Southwest Edition (AZ, NV. and NM.)

Southwest Edition (AZ, NV. and NM.)

I am admittedly a die-hard Suns fan. The 2023-2024 season hasn’t been outstanding, by any stretch of the imagination. Still my beloved team did well enough to secure Playoff spot #6.

But as we go to print in Round 1, the Suns are down 2 games to number 3 seated Minnesota and they look terrible. As the season started, everyone knew that having three star scorers (Devin Booker, Kevin Durant and Bradley Beal) would be a great strength of the team. Instead, it’s been a weakness.

How does this happen and whose fault is it? We have all likely experienced this in the workplace at some time in our careers. Many bright, energetic team members and yet the sum is not greater than the parts.

As I have watched other playoff games, I hear verbiage like ‘connected’, ‘one mission’, and ‘locked in’. These terms are tossed around when the Oklahoma Thunder are playing. Oklahoma City is not only the youngest team to ever secure the top spot in the West heading into the playoffs, but they are also the youngest 1-seed in NBA history. Their average age is 23.4.And they do look ‘locked in’.

What does it mean to be a connected team, whether in business or in sports, or just in life? A definition of a connected team means that the team has deep emotional connections with each other and operates more like a family.

In business, the more connected we are as colleagues, the more efficient our workplace will be. This seems obvious, but how do you make it happen.

At the most basic level, a team’s success (or failure) at working together reflects the philosophy of the leaders. Teams do well when its leaders invest in supporting social relationships and demonstrate collaborative behavior themselves.

In an article in the Harvard Business Review titled, “Eight Ways to Build Collaborative Teams”, it found that the greater the proportion of experts a team had, the more likely it was to disintegrate into nonproductive conflict or stalemate.

While executive support is necessary to create a collaborative culture, so too is what the article termed creating a ‘gift culture’. This means that mentoring and coaching must be embedded in their own routine behavior, and throughout the company. Daily coaching, they state, helps establish a cooperative ‘gift culture’ in place of a more ‘tit for tat’ culture.

Additionally, collaborative teams who score well have clarity in their roles and in the roles of their team members. There is little overlap between the responsibilities of each individuals. Maybe this is where the Suns went wrong this year, maybe it is the leadership. I can’t be sure.

Strengthening your team’s capacity for collaboration requires a combination of long term investments —in building relationships and trust, in developing a culture where the leaders ar role models of cooperation, and in clearly defining roles. This is something small and large business should strive for in their organizations. Until next issue, I wish you the best, and as always, God bless our troops.

Linda Daly,Publisher

Address: 1538 E La Vieve Lane Tempe, AZ 85284

www.a2zMFG.com

CONTRIBUTORS

Kim Carpenter Takashi Sato Gene Wirth

Published bi-monthly to keep precision manufacturers abreast of news and to supply a viable vendor source for the industry. Circulation: The A2Z MANUFACTURING has compiled and maintains a master list of approximately 8500 people actively engaged in the precision manufacturing Industry. It has an estimated pass on readership of more than 19,300 people.

Advertising Rates, deadlines and mechanical requirements furnished upon request or you can go to A2ZMANUFACTURING. com.

The Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

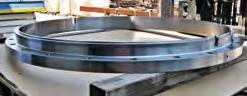

Designed and built for use with Haas ST and DS series CNC turning centers, the Haas Bar Feeder connects directly to the Haas control.

Robot Systems

• HRP-1 System – 7 kg capacity • HRP-2 System – 25 kg capacity

• HRP-3 System – 50 kg capacity

Pallet Pool Systems

• 3-Station for VF-2YT/SS, VM-2

• 6-Station for EC-400

• 6-Station for VC-400/SS

• 6-Station for UMC-1250/SS

• 10-Station for UMC-750/1000/SS

• 10- or- 20-Station for UMC-500/SS Automatic Parts Loaders

• Turning Center APL

• VMC APL

• Small UMC APL

Haas Bar Feeder

All-inclusive design, with plug-and-play capabilities to Haas lathes

• 4th- and 5th-Axis Rotaries

• Sub-Spindles

• Parts Catcher System • Auto Door for Mills and Lathes

• Automatic Coolant Refill

Mill and lathe classes are scheduled every other month. Each course consists of 3 days of hands-on instruction led by a Haas Certified Instructor. Students will learn the basics of the Haas control, operation of machines, and Haas programming using G & M codes. Classes are free to all Haas CNC machine owners and operators. Classes are held Monday through Wednesday from 2:00 P.M. to 5:30 P.M.

Please join us for an upcoming session of the Haas CNC training. We recommend registering as early as possible as class sizes are limited.

Training is held at Haas Factory Outlet- Phoenix, a Division of Ellison Machinery facility located at 1610 S Priest Drive, #101 Tempe, AZ 85281. To register and for additional information visit www.EllisonAZ.com or call 480-968-5877.

A1 Precision Metal & Aerospace, LLC, an ISO 9001 certified, AS9100 Rev D compliant company, is pleased to announce that it recently successfully registered with ITAR. ITAR registration means the company follows the

International Traffic in Arms Regulations (ITAR), which controls the export and import of defense-related articles and services on the United States Munitions List (USML).

It additionally completed its Cybersecurity certification. Owner, Jack Terrell says, “This process took 6 to 8 months to complete and was very comprehensive. We knew that we needed to have this in place so we could get Government contracts and work on aerospace parts for our large aerospace customers. It is also a must have for ITAR registration.”

A1 Precision Metal & Aerospace is a woman-owned, advanced metal fabrication manufacturer, delivering high-quality custom sheet metal fabrication service. As a single-source provider,

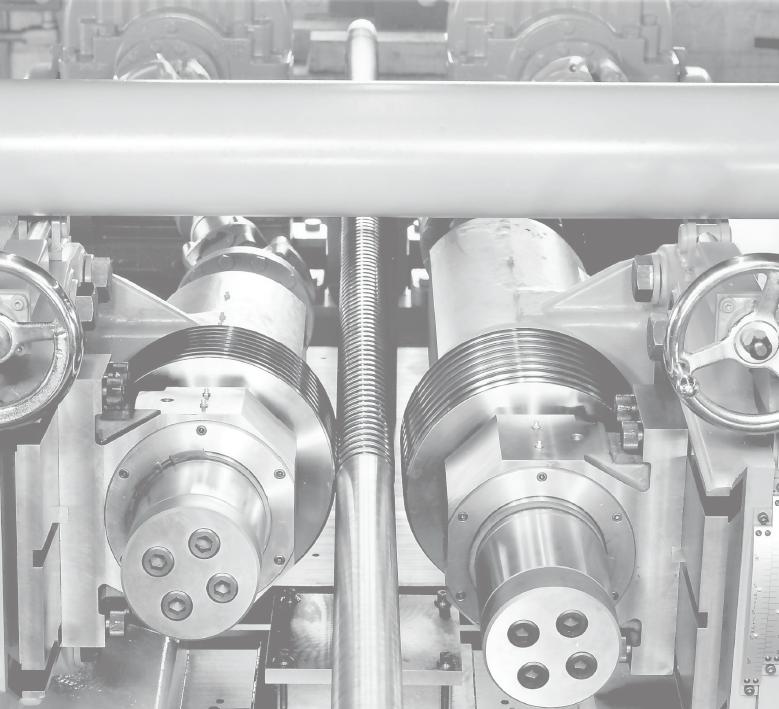

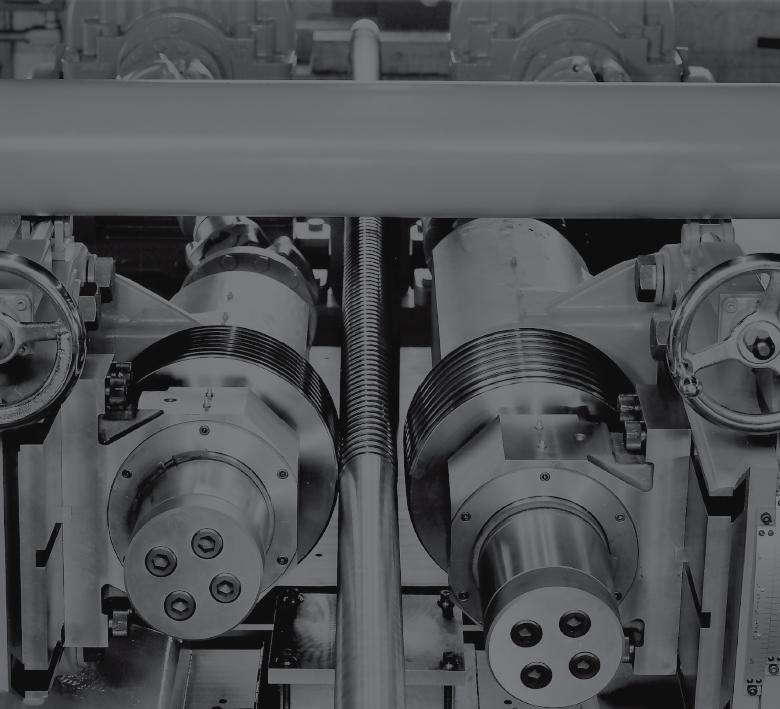

Okuma’s MULTUS U3000 Multitasking Machine offers an ideal combination of power, speed, and process flexibility. A broad scope of machining functions and the ability to complete tasks in a single setup make this machine simple and efficient for producing a variety of parts. Combining powerful turning and milling capabilities, made possible with Okuma’s OSP-P300 control, equals one thing – increased production capacity.

Explore all of the powerful features of the MULTUS U3000, including:

• Full 5-axis contouring (available as an option)

• New compact B-axis spindle

• 240-degree B-axis range

• 30 hp milling motor spindle

• 12,000 RPM H1 milling spindle

• Wide range of ATC configurations available (40 to 180 tools)

the company specializes in the manufacture and assembly of custom fabricated metal components and assemblies – with services extending to developing manufacturing based upon customer design, helping to reduce your overhead burdens.

A1 Precision Metal & Aerospace, LLC, offers precision metal fabrication services. Their capabilities include Shearing, Laser cutting, Turret punching, Press brake forming, Roll forming, Welding (MIG, TIG, spot), Hardware installation, and Assembly. Jack has decades of experience in fabrication, and has spent over 30 years in the Aerospace industry, before opening his own business with wife and partner Shelley Terrell. Jack says, “We can fabricate with a variety of materials including Aluminum, Stainless steel, Mild steel, and Galvanized steel, and we offer short and long production runs.”

For more information on how they can help your fabrication needs, contact them at: 623-377-2191 or visit a1pma.com

Phoenix Heat Treating is proud to announce that we have formal FAA Drug and Alcohol Program compliance.

Phoenix Heat Treating is especially known for its ability to

resolve difficult heat-treating problems that are beyond the capability of a typical application. We offer a wide array of processing and consulting services. We take great pride in finding unique solutions to meet each individual customer’s requirements.

To learn more about how Phoenix Heat Treating can support all your heat treat needs, as well as specialized services, contact Tim Johnston, Director of Business Development.

Tim is available to assist you at Phoenix Heat Treating and can be reached at 623-512-3233 or by email at tjohnston@phxht.com

Luis Xavier Rodriguez is pleased to announce that his company has just celebrated 2 years in business. Though the company is young, Rodriguez brings 20 years of experience in the ‘lost art’ of

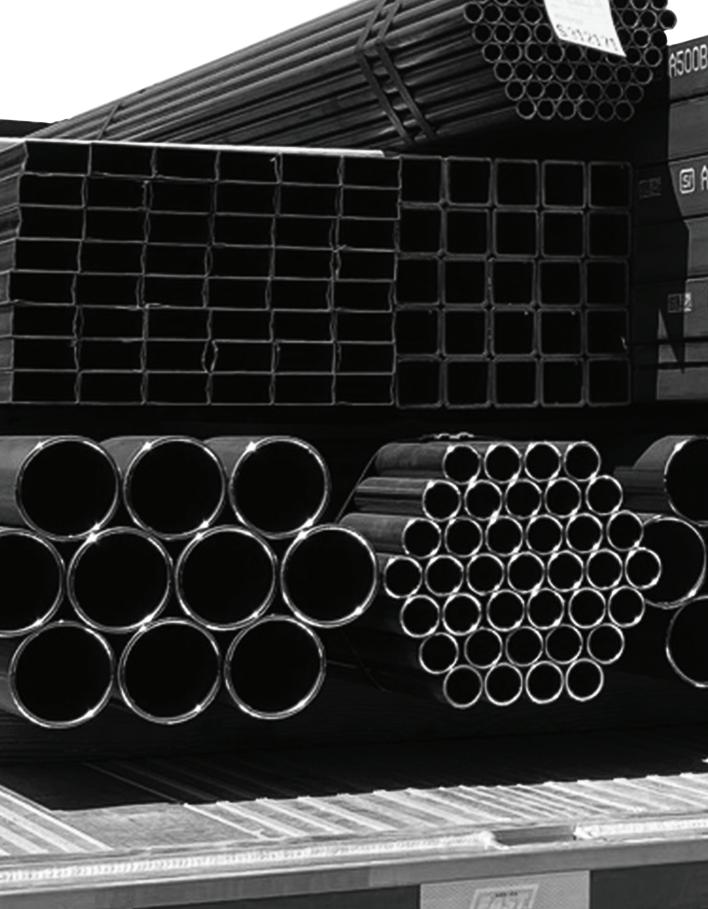

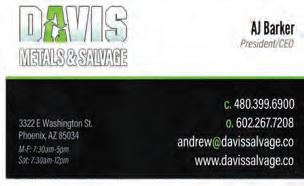

personal use, and business accounts. With the addition of Arizona Iron Supply, we can accommodate even larger industrial accounts and offer even more equipment and metal inventory to choose from.

projects others have turned down because they were too difficult or “impossible” to form. They’ll work with you to achieve your goals.

We feel privileged to continue to serve Phoenix and surrounding areas. We can’t wait to show you how this development will improve your metal purchasing, metal recycling, and Rolloff Service experience.

Visit one of our two locations to see how this exciting change will benefit you! Davis Metals: (602) 267-7208 / 3322 E. Washington Street, Phoenix, AZ 85034 Arizona Iron Supply: (602) 244-9649 / 130 S 23rd St, Phoenix, AZ 85034

metal spinning. He began his company with the goal of providing quality, reliable, and timely products that bring back precision manufacturing to Arizona.

“In an industry where skilled precision metal spinners are an echo of the past, I have developed my skills and mastery of metal spinning over the years through hard work and dedication to craft. I had the great opportunity of apprenticing under veteran metal spinner Paul Clark, formerly of Metal Spinning Solutions. During the years I spent under the tutelage of Paul, I learned a lot of the tribal knowledge of the trade that is only passed down through mentorship.”

Xavier Metal Spinning is known for its ability to spin a wide range of material, including high temperature alloys. While most of the parts they make are exclusively for the aerospace industry, Xavier enjoys serving commercial, energy, agriculture, lighting, artistic, and other industries throughout the United States. It’s not uncommon for Xavier Metal Spinning to take on

The company is currently working on its AS9100 certification, which it expects to complete by this summer. Known for precision, quality, and efficiency, the highly skilled team will exceed your expectations. To learn more about how Xavier Metal Spinning can support your precision metal spinning and manufacturing needs, contact them at 602-828-2359 or email Luis, owner/operator at luis@xaviermetalspinning. com

L andmark Solutions held an Open House event at Metzfab Industries in Phoenix earlier this month.

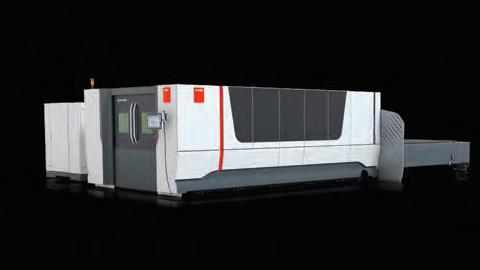

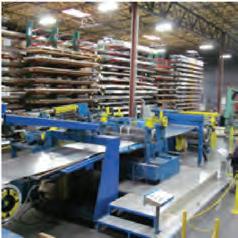

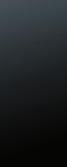

Metzfab recently installed a new OMAX 80x 5 axis waterjet, a Bystronic Tube Laser system, a Bystronic ByStar Fiber Laser with full automation, multiple large high performance press brakes, and a fully automated robotic press brake. Installing soon is a new material finishing machine also coming from the Landmark Team.

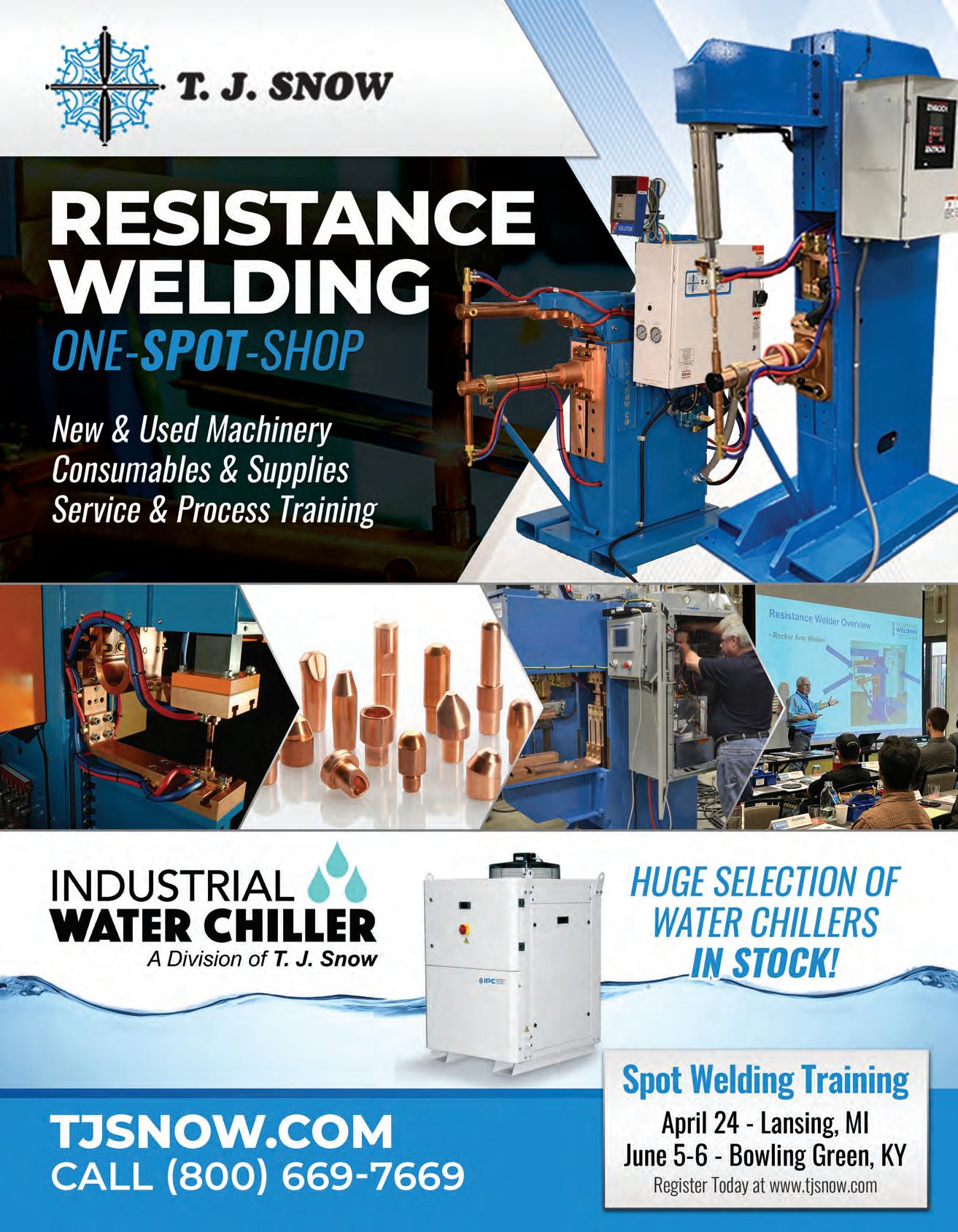

The Refrigeration School, Inc. (RSI) in Phoenix recently sponsored the annual Skills NATIVE competition, hosted by the Northeast Arizona Technological Institute of Vocational Education (NATIVE). This competition invites students from high schools on the Navajo Nation to compete in a variety of skills competitions, including welding.

Metzfab’s facility was chosen due to their company growth, and the addition of several new state of the art pieces of equipment. Metzfab is always pushing technology and equipment limits in an effort to build and deliver the best parts to their customers.

The Landmark Solutions open house event was a success, and we are all excited to continue our long term partnership with Metzfab. Everyone attending the event were impressed with the new equipment and technology, and how this has helped Metzfab grow and diversify their business.

Arizona MEP's mission is to make every Arizona manufacturer the most successful business it can be. As Arizona's Manufacturing Extension Partnership, Arizona MEP's manufacturing and business experts offer customized solutions and hands-on assistance to help your company achieve its goals.

Whether you're looking for incremental improvements to your operation or a major transformation, Arizona MEP can provide a solution designed just for you.

This year’s competition included 30 competitors in welding with representatives from each of the 8 participating high schools.

Winners in the 2024 Skills NATIVE welding categories were:

Individual Weld:

1st place: Aden Nakai, Red Mesa High School

2nd Place: Ashkii Nez, Piñon High School

3rd Place: Wyatt James, Ganado High School

Team Weld:

1st Place: Red Mesa High School

2nd Place: Window Rock High School

3rd Place: Ganado High School

The purpose of the Skills NATIVE competition is to increase awareness of the skilled trades among Native American youth and create more opportunities to pursue a post-secondary career technical education. With a looming shortage of welders entering the workforce, it’s more critical than ever to introduce new generations and communities to job opportunities and economic security within the welding industry.

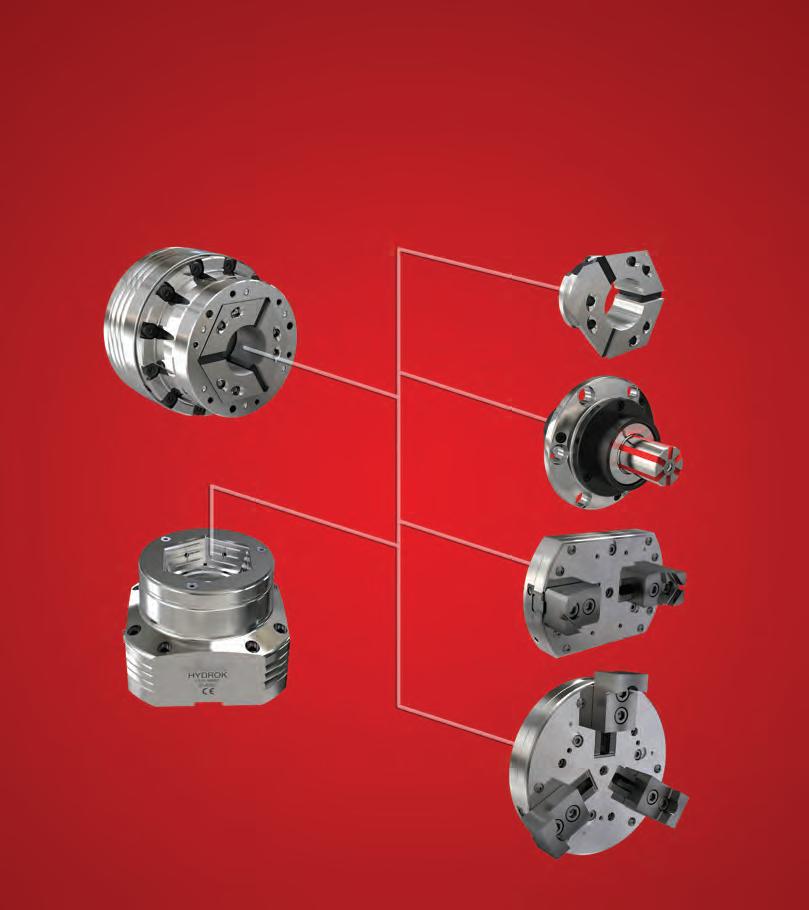

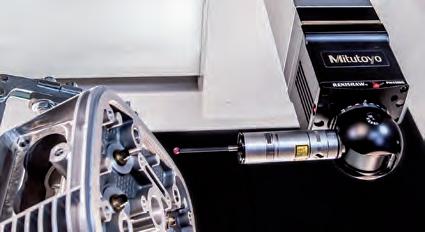

Sulli Tool & Supply, founded by owner Michael (Mike) Sullivan in 2009, is pleased to announce that it has expanded its territory with one of its principals, SMW Autoblok. Mike says, “We’ve had the line since I launched the business more than 15 years ago. Just last month, they awarded us an expansion to our territory, so that not only do we offer this line in California, Nevada and Arizona, but we will now also carry it in Colorado, New Mexico and Utah.”

Michaels’ son Matthew joined the business in 2022 after graduating from Arizona State University (ASU). Matthew says, “We are very proud of the top tier industry leading companies we represent. With top notch quality, reliable products, consistent production, and top tier customer service,

we simply supply the best of the best. Our premier partners include: Firetrace, Koma Precision, Northfield, Royal, SMW Autoblok, Stevens Engineering and Toolmex.”

The father and son team of Sulli Tool & Supply pictured above at a customer’s Open House is in partnership with several companies from around the world. We help original equipment manufacturers, machine tool dealers, industrial supply companies and end users manage their workholding, live tooling, part accumulation, and ensure clean and safe employee work environments, with a variety of products and services such as off-the-shelf quality products, engineered solutions, and excellent support.

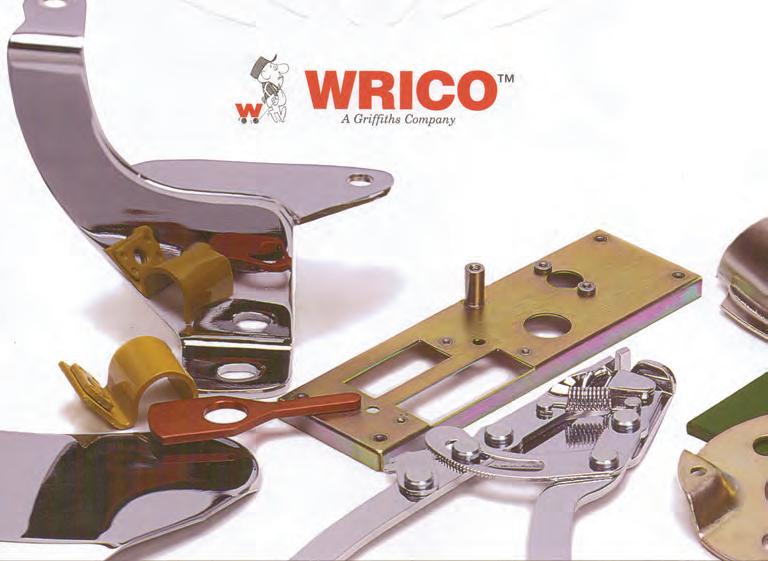

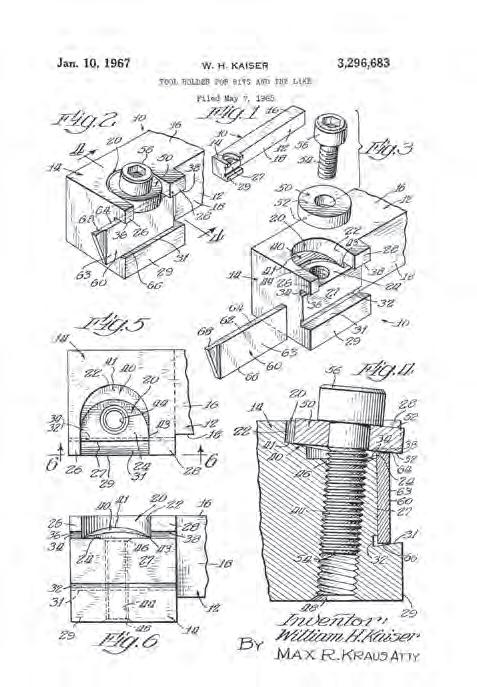

Autoblok Corporation was established in 1981 as a subsidiary of Autoblok of Italy, the largest power chuck manufacturer in Europe. Since 1942, Autoblok has been at the forefront of engineering and manufacturing state-of-the-art workholding, clamping and tooling solutions.

premier manufacturing entities resulted in the most extensive product line of high quality workholding devices in the world. Now available exclusively through its subsidiaries, reps and distributors, SMW AUTOBLOK customers are ensured a consistent, single source of superior product performance, support and service.

To learn more about how Sulli Tool & Supply can help your business, contact them at 714863-6019, email: mike@sullitool. com or visit their website at sullitool.com

If you’ve been buying tooling in the Southwest, likely you know Barry Powell. He’s been selling tooling lines to customers for more than 3 decades now. You may not have known, however, that Barry is a Journeyman Tool & Grinder, having spent many years working in the trade for Allied Signal.

Barry says, “ARNO USA combines German tradition

Challenged with meeting customer deliveries and adapting to their ever-changing requirements?

Optimize your manufacturing workflow with modular end-to-end solutions from Bystronic. Combine best-in-class machines, automated production cells, and software for a highly agile and efficient production process that can expand as your business grows. Bystronic will guide you through your transformation journey step-by-step. Your best choice for sheet metal processing.

3020 South Park Drive ,Tempe, AZ sales@stp-az.com • Tel: 602-426-9340

STP-AZ.COM

We Manufacturing Complex Intricate Parts Requiring Extreme Precision And Quality

We Are Built For High Production Parts And Can Handle Extremely Tight Tolerances

New State-of-the-art

Industrial

Announcements & Releases Continued

with state-of-the-art cutting and turning tool technologies. We offer outstanding tooling, particularly for Swiss Tooling and Production Turning.” He adds, “While not a household name in the Western USA, since 1962, ARNO USA has been manufacturing and selling high-quality products for customers in the industrial tooling and machining markets. ARNO USA represents the US branch of ARNO Werkzeuge, headquartered in Germany.

The Federal Reserve reported that industrial production in March rose 1.4%, returning to growth after an unseasonably stormy February knocked it down 2.6%. The report shows total industrial production rose 2.5% at an annualized rate

Motor vehicles and parts production, which fell 10% in February, rose 2.8% in March but remained depressed by a persistent shortage of semiconductors. Most durable goods indexes rose between 2% to 3%.

during the first quarter of 2021 despite the losses endured in February by manufacturing, mining, and utilities companies.

To learn more about the ARNO German quality industrial tooling and machining products that offer value added solutions to benefit your productivity every day, contact Barry at bpowell@arnousa.com or call 815-236-8118.

The industrial production gauge includes productivity in three sectors: manufacturing, mining, and utilities. Manufacturing production (which excludes mining and utilities output) rose 2.7% in March after falling 3.7% the month before. Mining production improved 2.7%, while utility output fell 11.4% thanks to unseasonably warm March temperatures. Manufacturing output rose 1.9% at an annualized rate.

- Connect with Arizona MEP for New Business Opportunities

Arizona MEP frequently gets requests to help companies find local manufacturers for new products, outsourced production, support for excess demand and reshoring opportunities.

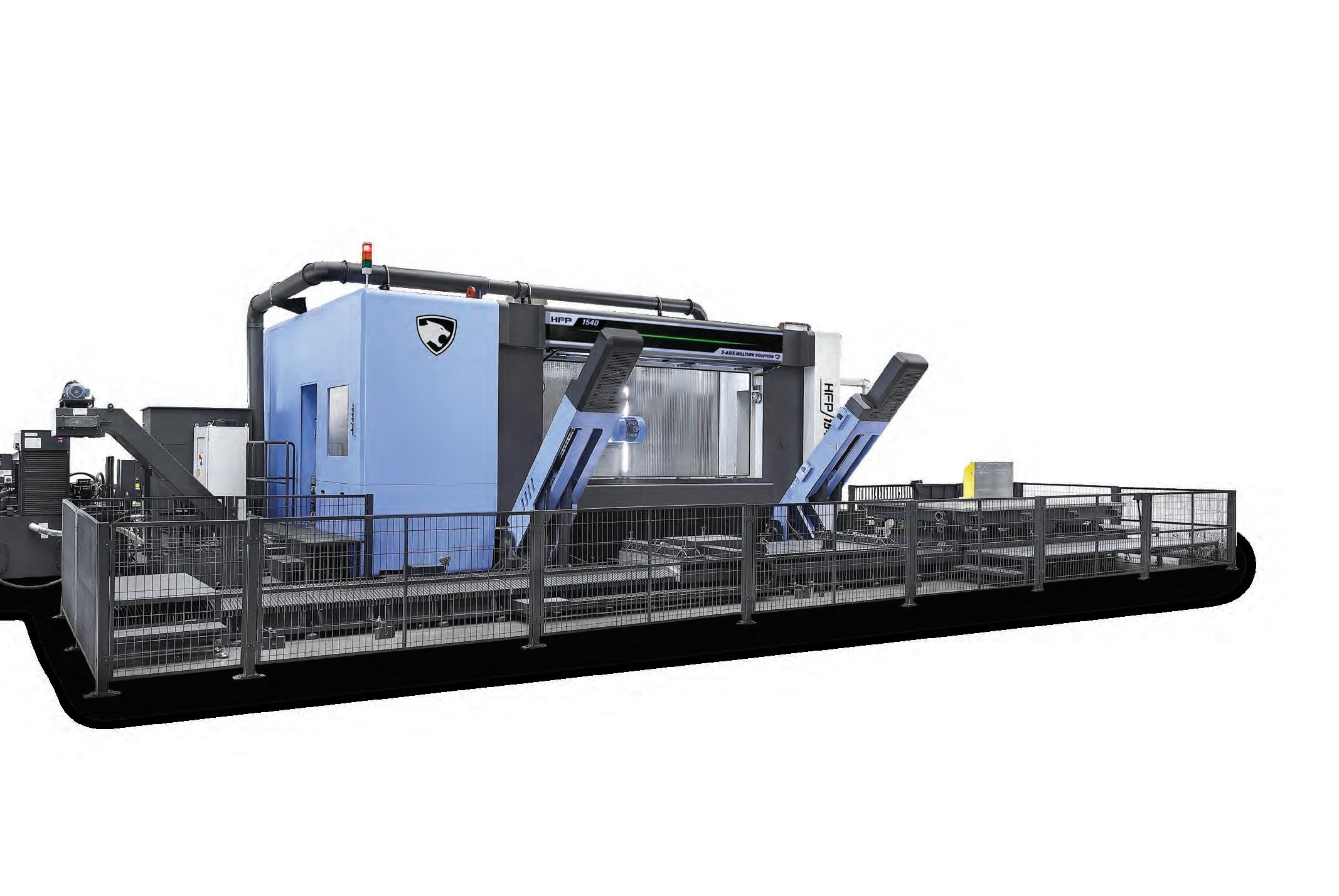

We are excited to introduce a new member of the DMG Mori team in Arizona. Charlie Ernest has been with DMG Mori for over 11 years. He started with Mori Seiki in the Davis, CA factory building NHX horizontal milling machines, then transferred to quality control for a total of 4 years in precision CNC manufacturing. In 2017 he completed the Sales Engineer apprenticeship program and assume the role of Area Sales Manager.

Capacity utilization in manufacturing rose by 1.9 points, also reversing February losses.

In nondurable manufacturing, the index for the chemicals industry rose 4.1%, and petroleum and coal products rose 5.7%, although neither sector has fully recovered from severe weather damage—the Federal Reserve noted that some chemicals factories remain offline thanks to damage sustained from February’s winter storms. Most nondurable goods indexes rose between 0.9% and 3.0%.

If you are a contract manufacturer or have extra capacity and would be willing to manufacture for other Arizona companies, contact your Arizona MEP Client Advisor at 602-845-1256 or info@azmep.com.

Almost all market groups saw improvements in March, despite lingering challenges. The Federal Reserve’s index for other manufacturing, which includes publishing and logging, remained the same, but durable goods and nondurable goods indexes rose 3.0% and 2.6%, respectively.

Charlie has managed the Northern California/ Northern Nevada territory for the last 7 years, providing customer with factory direct service and support. He is a Certified Manufacturing Technology Sales Engineer (CMTSE), having completed the program that provides national

If February was notable for its storminess, March was notable for its heat. The unseasonably warm month coincided with a roughly 10% drop in consumer energy products, and the 11.4% drop in utilitie s utilization was the largest recorded in the history of the index’s 48-year history.

√ 3 Companies - 1 Ownership

validation and recognition of exceptional business acumen and technical knowledge among sales engineers.

As the Arizona market continues to grow, DMG MORI decided to add Charlie to the local team alongside Bob McCool. Bob has supported the Arizona DMG MORI partners since 2018 when they went factory direct as the Area Sales Manager. Bob says, “The DMG MORI product line is an excellent fit for the Arizona market, where many machine shops process high precision and difficult to machine alloys for the Aerospace and Semiconductor Industries. DMG MORI is the industry leader in providing complete single source automated solutions for lights out production.”

The recent sled test, conducted with a 103-pound mannequin, is the latest sign that the JPO can make good on its promise to finish the three design fixes by Nov s to lift restrictions on lightweight pilots ws first repor ted that pilots under 136 pound fifth-generation aircraft after testers discovered ge to lightweight pilots ejecting from so acknowledged an “elevated level of r isk n 136 and 165 pounds.

The proto t 4.63 pounds, approximately 6 ounces lighter than the orig inal Gen III helmet, and is designed to ease some strain on smaller pilots’ nec ks during ejection

Please feel free to reach out to Charlie. He can be reached at 480-980-9678 or you can email him at cernest@dmgmori-usa.com

The first test of a new, lightweight F-35 helmet was successful, according to the prog ram office, a promising sign that the Pentagon can qualify and implement all three fixes to the jet’s escape system by the end of the year.

Walker Move Business From Cottonwood To Phoenix

Alan Walter was a loyal machinist to two companies

Recently, at Holloman Air Force Base, New Mexico, Lockheed Martin’s F-35 conducted the fir st test combining all three solutions designed to reduce the r isk of neck injury to F-35 pilots during ejection, according to spokesman Joe DellaVedova. Once the full gamut of testing is completed, hopefully by the end of the summer, the JPO can beg in implementing the two modifications to the ejection seat and issuing the new Generation III “light” helmet to the fleet, he said

Although the test was the fir st test of the new helmet, the JPO, Loc kheed Mar tin and seat-maker Mar tin Baker have conducted at least seven other tests with the latest version of the seat, which is equipped with two modifications designed to reduce r isk to pilots.The fixes to the ejection seat itself include a switch for lightweight pilots that will delay deployment of the main parachute, and a “head support panel,” a fabric panel sewn between the parachute r isers that will protect the pilot’s head from moving backward dur ing the parachute opening.

for nearly 3 decades prior to embarking upon a business of his own. He spent 17 years working for Genie, a manufacturer of boom lifts, telescopic boom lifts, scissor lifts and telehandler products, in Seattle, WA. There he grew through the ranks while building his skills in Machining, Tooling and Engineering Support, Implementation of NPD, and in Leadership. When he moved to the Phoenix area, Alan spent over 9 years working in Production Leadership for the Knox Company, a manufacturer of Rapid Access Solutions that have provided first responders with immediate access into secure buildings, campuses, residences, and commercial properties when it matters most. It was there that he developed his skills in automation integration and robotic manufacturing.

The prog ram office has about another 10 tests planned, which will use a mix of low-, middle- and high-weight mannequins.

Alan has 2 brothers who are entrepreneurs and when he talked to them about owning his own business, they recommended he purchase an existing

“This initial test had promising results and the F-35 enterpr ise is on a path to qualify the helmet . by the end of this summer,” DellaVedova told Defense News. “The lighter helmet expected to be fielded by the end of the year is in line with the seat timeframe as well.”

1704 West 10Th St • Tempe, AZ 85281

Ph: 480-967-2038 • F: 480-829-0838 • www.PrecisionDie.com

and dedication to customer service are number one priorities. This type of expertise and dedication has fostered a reputation of excellence in the tooling and stamping industry.

Located in Tempe, Arizona, our 100,000 Sq. Ft. Facility contains state of the art equipment , with production capabilities ranging from simple geometries to complex forms with intricate details. Precision enjoys a world-class reputation supplying a variety of OEMs, managing their inventory levels, and making certain product quality and timely delivery are NEVER compromised.

Announcements & Releases Continued

established company. After researching many businesses, Alan took their advice and in June of 2022 he purchased C&R Machining, a small shop in Cottonwood, AZ. After the purchase, he changed the name to Multi-Axis Machining.

Six months passed, Alan and his wife Lyssa moved the business to North Phoenix. Though the shop under new ownership is relatively young, with Alan’s expertise he has secured business from some commercial OEMs and has been performing contract work for a few established shops; including work for the firearm, defense, and food & beverage industries. With his years of experience as a guide, Alan has continued to upgrade their capabilities and equipment through the purchase of a CNC Lathe and a Horizontal Machining Center.

Since Alan spent years working at major OEMs, he is very accustomed to supporting production manufacturing, but that isn’t all he can do. “As a small shop, we can offer larger shops and OEMs quick turns, whether they are looking for prototype, small batch, or production. For established parts, we can manufacture them typically in 2-3 days from the time we receive the material.”

Multi-Axis Machining has both CNC and manual machines to support their customers’ requirements. To learn more about

how they can help your business with experienced, professional quick turn parts, contact them at: 623215-8588, email: contact@mamachining.com or visit their website at www.mamachining.com.

In Phoenix, AZ on May 22nd

Join Landmark Solutions in The Valley on Wednesday, May 22nd for an exciting, highly productive event highlighting precision laser cutting and automation solutions from Bystronic.

Hear about advancements in fabrication equipment; see high-performance machines in action; and get real owner and operator feedback from host, Westcott Designs, about why they trust Bystronic to support their success. Lunch Provided. For Free Registration, Contact:

Matt Kassman, Landmark Solution Applications Specialist (480) 549-9805 | matt@landmarksolutionscorp.com

We are proud to announce QualityMTS has expanded sales and service to Arizona and New Mexico. For 20 years, QualityMTS has supported customers in the Midwest.

ARNO USA’s Barry Powell Signs Next Generation Tooling Rep Firm to Distribute Their Tooling Products in California and Nevada

Barry Powell, Business Development Specialist for ARNO USA, is pleased to announce that Next Generation Tooling will now distribute ARNO USA’s tooling products throughout California.

Barry says, “Next Generation Tooling, founded in 1995, is a technical marketing company that provides sales support and technical product training to industrial distributors, machine tool dealers and end users. The team of Rob Aldama, Tim Fugazi, and Chris Savolainen (Founder), all are highly technical in industrial tooling and provide hands-on technical support on the machine shop floor to their end-user customers as well as valuable feedback on applications and new product design ideas to our principals. I expect them to be an

& Releases Continued

asset to our current and new customers throughout California and Nevada.”

Barry says, “ARNO USA combines German tradition with state-of-the-art cutting and turning tool technologies. We offer outstanding tooling, particularly for Swiss Tooling and Production Turning.” He adds, “While not a household name in the Western USA, since 1962, ARNO USA has been manufacturing and selling highquality products for customers in the industrial tooling and machining markets. ARNO USA represents the US branch of ARNO Werkzeuge, headquartered in Germany.

To learn more about the ARNO German quality industrial tooling and machining products that offer value added solutions to benefit your productivity every day, contact Chris at chris@nextgentooling.com or call 916.765.4227.

On February 22, ATMA partnered with NTMA member, Lux Precision Manufacturing and Grand Canyon University for a tour of Building 66 on the GCU Campus.

Cont Page 24

Hysol® MB products are the best-selling, highest volume coolants sold by Castrol® due to their all-around performance and overall value.

Product advantages

• High-quality finish across multi-metals and operations

• Excellent anti-corrosion properties

• Clean running and have a very mild odor

• Wide tolerance to water hardness

• Robust pH stability fights bacterial growth

Simplify operations and make it easier to meet the demands of your business.

Contact Star Metal Fluids today to learn why Hysol® MB products are the favorite among machine operators.

ABS is

Machine, Omegasonics Pro Series Ultrasound Unit and more, followed by lunch served up by the Kurzawski family and their team.

March 21 featured the ATMA Eat. Drink.Mingle passport night with attendees sampling 4 unique food stations and an open bar. This event was sponsored by the ATMA Industry Partners, with over 100 people attending, great networking and prizes being awarded every 15 minutes.

The Skill Up Arizona Apprenticeship and Awards Foundation is building the first Uniquely Abled Academy, which is a 10 week cohort designed to prepare candidates on the autism spectrum for apprenticeships in precision manufacturing. For more details visit: skillupaz.org

The NTMA/ Arizona Chapter welcomes Micro-Tronics and Liberty Precision Works as our newest members. Not a member and want to be a part of our active manufacturing community? Membership information can be found on our local website: arizonatooling.org or ntma.org

The tour included Canyon Ventures, GCU City Serve and Lux Precision Manufacturing, who in partnership with GCU, offers a pre-apprenticeship opportunity that allows students to gain work experience in CNC machining, helping to strengthen workforce development in manufacturing.

ATMA Industry Partner, Star Metal Fluids, held a tour March 5 of their in-house product analysis lab and warehouse area with demonstrations featuring Giant Finishing Vibratory Deburring

Alpha Manufacturing Solutions (AMS) Is Now HUB-Zone Certified and an Approved Boeing Supplier

Alpha Manufacturing Solutions is pleased to announce that they recently became a HUB-Zone Certified entity, with certification #72436.

Christian Escobar, president of the company, says, “Months ago, I approached Boeing in an effort to win their business. When I mentioned that we resided in a designated Hub-Zone, I was told that if I secured this certification, it would make it easier for them Announcements Cont Page 26

✓ Integrated trunnion table design provides more clearance in Z-axis and ability to machine heavier parts compared to 3-axis mills with trunnion table added.

✓ +30°/-110° A-axis motion delivers better undercut capability.

✓ Solid one-piece cast iron frame

✓ Best-In-Class Yaskawa Sigma V Drives.

✓ LED lighting shines brighter and saves energy.

✓ 2 or 4 passage rotary unions for hydraulics and/or air.

✓ 5-axis/5-sided software features – Tool Path Linearization, Tool Center Point Management, Transform Plane, 3D Tool Compensation, Tool Vector Input & Retract, Shortest Angular Traverse, 3D Import.

• Table Diameter: 9.8"

• X/Y/Z Travel: 30" x 20" x 20.5"

• X/Y/Z Rapids: 1,496, 14,496, 1,260 inches/minute

• 12K RPM Spindle

✓ Robust control specifications (standard not an option) – 4GB RAM Memory, 10,000 block lookahead, 128GB Solid State Hard Drive, 2.7GHz Dual Core Processor.

✓ Ergonomically designed control console with two* 19” LCD touch-screens.

✓ Adjustable height control arm.

✓ WinMax ® Mill Conversational and Industry Standard NC programming.

✓ Patented Motion Control System (UltiMotion ® ) is standard not an option.

*The VM10Ui has a single-screen 19” LCD touch-screen.

to get us on the Boeing approved supplier list.”

He adds, “The process took several months, and today we are both Hub-Zone certified and an approved Boeing

Alpha Manufacturing Solutions LLC is a family owned, minority owned precision machine shop founded in 2009. Today, the AS9100 certified company offers precision mill and lathe, including 5 axis machining. They can support your prototype to production requirements. For more information, contact them at: (602) 281-6760 or visit alphamanufacturingsolutions. com

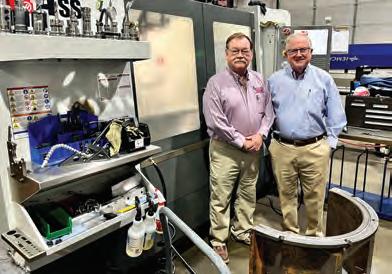

Tyler Carroll and Kyle Huth met while both worked for an EDM company in the Valley. Tyler had spent his entire career at his previous employer, having joined the company where his father still works today. “I am a 4th generation machinist and I love the industry”, Tyler says.

Like Tyler, Kyle began his career in the precision machining industry shortly after graduating from High School. He didn’t have generations of family members, though, and he started his journey as a hand finisher. When one of his colleagues, a grinder, was retiring, Kyle took the opportunity to learn from his colleague, and he became expert at grinding. The company had a sinker EDM that sat unused, since nobody at the shop knew how to run it. “I read the manual and did a few YouTube videos, and I learned how to run the sinker EDM”, he says.

Kyle learned how to EDM so well that he was hired by the same EDM shop that Tyler was working at. The two got to know each other well, and remained at the company until it changed ownership, both with expertise at sinker EDM, CNC machining and programming.

When Tyler made the decision to start his own company, he approached Kyle to form a partnership in the new entity. Tyler says, “We both want to build a manufacturing business that our children can take over in the coming years.” Kyle adds, “We want this to be a legacy, not just for our children, but also for the next generation of machinists. As we grow the business, we want to support apprenticeships in this great industry.”

Today, the company resides in a 3500 square foot facility and it offers customers sinker EDM as well as CNC machining. Tyler says, “When you come to Liberty Precision Works, you will experience superior service. Kyle and I have experience in larger shops, and we know what they did well just as we know what they could be better at. We’ll take these learnings to provide our customers with the best pricing,

turnaround time and quality.” Kyle adds, “With our background in programming, we selected the very best CAM software, and this will enable 30-70% faster material removal – again supporting our ability to provide quick turnaround and lower pricing.”

Liberty Precision Works offers you the attention to detail that is best achieved with owners who are also your machinists and programmers. “This is our opportunity of a lifetime”, Tyler says, “and it is our commitment to provide unmatched service to our customers.” Contact this start-up with 20 years of experience in machining and EDM. To learn more, contact them at 480-584-5227 or you can email tyler.carroll@ libertyprecisionworks.com or kyle.huth@libertyprecision.com

Davis Monthan AFB 2024 “State of The Base”

The Command, Mission, and Outlook for Davis Monthan Air Force Base

Date: Thursday, May 16, 2024 from 12:00 pm to 2:00 pm

Location: Embassy Suites by Hilton Tucson East ; 6555 East Speedway Boulevard Tucson, AZ 85710

Cost: Military: Free; General Admission: $20.00

Register: www.eventbrite.com/e/davis-monthan-afb-2024-state-of-the-basetickets-839202656737?utm-campaign=social&utm-content=attendeeshare&utmmedium=discovery&utm-term=listing&utm-source=cp&aff=ebdsshcopyurl

Sterling Fab Tech is a fabrication machinery supplier that represents the most cutting-edge manufacturing technologies in the fabrication industry. With locally based sales and service employees, we support the Southwest region from California to Louisiana.

We pride ourselves in being the subject matter experts in fabrication processes and machine technologies. Combining this engineering approach to sales, our goal is to understand your needs and educate your team without any sales puffery.

Coil Lines

Coil Lines

Flat Sheet & Tube Lasers

Flat Sheet & Tube Lasers

Punch and Laser/ Punch Combo

Punch and Laser/ Punch Combo

Waterjets

Waterjets

Press Brakes & Robotic Bending Cells

Press Brakes & Robotic Bending Cells

Panel Benders

Panel Benders

Plate Rolls

Plate Rolls

Tube Bending

Tube Bending

Deburring & Finishing Machines

Deburring & Finishing Machines

Robotic Mig & Laser Welding Cells

Robotic Mig & Laser Welding Cells

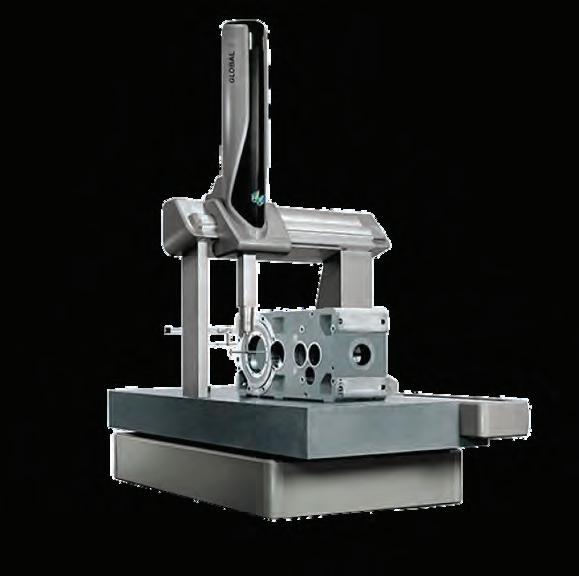

Quality Inspection Machines

Quality Inspection Machines

Sheet & Tube Storage Racks

Sheet & Tube Storage Racks

Nitrogen Generators

Nitrogen Generators

Plasma & Oxy-Fuel Burning Tables

Plasma & Oxy-Fuel Burning Tables

Gantry Style Machining Centers

Gantry Style Machining Centers

Pipe & Tube Cutting

Pipe & Tube Cutting

Robotic Plasma for Profile Cutting

Robotic Plasma for Profile Cutting

High Tonnage Press Brakes

High Tonnage Press Brakes

Heavy Duty Plate Rolls

Heavy Duty Plate Rolls

Angle & Pipe Bending

Angle & Pipe Bending

Automated Beam Welding

Automated Beam Welding

Power Tools for Bevelings

Power Tools for Bevelings

SFT’s Applications team supports you during machine selection, installation/commissioning throughout the life of the machine. We offer services to improve efficiency and productivity, while reducing the common headaches of implementing new technologies or dealing with labor shortages.

SFT’s Applications team supports you during machine selection, installation/commissioning throughout the life of the machine. We offer services to improve efficiency and productivity, while reducing the common headaches of implementing new technologies or dealing with labor shortages.

SFT’s Service team are factory trained technicians dedicated to getting your machine installed correctly, preventing unexpected downtime through preventative maintenance, assisting with machine relocations, and promptly completing machine repairs. They are also trained to handle TRUMPF and Bystronic lasers.

SFT’s Service team are factory trained technicians dedicated to getting your machine installed correctly, preventing unexpected downtime through preventative maintenance, assisting with machine relocations, and promptly completing machine repairs. They are also trained to handle TRUMPF and Bystronic lasers.

Phoenix Swissturn Solutions is a screw machine shop opened in Tempe, Arizona to provide swiss screw machining capabilities to the RF/microwave, Medical, Aerospace and other specialized markets.

Expertise, Precision machining, dedication, Timely & quality service. We can machine difficult materials:

Titanium, Stainless Steel, Brass, Beryllium Copper (BeCu), Various types of plastic

Phoenix Swissturn Solutions LLC

www.phoenixswissturn.com

607 S. 48th Street, Ste. 104 Tempe AZ, USA 85281

602.600.8436

Info@phoenixswissturn.com

MEIDOH Co., Ltd., an international leader in the production of automotive fasteners, is pleased to announce it has acquired Pilgrim Screw Corporation d/b/a Pilgrim Aerospace Fasteners (“Pilgrim”).

Pilgrim is a leading manufacturer of screws, bolts, rivets, clevis pins, and other fasteners for the aerospace market with manufacturing operations located in Chandler, Arizona and a small office in Providence, Rhode Island. Pilgrim’s customers include some of the world’s biggest names in the aerospace industry.

MEIDOH, a third-generation company owned by the Hasegawa family, is the premier supplier of bolts to Toyota. They have manufacturing plants in Japan, China, Indonesia, Thailand, and the United States with more than 2,000 employees worldwide.

Pilgrim established its Chandler operations in 1998. There are currently 50 employees at the 24,500-square-foot facility, located at 2875 W. Frye Road within the Price Corridor. The property includes land for future growth.

Pilgrim Aerospace Fasteners is a manufacturer of screws, bolts, and specialty fasteners. The company’s products include goods based on stainless steel, stainless alloy, titanium, nickel alloy, aluminum, and brass. Today, Pilgrim Aerospace Fasteners has 60 employees with manufacturing operations in Chandler, Arizona.

Calgon Carbon Corp., a Pittsburghbased water treatment product manufacturer, is moving into Northwest New Mexico via an asset purchase in Bloomfield.

The company completed an asset purchase of locally owned Benchmark Tank and Bloomfield Machine and Welding this past October, and plans to retain all 42 employees from both companies. The department also said Calgon Carbon plans to hire nine new employees in 2024 and 16 in coming years. Calgon Carbon has around 1,700 employees globally and manufacturing centers throughout the United States, Europe and Asia.

The facility will produce activated carbon vessels — a common technology used in water filtration —

for customers in the Western and Southwestern United States. “This investment will expand a skilled workforce and increase wages in a part of the state that has seen a lot of job displacement,” Mark Roper, acting EDD cabinet secretary, said. The state will also award Calgon Carbon $150,000 in Local Economic Development funds (LEDA). The company said it plans to use New Mexico’s Job Training Incentive Program (JTIP). By Drew Goretzka –Albuquerque Business First

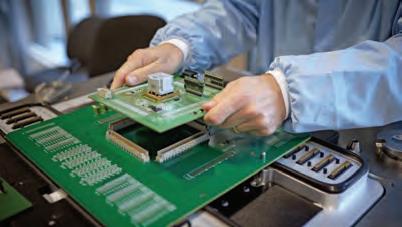

UPE provides comprehensive kitting solutions to businesses—from startups to Fortune 500 companies. We specialize in assembling complex BOMs (Bill of Materials) into production-ready kits, streamlining the process and saving you valuable time and resources. Our team of experts has 50+ years of experience in kitting, ensuring that your products are assembled to the highest standards.

Save time, energy and money.

At UPE we customize every kit to meet your unique needs and requirements. Our electronic component kitting services cater to a broad spectrum of industries, including aerospace, telecommunications, military and more. We use state-of-the-art equipment and technology to ensure that your kits are assembled with precision and accuracy. Our commitment to customer satisfaction means that we work closely with you to ensure that your needs are met.

We take pride in our attention to detail and our ability to provide cost-effective kitting solutions without sacrificing quality. Your time is a valuable resource—UPE understands what it takes to keep production moving.

Choose UPE for all your kitting needs. SERVICES

Our experienced team is always available to offer expert guidance and support. Contact us today to learn more about our services and how we can help you streamline production.

‣ AEROSPACE

‣ AGRICULTURE

‣ AUTOMOTIVE

‣ AVIATION

‣ COMPUTING

‣ COMMUNICATIONS/ TELECOM

‣ CONSUMER PRODUCTS

‣ DEFENSE

‣ ENERGY

‣ INDUSTRIAL

‣ MARINE ‣ MEDICAL ‣ MILITARY ‣ TECHNOLOGY

Perfection Industrial Finishing is one of the leading metal finishing companies in Southern Arizona, providing services to a wide range of industries. Local and national manufacturing businesses in the defense, aerospace, industrial and commercial fields have come to rely on the high quality metal finishing services that Perfection Industrial Finishing has provided for more than 20 years.

Big Factory Capability — Small Shop Agility

‣ Kitting — Complete BOM

‣ Consigned / Turnkey Kits

‣ Purchasing Services

‣ Project Management

‣ Materials Management

‣ Assembly Services

‣ Engineering Services

‣ Bonded Inventory

‣ PCB Fabrication

‣ Component Evaluation

760.438.2370

unitedpacificinc.com sales@unitedpacificinc.com

2075 Corte Del Nogal, Suite K, Carlsbad, CA 92011

America Inks MOU with GloballyRecognized Economic Development Engine

and conversion coatings), sandblasting and more. Click here to learn more about our services.

The company’s founder, Chuck Zinke, developed the concept from his long time passion – cars. Chuck began rebuilding cars and trucks in his spare time as a teenager, and initially used the services of the only powder coating company in Tucson. As his hobby grew, he began to look at ways of improving the quality of painted parts as well as reducing the overall cost and time for delivery. He decided to try it himself, and by 1991 his garage became his first paint shop – run in his spare time, but taking on work for others after word quickly spread. A few months later, he turned his hobby into a full time career and established himself as a recognized supplier of painting excellence.

LAS CRUCES, N.M -The Borderplex Alliance and Spaceport America today signed a Memorandum of Understanding, formalizing a new collaboration between the two organizations. This partnership will open up thrilling opportunities to propel the Borderplex region’s economy to new heights.

“We are thrilled about teaming up with Spaceport America,” said Jon Barela, CEO of The Borderplex Alliance. “Together, we will initiate new programs that stimulate job creation and capital investment in our region. The commercial space industry is expanding rapidly, and this alliance ensures the Borderplex will be at the forefront of this 21st-century industry.”

Since those humble beginnings a number of other services have been added to the original powder coat capability, including conventional (wet) paint, chemical processing (such as anodizing

Our business was established in 1992 and has been adding capabilities and prime customers over the past 29 years. We are known in the industry for high quality and quick turns. With the two facilities it enables us to find the best facility to support our customers and their products at the highest levels. Having so many processes in house allows our customers to save time and money with minimizing the outsourcing to multiple companies.

Spaceport America, the world’s first purpose-built commercial spaceport,

Borderplex to launching that growth.

Spaceport commercial licensed acres adjacent to the U.S. Army New Mexico, has a rocket-friendly restricted airspace, low population vertical launch complexes, and

Some of the most respected companies are tenants at Spaceport America: AeroVironment, UP Aerospace, subsidiary of BAE Systems.

The Borderplex Alliance is an policy advocacy organization. sector-led. The mission of The and opportunity to the Borderplex

We currently hold NADCAP, AS9100, ISO, and ITAR certifications. For more information on how Perfection Industrial Finishing can help you shine contact them at: 520-434-9090, “Toni Gauna” toni@ pif-az.com, www.pif-az.com

Equipment Leasing and Finance Association’s Survey of Economic Activity: February New Business Volume Up 4.9% Year-to-date

The Equipment Leasing and Finance Association’s (ELFA) Monthly Leasing and Finance Index (MLFI-25), which reports economic activity from 25 companies representing a cross section of the $1 trillion equipment finance sector, showed their overall new business volume for February was $7.9 billion, up 4% year-overyear from new business volume in February 2023. Volume was down 15% from $9.3 billion in January. Year-to-date, cumulative new business volume was up 4.9% compared to 2023.

Receivables over 30 days were 2.2%, down from 2.3% the previous month and up from 1.8% in the same period in 2023. Charge-offs were 0.4%, down from 0.5% the previous month and up from 0.3% in the year-earlier period.

Credit approvals totaled 76%, unchanged from January. Total headcount for

e quipment finance companies was up 1.8% year-over-year.

Separately, the Equipment Leasing & Finance Foundation’s Monthly Confi dence Index (MCIEFI) in March is 55.2, an increase from the February index of 51.7 and the highest level since April 2022.

ELFA President and CEO Leigh Lytle said, “Given continuing high interest rates and inflationary pressures, new business volume performed well in February. Tightening lending standards at banks are expanding opportunities for independent and captive equipment fi nance companies to provide critical productive assets that businesses need to operate.

Credit quality, while still elevated year over year, showed improvement with delinquencies slowly returning to normal levels and charge-offs moving in a positive direction.”

Stan Walker, Managing Director, Citizens Asset Finance, said, “As we’ve turned to March, the equipment finance industry continues to show its resiliency as evidenced by the second straight month of higher business volume year over year.

Despite the continued high interest rate environment and uncertainty around when rates may fall, Citizens is helping clients move forward with new equipment solutions both for growth and replacement needs.

After a turbulent 2023, Citizens and most equipment finance groups in the banking sector are targeting growth by focusing on supporting their client base as trusted partners and adding select prospects where we can deliver smart advice and solutions.”

$400,000 with Rigging Included

The NHP 4000 Horizontal Machining Center delivers with automatic tool changes in under a second and 15,000 RPM spindle with axes acceleration of up to 1G, thru-spindle and flood coolant, center-thru chip evacuation, highly precise linear guides, larger work area, and a smaller footprint.

The latest software iteration for a Raytheon-built missile successfully knocked out a medium-range ballistic missile during a test in the Pacific Ocean, demonstrating the weapon’s enhanced capabilities for the U.S. Navy.

The Standard Missile-6, or SM-6, was built by Raytheon, whose missile manufacturing operations are based in Tucson. During this flight test, the Navy used a new configuration with newly qualified software that it said enhances the missiles capabilities.

Fired from the USS Preble at the Pacific Missile Range Facility in Hawaii, the test was dubbed Fight Test Aegis Weapon System. Raytheon said the ballistic missile was intercepted during its final seconds of flight.

Raytheon said the test showed its SM-6 is effective not just for anti-air and anti-surface warfare but also for advanced ballistic missile defense at sea. It’s the only single missile that can handle all three uses.

The SM-6 uses the Standard Missile airframe and propulsion system. Besides being used on Navy ships, sales of the SM-6 have been approved for several allied nations.

• Purchased in August of 2020

• Under power for inspection, and ready to ship immediately

• The machine has 5300 hours on it

• It will come with all 12 tombstones and all of the orange vise vises you see (64 total)

• Travels are 22 x 25.2 x 26

• Spindle RPM is 15,000 and 40.2 Horse power

• Max workpiece size is 24.8” x 35.4”, and 881 lbs

• 300 PSI through spindle coolant pressure

• Renishaw tool setting laser

• BK micro tool touch probe for break detection

• Rapids are 2362 In/min

I t has been a busy start to 2024 for Raytheon, Arizona's largest defense contractor based on total dollar value of annual contract. The company has also successfully tested a variety of weapons, while reaching a major milestone with a $116 million hypersonic missile program.

Raytheon’s Tucson-based operation also logged a few more contract awards during the past month. They are:

• A $49,413,549 modification of a Marine Corps contract for the procurement of low-rate initial production units of the Navy Marine Expeditionary Ship Interdiction System Launcher. Work will be performed in Tucson and elsewhere.

• A $287,000,000 contract modification from the Navy that adds scope to provide for recertification and modernization of 166 Tomahawk Block IV All-Up-Round Missiles (142 for the Navy and 24 for Foreign Military Sales customers). The work will help make the missiles operational for up to an additional 15 years of service. Most of the work will be performed in Tucson and is expected to be completed in March 2026.

•The Navy also awarded Raytheon a $8,573,968 contract modification to exercise options for design agent and engineering support services for the Rolling Airframe Missile. Work will be performed in Tucson and is expected to be completed by March 2026. By Jeff Gifford – Phoenix Business Journal

and Finance Association, said,

“The Foundation’s Q2 Outlook shows that the ‘soft landing’ appears to be on track. The Fed is likely to be cautious about rate cuts, particularly given recent backtracking on inflation, but we still expect borrowing costs to fall later this year.”

Equipment investment was negative for the second consecutive quarter, but continued strength in software investment led to overall E&S growth of 3.2% (annualized) in Q4. Economic conditions are generally positive, however, and a modest improvement in investment activity is expected later this year.

Driven by strong consumer spending and a resilient labor market, the U.S. economy continues to expand at a healthy clip, according to the Q2 update of the 2024 Equipment Leasing & Finance U.S. Economic Outlook. Real equipment and software investment growth is projected to be 2.2% in 2024, with activity expected to pick up in the latter half of the year. The report, which was prepared by Keybridge and released today by the Equipment Leasing & Finance Foundation, also forecasts real GDP growth of 2.3% this year, an improvement over the 1.7% growth forecasted in the Foundation’s 2024 Economic Outlook last December.

The Foundation’s report is focused on the $1.16 trillion equipment leasing and finance industry and highlights key trends in equipment investment, placing them in the context of the broader U.S. economic climate.

Leigh Lytle, President of the Foundation, and President & CEO of the Equipment LeasingThe U.S. economy continues to hum, driven by solid consumer spending and robust job growth. Borrowing costs and year-to-date inflation remain elevated, however, putting pressure on U.S. consumers and raising the potential for a spending slowdown later this year. Meanwhile, a sluggish global economy may reduce business investment and demand for U.S. exports. For now, the Foundation expects both job growth and consumer spending to slow but remain healthy while inflation continues along its path toward the Fed’s 2% target.

Overall manufacturing activity remains soft in early 2024. Both industry production and capacity utilization have trended downward for most of the last 18 months, and manufacturing hours worked is near its lowest point since 2010 (excluding the pandemic’s peak).

Despite a general consensus that the U.S. economy remains on track for a soft landing,

small business owners have a somewhat pessimistic outlook. Concerns regarding inflation are heightened, and both hiring and investment plans have slowed.

The Federal Reserve remains cautious, further delaying its longawaited rate cut cycle in March, as progress toward its 2% target stalled in Q1. With job growth still robust, Fed officials are unlikely to begin cutting rates until this summer or fall. Two rate cuts in 2024 are the most likely outcome.

Matsuura joins Productivity’s unrivaled array of premium machine tools available in New Mexico.

Denver, CO: Productivity is thrilled to announce it has received exclusive authorized distributor and service provider status for Matsuura Machinery USA in New Mexico. For nearly 40 years, Productivity has been a trusted provider of sales, service, support, training, and installation for the entire lineup of Matsuura products for portions of the Midwest and Rocky Mountain regions.

Building upon a rich history and partnership, Mark Smith, Vice President & General Manager at Productivity, expressed enthusiasm about the expansion, stating, “It’s an exciting opportunity to bring our experience and an industry-leading machine tool line to manufacturers and machine shops in New Mexico.”

Matsuura Machinery USA is renowned for its cutting-edge technology, delivering unparalleled excellence and innovation to its customers. Whether it’s high-speed machining, full 5-axis machining centers, vertical, horizontal, linear motor, or multi-tasking CNC machine tools, Matsuura offers a comprehensive range of solutions to a variety of industries.

Customers can achieve higher spindle speeds, faster turning times, advanced automation solutions, and lights-out machining capabilities with Matsuura’s technology. With local support in New Mexico, Productivity ensures seamless project management from concept to production, including comprehensive training and after-sales technical support. This partnership signifies a commitment to delivering top-notch service and support to manufacturers in New Mexico, empowering them to achieve new levels of productivity and efficiency.

Since 1968, Productivity Inc., based in Plymouth, Minnesota, has been distributing a broad range of CNC metalworking products and services. As a single source machine tool supplier, Productivity offers machine tools, tooling and accessories, machine repair, preventive maintenance, rotary and live tool repair, turnkey systems, robotics and automation and much more. In addition, their MachinesUsed.com division will sell your surplus equipment via its online auctions. Productivity services 12 states with five branch offices located in Minneapolis, Cedar Rapids, Omaha, Denver, and Salt Lake City.

• 80,000 sq. ft. Facility With Extensive Inventory

• Stocking Stainless Steel, Aluminum Stock and Specialty Metals

Selecting the right tool is pivotal in optimizing manufacturing processes, and press brakes play a crucial role in bending operations. While many companies opt for larger, versatile press brakes to accommodate a diverse range of materials and bending requirements, the ideal choice may lean towards compact high-speed brakes for enhanced productivity.

Press brakes have a specific bending length and a specific tonnage that are suited for the range of parts that each company processes. Companies normally use press brakes that can process a diverse range of materials to maintain flexibility in their production scheduling. Usually, this means having a ten- or twelve-foot bend length and a tonnage that can process from thin to thick. From a scheduling perspective, this is an ideal situation as it provides maximum flexibility in scheduling jobs. But from a productivity /capacity perspective this may not be the ideal situation.

The Physics of Working with Mass - Press brakes come in all different sizes and tonnages and they have vastly different technologies to aid in the bending process. It is possible to process thin small parts on a large tonnage brake. However, it is not possible to process longer thicker parts on a small tonnage brake. The reason is that the longer, thicker parts will most likely exceed the tonnage capacity of the brake. Additionally, running small parts on a large tonnage brake with a long upper ram length is not efficient.

It all comes down to simple physics. A larger, heavier mass is more difficult to accelerate and takes longer to reach top speed than a smaller, lighter mass. Likewise, decelerating a larger, heavier mass is more difficult and will require more time. This all adds up to lost time. Henceforth, small thin parts are more efficiently formed on a smaller press brake.

An Opportunity to Realize Greater Profits - If you find that most of your smaller parts are being formed on oversized press brakes, then this is an area of opportunity to investigate. When you compare to larger press brakes, small brakes such as the Bystronic ByBend Star 40 and 80 ton can process two to three times more parts in the same amount of time. The smaller brake press is faster due to the ability of the machine to accelerate and decelerate both the smaller and lighter upper ram and the smaller back gauge system. This provides not only more throughput capability but also more capacity to bend even more parts on your existing press brakes. Processing smaller, thinner parts on the smaller press brakes is much faster which speeds up the capacity for the larger brakes to process more parts in the larger size range.

The Right Tool for Increased Efficiency

- Using the correct press brake on the right applications can not only speed up bending operations but can also create greater machine capacity and flexibility in scheduling. Compact high-speed press brakes can bend up to two times more parts than larger conventional hydraulic brakes. This makes the perfect complement to the production capabilities of a fiber laser. Fiber lasers produce up to 4 times more parts per unit of time. High-speed bending is a major consideration for eliminating bottlenecks at the press brake.

Speed and Safety- The next big time-saver comes into play once the press brake starts the active bending program. Wide-view Fast Bend safety cameras enable faster approach, bending, and retract speeds without compromising operator safety. Safely achieve bending speeds of up to 1 inch per second, and approach and retract speeds > 590 inches/minute.

Keeping The Pace- There are opportunities with compact highspeed press brakes that are different for each production environment. Investing in new technology means being able to maintain the pace within your fabrication process as newer fiber lasers are capable of producing higher part volumes. Compact high-speed press brakes can help eliminate these bending bottlenecks.By Frank Arteaga, Regional Director Marketing – Americas; Bystronic Inc., Voice. bystronic@bystronic.com

In my industry, functionality is the most important feature, but aesthetics is still very important. The Milltronics CNC machines help me to make well-functioning parts that look really good. The finish is an art, and today our parts are attractive. — Don Bevers, Owner, Cutting Edge Machine

It’s not clear whether Ukrainian aid is entirely the cause, but there’s no question that defense spending has been good to the state. The Pentagon spent $15 billion in Arizona in fiscal 2022, the last year for which data is available, up from $14.6 billion the year before. That boosted Arizona back into the top 10 among states, from 13th place in fiscal 2021.

And the amount spent in fiscal 2022 may be more than what the Pentagon reported: A study done last fall for the governor’s office said that total military spending in the state in fiscal 2022 was $15.5 billion on an industry that supported 78,780 jobs directly or indirectly.

In its annual Defense Spending by State report for fiscal 2022, the Pentagon said more than half of the spending in Arizona – $8.2 billion – went to Raytheon. Northrop Grumman and Honeywell came in a distant second and third with $855 million and $642 million in Pentagon business, respectively, that year.

The defense bill would provide $60 billion to support Ukraine, $14.1 billion in security provisions to Israel, $9.2 billion in humanitarian aid, and $4.8 billion to support Taiwan. It passed 70-29 – both Arizona senators voted for it. Alan Maguire, president of The Maguire Company, said,“Virtually all the money that drives the military industry in Arizona is money that comes out of the Department of Defense,” said Maguire, who wrote the comprehensive Military Economic Impact Report for the governor’s office.

Intel is constructing two fabs totaling $20 billion at its Ocotillo campus in Chandler, while Tempebased Amkor Technology Inc. is investing $2 billion in an advanced microchip packaging and testing facility in the West Valley that’s expected to create 2,000 new jobs. TSMC is expected to start highvolume production at its first fab — which currently is under construction in north Phoenix — in the first half of 2025.

TSMC Chairman Mark Liu said the company might shift the second fab’s opening date to 2027 or 2028, depending upon customer demand and U.S. government incentives. TSMC had previously announced plans to begin production at the second fab in 2026.

Taiwan Semiconductor Manufacturing Co. is slated to land more than $5 billion in federal grants to support its Arizona chipmaking facility, according to Bloomberg. TSMC is making “steady progress in productive, ongoing discussions” with the U.S. government for federal incentives, Bloomberg reported.

The federal grant, however, is not yet finalized and it’s unclear whether TSMC plans to tap into loans and guarantees offered under the CHIPS Act, according to Bloomberg.

The CHIPS Program Office is in the midst of negotiations with large semiconductor companies for CHIPS Act subsidies and expects to make significant award announcements within four to six weeks, the Business Journal previously reported.

The agency is working through “a dynamic process” with applicants, including discussions about project milestones, funding timelines, and onshoring specific technologies, a U.S. Department of Commerce official told reporters.

The CHIPS Act includes $39 billion in grants, as well as loans and loan guarantees worth $75 billion to spur semiconductor manufacturing in the U.S., according to the Department of Commerce.

Advanced semiconductor companies — including Intel and TSMC — have requested more than $70 billion in CHIPS Act subsidies, more than double the amount available for U.S.-based projects, Commerce Secretary Gina Raimondo said in Feb. 26 remarks at the Center for Strategic and International Studies in Washington.

TSMC’s reported grant award comes as Intel was named a likely recipient of a $3.5 billion grant to create a “secure enclave” to produce advanced semiconductors for the U.S. military and intelligence programs. The grant is part of a spending plan that passed the U.S. House on March 6 and pulls funding from the CHIPS Act, according to Bloomberg.

What’s more, Intel is reportedly negotiating a $10 billion federal CHIPS Act funding package in what would be the largest award announcement to date. It’s unclear whether the $10 billion CHIPS Act award package would be separate from Intel’s $3.5 billion military grant.

To date, the Department of Commerce has announced three CHIPS Act investments for BAE Systems Inc., Arizonabased Microchip Technology and GlobalFoundries, which is set to receive nearly $1.5 billion in federal subsidies for a new fab and modernization of its existing facilities in New York and Vermont. By Amy Edelen – Phoenix Business Journal

Despite 2023 being a challenging year for manufacturers, global manufacturing output is set to achieve a compound annual growth rate of three percent between now and 2027 according to technology insight business Interact Analysis.

From digitalization and demand forecasting to economic uncertainty and emissions targets, 2023 presented several challenges for the manufacturing industry. However, these difficulties also provided opportunities for manufacturers to innovate and increase their competitiveness as the industry transforms.

Strengthened sustainability focus - The focus on reducing our environmental impact intensified in 2023, with IBM’s Institute for Business Value data showing 86 percent of companies now have a sustainability strategy in place. While this figure is promising, data shows that only around a third of businesses have acted on those strategies.

2024 will hopefully see the rise of businesses treating sustainability as a priority. This is especially important within the manufacturing industry, which is responsible for one-fifth of global carbon emissions according to World Economic Forum data. Currently, the sector is not sustainable enough, and we can do a lot more.

Ensuring that sustainability is not just a strategic ambition but a tangible, integrated part of daily operations is key to reducing emissions and achieving green targets. By combining strategic alignment, employee engagement and continuous data-driven improvements, manufacturers can not only achieve environmental and social goals but also drive innovation, reduce costs and enhance the company’s reputation and competitiveness.

Developing digital capabilities to meet demand - 2023 saw manufacturers feel the aftershocks of several supply chain issues. This particularly impacted the aerospace manufacturing sector, which was still in post-pandemic recovery mode.

However, with demand bouncing back, there has been a revived need from airlines looking to expand or renew their fleets to accommodate the resurgence in passenger travel and to meet new environmental standards with more fuel-efficient aircraft. The industry’s growth in 2024 will likely depend on how well manufacturers and the broader ecosystem can adapt to these evolving challenges and opportunities.

Aerospace manufacturers can increase their productivity by focusing on resilience, innovation, agility and sustainability. A key way to achieve this, especially

fo r those involved in metal cutting processes, is to integrate digital manufacturing tools for enhanced operational efficiency. A 2021 study of manufacturing companies conducted on behalf of Sandvik shows over two-thirds of manufacturers now implement these tools. Use cases include areas such as digital twins, computer numerical control (CNC) integration, process monitoring systems and cloud computing.

Digital tools support “datadriven manufacturing,” the fifth of Sandvik Coromant’s Manufacturing Wellness habits, which helps businesses spot potential improvements and accelerate productivity from CAD to delivery. Processes that are informed by data can help improve equipment uptime and extend working life by enabling manufacturers to identify potential failures before they occur. As 2024 progresses, we are likely to see the increased adoption of artificial intelligence (AI) tools to analyze data, with this level of automation helping to meet renewed demand while reducing costs. Incorporating AI tools is a core part of the Manufacturing Wellness mindset, outlined in the second habit of “embracing new technology” and the eighth habit of “automation.”

As well as allowing businesses to meet resurgent demand, digital manufacturing tools also facilitate the resource planning process for industries where demand is difficult to predict. This is particularly useful for automakers, who are facing increasing pressure to prepare for the upcoming phase-out of fossil fuel cars. It is important that manufacturers

/company/davis-salvage-co.-l.l.c. /davismetalsandsalvage /davissalvage

have sufficient EV capacity in time for the 2035 fossil fuel car ban in the U.K. and the EU, which has made resource planning difficult.

Data-enabled manufacturing allows for more flexible production systems that can quickly adapt to changes in product design or customer demand, facilitating the production of customized or small-batch items without significant efficiency loss. Integrating digital tools with supply chain management systems can improve forecasting, reduce inventory levels and enhance coordination with suppliers and customers, leading to a more responsive and efficient supply chain.

As the year progresses, the importance of industry trends such as sustainability, digitalization and demand forecasting will continue to grow. However, viewing these challenges as opportunities to innovate will help to develop successful, resilient manufacturers that thrive in 2024 and beyond.

To discover Sandvik Coromant’s eight Manufacturing Wellness habits, visit www. sandvik.coromant.com/en-us/manufacturing-wellness.

Owl Vans, a leading adventure accessory company and the largest aftermarket MercedesBenz Sprinter van manufacturer, is moving its headquarters from California to Mesa.

The company said its strategic vision for its new 40,000-square-foot space is to expand and capitalize on the increased interest in the van lifestyle.

Owl Vans, which is led by CEO John Willenborg, has a goal of reaching $100 million in annual sales over the next five years. The company also hopes to establish new locations across the United States, Canada, and Europe within the next 12 months.

Owl Vans’ growth has been aided by an exclusive partnership with automotive brand Mercedes-Benz, the only one that has garnered their association.

Owl Vans manufactures all of its products in

the United States, utilizing domestically sourced materials. It employs approximately 35 people in Arizona and another 35 across the country. The company’s Valley headquarters move adds to the hundreds of California companies that have reportedly relocated to other states in the past three years.

The Southeast Valley submarket, which includes Owl Vans’ new home in Mesa along with Chandler and Gilbert, recorded a vacancy rate of 24.8% in the fourth quarter of 2023, according to data from CBRE. That was up from a 23.6% vacancy rate in the fourth quarter of 2022.

Other companies like Boho Camper Vans have moved their facilities to the Valley, and have seen exponential growth and interest in the market. In 2021, Boho expanded to a 25,000 square-foot production facility in Tempe where it continues to build, rent and sell customized vans to customers globally.

Specializing in building, renting and selling new and used camper vans, the company has put an emphasis on curating their products to fit the interests of their customers.

David Sodemann, co-founder of Boho Camper Vans, said most builds are falling in the $65,000 range.” By Sam Stern – Phoenix Business Journal

Whether you’ve been in the RFID game for over two decades, are currently harnessing RFID tech, or have yet to dip your toes into its potential, picture this: a game-changer in real-time asset management. This disruptive system not only identifies, locates, and tracks items but does so with precision at distances previously deemed impossible. And it all runs on standard RAIN RFID passive tags.

Founded by Mary Dillon in Phoenix, AZ, Accu-traq ventured into RFID technology in 1998, initially to cater to the asset management needs at the Palo Verde Nuclear Plant. This led to a successful partnership with CribMaster, integrating Accu-traq’s proprietary technology with CribMaster’s enterprise inventory management.

In 2021, Accu-traq embarked on a groundbreaking journey to address the complexities of managing mission-critical assets. Under

Dillon’s leadership, the company developed a cutting-edge software solution which underwent rigorous testing and validation at the Callaway Nuclear Plant in Missouri.

Unlike traditional Active RFID technology requiring battery-operated tags and substantial infrastructure investments, Accu-traq’s solution presents a more cost-effective and scalable alternative.

Accu-traq’s innovative technology not only addresses the critical gap in asset tracking but also significantly enhances operational efficiency. By providing real-time visibility into asset movement and utilization Accu-traq’s solution empowers organizations to optimize resource allocation, minimize downtime, and streamline workflow processes. For industries with stringent compliance requirements, such as healthcare, aerospace, and manufacturing, Accu-traq offers a turnkey solution that ensures adherence to regulatory standards and auditability. This approach to asset management not only reduces operational risks but also fosters a culture of accountability and transparency within the organization.

Recognizing the remarkable potential of Accutraq’s software solution, Great Lakes Industrial, Accu-traq’s customer, took the opportunity to invest in Accu-traq. This strategic acquisition empowered GLI to leverage the software to oversee its inventory nationwide and enhance operational efficiency without geographical constraints.

Jessica Meller, Commercial Sales Director for Accu-traq states, “Accu-traq’s acquisition by a larger global entity like GLI bolsters the resources available to serve our customers. The infusion of capital is fueling the expansion of our product portfolio, providing tangible benefits to our customers who value partnering with a wellestablished organization.”

“The acquisition has bolstered Accu-traq’s ability to partner with industry leaders,” Jessica explains. “Today, we’ve expanded our partnerships to include RF Controls for antennas, Zebra and Sato for RFID printers, and Avery & Checkpoint for RFID tag manufacturing, alongside our longstanding collaboration with CribMaster for asset management software and devices.”