Vol. 24, No. 3, May / June 2018

Southwest Edition (AZ, NV, and NM)

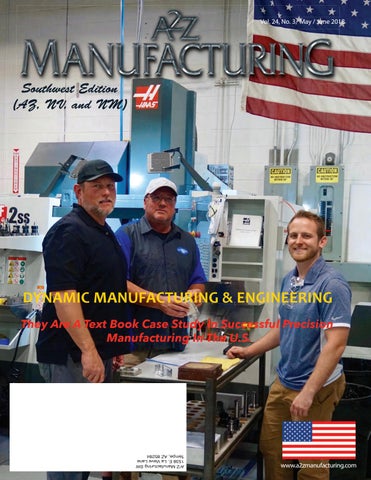

DYNAMIC MANUFACTURING & ENGINEERING They Are A Text Book Case Study In Successful Precision Manufacturing In The U.S.

www.a2zmanufacturing.com

A2Z Manufacturing SW 1538 E. La Vieve Lane Tempe, AZ 85284