CIRAS

reporting app

reporting app

Report it in confidence, on the go.

CIRAS is the confidential safety hotline for transport. Download the CIRAS reporting app on Google Play or the App Store to raise your health, safety and wellbeing concerns. We protect your identity and share your concern with the right people, so they can act.

HS2’s benefits squandered

A new report by the National Audit Office paints a sorry picture of the handling of HS2.

Before and after the election

The new government will take a different approach than its predecessor but what does that mean for rail?

10|

Pendolino plan for HS2

David Shirres considers a plan to maximise HS2/WCML passenger capacity using lifeextended Pendolinos.

Innovations in traction

There’s no question that rail must decarbonise but plenty of debate about how, as discussed at an IMechE seminar.

West Midlands Trains’ new rolling stock and depots

New trains are joining WMT’s fleet and much work will be required to accommodate them. Malcolm Dobell reports.

Getting better each year: The 2024 Railway Challenge

Run by volunteers and IMechE staff, this year’s event was the best yet, as reflected by the scores.

Levenmouth reconnected

After 55 years, the residents of the Levenmouth area got their railway back on Sunday 2 June.

Network Rail:

Rail Innovation and Development Centres

Paul Darlington reports on a visit to the Melton Mowbray RIDC, where Network Rail tests critical infrastructure.

Sustainable FFU on Kent’s Military Canal & Blockhouse bridges

Sekisui celebrates 10 years since the installation of its synthetic wood on these two historic railway bridges.

Rail Live 2024

Matt Atkins provides a whistlestop tour of Rail Live 2024, held at Porterbrook’s Long Marston Rail Innovation Centre.

Revolutionising the global rail industry

Unipart Rail is delivering transformative innovations for construction, maintenance, and renewal projects.

Wi-Fi on trains: Why is it difficult?

Providing Wi-Fi on trains is relatively straight forward, but maintaining a stable connection to the internet is another matter.

Beaulieu Park Station

Building and operating a new station on the Great Eastern mainline will be no easy feat, says David Fenner.

Where’s my tube?

Using the underground can be a perplexing experience and getting accurate information to passengers is critical.

Twenty years of Darwin engineering

Paul Darlington looks in depth at the engineering behind the Rail Delivery Group’s customer information system.

Railways fit for the future

One certainty facing Britain’s rail network is that it must adapt to new, extreme weather patterns.

Wi-Fi HaLow

This underused Wi-Fi protocol offers lower energy consumption, higher data rates, and wider coverage than others.

Innovation in its many guises

Clive Kessell reports from RIA’s Southern Unlocking Innovation event, held in London on 12 June.

In 2018, the opportunity to electrify East West Rail (EWR) at low cost as it was built was lost when then Transport Minister declared that neither electrification nor diesel trains were needed as EWR will have “a completely new generation of low-emissions trains.” Despite commitments in the Integrated Rail and Decarbonising Transport plans to deliver an ambitious electrification programme, since March 2021 only 64 single track kilometres of electrification have been delivered in England. This was mainly for the new Elizabeth line.

Between 2013 and 2017, 7,000 new rail vehicles, equivalent to half the UK passenger train fleet were ordered. This both created a surplus of thousands of serviceable vehicles and an orders famine that now threatens UK train plants. The 2021 William Shapps report proposed the creation of Great British Railways (GBR) for which legislation has yet to be enacted. Government then committed to set out the rail network’s key strategic priorities for the next 30 years in 2022. These were never produced.

2021 also saw publication of the Integrated Rail Plan (IRP) which cancelled HS2’s leg to Leeds that had been the subject of years of planning by HS2, Network Rail, and regional authorities. In October 2023, the HS2 leg to Manchester was similarly cancelled without any consultation with relevant bodies including the National Infrastructure Commission.

As we describe, a recent National Audit Office (NAO) shows how this hasty decision will reduce passenger capacity on the already congested West Coast Main Line north of Birmingham. It thus considers that passengers may have to be priced off trains to discourage passengers from travelling on this congested route. It also shows how high-cost infrastructure will be left unused instead of being used to relieve WCML congestion. The NAO report also notes that in the nine months since HS2 was cut back, no decisions have been taken on HS2 Euston station’s scope, funding or governance. As these examples show, the previous Government’s stewardship of the rail network has wasted billions, disregarded the benefits of electrification, ignored expert opinion, and squandered an opportunity to transform connectivity between major cities.

Our article on the general election considers what might be expected of the new Government. Transport Minister, Louise Haigh has stated that her priorities are improving railway performance, rail reform, transforming infrastructure to work for the whole country and delivering greener transport. To achieve these aims, she is supported by Rail Minister Lord Peter Hendy (pictured below) who certainly has the required expertise.

As the author of the Union Connectivity Review, he highlighted how rail connectivity can grow the economy.

Labour’s manifesto promises mission-driven government supported by industrial and infrastructure strategies to kickstart economic growth. Furthermore, Hendy is working on a long-term rolling stock procurement strategy. These are promising signs of a systematic approach to ensure the best value from infrastructure and rolling stock investment.

Yet the Labour Party manifesto committed no specific sums to rail infrastructure investment given the need to first assess the economic situation. As this is much worse than first thought, large investments on rail infrastructure are a big ask. Nevertheless, the Chancellor accepts that borrowing can fund worthwhile investments. The extent to which this applies to rail enhancements, and in particular, expenditure to maximise the benefits of what is left of HS2, remains to be seen.

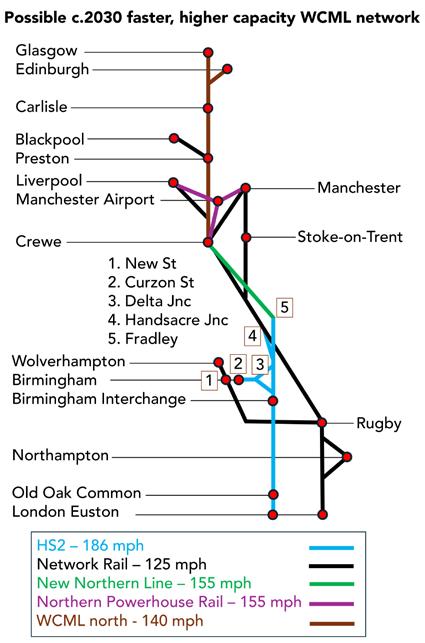

An urgent decision is needed to avoid a significant reduction in passenger capacity once shorter HS2 trains start running north of Birmingham. One solution to this problem, as proposed by Chris Gibb, is that HS2 services should include Pendolino trains upgraded for 155mph running. Chris also backs the construction of a New Northern Line as proposed by the Mayors of Manchester and Birmingham to relieve WCML congestion and realise the benefits of otherwise unused infrastructure, particularly at Birmingham’s Curzon Street station.

Growing the local economy was the Scottish Government’s main justification for the reopening of the 10km Levenmouth branch which adds two new stations to the rail network. A new station at Beaulieu Park, near Chelmsford, is also due to open in 2025. As David Fenner explains, constructing a new station on such a busy main line requires the provision of a central bi-directional main line.

We also feature technologies that improve passenger journeys. Of these, on-train Wi-Fi often fails to meet passenger expectations. Paul Darlington explains why providing train Wi-Fi is so difficult and what is being done to improve it. He also explains the latest Wi-Fi technology, Wi-Fi HaLow. The real-time train information system Darwin is now over 20 years old. We report how this has been developed to take account of its increasing ‘peaky’ demand. The development of passenger information systems on London Underground and LU’s Trackernet system to inform both staff and passengers is the subject of an article by Clive Kessell.

Passengers on West Midlands Trains benefit as the company increases its fleet by 110 vehicles, with 404 new vehicles being delivered and 294 older vehicles leaving the fleet. As Malcolm Dobell explains, trying to juggle the introduction of new trains and retirement of older trains whilst rebuilding most of the depots is a real challenge.

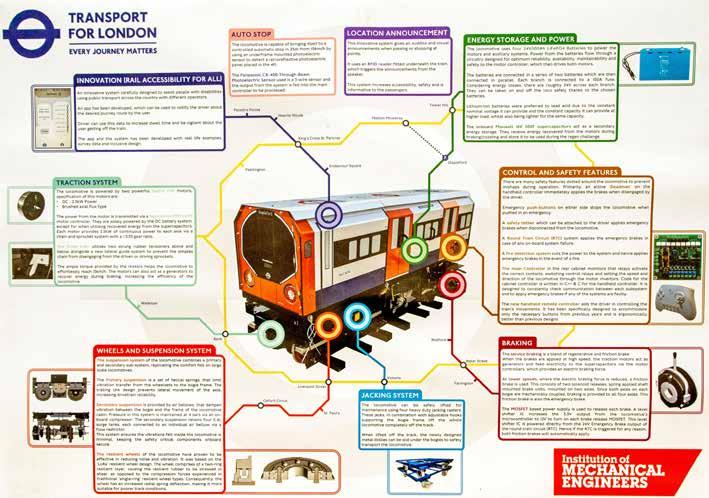

Train traction innovations were the subject of a recent IMechE seminar which considered the role and safety risks of battery and hydrogen power. As we describe, this event also considered cost effective electrification and the use of a 3kV DC supply for metros. Another worthwhile IMechE seminar

‘Adapting Railways for a Sustainable Future’ explained how railways must adapt to new extreme weather patterns if they are to continue to operate a safe and reliable service.

We also report how innovations were spotlighted at an Unlocking Innovation event organised by the Railway Industry Association. This forum put various innovations in front of potential clients and encouraged collaboration between organisations to address specific challenges, in particular those faced by the railways of London and the South East.

A tri-mode locomotive, hedgehog sleepers, quadruped robots, mobile maintenance trains, a spider excavator, and much other innovative plant were amongst the innovations on display at Rail Live 2024. As Matt Atkins reports, this impressive event brought together the very best of the industry.

Another innovation-related feature describes Network Rail’s Railway Innovation and Development Centres (RIDC) at Melton and Tuxford. These RIDC facilities, with respectively 13 and 10 miles of track, provide a safe and

DAVID SHIRRES

RAIL ENGINEER EDITOR

convenient environment to test rolling stock, on-track plant and infrastructure away from the main rail network.

The IMechE’s Railway Challenge tests locomotives on a quite different railway. As we explain, this event, now in its 12th year, gives young engineers real-life experience of design, manufacture, project management, and teamwork. To date the event has provided over a thousand young engineers with this invaluable experience. By running this event the IMechE’s Railway Division are doing them, and the rail industry, a great service.

Editor

David Shirres

editor@railengineer.co.uk

Production Editor

Matt Atkins matt@rail-media.com

Production and design Adam O’Connor adam@rail-media.com

Lauren Palin lauren@rail-media.com

Engineering writers bob.hazell@railengineer.co.uk

bob.wright@railengineer.co.uk clive.kessell@railengineer.co.uk

david.fenner@railengineer.co.uk graeme.bickerdike@railengineer.co.uk malcolm.dobell@railengineer.co.uk

mark.phillips@railengineer.co.uk paul.darlington@railengineer.co.uk peter.stanton@railengineer.co.uk stuart.marsh@railengineer.co.uk

Advertising Asif Ahmed asif@rail-media.com

Craig Smith craig@rail-media.com

Rail Engineer

Rail Media House, Samson Road, Coalville Leicestershire, LE67 3FP, UK. Switchboard: 01530 816 444 Website: www.railengineer.co.uk

Rail Engineer Videos http://rail.media/REYouTube

Editorial copy to Email: news@rail-media.com

Free controlled circulation Email: subscribe@rail-media.com

The small print

Rail Engineer is published by RailStaff Publications Limited and printed by PCP Ltd.

© All rights reserved. No part of this magazine may be reproduced in any form without the prior written permission of the copyright owners.

Part of: www.rail-media.com

A recent report by the National Audit Office (NAO), titled ‘HS2: update following the cancellation of phase 2’, has concluded that the Department for Transport (DfT) does not know how to maximise the benefits of HS2 now that phase 2 to Manchester has been cancelled. It notes that most of HS2’s original benefits were from the now-cancelled phase 2. Furthermore, HS2 Ltd estimates that once HS2 services start there will be a 17% reduction in passenger capacity.

Without HS2 phase 2, there remains a capacity issue that the DfT will have to resolve by either pricing passengers off rail or providing additional rail infrastructure which would create major disruption unless a new line was built.

The DfT is currently developing a train service specification to maximise the benefits of the current HS2 scope. This is considering options to run longer HS2 trains by lengthening platforms at Crewe or Preston where trains formed of 2 x 200-metre units could be split. The NAO report does not mention the Pendolino proposal described elsewhere in this issue.

With HS2 services expected to commence between 2029 and 2033, there is an urgent need for action to ensure that HS2 services will at least provide the same number of seats as conventional services.

After the phase 2 cancellation, the DfT had to decide how much of the ongoing HS2 work needed to be stopped or changed. The general principle is to stop work that is no longer needed unless it would cost more to stop it. It was decided to retain the current rolling stock design and fleet size as changes could lead to significant additional costs and operational issues. In some cases, the decision was to continue with committed work. For example, Birmingham Curzon Street station will be completed with seven platforms, though tracks will only be provided at three platforms. Some decisions have yet to be taken such as whether to retain passive provision for a connection to a future eastern HS2 leg.

DAVID SHIRRES

HS2 estimates that closing down phase 2 will take three years and cost up to £100 million. This includes restoring land where over a thousand boreholes have been drilled.

£429 million has been spent on land and property along the phase 2 Manchester route of which £224 million was for phase 2a between Handsacre and Crewe. As at the end of June 2024, HS2 has sold none of this land. It is estimated that disposing of this phase 2 land and property will take several years.

The HS2 cutback decision included the requirement to reset the design of HS2’s Euston station. The DfT is currently developing revised requirements for a six platform station though no decisions have been taken on its scope, funding, or governance. Although it is considered that much of the rescoped station could be funded privately, such private finance is not expected to be available for several years. Furthermore, it will take two to three years to set up a development corporation for the wider Euston quarter. The DfT has yet to set a revised date for the start of HS2 services from Euston.

The NAO report notes that the decision to proceed with tunnelling from Old Oak Common to Euston is needed this summer to avoid much higher future costs.

Up to the end of March 2024, £30.1 billion (in 2019 prices) has been spent on HS2, with £27.8 billion spent on phase 1. HS2’s estimate of final cost is £45 billion to £57 billion, though the DfT considers it should be lower than this. The report identifies reasons for HS2’s high costs which include contract incentivisation, HS2 contract management, estimates, design, and consents.

It also notes that costs have risen for reasons outside of HS2’s control, for example, inflation, Covid, Brexit, and the war in Ukraine. In addition, HS2 considers that an annual funding constraint imposed between 2023 and 2025 has increased costs by £1.9 billion to £3.1 billion.

Whatever your political views, it is undeniable that the new Labour government has a different approach to its predecessor. Here, we consider what this might mean for the nation’s railways, which were not a key factor in the election campaign.

A cash-strapped new government has far greater priorities including health, education, defence, and economic growth. Yet rail is a driver of economic growth as well as being a key part of the drive for net zero carbon transport.

The election manifestos provide an insight into the transport priorities of the different

parties, and by implication, their supporters.

The two main parties did not have transport sections in their manifestos and instead considered transport as part of their plans to grow the economy.

The Labour manifesto promised missiondriven government offering economic stability and kickstarting economic growth.

Part of this is the creation of a £7.3 billion National Wealth Fund to support growth and clean energy. There is also to be an industrial strategy council and a 10-year infrastructure strategy which includes improving rail connectivity across the

north of England. There were, however, no specific sums committed to rail investment.

As contracts expire, train operations are to be brought into public ownership, yet it is recognised that open access operators will continue to have an important role.

There were also commitments to promote rail freight and create Great British Railways (GBR) which will be responsible for investment and operational delivery.

Labour’s manifesto recognised that cars are by far most popular form of transport and so committed to maintaining and renewing road networks. It also stated that local leaders will have power to franchise local bus services and mayors will have powers to create integrated transport systems.

The Conservative manifesto essentially restated the Network North document which committed to invest the claimed £36 billion from HS2 savings on rail, buses and local roads, including £8.3 billion to fill potholes. This included upgrading the line between Newark and Nottingham as this was somehow going to halve journey times between Nottingham and Leeds. There was also an additional commitment to invest £12 billion for Northern Powerhouse Rail and to reopen Beeching lines.

The manifesto recognised the need for rail reform with the creation of GBR which is to be tasked with growing the private sector to deliver a modern innovative railway with reliable services and simpler tickets. Beyond rail, it committed to £1 billion to support hundreds of new bus routes and £4.5 billion to secure strategic manufacturing sectors. It stressed that the Conservatives were on the side of drivers, with pledges to stop road pricing and put constraints on low emission zones and 20mph traffic zones.

Agency - a public body which would help to join up the industry to put customers first, holding train companies to account, and reforming of the broken fare system.

It also required a review of the cancellation of HS2’s Manchester leg to see if it can still be delivered in a way that provides value for money, the delivery of Northern Powerhouse Rail, a 10-year rail electrification plan, and the need to work with local authorities to deliver light rail schemes. There was also a proposal to introduce a national freight strategy to move as much freight as possible from road to rail. Modal shift from air to rail was also to be achieved by banning short domestic flights where a direct rail option taking less than 2.5 hours is available and requiring airlines to show comparative air / rail carbon emissions when domestic flights are booked. The Liberal Democrats also supported maintaining the £2 cap on bus fares and wished to encourage alternatives to rural buses where they are not viable, such as ondemand services.

The Liberal Democrat’s manifesto aimed to make rail a genuinely convenient, affordable, and environmentally friendly option for both passengers and freight by establishing a new Railway

The Green party has an ‘Investing in Fairer, Greener Transport’ section in its manifesto. This does not mention rail reform and advises that elected Green MPs will push for a modern, efficient,

publicly-owned railway, with affordable fares with the required investment which should include £30 billion for rail electrification. They also require a national strategic approach to identifying lines and stations which could be re-opened.

The Greens are the only party that require a significant reduction in car use given the huge and growing contribution that private-vehicle transport makes to our carbon emissions. In respect of buses, they would push for local authority control and proper funding for bus services, to increase services in urban areas, and provide a bus service to every village.

Reform also fails to mention rail reform in its manifesto. This, however, is the only similarity with the Green manifesto as Reform would scrap all net-zero targets as these are “pushing up bills, damaging British industries like steel, and making us less secure.”

The party pledged that in its first 100 days it would save £25 billion by scrapping HS2 which it considers to be a “bloated vanity project”. During this time, it would also stop the war on drivers and accelerate transport infrastructure investment by focusing on our coastal regions, Wales, the North, and the Midlands to improve existing rail and road links.

When Kier Starmer announced his cabinet on 5 July, the day after the election, it was no surprise that the previous shadow transport secretary, Louise Haigh, had been appointed Secretary of State for Transport. However, the appointment of crossbench peer and distinguished transport professional Lord Peter Hendy as Rail Minister on the 8 July was a surprise. Former Shadow Transport Secretary Lilian Greenwood, now Minister for the Future of Roads, commented on X that “appointments don’t get better than this.” Others in the industry expressed similar comments.

In 2021, Lord Hendy led the Union Connectivity Review which highlighted the importance of the railway in delivering the economic growth needed across the nations and regions of the UK. It also recommended that WCML rail capacity between London, the Midlands, North West England, and Scotland should be increased.

8 July was also the day that Haigh addressed Department for Transport (DfT) staff to set out her five strategic priorities which she said put transport at the heart of mission-driven government. She also considered that the DfT’s motto must now be “move fast and fix things”. Her priorities were:

» Improving performance on the railways and driving forward rail reform.

» Improving bus services and growing usage across the country.

» Transforming infrastructure to work for the whole country, promoting social mobility and tackling regional inequality.

» Delivering greener transport.

» Better integrating transport networks.

Some of these priorities were reinforced in the Kings speech on 17 July. This announced that a Better Buses Bill will be presented to Parliament. It also advised that there will be legislation to improve the railways by reforming rail franchising, establishing GBR, and bringing train operators into public ownership.

The overall context for transport policy was the statement in the speech that securing economic growth will be a fundamental mission for which the Government will seek a new partnership with both business and a newly created Industrial Strategy Council. An example of this is Haigh’s visit on 24 July to Hitachi’s Newton Aycliffe plant which is soon to run out of orders. The purpose of her visit was to consider a sustainable future for the plant. In a letter to local MPs Lord Hendy advised that the government was working on a long-term strategy in a bid to “end the current boom-and-bust cycle” in train production.

In a speech immediately after the election, Chancellor Rachel Reeves advised that she wants the Treasury to be about more than

tax and spend as it has also to be a “growth department”. Though she considers that the government has inherited the worst set of financial circumstances since the World War II, she has stated that, although day-to-day expenditure must be paid for from tax receipts, the government would be prepared to borrow to invest.

The new government’s immediate priority for rail is improving performance which includes ending industrial action. Then, there is rail reform and the implementation of the policy to end private rail franchises as they become due for renewal. Finally, there is the need to consider future investment, be it infrastructure enhancements, electrification, HS2-related, and rolling stock.

Haigh has summoned poor performing train operators and associated Network Rail route directors to meetings at which she demanded action to improve performance otherwise contracts will be terminated. This included Avanti which last year cancelled 7% of its trains. Meetings were also held with trade union leaders within seven days of the election. ASLEF’s Mick Whelan considered this to be a “a major step forward and that the whole tone has changed”. He noted that he last met a government minister in January 2023.

The Passenger Railway Services (Public Ownership) Bill received its first reading in the House of Commons on 18 July. This Bill amends the 1993 Railways Act to specify that public-sector operators must provide train services except when it is not reasonably practicable to do so. Currently, the 1993 Act presumes that services will only be provided by private-sector operators unless it is not feasible.

In their “Getting Britain Moving” plan to fix Britain’s Railways, published in April, the Labour Party specified that GBR will be an arm’s length body and ‘directing mind’ of empowered rail industry experts and professionals, tasked by the Secretary of State who will set strategic direction. GBR will be responsible for planning timetables, improving services, and the operation, maintenance, and improvement of rail

infrastructure. It will also bring finances together into a single body, enabling it to take long-term decisions to increase patronage and deliver improvements for passengers and freight. Legislation to implement GBR is expected soon.

Although there is a pressing need for rail investment, the Labour Party has not specified any sum for this. Finances are constrained, however the Chancellor accepts that worthwhile investments can be funded by borrowing. She also has recently announced a review to unlock the investment potential of pension schemes. It would thus seem likely that funding will be available for schemes with a good rate of return. Moreover, Lord Hendy’s work on a long-term rolling stock strategy indicates that the new government will be taking an informed view about the future rail investment.

As highlighted by the National Audit Office’s (NAO) recent report ‘HS2: update following the cancellation of phase 2’, decisions are needed on how to maximise the benefits of what is left of HS2 and how to best resolve West Coast Main Line capacity north of Birmingham. As mentioned in our ‘Pendolino plan for HS2’ feature, these issues could be resolved by constructing a ‘New Northern Line’ along the route of HS2 phase 2a at a lower cost than HS2. The NAO report also showed that none of the land purchased for the building of HS2 phase 2a has been sold.

The new government’s approach to rail generally seems to mirror that required by the industry. For example, the Railway Industry Association’s rail manifesto calls for a long-term strategy, rail reform, and supporting the supply chain. However, Rail Partners, which represents private sector operators considers that “full nationalisation is a political not a practical solution which will increase costs over time.”

In the few weeks since the election, the new Labour transport team has certainly not been idle. Although it is too soon to judge how effective it will be, it has the required expertise, a strategy, and an understanding that rail has a vital part to play in the Government’s declared mission of growing the economy.

Under current plans, in about seven years’ time HS2 trains from Old Oak Common (OOC) will join the West Coast Main Line (WCML) at Handsacre Junction just north of Lichfield. These trains will replace most of the WCML long distance trains that currently start at London Euston as this line is now almost full to capacity. As the HS2 trains will have 100 fewer seats than the current Class 390 Pendolino trains, introducing HS2 services will reduce WCML passenger capacity north of Birmingham by 17%.

HS2 trains running between OOC and Handsacre will be 25 minutes faster than conventional trains on the WCML from London. Yet HS2 trains do not tilt and so are estimated to be 13 minutes slower than Pendolinos between Handsacre and Glasgow. As a result, with current stopping patterns, HS2 trains will only offer, at best, a 12-minute time saving between London and Glasgow which is a 4.4% saving in journey time. Manchester will get a 22-minute journey time saving as the HS2 train’s lack of tilt is less of a problem for this shorter journey.

HS2 will offer a significant increase in capacity both between London and Birmingham and between London and Rugby, as it will take traffic off this section of the WCML. It will also reduce the journey time between London and Birmingham from 81 to 45 minutes.

Hence, while HS2 will greatly benefit Birmingham, it will reduce passenger capacity on other long distance WCML services and offer minimal time savings for longer distance trains. Given the huge cost of HS2 this will, to say the least, be an embarrassment.

This situation is the result of the previous Prime Minister’s decision to cancel the HS2 line between Fradley, near Handsacre Junction, and Manchester (HS2 phase 2) without considering the consequences. For example, the first part of this line between Fradley and Crewe (HS2 phase 2a) would have significantly increased the benefits from the core HS2 route from London to Birmingham and Handsacre by relieving capacity on the WCML.

As HS2 phase 2a is routed through open countryside, this line would also have been much less expensive than the core HS2 route which required extensive tunnelling and multiple viaducts.

Parliament recognised that there is a strong case for HS2 phase 2a by passing an Act in 2021 granting powers for its construction.

HS2 stations have 400-metre station platforms to accommodate 1,000-seat HS2 trains formed of 2 x 200-metre units. With the possible exception of Crewe and Carlisle, conventional stations would require major alterations to accept 400-metre trains and so can only be served by single 200-metre HS2 trains.

With the cancellation of HS2 phase 2 there will be no station at Manchester with 400-metre platforms. Hence HS2 trains to Manchester have to be single 200-metre units with only 504 seats. The current 11-coach Pendolinos are 266-metres long with 607 seats.

The Network North document justified HS2’s curtailment by claiming that what is left of HS2 will increase WCML passenger capacity by 86% to 250,000 seats a day. This contrasts with the reality of HS2 trains having 17% fewer seats than current trains.

A further consequence of cancelling of HS2 phase 2a is that it removes the requirement for the north chord of the delta junction outside Birmingham as there is now no capacity for HS2 trains between Birmingham and Manchester. This chord is 4.4km long and consists of cuttings, embankments, and the 1.5km,

42-span, Water Orton No 1 viaduct. Although this work will be completed, Chris understands that it is now proposed that no track will be laid on this chord. Hence, without HS2 phase 2a there can no benefit from the huge expense of constructing this chord, or indeed the cost of building the large Birmingham Curzon Street station which was intended to serve HS2 trains to Manchester. Yet this botched cancellation is a reality that must be faced. This leaves the urgent question of how to make the best use of what is left of HS2 and, in particular, to ensure no loss of WCML passenger capacity north of Handsacre Junction.

and Scotland formed of two 200-metre sections for Glasgow and Edinburgh which were to split / join at Carlisle. However, the power draw and wire bounce from a 400-metre train with two pantographs would limit speed north of Handsacre to 110mph. Chris estimates that running a single 125mph tilting Pendolino between London and Glasgow would be 17 minutes faster than HS2 trains.

A recent assessment concluded that, with the current maintenance regime, Pendolinos can remain in service until 2046. One reason for this is that they have a good fatigue life as they were commissioned for

In the absence of any Government or industry plan, enter Chris Gibb an experienced railway manager whose CV includes six years as chief operating officer of Virgin West Coast Trains. On his own initiative, in discussion with his numerous senior industry contacts, Chris developed a plan to maximise HS2/WCML passenger capacity using life extended Pendolinos running at 155mph. He intends this to be an interim plan from 2030 to 2040 which allows time for decisions to be taken and executed on Northern Powerhouse Rail, HS2 extensions, Euston, the provision of longer platforms, and the development of a long-term rolling stock strategy. Using Pendolinos in this way will not only increase the passenger capacity of HS2 trains but would also reduce journey times on Scottish services. HS2 originally proposed to run two 200-metre trains between London

140mph running but are limited to a 125mph. Furthermore, their recent refurbishment showed that these trains had minimal car body corrosion.

On a special test run in 2003, a Pendolino recorded 145.5mph. Chris has been in discussions with Alstom engineers who have no doubt that Pendolinos can be fitted with new bogies and traction systems for 155mph running in non-tilt mode on HS2 lines as this technology is in reliable operation on recent Pendolino builds.

The UK’s Pendolinos were built in 2004 at Washwood Heath in Birmingham (where HS2’s train depot is now being built) with additional coaches built in Savigliano, Italy, in 2009. The Pendolino tilting train platform is widely used across Europe, in particular on Italian conventional and high-speed lines. Of the 56 Pendolino trains in service, it is the 35 x 11 coaches sets that Chris proposes should be upgraded for 155mph running.

HS2 has ordered 54 x 200-metre trains with a maximum speed of 225mph. With the lack of 400-metre platforms north of Birmingham, it might be thought a good idea to vary this order to produce fewer longer trains. Yet, this is not feasible as the Washwood Heath depot is being built to accommodate 200-metre trains. Furthermore, having 200-metre trains makes it possible to run 400-metre trains once 400-metre platforms can be provided.

Hence, this proposal does not require any variation to the HS2 train order. However, it does propose reducing their normal operational speed from the planned 206mph to 186mph to limit the speed differential with the Pendolinos to maintain capacity on the HS2 line. This would increase the journey time between OOC and Birmingham by three minutes. Chris estimates that using Pendolinos on HS2 services would leave 27 HS2 trains to be redeployed on conventional and HS2 services. This would enable the 9-car Pendolinos to be withdrawn and the displacement elsewhere of the 10 x 7-car Class 807 units that are currently being delivered.

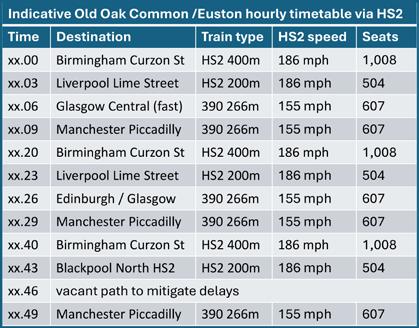

Chris proposes that there should be 11 trains per hour (tph) on HS2 out of London of which 6 are HS2 trains and 5 are Pendolino as shown in the table.

In addition, two trains per hour from Birmingham Curzon Street to Manchester using single 200-metre HS2 trains are proposed. However, this would require completion of the delta triangle’s north chord and a “New Northern Line” as described later.

These trains would be flighted so that the leading 186mph train from London will be three minutes behind the trailing 155mph train when it reaches Birmingham’s delta junction. Chris advises that this plan would still work if it was only possible to run the Pendolinos at 140mph, although it would entail a slight increase in journey time.

There are reports that the boring of the 7.2km twin tunnels between OOC and Euston will start in 2025 as Government is now funding the £1 billion for this work. However, as both funding arrangements and the design of HS2’s Euston station have yet to be finalised, it would seem that OOC will be HS2’s interim London terminus for some years.

This is a matter of concern as, while the Elizabeth line makes OOC a more convenient destination for many travellers, a large number will prefer Euston and so may avoid HS2 trains as a result. Having a mix of HS2 and WCML services terminating at two different London stations is likely to present a confused product which may reduce passenger numbers until HS2’s Euston station becomes operational.

With OOC likely to be a terminal station for some years, it is important to maximise its capacity. On the basis of experience at other similar terminal stations, Chris considers that it should be possible to operate 11 trains per hour. However, this will require improvements to manage passenger flows and, at the station’s eastern end, a reversing siding located in the Euston tunnel connected to each platform. This siding would reduce the movements needed through the west end crossovers. Currently, there is no published track layout for the eastern end of OOC while it functions as a terminus.

The proposal to use Pendolinos would give HS2 stations a mix of rolling stock with different door positions. Hence it will no longer be possible for HS2’s stations to have platform screen doors (PSD). Chris does not consider that his proposal would affect HS2 station platform stepping distances as the Pendolino’s fold-out step is higher than the standard. However, there may be a requirement to redesign platforms and vary the train platform step configuration as HS2 platforms (and indeed all of HS2) is designed to accommodate trains built to continental GC gauge.

As a result, there will be a gap of about 350mm between coaches built to UK loading gauge and the platform edge. This may be considered unacceptable without PSD. Reducing HS2’s specified 1.655-metre platform offset to bring platforms closer to the track may be the best way of addressing this issue. However, this would rule out the future use of dedicated GC gauge HS2 trains.

HS2’s core line was designed to carry 18 tph and be signalled with the European Train Control Signalling (ETCS) and Automatic Train Operation (ATO). The cab signalling provided by ETCS is essential as drivers cannot reliably respond to lineside signals above 125mph. It was considered that ATO was essential to achieve 18 tph as this needs each train to have exactly the same performance characteristics.

However, with the cancellation of the HS2 legs to Leeds in 2021 and to Manchester last year, the core HS2 line will now have fewer trains. Hence, Chris considers that ATO is not required. Dropping ATO would save significant costs and significantly reduce both the driver training workload and the complexity of commissioning the new HS2 line. Between Warrington and Gretna, it is planned to fit ETCS by 2030 as part of the TriLink programme for intelligent renewal and enhancement of the WCML north as described in Issue 206 (JanFeb 2024). This will allow Pendolinos to run at 140mph. If a similar enhancement / ETCS programme were to be implemented in Scotland, Chris expects that a 3 hour 40 minute London to Glasgow service stopping only at Preston and the Birmingham Interchange station would be possible. He considers that, north of Crewe, it should be possible to flight 2 x 140mph Pendolinos in a 20-minute period each hour to avoid delaying or being delayed by other trains.

As ETCS provides the driver with a continuous advice of permitted speed, it also offers a more flexible application of enhanced permissible speeds which could enable non-tilting HS2 trains to run at higher speeds.

Although London to Manchester is one of the busiest inter-city train routes, it will only be possible to run 266-metre Pendolinos to Manchester until 400-metre platforms can be provided there. Current plans are that this will be done as part of the Northern Powerhouse Rail (NPR) proposal to build a high speed line between Liverpool and Manchester via Warrington and Manchester airport which will use part of the cancelled HS2 Manchester leg. The aspiration is that the NPR high speed line will have an underground station in Manchester city centre with 400-metre platforms which would be on the scale of Stratford International. It would be expected that the NPR Manchester Airport station would also have 400-metre platforms to enable 400-metre HS2 trains to also serve the area south of Manchester.

As it will take over 10 years to provide this NPR station, there may be a case for an interim solution. One possibility is the provision of 400-metre platforms within Piccadilly station if new platforms could be provided on the north side of the station for Hadfield services.

Chris’s proposal suggests extending the NPR high speed line by building a “New Northern Line” (NNL) between Fradley and Manchester, designed for 155mph. NNL is the proposal suggested by the Mayors of Manchester and Birmingham after HS2 was curtailed. This would take HS2 services from London to Manchester, Glasgow, Liverpool and Blackpool. It would also be able to carry HS2 Birmingham to Manchester services which would take 50 minutes instead of the current 88 minutes. Once NNL is built, London to Manchester HS2 services could be extended to Leeds.

He advises that the NNL would be built using the Parliamentary powers of the High Speed Rail (West Midlands to Crewe) Act, which has not been repealed. NNL would therefore essentially follow the route of HS2 phase 2a. Chris believes that the NNL line can be built at a much lower cost than the HS2 line, although connecting it onto the conventional network at Crewe will be a significant cost. For this reason, he believes that the construction of NNL should be managed by Network Rail as it should be an integral part of the Crewe remodelling project.

The problem that the Gibb proposal addresses is urgent. Unless a government-backed plan is agreed soon, introducing HS2 services will reduce WCML passenger capacity north of Birmingham. Although this proposal is an entirely rolling stock solution, there are infrastructure issues that need to be considered. These include beneficial infrastructure enhancements to maximise the capacity of OOC as an interim terminus, an assessment of whether 400-metre platforms could be provided at Manchester Piccadilly, and whether HS2 station platforms need to be redesigned to reduce the gap between coach and platform.

The Pendolino proposal increases passenger capacity on HS2 services north of Birmingham without the need for any infrastructure enhancements or variation to the order for HS2 trains. It also reduces the cost, time, and complexity of commissioning and traincrew training. Essentially it makes the best use of existing infrastructure, people, and the HS2 trains that have been ordered to achieve the required benefits as quickly as possible. It also is sufficiently flexible to allow for different project completion dates in the early 2030s e.g. HS2 phase 1, NNL, NPR, WCML, and ETCS.

This rolling stock solution also does not require public finance. The Pendolinos are owned by Angel Trains which could fund the enhancements and negotiate their upgrade programme with Alstom. It is also worthy of note that a major fleet overhaul is scheduled for 2026-2029 when ETCS, new bogies, and new traction systems could be installed. The

overhaul is being planned now at Angel Trains’ facilities in Widnes, Crewe, and Derby.

Chris has certainly done the industry a great service in developing this proposal. In it he advises that “I am not being paid by anyone to prepare this idea and have no vested interest in any of the organisations mentioned in it. I am an experienced WCML railway operator who wishes to see the emerging HS2 move forward in a manner that best integrates it with our rail network, for our future customers, colleagues, economy and environment.”

He also advises that he is “grateful to the many railway professionals who have encouraged and helped me develop this proposal.”

Whilst speaking to him for this feature I asked what inspired his proposal which clearly involved a lot of work. He advised that he had been speaking to a retired Polmadie driver who, in the early 1980s, drove the Advanced Passenger Train (APT) at 138mph week after week through his hometown of Carluke. After he chided Chris by saying that today’s railwaymen had wasted a golden opportunity, Chris felt he had to do something about it.

So, it seems that a retired Polmadie driver should also be thanked for this Pendolino proposal.

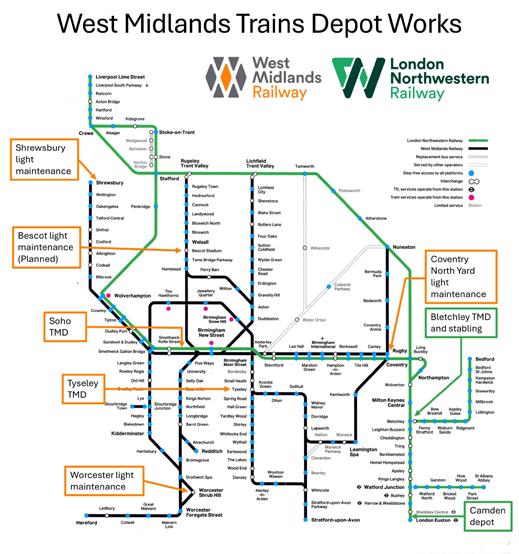

West Midlands Trains (WMT) is the operator of suburban services radiating from Euston as well as operating inter-urban services from Euston to Crewe and Birmingham New Street to Liverpool Lime Street under the London Northwestern Railway brand (LNR). In addition to suburban services radiating from Birmingham New Street under the West Midlands Railway brand (WMR), it also operates three branch lines: Watford Junction to St Albans Abbey; Bletchley to Bedford; and Stourbridge Junction to Stourbridge Town, the latter using the unique Parry People Movers.

WMT, formed by Abellio UK (now Transport UK), JR East, and Mitsui & Co was awarded its franchise in 2017 and runs just under 1,200 weekday services. It employs just under 3,000 staff of whom around 500 are in engineering. Its fleet of 462 EMU vehicles and 133 DMU vehicles (total 595), is increasing to 524 EMU and 181 DMU vehicles (total 705). WMT also services trains for CrossCountry, Transport for Wales and, from summer 2024, East-West Rail.

In 2017, WMT ordered 80 Class 196 DMU vehicles from Construcciones y Auxiliar de Ferrocarriles (CAF), formed into 14 four-car and 12 two-car units. It also ordered 324 Class 730 EMU vehicles from Bombardier (now Alstom) formed into 48, three-car and 36, five-car units. These trains are financed led by Corelink Rail Infrastructure, a joint venture between Infracapital and Deutsche Asset Management. The five-car units are branded LNR, and the remainder WMR.

Clearly, with 404 new cars delivered or under construction but fleet size increasing by 110 vehicles, 294 vehicles are leaving WMT. Even so, additional depot and siding space must be provided for the bigger fleet; if all these additional coaches were to be marshalled end-to-end, the resulting train would be 3.5km long, so think 3.5km of additional stabling capacity. This article describes the trains and the works to accommodate them.

Most of the Class 196 vehicles were assembled at CAF’s facility in Newport, Wales. They were launched by WMT in October 2022. A four-car set has 311 seats and two-car has 141. Seats are cantilevered from the bodysides and all units have the usual accessible toilet, three bike spaces, at-seat power, and USB sockets. Four-car sets also have a second more compact toilet. In concept they are similar to Class 197 units described in Rail Engineer 197 (July/Aug 2022).

Since entering service there have been some technical challenges for which fixes have been made or are under way, including:

» Software functionality, affecting many systems such as passenger information.

» Build quality snags e.g. wiring, relay issues/ security, auto reversing gear.

» On board hot box detection faults.

» Cab to saloon door faults.

» Leaking window seals.

» Yaw damper brackets (see Rail Engineer 195 (March/April 2022).

This fleet has two sub-classes, all built at Alstom’s (formerly Bombardier’s) factory in Derby. The 730/0 three-car units are 90mph EMUs and each car is 24 metres long. They were first introduced on London EustonTring/Bletchley stopping services in mid-2023 allowing elderly Class 319 units to be withdrawn, but are really intended for West Midlands suburban services. They have 199 cantilevered seats in a 2+2 and 1+1 seat layout to promote space around doorways and space for 344 standees giving a total of 546 - 149 more people than can be accommodated on a Class 323. There are three bike spaces and a universal toilet.

The five-car Class 730/2 has 463 cantilevered seats in 2+2 layout (with armrests between the seats unlike Class 730/0) with plenty of table seats, two standard toilets, and one universal toilet. These trains are configured for 110mph operation (the differences in top speed for the two subclasses is the result of different dear ratios). The 24-metre-long coaches provide a10-car train that is the same length as a current 12-car Class 350 train. Both sub-classes are the first Aventra models with though gangways between units. Some of the issues that have arisen

include software/train control and monitoring faults which seem to have affected all the Aventra trains. Unlike earlier Aventra trains, the Class 730 has sliding plug cab doors and these are prone not to close on canted track. There have also been issues with the cab door droplight design. Additionally, problems have been found with the Automatic Selective Door Opening system, master Input/ output unit analogue to digital converter, passenger information screens, water ingress, and battery chargers. The trains’ three phase drives include large capacitors and an explosive failure in the line converter module of a Class 345 Elizabeth line Aventra led to a variety of risk management activities that delayed testing. Finally, these are the first Aventra trains intended for 110mph operation and ride quality is still being tuned.

Rail Engineer has frequently described the complexity of putting new trains into service. They are part of a complex integrated system with many interfaces, and, on some parts of the network, it might be the first change in 30 years requiring people to change duties and/ or learn new skills. Right now, the commercial conditions for the railway are not what they were before the pandemic, leading to even more commercial pressures for all parties. This is an expensive transition in a money constrained industry. The new fleets sometimes require a different approach to operation and maintenance, and everyone in the train operating company is affected in some way.

That said, there is a great opportunity for customer improvements, marketing, and growth. But, back to risk, stakeholders expect performance improvement even during fleet transition despite experience to the contrary.

Some examples of the real-world issues include:

» Traincrew consultation, agreement and training, linked to trains being built for Driver Only Operation, then converted for guard operated doors.

» Signal sighting with through gangways/longer trains, some relocation of signals needed. For example, at Lichfield Trent Valley high level, there is a signal at each end of the station. The combination of slightly longer trains and the gangway meant that one signal had to be relocated.

» Car stop marker boards, stopping positions and Platform Train Interface risk assessments, e.g., location of wheelchair spaces has changed and every platform requires assessment to ensure the access ramp can be accommodated at the new train’s stopping location.

» Cyber security vulnerability risk.

» Train to wayside systems, data access compatibility, links to shore systems.

» Automatic Selective Door Opening system interface (160-Metre-long trains already require selective door opening at some stations on the Euston-Crewe service, more doors will be locked out on 10-car new train services).

The long running national disputes with railway trade unions led to some issues with local engagement which were overcome, but it was still challenging to get the staff trained and on to rostered operation before their training ‘expired’ requiring refreshers. There was also a huge commercial workload. Each new fleet involves the train manufacturer, the financier (e.g. ROSCO), and WMT, often with DfT involvement too, in activities such as revised delivery schedules and financial settlements of one sort or another. As mentioned, the Class 730 fleet size was changed from 36 to 48, three-car units and from 45, five-car (with first and standard class and two standard class layouts) to 36, five-car with one standard class only layout.

Delays to the new trains mainly arising from Covid meant that other negotiations to extend leases for the trains being replaced were required.

Class 170 DMUs and Class 323 EMUs are being cascaded from WMR. Class 319 EMUs have been, and Class 350/2 will be, returned to their ROSCO. Finally, all this has to be reflected in support contracts and WMT’s National Rail Contracts.

Depot works were delayed and interim solutions to maintain the new trains were required. These delays have resulted in increasing cost due to construction inflation forcing additional reviews including scope reduction and re-pricing, but work is now underway at all depots to accommodate more trains and their maintenance requirements. Another complication is that the LNR Class 730s will not be maintained at Siemens’ Northampton depot.

Earlier, it was stated that the increased fleet would need more stabling space. Of course, during transition when new vehicles have arrived but cannot yet be used, pressure is even greater. Unless something changes, this risks depot gridlock and/or poor safety practices. All this means that there is a major programme of depot construction and upgrades. What follows is a site-bysite summary of the works.

Tyseley depot to the south of Birmingham is a large DMU depot and stabling location where changes are being made to accommodate longer

units, such as track remodelling and extensions to maintenance sheds. In addition, mobile gantries with hoists, side pits, and facilities for synchronised lift are being provided. Accompanying all this are improvements to arrangements for refuelling, cleaning, waste oil removal, electrical shore supplies, replenishing controlled emission toilets (CET), and filling sand hoppers. An automatic vehicle inspection system is being provided at one end of the stabling sidings.

At Worcester a new four-car fuel/adblue/CET point has been built together with three new sidings for four-car trains. Despite being adjacent to Worcester Shrub Hill station, these are known as the Hereford Sidings.

Soho EMU depot to the west of Birmingham has received a new mobile access gantry and hoist system to access roof mounted equipment such as air conditioners not fitted on the current Class 323 units. There will also be changes in the sidings to walkways and provision for servicing CETs will be provided.

A major expansion of Bletchley depot is under way so that it can be the main base of the LNR Aventra fleet. The depot building will be extended and internally modified to accommodate a five-car synchronised lift, gantries with a hoist for access to air conditioners, and more suitable pits. Additional stabling sidings will be provided alongside the depot building. Complicating all this is that the three two-car Marston Vale DMUs also have to be maintained/serviced at Bletchley whilst the works continue. The depot is located approximately at right angles to east of the West Coast main line. This is a major investment which is being financed by Porterbrook Leasing. The stabling sidings parallel to the main line will also receive attention.

Further works are being carried out at Shrewsbury, Coventry, North Yard, Camden depot, and, subject to planning permission, a new light maintenance/servicing facility will be constructed at Bescot.

As is probably clear, ‘just’ buying some new trains has resulted in massive change to WMT. Whatever the programme was pre-Covid, trying to juggle introducing new trains and retiring older trains whilst rebuilding most of the depots must have affected the work of everyone in the organisation, and there’s probably another two years work before it is all finished. Rail Engineer wishes them all well.

This article is based on a presentation given to the Milton Keynes Centre of the IMechE Railway Division by John Doughty, WMT’s engineering director.

Improve the efficiency of your workshop with our range of prefabricated steel maintenance and inspection pits, built to UKCA and CE certified standards.

Premier Rail Pits offer the following benefits:

• Guaranteed water tight

• Up to 70% quicker installation time compared to precast concrete

• High quality finish

• All internal service ducts fitted prior to installation

• Any length available

• Rail attachments fitted prior to installation

• Full or part installations are offered

A full range of accessories and safety products is also available.

Tel: +44 (0)1775 821222

Email: info@premierpits.com

Web: www.premierpits.com/railpits

At last year’s Railway Challenge, the chief judge, Bill Reeve announced that without doubt it had been the best challenge yet. This year he said the same thing, and the scores showed that this was no mere repetition. Indeed, this year’s challenge was the first in which all the locomotives present were operational and set out to complete the circuit. Unfortunately, however, one was unable to complete it.

This event is run by volunteers and staff from the Railway Division of the Institution of Mechanical Engineers (IMechE). Their contribution is much more than the challenge weekend as it requires many hours developing the competition, judging paperbased challenges beforehand, and supporting the teams. For example, a virtual team networking day was run in December to introduce the challenge, offer technical advice, and describe common pitfalls and good practice.

The competition takes place over three days on the Stapleford Miniature Railway on the Gretton Family estate near Melton Mowbray, operated by the Friends of the Stapleford Miniature Railway (FSMR). This 10 ¼ inch gauge, 1/5th scale railway which is 3km long, has a balloon loop and a station with sidings that have hard standing for the competing locomotives. The main track challenges are done on Sunday which is also the spectator day.

Although the FSMR is not normally open to the public, it has occasional open weekends such as that on 24 to 26 August for which details are available on links here.

For the winning team from the University of Sheffield, it was certainly their best challenge yet. Of the 12 challenges to date, Sheffield had competed in nine of them, taking fourth place on three occasions and coming second in 2021.

While most teams have a university or business leader, the Sheffield entry is managed by the student-led Railway Challenge at Sheffield (RCAS) club. This has about 30 undergraduate students from all years across multiple engineering disciplines. As a result, its final-year students have significant experience of the challenge.

As regular readers may recall, Rail Engineer has reported on the Railway Challenge since the first event in 2012. Our feature in Issue 203 (Jul-Aug 2023) has a detailed description of the locomotive specification, the on-track and paper-based challenges, how the locomotives are deemed fit to run, and the challenges are assessed. This feature focuses on the 2024 results and what was new for this year’s challenge.

Alstom/University

challenges

The challenges in the first 2012 event were ride comfort, traction power, and energy recovery (distance moved using stored energy). In addition, the teams were judged on their design philosophy and business case presentation.

In 2014, noise and reliability challenges were introduced where teams points were deducted for any failures or significant late running. A maintainability challenge which timed the removal and replacement of a powered wheelset was introduced in 2015.

2019 saw the introduction of three new challenges: an auto stop challenge which required the locomotive to stop at a precise location automatically; an innovation report; and the production of a technical poster.

This year saw the removal of the noise challenge as almost all teams had battery locomotives, hence the noise measured was largely that of the FSMR’s coaches they hauled. It also saw the introduction of a further four new challenges. However, these were optional and teams were invited to enter one or more. Only a team’s best optional challenge score was included in the overall result. These were:

» Autocoupler challenge to design, implement, and demonstrate an automatic coupler system.

» Aerodynamic challenge to simulate the locomotive running at high speed to demonstrate its aerodynamic performance.

» Location Announcement challenge to design an audio-visual announcement/ display system that announces key locations around railway.

» Remote Data Recording and Monitoring challenge to transmit locomotive performance data to a central location.

A new option for the 2023 challenge was an entry level competition for teams aspiring to enter a working locomotive. This required teams to undertake the presentation challenges of producing a technical poster, design and innovation reports, and a business case presentation. They were also required to use Computer Aided Design (CAD) to demonstrate that a key feature of their locomotive design is fit for purpose.

As well as not having to enter the track-based challenges, the rule that no more that 40% of a team can have previously participated in a Railway Challenge does not apply to the entry level teams. Although there were no entry level teams in 2023, three such teams entered the Railway Challenge this year.

As can be seen from the 2012 to 2024 results table, almost all the teams entering a locomotive were regular entrants. These were the Universities of Aachen (7), Birmingham (8), Huddersfield (10), Sheffield (9), as well as Transport for London (9) and a joint Alstom/ University of Derby team (8). In addition, the University of Warwick and Newcastle University respectively entered the challenge for their fourth and second years.

While regular entrants often re-enter the same locomotive, this is usually modified to address lessons learnt from the previous challenge. In addition, new challenges and amended competition rules require teams to alter their locomotives.

This year, for the first time, there were three entry-level teams. These were from Herriot-Watt University, Siemens Mobility, and, from India, the Institute of Technology (IIT) Kharagpur in West Bengal. All aspire to enter a locomotive next year, though for IIT Kharagpur this is a particular challenge as freight costs will be about the same as the cost of their locomotive.

One of the challenges for the organising committee is attracting more entrants. However, although the Stapleford Miniature Railway is ideal for the Railway Challenge, its layout needs to be enhanced to realise this vision. To date, the maximum number of entries has been 11 locomotives on site which is about the maximum number that the railway can accommodate. To accommodate an increased number, two constraints need to be addressed. These are the lack of space around the station to work on locomotives and the need to increase the number of locomotives that can undertake challenges on the railway’s loop.

To provide more space at the station, a siding from the present headshunt to a new turntable has been constructed. This will eventually have provision for 20 track spurs. These will have hardstanding with several able to accommodate two locomotives and

so will provide sufficient space for 24 teams to work on their locomotives with the flexibility to change the order of despatch if required.

Professor Simon Iwnicki, who proposed the Railway Challenge in 2010 and has chaired the organising group ever since, explained that this work has been generously supported by Network Rail which surveyed the site and provided an initial layout for the turntable, as well as donating ballast. The FSMR has also actively supported this project for which various volunteer weekends have been organised which have included Railway Challenge teams and Railway Division young members.

Currently, two locomotives an hour can undertake the track challenges on the railways 1.2km loop. As a result, the maximum number of locomotives that can be tested during the Sunday track challenge day is 12. As the balloon loop provides an out and back layout from the station, the number of locomotives that can be tested is limited to two trains an hour. To increase the railway’s capacity and flexibility, it is proposed to provide a holding loop close to the balloon loop together with a chord that could provide a continuous circuit. One issue with this proposal is that a river bridge may have to be rebuilt as one of the chord’s turnouts would have to be placed on it.

With 15 challenges to evaluate for the 10 locomotives and three entry level teams, the judges themselves had a challenging task especially as the award ceremony started immediately after the last on-track challenge run.

The award ceremony was hosted by chief judge, Bill Reeve who advised that the judges considered that this Railway Challenge has seen the most impressive set of entries in all the years of the competition. He was also impressed by the teamwork shown at the event and stressed that this really matters as railways only work well when all the operators help each other. The judges felt that the teams from the Universities of Warwick and Sheffield had done a great deal to help their fellow teams and so had awarded them additional discretionary points.

Prizes were first awarded to the entry level teams. Siemens Mobility Limited were the overall winners and Herriot-Watt University won the CAD challenge. Bill particularly wished to thank the IIT Kharagpur team members who, coming from India, were the longest-travelled entrant ever.

With so many challenges it took some time to present all the prizes. These were as follows:

» University of Sheffield – Auto stop; Reliability (joint first); Innovation; Autocoupler; Location announcement and Remote data recording.

» University of Derby / Alstom – Ride Comfort; Energy storage; Traction; Reliability (joint first).

» Pozan University of Technology – Maintainability; Aerodynamic.

» Transport for London – Design; Business Case; Technical poster.

With the University of Sheffield team having won six of the challenges, it was perhaps no surprise when Bill announced that they were the overall winners of the Railway Challenge. He noted that this was the team’s ninth year at the challenge and during this time they had learned much. He considered them to be worthy winners as from their arrival on site they had impressed the judges with the consistent quality and intelligence of all aspects of their design, presentation and operation. As a result, Sheffield scored 1,724 points out of a possible 2,000.

In second and third place were respectively the University of Derby / Alstom and Poznan University of Technology. Bill noted that the top three teams had very creditable and very impressive results.

Advance notice has been given that next year it is proposed that there will be:

» An energy efficiency challenge.

» The option for drivers to ride on their locomotives.

» An increased number of carriages hauled, from two to three.

» Locomotives that are fully bi-directional for both operation and coupling.

In this way the IMechE’s Railway Division is continuing to develop this successful competition which to date has seen 89 teams experience the Railway Challenge. While this concerns small scale locomotives, what the teams face are real world challenges of project and supplier management, producing a workable design then building, testing, and running it. Working as an effective team which, as one sponsor noted “doesn’t want to murder each other by the end of the event”, could also be considered quite an achievement.

By providing over 1,000 young engineers with this experience in a risk-free supportive environment, the IMechE’s Railway Division has provided an invaluable service to the industry. Indeed, Bill Reeve advised that past participants, who are increasingly filling quite senior roles within the railway industry, say that the Railway Challenge experience was the highlight of their training.

When reporting on the Railway Challenge, it is always a pleasure to experience the buzz at Stapleford and see the effort and enthusiasm displayed by the teams. It is also impressive to see how the FSMR, Railway Division volunteers, and IMechE staff ensure the success of this event and its smooth running. The contribution of the event sponsors whose financial contribution made the event possible must also be noted. These were: AtkinsRealis; Angel Trains; CAF; RSSB; and Network Rail.

Output at full power: up to 240 hours without additional sunlight

Maximum visibility: approx. 900 m (depending on the course of the road)

temperature range: -20 °C to 85 °C

one-side and two-side reflectors and different colours possible

STRAIL (UK) Ltd. | Tannery Lane // Send / Woking // GU23 7EF // Great Britain Head Office +44 (14 83) 22 20 90 // info@strail.com

Sunday 2 June was a good day for residents of the Levenmouth area as, after 55 years, they got their railway back. The first public train services between Leven and Edinburgh were celebrated by a street fair and funfair on the promenade. The day before, a special train ran from Levenmouth to Edinburgh and back for Golden Ticket holders who were members of the community with a close connection to the railway, including members of the Levenmouth Rail Campaign (LMRC).

The railway was officially opened on Wednesday 29 May when 300 invited guests were welcomed at Edinburgh Waverley station by Network Rail Scotland managing director Liam Sumpter. Following this, a specially branded train took guests to ceremonies at the lines’ two new stations, Leven and Cameron Bridge, where the guests of honour were Scottish First Minister John Swinney; Scottish transport secretary, Fiona Hyslop; Fife Council leader, David Ross; ScotRail managing director Joanne Macguire.

In his speech, First Minister Sweeney emphasised how the new railway would provide economic, educational and social opportunities and attract inward investment. He also paid tribute to the tenacious members of the LMRC for their successful campaign. LMRC Chair Dr Allen Armstrong was proud that the disadvantaged Levenmouth area had been able to mount an intensive community-led

campaign which was supported by the council and had cross-party support in the Scottish Parliament. He also thanked rail experts from the Scottish Retired Railway Officers Association (Scotland) who had an important role in advising the campaign and helping it to present its case in a coherent manner.

Although this opening ceremony had been planned for some time, having politicians making speeches at such a high-profile event could have been considered a breach of the pre-election purdah period, hence this opening ceremony had to be approved by the Cabinet Office. It was for this reason that Network Rail issued no press releases about the Levenmouth re-opening.

The Leven service opened with an hourly frequency of trains to Edinburgh via Kirkaldy due to a shortage of diesel multiple units (DMU). The provision of a half hourly service would require an additional six DMUs which are not likely to be available until 2025 from, for example, the completion of the East Kilbride electrification. Once these units become available a half-hourly service will be introduced with one train running between Leven and Edinburgh via Dunfermline to create additional journey opportunities.

The re-opening of the 10km Levenmouth line was the fifth Scottish rail re-opening in the last 20 years. Previous re-openings were the Larkhall branch (5km) in 2005; Stirling to Alloa (21km) in 2008; Airdrie to Bathgate (22km) in 2010; and the Borders Railway (49km) in 2015. In contrast to previous projects, the Levenmouth branch was never formally closed although it last carried freight traffic 20 years ago. Hence the line was still owned by Network Rail and parliamentary powers were not required to reopen it. Construction of earthworks to current standards did however require the purchase of some parcels of land.

PHOTO: DAVID SHIRRES

In August 2019, the Scottish Government announced the go-ahead for design work to support the reopening of the branch. A further announcement in January 2022 confirmed that £117 million was to be invested in the Levenmouth railway and that it will open in spring 2024.

The 9.7km-long Levenmouth branch has few straight sections as it follows the Rivers Ore and Leven for almost all its length, so its line speed is generally 45mph. It has no major earthworks although it has some steep slopes which required regrading or reprofiling. River protection work was also required. The branch’s five river bridges were generally in good condition but needed grit-blasting to bare metal, recoating with a special paint system, and the installation of new timber decks.

The railway was built as a double track railway but had single track when it closed to passenger services. To ensure timetable resilience, the reopened railway is double track except for a 1.5km single line section from Thornton North Junction where it joins the main line.

As part of the Scottish Government’s plan to decarbonise its railway, the Levenmouth branch will eventually be electrified. To minimise the disruption and cost of the branch’s future electrification, mast foundations were installed as part of the reopening project. As this was done in accordance with a detailed electrification design, there will be no infrastructure clashes or signal sighting issues when the line is electrified.

The line has two new stations at Cameron Bridge and Leven. Cameron Bridge is 3km from Leven and has two 196-metre platforms and a 125-space car park. As it is situated on the main road to Fife’s East Neuk it could be a well-used railhead. Hence there is space for a further 300 cars. The terminating station at Leven is a single seven-metre-wide island platform. Its two platforms are 205-metres long. The station has a pavilion with customer facilities and a welfare facility for ScotRail staff. It has a 134-space car park and is adjacent to the town’s bus station.

Work to re-open the Levenmouth branch started with devegetation work late in 2020 followed by site investigation work in 2021. Work started to remove the old disused track and other redundant infrastructure in July 2022. Track laying was done in stages and was completed in August 2023.

The reopening project was managed by Network Rail with the main suppliers being: AmcoGiffen, Atkins, BAM, Siemens, SPL Powerlines, Story, QTS, and Rail Systems Alliance Scotland (RSAS).

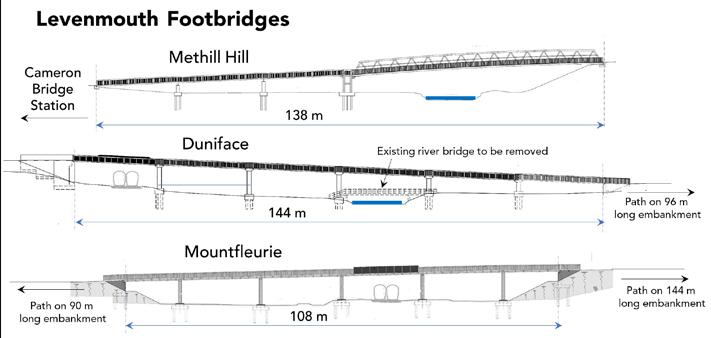

Whilst the line was mothballed, it was crossed by various paths. For understandable reasons, Network Rail did not wish to create level crossings on the line. Hence, various paths across the line had to be closed where the significant cost of a footbridge could not be justified. At the thinly-populated area at the start of the branch, there was some protest at the closure of a path which was neither a right of way nor an adopted Fife Core path. Hence the cost of a footbridge could not be justified. However, three new substantial footbridges are to be provided in the populated area between Cameron Bridge and Leven to maintain existing active travel routes and provide new routes to railway stations. These are being provided by the Levenmouth Connectivity Project which is funded by the Scottish Government’s Places for Everyone programme, as well as funds that Fife Council received from the UK Government’s Levelling Up Fund. Although these bridges were not part of the reopening project, Network Rail worked

closely with this connectivity project to minimise its cost and submitted planning applications for the three footbridges. With low land by the River Leven and disused coal mines in the area, these planning applications required flood and mining risk assessments.

Around 8,000 people live within 2km of the Cameron Bridge. This includes the settlement of Methilhill which is 200 metres from the station, though separated from it by the River Leven. It is to be connected to the station by a 140-metre-long active travel bridge over the river with one 70-metre and 2 x 21-metres spans. As the steelwork fabricator recently went into administration it was not possible to complete this bridge in time for the re-opening. It is hoped that it will be completed by the end of the year. In the meantime, residents face a longer walk using existing footpaths.

A Fife core path crosses the railway at Duniface, 600 metres east of Cameron Bridge. Here a 144-metre active travel bridge with 6 x 24-metre spans was craned into position in May. The bridge was not quite complete at the time of the opening. Another previously well used core path used to cross the railway at Mountfleurie, 1.3km from Leven. In October, Fife Council announced that it was to provide a 108-metre active travel footbridge of 2x14-metre and 4x20-metre spans over the railway and Fife Heritage Railway at an expected cost of £5.8 million. Unfortunately, land issues have delayed the construction of this bridge which is not expected to open until 2025. In the meantime, local residents using this path to commute to work face an additional 40-minute walk per day.

The LMRC branded its campaign as “more than just a railway” as it believed that a re-opened railway would be the catalyst to regenerate the largest settlement in Scotland without a railway. Many of the 46,000 people in its catchment area have a quite low standard of living with the closure of mines, docks, and other industries. A Scottish index of multiple deprivation (SIMD) report showed that 44% of the Levenmouth population were in the bottom 20% of the SIMD ranking.

When, in August 2019, Michael Matheson, the Scottish Cabinet Secretary for Transport, Infrastructure and Connectivity, announced that the case had been made for the Levenmouth rail link, he said that “giving Leven a direct rail link to the capital, will lead to an enhanced local economy, bringing better access to employment and education and the potential for new investment.”

The LMRC’s argument that a new railway would regenerate the area had thus been accepted by the Scottish Government.