by rail engineers for rail engineers

SCOTLAND’S HYDROGEN TRAIN

IS BELIEVING

SEPT-OCT 2022 ISSUE 198

www.railengineer.co.uk

Scotland’s hydrogen train project will provide the understanding and knowledge to make hydrogenpowered rail a reality.

INNOTRANS The world’s largest transport trade fair returns and does not disappoint.

upgrades

FOCUS FEATURES SIGNALLING A ££ ORDABLE SIGNALLING & TELECOMMUNICATIONS STRUCTURES & INFRASTRUCTURE SUSTAINABILITY & ENVIRONMENT

SEEING

Galvanized steel is an ideal partner for network

and expansion, HS2, and beyond.

Total

Visit totalrailsolutions.co.uk or call 01962 711642 to find out more

total rail Service

Rail Solutions now offers a unique concierge Meet and Greet team further improving your quality of service.

• Ensuring the plant, equipment and people you need is where it needs to be, when it needs to be

• Meaning you and the kit you have hired is ready to go to work

Improving efficiency and effectiveness whilst delivering a positive customer experience, every time. scan this Visit totalrailsolutions.co.uk or call 01962 711642 to find out more Watch the new meet and greet team at work

Paul Darlington unpicks the terms used in competence assurance and asks why competency is so important.

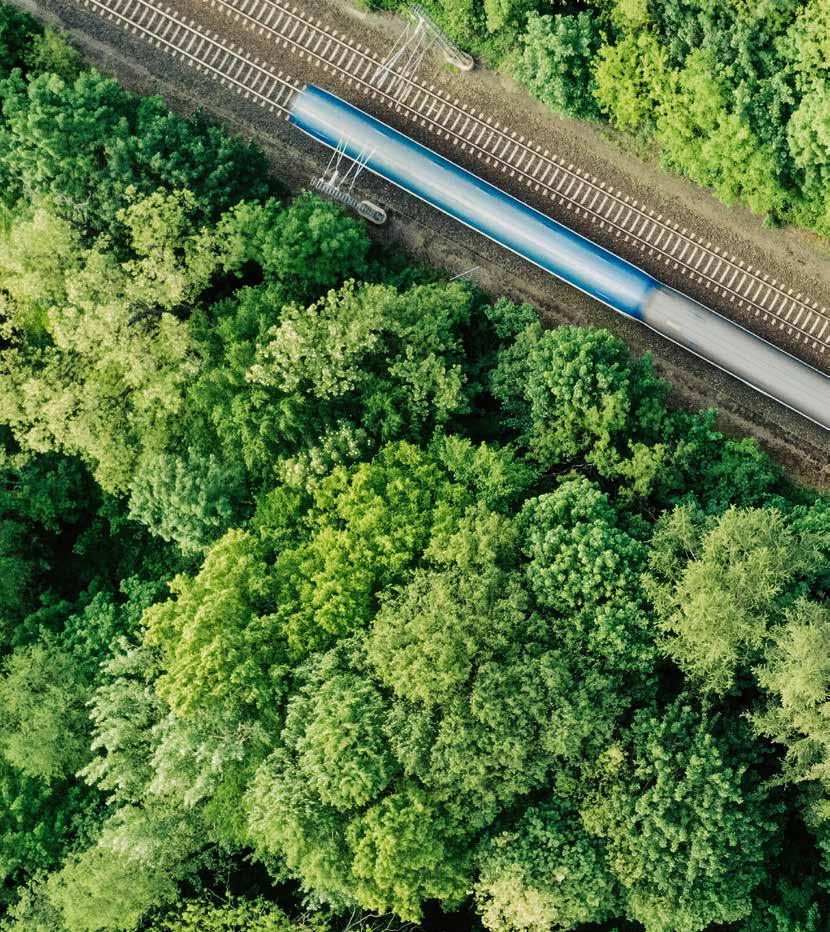

Making a step change with improved guidance for the Rail Carbon Tool

RSSB’s Rail Carbon Tool allows the rail industry to calculate the carbon footprints of its projects.

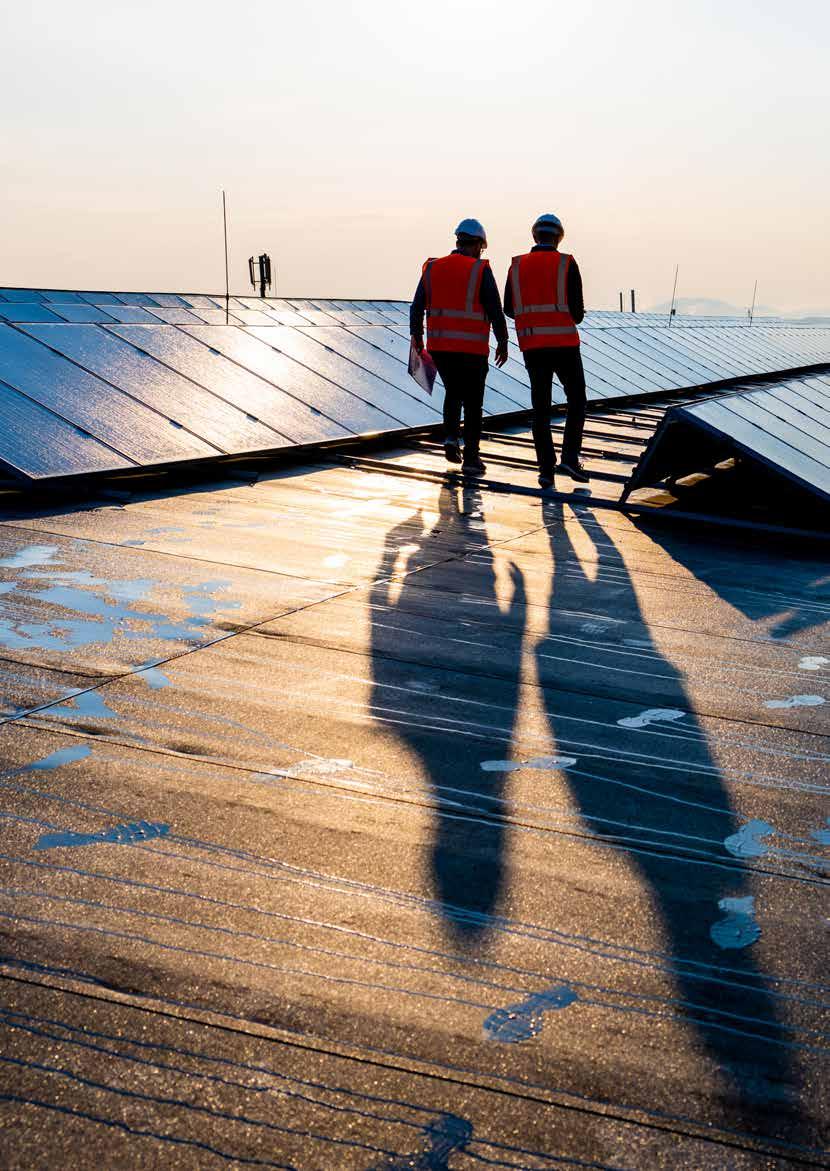

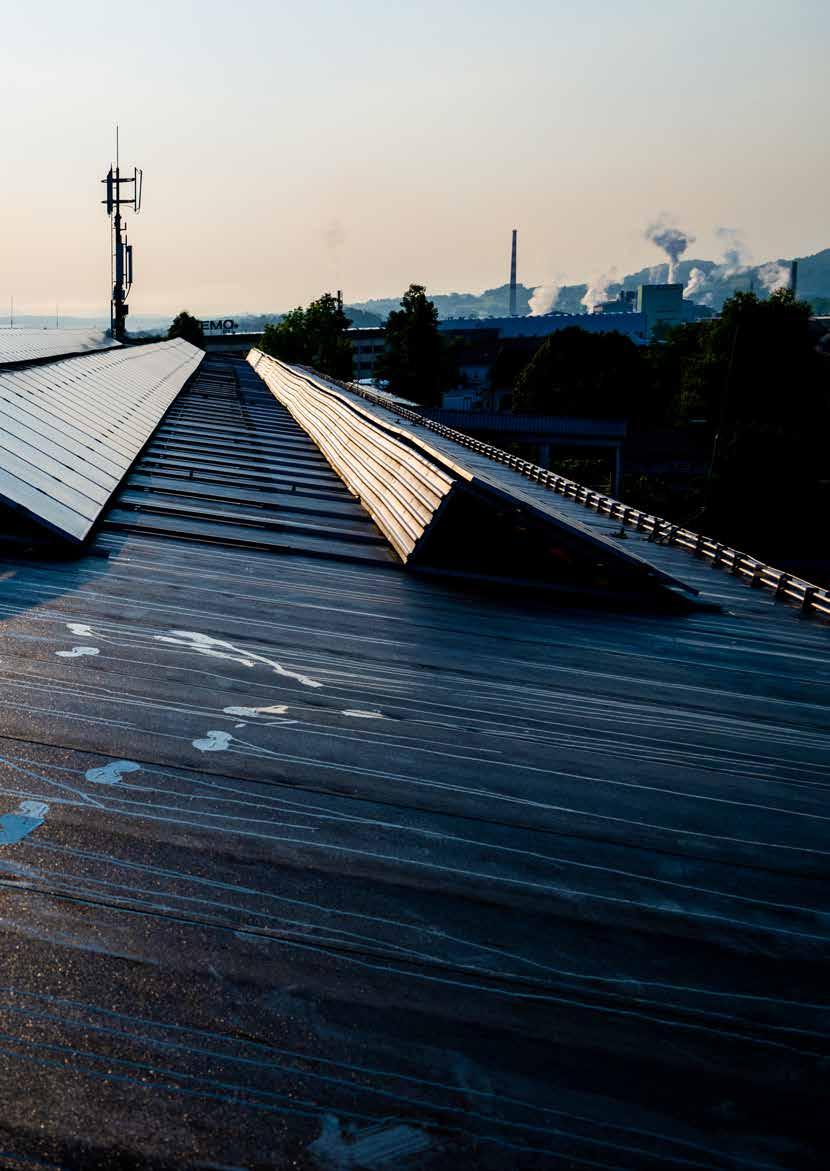

Renewables non-traction energy for Network Rail Network Rail and EDF Renewables have signed a solar power agreement to make the railway cleaner and greener.

Scotland’s hydrogen train

Though some consider them an unnecessary distraction, hydrogen trains have a role to play in Scotland’s decarbonisation plans.

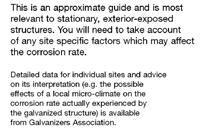

Seeing is believing Galvanized steel is an ideal partner for network upgrades and expansion, HS2, and beyond.

Great Musgrave bridge lessons learned Bob Wright looks at the Great Musgrave saga from an engineering perspective and considers the Bill Harvey Associates report.

32 64 CONTENTS 46 10| 16| 40| 44| 46|

Assuring competency

Affordable signalling Signalling renewals are a major cost for Network Rail at around £200 million a year during Control Period 6. New rail siding

A new

will serve

Jointing of signalling power cables – what’s all the fuss about? 48|

at Hillhead Quarry

railhead connection to the Buxton and High Peak Junction line

the reopened Hillhead Quarry.

18|

22| A signalling exposition Clive

28| Prysmian

an

the

for enhanced unarmoured

28 54|

58|

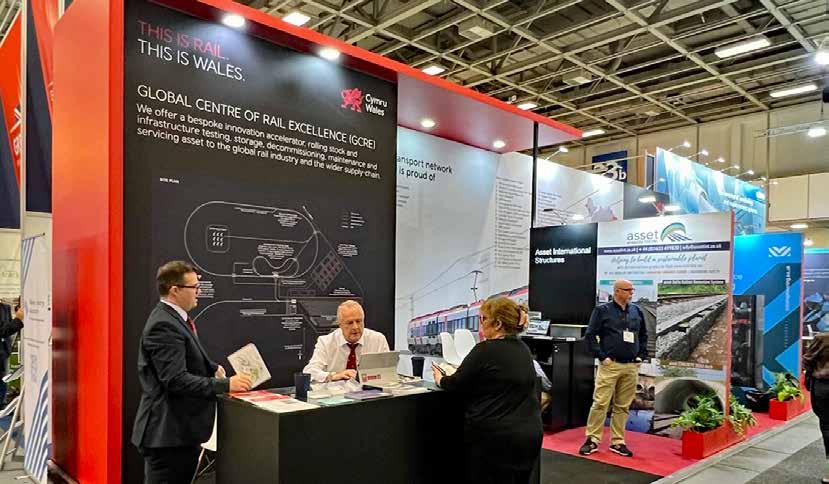

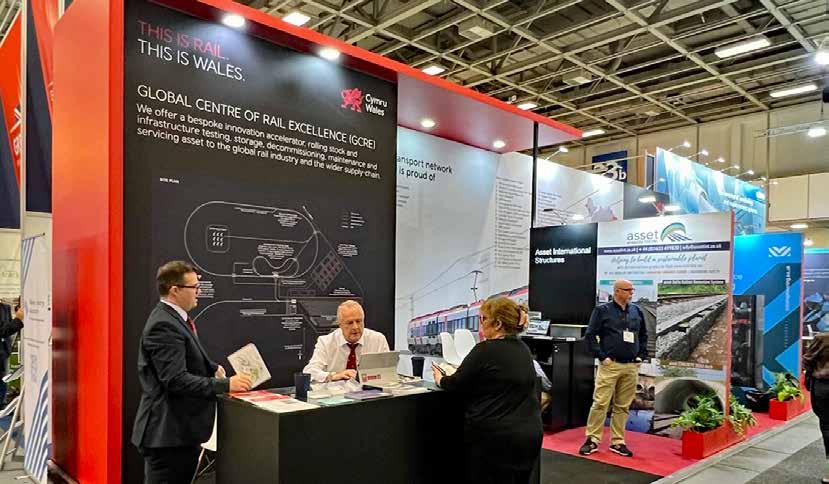

Innotrans returns This year’s Innotrans was the first since 2019, and it certainly didn’t disappoint its thousands of exhibitors and attendees.

SigTech Rail one year on Rail Engineer catches up with SigTech Rail to discuss its plans and abilities to support the operational highway.

Kessell files a report from the IRSE’s recent five-day signalling convention held in Glasgow.

Group gives

insight into

Network Rail standard

Signalling Power Distribution cables.

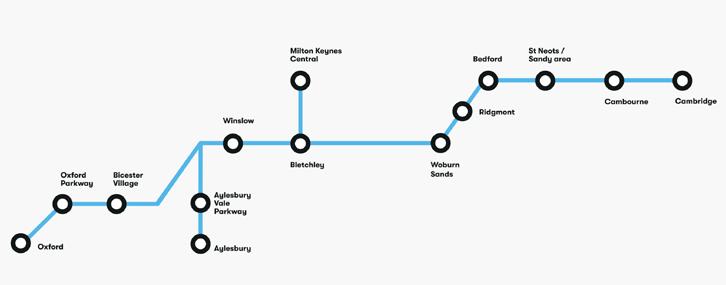

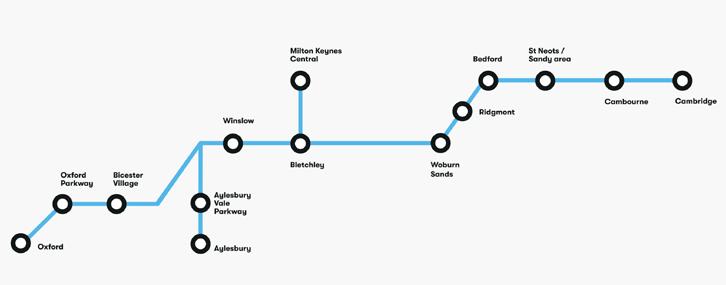

Progress and delay for East West Rail In his first contribution, David Fenner discusses the challenges met in linking Oxford, Milton Keynes, and Cambridge by rail.

32| 36|

64| 60| 3 Rail Engineer | Issue 198 | Sept-Oct 2022

IMechE Railway Division Chair’s Address 2022 Noel Travers is on tour, summarising his career, highlighting the contribution of engineers, and explaining the value of the Railway Division.

EDITORIAL

Lessons from

Europe

There was much to see at Innotrans. No doubt those on its 2,834 stands from 56 different countries were able to learn much from each other. Yet it was my rail journey home that showed me what Britain could learn from Europe’s rail networks.

My trip started at the multi-level Berlin Hauptbahnhof station. Here Deutsche Bahn’s high-speed ICE services operate from eight underground platforms between 3.5-kilometre long tunnels under the city. From here, my journey to Frankfurt included a high-speed line and existing track upgraded up to 250km/h. After staying with friends in the Darmstadt suburb of Eberstadt (population 3,000), my journey home started with a tram at 05:50 on Sunday morning which was part of an all-night service. A bus then took me to Frankfurt Airport for an ICE train to Brussels which took just over three hours as much of this trip was on 300 km/ hr high speed lines. The Brussels to London Eurostar train is entirely on high-speed lines and took just two hours five minutes for its 372-kilometre journey.

France completed its first high-speed line in 1981 and there is now a European network of 9,500km of high-speed lines of over 250km/hr. Britain will open its first cut-back 176km domestic high-speed line in about 10 years’ time. Paris opened its RER

line in 1977 to connect suburban services between main line stations by tunnels under Paris. London’s equivalent, the Elizabeth line, opened 45 years later.

As well as Berlin, stations such as Zurich, Vienna, Rotterdam, and Antwerp have been rebuilt to cope with growing traffic. In contrast, there is no long-term strategy to alleviate rail congestion in the north where plans for an underground station in Manchester and an HS2 station in Leeds have been shelved. Britain’s nine light rail systems compare with around 30 in France and 60 in Germany. This includes Darmstadt whose population of 200,000 is served by a 42km tram network.

Office of National Statistics figures show that, in 2019, worker output per hour in France and Germany was respectively 17% and 14% greater than in the UK. Whilst there are many reasons for the UK’s historically poor productivity record, poor rail connectivity must be a factor. The UK Government’s 2021 ‘Build Back Better’ strategy identified that the three core pillars of growth were infrastructure, skills, and innovation (with no mention of tax cuts). As Peter Hendy’s Union Connectivity Review noted, these pillars are reliant on transport to deliver their full potential.

An effective rail network is also needed to

attract modal shift from road and air if the Government’s net-zero carbon targets are to be achieved. At Innotrans, all the freight locomotives on display were electric. This was an indication of UK rail’s poor carbon record compared with European railways. In Britain there is little demand for electric rail freight traction with an analysis of the latest ORR rail emission figures showing that less than 4% of the energy used by UK freight locomotives is electric. Clearly there is much to learn from Europe.

The decarbonisation imperative was clear at Innotrans where various hydrogen powered rail vehicles were on show, though not much was said about where the hydrogen comes from. Our feature on Scotland’s hydrogen train explains how such trains should be an important part of the developing hydrogen economy. To decarbonise its non-traction energy Network Rail is to take the entire 49.9MW output of a new 200-acre solar farm near Norwich. We also show how the RSSB Rail Carbon Tool can help reduce the rail industry’s carbon footprint.

East West Rail offers carbons benefits from modal shift yet, as David Fenner describes, the future of its eastern part is under threat. Moreover, the decision not to electrify this railway as it is built means

4 EDITORIAL

Rail Engineer | Issue 198 | Sept-Oct 2022

that it will be operated by diesel traction. In contrast we describe how ScotRail’s electrification enables old, expensive-tooperate diesel trains to be replaced with electric trains that are much cheaper to buy and run.

With signalling renewals costing around £200 million a year, Paul Darlington considers how signalling can be more affordable through, for example, improved competition, better sharing of best practice and the elimination of lineside signals by ETCS. As we show, a good example of low costsignalling is the use of a ground frame and token machine to control train movements to Hillhead Quarry.

Clive Kessell reports on the IRSE’s five-day convention in Glasgow which also highlights opportunities for affordable signalling including faster designs with pre-wired components, fewer lineside cases, and plugcoupled tail cables. He notes that the latest signalling technologies yield undoubted benefits for reliability, capacity improvement,

and decarbonisation. Yet their adoption is only piecemeal as investment fails to take a long-term view of their benefits.

Another feature describes the IRSE’s licensing scheme which ensures individuals are competent to undertake safety critical work. This also considers professional registration by other bodies.

It would be interesting to know how the competence of those who took the decision to infill the bridge at Great Musgrave was assessed. Bob Wright revisits this issue in his review of the Bill Harvey Associates report on this bridge. His article shows that this report is essential reading for anyone with a professional interest in masonry arch bridges. It also shows that Highways England’s infilling of Great Musgrave Bridge was both unnecessary and ineffective.

Malcolm Dobell was at the address given to IMechE Railway Division by its new Chair, Noel Travers. He reports how Noel considered the contribution engineers can make when working ‘outside their

engineering boxes’ and that his key message was that leaders with an engineering understanding can really make a difference. Our readers would no doubt agree.

Editor

David Shirres

david.shirres@railengineer.co.uk

Production Editor

Matt Atkins matt@rail-media.com

Production and design Adam O’Connor adam@rail-media.com

Engineering writers

bob.wright@railengineer.co.uk clive.kessell@railengineer.co.uk collin.carr@railengineer.co.uk david.fenner@railengineer.co.uk graeme.bickerdike@railengineer.co.uk malcolm.dobell@railengineer.co.uk mark.phillips@railengineer.co.uk paul.darlington@railengineer.co.uk peter.stanton@railengineer.co.uk stuart.marsh@railengineer.co.uk

Advertising

Asif Ahmed asif@rail-media.com Chris Davies chris@rail-media.com Craig Smith craig@rail-media.com

Rail Engineer

Rail Media House, Samson Road, Coalville Leicestershire, LE67 3FP, UK. Switchboard: 01530 816 444 Website: www.railengineer.co.uk

Rail Engineer Videos http://rail.media/REYouTube

Editorial copy to Email: news@rail-media.com

Free controlled circulation Email: subscribe@rail-media.com

The small print

Rail Engineer is published by RailStaff Publications Limited and printed by PCP Ltd.

© All rights reserved. No part of this magazine may be reproduced in any form without the prior written permission of the copyright owners.

Part of: ® www.rail-media.com

THE TEAM

DAVID SHIRRES

RAIL ENGINEER EDITOR

5 Rail Engineer | Issue 198 | Sept-Oct 2022

(Left) Berlin Hauptbahnhof multi-level station. (Right) Darmstadt’s early Sunday morning trams.

Electrification and the Williams-Shapps Plan for Rail

It is always good to hear from our readers. Recently, Jack Smith, a Network Rail overhead conditional renewals engineer, sent us his paper ‘The Impact on Electrification behind the Williams-Shapps Plan for Rail (WS-PFR)’ which he thought might be of interest. We agreed.

Jack’s paper considers whether the WS-PFR might result in more electrification. To do so, he surveyed two different groups.

Group One comprised 20 staff working across the business in the planning, development, delivery, design, or management of electrification. Group Two consisted of 10 more senior professionals throughout the industry. The response rate from Group One and Group Two was, respectively, 50% and 80%. Jack concluded that the lower response rate from Group One reflected a low understanding of the WS-PFR’s proposals.

His survey asked three questions:

1. Have you read the WS-PFR?

2. How do you think it will impact electrification?

4. How do you think the WS-PFR will affect the wider business?

The responses showed that Group One (those directly responsible for delivery) had a low understanding of the WSPFR and its proposals, whereas Group Two (senior professionals) clearly understood it and made significant comments.

These included the need to reduce electrification costs and why this needs a rolling programme. Comments also acknowledged the valuable work done to reduce electrification clearances.

Network Rail Programme Manager Justin Davis commented that WS-PFR should reduce project overhead costs as it should “remove supplier, client layers and conflicting views and interests by a centralised controlling mind.”

Network Rail’s CEO, Andrew Haines considers that Great British Railways (GBR) will be able to better plan access by balancing “the trade-off between line closures and the revenue loss that occurs as result.” He also stressed the crucial important of cost reduction as decision makers consider that “even diesel trains are relatively green when compared to, for instance, road freight.

Therefore, the decarbonisation benefit per pound spent in the railway is not as high as in other sectors.”

The report concluded that:

1. It is fair to conclude that electrification is a future proof technology that is a good investment offering larger passenger and freight services as well as greater employment opportunities.

2. That the UK government is on board to make electrification the top of the hierarchy of choices. Hence the future of electrification looks very safe provided that costs can be contained.

Whilst the first conclusion cannot be denied, the second is doubtful as shown by UK Government inaction. Although WS-PFR is upbeat about electrification there is, as yet, no commitment to the required electrification rolling programme.

NOTICES 6 Rail Engineer | Issue 198 | Sept-Oct 2022

dirty truth about rail cleaning...

63% of cleaners were struggling to make ends meet BEFORE the cost of living crisis

Rising prices mean that a cleaner on the National Minimum Wage would need a £2,000 pay rise to have the same spending power as last year

Cleaners get no company sick pay

69% of cleaners say they have gone into work sick because they can’t afford not to work

Cleaners get no travel facilities

The number of cleaners has been cut leaving people overworked and underpaid.

Britain’s Largest Specialist Transport Union Protecting our members’ interests is our priority Join us today rmt.org.uk FREEPHONE 0800 376 3706 RMTunion IT’S TIME FOR JUSTICE for CLEANERS More cleaners than ever before are balloting for industrial action and taking strike action. If you’re NOT a member JOIN NOW!

•

•

WE DEMAND... • A pay rise to £15 an hour • A proper sick pay scheme • Travel provision • Proper pension provision • An end to outsourcing and profiteering on cleaning.

The

•

•

•

•

ScotRail fleet replacement

Notice of the first contract to replace a large part of ScotRail’s train fleet was recently posted on the Public Contracts Scotland website. This was a framework for the provision of legal services to support the new train procurement programme as well as ad hoc legal support during design, manufacture, testing, commissioning, and approvals.

This requires legal advice services to support an efficient and compliant procurement competition that provides trains to meet our customer, technical, and operational requirements whilst minimising the impact on the environment from their construction. As part of the need to give the taxpayer value for money, it specifies that this must include the economic and societal benefits for local communities and businesses.

The notice specifies that the train supplier must also submit options for maintenance, including a technical services agreement as well as a technical support and spares supply agreement with the decision on which provides best overall value for money being taken prior to contract award.

It states that ScotRail plans to replace 65% of its train fleet, around 675 vehicles, between the period 2027-2035 as by this time the operation of these trains will become increasingly costly. There is also the requirement to replace all existing diesel trains with new trains powered by overhead electrification, batteries, or hydrogen as part of the Scottish Government’s plan to decarbonise its passenger trains by 2035. This

procurement programme also offers a further opportunity to reduce costs significantly by reducing the number of types of trains. ScotRail currently has eleven different sub fleets.

The notice also advises that the new train fleet procurement will be done in three stages:

» Phase 1 in 2022-23 for a new fleet of suburban trains entering service between 2027 and 2030 to connect local communities with Edinburgh, Glasgow, Perth, Dundee, and Aberdeen. These will be suburban electric and battery electric multiple units. It is envisaged that this will consist of around 120 units comprising of 550 vehicles.

» Phase 2 is likely to be in 2024-25 for a new fleet of trains for rural routes which will be battery or hydrogen vehicles.

» Phase 3 is likely to be in 2025-26 for a new fleet of intercity trains to connect Scotland’s central belt with Aberdeen and Inverness to replace the current diesel HST fleet.

The deadline for a request to participate in this tender was the 2 September 2022 and the contract award is expected to be announced soon.

SHIRRES All about people people working in public transport...people like you! Health, welfare and financial help in times of need, hardship and distress. £1.25 a week covers you, your live-in partner and dependent children. 0300 333 2000 | help@tbf.org.uk | www.tbf.org.uk Transport Benevolent Fund CIO, known as TBF, is a registered charity in England and Wales, 1160901, and Scotland, SC047016. less than 20p a day NOTICES 8 Rail Engineer | Issue 198 | Sept-Oct 2022

DAVID

PAUL DARLINGTON

PAUL DARLINGTON

A ££ ORDABLE

SIGNALLING

Value for money and an affordable railway is the objective of many in the rail industry. Issue 184 of Rail Engineer (May/June 2020) looked at the affordability of railway electrification and, in this edition, we look at the affordability of signalling renewals and the ORR’s July 2022 update to its signalling market study’s report published in November 2021.

Signalling renewals are a major cost for Network Rail at around £200 million a year during Control Period 6. The ORR market study found that the market for major renewals is dominated by Siemens and Alstom, and the ORR has concerns over value for money together with the barriers to competition and new players being able to enter the market. UK signalling equipment is also provided by others, including Hitachi (which owns Ansaldo and plans to buy Thales), Atkins, and, more recently, Amey using Sella Controls PLC. Therefore, railway signalling competition is actually better than, for example, the far bigger mobile phone network market which is dominated by Nokia, Huawei, and Ericsson, especially as Huawei equipment will be removed from UK 5G networks by 2027 due to security concerns. A way just needs to be found for all rail signalling suppliers to compete more equally.

The ORR’s analysis of Network Rail’s expenditure on signalling identified that average prices were lower when projects were competitively tendered, as opposed to directly awarded via framework contracts. The ORR also said that GB signalling rates have been increased over recent years and are more expensive than Europe, and therefore the ORR suggests that more competition and more viable players will reduce costs. However, Siemens, Alstom, and Hitachi (Ansaldo and Thales) supply signalling to Europe and throughout the world. Therefore, the suppliers themselves may not be the entire problem.

The ORR identified barriers to competition and a difference between the objectives of Network Rail’s centre (procompetition and value for money) and the Network Rail regions (risk averse and delivery focused). The need to interface with the existing signalling technology was also identified as a significant barrier to new signalling suppliers. However, despite these concerns the ORR decided not to make a Market Investigation Reference to the Competition and Markets Authority, but to take a collaborative approach to improve the market situation with Network Rail.

10 Rail Engineer | Issue 198 | Sept-Oct 2022 SIGNALLING & TELECOMMUNICATIONS

Recommendations

A series of recommendations or ‘remedies’ were made, including one to reduce costs through increased competition between suppliers. The July update summarised the progress with the remedies and the ORR confirmed it is satisfied with the progress Network Rail has made.

Increased regulatory oversight

There will be increased regulatory oversight to increase transparency and Network Rail’s accountability with signalling procurement. On an annual basis, Network Rail will report to the ORR on major signalling projects, which will include the technology and the route to market (competitively tendered or framework and the number of bidders). Network Rail’s own costs will also be included.

A pro-competitive approach to procurement

Network Rail will widen the pool of suppliers and reduce its long-term dependence on the incumbent suppliers. Framework contracts will be longer and use a wider set of selection criteria, with a wider range of factors including interfacing behaviour, and will be outcome based and will not prescribe the technology of particular suppliers. Network Rail has also committed to partially reimburse development costs to suppliers.

Interfacing

This is aimed at increasing the ease of interfacing at the fringes of technology provided by different suppliers. Specific measures include open interfacing; limiting the costs when suppliers work for one another; and selection criteria to reward positive commitment to open interfacing. All future signalling contracts will require EULYNX compliance.

EULYNX is a European initiative to standardise interfaces and elements of signalling systems, by defining and standardising signalling interfaces, with the goal of significant reduction of the lifecycle costs. Standardisation of the signalling system interfaces is proving difficult, but it will also help with equipment obsolescence and not having to replace the whole signalling system. However, EULYNX will only deal with the interfacing of future systems so will not help with existing signalling systems.

With the EULYNX adapter from Pilz, railway infrastructure companies can use the manufacturerand country-independent EULYNX standard in existing interlockings and drive digitalisation forward.

11 Rail Engineer | Issue 198 | Sept-Oct 2022 SIGNALLING & TELECOMMUNICATIONS

PHOTO: PILZ GMBH & CO. KG

The control centre technology and predominance of a particular technology on the fringes of a scheme can influence the choice of supplier, which is why limiting the costs when suppliers work for one another implementing fringe and control centre arrangements is so important.

The mobile telecoms industry is also doing something similar to EULYNX with its Open intelligent Radio Access Network (O-RAN) initiative. A £250 million 5G Diversification Strategy, published in November 2020, sets out where the government will remove barriers for new vendors, invest in open RAN (O-RAN), and work with like-minded countries to achieve secure and resilient telecoms supply chains.

Like EULYNX, O-RAN is intended to provide flexibility and interoperability with complete openness to multi-supplier deployments. However, the European Union has published a report on security risk concerns, including a larger attack surface, increased risk of misconfiguration, and immature specifications that are not secure by design. A German Federal Office for Information Security report said the O-RAN specification provides only a few guidelines in the area of security, and that security risks can be identified in numerous interfaces and components. It said the current specification doesn’t adhere to the principle of security by default, and fails to take account of the principles of multilateral security.

Therefore, the rail industry and the ORR need to be aware of the safety and security issues that may arise with the open interfacing of signalling and learn from other technologies, such as O-RAN with far larger R&D resources.

Balancing

ORR said Network Rail should play a more active role in the oversight of signalling procurement, and Network Rail has committed to reducing the risk to regions with the introduction of new technology. This will also include an innovation fund to assist regions with implementing new technology and limiting risks.

Funding

This consists of recommendations to all the industry, including the ORR, to highlight the importance and mitigate the persistent historical uncertainty around future re-signalling volumes, at both a total market and individual supplier levels. Network Rail has committed to strengthen the linkage between supplier tendering success and the volumes of work delivered; and encourage further innovation and reduce the dependency on supplier innovation investment by including signalling innovation in its future research and development funding.

Rail Engineer | Issue 198 | Sept-Oct 2022 12 SIGNALLING & TELECOMMUNICATIONS

Competition

Competition is important in driving engineering innovation and creativity at an affordable cost. Additionally, new suppliers, technology, and new ways of doing things can transform industries. However, this needs to be handled carefully to incentivise the right outcomes and provide systems that are safe, reliable and can be supported throughout their lifetime.

Attracting new suppliers and technology to the UK signalling market has been tried before with mixed results. In 2002, Siemens installed their SIMIS-W Computer Based Interlocking (CBI) in Bournemouth for the Dorset Coast resignalling. This was supplied by Siemens Germany and before Siemens bought Invensys Rail (formally Westinghouse) located in Chippenham. No other SIMIS-W systems were installed in the UK, so spares and people with the required competency to operate and maintain the system are limited. It’s understood that during recent industrial action, managers did not have the specialist competency to operate the SIMIS-W system as it’s so different to other signalling systems in the area.

In 2004, Ansaldo’s CBI interlocking was provided in the Manchester South area as part of the West Coast Main Line modernisation programme. The system was advanced compared to other signalling systems of the time with, for example, extensive remote diagnostic capabilities.

However, Ansaldo’s ACC was designed for Roma Termini with a 3kV DC traction railway, and it proved difficult to adopt the system to the UK signalling environment with 25kV AC traction and a long, thin and different type of route, without compromising the advantages and benefits of the system. The issues included: The scope and scale of approvals activities took years, and approvals have since become even more complex: for example, with the Common Safety Method (CSM). Cross acceptance was used, but the Ansaldo system was relatively new in its home market and still undergoing changes.

The Segnale Dichroico Ottico (SDO) signal head used halogen lamps and a clever arrangement of dichroic mirrors to transmit/ reflect each colour through a single aperture

with no moving parts. The selection of aspect was made through a VF interface with selected frequencies driving a specific lamp. The UK use of this VF drive was a problem, given the different electric traction systems. The SDO signal also required a different lamp and voltage from its native design to comply with UK readability requirements, and proved to be unreliable.

The systems T72 point machine was designed with heaters under its contact units, but to comply with the UK ballast requirements these could not be fitted, resulting in contact failures. The T72 point machine was used on HS1, but with the heaters and is reliable.

A form of limited automatic route setting was available within the Italian application. However, it was concluded that the changes required for the UK would be far too intrusive to be viable. Today, spares and competent people to look after the system are limited. The Manchester South system is relatively reliable, but a fault occurred two years ago that took several days to resolve and required engineers to fly in from Italy. During this time no trains could be operated between Manchester and London.

Given that the system is totally different to operate than other UK signalling systems in the area there is no case to move the control of the system into the nearby Railway Operating Centre. With problems such as this it is understandable that Network Rail regions may be hesitant with taking on new technology.

Rail Engineer | Issue 198 | Sept-Oct 2022 13 SIGNALLING & TELECOMMUNICATIONS

Best practice

It is important that the rail industry learns and adopts best practice from other industries, but it is not always the case that things are done better elsewhere. Five years ago, on an IRSE visit to the M6 Smart motorway scheme, engineers from road and rail found they had much in common, such as dealing with poor legacy records, poor asset condition, and the need to keep road and rail moving with the minimum of traffic closure. However, when the rail engineers asked the road engineers about the Smart motorway ‘fail safe’ design to alert vehicles of a lane blockage, and what independent safety analysis had been undertaken of the design, their faces went blank. We now know the use of the hard shoulder to increase capacity for vehicles has proved controversial due to safety concerns and a number of fatal accidents.

But where could new competitors come from? As mentioned, Hitachi owns Ansaldo and plans to buy Thales, and Alstom has bought Bombardier. The telecoms industry (on government instruction) is not using Huawei due to security concerns. Any ‘new player’ would need staff with UK competencies, which they could only get by paying people more to attract them. Therefore, there could be a risk of increasing costs not reducing them.

a completely new way of delivering signalling schemes using new and modern cost-effective techniques. It means standard sets of data, produced and tested by tools makes the design production and verification far easier, more repeatable, and efficient.

Rising costs

So why has the unit rate of signalling increased over the recent years and is it more expensive than in Europe? UK signalling is very safe but has become more complicated and, therefore, expensive. For example, more complicated signalling overlaps (in simple terms, the distance for a train to stop should it pass a red signal) provides increased protection and, while trackside equipment needs less maintenance, there’s more to maintain, manage, and replace. The UK interlocking data of today is more complicated than it was 30 years ago, with some systems relying on increasingly bespoke and complicated software. Mass production is therefore unlikely to happen on the scale required.

It’s not just the signalling that costs more, either. Signal structures have become bigger and are not as easy to install, so the civil and structural engineering required to support the signalling can be expensive. Sometimes when a signalling scheme takes place, years of deferred renewals of assets such as cable routes, power supplies, equipment rooms, and level crossings have to be funded by the signalling scheme. Access points and walkways to modern safety standards may also be required. Using equipment housings instead of equipment buildings is one way of removing the need for expensive civils and new power supplies. They all need designing, constructing, and maintaining, but some regions still require equipment buildings and not more cost-effective equipment cabinets. Signallingindependent safety assurance and testing processes are excellent, but not cheap, and it’s such an important area that making savings in this area is not easy.

Some of the incumbent suppliers may be international companies not based in the UK, but they have large, successful, and predominantly British supply chains, and there are large UKbased R&D teams, with at least one supplier having a major factory in the UK.

Much innovation and new ways of working have been introduced by existing UK suppliers. For example, Atkins has developed its Advanced Signalling Method (ASM) which currently uses the ElectroLoglXS interlocking. ElectroLoglXS was developed by General Electric Transportation Systems (GETS) in America, which was acquired by Alstom, who license its use to Atkins for use in Great Britain. Atkins ASM is an example of

Sometimes, re-signalling may be scheduled many years ahead, with possessions booked way in advance. Project teams and consultants can then spend a lot of time and money ‘developing’ the scheme, followed by lengthy approvals and a procurement process before the signalling supplier is appointed. This can then lead to the signalling supplier having to recruit and subcontract aspects of the scheme in a relative short period of time to meet the published timescales. All of this adds to the cost.

A key finding of the Dearman/ McNaughton National Electrification Efficiency Panel (NEEP) initiative was the avoidance of high overheads and ‘boom and bust’, and this applies equally to signalling. This is why the recommendations of ‘Increased regulatory oversight’ and ‘Funding’ are so important.

14 Rail Engineer | Issue 198 | Sept-Oct 2022 SIGNALLING & TELECOMMUNICATIONS

More affordable signalling

In a recent IRSE presidential address − ‘ETCS – The impact on the signal engineer’ − Council member Andy Stringer explained how European Train Control System (ETCS) Level 2, with no signals deployed, could reduce signalling costs. Complex station areas with lots of mixed stock is not easy, but could more simpler routes be fitted with ETCS and rolling stock transferred between operators to make the route all ETCS?

With ETCS Level 2, miles of expensive concrete and copper cabling, and thousands of tonnes of steel for signalling structures would not be required. Power supplies would be simpler and could consist of local battery and solar-powered axle counters linked by radio. Points could be located near to existing 415V three phase supplies or battery power. Bi-directional movements could more easily be provided, which would increase rail flexibility and service resilience. Route learning and knowledge would be easier and less of a constraint for diversions. Faster trains would also be possible as they would not be limited by fixed signal spacing, and better, safer, and more costeffective staff protection systems would also be easier to provide.

In the past, ETCS rollout has been hampered by train fitment, but now many trains come with ETCS and other railways around the world have proved that retro fitment is possible. Andy Stringer believes simpler signalling principles are

possible and more efficient, and cost-effective engineering techniques are also now available to bring costs down, for example, digital twins, formalisation of requirements processes, auto design/testing, and value-added system engineering and safety assurance processes.

One of the significant costs in implementing new signalling systems is the time required to fully test and commission. Enhanced factory testing with more sophisticated auto testing tools, including the use of ‘formal methods’, is now also possible.

In his address, Andy stressed that everyone in the rail industry − be they the regulator, infrastructure manager, maintainer, supplier, train operator, or rolling stock provider − are on the same team. The real competitors are the road and air transport industries. Rail has a fantastic advantage with the far more efficient steel wheel and rail interface. It just needs to use the right competition to make signalling more affordable.

15 Rail Engineer | Issue 198 | Sept-Oct 2022 SIGNALLING & TELECOMMUNICATIONS

PAUL DARLINGTON

NEW RAIL

Hillhead Quarry SIDING AT

Tarmac, the

is to reopen the Hillhead Quarry,

via

As such, a new railhead connection to the Buxton and High Peak Junction line has been opened. Rail freight is now carrying more material than ever before, hauling medium to long distance heavy loads, at speeds of up to 75mph and a train load of freight can replace up to 75 heavy goods road vehicles.

The railhead connection siding at Hillhead has required an interesting signalling solution, from a legacy signalling equipment perspective, with a new mechanical ground frame and token machine, to control train movements along the freight-only single line.

The reopening of the quarry and railhead is part of an upturn in building development, due largely to HS2 and the subsequent increase in demand for aggregate materials. The site was previously connected to the Buxton High Peak Junction line via a ground frame called Hindlow No.1 Ground Frame, but this had been out of use for many years and the track plain lined. There was no rail infrastructure that could be reused.

Extensive civil engineering work was required to provide access for the new siding and the construction of an onsite loading facility. This was contracted by Tarmac to Story Contracting Limited, who also delivered the track for the siding and the crossover connection to the single line.

Network Rail contracted the signalling and telecoms development work to Volker Rail which employed Arup to undertake the detailed design, with installation undertaken by VolkerRail Ltd. HCOMM delivered the telecoms element with a ‘box on post’ telecoms location spliced into the existing copper lineside cable and a direct line telephone to Buxton Signal Box.

No power

The option of clamp lock operated points was considered, but with no power in the area it was decided to install a three-lever mechanical ground frame released by a token machine next to the frame along with the direct line telephone. The ground frame was constructed by Network Rail’s Crewe-based locking fitters and the project team commented that the work delivered by the young enthusiastic fitters was excellent.

The token machine is powered by a battery and located with the token machine in a wide cabinet supplied by Tyrone Fabrication. This mechanical arrangement also avoids the requirement for deadlocking train detection. Access to the new

owner of Hillhead Quarry, near Buxton, Derbyshire,

for the production and delivery of aggregates to its customers

rail.

owner of Hillhead Quarry, near Buxton, Derbyshire,

for the production and delivery of aggregates to its customers

rail.

16 Rail Engineer | Issue 198 | Sept-Oct 2022 SIGNALLING & TELECOMMUNICATIONS

siding at Hillhead Quarry is via a single crossover connection from the Buxton and High Peak Junction line, in the vicinity of the old Hindlow No.1 Ground Frame site. Trains access the sidings via the facing crossover connection from the Buxton direction.

Prior to any move being authorised from the mainline to Hillhead Quarry siding, the shunter checks that the hand points are correctly set after operating the ground frame. The ground frame release is via the possession of a single line token, which is consistent with the existing arrangement at Briggs Ground Frame further along the line. The token machine at Hillhead Quarry also allows a train to be ‘locked’ inside the quarry facility, and a token released by Buxton Signal Box allows the train access back onto the Buxton and High Peak Junction line.

The shunter contacts the Buxton signaller and requests the release of a token. Once a token is obtained it is inserted into the lock of the release lever, and both point levers are operated to move the points reverse to allow the train to join the main line. The shunter ensures that the points on the ground lie in the desired position before authorising any movement. For the crossover to be normalised via the ground frame, drivers are required to ensure that the rear of the train is clear of the points on the main line. This is achieved by radio communications between the shunter and driver. The token is then transferred to the loco for onward movement.

Buxton

The existing Buxton and High Peak Junction line token equipment at Buxton Signal Box has not been changed and the regulation of train movements on the line remains with the Buxton signaller as before, taking into account any additional token release requests from Hillhead as well

as Briggs. Because the single line token type is unique to the Buxton and High Peak Junction line, the token can be used for either Hillhead or Briggs ground frames.

A sufficient quantity of tokens is provided to avoid any imbalance of tokens between Buxton, Briggs, and Hillhead, it being assumed that only one train may be locked inside Hillhead Quarry, plus one additional light-engine (for rescue purposes) also locked inside the siding. The use of the existing single line token apparatus to access Hillhead Ground Frame means the same token keys can be used at all ground frames on the route. The implementation of Hillhead Ground Frame and the trackwork for the crossing

has been a great railway collaboration project, and the signalling was signed into use on 4 September, ready for the railhead connection siding to be used towards the end of the year. The simple mechanical ground frame requires no power and the experience gained by the locking fitters and designers will no doubt be used elsewhere on the network.

It is a great example of collaborative working between different sectors of the rail industry to provide a sustainable railway facility to reduce the number of HGVs on the roads and bring down carbon emission.

With many thanks to Richard Wright and Sean Nicholson for their help with this article.

17 Rail Engineer | Issue 198 | Sept-Oct 2022 SIGNALLING & TELECOMMUNICATIONS

ONE YEAR ON R

ail Engineer first met SigTech Rail Consultancy Ltd in November 2021 to discuss its abilities and plans to support the operational railway. A year later, we met up with SigTech again to learn how the company is progressing.

SigTech Rail provides specialised, efficient signalling support for track and point renewals, civil engineering works, maintainers, and any project that involves signalling. The company has developed to become a first-class provider of specialist signalling services, including nonconceptual design, installation and permanent way signalling support, along with operational telecoms.

Adaptive and innovative

Network Rail has said it is committed to delivering more work via small and mediumsized Enterprises (SMEs) such as SigTech, and that 33% of its annual expenditure is being spent via SMEs. Over the last four years, Network Rail has increased its expenditure with SMEs, achieving 25.61%, 26.78%, 30.4% and 35.6%, respectively. SMEs are important to Network Rail as, it says, such companies are recognised as being highly adaptive and innovative, and are not constrained by large overheads and excessive company processes. The government also says small companies play a significant role in the growth of the economy, with SMEs accounting for approximately 15.7 million jobs in the UK and 60% of all private sector employment.

The company operates throughout the country and was originally based near Canterbury in Kent. However, to enable quicker and easier travel to its clients, the company has moved its base to Derbyshire. This is an ideal location to support routes such as the East Coast Main Line, West Coast Main Line, and HS2; together with major rail locations such as Derby, Birmingham, Crewe, Liverpool, Manchester, and York. The company is now ideally placed, being closer to all of the cities in the running to become the HQ of Great British Railways.

SigTech Rail’s unofficial motto is however “have van will travel” and it considers its work area as all of the UK. This summer it had six projects successfully taking place at the same time in: Newcastle upon Tyne, Liverpool, Manchester, Birmingham, London, and Southampton. The company’s support teams are also located around the country, including Kent, Edinburgh, Nottingham, and the Wirral.

Hammerton lever frame renewal

Typical of the type of work SigTech has been involved in during the last year is the renewal of the locking frame at Hammerton station to the West of York. Over the weekend of 12-15 August, the firm worked alongside locking fitters from Network Rail to renew the lever frame.

Hammerton is an intermediate station on the York to Harrogate route, which is signalled by traditional mechanical branch line signalling, located between the modern electronic signalling at York and Leeds. However, the lever frame is unusual as it is located in an exquisitely designed

Rail Engineer | Issue 198 | Sept-Oct 2022 18 SIGNALLING & TELECOMMUNICATIONS

PAUL DARLINGTON

wooden ‘hut house’ on the platform. It is thought to date from the signalling of the line in the 1880s and an 1895 survey records eight ‘signal boxes’ on the line as being “Wood Cover on Platform”. In 1914 a McKenzie and Holland No.16 lever frame was provided, and it was this frame that was being replaced over the weekend in August.

The frame was heavily worn with salt and grit from the many years of signallers’ boots walking to and from the nearby gated road crossing. A replacement frame was recovered from Bardon Mill, Northumberland; which was renovated and re-built at Holgate depot in York, with only the necessary 10 levers from the 20 recovered. The frame was then dismantled and transported to Hammerton.

The company’s role was to disconnect all the electrical lever locks and circuit controllers attached to the frame. After the frame was replaced by the locking fitters, SigTech’s installers re-terminated the 89 wires under the control of its lead tester. Following installation (with it working first time) the frame was transferred to the test team of SigTech and Network Rail for them to undertake the required testing. It was then handed back ready for the first train on the Monday morning.

Joe Young, mechanical and electrical locking supervisor for Network Rail North East, said: “I would personally like to thank everyone who has been involved and dedicated to the Hammerton lever frame renewal. There have certainly been many tense moments and issues to overcome, however as a team we have conquered and succeeded. The renewal of the frame is a fantastic achievement which should be celebrated by everyone, bearing in mind the last time a lever frame renewal on this scale was conducted was by British Rail back in 1981. In my eyes, this is an accomplishment that we should all be proud of.”

Southport Birkdale platform extension

Another example of work successfully carried out by SigTech Rail is the modification of the tuned TI21 track circuit system at Birkdale station near Southport. New for the Merseyrail network is a specifically designed variant of the Stadler Class 777 units. The existing Class 507/508 trains are 60.7 metres (3-car) and 121.4 metres (6-car), but these new Stadler trains are longer at 65 metres (4-car) and 130 metres (8-car). Extensive platform works at 92 platforms at 56 stations and track realignments have been required to accommodate the new trains.

The works are essentially civil engineering, but in the case of Birkdale station the TI21 track circuit needed modifying with an Insulated Block Joint (IBJ), so the company was brought in by the civil engineering company to resolve the issue. This sort of situation can often occur with railway civil engineering works, when the main contractor needs a quick efficient way of delivering any S&T asset work that is affected by their core works. SigTech is ideally placed to arrange any design work and carry out the work and testing out safely in compliance with all Standards requirements.

The company has also been involved with supporting track work and switch renewals around the country, for example supporting the Tyne and Wear Passenger Transport Executive network (Nexus). Working around the country and on different railways allows SigTech to experience and then share best practice; which is even more important for today’s non-centralised, devolved, national rail network.

SigTech is also available to assist with ‘tricky’ faults and it can sometimes help a maintainer for an independent person to assist with a difficult fault. No matter how competent a maintainer may be, a fresh pair of eyes and a different approach can often help.

SigTech Rail has recently assisted with resolving a wide to gauge set of points at Edge Hill Liverpool, caused by excessive rail wear due to extensive freight traffic and tight curves.

Meeting clients’ needs

It is clear that the company has established very good relationships with its clients, enabling it to provide a quality service and more meaningful interactions. This results in a good, personalised service, and for the clients’ needs to be met more accurately. As with most SMEs, which have fewer employees, it’s easier for people to get to know one another and form deeper working relationships. As a result, everyone can support one another and pick up on particular strengths and qualities, which improves teamwork skills and performance. Knowing colleagues on a personal level makes the working environment a comfortable one, and this is reflected by the level of service provided to customers.

SigTech Rail’s simple employment structure allows for adaptable individual requirements; such as working from home, working flexible hours, or attending family commitments.

Specialised service companies offering niche, quality services are distinguished from other larger businesses and organisations. This instils a sense of confidence amongst clients.

Rail Engineer | Issue 198 | Sept-Oct 2022 19 SIGNALLING & TELECOMMUNICATIONS

The personal relationships that are established with smaller workforces help to create a strong team spirit, whilst instilling mutual goals. Each individual in an SME is crucial to the success of the business, creating mutual respect and a sense of camaraderie. SigTech is also keen to train and mentor new entrants into the industry, and has plans to support heritage railways and provide apprentices the opportunity to learn and work on mechanical signalling. This is a win-win for everyone; providing apprentices valuable experience and heritage railways with more costeffective signalling.

Reduced costs

It’s perhaps inevitable that SMEs will consume much less energy when compared to larger businesses – a factor which is now more important than ever. There are fewer computers, printers, and lights running, which reduces both initial and maintenance costs. In many cases, the money that’s saved on resources can be used to offer a lower price to potential clients – making them not only a more specialised, but a more cost-effective option.

Within an SME like SigTech Rail, decisions can be made and implemented much more efficiently. Instead of having to be discussed by large groups and layers of people, decisions are quickly made and accurately communicated directly to everyone in the business.

Certifications

Being an SME doesn’t mean a company does not have independent assessments. SigTech has impressive certifications, which include ISO 9001 Quality Management. It has been verified and audited by RISQS to undertake fixed price works and is also a Certified Member of CIRAS (Confidential Incident Reporting Analysis System for Transport).

The company has also achieved Gold Membership with Constructionline and is now a verified and pre-qualified contractor, providing signalling maintenance and support services throughout the UK rail industry. The Constructionline Gold Award also verifies to PAS91 and includes Acclaim Accreditation which certifies SigTech within Safety Schemes in Procurement (SSIP) by demonstrating the company’s compliance with relevant health and safety legislation.

As signatories of the Rail Supply Group Work Pipeline Visibility Charter, SigTech will also provide its work pipeline visibility across its supply chain in order to allow suppliers to plan and invest with confidence, driving improvements in productivity, and enhancing collaborative delivery.

If you need a cost effective, knowledgeable, safe, and reliable firm to undertake signalling work to support your project or maintenance area, give SigTech Rail a call on 01303 764344 or visit www.sigtechrail.co.uk. SigTech Rail is always ready and waiting to share best practice and help any project over the line.

20 Rail Engineer | Issue 198 | Sept-Oct 2022 SIGNALLING & TELECOMMUNICATIONS

VIEW AND DOWNLOAD OUR E-BOOK trust us to deliver onSaveC02 emissions with our generatorsbattery PRE PLAN YOUR RAIL FESTIVE BLOCKADES By working in partnership with Speedy Rail, we can: • Deliver a complete managed service for your site • Supply up-to-date quality products / engineers / operators to match your needs • Reduce carbon footprint • Manage transport costs • Advise the correct products for safely lighting up your site • Support you with our on-call 24/7 dedicated rail desk Visit speedyservices.com/rail/festive-blockades or contact 01942 277 982 for more information and to plan for your festive blockades SUSTAINABILITY IN A WHOLE NEW LIGHT Portable and Managed Lighting Solutions for every Scenario We can provide managed site lighting services for all scenarios. • Plan ahead • Save on cost • Reduce risk See how our lighting solutions can reduce your carbon emissions with our online calculator. Visit: speedyservices.com/rail-calculator 01942 277 982 speedyservices.com

A signalling exposition

Periodically, the signalling and telecommunication profession demonstrates and shares its technology and innovations, safety policy, business methods and finances as seen by rail infrastructure organisations, train companies and the supplier base.

CLIVE KESSELL

CLIVE KESSELL

Most recently, this was achieved through a fiveday convention in Glasgow, organised by the IRSE. The subject matter had a Scottish flavour but the success stories and lessons to be learned had relevance for all the UK railways and many overseas railways as well. With attendees from right across the world, it was remarkable to hear during the socialising sessions, just how many of the problems being experienced in Britain were the same elsewhere. With a mixture of talks and technical visits, real progress was evident in some areas, though deployment of the gamechanging technology that could yield substantial commercial benefits continues to struggle.

Current signalling technology

British Rail led the way back in the 1980s in the development of computer-based signalling commonly known as Solid State Interlockings (SSI). This took many years of tripartite cooperation between British Rail, Westinghouse (now part of Siemens Mobility), and GEC (now part of Alstom) to get an acceptable product standardised and approved for general use. The computer technology has moved on from those early days and improved versions of the interlocking have evolved into WestLock from Siemens and SmartLock from Alstom.

Both have much greater computing power but retain the same data formats. Being bespoke products, they are expensive and increasingly only used where much of the associated trackside equipment is to be retained.

Ben Hugh from Siemens Mobility described an alternative approach that provides a complete solution for all the required signalling intelligence including the interlocking. Known as the Westrace Trackside System (WTS), this may be regarded as a ‘toolbox’ of Westrace units. The interlocking element is designed as ladder logic and was first used on some metro line projects including the London Underground Central Line upgrade. Westrace uses standardised templates which leads to faster designs with pre-wired components, this allows factory testing such that when the system leaves the test yard, it is known to work.

Rail Engineer | Issue 198 | Sept-Oct 2022 22 SIGNALLING & TELECOMMUNICATIONS

Traditional Lever Frame at Larbert Training Centre.

Another objective is to cram as much equipment into the lineside equipment room, itself being designed with a modular layout. This results in fewer lineside cases and thus fewer maintenance visits. External elements such as points and signals are connected by plug-coupled tail cables, measured beforehand to be the correct length. Each Westrace unit is a standard module design (e.g., a point module, a signal module, etc.) such that multiple connections can be made into one unit. Thus, a point module might be capable of serving, say, four point machines. If only one point machine is served, it might seem that the unit has more capacity than needed but the fact that it is standardised means that overall cost saving is achieved.

Westrace is designed to provide better remote condition monitoring including earth leakage detection with connection to thirdparty non-SIL equipment. Future developments include the use of cloud diagnostics and the use of alternative transmission links to replace customised cables. These might include lowpowered radio and existing lineside comms. The WTS installed base is impressive and includes London Bridge, Derby, Liverpool Lime Street, Kings Cross, and, most recently, Macclesfield.

Lower cost signalling

The cost of signalling is a contentious issue and several initiatives have occurred recently to provide more cost-effective technology, especially for rural lines. Park Signalling made much of its replacement design for a lookalike single line token instrument. Known as DiBloc, this is a digital block controller that connects to other instruments using secure IP

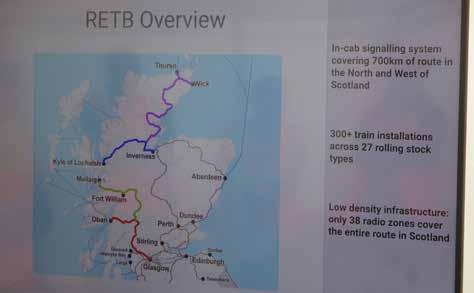

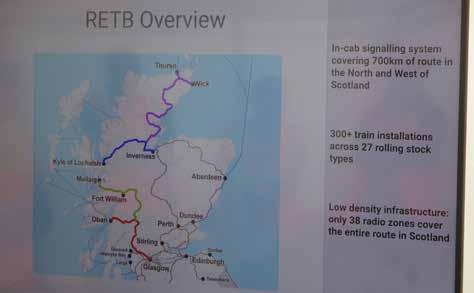

Communication. A full description of the system was given in Rail Engineer Issue 174 (May 2019) so will not be repeated here. The first application has been on the Romney Hythe and Dymchurch narrow gauge railway in Kent and a contract is let for the Whitland to Tenby line in West Wales. There are still a few single lines that are operated by token machines so, although the market is not huge, it is significant and may have opportunities for overseas railways. Radio Electronic Token Block (RETB) has been around for over 30 years but recent work to improve performance, partly necessitated by a radio frequency change, has made the system more reliable with more features. Under a main contract with Telent to provide overall delivery, both the West Highland Line and the Far North lines in Scotland have benefited from the upgraded system. Whilst the basic principles of a chain of radio links from the control centres at Bannervie and Inverness remain, the radio network has been completely renewed with equipment being designed and supplied by Comms Design Ltd, a Harrogate company specialising in bespoke radio equipment. These lines are in remote areas and very often there are no passengers to join a train at the stations. To avoid the driver having to slow down in case a passenger is waiting, Request Stop units have been developed by Park Signalling linked into the RETB network. On the platform, a unit is provided that gives the time of the next train services, usually in both directions. A button is then pushed to request the train to stop, with this then being posted on to the driver’s RETB token screen. Currently being trialled at Scotscalder, it is expected that these units will be rolled out to all stations on these lines.

A limitation of RETB operation is the hydraulically controlled loop points (effectively spring points) that can be trailed through in the wrong direction, necessitating a severe speed restriction. Park Signalling is investigating

RETB overview.

RETB overview.

23 Rail Engineer | Issue 198 | Sept-Oct 2022 SIGNALLING & TELECOMMUNICATIONS

Request Stop Indicator.

the motorising of points and control of their movement by RETB commands. This would improve the speed profile and enable valuable time savings to be made, particularly if a train does not have to stop at the loop location. It would however require a power source to be provided, not always easy in very remote places. Another future initiative is to use GPS positioning information which trains are increasingly equipped with, to link into the RETB network and provide the signallers with accurate and continual train location data. Watch this space to see how these developments turn out.

Asset management

Keeping signalling in reliable and safe condition is always an important responsibility, however the processes for assessing when and how to renew assets must consider many factors. Lynsey Hunter, the Regional Asset Manager for signalling in Scotland, explained some of the challenges. Signalling equipment has an average life span of 30 years, meaning regular maintenance until when it is not possible (often because of obsolescence issues) whence renewal is required. The spend profile for different assets, if renewed piecemeal, means spending more than if you renew a complete system in one go. Other influences may prevail:

» Passengers want enhancements which signalling can help provide.

» The regulator will hold you to the promises you made.

» Train operators expect the infrastructure owner to pay.

» Other assets, such as stations, may influence the future signalling system.

» The funder wants value for money.

Signalling costs do not vary that much if the line has eight trains a day or eight trains an hour, but enhancements such as a loop extension create questions around who pays for what. Modification or updating an asset is not always acceptable. Dressing up a donkey still leaves you with a donkey! Stakeholders need both a perception of the risk and the willingness to take risk. The supply chain needs regular orders to keep them in business.

Decarbonisation and technology

Decarbonisation, buzz word of the moment, is often seen as having little relevance for signalling, however there are areas where carbon reduction can be influenced by some of the more recent technologies. Stephen Wright from Siemens Mobility went through some of the systems that can help. ETCS, TMS, and C-DAS can all contribute to improving train performance and thus to energy reduction. Fine in theory, but these systems have been available for many years. Whilst some are being introduced in dribs and drabs, deployment in the quantities originally intended has never happened. When questioned, the general opinion is that upfront investment in such systems fails to take a long-term view of the benefits that are realisable and thus the money is not forthcoming.

One can only hope that this situation improves as countries are setting challenging targets for carbon reduction, Scotland wants all passenger services to be decarbonised by 2035 but TMS and ETCS seems as far away as ever.

Staff training

The shortage of competent engineers and technicians is well documented, so training new recruits to the profession is vital. Scotland has a dedicated training centre at Larbert which covers all aspects of signalling systems, from traditional lever frames to ETCS, with a full range of rail and trackside equipment housed in a simulated railway hall as well as outside. Point operating mechanisms abound, both electrical machines and clamp locks.

Two elements of training were given specific focus to the visiting members: » Level crossing modernisation is prominent with obstacle detection crossings and the supporting radar and lidar equipment needing to be fully understood. It is often thought that OD (obstacle detection) crossings are there to upgrade a crossing from AHB (Automatic

Larbert Training School Points and Signals.

Obstacle Detection

24 Rail Engineer | Issue 198 | Sept-Oct 2022 SIGNALLING & TELECOMMUNICATIONS

Crossing LIDAR and inset RADAR.

Half Barrier) but this is not the case. With the concentration of signalling into ever more centralised centres, full four-barrier CCTV controlled crossings could well overwhelm the capability of a single signaller. Thus, OD crossings are primarily there to remove the responsibility of the signaller to prove the crossing clear, with the additional benefit of automating the crossing in the process. A full understanding of these crossings is needed, particularly the sequencing of operation during the barrier lowering and detection processes.

» TCOD (Track Circuit Operating Device) is an important element in improving staff protection when needing to work on running lines. Placing such devices and managing their presence can be a challenge for local staff. An improved version which includes its GPS positioning and is capable of interrogation has now been developed. Whilst still portable, the TCOD is sprung into position at the desired location and activated by a single person at the site. With a unique serial number and its GPS position shown by a seven-digit numeric code, the battery powered GPS and mobile radio is placed nearby in a secure box.

When needed, the site supervisor consults with the signaller and, once satisfied, the TCOD is then activated. In busy areas where track maintenance is undertaken frequently, the TCOD can be left in position permanently, the battery life being several months. It can be interrogated and activated remotely, thus saving the need to walk out and put a TCOD in position. This is a fully approved product with around 400 already in use.

Satellite communication

Satellites have the advantage of being able to provide communication in even the remotest of areas. Scotland has many such locations and at some places where level crossings exist, providing a telephone service to the public can be a challenge. A trackside SatPhone has therefore been developed by Iridium for which Dr. Bob Gardner from Network Rail gave details. Power is provided either by solar panels or a local wind generator. Use is made of low-orbit satellites, so guaranteed connection to at least one of them is assured.

Monitoring for flooding and bridge scour was featured in Rail Engineer issue 197 (July/ August 2022), whereby the transmission of alarm data also uses a satellite connection to Iridium’s control centre in the US, and then to a customer’s operations centre by a virtual private network (VPN).

25 Rail Engineer | Issue 198 | Sept-Oct 2022 SIGNALLING & TELECOMMUNICATIONS

TCOD in position.

Delivering broadband to trains is an ever-demanded request from the travelling public and Network Rail is investigating a satellite derived service for the East Coast Main Line. An IC225 was fitted out with a Starlink terminal but, for some reason, this was never used. A new initiative is underway on the same train with the intention of providing a 500Mbits/sec connection. Tests are taking place over a 200-mile stretch of the route and, so far, have achieved 190Mb/s in the download direction and 17Mb/s for the upload. Work is ongoing. Inevitably, where tunnels exist, the connection will be lost but, with higher speed trains, maybe a holding facility can be used to automatically re-connect once daylight is reached again. Using satellite connections does invoke a financial charge reckoned to be between £80 and £400 per month, dependent on the capacity required.

The Carstairs remodelling

One of the biggest projects in Scotland is remodelling the triangular junction at Carstairs, the place where the West Coast Main Line from London splits for Glasgow or Edinburgh, as well as providing another Glasgow to Edinburgh route. It is also the place where the overnight sleeper service to and from London splits into two portions. The present layout is complex with significant speed restrictions imposed. Around 200 trains pass through on a daily basis.

The remodelling will segregate the fast lines from the station platform lines to give much improved line speeds of 100mph to Glasgow and 40mph to Edinburgh. Thirty-five point ends will be reduced to 28 and a complete resignalling is necessary with flashing 5th aspects being deployed. The revised track layout demands new portal overhead line gantries to be provided for the OLE. The total cost is £160 million, so this is a major project. The work will be carefully staged to minimise disruption with most of the rudimentary work having been completed, however a 16 day closure will take place in early 2023 requiring LondonGlasgow trains to be diverted via Kilmarnock.

West of Scotland Signalling Centre

A visit to this centre proved revealing. The signalling area covered is continually being expanded and already has taken over the routes covered by the now closed Glasgow Central and Motherwell power boxes of 1970s vintage. The route from Paisley to Ayr is included and further routes towards Kilmarnock will eventually be added.

Gone are the days of large mimic panels and all train movements are viewed on computer screens, some of which are quite large. Around 10 workstations exist, tailored to specific areas. Train movements are generally set automatically from the timetable database using the automatic route setting facility but the signallers choose to do manual route setting from time-totime so as to remain competent. The interlockings are Westlock but as the signalling centre has grown, more modern variations of the product have been used. A new Westlock will be provided for the remodelled Carstairs area.

From a telecoms perspective, it was interesting to talk to the signallers. Communication with drivers is invariably by the GSM-R radio network. Just occasionally, a call may be picked up by a ‘wrong’ base station and sent to the wrong signaller. Local procedures deal with transferring the call to the ‘right’ signaller. The only users of SPTs are track staff and even this is rare. As one who has campaigned for years to have SPTs removed, it would seem that Network Rail should bite the bullet and take the decision not to provide these in future. New SPT systems are increasingly expensive to construct (sometimes over £1 million for a big centre) when budgets are constrained.

Final thoughts

Scotland has an enviable reputation for being proactive in expanding its rail network. Several lines have re-opened in recent years with the latest – to Levenmouth – expected to open in 2024. All of these have employed traditional signalling and there is little evidence that the adoption of ETCS will feature in future proposals. The use of RETB is commended but whether this will ever be expanded to other lines is debatable. Some deployment of C-DAS is beginning to happen but no plans for Traffic Management Systems were evident.

The adoption of the latest technologies to yield undoubted benefits for capacity improvement and decarbonisation seems only to be happening piecemeal throughout the UK. Maybe the future Great British Railways and government thinking might be persuaded to take a new look at this.

Work Station at WSSC.

26 Rail Engineer | Issue 198 | Sept-Oct 2022 SIGNALLING & TELECOMMUNICATIONS

Westlock Computer Based Interlocking.

VIRTUAL REALITY SIGNAL SIGHTING

True North Rail use the latest gaming engine technology incorporating project Survey/Design and GIS data to create high fidelity virtual reality worlds that ensure all Signals, Signs and Indicators are Sighted to project requirements.

•

• Project SnakeGrid compatible

•

• Asset modeller - Quickly add rolling stock to adjacent lines to review sighting impact, with future provision to add OLE structures to define REFOS requirements for proposed structure renewals to achieve compliant sighting, as well as OLE SPS alteration.

• Save and review multiple scenarios for individual Signals

• BIM Integration - Export 3D asset models to inform detail design

• Quickly adjust time of day/date/weather – accurate sun paths for real-world sunlight impact analysis

• Supply of cloud-based models with sleeker more intuitive user interface, requiring minimal support/ training with access via a standard laptop/computer and internet connection

• Single-click export of all typical images required for Signal Sighting Assessment Records

OPTIMISE INNOVATE DELIVER

info@truenorthrail.com Call 07715

768

547

www.truenorthrail.com

Generate 3D assets from simple text-based data files

Import and export asset meta data (E.g., Line speed, ELR, Track ID etc.)

signalling power cables what’s all the fuss about? Jointing of

The Network Rail standard for enhanced unarmoured Signalling Power Distribution cables - NR/L2/SIGELP/27408 was introduced to tighten the specification for signalling power cables and support the introduction of class II methodology. The cable standard introduced several key requirements that drive the need to correctly specify the cable and the associated accessories – specifically the joints and jointing methodology used.

The cable standard re-introduces the use of aluminium as a conductor of choice alongside the traditional and more expensive stranded copper option. For the aluminium option NR/L2/SIGELP/27408 specifies solid conductors up to 95mm² and allows both solid and stranded conductors for sizes equal or greater than 120mm². To protect the cable from water and rodent-related degradation, the cable standard requires the use of water blocking tapes and fibreglasswoven rodent resistant tapes.

To supplement NR/L2/SIGELP/27408 and support the required target asset life of 35+ years, specific accessories standards have been written. NR/L2/SIGELP/27423 covers the requirement for cable joints and connectors. The standard says that, to achieve the target asset life, joints using resinous compounds are preferred.

Previous joints history

The history of jointing signalling power cables is chequered – at one end of the scale there are manufacturer assembled, fully compatible and tested joints, which include connectors designed and tested to meet the Network Rail requirements of the day. At the other end of the scale are joints assembled by third parties at the last minute to try to fulfil a particular urgent need, and which may or may not have been approved by Network Rail.

At both ends of this scale there would be a mix of technologies which may or may not produce a reliable installed joint capable of protecting the cable and meeting the Network Rail asset life expectations. This chequered history might have influenced the cautious approach of the industry related to the speed of the reintroduction of aluminium conductors.

28 Rail Engineer | Issue 198 | Sept-Oct 2022 SIGNALLING & TELECOMMUNICATIONS

DR. DAVID LAMB & JONATHAN RAWLINSON

Next generation cable joints

The standard NR/L2/SIGELP/27423 relates to joints intended for connecting signalling power cables, where the electrical system is either TN or IT and the nominal voltage is up to 650V AC. The cable types are defined as follows:

» a) Enhanced unarmoured cable to NR/ L2/SIGELP/27408.

» b) B2 ethylene propylene rubber (EPR) cable to RT/E/PS/00005.

» c) Armoured cable to BS 5467.

» d) Armoured cable to BS 6346.

Within the joints standard, particular attention has been focussed on the conductor connectors or splices which requires full compliance with BS EN 61238-1 for both aluminium and copper conductors:

“Connector resistance, temperature, mechanical strength and short-circuit behaviour shall be in accordance with a Class A connector as specified in BS EN 61238-1.” (Network Rail, 2015)

In particular, connections between dissimilar metals, i.e., copper and aluminium, are specified to be made using bi-metallic connectors. These are required by NR/L2/SIGELP/27423 to be made by friction welding and similarly tested and approved to BS EN 61238-1.

Mixed experience

Network Rail has mixed experience with the aluminium conductor type cables leading to a previous preference for the copper conductors. However, driven by the recent high copper prices these cables are significantly more expensive and more liable to theft. Looking outside of the rail sector it was noted that the UK power utilities had been using aluminium conductors and their associated joints and connections without significant problems for over 40 years. It was also recognised that the industry had tight product specification and training requirements in place.

To ensure an equivalent success rate on the product specification, the Network Rail joint standard sets out specific requirements for conductor connections and their installation:

“Unlike copper conductor based distribution systems, aluminium cable is very intolerant of poorly designed and badly made-up connectors. Failure of a connector can lead to loss of the power distribution system, which in turn can cause severe operational disruption. This specification has been developed to ensure that connectors used in signalling power distribution systems are made to a consistent standard and the measures identified in this standard, when adhered to, prevent premature failure.” (Network Rail, 2015)

Focussing on installation, the Network Rail accessory standard requires that all connectors supplied shall be suitable for installation in accordance with BS 7609. This is the ‘Code of practice for Installation and inspection of uninsulated compression and mechanical connectors for power cables with copper or aluminium conductors’ and covers installation methodology, tooling and the maintenance and calibration of tooling. The Network Rail standard says that the preferred crimping tools are either battery-powered or electro-hydraulic and includes requirement for auto-checking. It also requires that manufacturers of connectors provide the necessary training packages to support their use.

Prysmian Group has over 40 years’ experience in the development and testing of crimp connectors, including our inhouse friction welding facility. To fulfil the Network Rail requirements the company