PROFESSIONAL

When international refrigeration, AC, ventilation and heat pump experts flock to Exhibition Centre Nuremberg from 11 to 13 October 2022, it will be the first reunion of this kind since 2018. Chillventa, the world’s leading trade fair for refrigeration technology, brings together the specialists and leading lights of the sector from all around the globe. In the eight exhibition halls, Chillventa CONGRESS on 10 October, and numerous events from the supporting programme, you will finally get the chance to make busi ness contacts face-to-face again, discover trends and interesting solutions, and refresh your knowledge. The number of registrations received so far is excellent. The professional community can look forward to an exciting event with a first-class supporting and congress programme. The world’s leading fair for refrigeration technology is renowned for its coverage of the entire spectrum of products and solutions for AC, venti lation, heat pump, refrigeration, insulation and C&I technology, as well as its high-calibre discussions about current developments and interesting presentations by experts from the R&D environment and industrial practice. “Over the last four years, the Chillventa community has sorely missed the personal interaction and opportunities to gain new professional knowledge and fresh inspiration. The prospects for the autumn are looking extremely good. With an international exhibitor contingent of 69%, we have already matched the high level of previous events. This is evidence of a fantastic

commitment by the community, especially in times like these. Likewise, 90% of the total display area from 2018 has already been booked. You can tell that the sector is genuinely keen to meet up and get talking again. All registered exhibitors can already be found online in our exhibitor database. Visitors can look forward to plenty of input on our key topics of energy efficiency, reduced greenhouse gas emissions, sustainability, waste heat utilisation, circular economy, indoor air quality, indirect cooling and digi talisation. They will find all this and more at the exhibition stands and in the supporting programme, which offers some interesting new features alongside established and popular highlights. Chillventa 2022 has a lot to offer industry stakeholders,” says Elke Harreiß, Director Chillventa at NürnbergMesse.

NEW ADDITION TO EXHIBITOR FORUMS

In the three established exhibitor forums featuring more than 160 presen tations by experts, the around 90 exhibiting companies, organisations and associations provide visitors with compact, practice-driven insights from various thematic areas. The title of the forum in Hall 4A is “AC, ventilation & heat pumps”, Hall 7A focuses on “Refrigeration technology ” and Hall 9 will attract all those interested in “Applications, training & codes of practice”.

A new addition this year is the forum in Hall 8, which takes a special look at a trending issue: “A practical guide to digitisation for craftspeople”. Trades-based businesses can head here to get practical tips on digitalising their business operations and workflows. Another new feature is the Expert Talks forum with specialists from the sector in Hall 7A.

SPECIAL PRESENTATIONS, GUIDED TOURS AND WALKABOUTS FOR TRAINEES

As well as the extensive programme offered by the specialist forums, Chill venta has other highlights in store for various stakeholder groups: Hall 4 is the venue for a special presentation on the topic “Insights into the handling of flammable refrigerants (R290)”, organised by the German Federal College of Refrigeration and Air Conditioning Technology. Hall 4A also has a special display area dedicated to the “Heat pump” and organ ised by AIT, the Austrian Institute of Technology. Anybody wanting to focus specifically on innovations in refrigeration technology/AC and ventilation technology should join the guided tours organised by publishing house Gentner Verlag, which also offers a special tour for trainees. The German Federal College of Refrigeration and Air Conditioning Technology is also conducting trainee tours of the exhibition. ■

CHILLVENTA CONGRESS: THE FUTURE OF THE INDUSTRY UNDER THE SPOTLIGHT

At the Chillventa CONGRESS on 10 October, the day before the exhibition, high-calibre speakers will share their knowledge from the R&D, industrial and political arenas. It’s where you will learn at first hand how the future of the industry is evolving and have the opportunity for in-depth professional discussions. The main themes of the congress will be explored in four different streams: heat pump technologies (English), Innovation Day Refrigeration Technology (German), Data Centres (German) and the ASERCOM-EPEE Symposium (English) on the topic “Multiple Transition Challenges in Heating, Cooling and Refrigeration”. The keynote address will be given by a speaker from the European Parliament or European Commission. The symposium provides information about current policy frameworks and regulations in Europe and worldwide. The Chillventa CONGRESS will also focus on issues like sustainability, energy efficiency, circular economy, indoor air quality, low GWP refrigerants for heat pumps, updated F-gas regulation, REACH and PFAS. “From the very start, the Chillventa CONGRESS has been the No. 1 think tank for international Chillventa experts. On the day before the Chillventa exhibition, it explores current developments and presents the latest scientific findings to the professional community. “What sets the event apart is the networking and knowledge-sharing and the chance to discuss all these issues with one another,” says Dr Rainer M. Jakobs, technical coordinator of the Chillventa CONGRESS.

TRANSITION TOWARDS LOW ENVIRONMENTAL IMPACT REFRIGERANTS IN VRF SYSTEMS

Luca Molinaroli Polytechnic University of Milan

Luca Molinaroli Polytechnic University of Milan

INTRODUCTION

In the refrigeration and air conditioning sector, meant in its broadest sense as cooling and/or heating, recent actions taken at the European and global level on the reduction of environmental impact related to human activities have been pushing manufacturers of machinery and systems using “fluorinated greenhouse effect gases” to face the issue of replacing traditionally used refrigerants with substances having low impact on the environment.

More in detail, the EU 517/2014 (EU, 2014) regulation,

1. in some specific applications, most of which belong to the refrigera tion sector, introduces a set of deadlines for banning fluids with Global Warming Potential (or GWP) above a certain threshold;

2. more generically, it introduces a maximum quantity of refrigerants to be placed on the market by setting an annual quota mechanism. Such limit is not set for each refrigerant as the maximum quantity of mass of the individual substance to be placed on the market. Rather, it is set with reference to the overall environmental impact of the entire range of refrigerants expressed in tons of CO2 equivalents. These amounts are specific to each nation and they decrease over time according to a plan that shall reach a 21% decrease in 2030 compared to the 20151 level as shown in Figure 1

The Kigali amendment to the Montreal protocol (United Nations, 2016) fol lows the same pattern, referring to the mechanism of quota for placing refrigerants on the market, yet it considers different thresholds and time frames, as shown on Figure 1.

Consequently, these regulations have forced, on the one hand the refriger ant fluid industry to carry out research and development of new low envi ronmental impact substances, and, on the other hand, the air-conditioning and refrigeration industry to gradually abandon high-GWP refrigerants in favour of more eco-friendly ones that may be already known, but not widely used yet, or recently introduced. In fact, refrigerant producers’ projections show that the average GWP of substances for sale in 2015 was about 2000, while in the three-year period 2021-2023 it is expected to settle around 900 then to drop to about 400 starting from 2030.

LOW ENVIRONMENTAL IMPACT REFRIGERANT FOR VRF SYSTEMS

In the small to medium sized air-conditioning sector, which includes Vari able Refrigerant Flow systems (VRF systems), these regulations have led to the replacement of the traditionally used refrigerant, R410A, with a lower environmental impact refrigerant, since its GWP is equal to 2088. As it is well known by the sector’s operators, the refrigerant choden to replace R410A in such application is R32 , with GWP equal to 675, which is one of the components of R410A. The main characteristics of these two fluids are shown in Table I (data from Refprop 10, Lemmon et al. 2018). From a thermodynamic standpoint, compared to R410A, R32 has higher critical pressure and critical temperature, lower specific heat at constant reference pressure and very similar saturation temperature at

1 At the time of writing this article, EU 517/2014 regulation is being revised to harmonize the Kigali amendment to the Montreal protocol.R32 REFRIGERANT IS CURRENTLY THE MOST WIDELY USED LOW GWP ALTERNATIVE, YET IN A MEDIUM TO LONG PERIOD THE NEED TO FIND A NEW REFRIGERANT, ESPECIALLY FOR LARGE SYSTEMS, MIGHT ARISEFIGURE 1 – Maximum quantity of hydrofluorocarbons to be placed on the market according to regulation EU 517/2014 and according to the Kigali amendment to the Montreal protocol

ambient pressure. Overall, these features make a newly designed vapour compression system more efficient, but higher operating pressure and higher compressor discharge temperature are expected. The substantial difference between the two fluids is the safety classification according to ISO 817 (ISO, 2014): R410A is in fact classified as non-toxic fluid (class A) and non-flammable (class 1), while R32 is non-toxic (class A) but with low flammability (class 2L). The implications of this characteristic are discussed in the section devoted to it.

Table I – R32 and R410A main properties Features R32 R410A

Composition Pure 50% R32 50% R125

Critical pressure 5782.0 kPa 4901.1 kPa

Critical temperature 78.105°C 71.342°C

Molar mass 52.024 g·mol-1 72.585 g·mol-1 cP01 42.942 J·mol-1·K-1 58.511 J·mol-1·K-1

NBP2 -51.651 °C -51.364 °C ODP 0 0

GWP100 (UE 517/2014)3 675 2088

ASHRAE Classification A2L A1

1 Specific heat at constant pressure at 0 kPa pressure and 25 °C temperature

2 Normal Boiling Point, saturation temperature at atmospheric pressure. Dew temperature for R410A

3 GWP values as per the EU Regulation 517/2014 (European Union, 2014). The values in the IPCC 5th report (Stocker et al., 2013), are slightly different.

From the standpoint of application of R32 in VRF systems, Tsujii and Imada (AHRI, 2013) carried out a comparative study highlighting the differences between the use of R32 versus R410A. The analysis considers a drop-in application, i.e. an application where a VRF commercial system undergoes the same laboratory tests using both R410A and R32 and without replacing any system component but changing only the refrigerant. The results of this analysis show that with R32:

1. the optimal charge in the system is lower, around 83% of the same system’s charge operating with R410A;

2. the cooling and/or heating capacity is generally higher, with maximum increments up to +4.8% in full load conditions compared to the baseline;

3. the energy efficiency indexes (EER or COP) are higher, with maximum increments up to +6.4% in full load conditions;

4. with same saturation temperature, operating pressures are slightly higher, with maximum increments of about +5%, due to the higher sat uration pressure as shown on Figure 2;

5. the compressor discharge temperatures are, on average, higher, with increments up to about 14 °C.

Since its publication, (note that the paper is dated 2013, A/n), this study has highlighted the R32’s excellent performance, which makes it the first choice for the replacement of R410A in VRF systems. At the same time, they show the need for a partial redesign/adjustment of the components of the VRF system to address the issue related to the compressor’s higher discharge temperatures.

As evidence of this, nowadays the R32 is used by almost all manufactur ers of VRF systems as a replacement for the R410A . However, with few exceptions, the transition towards the use of this eco-friendly refrigerant is limited to small size VRF systems i.e. those with nominal cooling capacity around 14 kW – 28 kW. The reason behind this limitation can be found in the R32 flammability, as mentioned earlier, which restricts its wider use. This topic is discussed in the next section.

TOXICITY AND FLAMMABILITY OF R32 AND R410A

As mentioned, both R410A and R32 refrigerants are non-toxic (class A) but they are different form the flammability point ov view, as the former is not flammable (class 1), while the latter belongs to the class of low flammability substances (class 2L).

Table II shows R32 flammability features where:

1. autoignition temperature is the temperature to which a mixture of R32 and air must be brought to trigger a spontaneous combustion phenom enon without needing a flame or spark;

2. hot surface ignition temperature is the temperature a surface must reach to develop a flame when sprayed with R32;

3. the lower flammability limit (or LFL) is the minimum concentration of R32 capable of propagating a flame in a homogeneous mixture of refrigerant and air at 23 °C and 101.3 kPa;

4. combustion velocity is the speed at which a flame propagates relative to the unburned surrounding gases.

Table II – R32 Flammability Features

Features

Autoignition temperature

R32

648 °C

Hot surface ignition temperature > 800 °C

Low flammability Limit (LFL)

0.307 kg·m-3

Burning Velocity 6.7 cm·s-1

A few considerations must be introduced here. Firstly, R32 is classi fied as a flammable substance (actually, a low flammability one), but it has to be considered so only if suitable concentration conditions exist. Ambient R32 concentrations below the lower flammability limit in the environment are such that it is impossible for a combustion phenom enon to occur. Therefore, systems with low refrigerant charge can be safely installed indoors because even full release of the entire refrigerant charge contained in the system is not such to raise the concentration above the minimum flammability threshold. Secondly, the speed at which the flame propagates is significantly slower than that of hydrocarbons (e.g., propane’s burning velocity is about 45 cm·s -1). Therefore, in case of R32 combustion, the mixture reactivity is lower and the risk of violent detonations is mitigated. Lastly, autoignition temperature and hot sur face ignition temperature are very high and hardly occur during normal operation of a VRF system.

CONSTRAINTS IMPOSED BY SAFETY RELATED REGULATIONS

Safe use of VRF systems, and more generally of air conditioners and heat pumps, follows EN 378 (CEN, 2021) and IEC 60335-2-40 (IEC, 2018) stan dards. The first one is a general standard for air conditioning and cooling systems, while the second is a product-specific standard for air condition ers and electricity-powered heat pumps. In these regulations, the safe use of these devices is analysed under various aspects, but hereinafter only the aspects related to refrigerants are discussed. The safety of refrigerants is discussed in terms of toxicity and flammability of these substances and their accidental release in the environment. In fact, while it is true that the refrigerant is completely inside the refrigerating circuit, which is sealed, it is also true that an accidental breakage (such as a crack in a welding, leakage from joints etc.) can cause a leakage. In direct expansion systems such as the VRFs, this must be carefully assessed because the indoor units, joints and exchangers, and the pip ing connecting to the outdoor units are placed indoors and therefore a dangerous leakage of the refrigerant in areas occupied by people is a real concern. Another consideration stems from the fact that, unlike split systems where the indoor units that can be connected to the outdoor one are only a few, in VRF systems it is possible to connect many indoor units to the same cooling circuit, creating wide networks containing a significant amount of refrigerant.

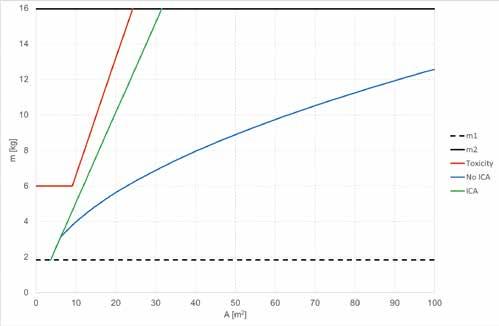

curve of R32 and R410A refrigerants4. the charge general limit, shown as “no ICA” (blue line). According to that limit, for a given floor area, the accidental release of the entire charge of refrigerant contained in the VRF system creates a concentration of R32 such that the air-R32 mixture is not flammable. Installation and use of the VRF systems with R32 charge lower or equal to the “no ICA” cor responding value can therefore be safe even without additional safety and/or protection devices;

5. the load limit in the presence of Incorporated Circulation Airflow, shown as “ICA” green line, which represents the VRF system maximum admis sible charge operating with R32 provided with additional safety devices. Incorporated Circulation Airflow occurs when the fan installed in an indoor unit is either continuously working, or is activated by a refrigerant detection system and produces airflow above a threshold value. In case of accidental release of the entire charge of refrigerant, the mixing of the ambient air generated by this airflow is such to reduce the average concentration of R32 in the air averting the formation of pockets of airR32 flammable mixtures.

The installation is subject to the appli cation of the standards mentioned above, which defines a minimum surface for the area of installation of the VRF system with reference to the charge of refrigerant contained in it (or the maximum charge of refrigerant contained inside a VRF system with reference to the surface of the area served). Specifically, in standard EN 378 (CEN, 2021) such value is set considering both toxicity and flammability of the refrigerant, whereas in IEC 60335-2-40 (IEC, 2018) only flammability is taken into account. As IEC 60335-2-40 (IEC, 2018) is a product standard that takes precedence over the generic EN 378 standard, the requirements related to flammability are discussed considering only the application of IEC 60335-2-40 (IEC, 2018).

Without getting into the details of the various calculation procedures, Fig ure 3 shows the charge limit as a function of the floor area of the room where the VRF system is installed, considering ceiling installation of the indoor units. The figure shows five curves:

1. The charge limit resulting from toxicity constraints (red line). For a given surface of the room, if the charge of refrigerant contained in the VRF system is greater than the one set by this limit, the system cannot be installed as an accidental release of the entire charge of refrigerant may harm people’s health;

2. a first charge limit resulting from flammability constraints, indicated by m1 (dashed black line), which is 1.842 kg for R32. If the refrigerant charge contained in the VRF system is lower than m1, then indoor installation can take place with no constraints on the minimum area. In fact, in case of accidental release of the entire refrigerant charge in the area, the resulting R32 concentration is below the LFL, therefore the air-R32 mixture is not flammable;

3. a second charge limit, indicated by m2 (solid black line), which is 15.964 kg for R32. For refrigerant charge above that threshold, the standard specifies that it is mandatory to adopt additional measures, such as ambient ventilation with outside air, shut-off valves and alarms;

BIBLIOGRAPHY

•

•

•

pumps, air-conditioners and dehumidifiers (IEC 60335-2-40)

• International Standard Organization (ISO), 2014. Refrigerants - Des ignation and safety classification (ISO 817)

• Lemmon, E.W., Bell, I.H., Huber, M.L., McLinden, M.O, 2018. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and

This

was originally published in the

issue of

VRF system models currently available on the market comply with these standards, thus the use of R32 in these systems is safe. However, to com ply with these standards an upper limit to the nominal cooling capacity has to be set since the higher is the capacity, the higher is the refriger ant charge. With current technology, the value of admissible charge m2 = 15.964 kg is typical of VRF systems whose nominal cooling capacity is about 14 kW – 28 kW, and consider ing a standard installation of a VRF system with approximately 100 m piping. It is worth noting that these values change as per manufacturers’ models and installation conditions.

CONCLUSIONS

In the refrigeration and air conditioning sector, environmental regulations on fluorinated greenhouse effect gases have started off the gradual phasing out of high environmental impact traditional refrigerants in favour of lower GWP substances.

Specifically, in VRF systems, the R32 refrigerant is the low GWP alternative adopted by manufacturers to replace the traditional R410A. In addition to its environment friendly characteristic, this fluid also has excellent thermo dynamic properties, which make its use also appealing from the standpoint of energy. The transition towards the use of this fluid in small size VRF systems is now completed. However, at present, further expansion of R32 use in higher capacity systems is hampered by the need to comply with safety regulations for the use of low flammability refrigerants. Lastly, it should be mentioned that in the coming years the actions of envi ronmental regulations currently in force will become increasingly more strin gent, pushing towards wider use of low-GWP refrigerants. It is the opinion of the present author that this shall force, in a medium to long-term period, the need to replace the recently introduced R32 with a “new” refrigerant with lower environmental impact. It shall therefore be necessary to find a new substance for this type of application, resulting from the research and development of new-generation synthetic refrigerants or from the redis covery and gradual introduction of natural refrigerants, whose energy and safety features shall be carefully evaluated.

■

Transport Properties-REFPROP, Version 10.0, National Institute of Stan dards and Technology, Standard Reference Data Program, Gaithersburg

• United Nations, 2016. The amendment to the Montreal Protocol agreed by the Twenty-Eighth Meeting of the Parties (Kigali, 10–15 Oc tober 2016)

• Stocker T., Qin D., Plattner G.K., Tignor M., Allen S., Boschung J., Nauels A., Xia Y., Bex V., Midgley P.M. Climate Change 2013. The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA.

• European Union (EU), 2014. Regulation (EU) No. 517/2014 of the Eu ropean Parliament and the Council of 16 April 2014 on gas fluorinated greenhouse gases repealing regulation (EC) No. 842/2006. Official Jour nal of European Union 2014, 150: 195-230.

Journal, September 2021. Translated by Interconsul S.r.l.

IS PROPANE A SOLUTION FOR MORE SUSTAINABLE AIR CONDITIONING?

Switching to propane for space cooling we could avoid a 0.09°C increase in global temperature by the end of the century

Split-air conditioners (Split ACs) that use an indoor and an outdoor air unit con nected by pipes are the most common appliances used for space-cooling. They mostly utilize HCFC-22 and HFC-410 as refrigerants, both of them characterized by a very high global warming potential score, up to 2,256—meaning that they trap up to 2,256 times more heat than car bon dioxide over 100 years. Urged by the Kigali Amendment to the Montreal Proto col, many manufacturers are looking for alternative refrigerants with lower global warming potential scores , such as HFC-32. However, with a global warming potential score of 771, HFC-32 still poses a significant climate hazard. A study led by IIASA, published in PNAS in August 2022, researcher Pallav Purohit in collaboration with researchers from the United Nations Environment

by IIASAProgramme and the University of Leeds, showed that by switching to propane, an alternative low (<1) global warming potential refrigerant for space cooling, we could avoid a 0.09°C increase in global temperature by the end of the century, thereby making a significant contribution towards keeping the global temperature rise below 1.5 °C. Energy-efficient splitACs using propane are already available commercially in the Chinese and Indian markets. Despite performing similarly to split-ACs using HFC-32, and even better than the currently widespread appliances using HFC-410A and HCFC-22, some national regulations prohibit their use, primarily due to standards and codes restricting the use of refrigerants with higher flammability, hindering their wider adoption.

DECARBONISING THE ENERGY SYSTEM BY 2050 COULD SAVE TRILLIONS

New study shows a fast transition to clean energy is cheaper than slow or no transition

by Oxford UniversityTransitioning to a decarbonised energy sys tem by around 2050 is expected to save the world at least $12 trillion, compared to continuing our current levels of fossil fuel use, according to a peer-reviewed study by Oxford University researchers, published in the journal Joule. The research shows a win-win-win scenario, in which rapidly transitioning to clean energy results in lower energy system costs than a fossil fuel system, while providing more energy to the global economy, and expanding energy access to more people interna tionally. The study’s ‘Fast Transition’ sce nario shows a realistic possible future for a fossil-free energy system by around 2050, providing 55% more energy services globally than today, by ramping up solar, wind, batteries, electric vehicles, and clean fuels such as green

hydrogen (made from renewable electric ity). The researchers analysed thousands of transition cost scenarios produced by major energy models, and used data on 45 years of solar energy costs, 37 years of wind energy costs and 25 years for bat tery storage. They found the real cost of solar energy dropped twice as fast as the most ambitious projections in these models, revealing, over the last 20 years, previous models badly overestimated the future costs of key clean energy technol ogies versus reality. The research is a col laboration between the Institute for New Economic Thinking at the Oxford Martin School, the Oxford Martin Programme on the Post-Carbon Transition and the Smith School of Enterprise & Environ ment at the University of Oxford, and SoDa Labs at Monash University.

IMPORTING CITRUS FRUITS INTO THE EU: COLD TREATMENT IS NOW MANDATORY

As of 24 June 2022, precooling at origin and a cold treatment in transit are mandatory for citrus fruits imported from non-EU countries

The European Union has adopted stricter import regulations for citrus fruits in order to limit the entry of the False Codling Moth (FCM, Thaumatotibia leucotreta), a crop pest. As of June 24, the new regulations state that all imports departing from coun tries affected by False Codling Moth must have the new phytosanitary certificate indi cating that their oranges have been grown in an authorised place. The regulations require precooling to 5°C at origin and cold treatment in transit at -1°C to 2°C degrees for 25 days. From 2023 onwards, export ers will have two options: either cold treat

by IIFIIRment between -1°C and 0°C for 16 days or between -1°C and 2 °C for 20 days. In both cases, the operators will be required to pre-cool at 0°C and 2°C, respectively. According to FAO data, South Africa and Spain are the two largest exporters of cit rus fruit globally. As the largest exporter of citrus to the EU market in 2021-2022, the South African citrus industry had severely opposed this new legislation. On the other hand, the Spanish citrus industry wel comes the new regulation which appears to be in line with scientific studies, as dis cussed in a previous news item.

“HELIOS”, THE NEW GAS COOLER POWERED BY SOLAR ENERGY

In recent years, the problems arising from global warming have steadily increased attention paid to environmentally friendly solutions and products. LU-VE Group, which has always pursued sustainable models, has invested resources in innovations that can reduce direct and indirect emissions into the environment of all its products. In the refrig eration industry, the use of CO2 as a nat ural refrigerant has increased considerably in recent years as an alternative solution to traditional high GWP refrigerants.

Although it is not impactful in terms of emissions, the use of CO2 as a refriger ant is not always recommended, in fact efficiency and consumption vary depend ing on the geographical areas, turning out to be less economical especially in those areas with medium/high temperatures. For this reason, LU-VE Group has always pioneered the search for new solutions and possibilities to use this noble fluid, obtaining over the years excellent results:

• EUROVENT certification of CO 2 heat exchangers (already obtained for unit coolers, in progress for gas coolers) which guarantees the declared perfor mance avoiding surprises in the electricity bill and unexpected emissions;

• The use of adiabatic systems such as EMERITUS® to improve the performance of gas coolers, a component that determines the consumption of the entire system;

• The use of EC motors with Whisperer ® silencers capable of reducing electricity consumption especially during the regulation phase;

• Optimized heat exchangers.

Evolution brings with it continuous advancement and today we are proud to be able to take a new step forward. Thanks to the historic collab oration between LU-VE Group and Politecnico di Milano with the support of the Laboratory of Energy Conversion and Storage (LabX), it was possible to create the “Helios” project, which will be presented next October at Chillventa, aiming to be an innovation in the field of “green” technol ogies and to trace a path towards a more sustainable world.

Helios is the synthesis of a combination made up of a CO2 gas cooler with low RPM EC fans, integrated photovoltaic panels and inverters. It also has a storage system for the energy captured by the panels.

The photovoltaic panels can generate suf ficient energy to operate the EC fans. Sim ulation software makes it possible to quan tify the energy yield and savings in different geographical areas.

Tests conducted in the laboratory and on a pilot plant installed at the Politecnico di Milano have shown how Helios allows energy consumption to be reduced by more than 50% compared to a gas cooler with the same characteristics, but powered exclu sively by the mains electricity grid.

The use of CO2 as a refrigerant (low GWP) also allows the machine to operate with a reduced environmental impact. This, com bined with solar energy power, gives life to a unique gas cooler in terms of energy savings and emission levels. ■

HELIOS IS THE SYNTHESIS OF A COMBINATION MADE UP OF A CO2 GAS COOLER WITH LOW RPM EC FANS, INTEGRATED PHOTOVOLTAIC PANELS AND INVERTERS. IT ALSO HAS A STORAGE SYSTEM FOR THE ENERGY CAPTURED BY THE PANELS

ENERGY EFFICIENCY AND PERFORMANCE SIDE BY SIDE WITH REFRIGERATION ENGINEERS

ADVANCED REFRIGERATION SYSTEMS

These are the technologies the Company will feature at Chillventa 2022:

• chiller for process fluids, with remote control as standard;

• evaporative condensers, with electronically controlled fans for energy optimisation;

• adiabatic subcoolers, to increase the performance of refrigeration units or CO 2 systems

These are three types of solutions for different uses, but always scalable via optimisation software and with a partner at your side

REFRIGERATION, COOLING AND SUBCOOLING UNITS

Refrigeration consultants are always tasked with integrating energy savings and performance. Further dynamics to be managed should not be forgot ten: on the one hand, the rise in global temperatures, on the other the need for “green” refrigerants (with reduced GWP). How can these needs be met? MITA Cooling Technologies proposes the selection of technology, specific to the individual project, following an anal ysis of consumptions, plant requirements and expected ROI via the MITA Cooling Simulator calculation software. In addition to a full range of cooling technologies to choose from.

The Company will therefore bring three solutions for industrial and com mercial refrigeration to Chillventa.

Among these, the Frigofluid (a MITA Group company) brand chiller can operate in free-cooling, thus enabling energy savings of up to 80% with respect to devices without this operating mode, depending on the time of year and the installation site. MCE-EC is an extremely silent evaporative condenser with centrifugal fans: it is also suitable for indoor installations and in case of limited space. The electronically controlled motor-fan units enable to modulate power at different times and periods of the year. The Alchemist subcooler instead falls within the field of CO 2 systems, a natural and eco-sustainable refrigerant. Alchemist is a plug-play, integrable solution, patented by MITA Cooling Technologies. This technology, placed downstream of the gas cooler, increases the “useful effect” of the refrig eration circuit by sub-cooling the circulating refrigerant fluid.

SUPPORTING THE ENGINEERS

MITA Cooling Technologies has built its 60-year history around the goal of being at the customer’s side throughout the project, with more than 30,000 pieces of equipment installed worldwide. A goal strengthened by the engineering firms: MITA consultants can rep resent for them a unique contact, providing support throughout all project stages: solution selection, assistance during installation, operator training. Nevertheless, the use of advanced calculation software makes the selection as objective as possible according to the project parameters provided. Furthermore, the company has already made some of its leading products available on a BIM database. The purpose is obviously to provide a digital representation of the physical and functional features of the product, designed to be integrated with the drawings of the system in which it will be inserted. ■

MITA AT CHILLVENTA AND

MITA COOLING TECHNOLOGIES BRINGS ITS RANGE OF CHILLERS, CONDENSERS AND SUBCOOLERS TO CHILLVENTA AND A CALCULATION SOFTWARE FOR AN “OBJECTIVE” CHOICE OF THE BEST SOLUTION FOR EACH INDIVIDUAL SYSTEM

WATER COOLED CHILLERS with “double screw” compressors

Established in 1987 by a group of expert engi neers, ACM is a professional industrial refriger ation company based in Italy and specialized in designing, production and sales of commercial air-conditioning systems. Our focus on quality and liability has earned us the recognition of Italian and European enterprises as a reliable refrigeration company manufacturing air-con ditioners, industrial chillers, roof-top units and all types of process cooling systems. ACM is proud to present its latest range of water cooled chillers LCWT R1234ze equipped with screw compressors. This model is fully compliant with the ERP 2021 regulations. Chillers have a frame made of strong welded steel frame protected with polyester powder painting, for internal installation. They are equipped with semi-hermetic «double screw» compressors with a built-in thermal switch protection motor complete with: suction (option) and discharge shut-off valves, oil separator, step control, crankcase heater, oil level switch (option), oil sight glass, safety

thermostat, oil strainer, suction strainer, liquid injection device (option), vibration dampers. Other features are:

• Shell and tube evaporator, made by copper tubes and carbon steel shell and with one or two independent refrigerant circuits and one water circuit. The thermal insulation is made of flexible closed-cells lining. Differential pressure switch will stop the unit in case there is no water cir culation.

• One or two shell and tube condenser, made by copper tubes and carbon steel shell.

• One or two independent refrigerant circuits; each one includes: filter dryer, refrigerant sight glass, electronic expansion valve, discharge compressor and liquid line shut-off valve, ser vice valve, HP/LP gauges. Following devices are installed to protect the refrigerant circuit: automatic reset low pressure switch, manual reset high pressure switches, safety valve, antifreeze thermostat.

www.acmonline.it

EXPANSION OF THE ECOLINE CO2 SERIES for applications with higher performance

Since 2003, BITZER, a specialist in refrigera tion, air conditioning and heat pump technology, has sold more than 260,000 CO2 compressors, mainly for commercial refrigeration systems and with a rapidly growing trend. Demand is also increasing for the transport and heat pump sec tor, as well as for smaller industrial applications. The new 8 cylinder CO2 reciprocating compres sors for transcritical CO 2 applications enrich the ECOLINE CO 2 series for even larger per formance ranges with CO2 in refrigeration and heat pump applications. BITZER has developed the new 8-cylinder CO2 compressors with deliv ery volumes between 69.4 and 99.2 m3 /h. With the mechanical power control VARISTEP, they

offer a stepped power adjustment of 50, 75 and 100%. The energy efficiency of the new compressors is around 10 percent above the market average. In combination with a good performance gradation, this reduces operat ing costs. The compressors are also charac terized by optimized operating properties such as low gas pulsations and vibrations as well as low starting currents and are optimized for frequency converter operation. Due to the opti mized internal gas flow, the internal pressure drop is minimized and the oil transfer rate is low. The compressors are easy to install, inte grate, operate and maintain thanks to the IQ module. www.bitzer.de

PERSISTENT EFFICIENCY: the role of services in ensuring that a great project lasts a lifetime

Life cycle analysis of an HVAC system shows that correct commissioning and regular main tenance is more cost effective in the medium term than the alternative of non-optimal per formance, extended downtime, occasional repairs and, in the worst-case scenario, the need to replace the product with a new one earlier than expected.

The services of extended warranty, the mainte nance contracts and genuine spare parts that CAREL offers for its humidifiers can be consid ered complementary to each other, and are in fact designed to guarantee optimal operating conditions throughout the product’s life cycle. In this way, unit performance remains constant over time, and any unexpected costs, both direct and indirect, are limited and managed wherever possible. A fundamental role in ensuring control and optimisation of energy con sumption remains sustainable over time is played by the digital systems

used to support both occupants and mainte nance technicians in the optimal management of buildings. Modern data mining and machine learning techniques now make it possible to aggregate the data collected and conse quently provide effective analysis of system performance. This makes it possible to high light any deviations from optimal performance and focus the work of experts on the cases that are actually critical. CAREL’s digital ser vices as mobile APP as APPLICA for main tainer and CONTROLLA for the owner of the systems, as well as cloud portals DigitalHUM and RED for asset and plant management, make interaction with the system simple and intuitive, giving each user only the information they need to achieve the system’s control and energy efficiency objectives.

www.carel.com

BITZERNEW VRF SERIES of outdoor and indoor units

Clivet presents a preview of the 2023 VRF

CVT8 range characterised by:

• wide operating range: from -15°C to +55°C in cooling mode, essential in technical rooms with electrical equipment, and from -30° to +30°C in heating mode;

• compact design and even longer refriger ant line lengths to adapt to different system requirements;

• silent operation;

• intelligent control via app;

• flexible and efficient installation thanks to automated procedures.

The outdoor units ensure high savings and reli ability: environmental variables can be accu rately controlled for maximum performance and minimum consumption (3W) in standby.

Installation is flexible and simplified, as is maintenance. The use of Mild Air Technology improves wellbeing and air purity, while the new EasyCom, an advanced two-wire self-powered and independent communication & control bus for indoor units, ensures fast communication and is extremely resistant to electromagnetic interference.

The capacity of the single VRF system extends up to 90 kW (single module) and 270 kW (in com bination), operation is thoroughly controlled by 19 sensors distributed throughout the cooling circuit and the box, where the electronic boards are housed, is completely insulated from dust and water splashes. The range of outdoor units is completed by Mini VRF units with R32 gas from 8 to 18 kW and R410 gas from 8 to 67 kW, combinable up to 3 modules (200 kW) and with ductable air expulsion (80Pa), with a wide oper ating range from -15°C to +55°C in cooling and -30° to +30°C in heating.

The 13 series of indoor units with power ratings from 1.5 to 56 kW ensures excellent control, accurate filtering, maximum air purification with a capacity rate of up to 200%.Main strengths:

• advanced control;

• health & comfort thanks to silent units, equipped with optional excellent filtration (Plasma, HEPA filters) and air flow direction adjustment;

• energy saving thanks to sensors and full DC fans;

• simplified and fast installation.

www.clivet.com

HVACR SOLUTIONS ready for connectivity

Eliwell is returning to Chill venta to introduce the latest and increasingly efficient, sus tainable and connected HVACR solutions, and to launch a pre view of the innovative solutions that will be taking centre stage in 2023.

Secure Interface, the connected HVAC from Field to Cloud

Having connected machines and devices available is now also a must-have in the HVAC sector. For this reason, Schnei der Electric has developed Secure Interface, an extremely compact Linux embedded PC (72 x 110 x 60 mm) to enable IoT connec tivity efficiently, intuitively and competitively, allowing communication with connected devices, whether they are our own or from a third party. Secure Interface can connect to any device fitted with a Modbus bus over RS485, collect data from them and convey it to the Cloud, where specific appli cations analyse the data and enable predictive maintenance. As it is a programmable unit, it is very easy to develop any Modbus driver in order to communicate with every type of compatible device.

DOMINO ZERO, now more compact, flexible, and easier to use in conjunction with third-party valves

The latest upgrades to the DOMINO ZERO solution – for electronically controlling a refrigeration system running on either nat ural (CO2) or synthetic refrigerants – have made it more compact, open to the use of third-party valves, scalable due to its modularity, and capable of offering more stable control.

EWCM is the DOMINO ZERO component used for rack con trol. Recently improvements have been made to this controller, which is now capable of work ing with a number of third-party valves, giving the manufacturer the utmost freedom of choice. Plus, the space occupied by the new EVEVD drivers for EWCM 9000 PRO-HF and by the two backup modules has been halved, with a 50% space sav ing in the electrical panel solely in terms of the drivers, leading to a solution which overall is 35% more compact than the products currently available on the market.

Certification update for NSD mini pressure switches

The Eliwell NSD range of electromechanical pressure switches with fixed setting, designed to protect refrigeration systems, has recently undergone a certification upgrading process to make NSD products suitable for new and future applications. In recent months Eliwell has actually conducted a series of technical tests which have made it possible to certify that the fixed-setting NSD range can work with more demanding temperature and pressure values than in the past, thereby opening up to more environmen tally conscious applications using low GWP refrigerants.

2023 Previews

Eliwell is still moving forward in order to improve the user experience for its products and, to achieve this, is working towards a new TelevisGo user interface, which will be introduced to the market in 2023. The com pany is also continuing its innovative connectivity journey: next year will see the introduction of technologies capable of working with Wi-Fi and Bluetooth alike.

www.eliwell.com

ELIWELLEND-FEED FITTINGS

Fra.Bo and Rubinetterie Bresciane S.p.A , both part of Bonomi Group, during Chillventa 2022 Trade Fair will exhibitBooth 5/136 - a wide range of Made in Italy fittings specifically designed to meet the needs of its industrial partners. Especially FRABO G-SIZE and FRABO 5000 endfeed fittings are made of copper Cu-DHP (CW024A) and manufactured according to the production know-how developed and optimized by the Company for more than 50 years. FRABO G-SIZE solutions are perfect for industrial refrigeration plants, compressed-air systems and high-pres sure technical gas distribution systems.

In this fields of application, the static or dynamic stresses commonly asso ciated with the standard operating conditions may substantially reduce the lifespan of the component with a direct and immediate impact on the installation durability and reliability. FRABO G-SIZE line features an increased wall-thickness, produced in a wide range of diameters, and designed to properly address the technical issues our partners face on a

daily basis. The wide range already avail able can be further expanded whenever specific needs or requests arise from the customer. FRABO G-SIZE Cu-DHP cop per solder fitting series is available in a dimensional range between 22 and 133 mm and compliant with UNI EN 1254-1 European standard. These products are designed and produced to realize sol dered joints able to handle high working pressures and heavy mechanical stress (the application is difficult to manage by using traditional fittings and they require high-quality products and reliability).

The key benefits of these products are: resistance to high operating pres sures, high vibration resistance, resistance to heavy mechanical stress and increased wall thickness.

Fra.Bo is a perfect technical partner for the development of tailor-designed solutions in the framework of all the applications covered by the Pressure Equipment Directive 2014/68/UE (PED). www.frabo.com

AIR-SOURCE CHILLERS AND REVERSIBLE HEAT PUMPS for outdoor installation

MECH-iS-G07 and MEHP-iS-G07 are the new lines of Mitsubishi Electric chillers and heat pumps that represent exponential advances in technology and attention to detail. Suited to a range of applications, from ambient comfort to industrial and IT cooling, MECH-iS-G07 and MEHP-iS-G07 pack top levels of energy efficiency into an extremely compact foot print. With 7 new sizes in 3 modules and thermal loads of up to 110 kW, MECH-iS-G07 and MEHPiS-G07 can be extended up to 220 kW through an optional twin-module configuration, which connects two modules of the same size. The core of the sys tem is the W3000+ software, available in both stan dard and touchscreen versions.

MECH-iS-G07 and MEHP-iS-G07 achieve the highest standards of quality thanks to the Japanese design philosophy known as poka-yoke, a technique that aims to prevent errors in assembly and make

OLIMPIA SPLENDID

maintenance as simple as possible. MECH-iS-G07 and MEHP-iS-G07 provide impeccable levels of performance, especially under partial load, which helps to significantly reduce energy consumption. Their noise-insulated exteriors, which are standard on both the compressors and the hydronic kits, mean that these two new products are among the quietest on the market without the need for addons. Their reduced footprint also minimizes space needs during both transport and installation. A focus on the environment is at the heart of the Mitsubishi Electric philosophy, and this is embodied in both MECH-iS-G07 and MEHP-iS-G07 as well. These two new models use R32, a low global-warming potential (GWP) refrigerant, making them the preferred choice for installations that look to a more sustainable future.

www.mitsubishielectric.com

HIGH EFFICIENCY MULTI-PURPOSE SPLIT HEAT PUMPS

Sherpa Aquadue is Olimpia Splendid’s range of multi-purpose split heat pumps for residential buildings that stand out for their superior energy efficiency class (up to A+++ in heating mode – average climate conditions) and their patented double refrigeration circuit, which significantly improves both comfort and efficiency.

Sherpa Aquadue provides cooling in summer, heating in winter and DHW simultaneously, which not only means that indoor comfort is ensured all year round, but also that energy can be recovered during the cooling stage in the summer months, thus improving the efficiency of the whole system. In addition to that, Sherpa Aquadue heats DHW up to a temperature of 75°C without the need to use electrical resistors or supplementary power units (such as boilers or solar thermal systems). The possibility of storing DHW at a high temperature, in turn, allows to avoid

Legionella disinfection cycles (and the resulting peaks in energy consumption) and to reduce by 30% the size of the tank (without reducing DHW supply). It is also noteworthy to underline that the potential of this technology may be even greater if combined with a photovoltaic system: all Sherpa Aquadue heat pumps are equipped with a contact that allows to increase the self-consumption of PV electricity, storing the over-produced energy and reducing the amount of energy to purchase from the grid, even when solar radiation is zero.

Olimpia Splendid’s multi-purpose split heat pumps are available in the tower version – with integrated 150-litre tank – and in the suspended version. Thanks to a special kit, the latter can be installed in several, flexible ways: from built-in to semi built-in, both indoors and outdoors.

www.olimpiasplendid.it

MITSUBISHI ELECTRIC

MITSUBISHI ELECTRIC