“There are only three measurements that tell you nearly everything you need to know about your organization’s overall performance: employee engagement, customer satisfaction, and cash flow. It goes without saying that no company can win over the long run without energized employees who believe in the mission and understand how to achieve it.”

Former General Electric CEO Jack Welch

Former General Electric CEO Jack Welch

In this past month, I attended 2 kick-off events for machine apprenticeships. We all know this is long overdue in our industry. But what may be even more critical in the short term, at least, is the enormous benefit to retaining valuable employees. There is no doubt that high employee churn is costly: Gallup estimates that replacing an employee costs anywhere from one-half to two times that person’s salary.

Why do employees quit? As a manager or business owner, you might chalk up your turnover to people leaving for better pay. In fact, Pew Research confirms this in their study, where more than 6 in 10 said they left their jobs for more money. But this same research study found that this wasn’t the number 1 reason they left their jobs — it was actually tied to a lack of opportunities to advance.

A surprising number in the Pew study, 57%, say that they quit their jobs because they didn’t feel respected at work, and more than 1/3 of those surveyed highlighted this as a major reason for quitting.

Poor benefits and childcare issues were cited as reasons for quitting, as was lack of flexibility. A Gallop poll found that more than 1/3 of employees would switch to a job that offered them more flexibility.

Company culture is not one we necessarily consider when analyzing why employees quit. In a Hays survey of 2000 employees looking for a new job, ‘company culture’ was one of the reasons they wanted to leave their current employer. Strong leadership, open communications, work-life balance, and career development are only going to become more important for attraction and retention.

For many employees, the job or the company isn’t the problem – it’s the person managing them. The Gallup study found that one in two employees left their position to get away from a bad manager.

You often hear, “I lost an employee who went down the street for $.50 more.” Yes, this happens, but isn’t this just an excuse for us not looking into our business to examine what we can do to retain superior employees? You can only increase pay by so much before you can’t afford to run your business. But you can impact many of the issues employees cite as reasons for leaving, including job flexibility, opportunities for advancement, and perhaps most importantly ensuring that every member of your team feels respected and has a manager and leadership team that helps to create an engaged, positive working environment.

I encourage you to learn more about what motivates your employees. Ensure that you are doing more than the business next door to retain your workforce. Hiring and retaining a strong team of employees gives your company a key competitive advantage—your people are an asset your competition does not have. Without them, operations will certainly come to a standstill. Until next issue, I wish you the best, and God Bless our troops.

Published

keep precision manufacturers abreast of news and to supply a viable vendor source for the industry.

Circulation: The A2Z Manufacturing has compiled and maintains a master list of approximately 6500 people in the Rocky Mountain states actively engaged in the Precision Manufacturing Industry. It has an estimated pass on readership of more than 18,000 people.

Advertising Rates, deadlines and mechanical requirements furnished upon request or you can go to www.azManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

JM

www.jmgrisleymachine.com

The versatile VMC lineup at DN Solutions is enough to get anyone excited.

The lineup of vertical machining centers at DN Solutions is versatile, compact and born to make incredible parts for as long as you need them to.

Get your ideal VMC, then get ready for the vertical leap. Talk to your local DN distributor or visit dn-solutions.com.

Colorado, Montana, Idaho and Wyoming

DEM: entry-level part producer

SVM: swift and strong

DNM: global bestseller

The lineup of vertical machining centers at DN Solutions is versatile, compact and born to make incredible parts for as long as you need them to.

BVM: premium powerhouse

Get your ideal VMC, then get ready for the vertical leap. Talk to your local DN distributor or visit dn-solutions.com.

KD Capital Equipment, LLC is thrilled to announce that we have been recognized by Inc. Best in Business as one of the top companies making an extraordinary impact in the manufacturing field.

As a leading provider of high-quality pre-owned manufacturing equipment, KD Capital Equipment has been dedicated to helping our clients improve their technology for over 25 years. Our team of experts work closely with each client to understand their needs and provide solutions that help them increase efficiency, reduce costs, and improve the quality of their products.

We are humbled to be recognized by Inc. Best in Business for our contributions to the manufacturing industry. This recognition is a testament to the hard work and dedication of our team and our commitment to our valued customers.

At KD Capital Equipment, we understand that the key to success in the manufacturing industry is staying ahead of the curve in terms of new technologies and innovations. We are constantly exploring new ways to improve our products and services, and we are committed to providing our clients with the latest and

most up to date equipment on the market.

We would like to thank our clients for their trust in our company. We look forward to continuing to serve the manufacturing industry and help our clients achieve their business goals.

“Erickson Metals Colorado is making big moves!” After spending the last twenty-two years at 5045 North Oakland Street in Denver, they have made the big move to Aurora calling 3559 North Himalaya Road Suite 100 home. They are now located conveniently off of I-70 and Tower Road in the Majestic Industrial Park. The new facility offers 60,000 square feet of warehouse space and provides ample space to stock a wider variety of aluminum products at a higher volume.

The new location also offers state-of-the-art communications equipment as well as a high tech and efficient office environment. “It’s a lot of work,

We Specialize in Close Tolerance Precision Grinding and Small Parts Manufacturing Celebrating 28 Years In Business

Grinding Capabilities:

√ OD,ID Centerless Plunge and Thru Feed (OD Between Centers up to 72” L x OD Swing up to 24”) (ID - 9” depth x 10” LD)

√ Surface, Angled and Blanchard

√ Long Bar Grinding for Screw Machines

√ We grind all types of Industrial Blades

Announcing AS9100

Revision D

Certification!

Grinding & Swiss Machining Capabilities:

√ CNC Universal Grinding Capabilities of 5” x 24”

√ We Have 4 Swiss Turning Centers with Diameter capabilities up to 32mm

√ CNC Circular Blade Grinding up to 20” Diameter

WE’RE GROWING! We Added a 2nd Supertech CNC Universal Grinder, We’ve Hired New Machinists and More!

but it’s worth it”, said Randy Adkisson, EMC Colorado’s Director. An open house will be held in the early summer when the move is complete.”

Since 1972, Erickson Metals Corporation has been committed to being the premier supplier of aluminum sheet, plate, rod & bar, pipe & tube and extruded shapes both domestically and internationally. We have three locations in MN, CO, and NM. For more information, visit: www. ericksonmetals.com

Phoenix Heat Treating is pleased to announce another successful NADCAP audit. The 5 day audit resulted in three minor findings. As a result, Phoenix Heat Treating has officially been granted NADCAP merit status for heat treat processing.

This award recognizes companies who exhibit excellence in their scope and meet rigid audit criteria. Excellence in quality is just one of the reasons why prime aerospace companies and commercial manufacturing companies trust Phoenix Heat Treating for their endothermic, vacuum,

aluminum, and salt processing.

Thanks,Charlie Hushek,General ManagerThe recovery in domestic air passenger traffic continued into 2022, when the number of aircraft departures in the first nine months were 90.4% of departures in the same months of 2019, according to the U.S. Department of Transportation Bureau of Statistics Annual Report 2022. Despite year-end holiday travel delays and numerous flight cancellations, U.S. air travel is on track to soon surpass pre-pandemic levels. With China easing travel restrictions, international air travel numbers likely will follow a similar upward trajectory. Airlines returned parked jetliners to service, but more importantly, are seeking to replace current airplanes with more fuel-efficient versions as oil prices rise.

Predictions of a recession in 2023 are contradicted by statistics showing consumer demand is resilient, with

Continued page 10

is the perfect product when your business has a project or additional expenses. Simple application process and funds up to $250,000. Capital intended to grow your business.

up to $500,000 (without financial review) for your new or used equipment acquisitions. With 100% financing and terms up to 84 months, it allows you to reserve cash in your bank account.

economic experts suggesting a softer landing or a downturn delayed to later in the year. This bodes well for the continued rebound in commercial aerospace, especially as supply chain disruptions diminish. The demand for newer, more economical aircraft should continue this year.

Airbus delivered 661 commercial aircraft to 84 customers in 2022 – an increase of 8% compared to 2021 – and reported 820 net new orders, higher than 2019’s 768. At the end of 2022, Airbus’ backlog was 7,239 aircraft, the highest number since 2019.

In the single-aisle category, Airbus’ A220 won 127 firm gross new orders while the A320neo family won 888 gross new orders. In widebodies, Airbus tallied 63 gross new orders including 19 A330s and 44 A350s of which 24 were for the A350 freighter.

Boeing reports 774 commercial orders for 2022 after cancellations and conversions, including 561 orders for the 737 family and 213 orders for the company’s twin-aisle airplanes. The company delivered 480 airplanes for the year. “We worked hard in 2022 to stabilize 737 production,

resume 787 deliveries, launch the 777-8 freighter and, most importantly, meet our customer commitments,” Boeing Commercial Airplanes President and CEO Stan Deal says. “We will stay focused on driving stability within our operations and the supply chain as we work to deliver for our customers in 2023 and beyond.”

Notably, during Q4 2022, the company secured net orders for 376 aircraft, including an order from United Airlines for 100 737 MAX and 100 787 airplanes.

Commercial deliveries include13 P-8A Poseidon military-derivative 737s and 44 new production freighters.

The final Boeing 747 leaves the Everett, Washington factory. The 747-8 freighter will be delivered to Atlas Air in early 2023. A total of 1,574 airplanes have been built since production began in 1967.

The 737 program is stabilizing production rate at 31 per month with plans to ramp production to approximately 50 per month by 2025 or 2026. The 787 program continues at a low production rate with plans to ramp production to five per month in late 2023 and to 10 per month by 2025 or 2026. By Eric Brothers

So�ware

AllCMMso�warepackagesand op�onsavailablefromLKMetrologyare availablewithALTERAC

Mul�-sensorTechnology

Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

sales.us@lkmetrology.com

1963 2022 59 years

measuringmachineisperfectwhenfloor spaceislimitedoronlyavailableata

measuringmachineisperfectwhenfloor spaceislimitedoronlyavailableata premium

CompactFootprint Picturedonright:ALTERAC10.7.5 withPH10TProbeHead Picturedonle�:ALTERAC7.7.5with KeyboardandMonitorArmand

IntegratedTech

op�onsavailablefromLKMetrologyare availablewithALTERAC

op�onsavailablefromLKMetrologyare availablewithALTERAC

LKMetrology'sALTERACcoordinate measuringmachineisperfectwhenfloor spaceislimitedoronlyavailableata

IntegratedcontrollerandPCaretuckedaway undertheCMMgranitetable,withop�onal monitorandkeyboardarmavailable

IntegratedTech

Mul�-sensorTechnology

AllCMMso�warepackagesand op�onsavailablefromLKMetrologyare availablewithALTERAC

Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

So�ware Tac�le,op�cal,andlasersensorsare integratedintoasinglemeasurement pla�orm

(810)263-6100 or Mul�-sensorTechnology

UTAH

www.umw.com

Tollfree: 866-434-5679

Local: 801-364-5679

At Utah Metal Works, recycling industrial-related scrap metal is one of the things we do best. You simply won’t find more knowledgeable, capable partners for your scrap handling and recycling efforts anywhere. We are known in the industry for our honesty and integrity, and you can be sure you are always getting a competitive return along with superior service. We make it easy for you to cash in on non-ferrous metals from:

Mexico and Arizona. The firm has previously led early-stage rounds for Colorado startups, including SonderMind, Havenly and Nomad.

The latest round is the sixth for the firm, and Kickstart has a total of $487 million in assets under its management. So far, Kickstart has invested in more than 200 startups, focusing its money on seed-stage rounds.

Venture deals slowed last year, as rising inflation and an uncertain economic environment led venture capitalists to take a more conservative approach with their investments. According to PtichBook, the amount of capital sought by U.S. startups during the last quarter of 2022 was billions of dollars more than the capital supplied. For early-stage rounds, the need outpaced the supply by about 50%.

With its new fund, Kickstart hopes to bolster investing in Mountain West states and be the most active seed-stage investor in the region. The firm has “never been more bullish” on startups founded in the area.

The Salt Lake City-based venture firm Kickstart plans to reinforce its focus on Colorado and other Mountain West states with the close of a new $230 million fund.

Kickstart announced the close of its new fund and revealed plans to expand into Colorado. Dalton Wright, a general partner at Kickstart who helped to launch the firm in 2008, will move with his family to Denver this summer and open a new office. “Kickstart is ready to establish a permanent in-state presence in Colorado and will extend its community platform... to more entrepreneurs in the region.”

The firm plans to invest its $230 million fund into startups in Colorado, Utah, New

“This is exciting news for earlystage startups in the Mountain West at a time when many question how active venture investors might be for the foreseeable future,” Kickstart’s announcement reads. “Kickstart will use these funds to support founders fostering innovation and help their companies scale at a time when so many venture firms are pulling back.”

Eric Roza, a managing director at Vista Equity Partners, said Kickstart’s expansion to Colorado was a “clear positive for the startup ecosystem here.”“It’s clear that Kickstart values longterm thinking and doing the right thing, even when it’s hard.”

We help our clients grow business by independently validating their management systems for conformance to national and international standards, helping to ensure the best business practices.

Woman-Owned ▪ Woman -Run

Alignable’s February Small Business Hiring Report shows that 54% of small business employers have broken away from the hiring freezes which were common during much of last year.

This hiring rate is up eight percentage points from 46% in January and up 28 percentage points from December’s rate of just 26%. This trend matches what some small business owners say is a better 2023, with more stabilized inflation, an increase in revenues, and cautious optimism for the future.

This optimism was reflected in Alignable’s January Road To Recovery Report, which showed that 61% of small business owners expect 2023 to be a good year for their businesses.

And 56% went so far as saying that they feel better about what’s to come in 2023, than they did about 2022 this time last year.

So, What About A Recession? And The Other 46%?

Platinum is an ANAB-accredited certification body focused on affordable certification with personalized service. Call or email for your customized quote.

Phone: 303-639-9001

Website: www.platinumregistration.com

E-mail: info@platinumregistration.com

But this optimism is tempered by economic concerns, for sure.

The majority of small business owners (55%) remain worried that either we’re already in a recession or that it’s coming soon, though fewer are concerned than they were last month (56%) or in December, when the figure was 75%.

That said, most small business owners realize that we’re far from out of the woods yet. In fact, the relatively good news that 54% are actively trying to hire still means that 46% of SMBs have stopped looking for new workers, and don’t expect to start again for several months. That’s because of their personal concerns about ongoing economic challenges, including an impending recession, and rising interest rates.

And while some are seeing revenues go up and they’re effectively combating inflation, the percentage of those who have only one month or less of cash reserves is at 31% this month, up five percentage points from 26% in January. While we don’t usually sound the alarm about cash reserves until that number reaches 35% or more, it’s still something to watch closely in the next few months.

Layoffs Are Still At 6%, But That’s Down From Q4.Beyond

that, six percent of small business employers continue to lay off their staffers, though that figure shrank from seven percent in January and 15% in December.

These findings are based on an Alignable poll of 3,846 randomly selected small business owners surveyed from 2/4/23 to 2/15/23. This report also includes historical data based on another 25,000+ respondents over the past five months.

Seeking Permanent Help Is Up, But So Is Temp Hiring.Examining this data more closely, it’s encouraging to see the percentage of small businesses hiring full-time, permanent staff is up to 35% this month, from just 28% last month and a mere 20% in December.

At the same time, the percentage of temporary or part-time workers being hired is way up over Q4 and continues to climb this year.

Only 6% of small business employers in December hired temporary help, largely because they said they were fully staffed to handle their current business. But now in 2023, 18% in January hired temps, and the trend continues this month, lifting to 19%.

In many cases, this reflects the economic uncertainty expressed by the 55% of small business owners with recessionary fears.

Being Uneasy Results In Alternative Solutions.The small business owners opting to hire temporary help say they want to hedge their bets, and take

on who they can afford now, while watching what happens with the economy.

This way their hiring also can be on a per-project basis, and they don’t have to worry about paying benefits or future layoffs.

What’s The Hiring Picture Look Like Across Industries? Drilling down into key sectors, the news is much better looking at hiring rates than it is looking at layoffs. So, let’s start with the current hiring rates reported by small business owners.

As you can see from this chart, there’s a lot of encouraging data here, as many sectors we follow closely have increased their hiring efforts in 2023.

Current Hiring Rates For Small Business By Sector.Leading the pack, 76% of manufacturers said they’re looking for help, up 20 percentage points from January. Chuck Casto from Alignable

We set containers for:

• Machine, welding & fab shops • Manufacturing facilities

• Demolition projects • One-time clean-ups

• Containers: 1 to 60 yards • Flatbed, cargo trailers, rolloffs

• Small boxes on wheels • Locking Lids • Leakproof boxes

Top prices paid for:

• Aluminum • Copper • Brass • Stainless • Steel/Iron

• Alloys • Lead & more

Convenient drive-in recycling:

• Easy acces from I-25, I-70 and Commerce City

• Fully paved • Se Habla Espanol ~

Combat Motors is moving to southwest Utah. Manufacturer and developer of the F-113 and F-131 Hellcat, B-120 Wraith, P-120/R-131 Fighter, X-132 Hellcat, Hellcat Speedster, P-51 Combat Fighter, FA-13 Combat Bomber, F-117 Fighter and Combat Wraith motorcycles, Combat Motors will open a new manufacturing facility in Hurricane in April.

This latest expansion comes on the heels of strong year-over-year growth for the company and is one of several new investments Combat Motors has made in recent months. New equipment expenditures for motorcycle design, manufacturing and apparel production, a soonto-be revamped online presence and shortly beginning production of the new Hellcat model signal strong business growth for the motorcycle manufacturer.

With this move, Combat Motors is consolidating its business offices, apparel and primary motorcycle manufacturing and service support to Hurricane in a newly built-to-suit 8,000-square-foot facility. The new facility’s geographic location will expedite delivery and service support while enabling participation in more events on the West Coast of the

Combat Motors’ growth will be supported by existing staff and new hires, but also by new local manufacturing partners that the company intends to utilize for CNC manufacturing, welding and carbon fiber production. Combat Motors also intends to build relationships with local universities in nearby St. George for their internship program in design and manufacturing.

Southwest Utah was the first pick location for a new facility for Combat Motors’ master builder and test pilot, Jason Reddick, who is looking forward to all that the area can offer. With more than 10 different locations on the prospective list for relocation of the manufacturing facility, Reddick had his sights set on St. George from the start.

Combat Motors’ highly anticipated new Hellcat is scheduled for release in June, followed by a 2024 Combat Fighter and an all-new Wraith thereafter.

Continuing a 30-year tradition of designing and crafting America’s most iconic, heirloom-

quality motorcycles, Combat Motors aims to represent the motoring purist. Combat Motors currently manufactures the F-117 Fighter, the P-51 Combat Fighter, the Combat Bomber and the all-new Combat Wraith by hand in its facility in Birmingham, Alabama. For more information, please visit CombatMotors.com.

The U.S. Navy has awarded Lockheed Martin Space a contract worth as much as $2.2 billion to cover supplying newly developed hypersonic missiles to destroyer ships and Army truckmounted launchers.

The contract has an initial value of just under $1.2 billion but includes options expanding it to $2.2 billion if all the options are exercised.

Most of the work in the project will be done at Lockheed Martin Space’s facilities outside Denver, in Sunnyvale, California, and Magna, Utah, and be completed by Sept. 30, 2027, the Navy’s Feb. 17 award notice said.

The award covers providing launcher systems, weapons control, the missile rounds and integration into the Zumwalt-class destroyers, stealth ships used by the U.S. Navy, and into truck-mounted launching systems used by the Army for its Long-Range Hypersonic Weapon program.

The quick turnaround times in the contract award underscore the weapon system’s importance to the U.S. military, which is spending billions to field hypersonic missiles that can launch from sea, land and air.

Prompt-strike, glide-body hypersonic missiles are meant to carry conventional explosives on a rocket-powered missile that’s maneuverable in flight at speeds over 13,000 mph — five times the speed of sound — and travel above traditional antimissile defenses through the upper atmosphere, according to the Congressional Research Service.

China, Russia and other global powers are developing similar weapons to make their militaries capable of striking distant locations with little or no warning.By Greg Avery – Denver Business Journal

www.westernstatesmetals.com

After fine-tuning a camper design for trucks during the Covid-19 pandemic, five outdoor enthusiasts are ready to launch a business and have found a new home in Denver.

For more than two years, the group of founders has been perfecting the design and prototypes of a lightweight camper that can fit over most trucks. Their product is unique to the truck camper industry, providing a roomy space without a weighty structure.

After securing a round of outside investment late last year, the founders have been busy finding a permanent headquarters in Denver and preparing for their launch.

Sean Kepler, president of Tune Outdoor, said the company needed assembly space with access for customers to drive their trucks inside so their campers can be installed. In addition, Tune Outdoor also needed showroom space to display their product, as well as office space to run the business. By Kate Tracy – Denver Business Journal

Woodward Inc., Fort Collins, Colorado, is awarded a $10,764,606 firm-fixed-price, indefinite-delivery/indefinite-quantity contract for the procurement of next generation ship service gas turbine generator full authority digital control cabinets. A maximum quantity of 32 will be provided over the life of the contract. Work will be performed at the contractor’s facility located in Fort Collins, Colorado, and is expected to be completed by January 2029. Fiscal 2023 other procurement (Navy) funds in the total amount of $914,900 will be obligated at time of award, and will not expire at the end of the current fiscal year. This contract was not competitively procured in accordance with 10 U.S. Code 2304(c)(1) — only one responsible source and no other supplies or services will satisfy agency requirements. The Naval Surface Warfare Center, Philadelphia, Pennsylvania, is the contracting activity (N64498-23-D-0001).

Arizona-based vehicle maker Nikola Corp. quietly purchased nearly 1,000 acres in the Phoenix metro at the end of September for $16.5 million, according to Maricopa County records.

Nikola acquired the 920-acre site through Phoenix Hydrogen Hub LLC from Hardison Farms on Sept. 30, real estate database Vizzda shows. George Quinif of Peak Group LLC represented Nikola in the sale.

Vectrus Systems Corp., Colorado Springs, Colorado, was awarded a $264,951,370 modification to contract W52P1J-21-F-0035 for the Enhanced Army Global Logistic Enterprise. Work will be performed at Fort Benning, Georgia, with an estimated completion date of Dec. 10, 2023. Fiscal 2023 operation and maintenance, Army funds in the amount of $16,304,162 were obligated at the time of the award. U.S. Army Command, Rock Island Arsenal, Illinois, is the contracting activity.

The massive site is located at 28702 W. Patterson Road in south Buckeye just west of State Route 85 near the Arizona Department of Corrections Lewis Prison, which is one of the largest prisons in the state and houses more than 4,400 inmates.

The sale comes after Nikola made multiple announcements that it planned to break ground on a hydrogen production hub in Arizona. The company’s CEO said in August that Nikola would start construction on the new facility by the end of this year but did not disclose the location.

Keysight Technologies Inc., Colorado Springs, Colorado, was awarded a $28,616,166 firm-fixed-price contract for the CM-523/U battery-operated, handheld spectrum analyzer. Bids were solicited via the internet with two received. Work locations and funding will be determined with each order, with an estimated completion date of Jan. 29, 2028. U.S.

According to the Arizona Corporation Commission, Corey Hessen and Omar Khayum, senior vice president and vice president of Canada-based TC Energy, respectively, are the managers of Phoenix Hydrogen Hub LLC. Oil and gas giant TC Energy partnered with Nikola last year to develop large-scale hydrogen production hubs across the U.S. and Canada.

Army Contracting Command, Redstone Arsenal, Alabama, is the contracting activity (W31P4Q-23-D-0009).

The Boeing Co., Hill Air Force Base, Utah, was awarded a $1,615,000,000 indefinitedelivery/indefinite-quantity contract for guidance subsystem support. This contract provides for Minuteman III Intercontinental Ballistic Missile guidance subsystem support. Work will be performed at Hill AFB, Utah, and is expected to be completed by Feb. 1, 2039. Fiscal 2023 operation and maintenance funds in the amount of $8,345,086 are being obligated at the time of award. The Air Force Nuclear Weapons Center, Hill AFB, Utah, is the contracting activity (FA8214-23-D-0001).

Nikola hasn’t confirmed, though, whether it plans to build a hydrogen production hub in Buckeye. Nikola said it has no comment about the Buckeye land sale or its plans for the property. The city of Buckeye said nothing has progressed with the company beyond negotiations.

The automaker is currently producing battery electric vehicles and has produced several alpha prototypes of its fuel cell electric vehicles, which run on hydrogen. Nikola is planning to build out a hydrogen fueling network to support its vehicles. Its first three locations will be established in California.

In addition to the fueling stations, the

L3 Harris Technologies Inc., Colorado Springs, Colorado, was awarded a maximum $10,500,000 cost-plus-incentivefee undefinitized contract action for sustainment support. This contract provides for Combat Mission Systems Support contract sustainment of the Space Systems Command portfolio of ground-based electronic warfare. Work will be performed in Colorado Springs, Colorado; and Palm

Bay, Florida, and is expected to be completed on May 1, 2023. Fiscal 2023 operations and maintenance funds in the amount of $7,875,000 will be obligated at time of award. The Space Systems Command, El Segundo, California, is the contracting activity (FA881919-C-0002).

Zimmer Biomet Spine Inc., doing business as ZimVie, Westminster, Colorado, has been awarded a maximum $48,895,527 fixed-price, indefinite-delivery/indefinitequantity contract for spinal procedural packages and supplies. This was a sole-source acquisition using justification 10 U.S. Code 2304 (c)(2), as stated in Federal Acquisition Regulation 6.302-2. This is a one-year base contract with four one-year option periods. Using customers are Army, Navy, Air Force, Marine Corps and federal civilian agencies. Type of appropriation is fiscal 2023 through 2024 defense working capital funds. The contracting activity is the Defense Logistics Agency, Philadelphia, Pennsylvania (SPE2DE-23-D-0015).

L3Harris Technologies Inc., Colorado Springs, Colorado, has been awarded a $31,456,050 contract modification (P00160) to previously awarded contract FA8823-20-C-0004 for Maintenance of Space Situational Awareness Integrated Capabilities (MOSSAIC) sustainment services. The modification brings the total cumulative face value of the contract to $681,564,012. Work will be performed in Colorado Springs, Colorado, and is expected to be completed by Jan. 31, 2024. Fiscal 2023 operations and maintenance

funds in the amount of $25,164,839 are being obligated at the time of award. The Space Systems Center, Colorado Springs, Colorado, is the contracting activity.

Infinity Technology Services LLC, Colorado Springs, Colorado (47QTCA19D00KF), is being awarded a competitive firm-fixed-price, General Services Administration federal supply schedule task order (HQ0854-23-F-0005). The total value of this task order is $40,036,771. The Cyber Threat Hunting program detects, identifies and mitigates, through use of advanced tools and capabilities, adversary attempts to steal, manipulate, or otherwise alter Missile Defense Agency (MDA) classified information. Under this order, the contractor will support MDA and its specified program offices by providing technical services in support of MDA, and other government agencies, in the areas of cybersecurity, cyber threat hunting, cyber threat intelligence and countermeasures identification. The work will be performed primarily in Huntsville, Alabama; and Colorado Springs, Colorado. Fiscal 2022-2023 research, development, test and evaluation funds in the amount of $2,250,000 are being obligated on this award. The Missile Defense Agency, Huntsville, Alabama, is the contracting activity.

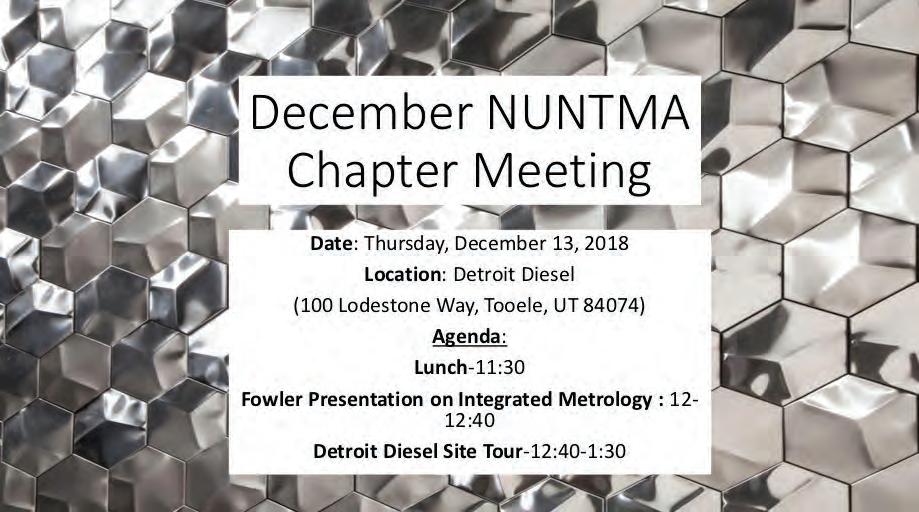

On February 9th, nearly 100 attendees were introduced to the Utah CNC Machinist Tech Apprenticeship Program. The program was put together in conjunction with a number of organizations, typically non-profits, including Utah Manufacturers Association (UMA), the Northern Utah Chapter of the National Tooling and Machining Association (NUNTMA), the Utah System of Higher Education, Talent Ready Utah, Apprenticeship Utah and NIMS.

Melissa Stark from Apprenticeship Utah provided an overview of what an apprenticeship means, how it works, and the benefits/ROI. She defined Apprenticeship as a training strategy that combines paid on-the-job learning with formal classroom instruction

to prepare workers for highly skilled careers.

Martin Moore and Rachelle Ackley represented the Utah Manufacturers Association and presented ‘Apprenticeships as a strategic approach to growing your talent pool’. They discussed a ‘Student Outreach approach’ to build interest in machining, not just for the students but also to help the parents understand more about our industry. Megan Ware also represented the Utah Manufacturers Association.

Peter Reed represented the Utah System of Higher Education, and discussed the need for classroom training, not just in high school, but also through a combination of high school and a technical college, and then the option to learn more about precision machining in the Tech college environment. He offered opportunities for funding to support these programs.

Montez King from the National Institute for Metalworking Standards (NIMS) provided a presentation on Smart Training Solutions, and Brad Robeson, member of the NTMA and owner of Clean Machine, discussed the employer’s role in the apprenticeship program.

Questions:

1)When should I start preparing?

a)Now! An Apprenticeship Program takes some preparation. If you would like to participate in the launch in the Fall, please let us know

March 9:

Established in 2010, the NUNTMA is a gathering place for machine shops in Northern Utah.

April 13:

Cybersecurity Best Practices by TOTEM

Time: 11:30 am-1 pm

Location: DTECH Allied Health Building

Greatroom (550 E 300 S Kaysville 84037)

Time: 11:00 am-1 pm

Location: OTECH (200 N Washington Blvd, Ogden, UT 84404)

Submit questions for the panel here: https://www.proprofs. com/survey/t/?title=6vffk

REGISTRATION REQUIRED FOR ALL EVENTS. VISIT: NUNTMA.ORG/UPCOMING-EVENTS

and we’ll connect you to the resources and partners you will need to get things going.

2)How do I get on board with my local education partners?

a)The UMA will reach out to you and start the dialog with your company, the local school district and local tech college.

b)Once these contacts have been made, be prepared to participate in the recruiting process. Field trips, open houses, job fairs and speaking opportunities will enhance your success in bringing in the best and brightest to your company.

3)Are program participants going to be fully functional machinists by the end?

a)No, in this 2-year apprenticeship program it would be impossible to have a journey level machinist by the end. The hope is to give the apprentices enough information to get them hooked on the industry. They can continue their education and OJT to improve each day.

4)How do we know this model will be successful?

a)We have all key players at the table this time. Apprenticeship Utah, The Utah

System of Higher Education, and Utah Manufacturers Association. Megan Ware, UMA, was heavily involved with the launch of the Stadler Rail Apprenticeship Program and has been instrumental in the development of this program.

5)So, I train these people, won’t they just take that training and leave?

a)Not if it’s done correctly. Training done properly builds loyalty. Studies show that employers who invest in training their team have lower turnover

6)What is the age range of apprentices in this program?

a)16-18

7)Other states to benchmark with that are making similar efforts?

a)The National Tooling and Machining Association (NTMA) has 28 different chapters across the US. Many of these chapters have developed apprenticeship programs and have been helpful in the development of this one. Questions will come up along the way, and we have a vast network of resources to pull from.

8)Who and how do we contact now to get started?

a)Chapterexec@nuntma.org will compile a list and send it to the UMA, who will contact you to get started.

1704 West 10Th St • Tempe, AZ 85281

Ph: 480-967-2038 • F: 480-829-0838

and dedication to customer service are number one priorities. This type of expertise and dedication has fostered a reputation of excellence in the tooling and stamping industry.

Located in Tempe, Arizona, our 100,000 Sq. Ft. Facility contains state of the art equipment , with production capabilities ranging from simple geometries to complex forms with intricate details. Precision enjoys a world-class reputation supplying a variety of OEMs, managing their inventory levels, and making certain product quality and timely delivery are NEVER compromised.

A phase one technology transfer contract through the Department of the Air Force will help Santa Fe-based Solstar Space Co. test one of its new space connectivity products.The company announced that it received the three-month, $75,000 contract to further its Slayton Space Communicator. It’s one of a few technologies currently under development by Solstar.

A Centennial space company’s Vulcan rocket has notched a first launch of sorts, weeks before its debut mission carrying a NASAfunded lunar lander and a pair of Internet satellites to orbit.

United Launch Alliance, the rocket-making manufacturer that supplies the federal government with most of its space launches, loaded the Vulcan rocket’s first completed booster stage onto a ship outside its Decatur, Alabama rocket factory to sail it to a Florida launch pad where it will blast off in coming weeks.

The Slayton product is essentially a broadband network device that allows constant high-speed uplink and downlink data relays on various space assets that range from satellites to space stations to lunar habitats.

Solstar’s CEO Brian Barnett told Albuquerque Business First that money from the contract would support Solstar as it readies the Slayton Space Communicator for commercial and government applications.Through the contract, the company will partner with Andrei Zagrai, Ph.D., a mechanical engineering professor at the New Mexico Institute of Mining and Technology, to test the space communicator using a satellite health monitoring unit developed at the university.

ULA’s custom-built ship is expected to arrive at Cape Canaveral next weekend and deliver the booster for final preparations ahead of the rocket’s first launch, which is expected before March 30.

Solstar’s Slayton Space Communicator complements one of the company’s other products, Barnett said. Called WiFi access points, they are small connectivity devices designed to be used inside space stations, on lunar rovers or lander cabins, according to Solstar’s website.

“The ULA team has worked tirelessly to complete the rocket for the first certification flight,” said Mark Peller, vice president of Vulcan development for ULA. “Now that production is complete, our launch team will begin processing and testing this innovative new rocket in preparation for the first mission which will deliver a payload to the Moon.”

The company plans to deploy one of those access points inside NASA’s Habitation and Logistics Outpost. It’s one part of the agency’s lunar-orbiting space

The Vulcan rocket is meant to handle all the company’s space launches in

coming years and help the business to quicken its pace and launch payloads to orbit every couple of weeks.

station called Gateway, which is under development for its Artemis program.

Solstar has another space communication product called the Deke Space Communicator, which is a narrowband network device used to connect satellites with other Internet of Things devices.

ULA has been designing Vulcan since 2015 to replace its existing rockets and allow the company to move U.S. national security launches away from the Russianbuilt RD-180 engines that power ULA’s workhorse Atlas V rockets.

Solstar is developing this suite of space communications technologies to be ready for commercial and government application in the next couple of years, Barnett said. Solstar’s Deke Space Communicator provides narrowband network connections.

Blue Origin, the space manufacturer founded by billionaire Jeff Bezos and based in Kent, Washington, makes the methane-fueled BE-4 engines ULA chose to power Vulcan rockets off the launch pad.

ULA has been waiting for the first flight versions of BE-4 engines to be delivered so it can build the first Vulcan rocket booster and send it to Cape Canaveral to launch.

Solstar plans to apply for a phase two contract once the current contract for the Slayton Space Communicator technology is done, Barnett said. That phase two contract would give Solstar over $1 million to further develop the product through more testing and prototyping. Barnett said the broadband technology could be ready for commercial use in 2025. By Jacob Maranda - New Mexico Inno Reporter

Each Vulcan uses two BE-4 engines to provide 1.1 million pounds of lift for its booster stage.The 2,500-em-

ployee rocket maker expects the RocketShip boat to deliver the rocket to ULA’s Cape Canaveral launch site Saturday. The Vulcan booster stage will go through test fueling and a test firing of its en gines and is expected to be ready for a first-quarter launch, assuming that the mission’s payloads are ready.

the same physical, chemical and optical properties as mined diamonds.

The company said in the SEC filing it will use some proceeds from the IPO for sales and marketing, and research and development to improve the chemical vapor deposition process, in addition to expanding its manufacturing operations.

The first flight version of a Vulcan rocket booster stage, made by United Launch Alliance, was loaded into a company cargo ship Jan. 9, 2023, to sail the rocket to the Cape Canaveral launch pad for launch.

Adamas said its diamonds could be monetized through endproduct sales, joint ventures and licensing agreements with third parties as well as continued development of intellectual property. Market opportunities include diamond gemstone jewelry, cutting devices for precision manufacturing, thermal management for semiconductor and medical science technology.

Vulcan’s first launch is of a robotic lander that Pittsburgh-based Astrobotic is sending to the surface of the Moon. Vulcan will also release a pair of test satellites for Amazon’s Kuiper Project internet service into orbit during the mission.

The debut flight of Vulcan has been pushed back for months, partly delayed by the production of the BE-4 engines and partly due to payload readiness.

Prior to establishing Adamas, Grdina founded AMMO Inc., a publicly-traded Valley ammunition company. He also served as CEO of NOHO, a former lifestyle beverage company. He is co-owner of celebrity blogs, TheDirty.com and Kikster.com. Grdina was the founder and former CEO of Club Jenna Inc., which was sold to Playboy Enterprises in 2006.

Blue Origin delivered the flight versions of the BE-4 engines last year, and both have since passed acceptance testing at ULA and have been installed prior to the booster being shipped out, spokeswoman Jessica Rye confirmed.

Adamas was incorporated in Nevada in 2018. A year later, it acquired Scio Diamond Technology’s assets, which consisted of diamond growing machines, patents and intellectual property valued at more than $8.6 million.

Adamas said Scio’s funding constraints contributed to its downfall and the company claims it has improved upon its recipes for pink and white diamonds to make them commercially competitive, in addition to adding new capabilities for diamond planning and laser cutting, according to its SEC filing. By Amy Edelen – Phoenix Business Journal

Vulcan rocket is key to the future of ULA because it’s taking the place of the Atlas V and Delta IV rockets the company has been flying since it formed in 2006.

To handle the military launches for U.S. Space Force, ULA must first successfully launch Vulcan rockets twice to certify them as ready for national security payloads.

Vulcans are designed to be flexible enough to be able to handle the missions that the two rocket families used to launch but also fly at a significantly lower cost than its predecessors.

The debut launch is for Astrobotic and Kuiper Project.

Tesla is reportedly considering purchasing Sigma Lithium, a Brazillian lithium mining company, for an estimated $3 billion.

ULA has said it aims to have basic Vulcan launches be as cheap as $100 million.

Scio failed to commercialize the chemical vapor deposition technology, despite having created lab-grown diamonds for industrial use. As a result of failing to file its periodic reports with the SEC, the company’s registration was revoked in August 2019.

The launch vehicle has already won ULA a contract to handle 60% of U.S. military and spy agency space missions over five years and to launch 37 missions putting hundreds of Kuiper Project satellites into orbit.

Tesla and its CEO Elon Musk have shown a continued interest in the extraction and refinement of lithium over the past five years. With the company’s exponentially growing demand for the substance, and its alacrity to vertically integrate, a corporate purchase of a lithium miner certainly is within its MO. But now, Tesla may be closer than ever to such a purchase, as Bloomberg reports that the automaker is exploring purchasing Sigma Lithium for $3 billion.

Vulcan’s second mission is slated to carry the Dream Chaser space plane, made by Louisville-based Sierra Space, on its first launch carrying cargo to the International Space Station. That mission is scheduled to take place later this year and certify Vulcan as ready for military satellite launches.

Greg AveryWe are an authorized distributor of genuine OEM parts from Flow, H2O Jet and KMT

From cutting heads, on/off valves, and orifices to ROCTEC nozzles and more, most parts are in stock, and ordering is fast and easy. Visit store.barton.com or call (800) 741-7756 to speak with a parts expert.

FREE SHIPPING EVERY DAY on qualifying online orders at store.barton.com

try to launch Starliner carrying a crew of two astronauts to the ISS.

Boeing and NASA have been working on Starliner hardware and software in advance of the next flight, they said. The Starliner is on track for launch in the second half of April, and, barring any surprises, NASA should know by early March whether to have ULA start preparations to fuel its Atlas V rocket on the Cape Canaveral launch pad.

The timing is being coordinated to work amid the arrival and departure traffic of SpaceX Dragon capsules and Russian Progress capsules carrying astronauts and cargo to the ISS.

ULA trying to launch a Vulcan Centaur rocket for the first time is being taken into account along with the ISS traffic management, said Steve Stich, manager of NASA’s commercial crew program.

“We’re balancing that with what they need,” he said of ULA’s Vulcan debut.

BARTON INTERNATIONAL USA/Canada 800-741-7756

518-798-5462 • info@barton.com • barton.com • store.barton.com

BARTON is a trademark of BARTON Mines Corporation.

The first United Launch Alliance mission carrying astronauts into space could blast off in a few weeks and may occur before the Vulcan rocket debut that was expected to be the Centennial-based company’s first mission in 2023.

NASA and Boeing provided an update about the timing of the first launch of the Boeing CST-100 Starliner capsule carrying U.S. astronauts to the International Space Station, saying that high-profile mission using one of ULA’s Atlas V rockets is being planned for mid- to late-April.

The long-awaited Boeing capsule, which would be the second spacecraft certified to carry NASA astronauts into orbit, flew without crew last year.

The flight was successful, but not flawless.

It has been unclear how soon this year the agency would

Should preparations delay the Starliner mission to toward the middle of May, that could complicate ULA’s Vulcan launch and prompt a decision about which ULA mission should blast off first, Stich said.

ULA’s debut Vulcan launch is carrying a NASA-funded moon probe, made by Pittsburgh-based Astrobotic, that’s expected to land on the lunar surface.

The mission will debut ULA’s Vulcan rocket and be the inaugural space flight for Astrobotic.

ULA has shipped the first Vulcan rocket to Cape Canaveral to be assembled on the launchpad, fueled for a test engine firing and then readied to launch.

The liftoff has been tentatively forecast to be before the end of March, though that timeline was dependent on Astrobotic’s Peregrine lander successfully completing final testing.

Astrobotic announced on Jan. 25 that the lander had passed testing in a thermal and vacuum chamber, which simulates the extreme temperatures and oxygen-free environment of space, and was ready to be shipped to Cape Canaveral for launch preparations.

The timing of Vulcan’s launch is important to ULA.

The Vulcan rocket is designed to start flying all of ULA’s space launch missions in coming years, replacing the company’s now-retired Delta IV rockets and, in coming years, the Atlas V rockets.

The Vulcan rocket needs to successfully fly two civilian

LTM Plastics has a Transfer Tooling Program that will get you online and receiving quality parts again quickly. Trust our experts to get your job done right.

www.LTMplastics.com

missions before it can start carrying national security-related payloads into orbit for U.S. military and intelligence agencies.

That national security work is a key part of ULA’s business.

The U.S. Space Force has contracted ULA for 60% of national security-related launches that are awarded through the fall of 2024, with Elon Musk’s SpaceX tapped for the other 40%. The missions awarded under that contract are expected to lift off in 2027.

ULA is a joint venture owned by Boeing Co. and Lockheed Martin Corp. It won the Space Force work using Vulcan rocket capabilities and committed ULA to prices based on Vulcan’s cheaper costs compared to Atlas V.

Vulcan’s debut is months behind schedule for various reasons, including delays in Blue Origin’s BE-4 booster-stage engine deliveries, putting pressure on ULA to field Vulcan and meet its upcoming military launch schedule.

After the Astrobotic Peregrine land mission, ULA plans to use a Vulcan to launch the first flight of a Dream Chaser spaceplane, built by Louisville-based Sierra Space, on a NASA cargo resupply mission without crew on board.

If that Dream Chaser launch is delayed, ULA has prepared a

dummy payload and would consider launching that to keep Vulcan’s certification for military launches on schedule, according to CEO Tory Bruno.

Having Vulcan launching regularly would help ULA win future business.

Space Force last month revealed that it expects to open new contract bidding in the coming months for its next round of space-launch awards, which would start in 2025.

It plans to accept bids by new space launch companies for simple missions in addition to selecting two companies separately for more complicated missions and distant orbits, said the announcement by Space Force’s Space Systems Command. That means ULA could have broader competition for military launch business than it has previously faced.

Boeing also said that it has been talking with multiple companies about what launch vehicles the Starliner capsule will use after its run of eight launches atop Atlas V rockets is done. It plans to select launch providers next year, said Mark Nappi, Boeing’s vice president and program manager for its Starliner capsule work.By Greg Avery – Senior Reporter, Denver

Through a little trial and error many years ago, Russ Kurzawski landed on a recipe for business success. Today, Star Metal Fluids (SMF) is a leader in the distribution of industrial process fluids, including metalworking coolants, machine lubricants, and cutting oils. They have developed an extremely diverse customer base in industries such as aerospace, medical, defense, firearm, semiconductor, and so on.

When Russ launched the company 31 years ago, it was originally called Star Fluid & Tool. In those early years, Russ found that there was a void in the market for metalworking fluid specialists, and he dropped the tooling from his product portfolio, focusing exclusively on metalworking fluids, along with the equipment to accommodate these fluids. Today, the name Star Metal Fluids (SMF) accurately reflects the niche that the company serves. Metalworking fluids are complex, and most machinists and owners recognize that having a well-trained supplier who only sells and services these products, is what they need to keep the costly machine tools they purchase operating to their optimal capabilities. You just don’t purchase metalworking fluids like you are purchasing office supplies.

SMF is a family run company, and nearly every Kurzawski family member has been involved with the business at some time. Russ’s oldest son Nick, came to work for the company after completing his LDS mission, and spent many years on SMF’s operations team. After working for the family business, Nick went on to work for a company helping to design firearms. Sadly, COVID took Nick’s life in December 2021, but the family will always be appreciative of the role he played to help grow the business. Aaron, the 2nd oldest, has been with the family business for almost 20 years and can remember being 10-years old when Russ started SMF out the home garage. He started selling for the company after returning from his LDS mission. Russ’s oldest daughter, Leigh Ann Waters, does some of the AR/AP work for the company, and

Russ’s wife Shelley also supports finances for the business. Today, Aaron’s 17-year-old son, Kaden, can be seen working in the business during summer and winter breaks, when he is off from school.

“Our strict focus on the fluids used in metalworking processes has clearly been a recipe for success”, Aaron Kurzawski, General Manager for the company, says, “and our customer base continues to grow each year.”This growth has led to many expansions throughout the company’s history. The company has been headquartered in Phoenix, Arizona since 1992, and in 2008, SMF opened a second location in Salt Lake City, Utah. Today, they distribute and service products in Arizona, Utah, Nevada, New Mexico, Colorado, Idaho, Wyoming and California.

Business was growing in the Arizona market with double digit growth year over year when Russ made the decision to expand into Utah. “We always had a few customers in Utah, and until 2008, we supported them from Arizona”, Aaron says. However, for anyone who knows Russ, tough, aggressive, bold, hardworking and market savvy are terms that come to mind. Aaron says, “There are many Russ-isms that Russ is known to share with our team, and one that comes to mind is, ‘If you’re not growing, you’re dying!’”.

When the company made the decision to expand to Utah in 2008, they started with a small storage locker (10’x10’) filled with inventory, and either Russ, Aaron, or another SMF team member would travel up to Salt Lake City every week to support and grow the business. Business grew quickly and within 6 months, SMF moved to a 1600 square foot warehouse in North Salt Lake City to support their new customers. “We had a truck with a lift gate and we did all the sales, all the deliveries, and all the machine cleans, and this is what got us in the door. There was a lot of blood, sweat, and tears produced during the early years of this venture”, Aaron recalls.

“We had this fabulous foundation, and we had a few trial employees that didn’t work out over the first several years. Then we found Jason Hicken – he was the perfect fit to support SMF’s growth in Utah.” Prior to joining SMF in 2012, Jason worked in Ogden for an aerospace company and worked in their heat treat department. Aaron says, “Jason fit the SMF mold – he was eager to learn and hungry to grow our business. It was a perfect storm — we had established a good customer base, but had dozens of open trials out in the field and many prospects interested in giving SMF an opportunity; we just needed someone local to support these customers in making the decision to switch to SMF, and Jason was it.”

In 2013, SMF had experienced enough growth to justify the hiring of a full-time delivery driver, Trevor Weaver. “Trevor has been an important asset to SMF’s growth in Utah and is an exceptional person and an exceptional team member” says Aaron. Trevor can be seen daily, traveling the freeways of the Wasatch front in a stake bed truck, delivering the products their customers need.

In 2015, Raul Esparza joined the SMF sales team, as their growth had reached the point of needing additional sales help in Utah. Jason says, “Raul has been instrumental in the continued growth of our Utah market. From day one he has embraced the core values we have built the business on and our customers trust Raul. His continued growth, both professionally and personally, has made a difference in the many accounts that he calls on.” Raul covers a territory that stretches from North Salt Lake City all the way to the southern border of Idaho.

Just months ago, SMF added Lucas Cassil to their team. Lucas was in the carpet cleaning business, and the last carpet he cleaned was Jason Hicken’s. Today, Lucas is working hard, training, and accompanying his sales colleagues on calls to support SMF’s customers. Lucas focuses his efforts from Salt Lake City, all the way down to Gunnison.

Since that initial journey in 2008 to expand their business in Utah, mind you in the heart of a recession, SMF has established itself as the leader in the metalworking fluid industry in the southwestern United States.

“We now occupy almost 9000 sq ft of warehouse in space in West Valley, UT, to inventory the products our customers need and expect from us” says Aaron. Russ has exceptionally high expectations for his employees, as they are the backbone to their success. “We work hard and we treat our customers really well, going above and beyond”, Aaron says, adding, “We have also been blessed to have superior employees who we have retained for many years.”

SMF also believes in building strong relationships with local machine tool dealers and has been able to do so over the past 30 years. “Where we have these relationships, we are able to offer a free coolant fill for each new machine sold”, Aaron says, “and this goes a long way for someone just getting into the industry, who just spent tens of thousands of dollars, if not hundreds of thousands of dollars on a new machine.” These relationships are a key component to SMF’s growth and a huge benefit for the machine tool dealers to have an expert to reach out to when their customers start asking questions about metalworking fluids.

Like SMF’s expectation for excellence within its own team, SMF has strategically aligned themselves with the best manufacturers of metalworking fluids and precision cleaners in the

Continued NEXT page

industry, including: Qualichem, Castrol, Quaker Houghton, Brulin, Envirotech, and Hangsterfers.

Aaron says, “When we are onboarding a new supplier, we evaluate their ability to provide the superior support that our customers are accustomed to. It is our expectation that our vendors share the same drive and ambition that we have within our team.” Utilizing the best resources from each manufacturer’s product lineup, SMF can accommodate any metalworking or cleaning application they come across. Rick Mattise, Senior Sales Engineer for Qualichem, said, “For over a decade SMF has been the largest Qualichem distributor in the world!”

SMF also believes that it is important to invest back into the company. Aaron says, “We recently performed a website overhaul, and with this upgrade, our customers can order any of our products online, they can access technical information, or they can contact us directly. Our customers are increasing their use of online ordering each year, but for those who prefer to talk with someone directly, at SMF they get a person on the phone when they call, not an automated message.” Online ordering has become second nature to many of us, and for this reason, SMF has made it a point to have an online presence.

Russ says, “From the beginning, Star Metal Fluids LLC has been dedicated to providing the metalworking industry with the latest in technology to meet the demanding challenges and constant changes of today’s high-tech operations. We know applications...and we will find the best possible metalworking fluid to not just ‘meet your needs’, but improve finishes, tolerance and part size. We are not a ‘Me Too’ company... but specialize... so we can offer you the technical expertise and products you will find nowhere else.”

SMF is growing and they are looking for great people to join their team. Today, there is an immediate opening for a sales/account manager in AZ, and in Utah, there is a part time warehouse position open. Aaron says, “SMF is a very good place to work. We give our team the tools, the training and the support to enable them to succeed.” For more information on hiring or learning more about SMF’s product line, call: 800367-9966: email: customerservice@ metalfluids.com or visit their website at: metalfluids.com

“I started working with SMF ~5 years ago. They are great people and they carry a superior product line. They have been instrumental in helping me to automate the coolant process at my company, and their customer service cannot be beat.” Sid, President Utah Precision Machine Shop

“With my previous supplier, they did a delivery once a week. If you forgot to order, you were out of luck. Not so with SMF. They don’t hire salespeople, they hire service people, and they genuinely don’t want to sell you anything you don’t need. They call it like it is and their product works as they say. I use Qualichem for my coolant and it is the most consistent, reliable product on the market. For my oils, I purchase Bosse because it is as good as the name brands but significantly less expensive. SMF is simply the best.”

Kurt, Shop Foreman, Utah Precision Machine & Fabrication Shop

of requirements, to measure how the missile would respond to various atmospheric, load and speed conditions. Tests simulated everything from firing the missile, to stage separation and various flight maneuvers. The team is now updating models to enable full scale predictive environments for the development of Sentinel flight hardware.

“Tests were conducted at industry and governmentrun facilities across the U.S. in under a year,” said Willoughby. “This is an extremely complex effort proving the value of digital engineering in helping us move to the next phase with certainty.”

The U.S. Air Force’s Sentinel weapon system is a critical modernization of the current land-based leg of the U.S. nuclear triad, replacing the Minuteman III ICBM system that has been in service for more than 50 years.

The program represents advancements in technology with the use of digital engineering, advanced tooling, and a modular, open-architecture approach.

ROY, Utah – Northrop Grumman Corporation successfully completed a series of wind tunnel tests of the LGM-35A Sentinel intercontinental ballistic missile (ICBM). Using scaled models of the vehicle, stressed under environments from sub to hypersonic speeds, the robust test campaign validated digital modeling and simulations and proved design maturity of the missile.

“This wind tunnel campaign is an opportunity to put our digitally engineered designs to the test, under conditions that mimic a missile launch,” said Sarah Willoughby, vice president and program manager, Sentinel, Northrop Grumman. “Predictions from the modeling correlated with the testing results, giving us confidence in our modelbased engineering approach. Data from these tests will inform future engineering decisions as we mature the design and continue on a path to deliver this critical capability to the Air Force.”

Wind tunnel testing is a key early step in any missile development program because it determines how a vehicle will perform during flight. A team of engineers created seven comprehensive test campaigns, each with a unique set

Last month, the Utah Governor’s Office of Economic Opportunity awarded Texas Instruments Incorporated (TI) a post-performance tax reduction for its new semiconductor factory in Lehi, Utah. The corporate incentive is part of the state’s Economic Development Tax Increment Financing (EDTIF) program.

“Companies like Texas Instruments continue to invest in Utah because of our world-class business climate and exceptional workforce,” said Gov. Cox. “TI’s new semiconductor factory will solidify Utah as a global semiconductor manufacturing hub for generations to come.”

As part of the agreement, TI plans to add 800 new, high-tech jobs and invest $11 billion in Utah. This investment is the largest economic investment in Utah history.

“We’re excited Texas Instruments has decided to build a second factory in Lehi,” said Ryan Starks, the Office of Economic Opportunity’s executive director. “This new factory will bring significant capital investment to the state along with hundreds of high-tech jobs. This is a big win for the state and Lehi City.”

Texas Instruments designs and makes semiconductors

that are then sold to electronics designers and manufacturers all over the world. With its headquarters in Dallas, TX, the company has design, manufacturing, and sales operations in more than 30 countries with around 33,000 employees worldwide.

“Our decision to build a second fab in Lehi underscores our commitment to Utah, and is a testament to the talented team there who will lay the groundwork for another important chapter in TI’s future,” said Haviv Ilan, TI executive vice president and chief operating officer, and incoming president and chief executive officer.

“With the anticipated growth of semiconductors in electronics, particularly in industrial and automotive, and the passage of the CHIPS and Science Act, there is no better time to further invest in our internal manufacturing capacity.”

TI may receive up to 30% of the additional state taxes it will pay over the 20-year life of the agreement in the form of a Utah Legislature-authorized Economic Development Tax Increment Financing (EDTIF) tax credit (U.C.A. 63N-2-106(2)). Each year TI meets the criteria in its contract with the state, it will qualify for a portion of the total tax credit.

“The federal government recognized at the front end of the pandemic that our country’s reliance on overseas semiconductor manufacturing is a national security issue. This project represents a significant step toward strengthening the U.S. supply chain,” said Scott Cuthbertson, president and CEO of EDCUtah. “Texas Instruments’ commitment of this transformational investment will have a lasting impact on Lehi and Utah’s manufacturing industry for generations.”

“Lehi City has been pleased to have TI as a community partner. TI has brought great opportunities to our city, our state, and our country at a critical time in the semiconductor industry,” said Lehi City Mayor Mark Johnson. “We are excited for our relationship to continue with TI regarding this expansion.”

Timeline: 20 years

Capital investment: $11 billion

Jobs: 800

Wages: $2,444,107,915

New state tax revenue: $111,451,554

EDTIF new state tax credit: 30%

Learn more about the state’s post-performance EDTIF program here.

Under Gov. Spencer J. Cox’s direction, the Governor’s Office of Economic Opportunity provides resources and support for business creation, growth, and recruitment. It also drives increased tourism and film production in Utah. As stewards of Utah’s economy and quality of life, the Economic Opportunity office utilizes federal, state, and private sector resources to administer programs in areas demonstrating the highest potential for economic development and the most opportunity for Utahns.

Texas Instruments Incorporated (Nasdaq: TXN) is a global semiconductor company that designs, manufactures, tests and sells analog and embedded processing chips for markets such as industrial, automotive, personal electronics, communications equipment and enterprise systems.

Our passion to create a better world by making electronics more affordable through semiconductors is alive today, as each generation of innovation builds upon the last to make our technology smaller, more efficient, more reliable and more affordable – making it possible for semiconductors to go into electronics everywhere. We think of this as Engineering Progress. It’s what we do and have been doing for decades. Learn more at TI.com.

SpaceX launched the first of the GPS III satellites in late 2018 and regularly adds satellites to the GPS fleet in orbit.

GPS III satellites are designed to be several times more precise than the previous GPS satellites and use more powerful signals that help improve reception on the ground or in the air. The GPS III satellites’ military signals are designed to be eight times more impervious to signal jamming.

The satellite launched is the sixth of 32 GPS III and GPS III-F satellites that Lockheed Martin Space is contracted to build for the U.S. Space Force.

The military’s space branch maintains the GPS signal-timing system used by the armed forces and that civilians around the world also use for navigation and location finding. The Space Force aims to have at least 27 functioning GPS satellites in orbit. It replaces aging orbiters over time, launching new GPS satellites regularly.

Locations in AZ, NC, TX, FL, WI, MN

Arizona Facility: 1310 N. Hobson Street Gilbert, AZ 85233

Lockheed Martin Space, a 21,000-employee division of Bethesda, Maryland-based Lockheed Martin Corp., invested $128 million to modify a large clean room and testing chamber at its campus outside Waterton Canyon southwest of Denver after it won the initial GPS III satellite contract nearly 15 years ago.

A SpaceX rocket blasted off from a Florida launchpad and carried the newest, Colorado-made global positioning system satellite to orbit for the U.S. Space Force.

The Falcon 9 rocket took off from the Space launch complex on Cape Canaveral and 89 minutes later released the GPS spacecraft into a transfer orbit. From there, the satellite will move to its operating destination about 12,500 miles above the Earth.

Jefferson County-based Lockheed Martin Space built the GPS III satellite on the company’s campus in the foothills southwest of Denver. It’s the sixth of the modernized global positioning satellites the company designed and builds for

The space company has finished construction on the first 10 of the satellites, a handful of which are through testing and are waiting to be called up by the Space Force and launched. The GPS III fleet of satellites is expected to cost $16 billion when it’s finally completed.

Lockheed Martin Space won contracts in 2009 to design and build the first 10 orbiters and later won a second contract worth $7.2 billion to build the follow-on series of improved satellites, which became known as GPS III-F. The GPS III-F satellites are the ones Lockheed Martin Space is starting to build in Colorado now.

Fullerton Tools 989-799-4550

Horizon Carbide Tool __ 480-968-0957

Industrial Supply ___ 800-288-3838

Machine Tool & Cutter Grinding 435-512-4416

NTK Cutting Tools 425-365-3613

SCHUNK 919-452-4535

THINBIT 888-THINBIT

Von Ruden Manufacturing 763-682-0322

Drilling/ Threading Tools

Industrial Supply 800-288-3838

Dormer Pramet 801-230-6794

Dormer Pramet 720-837-3232

Fullerton Tools 989-799-4550

Drills

Fullerton Tools 989-799-4550

Machine Tool & Cutter Grinding 435-512-4416

Dust Collectors, Filtration Equip.

Star Metal Fluids 800-367-9966

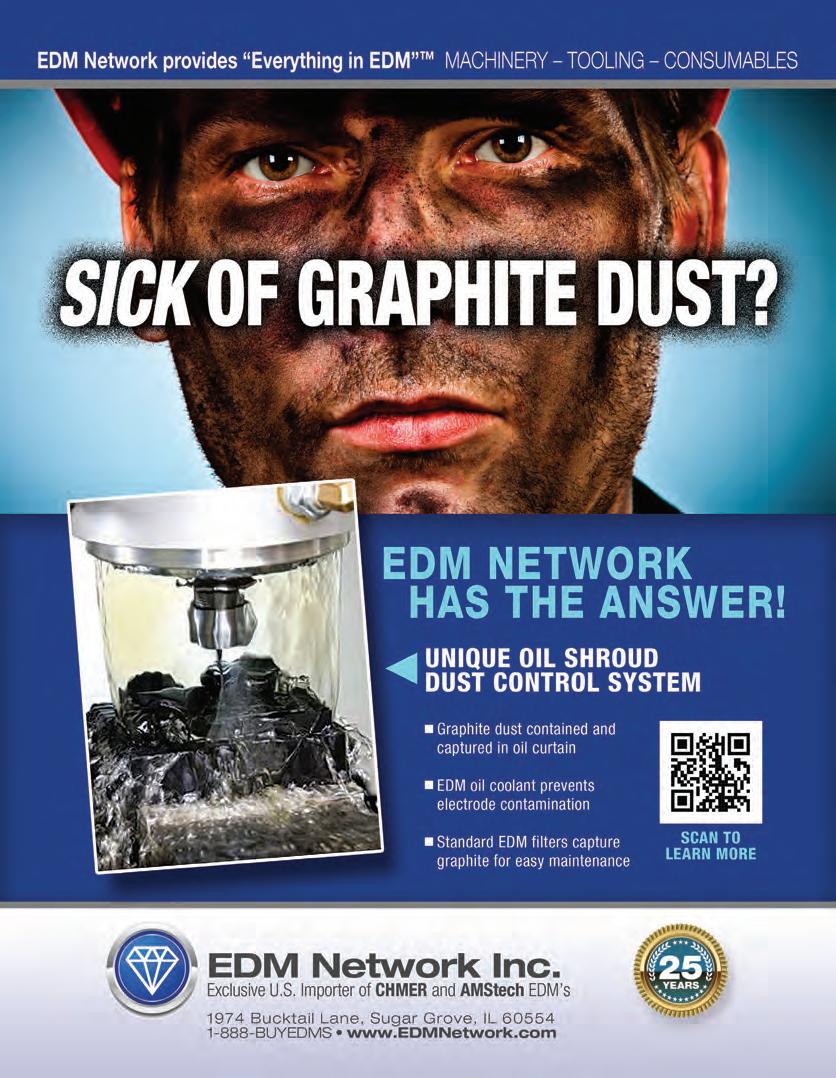

EDM Materials & Supplies

Desert EDM Sales 480-816-6300

EDM Network 480-836-1782

EDM Perform. Access. ___ 800-336-2946

Star Metal Fluids

Royal Products ______

Gage Blocks

___ 800-741-7756

Knives: Replacement

Lifting & Material Handling

Machine Tool Cool. Filtration Chipblaster 310-502-4184

Star Metal Fluids 800-367-9966

Milling and Turning Products

Dormer Pramet _____ 801-230-6794

Dormer Pramet 720-837-3232

Industrial Supply 800-288-3838

Von Ruden Manufacturing 763-682-0322

Parts Washing Equipment

Star Metal Fluids 800-367-9966

Power Tools

Ingersoll Rand 206-472-0826

R8 Quick Change Tool System

Royal Products 800-645-4174

Robot Accessories

SCHUNK 919-452-4535

Rota-Rack Parts Accumulator

Royal Products _______ 800-645-4174

Solvents /Degreasing Agents

Castrol 800-894-7773

Hasco Oil 562-595-8491

Star Metal Fluids 800-367-9966

Spindles

GMN USA 800-686-1679

Sulli Tool & Supply 714-863-6019

Surface Plates

Starrett 949-382-4123

Toolholding

Hainbuch 818-970-7874

Industrial Supply 800-288-3838

Tooling for Swiss Type Lathe

NTK Cutting Tools 425-365-3613

Vices and Vice Jaws

Desert EDM Sales 480-816-6300

Hainbuch 818-970-7874

Sulli Tool & Supply 714-863-6019

Waterjet Cutting Abrasives

Barton International 800-741-7756

Workholding

Hainbuch ________ 818-970-7874

______

Renishaw 847-286-9953 Total Qual. Syst. ______ 480-377-6422

Zeiss Industrial Metrology 800-327-9735

Barcode Scanners

KEYENCE _____720-614-9241

CMM

Zeiss Industrial Metrology 800-327-9735

Gauging Equipment

Gage Lab Products 801-716-2972

Innovative Measuring Systems 602-527-5488

Klontech Industrial Sales 480-948-1871

LK Metrology 949-716-4440

Renishaw _________ 847-286-9953

Starrett 949-382-4123

Total Quality Systems 720-338-2581

Laser Marking Systems

KEYENCE _____720-614-9241

Measurement Systems

KEYENCE _____720-614-9241

Starrett 949-382-4123

Metrology Instruments

Gage Lab Products 801-716-2972

Innovative Measuring Systems 602-527-5488

KEYENCE _____ _____720-614-9241

Klontech Industrial Sales

LK Metrology

Renishaw

Starrett

Total Quality Systems

Zeiss Industrial Metrology

KEYENCE _____ Optical Comparators

Gage Lab Products

Innovative Measuring Systems

Klontech Industrial Sales

LK Metrology

Renishaw

Total Quality Systems

Sensors: Contact & Optical

Zeiss Industrial Metrology

Video Measuring Systems

Gage Lab Products

Klontech Industrial Sales

Total Quality Systems

Horizon Carbide Tool Utah Metal Works, Inc.

Pre-Honed Tube

Renishaw CHIP CUTTING

CNC

Bronze Coastal Metals 800-811-7466

Olympic Metals 303-286-9700

Carbon Coastal Metals 800-811-7466

Ryerson __________

Copper

303-227-6310

Olympic Metals 303-286-9700

Garnet Abrasives

Barton International 800-741-7756

Metals: Bar & Plate

AZ Tool Steel LLC 480-784-1600

Coastal Metals 800-811-7466

Ryerson 303-227-6310

TW Metals 800-203-8000

Mold Steel

AZ Tool Steel LLC 480-784-1600

Nickel Alloys

AZ Tool Steel LLC 480-784-1600

Ryerson _________ 303-227-6310

TW Metals ________ 800-203-8000

United Perform. Metals 317-946-0025

Plate-Precision Saw Cut Erickson Metals 877-543-6061

Titanium

Laube Titanium___805-388-1050x124

METAL DISTRIBUTORS

Erickson Metals 877-543-6061

Coastal Metals 800-811-7466

Laube Titanium __ 805-388-1050x124

Olympic Metals 303-286-9700

Ryerson 303-227-6310

TW Metals 800-203-8000

United Perform. Metals 317-946-0025

Western States Metals _ 801-978-0562

NEW MACHINERY

3D Metal/ Additive Manufacturing Machines Production Machine Tools 425-881-1200

Iron Workers ______888-289-9100

Bystronic Inc__

Latitude Machinery

Production Machine Tools

Rotary Surface Grinders

DCM Tech _________

Sawing Machines

Action Machinery

Fullerton Tools

Latitude Machinery

Production Machine Tools

Shearing Machines

Action Machinery

Bystronic Inc__

Latitude Machinery

S&S Machinery Sales