Renishaw _________ 847-286-9953

Starrett ___________ 949-382-4123

Total Quality Systems ___ 720-338-2581

Laser Marking Systems

KEYENCE _____ _____720-614-9241

Measurement Systems

Hexagon _________ 303-859-7159

KEYENCE _____ _____720-614-9241

Starrett ___________ 949-382-4123

Metrology Instruments

Gage Lab Products_____ 801-716-2972

Hexagon _________ 303-859-7159

ACCUDYNE CORPORATION

Innovative Measuring Systems

KEYENCE _____

Klontech Industrial Sales

LK Metrology _______

Renishaw _________

Starrett ___________

Total Quality Systems

Zeiss Industrial Metrology

KEYENCE _____ Optical Comparators

Gage Lab Products

Hexagon _________

Innovative Measuring Systems

Klontech Industrial Sales

LK Metrology _______

Renishaw _________

Total Quality Systems

Sensors: Contact & Optical

Zeiss Industrial Metrology

Video Measuring Systems

Gage Lab Products

Klontech Industrial Sales

Total Quality Systems

Horizon Carbide Tool

Utah Metal Works, Inc.

METALS & MATERIALS

AZ Tool Steel LLC

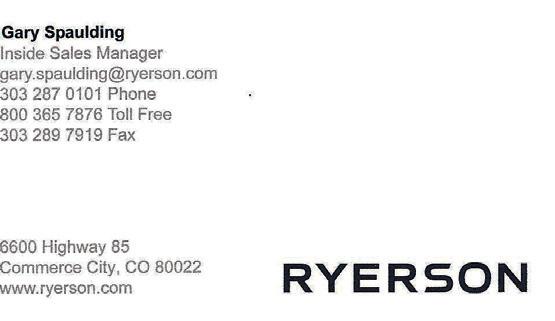

Ryerson __________ 303-227-6310

Bronze

Coastal Metals ______ 800-811-7466

Olympic Metals _____ 303-286-9700

Carbon

Coastal Metals ______ 800-811-7466

Ryerson __________ 303-227-6310

Copper

Olympic Metals _____ 303-286-9700

Garnet Abrasives

Barton International ____ 800-741-7756 Metals: Bar & Plate

AZ Tool Steel LLC ____ 480-784-1600

Coastal Metals ______ 800-811-7466

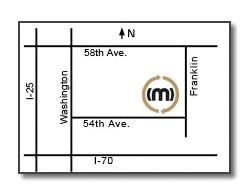

Erickson Metals ____ 303-373-0820

Ryerson __________ 303-227-6310

TW Metals ________ 800-203-8000

Mold Steel

AZ Tool Steel LLC ____ 480-784-1600

Nickel Alloys

AZ Tool Steel LLC ____ 480-784-1600

Ryerson _________ 303-227-6310

TW Metals ________ 800-203-8000

United Perform. Metals 317-946-0025

Plate-Precision Saw Cut

Erickson Metals ____ 303-373-0820

Pre-Honed Tube

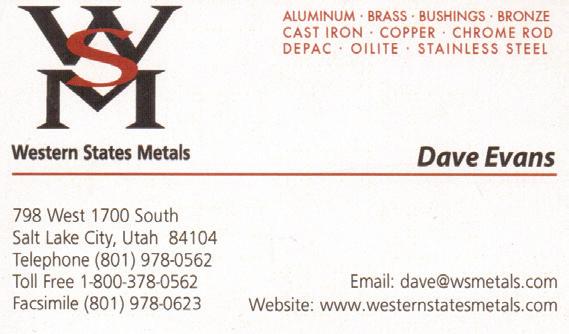

Western States Metals _ 801-978-0562

Stainless Steel

AZ Tool Steel LLC ____ 480-784-1600

Coastal Metals ______ 800-811-7466

Olympic Metals _____ 303-286-9700

Ryerson __________ 303-227-6310

United Perform. Metals 317-946-0025 Steel

AZ Tool Steel LLC _______ 480-784-1600

Coastal Metals ______ 800-811-7466

Olympic Metals _____ 303-286-9700

Ryerson __________ 303-227-6310

Ryerson __________ 303-227-6310

United Perform. Metals 317-946-0025

Titanium

Laube Titanium___805-388-1050x124

METAL DISTRIBUTORS

Erickson Metals ____ 303-373-0820

Coastal Metals ______ 800-811-7466

Laube Titanium __ 805-388-1050x124

Olympic Metals _____ 303-286-9700

Ryerson _________ 303-227-6310

TW Metals ________ 800-203-8000

United Perform. Metals 317-946-0025

Western States Metals _ 801-978-0562

NEW MACHINERY

3D Metal/ Additive

Manufacturing Machines

Production Machine Tools _ 425-881-1200

Renishaw _________ 847-286-9953

CHIP CUTTING

CNC Drilling/Tapping

Methods West ______ 602-437-2220

CNC Mills

Action Machinery ______888-289-9100

AME, Inc. ________ 303-922-9266

DATRON _________ 480-826-3689

DMG Mori ________ 801-561-2001

Doosan _________ 973-618-2500

Hurco __________ 800-634-2416

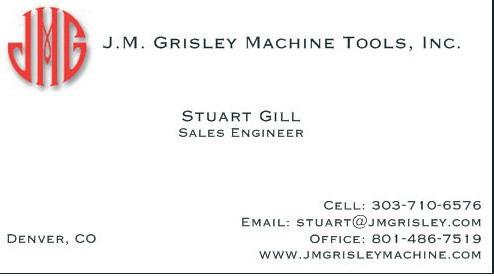

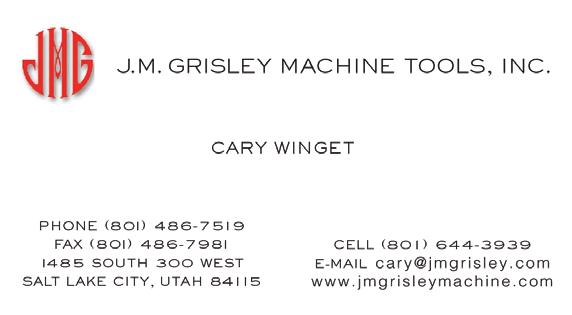

J.M. Grisley _______ 801-486-7519

J.M. Grisley _______ 208-861-8991

KTR Machine ______ 623-202-7177

Methods West ______ 602-437-2220

Productivity Inc. ____ 303-571-4933

Romi Machine Tools LLC 859-647-7566

Sharp Precision _____ 310-370-5990

Smith Machinery Co __ 801-263-6403

Tornos USA ________ 951-695-0342

Triad Machine _______ 303-424-0268

CNC Lathes Action Machinery ______888-289-9100

AME, Inc. ________ 303-922-9266

DMG Mori__________801-561-2001

Doosan __________ 973-618-2500

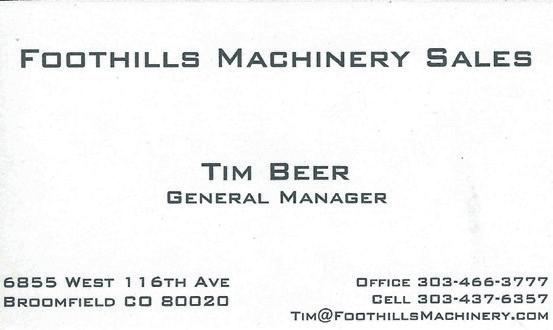

Foothills Machinery ___ 303-466-3777

J.M. Grisley ________ 801-486-7519

J.M. Grisley ________ 208-861-8991

Methods West ______ 602-437-2220

Productivity Inc. ____ 303-571-4933

Smith Machinery Co __ 801-263-6403

Triad Machine ______ 303-424-0268

EDM Tooling Systems Desert EDM Sales ____ 480-816-6300

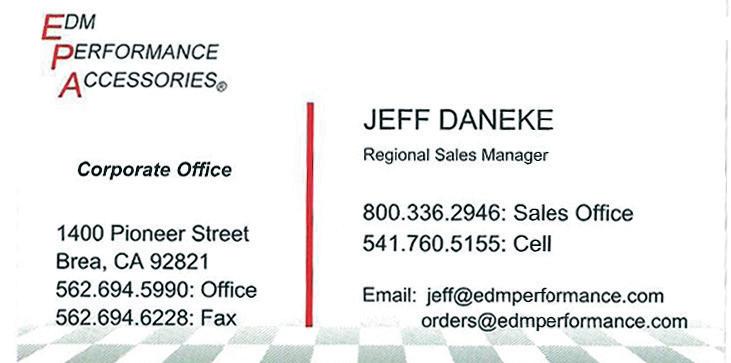

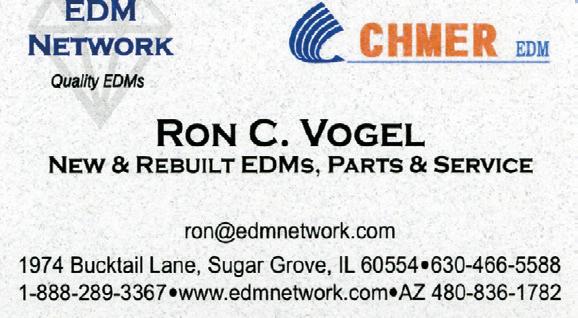

EDM Network ______ 480-836-1782

EDM Perform. Access. ___ 800-336-2946

Global EDM Supply ___ 480-836-8330

Manual Mills & Lathes

KNUTH Machine Tools ___ 847-415-3333 NEW MACHINERY FABRICATION

Multicam _________ 970-218-9046

Latitude Machinery ____ 602-517-7153

Production Machine Tools _ 425-881-1200

Band Saws

KNUTH Machine Tools ___ 847-415-3333

Ultimate Machinery ____ 480-966-2000

Bar Feeders

Edge Technologies _____ 951-440-1574

Bending

Bystronic Inc____ ____ 702-340-6964

Cold Saws

Fullerton Tools ____ 989-799-4550

KNUTH Machine Tools ___ 847-415-3333

CNC Punching Centers

Latitude Machinery ____ 602-517-7153

S&S Machinery Sales __ 602-368-8542

CNC Routers

Multicam _________ 970-218-9046

Drill Lines

Production Machine Tools _ 425-881-1200

Fiber Lasers

Budʼs Machine Tools ___ 385-271-6718

Multicam _________ 970-218-9046

Production Machine Tools _ 425-881-1200 Grinding Machines DCM Tech ________ 800-533-5339

Latitude Machinery ____ 602-517-7153

KNUTH Machine Tools ___ 847-415-3333 Multitool USA ______ 800-660-0880

Iron Workers Action Machinery ______888-289-9100

Latitude Machinery ____ 602-517-7153 Production Machine Tools _ 425-881-1200

S&S Machinery Sales __ 602-368-8542

Laser Cutters

Action Machinery ______888-289-9100

Budʼs Machine Tools ___ 385-271-6718

Bystronic Inc__ ______ 702-340-6964

KNUTH Machine Tools ___ 847-415-3333

Latitude Machinery ____ 602-517-7153

Production Machine Tools _ 425-881-1200

Productivity Inc. ____ 303-571-4933

S&S Machinery Sales __ 602-368-8542

Triad Machine ______ 303-424-0268

Magnetic Particle (NDT) Machines

DCM Tech _________ 800-533-5339

Pipe & Tube Benders/Notchers

Bystronic Inc__ ______ 702-340-6964

S&S Machinery Sales __ 602-368-8542

Plasma Cutters

Action Machinery ______888-289-9100

Bystronic Inc__

KNUTH Machine Tools

Multicam _________

Production Machine Tools

Action Machinery

Bystronic Inc__

Latitude Machinery

Production Machine Tools _ 425-881-1200

Rotary Surface Grinders

DCM Tech _________ 800-533-5339

Sawing Machines

Action Machinery ______888-289-9100

Fullerton Tools ____ 989-799-4550

Latitude Machinery _____ 602-517-7153

Production Machine Tools _ 425-881-1200

Shearing Machines

Action Machinery ______888-289-9100

Bystronic Inc__ _______ 702-340-6964

Latitude Machinery _____ 602-517-7153

S&S Machinery Sales __ 602-368-8542

Vacuum Tables

DATRON _________ 480-826-3689

OTHER ACCESSORIES

Grinding Accessories

Multitool USA ______ 800-660-0880

Tooling Systems

Desert EDM Sales _____ 480-816-6300

USA EDM Supply _____ 480-836-8330

PALLET SYSTEMS

Automatic Pallet Systems Midaco __________ 847-593-8420

Automatic Door Opener Systems Midaco __________ 847-593-8420

Robotic Part Loading Systems Midaco __________ 847-593-8420

PLASTICS

Acrylics And Polycarbonates Laird Plastics ______ 303-292-1687

Plastics: Fabrication Laird Plastics ______ 303-292-1687

Graphics Materials Laird Plastics ______ 303-292-1687

Mechanical/Engineering Material Laird Plastics ______ 303-292-1687

PROTOTYPE

ROBOTIC EQUIPMENT

Acieta __________

402-650-8132

Integrated Systems Inc _ 928-649-9600

Robot Accessories

Acieta __________

402-650-8132

SCHUNK __________ 919-452-4535

Robotic Repairs

Acieta ___________

SERVICES

402-650-8132

AS9100 Certification

ABS Quality Evaluations 702-371-7591

BMSC __________ 602-445-9400

Cavendish Scott _____ 303-480-0111

Business Forms/ Custom labels/Brochures

Pryntink __________ 855-675-1444

Calibration Services

Advanced Coord. Tech __ 303-469-6161

Klontech Industrial ____ 480-948-1871

Quality Measurement Services970-413-2438

Western States Calibration 801-466-1700

Consultant,Operational Consultant, ISO

ABS Quality Evaluations 702-371-7591

BMSC __________ 602-445-9400

Cavendish Scott _____ 303-480-0111

MEP 801-863-7001

Contract Inspection

Advanced Coord. Tech __ 303-469-6161

Klontech Measure Sol __ 480-626-8131

Quality Measurement Services970-413-2438

Education

Ogden-Weber Tech College_801-395-3795

Electrical: Breakers/Switches/ Starters

Denver Breaker Supply _ 855-4UR-BRKR

Engineering Services

Advanced Coord. Tech __ 303-469-6161

Financing

Tech Financial Services ____ 414-224-0209

Univerity Federal Credit Union 801-463-3597

First Article Inspection

Advanced Coord. Tech ____ 303-469-6161

Heavyhaul

IRH ___________ 801-972-5581

Injection Molding

3D Parts To Go _____ 801-380-7935 Inspection Services

Advanced Coord. Tech ____ 303-469-6161

Quality Measurement Services970-413-2438

Lean Consulting

ABS Quality Evaluations 702-371-7591

MEP Center _______ 801-587-0713

Logistics/Freight

R&R Transportation ____801-747-2607

Metrology Services

Advanced Coord. Tech __ 303-469-6161

Hexagon _________ 303-859-7159

Klontech Industrial ____ 480-948-1871

Quality Measurement Services970-413-2438

Western States Calibration 801-466-1700

Process Improvement/ Audit

ABS Quality Evaluations 702-371-7591

BMSC _____________ 602-445-9400

Cavendish Scott _____ 303-480-0111

X-Ray

Certified Inspection Service _ 602-267-0661

ISO9000 / AS9100 Cert.

BMSC _____________ 602-445-9400

Cavendish Scott _____ 303-480-0111

Platinum Registration______ 303-639-9001

Orion Registrar _______ 303-645-4017

ISO Registrar

Platinum Registration______ 303-639-9001

Orion Registrar _______ 303-645-4017

Machine Tool Rebuilding

EDM Network ______ 480-836-1782

Nadcap Approvals - Consulting

Level III NDT Consulting 602-578-8109

Non-Destructive Testing (NDT)

Level III NDT Consulting 602-578-8109

Frontier Group ________ 602-437-2426

Phoenix Heat Treat_____602-258-7751

Process Improvement

BMSC _____________ 602-445-9400

MEP Center _______ 801-587-0713

Reverse Engineering

Advanced Coord. Tech __ _303-469-6161

Diversified Metal Services__ 801-972-6093

Klontech Measure Sol__ 480-626-8131

Rigging & Transfer

IRH _____ _____ _801-972-5581

R&R Transportation ____801-747-2607

Transportation

IRH ____________801-972-5581

R&R Transportation ____801-747-2607

SPINDLE REPAIR

RMS Assembly & Mfg__ 303-777-3064

TOOLING

PrecisionToolholding Products

Industrial Supply ___ 800-288-3838

Tooling Systems

Industrial Supply ___ 800-288-3838

Live Tool Holders

Industrial Supply ___ 800-288-3838

Static Tool Holders

Industrial Supply ___ 800-288-3838

CAD/CAM Training

Blackwing Machine__ __ 801-645-4485

MultiCAM ________ 970-218-9046

Machining Software MultiCAM___________ 970218-9046

USED MACHINERY Action Machinery _______888-289-9100

DATRON___________480-826-3689

EDM Network ________ 480-836-1782

K.D. Capital Equipment___480-922-1674

Methods West________602-437-2220

Resell CNC__________844-478-8181

S&S Machinery

Machʼd Products 970-482-7676 Specialty Steel Services __ 801-539-8252

CASTINGS

Aluminum Casting Precision Enterprises ___ 731-642-8709

Die Casting

TVT Die Casting _____ 800-280-2278

Die Casting: Aluminum/Zinc

TVT Die Casting _____ 800-280-2278

CHEMICAL PROCESSING

PAS Technologies ____ 602-744-2648

COATING

Coating:Black Oxide

Phoenix Heat Treat _____ 602-258-7751

Coating: Liquid

Pilkington Metal Finishing 801-972-2146

Coating: Nickel/ Teflon/Chrome

Coating Technologies ___ 623-581-2648

PAS Technologies _____ 602-744-2648

Coating:Zinc & Mag.Phos.

Coating Technologies ___ 623-581-2648

PAS Technologies _____ 602-744-2648

COMPOSITES

S.A. Composites ________ 970-776-3877

DESIGNCAD/CAM

CNC Machine & Design Inc _ 801-531-9922

DIES

Able Machining & Eng. _ 801-268-6766

EDM

EDM: Drilling Small Hole

LAYKE, Inc.___________ 602-272-2654

Micropulse West _______ 480-966-2300

EDM: Ram-Type (Sinking)

Innovative Precision 801-334-6317

Maverick Mold & Machine _ 970-535-4604

Micropulse West _______ 480-966-2300

Kustom Koncepts _____ 307-472-0818

Star Precision _______ 303-926-0559

Fabrication: Medium & Large

CAID Industries _____ 435-890-8823

EMJD Corp _________ 303-761-5236

EPOCS Mfg ________ 970-535-4540

Group Mfg Serv _____ 480-966-39528

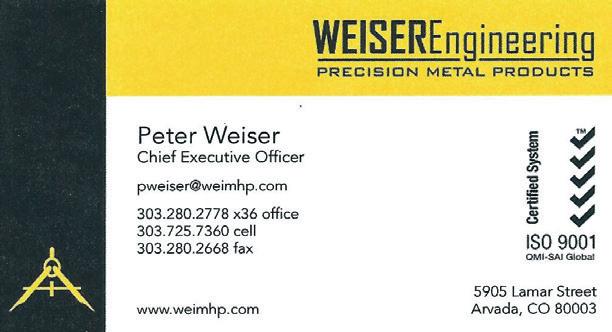

Weiser Engineering _ 303-280-2778

Fabrication: SheetMetal

A1 Precision Metal ____ 623-377-2191

Advantage Manufacturing 877-727-0281

CAID Industries _____ 435-890-8823

Denver Machine Shop ___ 303-295-6000

Dynamic Design & Mfg __ 303-652-0431

EMJD Corporation _____ 303-761-5236

EPOCS Mfg ________ 970-535-4540

Group Mfg Serv ______ 480-966-3952

JD Machine ________ 801-782-4403

Jensen Precision ______ 801-866-0175

Kustom Koncepts _____ 307-472-0818

Metalcraft _________ 888-280-7080

Pillar Machine _____ 801-965-1900

Richards Fab _____ 801-409-0392

Star Precision _______ 303-926-0559

Weiser Engineering _ 303-280-2778

Wrico ___________ 480-892-7800

Fabrication: Steel

Bandsaw LLC ________ 303-744-7181

CAID Industries _____ 435-890-8823

EMJD Corp _______ 303-761-5236

FINISHING

Advantage Manufacturing 877-727-0281

Coating Technologies ___ 623-581-2648

Coating Technologies ___

Phoenix Heat Treat ______ 602-258-7751

Iron Phosphates

Metals Finishing LLC _____ 801-718-7969

Wasatch Powder Coating _ 801-718-7969

Passivation

Certified Inspection Service___602-267-0661

Coating Technologies __ _623-581-2648

Collins Metal Finishing __ 602-275-3117

Photochemical/Etching

VACCO Industries _____ 626-443-7121

Powder Coating

CPCS ____________ 303-438-8328

Metals Finishing LLC _____ 801-718-7969

Pilkington Metal Finishing 801-972-2146

Star Precision _______ 303-926-0559

Wasatch Powder Coating _ 801-718-7969

Sandblasting

Metals Finishing LLC _____ 801-718-7969

Phoenix Heat Treat ____ 602-258-7751

Wasatch Powder Coating _ 801-718-7969

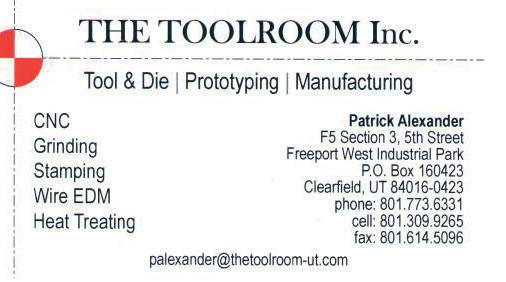

The Toolroom Inc.

Grinding, Blanchard

Auburn Tool & Machine

Diversified Metal Services

Steel Services Grinding

Superior Grinding

Grinding, Centerless

Ron Grob Co. _______

Grinding, Cold Saw

AA Carbide _______ Grinding: OD

Ron Grob Co. _______

Superior Grinding

Grinding: Tool & Cutter

BC Tool & Cutter Grinding

Exact Tool Grinding

Machine Tool & Cutter Grinding

HEAT TREATING

Blanchard Metals Proc.

Controlled Thermal Industrial Heat Treat

Phoenix Heat Treat

Pilkington Metal Finishing__801-972-2146

Quick Turn Machine

The Toolroom Inc. ____ 801-773-63311

Large Capacity Drop Bottom

Oven/ Aluminum Phoenix Heat Treat ____ 602-258-7751

Richards Fab _____ 801-409-0392 MACHINING

435-890-8823

CNC Machine & Design Inc 801-531-9922

406-543-4450

303-652-0431

970-535-4540

480-773-3239

801-634-5894

801-337-5926

801-262-1414

800-244-4130

435-755-0500

731-642-8709

801-334-6800

801-977-0447

303-789-4247

719-548-8995