TA Ann Tasmania (TAT) was established in 2005 to make better use of previously woodchipped eucalypt regrowth log billets by peeling them to create a high value veneer for the domestic and international market.

Ta Ann Tasmania invested over $79 million to develop two veneer mills - the Huon mill built in 2007 and the Smithton mill in 2008 – and in 2015 commissioned a new plywood manufacturing plant in Smithton.

Veneer is produced using a rotary technology from short logs known as billets, in a process not dissimilar to unfurling a roll of kitchen paper. Green veneer sheets are dried before stacking on to pallets and wrapping for shipment.

SMITHTON plywood manufacturer Ta Ann Tasmania (TAT) has teamed up with Victorianbased Australian Sustainable Hardwoods (ASH) to produce the only wholly Australianmade pre-finished engineered timber flooring.

TAT’s General Manager Robert Yong said today the partnership with ASH was an example of the growing demand for products for the local building industry.

“TAT and ASH have been working together to develop engineered flooring with our Smithton plant supplying a high-quality substrate and ASH adding a Tasmanian Plantation oak laminate facing,” Mr Yong said.

The Plantation Oak was sourced from Sustainable Timber Tasmania (STT), along with private growers in Tasmania, and processed by Western Junction Sawmill in Tasmania.

“We have been working with ASH since August last year doing trials of our base substrate panel for their engineering flooring. ASH will laminate 4mm thick sliced hardwood veneer and cut into 200mm-wide tongue and groove flooring strips and then pre-coat into a range of architectural finishes.”

ASH director Daniel Wright said while there were other pre-finished engineered flooring products on the Australian market, they were all imported.

“This will be the only prefinished engineered flooring plant in Australia,” Mr Wright said.

“Previously we produced part of it overseas, sending our feedstock to have it pressed to their plywood and then bringing it back to Australia for coating. But quality and coordination has become more difficult in recent years.”

Mr Yong said Ta Ann employed 45 people at the Smithton plant and was now advertising nationally for 10 more skilled workers to expand production to meet the growing demand.

Mr Wright said the partnership with Ta Ann was a good fit for ASH.

“We have third-party reviewed chain of custody certification under the Australian Forestry Standard and the Program for the Endorsement of Forest Certification schemes (PEFC) for all our products, as does TAT, so this gives us much better control to ensure wood used in production comes from certified sustainable sources,” he said.

Logs are supplied to TAT from managed native forests and plantations. The native forest logs come from forests agreed for production by environmental non-government organisations and are independently certified to the international PEFC standards. Furthermore, this is a condition under TAT’s contract with STT and the Federal Government.

“Our Smithton plant is the only Tasmanian business able to process small-sized peelergrade largest hardwood timber product manufacturer. The company operates eight on-site manufacturing lines to add value from logs to finished product.”

These include mass timber, staircase components, window components, architectural joinery, furniture timbers and engineered flooring. Its range of timber species includes Plantation Oak, Victorian ash, Tasmanian Oak and American Oak.

Circular Head Mayor, Gerard Blizzard, has welcomed the logs previously suitable only for chipping or export to produce a value-added structural product,” Mr Yong said.

Mr Wright said ASH aimed to have the flooring available on the Australian market by March 2023. ASH, based at

Heyfield in Victoria, is a privately owned Australian timber mill and manufacturer. Established over 30 years ago, ASH has grown to become Australia’s announcement saying, “An increase in locally manufactured building materials is greatly needed to meet the Australianwide demand to build more homes, as has been acknowledged in recent federal and state budget announcements.

“Here in Circular Head, we are keen to grow the population and look forward to increased local employment.”

Mr Blizzard said partnerships such as today’s announcement of that between TAT and Victorian company ASH helped meet the national demand as well as create local jobs.

“I’m advised by TAT that it is their aim to use the additional skilled workers to train up more people locally to allow further expansion of production at the Smithton plant in the mid-term future,” Mr Blizzard said.

“Providing opportunities for people to upskill and create more job opportunities is great news for the region.”

- Circular Head Chronicle

Ta Ann is a socially and environmentally responsible company and is committed to best practice in the development of new eucalypt wood products. The company receives its wood supply from Forestry Tasmania under long-term Wood Supply Agreements.

As a result of the Wood Supply Agreements, Ta Ann Tasmania has gained Chain of Custody certification for its Tasmanian eucalypt veneer under the Australian Forestry Standard and the Program for the Endorsement of Forest Certification schemes (PEFC). This assures its customers that the product is sourced from sustainably managed forests.

Ta Ann continues to honour its commitment under the principles of the Market Compact with Environmental Non-Government Organisations (ENGOs) to only accept logs supplied from State Forest areas that had been agreed for long term sustainable wood supply through a contract with Forestry Tasmania.

Ta Ann’s two rotary veneer plants currently employ 100 FTEs and over the past five years have contributed $184 million into the local regional economies.

Ta Ann continues to invest in research and development of new products. Future growth in veneer and plywood production will come from private forests and plantation log supplies.

FEBRUARY 2023

Issue 1 – Volume 33

Incorporating Australian and New Zealand Timberman. Established 1977. News 3-9

Flooring

FRONT Cover:

The Tasmanian forestry industry says it has geared up production to assist the government meet its commitment to build 10,000 new homes by 2032.

PUBLISHER and Chief Executive:

Hartley Higgins

General Manager: Robyn Haworth

Editor: Bruce Mitchell b.mitchell@ryanmediapl.com.au

Adelaide Office (08) 8369 9512

Advertising: Gavin de Almeida g.dealmeida@ryanmediapl.com.au

Adelaide Office (08) 8369 9517

Creative Services: Tim Coleman

Publication Design: Tim Coleman

Timber classifieds: g.dealmeida@ryanmediapl.com.au Adelaide Office (08) 8369

subs@forestsandtimber.com.au

THE Tasmanian forestry industry says it has geared up production to assist the government meet its commitment to build 10,000 new homes by 2032.

In last year’s State of the State report, the then Premier announced the Government would commit to building 10,000 new homes within a decade to help solve the state’s low cost and social housing crisis.

At the time, concerns were raised about the ability to meet the commitment, with a shortage of labour and materials plaguing the construction industry across the state.

But Chief Executive of the Tasmanian Forest Products Association (TFPA), Nick Steel, said forestry businesses saw the announcement as an opportunity to invest in the industry to meet the future demand.

“One of the biggest challenges for the forestry industry is having the confidence to invest in long-term projects to grow our businesses,” Mr Steel said.

“The industry saw the Government’s commitment to housing construction as a signal that demand for highquality Tasmanian timber would continue for the next decade.

“And while there’s more we can do with Government to ensure the long-term prosperity of the Tasmanian forestry industry, this commitment is a welcomed step.”

Mr Steel said the Tasmanian industry was ready to pro-

Hawthorn VIC 3122 Phone: (03) 9810 3262

Website www.timberbiz.com.au

vide a wide range of timber products essential for the construction of new homes.

“Forest products are an essential component in so many parts of the housing construction process,” Mr Steel said.

“While most people are aware of the need for softwood for timber framing, there is much more in every home that’s made of timber,” he said.

“Look around your house today, and you will often find that the things that make your house your home are built by forest products.

“As well as the 140,000 cubic metres of softwood that will be needed to build 10,000 new homes, the government needs to find 48,000 cubic metres of hardwood for floors, kitchens, doors and windows.

“Plywood, MDF and chipboard will also be needed for kitchen cabinets, wardrobes and substrates, and treated pine will be needed for fencing, decks and landscaping.

“Then there’s the specialty timber and veneers needed for furniture, benchtops and architectural design. Tasmanian timber businesses are ready to provide all of this for the 10,000 new homes committed to by the government.”

But beyond the creation of the homes, Mr Steel said the commitment will help all Tasmanians.

“By guaranteeing the timber needed will come from Tasmanian businesses, the government can ensure the money is kept in Tasmanian pockets, as opposed to being shipped offshore or overseas,” he said.

2023 seems to have arrived with very little good news for employees at Opal’s Maryvale mill.

Just before Christmas Opal was forced to tell 35 workers that they were going to be stood down until mid-February with full pay.

The last ream of Reflex white paper has been produced at the mill, creating uncertainty for more than 90 workers in the production room.

australasian

The stand downs had been looming for some time following a supreme court ruling and a timber shortage.

In early November, government-owned timber business VicForests lost a Supreme Court case which found it was

not doing enough to protect endangered wildlife including two possum species.

As a result, the company was ordered to scale back its timber harvesting in parts of rural Victoria.

VicForests was a massive supplier for Opal Australian Paper and they have been unable to obtain the necessary materials since for paper to be created.

After the court order, the

“By supporting the Tasmanian forest products industry, you are protecting jobs in the state. Over 5600 jobs are directly or indirectly involved in forestry and it’s vitally important that the money is kept in these Tasmanian families and communities.

“And with every tree that is harvested to help build these 10,000 homes to be replanted, the benefit to the environment in storing carbon will help future generations too.”

Mr Steel said the TFPA and its members are ready to assist the government in meeting its commitments and is ready to work with all sides of politics to ensure this important industry remains successful, for the benefit of all Tasmanians.

paper producer flagged that stand downs was a very real possibility.

Opal says it has been unable to identify viable alternative sources of wood.

Which leaves many Maryvale employees facing the possibility of a bleak future in a region of the State already battered by the original decision by the State Government to shut down the native timber industry.

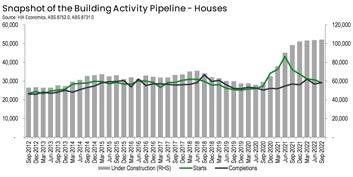

FOR more than two years, Australia’s home builders had been starting more new projects than they had been completing.

HIA Senior Economist Tom Devitt said that according to ABS figures there were only 29,153 detached houses completed in the September Quarter 2022, just 2.5 per cent up on the same time the previous year.

The ABS this week released its building activity data for the September Quarter 2022. This data provides estimates of the value of building work and number of dwellings commenced, completed and under construction, across Australia and its states and territories.

“The number of homes reaching completion remains no higher than those being commenced with 29,177 new projects started in in the September quarter,” Mr Devitt said.

“Supply constraints were holding back completion of these projects. Materials constraints have plagued builders over the last two years, but the shortage of skilled trades is the number one constraint on Australian builders.

“Over 104,000 houses are still under construction across Australia, almost double the pipeline that existed in mid-2020.

“New house commencements continued to decline in the September quarter with a further 4.9 per cent fall. Commencements peaked in the

previous cycle in mid-2021 and are expected to continue to decline into 2024.

“The volume of houses under construction is expected to keep Australia’s home builders busy this year, despite the slowdown in the number of homes expected to commence construction.

“In addition to this, the volume of multi-unit dwell-

ings under construction continues to grow as commencements exceeded completions over the 18 months to September 2022.

“The multi-units sector should continue to be supported by the return of overseas migrants, students and tourists and the incredibly tight rental markets across the country.

“With interest rates increasing rapidly, affordability constraints will push home buyers back towards more affordable, higher density living.

“This large volume of work under construction at the end of 2022 will ensure elevated demand for skilled trades across the economy,” Mr Devitt said.

Only two months into his role, Tasmania’s new northern-based Wood Encouragement Officer has already begun working with stakeholders to promote project outcomes using Tasmanian produced wood and hopes to facilitate a healthier culture around wood.

As a registered architect, Gary Fleming understands only too well the benefits of incorporating locally sourced wood and wood products into buildings.

“Historically, our buildings were constructed—out of necessity—almost entirely from wood,” Gary said.

“From this, other benefits became apparent such as aesthetics, tactile qualities, durability, versatility, sense of wellbeing and it is renewable.

“In current times locally sourced and produced, low embodied energy materials make a lot of sense, environmentally and economically.”

Gary said his new role— which is a government-funded joint appointment by the Tasmanian Timber Promotions Board and the University of Tasmania—is focused on making meaningful connections with industry stakeholders who both produce, sell and use wood.

“The use of wood and wood products is multi-faceted. I have started working with government agencies looking at policies and incentives and how this might better inform and assist with future projects, including the development of programs and partnerships that encourage a culture of wood,” he said.

Over the term of his employment, Gary will seek out project opportunities where locally sourced wood can be showcased in traditional and innovative ways.

He said open communication with industry stakeholders and the facilitation of meaningful connections, as well as assistance in problem solving at any stage of the building process, is key.

‘Encouraging a healthy culture of wood not only has benefits for the industry but also for the wider community and the whole of Tasmania,” Gary said.

BOWEN’S is on a journey, and the company is keen to let its customers take the business to that destination.

Bowens is a fourth-generation family-owned Australian business and market leader in supplying the largest variety of quality timber and building supplies in Australia.

In 1894 Richard Bowen and Redmond Pomeroy began selling timber products from a small yard in North Melbourne under the name Bowen & Pomeroy, Timber Merchants.

For the past 11 years Bowens has also owned Timbertruss, one of the nation’s largest prefabrication timber manufacturers which employs staff in Victoria and Queensland.

“Like most businesses over the last couple of years, we’ve been very myopic,” Managing Director John Bowen told the Timber Offsite Construction conference last year.

“We’re just worrying about what we’re up to, probably haven’t taken as much interest in some of what others are doing,” he said.

Mr Bowen said he had visited Europe about six or seven years ago, Northern Europe particularly, and went to several factories.

“And it was our belief straight away that the Australian version was going to be different from what we’re seeing overseas.

“We’re also very aware that if we want to last, if we want to create a vision of building something beyond roof trusses, and wall frames, we had to operate a very efficient roof truss and wall frame business that could pay for our vision or our future.”

And that’s precisely what Bowens did.

“The focus became very much about doing the business we did today, with a more technical element, more machines more automation, understanding that that was going to pay for anything that we’re able to do and play with. And that’s what we’re doing at the moment,” Mr Bowen said.

“We’d already started a cassette business, we had a cassette flooring machine,” he said

“Customers love the look of it, they love the story, but the

orders wouldn’t come and so we had to put our staff back into roof trusses and wall frames.

“So it was a timid approach. But with that experience, I think it helped us understand where we’re going to hit with panelised building.”

The European experience gave Bowens an insight into a prefabricated industry it could never match.

“I’m sure you have watched Grand Designs and seen these incredible houses being built,” Mr Bowen said.

“Our version of that truth is that the builders mostly own the construction. The good part of it is they know what’s best for their production. So they’re designing homes for the machines that they have, for the staff and the experience that they have, and also geographically what they need,” he said.

“They definitely own the quality. And they can coordinate the timing of jobs to site.”

“If you are a builder creating these incredible houses they do particularly in northern Europe, it’s a very different story, they can time those buildings very easily.”

Mr Bowen said the European factories were “only building 800 houses a year”.

“We’re having to do a couple of 100 rooms a week at the moment for our truss business. So if we then took that learning back to Australia, there’s no way we’re ever going to keep up with that.”

■ 1894 - Richard Bowen and Redmond Pomeroy began selling timber products from a small yard in North Melbourne under the name Bowen & Pomeroy, Timber Merchants. Both tragically passed away in the same year, 1924, before Richard’s son, John senior, became managing director in 1931.

■ 1971 - John senior’s son, Jack, took over the business.

■ For the past 11 years Bowens has also owned

Mr Bowen said there was heavy capital investment for those builders.

“It’s a very different way of building of course,” he said.

“At the moment, in our journey, we’re discovering what the market really wants. And

Timbertruss, one of the nation’s largest prefabrication timber manufacturers which employs staff in Victoria and Queensland.

■ Andy Bowen’s focus has been establishing an e-commerce function for the business. Principally for the trade, but also increasingly for retail customers.

■ Bowens’ 16 stores across Victoria and its range of delivery options were repurposed by creating a digital front end, allowing

we will let our customers take us there. We will eventually identify what is best for us.

“We’ll keep manipulating what we do inside those walls, so that we can find the best solutions, both for us and our customers.”

it to make promises to customers around tight delivery times, especially for large and often fragile products needed by builders on work sites.

■ The e-commerce site was launched as a retail service in December 2020.

■ During the pandemic Bowens continued to invest in its operations, including in a new prefabrication plant, showroom and a new timber yard in Geelong.

grown trees will be building and refurbishing affordable public homes for South Australians.

“The South Australian forest industries processes about 35 per cent of Australia’s structural house framing timber and about 25 per cent of the nation’s particleboard, and its great news that this policy will support our domestic manufactured product over imported product thereby support local jobs,” he said.

PUBLIC houses built in South Australia must use products manufactured in the state, under ground-breaking mandates introduced by the State Government.

It’s the first change announced as a result of sweeping and broad reforms to government procurement – a Labor election promise which will benefit local businesses, manufacturers and workers.

From now, South-Australian

manufactured products must be used on public housing construction and maintenance programs, where available.

The policy will ensure local manufacturers and SA businesses benefit from the State Government’s $177.5 million commitment to build 400 new affordable homes and refurbish a further 350, to help those most in need during a stressed housing market.

“This is a big win for manufacturing industries in South Australia, particularly the forest industries, giving such sectors a boost of confidence and recognition by the State Government,” South Australian Forest Products Association CEO Nathan Paine said.

“Timber frames are a core manufactured product in South Australia that supports our residential construction and building industries, and we are pleased that locally

“Not only will this initiative be supporting forestry, but it will be supporting job creation in our regions, our local and state economy and most importantly, our regional communities who rely on thriving forest industries.”

Mr Paine said that with Timberlink expected to complete its new CLT and GLT plant in Tarpeena this year, it will secure the South East as one of Australia’s leading timber manufacturing regions, unlocking further economic activity for the region.

The South Australian Housing Authority will release tenders for construction of 103 homes, including the first six homes at Broadview this

week, which will also require South Australian workers be used for a minimum of 90 per cent of labour hours, with 20 per cent of those being supplied by apprentices, trainees, Aboriginal workers or the long term unemployed.

Setting an example for the broader industry, the government will require core products used in construction to be manufactured here in SA, including bricks, timber frames, concrete, reinforcing steel, steel frames, windows, security doors and steel for roofing, fencing and rainwater tanks.

It’s estimated these products account for approximately 58 per cent of the cost of building an average dwelling. Labor pledged to reform government procurement to help give South Australian businesses and workers a competitive edge when deciding where taxpayers’ dollars end up, creating more work and a stronger economy.

The government is targeting an increase of $425 million per year in work awarded to SA businesses.

THERE has been significant progress on the construction of Australia’s first combined Radiata Pine Cross Laminated Timber (CLT) and Glue Laminated Timber (GLT) manufacturing facility in Tarpeena

in the Green Triangle.

The NeXTimber facility will be co-located at the existing Timberlink site and will produce CLT panels and GLT members. These products provide the biophilic and environmental benefits of

traditional timber but with the strength to support taller and more complex structures.

The NeXTimber range offers timber building solutions for commercial, residential, and public projects; used on their

own or in conjunction with traditional building materials.

NEXTIMBER CLT RANGE:

• Roof panels

• Floor panels

• Wall panels

• Lintels & other framing

NEXTIMBER GLT RANGE:

• Beams

• Columns

• Frame & truss members

Since initial works began in 2021, it’s been a hive of activity on the site with the first

pieces of Kallesoe Machinery A/S being lifted into place in August 2022 and erection of the steel structure commencing in October 2022. 2023 will see the commencement of equipment installation followed by commissioning and performance testing. Full production of the NeXTimber range is scheduled to begin in late 2023.

Timberlink is committed to product and service excel-

lence and has partnered with world leading equipment and software providers as part of the project including Kallesoe Machinery A/S for plant design, manufacturing equipment and installation as well as Hans Hundegger AG who will supply the PBAIndustry panel processing machine with the latest CNC machining technology. This equipment will be supported by a fully integrated end-to

end software platform provided by hsbcad.

“This world leading technology provides the latest capabilities in CLT GLT production and will place Timberlink at the forefront of supply capability in the Australian and Oceania region” Timberlink Australia Chief Executive Officer, Ian Tyson Infeed stock for the NeXTimber range will come from local plantations in the Green Triangle region and is supported through Timberlink’s vertically integrated supply chain. The majority of log supply to Timberlink’s manufacturing facilities is dual certified to both FSC® and PEFC/ Responsible Wood.

Over the last three years, Timberlink has invested over $200M into upgrades at the Tarpeena Bell Bay sites, demonstrating their commitment to the forestry industry and regional communities. Upgrades include the construction of the NeXTimber facility created by a $63m investment by Timberlink, as well as a state of-the-art Light Organic Solvent Preservative (LOSP) treatment plant, a new green mill in Tarpeena and vision scanning system in Bell Bay.

2013

■ Timberlink began

2015

■ World first low-odour LOSP launchedTimberlink Green

2017

■ Bell Bay upgrade commenced

■ First Australian timber producer to achieve dual sustainability certification

2018

■ Made of Tasmania campaign launched

■ $100M upgrade program begun

2020

■ Paris Agreement commitment: Cutting carbon emissions by 53% using SBTi – The first Australian company in our sector to do so.

■ Cross Laminated Timber & Glue Laminated Timber project– the only combined CLT/GLT plant in Aust.

2021

■ Wood Plastic Composites (WPC) project announced

■ NeXTimber brand launched

■ Bell Bay $63m upgrade announced

2022

■ CLT/GLT construction commenced (Tarpeena)

■ WPC facility construction commenced (Bell Bay)

■ Tarpeena treatment plant construction commenced

2023

■ Timberlink celebrates 10 years in business

■ Launch of WPC products

■ Production of NeXTimber scheduled to commence

INNOVATIVE SOLUTION 12,000 RPM HSK TECHNOLOGY MOULDER TO GRINDER CONNECTIVITY

HAS your superannuation been lurking on your To Do list? It’s a New Year, and there’s never been a better time to consider how First Super can help you sort your super in 2023.

First Super is the super fund for the timber, furniture and joinery, and pulp and paper industries – though it welcomes all Australians.

It manages over $3.6 billion in retirement savings for about 47,000 members Australia-wide, many of whom work in timber.

First Super is an industry superannuation fund that is run only to benefit its members. This means it is solely focussed on providing members a dignified retirement by delivering strong, long-term investment returns, competitive fees, flexible products and a great member experience that helps every member sort their super.

Big enough to perform

First Super was a top 10 super fund in 2022. It was one of only a handful of funds to produce a positive result in its Balanced option, despite globally tough market conditions.

You don’t have to take our word for it – First Super’s MySuper product was ranked in the top 10 of APRA’s latest performance rankings for MySuper products. APRA is Australia’s super prudential regulator.

First Super offers a choice of five investment options: Shares Plus, Growth, Balanced, Conservative Balanced and Cash, as well as Retirement products that let you stay with First Super when you stop working.

It also offers Insurance cover that’s competitively priced, tailored to the timber industry, and easy to manage. When you include your insurance with your super, your insurance premiums are automatically paid via your First Super account.

First Super’s history of strong, longterm performance is only one of the reasons to join First. It prides itself on delivering great service.

First’s team of member and employer Coordinators across Australia offer in-person, tailored support.

Financial planning services such as the First Super Retirement Health Check, and education seminars are available to members at no additional cost. Comprehensive financial planning is available for a fee.

And with contact centre wait times of less than two minutes on average,

the Member Services team can help you sort your super!

To learn more, go to firstsuper.com. au or call us for a super chat: 1300 360 988

First Super is issued by First Super Pty Limited (ABN 42 053 498 472, AFSL 223988). Past returns are not an indicator of future returns. General advice only. Read the Product Disclosure Statement (PDS) before making any investment decisions. PDS or Target Market Determination available from First Super on 1300 360 988 or firstsuper.com.au/pds.

VICTORIANS who are beginning the process of rebuilding or repairing homes damaged by the recent flooding in Central and Northern parts of the state need to watch out for unregistered practitioners.

The Victorian Building Authority (VBA) warns consumers to check that any builder or plumber advertising services in the wake of the emergency events is registered and/or licensed.

The VBA’s state building surveyor Andrew Cialini says that it was unfortunately common for unscrupulous operators to take advantage of a crisis and offer services when they aren’t qualified to do so.

“We encourage all Victorians to check whether a practitioner they are hiring is registered and or licensed to carry out the services they are offering,” he says.

“In Victoria, building practitioners must be registered with the VBA to perform certain kinds of work, so do your research and ask for some key

information up front, so there are no shocks later on.”

Andrew adds that consumers should be wary of anyone offering their building or plumbing services via online marketplaces and through apps.

“With the rise of online apps and websites where anyone can advertise their services without qualifications, it’s important to always check the credentials of anyone you hire,” he explains.

“You can check whether the builder or plumber you’re looking to use is registered with the VBA and whether they’ve faced any disciplinary action. We want consumers to be in a position to make informed decisions especially where it may impact their safety and wellbeing.”

While some work around a property can be done yourself, if a job requires two or more of these trade skills, or if you want to undertake any other task that exceeds the $10,000 limit, you must hire a registered practitioner.

WITH supply shortages continuing to jeopardise construction projects across Australia, the industry is facing a number of significant challenges.

For builders’ merchants responsible for providing vital supplies, this has been a recurring issue with many having to withstand 8 to 12 week waits for supplies as timber stores fell to dangerously low levels.

Unfortunately, it seems inevitable that these issues will continue into 2023, meaning that now is a crucial time for merchants to reevaluate their processes and systems to drive efficiency.

Last year certainly presented many hurdles for builders’ merchants. In fact, shortages across Australia have led to environmental court orders placed upon state government backed VicForesters to be partially suspended by the Victorian Supreme Court. If implemented the court order would have prevented timber harvesting in the state’s central highlands, perhaps further exacerbating supply issues.

In the past three years the prices of timber, boards and joinery have shot up, rising by as much as 37.8%, according to Master Builders Victoria’s latest analysis data.

In reaction to this challenging landscape, a growing number of builders’

merchants are considering implementing specialist technology - not only as a means of minimising supply disruption, but to also boost performance and productivity across their business.

In financially uncertain times, maintaining a steady flow of stock is a key priority. Having a large quantity of timber or building supplies sitting in the warehouse can be costly and reduces space for more in demand product, while not ordering enough may prevent a merchant from being able to fulfil orders in full, on time.

Achieving seamless monitoring of inbound deliveries and outbound orders helps merchants to avoid these costly mistakes, but relies heavily on them having a clear overview of the whole supply and demand chain. Those relying on stand-alone or disintegrated systems may struggle to streamline this process, especially when dealing with large quantities of items. These legacy or paper-based systems can also easily become overwhelmed when intricate orders, delays or complications arise.

Specialist enterprise resource planning (ERP) systems, such as ECI Spruce, can act as a valuable coworker, designed to seamlessly link and monitor all departments.

With complete visibility of the entire business opera-

tion, an ERP system can be relied upon to automatically monitor stock levels in real time. Not only will this prevent the costly mistake of over or under ordering stock, a fully integrated system ensures that the whole business is kept up-to-date on item availability. Similarly, should a customer request an update on their order status, this can quickly and easily be actioned. Anyone in the team can log-in and be confident that the information on the system is accurate, without having to manually pull together spreadsheets or bundles of paper. During uncertain times, offering this level of service and speed will help customer satisfaction and pave the way for growth.

When resources are strained, time-consuming

manual processes cause inefficiencies. These inefficiencies are especially apparent when using systems that are disjointed or require some form of manual data transfer. Small errors and oversights can fall under the radar which can collectively take a toll on a businesses’ overall reputation.

With an ERP system in place, as soon as a piece of information is entered into the system, it’s saved across the whole database - not only helping to improve data accuracy, but also minimising time spent on data input.

While legacy and paperbased systems have been perfectly adequate for many businesses, as the digitisation of the sector has continued at pace they are proving to drain valuable time, space

and especially in the case of physical servers, finances. Implementing a specialist cloud-based ERP system removes the need for bulky and cumbersome hardware, instead delivering a software solution that is fully scalable as a business grows.

Overcoming the hurdles builders’ merchants currently face is no small task. But, by deploying technology to act as a much needed ally, working alongside existing employees to reduce their administrative burden and drive efficiency is a strong start towards a more straightforward 2023.

To find out more about the ECI software and how it can help your business, please visit https://www.ecisolutions.com/en-au/.

Greg Gill is regional director of sales across APAC at ECI Software Solutions.

PRIZED for its natural warmth and reliable performance, timber flooring represents a quarter of the flooring market.

Within this category, engineered timber flooring has emerged as a preferred choice due to its superior stability and durability, and a natural look that is almost indistinguishable from solid timber. Not all engineered timber flooring performs the same however; product type, species, composition, installation method and the climatic conditions of the install environment all affect performance and stability. In today’s market, sustainability and health requirements must also be considered.

With the growth of engineered timber products on the market, it is critical for architects, designers and specifiers to know what to look for when choosing the solution best suited to their intended application. Leading timber supplier Big River Group has released an informative guide to specifying engineered timber flooring for architects and specifiers titled, Australian Native: A Specifier’s Guide to Engineered Flooring.

ENGINEERED TIMBER VS SOLID TIMBER

Engineered timber is comprised of a decorative surface layer of timber,

called a veneer or lamella, bonded over a timber substrate. By comparison, solid timber floors consist of planks made out of solid pieces of wood and is the more traditional style for flooring. The processes of layering, compression and lamination used to manufacture engineered timber provide additional stability and durability to the end product. Every board is created by bonding together layers of wood, creating a solid core board. The core is then covered with a real wood top layer or lamella. This construction makes engineered timber less susceptible to warping and bowing while maintaining a high degree of structural integrity.

THE IMPACT OF THE INSTALL ENVIRONMENT

Australia has a diverse range of climates across the country and the location – climatic conditions and the specifics of the interior space – is critical to successful timber flooring specification and installation. Heat, cold and humidity fluctuations may

JS-50 X6B NEW

CARRIAGES & SHORT-INFEED EDGERS

JS-50 WX TRIMMERS, EDGERS BUCKING & MORE

cause timber to shrink, expand and/ or swell, causing the floorboards to move and warp. Solid timber flooring is more susceptible to movement than engineered timber, which is more resistant to climatic changes provided it is specified correctly.

Stability – Enhanced stability is a key advantage that engineered timber has over solid timber. However, not all engineered products perform the same in this regard. For exam-

ple, three-ply and multi-ply products have different structural characteristics that will impact their suitability for an application. The composition and species used in a board should also be considered whereby some engineered timber products have a core that is a different species to the face lamella and the face lamella may have a different density to the core.

A core that is the same species as the face lamella results in a product that has superior balance and stability. One of the most stable engineered

floors in Australia and New Zealand is Big River Group’s Armourfloor; its base board is the same species as the face veneer, providing optimum balance and stability.

Durability – The durability of engineered timber products is influenced by several factors such as surface finish, thickness of top layer, timber hardness and the quality of installation and maintenance.

Quality of lamella – The lamella can be made of any species of wood. A stable lamella is essential for a high

quality engineered timber floor. The main options for cutting the solid wood lamella layer are dry, solid sawn, rotary cut or peel and sliced cut or peel.

Aesthetics – High quality engineered timber retains the aesthetic of real wood. Different species and manufacturing methods will result in different looks. Engineered timber flooring also tends to have more stylistic variations than solid timber flooring. As a natural product, engineered timber is subject to some degree of colour vari-

ation and there will be natural variations in knots, grain and sap marks.

Installation method – Engineered timber flooring is installed using either the floating or glue-down installation method. The choice should be determined by the species of the flooring product, cost and time constraints. All installations should follow the manufacturer’s specifications and guidelines.

Sustainability – Sustainable product certification and Chain of Custody (CoC) of forest products help specifiers identify timber products that are sourced and produced in a sustainable manner. Buying local manufactured engineered timber products is more sustainable than importing products in the same category.

Manufactured in Australia, Armourfloor is a stable timber floor. The product is manufactured using a five-layer, cross-ply construction – a quality that enables Armourfloor to perform to expectations in all geographical locations. No expansion is required through the floor unless the area exceeds 15 meters in length and width, although perimeter expansion gaps are still required. The rotary-

peeled lamella on Armourfloor opens the grain, giving a distinctive flowing appearance and is unique in appearance compared to conventional back sawn products. As a raw uncoated product, Armourfloor must be coated in-situ, enabling the use of different finishes to be applied to produce desired sheen levels. Finishes, such as polyurethanes, oils or wax, can be chosen based on the specifics of the application.

Engineered timber technology has improved greatly over recent decades, resulting in superior performing flooring materials that boast high levels of inherent stability and durability, and greater resistance to temperature and moisture than solid timber. Leading quality products, such as Armourfloor by Big River Group, also offer a natural look that is almost indistinguishable from a solid plank floor.

All Big River engineered flooring and plywood is milled from managed regrowth and plantation forest hardwoods. Big River hardwood is Australian Forestry Standard (AFS) certified.

Big River’s pre-finished engineered flooring comes with a lifetime warranty against warping, buckling or bond failure and a 20 year limited warranty for the finish against wear-through under normal residential usage.

TIMBER construction is making headlines across the world with new high-rise projects choosing this popular building material over cement and steel to reduce their carbon footprint and offer a pathway to sustainability.

But how can timber construction be sustainable when you have to cut down trees to source the material?

A report by the Clean Energy Finance Corporation (CEFC) reveals that the traditional steel-and-concrete construction sector is one of the biggest contributors to carbon emissions, accounting for around 39% of total global emissions – 28% from building operations and 11% from embodied carbon in building materials and construction.

Australia’s $65-billion construction material industry alone accounts for 30-50 million tonnes of CO2-eeach

year, amounting to approximately 5-10%of the national greenhouse gas emissions (GHGs).

Substitution of carbon-intensive materials such as steel and cement with low embodied carbon materials is one of the strategies being adopted to reduce the industry’s carbon footprint. Timber is an infinitely renewable resource, stores carbon (approx. 1 tonne/m³) and has very low embodied carbon. By replacing steel and concrete with timber products for instance, embodied carbon can be reduced by up to 75% (https://www. cefc.com.au/media/media-release/ cefc-targets-timber-transformationwith-300-million-building-program/) according to the CEFC.

However, given the global campaign against deforestation, how will we get the timber for our buildings?

According to the Federal Govern-

Certificates II, III and IV

Wood Machinists

Saw Technicians

Sawmilling, including portable sawmilling

Grading

Timber Drying

Truss Fabrication, Estimating and Detailing

Forest Growing and Management

Forest Products Diploma

Workplace Assessments

OH&S and Environmental Care Chainsaw Courses

Pole saw SES and Fire ServicesChainsaws, Rescue Saw, Pole Saw

ment’s Department of Agriculture, Fisheries and Forestry, Australia has a total forest cover of 134 million hectares, equivalent to 17% of the country’s total land area.

While 132 million hectares (98%) are designated ‘native forests’, 1.74 million hectares are ‘commercial plantations’. More than 85% of the 32.9 million cubic metres of logs harvested in Australia each year is sourced from plantations.

A key objective of Australia’s national forest policy has been to increase the plantation timber resource ‘to expand Australia’s forest industries and offset the reduced access to native forest resource’, states the Department of Agriculture, Fisheries and Forestry. Towards this, the Federal Government has committed $86.2 million (https:// www.agriculture.gov.au/agricultureland/forestry) in the 2022-23 budget to support a 5-year program for the establishment of new plantations and help secure future domestic timber supply.

Sustainable timber is timber sourced from sustainably managed and certified forests. Applicable to both native forests and plantations, forest certification demonstrates the implementation of sustainable forest management practices and is conducted through an audit by an independent third-party certification agency.

In Australia, forests can be certified by the two major global forest certification bodies – the Program for the Endorsement of Forest Certification (PEFC) under the Responsible Wood Certification Scheme, or the Forest Stewardship Council (FSC).

Currently, 26.7 million hectares of native forests and plantations are certified under the Responsible Wood Certification Scheme, and 1.2 million hectares under the FSC.

Both forest certification schemes provide chain-of-custody certification, which can be used to track wood and wood-based products sourced from certified forests throughout the supply chain from the forest to the market. This provides buyers the assurance that the timber products they have purchased have originated from a sustainably managed and certified forest that practises responsible forestry.

The mass timber building movement across the world is seeing leading developers competing for the “tallest timber building” crown, with new projects announced almost every month.

A global audit of talltimber buildings (8+ storeys) conducted by CTBUH (https://www.ctbuh.org/masstimber-data) in February 2022 yielded a total of 139 buildings that were either proposed, under construction or completed, and featured all-timber or hybrid construction methods, with Europe leading the way with 60 buildings, followed by North America (15) and Australia (8).

Having identified the potential to cut emissions in the building and construction sector, the CEFC announced a new $300 million program in early 2022 to encourage and accelerate the use of mass timber construction across the property industry. Seeking to transform Australia’s approach to large-scale building construction, CEFC believes the program can substantially cut construction-related emissions, providing a greener alternative to conventional construction materials.

CEFC CEO Ian Learmonth said: “Timber has been used in construction for generations. Innovations in engineered wood products have created new opportunities for mass timber construction to be used in larger projects, creating the potential for immediate and long-term environmental benefits. Our new Timber Building Program will help finance this transition by encouraging owners, developers and builders to use lower carbon engineered wood products in their projects.”

CEFC director of property investment Ryan Rathborne added: “The time is right for the development of more timber buildings across the property sector. By locking in mass timber construction in new projects, we can also help develop local skills and experience, supply chains and delivery capabilities, all of which can catalyse more timber-based building activity into the future.”

While the jury is still out on how much sustainable timber can contribute to carbon emissions reduction, the use of mass timber in construction is already delivering a slew of benefits: Engineered wood is lightweight, allowing for simple handling and machining; offers structural strength comparable to steel and concrete; enables prefabrication offsite with onsite assembly, reducing construction time and labour costs; is fire-resistant; and can be dismantled and reused in new structures.

WHEN pre-planing, large chip removal can result in surfaces requiring costly rework when the desired quality is not reached.

The Leitz HeliPlan planing cutter provides fast milling for excellent finishes in solid woods.

HeliPlan is designed for pre-planing tear-free planed surfaces and is suitable for finish machining, producing perfect planing results with a long tool lifetime.

Leitz HeliPlan planing cutter also offers a Hydro-clamp option. As the interface between tool and machine, clamping systems play a decisive role in all machining processes.

Inaccurate clamping systems can quickly lead to low machining quality.

With Leitz Hydro-clamping elements, tools can be mounted on the spindle accurately centred.

Subsequently, perfect machining results and longer tool life is possible with the high concentricity and balancing quality.

The optimal balancing quality of the clamp also protects the machine spindle and bearings. Leitz Hydro Heliplan allows for even faster feed speeds thanks to greater knife accuracy, resulting in

increased production and higher finish quality, and can be clamped up to 2500 times without loss of accuracy or requiring any maintenance.

With the help of unique cutting edge geometry, Leitz HeliPlan Planing Cutterhead features unique cutting edge geometry, ensuring particularly smooth finishes.

The optimized gullet design allows planing with a noticeable better large chip removal, reflected in the feed speed and the cleanliness of the machined plates and workpieces. Turnblade knives can be changed quickly thanks to precision wedge-free knife mounting.

Designed for pre-planing, Leitz HeliPlan cutterheads can also be used to reach a

fine finish quality, thanks to the curved cutting edges, higher shear angles and precise knife seating.

The use of exchangeable tungsten carbide turnblade knives enables the tool life of each cutting edge to be increased fourfold, and in combination with the reusable tool body, results in a resource-saving and cost-efficient tool solution.

Noise and power consumption is also reduced due to the unique cutting edge ar-

rangement, with up to minus 10dB(A) noise reduction compared to standard planer knives.

The cutters offer five times longer tool life from HW cutting edges, compared to HS planer knives. Opting for the Hydro-clamping element increases the tool life again by up to 30% in comparison to conventional clamping.

With the development of the HeliPlan system, Leitz has reinforced its position as the world leader in the customer-

oriented development of tool systems. With more than 120 Leitz Service Centres around the globe, users can easily have their tools serviced and resharpened perfectly to manufacturer quality conveniently. Leitz Tooling stand by their motto ‘Solutions in New Dimensions’ and the HeliPlan and Hydro-Clamp are examples of new dimensions in planing solutions. Leitz simply offers more in quality, efficiency and productivity.

2019

Australian Sustainable Hardwoods has assured its customers that the Victorian Government’s ban on the harvesting of native timber by 2030 will not affect supply in the immediate future.

And the company says it will be working hard to ensure that sustainably certified, regrowth sawlogs are made available after 2030.

In a statement to customers the company’s managing director Vince Hurley said it would be business as usual for the next six years as ASH did not process of growth.

2016

Composite flooring systems consisting of cross laminated timber with reinforced concrete have significant potential for use in multi-storey buildings such as offices, hospitals and schools throughout Australia, according to a leader within the engineered timber sector in Australia.

MC33 Planing Knives from Leitz offer longer tool life and reduced sharpening cycles thanks to our exclusive Marathon coating technology Our long tool life is proven to reduce machine downtime and the number of times the machine is required to be set-up, ensuring consistent and optimum productivity, compared to conventional planing

knives

Following tests in the US in which a flooring system involving a cross layered timber deck topped with a thin layer of reinforced concrete was shown to support loads of around eight times what is required by code in that country, XLam technical manager Nick Hewson says there are opportunities to use similar types of systems in Australia.

high quality planing results.

2011

Wood has long been seen as an attractive option for buildings and renovations, and now a new consumer awareness campaign from environmental education organisation Planet Ark is encouraging consumers, architects and builders to see wood for its environmental benefits too.

Planet Ark’s Make It Wood

– Do Your World Some Good campaign promotes the increased use of certified, responsibly sourced wood as a building material.

A recent survey conducted by campaign partner Forest and Wood Products Australia (FWPA) showed that although 93% of people understood that trees absorb carbon, only 39% of them realised that when the tree is responsibly harvested and used to make wood products, the carbon remains locked in the wood for the life of the product.

Suitable for the use in all conventional wedge-type planer-heads designed for 3mm thick planing knives

Available in 30mm and 35mm height

135 127

Up to 6-fold tool life in comparison to uncoated HS-planing knives

Protects the machine bearings due to increased balance and precise weight tolerance

DAYNE Davis, an international construction consultant and timber specialist, has joined Cusp on a part-time basis as the company’s General Manager – Construction.

Founding Timber Design Studios in 2020, Dayne worked alongside the Cusp team on numerous projects, including Launceston’s mass timber build and the Australian Pavilion for the Dubai World Expo. He continues to work at the studio, which is comprised of Europe’s leading timber experts who collaboratively bring international timber projects to life.

While Dayne’s focus and expertise now rest in timber projects and builds, his career in construction management has landed him where he is today.

Notably, Dayne was a construction manager on the prestigious London Shard

project. At 310 metres it’s the tallest skyscraper in Europe and cost more than $ 1.2 billion to build. He’s also worked on one of Central America’s largest hydroelectric dams in Honduras, Central America, the La Vegona Hydroelectric Project. This project saw extraordinary challenges with constructability and logistics, since the construction site was located several hours in the Honduran jungle.

“At Cusp we are looking to work with industry to create sustainable structural solutions for all forms of development,” he said.

Dayne’s main attraction for joining Cusp was due to the company’s innovative thinking and its commitment to developing and producing leading-edge timber products in a growing market.

“Cusp is working with a repurposed species of timber, Eucalyptus Nitens, and it is

always exciting to break new barriers,” he said.

“Their new investment into one of the largest glulam presses in Australia and now their ability to not only block glue large sizes comparable to European producers, but also produce curved beams, will see them become a leader in this space in a short amount of time.”

Dayne is a member of the DGNB, the German Institute for Sustainable Construction, and is committed to working with developers, designers, and investors to find innovative, carbon-neutral and hybrid solutions to deliver the buildings of tomorrow

Architects, engineers and developers are encouraged to speak with Dayne about the use of Cusp’s CLT, lightweight prefabricated or GLT products by calling 1300 792 519 or emailing enquiries@ cusp.com.au

ALTHOUGH we often use the term Type 17 screw or T17 in reference to a specific screw, it doesn’t really refer to the fastener as a whole, the type 17 reference is a manufacturer’s term for the point shape on the end of the screw. This is then nicknamed T17.

When screws are being made the design will include many features, head style, drive type, shank style, material, plate finish etc. and of course the point type.

Examples include Type 23, Type A, Type AB, gimlet and Type 17.

All these points have slightly different purposes.

The washer-like head of the screw enlarges the contact surface on the

workpiece, thus guaranteeing considerably higher tightening torques compared to a countersunk screw.

So what is a Type 17 screw and why should i be using it? To clarify, Type 17 is just a type of drill point.

For type 17 this is a sharp pointed design with a cut out flute to help capture and remove the waste allowing a self-drilling type function similar to a drill bit.

This point type is primarily used in self drilling wood screws for particularly hard timbers like hardwoods. The sharp point and flute cut out helps remove wood chips and debris when drilling, reducing overall torsion on the screw heads and driver.

You find this type of point on a lot on

decking screws, bugle batten screws, hex head self-drill screws etc.

The type 17 points also prevents wood fibres separating which leads to splitting and so these screws are very useful for close to edge work.

They also benefit from fast insertion and self-centering starts and so are ideal for use with powerdrivers.

The sharp point means you can also use them also in thin steel sheeting without pre-drilling e.g. fixing roofing and cladding sheets (this is a very common use for T17 points)

At Scrooz our type 17 fasteners are all branded under our Razr range which denotes their self-drilling thread cutting function along with other features.

HAVING successfully achieved UKAS accreditation for its new Fastener Testing Laboratory, Warringtonfire is reminding manufacturers that the UKCA marking deadline is looming, and that new or updated products planned for launch in 2023 need to be tested to be able to be sold in the UK.

Under the UK Construction Products Regulation, from 1st January 2023, manufacturers of structural timber fasteners and fixings within the scope of the UK Designated Standard BS EN 14592 must successfully complete the UKCA testing process for any new product to be placed on the GB market.

The move comes as the UK transitions away from the EU-recognised CE Marking. Products undergoing a change in their specification, for instance, fasteners and fixings that

have a change in design or coatings, will also need to be re-tested to gain the UKCA marking and confirm their stated performance.

For this reason, Warringtonfire has launched its, which is located in High Wycombe. One of only a select few UKAS-accredited ‘Approved Laboratory’ facilities, the laboratory can undertake assessments of performance for structural timber fastener and fixing products, so that manufacturers can UKCA mark them to BS EN 14592.

The laboratory achieved the accreditation thanks to the expertise of its technicians as well significant investment into high-calibre testing equipment, which includes a universal testing machine for compression and tensile testing, a series of bespoke testing rigs, and conditioning rooms for structural timber samples.

The organisation will offer a range of geometric and mechanical testing procedures for dowel type fasteners from a particular group of structural timber fixings, comprising of nails, screws, staples, dowels and bolts with nuts. The laboratory will also test steel fixings used to create joints between timber components or to attach other materials to timber.

Ben Sharples, Commercial Lead at BM TRADA, comments: “The deadline for the changes in the way UKCA marking is achieved for manufacturers of structural timber fasteners and fixings is now less than two months away. While the testing process itself may not take too long, a lack of accredited laboratory space within the UK means manufacturers placing new or updated products on the GB market after the 1st January 2023 deadline should not delay with arranging testing.

“However, to further support our customer base within the construction products sphere, we have invested heavily into our High Wycombe Fastener Testing Laboratory to achieve UKAS accreditation and undertake UKCA testing.”

Alongside offering fastener and fixing testing, the laboratory can also offer third-party certification through its BM TRADA Q-Mark certification scheme.

“We have already undertaken several UKCA assessments of performance for structural timber fastener and fixing manufacturers, and I would strongly urge those who need to secure testing time for new products to do so as soon as possible to avoid delays,” Mr Sharples said.

To find out more about UKCA testing for structural timber fasteners and fixings, please visit: https://www.warringtonfire.com/testing-services/nonfire-testing/fastener-testing.

HUBTEX is delighted to announce it has given its FluX electric multidirectional counterbalance forklift truck some significant, innovative updates. The latest generation for load capacities of up to 3 tonnes is making its debut at LogiMAT 2023. Visitors to Stand 10B20 in Hall 10 at the LogiMAT trade fair will be able to see the new central drivers’ position, which provides a higher-up all-round visibility compared to its predecessor. Additionally, the patented 360° HX steering has been added to the compact three-wheel running gear for the first time, ensuring smooth changes in direction from longitudinal to transverse travel.

The new generation of HUBTEX’s FluX handles both pal-

let and long-load transport in a single vehicle. This hybrid used as a front and sideloader makes the new 3T FluX 30, suitable for a wide range of sectors, from the timber and metalworking industries, through to the building materials trade. HUBTEX has moved the driver’s cab to the middle of the vehicle giving the operator a better all-round view, including towards the load being carried. This improved visibility is enhanced by the vehicle’s new, more compact dimensions which include a new mast tilt feature. Being up to 20% smaller, the FluX is more manoeuvrable and agile too. The innovative design has made access to individual components, making them easier to access for servicing and programmed maintenance.

The switch from a four to a three-wheel running system has done nothing to impair the features that people have come to expect from HUBTEX in terms of ergonomics and freedom of movement. For instance, the new FluX has retained the spoked steering wheel and joystick for userfriendly operation as well as the spacious driver’s cab, providing the operator with greater comfort, for those jobs that can end up taking a little longer.

In addition, the patented HX steering has been developed further to enable it to be fitted to all HUBTEX electric vehicles with a threewheel running system.

The HX steering mechanism permits smooth transitions

australasian2020

STRONG house price expectations over the next 12 months have offset modest confidence in the economy to deliver an improved outlook for the property industry according to the ANZ / Property Council Survey for the March 2020 quarter.

National property industry confidence levels have increased by five index points from the previous survey to 123. This is slightly above the average for 2019 of 121 index points, and three index points below the survey historical average. A score above 100 index points indicates net positive sentiment among survey respondents.

2017

VICFORESTS has donated Ash and Acacia timber to the Eildon and District Woodworkers Guild/Alexandra Community Shed to support their local wood craft activities.

The Eildon and District Woodworkers Guild is a community group in Alexandra that is part of the Australian Men’s Shed Association which looks after men’s health in regional communities.

The Guild supports its members by providing materials and tools to produce wood working pieces, as well as the opportunity for them to socialise and feel part of their community.

2012

between steering modes, thus reducing tyre wear. Operators can also wave goodbye to time-consuming and fiddly manoeuvring, resulting in fast throughput times.

Furthermore, the compact multidirectional truck is ideal for combined indoor and outdoor use in the warehouse thanks to its soft elastic tyres and a maximum speed of 12 km/h, while its large battery (48 V, 930 Ah) means it can go on for more than a whole shift. An optional lithium-ion battery provides very quick charging supporting its use in a multi-shift operation.

You can find more details of HUBTEX’s appearance at LogiMAT 2023 at https:// www.hubtex.com/en-gb/ products/electric-multidirectional-counterbalanceforklifts

WOODWORKS, a cooperative venture of major North American wood associations, recently launched an online tool that estimates the carbon benefits of wood buildings. Released as a complement to the online cost calculator launched earlier, the carbon calculator estimates the amount of carbon stored in a building’s wood products (which was absorbed by the trees while growing) and the greenhouse gas emissions avoided by not using steel or concrete. The calculator is available at www.woodworks.org

“This new calculator is an excellent tool for architects, engineers, developers, builders and anyone who has an interest in green building and reducing greenhouse gases in the atmosphere,” said Dwight Yochim, national director of WoodWorks.

DEMAND for building materials like timber and steel is skyrocketing while supply is dwindling, with the Australian Institute of Project Management’s (AIPM) recent report with KPMG, The state of project management in Australia 2022, finding that 51% of respondents faced rising costs of materials.

Australia is about to reach the lowest point in log availability in decades according to the Australian plantation statistics and log availability report 2021 by the Department of Agriculture, Water and the Environment.

The Australia Bureau of Statistics reports that the prices of reinforced steel, structural timber, and steel beam increased by about 40% in 2022. Timber has a 73% market share in Australia, while lightweight steel beams feature in 14% of home construction projects (source: Forest and Wood Products Australia). Average costs have been comparable, and the choice was more often about technicalities than price.

But the answer to the timber shortage isn’t a switch to steel because the steel industry is also going through a sharp increase in prices fuelled by low investment, troubled supply chains, high energy prices, and the war in Ukraine.

• BlueScope Steel prices are up by 38%: BlueScope Steel, the major player in the Australian light gauge steel framing market, increased prices by 38% this year, according to a report by Smart Company.

• Dumping duties add pressure: A decision from the Australian Government in December 2021 to impose dumping duties of up to 20.9% on steel imports from Korea and Vietnam put extra pressure on the market.

Before the pandemic, the ABS’ Construction Cost Changes report estimated almost half of new residential dwellings would cost more to build than they were approved for, and now that number is close to 100%.

Business Wire’s Residential Market Analysis 2022-2026 predicts the output of the construction industry to expand by over 4% in 2022 to reach prepandemic levels and continue growing by over 3% per year from 2023-2026.

The Australian Bureau of Statistics (ABS) reported a 30% increase in new dwellings under construction during the pandemic, largely fuelled by Homebuilder, the Government initiative designed to restore confidence in the housing market.

SUPPLY WILL WORSEN.

Research from the Australian Bureau of Agricultural Bureau of Agricultural and Resource Economics and Sciences estimates a shortfall of 3.4 million cubic metres of logs by 2050. An additional 200,000 new plantations are needed, but few new plantations have been established, and native forest production is more restricted.

Demand for house construction will keep its momentum, with the federal budget targeting one million new homes from 2024 to 2028.

Supply-side budget measures (measures that the government takes to increase the availability or affordability of goods and services) are:

• $100m investment in research and development

• $10m for skills and training

• $86.2m for plantation establishment

• $112.9m for wood processing innovations

Project management is central to these initiatives if the construction industry is to make good use of the money.

Steel supply will increase: BlueScope plans to reline its No.6 Blast Furnace at Port Kembla. They are developing scope, cost, and timing with an indicative investment of over $700m. They are also working on innovative, sustainable alternatives.

A recent decision to cancel tariffs on steel pipes from China and South Korea opens the door for revisions of anti-dumping measures that can re-establish the flow of other steel imports.

With no silver bullet on the horizon, project optimisation could be the key to mitigating the immediate problem. While the future looks brighter, supply will continue to be constricted and prices will not ease in the short term. Building projects, which are taking an additional 10-12 weeks to be completed, will continue to face delays.

Increasing extreme weather events and natural disasters like bushfires contribute to supply shortages. The Department of Agriculture, Fisheries and Forestry reported 85,000 hectares of softwood plantations lost to bushfires in 2019-2020.

Spending more time in the design process: While initially costly, design improvements can save tonnes of construction waste from going into skips. Many builders are locked in outdated practices focusing on implementation rather than planning, with little attention to waste reduction.

Designing for efficiency must be the new norm: There is an urgent need for a better project material management process in the construction industry. New parameters are needed on the construction site to improve accuracy, so that procurement departments can stop over-ordering materials and start saving money.

An increase in the use of prefab, size standardisation, and use of Design for Manufacturing (DFM) practices can significantly reduce the amount of timber and steel needed. Not only will these measures address the urgent need, but there will also be long-lasting benefits to the construction industry.

Flavio Macau is an Associate Professor from the School of Business and Law at Edith Cowan University and was recently featured in AIPM’s Paradigm Shift publication.

Associate Professor Flavio is the Associate Dean (Teaching and Learning) and a Senior Lecturer in the School of Business and Law and Edith Cowan University.

AIPM’s newly released annual report, the ‘State of Project Management in Australia’, is based on a survey of the profession conducted with KPMG Australia. The report survey was conducted from July to August 2022 amongst AIPM members with 329 respondents working in project management roles across a range of industries.

though we have always invested in programs to support fabricators, we gone this far and we are excited about the work we have a head of us over the next three years.

FTMA Australia was formed as a National Association representing fabricators and suppliers of the Australian timber frame and truss sector in 2007.

Since our inception, we have grown to be recognised as the trusted representative body and unified voice for all timber frame and truss manufacturers in Australia, whilst strengthening the connection with the broad supply chain. This has resulted in our membership growing from 13% in 2007 to over 54% representation today.

Our vision is to create an industry where manufacturers thrive and contribute to Australia’s green built environment and we achieve this by supporting timber manufacturers whilst investing in the industry to grow and strengthen the professionalism of the timber fabrication market and viability of our members.

FTMA wants to support fabricators to become better businesses, which in turn makes them better customers for suppliers and better suppliers to the construction industry, which in turn will help grow our markets.

This is why FTMA is investing in various projects over the next three years to help grow and strengthen the professionalism of the timber fabrication market and viability of our members.

Our three-year plan has identified the following six areas as key focus areas for the Association:

As part of our three year planning, we have also undergone a review of our sponsorship program. Our valued sponsors will now be referred to as partners, and they have all signed on to our three year plan.

This is the biggest change to our association since our inception 16 years ago. Even

1. Forecasts & Data Collection

■ Quarterly Trussted Insight forecasts publications

■ Industry Census & Salary Benchmarking (alternative years)

■ Australian House Framing & Fabrication Review & Outlook

■ An ongoing quarterly Frame & Truss Sector Outlook (FATSO)

2. Timber Projects

■ FTMA Strategic Technical Committee

■ Timber Waste program looking at the circular economy

■ Explore an independent Engineering Testing Panel for inclusion of timber in nail plate software

■ Develop targets for Timber Social Housing based on Carbon Stored

3. Building Better Businesses

■ HR Platform for FTMA Members

■ DFV Policy

■ Employee Wellbeing Programs

■ Current Wage Rate & Award Breakdowns

■ Credit Application Forms

■ Mental Health First Aid training

■ Employment Contracts

■ FTMA Safety SOP Videos with FTMA NZ

4. Resilient Timber Homes Project

■ FTMA is one of two Research Partners for the FWPA Program Investing in this program on behalf of FTMA Members to ensure future resilient timber homes can be manufactured by our sector and are environmentally friendly.

FTMA plans on employing a trainer to help fabricators implement training, and whilst we have no plans on becoming an RTO, we will continue to work closely with our industry RTO’s TABMA and Timber Training Creswick as well as explore other options for increased training within the sector.

We would like to thank our amazing partners for their outstanding continued support of the Association:

Principal: MiTek, Multinail & Pryda

Strategic: AB Phillips, AKD Softwoods, Australian Panel Products, Meyer Timber, Timberlink, Vekta Automation, VIDA Wood and Wespine

Supporting: Bliss & Reels, Combilift, Daw Trading, Dindas, Hundegger Australasia, Hyne Timber, Independent Hardware Group, McCormacks Australia, OneFortyOne Wood Products, Pinewood Products, Programmed Timber Supplies, Road Pods, StoraEnso Australia, Tilling Timber and VTW.

If you would like information on how you can partner with FTMA, please contact the me on 0418 226 242.

5. Recruitment & Retention

■ Creating online training with our Designer Short Course

■ Mapping all jobs within the industry

■ Creating job descriptions and job advertisements

■ Continuing FTMA’s Rebuild & Design program.

■ Developing Employee Wellbeing programs

■ Employing a TAE to support fabricators with increased training.

6. Timber vs Steel

■ Promoting the environmental benefits of timber offsite fabrication

■ Lobbying for policy changes recognising the benefits of timber

■ Educating builders on Carbon Warrior policy

■ Further developing and promoting the Carbon Warrior program

FRAME & TRUSS MANUFACTURERS ASSOCIATION OF AUSTRALIAFTMA Australia is an independent, national organisation representing fabricators of and suppliers to the timber prefabricated truss and wall frame industry in all Australian states & territories providing a unified voice, to protect and advance our multi-billion dollar industry.

FTMA Australia thanks our dedicated supporters and encourages you to support those who support your industry

GOLD SPONSORS

For a full list of the conditions of membership and a downloadable application form visit: www.ftmanews.com.au

IDON’T know about everyone one else, but Christmas feels like it was some time ago – there is always a lot going on!

We’ll utilise the first contact of 2023 to wish all our members and industry contacts a happy and prosperous new year.

Whilst the past few years have had significant challenges, it unfortunately still doesn’t appear that this year will be smooth sailing without any issues facing our industry. We will hope for the best and see how we all fare at the end of the year.

MARIE-CLAIRE MCKIERNAN NATIONAL MEMBERSHIP MANAGER