West Coast Edition For: WA, OR, and CA Vol. 13, No. 4 AUG / SEPT ’23 BUYER’S GUIDE PAGES 32-45 a2zMFG.com MetzFab Industries Your Manufacturing Partner For Laser Cutting, Tube Laser Cutting, Machining, Waterjet Cutting, Welding And More a2zMFG.com

GROOVING THREADING PARTING BORING TURNING FACE GROOVING CUSTOM TOOLING FORM TOOLING MILL TOOLING Follow us on: 888-THINBIT | WWW.THINBIT.COM

What Is The Only Constant In Life?

“The Only Constant in Life Is Change.”- Heraclitus “ Heraclitus, I believe, says that all things pass and nothing stays, and comparing existing things to the flow of a river, he says you could not step twice into the same river. ” –Plato One constant since the beginning of time might be change, however, the fear of change is also a constant.

Time Flies, And Everything Changes

Humans tend to like routines, rituals, and the good ole days and ways. When we are taught something there is a formula, a recipe we follow to learn by repetition or a means to the end, a baked cake, just like the one we baked last time. But every good chef knows one thing leads to another and we evolve by trying new things, even small subtle changes can improve the way we cook, eat,or live.

When evolution is evident, change is the catalyst to moving forward and growing.We all have a core or a foundation within us, and while we feel it is a constant, it is a paradigm. Changing a personal paradigm opens up a range of new lifelines for our personal and professional growth, presenting us with more opportunities than before.

The alphabet is a rigid sequence of letters that never changes from A to Z until words are formed.

In manufacturing we learned a set of principles and rules to embark on our creative path to making things. At first the speeds were slow and careful, but as we evolved we pushed the limits of what we learned and embraced new methods and paradigms to get us to a better conclusion. Accordingly, a paradigm shift is defined as “an important change that happens when the usual way of thinking about or doing something is replaced by a new and different way.

The manufacturing facilities of today small or large are hit with changes within their respective supply chains. The material we purchased and machined 10 years ago was cheaper, higher quality, readily available and one could shop between many suppliers and come up with a better price and faster delivery. Today our lead times are stretched, availablility is not constant, and what once had a standard cost of X is now three times that amout.We must make components faster, program in machined deburr methodology, create ways to check these parts faster, and over all rethink the way our facility operates. We constantly want to make a quality part, like we did last month, and our customers want a competitively priced item so they can stay viable. We must change the way we think, the way we operate, change the tools we utilize, and embrace new paradigms so that we can evolve.

Thank you all for supporting our precision A2Z Manufacturing Magazines in the Southwest, the Rocky Mountains and on the West Coast. We want to write your story to help others and to get you noticed (some eyeballs). Give us a call or drop us an email and we will be glad to schedule some time to interview you, do a photo shoot, and write about your business so we all can evolve. We hope to see you at the Design 2 part show in Ontario in September and Westec in November.

Thank you!

Kim Carpenter

MetzFab

Your Manufacturing Partner

Pages 20-22

Marzee 5-8 days turn time Page 11

Published by: A2Z Manufacturing West Coast

PUBLISHERS/EDITORS

Kim Carpenter & Linda Daly

Kim@A2ZManufacturing.com

Mail Address: 1538 E. La Vieve Ln. Tempe AZ 85284

Telephone: (480) 773-3239

Website: www.A2ZManufacturing.com

CONTRIBUTORS

Linda Daly, Eugene Wirth, Stephen Hannemann,

Published

turers abreast

contracts, trends, and to supply a viable supplier source for the industry.

Circula tion: A2Z Manufacturing West Coast maintains a master list of over 14,000 decision makers consisting of fortune 1000 companies, small manufacturing companies, engineering firms, DOD & Scientific Lab facilities, machine shops, fab-shops, and secondary source businesses. It has an estimated pass on readership of more than 25,000 people. The majority of our readers are based in CA, OR, WA area!

Advertising Rates have remained the same since 1999, deadlines and mechanical requirements furnished on our website at: www.a2zManufacturing.com.

All photos and copy become the property of A2Z Manufacturing.

T he Publisher assumes no responsibility for the contents of any advertisement, and all representations are those of the advertiser and not that of the publisher.

The Publisher is not liable to any advertiser for any misprints or errors not the fault of the publisher, and in such event, the limit of the publisher's liability shall only be the amount of the publishers charge for such advertising.

bi-monthly to keep precision

manufac-

of news,

Cover

E-mail:

Announcements/Releases ................... 6-14 Feature Articles ...................... 1,20-21, 28-29 Buyers Guide Equipment Services ..... 32-38 Buyers Guide Processes ...................... 39-45 Card Gallery ........................................ 32-45 Index Of Advertisers ............................... 46 Editorial .................................. Throughout A2Z MANUFACTURING WEST COAST • 4 • AUG - SEPT ’23

Kim@A2ZManufacturing.com

Industries

Editor’s Corner

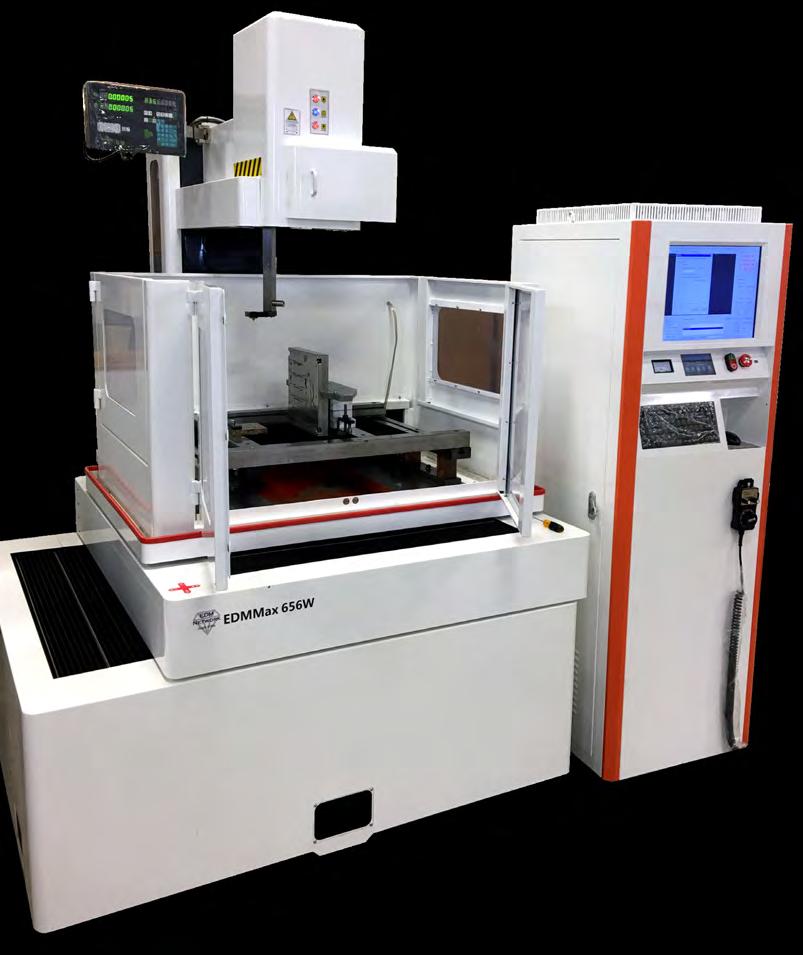

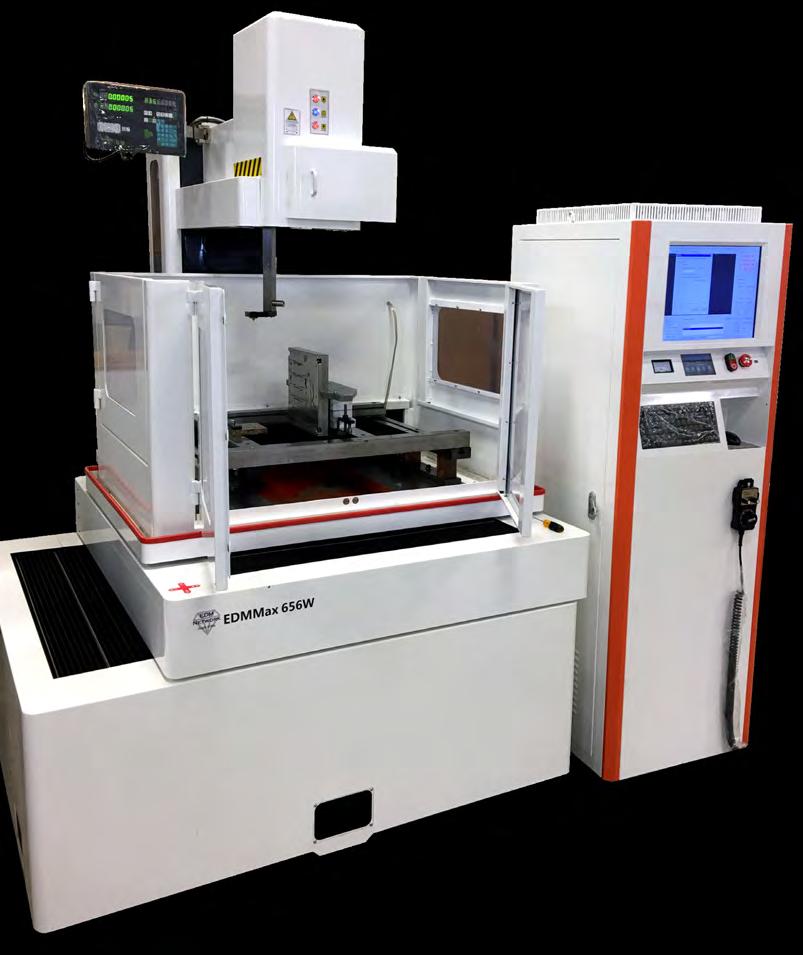

We have added a number of improvements over the standard Fast Wire Edms including:

• Cutting capacity of 625 x 625 mm

• Panasonic AC Servo motors and drivers

• Hiwin Linear Guideways

• Build in Cad System

• Two filters

• Increased height side walls to reduce splashing

• View windows to see the wire progress

• Automatic spent wire spooler

• Optional build plate support fixture

• Optional Anti Electrolisis (AE)

sizes available: • 400x320x410mm H

630x500x625mm H

1000x800x1050mm H

Horizontal Model 1000x1000x1000mm 1974 Bucktail Lane, Sugar Grove, IL 60554 1-888-289-3367 www.edmnetwork.com EDM Network provides “Everything in EDM”

EDMMax 656W 37 min TIME TO CUT

Four

•

•

•

The new model

Announcements & Releases

Elliott Dundas Tapped as Vice President at 3D Plastics

By Stephen Hannemann

What we have here is a 12-1/2 year inspirational success story. Following in his grandfather’s and father’s footsteps Elliott Dundas began his thirdgeneration plastics career at 3D Plastics in 2010. It’s much like making fine family vintage wine. It’s in the blood! Under the tutelage of his father Kelly, and his uncle Lee, I have had the privilege of witnessing this young man become a consummate representative for not only his company, but the regional plastics industry as well.

Elliott began his pilgrimage in the injection molding industry as a machine operator in 2010. A year later he moved to materials handling for a couple of years. He spent another two years in estimating. In 2015 Elliott came into his own when he made the jump to project manager. He made and continues to make favorable impressions with his customers as well as the mold makers he collaborates with to bring projects to fruition.

In giving back and supporting the industry, Elliott became president of the Columbia River chapter of the Society of Plastics Engineers in 2020. Elliott jumped into the fray intent upon growing the SPE chapter’s membership and better supporting injection molding in the Northwest.

Elliott lives in Lafayette, Oregon with his wife Laycie and three children, Hannah, Hailey, and Dakota. In their leisure time the family enjoys camping and spending time at the beach. Elliott’s rejuvenative time is spent in his garden and greenhouse tending his plants and vegetables. He also enjoys playing disc golf and hunting when he can eke out a bit of me-time.

Congratulations Elliott – Live Well!

Be sure to visit our 3D Plastics ad on page 16 of this issue.

For more information regarding 3D Plastics in Newberg, OR visit 3d-plastics.com or phone 503.537.0979

Thermal-Vac Arizona’s Chino Valley Location Opens for Business

Thermal-Vac Arizona is excited to welcome customers at its new, state-of-the-art facilities on State Route 89 in Chino Valley, Arizona.Thermal-Vac is a trusted name in the industry, having served Southern California’s aerospace industry since 1985 from its sibling shop in Orange, California.

Thermal-Vac Arizona carries forward a family tradition of obsessive customer service, rare technical expertise, and no-nonsense attitude.

Along with vacuum brazing, heat treatment, machining, and testing, Thermal-Vac Arizona offers manufacturers comprehensive engineering support and full-fabrication process management services.

Unparalleled Customer Focus

In today’s Industry 4.0 landscape, customers demand connectivity, quality, and advanced technology to streamline production. At Thermal-Vac Arizona, cutting-edge solutions and customer-centricity are a way of life. The company’s engineering experts listen attentively to each customer’s unique requirements, offering tailor-made, reliable solutions from the drawing board to final delivery.

Exacting Quality Control: Setting the Gold Standard

In industries where precision is paramount,Thermal-Vac Arizona leaves no room for compromise. Its quality control process, built through decades of trial and error, leaves nothing to chance. Every component is meticulously inspected by skilled technicians to ensure flawless metallurgical integrity and a refined look.

Science With a Side of Art

Thermal-Vac Arizona’s crew may look rough and tough, but underneath they’re all nerd. Metallurgy involves plenty of hands-on work, where having experienced hands makes the difference. But it also requires the kind of precision you can only get with technologies. The new shop uses all the latest monitoring and control equipment to ensure every job is done right.

A Trusted Partner with Fire In its Belly

Embracing the Southwest’s warmth and downhome spirit, Thermal-Vac Arizona’s obsession with customer outcomes shines through in every project it undertakes. Manufacturers seeking a trusted partner need look no further than this blazingly hot new arrival in town.

Visit www.thermalvacaz.com or call 714-5148382 to discuss your parts treatment needs with their team today.

A2Z MANUFACTURING WEST COAST • 6 • AUG - SEPT ’23

Marzee Inc., An ISO 9001 Certified Company Renowned For Their Waterjet Cutting

Ed Wenz, owner of the company, says, “The Eagle iNspire 2040 Fiber Laser Cutting System is our 2nd laser cutting machine, and it offers a 20kW laser source, unmatched 6G acceleration, a rigid composite base, a lightweight carbon fiber bridge, and a 9 to 12 second pallet changer. What’s more, the iNspire fiber laser machine has its own patented best-in-class eVa Laser Cutting Head and it operates with the brand’s premium software technologies like CatLine, Fast Line, MixLine, CutEye, and Drop&Cut. With cutting speeds up to 5,906” per minute, top positioning speed of 13,780” per minute, acceleration of nearly 6G, and fiber laser power of 1 to 20 kW, the iNspire series are the fastest and most efficient laser machines in the world.”

He continues, “We’ve been offering precision waterjet cutting since we opened for business in 1997. While waterjet cutting is ideal for a wide variety of applications and materials, including thicker parts (1”), laser cutting is a superior solution for incredibly fast cutting of stainless steel and aluminum up to 1” thickness.” On a particular job, Ed says that it would take 50 hours to cut on the waterjet and today is cut on the iNspire fiber laser machine in 8 hours. Ed is pictured with 1” parts cut by the water jet machine.

“We love this machine”, Ed says. Not only can it run 24x7, but it is also a highly intelligent machine. It tells us when it needs service, provides a cutting head with automatic focusing and it offers a super-fast pallet changer, to be coming in the end of year. For many jobs, we can use the Eagle Inspire to reduce costs for our customers.

cutting windows of 80” by 250” and cutting 13” plus thick. In addition to waterjet cutting and laser cutting, they offer forming with their Accurpress 12’ x 250 ton press brake to serve their clients’ needs.

Marzee has its own internally designed online quoting system that facilities ordering. Ed says, “We even have a button for those who aren’t sure if their parts need to be waterjet cut, laser cut or formed. Many of our customers are simplifying their order process with our system.”

Marzee can cut parts as small as 1” x 2” and they can cut parts as large as 20’ just as well. In fact, when it comes to doors, elevators, railings, structural, and anything else in architectural metal work, Marzee can provide value added engineering to save time and money.

Marzee is a family-owned and operated business, with 3 generations of Wenz family members having worked at the business, and their team includes over a dozen employees. Ed says, “When I hire someone, you’re not a number, you are an integral team member.” Marzee is always looking for new team members who are hardworking with an attention to detail.

Located in Phoenix, AZ, MarZee is the industry leader for Waterjet, Forming, and Laser cutting with their CNC-controlled state of the art machines.

For more information on how they can support you, call: 602-269-5801 or visit marzee.com

A2Z MANUFACTURING WEST COAST • 7 • AUG - SEPT ’23

CA 94538

Your One-Stop Distributor for Cutting Tools, Mist Collectors, and Coolant Solutions for CNC Machine Shops

Seattle, WA – Cutting Tool Control, founded in 1984 by Bruce Lowry, is a distributor of cutting-edge cutting tools, advanced mist collectors, and high-performance coolant solutions tailored exclusively for CNC machine shops. With an unwavering commitment to elevating machining operations, Cutting Tool Control is poised to redefine precision manufacturing.

A Comprehensive Solution Suite

With an in-depth understanding of CNC machining needs, Cutting Tool Control presents a comprehensive suite of solutions that cater to the diverse requirements of modern machine shops. From high-feed tooling to specialized cutters, Cutting Tool Control offers an extensive range of cutting tools engineered to enhance accuracy, speed, and durability in machining processes.

Clearing the Air with Innovative Mist Collectors

Machining environments often grapple with the challenge of airborne particulates and coolant mist that affect air quality and the health of machine operators. Cutting Tool Control addresses this concern with cutting-edge mist collectors designed to efficiently capture and eliminate departing oil mist. These state-of-the-art solutions contribute not only to a cleaner workplace but also to improved employee well-being.

Are you ready to implement or upgrade your Quality Management System to the new ISO 9001:2015 or AS9100D / ISO 9001:2015 Standard, AS9110C or AS9120B? Special Packages available, take advantage of 20 plus years’ experience implementing and auditing quality management systems for commercial and aerospace companies!

Bretta Kelly, President and Owner of BMSC, LLC www.businessmsc.com has proven, copy written templates for ISO 9001:2015, AS9100D / ISO 9001:2015, AS9110C / ISO 9001:2015 and AS9120B / ISO 9001:2015 Standards with more than 30 companies upgraded and certified with zero to one finding results to date in their upgrade audits!

Packages Available:

Complete Electronic QMS System/Templates and 4 hours consulting – Manual, Policy, System Procedures, Work Instruction / Flow charts for some processes, internal audit program, management review program (including forms), competency / training program, objectives training template, risk training and how to document a corrective action training PowerPoint’s - $3,500

Complete Electronic QMS System/Templates and online webinar of how to complete – Manual, Policy, System Procedures, Work Instruction / Flow charts for some processes, internal audit program, management review program (including forms), competency / training program, objectives training template, risk training and how to document a corrective action training PowerPoint’s - $2,500

Do you need Quality Management System Software? Bretta Kelly is also President of CIS WWSG, LLC and is now offering the $3,500 Templates for FREE with purchase of CIS Software! www.cissoftware.com. CIS Software costs $5,000 upfront (one time) and $385/month license and server fees for UNLIMITED users, request a demo today! Testimonial from BMSC Clients featured in the A2Z Manufacturing Magazine who have taken advantage of the BMSC Templates for successful upgrades:

Bretta, I wanted to email you and let you know that because of the help of yourself and Debbie we completed our audit to the new revision with no findings! :) We very much appreciate all of the help that you both did for us and will recommend your company to anyone looking to get certified. Your system really makes it easy for companies like ours to stay organized and compliant to the guidelines. Kristie McKee, Gibbs Precision Machine

Optimized Coolant Solutions for Enhanced Performance

Coolant systems play a pivotal role in maintaining consistent machining quality and prolonging tool life. Cutting Tool Control offers a range of advanced coolants from Blaser Swisslube that are engineered for precision, reliability, and efficiency. These systems ensure optimal cooling, lubrication, and chip evacuation, resulting in extended tool longevity and minimized downtime. Cutting Tool Control also supplies various filtration solutions for CNC machines and grinders.

Tailored Solutions, Unparalleled Support

Cutting Tool Control understands that every CNC machine shop is unique, and its requirements vary. That’s why the company takes pride in offering tailored solutions that match the distinct needs of each client. With a team of knowledgeable experts, Cutting Tool Control provides personalized consultations, expert advice, and ongoing support to ensure that every machining operation achieves peak performance.

Advancing CNC Machining Excellence

As a distributor at the forefront of innovation, Cutting Tool Control is dedicated to advancing the standards of CNC machining excellence. By delivering cutting tools, mist collectors, and coolants/oils that blend precision, efficiency, and consistency, the company empowers machine shops to stay competitive in today’s dynamic machining landscape.

For More Info Contact Them At: 206-789-7277, Orders@CuttingToolControl.com

A2Z MANUFACTURING WEST COAST • 8 • AUG - SEPT ’23

CNC AND MANUAL MACHINERY SINCE 1979 New - Used -Appraisals - Auctions Our Showroom At: 3305 Edison Way, Fremont,

Is Open Monday - Friday From 8am To 5pm BOB KROHA ROB KROHA CONTACT US TODAY: 510-249-1000, PERMACH.COM

Landmark Solutions

Demonstrates State-of-theArt Fabrication Equipment at Recent Open House

Landmark Solutions demonstrated some of their leading-edge fabrication equipment at a High-Performance Open House Event they hosted at customer Reiter’s Custom Welding Inc. in Glendale, AZ this summer. Chad Mooneyham, Landmark Solutions’ Vice President, says, “Reiter’s Custom Welding has grown substantially with equipment procured through Landmark, including their newest 10kW Bystronic fiber laser.They also have waterjet cutting purchased through our company as well as a new CNC press brake. We very much appreciate their willingness to allow us to demonstrate this equipment to other fabrication companies in Arizona.”

Landmark Solutions and its team of industry experts brings over 100 years of industry experience. We pride ourselves on being a professional manufacturing consulting, project management and capital equipment distributor. Based in Orange County, California, Landmark Solutions serves customers throughout North America.

Our team members each have decades of expertise in manufacturing allowing us to consult and understand our customers’ needs. We focus on providing the Best-inClass Equipment with Best-in-Class Support so that we can help our customers produce better quality parts at a lower price point with the most amount of uptime.

MILL S & THRILLS

The versatile VMC lineup at DN Solutions is enough to get anyone excited.

The lineup of vertical machining centers at DN Solutions is versatile, compact and born to make incredible parts for as long as you need them to. Get your ideal VMC, then get ready for the vertical leap. Talk to your local DN distributor or visit dn-solutions.com.

DEM: entry-level par t producer

SVM: swift and strong

DNM: global best seller

BVM: premium powerhouse

To learn more about Landmark Solutions’ fine line of precision fabrication equipment, visit: www. landmarksolutionscorp.com, call: Phone: 714-393-3783 or email: info@landmarksolutionscorp.com

To learn more about Reiter’s Custom Welding, contact them at 623-847-4028 or email sales@azwelder.com

SALES (866) 567-2580 SERVICE (800) 994-0146

PARTS (888) 207-2787

www.ellisontechnologies.com |

Southern California Design-2-Part Show

Ontario, CA • September 13 & 14, 2023

Ontario Convention Center

Wednesday 9:30 – 3:00 • Thursday 9:30 – 3:00

As of 2021, the state of California is home to 23,078 manufacturers employing 1,385,974 workers. Total manufacturing output equaled $394.83 billion. ~ Industry Select/MNI California accounts for 14.5% of U.S. manufacturing output…and is still the largest contributor to the U.S. manufacturing industry – both in terms of output and employment. ~ CMTC

Top manufacturing companies in California include Northrop Grumman Aerospace International, General Atomics, Chevron, Raytheon, Jet Propulsion Laboratory, Lockheed Martin, and Intel.

A2Z MANUFACTURING WEST COAST • 9 • AUG - SEPT ’23

Doosan Machine Tools is now

Boeing Plans To Restart 777X Production This Year, But Regulatory Hurdles Remain

By Marissa Nall

By Marissa Nall

New 777X planes will come off the line again later this year, as the Boeing Co. (NYSE: BA) plans to restart production earlier than expected.

But it has also warned of risks to its backlog of orders for the jet if it’s not able to get regulators to sign off soon.

“We’re still confident in the regulatory process,” Boeing CEO David Calhoun said last week during the company’s earnings call.

In the jet maker’s regulatory filings, however, it said if entry into service faces further delays, it “may experience reductions to backlog and/or

significant order cancellations.”

That is also true for its 737 Max 7 and Max 10 programs, as well as its ability to deliver 737 planes to China.

In the meantime, Boeing is reviving production of the 777X in Everett, which it put on hold last April, choosing instead to focus on freighter production. Chief Financial Officer Brian West said the company plans to resume production by the end of 2023, instead of next year, and pared back its estimates of how much the delays would cost from $1.5 billion to $1 billion. Around $587 million of those abnormal costs have already been recognized.

“This is our desire to simply get ahead of the production curve,” Calhoun said, despite there being “no breaks on the regulatory side.”

Boeing has 318 confirmed 777X orders, which would amount to about $130 billion to $140 billion in revenue at the most recent list prices Boeing has provided.

The company’s total backlog grew just shy of $13 billion in the most recent quarter.

The first 777X jets are expected to be delivered in 2025, with a freighter variant to follow in 2027. It builds three 777 aircraft each month at its Everett facility.

A2Z MANUFACTURING WEST COAST • 10 • AUG - SEPT ’23

Marzee Inc., an ISO 9001 Certified company renowned for their waterjet cutting (they have 5 waterjets), now has one of the fastest laser cutting machines in the Valley.

Ed Wenz, owner of the company, says, “The Eagle iNspire 2040 Fiber Laser Cutting System is our 2nd laser cutting machine, and it offers a 20kW laser source, unmatched 6G acceleration, a rigid composite base, a lightweight carbon fiber bridge, and a 9 to 12 second pallet changer. What’s more, the iNspire fiber laser machine has its own patented best-in-class eVa Laser Cutting Head and it operates with the brand’s premium software technologies like CatLine, Fast Line, MixLine, CutEye, and Drop&Cut. With cutting speeds up to 5,906” per minute, top positioning speed of 13,780” per minute, acceleration of nearly 6G, and fiber laser power of 1 to 20 kW, the iNspire series are the fastest and most efficient laser machines in the world.”

He continues, “We’ve been offering precision waterjet cutting since we opened for business in 1997. While waterjet cutting is ideal for a wide variety of applications and materials, including thicker parts (1”), laser cutting is a superior solution for incredibly fast cutting of stainless steel and aluminum up to 1” thickness.” On a particular job, Ed says that it would take 50 hours to cut on the waterjet and today is cut on the iNspire fiber laser machine in 8 hours. Ed is pictured with 1” parts cut by the water jet machine.

“We love this machine”, Ed says. Not only can it run 24x7, but it is also a highly intelligent machine. It tells us when it needs service, provides a cutting head with automatic focusing and it offers a super-fast pallet changer, to be coming in the end of year. For many jobs, we can use the Eagle Inspire to reduce costs for our customers.

Today, Marzee specializes in production and prototype cutting, serving

a number of industries, including aerospace, architecture, defense, machine shops, and environmental design. They provide one of Arizona’s largest cutting windows of 80” by 250” and cutting 13” plus thick. In addition to waterjet cutting and laser cutting, they offer forming with their Accurpress 12’ x 250 ton press brake to serve their clients’ needs.

Marzee has its own internally designed online quoting system that facilities ordering. Ed says, “We even have a button for those who aren’t sure if their parts need to be waterjet cut, laser cut or formed. Many of our customers are simplifying their order process with our system.”

Marzee can cut parts as small as 1” x 2” and they can cut parts as large as 20’ just as well. In fact, when it comes to doors, elevators, railings, structural, and anything else in architectural metal work, Marzee can provide value added engineering to save time and money.

Marzee is a family-owned and operated business, with 3 generations of Wenz family members having worked at the business, and their team includes over a dozen employees. Ed says, “When I hire someone, you’re not a number, you are an integral team member.” Marzee is always looking for new team members who are hardworking with an attention to detail.

Located in Phoenix, AZ, MarZee is the industry leader for Waterjet, Forming, and Laser cutting with their CNC-controlled state of the art machines. For more information on how they can support you, call: 602-269-5801 or visit marzee.com

A2Z MANUFACTURING WEST COAST • 11 • AUG - SEPT ’23 A2Z MANUFACTURING SW • 26 •Sept /Oct 2023

With Their Newest INspire Fiber Laser Cutting Machine, Marzee Improves Its Turnaround Times To 5-8 Days, On Average

Amazon’s Kuiper On Track To Begin Satellite Production In Kirkland By Year’s End

By Marissa Nall

Amazon’s Kuiper on track to begin satellite production in Kirkland by year’s end

The first two prototype satellites in Amazon’s (Nasdaq: AMZN) Project Kuiper constellation are grounded, still awaiting the rocket that will take them to orbit.

But the delay doesn’t mean Kuiper’s plans for mass satellite production in Kirkland aren’t ready for liftoff, the company says.

Kuiper completed the design and testing of the two satellites on time for its initial launch, which was scheduled for May.They are set to go to space aboard the debut flight of United Launch Alliance’s Vulcan Centaur rocket, which will also convey a lunar lander developed by Astrobotic Technology carrying NASA research and other tech demonstrations.

But takeoff will have to wait until ULA can make necessary changes to the rocket’s upper stage, after a launch test in March resulted in an explosion, the Denver Business Journal, a sister publication, reported last month.

ULA did not return requests for comment on the rocket’s progress or when the launch is expected to take place, but the company’s leadership had

been targeting this month, a source with knowledge of the operation said.

Meantime, the rocket’s redesigns aren’t going to hold up Kuiper’s plans to start producing the more than 7,700 satellites it will need to construct its communications network. The manufacturing effort was always intended to run parallel to its analysis of the prototypes’ performance and development of the next generation of the satellites.

That work will happen in Kirkland at Kuiper’s 172,000-square-foot production facility, which it expects to be fully operational by the end of the year. Design work and initial production on the satellites has so far taken place at Kuiper’s site in Redmond.

The first few satellites are expected to come off the Kirkland line by the end of the year and head into space in early 2024.The company is required by its licensing deal with the Federal Communications Commission to have at least half of its constellation operational by mid-2026.

Project Kuiper employs around 1,400 people, most of whom are in the Puget Sound area.The prototype satellites will test the technology from propulsion to connecting with customer terminals and even to deorbiting.

The Kirkland factory will produce as many as five satellites per day when it’s fully operational, James Watkins, head of communications for Kuiper, told the Business Journal at a recent space technology conference at Blue Origin’s headquarters in Kent.

A2Z MANUFACTURING WEST COAST • 12 • AUG - SEPT ’23

Launch costs were one factor in making the project feasible, Watkins said. The company is spending billions of dollars procuring more than 70 rockets to take the first half of its constellation to orbit.

But more important to the program’s success was the ability to bring costs down for consumers, he said.The company debuted the terminals customers will use to connect to the satellite network in March, which cost around $400 to produce.

Kuiper’s top competitor, SpaceX, charges $500 for the dishes its residential customers use to connect to its Starlink network. SpaceX’s Starlink operation is based in Redmond.

Balancing size, capability and cost for the terminals had been the “Achilles’ heel” for the program for years and forced Kuiper to develop more sophisticated satellites, Watkins said.

“Things would have looked very different if we’d started this project 10 years ago,” he said. “The tradeoff is, simple things on the ground mean more complexity in space. … We wanted to have conviction that this critical component was solved and something we could do at scale.”

Spacex To Launch Vast’s Commercial Space Station And First Human Spaceflight Mission

Phoenix Heat Treating Phoenix Heat Treating

Servicing our industry and trade customers in intelligence heat treating for over 60 years. www.phoenix-heat-treating.com

Vast announced today that SpaceX will launch what is expected to be the world’s first commercial space station, known as Vast Haven-1, quickly followed by two human spaceflight missions to said space station. Scheduled to launch on a Falcon 9 rocket to low-Earth orbit no earlier than August 2025. Haven-1 will be a fully-functional independent space station and eventually be connected as a module to a larger Vast space station currently in development.

Upon launch of Haven-1, Falcon 9 will launch Vast’s first human spaceflight mission to the commercial space station, Vast-1. Dragon and its four-person crew will dock with Haven-1 for up to 30 days while orbiting Earth. Vast also secured an option for an additional human spaceflight mission to the station aboard a Dragon spacecraft.

The Vast-1 crew selection process is underway and the crew will be announced at a future date. Once finalized, SpaceX will provide crew training on Falcon 9 and the Dragon spacecraft, emergency preparedness, spacesuit and spacecraft ingress and egress exercises, as well as partial and full mission simulations including docking and undocking for return to Earth.

Vast’s long-term goal is to develop a 100-meter-long multi-module spinning artificial gravity space station launched by SpaceX’s Starship transportation system. In support of this, Vast will explore conducting the world’s first spinning artificial gravity experiment on a commercial space station with Haven-1.

This new partnership between Vast and SpaceX will continue to create and accelerate greater accessibility to space and more opportunities for exploration on the road to making humanity multiplanetary.

A2Z MANUFACTURING WEST COAST • 13 • AUG - SEPT ’23

GET TO KNOW US

602-258-7751

Established in 1963 Real Time Live Job Tracking 10+ Processes Performed 50+ Furnaces AOG and Line Down Services Over 10+ Prime Approvals 24/7 Processing

cs@phxht.com

Contracts

General Atomics Aeronautical Systems Inc., Poway, California, is awarded an $11,717,322 firm-fixed-price order (N0001923F2503) against a previously issued basic ordering agreement (N0001922G0006). This order procures 10 conversion kits in support of modifying 10 MQ-9A UHK97000-20 air vehicles to a MQ-9A UHK97000-25 air vehicle configuration and necessary data for the Navy. Work will be performed in Poway, California, and is expected to be completed in February 2026. Fiscal 2023 aircraft procurement (Navy) funds in the amount of $11,717,322 will be obligated at the time of award, none of which will expire at the end of the current fiscal year. Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

Raytheon, El Segundo, California, has been awarded a $175,050,289 indefinite-delivery/indefinite-quantity contract for the B-2 Advanced High Frequency Radar Components and end items. This contract provides for overhaul and repair of the B-2 Advanced High Frequency Radar Components and end items. Work will be performed in El Segundo, California, and is expected to be completed by July 31, 2033. This contract was a sole-source acquisition. Fiscal 2023 operations and maintenance funds in the amount of $24,558,473 are being obligated at time of award. The Air Force Sustainment Center, Tinker Air Force Base, Oklahoma, is the contracting activity

(FA8119-23-D-0002).

BAE Systems - San Diego Ship Repair, San Diego, California, was awarded a $37,730,467 firm-fixed-price contract action for maintenance, modernization and repair of USS John P. Murtha (LPD 26) fiscal 2024 Selected Restricted Availability. The scope of this acquisition includes all labor, supervision, equipment, production, testing, facilities, and quality assurance necessary to prepare for, and accomplish, the Chief of Naval Operations Availability for managing critical modernization, maintenance and repair programs. This contract includes options, which if exercised, would bring the cumulative value of this contract to $42,442,680. Work will be performed in San Diego, California, and is expected to be completed by September 2024. If all options are exercised, work will continue through September 2024. Fiscal 2023 operations and maintenance, Navy funds in the amount of $37,725,469 (99.99%); and fiscal 2023 other procurement, Navy funds in the amount of $4,998 (0.01%), will be obligated at the time of award, of which $37,725,469 will expire at the end of the current fiscal year. This contract was awarded on a sole source basis in accordance with Federal Acquisition Regulation 6.302-3, Industrial Mobilization.The Naval Sea Systems Command, Washington, D.C., is the contracting activity (N0002423C4405). (Awarded July 24, 2023)

AeroVironment Inc., Simi Valley, California, was awarded a

A2Z MANUFACTURING WEST COAST • 14 • AUG - SEPT ’23

$12,051,941 firm-fixed-price contract for RQ-20B Puma AE3 UAS systems. Bids were solicited via the internet with one received. Work will be performed in Simi Valley, California, with an estimated completion date of Sept. 30, 2024. Fiscal 2023 other procurement, Army funds in the amount of $12,051,941 were obligated at the time of the award. U.S. Army Contracting Command, Redstone Arsenal, Alabama, is the contracting activity (W58RGZ-23-C-0039).

Pacific Propeller International LLC, doing business as PPI, Kent, Washington, has been awarded a $22,804,292 modification (P00001) to a previously awarded contract (FA8553-23-D-0002) for the overhaul support for the C-130 54H60 series propeller. This contract provides for the overhaul and repair of the C-130 54H60 series propeller for the Air Force and multiple countries. All work will be performed in Kent, Washington, and individual orders will be placed by the Air Force and Foreign Military Sales partners through Feb. 27, 2028. The modification brings the total cumulative face value of the contract to $73,704,292. No funds are being obligated at the time of award. Air Force Life Cycle Management Center, Robins Air Force Base, Georgia, is the contracting activity.

L3Harris Technologies, Inc., Van Nuys, California, is awarded a $10,506,355 cost-plus-fixed-fee delivery order under Basic Ordering Agreement N00024-19-G-5500 for the procurement of supplies and services for the Land Based Radars refurbishment of AN/SPS-48. This

delivery order includes options which, if exercised, would bring the cumulative value of this contract to $14,553,316. This delivery order involves Foreign Military Sales to Egypt. Work will be performed in Van Nuys, California (87%); and Egypt (13%), and is expected to be completed by April 2026. If all options are exercised, work will continue through April 2026. Fiscal 2023 research, development, test, and evaluation (Navy) funds in the amount of $10,506,355 will be obligated at time of award and will not expire at the end of the current fiscal year. The Naval Sea Systems Command, Washington, D.C., is the contracting activity (N00024-23-F-5502).

Keysight Technologies Inc., Santa Rosa, California, has been awarded an $18,507,313 definitive contract for Radio Frequency Threat Simulators. This contract provides for the procurement of two Radio Frequency Threat Simulators with sustainment support consisting of patch management, field engineer support, non-critical spare parts, critical spare parts, and storage. Work will be performed in Santa Rosa, California, and is expected to be complete by March 18, 2024, for the first Radio Frequency Threat Simulator, and March 20, 2024, for the second Radio Frequency Threat Simulator. This contract was a competitive acquisition and three offers were received. Fiscal 2023 operations and maintenance funds in the amount of $13,337,436 are being obligated at time of award. The Air Force Test Center, Eglin Air Force Base, Florida, is the contracting activity (FA2487-23-C-A005).

A2Z MANUFACTURING WEST COAST • 15 • AUG - SEPT ’23

More Contracts

General Atomics Aeronautical Systems Inc., Poway, California, has been awarded a $21,547,240 modification (P00004) to costplus-fixed-fee contract HR001123C0016 to exercise Option One of the Liberty Lifter program. The modification brings the total cumulative face value of the contract to $29,514,384.00 from $7,967,144. Work will be performed in Poway, California, with an estimated completion date of July 2024. Fiscal 2023 research and development funds in the amount of $4,897,610 are being obligated at the time of award. The Defense Advanced Research Projects Agency, Arlington, Virginia, is the contracting activity.

Ormond LLC,* Auburn, Washington, was awarded a $9,714,128 firm-fixed-price contract for waterjet technology to hone, grind and machine coatings on gun barrels. Bids were solicited via the internet with one received. Work locations and funding will be determined with each order, with an estimated completion date of July 26, 2028. Army Contracting Command, Newark, New Jersey, is the contracting activity (W15QKN-23-D-0046).

Northrop Grumman Systems Corp., San Diego, California, is awarded a $12,741,430 firm-fixed-price modification to previously awarded contract N00024-17-C-6327 to procure materials for Joint Counter Radio-Controlled Improvised Explosive Device Electronic Warfare Systems.Work will be performed in San Diego,

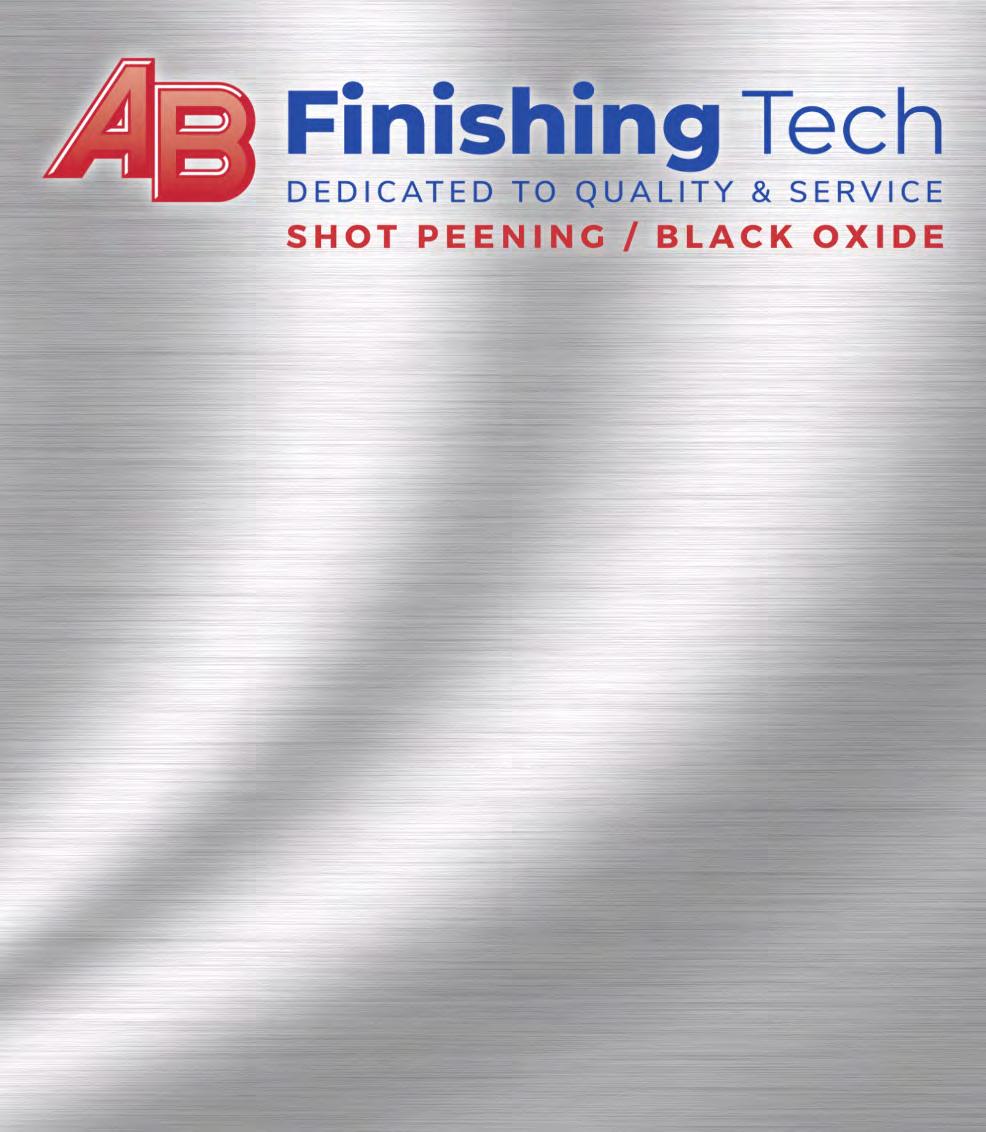

Precision Injection Molding Is What We Do!

3D can provide design assistance and work with existing products to produce them more economically.We are a ‘UL Certified’ molder offering low to high quantity production runs.

We produce many of our customer’s products with metal and plastic sub-components molded in. It is very common to use threaded inserts, bushings, contacts, and plastic substrates.

California, and is expected to be completed by October 2025. Fiscal 2023 other procurement, Navy funds in the amount of $10,714,685 (84%); and fiscal 2023 research, development, test and evaluation, Navy funds in the amount of $1,721,159 (14%) will be obligated at time of award and will not expire at the end of the fiscal year. Fiscal 2023 operations and maintenance, Navy funds in the amount of $305,586 (2%) will be obligated at time of award and will expire at the end of the current fiscal year. The Naval Sea Systems Command, Washington, D.C., is the contracting activity (N0002422-C-6407).

Archer Aviation Inc., San Jose, California, was awarded an $110,000,000 firm-fixed-price, indefinite-delivery/indefinite-quantity contract for Midnight Based Advanced Vertical Lift. This contract is a Small Business Innovative Research (SBIR) Phase III to iteratively conduct government operational experimentation on military installation for government-owned, government-operated flight operations to execute and experiment with key missions or mission elements to substantiate government use cases, concept of operations/mission design, and cost/benefit analyses of the Midnight aircraft that extend, derive, and complete previously awarded SBIR Phase I and II efforts.Work will be performed in San Jose, California, and is expected to be completed by July 31, 2028.This contract was a sole-source acquisition. Fiscal 2023 research, development, test, and evaluation funds in the amount of $1,293,077 are being obligated at time of award. AFWERX Enterprise Contracting, Dayton, Ohio, is the contracting activity (FA2280-23-D-0001).

A2Z MANUFACTURING WEST COAST • 16 • AUG - SEPT ’23

Injection

3D Plastics, Inc. Custom

Molding 800. 280.2278

Contact Us Today: info@3d-plastics.com, 503-537-0979 3d-plastics.com, 503-537-0979

Safe Boats International LLC,* Bremerton, Washington, is awarded a METALS Aluminum Steel Stainless Brass Copper Ornamental SHAPES Sheet/Plate Shim/Bar Tube/Pipe Channel Angle Beam Perf./Expand. SERVICES Production Cutting Precision Sawing Shearing So-Cal’s Source For All Your Metal Needs Next Day Delivery - No Minimum - Open Saturdays STOP BY TODAY! Los Angeles | Orange County | San Diego | Inland Empire www.industrialmetalsupply.com

$22,271,829 firm-fixed-price modification to previously-awarded contract N00024-21-C-2201 for the exercise of options for procurement and installation of six Gun Weapon Systems onto the Island Class patrol boats with spares.Work will be performed in Tacoma,Washington, and is expected to be completed by October 2024. Foreign Military Financing (Ukraine) funds in the amount of $22,271,829 will be obligated at time of award and will not expire at the end of the current fiscal year. The Naval Sea Systems Command, Washington, D.C., is the contracting activity.

(Awarded Aug. 3, 2023)

University of Southern California, Los Angeles, California, was awarded an $8,988,793 cost reimbursement contract for the Processor Reconfiguration for Wideband Spectrum Sensing (PROWESS). PROWESS seeks run-time reconfigurable processors, with the specific goal to develop processors that provide autonomous radiofrequency systems with decision-directed situational awareness about complex and uncertain electromagnetic environments. Work will be performed in Arlington, Virginia (77%); Cambridge, Massachusetts (8%); Los Angeles, California (4%); Vienna, Virginia (6%); and Brooklyn, New York (5%), with an expected completion date of November 2026. Fiscal 2023 funds in the amount of $4,873,076 are being obligated at time of award. This contract was a competitive acquisition under Broad Agency Announcement HR001122S0006 and 13 offers were received. The Defense Advanced Research Agency, Arlington,Virginia, is the contracting activity (HR001123C0101).

The Boeing Co., Tukwila, Washington, is awarded a $12,288,486 costplus-fixed-fee, firm-fixed-price task order (N0001923F0521) against a previously issued basic ordering agreement (N0001921G0006). This order procures one wide band satellite communications Radome A-kit, to include installation; one platform integration kit, to include lower lobe structural and electrical (auxiliary bus 1 components) components; and one mission crew workstation floor structural modification in support of P-8 wideband satellite communications upgrades for the Navy. Work will be performed in Jacksonville, Florida (75%); and Tukwila, Washington (25%), and is expected to be completed in March 2026. Fiscal 2023 research, development, test and evaluation (Navy) funds in the amount of $200,000; and fiscal 2022 aircraft procurement (Navy) funds in the amount of $11,990,618, will be obligated at the time of award, none of which will expire at the end of the current fiscal year. Naval Air Systems Command, Patuxent River, Maryland, is the contracting activity.

Raytheon Co. – Raytheon Intelligence & Space,* McKinney, Texas, has been awarded a $9,995,709 cost-plus-fixed-fee contract for the Persistent Optical Wireless Energy Relay Program. Work will be performed at El Segundo, California (75%); Kent, Washington (5%); Albuquerque, New Mexico (12%); and Mojave, California (8%), with an expected completion date of May 13, 2025. Fiscal 2023 advanced research funds in the amount of $700,000 are being obligated at time of award. This contract was a competitive acquisition in accordance with the original Broad Agency Announcement (HR001123S0004). The Defense Advanced Research Projects Agency, Arlington, Virginia, is the contracting activity (HR001123C0144).

A2Z MANUFACTURING WEST COAST • 17 • AUG - SEPT ’23 (800) 481-6271 www.pmplating.com We Are The Noble Partner With The Personal Touch! Precious Metals Plating Co., Inc + Gold Plating + Silver Plating + Nickel Plating + Electroless Nickel Plating + Tin Plating + Heat Treat With Plate + Nadcap Approved Processes + Boeing Approved Processes + Expedited Turnaround + X-ray Fluorescence Thickness Verification + In-House Laboratory With Atomic Absorption (AA) + Expanded Capacity In Vibratory Plating

New Era of Collaborative Automation Deployments are Application-Focused and Programming-Free

The next phase of collaborative robots eliminates the need for programming. Applications such as machine tending and palletizing can be deployed in a few simple steps.

Combined with the growing trend towards open, plug-and-play hardware, these new, simpler approaches to automation deployments not only make robotics more accessible to small and medium-size (SME) companies, but they also help to address the labor and skills shortages being experienced by both manufacturers and integrators.

Every improvement in the usability of collaborative automation plays its part in reducing deployment lead times and costs. This greater efficiency

enables integrators to take on more work and minimize reliance on expert robot engineers to get applications up and running.

Simplicity Boosts Cobot Adoption

Collaborative automation is now the fastest growing segment of the industrial robot market. Cobotbased systems are attractive to companies of all sizes thanks to their affordability, fast ROI, small footprint and ability to switch between different products and applications. Most of all, collaborative automation breaks down the traditional barriers to automation adoption experienced by SMEs.

Collaborative automation, to varying degrees, breaks down this complexity through a range of usability features that enable companies with little or no previous robotics experience to deploy automation quickly, safely and effectively.

Programming-free deployment liberates integrators from a wide range of tedious manual processes and provides a giant leap in usability that makes collaborative industrial automation deployments faster and easier than ever before.

Guided by Hand

Many leading cobot brands provide hand-guiding features designed to speed up the deployment process. Instead of spending time on complex, solely pendant-based programming, cobot users can program the system by guiding the robot and endeffector into position by hand and setting various points along the way. This intuitive programming method saves time and money by reducing project complexity.

Plug & Play Hardware

What’s even better than usability feature enhancements across individual cobot brands? Cross-platform systems that enable speedy deployments across multiple cobot brands.This so-called “one system, zero complexity” philosophy supports easy programming across a wide range of cobots and across a range of collaborative application domains from machine tending to pick & place operations. By providing a unified mechanical interface and communication standards across robot brands, this approach enables scalable automation expansion.

A2Z MANUFACTURING WEST COAST • 18 • AUG - SEPT ’23

Call Now! (503) 282-7239 info@abfinishingtech.com www.abfinishingtech.com 6724 NE 46th Ave. Portland, OR 97218 Quality and Service Since 1936 ON TIME, EVERY TIME! AB Finishing Tech prides itself on setting the standard for: • black oxide finishing • shot peening • sandblasting

Limited Programming Systems

Designed to simplify deployments of collaborative systems, so-called “low/ no-code programming” approaches typically incorporate visual modeling and drag-and-drop user interfaces. Little programming knowledge is required to operate these systems, especially if the application is an extremely simple one. If, on the other hand, the application is complex, some programming knowledge is typically required to ensure a safe and successful deployment.

OnRobot

The author, Kristian Hulagard, described how using his company’s D:PLOY platform supports a collaborative automation deployment process. “First, an integrator installs the OR:BASE hardware and cell components and configure the robot. Next, they scan the QR codes provided to connect their device (such as a tablet or laptop) to the OR:BASE and then login to D:PLOY,” Hulgard noted. “The platform removes a huge amount of manual work for integrators by automating program logic, signals exchange, event handling and robot motion planning.”

The author, Kristian Hulagard, described how using his company’s D:PLOY platform supports a collaborative automation deployment process. “First, an integrator installs the OR:BASE hardware and cell components and configure the robot. Next, they scan the QR codes provided to connect their device (such as a tablet or laptop) to the OR:BASE and then login to D:PLOY,” Hulgard noted. “The platform removes a huge amount of manual work for integrators by automating program logic, signals exchange, event handling and robot motion planning.”

New Era of Automated Deployments

We’ve covered the main trends and incremental improvements in usability, but the latest and greatest— and the culmination of all these trends—is a new application-specific platform that eliminates the need for programming altogether. This is not easy programming, less complex coding or no code programming, but a platform

that requires no programming at all.

This approach fully automates the process of building, running, monitoring and re-deploying collaborative automation. Complete applications, such as machine tending and palletizing, can be deployed and redeployed directly on the manufacturing floor in a few simple steps—and with zero programming required.

The usability features we’ve looked at so far have been incremental from better interfaces, and more intuitive programming techniques to reduced programming requirements. The elimination of programming is a completely different proposition and one that brings exceptional time savings versus traditional automation deployment techniques. The result is a leap in usability that’s comparable to the industry-changing emergence of the first commercial collaborative robot systems.

A2Z MANUFACTURING WEST COAST • 19 • AUG - SEPT ’23

Metzfab Industries Has Come A Long Way Since It Opened For Business 13 Years Ago.

And, since its inception, the company has pursued cutting edge technology and processes, always with the end goal of making parts faster and more economically. Their keen adoption of automation has been instrumental in their growth.

Over the years, Metzfab has consistently added new services for their customers. In the last 5 plus years, they estimate that they have invested more than $1 million each year in new equipment. And while they offer the latest in technology, they focus less on acquiring ‘the fastest’ model, and more on acquiring the model that enables automation. Here are some of the main services Metzfab provides:

Laser Cutting

Metzfab offers comprehensive laser cutting services for short and long production runs. The company offers a full “lights-out” operation to accommodate largest production volumes and turnaround requirements for any business.

The company’s laser cutting technology produces consistently accurate parts with the highest edge quality possible across a wide range of materials and sheet thicknesses. They use advanced nesting software, so that they can utilize the majority of the raw material and eliminate metal waste, maximizing the value for their customers.

CNC Forming

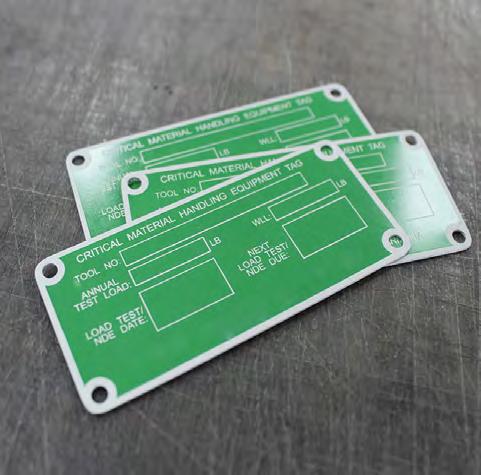

Today, the company resides in a 16,500 square foot facility in Deer Valley, a Phoenix, Arizona suburb. It is an understatement to say that Metzfab has state-of-the-art machinery, and that they offer more fabrication/ machining services than you will see in nearly any other shop. While established as a fabrication shop, today, Metzfab provides much more than general metal fabrication — they also specialize in CNC machining, waterjet cutting, laser cutting, forming, tube bending, manufacturing, design and assembly. In fact, a number of Metzfab’s customers bring either new products or products that have been around for years — and with Metzfab’s expertise and their equipment, the end product that results is now better and less expensively manufactured. (They even guarantee to beat any competitor’s price by 5%). Often, Metzfab does all the sourcing and manufacturing, and drop ships the finished product, engraved and packaged, complete to their customers.

Metzfab’s customers hail from all over the world. Customers have made the company one of their key trusted suppliers because not only do they manufacture products on time and with high quality, but also because of the flexibility and plethora of services the company provides.

At Metzfab, capital machine purchases are made with significant research and analysis of the market and with surveys of their current customers. A few years ago, their customers who require tube Laser Cutting , as an example, were sending their parts to California or even further away.The company’s purchase of the ByTube 130 tube laser enabled them to get their tube Laser Cutting done locally through Metzfab.

an extensive array of press brakes and tooling to support their customers’ needs. They also manufacture custom tooling inhouse when it is required to produce parts for custom applications.

CNC Tube Bending

Metzfab’s CNC

bending service

will bend and form materials to your requirements. Owner Brandon Metzger says, “At Metzfab Industries, we have invested in a Starbend 800 Rotary draw with mandrel and 3D Freeform capable CNC bending machine in order to offer our customers the creative freedom

A2Z MANUFACTURING WEST COAST • 20 • AUG - SEPT ’23

to not only bend tight radius traditional rotary draw bends with mandrel but also the very unique capability to design their parts with true variable radius and variable plane bends (3D Freeform).”

Tube Laser Cutting

Metzfab’s laser tube cutting services will cut all types and shapes of tubing – from stainless steel, carbon steel, aluminum, round, square, rectangular, oval, semi-oval, and elliptical with diameters from 3/8 to 5.25 “ and lengths up to 21.5’.

Brandon says, “Any company that still is using traditional methods to manufacture tubular assemblies is, in essence, wasting time and money.To put this into perspective, traditional methods versus tube laser cutting is synonymous with a writer using a typewriter versus a laptop. In the past, tubing was difficult, time consuming and expensive to process. With the introduction of tube lasers and CNC mandrel benders, tubes can now be cut with revolutionary accuracy and speed. Metzfab’s system offers the flexibility and freedom to create innovative new tubular designs by allowing the designer to specify complex end forms and hole geometry that cannot be created in a cost-effective manner with any other process.”

He adds, “Mix in CAD. Everything we do, we draw in 3D. 3D bending programs. In Solldworks in 3D. Regardless of how we get it, we leverage our software.”

Waterjet Cutting

Metzfab specializes in 5-axis precision waterjet cutting and machining for prototype, short run and long run productions. Metzfab’s waterjet cutting system is capable of cutting parts from 0.005” to 12 “ in thickness and their cutting area is able to handle 20’ parts.

CNC Machining

Metzfab’s full line-up of multi-axis CNC machines, including a Renishaw probe to assist in measurements, enables them to manufacture even your most complex components on time and within budget.They can machine parts to tolerances as close as +/-.0005”.

3D CAD/CAM Design and Assemblies

Using the latest 3D CAD/CAM systems, Metzfab’s engineers start by studying your current design environment, your operating constraints, and your design goals. Metzfab’s 3D CAD/CAM and assembly services offer machine prototypes and finished parts.

For customers who have parts that lack prints or digital files, Metzfab will create both the 3D model plus the drawing.When a customer opts to own the model and CAD files, they can be purchased through Metzfab via a Non Recurring Engineering (NRE) fee.

Metzfab got its start as a precision sheet metal shop and today, their experienced team of precision metal fabricators are able to provide their customers the highest quality component parts and will guide you through initial design through prototyping to the completely welded and assembled product.

Product Manufacturing and Assembly

Brandon says, “By using our CAM software package, we are able to program using 3D data to program complex 3 and 5-axis simultaneous machine movements.We can import any 3D data and generate tool paths from your solid. Don’t have 3D data? Don’t worry; we can still operate with 2D data or print designs.”

Stainless Steel Fabrication

From architectural designs to restaurant kitchen equipment, the Metzfab team has completed countless projects, with customers as well known as Starbucks, Chickfil-A, and Baskin Robbins., to name a few.

A2Z MANUFACTURING WEST COAST • 21 • AUG - SEPT ’23

Precision Sheet Metal

Metzfab has invested in a COSTA grinding and deburring machine, which is designed for edge rounding and oxide layer removal from steel and stainless steel parts in one operation.

Metzfab’s COSTA is a 4 headed configuration, which results in the most aesthetically and consistently beautiful parts.

This machine’s unique method of simultaneously edge rounding and oxide removal on inside and outside contours of laser cut parts on both sides in one single pass is highly efficient. It is estimated that Lissmac saves processing times of up to 60% compared to conventional grinding machines.

In addition to deburring, Metzfab’s tumbling services can be used to burnish, clean, descale, remove rust, and brighten or harden the surface. The surfaces of the parts get worn away, sharp edges are broken, surface discoloration and blemishes are erased, and your parts come out smooth.

3D Scanning Arm

Metzfab’s Absolute Arm 7-Axis delivers tactile probing and non-contact scanning in a uniquely ergonomic package. It’s an excellent choice for high-end portable measurement applications. With the full-speed, fullaccuracy measurement delivered and its wide scan line – 150 millimeters wide at mid-range – 3D scanning and digitization is fast, delivers full performance at all times on all materials – full accuracy, full frame rate, and full laser scan width for full measurement productivity.

Welding Services

Metzfab offers a number of welding services, including LASER, TIG/ MIG, ARC and Robotic.

Laser welding is often recommended for welding steel, aluminum, copper, titanium, and nickel alloys. Laser welding is often preferable for thick, thin, reflective and dissimilar metal welding without wire that is difficult or

impossible with traditional methods, plus weld materials with different electrical conductivity.

Metzfab’s free-hand TIG, MIG, and ARC welding services can handle a broad variety of materials up to 1.25 inches thick. Additionally, their TIG, MIG, and ARC welding services can be applied to a wide range of applications, including boilers and precision assembly.

With its Robotic Cell, Metzfab specializes in automated robotic welding projects with a wide range of metal types with material thicknesses from 1/16 in. to 1/2 in. as well as circular welds or welding with contours.

What’s it Like Partnering with Metzfab?

When you choose to partner with Metzfab Industries, you get an extremely versatile and experienced team that has a tremendous amount of knowledge and experience in all areas of manufacturing in a wide range of industries.You get a shop that stands behind what they do, and always does the right thing. You get a shop that is on the cutting edge of technology and is always improving for our customers as well as making our employees’ lives easier. We are here for the long-haul and only interested in long-term relationships.We believe honesty and transparency is an essential part of being your partner and without these things, you cannot have a successful, long-term partnership. Which is why the culture at Metzfab is perfection — always clean — always organized — always striving to exceed customer expectations.

To learn more about how they can support you, contact: 602.539.9591; sales@Metzfab.com or visit their website at Metzfabindustries.com

A2Z MANUFACTURING WEST COAST • 22 • AUG - SEPT ’23 Deburring & Tumbling Services

A2Z MANUFACTURING WEST COAST • 24 • AUG - SEPT ’23 OIL MIST AND SMOKE IN YOUR SHOP? Low-Cost, Highly Efficient Mist and Smoke Collectors Designed Specifically for the Metalworking Industry www.mistcollectors.com 1-800-645-4174 BARTON’s Transfer Hopper holds up to 4,400 lbs. of garnet eliminating the need to handle individual bags of abrasive. • Saves time and labor • Increases worker safety • Minimizes clogs • Reduces waste Interested in learning more? Call 800-741-7756 or email info@barton.com BARTON INTERNATIONAL USA/Canada 800-741-7756 • 518-798-5462 info@barton.com • barton.com • store.barton.com BARTON is a trademark of BARTON Mines Corporation. Maximize the Efficiency of Your Waterjet Operation

New Orders Of Manufacturing Technology

New orders of manufacturing technology totaled $411.3 million in June 2023, according to the latest U.S. Manufacturing Technology Orders Report published by AMT – The Association For Manufacturing Technology. June 2023 orders increased 12.6% over May 2023 but fell 1.7% below orders in June 2022. This brings total orders through the first half of 2023 to nearly $2.5 billion, about 13% below the total for the first half of 2022.

“Orders of manufacturing technology have continued their downward trend since peaking in the second half of 2021; however, for perspective, they remain above historical averages,” said Douglas K.Woods, president of AMT. “Even in non-IMTS years, the majority of orders tend to come in the second half of the year. Despite some headwinds, including fears of a recession, it would seem reasonable that manufacturing technology orders could outperform some of the more pessimistic expectations if we return to that historical trend.”

Job shops, the largest customer segment, only increased spending by 4.2%, well under the industry growth of 12.6% from May to June 2023. They also decreased the number of units ordered, while the industry remained about flat.

There was one surprising bright spot despite high interest rates and the ever-looming fear of a coming recession: Manufacturers of automotive transmissions have been noticeably increasing investment in manufacturing technology.

“Investments on this scale show how manufacturers are preparing for a prolonged transitional period from internal combustion engines to electric vehicles,” said Woods. “Moving toward electrification means facing numerous supply and logistical hurdles, from the sourcing of elements to grid reliability. Auto manufacturers recognize that until these challenges are overcome, demand for internal combustion engines will justify further investment.”

Year-to-date orders for manufacturing technology from the automotive transmission and powertrain parts manufacturing sector are at the second-highest level since the first half of 2015.

The United States Manufacturing Technology Orders (USMTO) Report is based on the totals of actual data reported by companies participating in the USMTO program. This report, compiled by AMT –The Association For Manufacturing Technology, provides regional and national U.S. orders data of domestic and imported machine tools and related equipment. Analysis of manufacturing technology orders provides a reliable leading economic indicator as manufacturing industries invest in capital metalworking equipment to increase capacity and improve productivity.

AMT – The Association For Manufacturing Technology represents U.S.-based providers of manufacturing technology – the advanced machinery, devices, and digital equipment that U.S. manufacturing relies on to be productive, innovative, and competitive. Located in McLean,Virginia, near the nation’s capital, AMT acts as the industry’s voice to speed the pace of innovation, increase global competitiveness, and develop manufacturing’s advanced workforce of tomorrow. With extensive expertise in industry data and intelligence, as well as a full complement of international business operations, AMT offers its members an unparalleled level of support. AMT also produces IMTS – The International Manufacturing Technology Show, the premier manufacturing technology event in North America. AMTonline.org

A2Z MANUFACTURING WEST COAST • 25 • AUG - SEPT ’23 Cutting Tool Control has been a provider of high quality product lines and services to machine shops in Washington, Oregon, Idaho, Montana and neighboring British Columbia since 1981,

a focus on personalized customer service.

with

1411 NW 51ST ST. SEATTLE, WA 98107 CHECK US OUT ONLINE: CUTTINGTOOLCONTROL.COM PHONE: 206 789 7277 FAX: 206 784 8122 EMAIL: ORDERS@CUTTINGTOOLCONTROL.COM Cutting Tool Control services machine shops in Washington, Oregon, N.\ Idaho, Montana, and neighboring British Columbia 1411 NW 51st St. Seattle, WA 98107, CuttingToolControl.com Phone: 206-789-7277, Fax: 206-784-8122, email: orders@CuttingTool Control.com

In today’s highly competitive global marketplace, quality, precision and cycle time is critical. In our industry, maintaining your competitive edge requires a continual effort to acquire the most current tools and services available. We are a premier provider of leading brand CNC support products for all phases of machining operations, committed to your success.

Adapting to New Possibilities

In The Past Five Years, Dassault Has Added 19 MRO Facilities And 1,000 Employees To Its Worldwide Network

Business jet manufacturers are taking giant steps into the MRO realm as they seek to tap into new revenue streams, as well as address ongoing capacity and supply constraints. “It’s a whole new way of looking at business,” said Ken Thompson, managing director of regulatory affairs for the National Air Transportation Association.

These moves are necessary to increase capacity because the business jet fleet is growing. But so too are the sizes of aircraft.

“Some of these larger [independent] MROs are building bigger hangars

because the aircraft are getting bigger,” Thompson added. But not all have that ability. “Some new aircraft are too large for their hangars.”

“Maintenance requirements and fleet size have outgrown existing shop capacity,” agreed Tim Ferrell, senior v-p at JSSI Tech Services. “OEMs and independent MROs have been expanding their footprint to meet demand, which is beneficial to operators worldwide and eases availability constraints.”

At the same time, there are OEMs that are bringing work back in to manage parts and components. “They want to control the environment rather than be at the mercy of the vendor,” Thompson said.

As for the move by the OEMs into MRO, “It’s a big change. I think it is the opportunity being seized,” said Rolland Vincent, JetNet IQ creator and president of Rolland Vincent Associates. “There’s been recognition for many years that the aftermarket is where OEMs make money. It’s been that way for the engine world forever. In a development program, the monies are made long term—10 years out, 20 years out sometimes, especially with the airlines. So that business model has been introduced to business aviation over the past years.”

He added that he sees this as a recognition by the OEMs that they need to do a better job of keeping customers and not let them drift away to third-party independents.

Manufacturers of the largest business jets—Bombardier, Gulfstream, and Dassault—have invested heavily in expanding their MRO footprints.

Bombardier has poured hundreds of millions into its strategy to “Bring Our Jets Home.” The Canadian manufacturer of the super-midsize Challenger and ultra-long-range Global families has increased its MRO facilities footprint worldwide by 1 million square feet in the past two years alone, noted Paul Sislian, executive v-p of Bombardier aftermarket services and strategy. And more is coming. “It’s a massive investment we’ve made into our future,” Sislian said.

A2Z MANUFACTURING WEST COAST • 26 • AUG - SEPT ’23

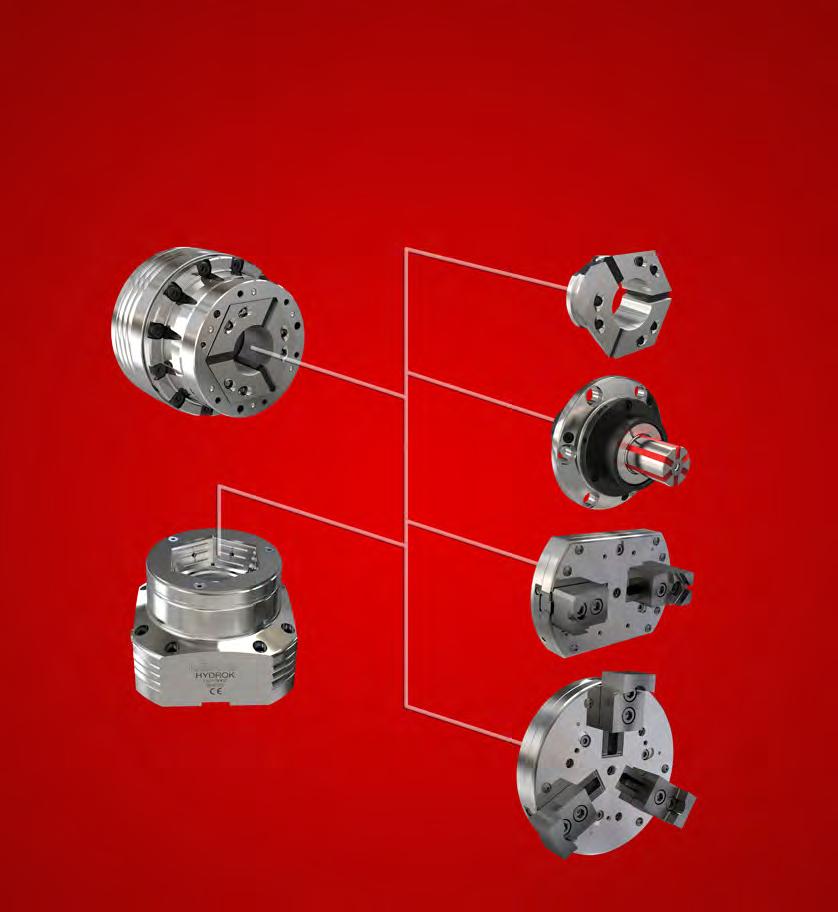

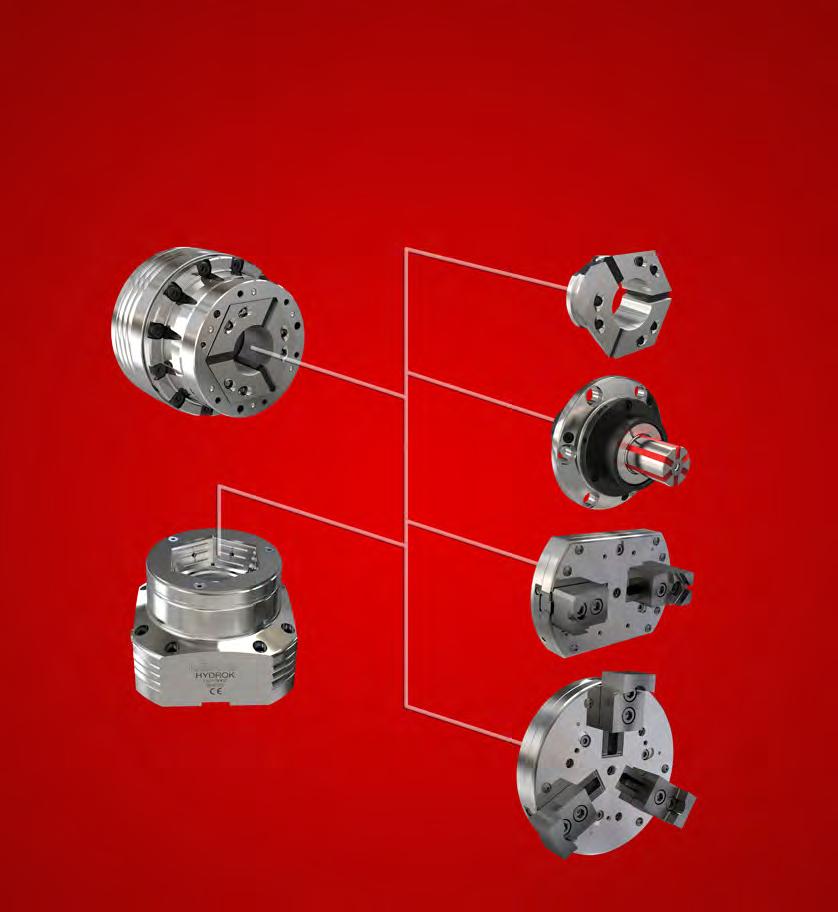

1.800.281.5734 Germantown, WI USA www.hainbuchamerica.com

n Change from O.D. to I.D. to jaw clamping in < 2 minutes

n Use the same adaptations on your HAINBUCH turning or stationary chucks

n Keep the basic clamping device mounted on the machine

Chucks and adaptations are available in round or hexagonal configurations

This growth comes from a strategy laid out about six years ago. “In 2017, we set the vision as a company of this is who we want to become and then we set the journey of the whole team driving towards there,” he said. “It was a pinnacle strategy to Bombardier because it sent a clear message to the industry and mostly to our customers that we are here and we want to make sure that we take care of our customers and we add value.”

Announcements & Releases Continued

just got to keep going,” he said.

from outside North America to North America. Reshoring includes work that is produced either in-house or outsourced. A complete definition of “reshoring” is available here. Applications must be submitted by June 30. To view award details and enter to win, visit this webpage.

He noted Bombardier supports a fleet of 5,000 aircraft. “We have to make sure that we properly serve our customers. It’s a life cycle, the relationship we have with them.”

To back that sentiment, he said, Bombardier needed to have the right infrastructure.

materials and services to the industry.

Bombardier vies to double its services revenues from $1 billion in 2020 to $2 billion in 2025, and this year brought in $424 million from services in the first quarter alone, a 17 percent year-over-year increase.

“From 2010 to 2020, more than one million jobs were announced as coming to the United States from offshore. This is a tremendous achievement, and we seek to motivate and honor the companies that have made reshoring a reality,” said Harry Moser, founder and president of the Reshoring Initiative.

The Association For Manufacturing Technology (AMT) represents U.S. builders and distributors of manufacturing technology – the advanced machinery, devices and digital equipment that U.S. manufacturing relies on to be productive, innovative, and competitive.

While it continues to look for opportunities, perhaps in new areas, Sislian said Bombardier faces the same constraint as the rest of the industry: workforce. “Do I think that we have enough brick-and-mortar capacity presently to meet the demand? The answer is yes. Do I think that we’re going to need to grow our brick-and-mortar over the next five years? Yes. But do I think that we have enough human capacity today? Not yet.”

Questions about the National Metalworking Reshoring Award can be directed to Harry Moser at 847-867-1144 or harry.moser@ reshorenow.org. For more information on AMT’s efforts on reshoring and supply chain efforts, visit IMTS.com/supplychain.

This is key because Bombardier’s aircraft have become larger with the addition of the Global 7500, which sports a 112-foot fuselage length, a wingspan of 104 feet, and a height of 27 feet. With the expansion at London Biggin Hill, Bombardier now has one of its largest centers based in the London area and the ability to fit 14 Global 7500s in its service center at a time. Its new Miami-Opa locka center has that same capability, while the Singapore center was quadrupled in size.

Bombardier is working with local officials and schools in the regions it enters to develop a talent pipeline, which in turn will help the company increase capacity within the same square footage.

Bombardier maintenance inspection of landing gear

The Reshoring Initiative, founded in early 2010, helps manufacturers realize that local production, in some cases, reduces their total cost of ownership of purchased parts and tooling. The Initiative also trains suppliers how to sell against lower-priced offshore competitors.

While not ready to detail Bombardier’s plans, Sislian made it clear that the company is continuing to explore opportunities for further growth.

NTMA is the voice for the precision manufacturing and tool and die industries in the United States. Backed by nearly 1,300 member companies, representing more than $30 billion in sales, NTMA provides an array of benefits to members and the industry including advocacy in Washington, training and education programs and networking events nationwide.

Bombardier hopes to double its service revenue from 2020 to 2025 and plans to keep adding MRO capabilities.

The Benefits Of Worki ng With P4Swiss / Lindel CNC Machining

Another aspect of having its own centers is supply chain, Sislian said. “Obviously having your own MROs, you have a little more control over that.There’s a very, very close coordination between the MRO needs and

PMA, an inaugural sponsor of the National Reshoring Award, is the full-service trade association representing the North American metalforming industry — the industry that creates precision metal products using stamping, fabricating, spinning, slide forming and roll forming technologies, and other value-added processes. Its

“As far as I’m concerned, it’s an evolution, there’s no destination, you

Continued Page 29

Founded in 1987, Lindel Precision CNC Machining merged with Precision 4 Swiss in 2019. Together, P4Swiss / Lindel CNC Machining is dedicated to providing quality CNC machined parts at

A2Z MANUFACTURING WEST COAST • 27 • AUG - SEPT ’23

nearly 900 member companies also include suppliers of equipment,

our supply chain capability.” Bombardier is able to balance its inventory between its original equipment manufacturing and MROs. “If parts are in scarce resources, then having your own MROs allows you to be able to move the materials to best suit the customers.”

Gulfstream is another OEM that’s poured hundreds of millions into its service center network—in fact, the company estimates upwards of $500 million—as it looks to keep up with its growing fleet. Just in April, the manufacturer of the G280 super midsize aircraft and a line of large-cabin long-range models announced it was investing another $100 million into its service center at its headquarters facility at Savannah/ Hilton Head International Airport in Georgia.

This is only one of numerous projects that Gulfstream has been developing over the past 15 years as it saw a need to increase capacity as its aircraft sizes grew. In the past decade, Gulfstream has added more than 2 million sq ft of hangars, shops, warehouse space, and offices and has numerous other expansion projects still ongoing in the U.S. and the UK.

“When the G650 was introduced in 2008, we saw the need to modernize our service facilities to accommodate the very large cabin business aircraft Gulfstream brought to the market, and with that came building larger hangars and streamlining the support experience for our customers,” explained Derek Zimmerman, president of Gulfstream customer support. “The introduction of the G400, G500, G600, G700, and G800 further reinforced that need for modernization and expansion.”