SEKISUI CHEMICAL GROUP : Enhancing Lives, Preserving the Planet.

Railway 200: the steam locomotive

The railway community is celebrating the 200th anniversary of the modern railway. Rail Engineer digs into its history.

Electrified freight with Class 99s

Almost all freight trains in Europe are electrically hauled, in contrast to just 2.8% in Great Britain. David Shirres reports.

16|

Aurora: a new dawn for the East Midlands

Peter Stanton meets EMR’s Rachel Turner, to discuss major rolling stock changes planned for the Midland Main Line.

Poor ride - a cure for hunting?

Hunting is one of the causes of poor ride on some fleets. But what can be done about it?

Ashington and Blyth get their trains back

These North-Eastern communities have been without a train service for 60 years. Rail Engineer covers its reinstatement.

KeTech: bridging data silos to improve journeys

Rail Engineer caught up with Paul Warren and Graham Cooke to discuss KeTech’s Universal Information System.

Euston: a personal perspective

Much has been written about the inadequacies of Euston station. So why the present controversy? And is it justified?

Siemens Mobility: revolutionising main line, light rail, and metro networks management

Siemens Mobility’s DSPM improves performance and reduces costs for main line railways and light rail systems.

Levelling up electrification efforts

Gripple is making waves with innovations designed to enhance efficiency, improve safety, and reduce costs around electrifications.

Controlling the electrified railway

Clive Kessell investigates how the electrified railway is controlled to ensure safe operation and isolation for maintenance.

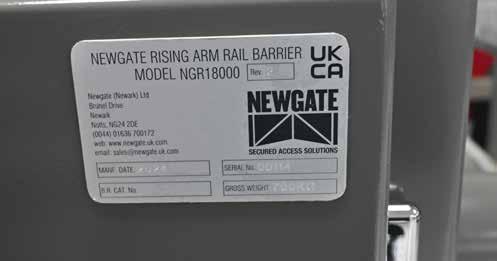

A new approach for level crossings

Unipart, AtkinsRéalis, and Newgate have embarked on a new initiative for the off-site construction and testing of level crossings.

Christmas & New Year works 2024/25

Significant works were delivered during the festive season. We present a snapshot of this substantial and varied programme.

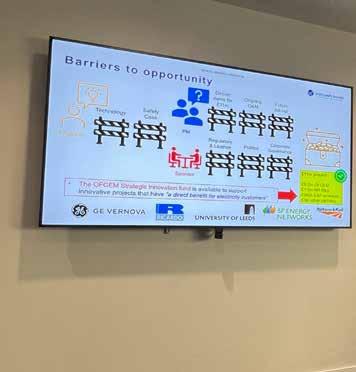

SigEx 2024: control, command, and signalling

RIA’s SigEx event attracted over 250 professionals with its impressive line-up of speakers and exciting exhibition stands.

Signalling: the carbon challenge

A recent talk given to the IRSE shone a spotlight on the less obvious polluters of the rail network.

Young Engineers and Apprentices Railway Seminar 2024

Connecting Regions by Rail was the theme of this IMechE seminar held in November 2024. Malcolm Dobell covered the event.

RIA’s Unlocking Innovation goes large

This December 2024 event saw RIA partner with Network Rail for an ‘Engineering and Climate Action Conference’.

Killing investment

As we celebrate Rail’s 200th anniversary, Michael Byng reflects on the postponement and cancellation of much-awaited major projects.

DAVID SHIRRES

DAVID SHIRRES RAIL ENGINEER EDITOR

This year, we celebrate the 200th anniversary of the first practical steam-powered public railway. The 7% of GDP spent building early railways was a worthwhile investment as it gave a profound economic benefit by drastically reducing the time and cost of transportation. Cardiff coal shipments, for example, increased twentyfold between 1840 and 1874. Railways also facilitated dramatic growth of our cities by their cheap transportation of food, people, and building materials.

Thus, the steam engine was a truly transformative invention and in a special Railway 200 feature we describe its early development. However, its use required

rails which could support its weight. Hence, the Stockton and Darlington Railway (S&DR)’s use of wrought iron rails was, arguably, a more significant innovation than its steam locomotive. From the start, railways had to be a well-engineered system.

For over a hundred years, rail was the only way to carry significant passenger and freight traffic over land. Although roads now account for 90% of all passenger kilometres, rail can best move large numbers into city centres and offers the fast journeys between city centres. Outside the UK, high speed rail lines have transformed local economies. As a 2012 Government White Paper noted, without high-speed rail Britain loses out while our global competitors gain.

The physics that enabled the 12-horsepower Locomotion No. 1 to haul 79 tons on its inaugural S&DR journey also enables a modern freight train to replace 76 heavy goods vehicles, and passenger trains to provide energy efficient high-speed travel. Between London and Glasgow, the energy used per seat by a plane is 37 times more than a Class 390 Pendolino train. Electric cars use 3.4 times the amount of energy per seat on this journey.

It is to be hoped that Railway 200 can be used to promote a greater understanding of how and why railways, especially when electrified, are engineered to be highly efficient and so consume far less energy than other modes of transport.

Lifting passengers seven miles into the air and propelling them at 500mph uses huge amounts of energy. Hence decarbonising aviation is almost certainly an impossible challenge. Storing the energy of the six tonnes of jet fuel used between London and Glasgow would require a battery weighing 200 tonnes. Hence the Jet-Zero campaign pins its hopes on sustainable aviation fuels (SAF). Yet, a Royal Society report concludes that the production of sustainable biofuels to replace the UK’s aviation jet fuel consumption would require over half the country’s agricultural land.

In its net zero report, the Committee for Climate Change (CCC) also considers that SAF produced from biomass or waste oil would be a scarce resource and that SAF made from green hydrogen would be very costly. This report also states that Government “will also need to set out an approach to limiting growth in aviation demand” which could include modal shift to high-speed rail.

The decision to build Heathrow’s third runway did not heed this advice. Instead, it was stated that “we are already making great strides in transitioning to cleaner and greener aviation.” It is difficult to reconcile this statement with aviation’s high energy consumption and the realities of SAF.

It seems that the CCC’s suggested option of encourage modal shift from aviation to high-speed rail was also not considered as it is looking increasing unlikely that HS2 will be extended to Crewe. Yet the report prepared for the Mayors of Birmingham and Manchester indicates this will generate a higher GDP growth than the 0.43% forecast for Heathrow third runway. Furthermore, as it already has Parliamentary powers (which expire in February 2026), this line could be built relatively quickly.

Clive Kessell considers the history of Euston station and its proposed six-platform HS2 station that will permanently constrain HS2 services unless there is provision for future additional platforms. We also report on the opening of the Northumberland line, which will no doubt bring benefits far greater than its £298 million cost to the local community, though in 2021 its estimated cost was £166 million.

It is widely recognised that high costs are killing investment. Michael Byng explains why from his perspective as a quantity surveyor. Please email hello@rail-media.com with your views on this feature.

High electrification costs are one reason for the lack of freight infill electrification which led to the development of the Class 99 bi-mode locomotive. As we describe, this

is an impressive machine. Peter Stanton also considers the introduction of new rolling stock and the associated challenges. He describes the Hitatchi-built Class 810 units, known as ‘Aurora,’ which are expected to carry passengers on East Midlands Railway later this year.

The interaction between trains and track is a complex issue as shown by Malcolm Dobell’s feature on hunting. In this, he describes how this can be caused by a tiny amount of wheel wear and how new ontrain technology offers a solution.

The Railway Industry Association’s (RIA) Unlocking Innovation (UI) events are always worthwhile. RIA’s recent Glasgow UI event was combined with Network Rail Scotland’s engineering conference and so was particularly valuable, particularly the contributions from younger engineers. We also have features describing innovative station management and electrical control technologies.

Another recent RIA event was SigEx, its Control, Command and Signalling (CCS) exhibition and conference. As Paul Darlington reports this was another large event with numerous exhibitors and speakers from different railways which included Network Rail, Northern Ireland’s Translink, as well as the Tyne and Wear Metro.

Another signalling feature considers embodied carbon in the Transport for London’s Four Lines Modernisation project. We also describe the LX PLUS level crossing system that can be designed, manufactured, assembled and tested off-site.

The ‘Connecting Regions by Rail’ conference organised by the IMechE Railway Division’s Young Members’ Board gave young engineers opportunities to learn about engineering issues and see work done at depots and workshops. This took place in Cardiff and featured presentations on High Speed 2, MerseyTravel, Transport for Wales, Transport for London, and the GWR Fast Charge battery train trial. Its organisers are to be commended for organising an event for young engineers, who are the industry’s future.

Between 20 December and 2 January, work valued at £142.3 million was delivered within 2,178 network-wide possessions of which 12 (0.6%) overran to cause train delays. Almost all this work was done safely with three reported accidents, one of which was a lost time accident. We describe the wide variety of work done, much of which was done in wet, windy, cold weather. We should be grateful to those who work on rail infrastructure in all weathers, especially at Christmas.

Editor David Shirres editor@railengineer.co.uk

Production Editor Matt Atkins matt@rail-media.com

Production and design

Lauren Palin lauren@rail-media.com

Adam O’Connor adam@rail-media.com

Engineering writers

bob.hazell@railengineer.co.uk

bob.wright@railengineer.co.uk clive.kessell@railengineer.co.uk

david.fenner@railengineer.co.uk

graeme.bickerdike@railengineer.co.uk malcolm.dobell@railengineer.co.uk mark.phillips@railengineer.co.uk paul.darlington@railengineer.co.uk peter.stanton@railengineer.co.uk

Advertising

Asif Ahmed asif@rail-media.com

Craig Smith craig@rail-media.com

Rail Engineer

Rail Media House, Samson Road, Coalville Leicestershire, LE67 3FP, UK. Switchboard: 01530 816 444 Website: www.railengineer.co.uk

Rail Engineer Videos http://rail.media/REYouTube

Editorial copy to Email: news@rail-media.com

Free controlled circulation Email: subscribe@rail-media.com

The small print

Rail Engineer is published by RailStaff Publications Limited and printed by PCP Ltd.

© All rights reserved. No part of this magazine may be reproduced in any form without the prior written permission of the copyright owners.

Part of:

www.rail-media.com

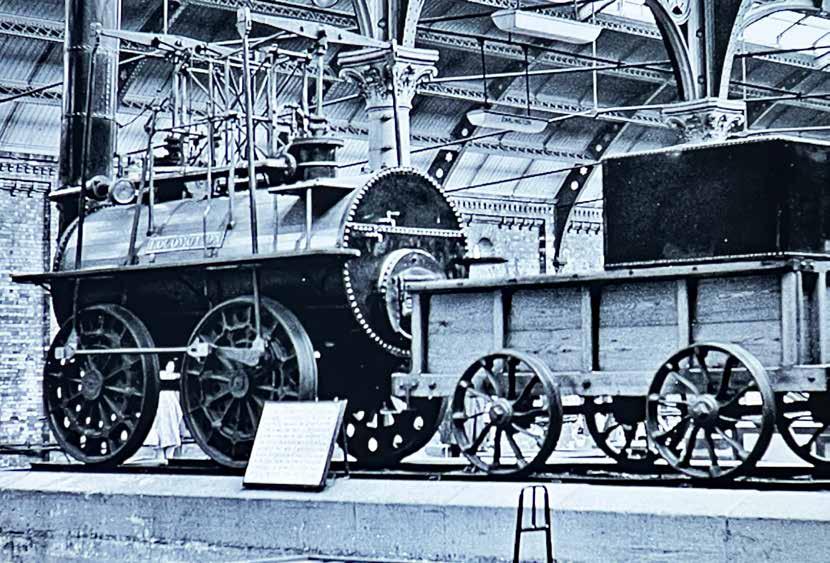

This year, the railway community celebrates the 200th anniversary of what is said to be the birth of the modern railway. On 27 September 1825, George Stephenson’s ‘Locomotion No. 1’ set off on its inaugural journey from Shildon to Stockton to open the 26-mile Stockton and Darlington Railway (S&DR). This was the first practical public railway to carry both freight and passengers.

Yet both railways and steam-powered locomotives existed long before the S&DR’s opening. Between 1801 and 1825, 16 railways authorised by acts of Parliament were built. In 1801, the eight-mile Surrey Iron railway between Wandsworth and Croydon became the first horse-drawn public railway for independent goods hauliers. The Swansea and Oystermouth railway operated horse drawn carriages in 1807 to become the first farepaying passenger railway.

Some of these early railways did try the use of steam locomotives. In 1812, a steam powered rack railway locomotive operated on Middleton Railway. A steam locomotive also operated on the Kilmarnock and Troon Railway (K&TR) in 1817. However, its weight caused frequent broken rails. A local entrepreneur operated a passenger service with empty coal wagons to carry passengers from Kilmarnock to the coast at Troon. To do so he paid the railway a toll based on tonnage of passengers carried.

Prior to the railways, canals were the only way to carry goods in bulk. The first canal opened in 1757. By 1840, there were over 4,000 miles of canals on which horses could haul 50-ton loads compared with just over half a ton over an unmade road. At slow speeds canals offered less resistance to motion than railways on which a horse could only haul eight tons. However, canals could not compete with the speed and capacity of even the early steam-hauled railways which offered a huge increase in connectivity and turbo-charged the industrial revolution. Thus, the steam locomotive can be said to be one of the world’s most transformational inventions. As part of Rail Engineer’s contribution to Railway 200, this article describes the development of the early steam locomotives. Yet, as the K&TR’s broken rails showed, railways are a system. Hence future Railway 200 articles will describe the development of the track and other aspects of the early railway.

The credit for the first steam engine to produce thrust from a piston in a cylinder goes to French physicist, Denis Papin. Between 1690 and 1707 he built various steam engines but did not develop them commercially. In 1698, military engineer Thomas Savery patented a pistonless steam pump that used the vacuum created when steam condensed in a vessel to raise water under atmospheric pressure. This meant that the pump could be no more than 30 feet above the water level.

The first practical steam-driven pump was produced by an Exeter ironmonger, Thomas Newcomen, and thought to have been first used in 1712 at a coal mine in Dudley. Newcomen engines were also installed at the Byker colliery in Northumberland around 1718. These engines used steam with a pressure of less than one pound per square inch (psi) which could do no useful work.

They had a piston coupled to a pump rod via a rocking beam. The weight of the pump rods pulled down the beam and so lifted the piston allowing steam into the cylinder. At the top of the piston stroke, cold water was injected into the cylinder to condense the steam and create a vacuum that forced the piston down under atmospheric pressure and lift the pump rods.

The Newcomen engine had an efficiency of less than 1% as the cylinder had to be reheated after it had been cooled. Yet, these machines, which typically produced 10 horsepower, were the only way to drain deep mines. Furthermore, the supply of coal was not a problem at coal mines.

In 1769, James Watt patented condensing steam in a separate condenser to avoid reheating the cylinder. He filed a further patent in 1784 to give a steam engine rotary motion using a planet gear at the end of a connecting rod to drive a sun gear on a rotating shaft. Prior to that, reciprocating steam engines could only power pumps. However, to drive machinery their speed had to be controlled. For this, in 1788, Watt patented the conical pendulum steam governor.

Watt then doubled the cylinder’s power output by making it double acting. This required effective seals for piston rods moving through cylinder covers and a parallel motion for piston rods to move in straight lines. These arrangements were patented respectively in 1781 and 1782.

Increasing a steam engine’s power-to-weight ratio in this way made a steam powered vehicle feasible. However, Watt seems to have had no interest in this and was concerned about the practicability and safety of high-pressure steam. His business partnership with Matthew Boulton to produce static engines was a great success and, as shown below, in the early 1800s, there was no market for steam powered vehicles.

Richard Trevithick

The development of steam-powered vehicles was pioneered by Cornish mining engineer Richard Trevithick (1771 to 1833). However, he wasn’t the first to do so. For example, French military engineer Nicolas Cugnot produced an unsuccessful cumbersome large steam carriage in 1769 to haul cannons. Trevithick’s road vehicles, which used high-pressure steam, did achieve a measure of success. He also produced the first working railway steam locomotive.

By the late 1790s, boilers could safely contain steam at pressures of around 60 pounds per square inch (psi). Such ‘strong steam’ required cylinders of a much smaller diameter than the Watt engines which

operated at typically 2 psi. Furthermore, as they do not rely on atmospheric pressure, high-pressure engines can exhaust into the atmosphere without the need for a condenser. The resultant space and weight savings made possible the use of high-pressure steam engines for road and rail traction.

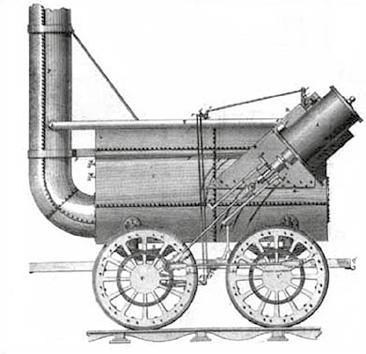

The boiler pressure of Trevithick’s first road vehicle, the Puffing Devil, was 60 psi. This had a single cylinder which exhausted into the chimney to cause a draught to draw the fire and heat the boiler feed water. In 1801, Puffing Devil successfully carried six passengers up an incline in Camborne, though the poor road surfaces of the time were problematic.

In 1803, Trevithick built another a steam road carriage which he drove between Holborn and Paddington. This was lighter than Puffing Devil and had larger wheels to accommodate the poor road surfaces. However, it was abandoned as it was more expensive to operate than a horse drawn carriage.

Trevithick then produced a locomotive for the Pen-y-Darren Ironworks at Merthyr Tydfil. This operated at 40 psi and had a cylinder diameter of 4.75

inches. It relied on wheel / rail adhesion to haul the train though its four wheels were coupled by cogwheels. In 1804, this hauled 10 tons of iron in five wagons for 10 miles from the ironworks to the Abercynom canal wharf to become

the world’s first recorded locomotivehauled train. However, its weight significantly damaged the railway and so it was consigned to a static role. His next locomotive, ‘Catch me who can’, weighed eight tons and ran on a circular track at an exhibition near Euston in 1808 at speeds of up to 15mph until the exhibition closed after a few weeks due to rails breaking under the locomotive. This was the first locomotive to haul fare-paying passengers.

While Trevithick demonstrated the potential for steam railway traction and achieved some notable world firsts, he did not profit from this and was made bankrupt in 1809. There was no market for his engines which were too heavy for the rail track of the time.

The 1757 Middleton Railway Act was the first Act authorising the construction of a railway. This was a two-mile wagonway between the Middleton coal mines and the River Aire’s coal wharves in Leeds. With the Napoleonic wars dramatically increasing the prices of horses and their feed, it was decided to use steam locomotives.

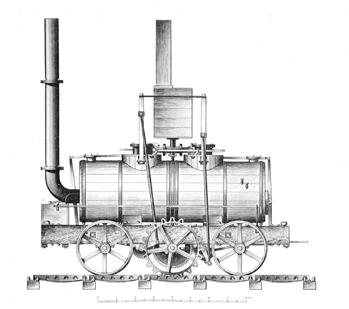

At the time it was felt that an engine light enough not to break the track would not have sufficient adhesion to haul a heavy load. Hence the locomotive’s driving wheel had a pinion gear that meshed with a toothed rail. This was designed by Matthew Murray of Leeds and was based on Trevithick’s ‘Catch me who can’ but had two cylinders and six wheels with pinions on their centre wheels. This five-ton locomotive was named Salamanca and successfully hauled its first train of eight wagons weighing a total of 26 tons on 24 June 1812. This was the world’s first rack railway and the world’s first commercially viable steam railway as Salamanca and three other engines replaced 50 horses. However, two of these locomotives suffered boiler explosions in 1818 and 1834.

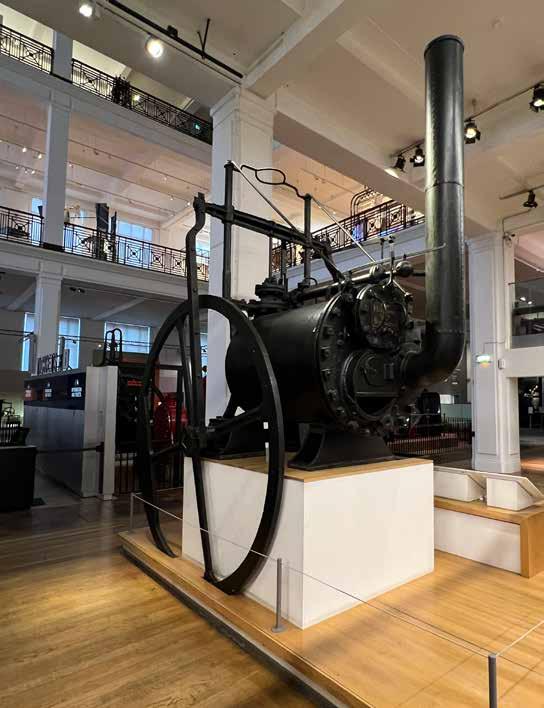

In 1812, William Hedley, a Wylam coal mine manager, undertook various experiments with carriages on the colliery’s cast iron plate rails to confirm that the friction between wheels and rails was sufficient to haul a heavy train. He also considered that locomotives would be less likely to slip if their driving wheels were connected. With the assistance of his blacksmith, Timothy Hackwork, in 1814 Hedley build the locomotive Puffing Billy. This had two vertical cylinders driving a single crankshaft between the frames from which gears drove and coupled the two driving axles by underframe gearwheels. However, these eight-ton locomotives were too heavy for cast iron plate rails and so were modified to have four axles. Puffing Billy is the world’s oldest surviving locomotive and is on display at the Science Museum.

The Middleton rack railway was symptomatic of a concern that the adhesion between wheels and rails was not sufficient to haul a heavy train. To solve this imagined problem various solutions were proposed including chain haulage and a locomotive with mechanical legs.

In the early 1810s, George Stephenson was the engine wright at Killingworth collieries, where he had invented a miner’s safety lamp. While there, he followed steam locomotive developments with interest. One of Murray’s Middleton locomotives had worked on Tyneside, and he was aware of the use of locomotives at his birthplace in Wylam.

After the Killingworth Colliery owners had agreed to his suggestion to use steam traction, in 1814 he built his first locomotive modelled on Murray’s locomotive. As Killington colliery had edge rails, this was the first successful flanged-wheel locomotive which could pull 30 tons up an incline of 1 in 450 at 4mph. In 1815, Stephenson patented an improved locomotive that used the steam exhaust to draw the fire.

While at Killingworth, Stephenson produced around 15 locomotives. While most of these for use at Killingworth or the Hetton colliery railway, they included the KT&R’s locomotive and one for a Swansea colliery.

He also considered the problem of heavy locomotives causing rail breaks. At the time, cast iron plate rails were the norm although, as at Killingworth, iron edge rails were being introduced. To improve the resilience of fishbellied edge rails Stephenson developed and patented a half lap joint.

To reduce the impact load on the rails, he unsuccessfully experimented with a steam spring that supported the locomotive frame by steam pressure acting on pistons.

In 1820, the owners of the new Hetton Colliery engaged Stephenson to build an eightmile railway from the colliery to the River Wear’s coal wharves in Sunderland. This was the first railway designed for mechanical haulage but used a combination of locomotives and five cable hauled inclines. From Hetton, the line climbed 200ft in three miles and then descended 500ft to the River Wear for five miles. This railway opened on 18 November 1822.

It was built using fish-bellied edge rails with Stephenson’s patented joints. More significantly, its gauge was Stephenson’s 4ft 8 ½ inch which was also that of the Killingworth wagonway and would eventually, thanks to Stephenson’s influence, become the standard gauge of railways throughout the world.

Robert Stephenson and Company

In 1821, Stephenson was appointed to plan the Stockton and Darlington Railway (SD&R) and tasked with building it in 1822. Edward Pease, its principal promoter shared Stephenson’s conviction that locomotives were the future and so they formed a partnership to manufacture them.

As a result, the world’s first locomotive manufacturing company, Robert Stephenson and Company (RS&Co) was founded in 1823 with a workshop at Forth Street, Newcastle. George’s son, Robert was made the managing partner. Initially, the company had orders for five static engines

and two steamboat engines. In September 1824, it received an order for two S&DR locomotives.

The first of these was the 6.5-ton Locomotion No 1 which, on 27 September 1825, hauled The SD&R’s inaugural train which had an estimated load of 79 tons. By 1826, RS&Co had produced three more S&DR locomotives: Hope, Black Diamond, and Diligence. Yet, other than their blast pipe and coupled wheels, these locomotives were similar to the locomotives produced by Trevithick and Murray. They also only had single flue boilers which wasted a lot of heat.

Thus, while George actively promoted the steam locomotive, several fundamental improvements were yet to be made. It was to be his son, Robert who would introduce further significant innovations. Rather than its locomotives, S&DR became a practical operational railway as its novel malleable wrought iron rails could withstand the weight of the line’s locomotives.

Robert Stephenson missed the S&DR’s opening as he had a three-

year contract with the Columbian Mining Association. He did not return to Newcastle until 1827 when his immediate priority was reviving the fortunes of RS&Co by improving its locomotive designs. In 1828, RS&Co supplied the Bolton and Leigh Railway with the Lancashire Witch. This had cylinders inclined at 45° which enabled its axles to be sprung, making it probably the first locomotive with steel springs. Another first was an expansion valve that used a plug valve to cut off steam admission halfway through the inlet valve stroke.

When the Liverpool and Manchester Railway (LM&R) was planned, it felt that cable haulage might be necessary as it was not known whether locomotives could haul trains up its steep gradients. To resolve this issue, the Rainhill trials were planned to take place in October 1829. The requirement was for a 20-ton load as the L&MR was to carry passengers as well as freight. After the trials, Rocket was successfully tested on a 1 in 96 incline. With the requirement to haul such a light load, success required a fast, light engine more efficient than any before it. The locomotive that RS&Co entered for the trial was the Rocket. Robert Stephenson is generally given credit for its design as George was in Liverpool at the time overseeing the L&MR’s construction. Rocket featured the innovations on the Lancashire Witch such as springs and wheels driven directly from inclined cylinders. To reduce weight, it only had two driven wheels. It also had a radically new type of boiler with 25 three-inch diameter tubes. These required tube-

plates at each end of the boiler and provided considerably more heating area than a single flue. This arrangement required a separate fire box which was formed of a double layer of copper plates, with water filling the space between them. These provided excellent conductivity and were shaped to provide a crown around the fire-grate to direct hot gases directly through the tubes and up the chimney below which the cylinder blast pipes drew the fire. This was maximised by experiments to optimise the blast pipe diameter. A rear back-plate had a door for the crew to feed coke to the grate. Coke was used as the LM&R’s Act required its locomotives to consume their own smoke.

As is well known, with such innovations, the 4.25-ton Rocket, hauling 13 tons at up to 28mph won the Rainhill trials to become, perhaps, the best-known steam locomotive. After Rocket, RS&Co continued to improve its designs to the extent that when the L&MR opened in 1830, a year after the trials, Rocket was an outdated locomotive. In November that year the RS&Co’s Planet locomotive ran the 30 miles between Liverpool and Manchester in an hour. This had cylinders below the boiler which drove the wheels through cranked axles. Thus, in just three years, RS&Co had transformed the design of cumbersome colliery locomotives into main line engines that had almost all the features of future steam locomotives. In 1842, the company perfected one more innovation, the Stephenson link valve gear which enables crews to vary cylinder steam admission by operating a lever on the footplate.

By 1899, RS&Co had built 3,000 locomotives at its Newcastle plant and in that year opened its Darlington works. The company eventually became part of English Electric in 1944.

While it is right to celebrate the opening of the SD&R in 1825, it should be recognised that this was but one of the early railway milestones that laid the foundations of today’s railways. Before then, significant firsts were achieved by railways at Middleton, Wylam, and Hetton and, after the SD&R, the opening of the Liverpool and Manchester Railway gave the world its first main-line railway. Although the Stephensons did much to develop early steam engines, the role of early pioneers such as Watt, Trevithick and Murray should not be forgotten. Indeed, it is fair to say that Trevithick was the inventor of the steam locomotive.

It is also important to appreciate that, from the start, successful locomotivepowered railways could only operate as a system. The early locomotives were not much more powerful than the horses that they replaced and were only able to use their power due to the low rolling resistance of their wheels on early railway tracks. Furthermore, they could only operate reliably if the rails could withstand the locomotive’s weight. Hence the novel wrought iron railways of the SD&R could be said to be the key innovation that made this railway a success.

Thus, the evolution of the early railways is a story that is both fascinating and has lessons for today.

As we reported in the last issue, the Innotrans rail trade fair in Berlin offers a great insight into railway operations outside the UK. At this fair, the only diesel-only freight locomotives on display were shunters as almost all freight trains are electrically hauled in Europe where it is recognised that electric freight trains offer many advantages. This includes them being more powerful and offering net-zero carbon traction.

In contrast, in Britain a mere 2.8% of rail freight traction energy consumption is from electricity. ORR figures show that in 2023/24 rail freight’s traction electricity consumption was 46 million kilowatt hours and its diesel consumption was 156 million litres of diesel (energy in a litre of diesel is 10.7 kWh).

Although a large amount of the main rail freight network is electrified, lines to the ports, freight terminals, and other key infill routes are not. For some time, the Rail Freight Group and others have lobbied for the electrification of such lines. In March 2023 the Chartered Institute of Logistics and Transport published a report calling for such infill electrification. Rail Partners has estimated that electrification of the 6km London Gateway has a cost benefit ratio of 4.7:1.

With no sign of such electrification being authorised, the rail freight business took it upon itself to find ways of increasing electrified rail freight by the introduction of bi-mode electric locomotives with diesel engines that can haul freight trains on unelectrified routes, albeit at low speeds.

The first to do so was Direct Rail Services which ordered 10 Class 88 Bo-Bo locomotives from Stadler which were introduced in 2017. Under the wires, these electric locomotives have a 4MW power output, off the wire, their diesel engines have 750kW of power.

Rail Operations UK then ordered 30 Class 93 tri-mode locomotives from Stadler. As described in issue 185 (July-August 2020), these are based on

the Class 88 but have a 900kW engine. When in diesel mode, their power output can be boosted by 400kW for short periods when accelerating by a Lithium Titanate Oxide battery. These locomotives are currently under test in the UK.

One of the highlights of last years’ Innotrans was the unveiling of the next UK electric bimode locomotive number 99002. Unlike its predecessors, this Class 99 Co-Co locomotive is a heavy machine that weighs 113 tonnes. This compares with the 86 tonnes for a Class 93. Yet, the Class 99 is not as heavy as the 130-tonne Class 66 diesel locomotive.

During the Class 99’s unveiling speeches, GB Railfreight (GBRF) CEO John Smith said that “the Class 99s are a game-changing moment for the UK rail freight industry. These locomotives offer our customers the chance to run faster, wholly sustainable, heavy-haul services across length and breadth of the country.”

Innotrans provided an opportunity to go inside the Class 99 locomotive to see how its engine and other equipment fits inside as shown by the photographs.

He considered that these locomotives were “the new Class 66” as they are envisioned as the replacement for diesel traction for many freight flows.

Speaking to Rail Engineer at Innotrans, Smith advised that typical freight haul using the West Coast Main Line (WCML) involves around 30 miles of non-electrified routes. As it is not operationally feasible to change locomotives, these freight trains are currently diesel hauled despite almost all their haul being under the wires.

In April 2022 Stadler, leasing company Beacon Rail and GBRF signed an agreement for the supply of 30 Class 99 bi-mode Co-Co locomotives that have a maximum speed of 120km/hr. This order includes spare parts and an option for a further 20 locomotives.

The Class 99 locomotives are being built at Stadler’s Valencia factory in Spain and are essentially a UK loading gauge version of the company’s EURODUAL locomotives, of which about 100 are in service in Europe.

In January, locomotive number 99001 left Spain for testing at the Velim test centre in the Czech Republic. No 99002 will join it there in February. After extensive testing the first Class 99 locomotives should arrive in the UK later this year and it is hoped they will be in service by the end of the year when, GBRF advises, its diesel engine will be fuelled solely by renewable fuels such as Hydrotreated Vegetable Oil (HVO).

Other than the ABB-labelled casing, there was little to see of the electric traction equipment that can deliver up to 6.17MW to provide a continuous tractive effort of 430kN. The traction system has one IGBT inverter per axle.

The diesel engine, its alternator and cooler group, which delivers 1.79 MW, took up much of the locomotive interior. The engine is a Cummins QSK50, 50 litre 16- cylinder 60° Vee engine which is turbocharged and aftercooled. It is EC26/2004 Stage V compliant. The alternator is provided by VEM Sachenwerk GmbH model DREBZ 4516-6. This can deliver up to 2,204kVA, 1,404V at 1,860 rpm.

Also visible inside were the traction motor cooling fans and the brake panel which has two pneumatic distributors which blend with the electrical brake which can either be rheostatic or regenerative.

The driving cab has a central desk with good visibility.

It has a screen which will provide an ETCS display. The Class 99 also has Stadler’s latest generation of vehicle control system and advanced remote diagnostics. It has front view, pantograph, and shunting cameras.

Outside could be seen the three-axle bogies with primary coil springs and rubber metal secondary suspension that provide high adhesion with low track forces. The underframe equipment includes a 3,000-litre diesel tank.

Throughout Europe, rail freight operators benefit from the highpowered electric freight trains.

As an example of such benefits, our feature on the Class 93 locomotive in issue 185 (Mar-Apr 2022) showed that the running time of a 1,500-tonne freight train between Felixstowe and Mossend, outside Glasgow, is 11 hours 9 minutes with a Class 66 locomotive and modelling shows that a Class 93 locomotive would reduce this to 8 hours 32 minutes.

A further example is that a Class 93 would enable a train to make two return trips each day between Thames Gateway and Corby. The Class 99 will offer similar benefits, albeit with heavier trains.

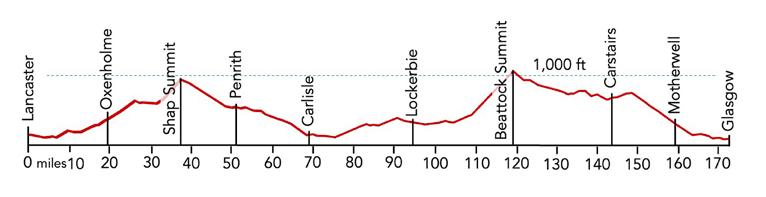

As shown below, on the core WCML route to Glasgow, freight trains have twice to climb around 1,000 feet up the steep banks of Shap and Beattock summits.

GBRF CEO John Smith advised Rail Engineer that a typical dieselhauled freight train will climb up to these summits at around 55km/h whereas the Class 99 is expected do this climb at 100km/h.

As these freight trains have to be timetabled around passenger trains that climb these summits at speeds over 160km/h, fully electrified freight services would also increase line capacity and so would also benefit passenger services.

Despite the benefits of electric traction, it has to be acknowledged that the cost of electricity has doubled in the last 10 years, while fuel duty has been frozen at 58p a litre since 2011, with a further cut to 53p a litre in 2022 which has yet to be lifted. However, GBRF’s substantial investment in its Class 99 fleet indicates it considers that, despite such fuel prices, electric traction still offers significant business benefits as well as a reduction in carbon emissions. It is to be hoped that the introduction of the Class 99 fleet will significantly increase the percentage of electrically-hauled freight trains. However, if there are to be increasing numbers of electric freight locomotives under the wires, the OLE power supply will need to be able to provide sufficient power for them.

To learn about the major rolling stock changes planned for the Midland Main Line, Rail Engineer was pleased to meet Rachel Turner, head of new trains at East Midlands Railway (EMR).

The Midland Railway Main Line from London St. Pancras to Nottingham, Sheffield, Derby, and Leicester has had a varied history of traction and rolling stock allocation. The move from steam traction led to an era of heavy diesel locomotives and British Railways-hauled carriages moving through to air-conditioned vehicles and electric train heating. The sectorisation of British Rail in the early 1980s brought the reallocation of high-speed trains to the route while the ‘Bedpan’ electrification scheme from London to Bedford introduced Class 317 electric multiple units under overhead lines to Bedford itself, only. Class 170 diesel multiple units made an appearance in the early 1990s, and eventually Meridian Class 222 units appeared in a mix with High-Speed Train sets. Plans were drawn up and design commenced for the electrification of the entire route and several assumptions were made for electric trains, either new or cascaded. With pauses to the electrification scheme influenced by short-term development questions, decisions were made to order diesel / electric hybrid multiple units. As electrification had proceeded to the branch to Corby Class 360, electric multiple units were cascaded to the line as an outer suburban service.

At the time of writing, the mainline overhead line installation stops short south of Leicester at Wigston and it may be assumed that there is no middle term strategy for electrification of the regular diversionary routes through Melton Mowbray, the Erewash Valley line, and the ‘Old Road’ from Chesterfield to Sheffield.

New dawn

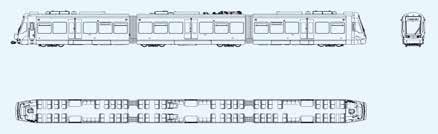

Thus came togther the specification for new electric bi-mode rolling stock for the route and this has begun construction, appearing as the Class 810 - the ‘New dawn’. The new trains comprise 33 five-car sets of Class 810 (known as ‘Aurora’) and are manufactured by Hitachi Rail at its facility in Newton Aycliffe. Finance is being dealt with by Rock Rail. The first units are planned to be delivered to EMR for the second quarter of 2025 with all being in place by the third quarter of 2026. Entry into service will be dependent upon the driver training programme. Although based on the AT300, Aurora is a substantially new product, specifically designed to EMR requirements. Those main requirements are the ability to cover the core routes of London St. Pancras to Nottingham, Derby, Sheffield (including via Corby & Melton Mowbray), and Lincoln, together with Sheffield to Leeds and York. Consideration will be given to covering short-term routes from Derby to Crewe and Nottingham to Skegness. Within the tentative consideration for capable routes are Oakham to Peterborough and other tertiary destinations.

The Class 810 is known by Hitachi as the AT300-SXR - the SXR stands for Shortened and Extended Range. The ‘S’ part has been particularly challenging. There is no less equipment on the 24-metre coaches of the Class 810 than those on a standard 26-metre AT300 Bi-Mode. In fact, there is one more generator unit and associated fuel tank per five-car and an additional toilet. Packaging that extra equipment into 10 metres less of underframe length per unit has been complex.

Compared to the existing long-distance Inter-City fleet, the new trains in diesel mode will bring significant benefits to the environmental impact with Euro5 engines producing reduced nitrous oxide and particulates, allowing improved air quality at stations, and carbon dioxide emissions reduction in diesel mode (66% with OCS to South Wigston). Noise reduction emerges as a positive contribution to the environment of the railway.

Customers will benefit from higherquality communications, allowing better passenger information system connectivity with improved Wi-Fi and mobile signals. Comfort will be enhanced by seats with improved legroom and luggage space, and added value will come from a train manager interface to those onboard passenger information systems. Passenger capacity will increase with 19% more seats than a Class 222 five-car, providing 46%

more seats to the fleet compared to Class 222 capacity. An accompanying bonus will be a larger overall fleet, with four more units than current numbers.

Operationally, a single-unit design simplifies interfaces at stations making diagramming simpler, while 10-car operation will support a significant capacity boost and flexibility. As indicated, there are key differences from the 80X fleets currently in service on the UK rail network but, where appropriate, many features are retained.

Still in place are an Automatic Selective Door Operation system with a GPS database, a power changeover system and the same driver’s and second person’s seats (though the driver seat is in slightly more centred position). Inter-car jumper arrangements are modified to give increased distances between ‘loops’, as per the modification made to other AT300 fleets as mitigation for train surfing. Regarding the body, the catering trolley interface is the same although the storage area is different due to the body end profile. Other similarities are exterior doors and the interior doors (with IR detection). However, there are significant differences from other fleets, and these can be identified by vehicle sub-group.

Despite the difference in length, the structure is recognisably similar to the Inter City Express Programme. Regarding the fatigue issues which occurred in the predecessor, the Class 810 has a different interface arrangement with no welds being used in the vulnerable areas. In terms of materials, the Class 810 uses 6000 series aluminium as against that used in the AT200/AT300 which used aluminium vulnerable to stress corrosion cracking.

There has been no shipment from Japan – all car bodies have been welded and painted in the UK at Newton Aycliffe. Structurally, Aurora uses a ‘roll cage’ cab design and there is no taper at gangway ends - the doors open ‘out ways’. Significantly, there are more windows and fewer ‘deadlight’ areas.

Hitachi has used some new (to them) manufacturing techniques for the Class 810 which are based on Hitachi Rail Italy’s preferred methods. For example, the ‘Megarack’ assembly of underframe cabling and pipework which is built and tested away from the line and offered up as a whole. Additionally, the ‘roll cage’ approach for the cab end is also new to the Hitachi UK fleet and has saved a significant number of hours for cab assembly.

Interior layouts and finishes

An important part of the travel experience for customers is the seat. Installed in the new units is the FISA LEAN seat, a design based on the innovative concept of the self-supporting iron shell bolted to the structural underframe. However, this has been selected and customised for EMR in conjunction with DGD Design of Derby. The FISA seat is comfortable, but the EMR version has additional support in key areas, looking comfortable, inviting, and unique. Interestingly customer reaction was tested by provision of a set of seats at Derby, Nottingham, and Sheffield stations for passers-by to test.

Underfloor heating is installed while the 800mm standard seat pitch has a spacious feel. Further enhancements include racks, bike-space, real time passenger information, screens in vehicle ends and vestibules, and even defibrillators.

The power supply off-wire is provided by four 735kW Euro5 engines per 5-car set: water-cooled. Four motored bogies (cars 2 and 4) with 8 x 290kW traction motors. Incorporated is redundancy design of high/medium/low voltage architecture with battery load-shedding.

The new trains bring with them significant issues with systems changes from previous times. These cover heating, ventilation, and air conditioning by Merak and Brakes by Knorr Bremse. Sanding is variable on first motored axles. Fire Suppression is by Total Mist Services and is Class 810 specific. These issues have been approached with rigor to allow successful introduction to service.

The main depot facilities can be found at Derby Etches Park, EMR’s main regional and Intercity maintenance depot.

Located south-east of Derby station, the depot is a residual part of the former, extensive, 19th century railway works. The facilities consist of the South Shed, used for the maintenance of the regional fleet (recently HSTs and Class 180s).

The North Shed is currently used for the maintenance of the Class 222 fleet, together with other facilities including fuelling, wheel lathe, carriage washes, and a five-car underframe clean facility.

The scope of work is considerable, and multiple changes have been required at the site. Around the South Shed has been the relocation of the stores accompanied by the temporary relocation of meeting rooms

facilities, leading to the build of a new office block and the upgrading of existing offices. Functional improvements at the shed are of significant scope including fume extraction, fluid delivery, and the delivery apron.

At the North Shed, the fuel road extension has taken place in line with the shed extension and track works. Main works here have included the fuel road equipment renewal, the north shed side extension, and revised extraction and gantries.

With the increasing main line electrification on the route, a necessary installation has been the erection of OLE meeting the requirements to test and maintain the new electric traction equipment at the Derby location.

Additionally, the London Cricklewood servicing and stabling location will see the installation of portable AdBlue facilities.

Rachel emphasised that the introduction of the rolling stock met significant challenges. A major profile impact came from the changes of standards since the AT300 design first appeared with new homologation requirements, allied to the change of design authority to Hitachi Italy.

To further drive the need for focussed management effort was the development of welding capability at Hitachi Newton Aycliffe, paralleled by the development of painting capability with a change of supplier.

Testing and commissioning are a vital part of any engineering project and the EMR team concentrated considerable effort in securing testing capacity in the United Kingdom. However, progress on this was not helped by landslips at the Rail Industry Development Centre at Melton.

Added to the challenges were the disrupting influences of the economic conditions during the work as well the supply chain impacts that bedevilled

These challenges will be met in the progression of testing and commissioning and are illustrated on the flow chart below.

At the core of the new vehicle’s introduction are a significant basket of Key Safety Imperatives (KSIs). Though the overall change is deemed significant, many of the activities present either no change or minimal changes to how the railway operates today.

To ensure the focus of the independent external safety review by the Assessment Body (ASBO) is commensurate with the risk, it has been deemed that items that are new and/or novel to EMR operation, extensive and complex, and which impact safety are KSIs.

For the Aurora project, meeting these criteria are Power Changeover, Automatic Selective Door Opening, and a distributed, high-pressure, water fire suppression system for the engines.

To summarise, EMR has a set of views on future development. It is discussing the potential for the use of batteries on Class 810 as per a recent Angel/ Transpennine Express trial. This would be for those journeys beyond the currently planned electrification of the MML, for example from Nottingham to Lincoln or via our diversionary routes.

EMR is also discussing the potential for fitment of Hitachi’s HMAX data suite which brings advantages to operator, maintainer, and the route authority through the use of on-board sensors and cameras.

Many thanks are due to EMR, in particular Rachel Turner, for access to the story of the ‘New Dawn.’ Much of this article was assisted by the presentation given by Rachel to the Institution of Mechanical Engineers, Railway Division.

The route is deserving of 21st century hardware and it can only be hoped that the provision of electrification contact systems will proceed apace to deliver a fully modernised, energy efficient

Class leading Natural Rubber wiper blade range (RWB) now available in sizes up to 1200mm

Robust 316 Stainless Steel Construction

Rail Safety Claws Prevent Screen Damage

Optimised Natural Rubber Profile For Rail

The class leading RWB range of glass safe stainless steel wiper blades has now been extended following investment in equipment and tooling technology. This advantage now enables us to extend the range previously capped at 1000mm up to 1200mm in length.

Our popular RWB heavy-duty blade has all the benefits of robust construction and corrosion resistance that you would expect from its 316 stainless steel build, combined with our unique polymer safety claws and moulded natural rubber wiping profile.

Although rare, rail wiper blades can be compromised in service by bird stikes and debris.

The RWB blades are not only stronger to resist damage whilst providing maximum water clearing performance, they remove the risk of damage to windscreens from metal claws and the huge cost and downtime of having to subsequently change screens.

Wabtec Faiveley Project Engineer

(Above) Hitachi Rail accelerometers attached to the axleboxes of a GWR Intercity Express Train. (Below) Flange thickness.

In Rail Engineer 208 (May-June 2024), we reported that Dr Mark Burstow, Vehicle Track Dynamics Engineer at Network Rail, had identified hunting as one of the causes of poor ride on some fleets resulting from high equivalent conicity between wheels and rails – a system problem. Although not all poor ride issues are the result of hunting, having identified this root cause, the next challenge was to do something about it.

This article covers what is being done on the Great Western main line which can potentially be rolled out to other fleets, as well as work by a Network Rail engineer exploring methods of evaluating track features contributing to high equivalent conicity.

Hunting is usually triggered where the equivalent conicity is high, and this tends to be at locations where the gauge is tight, but it would be wrong to think that this is solely a track issue. There are two factors contributing to ‘tight gauge’. Standards define the gauge and wear limits for wheels and rails, but hunting can occur when both wheels and track are within these limits. There are some locations where the gauge is a nominal 1432mm (within allowed limits) rather than the normal 1435mm, a hangover from a standard that was superseded in the 1980s. But wheels can and do contribute to tight gauge. When running on straight track there is necessarily clearance between the rail gauge faces and the wheel flanges. On older trains, as wheels wear rail to flange

clearance might be maintained or, as the flange wears, might effectively slightly widen the gauge. Modern bogies can run for hundreds of thousands of miles with their wheelsets remaining within allowed wear tolerances.

But, as the wheel tread wears, the flange can become effectively wider (illustrated left), reducing the clearance between the flange and rail gauge face, effectively needing to run on track with a gauge of 1436mm or 1437mm to maintain the clearance that a new wheel would see on nominal 1435mm track. Moreover, this sort of tread wear tends to lead to a steeper transition from tread to flange, leading to higher equivalent conicity and hunting, sometimes even on nominal track. That said, as Dr Burstow reported, wheels that have run for over 300,000 miles and which are still within flange height limits, width limits, and are free from RCF or other surface defects, are a tribute to the bogie designer. Also, note how quite small dimensional changes can have a significant impact.

Rail Engineer’s interest in a further article was prompted by news that Hitachi is fitting HMAX accelerometers (formerly Perpetuum Onboard) to all of the axleboxes on Great Western’s Inter City Express Trains (IET) and this will be extended to other IET fleets. The purpose is to help optimise axle bearing and wheel maintenance (see Panel 1), but Rail Engineer wondered whether the lateral accelerometers on the HMAX product could be used to detect the onset of hunting before it becomes apparent to the customers. We learned that is exactly what is being done.

Clive Burrows, group engineering director at FirstGroup, took the lead. He said: “Excellent collaboration, sharing of data and trust have been the essential elements of bringing together the knowledge, experience, and insight we now have from these impressive data collection and analysis systems. It has been a real pleasure for me to coordinate and steer the work of this cross-industry team that includes Hitachi Rail, Omnicon Balfour Beatty, Network Rail Wales & West, Network Rail Technical Authority, RSSB, GWR, MTR Elizabeth Line, and FirstGroup.

“I am confident this work will enable us to improve the way we manage our railway assets in a more efficient and effective way. After all, the wheel-rail interface and its associated system must be one aspect of engineering that is almost unique to railways.”

Clive added that it is the Hitachi Rail system and Omnicom Balfour Beatty Unattended Geometry Measurement System (UGMS) (see panel 2) being used together that provides the most useful information.

For example, UGMS outputs enable track gauge to be compared with the HMAX outputs to identify precise locations where narrow gauge is causing lateral ride instability. The investigation team has been supported by experts including Network Rail’s Dr Burstow, RSSB’s Professor Bridget Eickhoff, and Hitachi Rail’s Dr David Vincent.

When Rail Engineer discussed this with David Vincent, it was apparent that the work is not yet a routine activity but is showing that:

» Analysis of data showed that the accelerometers picked up signs of the onset of hunting when wheels have run around 230,000 miles.

» While it might be thought that turning wheels at a lower mileage is a disadvantage compared with the >300,000 miles routinely achieved, Hitachi is already demonstrating that turning at 230,000 miles whilst still well within limits improves wheel life because less metal is removed on each turn.

» When reports are received of ‘rough ride’, Hitachi is quickly able to show if it is a train issue (high conicity needing wheel re-profiling),

Axle bearings tend to have a good long life but can occasionally fail prematurely. They are single point failure, safety critical components. Bearing and rolling stock manufacturers generally specify a conservative life/maintenance regime, yet most bearings cleaned and examined at this life show no signs of distress. Indeed, your writer has experience of fleets where the overwhelming majority of the bearings last the life of the fleet. If a bearing is soon to fail, it generally gets hot, and all over the UK main line, Hot Axlebox Detectors (HABD) are fitted to identify this serious imminent failure. If one of these is triggered, the train must be stopped and examined immediately.

Detecting imminent failure is not good enough in a number of industries; much more notice is required. Engineers thought this principle could be applied to rail and that likely failure could be identified before such a fault becomes service affecting. Roller bearings exhibit vibration patterns related to factors such as the number of rollers and the bearing speed. If these vibrations are monitored, changes in the vibration pattern from, for example, pits in rollers or spalling in the races, will indicate deterioration, giving plenty of warning before the bearing finally fails.

Indicative progression of bearing failure with the vibration signature giving earliest warning (from 2015 Perpetuum Presentation).

This approach was adopted by SouthEastern Trains over 10 years ago when it fitted Hitachi Rail’s Perpetuum self-powered tri-axial accelerometers/ RF transmitters to its 170-strong Electrostar fleet (other axlebox vibration monitoring systems are available). This involved fitting eight axlebox accelerometers and a body mounted radio receiver/data concentrator (some with their own accelerometer, giving the ability to monitor ride comfort) to each of its 680 cars.

The self-powered/radio feature minimised the amount of wiring. The aim was to extend the intervals between bogie overhauls and eliminate the risk of premature bearing failure. As wheels on rails are forms of rolling element bearings, albeit rather large ones(!), it was soon realised that wheel flats and other wheel defects could be monitored by the system. Rolling forward to 2024, SouthEastern Trains:

» Plans wheel turning based on reported condition from the Perpetuum system, identifying wheels that need reprofiling even though many defects are invisible to the naked eye.

» Identifies wheel flats as soon as they occur providing time to plan their rectification.

» Avoids trying to ‘roll out’ flats which just stores up greater problems later on, sometimes avoiding the need for a ‘balancing turn’ on other wheelsets on the same car.

» Achieves longer wheel life. With reprofiling being carried out when the system identifies the need, less metal is removed (5mm compared with 10-15mm for wheels managed visually). In general, when presented for reprofiling as part of planned routine maintenance based on vibration analysis, the wheels look in good condition and are well within the flange thickness/flange height limits allowed.

» Has moved largely to planned wheel lathe work enabling a significant saving on avoiding having to purchase one new wheel lathe – a saving that more than paid for the installation of the sensors.

Example timeline illustrating the onset of hunting.

helping Network Rail to manage the event more efficiently. Currently, when rough riding is reported by staff or customers the standard response is to ‘stop and caution’ until the track has been inspected. With monitoring, wheels are re-profiled before there are any reports of poor customer comfort related to high equivalent conicity.

» Equally, if the system shows many trains experiencing “rough ride” (of which hunting is one example) at the same location, this points to a possible track issue.

» The system can detect the issue before the customer notices.

David added that much of the data analysed so far uses the body-mounted accelerometer which is not fitted to all cars, but even earlier detection is likely to be possible if the axlebox lateral accelerometer signal is used.

Next steps include setting all this out in systems, process, limits, and training so it becomes business as usual, extending fitment to all the other IET fleets and working with other Train Operating Companies and other regions of Network Rail to embed the approach being piloted on GWR.

Clearly, hunting can be detected if the fleet has axlebox accelerometers, but what of fleets that are, perhaps somewhat older and are not so equipped? As stated earlier, reports of hunting and rough riding might lead Network Rail to impose a speed restriction and also send resource to site to inspect and measure profiles and gauge. Clearly this requires a line block and people proficient in taking very accurate measurements (often in the dark) and assessing the results. But what if this could just be data/information obtained from one of the vehicles that Network Rail uses routinely to measures its track?

An approach to evaluating equivalent conicity from train-borne rail measurements and reference wheel profiles was explored by Network Rail’s Chris Fuller in his MSc thesis at the University of Birmingham. His work compared on-site measurements made using Miniprof instruments against profiles measured by one of Network Rail’s Ultrasonic Testing Units (UTUs).

Assessment of equivalent conicity also requires track gauge which is measured by Network Rail’s Track Recording Vehicles (TRV). The work showed that the UTU profiles are of sufficient quality to be used to assess equivalent conicity, albeit some smoothing was required to remove the slight variability (or glitches) in the optical measuring method. The UTU provides a rail profile every two metres - much shorter intervals than is

practicable to do manually. It is important to have accurate gauge results from the TRVs and one of Chris’ recommendations is to validate the geometry channels from its TRV fleets against a known track datum. Another issue is that the calculation of equivalent conicity is mathematically complex.

Chris also investigated the ‘quick conicity’ (see Panel 3) assessment method to determine whether particular characteristics of rail profiles or track geometry could be identified that were likely to contribute to high equivalent conicity. He was able to make recommendations which might lead to a ‘conicity indicator’ channel on the UTU’s recordings, assuming that reliable track gauge data can be obtained (e.g. adding it to the UTU). Much more work is required but the promise is that Network Rail and the train operators will be able to set maintenance intervention limits (e.g., rail shape/gauge and wheel mileage) that virtually eliminate hunting.

Hunting is a system issue which requires joint understanding and action, this article showing the benefits to be obtained from such cooperation. The deployment of both on-train technology and newly developed assessment techniques offers much promise and is welcome. As well as improved ride for passengers, there is a potential reduction in maintenance costs for both trains and track which could be applied across the UK network, hopefully relatively quickly and with minimal disruption. There is more work to be done in fully scaling all this including ensuring that data from multiple sources can be integrated into useful information that operators and maintainers can respond to effectively.

In research published in 2016, Dr Mark Burstow (Network Rail) and Andreas Haigermoser (Siemens) proposed and evaluated a ‘quick conicity’ measurement by measuring gauge between the two rails at different points across the rail head.

Whilst tight gauge contributes towards an increase in equivalent conicity, they concluded there was a poor correlation when using gauge values measured 14mm down the gauge face of rail, the usual measuring point for track gauge. This is because it provides no indication of the rail shoulder height. Instead, they proposed taking track gauge measurements 3mm below the crown of the rail. These measurements identified rail profiles with a high gauge face shoulder caused by uneven wear, a feature which can contribute to a high equivalent conicity and dynamic wheelset instability, particularly when encountered by wheel profiles with a high wear resulting in a thicker flange root area.

A number of Intercity Express trains have been fitted with Omnicon Balfour Beatty’s Unattended Geometry Measurement System (UGMS) system. It does the same job as the track geometry measurement system on Network Rail’s New Measurement Train (NMT), but a UGMS train might run over a section of track perhaps a couple of times a day whereas the NMT only covers each section once every eight weeks. Apart from the benefit of providing an accurate gauge measurement when hunting is detected on the train, UGMS provides Network Rail engineers immediate validation that repairs have achieved the required geometry improvements and can provide information about the rate of geometry degradation. Each train has had to be individually calibrated to demonstrate to Network Rail’s Technical Authority that its data/information is accurate. UGMS comprises the following key elements:

» A Main Processing Unit housed in a 19-inch rack located behind the drivers cab of the leading vehicle, including means to transmit data wirelessly.

» A pair of optical/inertial units attached to the trailing bogie of the leading vehicle the unit. These house the cameras, lasers and six-axis inertial transducers.

» A speed probe, independent of the train’s probes, fitted to the axle box housing and connected to one of the optical/inertial units.

» An independent Audible Warning System detector mounted onto the bogie frame on the track centre line and connected to one of the optical/inertial units.

» A tri-band (GSM/GPS/Wi-Fi) antenna.

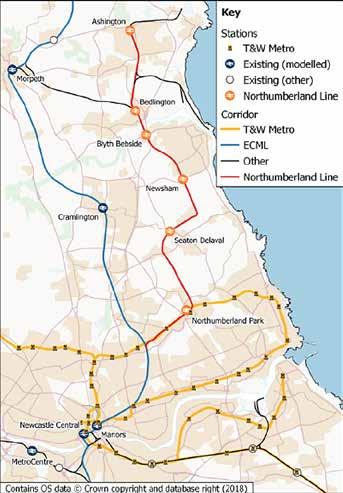

The communities of Ashington and Blyth have been without a train service for 60 years. Following the Beeching report, their branch of the Blyth and Tyne Railway (B&TR) closed to passengers in 1964 but remained open to serve local collieries. Although these have since closed, the line has around five freight trains per day to provide the Lynemouth bio-mass power station with wood chips from the Port of Tyne.

In the 1980s, the southern part of the B&TR saw a resurgence in traffic when it became the newly created Tyne and Wear Metro’s North Tyneside Loop. Yet, just north of the Metro, the communities of Ashington and Blyth were left without a passenger train service despite being on an operational railway.

From Newcastle, it is 30km by rail to Ashington, with the first 6.9km being on the ECML to Benton Junction.

Since the 1990s there have been various calls to restore the line’s passenger service. In response, Northumberland County Council (NCC) commissioned AECOM and SLC Rail to produce a Strategic Outline Business Case which was published in 2019. This showed that the Northumberland Line has a catchment area of over 90,000 people and estimated the annual benefit to the local economy of a restored passenger railway

to be £70 million gross value added. It also noted that the 35-minute rail journey from Ashington to Newcastle would be half the bus journey time.

In January 2020, NCC, which was leading the project, approved £10 million for ground investigation and detailed design supported by AECOM which provided technical consultancy, business case development, and project management services.

The Department for Transport (DfT) contributed £34 million under the Restoring your Railway scheme in 2021 when the estimated cost of the project was £166 million. In May 2021, NCC applied for a Transport and Works Act Order (TWAO) for powers to open the line such as closing level crossings and acquiring land. This was granted in June 2022 after a public inquiry. By March 2022, planning permission had been granted for the line’s new stations.

The project’s first substantial work took place in June 2021 when 550 metres of track was renewed. The project’s trackwork comprised of 25km of track renewals and the installation of 22 sets of switches and crossings. This was delivered by the Central Rail Systems Alliance (CRSA), a grouping of Network Rail, Balfour Beatty, AtkinsRéalis, and TSO.

Of the 23km branch from Benton Junction to Ashington, 11.3km was single track which, in addition to its current five freight trains per day, could not accommodate the required two passenger trains per hour. To accommodate this extra traffic a 2.4km loop was provided between new junctions at Holywell (5km) and Seghill (7.4km) and existing double track was extended southward for 1.9km from Newsham to the new House Farm junction (11.1km). Figures in brackets are the distances from Benton North junction.

In addition to the earthworks required for this double tracking work, two replacement under bridges were required.

At around 12 locations, the track was realigned to provide an increase in linespeed. As a result, for three quarters of its length the passenger train line speed is between 55 and 70 mph. On the rest of the line there are various locations where sharp curves and junctions reduce the linespeed to 25 or 30mph.

In August 2021, Morgan Sindall Infrastructure (MSI) was awarded a contract for the construction of the line’s six new stations and other civil engineering work. MSI contracted Ground Control, to undertake the vegetation clearance along the line. These stations are:

» Northumberland Park (3.5km) with a single 80-metre platform that will provide an interchange with the adjacent Tyne and Wear Metro station.

» Seaton Delaval (8.8km) with a single 100-metre platform and a 284-space car park.

» Newsham (13.0km) with two 100-metre platforms and two car parks either side of the line with 140 and 97 spaces. Southwest of the station were the remains of iron age/Romano-British enclosure and possible roundhouse which required an archaeological investigation prior to construction.

» Blyth Bedside (16.4km) with two 100-metre platforms and a 283-space car park. This is separated from the town by the A189 trunk road and so a 400-metre footpath is provided with a new footbridge over the A189. This was installed by Rainton Construction which was part of MSI’s delivery team.

» Bedlington (18.3km) with two platforms 200-metres and 300-metres long and 35-space car park. This is immediately before the junction with the line to Morpeth.

» Ashington (23.0km) with a 200-metre single platform and a 269-space car park. This is on a spur off the double track freight line to Lynemouth to ensure that turning back passenger trains will not delay freight trains.

Trains between Newcastle and Ashington also stop at Manors station which is 0.9km outside Newcastle station.

The 717 documents submitted to obtain planning permission for these six new stations indicate the costs involved in this process to ensure that key issues are addressed. These included local objections and mining risk assessments which were a significant issue at most stations. Yet, having read some of these lengthy documents, your writer is left thinking there should be a more cost-effective way of dealing with such issues.

When the line opened on 15 December 2024, only Seaton Delaval and Ashington stations were open. Newsham is expected to open early this year with other three stations opening around the end of 2025.

In February 2022, Siemens Mobility was engaged for the design and delivery of telecoms, lineside infrastructure, and power upgrades as well as the upgrades at eight level crossings.

Before the start of the project, the 23km Ashington branch had no less than 21 level crossings of which 10 were public highway crossings. The increased level crossing risk from the provision of a passenger service required a programme of crossing upgrades and closures.

As a result, eight crossings were closed. One of these was the highway crossing at Newsham station (8.1 km) which was replaced by a new 480-metre road and overbridge. The other closures were public footpath and private highway crossings.

Closed footpath crossings at Palmersville Dairy (0.5km) and Chase Meadows (15.7km) were respectively replaced by an underpass and footbridge. The other five closed crossings had their rights relinquished by the TWAO.

Bedlington South (16.6 km). The provision of obstacle detectors and CCTV was a significant aspect of upgrades to the other crossings as shown below:

» Holywell (4.9 km) from ABCL (Automatic half-Barrier crossing locally monitored) to AHB.

» Bebside (16.7 km) from AHB to MCB with Obstacle Detection (OD).

» Bedlington North User Worked Crossing (UWC) (18.5 km) from MCB to MCB-CCTV.

This left the line with four footpath crossings and nine highway crossings. Of the four remaining footpath crossings, two were considered to have sufficient line of sight, the crossing at Earsden (4.2 km) was upgraded to one with Overlay Miniature Stop Lights (OMSL), and the crossing at Bedlington North Wicket Gate (WG) was provided with an Integrated MSL.

Of the nine remaining highway crossings, risk assessment showed that there was no requirement to upgrade three of them: the Automatic half-Barrier (AHB) crossing at Seghill (7.5 km), the Manually Controlled Barrier (MCB) CCTV crossing at Plessey Road (14.1 km), and the MCB crossing at

» Marcheys House (20.8 km) from MCB to MCB-OD.

» North Seaton (21.5 km) from MCB to MCB-OD.

» Green Lane (22.5 km) from AHB to MCB-OD with pedestrian stop lights.

In addition to the level crossing work, Siemens resignalled the line with its modular signalling system which has been used in North Wales and elsewhere. This equipment is manufactured and tested at the company’s Chippenham factory before being transported to site.

The new signalling transferred control from local signal boxes to the Tyneside Integrated Electronic Control Centre (IECC). As a result, signal boxes at Newsham, North Seaton, and Marcheys House were demolished. The signalling was commissioned in two stages. Easter saw the signalling going live between Ashington and Bedlington, while the remainder of the line between Bedlington and Benton Junction on the ECML was commissioned in August.

Following this commissioning, Northern ran its first train along the length of the line on 5 August 2024 and was then able to start driver training.

When Ashington line was reconnected to the rail network on 15 December, this added two stations to the main line railway network, bringing the total number of stations on the main line network to 2,588. Since 2010, the network has seen 67 new stations though only 15 of these were from six railway re-openings. In addition to Ashington, the other re-openings were Airdrie to Bathgate, Ebbw Vale extension, Borders, Okehampton and Levenmouth. The Ashington re-opening has some similarities to the Levenmouth reopening. Both communities suffered high unemployment after the closure of their mines and had an existing freight line

which made their rail re-openings a realistic proposition even if the Levenmouth branch did have six-foot-high trees growing through the track.

Yet such re-openings come at a cost. In 2021, the cost of the Ashington re-opening was estimated to be £166 million. Last August the cost of the line was estimated to be £298 million which is being funded by the DfT, Northumberland County Council, and Network Rail. It has been explained that the reasons for the additional cost of the Ashington re-opening include poor weather and construction inflation.

At £13 million per kilometre, introducing a passenger service on the operational Ashington branch is comparable to the £116 million cost of re-opening the closed 9.7 km Levenmouth branch.

Whatever the cost of the Ashington branch, its new services will no doubt bring significant benefits to local communities especially when the remaining stations are opened. Indeed, the promise of the Ashington line is shown by the 50,000 passenger journeys that have been made in its first month. NCC considers that the Northumberland Line will:

» Improve access from towns such as Ashington and Blyth to employment hubs like Newcastle, as well as opening new opportunities for education and travel.

» Provide a real incentive for potential employers to relocate to and invest in the area.

» Provide vital infrastructure to help deliver the region’s aspirations for population and economic growth.

» Help to attract visitors and improve local tourism.

» Enhance public transport connectivity within and beyond the region.

» Help to reduce congestion and improve air quality on key corridors by moving people away from car travel and onto public transport.

» Support the delivery of significant growth in sectors such as renewable energy, offshore oil and gas and engineering.

With the train journey taking half the time of the bus journey, it seems most likely that these aims will be achieved. The business case that NCC published in 2019 quantified the benefits of the Ashington line to be worth £70 million per annum for the local economy. Thus, as is almost always the case, the benefits of this new rail service will far outweigh the cost of its provision.

With staff drawn from across all areas of the rail industry, KeTech is an innovative technology company with a deep pool of expertise and experience, real-time data, software, and electronics both on the wayside, and on-train systems.

Rail Engineer caught up with and Sales Director Paul Warren and Technical Consultant Graham Cooke to discuss the company’s Universal Information System (UIS) which directly increases connectivity of the rail environment, removing duplicate information while enhancing the customer experience.

Can you tell us more about UIS?

UIS is truly unique, we believe it is the only system in the UK rail industry that harnesses technologies including Artificial Intelligence (AI) and the Internet of Things (IoT). Providing unlimited data processing, cloud hosted environment, and advanced analytics to provide a whole new level of ‘connectedness’ and automation.

The system was developed to create digital railways, integrating systems and streamlining operations and customer experience by strengthening the technology architecture. UIS removes the barrier of siloed systems, allowing disparate parts of the railway to talk to each other, share data, and create information, unlocking a system’s full potential.

UIS connects individual components, sensors, and third-party systems. It processes the data, and provides intelligent outcomes, resulting in lower operational costs and next level customer experience. It unlocks the potential of what individual systems can do in isolation, connecting them to reach full functionality.