West Coast Edition (WA, OR, and CA)

West Coast Edition (WA, OR, and CA)

We offer fast and simple financing solutions for businesses with an opportunity for growth and a need for capital.

is the perfect product when your business has a project or additional expenses. Simple application process and funds up to $250,000. Capital intended to grow your business.

up to $750,000 (without financial review) for your new or used equipment acquisitions. With 100% financing and terms up to 84 months, it allows you to reserve cash in your bank account.

Balancing the budget is a little like protecting your virtue:You just have to learn to say “no.”

Government’s view of the economy could be summed up in a few short phrases: If it moves, tax it. If it keeps moving, regulate it. And if it stops moving, subsidize it.

Ronald Reagan

When Ronald Reagan took the oath of office as America’s 40th President on January 20, 1981, the country was experiencing some of the bleakest economic times since the Depression. Taxes were high, unemployment was high, interest rates were high, and the national spirit was low.

To reverse the economic climate of the time, President Reagan put forth an economic policy that aimed to reduce government regulation, lower taxes, and promote free-market capitalism as a means to stimulate economic growth and increase individual wealth.

President Reagan earned a degree in Economics at Eureka College, and even though he would sometimes joke about “two economists having three opinions,” he knew what needed to be done and how to do it.

He consistently advocated for a straightforward and simple, yet detailed plan during his campaign: cut taxes, get control of government spending, and get the government out of the way so that the entrepreneurial spirit of the American people could be unleashed.

Given actual rates of inflation, through 1987, the Reagan tax cuts saved the median-income two-earner American family of four close to $9,000 in taxes from what it would have owed in 1980.

Tax cuts were only one “leg of the stool.” The second, jobs, was equally strong. Not only were there millions of new jobs, but the benefits of job creation were not limited to one segment of society. Employment of African-Americans rose by more than 25% between 1982 and 1988, and more than half of the new jobs created went to women.

Taming the lion called government spending was another key component of the plan – the “third leg of the stool.” Here, too, President Reagan did what he said he would do. During his Administration, growth in government spending plummeted from 10% in 1982, to just over 1% in 1987. With inflation factored in, Federal spending actually went down in 1987 – the first time that had happened in well over a decade.

So impressive was the Reagan Recovery that at the G7 Economic Summit in 1983, when it was obvious the President’s plan was working, the West German Chancellor asked him to “tell us about the American miracle.” That was quite a turnaround from two years earlier, when President Reagan outlined his economic recovery plan to an unconvinced group of world leaders.

Now, however, they all wanted to know how he did it, so he told them: reducing tax rates restored the incentive to produce and create jobs, and getting government out of the way allowed people to be entrepreneurs. From there, the free marketplace operated as it was supposed to.

History can ge a great teacher as long as we have a good memory. We’ve turned our country around before, we sure need the wisdom and fortitude to do it again. If there is anything we can do to help you promote your business and gain new sales, please contact us.

Kim Carpenter

Kim Carpenter & Linda Daly Kim@A2ZManufacturing.com

Mail Address: PO Box 459 Higley AZ 85296

Telephone: (480) 773-3239 Website: www.A2ZManufacturing.com E-mail:Kim@A2ZManufacturing.com

Linda Daly, Stephen Hannemann, Eugene Wirth

Published bi-monthly to keep precision manufacturers abreast of news, contracts, trends, and to supply a viable supplier source for the industry.

Circula tion: A2Z Manufacturing West Coast maintains a master list of over 14,000 decision makers consisting of fortune 1000 companies, small manufacturing companies, engineering firms, DOD & Scientific Lab facilities, machine shops, fab-shops, and secondary source businesses. It has an estimated pass on readership of more than 25,000 people. The majority of our readers are based in CA, OR, WA area!

Advertising Rates have remained the same since 1999, deadlines and mechanical requirements furnished on our website at: www.a2zManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

T he Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

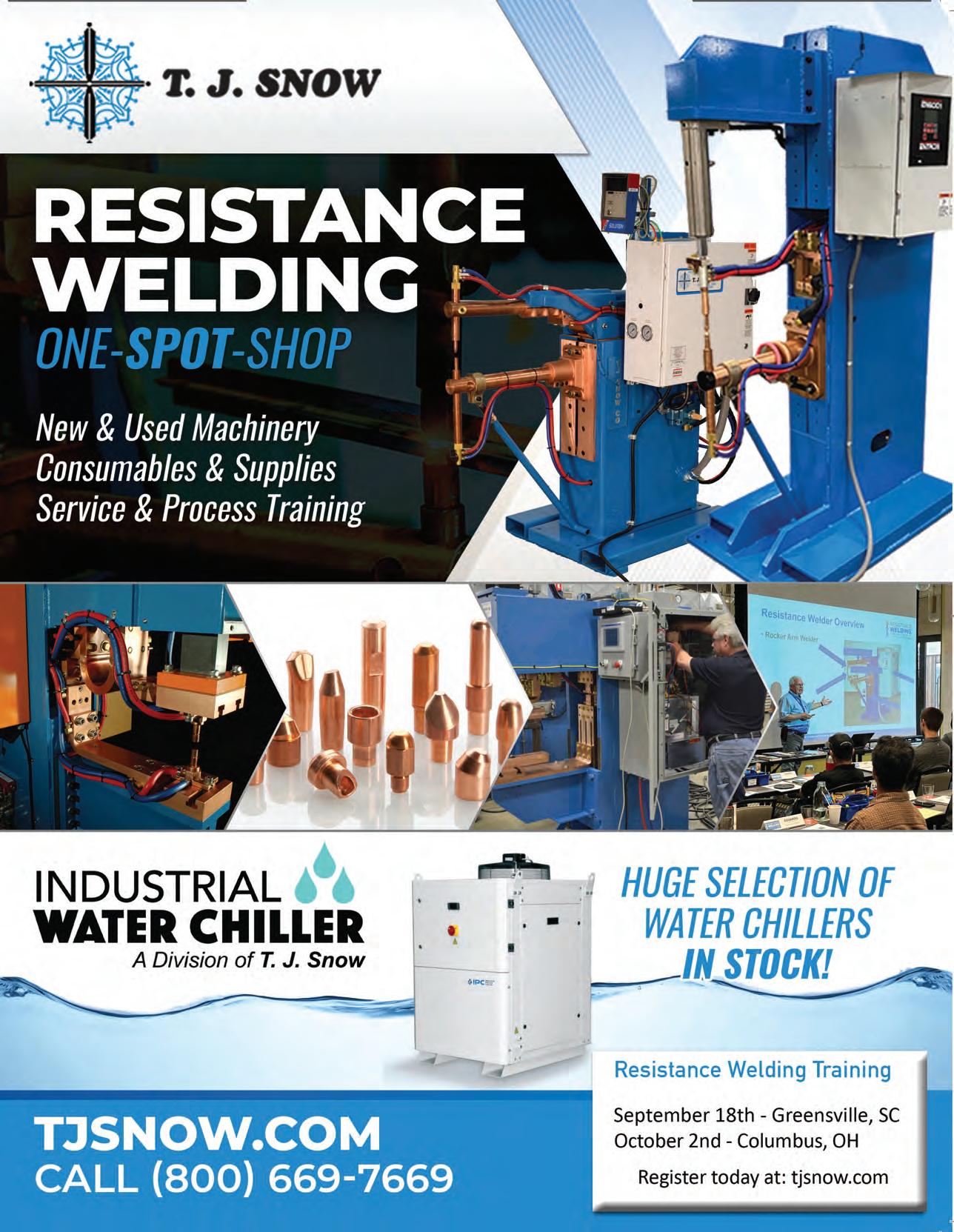

Germantown, WI, - Hainbuch America, a leading name in machining technology, is proud to unveil its latest innovation at IMTS 2024: the revolutionary AC (Automated Change) Line. This groundbreaking solution marks a significant milestone as the first fully automated system for workholding device changeover, setting new standards in manufacturing efficiency and precision.

The AC Line represents a paradigm shift in workholding technology, offering manufacturers a seamless and error-free alternative to manual changeovers. By harnessing cutting-edge automation, the AC Line streamlines transitions between workholding devices with unmatched speed and accuracy. This innovation not only reduces downtime but also enhances overall productivity, empowering manufacturers to maximize their machining capabilities.

Key features of the AC Line include:

1. Pr ecision Automation:

The AC Line’s precision-engineered automation ensures consistent and reliable changeovers, eliminating human error and optimizing machining processes.

2. Automated Clamping Heads (Collets) and End-Stops: In addition to workholding device changeover, the AC Line automates clamping heads (collets) and end-stops, further enhancing operational efficiency and accuracy.

3. User-Friendly Interface: Designed with ease of use in mind, the AC Line features an intuitive interface that allows operators to program and adapt quickly, enhancing operational efficiency.

4. Versatile Adaptability: From varying part geometries to diverse materials and machining techniques, the AC Line adapts seamlessly to meet a wide range of production requirements, ensuring versatility without

compromise.

5. Industry-Leading Support: Hainbuch America’s commitment to customer success extends beyond innovative technology. Our team of experts provides comprehensive support, from personalized solutions to hands-on guidance, ensuring a seamless integration of the AC Line into existing manufacturing workflows.

“We are thrilled to introduce the AC Line at IMTS 2024, marking a significant advancement in workholding technology,” said Tim Wachs, President at Hainbuch America. “This groundbreaking solution reflects our dedication to pushing the boundaries of innovation and empowering manufacturers with tools that optimize efficiency, precision, and productivity.”

Visit Hainbuch America at booth W-431636 at IMTS 2024 to experience the AC Line firsthand and discover how it is reshaping the future of manufacturing.

For media inquiries, please contact:

Michael Larson - Marketing Director • mlarson@hainbuchamerica.com

About Hainbuch America: Hainbuch America is a leading provider of innovative workholding solutions for the machining industry. With a commitment to excellence and customer success, Hainbuch America continues to push the boundaries of technology to drive efficiency and precision in manufacturing processes.

Anca’s

Industry 4.0 connectivity and AI-assisted guidance on ANCA’s new edge preparation machine revolutionizes edge preparation for cutting tool performance

Renowned for launching industry-first tool and cutter grinding technologies, ANCA continues its legacy of innovation with the EPX-SF, guaranteeing productivity, quality, and profitability in edge preparation. The new EPX-SF stream finishing machine was debuted at GrindingHub in Stuttgart, coinciding with the company’s 50-year anniversary.

Armando Manzano, EPX-SF Product Manager said, “More than just an edge preparation machine, the EPX-SF is a strategic business asset. Its high level of precision will help manufacturers to secure more contracts by meeting the rigorous standards of industries that demand clean and consistent cuts. Its ability to deliver flawless quality in a single pass enhances operational efficiency, eliminating the need for extensive post-processing and ultimately saving costs for businesses.”

Key highlights of the EPX-SF:

• Unmatched automation: Process up to 1,900 tools in 24 hours with lights-out operation at the push of a button.

• Resource optimization: Standardization minimizes setup and learning curves, making the process accessible to all operators.

• Machine learning capabilities: Tailored recipes enhance tool IP value, providing a significant selling point for edge preparation.

• Traceability: Every product meets quality expectations with results saved, tracked, and retrievable directly from the machine.

• Predictable precision: Achieve nano-smooth surfaces (roughness < 100 nm) and micron-honed edges with a controllable K-factor.

The EPX-SF is a future-ready solution, designed with advanced functionalities to meet the evolving needs of manufacturing. Its performance-driven design with 11 axes, delivers predictable nanosmooth surfaces and micron-honed edges within a minute per tool. The Advanced Cyclic Mode allows users to adjust angles, optimizing chip flow and effectively combatting surface burrs. It utilizes AI-assisted guidance to provide tailored recommendations, enhancing tool geometries and streamlining process efficiency. With Industry 4.0 connectivity, advanced safety features, and remote technical assistance, the EPX-SF seamlessly integrates into production lines.

Contact your local ANCA representation for more information on how the EPX-SF is redefining edge preparation, or visit https://machines.anca. com/Products/Machines/Edge-Preparation/EPX-SF

For further information, please contact: Amanda Bakun

Marketing & Communications Manager - Americas 248-497-1168 amanda.bakun@anca.com

ANCA CNC Machines is a global leader in the design, manufacture, and service of advanced CNC grinding machines. With an illustrious history spanning over 50 years, ANCA is renowned for its cutting-edge technology, innovative solutions, and exceptional customer support. ANCA’s comprehensive range of products includes tool grinders, CNC grinding machines, software, and automation solutions, catering to diverse industries such as aerospace, automotive, medical, and general manufacturing.

Landmark Solutions has steadily grown its team of experts over the past decade and now serves businesses in seven states, making it the largest fabrication equipment dealer in the Western US. Backed by over 100 years of collective experience, Landmark offers industry-leading machines and support to ensure their customers’ long-term success. Get the Landmark Advantage and contact the team today to find ways to take your operation to the next level.

Contact: Chad Mooneyham, VP | (714) 393-3783 info@landmarksolutionscorp.com

Best Choice Parts: Convenient Source For Omax Oem, Accustream, And Hypertherm Waterjet Parts

Best Choice Parts offers immediate will-call or guaranteed same-day shipment on over 5000 American-made waterjet parts. The region’s proud exclusive dealer for OMAX OEM parts, Best Choice also stocks Accustream and Hypertherm parts for Flow, KMT, and other systems, and has quickly become the preferred parts source for shops throughout the region.

Contact: +1 (855) WATRJET | info@bestchoiceparts.com www. bestchoiceparts.com

Phoenix Heat Treating Is Proud To Announce That We Are FAA Drug And Alcohol Program Compliance.

Phoenix Heat Treating is especially known for its ability to resolve difficult heat-treating problems that are beyond the capability of a typical application. We offer a wide array of processing and consulting services. We take great pride in finding unique solutions to meet each individual customer’s requirements.

To learn more about how Phoenix Heat Treating can support all your heat treat needs, as well as specialized services, contact Tim Johnston, Director of Business Development.

Tim Johnston Director of Business Development is available to assist you at Phoenix Heat Treating and can be reached at 623-512-3233 or by email at tjohnston@phxht.com

FAA Drug and Alcohol Program

GrovTec Machining, a leading production machining facility, is thrilled to announce a significant expansion in both capacity and expertise. We have recently acquired over a dozen pieces of equipment and welcomed ten highly skilled workers from a prominent local machine shop that recently closed.This strategic move underscores our commitment to delivering exceptional service and highquality products to our customers.

multiple Tornos screw machines, Hydromats and an ABC Index, allowing for greater automation, higher precision, and increased production speeds. These enhancements will enable us to meet the growing demands of our customers and offer more versatile machining solutions.

The ten skilled workers joining our team bring with them years of experience and a wealth of knowledge. Their expertise spans various aspects of production machining, from programming and operating advanced machinery to implementing quality control measures and optimizing production workflows. We are confident that their skills will integrate seamlessly with our current team, fostering an environment of innovation and excellence.

“We are excited and blessed to have this opportunity to expand our operations,” said Bob Grover, Owner of GrovTec US, Inc. “The acquisition of these machines and the addition of such skilled workers will significantly enhance our production capabilities. This growth not only allows us to support our existing customers with greater efficiency and quality but also gives us the ability to take on new projects requiring even higher production volumes. We are committed to providing precision parts and reliable machining solutions, and this expansion is a testament to that.”

GrovTec Machining would like to extend heartfelt thanks to our loyal customers, dedicated employees, and supportive community. Without your continued trust and support, this exciting growth would not have been possible. We look forward to serving you with these expanded capabilities and continuing to exceed your expectations. For more information about our services and how we can assist with your production machining needs, please visit our website at www. grovtecmachining.com or contact us at info@ grovtecmachining.com.

About: GrovTec Machining is a premier production machining facility specializing in high-volume, precision machining services. With a commitment to quality, innovation, and customer satisfaction, we provide comprehensive machining solutions to a diverse range of industries. Our state-of-theart equipment and skilled workforce ensure that we deliver exceptional products and services every time.

In an industry where precision, efficiency, and expertise are paramount, the addition of these machines and additional team members represents a substantial enhancement of our capabilities.The new equipment includes

By Stephen Hannemann

3D Plastics in Newberg, Oregon has created something unique in the injection molding industry – a company with HEART! From their inception, 3D management has focused on taking care of the business of “The Customer is King,” and that has been communicated across the line to the people on the production floor who produce the parts.

The success of any manufacturing endeavor must be attributed to the folks who get it done. It boils down to the culture.True, ownership and management set the framework, areas of responsibility, and tone that creates the atmosphere, the working conditions. But the workforce produces the products that land on your shipping dock. The prep people, the setup tech, the molding machine operators, the second ops and assembly people, and the packaging and shipping personnel – all take pride in getting the work done right!

For 25 years dedicated 3D employes have been molding, assembling and shipping peerless injection molded components and assemblies throughout the United States and countries around the world. This is a tribute to the committed production employees at 3D Plastics in Newberg, Oregon.

To learn more about 3D Plastics visit 3d-plastics.com or call 503.537.0979.

Be sure to check out the full 3D story on Page 32.

By Stephen MacLeod

The plan comes as the national EV market is slowing, and the company acknowledges that customers are more cost conscious than early adopters were. Despite the headwinds, work continues at BlueOval City which is still in line to launch an all-new electric truck, codenamed Project T3.

“Construction continues at BlueOval City, where we are excited to launch our next-generation electric truck, which will build on Ford’s centurylong heritage of truck leadership,” said Lisa Drake, Ford VP, EV Programs and Energy Supply Chain. “While we incorporate new lower-cost battery technology, we will use the extra time to make the truck even more competitive — for the long-term benefit of BlueOval City and beyond.”

When first announced, BlueOval City was expected to begin delivery of its vehicles in 2025. In May 2024, Ford updated that timetable to say it was hoping to deliver the truck to customers starting in 2026. While construction continues, it is past the peak it was last year as work enters the later stages. The company said the move was to take advantage of lower-cost battery technology.

“West Tennessee is a linchpin in our plan to create a strong and growing Ford in America,” said Ford president and CEO Jim Farley. “BlueOval City will be one of the most advanced manufacturing complexes anywhere

in the world, and we are counting on the workforce in West Tennessee to produce advanced batteries starting next year, and then our most innovative pickup ever starting in 2027.”

One thing that is still going forward on schedule is BlueOval SK’s battery facilities. The joint venture between Ford and Korea-based SK Innovation is expected to start producing at its Kentucky site in mid-2025 and at BlueOval City in late 2025. The company is also realigning its battery sourcing to lower costs and be more efficient, ultimately keeping EV costs down.

The Kentucky operation is anticipated to provide batteries for Ford’s E-transit commercial van and the F-150 Lightning. In addition to Project T3, Tennessee is slated to produce batteries for Ford’s new electric commercial van to be built at Ford’s Ohio Assembly Plant in 2026 and “future emerging technology electrified vehicles.”

The company is also planning on stepping up its local presence. The company’s own donations and that of its philanthropic wing, Ford Philanthropy, have eclipsed $21 million so far in West Tennessee.

“Ford and Ford Philanthropy are stepping up our community initiatives because we want residents in every community neighboring BlueOval City to benefit as the campus comes to life. I look forward to introducing our Good Neighbor Plan, developed with the help of resident input and the community leaders who make up our Equitable Growth Advisory Council,” said Gabby Bruno, Ford’s community relations director.

The Bystronic ByCut Eco 3015 and 4020 are the ideal laser cutting systems for fabricators who want an uncomplicated yet powerful fiber laser cutting system from a trusted industry leader. With the ByCut Eco, business owners can benefit from the technology of fiber laser cutting without high investment hurdles or long learning curves. The ByCut Eco is focused on the things that make a fiber laser attractive for users: cutting sheet metal parts as fast as possible and with high quality. ByCut Eco, with up to 6kW, is also automation-ready.

Viasat Inc., Carlsbad, California, was awarded a $7,668,960 firmfixed-price contract modification (P00021) to exercise a fourth option year for Naval Senior Leadership Communication – Aircraft satellite communications services. The total cumulative face value of the contract is $38,213,204. The face value of this action is funded by fiscal 2024 operation and maintenance funds. Performance will be at contractor’s facility in Carlsbad, California, with satellite communication services provided to aircraft traveling worldwide. The period of performance for Option Period Four is Sept. 10, 2024, through Sept. 9, 2025.The Defense Information Technology Contracting Organization, Scott Air Force Base, Illinois, is the contracting activity (HC101320C0005).

SRI International, Menlo Park, California, has been awarded a maximum $125,641,325 long term, indefinite-delivery, hybrid cost-plus-fixedfee and firm-fixed-price, requirements type contract for generalized emulation of microcircuits production program. This was a sole-source acquisition using justification 10 U.S. Code 3204 (a)(1), as stated in Federal Acquisition Regulation 6.302-1. This is a five-year base contract with one six-month option period. Location of performance is New Jersey, with a July 31, 2029, performance completion date. Using military services are Army, Navy, Air Force, and Marine Corps. Type of appropriation is fiscal 2024 through 2029 operation and maintenance and defense working capital funds. The contracting activity is the Defense Logistics Agency Land and Maritime, Columbus, Ohio (SPE7MX-24-D-0030).

NewVac LLC,* Chatsworth, California, is awarded a $13,669,843 firm-fixed-price modification to a previously awarded contract (N6339422C0009) for the procurement, manufacture, assemble, test, and delivery of cables in support of the MK 41 Vertical Launching System. This modification combines purchases for the U.S. government (78%); and the governments of Netherlands (12%); and Germany (10%), under the Foreign Military Sales (FMS) program. Work will be performed in Chatsworth, California, and is expected to be completed by September 2025. Fiscal 2024 shipbuilding and conversion (Navy) $6,955,716 (51%); presidential drawdown authority funds in the amount of $2,676,906 (19%); FMS Netherlands (12%); FMS Germany (10%); and other procurement (Navy) funds in the amount of $1,052,150 (8%), will be obligated at time of award and will not expire at the end of the current fiscal year. The Naval Surface Warfare Center, Port Hueneme Division, Port Hueneme, California, is the contracting activity.

ace Exploration Technologies Corp., Hawthorne, California, has been awarded a $661,025,403 modification (P00018) to a previously awarded contract (FA8811-20-D-0002) for National Security Space (NSS) Launch Phase Two launch service procurements for NSS launch services from fiscal 2020 through fiscal 2024, for launches planned between fiscal 2022 through fiscal 2027.The modification brings the total estimated face value of the contract to $4,000,000,000 from $3,338,974,597. Work will be performed Hawthorne, California; Cape Canaveral Space Force Station, Florida; and Vandenberg Space Force Base, California, and is expected to be completed by March 31, 2028. The Contracting Division, Assured

Access to Space, Space Systems Command, Los Angeles Air Force Base, El Segundo, California, is the contracting activity.

Armtec Countermeasures Co., Coachella, California; and Lillington, North Carolina, was awarded an $11,700,000 firm-fixedprice contract for RR-196 countermeasure chaff for the F-22. This contract provides for the impulse cartridge program and is used by F-22 aircraft for combat and training purposes. Work will be performed in Lillington, North Carolina, and is expected to be completed by Sept. 30, 2027. This contract was a sole source acquisition. Fiscal 2024 ammunition funds in the amount of $11,700,000 are being obligated at the time of award. The Air Force Life Cycle Management Center, Hill Air Force Base, Utah, is the contracting activity (FA8213-24-D-B009).

General Atomics Aeronautical Systems Inc., Poway, California, is being awarded a $500,000,000 indefinite-delivery/indefinitequantity contract (H9240824D0002) with a $436,900 initial task order for program management support related to Medium Altitude Long Endurance Tactical MQ-9 and MQ-1C Special Operations Forces-peculiar modifications in support of U.S. Special Operations Command (USSOCOM). This contract will be funded with operations and maintenance; procurement; and/or research, development, and testing evaluation funds under the applicable fiscal year, and is not multiyear. The work will be performed in Poway, California, and is expected to be completed by Aug. 16, 2029. USSOCOM, MacDill Air Force Base, Florida, is the contracting activity.

Servicing our industry and trade customers in intelligence heat treating for over 60 years.

Established in 1963

Real Time Live Job Tracking

10+ Processes Performed

50+ Furnaces

AOG and Line Down Services

Over 10+ Prime Approvals 24/7 Processing

cs@phxht.com

www.phoenix-heat-treating.com 602-258-7751

Northrup Grumman, Northridge, California, has been awarded a $26,800,000 cost-plus-fixed-fee ceiling increase modification (P00001) to previously awarded contract FA8651-24-D-B002 for on-going work within the scope of the statement of work and is needed to continue counter air science and technology efforts.The modification brings the total cumulative face value of the contract to $36,000,000.Work will be performed at Northridge, California, and is expected to be completed by Jan. 15, 2029. The Air Force Research Laboratory, Eglin Air Force Base, Florida, is the contracting activity.

Oshkosh Defense LLC, Oshkosh, Wisconsin, was awarded a $46,092,136 modification (P00002) to contract W912CH-24-F-0082 for the Family of Medium Trucks and related services. Bids were

solicited via the internet with three received.Work locations and funding will be determined with each order, with an estimated completion date of Nov. 30, 2026. Army Contracting Command, Detroit Arsenal, Michigan, is the contracting activity.

B.E. Meyers & Co.,* Redmond,Washington, is being awarded a contract (H9240324D0009) for the acquisition of the Miniature Aiming Systems –Laser (MAS-L) Squad Aiming Laser – Ultra High Power (SAL-UHP) and associated repairs. This indefinite-delivery/indefinite-quantity contract is being awarded with a maximum total ceiling of $49,900,000 and a $500,000 minimum ordering guarantee in support of U.S. Special Operations Command (USSOCOM).This contract will have an ordering period of five years. Fiscal 24 procurement funds in the amount of $11,000,110 are being obligated at time of award on the first delivery order. USSOCOM, MacDill Air Force Base, Florida, is the contracting activity.

Fluor Marine Propulsion LLC, Arlington, Virginia, is awarded a $1,396,995,054 cost-plus-fixed-fee modification to previously awarded contract (N00024-18-C-2130) to exercise fiscal 2025 options for naval nuclear propulsion work at the Naval Nuclear Laboratory. Work will be performed in Pittsburgh, Pennsylvania (52%); Schenectady, New York (39%); and Idaho Falls, Idaho (9%). Fiscal 2024 other procurement (Navy) funding in the amount of $14,979,962 (79%); fiscal 2024 research, development, test and evaluation in the amount of $3,551,000 (19%); and fiscal 2022 other procurement (Navy) funding in the amount of $495,000 (2%), will be obligated at time of award and funds in the amount of $495,000 will expire at the end of the current fiscal year. Naval Sea Systems Command, Washington, D.C., is the contracting activity.

Lockheed Martin Rotary and Mission Systems, Moorestown, New Jersey, is awarded a $61,000,000 cost-plus-fixed-fee and cost-only modification to a previously awarded contract (N00024-20-C-5392) for engineering integration, technical support, and depot operations in support of the MK 41 vertical launching system electronic systems and computer programs. Work will be performed in Moorestown, New Jersey (60%);Ventura, California (16%), San Diego, California (10%); Seattle, Washington (4%); Mayport, Florida (4%); Norfolk, Virginia (4%); and Virginia Beach, Virginia (2%), and is expected to be completed by July 2025. Fiscal 2024 shipbuilding and conversion (Navy) funds in the amount of $5,635,000 (43%); fiscal 2024 research, development, test and evaluation (Navy) funds in

the amount of $5,441,483 (41%); fiscal 2024 other procurement (Navy) funds in the amount of $1,254,750 (9%); and fiscal 2024 Defense-wide research, development, test and evaluation funds in the amount of $927,322 (7%), will be obligated at time of award and will not expire at the end of the current fiscal year. Naval Sea Systems Command,Washington NavyYard,Washington, D.C., is the contracting activity.

The Boeing Co., Seattle, Washington, is awarded a $27,658,912 modification (P00023) to a cost-plus-fixed-fee-order (N0001920F0647) against a previously issued basic ordering agreement (N0001916G0001). This modification exercises an option to procure three retrofit A-Kits for Royal Australian Air Force (RAAF) P-8A aircraft with Increment Three Engineering Change Proposal Six Capabilities. Work will be performed in Jacksonville, Florida (79.6%); San Antonio, Texas (10.9%); and Mesa, Arizona (9.5%), and is expected to be completed October 2026. RAAF Cooperative Funds in the amount of $27,658,912 will be obligated at the time of award, none of which will expire at the end of the current fiscal year. Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

General Atomics Aeronautical Systems Inc., San Diego, California, is awarded a $9,672,322 modification (P00005) to a firm-fixed-price order (N0001921F0060) against a previously issued basic ordering agreement (N0001916G0006). This modification provides for the procurement and installation of upgraded dual gate drivers for the Electromagnetic Aircraft Launch System Power Conditioning

Subsystem Half Bridges to address reliability and obsolescence concerns. This includes a total of 686 kits that will be installed on Navy aircraft carriers (CVN 78, CVN 79) and the Lakehurst System Functional Demonstration test site, including on-board and site spares for each location. Additionally, this modification includes associated labor for engineering, program management, and logistics products. Work will be performed in Tupelo, Mississippi (56.1%); San Diego, California (40.7%); Newport News, Virginia (1.7%); and Lakehurst, New Jersey (1.5%), and is expected to be completed January 2027. Fiscal 2024 shipbuilding and conversion (Navy) funds in the amount $3,442,009; fiscal 2024 other procurement (Navy) funds in the amount $2,277,737; fiscal 2023 other procurement (Navy) funds in the amount of $2,676,182; and fiscal 2022 other procurement (Navy) funds in the amount of $1,276,392 will be obligated at the time of award, $1,276,392 of which will expire at the end of the fiscal year. Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

Science Applications International Corp., Reston, Virginia, has been awarded a maximum $262,430,360 contract bridge modification (P00013) to previously awarded Government Wide Acquisition Contract Alliant 2 vehicle for continued Air Force cloud computing capability. The contract modification is for continued support of commercial cloud services, common architectural and foundational services, and software engineering services to assist with migration and modernization. The modification brings the total cumulative face value of the contract to $1,246,163,495. Work will be performed at the contractor’s designated facilities and is expected to be completed by Sept. 8, 2025. Fiscal 2024 operations and maintenance funds in the

amount of $13,804,881 are being obligated at the time of award. The Air Force Life Cycle Management Center, Hanscom Air Force Base, Massachusetts, is the contracting activity (FA8726-24-F-0001). Oshkosh Defense LLC, Oshkosh, Wisconsin, was awarded a $1,541,861,429 fixed-price with economic-price-adjustment contract for the Family of Heavy Tactical Vehicles. Bids were solicited via the internet with one received. Work locations and funding will be determined with each order, with an estimated completion date of Aug. 19, 2029. Army Contracting Command, Detroit Arsenal, Michigan, is the contracting activity (W912CH-24-D-0008).

Modern Technology Solutions Inc., Alexandria, Virginia, is being awarded a competitive, cost-plus-fixed-fee, indefinite-delivery/ indefinite-quantity contract with a maximum amount of $73,568,329. Under this new contract, the contractor will build advance the state-ofthe-art in collaborative, constructive experimentation and evaluation of missile defeat kill webs (MDKW). The contractor will create a digital engineering ecosystem that enables experiments and evaluations of MDKW including left-through-right of launch. A task order in the amount of $11,919,845 is being issued. The work will be performed in Huntsville, Alabama. The ordering period is from Aug. 19, 2024, through Aug. 18, 2029. This contract was competitively procured via publication on the government-wide Point-of-Entry website under the Missile Defense Agency’s (MDA) Broad Agency Announcement HQ0860-23-S-0001. Fiscal 2023 research, development, test and evaluation Congressional-Plus-Up funds in the amount of $1,804,347 are being obligated on the first task order. MDA, Redstone Arsenal, Alabama, is the contracting activity (HQ0860-24-D-0001).

The U.S. Navy is taking the first steps toward building the most advanced version of the Virginia-class fast attack submarine (SSN 774) -- an undersea warfare weapon expected to bring its reconnaissance and lethality from the ocean’s surface to the seabed.

Officials of the Naval Sea Systems Command in Washington announced a $181 million order in July to General Dynamics Corp. Electric Boat segment in Groton, Conn., for long-lead items for the Virginia Class Block VI submarines.

The Virginia Block VI submarines are to feature technology improvements in stealth, propulsion, and weapons, and should be one of the best submarines in the world for interacting with the water column from the surface to the seabed.

Long-lead items either are difficult and timeconsuming to obtain, and are funded early in the aircraft design process to keep overall production on schedule.

Related: Navy starts ramping-up production of large unmanned submarines for reconnaissance and special ops

The Virginia Block VI boats will be the second block of Virginia-class attack submarines with the Virginia Payload Module for large-scale land strike missiles.

The Virginia Payload Module places four multiple all-up-round canisters in the middle of the submarine in addition to two in the bow. Each tube can contain seven Tomahawk land-attack missiles.

Not only does the Virginia Block VI add land-attack firepower to the fleet, but it also offers the opportunity for the Navy to design mission-specific submarines.

The Navy is expected to order at least one Virginia Block VI specially designed for seabed warfare for undersea espionage and other special

The overall target of seabed warfare is infrastructure in place on the seabed

On this order, General Dynamics will do the work in Sunnyvale, Calif.; Minneapolis;York and Pittsburgh, Pa.; Spring Grove and Peoria, Ill.; Windsor Locks, Conn.; Tucson, Ariz.; Monroe, N.C.; and other locations, and should be finished by September 2035.

by Alex Hollings

The race to field reusable hypersonic aircraft got a whole lot hotter with GE Aerospace announcing a breakthrough in high-speed jet engine design that could potentially allow conventional aircraft to fly at speeds that exceed Mach 10.

According to GE’s press release, the company recently demonstrated “what is believed to be a world-first hypersonic dual-mode ramjet (DMRJ) rig test with rotating detonation combustion (RDC) in a supersonic flow stream.” This means leveraging rotating detonation combustion – a far more efficient means of power production – within a dualmode ramjet (also sometimes called a dual-mode scramjet).

Ramjets and scramjets are airbreathing jet engines that don’t function well at low speeds, but can power an aircraft or weapon from around Mach 3 up to Mach 5 and well beyond.

This would be a significant development toward producing dual-mode ramjet/scramjets with far greater range, but could represent an even bigger breakthrough if combined with a similarly Rotating Detonation Combustion-equipped turbofan engine in what’s commonly called a turbinebased combined cycle (TBCC) propulsion system. And those wheels are already turning. GE first acknowledged that it was working with the Defense Advanced Research Projects Agency (DARPA) and the Air Force Research Lab (AFRL) on an RDC-equipped TBCC engine in June of this year.

This TBCC engine would combine four different types of air-breathing jet engine technologies into a single combined system that would allow an aircraft to take off and land under conventional turbofan power, while also achieving hypersonic speeds under scramjet power during sustained flight – a concept that has been proposed by at least three other firms before.

But GE’s design is the first to incorporate Rotating Detonation Combustion,

which could make such an engine far more compact and efficient than previous efforts, potentially resulting in a much more practical approach to hypersonic flight.

A working TBCC engine has long been seen as the Holy Grail for reusable hypersonic aircraft, as the exotic propulsion systems powering today’s hypersonic weapons can’t function at low enough speeds needed to land aircraft, making them single-use.

Last November, Atlanta-based aviation firm Hermeus demonstrated their turbine-based combined cycle Chimera engine could successfully transition from turbojet to ramjet power in a high-speed wind tunnel. About a month later,Virginia-based Leidos secured a $334 million contract from the Air Force Research Lab to continue development on an even more capable turbofan-to-scramjet design that would function similarly but could potentially achieve much higher speeds. And most secretive of all, Lockheed Martin announced success in ground-testing a similar turbofan-to-dual-mode-scramjet design with Aerojet Rocketdyne back in 2017 as part of the now highly secretive SR-72 program.

But while each of these designs is quite promising, this new announcement out of GE Aerospace may represent the most promising combined cycle hypersonic propulsion system revealed to date, as it incorporates a similar turbofan-to-dual mode scramjet as the SR-72 and Mayhem efforts, but adds yet another exotic propulsion system into the mix in the form of a rotating detonation engine.

This addition could help to overcome the biggest technical hurdle Lockheed Martin’s SR-72 program was known to face: bridging the gap between speeds attainable under turbofan power (which begins to drop in efficiency above Mach 2) and scramjet power (which functions less efficiently at speeds below Mach 4).

to manage the placement of shockwaves in the airstream at different flight speeds.

Based on GE’s claims, their Hypersonic Dual-Mode Ramjet with Rotating Detonation Combustion engine could not only achieve similar or even greater speeds as other hypersonic engine designs, but could offer a significant boost in fuel economy — and as a result, range — in what may prove to be an overall smaller and lighter package.

This program has been underway for only about a year, according to the GE press release, but has matured rapidly thanks, in part, to GE’s acquisition of hypersonic-focused Innoveering LLC, last year. Inoveering brought a great deal of experience developing high-speed inlet designs, which play a vital role in the function of any jet engine. In a dual-mode scramjet, the inlet geometry must not only be precise but often also needs to be adjustable

In its simplest form, a rotating detonation engine (RDE) is a propulsion system that offers greater efficiency than traditional air-breathing jet engines thanks to a more effective means of ignition.

In some ways, a Rotating Detonation Engine is an extension of Pulse Detonation Engines (PDEs), which are, in themselves, an extension of Pulsejets. While this lineage may seem confusing, walking through each of them as developmental steps may make it easier to wrap our heads around how RDEs work.

Pulsejet engines work by mixing air and fuel within a combustion chamber and then igniting the mixture to fire out of a nozzle in rapid pulses, rather than under consistent combustion as you might find in other jet engines. In pulsejet engines, as in nearly all combustion engines, the way in which the air/fuel mixture burns is known as deflagration. In simple terms, deflagation means heating a substance until it burns away rapidly, but at subsonic speeds.

A pulse detonation engine works similarly, but instead of leveraging deflagration, it uses detonation. At a fundamental level, detonation is a

lot like it sounds: an explosion. In contrast to deflagration, in detonation, the mixture burns at supersonic speeds.

“You can get more efficiency by cramming all that reaction during a really short time in space. There’s, at least from a thermodynamic standpoint, potential for much higher efficiencies in engines that burn through detonation rather than deflagration,” Dr. Chris Combs, a Dee Howard endowed professor of hypersonic and aerospace engineering for the University of Texas San Antonio, told Sandboxx News.

When the air and fuel are mixed in a Pulse Detonation Engine, they’re ignited, creating deflagration like in any other combustion engine, but within the longer exhaust tube leading out of the engine, a powerful pressure wave compresses any unburnt fuel ahead of the ignition, heating it above ignition temperature in what is known as the deflagration-to-detonation transition (DDT). In other words, rather than burning through the fuel rapidly, the engine explodes it, producing more thrust from the same amount of fuel.

A rotating detonation engine takes that PDE concept to the next level. Rather than having the detonation wave travel out the back of the aircraft as propulsion, it travels around a circular channel within the engine itself. Fuel and oxidizers are added to the channel through small holes, which are then struck and ignited by the rapidly circling detonation waves. According to Dr. Combs, it’s not uncommon for a rotating detonation engine to have three to five of these detonation waves circling the chamber at once.

The result is an engine that produces continuous thrust, rather than thrust in pulses like a PDE, while also offering the improved efficiency of detonation combustion, rather than deflagration, as you’d find in a conventional jet engine.

But GE Aerospace has found a way to incorporate this Rotation Detonation Combustion (RDC) process into its dual-mode ramjet propulsion system, and it claims to be working toward incorporating it into its turbofan technology as well.This may just solve two of the most pressing challenges facing hypersonic aircraft propulsion today: first, managing the transition from turbofan to scramjet power; and second, reducing the weight associated with such a turbine-based combined-cycle (TBCC) engine.

Firms like Hermeus and Leidos are working to field a hypersonic aircraft that incorporates two different kinds of air-breathing jet engines into one: low-speed engines like turbojets and turbofans, and high-speed engines like ramjets and scramjets.This combination speaks to the innate challenges of managing airflow at speeds ranging from a dead stop, all the way up into the high-supersonic regime.

Turbojets and turbofans, the types of air-breathing jet engines that power many of today’s tactical aircraft, use a compressor fan near the inlet to suck air into the engine and compress it, before mixing that compressed air with fuel and igniting it for propulsion. As a result, these kinds of engines can work from a dead stop to accelerate an aircraft down a runway for takeoff and can continue to accelerate it up to around Mach 2 very effectively.Yet, they begin to see a drop-off in efficiency as they approach Mach 3. At that speed, the compressor at the front of the engine that’s meant to suck in and compress air instead becomes a hindrance to the air flowing in at the speed of the aircraft’s forward travel, limiting the engine’s efficiency. A2Z-Rosco-Hurco_DCX3226HT5Si_March_2024.indd

Phoenix Heat Treating is thrilled to announce the addition of Salt Bath Nitriding to its lineup of services. For over 60 years, Phoenix Heat Treating has been dedicated to servicing their customers’ unique heat treatment needs. This new addition supports the growing demand for advanced surface treatment solutions and complements our existing service offerings providing a one stop shop for all thermal process needs.

Salt Bath Nitriding, also known as Ferritic Nitrocarburizing, is a thermochemical process that diffuses nitrogen and carbon simultaneously into the surface of ferrous metals. During this process, a two-part surface layer is formed: an outer iron nitride layer and a nitrogen diffusion layer beneath it. Nitrogen and carbon are absorbed and diffused uniformly into the metal surface, creating reproducible and uniform layers with a predetermined thickness. This results in significantly improved surface properties for ferrous metal parts, all while maintaining dimensional and shape stability. Salt Bath Nitriding is a popular case hardening technique, alongside carburizing and carbonitriding, both of which Phoenix Heat Treating performs.

It was originally created as an alternative to gas nitriding that would produce a more uniform case through surface contact between the substrate and liquid salt.This method of directly heating the part via salt allows for faster process times compared to gas nitriding. Additionally, when steel parts are placed into a preheated liquid salt, there is sufficient energy localized near the surface due to differences in chemical potential that then allows

nitrogen and carbon species to diffuse from the salt into the steel substrate.The surface hardness a salt bath nitride part can range from 800 HV to 1500 HV. Not only is the surface hardness high the finish once polished is a beautiful jet black.

Salt Bath Nitriding/ Nitrocarburizing is well known under various trade names, including MELONITE® and QPQ®.

The benefits of Salt Bath Nitriding include:

• I ncreased Wear Resistance: Enhanced durability of metal surfaces, leading to longer part life.

• Impr oved Fatigue Strength: Greater resistance to cracking under cyclic loading.

• Cor rosion Resistance: Better protection against rust and oxidation.

• I mproved Lubricity: Reduced friction and wear during operation.

• C osmetic Black Finish: Aesthetic enhancement with a sleek black appearance.

• Quick processing time

• Reduced shape distortion during the hardening process: The low processing temperature reduces thermal shocks and avoids phase transitions in steel.

Processing can be tailored to meet customer specifications or adhere to AMS 2753 standards, ensuring flexibility and compliance with industry requirements. With the introduction of Salt Bath Nitriding, Phoenix Heat Treating will now serve as a single source for both core hardening and the salt bath nitride finish, streamlining the

supply chain and enhancing convenience for our customers. Not only can Phoenix Heat Treating adhere to AMS 2753, but they are pleased to share that Honeywell has approved them for this process.

Their process tank size accommodates parts up to 32” DIA X 48”. For smaller parts, drum processing is also available. Yet smaller parts such as detent buttons, rolls pins, internal firearm related parts and dental picks are all processed in handmade pouches, providing versatility in handling various component sizes.

Nitriding is used for a range of applications, including:

• Medical equipment.

• Firearms and small weapons systems.

• Pump and gear components

• High perfor mance automotive parts.

• Oil & Gas

• Mining & Marine equipment.

• Farming and Food processing equipment.

When asked for comment General Manager Charlie Hushek noted, “We are thrilled to add this business unit as it continues our efforts to be the most customer centric heat treater in the country. Salt bath nitriding is the first of a few big projects we are working on. It is nice to see it to fruition.”

Tim Johnston, Director of Business development added, “There is a huge need for quality salt bath nitriding not only in Phoenix but the entire west coast, we are pleased to offer support to those who need it.”

Phoenix Heat Treating continues to focus on its customers not only with the addition of new processes but by leveraging technology. Their entire quality system is paperless, and employees use iPads to track in and out of operations. Their latest 5 day Nadcap audit resulted in zero findings. This focus on technology has supply chain benefits for customers too. All Phoenix Heat Treating customers can log in and view live job tracking as well as download certifications and shipping tickets on demand. “I always like to say, we take the headache out of heat treat! Using digital tools to make communication effortless is what being a true partner looks like”, added Charlie.

For those not familiar with Phoenix Heat Treating, they offer an extensive array of services to their customers.Their heat treating processes include:

1. Ceramic Diffusion

2. Vacuum Processing

3. Aluminum Processing

4. Salt Processing

5. Atmosphere Processing

6. Metal Finishing

7. Specialized Ser vices, Including: Aluminum Spray Quench; Cryogenic Services; Straightening; Fixture Tempering; Titanium; Argon Oil Quench; and blast cleaning.

Phoenix Heat Treating is especially known for its ability to resolve difficult heattreating problems that are beyond the capability of a typical application. In fact, we fix many problems caused by other heat-treating shops who aren’t customer focused and unable to gauge microstructure and hardness chemistry. With state-of-theart automation, computerized monitoring and control systems, inhouse metallurgical engineering and inspection labs, our company can handle the most difficult heat treating and processing jobs. Guaranteed repeatable, documented procedures will ensure compliance to your required standards and certifications.

It is clear that Phoenix Heat Treating spends time thinking about its customers. The addition of Salt Bath Nitriding underscores their commitment to delivering high-quality, advanced heat treatment solutions.

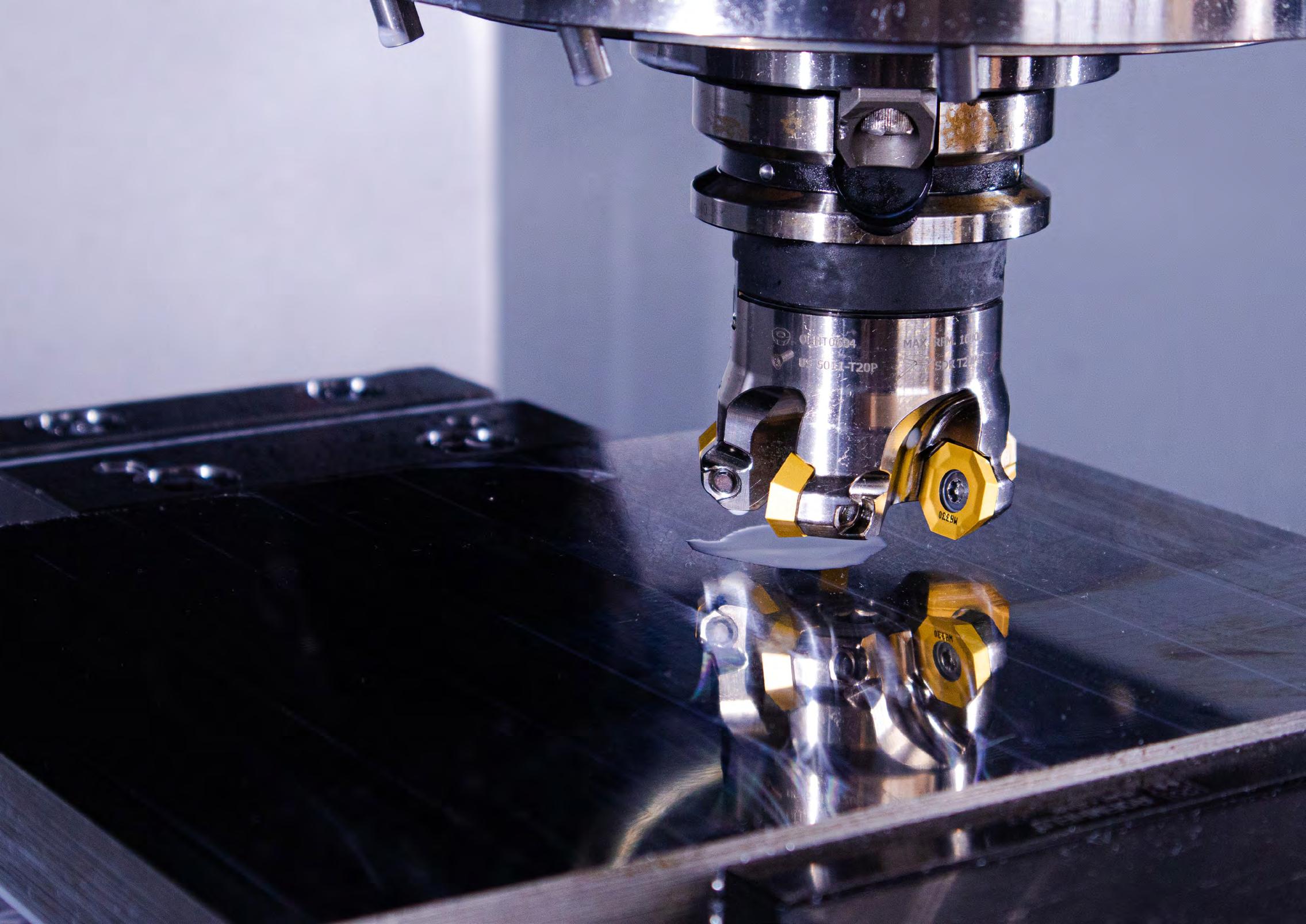

Ellison Technologies is a provider of advanced machining solutions to North American metal-cutting manufacturers and their global affiliates.

As a family of companies we are committed to the survival and growth of the American manufacturing industry. Independent offices provide us a local market focus and the flexibility to advocate the needs of each of our valued customers.

Our priority is to introduce technologies that strengthen our customers’ ability to compete in the markets they serve. Whether the solution involves a stand alone machine, multi-process equipment, or an integrated manufacturing system with robotic automation, our goal remains the same; to optimize throughput and quality at the lowest per-part manufacturing cost.

Our team of engineers, equipment and automation specialists, and project management professionals, are dedicated to helping manufacturers get the most from their technology investments. Service and parts engineers provide post-installation support aimed at optimizing machine availability, productivity, and cost of ownership.

The versatile VMC lineup at DN Solutions is enough to get anyone excited.

The lineup of vertical machining centers at DN Solutions is versatile, compact and born to make incredible parts for as long as you need them to. Get your ideal VMC, then get ready for the vertical leap. Talk to your local DN distributor or visit dn-solutions.com.

We strive to make every customer worldcompetitive. Whether our customer competes globally or not, Ellison Technologies brings its full mastery of advanced manufacturing technology to provide the most comprehensive and productive solutions the industry has to offer.

Whenever you add a new technology, there’s bound to be a learning curve. At Ellison Technologies, we act as an extension of your operation as you get up to speed. If you have any questions – whether before, during or after the machine install – we’re here to help you identify the best way to do things.

There are Ellison branches all over the United States, and all of our employees bring experience (and a willingness to share it) that’s simply unmatched. No matter how new your machining adventure is to you, we’ve seen it, and we’ve solved for it already. It’s a welcome dose of peace of mind as your journey begins.

Our mission is clear: at Ellison, we equip American manufacturers to compete and win, both locally and globally. If you can’t shake the feeling that there’s a better way to do things, we are ready to help you increase quality and efficiency, win more work and increase your profits. For more information on Ellison Technologies contact them at: 866-567-2580, www.ellisontechnologies.com

“Our overall confidence in the near-term future of the industry is high. We’re expecting economic conditions for businesses to improve over the next six months as interest rates decline and investment in U.S. manufacturing continues to grow,” says survey respondent Jeff Elliott, president of Huntington Equipment Finance.

Newly released survey results show improved confidence in the equipment finance sector. The August 2024 Monthly Confidence Index for the Equipment Finance Industry (MCI-EFI) reached 58.4, the highest level since February 2022, the Equipment Leasing & Finance Foundation reported Wednesday. The index shows an increase from the July figure of 50.7.

When asked to assess their business conditions over the next four months, 37.5% of the executives responding said they believe business conditions will improve over the next four months, an increase from 3.9% in July. 45.8% believe business conditions will remain the same over the next four months, down from 76.9% the previous month. 16.7% believe business conditions will worsen, down from 19.2% in July.

41.7% of the survey respondents believe demand for leases and loans to fund capital expenditures (capex) will increase over the next four months, up from 11.7% in July. 37.5% believe demand will “remain the same” during the same four-month time period, down from 73.1% the previous month. 20.8% believe demand will decline, an increase from 15.4% in July.

20.8% of the respondents expect more access to capital to fund equipment acquisitions over the next four months, up from 19.2% in July. 75% of executives indicate they expect the “same” access to capital to fund business, down from 76.9% last month. 4.2% expect “less” access to capital, relatively unchanged from 3.9% the previous month. When asked, 20.8% of the executives report they expect to hire more employees over the next four months, a decrease from 23.1% in July. 70.8% expect no change in headcount over the next four months, up from 69.2% last month. 8.3% expect to hire fewer employees, up from 7.7% in July.

None of the leadership evaluate the current U.S. economy as “excellent,” unchanged from the previous month. 91.7% of the leadership evaluate the current U.S. economy as “fair,” up from 84.6% in July. 8.3% evaluate it as “poor,” down from 15.4% last month.

37.5% of the survey respondents believe that U.S. economic conditions will get “better” over the next six months, up from 19.2% in July. 41.7% indicate they believe the U.S. economy will “stay the same” over the next six months, a decrease from 57.7% last month. 20.8% believe economic conditions in the U.S. will worsen over the next six months, a decrease from 23.1% the previous month.

In August, 33.3% of respondents indicate they believe their company will increase spending on business development activities during the next six months, an increase from 19.2% the previous month. 62.5% believe there will be “no change” in business development spending, down from 73.1% in July. 4.2% believe there will be a decrease in spending, down from 7.7% last month.

BARTON’s Transfer Hopper holds up to 4,400 lbs. of garnet eliminating the need to handle individual bags of abrasive.

• Saves time and labor

• Increases worker safety

• Minimizes clogs

• Reduces waste Interested in learning more?

Call 800-741-7756 or email info@barton.com

BARTON INTERNATIONAL USA/Canada 800-741-7756 • 518-798-5462 info@barton.com • barton.com • store.barton.com BARTON is a trademark of BARTON Mines Corporation.

“This flagship manufacturing facility will dramatically accelerate our efforts to deliver sodium-ion batteries to customers who are hungry for safe, reliable and environmentally responsible energy storage solutions,” said Natron Energy Founder and co-CEO Colin Wessells.

Anna

Smith

Battery manufacturer

Natron Energy has announced a $1.4 billion investment to establish a 1.2 million squarefoot sodiumion battery gigafactory in Edgecombe County, North Carolina. Once fully operational, the facility is expected to create 1,062 jobs and produce 24GW of sodium-ion batteries annually.

Subject to final approval from the Economic Development Partnership of North Carolina’s Board of Directors, Natron will receive around $30 million from the North Carolina Megasite Readiness Program. In addition, the factory at the Kingsboro megasite will be facilitated in part by a Job

Development Investment Grant.

The giga-scale facility will represent a 40x scale-up of the company’s current production capacity.The sodium-ion batteries are UL listed and will be delivered to industrial power space end markets.

The factory will join many other battery manufacturing facilities recently announced in the Southeastern U.S. as part of the ‘Battery Belt.’

Like traditional lithium-ion and lead acid batteries, Natron battery cells have a positive electrode (cathode), a negative electrode (anode), a porous separator between the two electrodes, along with a paste-like, non-aqueous electrolyte that enables charge (ions) to pass back and forth between the electrodes. The atoms in Prussian blue particles are arranged in large, cubic cages with empty spaces (pores) between them. Since the pores in Prussian blue are larger than sodium ions, they are able to rapidly absorb and release those ions in a process called intercalation. This rapid intercalation is the key benefit of Natron’s sodium-ion battery technology and sets it apart from other conventional storage materials found in lithium-ion and lead acid cells.

The Prussian blue structure also does not expand and contract as it charges and discharges sodium ions. This “zero strain” mechanism means greater chemical stability and less particle degradation that limits cycle life in other batteries.

Chucks and adaptations are available in round or hexagonal configurations

n Change from O.D. to I.D. to jaw clamping in < 2 minutes

n Use the same adaptations on your HAINBUCH turning or stationary chucks

n Keep the basic clamping device mounted on the machine

1.800.281.5734

Germantown, WI USA www.hainbuchamerica.com

Stefan Menin

Dimensional tolerances are critical for making parts that will fit together in an assembly and meet the design and performance goals. Getting the tolerances wrong could easily mean parts will be too expensive to make or will not fit properly with other components.

For example, if an engineering team designed a 0.875-in. diameter shaft that was supposed to mate with a precision bearing, but it sent out the drawings to a reputable manufacturer without specifying tolerances, the bearing may or may not fit on the finished shaft.

Machine shops that see an untoleranced diameter on a part and do not

know the design intent may typically apply a standard tolerance for threedecimal-place untoleranced dimensions, ±0.005 in. Unfortunately, this means the shaft may be too large for the hole it is designed to slide through. The machine shop will gladly rework the pieces to fit—for an additional charge—which will extend delivery times and possibly lead to missed deadlines and budgets.

Make no mistake, this happens all the time. Many machine shops take the extra step of verifying untoleranced dimensions, but many others don’t. Engineers who know the importance of tolerances, and how to use them, can easily avoid this problem.

ASME Y14.5M defines “tolerance” as “the total amount a specific dimension is permitted to vary. The tolerance is the difference between the maximum and minimum limits. This can be shown as upper and lower limits (0.2500/0.2498) or an allowable amount above and below a nominal dimension (0.2499 ±0.0001). Both methods define the same range—the tolerable band—of allowable dimensions rejected. The larger the difference between the upper and lower limits, the larger the tolerance band and the “looser” the tolerance. Conversely, a smaller tolerance band is considered a “tighter” tolerance.

Engineers should always use tolerances. Ambiguity is not a friend to mechanical designers. If dimension has no defined tolerance, no one will know the importance, or unimportance, of the dimension except the designer.

Tolerances ensure parts will fit properly and work as designed within an assembly whether it is uses a sliding or press fit. They also reduce costs. Unnecessarily tight tolerances make parts more expensive. And there is no reason to apply a ±0.0002 tolerance when ±0.002 will do. Also, although some manufacturers apply their own standard tolerances to untoleranced dimensions, many will not even begin making parts until all features are defined.

Expecting parts to be made to the machinist’s best effort is not realistic. The machinist does not know how parts interact, nor is that their responsibility. Furthermore, one machinist’s “best effort” may be maintaining features to within a few ten-thousandths of the dimension

indicated, while another may make the feature 0.015 in. larger or smaller than indicated.

Another significant benefit is that by using suitable tolerances, engineers pass the responsibility of making the part correctly to the manufacturer. By the same token, if the part is within tolerance but doesn’t fit or function properly, the manufacturer cannot be held accountable. Dimensions without tolerances leave the acceptable limits open, and it’s not the manufacturer’s responsibility to determine what is acceptable.

One of the most critical considerations when applying tolerances is to take into account fits.This refers to how shafts fit into bearings or bushings, how motors fit into pilot holes and so on. There are three basic types of fits: Clearance fits can compensate for thermal expansion, sliding fits provide better positioning; and interference (press)s have higher for holding capability. (For more information, check out Machinery’s Handbook.)

Another consideration is how “tolerance accumulation” (also called “tolerance stack”) affects a part. Consider a piece of equipment assembled from several different components, each with its own tolerances. If every part is at the low (small) end of its tolerance window or, conversely, very one is at its high (large end), will the machine still go together? Engineers must keep the final product in mind when they are setting tolerances.

Be careful when applying tolerances to a radius or

diameter.Tolerances on a radius will double when measured as a diameter. The tolerances on a radius might be looser than intended, while the one on a diameter might be tighter than intended.

Also, one need not assume measurements will be rounded when determining if a part conforms to its specified tolerance. If a part measured with a micrometer registers 0.2502, and the part’s dimension is supposed to be 0.250 +0.000/−0.002 the dimension is not rounded down to three decimal places; it is considered nonconforming. ASME Y14.5M states dimensions “are used as if they were continued with zeros,” even if not shown.

Both the location and size of alignment holes (such as for dowel pins) should not carry the same tolerances as clearance holes (such as for screws to pass through). If the dowel pin hole is too far from the desired spot (outside proper tolerances), it might make the parts impossible to assemble.The same level of an out-of-bound tolerance on clearance hole, however, will likely have effect to the assembly, except possibly a near-imperceptible aesthetic oddity.

Thoroughly dimensioning parts is important, but avoid redundancies. They can cause conflicts in inspection because certain features are defined more than once and in different ways. If a designer wants an over-defined dimension, they should use a reference dimension between parentheses and usually without tolerances.

Gartner survey says everyday AI is acting as more of a collaborator than a tool.

In less than two years, what Gartner calls everyday AI and digital employee experience (DEX) will be reach mainstream adoption, according to the firm’s new report, Hype Cycle for Digital Workplace Applications, 2024.

“Everyday AI promises to remove digital friction, by helping employees write, research, collaborate and ideate,” said Matt Cain, distinguished VP Analyst at Gartner, in a statement. “It is a core part of DEX, which is a concentrated effort to remove digital friction and improve workforce digital dexterity, which itself is one of the key factors that will drive organizational prosperity through 2030.”

Part of the reason for its increase in usage this year is the decrease in the focus on hybrid and remote work dwindles and the need for strategic concentration increases. The firm places AI on its Peak of Inflated Expectations on the Gartner Hype Cycle for Digital Workplace Applications, 2024.

“Everyday AI technology aims to help employees

deliver work with speed, comprehensiveness and confidence,” said Adam Preset, VP Analyst at Gartner, in a statement. “It supports a new way of working, where intelligent software is acting as more of a collaborator than a tool.The digital workplace is now entering the era of everyday AI. In many ways, everyday AI is the future of workforce productivity.”

Nearly all employees are becoming digital employees as they spend more time working with technology than ever before. Because of this, organizations must have a strategy to measure and improve DEX to attract and retain talent to improve employee engagement and maximize discretionary effort and intent-to-stay.

Business leaders are looking for guidance on how technology can help boost productivity and organizational alignment. DEX emphasizes best practices that boost digital dexterity, attract and retain talent, and help employees deliver against business outcomes.

DEX is in the Trough of Disillusionment on the Hype Cycle, meaning that interest is waning as experiments and implementations fail to deliver. To increase the appeal and relevance around DEX, business leaders should take a holistic approach across IT and non-IT partners to build a meaningful environment that empowers employees to adopt new ways of working.

Gartner says GenAI requires a higher tolerance for indirect, future financial investment criteria versus immediate ROI.

Poor data quality, inadequate risk controls, escalating costs or unclear business value are reasons that at least 30% of generative AI (GenAI) projects will be abandoned after proof of concept by the end of 2025, according to Gartner, Inc.

“After last year’s hype, executives are impatient to see returns on GenAI Investments, yet organizations are struggling to prove and realize value,” said Rita Sallam, VP Analyst at Gartner, in a statement. “As the scope of initiatives widen, the financial burden of developing and deploying GenAI models is increasingly felt.”

One the issues is the ability to justify the substantial investment in GenAI for productivity enhancement, which can be difficult to directly translate into financial benefit, according to Gartner. The research show that many organizations are leveraging GENAI to transform their business models and create new business opportunities. However the costs of this is high, , ranging from $5 million to $20 million.

“Unfortunately, there is no one size fits all with GenAI, and costs aren’t as predictable as other technologies,” said Sallam. “What you spend, the use cases you invest in and the deployment approaches you take, all determine the costs. Whether you’re a market disruptor and want to infuse AI everywhere, or you have a more conservative focus on productivity gains or extending existing processes, each has different levels of cost, risk, variability and strategic impact.”

Gartner research indicates GenAI requires a higher tolerance for indirect, future financial investment criteria versus immediate return on investment (ROI). Historically, many CFOs have not been comfortable with investing today for indirect value in the future.This reluctance can skew investment allocation to tactical versus strategic outcomes.

Earlier adopters across industries and business

Gold Plating

Silver Plating

Nickel Plating

Electroless Nickel Plating

Tin Plating

Heat Treat With Plate

Nadcap Approved Processes

Boeing Approved Processes + Expedited Turnaround

X-ray Fluorescence Thickness Verification + In-House Laboratory With Atomic Absorption (AA) + Expanded Capacity In Vibratory Plating

processes are reporting a range of business improvements that vary by use case, job type and skill level of the worker. According to a recent Gartner survey, respondents reported 15.8% revenue increase, 15.2% cost savings and 22.6% productivity improvement on average. The survey of 822 business leaders was conducted between September and November 2023.

“This data serves as a valuable reference point for assessing the business value derived from GenAI business model innovation,” said Sallam. “But it’s important to acknowledge the challenges in estimating that value, as benefits are very company, use case, role and workforce specific. Often, the impact may not be immediately evident and may materialize over time. However, this delay doesn’t diminish the potential benefits.”

by Brian Boyle

Artificial intelligence hype crashing headfirst into reality. The unwinding of the yen carry trade. The softening US consumer.

There were a lot of targets for finger-pointing amid the early-August meltdown-that-wasn’t. But Monday saw the eighth straight day of gains on the S&P 500, marking its longest winning streak of the year so far. Now the index, having recovered all its losses from earlier this month, sits just less than 2% away from the all-time peak it reached in July. As the dust settles, it’s becoming clear that the finger-pointing may have been a smidge aggressive.

The Vix Is In Doom-and-gloom headlines aside, it appears traders ultimately saw the AI sorta-crash simply as an opportunity to buy the

dip; Nvidia has now rallied some 30% since an early-August low, leading the charge for a megacap tech rebound. Meanwhile, Toby Gresham, investment counselor team lead at Citi Private Bank, said on CNBC this weekend that the unwinding of the yen carry trade has mostly “washed through,” and Nomura Holdings, Japan’s biggest brokerage, told Bloomberg that hedge funds and other investors are already pouring back into the carry trade game.

Last week, the Commerce Department also released new US retail spending data that pummeled expectations and suggested the American consumer isn’t slowing down just yet (a fear also allayed by a strong earnings beat from Walmart on Thursday). “Even the perma-bears would have struggled to find much in the slew of data released over the past week that would justify recent recession fears,” Neil Shearing, chief economist at Capital Economics, told the Financial Times on Monday.

You would be forgiven for feeling a fair amount of macroeconomic whiplash. Whether or not you should expect future volatility remains an open question:

The Cboe Volatility Index — a.k.a. the Vix, or Wall Street’s fear gauge — has fallen nearly 24 points since spiking on Aug. 5, which marks its longest decline since November 2008. Some experts are already saying that the spike was more likely a reflection of a quirk in how the gauge is calculated rather than a true reflection of trader panic.

But go a little deeper and there remains some doubt. The “Vvix” index, which is calculated on derivatives tied to the actual Vix, has similarly fallen since an Aug. 5 peak, but remains trading above its long-term average, per a recent FT analysis.

“We do think that volatility should normalise, it is mean reverting. But the speed at which [the Vix] came down was a bit too far too fast,” Maxwell Grinacoff, US equity derivatives strategist at UBS, told the FT. “We’re still not out of the woods yet.”

Hole in One: One thing that may or may not shoot some volatility back into the markets is Jerome Powell’s Friday speech in Jackson Hole,Wyoming, which he will give after spending the week conferencing with business leaders, economists, government officials, and fellow Federal Reserve bankers. The Fed is all but guaranteed to finally cut rates next month, though the question remains by how much

— and Wall Street is sure to hang on to every word that Powell says in search of clues.

Fiber Lasers

Press Brakes

Tube Lasers

Laser / Bending Automation

Waterjets

Deburring / Finishing

Plate & Angle Rolling

CNC Machining

Tapping Arms

Saws

Plasma & Oxy Cutting

Nitrogen Generation

Robotic Welding

Material Storage

Waterjet Parts

Industry Marketing

Technical Service

Tel: 1-631-273-1010

1-800-645-4174

Fax: 1-631-273-1066

1-800-424-2082

orders@royalprod.com

Abrasive Systems

KBC TOOLS & Machinery___714-278-0500

Air Cleaning Guns

Royal Products 631-273-1010

Auto-Bar Feed Systems

Western Machine Center____408-955-1000

Automation

Hainbuch Workholding____818-970-7874

Ballscrews

C & M Precision Spindle, Inc._ 503-691-0955

Band Saws/Saw Blades

Bandsaw Tech _________ 562--419-7675

Cycle Time Solutions_____510-708-8665

Saw Service

877-738-6437

Sterling Saw Blades 800-828-11800

Band Saw Replacement Parts

Saw Service 877-738-6437

Sterling Saw Blades ______ 800-828-1180

Band Saw Repair

Saw Service

Bar Feeders

Spinetti Machinery 775-996-3770

Boring

THINBIT

888-844-6248

Caabinet Spray Washers

ALMCO 507-380-1009

Cams

Dayton Lamina. 708-203-6684

Carbide Tools, Indexable

ARNO USA____________815-236-8118

Cycle Time Solutions 510-708-8665

Horizon Carbide 602-524-38028

Ceramic Cutting Tools

NTK Cutting Tools 425-365-3613

Chemicals: Ultrasonic

Star Metal Fluids 800-367-9966

ChuckJaws & Adapters

Hainbuch

www.coastaluminum.com jpalmer@coastaluminum.com

Palmer Jr. Vice President: Northwest Region

877-738-6437

Sterling Saw Blades 800-828-1180

KBC TOOLS & Machinery____714-278-0500

THINBIT 888-844-6248

Deburring Tools

Royal Products 631-273-1010

Die Tooling Springs

Dayton Lamina. 708-203-6684

Dot Peen Markers

MarkinBox 310-214-3367

Draw Tubes

Lucy’s Machine Co._______323-587-6162

Drills/Cutters-Magnetic

ARNO USA____________815-236-8118

Sulli Tool & Supply 714-863-6019

Drills/Reamers/Taps

ARNO USA____________815-236-8118

Sulli Tool & Supply ______ 714-863-6019

EDM Materials & Supplies

Desert EDM 480-816-6300

EDM Network_________480-836-1782

EDM Performance 800-336-2946

End Mills

ARNO USA____________815-236-8118

Horizon Carbide_______602-524-3802

Sulli Tool & Supply 714-863-6019

Filiter Mist Collectors

Royal Products_______631-273-1010

Fixturing

Hainbuch America______253-293-2062

KBC TOOLS & Machinery____714-278-0500

Form Tooling

THINBIT 888-844-6248

Grooving Head, Grooving Tools

CASEY JOHNSON

Head of Marketing (855) 222-7084

casey@sterlingfabtech.com sterlingfabtech.com

Cycle Time Solutions

510-708-8665

THINBIT ____________ 888-844-6248

Indexible Tools

SCT-USA.___________805-584-9495

Inserts

ARNO USA____________815-236-8118

Horizon Carbide_______602-524-3802

Sulli Tool & Supply______714-863-6019

Jaws

EDM Network________480-836-1782

US Shop Tools________800-243-7701

Keyseat Cutters

Sulli Tool & Supply 714-863-6019

Lifting & Material Handling

Ingersoll Rand 206-472-0826

Live Centers

Royal Products 631-273-1010

Load Unload Systems

Midaco Corporation _____ 847-593-8420

Lubricants / Systems

Star Metal Fluids 800-367-9966

Machine Tool Acccessories

US Shop Tools 800-243-7701

Mandrels

Hainbuch America 253-293-2062

Mounting Brackets

Lucy’s Machine Company 323-587-6162

Packaging/Shipping Supplies

Alliance Packaging 206-445-5898-

Parts Washing Equipment

Ebbco Inc 800-809-3901

Port Tools

“Equipping Your Success”

SCT-USA.

805-584-9495

Power Tools

KBC TOOLS & Machinery____714-278-0500

Precision Bearings

C & M Precision Spindle, Inc._ 503-691-0955

Probing Systems