Vol. 28, No. 2, March / Apr 2023 Southwest Edition (AZ, NV and NM) Formally Introducing YOUR Next Metals Service Supplier In Arizona

YOUR MACHINE TOOL BANK BANTERRA.BANK | MEMBER FDIC Contact Us Today For Your Machine Tool Financing Needs Why Shops Choose Banterra Bank Loan products designed speci cally for machine shops World-class deposit products including Treasury Management Industry-leading service with local decisions Bank commitment to Made In USA and Made In Arizona values ARIZONA DIVISION 950 W. Elliot Rd., Suite 114 | Tempe, AZ 15100 N. 78TH Way | Scottsdale, AZ 480-645-9005 Banterramachinetool.com

BUILDING LOANS EQUIPMENT LOANS SBA LOANS DEBT CONSOLIDATION LINES OF CREDIT BUSINESS CHECKING AND CASH MANAGEMENT

Product Offerings

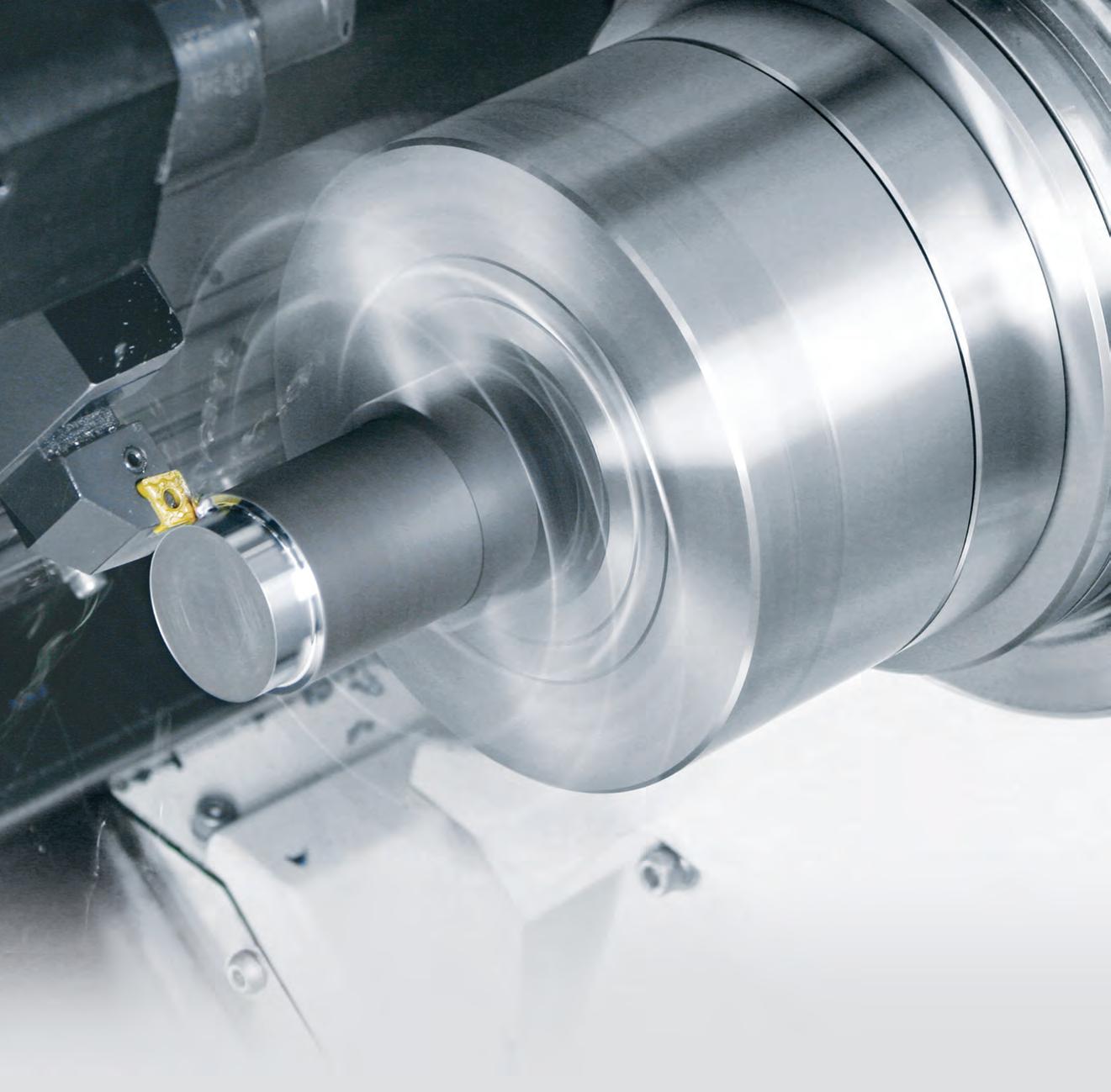

GROOVING THREADING PARTING BORING TURNING FACE GROOVING CUSTOM TOOLING FORM TOOLING MILL TOOLING Follow us on: 888-THINBIT | WWW.THINBIT.COM

Training for leadership is something frequently done in large corporations. Often termed some version of a high potential program (HiPo), it is a structured program designed to find talented employees who have high potential for growth. Organizations design these programs to develop leaders for the future of their organization. Chosen employees are those who innovate and improve company processes.

In smaller companies, preparing future leaders is just as critical, though you often won’t see formal HiPo programs in place. There just aren’t the resources available for this task. Still, every owner and business head should not leave their future leaders to chance.

A simple but not often used practice is to look for leaders instead of promoting bosses. Impactful leaders usually exhibit common behaviors. It’s not who you need to look for, but what you need to look for. Bosses tend to be more about the power of their position, while a good leader looks at the influence of their position.

Here is what the Denison Leadership Development 360 Survey, used by thousands of manufacturers over the past 25+ years, says are the top five drivers of what bosses, peers, and direct reports see in effective leaders:

1. Has earned the confidence and trust of others. They have gained respect and give respect. They are dependable, accountable and a model employee. People will probably describe this employee as a good person, knowledgeable and a hard worker.

2. Engages others in ways that ensure buy-in and commitment. This person works well with everyone. They are good at setting up informal networks with people throughout the facility. They are a good negotiator, setting their ego aside for the good of the organization. They understand success is about we, not me. They are probably known for having good suggestions, but also listen to others’ suggestions.

3. Builds effective teams that get the job done. People who are effective leaders are natural coaches. They understand the key to success for any team is to develop the people who work for them. This person’s boss has probably noticed they are naturally a good trainer. Note: this person might be an excellent candidate to manage an apprenticeship program.

4. Serves as a model that creates change in other parts of the organization. This person would not be described as negative, and people probably refer to them as a problem-solver.

5. Provides employees with a clear mission that gives meaning and direction to their work. They get how all the various parts of the organization fit together and what it takes for it to be successful. They are a good communicator and are good at sharing information with others.

Companies with great cultures never leave anything to chance. With everything being equal, they go the distance. They take the time to carefully promote future leaders and by doing so, put themselves ahead of their competition. And remember, talented people aren’t always tenured employees or those most visible in the organizational hierarchy. Use these 5 Denison Leadership Characteristics, and see if it yields a different set of leaders than you would have otherwise planned for. In closing, God bless our troops and I wish you continued success.

Linda Daly,Publisher

Feature Articles 1,36-37,42-43

Feature Articles........... 46-47,52-53,58-59

Buyers Guide Equipment...............73-81

Index of Advertisers 94 Editorial.................................Throughout

Published by: A2Z Manufacturing

PUBLISHER/EDITOR

Linda Daly

linda@a2zMANUFACTURING.com

Address: 1538 E La Vieve Lane Tempe, AZ 85284

Telephone: (602) 412-7696

Kim Carpenter

Takashi Sato

Gene Wirth

Published bi-monthly to keep precision manufacturers abreast of news and to supply a viable vendor source for the industry.

Circulation: The A2Z MANUFACTURING has compiled and maintains a master list of approximately 8500 people actively engaged in the precision manufacturing Industry. It has an estimated pass on readership of more than 19,300 people.

Advertising Rates, deadlines and mechanical requirements furnished upon request or you can go to A2ZMANUFACTURING.com.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

CONTRIBUTORS

Announcements. 6-19

Buyers Guide Processes 82-93 Card Gallery 73-93

Cover

A2Z MANUFACTURING SW • 4 • March / Apr 2023 Formally Introducing YOUR Next Metals Service Supplier In Arizona . BASIC METALS. Editors Corner

A2Z MANUFACTURING SW • 5 • March / Apr 2023 When you need to add 5-axis capability to your 3-axis mill, Haas dual-axis rotary tables and indexers are the perfect bolt-on solutions for machining complex parts. YOUR ONE SOURCE FOR THE BEST SELECTION IN AUTOMATION SYSTEMS HAAS FACTORY OUTLET A Division of Ellison Machinery Co. LLC 1610 S. Priest Dr., Ste. 101, Tempe, AZ 85281 | HaasCNC.com | 480.968.5877 Sales & Service Scan for our complete line of integrated automation products. Haas Integrated Automation Systems. Making your job as a machinist easier. Optional Automation • 4th- and 5th-Axis Rotaries • Sub-Spindles • Parts Catcher System • Auto Door for Mills and Lathes • Automatic Coolant Refill Haas Bar Feeder All-inclusive design, with plug-and-play capabilities to Haas lathes Pallet Pool Systems • 3-Station for VF-2YT/SS, VM-2 • 6-Station for EC-400 • 6-Station for VC-400/SS • 6-Station for UMC-1250/SS • 10-Station for UMC-750/1000/SS • 10- or- 20-Station for UMC-500/SS Automatic Parts Loaders • Turning Center APL • VMC APL • Small UMC APL Robot Systems • HRP-1 System – 7 kg capacity • HRP-2 System – 25 kg capacity • HRP-3 System – 50 kg capacity

Announcements & Releases

Haas Factory Outlet-Phoenix Invites Machinists to CNC Mill & Lathe G&M Code Programing Courses

Mill and lathe classes are scheduled every other month. Each course consists of 3 days of hands-on instruction led by a Haas Certified Instructor. Students will learn the basics of the Haas control, operation of machines, and Haas programming using G & M codes. Classes are free to all Haas CNC machine owners and operators. Classes are held Monday through Wednesday from 2:00 P.M. to 5:30 P.M.

Please join us for an upcoming session of the Haas CNC training. We recommend registering as early as possible as class sizes are limited.

Mill Training Class — 3/22 - 3/22

Lathe Training Class — 4/17 - 4/19

Training is held at Haas Factory Outlet- Phoenix, a Division of Ellison Machinery facility located at 1610 S Priest Drive, #101 Tempe, AZ 85281. To register and for additional information visit www.EllisonAZ.com or call 480-968-5877.

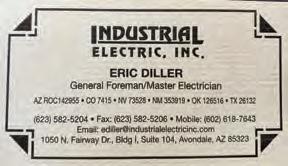

KD Capital Equipment Is Very Excited About The Addition Of Bill Bursik To Our Team

KD Capital Equipment is very excited about the addition of Bill Bursik to our team. Bill brings a wealth of experience and professionalism in particular in the area of specialty

cnc turning applications where for many years he was in charge of overseeing engineering and turnkey projects for major machine tool manufacturers. In addition, his technical expertise and 31 years of sales management experience for a major machine tool distributor will no doubt provide our organization and the used machine tool marketplace a tremendous resource for equipment values and manufacturing solutions for our valued customers. Please feel free to reach out to Bill for

A2Z MANUFACTURING SW • 6 • March / Apr 2023 Announcements Con’t Next Page

ALUMINUM,

ALLOYS 1138 W Watkins St, Phoenix AZ 85007 623-582-6544 Sales@RMGMachining.com 602-254-4173 Sales@ValleyMachineWorks.com BREAKDOWN, METAL SPRAYING WATERJET, PLASMA & LASER CUTTING STICK, MIG, TIG & PORTABLE WELDING FORKLIFT FORK STRAIGHTENING CNC,

STAINLESS, BRASS, PLASTIC, AND

SWISS, MILL & LATHE DESIGN, POLISHING, CAD, PACKAGING

• Latest Multi Function and 5 axis Technology from OKUMA

• Latest Multi Function and 5 axis Technology from OKUMA

• NEW Drill Tap Centers from NOMURA

• NEW Drill Tap Centers from NOMURA

• 7 Axis Swiss Turning from TSUGAMI

• 7 Axis Swiss Turning from TSUGAMI

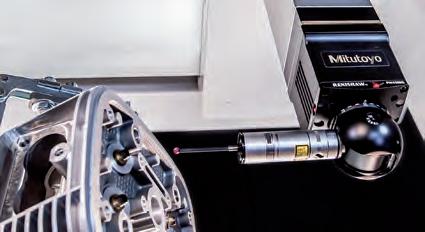

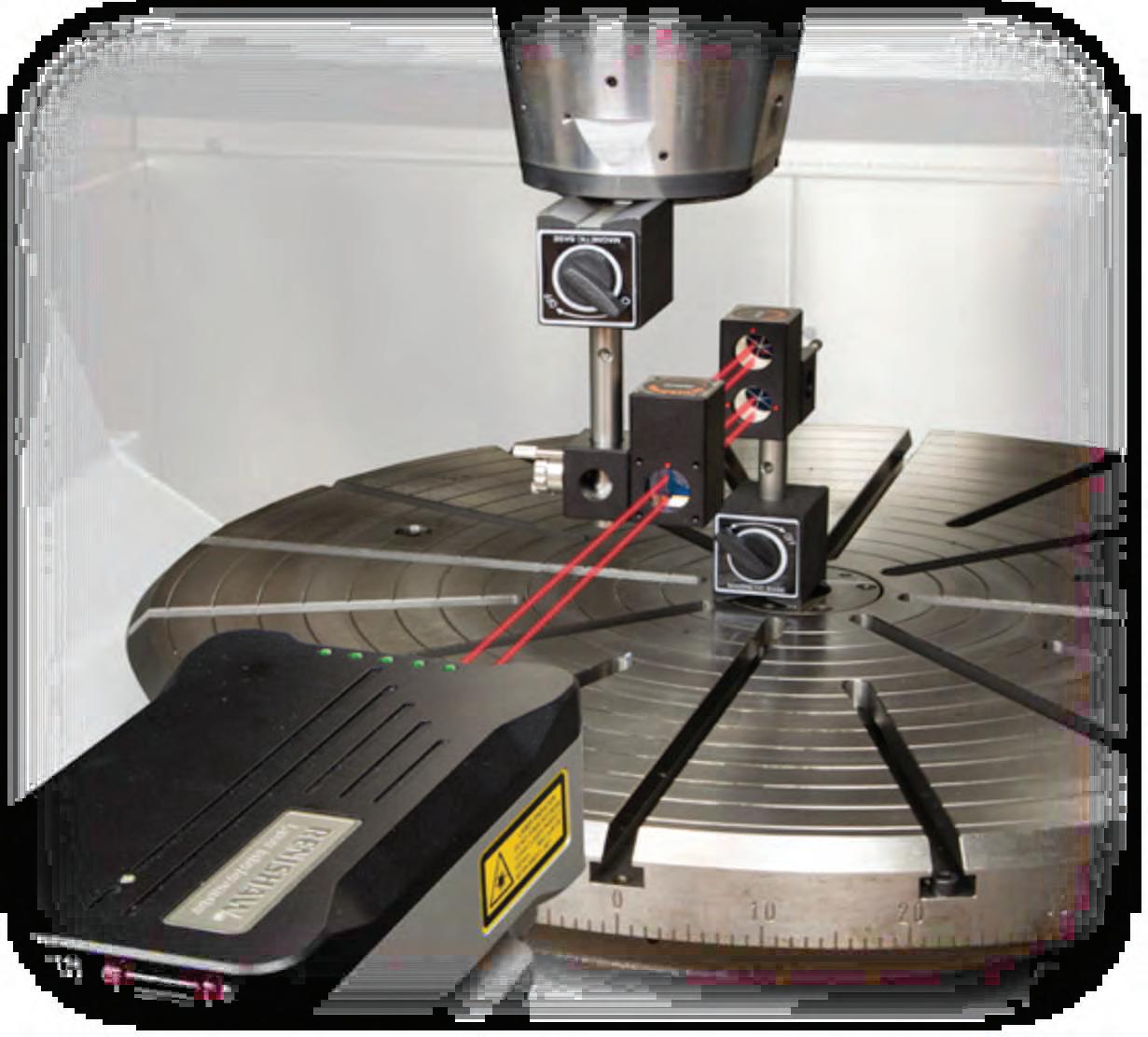

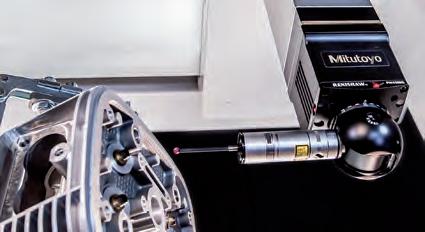

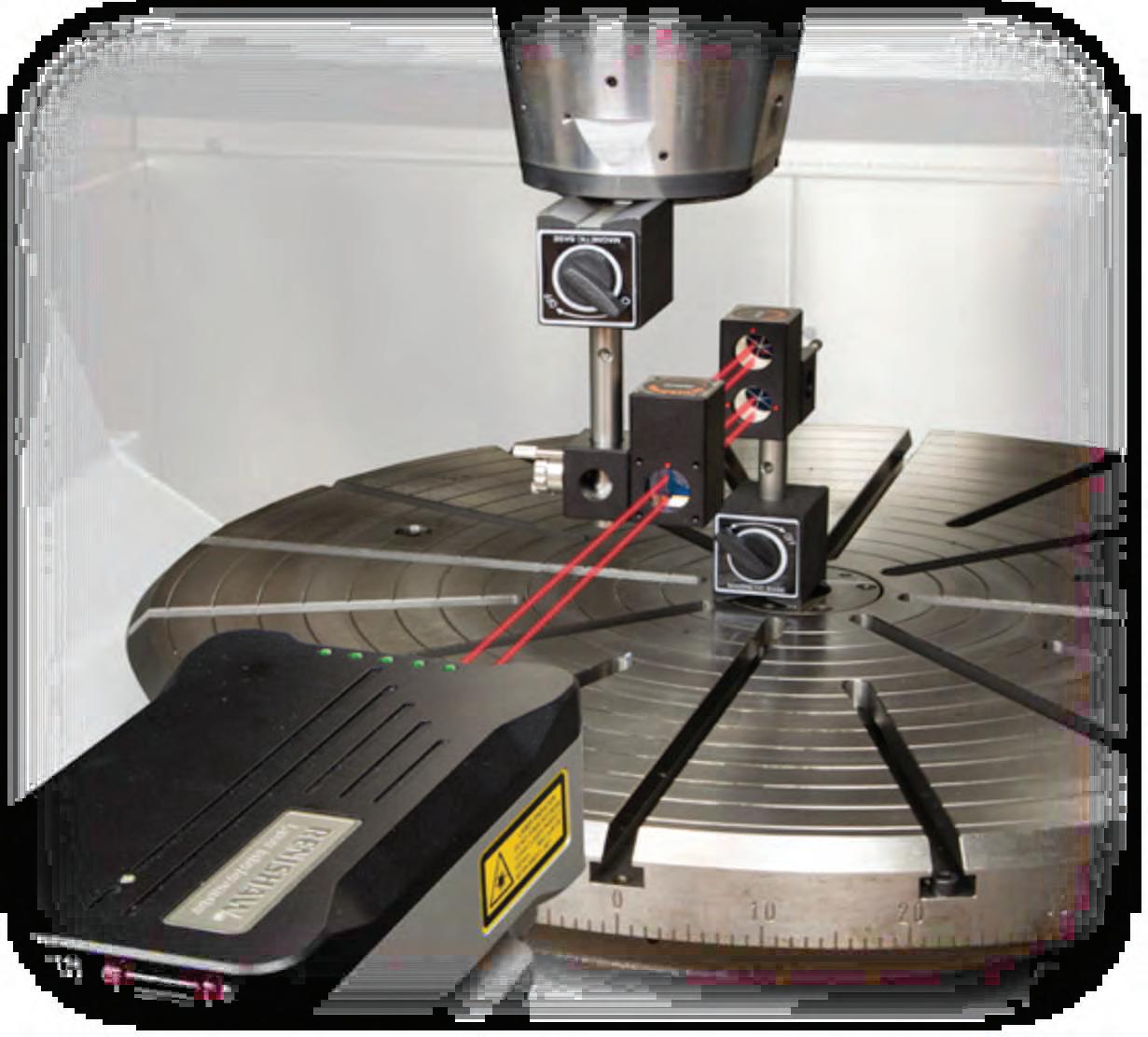

• Shop Floor Gauging from RENISHAW

• Shop Floor Gauging from RENISHAW

• Quick change technologies

• Quick change technologies

• Advanced Tooling

• Advanced Tooling

• Set up reduction

• Set up reduction

• Tool presetting

• Tool presetting

• And much more

• And much more

A2Z MANUFACTURING SW • 7 • March / Apr 2023 ARIZONA CNC OPEN HOUSE

22nd 10:00am

3:00pm ARIZONA CNC EQUIPMENT 1205

Lane, Suite #2 Tempe,

www.arizonacnc.com 480-615-6353

MARCH

–

South Park

AZ 85281

Lunch

Space Is Limited Register Today REGISTER ARIZONA CNC OPEN HOUSE

22nd 10:00am

3:00pm ARIZONA CNC EQUIPMENT 1205 South Park Lane, Suite #2 Tempe, AZ 85281 www.arizonacnc.com 480-615-6353

Will Be Served

MARCH

–

Lunch

Be Served Space Is Limited Register Today REGISTER

Will

your CNC Machining or Fabrication machinery needs. Welcome to our team Bill!

Thank you,

Jill Chadwell

KD Capital Equipment, LLC.

Direct: 480-212-0580

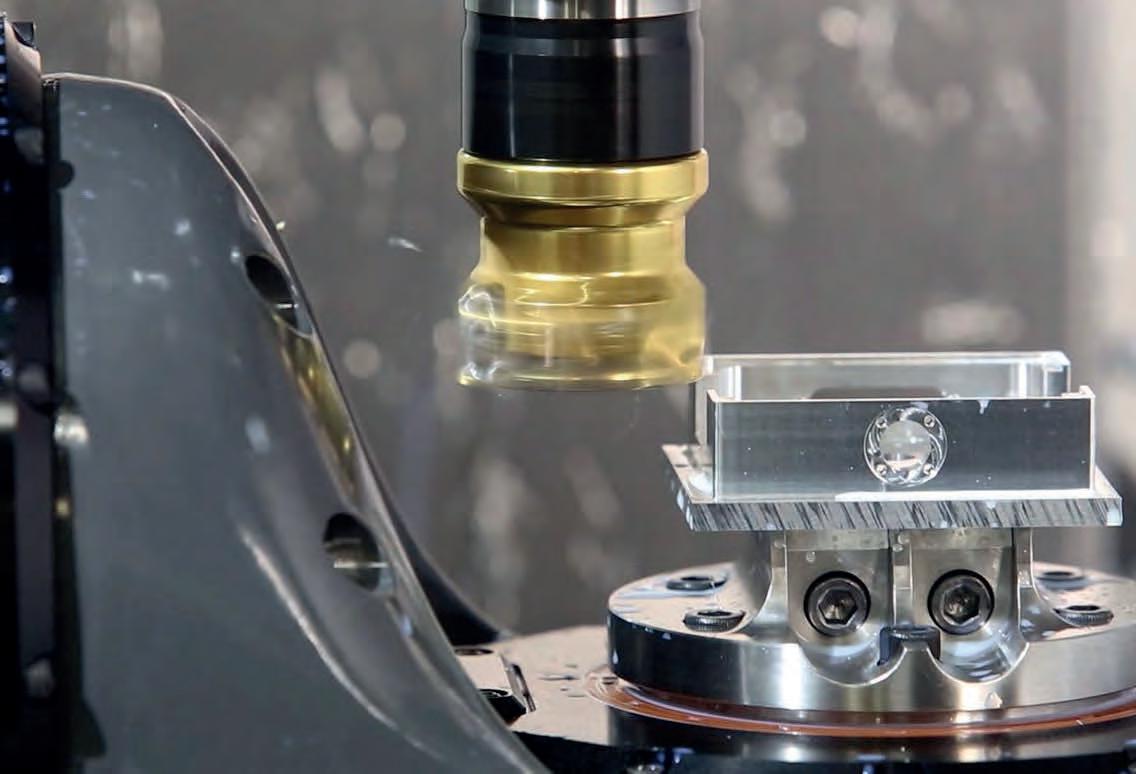

MPC Machines Expands With New Larger Facility and 2nd Star SR-38/B CNC Swiss-Type Automatic Lathe

MPC Machines is pleased to announce that they are expanding their capabilities for customers. Last year, the precision machine shop, in business since 2009, moved from their 4500 square foot facility into a new state-of-the art building, nearly 50% larger, but also with a 10,000 back property for storage.

In their new facility, they had the space to add a second Star Swiss-type machine, the Star SR-38 Type B 10-Axis CNC Swisstype Automatic Lathe.

Founder owner Jorge Ochoa and his wife Sofia came to this country 14 years ago, in 2009, where they started up their machine shop in Brea, California. The two made the decision to move

the minority-owned business to Mesa, Arizona 6 years later, Jorge says, because Arizona offered a much more business friendly environment.

Jorge says, “We are proactively adding products and capabilities that support our customers’ production needs. Though we are well equipped to handle our customers’ R&D needs, we additionally have the capability to support our customers’ production requirements. The Star SR38/B, our 2nd is ideal for this.”

MPC Machines is renowned for their ability to machine very complex parts.

A2Z MANUFACTURING SW • 8 • March / Apr 2023

& Releases Continued Announcements Continued Page 10

Announcements

CUSTOM-BUILT BUSINESS SUCCESS.

Deposit products offered by Alerus Financial N.A. Member FDIC.

COMMERCIAL BANKING

ALERUS.COM/BUSINESS

With a combination of convenient technology and personalized guidance, Alerus helps you manufacture long-term success.

BANK WITH PURPOSE.

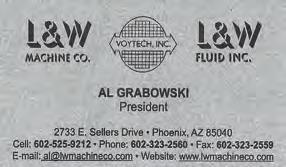

3 Companies Under 1 Roof

Family-Run For 34 Years

Competitive Pricing

11 CNC Swiss Screw Machines

First Light F-35 Helmet Test A Success

Announcements & Releases Continued

The Star SR-38/B offers the following capabilities:

• Rigid machine construction handles bar stock up to 1-1/2” (1.500) diameter

• Built-in main- and sub-spindles and high tool post rigidity ensure exceptional accuracy

• Designed for two-tool turning, heavy material removal, and/or rough and finished tooling

• 8-spindle backworking unit for complex parts production in one operation with the precision and accuracy required by quality critical applications

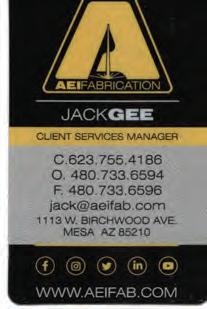

card, they encourage you to contact them.

The recent sled test, conducted with a 103-pound mannequin, is the latest sign that the JPO can make good on its promise to finish the three design fixes by November, allowing the military services to lift restrictions on lightweight pilots flying the F-35 Last year, Defense News first repor ted that pilots under 136 pounds were barred from flying the fifth-generation aircraft after testers discovered an increased r isk of neck damage to lightweight pilots ejecting from the plane. The US Air Force has also acknowledged an “elevated level of r isk” for pilots between 136 and 165 pounds.

The prototype helmet tested weighs about 4.63 pounds, approximately 6 ounces lighter than the orig inal Gen III helmet, and is designed to ease some strain on smaller pilots’ nec ks during ejection

• Programmable B axis for angular machining on both spindles

• Motion Control System significantly reduces idle machine time

The first test of a new, lightweight F-35 helmet was successful, according to the prog ram office, a promising sign that the Pentagon can qualify and implement all three fixes to the jet’s escape system by the end of the year.

MPC Machines offers Swiss-type machining as well as milling and turning capabilities, and they are able to run parts 24x7. They additionally have high speed saws that allow them to cut up to 6000 parts per day, Jorge says.

Recently, at Holloman Air Force Base, New Mexico, Lockheed Martin’s F-35 conducted the fir st test combining all three solutions designed to reduce the r isk of neck injury to F-35 pilots during ejection, according to spokesman Joe DellaVedova. Once the full gamut of testing is completed, hopefully by the end of the summer, the JPO can beg in implementing the two modifications to the ejection seat and issuing the new Generation III “light” helmet to the fleet, he said

Landmark Solutions is proud to announce the addition of Matt Kassman as Applications Specialist to their growing Arizona sales and service team. An Arizona native, Matt brings with him many years of experience in field sales serving a variety of industries. Matt looks forward to focusing on the metal fabrication industry in Arizona and being a key part of the growing Landmark Southwest customer support team.

Although the test was the fir st test of the new helmet, the JPO, Loc kheed Mar tin and seat-maker Mar tin Baker have conducted at least seven other tests with the latest version of the seat, which is equipped with two modifications designed to reduce r isk to pilots.The fixes to the ejection seat itself include a switch for lightweight pilots that will delay deployment of the main parachute, and a “head support panel,” a fabric panel sewn between the parachute r isers that will protect the pilot’s head from moving backward dur ing the parachute opening.

RM

To learn more about MPC Machines and how they can support your machining needs, both prototype and production, contact them at: mpcmachines@msn.com or 714-271-5319. Also, if you are a sales industry professional interested in adding a superior machine shop to your line

Machining Adds Space And New

The prog ram office has about another 10 tests planned, which will use a mix of low-, middle- and high-weight mannequins.

“This initial test had promising results and the F-35 enterpr ise is on a path to qualify the helmet . by the end of this summer,” DellaVedova told Defense News. “The lighter helmet expected to be fielded by the end of the year is in line with the seat timeframe as well.”

its acquisition

Announcements Continued Page 12 A2Z MANUFACTURING SW • 10 • March / Apr 2023

Matt Kassman Joins Landmark Solutions

Garrison

Equipment

Garrison Machining

is

of

A 2 Z MANUFACTURING SW 41 EDM Wir e/ Sinker Sma ll Hol e 14 Machines WATERJET CUTTING UP T O 6 ’ X 12’ 2 Mach ine s LASER NTC 2500 Watt DIE REPAIR & METAL STAMPING SCREW MACHINING Up To 32 M M whitleym achine.com www.s tp-az.com 4801 S 35 St, Phoenix Ar izona 8 5040 Tel 602-323-5550 Fax 602-323-9950 Em ail C liff@whitleym achine.com √ √ √

RM

Inc. (RMG)

proud to announce

its neighboring building which adds an

ISO 9001: 2015 Certified √

SPECIALTY TURN PRODUCTS

√ ISO 9001: 2015 Certified √ AS9100 Revision D Certfied √ Family Run For 35 Years √ Competitive Pricing √ 3 Companies - 1 Ownership

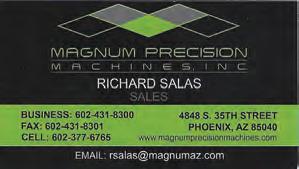

PHOENIX OFFICE P: 602-431-8300 F: 602-431-8301 E: sales@magnumaz.com EL PASO OFFICE P: 915-856-7900 F: 915-857-4700 E: sales@magnumep.com ALBUQUERQUE OFFICE P: 505-345-8389 F: 505-344-7167 E: magnumalb@magnumabq.com www.magnumprecisionmachines.com Contact your MAGNUM Sales Representative, for details on Available Showroom Inventory. Affordable High Quality Saws. RELIABLE SAWS. RELIABLE PEOPLE. www.hydmech.com

3020 South Park Drive ,Tempe, AZ

sales@stp-az.com • Tel: 602-426-9340

STP-AZ.COM

We Manufacturing Complex Intricate Parts Requiring Extreme Precision And Quality

We Are Built For High Production Parts And Can Handle Extremely Tight Tolerances

High Precision Swiss Lathe Machining 24x7

New State-of-the-art

12,500 square foot facility

ISO 9001: 2015 & AS9100D Certified

Our CNC Swiss screw machines can run lights out 24 x 7 Subsidiary of Whitley Machine

Industrial Production Returns to Growth After February’s Storms Subside

additional 16,500 square feet of manufacturing space. This takes the total square footage to 41,500 square feet.

recognition is a testament to the hard work and dedication of our team and our commitment to our valued customers.

RMG has also added a laser cutter and larger press brake to its equipment lineup which will increase its capacity in its fabrication division.Contact: RM Garrison Machining, Inc. (623) 582-6544; admin@rmgmachining.com

KD Capital Equipment, LLC is recognized by Inc. Best in Business

The Federal Reserve reported that industrial production in March rose 1.4%, returning to growth after an unseasonably stormy February knocked it down 2.6%. The report shows total industrial production rose 2.5% at an annualized rate during the first quarter of 2021 despite the losses endured in February by manufacturing, mining, and utilities companies.

KD Capital Equipment, LLC is thrilled to announce that we have been recognized by Inc. Best in Business as one of the top companies making an extraordinary impact in the manufacturing field.

Motor vehicles and parts production, which fell 10% in February, rose 2.8% in March but remained depressed by a persistent shortage of semiconductors. Most durable goods indexes rose between 2% to 3%.

At KD Capital Equipment, we understand that the key to success in the manufacturing industry is staying ahead of the curve in terms of new technologies and innovations. We are constantly exploring new ways to improve our products and services, and we are committed to providing our clients with the latest and most up to date equipment on the market.

The industrial production gauge includes productivity in three sectors: manufacturing, mining, and utilities. Manufacturing production (which excludes mining and utilities output) rose 2.7% in March after falling 3.7% the month before. Mining production improved 2.7%, while utility output fell 11.4% thanks to unseasonably warm March temperatures. Manufacturing output rose 1.9% at an annualized rate.

As a leading provider of high-quality pre-owned manufacturing equipment, KD Capital Equipment has been dedicated to helping our clients improve their technology for over 25 years. Our team of experts work closely with each client to understand their needs and provide solutions that help them increase efficiency, reduce costs, and improve the quality of their products.

We would like to thank our clients for their trust in our company. We look forward to continuing to serve the manufacturing industry and help our clients achieve their business goals.

Capacity utilization in manufacturing rose by 1.9 points, also reversing February losses.

In nondurable manufacturing, the index for the chemicals industry rose 4.1%, and petroleum and coal products rose 5.7%, although neither sector has fully recovered from severe weather damage—the Federal Reserve noted that some chemicals factories remain offline thanks to damage sustained from February’s winter storms. Most nondurable goods indexes rose between 0.9% and 3.0%.

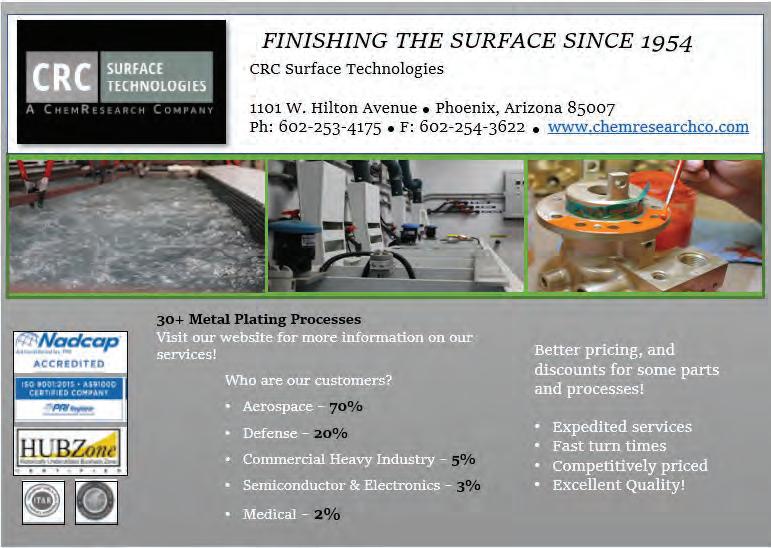

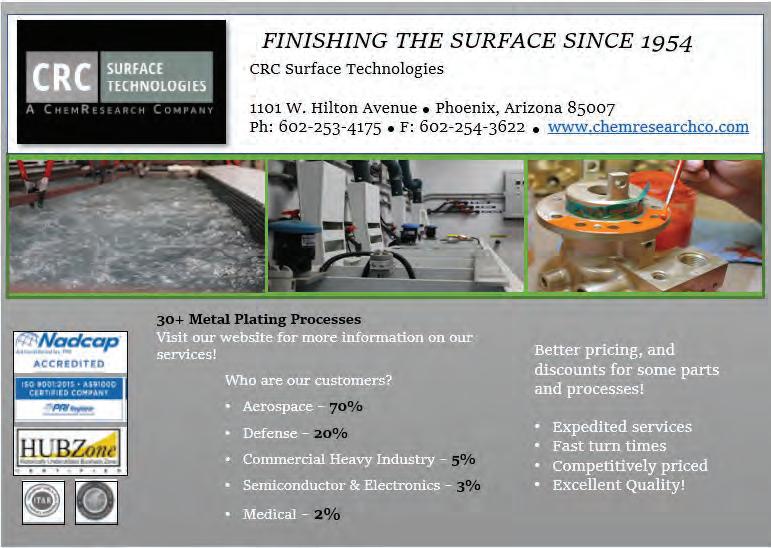

Phoenix Heat Treating Announces another successful NADCAP audit

Almost all market groups saw improvements in March, despite lingering challenges. The Federal Reserve’s index for other manufacturing, which includes publishing and logging, remained the same, but durable goods and nondurable goods indexes rose 3.0% and 2.6%, respectively.

We are humbled to be recognized by Inc. Best in Business for our contributions to the manufacturing industry. This

Phoenix Heat Treating is pleased to announce another successful NADCAP audit. The 5 day audit resulted in three minor findings. As a result, Phoenix Heat Treating has officially been granted NADCAP merit status for

If February was notable for its storminess, March was notable for its heat. The unseasonably warm month coincided with a roughly 10% drop in consumer energy products, and the 11.4% drop in utilitie s utilization was the largest recorded in the history of the index’s 48-year history.

A2Z MANUFACTURING SW • 12 • March / Apr 2023 Announcements & Releases Continued Announcements Continued Page 14

A2Z MANUFACTURING SW • 38 • May / June 2021

SPECIALTY TURN PRODUCTS

Tornos 6 axis Sigma

Tornos MultiSwiss 6x14

EQUIPMENT

FULL 5-AXIS

RANGE UP TO:

WE'RE LOOKING FORWARD TO MEETING AND EXCEEDING YOUR EXPECTATIONS

Announcements & Releases Continued

heat treat processing.

This award recognizes companies who exhibit excellence in their scope and meet rigid audit criteria. Excellence in quality is just one of the reasons why prime aerospace companies and commercial manufacturing companies trust Phoenix Heat Treating for their endothermic, vacuum, aluminum, and salt processing.

Thanks,Charlie Hushek,General Manager

Thanks,Charlie Hushek,General Manager

Introducing Skill UP Arizona,

Apprenticeship and Award Foundation

The Arizona Tooling and Machining Association, or ATMA, the leading trade association for the precision machining industry in Arizona, is rebranding the Arizona Precision Manufacturing Apprenticeship Program, or

AZPMAP, to Skill UP Arizona, Apprenticeship and Award Foundation. Skill UP Arizona will provide apprenticeship opportunities and award scholarships to help workers gain the skills they need to succeed in precision manufacturing.

This announcement came during the association’s annual Board of Directors Invocation dinner on January 12th, 2023. The meeting was attended by ATMA member companies, representatives of the educational and apprenticeship community, and students attending manufacturing programs in their high schools. During a panel discussion of educational partners that followed the announcement, several students shared thoughts on their futures in manufacturing careers and how manufacturers can appeal to younger generations to fill the skills gap.

“We are proud to be able to offer this opportunity to our members,” said ATMA President Rodger Shepherd. “The need for skilled machinists in our state is critical, and this program will help ensure that our member companies have the workforce they need to compete and thrive.”

A2Z MANUFACTURING SW • 14 • March / Apr 2023 Announcements Continued Page 16 Dynamic Machine & Fabrication Corp . 3845 East Winslow Avenue, Phoenix, Arizona 85040 Fax:602-437-8947 Serving the Aerospace/Aircraft, Military, and Commercial Industries Quality System is Certified ISO 9001:201 15 and AS9100" "D" HR-4R HAAS 4-Axis Horizontal Milling Center @ 150” x 66” x 48” Ikegai VTL CNC Lathe @ Ø 55” Diameter OKK VP9000-5-Axis Vertical Milling Center Ø 800 mm x 630 mm In Our 5th Decade of Manufacturing in Arizona 602-437-0339

CAPABILITIES

CAPACITIES

TheHurcoControlhastheflexibilityyouneedforthehighmixofpartsthatcomes throughyourshop.

EquallypowerfulforNCandConversationalProgramming(withtheaddedbonusof NC/ConversationalMerge),theHurcoControlreducessetuptimesoyoucanmake morechips.

Whetheryou’reababyboomer,amillennial,oraGenX-er,timeismoney.Eventhough Bob(left)andCharley(right)arefromdifferentgenerations,theyarebothmachinists whoappreciatetheimportanceofCNCtechnologythat’sdesignedtomakeshopsmore productiveandmoreprofitable.Checkouttheirvideoseries.

Hurco Companies, Inc. | One Technology Way | Indianapolis, IN 46268 | 800.634.2416 | info@hurco.com | HURCO.com | Machines shown with options. Information may change without notice. Double Column Boring MillsHorizontals3-Axis Vertical5-AxisDouble Column BridgeTurning Centers A CONTROL FOR EVERY GENERATION.

Watch the series at Hurco.com/mygeneration (303) 466-3777 FoothillsMachinery.com » Integrated

path simulation » No

click and

» Transform

created automatically for easy 5-sided conversational programming

data entry

Hurco’s 3D Import feature includes 3D DXF technology that now displays all CAD geometry, including splines and Z-depths. Go from “solid to part” seamlessly. Eliminate extra steps. Introducing 3D Import Hurco Companies, Inc. | One Technology Way | Indianapolis, IN 46268 | 800.634.2416 | info@hurco.com | HURCO.com | Information may change without notice. Find out more at HURCO.com/3DImport Contact your local distributor to find out which one of our 65+ models powered by WinMax® will make your shop more profitable D&R Machinery (480)-775-6462 dandrmachinery.com

CAD/CAM and tool

need to enter feature dimensions – simply

cut

Planes

no

required

personal use, and business accounts. With the addition of Arizona Iron Supply, we can accommodate even larger industrial accounts and offer even more equipment and metal inventory to choose from.

We feel privileged to continue to serve Phoenix and surrounding areas. We can’t wait to show you how this development will improve your metal purchasing, metal recycling, and Rolloff Service experience.

The Skill UP Arizona Tools of the Trade scholarship will cover the costs of training for new machinists and existing employees of ATMA member companies. The scholarships will range from $500 to $2000 per individual and will be awarded based on a combination of specific talents or achievements, need, and overall merit expressed through the completion of an online application and a sponsorship from a member of the ATMA. The first-round submission window will open on April 20, 2023, at an ATMA dinner meeting and reception.

Visit one of our two locations to see how this exciting change will benefit you! Davis Metals: (602) 267-7208 / 3322 E. Washington Street, Phoenix, AZ 85034 Arizona Iron Supply: (602) 244-9649 / 130 S 23rd St, Phoenix, AZ 85034

• 7 Axis Swiss Turning from TSUGAMI

• Shop Floor Gauging from RENISHAW

• Quick Change Technologies

• Advanced Tooling

• Set up Reduction

• Tool presetting

• And much more

Landmark Hosts Open House At Metzfab Industries

ATMA has been working to address the skilled labor shortage in Arizona for several years. In 2009, the organization launched the AZPMAP, which has provided training and education opportunities for individuals interested in careers in precision machining. For more information about Skill UP Arizona or the scholarship program, please visit skillupaz.org.

Arizona CNC Announces Their Open House!

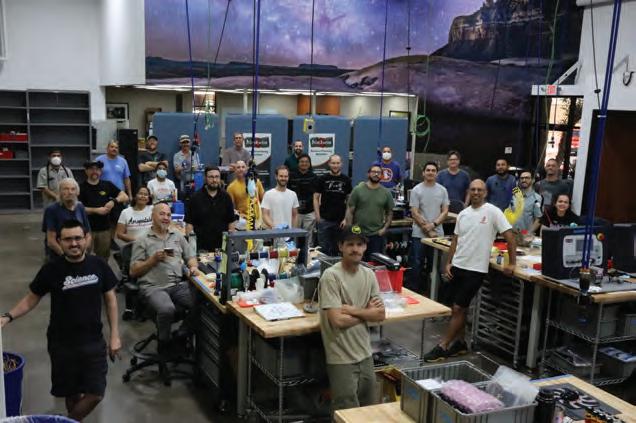

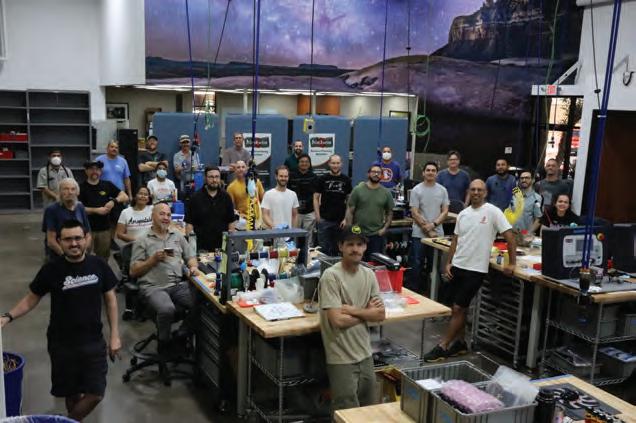

L andmark Solutions held an Open House event at Metzfab Industries in Phoenix earlier this month.

On Wednesday, March 22nd, Arizona CNC will host a Gala Open House. The event, scheduled from 10 am until 3 pm, will include a gourmet meal much like ones their customers have come to expect from Arizona CNC.

During the Open House, guests will have the opportunity to see the following:

• Latest mult function and 5 axis technology from OKUMA

• New Drill Tap centers from NOMURA

Metzfab’s facility was chosen due to their company growth, and the addition of several new state of the art pieces of equipment. Metzfab is always pushing technology and equipment limits in an effort to build and deliver the best parts to their customers.

Space is limited for this event, so register today: https://arizonacnc. com/event-registration/

If you have any questions, call 480615-6353

Landmark Solutions Accepts OMAX 2022 Dealer of the Year Award

Metzfab recently installed a new OMAX 80x 5 axis waterjet, a Bystronic Tube Laser system, a Bystronic ByStar Fiber Laser with full automation, multiple large high performance press brakes, and a fully automated robotic press brake. Installing soon is a new material finishing machine also coming from the Landmark Team.

The Landmark Solutions open house event was a success, and we are all excited to continue our long term partnership with Metzfab. Everyone attending the event were impressed with the new equipment and technology, and how this has helped Metzfab grow and diversify their business.

2022 saw Landmark Solutions’ second consecutive year as OMAX’s Dealer of the Year. OMAX Vice President, Steve Ulmer, proudly presented the award to Fred Mooneyham,

A2Z MANUFACTURING SW • 16 • March / Apr 2023 Announcements & Releases Continued Announcements Continued Page 18 A2Z MANUFACTURING SW • 16 • July / Aug 2022 Announcements Continued Page 18

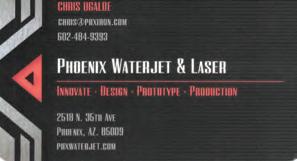

INNOVATION • DESIGN • PROTOTYPE • PRODUCTION

FLOW

Industries Served: Aerospace Military Defense Construction Automotive Marine Oil/Gas Mining Waste Water Metal Fab Hobbyist Heavy Equipment

Quick Turnaround (5-7 Days Typical) • Family-Owned & Operated Since 1981 • 3-D Scanning (Faro Arm Scan & Probe) • Cutting Capability Up” to 6’x12’

BYSTRONIC XPERT 80 PRESS BRAKE

IBF 4020 WATERJET BYSTRONIC 3015 BYSMART LASER

•

PHOENIX WATERJET & LASER 602-484-9393 WWW.PHXWATERJET.COM 2518 North 35th Ave, Phoenix, AZ 85009 I N N O V A T E D E S I G N P R OTOTY P E • P R O DUCTI O N P H O E N X E S T 2 0 0 7

The Ugalde Family

SOUTHWEST EDM Who Better To EDM Your Parts Than The #1 Fanuc EDM Expert in North America! 1125 W Pinnacle Peak Rd, Phoenix, AZ 85027 (623) 826-1025 southwestedm.com steve@southwestedm.com Wire EDM Job Shop With Full CNC Machining And Turning Capabilities... MANUFACTURING Capabilities 6 Matsuura Horizonal Machining Centers • Up to 80 Tools • 4-axis with Dual Pallets 8 Haas Vertical Machining Centers • Travels up to 60” • 4th and 5th Axis 2 Fanuc Wire EDMs • .004” - .012” Diameter • Up to 12” Thick Full Inspection / CMM Capabilities Engineering and Assembly Debur, Tumble, Media Blast, & Coating Type 7 FFL ITAR Registered “In conjunction with DillonAero Manufacturing, we offer EDM plus so much more in machining.” Steve Raucci, Owner Southwest EDM MANUFACTURING CAPABILITIES 6 Matsuura Horizontal Machining 8 Haas Vertical Machining 2 Fanuc Wire EDMs Full Inspection & CCM Capabilities Up to 80 Tools 4-axis w/ Dual Pallets Travels up to 60” 4th & 5th Axis .004”-.012” Diameter Up to 12” Thick Engineering & Assembly Deburr, Tumble, Media Blast, Type 7 FFL Contact: steve.raucci@dillonaero.com

One of the 8 Haas VMCs

Row of Matsuuras

Inspection/CMM Partnering with

Steve with DillonAero Engineer Jay Goodrich

President of Landmark, at the company’s annual sales meeting in Southern California in late January.

Mr. Ulmer remarked that, “every year, the Landmark team has consistently grown OMAX sales in the Southwest region, and they set a new record in 2022.” Accepting the plaque, Mr. Mooneyham responded, “We are proud of our long-term partnership with OMAX and look forward to continuing to grow the waterjet business together.”

Latitude Machinery, LLC, Announces It’s Machining Lines

Latitude Machinery, LLC, a new and used machinery distributor based in Mesa, AZ serving AZ, NM, CO and UT is proud to announce its association with the following machinery manufacturers:

• ESAB - XXL plasma/oxy-fuel water jet and CO2 laser products. ESAB also recently purchased Swift Cut, a UK based company manufacturing entry level plasma and water jet tables.

• Cutlite Penta – The new king in high power fiber lasers. This Italian manufacturer imports 2d and tube lasers from 4-40kw with optional bevel head and automation.

• Bendmak USA – Offering structural fabrication machinery that includes Beam Lines, Angle Lines, Plate Rolls, Section Rolls and weld positioners.

• Cosen Saws – Horizontal Miter, Scissor and Contour Saws, Vertical Contour, Plate and Tilt Frame Saws.

Virtek Vision International – Laser Inspection Equipment and Virtek Vision Iris 3d and LTG Laser Template Generator that eliminates the need for weld fixtures.

MSS Nitr ogen – Nitrogen Generators, Compressed Air Systems and Gas Mixing Systems for lasers. Please visitlatitudemachinery. com or contact sales@latitudemachinery.com for more information.

Announcements & Releases Continued Announcements Continued Page 20

Tram-Tek, Incorporated Is Pleased To Announce The Promotion of Jerry McKechnie To GM Tram-Tek Inc, an ISO9001/AS9100 Revision D certified and woman-owned company, is pleased to announce the promotion of Jerry McKechnie to General Manager. Your one stop shop for

- NEW 10KW BYSTRONIC FIBER LASER - NEW CNC PRESS BREAK - 5-AXIS WATERJET CUTTING (table 13’10” x 6’7”) - CERTIFIED MIG, STICK, & TIG WELDING - LASER CUTTING SERVICES - DEBURRING SERVICES - PUNCH & SHEARING - STAINLESS STEEL FABRICATION - PRECISION SHEET METAL WORK - GENERAL METAL FABRICATION & DESIGN - SAW CUTTING - TUBE BENDING SERVICES - PRODUCT MANUFACTURING & ASSEMBLY - PRODUCTION & PROTOTYPING - MOBILE FABRICATION & WELDING 623.847.4028 Address : 5815 W McLellan Rd Glendale, AZ 85301 Our Phone : 623.847.4028 Email : sales@azwelder.com QUICK TURNAROUND 1-2 Day Lead TIME

623.847.4028

FINANCIAL SOLUTIONS FOR YOUR BUSINESS

Working Capital

is the perfect product when your business has a project or additional expenses. Simple application process and funds up to $250,000. Capital intended to grow your business.

Equipment Finance

up to $500,000 (without financial review) for your new or used equipment acquisitions. With 100% financing and terms up to 84 months, it allows you to reserve cash in your bank account.

offer fast and simple financing solutions for businesses with an opportunity for growth and a need for capital. To learn more, contact: Chris Frans, CLFP 303-261-8200 chris@epicapprovals.com Denver, Colorado Credit approval required.

We

FINANCING FOR: Expansion/RemodelsInventory Equipment; New or Used Marketing/ Website Refresh Strengthen Cash Flow

Announcements & Releases Continued

Jerry isn’t a newcomer to TramTek; he has 24 years of tenure with the company. Jerry came to the company as a Manufacturing Engineer and spent much of his career in the Quality Department. With the support of his team, Jerry spearheaded the company’s ISO and AS9100 certification efforts.

Today, Tram-Tek manufactures parts from raw stock, castings, forgings and complete assemblies, in a variety of materials including aluminum, stainless, titanium, nickel-based, plastic, etc. They run volumes from one-off R & D to production. They offer 5 axis machining, EDM (plunge), NC lathe, ID Grinding, part marking and light assembly.

In addition to machining, Tram-Tek has a department which can provide you with precision springs and wire forms. They manufacture compression and leaf springs, as well as belleville washers, wave washers, snap rings and wire forms to aerospace tolerances and standards.

The company was founded in 1976 by husband and wife team Moe and Jacque Cowin. After the passing of Moe in 1997, Jacque has led Tram-Tek through the company’s continued growth.

Jerry says, “We specialize in quick turnaround with the added distinction of superior quality ((>99% On-Time and 97% Quality Ratings). Tram-Tek has the capability to complete very challenging work, and we also have an extensive network of outside processors that enables us to offer a complete solution to your precision machined product needs.”

The company enjoys low turnover with its exceptional staff, and within its customer base it has long term agreements in place. “We are hiring experienced machinists and inspectors, so qualified applicants are encouraged to apply.

To learn more about how this woman-owned business can support your machining needs, contact them at: 602.305.8100 or email Jerry at jmckechnie@tramtek.com

Totten Tubes is Pleased To Announce The Promotion of Eric Sovis To Branch Manager

A2Z MANUFACTURING SW • 20 • March / Apr 2023

Announcements Continued Page 20

Eric Sovis joined The Totten Tube’s Team in October of 2022 as Branch Manager of their Phoenix location.

OUR SERVICES

CNC FORMING – PRESS BRAKE

CNC MANDREL TUBE BENDING SERVICES

DEBURRING SERVICES

CNC SAW CUTTING

LASER CUTTING SERVICES

CNC MACHINING

3D CAD CAM DESIGN AND ASSEMBLIES

PRECISION TIG, MIG, ARC WELDING & FIXTURING

GENERAL METAL FABRICATION AND DESIGN

TUBE BENDING SERVICES

PRECISION SHEET METAL WORK

PRODUCT MANUFACTURING AND ASSEMBLY

MOBILE FABRICATION AND WELDING

STAINLESS STEEL FABRICATION

Why Choose Us ?

OUR EXPERTISE

MetzFab Industries provides custom metal fabrication and CNC-automated machining for a variety of industrial groups. Based in Phoenix, Arizona, we serve businesses across the U.S..

INDUSTRIES SERVED

MetzFab Industries works with you to ensure your order is completed to your specifications: on time, every time. We have completed projects for applications in a variety of industries.

QUALITY OF SERVICE

We specialize in metal fabrication and welding services of varying complexities for industrial groups. Our past clients include utility companies, truck and auto industries, real estate companies, and others.

Email: sales@metzfab.com Our

602.539.9591 Address : 23012 N 15th Ave, Phoenix, AZ 85027 Already have a project in mind? Contact us today to discuss your idea. Let’s work together! NEW BYSTRONIC PRESS BREAK, NEW FIBER TUBE LASER CUTTING, NEW FIBER FLAT LASER CUTTING,

Phone :

STANDARD AND 5-AXIS WATERJET CUTTING

Your one stop for design, laser cutting, tube laser cutting, 5 axis waterjet cutting and welding.

With him, he brings over 25 years experience in the tube and metal fabrication industry.

Prior to joining Totten Tubes, Eric served as The Director of Sales and Marketing for Atlas Manufacturing, a precision sheet metal fabricator in Minneapolis, MN.

Totten Tubes is a premium domestic distributor of structural steel tubing and pipe for an extensive range of industries and also provides precision laser tube cutting services.

Feel free to reach out to Eric. He can be reached at 602-680-4619 or via email at esovis@tottentubes.com

Semiconductor Supplier Picks Peoria For Manufacturing Plant

HyRel Technologies, a semiconductor modification and contract manufacturing company, announced it began operations at its Peoria plant that spurred creation of 50 new jobs.

HyRel is leveraging its micro-robotic systems to modify microelectronic components and semiconductors for companies from the 20,000-square-foot plant at 7820 W. Golden Lane. The company is also providing component recovery and contract manufacturing services at the facility.HyRel co-founders Scott Baker and Brian Watson said that the company chose to relocate from Torrance, California to the Valley because of its thriving semiconductor industry.“From the Arizona Commerce Authority’s ‘firstof-its-kind’ National Semiconductor Economic Roadmap and dedicated investments to the industry, to the white glove service we’ve received from the city of Peoria

in helping find our facility, we are very excited to launch this chapter and draw upon the wealth of expertise in the West Valley area,” Watson said.

After founding HyRel in 2021, Baker and Watson initially considered Albuquerque, New Mexico and other areas of the Valley as potential locations for the company’s new plant.They chose Peoria because of its closer proximity to semiconductor companies, such as Taiwan Semiconductor Manufacturing Co., which announced plans in December to build a second fab in north Phoenix, increasing its investment from $12 billion to $40 billion and marking one of the largest foreign direct investments in the state and U.S. history.

TSMC will produce 4- and 3-nanometer chips at its two north Phoenix fabs, which are both under construction. The nanometer chips are used in smartphones, AI, computers and autonomous vehicles.

The company aims to expand its vocational training and internship opportunities to increase diversity, retain skilled workers and boost awareness of jobs in the semiconductor industry among Valley students.

“One of my passions is also to develop new talent by providing hands-on educational opportunities for local students,” Watson said.

“We are very excited to announce that we are working with our first class of four interns from Cactus High School to learn and develop robotic systems.”

Additional jobs at HyRel’s Peoria plant will be determined in part by future semiconductor industry demand, Watson said.

A2Z MANUFACTURING SW • 22 • March / Apr 2023 (602) 267-7208 www.davissalvage.co 3322 E Washington Street, Phoenix, AZ 85034 Metal Supply | Roll-Off Services | Metal Recycling | Rags

Manual Lathes, Tool Room CNC Lathes, Big Bore Lathes, 2-6 Axis CNC Lathes, 7-16 Axis Mill/Turn Centers, Swiss CNC Lathes, Large Capacity VTL ’s

Manual Mills, Tool Room CNC Mills, 3 -5 Axis CNC Mills, VMC’s, HMC’s, Automation, FMS Systems, Large Capacity HBM’s

3-5 Axis Laser Solutions, Bending Solutions, Workholding, Quick Change Fixtures, Probe Integration, Inspection/Measurement Equipment, Machine Monitoring, Robotic Integration, Saws, Tombstones.

CNC PROS HAS PARTNERED WITH THE RIGHT SOLUTIONS TO ENSURE OUR TEAM OFFERS YOUR TEAM THE RIGHT TOOL FOR THE JOB.

Z MANUFACTURING SW 23 March / Apr 2023 CONTACT US FOR MORE INFORMATION

WWW.CNC-PROS.COM

602-483-4414

Waterjet Parts

A2Z MANUFACTURING SW • 25 • March / Apr 2023 Landmark Solutions is the exclusive licensed distributor for Bystronic Lasers and Press Brakes, OMAX Waterjets, and Timesavers Finishing Machines in this region. Stay in Touch (714) 393-3783 Info@landmarksolutionscorp.com landmarksolutionscorp.com 925 N. Shepard Anaheim, CA 92806 Best Choice Parts, a Landmark company, stocks thousands of OMAX and Accustream parts at our CA and AZ locations for immediate will-call or guaranteed sameday shipment to your facility. Proud Exclusive Dealer Fiber Lasers • Press Brakes • Automation • Waterjets • CNC Machining • Plasma & Oxy Cutting Deburring • Saws • Plate & Angle Rolling • Nitrogen Generation • Robotic Welding Project Management • Technical Service Your Partner in Manufacturing Equipment

Take your next step with us. Bringing over 100 years of industry experience

Assembly of 1,000th Lockheed Martin F-35 begins

The final assembly of the 1,000th Lockheed Martin F-35 lightning II fighter jet has begun.

The occasion was marked by BAE Systems, the manufacturer of F-35’s rear fuselage sections, which announced delivery of the 1,000th fuselage built at its facility in Samlesbury, Lancashire.

“This is a significant moment for everyone involved in the programme and a testament to the highly-skilled workforce we have in the North West of England,” Cliff Robson, Group Managing Director at BAE Systems Air, is quoted as saying in the company’s press release.

The milestone delivery marks a step forward in the aircraft’s manufacturing effort, which saw a steady production ramp-up, coupled with an increase in foreign sales.

Lockheed Martin has been preparing for this milestone for a while. The

1,000th engine for the jet was delivered by Pratt & Whitney in September 2022, although it is unlikely that the exact engine will be used on the 1,000th fuselage.

In 2021 Lockheed Martin estimated that the 1,000th F-35 would be delivered in 2023. However, the program encountered significant problems in that time, including the discovery that Chinese alloys were being used to manufacture the aircraft.

The discovery resulted in an investigation and deliveries of jet being placed on hold for a month. Lockheed Martin did not comment on the effect of this hurdle and how far back it had set the program.

Despite the difficulties, the F-35 is already by far the most numerous fifth-generation fighter jet in the world. Fewer than 200 F-22s were ever built.

The number of China’s own J-20 are also estimated at 200, while around 10 of Russia’s Sukhoi Su-57s are currently operational. By: Valius Venckunas

A2Z MANUFACTURING SW • 26 • March / Apr 2023 ,I NC. Equipment: Band saws Plate saws Shears Leveling Line Slitter Line Industries: Aerospace Semi-Conductor Medical Kitchen/ Restaurant Defense HVAC Automotive/ Racing Phoenix: Reno/Sparks NV Las Vegas, NV 602.278.5052 775.355.8100 702.719.6061 wwwCoastAluminum.com

ALUMINUM? • ISO9001/AS9120 Certified • Offering Next Day Delivery • 80,000 sq. ft. Facility With Extensive Inventory • Stocking Stainless Steel, Aluminum Stock and Specialty Metals

WHY SELECT COAST

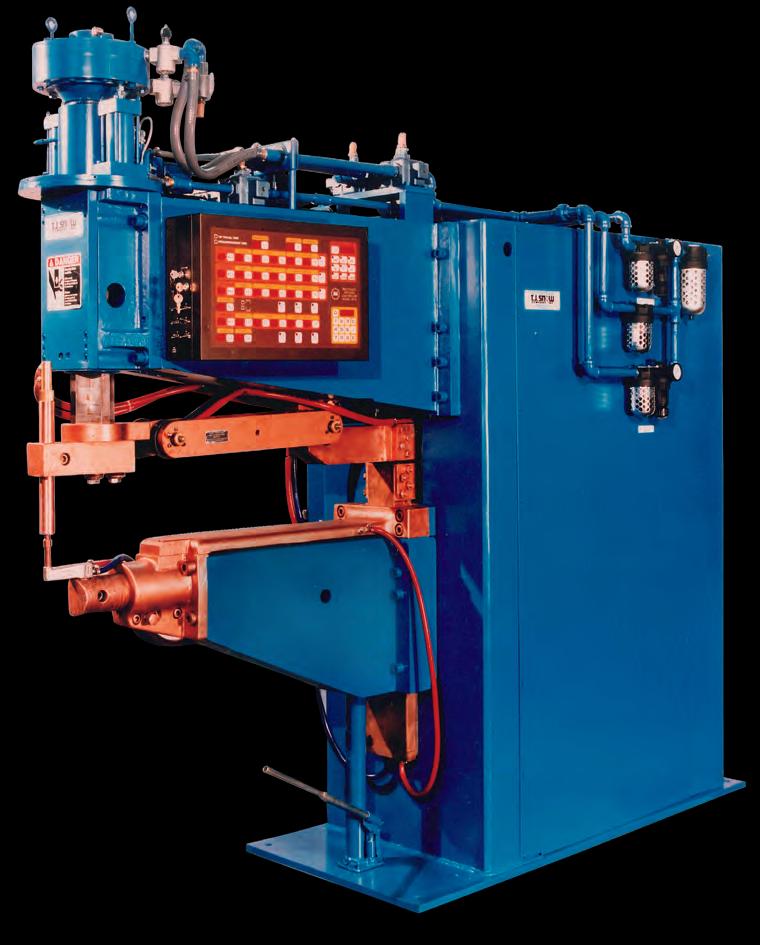

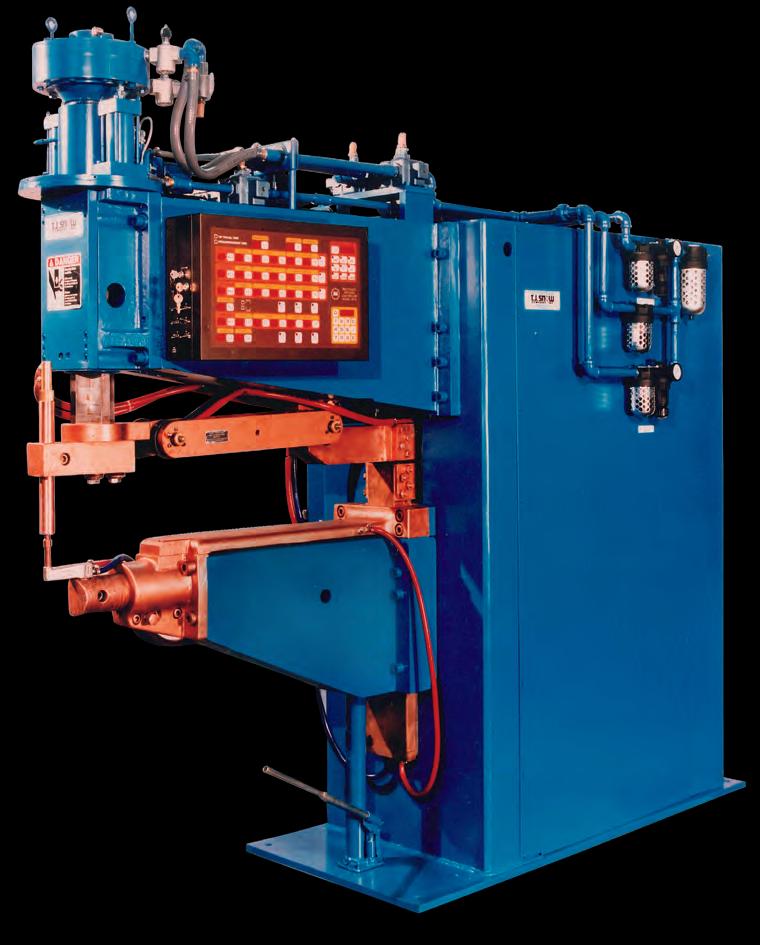

AEROSPACE SPOT SEAM WELDERS & TJSNOW.COM 800.669.7669 NEW OR REFURBISHED MFDC INVERTER POWER SUPPLY TECHNOLOGY USED FOR MIL SPEC AIRCRAFT WELDING OF ALUMINUM AND HIGH TEMP ALLOYS &

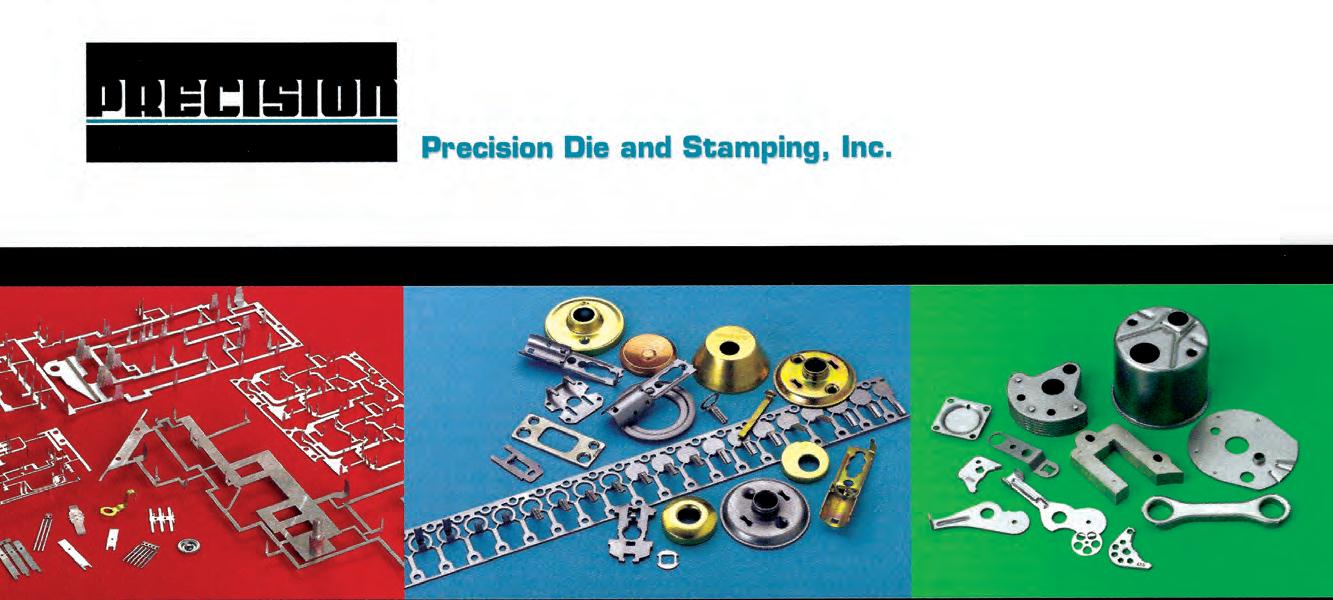

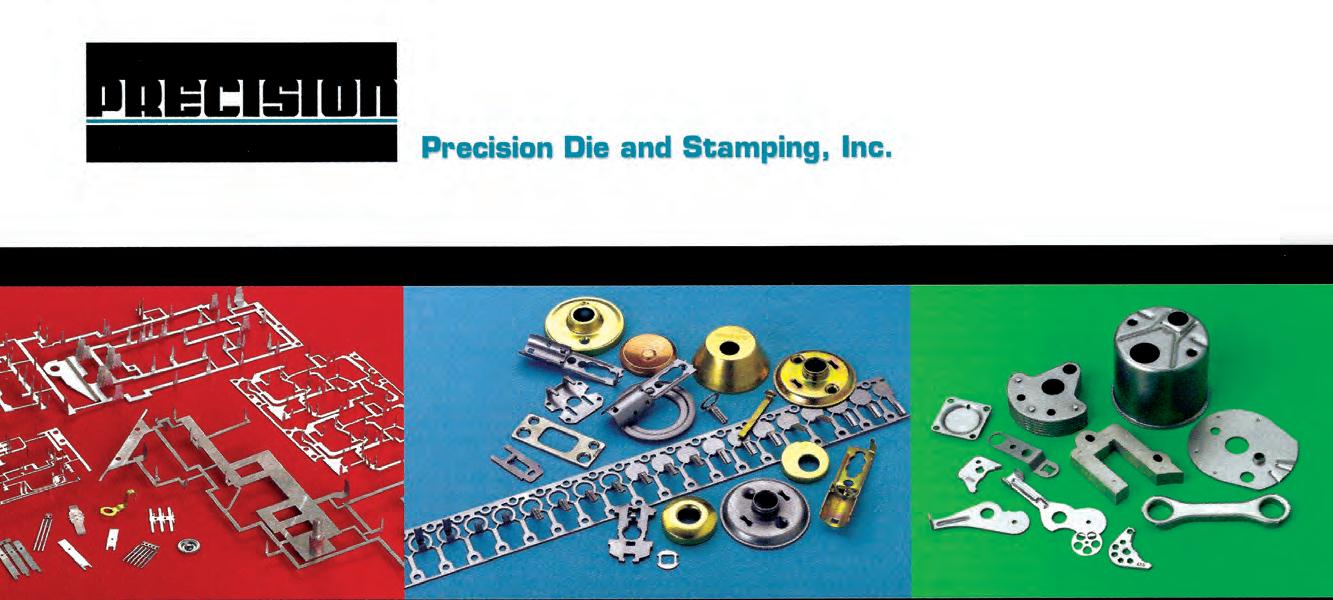

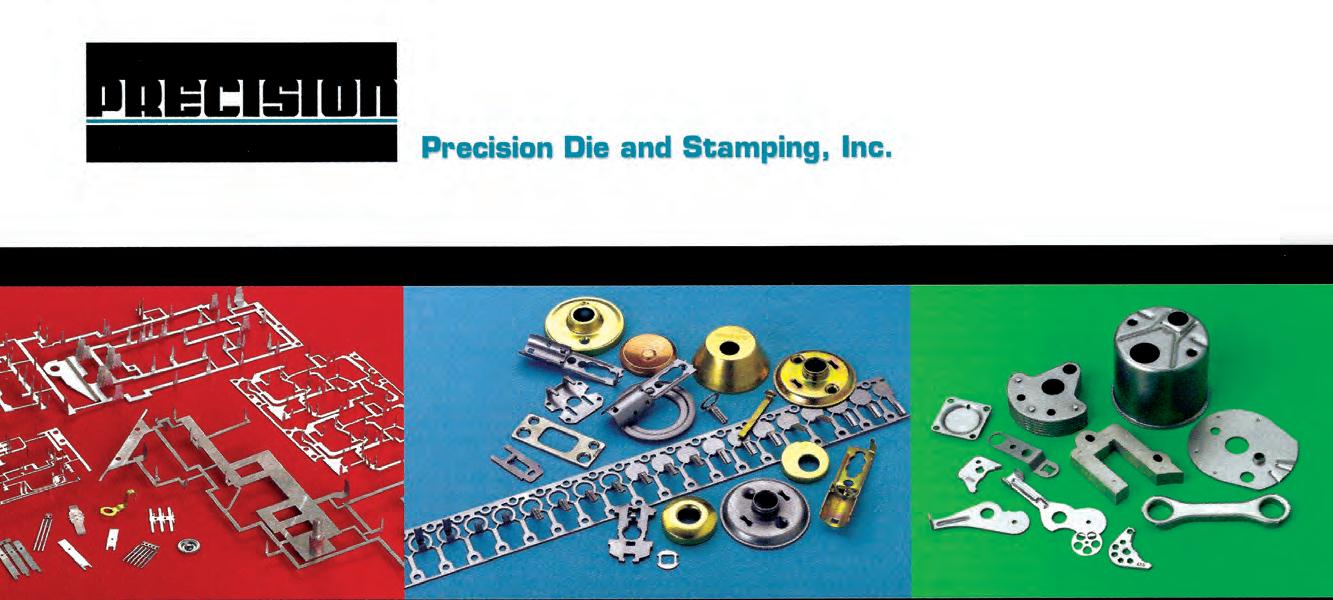

and dedication to customer service are number one priorities. This type of expertise and dedication has fostered a reputation of excellence in the tooling and stamping industry.

Located in Tempe, Arizona, our 100,000 Sq. Ft. Facility contains state of the art equipment , with production capabilities ranging from simple geometries to complex forms with intricate details. Precision enjoys a world-class reputation supplying a variety of OEMs, managing their inventory levels, and making certain product quality and timely delivery are NEVER compromised.

Solstar Space Co., last year’s Inno Madness champion, lands contract to test space technology

A phase one technology transfer contract through the Department of the Air Force will help Santa Fe-based Solstar Space Co. test one of its new space connectivity products.The company announced that it received the three-month, $75,000 contract to further its Slayton Space Communicator. It’s one of a few technologies currently under development by Solstar.

The Slayton product is essentially a broadband network device that allows constant high-speed uplink and downlink data relays on various space assets that range from satellites to space stations to lunar habitats.

Solstar’s CEO Brian Barnett told Albuquerque Business First that money from the contract would support Solstar as it readies the Slayton Space Communicator for commercial and government applications.Through the contract, the company will partner with Andrei Zagrai, Ph.D., a mechanical engineering professor at the New Mexico Institute of Mining and Technology, to test the space communicator using a satellite health monitoring unit developed at the university.

Solstar’s Slayton Space Communicator complements one of the company’s other products, Barnett said. Called WiFi access points, they are small connectivity devices designed to be used inside space stations, on lunar rovers or lander cabins, according to Solstar’s website.

The company plans to deploy one of those access points inside NASA’s Habitation and Logistics Outpost. It’s one part of the agency’s lunar-orbiting space

station called Gateway, which is under development for its Artemis program.

Solstar has another space communication product called the Deke Space Communicator, which is a narrowband network device used to connect satellites with other Internet of Things devices.

Solstar is developing this suite of space communications technologies to be ready for commercial and government application in the next couple of years, Barnett said. Solstar’s Deke Space Communicator provides narrowband network connections.

Solstar plans to apply for a phase two contract once the current contract for the Slayton Space Communicator technology is done, Barnett said. That phase two contract would give Solstar over $1 million to further develop the product through more testing and prototyping. Barnett said the broadband technology could be ready for commercial use in 2025.

By Jacob Maranda - New Mexico Inno Reporter

A2Z MANUFACTURING SW • 28 • March / Apr 2023

Stamping,

1704 West 10Th St • Tempe, AZ 85281 Ph: 480-967-2038 • F: 480-829-0838 • www.PrecisionDie.com Automotive • Semiconductor • Lockset Hardware • Power Tools • Lawn & Garden Equipment • Aerospace

Precision Die &

Inc.

A2Z MANUFACTURING SW • 29 • March / Apr 2023

Mesa Electric Vehicle Battery Supplier Collaborating With Global Company For US Production

Mesa-based graphite processing company Urbix Inc. says it’s closer to establishing a $280 million production facility now that it has signed a joint development agreement with South Koreabased global electric vehicle battery maker SK On (SKO) Co. Ltd. to develop materials for advanced lithium-ion batteries.

Under the deal, Urbix will work with SKO on industrialized anode materials that will supply the battery maker’s American gigafactories.

Urbix was founded in 2014 and describes itself as the only U.S. company producing natural battery grade graphite for use in electric vehicles and battery storage systems. It says that its partnership with SKO will accelerate its plans to establish a commercial anode production facility. Plans call for producing 28,500 metric tons of anode products yearly — enough to power 350,000 highperformance EVs — by 2025.

The Mesa company said through a spokesperson that it hasn’t decided yet where its production facility will be located but that it hopes to secure a site by the end of March, and places both inside and outside Arizona are being considered. Urbix currently employs 55 people in Arizona and said it hopes to hire at least another 30 over the next 12 months.

The partnership with SKO helps reduce the need for EV battery-grade graphite from China.

“Working with such a renowned battery manufacturer means that we can accelerate our production efforts, and more effectively address the supply of graphite,” Urbix CEO Nico Cuevas said in a statement. “By utilizing Urbix’s innovative technologies, we can shift more of the refinement and production of battery-grade graphite to the US, a mission we remain committed to.”

Urbix says its proprietary graphite processing system uses 10% of the energy, 6% of the acid and 7% of the time needed by existing processes. The Mesa company also said it eliminates the use of hydrofluoric and hydrochloric acids and has yields that are more than twice the industry standard.

SKO is the lithium-ion battery subsidiary of SK Innovation. It has two battery manufacturing plants in Georgia. It also has a joint venture with Ford Motor Co., called BlueOval SK, to build three more battery plants in the Southeast that will go online in

A2Z MANUFACTURING SW • 30 • March / Apr 2023

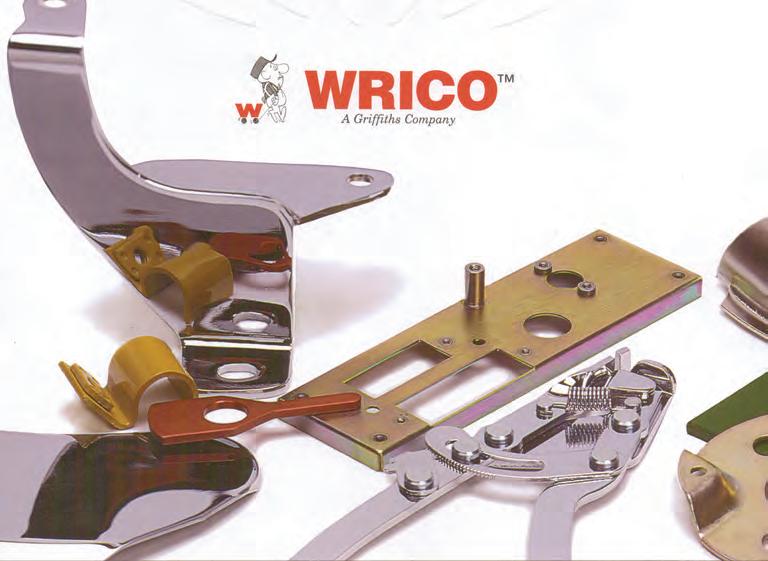

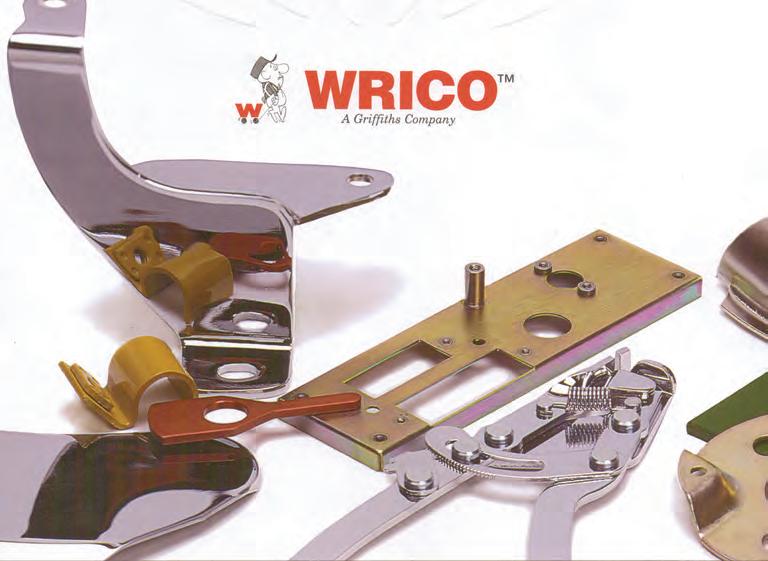

Locations in AZ, NC, TX, FL, WI, MN Arizona Facility: 1310 N. Hobson Street Gilbert, AZ 85233 (480) 892-7800 Email: wricoazjb@wrico-net.com We specialize in: • Custom Metal Stamping • Precision Sheet Metal • Laser Cutting • Press Brake Forming • Deep Draw Stamping • Mig & Tig Welding • CNC Machining • Wire EDM • Tube Bending • 5 Axis Laser Cutting • Wire Forming • Spot welding • Mechanical Assembly • Engineering Assistance

MORE SATISFIED CUSTOMERS WORLDWIDE

A GRIFFITHS COMPANY

2025. That ramp-up in U.S. production means more U.S. supplies are needed.

The deal also helps SKO benefit under provisions of the federal Inflation Reduction Act, or IRA, which uses tax credits to encourage domestic energy production and manufacturing using domestic supplies. The IRA also aims to reduce carbon emissions by about 40% before 2030. By Jeff

Gifford, Phoenix Business Journal

NASA, DARPA To Develop NuclearPowered Rocket To Reach Mars

NASA and the Defense Advanced Research Projects Agency (DARPA) will collaborate to develop a nuclear-powered rocket intended for crewed missions to Mars.

Last year, the space agency announced it would partner with the Pentagon’s research agency in a program called Demonstration Rocket for Agile Cislunar Operations (DRACO).

CNC Machining Centers

CNC Turning Centers

Swiss Machining

EDM

Manual Machines & Tool Room Equipment

High Production CNC Turning & Milling

Laser Marking

Metrology

Grinding

Fabrication

Saws Automation

Used Machines Tooling

Products, Service, & Expertise

Flex ROBO

Increase your manufacturing capabilities with Precision Machine Tools, Fabrication, Robotics & Automation, Tooling & Accessories, Workholding, Service & Parts, Preventative Maintence, Applications Engineering & Training.

Colorado Office: Serving CO, NM, & WY salesdenver@mmtproductivity.com 303-571-4933 MMTProductivity.com

“NASA will work with our long-term partner, DARPA, to develop and demonstrate advanced nuclear thermal propulsion technology as soon as 2027,” said NASA Administrator Bill Nelson. “With the help of this new technology, astronauts could journey to and from deep space faster than ever – a major capability to prepare for crewed missions to Mars. Congratulations to both NASA and DARPA on this exciting investment, as we ignite the future, together.”

According to NASA, a nuclear thermal propulsion system (NTP) could be three to four times

Utah Office: Serving UT, MT, WY & ID salesslc@mmtproductivity.com 801-886-2221

New Mexico Office: Serving NM & CO Western Slope dwhite@mmtproductivity.com 505-404-6148

rockets using conventional fuel. This would make a crewed mission to Mars less demanding in supplies and less straining for the astronauts.

more efficient than

In the United States, this concept was extensively tested as part of the Nuclear Engine for Rocket Vehicle Application (NERVA) program from 1959 to 1972 but was axed when NASA was forced to revise its budget downward. No NTP rocket ever flew.By Clement Charpentreau

A2Z MANUFACTURING SW • 31 • March / Apr 2023

Lathe Cutting, Live & Tool Blocks · Toolholders & Boring Systems · Spindle Speeders · Angle Heads & Coolant Inducers · Coolants & Cutting Oils · Vises & Workholding Products · EDM

R

CONTROLLED THERMAL TECHNOLOGY (CTT) AND TS WEST

2617 West Cypress Street Phoenix AZ

602-272-3714

A Heat-Treating Company OFFERING

Salt Bath Nitride-MELONITE®- Per AMS2753

Serving the Aerospace/Aircraft, Military, and Commercial Industries

Other Services;

• GASEOUS CARBURIZING

• GASEOUS NITRIDING

• VACUUM HEAT TREATING

• HEAT TREATING

• NORMALIZING, ANNEALING, HARDENING, COLD TREATMENT STRESS RELIEVING, PRECIPITATION

For More Info: Contact Danny Rosetta; 602-272-3714; drosetta@cttaz.com

For More Info: Contact Tim Johnston; 602-272-3714;

Department of Defense (DoD) Awards

Equipment Leasing and Finance Association Announces Top 10 Equipment Acquisition Trends for 2023

The Equipment Leasing and Finance Association (ELFA) which represents the $1 trillion equipment finance sector, today revealed its Top 10 Equipment Acquisition Trends for 2023. Real private investment by U.S. businesses in equipment and software is forecast to be more than $2 trillion in 2023, with a substantial amount of that investment activity financed, so these trends impact a significant portion of the U.S. economy.

ELFA meetings in compiling the trends.

Nammo Defense Systems Inc., Mesa, Arizona, was awarded a $498,092,926 firm-fixed-price contract for the full rate production of M72 Light Assault Weapon variants and components for shoulderlaunched munitions training systems. Bids were solicited via the internet with one received. Work locations and funding will be determined with each order, with an estimated completion date of Dec. 19, 2026. U.S. Army Contracting Command, Newark, New Jersey, is the contracting activity.

ELFA forecasts the following Top 10 Equipment Acquisition Trends for 2023:

ELFA President and CEO Ralph Petta said, “Slower economic growth underlies the trends this year as equipment acquisition continues to drive supply chains across all U.S. manufacturing and service sectors. Nearly eight in 10 of U.S. businesses currently use equipment leasing and financing to acquire the productive assets they need to operate and grow. We are pleased to provide the Top 10 Equipment Acquisition Trends to help businesses make their strategic equipment acquisition plans.”

Raytheon Co., Tucson, Arizona, is awarded a $55,121,826 costplus-fixed-fee modification to a previously awarded contract (N0002421C5434) for engineering and technical services in support of the Evolved Seasparrow Missile and NATO Seasparrow Missile Sys-tems programs. This contract combines purchases for the U.S. govern-ment (99%); and the governments of Japan and United Arab Emirates (1%) under the Foreign Military Sales (FMS) program. Work will be performed in Tucson, Arizona (82%); Portsmouth, Rhode Island (17%); Andover, Massachusetts (less than 1%); San Jose, California (less than 1%); Aranjuez, Spain (less than 1%); Brisbane, Australia (less than 1%); and Koropi Attica, Greece (less than 1%). Work is expected to be com-pleted by December 2022. The Naval Sea Systems Command, Wash-ington, D.C., is the contracting activity.

ELFA distilled recent research and data, including the Equipment Leasing & Finance Foundation’s 2023 Equipment Leasing & Finance U.S. Economic Outlook, industry participants’ expertise and member input from

The U.S. economy will experience sluggish growth in 2023. U.S. GDP growth bounced back during the second half of 2022, but underlying conditions remain troubling, including a struggling housing market, volatile financial markets and the slowing global economy. With a mild recession expected to begin midway through the year, U.S. GDP growth is forecast at 0.9% (annualized) for 2023.

Stability Timing (CREST) — a ruggedized atomic clock module with a unique combina-tion of performance and size, weight and power, capable of the abso-lute accuracy of a commercial cesium beam clock in a VPX-card-like form-factor. The CREST module will be designed to provide uninter-rupted Global Positioning System (GPS)-quality timing holdover in challenging military environments. Work will be performed in Phoenix, Arizona, with an expected completion date of Dec. 21, 2026. This contract was competitively procured under long range broad agency announcement (BAA) N00014-21-S-B001. The Office of Naval Research, Arlington, Virginia, is the contracting activity).

The pace of growth in capital spending will continue to slow. A surge of 12% annualized growth in capital spending in Q3 2022 provided a solid jumping-off point for 2023. While growth in equipment and software investment has been steady since the onset of the pandemic, rising interest rates, high inflation and other economic uncertainties are expected to weigh on investment with 4.2% growth forecast for this year.

Honeywell International Inc., Phoenix, Arizona, is awarded a $22,467,124 cost-plus-fixed-fee contract for the development, build and demonstration of the Compact Rubidium Extended

The Boeing Co., Mesa, Arizona, was awarded a $239,590,243 cost-plus-fixed-fee contract for the Apache Improved Turbine Engine Inte-gration Phase II. Bids were solicited via the internet with one received. Work will be performed in Mesa, Arizona, with an estimated comple-tion date of Dec. 31, 2026. Fiscal 2021 and 2022 research, develop-ment, test and evaluation, Army funds in the amount of $18,000,000 were obligated at the time of the award. U.S. Army Contracting Com-mand, Redstone Arsenal, Alabama, is the contracting activity.

Financial conditions will tighten regardless of interest rate hikes. Interest rate levels are expected to rise above 5% this year, and potentially higher as the Fed continues to battle inflation despite the risk of an economic downturn. Even if rate increases slow down or pause later in the year, the Fed’s shrinking balance sheet will contribute to tighter

A2Z MANUFACTURING SW • 32 • March / Apr 2023 A2Z MANUFACTURING SW • 44 • March / April 2022

D

tjohnston@cttaz.com

financial conditions.

The majority of equipment acquisitions will be financed. In 2023, more than half (55%) of equipment acquisitions are forecast to be financed. Eight out of 10 businesses use leases, secured loans or lines of credit for their acquisitions. Protection from equipment obsolescence, tax advantages and cash flow optimization will be the top drivers for end-users to finance.

Businesses will utilize equipment and software investment to offset labor costs. To reduce dependence on labor, businesses in some industries will increase their use of automation and other laborsaving equipment. Additional benefits will be increased economic productivity and downward pressure on inflation in the long term. Normal supply chain backlogs will ease equipment acquisitions. By most measures, supply chain backlogs have returned to their historical averages, and will ease equipment delivery delays or shortages this year. A combination of cooling demand and an improving public health situation have given suppliers a chance to catch up. In addition, global supply chains disruptions have triggered a paradigm shift with many large organizations “nearshoring” and/or “re-shoring” elements of their supply chains.

Many equipment types will thrive amid a slow-growth economy. Despite a souring economic backdrop, residual effects of the pandemic will spur demand for certain equipment types. Postpandemic hybrid work arrangements will require acquisitions of equipment types such as computers, software, office

equipment and communications equipment. Aircraft investment will boom early in the year as supply chains unwind and travelers return to the skies. Medical equipment appears to be another stand-out vertical for 2023.

Federal spending will provide a boost to equipment investment. Three major bills passed in Congress authorize at least $600 billion in new funding for a variety of industrial and infrastructure projects and should provide a sharp boost to equipment investment. Funding from these bills will be distributed over the next five years, and should help backstop the U.S. manufacturing sector and increase the demand for equipment in 2023 and beyond.

Explosive growth in green projects will drive demand for “climate financing.” Organizations are committed to cutting their production and emissions of greenhouse gases and require equipment from wind turbines and solar energy systems to microgrids, storage facilities for lithiumiron and hydrogen batteries, electric vehicles and more. Globally, an estimated $18 trillion of climatefocused equipment is forecast to be financed

Continued Next Page

A2Z MANUFACTURING SW • 33 • March / Apr 2023 WWW.NORTHSOUTHMACHINERY.COM | (800) 460-9014 | CA • OR • WA • AZ • NV LEAN. MEAN. 100% GREEN! • 100% Electric Precision Press Brake • 110 US Tons x 10.2’ • EC10 Touch Screen Control (EC20 Optional) • CNC X-Axis, R-Axis, Y1/Y2-Axis • Manual Z1/Z2-Axis (CNC Optional) • Mechanical Tool Clamping (Hydraulic Optional) • Tool Lighting on Front • 2x Front Support Arms • 2x Backgauge Stops • Installation & Training Included SAFANDARLEY E-BRAKE STANDARD FEATURES:

Continued From Previous Page

between now and 2030.

“Wild cards” will factor into business investment decisions. Businesses will keep an eye on other areas that could impact their equipment acquisition strategies in addition to the trends above. Tightening credit, a potential debtceiling showdown in Congress and energy price increases due to Russia’s war on Ukraine are among potential business impacts.

For an infographic highlighting the Top 10 Equipment Acquisition Trends for 2023, please visit ELFA’s Equipment Finance Advantage website for end-users at https://www. equipmentfinanceadvantage.org/toolkit/10trends.cfm.

Chandler Company Wins Exclusive Distribution Deal For Honeywell Aircraft Component

A Chandler-based company that provides aviation aftermarket products has signed an exclusive distribution deal for key aircraft parts made by Phoenix-based Honeywell Aerospace.

The deal makes AvAir the worldwide distributor of Honeywell’s 85- and 95-series auxiliary power units, or

APUs, which are in use on more than 1,400 aircraft globally, including C130 and P3 defense planes and Boeing 737-CL commercial jets.

“We’re excited to announce this new partnership with Honeywell and create a unique distribution channel for these APUs,” said Moe El-Khatib, vice president of defense at AvAir, in a statement. “This opportunity will allow us to continue to provide our existing and new customers improved access and more solutions to critical parts.”

AvAir has been in business for more than two decades. The company specializes in helping customers and suppliers buy, sell, exchange, loan, lease or consign aviation aftermarket parts, and offers customized options for its clients.

Honeywell Aerospace’s senior director of sales, Tim Van Luven, praised AvAir’s capabilities and said in a statement that his company looks forward to a long partnership with AvAir to improve market reach and customer service.

“Aligning with AvAir made sense as both companies will provide the best service, innovative technologies and aftermarket solutions in a world that continues to evolve,” Van Luven said in the statement.

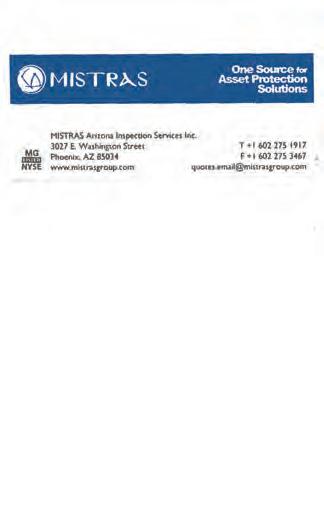

A2Z MANUFACTURING SW • 34 • March / Apr 2023 OVER 26 PRIME APPROVALS OUR CAPABILITIES 3027 E Washington St, Phoenix, AZ 85034 • (602) 275-1917 Semiray a Division of Mistras Group www.semirayinc.com www.mistrasgroup.com *Penetrant *Magnetic Particle *Anodize Type I, II, III *ChemFilm Type II ROHS Compliant *Passivation *Pre Penetrant Tech *Pressure Test *Paint *Dry Film Lube *Flow Test / AF5333 *Borescope Inspection *Ultrasonic Cleaning *Millipore Clean & Inspection ...And Many Other Value Added Services

Warranty Program

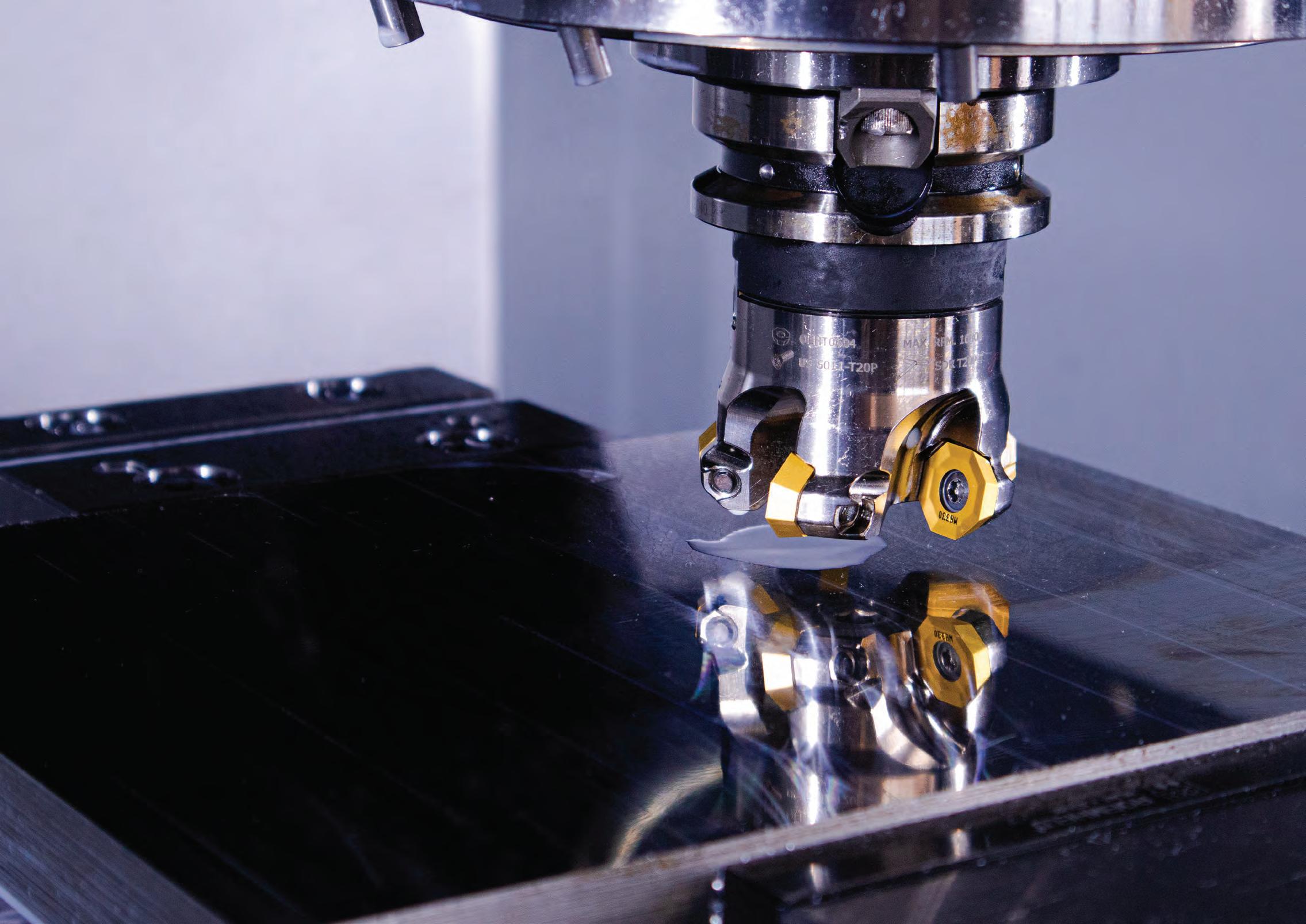

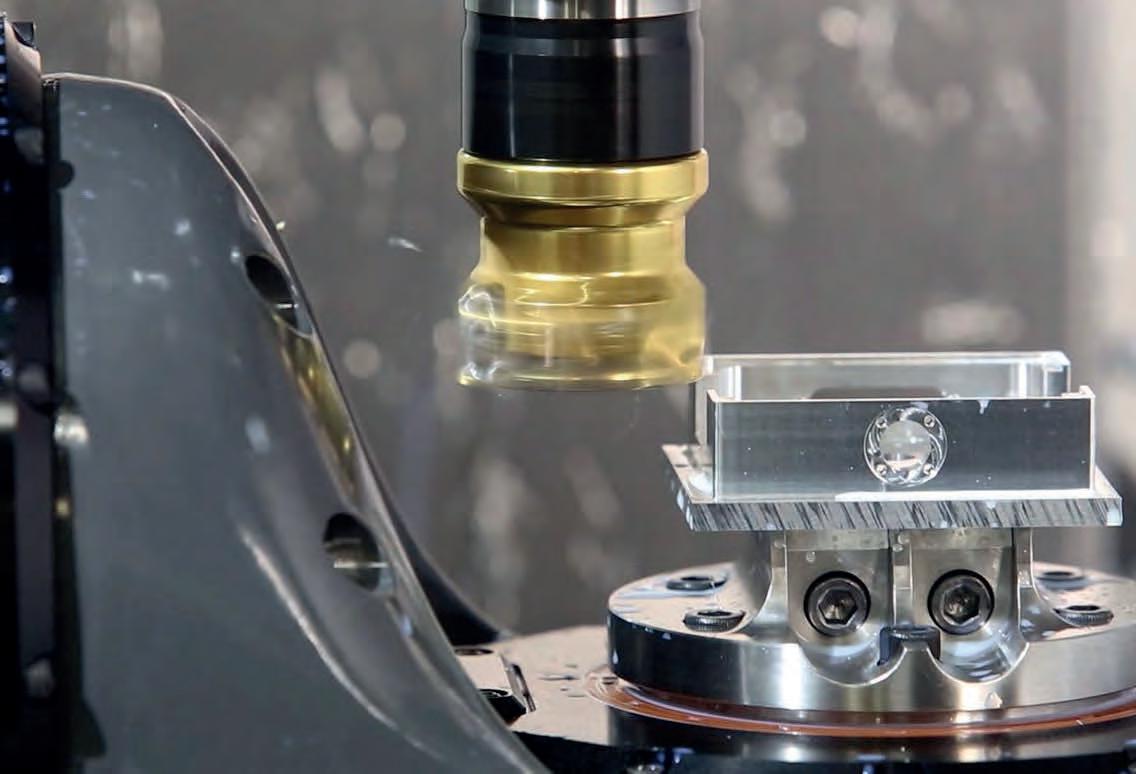

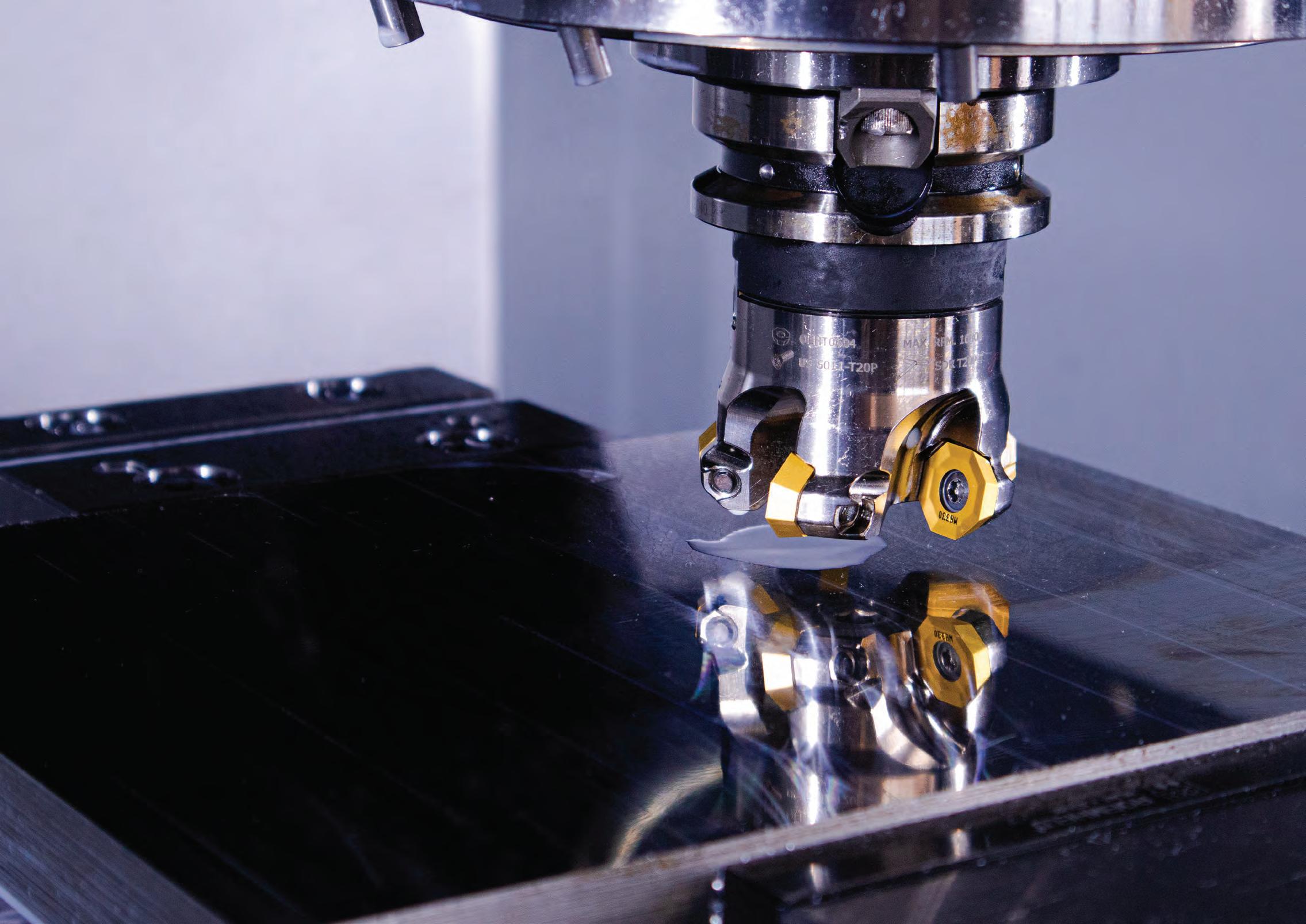

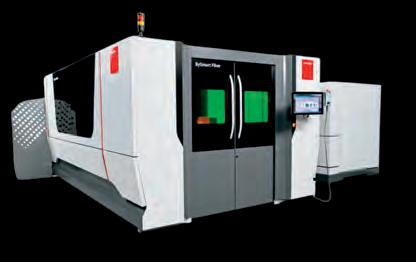

Okuma’s MULTUS U3000 Multitasking Machine offers an ideal combination of power, speed, and process flexibility. A broad scope of machining functions and the ability to complete tasks in a single setup make this machine simple and efficient for producing a variety of parts. Combining powerful turning and milling capabilities, made possible with Okuma’s OSP-P300 control, equals one thing – increased production capacity.

Explore all of the powerful features of the MULTUS U3000, including:

• Full 5-axis contouring (available as an option)

• New compact B-axis spindle

• 240-degree B-axis range

• 30 hp milling motor spindle

• 12,000 RPM H1 milling spindle

• Wide range of ATC configurations available (40 to 180 tools)

A2Z MANUFACTURING SW • 35 • March / Apr 2023 A2Z MANUFACTURING SW • 9 • March / April 2022

Okuma. Welcome to open possibilities.

CALLING ALL MULTITASKERS MORE IS POSSIBLE

www.arizonacnc.com 480-615-6353

Backed by Okuma’s Industry-Leading

To learn more, visit: okuma.com/products/multus-u3000 To inquire, visit: okuma.com/distributors Arizona CNC Equipment, LLC 1205 S Park Lane, Suite 2 Tempe, AZ 85281

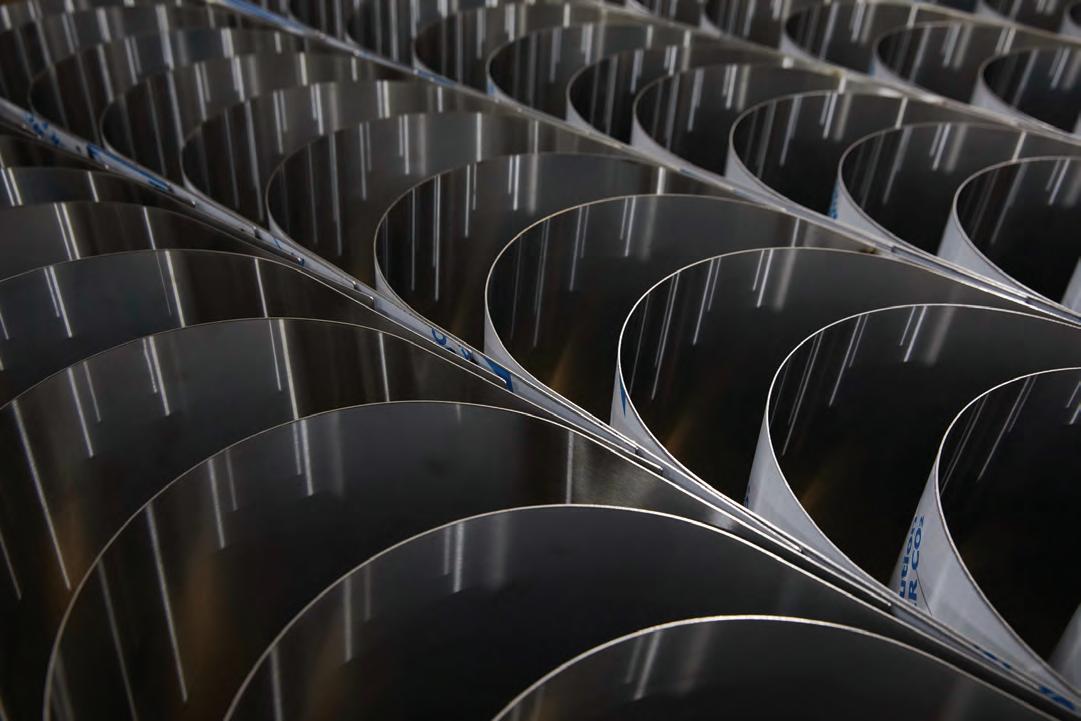

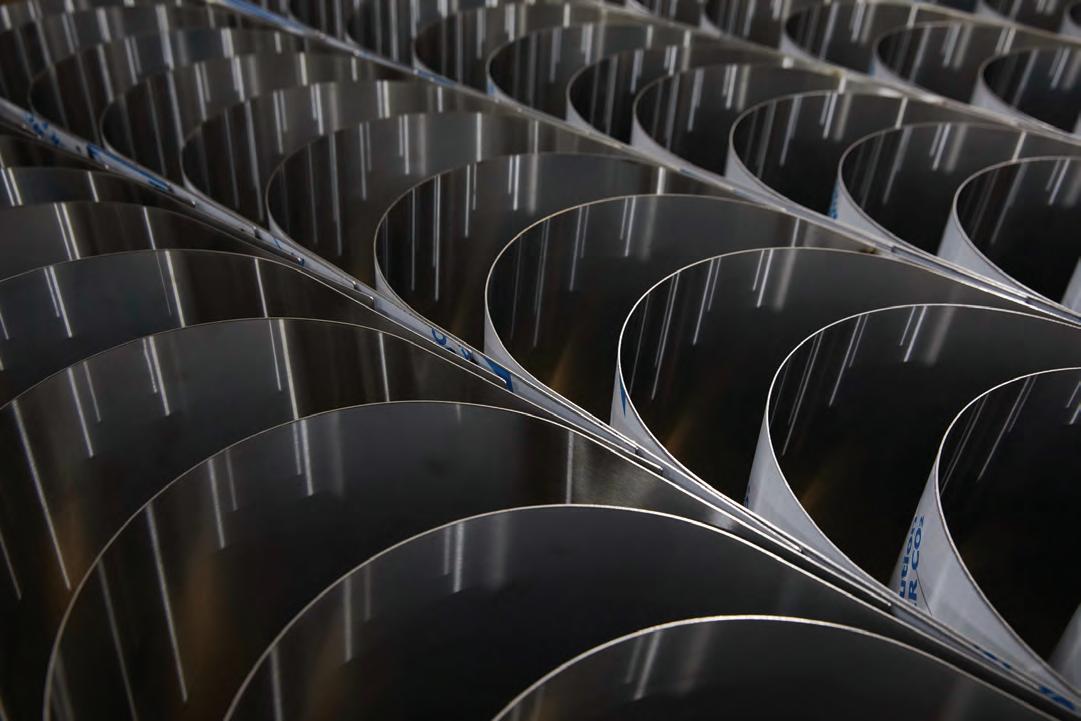

Formally

Introducing YOUR Next Metals Service Supplier In Arizona

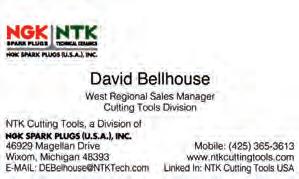

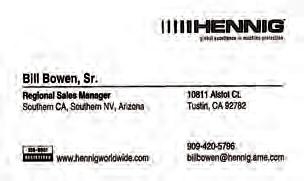

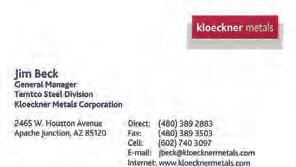

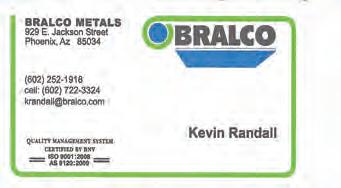

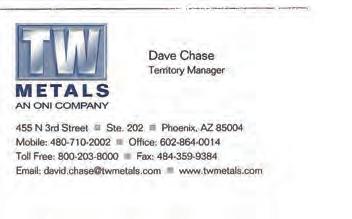

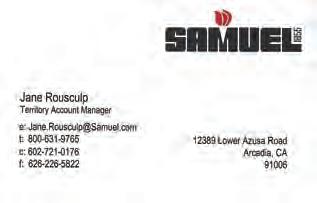

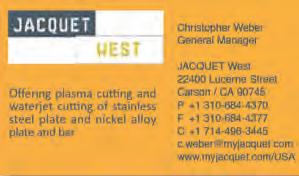

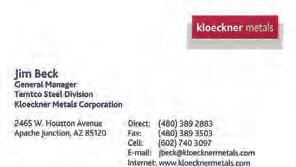

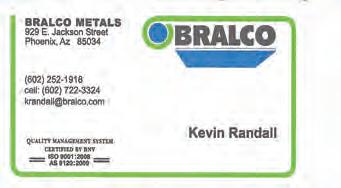

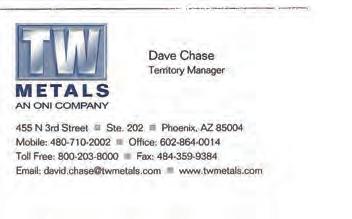

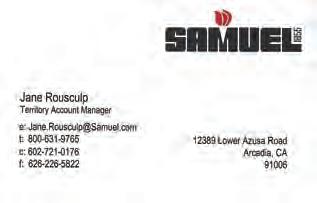

Basic Metals Inc. is an independent metal service center specializing in aluminum & stainless cut-to-length sheets, slit aluminum & stainless coils, and aluminum circles. And while it may not be a household name in the Southwest, yet, newly hired General Manager Kevin Randall certainly is well known within our industry. Today, Basic Metals’ presence in the Southwest includes large warehouses in Goodyear, Arizona; Dallas, Texas; and Monterrey, Mexico.

A little background on the Basic Metals’ history is warranted. Founded in 1980, Don Fogel was hired as the first employee of the Wisconsin based company. Don purchased a Paxton slitter and hired a machine operator to get the business started. Three years later, Don’s son Todd graduated from college and joined the Basic Metals team as employee #3.

Todd and Don transitioned between suits and shop overalls, manning machines and out selling to prospective customers. The two learned much about how to run and grow a metals distribution company in those early years. 5 years into their employment, in 1985, the two approached ownership with a compelling proposal and they purchased the assets of Basic Metals to become the sole owners.

Under Todd and Don’s ownership, the company grew rapidly. They invested in state-of the art Red Bud coil processing equipment and built a 36,000 square foot facility in Germantown, Wisconsin. In 1999 Todd became sole owner of Basic Metals. Todd continued to steward the relationships that his dad built and again expanded the company with a Mississippi warehouse, Germantown, Wisconsin expansion to >80,000 sq ft, and new processing equipment.

In 2010, Todd’s son, Andy, joined the Basic Metals team. And like in past years, once again a father and son Fogel team expanded operations, this time to the Southwest, to Goodyear, Arizona, where they added a cut-to-length processing line and became an ISO 9001:2015 certified company.

To this day, Basic Metals is still family owned and operated under Andy’s leadership, continuing the legacy that Don and Todd built. Millions of pounds

of metal have been shipped across the United States, Mexico and Canada from Basic Metals. The company offers the following services for its customers:

• Cut-to-length

• Slitting

• Shearing

• Laser Processing

• Circle Shearing

• Toll Processing

• Inventory Management

• Freight Management

• Next day delivery

Kevin Randall was hired in October of last year as the general manager to expand Basic Metals’ business in the Southwest. Kevin brings 3 decades of experience selling metals in Arizona to the company. Kevin says, “I started in the industry working for a family run business in early my years and then I spent 20 years with a leading corporation in metals distribution. I made many friends and learned a great deal in my corporate endeavor, and I was ready once again to work for a family run business. I can make decisions on the spot that help our customers, without being impeded with bureaucracy. If a customer needs a sample piece of material, I can just get it for them. It doesn’t take an act of Congress to get things done at Basic Metals, as our customers are treated like family, not a number on a spreadsheet.”

He adds, “To sell metal you need to have a substantial inventory, so that you can get product to your customers in timely fashion. We carry in excess of $3 million of inventory in our Goodyear facility, and we own five acres for expansion.”

The company expanded to Goodyear (a suburb of Phoenix) in 2016 when one of their largest customers expanded in Phoenix and asked Basic Metals to support their expansion. With the

A2Z MANUFACTURING SW • 36 • March / Apr 2023

opening of the Goodyear facility, the company hired Frank Barrerra as the plant supervisor.

Kevin says, “The Southwest is such an exciting high growth market to be in, and we are prepared to support customers here in the semi- conductor, electric vehicle, battery and solar markets. Basic Metals is fully prepared to continue to invest in equipment at our Goodyear facility to support this growth.”Kevin says that the company added Nick Olson to the team to operate the fabrication equipment they have invested in.

Basic Metals has the infrastructure and programs in place to support large customers. Kevin says, “We excel at selling programs to our customers, not just 5-10 sheets of metals. We are relationship driven in our customer base, as opposed to transactional. Also, in additional to selling aluminum & stainless through contracts and programs to our very large customers, we support local distributors who have a need for our products for their customers. Typically, regional distribution service centers come to us for our custom and pattern size sheet metal.” Kevin adds that as a testament to Basic Metals’ superior relationship with its customers, it has remained a key supplier for decades to a number of companies, included a Fortune 1000 manufacturer, a Forbes ‘Best Mid-Sized Employer’ and an “Inc 500 Best’, amongst others.

Basic Metals’ customer base is extremely diverse, including power generation, appliances, trailers, defense, automotive, metal fabrication, agriculture, heavy trucks, food service, lighting, as well as others.

Kevin says he is having a blast in his new endeavor. “It is refreshing to work for Basic Metals. We are an extremely well-run company with state-of-theart equipment. We communicate as a company – there are daily morning meetings via Zoom where we review schedules, deliveries, and any issues we must address. And not just management, but the inside sales force and all of the administration within corporate headquarters really cares about our customers. The support I receive is nothing less than outstanding.”

He adds, “We excel at aluminum slitting and cut-to-length sheet and can offer our customers slit coil faster than anyone, I believe, on the West Coast and Texas.” Kevin says the one thing he misses from his previous employer is the customers he has come to know and care about over the past decade. Some will be good candidates for Basic Metals, he believes, but there are a whole new set of customers that Basic Metals is extremely well suited to support.

In its quest for continuous improvement, Basic Metals has recently installed new software from Stratix Systems Technology. Kevin says the IT technology from Stratix Systems is enabling Basic Metals’ customers to have instant

access to their orders, delivery schedules and inventories, to name a few. He says that it will also help with overall document management and offer cyber security protection. “It is just another step we are taking to better serve our customers”, Kevin adds.

To learn more about how Basic Metals, Inc. can help you with your aluminum, stainless and carbon needs, contact: Kevin Randall, General Manager: 602-515-4341

krandall@basicmetals.com

BASIC METALS’ OFFERINGS

1. Aluminum

a) Sheet

b) Plate

c) Coil

d) Circles

e) Tread Plate

f) Pre-Paint Aluminum

g) Aluminum extrusions

2. Stainless Steel

a) 201 d) 316

b) 301 e) 409

c) 304 f) 430

3. Carbon Steel

a) Aluminized Steel

b) Electro-Galvanized

c) Galvanized Steel

d) Galvannealed Steel

A2Z MANUFACTURING SW • 37 • March / Apr 2023

Nikola Corp. unveils HYLA brand to represent its growing hydrogen business

N ikola Corp. has unveiled a new brand, HYLA, to represent its hydrogen business, the company announced last month.

HYLA encompasses Nikola’s energy products for producing, distributing and dispensing hydrogen to fuel its zero-emissions electric trucks and those of other manufacturers, Nikola said at a brand launch event attended by more than 300 people at its Phoenix headquarters.

Could businessyour be saving money ?

one of our customers to achieve their sustainability goals and dramatically reduce carbon emissions for our planet.”

Under the HYLA brand, Nikola intends to develop more than 300 metrictons per day of hydrogen, which is expected to be supported by the company’s planned hydrogen hub in Buckeye and its partnerships with Plug Power, Wabash Valley Resources, TC Energy and KeyState to develop additional hydrogen production facilities nationwide.

“Simply put, the strategic mission of HYLA is to secure supplies of clean hydrogen and then to distribute it to our customers at very competitive prices,” Carey Mendes, president of energy for Nikola, said. “This is going to help every

In December, Nikola agreed to sell 75 of its Tre Fuel Cell Electric Vehicles over the next three years to Plug Power in exchange for purchasing a liquefaction system for its hydrogen production hub in Buckeye.

Nikola’s hydrogen production hub will be built in phases to scale with demand for the company’s Tre FCEVs, which have an expected range of 500 miles and a refueling time of fewer than 20

Continued Page 40

A2Z MANUFACTURING SW • 38 • March / Apr 2023

Sign up at the link below or scan the QR code iac.engineering.asu.edu REQUEST AN AUDIT NOW!

Your partner for innovative manufacturing

The factory of the future, today

Smart. Connected. Data-driven. 4.0—whatever mission you choose, Renishaw is your source for achieving the highest level of precision and productivity in your manufacturing environment. From industrial metrology hardware to smartphone

www.renishaw.com

Continued From Page 38 minutes.

apps and interfaces, our automated and intelligent process control technologies collect data and respond in real time to keep your factory at its peak. The day to optimize your process, reduce costs, and increase throughput, is today!

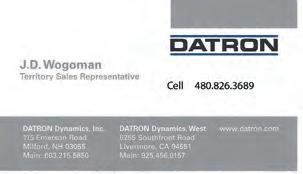

usa@renishaw.com