Let’s talk about Let’s talk about

RAW MATERIALS

Europe looks to circular economy

DIGITALISATION

The advent of smart laundry

INDUSTRIAL LAUNDRY

The steps of laundry process

TEXTILES

Washing table linen correctly

Follow

Europe looks to circular economy

DIGITALISATION

The advent of smart laundry

INDUSTRIAL LAUNDRY

The steps of laundry process

TEXTILES

Washing table linen correctly

Follow

The HiMiX Professional line ensures high performance, respect for surfaces and the environment, and guarantees the safety of customers and workers. Compliant with HACCP control plans, it ensures the highest standards of cleanliness and hygiene.

FOR OVER 60 YEARS, HIGH-QUALITY, EFFICIENT, AND RELIABLE PROFESSIONAL FORMULATIONS

For more information, visit our website

www.dimensionepulito.it

Monthly magazine pubished by

Quine Srl

Via G. Spadolini, 7 - 20141 Milano

www.quine.it | info@quine.it | Ph. +39 02 864105

Editor-In-Chief

Giorgio Albonetti

Editorial director

Ornella Zanetti | ornella.zanetti@quine.it

Technical director

Maurizio Pedrini

Editorial coordination

Chiara Scelsi - c.scelsi@lswr.it | Ph. +39 349 0099322

Editors Loredana Vitulano - l.vitulano@lswr.it Ph. +39 342 6618995

Cristina Cardinali - c.cardinali@lswr.it Ph.+39 347 4238879

Simone Ciapparelli - s.ciapparelli@lswr.it Ph. +39 344 0571950

Technical scientific consultants for the section

Environmental hygiene Chiara Dassi - Graziano Dassi

Circulations and subscription service

Ornella Foletti - o.foletti@lswr.it | Ph. +39 342 7968897

COVER

Operating on the national and international market for over 30 years, ICA is a paper converting company specialized in Away-from-Home products. ICA is committed to constantly expanding its wide range of products in a perspective of constant innovation and focus on the environment to offer products that are more and more performing, hygienic and sustainable.

Andrea Anelli, Michael A. Berry, Cristina Cardinali, Simone Ciapparelli, Francesca De Vecchi, Francesca Leoni, Niccolò Luongo, Marco Monti, Maurizio Pedrini, Francesco Pirovano, Michele Ruzza, Giacomo Torrenzi, Loredana Vitulano

Sales manager Costantino Cialfi

Advertising and development Filippo Viola - f.viola@lswr.it Edoardo Rossi - e.rossi@lswr.it

Elena Brusadelli - e.brusadelli@lswr.it

Graphic design Paolo Marchetti - KF Ivest Sagl

Production manager

Antonio Iovene - a.iovene@lswr.it | Ph. +39 349 1811231

Printing New Press Edizioni srl - Lomazzo (CO)

Prices and subscriptions

• Annual subscription: 49 euro

• Subscription outside Italy: 160 euro

• Back copies: 17 euro

• Cost of a copy: 1.30 euro abbonamenti.quine@lswr.it | Ph. +39 02 864105 www.quine.it

www.dimensionepulito.it

Responsibility

Dimensione Pulito is a Monthly Recorded Periodic: Authorization of the Court of Milan No. 598 of 9.11.92 Quine is registered in the Operators Register of Communication n. 12191 of 29/10/2005. The publication or reprint of articles and images must be authorized in writing by the publisher. The articles published on Dimensione Pulito are under the responsibility of the authors. Published manuscripts and drawings will not be returned. INFORMATION PURSUANT TO GDPR 2016/679 Pursuant to art. 13 European Regulation for the Protection of Personal Data 679/2016 below GDPR, the data of all readers will be processed both manually and with IT tools and will be used for sending this and other publications and information and promotional material. The methods of treatment will comply with the provisions of art. 5-6-7 of the GDPR. Data may be disclosed to subjects with whom Quine Srl maintains contractual relationships necessary for sending copies of the magazine. The data controller is Quine Srl, Via G. Spadolini 7 - 20141 Milan, to which the reader can turn to request the update, integration, cancellation e any other operation referred to in articles 15-21 of the GDPR.

© Quine srl - Milan

12 16 22 26 30

Raw materials: Europe looks to circular economy

Maurizio Pedrini

Risk assessment for enzymecontaining products

edited by Simone Ciapparelli

Trends and opportunities in the laundry sector

edited by Simone Ciapparelli

The advent of smart laundries

edited by Cristina Cardinali

The steps of the laundry process edited by Simone Ciapparelli

i

for a perfect aesthetic alignment with the trolleys of the Falpi Hotel line

Correct washing of table linen

Francesca Leoni

Carpet in the modern indoor environment

Michael A. Berry

MACHINES

Road sweeper: instructions for use

Maurizio Pedrini

Emphasize professionalism and experience for the brand

Niccolò Luongo

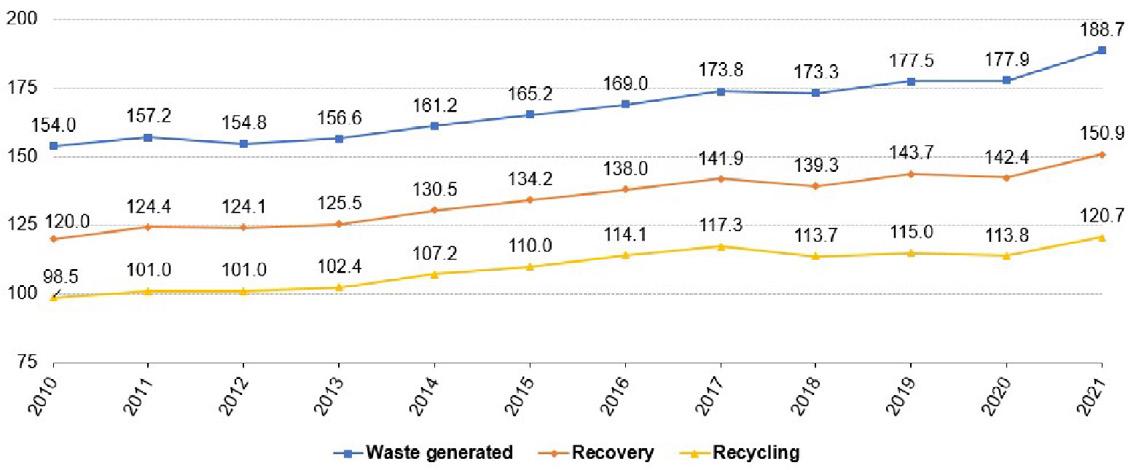

Reduction, reuse and recycling: the future of EU packaging

Francesca De Vecchi

Safeguarding the competitiveness of EU industry trends

edited by Cristina Cardinali

Paper industry in Europe

edited by Giacomo Torrenzi

Depuration of industrial wastewater

Giacomo Torrenzi

MARKETING

If you have more brains, then use it!

Fabrizio Pirovano and Marco Monti

ON THE MARKET TODAY

Technologies, research and development: the new products in the world of cleaning

Loredana Vitulano

Sustainable methodologies in the containment of commodity pests

Michele Ruzza and Andrea Anelli

As shown by the data in the report World Employment and Social Outlook: Trends 2024, although the economy slowed down, global growth in 2023 slightly exceeded expectations, and labor markets demonstrated unexpected strength. Fueled by robust job growth, both the unemployment rate and the jobs gap have fallen below levels seen before the pandemic. In 2023, the global unemployment rate stood at 5.1 percent, representing a slight improvement compared to 2022. Even with decreasing unemployment rates and favorable employment growth, real wages fell in most G20 nations, as salary increases did not keep up with inflation. Worries about labor and skill shortages continue to be a top priority for policymakers, particularly in advanced and certain emerging economies. Although overall labor force participation rates have rebounded quickly, sectors reliant on essential workers are struggling to attract individuals to meet the increasing demand.

The European Commission released its second status report on the Digital Decade, which reports on progress toward the goals set out in the EU's policy agenda for the Digital Decade to 2030. The report serves as an important warning that the region risks falling behind in digital transformation compared to its global rivals. For the first time, individual member states were analyzed, revealing that their overall performance falls far short of the EU's ambitions. The report raises concerns about the EU's performance in its digital transformation and urges member states to make greater efforts to achieve its goals.

The critical issues highlighted by the report, stemming mainly from a lack

of sufficient progress toward the targets set and significant disparities among member states, are analyzed in clusters, defined according to their contribution to: competitive, sovereign and resilient EU; protecting and empowering people; leveraging digital transformation for smart greening; harmonize digital policies and spending.

The EU has not yet achieved full convergence on most of the goals and targets, and the pace of progress on some of them is slower than expected especially in the areas of skills, high-quality connectivity, adoption of artificial intelligence (AI), and data analytics by companies, semiconductors, and startup ecosystems. In addition, it

points out that since the digital transaction has not yet been completed, the full potential of the Digital Single Market has yet to be tapped.

Growth and investment in infrastructure in China has increased demand for professional cleaning, disinfection and hygiene products and services, allowing this market to grow exponentially in recent years. According to Interclean, this rise can be attributed to several factors, aside from economic growth.One aspect is the focus on innovation: China is focusing on the development of cutting-edge technologies like AI-powered cleaning robots and eco-friendly solutions, definitively distancing himself from copycat products. Another aspect is the focus on sustainability: consumers in China are increasingly demanding eco-friendly products and services. This trend is driving innovation in biodegradable cleaning agents, recycled materials for cleaning tools, and energy-efficient equipment.

This growing market is basically shaped by: the rise of AI, that China is

increasingly integrating into the cleaning sector; the rising demand of high-quality, branded cleaning agents, detergents, and disinfectants alongside eco-friendly options; a growing

environmental awareness, that is leading China to be at the forefront in the development of the biodegradable detergents, recycled tools, and energy-saving equipment.

The 2024 edition of the European Cleaning & Hygiene Awards concluded on the night of 3 October with the crowning of the 11 winners (one for each category) which gave the major contribution to the professional cleaning sector over the past 12-months. The 2024 winners are:

• Best Use of Smart Solutions by a Service Provider - JPC by Samsic

• Investment in Training - CleanEvent

• Start-Up Business of the Year - Cliezen

• Excellence in Client-Contractor Partnerships - Derrycourt Cleaning Specialists at the National Rehabilita-

tion University Hospital

• Sustainability - Best Practice (Manufacturing) - Satino, a WEPA Professional brand

• Sustainability - Best Practice (Service Provider) - Principle Cleaning Services

• Commitment to Diversity in the Workforce - Breedweer Facilitaire Diensten

• Best Initiative Raising the Profile of the Cleaning Sector - Markas

• Technological Innovation of the Year - Nexaro for the NR1500

• Leader of the Year - Diane van Dijk, CSU

• Rising Star of the Year - Kelsey Hargreaves, The British Institute of Cleaning Science (BICSc)

Efficient, resistant, ergonomic and functional: this is Igeax’s Industrial line, designed to be excellent and made in Italy with a focus on sustainable materials.

A complete range that meets the specific needs of industrial cleaning, which by definition is more frequent and intense than domestic cleaning as it has to deal with high traffic areas where dirt accumulates quickly. The unique line also features high resistance to wear and tear making the

equipment suitable for industrial use. Besides, it protects the operator’s health by reducing effort and minimising the risk of work-related illness.

The special range includes all must-have products for cleaning in commercial and industrial environments, made with premium raw materials that guarantee high performance for frequent use: brushes, tube

brushes, cobweb brushes, brooms, dustpans, squeegees, handles and scrapers, without forgetting tools wall bars, Display units and Shadow board for the efficient organisation of working tools. Quality, ergonomics and durability are the distinctive features that characterise the Industrial line, making the whole range up to the task. Besides, the exclusive line is distinguished by certain peculiarities that make it unique.

First, Igeax products are the only ones with a universal connection for maximum compatibility , adapting perfectly to a wide range of tools. With a fixing ring designed for handles with a diameter of 21 to 25 mm, the Igeax’s universal connection ensures superior resistance and safety.

Lastly, the Industrial line features bristles with two different hardnesses to meet every cleaning need . Not only does the double bristle add a

touch of style to the products, but it also maximises their efficiency, making them suitable for a wide variety of operations. Dense punching, perfect cut, optimal inclination and greater contact surface further maximise the performance of Igeax bristles ensuring complete, effective and rapid cleaning

Plastic pollution has become a global problem, causing damage to our oceans, wildlife and ecosystems. Igeax strongly believes in action and positive impact; for this reason, the company uses recycled polypropylene and PET for the production of industrial brooms and brushes, reducing its dependency on virgin plastic and contributing to the circular economy

Moreover, the use of recycled materials reduces its carbon footprint, contributing to a greener and more sustainable future. Igeax’s commitment to sustainability does not compromise the exceptional quality of its products. The Italian company adopts rigorous testing processes and quality control measures to ensure that all its products meet the highest standards.

A level of precision greater than ever before

Countless dense and fine bristles Perfect cut for maximum precision

Designed to ensure even food distribution and complete dirt removal from the tightest spaces

Ergonomic handgrip with anti-drip hole

The strategic goal is to reduce dependence on third countries, particularly for raw materials deemed strategic. The EU intends to invest primarily in research and development, with a vision of sustainable extraction in its own countries, maximizing the recovery of valuable materials from waste

Maurizio Pedrini journalist and technical director of Dimensione Pulito

The European Council has made an important decision, full of repercussions for the future of the continent. Indeed, the highest institution that sets the European Union's overall policy priorities and directions has adopted the European Regulation on Critical Raw Materials, as demand for rare earths is expected to increase exponentially in the coming years. Critical raw materials are items of great economic importance to the EU, with a high risk of supply disruption due to concentration of sources and lack of viable and affordable substitutes. The regulation has some clear objectives: to increase and diversify the EU's supply of critical raw materials; to strengthen circularity, including recycling; and to support research and innovation in resource efficiency and substitutes development. The new rules will also strengthen Europe's strategic autonomy.

Critical raw materials

Raw materials are defined as metals, minerals and natural materials that, as we all know, are integral and indispensable parts of our daily lives. Among them, those that are of particular economic importance and have a high supply risk are called “critical raw materials.” These are essential elements for the functioning and integrity of various industrial ecosystems. The EU Commission has identified 34 critical raw materials that fall squarely within a number of areas considered particularly strategic to the functioning and integrity of a wide range of industrial ecosystems. Some areas are of extraordinary strategic relevance to the EU's renewable energy, space and defense objectives. From the 34 critical raw materials thus identified, a specific list of so-called strategic raw materials was subsequently drawn up, for which exponential growth in terms of supply is assumed in the coming years because, being the result of complex production, they are exposed to a higher

risk of supply and access problems. By now, as we all know, critical raw materials - also called rare earths - are used just about everywhere. In fact, without them, many of the tools and technologies critical to everyday life could not function, as they are found in many everyday devices.

Smartphones, a mine of precious metals

Think, just to give one example, of smartphones, which - in addition to being devices that are now indispensable in our lives - also store memories, photographs, contracts, notes and other precious material that is almost indispensable to our daily lives. Many people do not know, however, that they also represent a kind of mine of precious metals: rare earths, precisely. According to the American Chemical Society, a single iPhone contains 16 out of 17 rare earths, but together they do not exceed 1 percent of the weight of the device. Rare Earth Elements (REEs) are, for example, scandium, lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, and lutetium. Complex names for metals that are probably unknown to most, but because of their effective performance they are used in a variety of areas: from the electronics and technology industries to aeronaut-

ics and the military. Although little known, rare earths enable the production and operation of objects that are part of everyday life and also play a key role in green technologies.

These increasingly valuable critical raw materials are in the vast majority obtained outside the EU. The European Union is well aware that it is, unfortunately, not self-sufficient, but - finally - for some years now it has been firmly on the path to diversify its supply as much as possible: a path made all the more urgent and indispensable by the geopolitical upheavals that are sweeping through the West, the whole world and Europe in particular. At present, the picture is still highly problematic. The EU is heavily dependent on China for magnesium (98.9% of imports in 2023) and gallium (79.2%), Turkey for borates (76.0%), and Brazil for niobium (86.6%). An increasing weight of Russia for rare earths and gallium imports also emerges between 2022 and 2023 (30.1% and 12.5% in 2023, respectively, percentages rising to 62.2% and 23.9% in the first two months of 2024). In addition, the EU does not exceed the 7% share of global production in any of the 34 critical raw materials, thus denoting a strong vulnerability at the beginning of the supply chain, which only partially improves going downstream in the production process.

From the JRC assessments, five technologies in particular show strong vulnerability throughout the supply chain: batteries; photovoltaic panels; data storage and servers; smartphones, tablets and laptops; and drones. Looking at the most recent critical commodity prices, two trends emerge: in the long term, a marked increase in prices compared to the pre-Covid period; in the short term, a more heterogeneous picture, where some prices stabilize while others (such as copper) continue their growth.

But from the decidedly worrying analysis of the situation, let us see how in concrete terms the EU is acting to try to reverse the trend. Precisely in order to reduce dependence on third countries for access to rare raw materials, the EU has set important goals for 2030. One of these, diversification of EU imports to reduce stra-

tegic dependencies: at least 10% of the EU's annual consumption will have to come from extraction within the EU. There will also be a focus on domestic recycling: at least 25% of the EU's annual consumption will have to come from it. To this end, the EU will intensify trade measures, including: the establishment of a club for critical raw materials that brings together all countries ready to strengthen global supply chains; strengthening the World Trade Organization; expanding its network of investment facilitation agreements and free trade agreements; and increased focus on enforcement to combat unfair trade agreements. The European Union intends to invest primarily in research and development, with a vision of sustainable extraction in its own countries, maximizing the recovery of valuable materials from waste. One way to reduce, at least partially, de -

pendence on the complex dynamics of global markets for critical raw materials lies in enhancing its own “urban reserve” of technological waste. According to a recent ERION report, the proper and complete management, geared toward recycling instead of disposal, of post-consumer WEEE electrical and electronic equipment can become a real “mine” in the logic of the transition to the circular economy. According to data in the report, while more than 900,000 tons per year of electrical and electronic equipment is placed on the market, just over 350,000 tons per year of WEEE is collected separately, or 40 percent, compared to a European target of 65 percent. Of these, 89 percent go to recycling. With the right investments and policy choices, there could be many more recycled materials, reducing our consumption of primary materials.

Royal 15 is the compact walk-behind scrubber dryer ideal for cleaning small and medium-sized surfaces such as stores, laboratories, offices and restaurants and which, thanks to its 15-liter capacity and 385 mm cleaning width, guarantees an output of up to 1.540 m2/h.

The meticulously thought-out design is tailored to make this machine extremely compact and easy to handle, while at the same time providing top-notch professional performance to ensure excellent cleaning results, even in the tightest spaces.

This scrubber dryer is the ideal machine for working on all types of floors, even the most difficult ones (such as concrete, bolted, non-slip surfaces), ensuring excellent cleaning results.

Due to their versatility and positive benefits, enzymes are more frequently incorporated into professional cleaning products. But like all cleaning products, also those containing enzymes must undergo a safety risk assessment to ensure that they are safe to use by the end users

edited by Simone Ciapparelli

For many years, enzymes have been used safely in professional products for bulk laundering of fabrics and clothing from the manufacturing, healthcare, and service industries.

Enzymes have also been used in a variety of professional products such as surface cleaners.

Enzymes can contribute to the sustainability and environmental safety profile of formulations that use them. Enzymes do this through reducing the temperature at which the product needs to be used, replacing the function of harsher ingredients, being fully and quickly biodegradable, and virtually non toxic to people1, flora, and fauna.

Nevertheless, despite their low order of toxicity, exposure by inhalation may lead to the development of occu-

A.I.S.E. represents the detergents & maintenance products industry in Europe. Based in Brussels, A.I.S.E. has been the voice of the industry to EU regulators since 1952. Membership consists of 29 national associations across Europe, 19 corporate members and 23 value chain partners. Through this extensive network, A.I.S.E. represents over 900 companies supplying household and professional cleaning products and services across Europe.

pational allergy2. To have the potential to cause respiratory sensitisation, the enzyme must become airborne as a dust particle or mist droplet. Moreover, the concentrations required to cause respiratory sensitisation are extremely low. This means that not only do enzymes as raw materials present a risk, but also the finished products that contain them may present a risk. However, only a minor fraction of those individuals exposed to sufficiently high doses of airborne enzyme will at some point be at risk for developing a sensitisation towards the specific enzyme. Professional cleaning products are used across a wide variety of different scenarios, but broadly can fit into one of three classes:

X used in a fully closed system (e.g. in Cleaning in place or in a closed machine such as an industrial dishwasher/washing machine);

X used in a partially closed system or process (e.g. in Cleaning out of places, manually dosed into a closed system, cleaning of equipment items by manual immersion in a closed container);

X used in the open for cleaning of surfaces and/or equipment, (e.g. food preparation surfaces, floors and walls, sanitary equipment).

Each scenario imparts a different level of risk for the end user, and that information allows product development and design to reflect the risk in each scenario. The higher level of containment and control for the end use application, the lower the risk of exposure. Likewise, the elimination and/or minimisation of inhalable dust or aerosol through product design will also reduce the risk of exposure. Combining containment, exposure control and safe product design is the obvious target to achieve.

Of the three main scenarios, the use of enzyme products for open cleaning of surfaces carries the highest risk of exposure and therefore these products require very careful design and

use instruction. Training is also an important part of the safety management program for use of any professional cleaning product regardless of the formulation. But for enzyme-containing products, very specific training is required. In all scenarios, the risk from residual product contamination on surfaces, including the one coming from the enzymes used in the product, must also be considered. Residual enzymes on surfaces may become airborne from subsequent process steps or conditions resulting in uncontrolled exposure.

Since there is little difference in how consumer and professional products are manufactured and packed, it can be inferred that the experiences, mistakes, best practices, and historical data from detergent manufacturing are entirely relevant. However, as previously stated, the end use can be different. This makes the need for exposure data or benchmarks for every type of application extremely important, if not critical, for the completion of an effective end user risk assessment. The document developed by A.I.S.E. Guidance for the Risk Assessment of Enzyme-Containing Products for Professional Cleaning, on which this article is based, aims to inform and guide companies developing and marketing professional cleaning products containing enzymes to ensure, through the process of risk assessment, the design of professional products are safe for the intended application, and safe for the end users and others in the vicinity of their use.

Prior to introducing an enzyme-containing cleaning product onto the market, a risk assessment is conducted to ensure the safe use by the professional. Enzymes have a very good safety profile but, as with many other proteins, they can act as respiratory sensitizers and so may lead to allergy symptoms. This potential risk is the primary focus

for risk assessments for enzymes and must be managed carefully.

Risk assessment can be divided into four areas:

X hazard identification;

X dose-response or benchmark identification;

X exposure assessment;

X risk characterization.

Hazard identification

This is the characterization of the fundamental physical, chemical and biological effects of a material. The toxicology of enzymes poses no significant hazard. Acute and sub-chronic toxicity is not of concern for industrial enzymes. Enzymes have a low order of toxicity. In the context of this article, the safety concern being addressed is a potential induction of respiratory allergies.

Skin and eye irritation may be an issue in case of long-term exposure to high concentrations of an enzyme from the class of proteases. This hazard is not

related to enzymes outside the class of proteases, and it is not discussed in this guideline.

Dose-response or benchmark identification

Generally, in this step of the risk assessment process, the relationship between the level of exposure and the specific biological effect is characterized. However, since the dose-response relationship for enzyme allergy is not fully understood and there are gaps in our understanding of the relationship between exposure, sensitisation and symptoms, benchmarks are generally used to support decisions in enzyme risk assessments. Such benchmarks are based on studies in which measured or estimated exposure levels are associated with a demonstrated specific biological effect (such as whether an allergen-specific antibody is produced) in those exposed. A clear benefit of this strategy is that it can be based entirely on human data.

In EU countries, there is a requirement by the REACH legislation to define a Derived No Effect Level (DNEL) for registered substances. Where a DNEL cannot be established, e.g. for sensitizing substances like enzymes, then a Derived Minimal Effect Level (DMEL) is recommended. For enzymes, a DMEL has been established by thorough retrospective review of occupational and consumer experience4. The DMEL for occupational exposure has been set as 60 ng/m3 thereby following the Threshold Limit Value (TLV) set for Subtilisin by the American Conference of Governmental Industrial Hygienists (ACGIH) in 1971. For consumer exposure, the DMEL is 15 ng/m3. Professional uses should apply one of these DMELs depending on the character of the use. If the professional receives training in the safe handling of an enzyme containing product and have access to personal protective equipment like correct respiratory protection equipment, then the DMEL of

60 ng/ m3 may apply. For other professional users, the DMEL of 15 ng/m3 should apply.

It establishes the amount of airborne enzyme to which the user may be exposed during intended use or foreseeable unintended use. This value is then compared to the benchmark exposure (in most cases the DMEL) in order to make risk decisions. Measuring, or even estimating, exposure to enzymes is not necessarily a simple process. However, the determination of exposure values is needed for carrying out these risk assessments. In the absence of good quality exposure data, reasonable worstcase assumptions and uncertainty factors are employed, which lead to an overestimation of exposure levels and thereby limit unnecessarily the amount and type of enzyme that can be used in a professional cleaning product. It is therefore important that the exposure assessment be conducted thoroughly, in order to enable the optimum use of enzymes in the products. The most important step of an exposure assessment is trying to define the factors that may influence the exposure.

It is the examination of the relationship between human exposure (calculated or measured) and the inherent toxicity of a substance, in order that the likely incidence and severity of any effect can be assessed. This step is important because it integrates information regarding the hazard identification and exposure assessment associated with use and foreseeable unintended use of a product. It should be recognized that risk assessment is a continuously evolving discipline. The quality and reliability of a risk assessment is dependent on and is only as good as the data used to conduct the assessment. Uncertainties exist in dose-response relationships, exposure data and estimates from exposure models.

Assumptions and estimations need to be stated clearly as they can affect the reliability and quality of the risk assessment. It is important to consider these points when evaluating information from the risk assessment in determining whether the risk is considered acceptable.

The objectives of the risk management process are to determine the significance of risks to human health to ensure that the product use remains within the acceptable risk levels, and to communicate risks, or lack thereof, to appropriate audiences, in an effective manner.

In general terms, the risk control step of the risk management process should strive to reduce the risk by limiting airborne exposure to enzymes included in the product formulation. Risk reduction options may include product modification, only allowing certain uses or a decision not to market the enzyme containing product. Modification options may include changing the matrix or delivery system of the enzyme containing product, reducing the enzyme concentration in the product, substituting other ingredients that may be affecting the potency of the enzyme, or a combination of these approaches.

An integral part of the risk management process is to communicate enzyme product benefits, as well as potential risks, to appropriate audiences in an effective way. There are important audiences to target in designing a risk communication program:

X users of the company’s products;

X employers of professional users, e.g. cleaning companies;

X persons responsible for worker safety in the companies employing professional users;

X other stakeholders, such as the general public, governmental and non-gov-

ernmental organizations, or industry partners.

Product labels are the primary means of communication with consumers and professionals. For enzyme-containing products, as with all consumer products, labels are a mechanism for communicating composition of the product, first aid information, appropriate warning statements, and use and handling guidelines with detailed examples of correct use and concrete recommendations to steer towards proper use. For professionals, SDSs are available but these are often only suitable, i.e. understandable, for people with the proper training to interpret the SDSs. Hence, it is important for products used by professionals in small companies to provide all significant information in the same way as for consumers.

Notes

1 Basketter et al, Enzymes in cleaning products: An overview of toxicological properties and risk assessment/management, Regulatory Toxicology and Pharmacology 64 (2012) 117–123.

2 Basketter et al, Managing the Risk of Occupational Allergy in the Enzyme Detergent Industry, Journal of Occupational and Environmental Hygiene, 12: 431–437 (2015)

4 D.A. Basketter, C. Broekhuizen, M. Fieldsend, S. Kirkwood, R. Mascarenhas, K. Maurer, C. Pedersen, C. Rodriguez, H.-E. Schiff; Defining occupational and consumer exposure limits for enzyme protein respiratory allergens under REACH; Toxicology 268 (2010) 165–170

Source: A.I.S.E., Guidance for the Risk Assessment of Enzyme-Containing Products for Professional Cleaning (June 2024)

Christeyns presents its new Professional Hygiene product portfolio, designed to meet the needs of hygiene professionals worldwide. This innovative portfolio is divided into four macro ranges, each designed to offer specific solutions for each area of application: laundry, kitchen floors and interiors. For all the following ranges there are environmentally friendly alternatives belonging to the Green’r line, ECOLABEL branded products.

To meet the needs of the customers, laundry specialists have developed the CARETEX line, which includes products for non-delicate and delicate fabrics.

For those using ozone generators, offer the RAPID-O line, with compatible products that ensure deep and environmentally friendly cleaning.

With CARETEX, Christeyns guarantees impeccable results for every type of fabric.

The RELAVIT range is designed to help kitchen professionals maintain impeccable hygiene in the kitchen environment. The RELAVIT range includes periodic cleaners, degreasers, descaling agents, disinfectants and specific products in different packages, concentrations and forms, such as solids and sprays. These products ensure perfect cleaning results, leaving the kitchen spotless and safe.

Christeyns helps hygiene professionals select the right products for the maintenance and treatment of different types of floors, especially with the FLOORIT product range. FLOORIT products are designed for daily maintenance and also include

specialised products, all available in different fragrances and ecological variants. The range includes waxes, wax removers and degreasers, ensuring radiantly clean and well cared-for floors.

The LUFRA range comprises a wide selection of interior cleaning products, including cleaners for various surfaces and bathroom-specific purposes. Standard cleaners are available in both concentrated and ready-to-use formulas, accompanied by degreasers, descaling agents and polishes.

LUFRA offers specific solutions for glass and metal surfaces, ensuring excellent results for interior cleaning and maintenance.

Christeyns’ new portfolio represents a major step forward in the modernisation of the chemical industry, offering innovative, efficient and environmentally friendly solutions for Professional Hygiene. Stay tuned for further updates and details on the official launch.

The industry is moving toward increasing use of new technologies and strategies aimed at energy efficiency and environmental sustainability, including addressing energy and gas costs

edited by Simone Ciapparelli

The business of industrial laundries, including rental, covers the following products: flat linen (tablecloths, sheets, pillowcases, towels); work clothes and PPE; mattresses and pillows; carpets; sterile operating room sets.

In relation to the characteristics of the service provided and the target end market, the sector can be divided into three segments: Public and Private Healthcare, Hotel and Catering, and Community and Industry.

There is a high level of competition in the sector due to the presence of numerous players, especially in the Hotel and Catering area and in the Sanitation segment of the Healthcare area. Competition is basically based on price, except in some areas (sterilization activities, integrated services for Healthcare and PPE), where the quality of the service provided is much more relevant. Differentiation in the sector is rath-

er low, due to the rather basic needs of most of the market, however, some areas require special skills, certifications and periodic investments by sup -

pliers, in order to adapt technological resources and personnel to customer needs. The sector is coming out of a particularly challenging three-year

period, which saw the succession of several exogenous events (pandemic, Russia-Ukraine conflict) capable of affecting its performance both in terms of revenues and margins (see box). Strengths of the sector include an efficient and flexible organizational structure; the ability to preside over tenders; a balanced price/quality ratio; quality of service delivery, particularly in the health care sector.

The great focus on public health and welfare, indirectly amplified by the pandemic, has led to an even greater emphasis on ensuring sanitation, sanitization, and cleanliness, and represents an opportunity for the sector in the medium term as well. It must also be kept in mind that the sterilization segment still has wide margins for de-

velopment, and its evolution is closely related to possible outsourcing choices by healthcare facilities. There is also an increasing use of Reusable Technical Fabric products, replacing disposable ones, which may therefore lead to an increase in demand for laundry services.

In the restaurant industry, on the other hand, there is an increase in the use of disposable table linens, which could lead to a decline in demand in that sector.

Technological innovation and digitalization are central to the industry to simplify the organization of work, ensure process control, streamline operations and rationalize costs, reducing waste. Technological development affects all areas of the business and includes the adoption of advanced

management control systems, data analysis, and process automation (see article on page 26). More structured operators use platforms that manage all processes, from rental contracts, to organizing material pickup and delivery, to warehouse management, including general and analytical accounting and business intelligence. System certifications are increasingly common in the industry; most major operators are environmentally certified to ISO 14000 and some hold Emas registration. Process and product certifications are also widespread, for example, the RABC (Risk Analysis Biocontamination Control system) certification, which covers the entire process, from the collection of soiled items to their delivery to the customer. The goal is to make green not the individual product, but the entire produc-

tion process, thanks in part to technological innovation, which makes it possible to use less and less water, detergents and energy, limit waste and the use of resources, while ensuring quality of the result and greater durability of the fabrics.

Over the past few years, the topic of sustainability has become increasingly important to industry players, not only because of its ethical aspects, but also because of its impact on the efficiency and profitability of companies. In the industrial laundry sector, the implementation of sustainable practices concerns:

X water management, which involves rationalizing water withdrawals and optimizing its consumption and recovery. At the same time, the risk of water pollution is kept under control with modern sewage treatment plants and containment basins to eliminate the risk of soil contamination;

X the use of eco-friendly processes and products, such as detergents, and optimizing the use of chemicals, with the replacement of packaging and plastic collection bags with recycled and/or reusable materials;

X proper management of reusable textiles, seeking to lengthen the life cycle of products, and the spread of TTR

(Technical Reusable Fabrics), replacing TNT (Nonwoven Fabric) disposables. TTR allows significant waste reduction and can be sterilized through steam autoclaves, unlike disposable products, the sterilization of which involves the

use of chemicals, in addition to the fact that they produce a large amount of waste that is difficult to dispose of.

Source: Cerved Marketing Intelligence, Lavanderie industriali (August 2023)

Although industrial laundries do not fall under the definition of an “energy-intensive enterprise,” it is easy to see how energy aspects play a crucial role in running a business that involves washing and drying hundreds of tons of laundry each day. Over the past three years, the incidence of energy and gas costs for laundries has increased almost fivefold. According to data from the International Energy Agency (IEA), gas has gone from costing about Euro 20/MWh in May 2020 to

more than Euro 70 in the same month of 2021, with subsequent spikes taking it to Euro 343/MWh due to the war. Thus, it can be argued that the war has aggravated an already worrisome situation. Washing is one of the sectors most affected by the energy crisis, partly because a characteristic feature of the industry is the difficulty in passing on these price increases to customers, immediately translating into heavy budget losses for businesses. These difficulties have

led operators to implement energysaving strategies such as flexible use of processing temperatures and working hours and investments in extraordinary maintenance to reduce heat losses in the washing process.

Companies' investment projects aimed at implementing higherperformance production equipment capable of reducing processing temperatures and times for the same amount of linen processed have also continued.

Less working time, less effort required

More control over wash cycles, more efficiency in your business

designing your clean www.imesa.it

A

edited by Cristina Cardinali

When we talk about a smart industrial laundry, we are referring not to a technological upgrade for its own sake, but to a true technological conglomerate, integrated into an ecosystem, where every element, from smart IoT sensors to data management systems, from predictive analytics software to user interfaces, works in synergy to improve efficiency, reduce costs and increase sustainability.

Let's take an example for clarity and think about the benefits that can be derived from advanced sensors that can monitor various parameters such as temperature, humidity and levels of soaps and detergents, water quantity and quality, to optimize internal transportation routes and warehouse management by sending real-time data to a centralized management system. Here, in this “central brain,” AI algorithms and Machine Learning models analyze collected data to make accurate predictions about operation and maintenance needs in order to optimize resource use and even adapt processes in real time to unforeseen

circumstances.

Added to this is the strategic use of data analytics, which can provide valuable insights into customer behavior, market trends, and operational performance, assisting management in choosing which strategic plans to un-

dertake and the timeframes needed to align goals.

THE ROLE OF AI

One of the most revolutionary and important contributions of AI in the context of industrial laundries

Below is some useful information on how to calculate the amount of laundry to be washed based on weight and washing time, and how to calculate energy consumption.

The following can be kept in mind when calculating the amount of laundry for a utility:

- A 3-4 star hotel room produces about three to four kilograms of laundry with each change.

- As for catering, the amount of table cloth per cover can be calculated as 0.3 kg per person.

is in predictive maintenance. Traditionally, maintenance of industrial equipment has always been carried out following fixed schedules or in response to failures generated on the spot. The application of models borrowed from AI, however, allows for a much more proactive approach; by examining historical data and “real time” numerical values, it is possible to predict, with accuracy, when a piece of machinery may fail or otherwise require technical intervention, thereby avoiding production line stoppages.

If we have seen so far the importance of digital transformation and the growing expectations of the industrial laundry sector, it is equally important to understand how, in practice, it is possible to map out a roadmap for transformation, that careful planning to determine exactly what technology implementation to address and how to ensure that the goals are effectively achieved. Let's look, then, at how to map out a roadmap for digital transformation broken down into three ba-

To make calculations easier, always consider that a wash cycle takes at least 60 minutes.

To evaluate energy consumption as an indication, it is advisable to keep in mind that:

- To get an idea of water consumption, keep in mind that each kilogram of laundry needs 3 to 4 liters of water in each washing step.

-Each kilogram of wool needs 7 to 8 liters of water in each washing step.

-Each kg of washed laundry corresponds to the consumption of 1

kg/h steam or 0.75 Kw/h electric.

-Each kg of laundry dried corresponds to the consumption of 1.5 kg/h steam or 1.1 Kw/h electric.

If you have the potential in electric kw multiplying by 1.36 will give the equal consumption in kg/h steam. If you have the gas consumption expressed in kw multiplying by 862 you will get the Kg/cal of potential. If you have the potential in kg/cal divided by 600 you get the Kg/h steam.

sic phases: planning, implementation and monitoring.

The planning phase

The first step in any planning process is to conduct a thorough analysis of the business environment, which involves assessing internal competencies, existing infrastructure and market positioning. By examining these aspects, it is indeed very likely to be able to trace the critical areas that need technological innovation. It is therefore necessary to define objectives that must be specific, measurable, achievable, relevant and timed, linked to business drivers for profitability, improved operational efficiency or expansion into new markets.

implementation phase

Once the planning phase is completed, the next step is the implementation of the most appropriate technologies. Choosing the right technology stack is vital and must be aligned not only with business goals but also with the skills of the staff. Whether cloud-based solutions for data processing or AI platforms for

advanced analytics, the choice must be made with an eye toward scalability and compatibility with existing assets.

Important is that the team can also come “aligned” with the technology used, including through targeted training and appropriate training to make the transformation natural and effective.

The monitoring phase

It is not enough to implement new solutions and hope they work: it is critical to have clear and measurable metrics and KPIs in place to assess the effectiveness of initiatives. This goes beyond simple ROI analysis; it extends to more sophisticated metrics such as Time to Return on Investment (TROI), Customer Lifetime Value (CLV) or Net Promoter Score (NPS). But in an ever-evolving industry, such as precisely the technology sector, it is also crucial to monitor a “feedback loop” of continuous updating: the roadmap for transformation can never be a linear path defined once and for all, but a continuous cycle of improvement and adaptation.

Technological progress has revolutionized the industry in many ways. The industrial laundry industry is no exception. Automation, data analytics, and recycling systems are some of the numerous innovative technologies that can help industrial laundries boost efficiency and cut costs.

Predictive Maintenance Software utilizes data analysis and machine learning algorithms to anticipate when machinery is expected to fail, enabling industrial laundries to plan upkeep in advance of any malfunctions. This results in less downtime, prolongs the lifespan of equipment, and lowers maintenance expenses.

Industrial laundries can remotely control their operations using machine management systems from any location with internet access. This technology has the potential to enhance productivity, lower expenses, and enhance scheduling and resource allocation flexibility.

Robotic arms are employed in these systems to organize and transport laundry items during the washing and drying stages. This technology has the potential to greatly lower labor expenses and enhance processing speed, resulting in increased efficiency and savings. Automated sorting systems can additionally decrease the likelihood of harm to employees and enhance general

Water recycling systems collect and process used wash water from laundry, enabling its reuse for washing or other potential uses. This could greatly decrease the use of freshwater and the release of wastewater, ultimately resulting in better environmental sustainability and lower water expenses.

RFID technology utilizes radio waves to monitor items as they progress through the laundry process. An RFID system designed for industrial laundries can enhance inventory control, minimize losses, and enhance customer service. RFID technology has the potential to enhance workflows and decrease processing times, resulting in increased efficiency and cost savings.

To sum up, industrial laundries can greatly profit from adopting modern technologies like water recycling systems, predictive maintenance software, cloud-based management systems, RFID, and automated sorting systems. Industrial laundries can enhance sustainability, reduce costs, and increase efficiency by utilizing these technologies, all the while delivering excellent services to their customers.

https://www.wientjens.com/blogs/5-innovativetechnologies-for-industrial-laundries-to-boost-efficiencyand-cut-costs

Industrial laundries perform a service that is fundamental to the normal operation of the health and tourism sectors and of public benefit to the entire community through the provision, sanitization and sterilization of textile devices, work clothes, PPE, linens, surgical instruments

edited by Simone Ciapparelli

The first activity consists of the collection of soiled linen carried out at the customer's premises; this work step can also be contracted by the laundry to outside firms. The material to be picked up is already placed by the staff of the client company in closed bags, which are of different colors depending on the textile product contained and the adopted coding of the laundry. The bags are then loaded onto vehicles and transferred to the washing and sanitizing plant. After transport, the items are stored in a special unloading area until they are moved to the washing department, which is done, either manually, by means of closet or roll type trolleys, or automatically, by means of conveyor belts that are generally overhead.

This activity consists of sorting incoming linen, dividing it into: flat material (e.g., sheets, tablecloths, napkins); made-up material (e.g., suits, gowns, aprons). More and more laundries, particularly those whose customers are health care companies, are performing this operation downstream of the washing process. In this way, both the biological risk from possible operator contact with infected substances and the risk of abrasions and wounds due to the presence of foreign objects among the linen are reduced. Operators open the bags and drop the material onto a scale belt through which it is moved to the washing department when the predetermined weight-threshold is reached. Even where the presence of overhead lines to transport the material does not require direct operator intervention, the department is still manned. Traceability of items is ensured by making use of the reading of radio transmitter tags attached to each item (transponder-chips), which are read by low-frequency radio wave antennas. In other cases, the operation is carried out before washing, thanks to the use

of pit counters; the linen is manually selected and sorted by the operator according to the type of textile and the degree of soiling. In addition, the items are coded within the company's information system to ensure maximum traceability and optimize process flows, before being transferred to the washing department, inside appropriate bags, usually by means of an overhead handling and storage system that feeds the washing lines.

Washing is generally carried out by means of a continuous batch washer automatically powered by an overhead track conveyor system, on which the bags with the linen to be sanitized move, and by movable arms, while for garments with special characteristics washer-extractors are sometimes used. Detergents used are mostly water-based such as anionic, cationic and nonionic surfactants and fabric softener. Lines are generally dedicated to the treatment of a particular type of laundry. The wash centrifuge is a washing machine with a rotating drum, sup -

plied by cold water or heated by steam depending on the characteristics of the textile to be treated, and is generally used for washing delicate garments, with special specifications, or for stubborn dirt. The continuous washer, on the other hand, is an actual washing tunnel consisting of several “chambers” (from 6 to 24), through which the laundry is moved. During the process, the operator/trainer supervises the dosages, checking the correct concentration of the aqueous bath, and replacing the detergents when finished. In addition to the detergents listed above, the operation also involves the use of other chemical agents such as stain removers, acidifiers, and bleaches. The choice of washing method and mix of detergents and chemicals depends on the types of fabrics to be treated and the dirt to be removed. At the end of the washing phase, for linens destined for health care facilities, bleaching, acidification, and finally hydro extraction operations follow. Linen processed in the washer-continuum is pressed and scarfed, unlike linen from the washer-center, which is

Before shipment, the linen packed is counted again by transponder-chips to ensure that the flow of material incoming is the same as the outgoing

centrifuged. Pressing is generally done by means of a special press equipped with oil- or air-operated pistons. At the end of the process, the linen is advanced to the dryers for drying, by means of a shuttle or conveyor belt.

After washing, the linen is partially dried by means of dryers, of which there are two different types:

- steam: it is powered by 10 bar and 180 °C steam and is equipped with a rotating basket with closing doors, a first

chimney for air intake and a second chimney for expelling the water vapor produced during drying;

- gas-fired: operates similarly to the steam dryer, but is heated by means of a gas burner. It is equipped with a gas leak detector and solenoid valve, which cuts off the power supply in case of leakage.

The linen is then moved to the ironing department either by overhead conveyance or through metal cages equipped with wheels and an adjustable table top or by using specific trolleys, pushed manually by operators.

For flat material, the ironing department consists of three pieces of equipment for each ironing line: introducer,

ironer and folding machine. The introducer automatically feeds the ironer, inside which the drying process of the textile is completed, resulting at the same time ironed. In addition to advancing the linen, the mechanical action of the roller also makes it possible to eliminate any creases present on the textile. The linen is then run over a metal basin heated by steam or thermal oil to a temperature of 180 °C, where the ironing of the garments is completed. The high temperature of the basin is a further guarantee of the sanitization of the textile. At the exit of the ironer, a belt system transports the linen to the folding machine, which automatically folds and stacks the sanitized textiles, which are ejected from the machine when a predetermined

number of processed pieces has been reached. The resulting blocks of linen are finally advanced by conveyor belts to the bagging machines and then to the shipping department.

In the case of packaged linen, the operator picks up one garment at a time, visually inspects it to examine its integrity, and arranges it on hangers that, depending on the type of ironing, automatically direct the garments to the ironing tunnel or to special dummies. In the former case, the garments, still hanging on the hangers, are completely dried by means of hot air and steam jets at a temperature of 170 °C, which allows, at the same time, industrial ironing. In some cases, ironing can also be done or completed manually, using traditional ironing boards. Once the process is completed, the linen is folded (in some cases also manually) and bundled, either in an automated manner with the help of special robots, or manually, and from there it is sent to the mending department, or to the warehouse for replacement (in case of non-repairable damage). Mending is carried out with ordinary sewing machines.

After the sanitization treatment, the shipping department receives the material and makes up the rolls with the packed linen, on which labels prepared by the shipping department are affixed. The material is packed with heat-shrinkable polyethylene film to prevent contamination or damage during transport. The rolls are then placed in dedicated aisles within the shipping area, where drivers pick them up and load them into vans for delivery to customers. Before shipment, the packed linen is again counted by means of the same system used during sorting (transponder-chips) to ensure that the incoming flow of material is the same as the outgoing flow.

Laundries also perform other clean-

ing, washing and sterilization activities, including:

X Sterilization activities of the operating textile: Linen sterilization activities are carried out in a special central plant, located in a purpose-built room within the industrial laundry, equipped with microclimatic conditions to comply with the provisions of medical device legislation. Material entering the central unit is visually inspected for abrasions, holes or cotton dust, then sorted. The items are then washed and dried by means of a washer-extractor. This is followed by the composition of the kit, its packaging, and the sterilization phase. The latter takes place inside an autoclave by means of steam. The sterilized kit is therefore stored inside a dedicated sterile area, where it remains waiting until delivery to the customer, which is done by means of specific closed trolleys capable of preserving the material from external contamination, guaranteeing its sterile condition. The entire process is mapped at all stages to ensure maximum traceability of each individual component.

X Surgical instrument sterilization ac-

tivities: In addition to the sanitization and sterilization of drapery destined for operating rooms, another activity of industrial laundries related to the surgical field is the decontamination of surgical irons. Kits containing instrumentation from operating theaters are received by the laundry and, after an initial sorting phase performed manually, the irons are decontaminated using special chemicals diluted with water. Washing can be done manually (by contact or immersion) or automatically by means of the use of an iron washer, the operation of which is similar to that of a conventional dishwasher suitably modified. In the latter case, chemical dosages are handled automatically by the machine. Once the process is over, the instrumentation is allowed to dry and the kits are reassembled, which are, then, sterilized using the same procedure adopted for the drapery, that is, through the use of an autoclave. Return to the customer is also done in the same manner as described for surgical textile kits.

Source: Inail, Analisi dei rischi lavorativi nelle lavanderie industriali (2022)

The best way to prevent the spread of germs and bacteria during meals is to use tablecloths and napkins that have undergone a correct washing process

Francesca Leoni

The World Health Organization, in its operational considerations for the management of the Covid-19 virus for the tourist accommodation sector in addition to providing recommendations for the various activities carried out within the hotel, also intervenes in relation to proper management practice and sanitation with regard to catering. Catering, like the hospitality part, holds the characteristic of having a high degree of social gathering i.e., a large number of guests who not only interact with each other but also interact with the restaurant staff, with a high probability of contact.

They therefore need specific attention: - the guest accommodation system; - the management of services (food, drink, organization of the activity);

- sanitation of rooms and surfaces, especially tables; - interactions between guests and the facility and interactions with the environment.

Hygiene practices

Regarding sanitation aspects, WHO provides specific ways of handling dishes, cutlery and table linen. Among other things, since the transmissibility of the virus occurs by air via droplets produced by coughing or sneezing, which can settle and persist even on inanimate surfaces, or by contact with contaminated hands, it is urged to sanitize even items that have not been used directly by the customer. The attention in the restaurant to the hygienic aspect, especially to the work and support surfaces for dishes - cut-

lery, plates, glasses, etc. - and for hand hygiene turns out to be fundamental since the consumption of food and beverages inevitably involves direct contact of potentially contaminated objects or hands with the mucous membranes of the oral cavity, which represent one of the gateways for the entry of the virus.

That said, the issue of table hygiene and cleanliness deserves a closer look, not only in what has been a particular highlight, but as a constant and inescapable element of food risk control. It plays a central role in this context that table linens are properly sanitized and treated by specialized companies that also provide the customer with certifications about the mode of treatment dedicated to the linen before it is delivered.

The starting point is to be able to ensure that guests who enter the restaurant for the tasting of food prepared by the kitchen have a dining room with a high degree of hygiene, as well as the desired comfort and elegance, the result of a serious and constant practice of sanitization previously studied, then implemented and documented. In this way, the guest will feel that he or she is in a hygienically welcoming environment and can comprehensively appreciate his or her experience through all the senses such as sight, touch, smell and finally taste.

Good sanitation practice starts from the premise that it is necessary to clean and sanitize the room and table at every customer change. To do this, it is necessary that the room environment, including the furniture, service accessories and the table, are subject to prior sanitization by an operator properly and adequately trained on hygiene; a serious method for sanitization cannot disregard the use of materials and

manual actions for cleaning, for cleansing with the help of cleaning products and disinfectant agents, which, only if preceded by the previous actions, with adequate contact time, guarantee the basic sanitization of the room.

It is therefore evident that the operations of sanitizing the hall will have influence on the operational timelines and especially if they occur during the service they may also have repercussions on the decorum and customer service.

Considering the above for the dining room, it is now important to highlight the need for the table to be covered with a reusable fabric with a level of sanitization guaranteed by specialized laundries and certified according to a specific standards, which guarantee control over the biocontamination of textiles through a Risk Analysis Biocontamination Control system.

Elegant tablecloths and napkins made of reusable natural fabric thus offer the convenience of being easily replaceable at the end of each service. After all, it is improper to even imagine the use of disposable items of uncertified origin and significant environmental impact.

In this way, the room operator, through a fast and safe procedure will be able to change in the presence of other customers only the tablecloths, thus offering the next customer maximum hygienic safety.

To set the table, the worker, after removing the used tablecloths, simply puts on gloves and opens the package with the linen and picks up the needed item. Folding allows tablecloths and tablecloth covers to be set using only the fingertips of the thumb and forefinger. The used table linens will be placed in closed containers (bags or sacks in carts) by handling and shaking them

as little as possible in the environment before placing them in the container; the linens will then be picked up by the rental and sanitization company's driver (the truck is sanitized each time it is loaded) who will deliver them to a special area of the company, separate from the clean linen department. In contrast, the choice to use tables without table linens could create strong problems regarding good table sanitization practice because at the time of table rearrangement, the surface will have to be compulsorily washed in the presence of customers and presumably quickly through the use of cloths and products that have a high disinfectant content. This is therefore a highly inadvisable practice since in order to truly sanitize hard surfaces these must be cleaned by cleansing and sanitizing, but if this is done during service the risk is to negatively affect room service and induce out of haste a rushed sanitization to the detriment of the next customer.

The Standard in question is an essential prerequisite for ensuring the catering and hospitality establishments, but also the health sector, the supply of linen that is qualitatively and hygien-

ically safe from the point of view of controlling its biocontamination.

In other words, in order to prevent the spread of diseases transmissible by pathogens, the industrial process of sanitizing textiles - in addition to sensory cleanliness and comfortmust guarantee their hygienic quality and safety, achieved precisely through the technical standard “UNI EN 14065:2016 and the Assosistema Guidelines” based on a RABC (Risk Analysis Biocontamination Control) system.

In this sense, UNI EN 14065 guarantees the implementation of a business management system that ensures treated textiles have the appropriate microbiological quality according to their specific use (healthcare, tourism, catering, industry).

Microbiological analysis covers all stages of the process to which treated textiles are subjected in a laundry industry, from receipt of soiled linen to delivery to the customer, through: sorting, grading, washing, hydro extraction, drying, finishing, folding, packaging and transport.

It should be emphasized that the UNI EN 14065 standard dwells not only on the importance of sanitizing and decontaminating textile devices, but also on the need to protect them from po -

Different types of products are included within the heading “table linen”. Let's see which are the main ones. Tablecloths. The name “tablecloth” refers to the larger fabric that adorns a restaurant table. The tablecloth is an essential element of the most classic or elegant restaurants, although the trend in more modern restaurants is to adopt other solutions, such as American placemats. The size of a restaurant tablecloth can range from 130 to 160 cm.

Slipcovers. These are smaller

tablecloths, between 100 and 120 cm, that are placed above the tablecloths. The tablecover protects the tablecloth underneath and is changed with each change of guest at the table.

Napkins. They are the essential complement to tablecloths. They are made of different fabrics, but cotton is usually the favorite because it is pleasant to the mouth. They have a size of 40x40 or 50x50 cm.

American placemats Increasingly popular, American placemats are very

tential re-contamination through risk analysis and prevention measures implemented over the entire production cycle, up to the moment the products are returned for reuse.

The industrial process includes a thermal component, as washing is carried out at predefined temperatures suitable for sanitization and the subsequent drying/ironing phase reaches high temperatures. Then there is the mechanical action, the time factor, and the chemical treatment part, which takes place through the use of cleaning products and disinfecting agents with bactericidal, virucidal and fungicidal capabilities that guarantee perfect sanitation and safe use. The RABC System also includes actions to monitor and sanitize surfaces, machinery, means of transport and operators.

The UNI EN 14065 standard ensures a proper analysis of biocontamination risks that examines, for each stage of the textile treatment process, what the potential microbiological risk may be, its potential cause, the control method implemented as well as the identification of the intervention measures put in place in order to restore the conformity of the process in case of detection of any deviations and anomalies.

convenient for a restaurant to use because their maintenance is quick and easy. Their use is constantly increasing. They are about 40/50x30 cm in size.

Runners. Runners are a less bulky version of a tablecloth that only covers the place of two diners positioned next to each other, leaving the sides of the table visible and uncovered. This is a very useful solution when you have a nice table and do not want to cover it completely.

Carpet in the modern indoor environment poses no risk to public health, as long as it is properly maintained and cleaned

Michael A. Berry PhD

Arobust assessment of carpet is fundamental to any objective judgment related to carpet and human exposure indoors. A responsible decision with regard to carpet in sensitive environments, such as schools and health care facilities, should be based on factual, documented evidence. Therefore, it is intended that this body of information be considered in the process of establishing public and industry policies with regard to carpet, carpet buying decisions, and responsible communication with consumers, public administrators, and the technical community. A panel of ten academic and industry researchers and technical specialists met at the University of North Carolina at Chapel Hill to critically examine peer-reviewed or otherwise credible science with regard to the positive or

negative attributes of carpet in the modern indoor environment. The review was organized to assess environmental benefits of carpet, as well as negative perceptions and environmental concerns. The primary objective of the expert review was to examine key studies that address carpet as a major contributor to indoor environmental quality and as a possible source of adverse human response. Regarding the latter, the panel was asked to closely examine any relevant scienti fic data related to toxic substances and allergens commonly found, or alleged to be, in and over carpet and related non-carpet surfaces. The panel was also asked to evaluate maintenance and management practices related to long-term carpet performance and health protection. Hundreds of studies were examined in the course of this review.

This article is reprinted with permission from issue 1, volume 5, of the Cleaning Science Quarterly, the official peer-review journal of the Cleaning Industry Research Institute (CIRI)

The review examined the scienti fic literature at large, but mainly focused on information found throughout the peer-reviewed technical literature, National Health Sciences Libraries, EPA’s research information database, and previous reviews and conferences conducted by recognized experts. In advance of the meeting, each expert prepared a review paper for his or her specialty area. In the exchange, new sources of information were identi fied, points of view surfaced, and important issues were highlighted.

A comprehensive review of the literature supports the contention that carpet is a significant positive contributor to the quality of life indoors. The purpose of every indoor environment is to provide for security, comfort, social interaction and productivity. A

healthy indoor environment is one that achieves these four purposes and radiates a “sense of well-being” to inhabitants. An elevated sense of “well-being” is the basis for the human condition we call “healthy.” Reviewers, working independently, noted how carpet contributes to these “healthy design” factors: usable space that promotes social interaction and productivity; safety as in the prevention of slips and falls; aesthetics; physical comfort and ergonomics; lighting to include the management of glare or light reflectance; acoustics and the management of noise; climate control in keeping the surrounding space warm, cool, and dry; and cost-effective maintenance with minimal environmental impact.

• Carpet is a product designed specifically to enhance the quality of life indoors. From an environmental science

perspective, the desirable aspects of carpet are based on the fact that carpet is an energy absorber with a strong tendency to adsorb matter. Because of these properties, carpet is acknowledged in many health-related documents as having desirable attributes for sensitive environments.

• As with any high-volume-use indoor product, when carpet is reasonably maintained, it poses no adverse exposures or health effects. When installed and maintained as intended, carpet is not a risk to public health. When examined in proportion to its use, carpet is associated with minimal complaints, consumer dissatisfaction or concern. Research going back over 40 years consistently shows that carpet is a preferred and widely used floor covering associated with long-term consumer satisfaction. In the United

States alone, there are approximately 150 billion square feet of carpet currently installed in over 100 million buildings. A large proportion of the developed world's population is exposed to carpet, and so it is remarkable and significant that this review found no epidemiological or toxicological studies presenting clear or direct evidence that exposure to carpet in any environment causes an adverse human health response. Furthermore, where controlled studies have been conducted in relation to carpet chemical emissions and animal and human response, no adverse response was found to have occurred.

• Carpet does not emit concentrations of VOCs that present a real risk. Carpet entraps particulates and removes them from the indoor environment. When weighing the different factors in

making a flooring selection, health effects, if considered at all with regard to carpet, should be considered in a positive rather than negative context.

• The most controversial aspect of the impact of carpeting on air quality is the perception of indoor air quality in buildings containing carpeting. Only recently have scientists attempted to quantify this effect of carpeting, despite the fact that odor perception studies have been undertaken, primarily in occupational settings, for over 30 years. In the current review of the literature, the “perception” of the quality of air indoors may be the parameter most closely associated with non-quantified or non-quantifiable health effects including sick building syndrome and multiple chemical sensitivity.

• The review indicated that there are a vast number of studies that describe, measure, and address particles, dusts,

allergens, and other contaminants of all types in carpet and other indoor surfaces. In these studies, no source and exposure relationships were established between contaminant accumulations in carpet and airborne concentrations of particles and dusts. This is consistent with the lack of finding a direct link between carpet and human health effects. This is a fundamental risk assessment finding that has significant non-exposure implications. Human response cannot occur unless there is exposure and sufficient dose delivered to the human receptor.

• Wet, dirty carpet will support microbial growth. However, less is known by way of the literature about human exposure and response to this microbial growth - other than symptoms tend to diminish with drying and cleaning of these spaces. Studies of damp or water-damaged environ-

ments tend not to consider or sort out the specific roles of the various building materials.