Rocky Mountain Edition (CO, UT, ID, MT, & WY)

60 Years of Precision Machining 0 Precision Machining ® Vol. 17, No. 3 May / June 2024

High performing, long lasting coolants

Hysol® MB products are the best-selling, highest volume coolants sold by Castrol® due to their all-around performance and overall value.

Product advantages

• High-quality finish across multi-metals and operations

• Excellent anti-corrosion properties

• Clean running and have a very mild odor

• Wide tolerance to water hardness

• Robust pH stability fights bacterial growth

Simplify operations and make it easier to meet the demands of your business. Contact Star Metal Fluids today to learn why Hysol® MB products are the favorite among machine operators.

Bridge CMMs Absolute Arms Klontech Measurement Solutions Expert Analysis, Solutions, and Support www.klontech.com 480-626-8131 sales@klontech.com Optimize and automate your manufacturing quality process

Editors Corner

“Your tooling makes beautiful parts, the best I’ve ever seen. I wanted to convey to you because, probably in your field, like my field, rarely does anyone call up and say, “nice job, well done”. The only time you talk to them is when something doesn’t work right. So, I’m calling you up and saying, “very nice job, well done, your company makes good parts.” Quote from our Cover Story’s customer

I was at a machine shop in Tucson recently and I saw one of my customer’s products throughout the shop. I asked the owner, “Oh so you are using so and so? Aren’t they a great supplier?” I only asked this because I knew they had a great reputation. The owner said, “I don’t know how they do, and don’t know them, but I guess they do well for us because I only really get to know a supplier when there is a problem.”

Well, what does this mean for you as a business owner with a product you are selling? You aren’t known by the owners if you are doing a great job?

This tells me that the owner, if he or she attends industry events, apparently isn’t talking about your company or your product. They can’t, because they don’t even know you.

What can you do about this? While it may not seem intuitive, you really must find ways to market to your existing customers. Attracting new customers is important for any business, but marketing to existing customers is crucial, too. And since existing customers are already familiar with your business and products, marketing to them can mean spending less money while earning a higher return on your investment.

Some ideas for marketing to retain customers includes:

• Establish loyalty programs – these can reward your frequent buyers with perks or discounts, and it can be an opportunity to upsell your complimentary or premium products. It can also be an opportunity to re-engage your inactive clients.

• Capitalize on communication channels such as email, SMS or push notifications.

• Offer educational opportunities, including blogs, videos and webinars.

• Ask for feedback on your performance, with surveys, reviews and testimonials. Feedback you receive can be segmented by those who are promoters, passives and detractors. Promoters are ripe for referrals for your business, and you may set up a thank you program for these great customers. Passives may need better support or more communication to help them to become more loyal and detractors clearly need some attention if you want to retain them as customers.

Though there is a balance of just the right communication with your customers. It is critical that you keep in touch with your current customers. Don’t be that great supplier that almost nobody in the company knows about. Until next issue, I encourage you to brainstorm ideas to increase your visibility with existing customers, at all levels of the company. Also, we hope to see you at the D2P Show in Denver in June. And as always, God bless our troops.

THINBIT Thanks Their Customers For 60 Years In Business!

Website: www.a2zMfg.com E-mail: Linda@A2zMfg.com

CONTRIBUTORS

Published bi-monthly to keep precision manufacturers abreast of news and to supply a viable vendor source for the industry.

Circulation: The A2Z Manufacturing has compiled and maintains a master list of approximately 6500 people in the Rocky Mountain states actively engaged in the Precision Manufacturing Industry. It has an estimated pass on readership of more than 18,000 people.

Advertising Rates, deadlines and mechanical requirements furnished upon request or you can go to www.azManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

Kim Carpenter Gene Wirth Announcements/Releases .................................. 6-12 Feature Articles...................................................... 1,26-28 Buyers Guide Equipment................................... 33-38 Buyers Guide Processes 39-45 Card Gallery 33-45 Index Of Advertisers 46 Cover Published by: A2Z Manufacturing PUBLISHER/EDITOR Linda Daly linda@a2zmfg.com Mail Address:

Lane Tempe,

85284

1538 E La Vieve

AZ

Telephone: (602) 412-7696

A2Z Manufacturing Rocky Mountain • 4 • May / June 2024

Automation keeps the NHP running. Day and night.

Nothing is sweeter than the sound of a spindle making chips, especially when it’s the high-performance spindle found on one of our NHP Series of Compact Horizontal Machining Centers. These workhorses can handle whatever you throw at them, and are always asking for more.

That’s where our Linear Pallet System (LPS) comes in. It feeds the NHP around the clock, which leaves nothing but pallets upon pallets of precise, ready-to-ship parts. And if floor space is a concern, the Rotary Pallet System (RPS) will fit right in.

Learn more at DN-SOLUTIONS.COM

FEED THE BEAST

Learn more at DN-SOLUTIONS.COM JM Grisley Machine Tools, Inc. www.jmgrisleymachine.com 801.486.7519 Serving Utah, Colorado, Montana, Idaho and Wyoming

Full Consulting To Prepare You For Certification

BMSC LLC, A Woman Owned Business • Contact Bretta Kelly Today!

You Have 3 Very Good Reasons To Call BMSC:

√ Are you certified and ready to simplify your ISO 9001, AS9100, AS9110 or AS9120 System?

√ Do you need Quality Management System Software? Bretta Kelly also President of CIS WWSG, is now offering $3,500 Templates FREE with purchase of CIS Software!

√ Need Help Maintaining Your Internal Audits or Management Reviews?

Visit www.businessmsc.com today and review the more than 220 company referrals!

BMSC is now offering packages to come in and conduct Internal Process Audits and Facilitate Management Reviews to ensure you are effectively maintaining your ISO 9001 and/or AS9100 System.

We Can Help! We Have Helped Over 200 Manufacturing and Service Companies. Call to Learn About our Templates - From $3500. CIS Software visit www.cissoftware.com.

Announcements & Releases

Did You Know About Sidewinders LLC For Servicing Motor Rewinds or Reconditions?

Sidewinders is trusted in the power generation industry for our knowledge of rotating equipment motor recondition and rewinds.

Sidewinders provides swift and effective service to our customers in our motor shop and with our field service for power plants and utilities across the country. In addition, we are committed to serving the power generation. industry with outstanding safety, quality, and performance—in that order—on every project, without exception.

TESTING

• Insulation Resistance

• Polarization Index

• Resistance Checks

• Surge Test

• HiPot Test

• No Load Dynamic Testing

• Wedge Mapping

• Core Loss Testing

• Precision balancing EASA Accredited Shop.

ISO 9001 Certified Full machine shop capabilities

EQUIPMENT SERVICING All sizes, makes, and models of:

• AC and DC Motors

• Traction, Induction, Synchronous Motors

• Pumps

• AC Generators/Alternators

• Rotor pole rewind

• Dry ice blasting

• Walnut and glass bead blasting

• On site services

• VPI Tank and dip tank; Bake and Burn out oven; Motor Alignment

To learn more about Sidewinders LLC, call: (801)250-6267 Email erin@sidewindersllc. com or mdooney@sidewindersllc.com or visit sidewindersllc.com

A2Z Manufacturing Rocky Mountain • 6 • May / June 2024

From Do-It-Yourself With Our Templates To

ISO/AS9100 Services

Contact us today BMSC, LLC bretta.bmsc@gmail.com 602-445-9400 Businessmsc.com A 2 Z MANUFACTURING SW • 50 • May / June 2020 Continued page 8

Announcements & Releases

There’s POWER in a Team

By: Wes Michie; Skydandee Manufacturing

This year’s SkillsUSA contest gave me valuable experience working with a team. We knew coming out of last year’s contest that we had discovered something interesting. If we organize a good contest, with industry support, many instructors seem to come to the table ready to prepare students to compete. Pretty early on, we decided we wanted to hold three different CNC Machining Contests this year. CNC 2 Axis Turning. CNC 3 Axis Milling. And CNC Programmer (2 Axis Turning & 3 Axis Milling). When we introduced this to instructors at the beginning of the 2023-2024 school year, the instructors seemed excited and committed to support. Which meant they would be preparing students to compete.

1. The Team Needs a Captain.

As we started meeting as a technical committee to build out the contest and discuss specific testing areas, things got really complicated, really fast. All the technical questions started coming up. What do we want to test them on? Should we have them thread? Should we have them drill/ bore? How tight of tolerance should we ask them to hold? For many of these things, there isn’t one answer. We needed a champion to steer the team. And to help keep it all organized. Travis stepped into that role and handled it with precision. This allowed team members to come to the table with their expertise and opinions. We left the meetings with assignments and dates to complete them. Each assignment mostly aligned with our skills and interests. Which made it more fun to follow through and improved the overall quality of the contest.

2. The captain needs Support and the ability to steer the Team.

Travis would call/text and email to discuss progress. We brought up any developments, ideas, and issues that have come up. We would often discuss them and try to come up with a path forward that we all

Continued page 10

A2Z Manufacturing Rocky Mountain • 8 • May / June 2024

Challenged with meeting customer deliveries and adapting to their ever-changing requirements?

Optimize your manufacturing workflow with modular end-to-end solutions from Bystronic. Combine best-in-class machines, automated production cells, and software for a highly agile and efficient production process that can expand as your business grows. Bystronic will guide you through your transformation journey step-by-step.

Your best choice for sheet metal processing.

Agile Production. Scalable Solutions.

Modular end-to-end solutions from Bystronic. bystronic.com

Announcements & Releases

felt suited everyone involved. Once a decision was made, he would go to work, guiding the team with what that was and empowering them to accomplish their tasks.

3. Teams should communicate, be flexible, and be forgiving of one another.

I felt great about the number of emails, texts, and phone calls we exchanged. I was so appreciative that I wasn’t the only one thinking about how to administer this contest. We had an entire team thinking about it. Sometimes, we didn’t agree at first. But we communicated regularly. We expressed our opinions, and I felt we were ready to hear the other perspective. Once expressed clearly and explored, a decision would be made about how to move forward. Not out of emotion but out of practicality, and really, the path that made the best sense.

4. When we sail, we sail TOGETHER. When we sink, WE sink TOGETHER.

Yes, we had a few missteps. Running three contests took far more resources than two. Overall, it was an ABSOLUTE SUCCESS. The instructors were ecstatic with the industry support. As well as the opportunity

we provided their students to see that they are on a path to successful careers. We also showed them that there is an industry with real people working in it that has much in common with them.

5. What is the Team’s Goal?

Working with Art, Travis, the team of judges, and the NUNTMA board to put this contest together was a lot of fun. But being at the event with the contestants, educators, industry partners, shop owners, and others was a real privilege this year. Watching the whole thing come together to test contestants’ ability to enter the industry. These 26 individuals showed a passion for machining. They showed that they are capable of learning how to use the technology and that they are ready and interested to work in our shops. Yes, there is a shortage of workers. No, I don’t think that problem will go away any time soon. But I do believe there is hope for the next generation of machinists. They showed us that last Saturday.

In conclusion, if you missed the contest this year. Get involved next year. Make the decision now and speak up. Let someone at NUNTMA know that you are interested in helping next year. Your voice and opinion help determine what we should be testing

Continued page 12

A2Z Manufacturing Rocky Mountain • 10 • May / June 2024

A2Z Manufacturing Rocky Mountain • 11 • May / June2024

Virtual Cert® ISO-9001 certification with American Global Standards can lower operational costs, improve your bottom line and offer your business a competitive advantage.

Certifying United States & International Manufacturers, Services Organizations, and Government Entities

Contact: Steve Keneally at 617-838-4648; info@americanglobal.org; www.americanglobal.org

stronger than most of these metro areas,” Hess said.

Announcements & Releases

Phoenix market ahead in the national industrial rankings even as e-commerce and logistics started to slow down in the past year across the U.S.

their abilities against, which equals what the instructors will teach.

The Phoenix metro’s large labor pool and proximity to larger markets with R&D systems have attracted employers to the area as well.

Together, we literally build America and the World. I couldn’t be prouder of the line of work I am in. I hope that I continue to have opportunities to work with great individuals and teams such as you. Thanks for making the 2024 SkillsUSA CNC Machining contest so successful!

5-axis family

Growth is expected to continue for Phoenix and other markets in manufacturing as major projects are built out because of ancillary demand and third-party vendors that want to be close to the manufacturers.

• QTE100MSY – Cost effective late with live tooling and second spindle

• OTC Robotic Welding

• Timesavers Finishing and Deburring Machines

• Almco Tumblers

Hess said companies are mostly looking for communities that have a sustainable plan and visions for partnerships and strategies to address quality of life, infrastructure, housing and more.

Join us for an Exclusive Open House Event at Action Machinery International!

Newmark found that the Phoenix market had nearly 75,000 advanced manufacturing workers as of 2023, although finding the labor to fill the new jobs will be a challenge across all markets, especially in smaller regions that do not have as diverse

Discover the Future of Manufacturing with Leading Machine Tool Builders!

• Omax Water Jet

• Safan Electric Press Brakes

• Masters Precision Shop Floor Inspection

• FMB Band Saws

“There some challenges out there but I think Phoenix is always going to be a top 10 metro in the United States in the years to come,” Hess added. High-tech and digitalization such as semiconductors, automotive and transportation, energy and biomanufacturing are four of the main manufacturing sectors driving much of the growth.

• Wila Tooling

“Phoenix isn’t immune to the challenges of the greater advanced manufacturing sector,” Berthelette said. “Where Phoenix may excel is the diversity of its economy — it’s very large, there’s a lot of different industries there, the population growth is very fast.”

Dates: May 15th - 16th

Time: 10am – 3pm (Join us for lunch!)

Location: Action Machinery International, 7790 S Wheeling Ct. Englewood, CO

In Q3 2023, the manufacturing sector made up nearly 12% of the industrial inventory under construction in metro Phoenix, according to Newmark. In Austin, another major industrial market, manufacturing made up 13.5% of projects under construction in the same time period.

Experience the latest innovations in manufacturing technology featuring:

• Mazak Machine Tools –

Four main sectors drive growth These projects have helped push the

• VC Ez 26 – New highly affordable vertical machining center

Meet with Factory Representatives and Applications Engineers who will be on-site to answer all your questions and provide expert insights.

Witness the Power of Performance with All Machines Under Power for Live Demonstrations!

Other large markets that are seeing the most growth in the industry were Atlanta, which has had 12,713 jobs announced since 2020, and Austin, which has had 11,465 jobs announced since then.In mid-size and small metros measured, Syracuse, New York saw the most manufacturing jobs announced with 9,000 new jobs for a new Micron facility, while Savannah, Georgia, had nearly 9,000 jobs announced across two facilities since 2020. By Audrey Jensen – Phoenix Business Journal

• Variaxis C-600 - Meet the newest member of the Variaxis

Don’t miss out on this exceptional opportunity to elevate your manufacturing capabilities. Mark your calendars and secure your spot now!

For more information visit our website (www.

Continued page 14

A2Z Manufacturing Rocky Mountain • 12 • May / June 2024

A2Z MANUFACTURING SW • 39 • March / Apr 2024

A2Z Manufacturing Rocky Mountain • 13 • May / June2024 QUALITY ALUMINUM PRODUCTS SINCE 1972 SERVICES T PLATE GTH SHEET RING ING ALUMINUM SHEET - PLATE - ROD BAR - PIPE - TUBE STRUCTURAL SHAPES CUSTOM EXTRUSIONS COLORADO MINNESOTA NEW MEXICO 3559 N. Himalaya Road, Suite 100 Aurora, CO 80011 (303) 373-0820 SALESCO@ERICKSONMETALS.COM WWW.ERICKSONMETALS.COM COMPLETE STOCK - QUICK TURNAROUND TIME - SUPERIOR CUSTOMER SERVICE ISO 9001:2015 CERTIFIED "WHATEVER IT TAKES!"

METAL WORKS

www.umw.com

Tollfree: 866-434-5679

Local: 801-364-5679

At Utah Metal Works, recycling industrial-related scrap metal is one of the things we do best. You simply won’t find more knowledgeable, capable partners for your scrap handling and recycling efforts anywhere. We are known in the industry for our honesty and integrity, and you can be sure you are always getting a competitive return along with superior service. We make it easy for you to cash in on non-ferrous metals from:

Industrial/Manufacturing Scrap

• Punchings

• Solids of any metals

• Turnings and borings

• Skeleton plate

• Machine Shop/Fabricator

• Solids of any size or type

Aircraft/High Temperature Alloy Scrap

Stainless, titanium, Inconel, Hastelloy, Monel, cupronickel, aluminum;state-of-the-art metal analysis conducted on site; Mixed or contaminated items are accepted and sorted

Announcements & Releases

action-machinery.com) or register now using this QR code.See you there!

A1 Precision Metal & Aerospace, LLC Registers to ITAR and Completes Cybersecurity Certification

It additionally completed its Cybersecurity certification. Owner, Jack Terrell says, “This process took 6 to 8 months to complete and was very comprehensive. We knew that we needed to have this in place so we could get Government contracts and work on aerospace parts for our large aerospace customers. It is also a must have for ITAR registration.”

A1 Precision Metal & Aerospace is a woman-owned, advanced metal fabrication manufacturer, delivering high-quality custom sheet metal fabrication service. As a single-source provider, the company specializes in the manufacture and assembly of custom fabricated metal components and assemblies – with services extending to developing manufacturing based upon customer design, helping to reduce your overhead burdens.

A1 Precision Metal & Aerospace, LLC, offers precision metal fabrication services. Their capabilities include Shearing, Laser cutting, Turret punching, Press brake forming, Roll forming, Welding (MIG, TIG, spot), Hardware installation, and Assembly.

A1 Precision Metal & Aerospace, LLC, an ISO 9001 certified, AS9100 Rev D compliant company, is pleased to announce that it recently successfully registered with ITAR. ITAR registration means the company follows the International Traffic in Arms Regulations (ITAR), which controls the export and import of defense-related articles and services on the United States Munitions List (USML).

Jack has decades of experience in fabrication, and has spent over 30 years in the Aerospace industry, before opening his own business with wife and partner Shelley Terrell. Jack says, “We can fabricate with a variety of materials including Aluminum, Stainless steel, Mild steel, and Galvanized steel, and we offer short and long production runs.”

For more information on how

Continued next page

A2Z Manufacturing Rocky Mountain• 14 • May / June 2024 UTAH

How

Easy

Website 805 West Everett Ave • Salt Lake City, UT 84116 CALL US now to find out!

Much Is My Metal Worth?

Access To I80, I15, and I215 Detailed Directions On Our

Announcements & Releases

they can help your fabrication needs, contact them at: 623377-2191 or visit a1pma.com

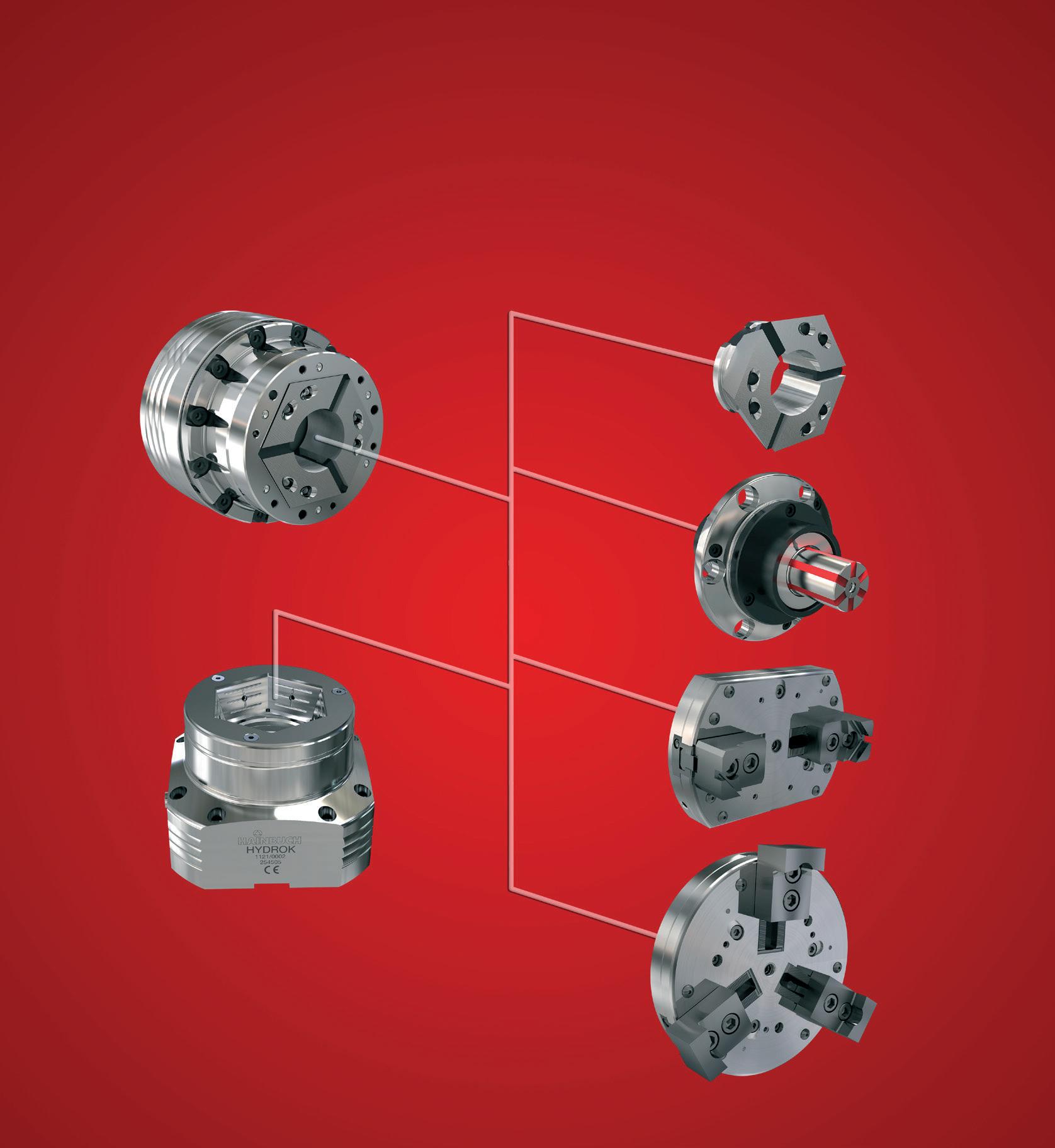

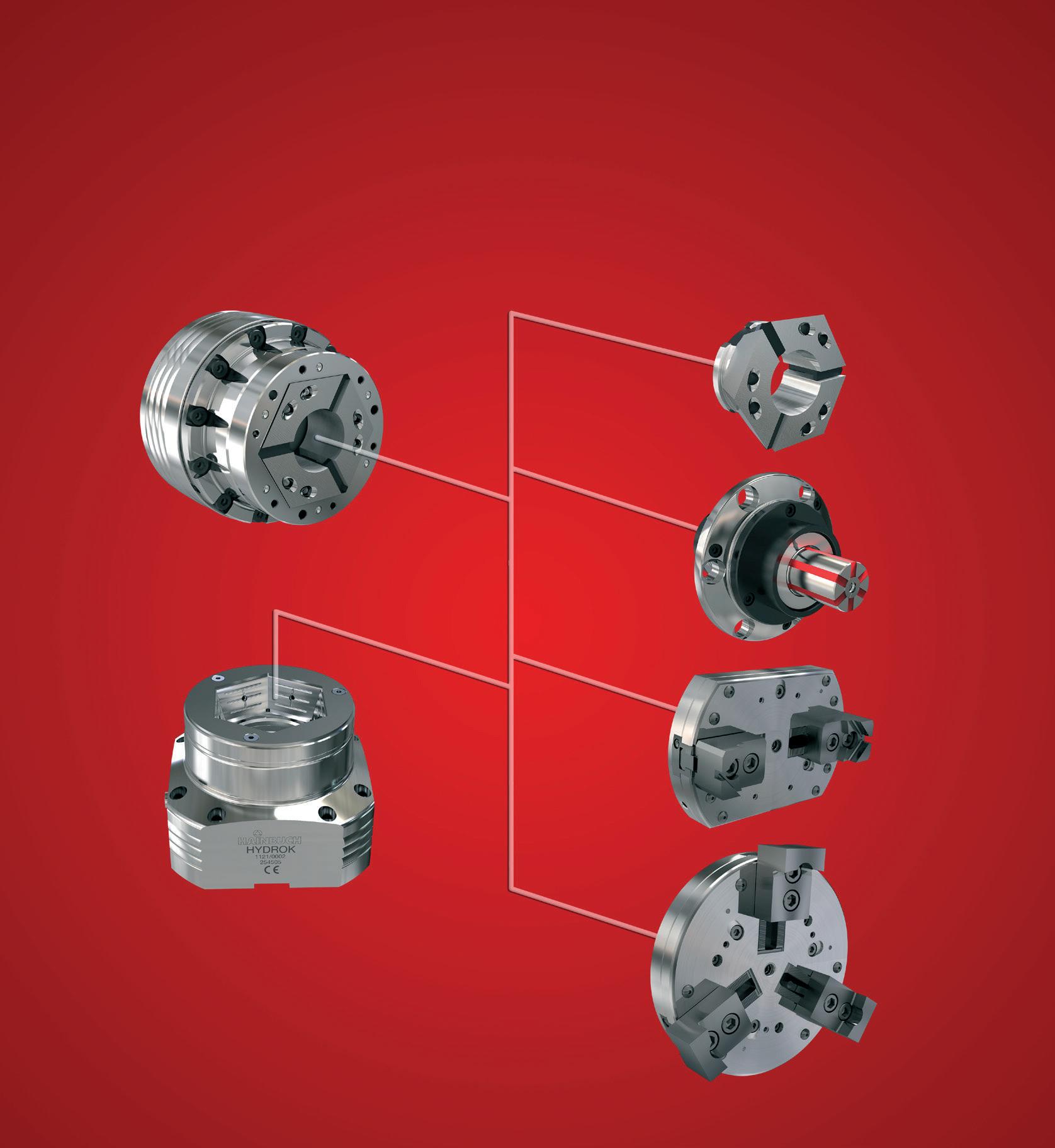

Sulli Tool & Supply Expands its Territory with SMW Autoblok in Colorado, New Mexico and Utah

Sulli Tool & Supply, founded by owner Michael (Mike) Sullivan in 2009, is pleased to announce that it has expanded its territory with one of its principals, SMW Autoblok. Mike says, “We’ve had the line since I launched the business more than 15 years ago. Just last month, they awarded us an expansion to our territory, so that not only do we offer this line in California, Nevada and Arizona, but we will now also carry it in Colorado, New Mexico and Utah.”

Phoenix Heat Treating Phoenix Heat Treating

Servicing our industry and trade customers in intelligence heat treating for over 60 years.

Michaels’ son Matthew joined the business in 2022 after graduating from Arizona State University (ASU). Matthew says, “We are very proud of the top tier industry leading companies we represent. With top notch quality, reliable products, consistent production, and top tier customer service, we simply supply the best of the best. Our premier partners include: Firetrace, Koma Precision, Northfield, Royal, SMW Autoblok, Stevens

cs@phxht com Established in 1963 Real Time Live

www phoenix-heat-treating com 602-258-7751

Engineering and Toolmex.”

The father and son team of Sulli Tool & Supply pictured above at a customer’s Open House is in partnership with several companies from around the world. We help original equipment manufacturers, machine tool dealers, industrial supply companies and end users manage their workholding, live tooling, part accumulation, and ensure clean and safe employee work environments, with a variety of products and services such as off-the-shelf quality products, engineered solutions, and excellent support.

About Autoblok

Autoblok Corporation was established in 1981 as a subsidiary of Autoblok of Italy, the largest power chuck manufacturer in Europe. Since 1942, Autoblok has been at the forefront of engineering and manufacturing state-of-the-art workholding, clamping and tooling solutions.

Continued next page

G E T T O K N O W U S

Tracking 10+ Processes Performed 50+ Furnaces AOG

A2Z Manufacturing Rocky Mountain • 15 • May / June 2024

Job

and Line Down Services Over 10+ Prime Approvals 24/7 Processing

SCRAP PICK-UP SPECIALISTS

We set containers for:

• Machine, welding & fab shops • Manufacturing facilities

• Demolition projects • One-time clean-ups

• Containers: 1 to 60 yards • Flatbed, cargo trailers, rolloffs

• Small boxes on wheels • Locking Lids • Leakproof boxes

Top prices paid for:

• Aluminum • Copper • Brass • Stainless • Steel/Iron

• Alloys • Lead & more

Convenient drive-in recycling:

• Easy acces from I-25, I-70 and Commerce City

• Fully paved • Se Habla Espanol ~

Announcements & Releases

In 1993, Autoblok acquired SMW of Germany. The combination of these two premier manufacturing entities resulted in the most extensive product line of high quality workholding devices in the world. Now available exclusively through its subsidiaries, reps and distributors, SMW AUTOBLOK customers are ensured a consistent, single source of superior product performance, support and service.

To learn more about how Sulli Tool & Supply can help your business, contact them at 714-863-6019, email: mike@sullitool.com or visit their website at sullitool.com

Productivity Expands Matsuura Partnership to New Mexico

Productivity is thrilled to announce it has received exclusive authorized distributor and service provider status for Matsuura Machinery USA in New Mexico. For nearly 40 years, Productivity has been a trusted provider of sales, service, support, training, and installation for the entire lineup of Matsuura products for portions of the Midwest and Rocky Mountain regions.

Building upon a rich history and partnership, Mark Smith, Vice President & General Manager at Productivity, expressed enthusiasm about the expansion, stating, “It’s an exciting opportunity to bring our experience and an industry-leading machine tool line to manufacturers and machine shops in New Mexico.”

Matsuura Machinery USA is renowned for its cutting-edge technology, delivering unparalleled excellence and innovation to its customers. Whether it’s high-speed machining, full 5-axis machining centers, vertical, horizontal, linear motor, or multitasking CNC machine tools, Matsuura offers a comprehensive range of solutions to a variety of industries.

Customers can achieve higher spindle speeds, faster turning times, advanced automation solutions, and lights-out machining capabilities with Matsuura’s technology. With local support in New Mexico, Productivity ensures seamless project management from concept to production, including comprehensive training and after-sales technical support. This partnership signifies a commitment to delivering top-notch service and support to manufacturers in New Mexico, empowering them to achieve new levels of productivity and efficiency.

A2Z Manufacturing Rocky Mountain • 16 • May / June 2024 Iron & Metals, Inc.

Call now for up-to-the minute price quotes and market info! 5555 Franklin St. Denver, CO 80216 www.ironandmetals.com 303•292•5555 1•800•776•7910

Since 1961 Call us first for FREE containers Iron & Metals, Inc.

Recycling Metals, Conserving Resources,

Continued page 18

Announcements & Releases

Electric Vehicle Maker Acquires Large Site In West Valley

Since 1968, Productivity Inc., based in Plymouth, Minnesota, has been distributing a broad range of CNC metalworking products and services. As a single source machine tool supplier, Productivity offers machine tools, tooling and accessories, machine repair, preventive maintenance, rotary and live tool repair, turnkey systems, robotics and automation and much more. In addition, their MachinesUsed.com division will sell your surplus equipment via its online auctions. Productivity services 12 states with five branch offices located in Minneapolis, Cedar Rapids, Omaha, Denver, and Salt Lake City.

Arizona-based vehicle maker Nikola Corp. quietly purchased nearly 1,000 acres in the Phoenix metro at the end of September for $16.5 million, according to Maricopa County records.

According to the Arizona Corporation Commission, Corey Hessen and Omar Khayum, senior vice president and vice president of Canada-based TC Energy, respectively, are the managers of Phoenix Hydrogen Hub LLC. Oil and gas giant TC Energy partnered with Nikola last year to develop large-scale hydrogen production hubs across the U.S. and Canada.

Press brakes have a specific bending length and a specific tonnage that are suited for the range of parts that each company processes. Companies normally use press brakes that can process a diverse range of materials to maintain flexibility in their production scheduling. Usually, this means having a ten- or twelvefoot bend length and a tonnage that can process from thin to thick. From a scheduling perspective, this is an ideal situation as it provides maximum flexibility in scheduling jobs. But from a productivity /capacity perspective this may not be the ideal situation.

Nikola acquired the 920-acre site through Phoenix Hydrogen Hub LLC from Hardison Farms on Sept. 30, real estate database Vizzda shows. George Quinif of Peak Group LLC represented Nikola in the sale.

Profiting With High-Speed Compact Press Brakes

Nikola hasn’t confirmed, though, whether it plans to build a hydrogen production hub in Buckeye. Nikola said it has no comment about the Buckeye land sale or its plans for the property. The city of Buckeye said nothing has progressed with the company beyond negotiations.

The massive site is located at 28702 W. Patterson Road in south Buckeye just west of State Route 85 near the Arizona Department of Corrections Lewis Prison, which is one of the largest prisons in the state and houses more than 4,400 inmates.

The sale comes after Nikola made multiple announcements that it planned to break ground on a hydrogen production hub in Arizona. The company’s CEO said in August that Nikola would start construction on the new facility by the end of this year but did not disclose the location.

Selecting the right tool is pivotal in optimizing manufacturing processes, and press brakes play a crucial role in bending operations. While many companies opt for larger, versatile press brakes to accommodate a diverse range of materials and bending requirements, the ideal choice may lean towards compact high-speed brakes for enhanced productivity.

The Physics of Working with Mass - Press brakes come in all different sizes and tonnages and they have vastly different technologies to aid in the bending process. It is possible to process thin small parts on a large tonnage brake. However, it is not possible to process longer thicker parts on a small tonnage brake. The reason is that the longer, thicker parts will most likely exceed the tonnage capacity of the brake. Additionally, running small parts on a large tonnage brake with a long upper ram length is not efficient.

The automaker is currently producing battery electric vehicles and has produced several alpha prototypes of its fuel cell electric vehicles, which run on hydrogen. Nikola is planning to build out a hydrogen fueling network to support its vehicles. Its first three locations will be established in California.

In addition to the fueling stations, the

It all comes down to simple physics. A larger, heavier mass is more difficult to accelerate and takes longer to reach top speed than a smaller, lighter mass.

Continued next page

A2Z Manufacturing Rocky Mountain • 18 May / June 2024 A2Z MANUFACTURING SW • 52 • Nov / Dec 2022

Likewise, decelerating a larger, heavier mass is more difficult and will require more time. This all adds up to lost time. Henceforth, small thin parts are more efficiently formed on a smaller press brake.

An

Opportunity to

Realize Greater Profits

- If you find that most of your smaller parts are being formed on oversized press brakes, then this is an area of opportunity to investigate. When you compare to larger press brakes, small brakes such as the Bystronic ByBend Star 40 and 80 ton can process two to three times more parts in the same amount of time. The smaller brake press is faster due to the ability of the machine to accelerate and decelerate both the smaller and lighter upper ram and the smaller back gauge system. This provides not only more throughput capability but also more capacity to bend even more parts on your existing press brakes. Processing smaller, thinner parts on the smaller press brakes is much faster which speeds up the capacity for the larger brakes to process more parts in the larger size range.

The Right Tool for Increased Efficiency - Using the correct press brake on the right applications can not only speed up bending operations but can also create greater machine capacity and flexibility in scheduling. Compact highspeed press brakes can bend up to two times more parts than larger conventional hydraulic brakes. This makes the perfect complement to the production capabilities of a fiber laser. Fiber lasers produce up to 4 times more parts per unit of time.

Adapting to New Possibilities

Chucks and adaptations are available in round or hexagonal configurations

n Change from O.D. to I.D. to jaw clamping in < 2 minutes

n Use the same adaptations on your HAINBUCH turning or stationary chucks

n Keep the basic clamping device mounted on the machine

1.800.281.5734

Germantown, WI USA

www.hainbuchamerica.com

High-speed bending is a major consideration for eliminating bottlenecks at the press brake.

Speed and Safety- The next big time-saver comes into play once the press brake starts the active bending program. Wide-view Fast Bend safety cameras enable faster approach, bending, and retract speeds without compromising operator safety. Safely achieve bending speeds of up to 1 inch per second, and approach and retract speeds > 590 inches/minute.

Keeping The Pace- There are opportunities with compact high-speed press brakes that are different for each production environment. Investing in new technology means being able to maintain the pace within your fabrication process as newer fiber lasers are capable of producing higher part volumes. Compact high-speed press brakes can help eliminate these bending bottlenecks.By Frank Arteaga, Regional Director Marketing – Americas; Bystronic Inc., Voice.bystronic@bystronic.com

A2Z Manufacturing Rocky Mountain • 19 • May / June 2024

Announcements & Releases

OIL MIST AND SMOKE

Colorado Companies Win NASA Contract For Lunar

Vehicle Development

NASA is including a moon vehicle from Colorado space companies in a program meant to develop autonomous lunar surface transportation, a projected $4.6 billion effort over 15 years.

A team led by Lunar Outpost, a Golden-based startup, won participation in a 12-month feasibility phase of NASA’s Lunar Transport Vehicle Service contract.

Other team members are Jefferson County-based Lockheed Martin Space, alongside automaker GM, tiremaker Goodyear and space robotics company MDA Space.

Lunar Outpost, an 85-employee company with offices in Colorado and Houston, is the prime contractor leading the development of what the team calls its Lunar Dawn vehicle.

After it was chosen by NASA, Lunar Outpost founder and CEO Justin Cyrus called it the ultimate off-road vehicle project. He said he considers it an inspiring chance to help bring U.S. astronauts back to the moon, this time to stay. “Our team will do our best to make the most of it,” he said.

Other teams competing include one led by Houstonbased Intuitive Machines, a space startup whose partners include Boeing, Northrop Grumman and tiremaker Michelin. California companies Venturi Lab and Astrolab, teamed with Axiom Space, Odyssey Space Research on their vehicle proposal.

Under the LTVS contract program, NASA will work with each group for a year to develop their designs. NASA will then bid a mission to the moon and select one of the three to test their vehicle there and be ready to deploy it before the Artemis V moon landing mission, which is scheduled in 2029 and is meant to be the third human landing this decade by the NASA program.

The hope is to have helped one of the teams prove their lunar vehicle design enough that NASA can contract it as surface transport for 10 years of Artemis program moon landings, which are expected to reach a twice-yearly cadence at the end of the decade.

NASA is asking its selected LTV service to be able to provide transport of up to 15 kilometers per hour for NASA crews, conduct fully robotic missions, travel distances of 20 kilometers and support astronauts outside their spacecraft

IN YOUR SHOP? Low-Cost, Highly Efficient Mist and Smoke Collectors Designed Specifically for the Metalworking Industry www.mistcollectors.com 1-800-645-4174

Nearly New DN Solutions NHP 4000 Horizontal Machining

Center (On a 12 Pallet LPS With a 275 Tool Matrix)

$400,000 with Rigging Included

FOR SALE

The NHP 4000 Horizontal Machining Center delivers with automatic tool changes in under a second and 15,000 RPM spindle with axes acceleration of up to 1G, thru-spindle and flood coolant, center-thru chip evacuation, highly precise linear guides, larger work area, and a smaller footprint.

• Purchased in August of 2020

• Under power for inspection, and ready to ship immediately

• The machine has 5300 hours on it

• It will come with all 12 tombstones and all of the orange vise vises you see (64 total)

• Travels are 22 x 25.2 x 26

• Spindle RPM is 15,000 and 40.2 Horse power

• Max workpiece size is 24.8” x 35.4”, and 881 lbs

• 300 PSI through spindle coolant pressure

• Renishaw tool setting laser

• BK micro tool touch probe for break detection

• Rapids are 2362 In/min

for eight hours, Astrolab said.

Enhanced Raytheon Weapon Takes Out Ballistic Missile During Pacific Test

The LTVS vehicle chosen will be capable of moving around the harsh lunar environment — autonomously, remotely steered or both — exploring the moon and helping conduct scientific experiments when astronauts aren’t around. NASA estimates put the total program cost at $4.6 billion.

The latest software iteration for a Raytheon-built missile successfully knocked out a medium-range ballistic missile during a test in the Pacific Ocean, demonstrating the weapon’s enhanced capabilities for the U.S. Navy.

The Standard Missile-6, or SM-6, was built by Raytheon, whose missile manufacturing operations are based in Tucson. During this flight test, the Navy used a new configuration with newly qualified software that it said enhances the missiles capabilities.

Lockheed Martin Space is the prime contractor designing and building the Orion capsules that the Artemis program will use to carry astronauts on journeys to the moon’s surface as soon as fall 2026 and then to regularly return.

NASA’s idea is to let the businesses compete and bring their own innovations, she said.The space agency aims to reserve about 75% of the vehicles’ time on the lunar surface for NASA at first and let the companies make the vehicles available for commercial purposes — scientific research, prospecting and other uses — when the Artemis program doesn’t need them.

I t has been a busy start to 2024 for Raytheon, Arizona's largest defense contractor based on total dollar value of annual contract. The company has also successfully tested a variety of weapons, while reaching a major milestone with a $116 million hypersonic missile program.

The company’s second lander mission, IM-2, expected to launch late this year, is slated to carry a Lunar Outpost robotic rover to the moon’s surface.Lunar Outpost has three other moon rover missions already planned to test its designs. Two of those missions are entirely commercial, one is a NASA mission and another for Australia’s space agency, Cyrus said.

Raytheon’s Tucson-based operation also logged a few more contract awards during the past month. They are:

• A $49,413,549 modification of a Marine Corps contract for the procurement of low-rate initial production units of the Navy Marine Expeditionary Ship Interdiction System Launcher. Work will be performed in Tucson and elsewhere.

Phoenix Heat Treating Announces FDA Drug and Alcohol Compliance

Fired from the USS Preble at the Pacific Missile Range Facility in Hawaii, the test was dubbed Fight Test Aegis Weapon System. Raytheon said the ballistic missile was intercepted during its final seconds of flight.

Phoenix Heat Treating is proud to announce that we have formal FAA Drug and Alcohol Program compliance.

Raytheon said the test showed its SM-6 is effective not just for anti-air and anti-surface warfare but also for advanced ballistic missile defense at sea. It’s the only single missile that can handle all three uses.

• A $287,000,000 contract modification from the Navy that adds scope to provide for recertification and modernization of 166 Tomahawk Block IV All-Up-Round Missiles (142 for the Navy and 24 for Foreign Military Sales customers). The work will help make the missiles operational for up to an additional 15 years of service. Most of the work will be performed in Tucson and is expected to be completed in March 2026.

Phoenix Heat Treating is especially known for its ability to resolve difficult heat-treating problems that are beyond the capability of a typical application. We offer a wide array of processing and consulting services. We take great pride in finding unique solutions to meet each individual customer’s requirements.

The SM-6 uses the Standard Missile airframe and propulsion system. Besides being used on Navy ships, sales of the SM-6 have been approved for several allied nations.

The Artemis program is targeting the southern polar region of the moon, which means the LTVS vehicles will have to be able to function where temperatures can change by hundreds of degrees between lunar day and night, there is ubiquitous lunar dust and intense radiation can fry electronic circuits.

•The Navy also awarded Raytheon a $8,573,968 contract modification to exercise options for design agent and engineering support services for the Rolling Airframe Missile. Work will be performed in Tucson and is expected to be completed by March 2026. By Jeff Gifford – Phoenix Business Journal

To learn more about how Phoenix Heat Treating can support all your heat treat needs, as well as specialized services, contact Tim Johnston, Director of Business Development. Tim is available to assist you at Phoenix Heat Treating and can be reached at 623-512-3233 or by email at tjohnston@ phxht.com

A2Z Manufacturing Rocky Mountain • 21 • May / June2024

A2Z MANUFACTURING SW • 35 • May / June 2024

FOR More Information, Contact: Justin Quinn jquinn@focusedonmachining.com 303-922-3076 Ext. 102

Our employees are efficiently skilled, pay attention to detail and take pride in high quality work.They set us apart from the competition by specializing in the ability to hold tight tolerances to .0001.

CNC Universal Grinding up to 5 X 24”, We have 4 Swiss Turning Centers Machining up to 32mm. Long Bar Grinding for Screw Machines. Contact Us Today: 801-487-9700, wendief@superiorgrinding.com

Swiss Machining & Close Tolerance Precision Grinding Celebrating 34 Years In Business

Swiss Screw Machining up to 1.5” OD, CNC ID/OD, ID, OD, Angled, Surface, Blanchard & Centerless Grinding, Circular Blade Grinding up to 20” Diameter, and all Types of Industrial Blades. Full Service Machine and Manufacturing with Lathe & Mill

AS9100 rev D & ISO 9001:2015 Certified, WOSB, WBE and Government certified Cage Code: 3CXJ2, UEI CKBVLHJK8PS5, DUNS 609260427

Department of Defense (DoD) Contracts

Lockheed Martin Corp., Littleton, Colorado, has been awarded a $9,513,838 firmfixed-price modification (P00069) to previously awarded contract FA8823-21-C-0001 for Space Based Infrared System Contractor Logistics Support Product Support Integration Contract Evolution. The modification brings the total cumulative face value of the contract to $1,233,214,146. Work will be performed on Peterson Space Force Base; Buckley SFB; Greeley Air National Guard Station; and Boulder, Colorado, and is expected to be completed by April 16, 2026. Space Systems Command, Peterson SFB, Colorado, is the contracting activity.

Akima Intra-Data LLC, Colorado Springs, Colorado; and Keesler Air Force Base, Mississippi, have been awarded a $28,958,885 firm-fixed-price modification (P00017) to previously awarded contract FA3002-23-C-0007 for base operations support services at Keesler AFB, Mississippi. Work will be performed at Keesler AFB and is expected to be completed March 31, 2025. Fiscal 2024 operations and maintenance funds in the amount of $24,178,885 are being obligated at the time of award. Total cumulative face value of the contract is $51,692,873. The 81st Contracting Squadron, Keesler AFB, Mississippi, is the contracting activity.

Lockheed Martin Corp., Littleton, Colorado, has been awarded a $46,173,222 firmfixed-price modification (P00064) to contract FA8823-21-C-0001 for space-based infrared system contractor logistics support, product support integration, and contract evolution. The modification brings the total cumulative face value of the contract $1,222,900,308. Work will be performed at Peterson Space Force Base, Buckley SFB, Greeley Air National Guard Station, and Boulder, Colorado, and is expected to be completed by Feb. 28, 2027. Fiscal 2023 and 2024 procurement funds in the amount of $46,173,222 are being obligated at time of award. Space Systems Command,

Peterson SFB, Colorado, is the contracting activity.

L3Harris Corp., Colorado Springs, Colorado, has been awarded a $7,682,118 contract modification (P00150) to the previously awarded contract FA8819-19-C-0002 for continued support, sustainment, infrastructure, and delivery for satellite communications and modifications. The contract modification continued the enhancements, maintenance, and support of the range control software, specifically including maintenance and support for minimal viable product deployments. Work will be performed at Kirtland Air Force Base, New Mexico; Schriever Space Force Base, Colorado; and MITRE Corp., Colorado Springs, Colorado. Fiscal 2024 research, development, test, and evaluation funds in the amount of $1,245,010 are being

A2Z Manufacturing Rocky Mountain • 22 • May / June 2024

A2Z MANUFACTURING WEST COAST • 17 • APR - MAY ’24 www.superiorgrinding.com

245 West Crossroads Square, S Salt Lake, Utah 84115, 801-487-9700

Your Reputation Depends On Us!

May 9: Spring Social - Lee Kay Public Shooting Range

Join Us for a Shotgun Social & Cookout!

Date: Thursday, May 9, 2024

Time: 5:30 PM - 8:00 PM

Location: Lee Kay Shooting Range

Cost: $30 per person

Come along for an evening of fun, food, competition, prizes, and networking! Please bring your own shotgun and shells. Plus-ones or more are welcome. We look forward to seeing you there!

Friday, September 20, 2024

13th Annual NUNTMA Golf Tournament

The 13th Annual NUNTMA Golf Tournament at Stonebridge Golf Club!

MORE INFO TO COME

Shotgun starts at 8:00 AM

Open to any Machining Company - not exclusive to NUNTMA Members!

RAFFLE PRIZE TICKETS and UNLIMITED MULLIGANS WILL BE AVAILABLE FOR PURCHASE!

*It is strictly prohibited to bring any outside beer or liquor onto the course in accordance with Utah State law. *

WE ARE ALWAYS LOOKING FOR NEW MEMBERS AND SPONSORS. VISIT: NUNTMA.ORG

obligated at time of award. Space Systems Command, Los Angeles AFB, California, is the contracting activity.

Lockheed Martin Space, Littleton, Colorado, was awarded a $98,999,952 cost-plus-fixed-fee contract modification (P00077) to previously awarded contract N00030-19-C-0025 to provide program management and systems engineering support for Army All Up Round plus Canister definition and support. Work will be performed in Denver, Colorado (48); Courtland, Alabama (39%); Huntsville, Alabama (7%); Sunnyvale, California (3%); and various other locations. Work is expected to be completed on Feb. 25, 2025. This contract is being awarded to the contractor on a sole source basis under 10 U.S. Code 3204(a)(1) and was previously synopsized on the System for Award Management online portal. Strategic Systems Programs, Washington, D.C., is the contracting activity.

Triumph Gear Systems Inc., Park City, Utah, is awarded $18,480,000 for a delivery order (N00383-24-F-S802) under previously awarded contract N00383-22-G-S801 for the repair of one item that is part of the V-22 pylon conversion actuator system. All work will be performed in Park City, Utah. Work is expected to be completed by April 2025. Annual working capital funds (Navy) in the full amount of $18,480,000 will be obligated at the time of award. Funds will not expire at the end of the current

fiscal year. Naval Supply Systems Command Weapon Systems Support, Philadelphia, Pennsylvania, is the contracting activity.

The Boeing Co., Layton Utah, has been awarded a $405,366,978 indefinite-delivery/indefinite-quantity contract modification (P00008) to previously awarded contract FA8207-17-D-0001 for operations, maintenance, and testing in support of the Minuteman III weapons system. The modification brings the total cumulative face value of the contract to $559,366,978. Work will be performed at the Little Mountain Test Facility, Ogden, Utah. The Air Force Nuclear Weapons Center, Hill Air Force Base, Utah, is the contracting activity.

The NUNTMA Is Seeking Interested Parties To Serve As Our Chapter Executive

We are looking for an individual to serve in this capacity. This is a paid position that requires a flexible schedule, strong communication, interpersonal, and organizational skills. The time expectation is around 80 hours per month. The amount of hours per week varies based on the chapter priorities for each month. It does have some peak time commitments in August and September supporting the Golf Tournament.

Please help any interested parties get in touch with Broc Bryson, brysonb@mscdirect.com or another member of the NUNTMA Board of Directors

A2Z Manufacturing Rocky Mountain • 23 • May / June2024

THE NORTHERN UTAH CHAPTER OF THE NATIONAL TOOLING & MACHINING ASSOCIATION

Upgrade Your Waterjet with HYDROBLOC®

Experience cleaner, quieter cutting and better looking parts with HYDROBLOC waterjetbricks. The flat, even, honeycomb surface keeps parts from falling into the tank and drains water away to minimize splash back. HYDROBLOC’s laminated high-density polyethylene layers are welded and screwed together for unrivaled durability.

• Cleaner Cutting • Quieter Operation

• Better Looking Parts • Recyclable

Watch the video to learn more at barton.com/hydrobloc

Industrial Manufacturer To Add 15k Square Feet To Colorado Facilities

A Colorado Springs company that produces parts used in industrial manufacturing will add a total of 15,000 square feet to its facilities.

Spectrum Advanced Manufacturing Technologies has accepted a bid to add more than 100 jobs to the area, the governor’s office announced Tuesday.

The Colorado Office of Economic Development and Trade in February offered Spectrum AMT $1.2 million in job growth tax incentives to locate its expansion in El Paso County instead of in Tulsa, Oklahoma.

BARTON INTERNATIONAL USA/Canada 800-741-7756

518-798-5462 • info@barton.com • barton.com • store.barton.com

The BARTON logo and our brands are registered trademarks of BARTON Mines Corporation.

The state incentives are contingent on Spectrum AMT meeting its job creation and salary requirements over an eight-year period. The new jobs created should pay an average of $85,407 per year.

How Millennials’ Technology Expectations Can Help Save Manufacturing

Spectrum AMT said it will add 3,000 square feet to its existing facility in Colorado Springs and add a new, 12,000-square-foot building for manufacturing and assembly spaces. Its expansion will nearly triple the company’s current employee count of 54.

Millennials’ technology expectations have been shaped by smartphones, Facebook and digital media – in other words, by easy and ubiquitous connectivity. It’s not surprising, then, that traditional manufacturing systems can seem as retro as waiting for dial-up internet to connect. And that’s bad for the manufacturing sector, because its skills gap is looming large.

The Colorado Springs Chamber and Economic Development Commission also offered a local enterprise zone package through the city and El Paso County that was valued at $275,496, according to a news release.

A joint study by the Manufacturing Institute and Deloitte Consulting projects a surge of nearly 3.5 million open manufacturing jobs created over the next decade. Some of the empty slots will come by way of retiring baby boomers, while others are related to new positions created as a result of natural business growth, the report found.What the report also predicts: As conditions stand now, 2 million of those jobs will go unfulfilled. In other words, the need for the manufacturing sector to appeal to Millennials – the generation typically defined as those born between 1981 and 1997 – is both critical and a very tall order.

Spectrum AMT creates products used for advanced manufacturing and assembly. It also provides quickturn product development and manufacturing services for aerospace, medical, industrial and commercial marketplaces, according to OEDIT.

Jeff Gilbert, the company’s chief operating officer, said in a statement that the expansion underscores a growing demand for Spectrum AMT’s “high-reliability electronics manufacturing.”

Indeed, manufacturing still has a negative image among younger generations, experts say. In a 2015 public perception of manufacturing study, also by The Manufacturing Institute and Deloitte, respondents ages 19 to 33 ranked manufacturing as their lowest preference in terms of potential career choices.

“We are deeply committed to not only supporting critical industries like aerospace and defense but also contributing meaningfully to the advancement of technologies that shape the future, from space exploration and scientific discovery to addressing global medical challenges,” Gilbert said. “We are proud to be part of an ecosystem that fosters innovation and economic growth, and we are excited to continue playing a vital role in Colorado

Manufacturing’s image problem is complex and in, some aspects, based on false assumptions. But one real obstacle is that some manufacturing systems can seem antiquated, and it’s an issue that many manufacturers and related organizations are already addressing.

A2Z Manufacturing Rocky Mountain • 24 • May / June 2024

Modern and accessible tech 8466 E US Hwy 34 PO Box 1417 Loveland, CO 80539 970-667-5320 Fax: 970-667-5322 Toll Free: 866-667-5320 haroldh@rongrob.com CNC Swiss & CNC Vertical Mill Machining Thread Rolling Lead Screws OD & Centerless Grinding ISO 9001: 2008 Certified Tesker Thread Rolling Machine WE OFFER WORLD CLASS THREAD ROLLING CABABILITIES YOU CANNOT FIND ELSEWHERE CNC Swiss & CNC Vertical Mill Machining Thread Rolling • Lead Screws OD & Centerless Grinding ISO 9001: 2015 Certified MARCO GROB, President 8466 E. U.S. Hwy 34 Johnstown, CO 80534 (970) 667-5320 marcog@rongrob.com Founder Ron Grob checks on the production of a Stub Acme thread on the Tesker 630 roller.

Springs, a community that has been instrumental in our continued success.”

Colorado’s aerospace and defense industry employs more than 240,000 people in Colorado, OEDIT officials said in a statement.

Colorado manufacturer part of $6 billion DOE industrial decarbonization push

An aluminum manufacturer near Denver is among the businesses landing $6 billion in federal grants helping fund projects cutting carbon dioxide emissions of heavy industries.

Golden Aluminum and 32 other U.S. businesses manufacturing everything from cement, aluminum and steel to paper pulp and food products were awarded grants for demonstration projects that U.S. Department of Energy Secretary Jennifer Granholm called the largestever investment in industrial decarbonization.

“These investments will slash emissions from these difficult-to-decarbonize sectors and ensure American businesses and American workers remain at the forefront of the global economy,” Granholm said.

CNC Screw Machine/Mill Setup Machinists/ Operators

“Retail sales are up, and sectors such as transportation, logistics, warehousing, and construction are performing extremely well,” Arora added. “Right now, business owners are confident in the future of their firms. August is typically a slow month for loan volume, but that wasn’t the case this year.”

Immediate Openings in St. George Area, UT

– Setup and operate machinery, install tools, make offsets, and troubleshooting

– 3 to 5 years’ experience preferred

Business loan approval rates rose at regional and community banks as well. Small banks granted 49.8 percent of the funding requests they received in August, up one-tenth from July. It represents the highest figure for small banks since November 2014.

Benefits and Perks:

– Competitive Pay

www.westernstatesmetals.com

Electric Truck Maker With Presence In Goodyear Partners To Make Battery Cells In The US

The awarded projects are expected to cut CO2 emissions by 14 million metric tons annually, or what the DOE says is equal to taking 3 million gas-powered cars off the road. Golden Aluminum won a $22.3 million cost-sharing grant for a plant upgrade in Fort Lupton, the DOE announced. The Department of Energy sought applications for the industrial demonstrations program a year ago.

Among the projects chosen, Golden Aluminum’s Next Generation Aluminum Mini Mill is the second-smallest grant.The company makes aluminum sheeting in various alloys used for beverage and cosmetic containers, automotive firewalls, building materials and other products. The company says at least half of what it produces is from recycled aluminum.

Daimler Truck, the German company that makes electric big rigs for the U.S. market in Portland, Oregon, and has a parts distribution center in Goodyear, is in a new joint venture to manufacture battery cells in the United States.

Daimler and partners Cummins and Paccar said they expect to invest $2 billion to $3 billion into the Accelera joint venture, which will supply cells for electric commercial vehicles and industrial applications.

Indiana-based Cummins and Bellevue, Washington-based Paccar and Daimler are “considering anywhere in the U.S.” for the planned 21-gigawatt battery factory, Jon Mills, a spokesman for Cummins, said.

The company plans to upgrade its process with the “minimill” project that landed federal funding.The project will allow the company to recycle 15% more mixed-grade scrap, reduce water needs for the mill’s production by about 86% and cut natural gas consumption, allowing the facility to more cleanly create products for the electrical vehicle and clean energy industries, the grant award summary describes.“In addition to reduced emissions, this project would be highly replicable among other U.S. aluminum producers and can help solidify the U.S. as a world leader in decarbonized secondary aluminum production,” it said.

The move follows a trend of investment in battery

Institutional lenders — pension funds and insurance companies — remained unchanged at an Index record 64.9 percent, up one-tenth of a percent from July’s figure.

– Medical, Dental, Vision, Life Insurance, 401k, Paid Time Off, and Holiday Pay

Loan approval rates among alternative lenders rose to 56.6 percent,

– Outdoor recreational activities, golf, water sports, and art & culture

Alternative lenders have become a source of quick capital. When small business owners, alternative lenders could approve riskier loans via innovations in fintech, which give them more flexibility than the banks to adjust rates and covenants on the deals. This includes an ability to accept non-conventional sources of collateral, such as real estate and outstanding invoices (h/t Forbes).

– Vibrant local Communities offer a wide range of housing options, dining experiences, and outdoor pursuits Questions or to visit our shop, contact us at 435635-1482 or visit lvswiss.com

Credit unions approved 40.2 percent of loan applications in August, a slight drop of one-tenth of a percent from July and a large drop from their all-time high of 57.9 percent in March 2012. By Anthony Noto – Reporter, New York Business Journal

A2Z MANUFACTURING SW 62 • Nov / Dec 2023

October Rocky Mtn 2018.indd 38

In the 1950s, William (Bill) Kaiser operated a job shop and took in jobs that other manufacturers did not want to do in house. Most of the time, these jobs were difficult and he was expected to do them quickly and for very little money.

Bill found that he continuously had to make his own tools to cut small grooves for O-rings or snap rings. Hand grinding consistent grooving tools took too long and when a tool became dull, he had to start all over again.

He had an idea. If he could make grooving tools in .001” increments with standardized bodies that could be replaced in a toolholder, he would solve his problem and have a marketable product.

It took Bill almost seven years of working at night (when he wasn’t doing his job shop work) to develop and test the design of the inserts and the toolholders. He perfected the design and was awarded patent 3,296,683.

Bill and his wife, Hazel, started Kaiser Tool Company (KTC) in 1964 with the purpose of supplying small lathe cutting tools. Lathe tools were known as bits and the tools were thin. THINBIT® was chosen as the product name. The first THINBIT® tools were insert sizes .010” through .050” in .001” increments made from high-speed steel with a 1/4”, 5/16” and 3/8” toolholders.

THINBIT® Celebrates 60 Years!

From 1964

until 1980, the production and sales of THINBIT® tooling was done at the family home on Weisser Park Avenue in Fort Wayne, Indiana. Manufacturing took place in the garage. The employees used the bathroom and kitchen of the house. The sales office was in the attic and was accessed via a set of pull down stairs. The raw material was purchased at a local hardware store.

A2Z Manufacturing Rocky Mountain • 26 • May / June 2024

Bill continued to innovate and expand THINBIT® products. Hazel designed the advertising, packed and shipped the tools, took orders, typed the invoices and juggled the money (or lack thereof) to pay the bills. Their daughter Lenore, our President, grew up with THINBIT® in every corner of the house.

Sales were very slow in the beginning as there was little money for advertising THINBIT® products. All revenue generated by THINBIT® was used to pay the company’s bills and the few employees. Bill still had to do job shop work and Hazel worked at an accounting firm to generate their income. After a decade, THINBIT® sales were sufficient to allow Bill to drop his job shop work and Hazel to leave her accounting job.

In 1980, KTC outgrew the garage and a new facility was built on Sherman Boulevard. The site was located along the St Mary’s river and terrible flooding in 1982 threatened to destroy the business. The extraordinary efforts of the employees and a few sand bags from President Ronald Regan saved the company.

Lenore took over KTC from her parents in 1982. She increased THINBIT® product offerings, digitized the shop and office operating systems, expanded advertising and modernized the manufacturing processes.

THINBIT® sales took off and more employees and equipment were added. Lenore’s husband, Doug, was brought on board in 1987. Doug utilized some of the first laser marking systems to engrave THINBIT® products with indelible identification codes and began the Laser Images division.

KTC outgrew the Sherman street location in 1994 and built a new manufacturing facility on Centennial Drive. The land purchased was large enough for a new building, future expansion and nature. The design of the manufacturing area was ahead of its time with painted floors, bright lighting and climate control. Windows let in natural light and views of animals and trees.

In the 1990’s, Kaiser recognized the advantages of CNC equipment and automation which allowed continued expansion of product lines and a focus on custom tools.

Machines, work cells, inspection equipment and material storage were added and processes upgraded until the manufacturing floor was too cramped

Continued next page

A2Z Manufacturing Rocky Mountain • 27 • May / June2024 Grooving Face Grooving Boring Parting Threading & Chamfering Turning & Profiling Milling Custom Tooling Form Toolling THINBIT® Tools By Application:

to function efficiently. In 2018, an addition was built to significantly expand the manufacturing space.

Industries served include: aerospace, medical, semiconductor, automotive, research, protective seals, jewelry, racing and those job shop innovators working out of their garages on the next big thing

Today, THINBIT® is an industry leader in precision cutting tools. THINBIT® stocks over 100,000 tools and offers millions of standard tools with fast delivery. Custom tooling is available for all products. Real people answer the phones and provide excellent service.

Bill and Hazel’s premise, during the early days, was always “customer service, quality product and fast shipment”. These are the foundations of Kaiser Tool Company and what has allowed the company to grow from an unknown entity to its respected place in the industry today.

Thank you for supporting THINBIT® for 60 years.

Hear From a few of THINBIT®’s Customers.

“We have been using THINBIT® tools for more than 20 years now.They make our custom tools, and they do a really good job with getting our tooling to us in a reasonable time. And though the cutting tools are custom, the holders are standard. Also, if we need the custom tools immediately, they will work with us, even sending the tools uncoated to help with the lead times.

I have heard from colleagues in the industry that when you get custom tools, there can be some variation from order to order. That is not the case with THINBIT®; their consistency is outstanding.

THINBIT® is an excellent supplier with great products and their customer support is outstanding.” Clinton, CFO Contract Manufacturer, Wisconsin

“I work with THINBIT®, and they do such a great job helping us with custom tooling. We make a lot of weird parts on our lathes, and it happens so often that there isn’t a standard tool on the market that we can use. We call THINBIT®, and we work with them on creating a custom tool for our application.

I am so impressed with the THINBIT® team. Back in December, we ordered a custom tool. It arrived

way earlier than we expected. When my operator started using it, he told me “This tool is such good quality.” We were even more impressed when we ran all of the parts with this one insert.

When I told the team at THINBIT® how the operator was so impressed, they sent a customer appreciation bag to me and my operator. It had a pen, a T-Shirt, and a hat. When I looked at the merchandise in the bag, everything sent was made in America! I was blown away. These guys who make tooling in the USA also purchase their customer appreciation merchandise that is made in the USA. They ‘Walk the Walk!”

I wish all my suppliers were as outstanding as THINBIT®!” Gary, Tool Room Supervisor, Machine Shop, Illinois

“We’ve been using THINBIT® tools since the 1980’s. For years, we’ve used their grooving tools and we just started using their tools for Swiss Machining. The quality of THINBIT®’s products is amazing. THINBIT® makes tools that work extremely well.

We get very good tool life with our THINBIT® tools, and their customer support is outstanding, from the Customer Service department to the Engineering department. Lastly, their inventory is phenomenal, and it is rare that they don’t have the tool in stock that we need.”

Cliff, COO Tool & Die Shop, Indiana

A2Z Manufacturing Rocky Mountain • 28 • May / June 2024

emissions for owners and lessees. The new IMP facility will be Nucor’s newest steel products addition to its growing Brigham City campus, which also includes Vulcraft-Utah (joists and grating), Nucor Buildings Group-Utah (metal buildings), Nucor Cold Finish Utah (cold finished bar products) and Nucor Wire Products Utah (steel mesh).

Micron lands $6.1B

in

CHIPS funding

Micron Technology will receive $6.14 billion in CHIPS and Science Act funding, the White House announced last month.

A portion of the funds will go towards constructing two Clay, New York, fabrication facilities focused on making memory chips, creating roughly 13,500 jobs.

Some of the money will help build a $25 billion memory chip fab in Boise, Idaho, located next to Micron’s research and development facilities, creating approximately 6,500 facility and construction jobs.

Nucor Corporation Expands Footprint with New Manufacturing Facility in Brigham City, Utah, Dedication April 16th

to software and electronics development in the areas of autonomy, precision ag, artificial intelligence and digital products.

“The Phoenix metro area and nearby universities with thousands of engineering students create an environment rich with tech talent,” said Seth Crawford, Senior Vice President and General Manager, Precision Ag & Digital. “With more than 27 million acres of farmland and a year-round operating climate, Arizona also provides a great backdrop to continue putting farmers at the center of everything we do. AGCO is excited to attract more of the brightest minds helping us build our tech stack and advance agriculture.”

Metl-Span®, a Nucor company, hosted an event to celebrate the opening of its new insulated metal panel (IMP) manufacturing facility located in Brigham City, Utah. Nucor Corporation is North America’s largest steel producer and recycler. Nucor produces steel by recycling scrap metal in electric arc furnaces to make new steel products, making the company one of the most sustainable steel producers in the world.

The acceleration center is located at SkySong Innovation Campus, which is an extension of Arizona State University (ASU) since 2003. SkySong supports the launch of startups and inventions in partnership with ASU researchers. This is AGCO’s second acceleration center affiliated with a university; AGCO’s acceleration center on the University of Illinois Champaign-Urbana campus opened in 2018 and helps nurture tech talent within undergraduate and graduate student populations.

The new $35 million, 127,000 square foot facility is bringing approximately 60 new high-quality manufacturing jobs to Brigham City, and will produce a comprehensive range of insulated wall and roof panels for use in end markets such as warehousing, distribution and data centers. IMPs facilitate cost-effective climate control in the built environment and reduce energy usage and overall operations related GHG

The two fabs in New York are the first step in Micron’s vision to invest approximately $100 billion in the state over the next two decades. The company plans to establish four total fabs in New York, each with 600,000 square feet of cleanrooms, the largest amount ever announced in the country, according to Micron.

Construction of the first fab is expected to begin in 2025 and production will come online in 2028, ramping up with market demand over the next decade.

The Idaho fab is expected to be operational in 2025, with DRAM production starting in 2026 and ramping in line with market demand over the second half of the decade, the company stated.

A2Z Manufacturing Rocky Mountain • 29 • May / June2024 A2Z MANUFACTURING SW • 65 • Jan / Feb 2024 24 HOUR TURN TIMES AVAILABLE FREE LOCAL PICK UP & DELIVERY DROP OFF ORDERS 24 HOURS A DAY M-F HEAT TREATING * ALWAYS BETTER SERVICE

is NADCAP Accredited To Meet Your Heat Treat And Passivate Needs. Since 1960. Fair Prices, Superior Quality, Quick Turn Times And Exceptional Customer Service Are Guaranteed When You Work With Us. ROCKWELL TESTING & GLASS BEADING PASSIVATE * * Honeywell, Boeing, MD Helicopter Specifications ABS METALLURGICAL PROCESSORS INC. 4313 EAST MAGNOLIA STREET, PHOENIX, AZ 602-437-3008 • ABSHeatTreat.com increase million our to U.S. require impose on United asset bonds, property foreigners for stated current CPA/Federal the the the point opportunity and Administration million need industries the in the author Manufacturing design, distribution and is talent development valuetechnologies Scottsdale, opened dedicated

ABS

www.westernstatesmetals.com

Boom Supersonic Approved To Fly Test Plane At Mach 1 For First Time

Boom Supersonic has passed another milestone in developing the supersonic jetliner it plans to build: Federal go-ahead to exceed the speed of sound during flight tests in southern California.

The Centennial-based startup received approval from the Federal Aviation Administration to exceed Mach 1 during test flights in its XB-1 demonstration plane, Boom announced Tuesday. The tests must be in specially designated airspace over the Mojave Desert used for proving supersonic aircraft. The authorization expires next April 7.

“Following XB-1’s successful first flight, I’m looking forward to its historic first supersonic flight,” Boom founder and CEO Blake Scholl said in a press release. “We thank the Federal Aviation Administration for supporting innovation and enabling XB-1 to continue its important role of informing the future of supersonic travel.”

“Retail sales are up, and sectors such as transportation, logistics, warehousing, and construction are performing extremely well,” Arora added. “Right now, business owners are confident in the future of their firms. August is typically a slow month for loan volume, but that wasn’t the case this year.”

Boom flew its single-seat demonstration plane, the XB-1, for the first time on March 22 at the Mojave Air & Space Port. The flight was well below supersonic speed, but it served to prove the viability of the company’s design and construction techniques and ideas that it will use in building its full-sized supersonic passenger plane, called Overture.

Business loan approval rates rose at regional and community banks as well. Small banks granted 49.8 percent of the funding requests they received in August, up one-tenth from July. It represents the highest figure for small banks since November 2014.

Institutional lenders — pension funds and insurance companies — remained unchanged at an Index record 64.9 percent, up one-tenth of a percent from July’s figure.

The first faster-than-sound flight won’t come right away. Boom said the FAA approval will allow the company to expand its flight testing to confirm the performance and handling of the plane through and beyond supersonic speeds. It plans 10 to 20 flights before reaching supersonic speed.

Loan approval rates among alternative lenders rose to 56.6 percent, one-tenth of a percent higher than in the previous month.

The second flight will have the landing gear retracted and extended. Other points for testing include sideslip performance — how an airplane moves sideways while flying, such as from crosswind — in addition the stability augmentation system and flutter, which is created by interactions between aerodynamic and inertial forces, the company said.

Alternative lenders have become a source of quick capital. When small business owners, alternative lenders could approve riskier loans via innovations in fintech, which give them more flexibility than the banks to adjust rates and covenants on the deals. This includes an ability to accept non-conventional sources of collateral, such as real estate and outstanding invoices (h/t Forbes).

Credit unions approved 40.2 percent of loan applications in August, a slight drop of one-tenth of a percent from July and a large drop from their all-time high of 57.9 percent in March 2012. By Anthony Noto – Reporter, New York Business Journal

Test pilot Tristan “Geppetto” Brandenburg explained in Boom’s press release that plans for the test call for Mach 1.1, 1.2, and 1.3 on the first three flights. Each test flight takes so much airspace that there is time to evaluate only certain things. Mach 1 is about 767 mph.

“We will be on condition for several minutes, we’ll get a flying qualities and handling qualities block, and have to come back home,” Brandenburg said.

Test flights at supersonic speed over the ocean, where the speed limit doesn’t apply, is not feasible, according to the FAA’s notice of its approval. Given the XB-1’s experimental designation, it can’t fly over populated areas or through congested airspace. Using available long-enough airways would mean flights are too long to carry out tests and return with adequate fuel reserves, and being over the ocean could put the plane out of range of the control room’s telemetry antenna.

“Being in the air with XB-1 during its maiden flight is a moment I will never forget,” Brandenburg said. “The team has been working hard to get to this point, and seeing today’s flight through mission completion is a huge accomplishment for all of us.”

Boom’s Overture aircraft are meant to fly between 64 and 80 passengers at speeds up to Mach 1.7 over water and just under Mach 1 over land. The company says super-fast international flights will change the nature of travel, making quick trips between the U.S. to Asia or Europe routine.

A2Z Manufacturing Rocky Mountain • 30 • May / June 2024

October Rocky Mtn 2018.indd 38 12/21/18 10:14