Vol. 12, No . 3, May / June 2019

Rocky Mountain Edition (CO, UT, MT, WY, ID.)

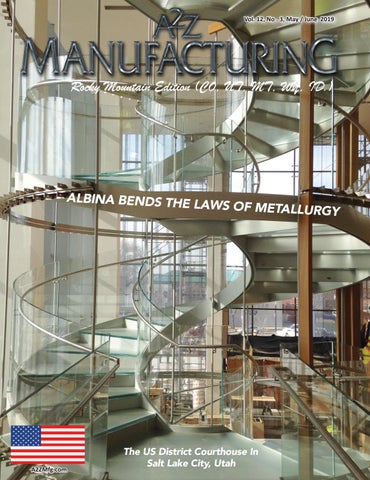

ALBINA BENDS THE LAWS

A2ZMfg.com

OF METALLURGY

The US District Courthouse In Salt Lake City, Utah

Vol. 12, No . 3, May / June 2019

Rocky Mountain Edition (CO, UT, MT, WY, ID.)

ALBINA BENDS THE LAWS

A2ZMfg.com

OF METALLURGY

The US District Courthouse In Salt Lake City, Utah