by rail engineers for rail engineers

STRUCTURES & INFRASTRUCTURE

STRUCTURAL FAILURE AT YARNTON PG.30

SIGNALLING & TELECOMS

BIRMINGHAM NEW STREET

Explore the work to upgrade signalling and control in the area around New Street station.

PHASE 7: OPEN HEART SURGERY PG.42

www.railengineer.co.uk

LEVEL CROSSING & TRACKSIDE SAFETY PG.12

LEVEL CROSSING

SAFETY PG.60

Among the safest in Europe, Great Britain’s level crossings still pose a risk to the public.

2024 – ISSUE 207

MAR-APR

RAIB releases its report into this collapsed wing wall which was struck by a train.

FOCUS: HS2’s ENGINEERING PHOTO: HS2

Train operations

Freight safety

Public behaviour

Passenger operations

Health and wellbeing

Passenger and staff assaults

Occupational health and safety

Level crossings

Fatigue

Safety and health: Asset integrity

We’re with you every step of the way

Leading joined-up thinking to support safer, smarter rail

Britain’s rail network originates from an industry with a uniquely collaborative culture – and every inch is underpinned by dedication to safety and health. But the network’s complexity means we can only get the full benefits of everyone’s safety when we join up the different areas of collaboration, to see the whole system. This lets rail direct its resources to where they’ll do the most good.

T he new Rail Health and Safety Strategy will lead us in this direction. Drawn on detailed consultation across the industry, and led by industry risk groups, it has been designed by industry, for industry.

Discover RSSB’s role in unlocking whole-system solutions. Read the new Rail Health and Safety Strategy: www.rssb.co.uk/thestrategy

42

64

30| 34|

42| 38|

46|

50|

12| 14|

HS2 update: Overview

HS2 hits peak construction this year, with work in motion and a workforce of 30,000 at 350 active sites.

HS2 update: Tunnels

With 104km of tunnelling underway on a scale never seen in the UK, HS2 remains Britain’s largest infrastructure project.

72 CONTENTS

Sekisui’s FFU: Newark flat crossing four years on Newark flat crossing is yet another example of the application of FFU technology on Network Rail infrastructure.

Gripple SwiftLine Rail Dropper

Recently approved by Network Rail, this new dropper changes the game for OLE maintenance and repair.

Birmingham New Street Phase 7: Open heart surgery in the Midlands

Paul Darlington reports on the work to upgrade signalling and control in the area around New Street station.

Siemens Mobility boost for Chippenham

Clive Kessell probes the decision making behind Siemens Mobility’s £100 million investment into the building of new premises.

Cyber security in rail

Protecting data and systems remains a low priority in rail and instances of hacking occur all too frequently.

54| 22|

HS2 Structuresupdate:and earthworks

Over 50 viaducts and a huge amount of earthworks are required to create Britain’s first domestic high-speed railway.

Company profile: GGP Consult

Consulting engineering firm GGP Consult provides resources and expertise to over 50 countries around the world.

56|

60|

64|

68|

72|

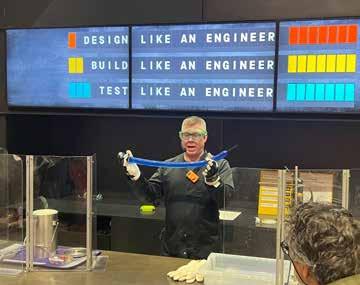

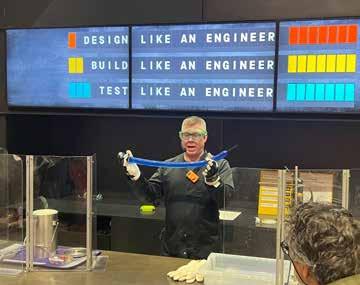

National Railway Museum inspires future engineers

The UK has an impressive railway engineering heritage and the National Railway Museum attracts over 650,000 visitors each year.

Level crossing safety

Great Britain’s level crossings are among the safest in Europe but still pose a significant risk to the public.

Improving level crossing safety using technology

Paul Darlington reports on how technology can deliver new engineering solutions and improve level crossing risk management.

Getting the on track experience

The ‘Practical Track Challenge’ run by the PWI gives officebased professionals an understanding of track work.

Ayr hotel fire closes railway for eight months

David Shirres reflects on the fallout of the recent fire at Ayr station hotel and considers the building’s future.

14

Structural failure at Yarnton

Mark Phillips examines the RAIB’s report into the collapsed wing wall which was struck by a train at Yarnton.

PHOTO: SIEMENS MOBILITY

PHOTO: DAVID SHIRRES

Rail Engineer | Issue 207 | Mar-Apr 2024 3

PHOTO: ISTOCK.COM/SOLSTOCK PHOTO: HS2

We make no apologies for returning to the subject of HS2 which was cut back as it “no longer reflected post-lockdown changes in travel”. Yet, as Matt Atkins describes, recent ORR figures show a trend of increasing rail passenger numbers. The last quarter’s 21% increase brings journeys up to 90% of the prelockdown levels. Cancelling HS2 phase 2 is apparently not a problem as the Network North proposal claims to double West Coast Main Line capacity to 250,000 seats a day, yet the reality is that it now offers little benefit north of Birmingham. It is not unreasonable to expect that the basis for figures used to justify major policy announcements should be made public, yet the Department for Transport (DfT) refuses to divulge how this HS2 capacity figure was derived. Readers can draw their own conclusions as to why this should be the case.

HS2’s former chief engineer, Andrew McNaughton once described HS2 as the work of generations. He was right to do so, though it will be more generations than he first thought. The problems that HS2 was to resolve have not gone away.

Years of work developing HS2 produced a solution that is unlikely to be much different from that developed by others trying to solve the same problem. Though it will take decades, it is quite possible that the full HS2 Y network will eventually be built. In the meantime, a huge amount of work is being done to construct HS2 phase 1. There are many reasons why this is an expensive railway. One is overheads and procurement arrangements from which lessons must be learnt. Parliament has also willed expensive environmental mitigation such as green tunnels which cost three times more than cuttings. HS2’s route requires costly engineering. Its 47km leaving London and 15km into Birmingham is almost all in tunnels or on viaducts, while its complex Delta Junction has 13 viaducts. High levels of construction inflation have also added £10 billion to HS2’s 2019 estimate.

UK Rail passenger journeys (millions)

In this issue we focus on the project’s impressive engineering and describe how innovative techniques are delivering cost reductions. This includes reusing millions of cubic metres of sometimes contaminated earthworks on site. We explain the bio-remediation of spoil from the derelict Washwood Heath site and how CL:AIRE and DIGGER enabled 26 million tonnes of spoil to be reused, avoiding the need for large numbers of HGV movements. The caterpillar shape of the Victoria Road crossover box also reduced the excavations required. There were also cost savings from constructing viaducts with all major components manufactured off site for HS2 which is a UK first. Another first for HS2 is the double composite design of some of its viaducts whose benefits we describe.

HS2’s 104km of tunnelling is a logistical exercise of feeding tunnel boring machines (TBMs) with concrete segments and removing their spoil. We describe the deployment of these machines to explain why the Northolt tunnels need four TBMs and how TBM Dorothy’s cutterhead is boring three tunnels.

HS2’s website has a legacy section with 200 papers describing the project’s innovations. A significant HS2 legacy is building a diverse, skilled, and talented workforce across its supply chain, of whom 4% are apprentices. Some of these engineers feature in website video clips where they, quite rightly, proudly explain the engineering for which they are responsible. Despite HS2’s curtailment, hopefully such engineers will be able to support the rail industry for years to come.

2000 200 0 400 600 800 1000 1200 1400 1600 1800 2000 2002 2004 2006 2008 2010 20122014 2016 2018 2020 2022

DAVID SHIRRES RAIL ENGINEER EDITOR DAVID SHIRRES Engineering HS2

TBM Cecilia’s breakthrough at Chiltern Tunnel North Portal on 24 March PHOTO: HS2 EDITORIAL 4 Rail Engineer | Issue 207 | Mar-Apr 2024

Inspiring future engineers is one of the aims of the National Railway Museum’s masterplan to increase visitor numbers. As we describe, the museum’s new Wonderlab and planned Railway Futures Gallery should encourage young people to engage and get excited by railway engineering.

Developing rail engineers by giving them a safe, practical on track experience is the aim of the Permanent Way Institution’s practical track challenge. As we report, this year 38 participants benefited from this worthwhile initiative which was held at the Bo’ness Heritage Railway in Scotland. The support of all the companies involved has to be acknowledged without whom this event would not have been possible.

Lessons from the collapsed wing wall at Yarnton are described by Mark Phillips who highlights key issues from the Rail Accident Investigation Branch’s report into this incident. These include the need to accurately measure bulges over time and improve structural defect risk scoring. Also at risk of collapse was an abandoned hotel which is closing the railway at Ayr for eight months. We describe why and suggest that there are lessons to be learnt to avoid this situation reoccurring elsewhere.

Birmingham New Street’s 1960s signalling equipment was becoming increasingly difficult to maintain and did not have the flexibility needed to reliably run 1,200 trains a day through its constrained infrastructure. Resignalling the station was done in seven phases over many years. In a comprehensive feature, Paul Darlington explains how the final seventh phase of this project was delivered and the benefits of its various innovations.

The innovations being developed to improve level crossing safety are explained in another feature. Although Britain’s

level crossings are among the safest in Europe, there are many near misses and, sadly, occasional fatalities, particularly at footpath crossings. We explain how Network Rail’s report ‘Enhancing Level Crossing Safety 2019 to 29’ has a strategy to reduce this risk.

With ever greater connectivity, cyber threats present an increasing risk to railway systems. For example, trains were stopped in Poland after hackers accessed an open channel VHF radio. Clive Kessell’s feature shows that this is a complex topic. Yet its key messages are to maintain awareness of this threat and ensure basic precautions are taken.

Rail Engineer was present at the Siemens Mobility press conference in Chippenham when it announced a £100 million investment in new premises which are expected to open in 2026. This will ensure that the company’s skilled local workforce of 800 people will continue to serve the UK signalling market. At this event, Chancellor of the Exchequer Jeremy Hunt advised that the Government will back this plan as part of the UK’s manufacturing revival which will be encouraged by tax reliefs of up to 25%. Unfortunately, tax reliefs were not enough to save the thousands of jobs at Alstom’s Derby plant and its associated supply chain.

The risk to such plants was highlighted in a 2023 Railway Industry Association’s report which warned of the consequences of the hiatus of rolling stock orders. It also called for a long-term industry strategy to create a smoother train order profile. Yet, it is now almost three years since the Williams Shapps report committed to the production of such a strategy. Sadly, the Derby closure is an example of the consequences of the lack of a plan for Britain’s railways.

Production

Production and design

Lauren Palin lauren@rail-media.com

Adam O’Connor adam@rail-media.com

Engineering writers

bob.hazell@railengineer.co.uk

bob.wright@railengineer.co.uk

clive.kessell@railengineer.co.uk

david.fenner@railengineer.co.uk

graeme.bickerdike@railengineer.co.uk

malcolm.dobell@railengineer.co.uk

mark.phillips@railengineer.co.uk

paul.darlington@railengineer.co.uk

peter.stanton@railengineer.co.uk

Advertising

Asif Ahmed asif@rail-media.com

Craig Smith craig@rail-media.com

Rail Engineer

Rail Media House, Samson Road, Coalville Leicestershire, LE67 3FP, UK.

Switchboard: 01530 816 444

Website: www.railengineer.co.uk

Rail Engineer Videos

http://rail.media/REYouTube

Editorial copy to

Email: news@rail-media.com

Free controlled circulation

Email: subscribe@rail-media.com

The

PHOTO: HS2 Editor David Shirres editor@railengineer.co.uk

HS2’s Colne Valley Viaduct construction crosses the Grand Union Canal

Editor Matt Atkins matt@rail-media.com

small print Rail Engineer is published by RailStaff Publications Limited and printed by PCP Ltd. © All rights reserved. No part of this magazine may be reproduced in any form without the prior written permission of the copyright owners. Part of: www.rail-media.com THE TEAM 5 Rail Engineer | Issue 207 | Mar-Apr 2024

Passenger journeys on the rise

A total of 417 million rail passenger journeys were recorded in Great Britain between October and December 2023, according to the Office of Road and Rail (ORR).

The organisation’s report ‘Passenger rail usage October to December 2023’ shows a 20% increase on the 348 million journeys in the same quarter of 2022. This mirrors the percentage increase for rail journeys for the year January 2022 to December 2023, which saw 1,570 million journeys.

According to the ORR’s report, a total of 15.2 billion passenger kilometres were travelled in Great Britain in Oct-Dec 2023, and total passenger revenue for the quarter was £2.6 billion.

These figures continue to show a rising trend in the recovery from the pandemic lockdowns although the number remains lower than prelockdown levels, at 90% of the 461 million in Oct-Dec 2019.

PASSENGER JOURNEYS

Elizabeth line saw the largest increase in journeys, which were up by 40%, driven in part by the increased number of services following the opening of the central section of the line.

Transpennine Express and Avanti West Coast both planned at least 40% more trains compared with the reduced timetables in Oct-Dec 2022, resulting in a large increase in passenger journeys. ScotRail saw a 34% increase compared with the previous year, but only a 12% increase in trains planned.

Heathrow Express saw the smallest increase in passenger journeys at 5%, followed by c2c and London North Eastern Railway, both up 6%.

Open access operators recorded 2.3 million passenger journeys combined, an increase of 14% on the 2.0 million in the same quarter of 2022.

The report shows that all train operators enjoyed a greater number of passenger journeys. This was due to fewer strike days impacting passenger services than during the same period in 2022.

The report also broke down the statistics by sector. The London and South East sector recorded 293 million journeys in the latest quarter, making it the largest sector. This was a 19% increase on the 245 million journeys in the same quarter in the previous year. The Long Distance sector recorded 34.8 million journeys, an increase of 21%, while the Regional sector recorded 87.7 million journeys, up 22% OctDec 2023.

UK passenger journeys April 2018 to December 2023

ALL GRAPHS: ORR Rail Engineer | Issue 207 | Mar-Apr 2024 NOTICES 6

MATT ATKINS

PASSENGER KILOMETRES

Just over 15 billion passenger kilometres were travelled in Oct-Dec 2023, a 20% increase compared on the previous year. Again, this remains lower than prelockdown levels.

All operators saw a greater number of kilometres travelled during the period. Elizabeth line recorded the largest increase (up 43%), and the smallest increases were shown by Heathrow Express (5%), London North Eastern Railway (6%), and c2c (8%).

Avanti West Coast and Transpennine Express ran reduced timetables in the previous year, which caused a large increase in passenger kilometres compared with OctDec 2022 (both up 39%).

Of the open access operators, Hull Trains, Grand Central, and Lumo, all saw large increases in kilometres travelled (between 23% and 28%).

The London and South East sector recorded 293 million journeys, making it the largest sector. This was a 19% increase on the 245 million journeys in the same quarter in the previous year. The Long Distance sector recorded 34.8 million journeys, an increase of 21%, and the Regional sector recorded 87.7 million journeys, a 22% increase on Oct-Dec 2023.

PASSENGER REVENUE

Total passenger revenue in Great Britain was £2.6 billion in Oct-Dec 2023. Adjusted for inflation, this was 20% more than the £2.2 billion generated in the same quarter in the previous year. Again, this remains below prelockdown levels, at 79% relative to the £3.3 billion in the same quarter in 2019.

Passenger revenue per journey was £6.27, a slight decrease compared with the £6.28 in the same quarter in the previous year.

Passenger revenue per kilometre was 17.2 pence, slightly lower than the 17.3 pence in the previous year.

With a total revenue of £1.3 billion, London and South East remained the largest sector in the latest quarter, though of the three sectors, it recorded the smallest increase in revenue (up 19% on the £1.1 billion in the previous year). The Long Distance sector showed the largest growth with £839 million of revenue in the latest quarter compared with the £694 million in the previous year, up 21%.

Percentage change in franchised passenger journeys, kilometres and kilometres per journey,

A total of £2.3 billion was generated across all ordinary fare tickets, compared with the £2.0 billion in the same quarter in the previous year. Of these, Advance tickets saw the largest increases (up 26%).

Off-Peak tickets saw the smallest percentage increase (up 15%), with £1.0 million in the latest quarter compared with £897 million in the previous year. Season tickets also generated more revenue in the latest quarter, with £208 million compared with £185 million in the same quarter the previous year (up 13%).

Overall, the change in revenue per kilometre was relatively small across all ordinary fareticket types. Anytime or Peak tickets showed a slight decrease (down 1%), Off-Peak tickets showed a slight increase (up 1%), and Advance tickets showed the least change (up 0.3%). However, season tickets showed a larger change (up 5%).

Percentage change

by sector, in Oct-Dec 2023 compared with Oct-Dec 2022

in franchised passenger revenue, kilometres and revenue per kilometre, by sector, in Oct-Dec 2023 compared with Oct-Dec 2022

Rail Engineer | Issue 207 | Mar-Apr 2024 7 NOTICES

TRAIN AND VEHICLE KILOMETRES

According to the report, Oct-Dec 2023 saw 123 million passenger train kilometres travelled - a 16% increase on the 106 million recorded in the same quarter in the previous year. Passenger train kilometres include only the distance covered by the train itself and so does not account for the number of carriages.

TransPennine Express (up 65%) and Avanti West Coast (up 42%) recorded the largest due to reduced timetables being operated in the previous year. No operators recorded fewer passenger train kilometres compared with the previous year, due to more strike action in the previous year.

INDUSTRY RESPONSE

The report clearly represents a step in the right direction for the industry, but reaction has been mixed. Industry bodies remain concerned that passenger numbers have not yet reached pre-lockdown levels, and that the lack of any long-term strategy will stymy further growth.

A spokesperson for Rail Partners said: “Although the latest ORR data shows an increase in passenger numbers, passengers are still not using trains at the levels seen before the pandemic lockdowns.

“This underlines the urgent need for rail reform to create a new public body to oversee the railways, but also to give operators the commercial freedoms to attract customers back to rail.

“Increasing passenger numbers will grow revenues, reduce taxpayer support, encourage modal shift and help Britain to reach net zero.”

Darren Caplan, chief executive of the Rail Industry Association (RIA) commented: “The return to rail continues apace and this substantial 20% uplift year-on-year is a really encouraging increase in the number of passenger journeys and revenues.

Passenger vehicle kilometres (for locomotive hauled trains this includes the distance travelled by the locomotive) also saw a sizeable increase, with 750 million passenger vehicle kilometres operated in Oct-Dec 2023. This is a 13% increase on the 663 million kilometres in the same quarter in the previous year. However, it remains below pre-lockdown levels, at 92% relative to the 816 million seen in OctDec 2019.

Only c2c and Caledonian Sleeper saw a reduction in vehicle kilometres operated, down 2% and 1%, respectively. TransPennine Express, (up 60%), recorded the largest increase. All open access operators saw an increase, with Grand Central and Hull Trains showing the largest increases (both up 8%).

“These new ORR and DfT figures are a reminder that the railway will need more capacity in the future, especially with the recent RIA-commissioned Steer report forecasting passenger numbers to grow between 37% and 97% to 2050, depending on which policy levers the UK Government adopts in the coming years.

It is clear that there needs to be rail reform and a long-term rail strategy, including a plan for more capacity, to deliver the connectivity, economic, levelling-up, and sustainability benefits everyone wants to see.”

The full report can be viewed here:

Passenger train kilometres by operator, Oct-Dec 2023, and percentage change from Oct-Dec 2022

Passenger vehicle kilometres by operator, Oct-Dec 2023, and percentage change from Oct-Dec 2022

Passenger train kilometres by operator, Oct-Dec 2023, and percentage change from Oct-Dec 2022

Passenger vehicle kilometres by operator, Oct-Dec 2023, and percentage change from Oct-Dec 2022

Rail Engineer | Issue 207 | Mar-Apr 2024 NOTICES 8

Rail Reform Bill – too little too late

On 20 February, the Government published its Draft Rail Reform Bill. This proposes the creation a new Integrated Rail Body (IRB) that brings together decisions on infrastructure and train operations. The IRB would become Great British Railways (GBR) as proposed in the WilliamsShapps report that was published in May 2021.

This report was the result of the Williams review which was established in September 2018. This in turn was the Government response to the May 2018 timetable debacle which highlighted how, in England, strategic decisions about trains and infrastructure only come together at Westminster.

Reaction to this draft Bill has been largely positive as the principle of GBR being a new strategic decision-making body is welcomed throughout the industry. It is common ground that bringing infrastructure and operational decision making together will tackle misaligned incentives which are the root of many of the railway’s problems and the reason why customer needs are not always put first.

WHY A DRAFT?

It is not clear why only a draft Bill has been prepared. The official reason is that:

NO WISP

A key aspect of the WilliamsShapps report was its proposal that GBR would produce a ‘Whole Industry Strategic Plan’ (WISP) to identify key strategic priorities for the whole rail network over the next 30 years. Although the first such plan was to be published in 2022, to date no such plan has been published.

Having a WISP addresses a weakness of the current structure that no organisation has the financial, technical, and operational authority to oversee the design, investment, and management of the major changes to track infrastructure and on-train systems required for programmes such as decarbonisation and digital signalling.

Yet, in contrast to the emphasis on private finance, there is no requirement for a WISP in the draft Bill, nor does its impact analysis refer to the need for a whole system technical authority.

“Given the scale and complexity of the changes being made to the sector, the draft bill will undergo pre-legislative scrutiny to provide parliamentarians and experts across industry the opportunity to review and test the legislation in draft.”

Yet surely the almost three years since GBR was first proposed should have been sufficient time to do this. Moreover, with a general election looming it could now be 2025 or even 2026 before a Rail Reform Bill becomes an Act of Parliament.

This is because this draft Bill is intended to ensure that GBR maximises private sector input by giving it a statutory duty to produce an annual report on private sector involvement. In contrast, the Labour Party’s plan is for an integrated publicly owned railway. Hence an incoming Labour Government would produce its own Rail Reform Bill which would then have to wait its turn in a crowded Parliamentary timetable.

Hence, whilst it is good to see proposed legislation to progress the formation of GBR, producing a draft Bill which does not have cross-party consensus adds years to the rail reform timetable. It is also disappointing that the engineering benefits of a whole system technical authority do not now seem to be recognised.

DAVID SHIRRES

DAVID SHIRRES

Draft Rail Reform Bill - gov.uk

Rail Engineer | Issue 207 | Mar-Apr 2024 9 NOTICES

250,000 seats a day on the WCML?

In the Parliamentary debate on the cancellation of HS2 phase 2, Transport Minister Mark Harper claimed that what remains of HS2 will deliver “a massive increase in capacity to the West Coast Main Line (WCML)” by providing 250,000 seats a day. This figure was subsequently repeated by the Prime Minister and Rail Minister who advised that it applies “across the primary long-distance operator on the West Coast.”

Yet without HS2 phase 2a, there is to be no WCML capacity increase north of Lichfield. Furthermore, with no HS2 station in Manchester it will not be possible to run the planned two-unit 400-metre HS2 trains to the city. Instead, there can only be single 200-metre unit HS2 trains which are

shorter than the current 265-metre Pendolino trains.

Furthermore, 250,000 seats a day is equivalent to running 17 x 605-seat Pendolinos an hour, 24 hours a day. This is clearly not credible.

ESTIMATING WCML HS2 CAPACITY

The table below estimates minimum and maximum capacity increases from HS2 phase 1. It shows a massive capacity increase between London and Birmingham with little benefit north of Birmingham unless all HS2 Manchester trains have a Liverpool portion and stop to split at Crewe. For many reasons, including an additional 10-minute journey time, this is a far from ideal arrangement.

Shadow Transport Minister Stephen Morgan has twice asked Rail Minister Huw Merriman to provide the evidential basis for the claimed 250,000 seats per day for HS2 phase 1. In neither case did he receive an answer. Since November, your writer has also unsuccessfully been trying to obtain the basis for these figures by pursing various stages of a Freedom of Information (FOI) request.

After the DfT press desk refused to provide this information, I submitted an FOI request in December. In January I was advised that more time was needed to consider my request as “a complex public interest test needs to be carried out to determine whether the information should be disclosed.”

ASSUMPTIONS:

1. Current WCML capacity north of Lichfield - 8 x Aventi; 1 x West Midlands and 4 x freight train paths.

2. HS2 offers no WCML capacity increase north of Lichfield.

3. Max capacity: Old Oa Common - 8 tph; Euston - 10 tph.

4. 400-metre-length trains north of Birmgham: Min - 1tph to Edinburgh/ Glasgow split at Crewe; Max - as Min plus 3 tph to Liverpool/ Manchester split at Crewe.

5. Trains operate at this average rate of 14 hours per day.

KEY

TPH: Trains per hour

SPT: Seat per train

SPH: Seat per hour

WCML Passengers per houraverge hourly service Present With HS2 phase 1 - Minimum With HS2 phase 1 - Maximum TPH SPT SPH HS2 from OOC % increase HS2 from Euston % increase TPH SPT SPH TPH SPT SPH Birmingham Pendolino 3 607 1821 2 607 1214 2 607 1214 1 x HS2 unit 3 1100 3300 3 1100 3300 Total 3 1821 5 4514 148% 5 4514 148% Other WCML Pendolinos 7 607 4249 2 607 1214 0 607 0 Voyager 1 200 200 1 200 200 1 200 200 1 x HS2 unit 4 550 2200 3 550 1650 2 x HS2 unit 1 1100 1100 4 1100 4400 Total 8 4449 8 4714 6% 8 6250 40% Grand Total PAX per hour 6270 9228 47% 10764 72% Total seats per day 87780 129192 150696

Rail Engineer | Issue 207 | Mar-Apr 2024 NOTICES 10

DAVID SHIRRES

It was considered that my request was subject to FOI Act clause 35 (1) which enables requests to be refused if the information requested relates to policy in development (i.e. the HS2 timetable) as disclosing it would detract from the time and space required by ministers and officials to develop policy options. The public interest of giving ministers such space must be balanced against that of letting the public understand how the capacity numbers were derived.

PUBLIC INTEREST TEST

In February, my FOI request was refused on the basis that the public interest is best served by not divulging this information. Yet, although it is perfectly reasonable to keep possible policy options confidential until they have been announced, my request was not for policy options (i.e. possible HS2 timetables) but for the baseline capacity information needed to derive such timetables.

For this reason, I requested an internal review of this decision and also referred to FOI clause 35(2) which states that once government has decided a policy, any statistical information used to provide an informed background is no longer subject

to FOI clause 35(1). Hence, the 250,000 seats a day figure used to justify the cancellation of HS2 should be exempt from clause 35(1).

On 22 March, I received a four-page letter explaining why it was not in the public interest to divulge the information I requested. Amongst other things, this letter advised that the 250,000 seats a day figure was not considered to be statistical information mentioned in clause 35(2) as “some of the information underpinning the assumptions and calculations used to derive the seat capacity is derived from comparable assumptions, estimates, and other judgements and opinions rather than being traceable back to factual data.”

This seems to substantiate my view that 250,000 seats a day was a guess. As shown by the table on the previous page, this is not a complex calculation.

FOI clause 35 is a dry subject, and so it is to be hoped that this explanation of its niceties has not been too dull. Yet this is an important subject as government transparency is in the public interest. Hence, anyone who wishes should be able to find out how figures used to justify polices have been derived. The public should also have confidence that the data used to develop policies is not uninformed assumptions.

www.railuk.com UK rail news as it happens. Over 15,000 rail articles. Daily email update. Latest rail video. Rail Engineer | Issue 207 | Mar-Apr 2024 11 NOTICES

HS2 update: Overview

The forecast date for initial HS2 services between Old Oak Common and Birmingham Curzon Street is between 2029 and 2033. Although this may seem some time away, this year HS2 hits peak construction with work well underway and a workforce of 30,000 at 350 active sites.

This work is being delivered by four main works contracts for which stage 1 is design and development and stage 2 is delivery and execution. In 2017, stage 1 of these contracts was awarded as shown below.

In April 2020, a ‘notice to proceed’ to stage 2 was issued to the companies concerned. This enabled construction work to formally start in September 2020. After almost three-and-a-half

SCS

Align JV comprising Bouygues, Volker Fitzpatrick, and Sir Robert McAlpineC

EKFB comprising Eiffage Genie Civil, Kier Infrastructure and Overseas Limited, Ferrovial Construction, and BAM Nuttall

BBV

years, work has begun on two thirds of HS2’s viaducts, over half of its bridges, and a third of the tunnelling has been completed.

With its civil engineering now well advanced, this year will be HS2’s peak construction year. 2024 will also see the award of contracts for the installation of track, signalling, and overhead line work. Although the HS2 route is now one long building site, it will not be that long before it starts to look like a railway. Yet before then there is still much complex civil engineering work to be done. HS2 has been described as a ‘project of megaprojects’.

Readers are invited to judge the truth of this statement for themselves as Rail Engineer provides an overview of HS2’s tunnels and viaducts.

Chilton tunnel southern portal - May 2023

Colne Valley viaduct – December 2023

PHOTO: HS2

PHOTO: DAVID SHIRRES

Area Chainage (km) Includes Let to joint venture South 0 to 25.8 Euston,

DAVID SHIRRES

Northolt tunnels

Colne

comprising Skanska Construction (UK) Limited, Costain Limited and STRABAG AG Central 25.8 to 47.5

viaduct, Chiltern tunnels

Central 47.5 to 125.7 Chiltern

north

Long

Wood

tunnel

portal to

Itchington

south portal

North Everything north of 125.7 Long

Itchington Wood tunnel, Delta Junction, Bromford tunnel, Birmingham approaches viaducts

is a joint venture between Balfour Beatty and VINCI

Rail Engineer | Issue 207 | Mar-Apr 2024 12 STRUCTURES & INFRASTRUCTURE

THE ROUTE

Without doubt, the most complex and expensive part of HS2 is from Euston to the Chiltern tunnel’s northern portal. Of this 47.2 route km, only 6.1km is on open ground as 37.7km is tunnels and 3.4km is the Colne Valley viaduct which will be Britain’s longest railway bridge.

The 109.5km from the Chiltern tunnel to the HS2’s Interchange station in Solihull is primarily through open countryside. This stretch has 22 viaducts of which five are over 300 metres long. They are Wendover Dean (450 metres); Small Dean (315 metres); Thame Valley (880 metres); Westbury (320 metres); and Edgcote (515 metres). To preserve the ancient woodland above it, a 1.7km tunnel has been bored under Long Itchington Wood. This part of the route also has five cut and cover ‘Green’ tunnels totalling 7.1km. It also has two railway crossings. A new bridge carries the new East West rail line over HS2 at Calvert (80.1km). Another bridge takes HS2 under the Coventry to Leamington Line at Kenilworth (142.2km).

HS2’s Delta Junction is immediately north of its Interchange station in Solihull. The Delta Junction has grade separation at its three junctions and is made up of embankments, cuttings, and a total of 13 viaducts taking high speed tracks over motorways, local roads, existing rail lines, rivers, and floodplains. The viaducts include six precast segmental viaducts, four composite viaducts, and three low viaducts.

Immediately after the Delta Junction, the 11.3km Birmingham spur starts with the 5.8km long Bromford tunnel which emerges at the eastern end of the Washwood Heath train maintenance depot. The spur is on a series of viaducts 1.7km long, immediately before it terminates at Curzon Street station 175.68 km from Euston.

Going north, the planned flyover over the Leeds spur (166.4 km) is 2km beyond the Delta Junction. Whether this will remain as passive provision is not known. Beyond that, HS2 again crosses the M42 on a box structure. From there, HS2 generally runs through open countryside to a point north of the city where a flyover was planned for HS2 phase 2a (185.8km) which now may well not be built. HS2 phase 1 ends at Handsacre junction 192.77km from Euston.

As at the start of 2024, 45km of tunnels have been dug and work is underway on two thirds of the project’s viaducts and over half of its bridges. The project is currently an unsightly building site passing though some areas of natural beauty. Yet by 2025, most of its civil engineering will be completed and a start will be made installing track and other railway systems.

The bare earth of the project’s excavations will then start to be covered by grass and vegetation. HS2 will then start to look like a railway and blend into the countryside as all railways do.

PHOTO: BASEMAP FROM HS2

PHOTO: HS2

PHOTO: HS2 PHOTO: HS2

Curzon Street Station construction site – January 2024

Delta Junction visualisation at Coleshill

Launch of Northolt Tunnel Boring Machines from South Ruislip - October 2022

Rail Engineer | Issue 207 | Mar-Apr 2024 13 STRUCTURES & INFRASTRUCTURE

HS2 update: Tunnels

Of HS2’s 208 route km, 52.2km is in tunnels. There will be 44.3km of twin bored tunnels comprising of Euston (7.3km); Northolt (13.6km); Chiltern (16.0km) Long Itchington Wood (1.6km); and Bromford (5.8km), as well as six cut and cover ‘green’ tunnels totalling 8km. In addition, an 850-metre logistics tunnel in London has been built to deliver materials and remove spoil between Old Oak Common and HS2’s London logistics hub.

This is a total of 104km of tunnelling which is being done on a scale never been seen in the UK. This explains why HS2 is Britain’s largest infrastructure project.

BORED TUNNELS

Ten new tunnel boring machines (TBM) have been procured from Herrenknecht to dig HS2’s 10 tunnel bores. These machines are typically 170 metres long, have a cutting head between 8.6 and 10.3 metres diameter and weigh 2,000 tonnes. Different types of TBM employ different methods of supporting the tunnel face during excavation depending on the ground conditions. With significant variation in ground conditions along the route, each one is designed for the specific conditions of its bore. TBMs are not generally redeployed for new tunnelling projects. TBMs typically advance 15 metres per day. Their main components are a rotating cutterhead, spoil disposal system of either slurry pipes or a conveyor, and a tunnel segment erection system.

All have shields to protect the machine until segments are installed. They also require a high voltage supply of typically 10MW. Multi-purpose vehicles (MPVs) run through the excavated tunnel to supply the TBM with concrete segments. The TBMs place seven 35cm-thick tunnel segments to form a 1.9-metre-long tunnel ring immediately behind the excavation. Each segment weighs 8.5 tonnes and has grout injected between it and the tunnel wall. Behind the TBM is a bridge under which a concrete invert is poured to provide a level surface for the MPVs. The TBMs operate continuously and require a crew of around 17 people on each shift to operate them. They have a control room, welfare facilities, and a rescue chamber. TBM personnel took refuge in such a chamber in May 2022 while they waited for smoke to clear after an MPV caught fire in the partly excavated Chiltern bore. The control room monitors the pressure at the cutterhead and the amount of spoil removed compared with the volume excavated.

ALL PHOTOS: HS2

DAVID SHIRRES

Rail Engineer | Issue 207 | Mar-Apr 2024 14 STRUCTURES & INFRASTRUCTURE

A typical TBM

The rings along the alignment are uniform, expect where there is a cross passage between the tunnel bores. Here, strengthened ring segments are needed to allow other segments to be removed for the cross passage. These passages provide an escape route for passengers in an emergency and also house mechanical and electrical equipment.

There are cross passages between the two tunnel bores, 15 to 20 metres long, and every 500 metres. These are dug by a remote-controlled excavator and immediately reinforced by a steel-fibre reinforced sprayed concrete primary lining, after which a sheet membrane waterproofing system and a secondary cast in-situ concrete lining is provided.

The bored HS2 tunnels have ventilation shafts about every 3km. These regulate the tunnel air temperature, extract smoke in the event of a fire, and give emergency services access to the tunnel.

INSIDE HS2’S LONGEST TUNNEL (YOUTUBE.COM)

BIM model of typical tunnel cross passage section

TBM Emily’s cutterhead lowered into the Victoria Road crossover box

INSIDE HS2’S LONGEST TUNNEL (YOUTUBE.COM)

BIM model of typical tunnel cross passage section

TBM Emily’s cutterhead lowered into the Victoria Road crossover box

Rail Engineer | Issue 207 | Mar-Apr 2024 15 STRUCTURES & INFRASTRUCTURE

TBM in the Herrenknecht factory ready for shipping to HS2

A headhouse at the top of each shaft contains ventilation and fire control systems.

HS2 considers that, with the use of TBMs, there should be very little ground settlement from tunnelling operations. Nevertheless, this is an understandable concern for those who may be affected. HS2 is providing all those with properties within 30 metres of its tunnels or other excavations with a settlement deed which records the protection that HS2 provides to the property in a legal document.

EUSTON TUNNELS

Following the government’s Network North announcement in October, it is considering alternative funding arrangements to construct the 7.3km twin bore tunnels between Old Oak Common (OOC) and Euston, which have 14 cross passages and two ventilation shafts.

Nevertheless, the two TBMs required, costing tens of millions of pounds, have already been procured. These are earth pressure balance (EPB) TBMs with a cutting head of 8.5 metres diameter. EPB TBMs operate in soft ground conditions by mixing the excavated material into a paste which is injected into the evacuation chamber behind the cutters so that the chamber pressure balances that of the surrounding soil and groundwater.

This year, these machines will be placed at the end of the OOC station box ready to start excavating the 7.3km tunnel to Euston. HS2 anticipates that this tunnelling will start in 2026. The final fitting out of OOC station cannot be completed until the Euston tunnel TBMs have tunnelled out of the OOC box. Furthermore,

concrete segments are supplied to the TBMs through the OCC box which also receives spoil from the TBMs.

This is possible due to the construction of the Atlas Road logistics tunnel which is another significant cost already incurred to support the Euston tunnelling. This is a 6.2-metre-diameter, 853-metrelong tunnel, from the OOC station box to the HS2 rail logistics hub at Willesden.

The Atlas Road tunnel TBM was one that had been refurbished by Herrenknecht after it had bored two Crossrail tunnels. It was named Lydia, after local school teacher Lydia Gandaa who launched it from HS2’s Atlas Road site in April 2023. It completed its bore by breaking into the OOC box in January.

This tunnel services both the Northolt East and Euston tunnels. It will have a conveyor to take the excavated London clay to HS2’s logistics hub when it will be taken by rail for reuse at sites in Kent, Rugby, and Cambridge. Assuming the Euston tunnels are built, over 83,000 tunnel segments manufactured at SRABAG’s Hartlepool plant will be delivered by train to the logistics hub and then through the logistic tunnel to the TBMs.

OLD OAK COMMON TUNNEL

HS2’s shortest tunnel is the 360-metre Old Oak Common tunnel between the OOC station box and the Victoria Road crossover box. Due to its short length and varying diameter at the station approach, this tunnel will be constructed by a cyclic excavation and support method. This uses excavators to dig a short length which is then rapidly sprayed with concrete to stabilise it. Work on this tunnel will start later this year.

Rail Engineer | Issue 207 | Mar-Apr 2024 16 STRUCTURES & INFRASTRUCTURE

First train with segments for London tunnels leaving the Hartlepool factory – December 2023

VICTORIA ROAD CROSSOVER BOX

Although this box is an open structure, it is an integral part of HS2’s tunnels. It forms a launch platform for the Northolt tunnel’s TBMs, provides tunnel ventilation, and houses the crossover before OOC station. This has now become a critical asset as it will be used by every HS2 service whilst OOC is HS2’s London terminus.

The box is 130m long, 24-metres deep, and 42-metres wide at its widest point. The initial design was for a rectangular box, though further optioneering developed its caterpillar shape. This reduced the amount of concrete required by 40% and avoided the need for temporary propping during construction.

The Victoria Road Ancillary Shaft has also been built adjacent to the crossover box. This will provide ventilation, emergency access and house signalling equipment. It has an internal diameter of 25 metres, is 25 metres deep, and was constructed with precast rings at the top, with a sprayed concrete lining at the bottom.

Enabling work to clear the 42,000 square metre crossover box site was completed in March 2019. This was done by a Costain Skanska joint venture and involved the demolition of eight buildings from which more than 98% of waste material was sent for reuse and recycling.

The first stage in the box’s construction was the provision of 77 x 44-metre tension piles to support the base slab (i.e. 19 metres below the slab). Reinforcement for the box’s diaphragm walls was then installed into the ground in 70 discrete panels and concrete for these walls was then poured. Excavation of the crossover box was done in three stages. Firstly, there was a 2-metre excavation to install a capping beam and the top props. A further 13 metres was then excavated for the installation of the intermediate row of props, then the final 10 metres was excavated to the level of the base slab. In total 240,000 tonnes of clay were excavated. The 3.3-metre-thick base slab was constructed in three different pours. The first and largest pour was of around 1,000 m3 of concrete. Headwalls of 1.5 metres thick were then built to support the diaphragm wall structure when the TBM breaks through the wall.

NORTHOLT TUNNELS

The 13.6km twin-bore Northolt tunnels face HS2’s most variable ground conditions, with the eastern section being completely bored in London Clay. Yet west of the Greenpark Way ventilation shaft where the TBMs will be extracted, there are gravels, sand, silt, and some quite high-waterbearing areas.

Although the EPB TBMs can deal with such varying ground conditions these tunnels require four TBMs. Two EPB 9.08m diameter shield TBMs are to bore the 5.5km from the Victoria Road crossover box, immediately west of OOC, to the Greenpark Way shaft. The other two TBMs have EPB 9.82-metrediameter shields which will also finish their bore at this ventilation shaft after boring 7.9km from the tunnel’s West Ruislip portal.

The use of four TBMs reduces the tunnelling time by about 12 to 18 months. Also, the eastern part of the tunnel is slower that the western part can be bored at a smaller diameter to reduce the excavated arisings.

Two TBMs named Sushila and Caroline were delivered to their West Ruislip launch site at the Northolt tunnel’s western portal in December 2021. They were named after local teacher, Sushila Hirani and astronomer, Caroline Herschel. Sushila was launched in October 2022. Caroline started her bore shortly afterwards. At the time of writing, Sushila and Caroline have bored respectively 4km and 3.5km. All four Northolt tunnel TBMs dispose of their spoil by conveyors.

Part of TBM Anne being lowered into the Victoria Road Crossover Box

TBMs Emily and Anne in the Victoria Road Crossover Box ready to start the eastern Northolt tunnels

Rail Engineer | Issue 207 | Mar-Apr 2024 17 STRUCTURES & INFRASTRUCTURE

TBMs Caroline and Sushila at the Northolt tunnel West Ruislip portal prior to their naming

The TBMs that will bore the eastern part of Northolt tunnel have been named after Emily Sophia Taylor, a midwife who became Ealing’s mayor and Lady Anne Byron, an educational reformer and philanthropist. Emily was launched from the Victoria Road crossover box at the end of February. Anne was launched in April.

The Northolt tunnel will have 20 cross passages with fire doors at each end. Construction of these at its western end will require ground freezing and dewatering in view of the soil conditions.

It will have four ventilation shafts from 30 to 40 metres deep. Of these, the Greenpark Way shaft must be built to allow for extraction of the four TBMs. One design constraint was that HS2’s Down line was to be directly under the main line to High Wycombe. During design development, the requirement for HS2 tunnels to be at least one diameter apart was relaxed so that the Down line tunnel need no longer be under Network Rail’s tracks. This allows shafts from both bores at Greenpark Way, with one being a satellite shaft. TBM extraction is possible from both these shafts although the satellite shaft will be capped after the TBM has been removed.

CHILTERN TUNNELS

The 16km-long Chiltern tunnels were almost exclusively excavated in chalk. They are 80 metres below ground level at their deepest point, though are only 20 metres below the River Misbourne, where care had to be taken to monitor and protect the rare chalk stream. The first 200 metres of their long bores passed under the M25 and so necessitated a lot of work with National Highways to get the necessary approval for these bores which resulted in very little ground movement.

Variable density (VD) TBMs with a 10.24-metrediameter cutting face have been used for these bores. VD TBMs have various slurry face support technologies including earth pressure balance. In addition, these Herrenknecht TBMs offer a continuous tunnelling technique with a newly developed centre of thrust system to more effectively maintain the specified alignment.

These TBMs are named after founder of modern nursing, Florence Nightingale and astronomer Cecilia Payne-Gaposchkin. Florence was launched from Chiltern tunnel’s eastern portal in May 2021 followed two months later by Cecilia. Florence completed her bore on 27 February. At that time Cecilia had completed 98% of her bore. This is an average excavation rate of 15.6 metres per day, though the record was 44 metres in a single day.

The Chiltern tunnels have 38 cross passages, 10 to 15 metres long, and five ventilation shafts, the deepest of which, at Chalfont St Peter, is 63 metres below ground level. There is a complex interface between the 18-metre-diameter ventilation shaft and the twin 9-metre shafts tunnel bores which are 25 metres apart centre to centre and so intersect with the ventilation shaft walls. There are three openings in the tunnel lining at this point. The largest, for tunnel ventilation, is 5 metres high and 4 metres wide. There are also two service openings for cables.

Arrangement of Greenpark Way ventilation shafts

Florence completing her 33-month, 16km tunnel bore under the Chilterns

Chiltern tunnel bore with cross passage visible to the right

Rail Engineer | Issue 207 | Mar-Apr 2024 18 STRUCTURES & INFRASTRUCTURE

Arrangement of Chalfont St Peter ventilation shaft and Chiltern tunnel bores

The ventilation shaft is built in advance of the tunnel so that the TBMs can advance through its walls which are formed by 1.2 metre thick Dwall panels. After that, openings are formed in the tunnel wall and the access passageways, with required reinforcement, are created.

Unlike the Northolt TBMs, Florence and Cecilia dispose of their spoil mixed with water through slurry pipes. There are also pipes for water to supply water to the TBM as well as conduits for HV electrical cables.

The slurry treatment plant at the south portal produces chalk cake material for use in HS2’s designated landscaping scheme. The plant’s input flow rate is up to 1,250m3 /h per TBM. On average, it produces 2,650m3 of filter cake per day. There was also a temporary pre-cast segment factory at the tunnel portal which produced the 112,000 segments needed for the Chiltern tunnels.

LONG ITCHINGTON WOOD

The 1.6km twin-bore Long Itchington Wood tunnel protects the ancient woodland above it and was excavated through mudstone and clays. A single VD TBM with a 9.92-metre-diameter cutting

face has been used for these bores. This has been named after Dorothy Hodgkin, the first British woman to win the Nobel Prize in Chemistry.

Dorothy was launched at the tunnel’s north portal in December 2021 and completed its bore in July 2022 after seven months. The TBM was then partially disassembled and returned to the north portal. Its gantries were then brought back through the tunnel, whilst nine larger items including the cutterhead (160 tonnes) and tailskin (130 tonnes) were transported by road.

When Dorothy was relaunched in November 2022, it only took four months to complete its second bore in view of the experience gained from the first bore. The 500,000 tonnes of mudstone excavated from both bores was processed at an on-site slurry treatment plant. From there, it was separated out before being transported by a 254-metre enclosed conveyer and used to build embankments along the route of the railway.

Dorothy has since been dismantled and many of her component parts were sent to be reused in the second Bromford Tunnel where the rebuilt TBM has been named Elizabeth.

Tunnel segment factory and yard at Chiltern tunnel’s southern portal

Dorothy about to start her first bore

Tunnel segment factory and yard at Chiltern tunnel’s southern portal

Dorothy about to start her first bore

Rail Engineer | Issue 207 | Mar-Apr 2024 19 STRUCTURES & INFRASTRUCTURE

Dorothy’s cutter head returning to the north portal for its second bore – September 2022

BROMFORD TUNNEL

The 5.8km Bromford tunnel ends 5km from HS2’s Birmingham Curzon Street station. Hence the linespeed through the tunnel (230km/h) is much less than that through Long Itchington Wood tunnel (360km/h). As a result, Bromford is a smaller 8.62-metrediameter tunnel. It is being bored through mudstone with some sandstone.

An 8.56-metre-diameter VD TBM is being used to bore these tunnels. The first one was launched in August and is named after Mary Ann Evans who is better known by her pen name George Elliot. At the time of writing, Mary Ann had bored 1.5km. A second has been assembled using the gantries and the centre part of the cutterhead from Dorothy. This TBM was launched in March and has been named Elizabeth after Dame Elizabeth Cadbury, who spent her life campaigning for the education and welfare of women in Birmingham.

Dorothy’s cutter head at Bromford about to become part of TBM Elizabeth – December 2023

Dorothy’s cutter head at Bromford about to become part of TBM Elizabeth – December 2023

Rail Engineer | Issue 207 | Mar-Apr 2024 20 STRUCTURES & INFRASTRUCTURE

Graphic of formwork used to construct the Copthall tunnel roof

GREEN TUNNELS

Green tunnels are cut-and-cover structures, backfilled above with restored or enhanced vegetation. They shield the local environment and neighbours from the noise and visual impacts of passing rail traffic.

At Copthall, between the Northolt tunnel and Colne viaduct, the HS2 Act specified a deep cutting. However, following a 2018 affordability exercise, it was decided to replace this cutting with a cut-and-cover tunnel. This avoided 400,000 m3 of excavated material and removed the need for off-site disposal of 1.35 million m3 and so has significant programme, community, and environmental benefits. Backfilling above this tunnel also limits long term heave by limiting the unloading effect of the removal of London Clay.

This 600-metre tunnel has a reinforced concrete box structure which is being constructed using innovative wall and roof travelling formwork systems that eliminate the need for formwork cranage. These 40-metre wall and roof travellers also significantly reduce the cycle time for pouring each 20-metre wall or roof sections.

The tunnel design includes several natural ventilation ‘chimneys’ which avoids the need for tunnel ventilation equipment.

North of the Chilterns there will be five green tunnels with a total length of 7.9km: Wendover (1.1km); Greatworth (2.7km) Chipping Warden (2.5km) Long Itchington Wood at the bored tunnel’s south portal (0.1km); and Burton Green (0.7km).

These tunnels are built using a series of M-shaped arches. The arches are made up of five precast units which are 20.4 metres wide, 2.5 metres long, to form two 8.4-metre-high tunnels. At

Chipping Warden and Greatworth these are placed on a 300mm reinforced concrete base slab, at other tunnels this slab is cast in situ. The tunnel is waterproofed using a double layer, compartmentalised membrane system which is placed in position by a bespoke gantry system. The M-arches are then backfilled to the depth required by the local topography. The deepest section, at Chipping Warden, has 18 metres of backfill.

Fire door openings in the centre wall are provided every 300 metres for train evacuation. In common with the TBM tunnels, the green tunnel will have 100-metre-long, progressively porous portals, to reduce noise from the pressure waves as trains enter and exit the tunnels at 360km/h.

TUNNEL LENGTHS

On the UK’s 16,000km rail network the total length of its tunnels is 186km which is around one per cent of the network. Britain’s 19th century railway builders tried to avoid expensive and difficult tunnels which were then generally only necessary to build a reasonably level railway through challenging terrain. Early railway builders generally did not have to contend with a dense built environment.

Those who planned phase one of HS2 faced not only extensive built up areas but environmental pressures to build green tunnels. As a result, of HS2’s 208 route km, 52.2km (25%) is in tunnels. As shown in this feature HS2’s tunnel engineering is impressive, yet tunnelling is an expensive option.

At the time of writing HS2 has completed 46.3km of its 75.9km of bored tunnels. Readers who wish to follow the progress of HS2’s tunnelling can do so at https://tunneltracker.com/

Rail Engineer | Issue 207 | Mar-Apr 2024 21 STRUCTURES & INFRASTRUCTURE

Work starts on the Chipping Warden green tunnel which requires 5,000 tunnel segments

HS2 update:Structures and earthworks

Along its 208 route km, HS2 requires over 50 viaducts of which 16 are over 300 metres long. One of these is the 3.4km Colne Valley viaduct which will soon be the UK’s longest railway viaduct. Less newsworthy is the huge amount of earthworks needed to create Britain’s first domestic high-speed railway.

This update features the Colne Valley viaduct, other viaducts of novel construction, as well as those required for HS2’s delta junction outside Birmingham over the motorway network. It also provides examples of the scale and complexity of HS2’s earthworks.

COLNE VALLEY VIADUCT

Between its Northolt and Chiltern tunnels, HS2 crosses the flat Colne Valley which is a mosaic of farmland and woodland with 200km of rivers, canals, and over 60 lakes. A hundred years ago it was not so attractivethe result of the extensive sand and gravel extraction for London’s building boom in the early 20th century. Following this, much of this area was restored as wetlands with lakes up to 400 metres long.

DAVID SHIRRES

All PHOTO: HS2

Temporary bridge and Colne Valley viaduct V piers – May 2023

link road – Feb 2024 Rail Engineer | Issue 207 | Mar-Apr 2024 22 STRUCTURES & INFRASTRUCTURE

Viaduct section moved over M42

M6

HS2’s route across this environmentally sensitive area requires a 3.4km viaduct which has to be blended into this landscape. To do this, its design was inspired by a skipping stone’s flight across the water. The result is a series of elegant spans 10 to 15 metres above the surface. Above the lakes these are up to 80 metres long, whilst shorter 50-metre spans cross wooded areas.

Before piles could be driven to support the viaduct’s piers, over a kilometre of temporary jetties had to be constructed. Cofferdams around each set of foundations were also required as were bases for the tower cranes required at each pier. The viaduct’s 56 piers support a thousand deck segments, each with a slightly different shape due to the viaduct’s gentle curves. Forty-five of these piers weigh around 370

tonnes and sit on concrete piles up to 55 metres deep. They are cast in-situ with special formwork. Eleven V piers support the 80-metre-long spans over the lakes. These 1,800-tonne structures are supported on six 60-metredeep piles which required a 520 cubic metre concrete pour taking nine hours. Due to their complexity a full-sized mock-up was first built to test working practices including formwork placement.

As on other HS2 structures, Ground Granulated Blast Furnace slag (GGBF) is being used as a cement replacement. When it is ground fine, GGBF has good cementitious properties and, when mixed with Portland cement, it provides a strong concrete with a lower carbon footprint. The Colne Valley viaduct is the largest UK use of GGBF.

To minimise construction traffic on local roads, the jetties built across the lakes provide a continuous road inside the project. The 140-tonne viaduct segments are made on site at a large purpose-built temporary factory close to the north abutment. This also reduces road movements as does the use of dedicated slipways on the M25 for construction traffic. At peak construction, this factory casts around 12 segments every week using a ‘match-casting’ technique in which each segment is poured against the previous one to ensure the whole deck fits perfectly.

A 700-tonne launching gantry positions the segments. This is 160 metres long, 18 metres high and 18 metres wide. It was originally built in 2004 and had been used in Hong Kong and Singapore. After it arrived in the UK in 49 containers, it took several months to assemble. Prior to its use it had to be assessed against applicable UK standards, including those for wind loading. Using this gantry determined the maximum segment weight and hence the number of segments required.

The gantry has two long trusses with two moveable main and secondary base supports. Between the trusses are trollies and cranes for it to simultaneously place segments either side of a pier. It uses its supports to advance over the already completed bridge deck so that its truss can extend to the next pier. It then positions a single segment on top of this pier on which one of its main supports is then placed.

Single segments are then placed either side of this pier. Props are secured under these segments and the gantry anchored to the pile cap before further segments can be placed. This increases the stabilising lever arm from two to six metres to resist the bending moment from placing further segments away from the piers. These then form an even cantilever either side of the pier. Epoxy is applied to the face of each segment as it is positioned after which the cantilever is temporarily tensioned to compress the epoxy whilst it sets. Once the span’s final segment is inserted, it is post tensioned with permanent steel strands. At peak rate, the gantry can position six segments per day.

The viaduct’s construction began in early 2021 when the first piles were installed. The last of its 292 piles were installed in January 2023. By then, 500 metres of the viaduct had been completed after the launching gantry commenced operation in spring 2022. As of February, over 700 of its 1,000 deck segments have been installed.

The installation of track and railway systems which start after construction of this 3.4km-long viaduct will be completed in 2025. It will then have stolen the title of the UK’s longest railway bridge from Dundee’s Tay Bridge by 100 metres.

First segment produced for Colne Valley viaduct – Feb 2022

Launching girder between Colne Valley viaduct piers 55 and 56 – Nov 2022

Rail Engineer | Issue 207 | Mar-Apr 2024 23 STRUCTURES & INFRASTRUCTURE

Colne Valley segment factory

DOUBLE COMPOSITE VIADUCTS

The 450-metre Wendover Dean and 345-metre Small Dean viaducts near Wendover have respectively nine and five piers, giving them average spans of 45 and 57.5 metres. Though successfully used in Europe, these viaducts are two of five HS2 viaducts that are the first in the UK with an innovative double composite design. This is described in an HS2 learning legacy technical paper by Razvan Capra, Pere Alfaras Calvo, and Paul Van Hagen of Acardis/EKFB.

For over a hundred years, steel-concrete composite bridges have been built with a top concrete slab in compression and a steel structure resisting tensile forces. However bending moments over intermediate piers can cause the concrete slab to crack unless there is sufficient steel reinforcement to control the tension forces.

The double composite section design adds a concrete slab to the lower part of the structure around its piers. This reduces the structural steel required by 10 to 15% and simplifies steel fabrication. There has recently been increased interest in this new form of construction as highspeed railway projects benefit from it.

These HS2 viaducts have an in-situ reinforced concrete slab over the pier regions. Outside this area there are precast concrete planks connected by an in-situ stitch pour. This provides increased damping and enhances the superstructure’s torsional resistance. For high-speed rail, this provides an improved dynamic response and limits noise from wheel-track induced vibrations. The resultant closed box section also creates a suitable enclosure for services and drainage.

Although they offer significant advantages, such bridges require additional construction stages for their in-situ concrete slabs and precast planks. They also add to the weight of the superstructure which may require bigger bearings and might slightly increase the viaduct’s cost.

A particular construction advantage is that the deck is launchable and so can be built at ground level and pushed over its piers. This allows the use of more factory-built precast sections and reduces working at height.

The first bridge slide of the Wendover Dean viaduct took place in January when 90 metres of bridge beam was slid over Teflon pads at nine metres per hour onto its first two piers. Due to its length, the deck is being assembled in three sections with each one pushed out before the next section is attached behind it. The deck’s steel girders are delivered to site in 25-metre lengths which are welded together on the assembly platform. As the deck is slid over, it bends under its own weight. An angled beam fitted to the front of the deck raises it when it reaches the next pier. The piers consist of a stem with a hammerhead on top. The stem is constructed by first installing a steel reinforcement column, then placing a pre-cast shell around it before pouring the concrete. Then, a 50-tonne pre-cast hammerhead shell is placed on top of the stem, a reinforcement cage is lifted into it and concrete is poured into it.

Construction of the Small Dean viaduct is less advanced. This requires piers to be built between the Chiltern main line railway and A413 road which needs to be diverted to accommodate the piers.

Wendover Dean Viaduct after the first deck beam slide – Jan - 2024

Section view of double composite viaduct

Wendover Dean Viaduct after the first deck beam slide – Jan - 2024

Section view of double composite viaduct

Rail Engineer | Issue 207 | Mar-Apr 2024 24 STRUCTURES & INFRASTRUCTURE

Steel reinforcement lowered into pre-cast hammerhead shell

Other double composite viaducts are being constructed at Westbury (320 metres), Turweston (70 metres) and Lower Thorpe (210 metres).

MODULAR VIADUCTS

The 880-metre Thame Valley and 515-metre Edgcote viaducts have respectively 34 and 20 piers giving them both average spans of around 25 metres, i.e. half that of the double composite viaducts.

These are the first UK viaducts to have all their major components manufactured off site. The Thame Valley viaduct requires 68 x 42-tonne fully formed pier sections and 72 x 97-tonne deck beams together with parapet and ancillary beams. On site, the pier sections

are plugged into their pile caps. Once the beams have been placed on the pier tops, they are braced until the deck slab is cast which is the only substantial in-situ concrete required. After this parapet beams are fitted.

The pretensioned hollow beams are coupled to each other through thickened end walls using post tensioned bars. In this way a continuously tensioned deck is created, with all main elements of the structure always in compression.

As well as improving site safety, the factory production of such enormous parts enables work to be done to millimetre tolerances. This is also expected to save around five months construction time.

DELTA JUNCTION VIADUCTS

Just north of HS2’s Birmingham Interchange station is the triangular Delta junction where HS2 trains from London will be routed to Birmingham or the West Coast Main Line (WCML). The junction has 10km of HS2 tracks with 13 viaducts crossing a network of motorways, local roads, railways, and rivers.

The junction’s west chord has the River Cole east and west viaducts and the M42/M6 link viaducts which had the first part of the first deck slid into position in February. Its full 158-metre composite deck will be positioned in April.

The east chord has Coleshill North and South Viaducts, Watton House viaducts and the River Tame East and West viaducts. The first 39-metre span of the 472-metre River Tame West viaduct was completed in December. The north chord has the separate single-track Water Orton northbound and southbound viaducts which, at up to 20 metres high, will be amongst HS2’s tallest structures. These two 700-metre-long viaducts will be supported on 32 piers, the first of which was completed in August.

VIDEO OF WESTBURY VIADUCT SLIDE

Completed Thame Valley viaduct piers at Pacadar factory on the Isle of Grain - May 2023

First span of River Tame viaduct in place – Dec 2023

First completed Water Orton viaduct pier – Aug 2023

VIDEO OF WESTBURY VIADUCT SLIDE

Completed Thame Valley viaduct piers at Pacadar factory on the Isle of Grain - May 2023

First span of River Tame viaduct in place – Dec 2023

First completed Water Orton viaduct pier – Aug 2023

Rail Engineer | Issue 207 | Mar-Apr 2024 25 STRUCTURES & INFRASTRUCTURE

Thame Valley viaduct cross section

A total of 153 piers will be built for the Delta Junction’s viaducts. Of these, 15 were completed by the end of 2023. There are three types of viaducts:

» Precast segmental viaducts with 45-metre standard spans (River Tame East and West; Water Orton 1 and 2; Coleshill East and West).

» Composite viaducts having concrete decks and weathered steel structures with standard spans of more than 45 metres (M42/M6 Link Road East and West; River Cole East and West).

» Low viaducts with standard spans of 25 metres with standard concrete deck and precast beams. (M42 Coleshill North and South; Watton House).

A 55,000 sq. m factory at Kingsbury employing 1,000 people started producing concrete viaduct segments in June. This will produce the delta junction’s 2,742 segments which weigh between 50 and 80 tonnes at a rate of eight per day.

INTO BIRMINGHAM

The last two kilometres to HS2’s Birmingham Curzon Street station are on five connected viaducts: Duddeston Junction viaduct; Curzon Street viaducts numbers 1, 2, and 3, and the Lawley Middleway viaduct.

After passing the HS2’s Washwood Heath depot, the line crosses the Derby to Birmingham railway at Duddeston junction on a 370-metre-long viaduct with a 1 in 33 gradient to connect it to the 690-metre Curzon No 1 viaduct which will be 30 metres high where it crosses the River Rea. From this point, the line drops at 1 in 200 to Curzon Street Station.

The 150-metre-long Curzon No 2 viaduct has a 25-metre- high truss in weathering steel incorporating dynamic colour lighting. This will be 40 metres above ground level as it crosses the Birmingham and Bushbury railway which is on a 15-metre-high brick viaduct.

The 213-metre Lawley Middleway viaduct between Curzon No 2 and Curzon No 1 viaducts widens out at its western end for the start of the Curzon Street station throat. The 300-metre Curzon No 3 viaduct is around 5 metres above ground level and widens into four separate decks on V piers to accommodate most of the station throat. This arrangement maximises daylight and space in the public area below. Where it crosses the Digbeth Canal, this viaduct has four inverted steel piers to reference Birmingham’s canal heritage.

Start of viaduct deck slide over the westbound M42 M6 link roads - Feb 2024

Graphic of completed Curzon No 2 viaduct

Start of viaduct deck slide over the westbound M42 M6 link roads - Feb 2024

Graphic of completed Curzon No 2 viaduct

Rail Engineer | Issue 207 | Mar-Apr 2024 26 STRUCTURES & INFRASTRUCTURE

First pier for the Curzon 3 Viaduct – Jan 2023

Work on Curzon No 3 viaduct is well advanced. Its first V pier was completed in January 2023. By November, its first two 90-metre decks and 26 piers had been completed.

EARTHWORKS

Whilst not so newsworthy or visually striking, HS2’s earthworks are a huge undertaking that present significant challenges. Phase 1 requires around 50 embankments of which the longest is at Grendon Underwood which is 3km long and up to 3.5 metres high. Sixty-six cuttings are required, of which the longest is the 4.1km Calvert cutting. The 750-metres-long, 30.5-metres-deep Lower Thorpe cutting is HS2’s deepest. Tens of millions of cubic metres have been excavated to create HS2’s cuttings of which 95% were reused on site.

Work to prepare the 65-hectare site at Washwood Heath for HS2’s train maintenance depot and control centre was completed in December. This heavily contaminated derelict site required over a million cubic metres of excavations which included rubble from demolished car factories and other industrial plants. Excavations were up to seven metres deep and were remediated by screening and bioremediation to remove oils and fuel contamination. This enabled all excavated materials to be reused on site, which eliminated the need to import and export aggregate materials and saved 54,400 HGV movements on local roads.

The reuse of excavations between the Chiltern and Long Itchington Wood tunnels is described in another learning legacy paper by EKFB’s

environmental design manager, Zara Rostance. This explains the use of the Definition of Waste Code of Practice (DoWCoP) managed by CL:AIRE (Contaminated Land: Applications in Real Environments), a charity committed to supporting all those involved in sustainable land reuse. The DoWCoP sets out good practice when assessing if materials are to be classified as waste and determining when treated waste can cease to be waste for a particular use.

Curzon Street Station site after first concrete pour of No 3 viaduct’s deck span – Nov 2023

Curzon Street Station site after first concrete pour of No 3 viaduct’s deck span – Nov 2023

Rail Engineer | Issue 207 | Mar-Apr 2024 27 STRUCTURES & INFRASTRUCTURE

Earthworks at Wendover Dean – June 2022

In HS2’s central section, it is estimated that there have been 35 million cubic metres of excavations of which made ground (any material affected by people) is approximately 1 million cubic metres. The most significant challenge is re-locating natural materials with distinct chemical fingerprints and leaching characteristics to geologically contrasting environments. This requires a detailed assessment of materials management at the scheme design and applying the four DoWCoP acceptance criteria as follows:

1. Protection of human health and environment – Advising site teams of constraints using graphical information systems with layers showing local wildlife, archaeological sites, and made ground. Regular meetings were held to inform the Environment Agency (EA) and CL:AIRE of site activities and project requirements.

2. Suitability of use – Zoning system agreed with the EA for re-use of made ground according to geology, aquifer classification, proximity to surface water and human health. Summarised Earthworks Quantity Schedules showing quantity and types of material in a section were compared with area material requirements.

3. Certainty of use – gaining HS2 Act schedule 17 consent for landscaping specification well in advance of the work to provide certainty of where material can actually be re-used.

4. Quantity required – Using EKFB’s DIGGER (Digital Graphical Earthworks Reporting) automated material tracking system to monitor excavated material movements from the place of origin to the final destination. This uses various data streams including GPS excavator trimble tracking and drone surveys to create a digital 3D earthworks model.

Reducing imported materials in this way reduces HS2’s carbon footprint. In 2022, the reuse of 25.6 million tonnes provided a reduction of 2.5 million HGV movements. Zara concluded her paper by emphasising the importance of effective engagement with the EA, local authorities, and CL:AIRE.

LEAVING A LEGACY

The London and Birmingham Railway’s (L&BR) proposal to build the world’s first long distance inter-city railway was the subject of much opposition and turbulent meetings in towns along the route. After a failed attempt, it eventually got its Act of Parliament approved in 1833. For its day, building the line was comparable to HS2. Twenty thousand men worked on it for five years and it required the movement of 12 million cubic metres of material.

When the line opened in 1838, there were six trains a day between the two cities and the train journey took five-and-a-half hours. This line’s legacy was demonstrating the feasibility and desirability of building railways between population centres, not least because of the economic activity they generate. This is still the case today as shown by the volume of freight and passenger traffic carried by the bottom part of the WCML which would have astounded the L&BR’s promoters.