by rail engineers for rail engineers www.railengineer.co.uk SUSTAINABILITY AND ENVIRONMENT Siemens Mobility’s Goole manufacturing plant has sustainability and social value at its heart. BEES, SHEEP, AND TRAINS PG.22 STRUCTURES AND INFRASTRUCTURE We revisit HS2's Thame Valley viaduct to discuss the benefits of its design and construction. MODULAR DESIGN SIMPLIFIES CONSTRUCTION PG.50 SIGNALLING AND TELECOMS ETCS could provide a revolution in signalling safety, so why isn’t it more widely adopted? ETCS: MORE DELIBERATIONS PG.34 PG.10 SEP-OCT 2023 – ISSUE 204 HS2 offered so much What might have been

SIEMENS MOBILITY

We understand that collaboration across the rail industry is crucial for reducing cost and driving transformation.

siemens.co.uk/mobility

People you can trust with rail transformation

26| 28|

HS2 offered so much

With Phase 2 cancelled, the UK is left poorer for it. David Shirres examines what could have been.

HS2: A glimpse of a green future

With Phase 1 still under construction, HS2 is showcasing green benefits which could have been enjoyed by all.

Siemens Mobility Goole component repair facility

Malcolm Dobell joined the excursion to Goole and investigated the site’s £7 million component facility.

Wi-Fi 7: the new kid on the block

Things move fast in the world of telecoms and Wi-Fi 7 is now setting a new standard.

Signalling maintenance testing improvements

Network Rail is working with the IRSE and its contractors to ensure compliance with the Signal Maintenance Testing Handbook.

ETCS: More Deliberations

If ETCS is a solution to capacity constraints and a revolution in signalling safety, why isn’t it in wider use?

Migrating from GSM-R to FRMCS

With GSM-R becoming obsolete, its replacement by FRMCS needs to be considered. Paul Darlington examines the challenges.

FRMCS – radio network planning fundamentals

Yahya Khaled from ATDI APAC gives his insights on the challenges of radio network planning and modelling an evolving technology.

22|

Bees, sheep, and trains

Paul Darlington visited Siemens Mobility’s train manufacturing plant at Goole, which has sustainability and social value at its heart.

54|

58| 70|

Improving railway gauging

Onboard technology and AI may make insufficient gauging data a thing of the past. David Shirres reports.

Modular design simplifies construction of HS2’s Thame Valley Viaduct

The design of the Thame Valley viaduct enables most of its structural elements to be constructed off site.

Synthetic wood saves Nottingham forest

Sekisui’s Nigel Keightley talks us through the state-of-theart upgrade of a Nottinghamshire Network Rail bridge.

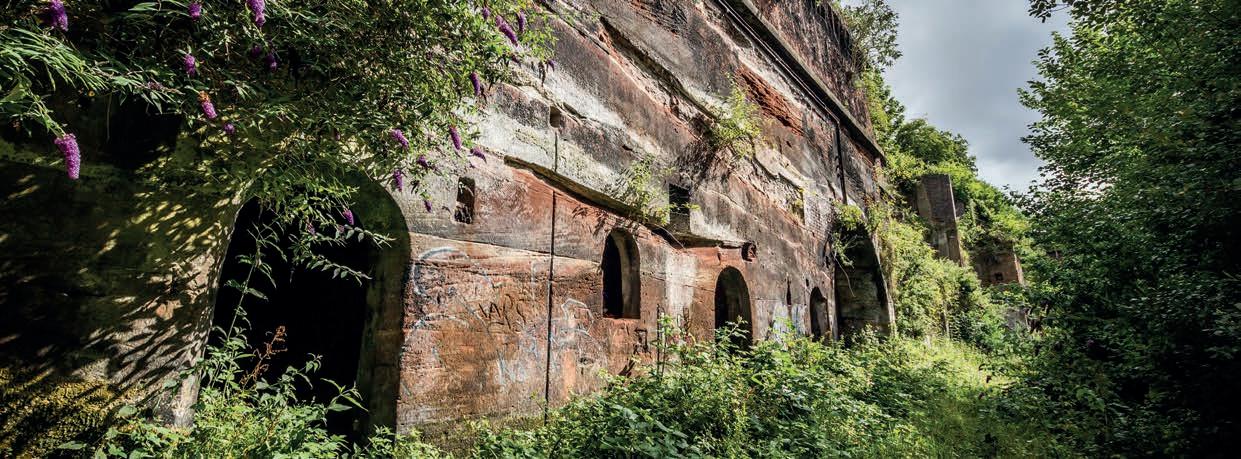

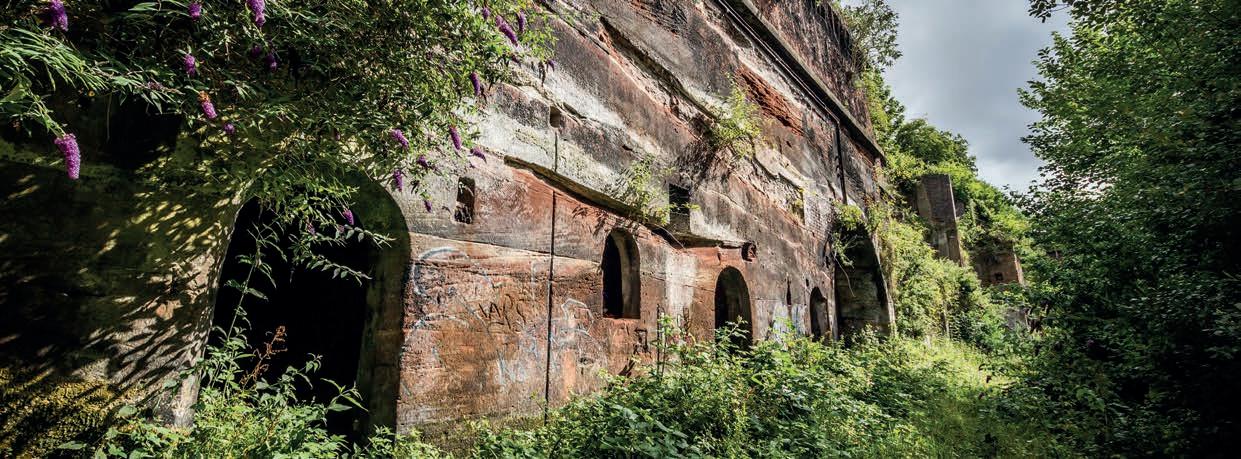

Dawlish Rockfall Shelter

Mark Phillips describes the complexities of building a rockfall shelter to protect one of Brunel’s early railways.

Improving passenger ride comfort

With humans coming in all shapes and sizes, ensuring they’re comfortable as they travel is a complex problem.

Edge Hill Engine Station: where it all began

Historic England has added Edge Hill Engine Station to its National Heritage List. Graeme Bickerdike tells us more.

Along the way: IMechE Railway Division Chair’s address 2023

Andrew Skinner’s traditional address covered railway engineering careers and his view of the future.

22 70 CONTENTS 46 26 10| 16| 40| 34|

30|

44| 50|

46|

62| 76|

3 Rail Engineer | Issue 204 | Sept-Oct 2023

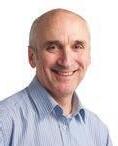

DAVID

SHIRRES

DAVID SHIRRES

RAIL

ENGINEER EDITOR

The 2012 High Speed Rail White Paper noted that many nations have high speed rail lines, transforming their economies, and that not building such lines means Britain loses out while our global competitors gain. Doing nothing leaves UK rail networks over-burdened and risks lost business, lower growth, and fewer jobs. HS2 was an essential part of raising regional productivity to create jobs, skills, and talent. For 15 years, this was cross party consensus under six Prime Ministers, with Rishi Sunak supporting HS2 during his Tory leadership campaign.

As we explain, HS2 is the result of years of planning. It was to serve eight of the UK’s 10 largest cities and release large amounts of capacity on the West Coast, Midland, and East Coast main lines. This huge increase in capacity offered significant improvements in local services and more freight trains. It would have given rail the capacity to accommodate the modal shift needed to significantly reduce the nation’s carbon transport emissions.

Yet polls show that HS2’s supporters are outnumbered two to one by its opponents who consider it wrong to spend billions just to save minutes off the journey time

Lost opportunities for future generations

from Birmingham to London. HS2 and the DfT bear the responsibility for this narrative as little was done to explain HS2’s huge benefits during the early project phase.

Hence, Sunak’s decision to cancel HS2 between Lichfield and Manchester was announced as an act of political showmanship at the Tory Party Conference. This masqueraded as a strong, long-term decision as “the facts around HS2 have changed”. Yet, as we show, the facts have not fundamentally changed. Replacing a strategy built up over 15 years with expert input by the hastily put together Network North plan that leaves many questions unanswered is not long-term decision making. It also reduces that nation’s standing with international investors.

Network North includes projects already promised, like the West Yorkshire Metro, and some already completed! It is said to be funded by the £36 billion saved from cancelling HS2 phase 2, yet most of this money was not to be spent until the 2030s.

This decision leaves a major gap in the UK’s rail strategy around which city regions have based their economic growth plans. It is also one that is extremely hard to reverse as land is being sold and route safeguarding removed. Capacity on the remaining

HS2 phase one line is permanently constrained by a small HS2 Euston station which will only be built if private finance is available. Getting the best from what remains requires a London terminus designed to maximise the line’s capacity rather than arbitrarily specifying six platforms. Clearly maximising benefits has not been considered.

It is also a decision that irrevocably denies future generations outside London the opportunities presented in Europe by a high-speed rail network. Though HS2 has been criticised as being expensive, innovative techniques are being used to reduce costs. Bob Wright explains how the modular design of HS2’s Thame Valley viaduct enables most of its structural elements to be constructed off-site. HS2 has also successfully pursued its environmental targets. As we report, it is the first UK transport sector client to achieve PAS 2080 accreditation for whole life carbon management.

Sustainability, environmental protection, biodiversity, social value, community support and engagement, rare sheep, and bees all feature in the new £200 million rail village that Siemens has constructed on its 67-acre site in Goole. Though the train manufacturing plant is not expected to commence work until March, we describe how components such as gearboxes and traction motors are already being overhauled there.

Overhauling diesel shunter gearboxes was one of Andrew Skinner’s first jobs as a railway engineering sandwich course student. His career, advice to young engineers, and challenges faced by the industry were the topics in his IMechE Railway Division Chair’s address. One of Andrew’s key messages is that the railway is a tightly integrated system. This was also the theme of a comprehensive feature by Malcolm Dobell on improving passenger ride comfort.

EDITORIAL

PHOTO: ISTOCKPHOTO.COM/ CHRISHEPBURN 4 Rail Engineer | Issue 204 | Sep-Oct 2023

Wide angle aerial view over Manchester Piccadilly train station

Gauging to ensure that trains can fit through the infrastructure is also a system issue for which the lack of infrastructure gauging data is problematic. We report on how it is now possible to use in-service trains to regularly collect this data and how artificial intelligence is being used to input the resultant large amount of data into a new gauging database. In this way the lack of gauging data should soon be a thing of the past.

ETCS is also a system issue requiring compatibility between train and trackside equipment. Though it is intended to be interoperable, £140,000 per cab is now being spent to upgrade the ETCS-fitted Thameslink Class 700 trains for the East Coast Digital Programme. This raises potentially costly issues of backwards compatibility for the largescale ETCS rollout. Clive Kessell considers this, and other ETCS cost issues.

Crucial to ETCS operation is a reliable radio system. With GSM-R fast becoming obsolete, its replacement by FRMCS needs to be considered. Paul Darlington describes the issues associated with possible migration strategies. He also considers the benefits of WiFi 7 which is expected to be available next year.

The worrying increase in signalling wrong side failures following signalling maintenance works indicates that memories of the lessons from the 1988 Clapham collision are fading.

Hence, Network Rail is working with the IRSE and its contractors to ensure compliance with the Signal Maintenance Testing Handbook (SMTH). This includes programmes to reinforce the attitudes and understanding as well as improved training materials and assessments.

The contrast between HS2 and the Liverpool and Manchester Railway which opened in 1830 is evident from Graeme Bickerdike’s informative feature on its original route from Liverpool Crown Street to Edge Hill. Another early railway was Brunel’s line through Dawlish which is particularly vulnerable from both sea and cliffs. Mark Phillips describes the complexities of building a rockfall shelter as rock bolted netting does not provide sufficient protection.

These early railways were the first of over 35,000km of railways built in the 19th century which transformed the nation’s economy. British engineers also built many railways outside the UK. In respect of the high-speed rail revolution, this situation is reversed. Japan built its first high-speed line in 1964, followed by France in 1981. Worldwide there are now 58,000km of high-speed lines, yet Britain’s high speed network is now to be permanently limited to 320km. What would our forebears have thought?

Editor

David Shirres

editor@railengineer.co.uk

Production Editor

Matt Atkins matt@rail-media.com

Production and design

Lauren Palin lauren@rail-media.com

Adam O’Connor adam@rail-media.com

Engineering writers

bob.hazell@railengineer.co.uk

bob.wright@railengineer.co.uk

clive.kessell@railengineer.co.uk

david.fenner@railengineer.co.uk

graeme.bickerdike@railengineer.co.uk malcolm.dobell@railengineer.co.uk

mark.phillips@railengineer.co.uk paul.darlington@railengineer.co.uk peter.stanton@railengineer.co.uk

Advertising

Asif Ahmed asif@rail-media.com

Craig Smith craig@rail-media.com

David King david.king@rail-media.com

Rail Engineer

Rail Media House, Samson Road, Coalville Leicestershire, LE67 3FP, UK. Switchboard: 01530 816 444 Website: www.railengineer.co.uk

Rail Engineer Videos http://rail.media/REYouTube

Editorial copy to Email: news@rail-media.com

Free controlled circulation Email: subscribe@rail-media.com

The small print

Rail Engineer is published by RailStaff Publications Limited and printed by PCP Ltd.

© All rights reserved. No part of this magazine may be reproduced in any form without the prior written permission of the copyright owners.

Part of: www.rail-media.com

TEAM

THE

5 Rail Engineer | Issue 204 | Sep-Oct 2023

BOB WRIGHT

BOB WRIGHT

The world’s first railway station identified

Following research by the Friends of the Stockton & Darlington Railway, which safeguards and promotes the heritage of the route, Heighington and Aycliffe Railway Station has been proven to have been in use since 1827 - 196 years ago. Until recently, Liverpool Road station in Manchester, dating from 1830, had been considered the earliest station. As a result, Historic England has increased its listing from Grade II to Grade II*, recognising it as a “particularly important building of more than special interest”. Just 5.8% of listed buildings are Grade II*.

The Stockton and Darlington Railway (S&DR) opened on 27 September 1825, with statutory powers to operate a public railway for the carriage of both passengers and a full range of goods. However, it was the transport of coal that was its main source of revenue. A regular passenger service was instigated between Darlington and Shildon, using a horse-drawn coach. At this time, the railway was open to any carrier to use its tracks, similar to today’s open access but without the same level of overarching coordination.

In 1826, the S&DR began to build inns to oversee the railway’s depots at Stockton, Darlington, and along the route, including a small depot where the railway crossed the lane between Heighington and the Great North Road at Aycliffe. It had been at this crossing that ‘Locomotion’, the company’s first locomotive, was placed onto the track when it was delivered by road from Robert Stephenson & Co. works in Newcastle on 16 September.

The combination of inn and management of depots is a curious one, especially as the railway’s funders were mostly Quakers who promoted temperance. At this very early date in the history of railways, the concept of a station had yet to be developed, but coaches used inns as calling points on their services and the railway inns probably reflected that tradition.

The buildings were designed by John Carter, a mason from Heighington who had superintended the construction of bridges along the line. Each was of squared, coursed sandstone, quoined at the corners, with projecting stone sills and multipaned vertical sashed windows.

In 1827, the S&DR advertised the leases for the buildings overseeing both Aycliffe Lane and Darlington depots, noting that they were seeking licences for them as inns. The magistrates refused and so the depot at Aycliffe Lane was let without an alcohol licence. An editorial in the Durham Chronicle criticised the decision and, in passing, mentioned that the depot was being used to shelter passengers awaiting coaches and as a collection point for goods and parcels being transported by rail. From this source it is clear this depot was providing some of the core functions that we would today recognise at a railway station, the first of around 7,000 in the UK.

Its use as a station appears to have been ad hoc and informal in its early days, especially as until 1833 passenger services were provided by a number of independent coach operators using horse-haulage, paying a toll charge to the railway. After this date the S&DR took over the running of these services, using its own steam locomotives. Aycliffe Lane probably then took on the booking office function. Previously, payment would have been made on the train.

Alongside the depot, water was drawn from a pond for use by locomotives. On 1 July 1828, ‘Locomotion’ exploded whilst taking on water at Aycliffe Lane, killing the driver John Cree and injuring Edward Turnbull.

long overlooked but truly

By 1856, the station was renamed Heighington and Aycliffe Station and, in 1873, Heighington Station. This ancient railway building remained in use as a station with attached housing until it fell into disuse in the 1970s, the station becoming an unstaffed halt. In 1984, it was renovated and converted into a public house called ‘Locomotion 1’, reflecting that locomotive’s double links with the station. Today, just a quarter of a mile away, Hitachi’s Newton Aycliffe plant is constructing today’s rolling stock. Since 2017, the building has been disused and empty. The Friends of the Stockton & Darlington Railway and Historic England hope that the raising of its historic significance will prompt an appropriate and long-term use for this long overlooked but truly pioneering station building.

Rail Engineer | Issue 204 | Sept-Oct 2023 NOTICES 6

The cobbled surface between the building and the line shown in historic photographs has been suggested as being the world’s earliest railway passenger platform

196 years separate the building of this modest structure and the vast station that will become HS2’s Old Oak Common

Curtailing HS2

Cancelling HS2 phase 2 was a decision of huge magnitude. The full HS2 Y network from London to Manchester and Leeds was designed as a fully integrated system intended to maximise its capacity. Cutting this back to the line now being built has significant adverse consequences, some of which may not be clear for some time.

Since this announcement, various sources have reported that neither Network Rail nor HS2 were consulted. Indeed, it is reported that a £300 million contract for HS2 phase 2 work was signed just days before it was announced that phase 2 was to be scrapped.

The money saved by cancelling HS2 phase 2 is now to be spent on a diverse collection of schemes entitled Network North, yet most of the spend on phase 2 was due to take place in the 2030s. These schemes include some that have already been promised, such as the West Yorkshire Metro and tram lines in Manchester and Nottingham that have already been built. Network North promises a new station for Bradford with a new line to Huddersfield that had not been previously mentioned. Without any development, this proposal is a line on a map and a £2 billion guessed estimate. It is clear that, in contrast to HS2 which has been the subject of years of development with expert input, the Network North document has been hastily produced with, to quote one report, “the whiff of the hotel photocopier about it”.

It is true that HS2 is a costly project. As described in our feature ‘HS2 offered so much’, its initial estimates were over optimistic and significant costs were added to satisfy objectors.

Since then, HS2’s phase 1’s funding envelope was set at £44.6 billion including £4.3 billion contingency (2019 prices).

The HS2 six-monthly report to Parliament in June 2023 reported that total estimated costs for phase 1 were between £35 billion and £45 billion which is around its budget price despite construction inflation of 24% since 2019.

The Network North document states that PwC’s High Speed Rail International Benchmarking Study of November 2016 found that the cost per mile of HS2 phase 1 is five times that of equivalent schemes in Europe. Yet this study relates to HS2 phase 2. On page 22 it shows phase 2 to be 49% more expensive than a comparable high-speed project. Hence, while HS2 is an expensive project, it is not true that its costs were spiralling out of control.

GETTING BEST VALUE

In the statement cancelling HS2 there was no mention of its benefits or how to maximise the benefits from what remains of the project.

HS2 was intended to provide a step-change in capacity to reduce the productivity gap between London and northern cities. This would also have

NOTICES 8

DAVID SHIRRES

HS2 Euston platforms

enabled the rail network to accommodate extra traffic, in particular freight, needed to reduce the nation’s transport carbon emissions. Yet even with both its Leeds and Manchester legs cancelled, HS2 can deliver significant benefits. It can do so by taking at least 12 trains per hour off the West Coast Main Line south of Lichfield and offering Birmingham, Manchester, Liverpool, Glasgow, and Edinburgh a frequent inter-city service that’s up to 15-minutes faster.

The Network North statement states that: “phase 1 will now need to be reviewed to make sure only what is required for the reduced HS2 scheme is being delivered.” This statement wrongly implies that a reduced HS2 scheme means a reduced HS2 phase 1 train service. Instead, the emphasis should be how best to maximise the use of the expensive HS2 phase 1 line. If its benefits are assumed to be at least equivalent to its cost, the value of an individual train path is in the order of £2 billion.

However, no train service has been specified and, instead of maximising phase 1’s capacity, HS2 is being instructed to review designs to reduce scope while the project is under construction. As anyone involved in project management knows, redesigning a project as it is built is most likely to add costs.

The capacity of the HS2 phase 1 line is determined by its terminus. Originally it was considered that 11 platforms were needed for the full HS2 Y network of 18 trains per hour. It has now been announced that Euston will have six platforms. This decision to minimise the cost of construction does not consider the required train service. As a result, it is likely that the highly expensive HS2 phase 1 line will have to run well below capacity with billions of pounds of benefit wasted.

While Prime Minister Sunak’s announcement commits to terminating HS2 at Euston, reports since then indicate that this will not happen unless £6.5 billion of private finance can be raised. If the line were to terminate at Old Oak Common, its capacity would be constrained, and half of its potential passengers would find that its 15-minute journey time saving was less than the extra time it took them to get to their destination. Without a central London terminus, it is doubtful whether HS2 would cover its costs.

HS2’S TRAINS

In December 2021, a Hitachi-Alstom joint venture signed a £1.97 billion contract for the construction of 54 high-speed trains to run on HS2 and conventional lines. These trains will have a top speed of 360km/h on the high-speed line and are 200 metres long. Two of these trains are to be coupled together for operation to HS2 stations which are built to accommodate these 400-metre trains.

Vehicle bodies are to be assembled at Hitachi’s Newton Aycliffe plant, bogies manufactured at Alstom’s Crewe plant, with final assembly at Alstom’s factory in Derby. The first train is expected to be completed in 2027.

A month earlier, the Government published its Integrated Rail Plan which cut back the eastern leg of HS2 from Leeds to East Midlands Parkway. At the time, a study of route options to take HS2 trains to Leeds was promised. However, immediately after the HS2 line to East Midlands Parkway was cancelled at the same time as HS2 phase 2, it was announced that this study is no longer relevant. With the cancellation of the HS2 lines to both Leeds and Manchester it is clear that not all the contract’s 54 high-speed trains will be required for possible likely services. It is understood that this contract is now to be reviewed. This may result in a reduction in the number of trains to be produced, with Alstom/Hitachi paid a cancellation penalty or the use of surplus trains on conventional routes only.

Hitachi’s Italian ETR1000 Frecciarossa. Much of this high-speed rail technology will be used in the Hitachi/Alstom UK high speed trains

The design of these trains to run on both the high-speed and conventional lines involves some compromises which have now become sub-optimal with the cancellation of large parts of the planned HS2 network. For example:

» 200 metre trains are too short. The only dedicated HS2 stations will now be in London and Birmingham. Nowhere else can accommodate 2 x 200-metre trains and the 200-metre trains are shorter than the 260-metre Pendolino trains that operate on the WCML.

» European gauge trains will now not run on HS2. It was originally envisaged that half the trains operating on the full Y network would be dedicated HS2 trains built to European loading gauge. As this will not now happen, platform heights and offsets need to be reconsidered. The trains have a high floor and offered level boarding at HS2’s 1150mm platform height. With only four HS2 stations this becomes more problematic.

» Trains do not tilt. They will be slower than the current Pendolino trains. This was not considered to be an issue when HS2 trains would have eventually saved 50 minutes on the journey between London and Preston.

In view of the above, a design review of the existing train design is needed to ensure that they are appropriate. Rail Engineer will return to this issue.

BEST HOPE

Cancelling HS2 was a huge decision. While there was certainly a need to review its cost against its benefits, it is clear that the announcement of the cancellation of phase 2 at the Conservative Party conference was a rushed decision. It involved no expert input taking account of the project’s benefits and will incur significant abortive costs. It is astounding that a major project, developed with expert advice over many years, can be cancelled in this way.

With the decision to sell land reserved for phase 2, it has also been done in a way that will ensure the UK can never have a high-speed rail network and thus denies the railway its full potential to support economic growth and decarbonise transport through modal shift.

The best that can be hoped for is that the UK’s only remaining domestic high-speed line is able to carry as much traffic as it can.

This requires Government to deliver on its commitment to deliver Euston, not to otherwise unduly constrain HS2 phase 1, and for a six-platform Euston station to be designed and operated to maximise train throughput.

Rail Engineer | Issue 204 | Sept-Oct 2023 9 NOTICES

HS2 offered so much “

“Whatever your view of this project, HS2 is now a reality – heading north, creating jobs, and building a brighter future for our country. This vital project is at the heart of the Government’s commitments to build back better from the pandemic, tackle the north-south divide, and drive growth across the country. I look forward to seeing spades in the ground to get this section built and deliver the benefits of high-speed rail to the North as swiftly as possible.”

Transport Secretary Grant Shapps, 2021

“Since its inception, Government has regularly restated the need for HS2. In 2013, the Department set out a comprehensive body of evidence illustrating the need for HS2; and this was restated again in 2015 and 2017. At each point, an increasing weight of evidence has demonstrated the pressing importance for a step change in capacity to alleviate crowding problems on the existing railway, and the scheme’s potential to redistribute opportunity and prosperity more evenly across the country.”

HS2 Business Case 2020

“Looking around the world, the evidence is clear. Nation after nation is planning, constructing, or already using high rail speed lines. High speed rail is transforming their societies and their economies. Self-imposed exile from this new frontier means that Britain loses out, while our global competitors gain. We can take the short-term option – leaving our rail networks over-stretched and over-burdened and risk paying the price in lost business, lower growth, and fewer jobs. Or we can take the longterm option – investing in our economic prosperity by pursuing high speed rail.”

Transport Secretary Justine Greening 2012

These quotes are from the full business case for HS2 phase one, published in April 2020. This document makes it clear that HS2 offers economic benefits far greater than its cost. Moreover, it does not fully quantify all the benefits set out in the strategic case such as the transformative benefits from changes in business location decisions.

It also shows that, of the 30 countries in the Organisation for Economic Co-operation and Development (OECD), the UK ranks 24th out of 30 for regional economic disparities. Furthermore, it notes that the UK has a long running nominal productivity gap with the six other G7 countries and that this is largely due to the gap between London and other UK regions.

”

HS2 Curzon Street station

DAVID SHIRRES

Rail Engineer | Issue 204 | Sept-Oct 2023 FEATURE 10

UK labour productivity by region, 2017

The business case notes that: “London’s success as a global city has been driven in part by the effectiveness of its transport system which allows the easy flow of skills, services, and products into and around the city.” It notes that government is keen to replicate the success of London’s transport network in the regions by improving connectivity between the cities of the Midlands and the North.

The above explains why, for over a decade, Government has consistently supported HS2. Yet since 2021, HS2 has been cut back and is now at risk of just being a line from Old Oak Common to Birmingham.

WHY HS2?

In 2008, Network Rail started a 12-month study on the long-term need for more railway capacity. This analysed a dozen options and concluded that a new high-speed line to relieve the West Coast Main Line (WCML) is needed. HS2 was established in 2009 to develop proposals for high-speed rail services. A year later, it had developed proposals for a Y-shaped network which would serve eight of the UK’s 10 largest cities. This network incorporated links to the West Coast and East Coast main lines for highspeed trains to additional destinations. It also served the East Midlands and South Yorkshire. In this way it would serve Britain’s largest cities and free up significant capacity for additional conventional passenger trains and freight on the West Coast, Midland, and East Coast main lines.

The first phase of HS2 is a line from London to join the West Coast main line north of Lichfield with a spur to Birmingham. This is essentially a by-pass for the busiest section of the West Coast main line. The initial train service plan had only a third of HS2 trains from Euston serving Birmingham. The remainder were to continue on the WCML to Manchester, Liverpool, Glasgow, and Edinburgh.

Until recently, all documents concerning HS2 published by Government and Network Rail emphasised that HS2 is the most effective way to provide much-needed additional rail capacity. There was also recognition that the UK lags behind the many countries in Europe and beyond which have recognised the massive benefits high-speed rail delivers in economic and environmental terms.

The rationale for a dedicated high-speed line is that it would be cheaper to build and considerably less disruptive than providing an existing rail route with additional lines. A recent Network Rail study found that upgrading the East Coast main line to provide to provide the same capacity of the HS2 Leeds leg would require continuous weekend closures for many years.

Rail Engineer | Issue 204 | Sept-Oct 2023 FEATURE 11

The 2012 HS2 White Paper concluded that additional benefits from a high-speed line outweigh the incremental costs of constructing high-speed rather than conventional lines by a factor of more than four to one.

HS2 also offers huge environmental benefits as it creates the rail capacity needed for modal shift of passengers and freight from more carbon intensive transport modes. As HS2 is an efficient highcapacity electric railway, it offers particularly low emissions per passenger kilometre. The 2020 business case states that HS2 will offer lower carbon journeys at 8g CO2e per passenger kilometre compared with inter-city rail (22g), inter-urban car (67g), and domestic aviation (170g).

ROUTE AND SPECIFICATION

HS2’s phase one route is the most direct route between London and the West Midlands. It also passes fewer population centres than the longer and more expensive routes such as those along the M1 and M40 corridors. It does however involve a significant amount of tunnelling to get out of London and pass under towns in the Chilterns Area of Outstanding Natural Beauty.

Following consultation, the length of the line in tunnel, including green tunnels, was increased by 50% to around 36km. In addition, 90km of the route will be partially or totally hidden in cuttings. Hence over half of the 225km will be in tunnels or cuttings.

HS2’s design is based on proven technology. Its reference train was the 360km/h (225mph) Alstom AGV which entered service in 2012. This was used to establish the performance characteristics of the HS2 service. Compared with 360km/h, a 300km/h maximum speed would have extended London to Birmingham journeys by 4.5 minutes with longer delays to stations north of Birmingham.

Taking this, and other factors into account, it was decided that HS2 should initially operate at 360km/hr and be designed for 400km/hr to avoid permanently forgoing opportunities for future journey time reductions. Recently constructed highspeed lines from Strasbourg to Paris and from Milan to Bologna in Italy, also have alignments designed for 400km/hr. The route therefore had to be designed with a minimum radius curve of 7,200 metres. The minimum radius curves required for 300 and 360km/h are respectively 4,000 and 5,800 metres.

To maximise its benefit, HS2 phase one has been designed to ultimately support a train service to Birmingham and cities on its Western and Eastern legs. This requires a capacity of 18 trains per hour. This is to be achieved by the use of ETCS signalling and Automatic Trains Operation. Infrastructure configuration, in particular the London Euston terminus, has been designed for this capacity which has been confirmed by operational reviews of converging and diverging junctions.

As it only carries high-speed trains, HS2 is, in effect, a high-speed metro and does not suffer from the capacity-destroying problems of a mixed train railway on which trains travel at different speeds. In part, this is why the original HS2 plan offers a large increase in passenger capacity. Due to this, and the capacity it releases on the WCML, HS2 could increase the peak-time seats per hour out of Euston from 12,100 to 31,200.

HS2’s trains are to be 200 metres long which can run coupled together to provide a train with 1,100 seats. The trains currently on order are classic compatible trains that can run on the conventional network. It was originally planned that, when the full Y network was built, half the HS2 trains would run only on the HS2 network which is being built to European GC loading gauge. Hence it was envisaged that a further order would be for trains built to GC gauge which offers the possibility of double-deck high-speed trains as run on the continent. However, dedicated HS2 trains are unlikely to be built for a cut-back HS2 network, so the cost of constructing phase one to GC gauge will be wasted.

Rail Engineer | Issue 204 | Sept-Oct 2023 FEATURE 12

European high-speed rail network 2022

WHERE DID IT GO WRONG?

In 2021, the Government published its Integrated Rail Plan which cancelled HS2’s Eastern leg to Leeds, leaving a spur to East Midlands Parkway. The Golborne link, which took HS2 to just South of Wigan on the WCML was cancelled in June 2022. On 4 October, Prime Minister Rishi Sunak announced the cancellation of HS2’s Western Leg to Manchester and Eastern Leg to East Midlands Parkway. He also confirmed that HS2’s connection to Euston will go ahead, with the number of platforms at the station being slashed to just six. In addition, management of the Euston site has been taken out of the hands of HS2 Ltd, and private investment must be found to fund that leg of the project.

In all the discussion about HS2, the focus is on excessive costs with hardly any mention of its benefits. It is perhaps not surprising that Government Minister’s statements on this issue contradict or ignore previous Government pronouncements, made over many years, that HS2 is essential for rebalancing the economy and increasing productivity. The mainstream media also hardly mentions the transformation benefits that HS2 offers and focuses on costs that are said to be ‘eye-watering’ and spiralling ‘out of control’.

HS2 has some responsibility for this perception. Although it now actively promotes the benefits of high-speed rail, for years little was done to sell these benefits. As a result, the narrative that HS2 is a vanity project which is spending billions to save a few minutes off the rail journey between London and Birmingham took hold. For this reason, polls indicate that those who oppose HS2 outnumber its supporters by two to one.

An 8-car TGV Duplex has 510 seats

HS2 phase one work east of the Chilton tunnel portal

An 8-car TGV Duplex has 510 seats

HS2 phase one work east of the Chilton tunnel portal

Rail Engineer | Issue 204 | Sept-Oct 2023 FEATURE 13

Tunnel Boring Machine ‘Florence’ about to start its 10-mile bore under the Chilterns

COSTS

HS2’s cost estimates have progressively risen since its first phase one budget of £16.3 billion in 2013 (at 2011 prices), as shown in Table 1. The current budget for phase 1, including Euston, is £40.3 billion plus a £4.4 billion contingency. A 2020 National Audit Office report concluded that the DfT and HS2 underestimated the complexity of the programme and that HS2 did not account for risk and uncertainty in its early estimates.

One reason for the higher cost of the 2019 estimate was the unforeseen extent of changes required by MPs as Parliament considered the HS2 Bill. This required a 50% increase in the amount of tunnelling and additional cuttings to lower the railway. Consider that such environmental mitigation made HS2 £1 billion more expensive than comparable European high-speed lines.

Detailed costs for the truncated Y network are currently not clear as phase 2 is at a very early stage. In 2019, the DfT estimated that the costs of the full current HS2 project would be between £65 billion and £88 billion at 2015 prices.

£ billions

201316.3 Basic estimate prepared for business case.

201527.0

201737.0

201944.4

For hybrid bill on basis of route drawings. No ground investigation.

After hybrid bill route finalised route, limited ground and site surveys, estimate comprised 15,000 lines of data.

Prior to start of construction after 80% design complete with input from contracts, estimate comprised 260,000 lines of data.

These costs are now significantly higher as construction inflation has increased the costs of new work by 24% since 2019.

In March, Government decided to rephase HS2 construction by halting work at Euston station to develop an affordable design and rephasing construction of phase 2a between Lichfield and Crewe by

two years. While this decision will reduce the annual cost of HS2, it will inevitably increase its total cost.

After various studies had shown that UK projects are typically 10-30% more expensive than those in Europe, in 2014 the Government commissioned a high-speed rail international benchmarking study.

This looked at 32 comparator European high speed rail schemes and was overseen by an expert panel chaired by Sir John Armitt. It included a detailed comparison which found that HS2 phase 2 was 49% more expensive than a European high-speed line with very similar characteristics. It found that the factors that accounted for this additional cost were:

» Strategic objectives requiring greater capacity and more intermediate stations (7%).

» Limited capacity of UK rail infrastructure requires dedicated high-speed lines into city centres (15%).

» Fragmented UK construction industry and continuity of work (12%).

» Onerous design requirements (5%).

» Scope development compounded by limited experience of delivering high-speed rail in UK (10%).

It was recently reported that sources close to the Prime Minister advised that HS2 costs were “spiralling out of control” and that HS2 bosses were “like kids with a golden credit card”. While this is good fodder for the tabloid newspapers, the above shows that the reality is more subtle. It is certainly true that there is scope for savings. However, construction inflation is at its highest level for decades, though as costs go up, so do the benefits. Moreover, the loss of momentum due to Government indecision and delaying progress also has an enormous impact on costs.

Although Government finances are under severe pressure, a distinction needs to be made between general spending and investment. For over a decade, it has been Government policy that HS2 is essential if the economy is to be rebalanced and regional productivity improved. Government borrowing to fund investment in HS2 should therefore be regarded a profitable investment.

Rail Engineer | Issue 204 | Sept-Oct 2023 FEATURE 14

WHAT MIGHT HAVE BEEN

Sadly, now that HS2 phase 2 to Manchester has been cancelled, the vision of this article cannot now be realised.

The full HS2 Y network was a major project that has been 15 years in the planning. During this time, cities and Network Rail have spent much time and money preparing for HS2 phase two. Now, the Government’s command paper “Network North – Transforming British Transport” claims the £36 billion to be spent on HS2 phase 2 is better spent on a package of transport projects. The hastily prepared nature of this plan is evident by its proposal to extend Manchester’s tram network to the city’s airport despite this line opening in 2014.

This paper seeks to prioritise worthwhile intra-city transport investment, such as a West Yorkshire mass transit system, over HS2. Yet both should be regarded as profitable investments to be funded by borrowing. Moreover, there is no timescale for the delivery of Network North. If this is to be funded by HS2 phase 2 savings, this implies that the projects will have a similar spend profile with most expenditure to be incurred in the 2030s. Yet the command paper claims that “we’re releasing a tidal wave of new investment into hundreds of projects.”

It justifies cancelling HS2 phase 2 as the facts have changed. The pandemic is said to have significantly changed travel patterns. Yet anyone travelling on long distance services knows trains are full. LNER passenger numbers, for example, have now exceeded pre-2020 levels. It also claims HS2 phase 1 is five times the cost of equivalent schemes in Europe. Yet the previously mentioned high-speed rail cost comparison study actually stated that HS2 costs 49% the cost of a comparable European high-speed rail project.

HS2 phase 2’s cancellation is irrevocable. The land purchased for it is to be sold, the route will no longer be safeguarded, and a downsized terminus at Euston

will permanently constrain the number of trains.

Though the command paper’s commitment that HS2 phase one will terminate at Euston is some small comfort, the way this has been specified is further evidence of the shallow thinking.

A huge sum of money is being spent on HS2 phase 1 which will enable high-speed trains to by-pass the first 186km of the WCML from London or go to Birmingham. This line is designed for 18 trains per hour (tph) for which it was considered that Euston needed 11 platforms. After cancelling HS2 phase 2, the key issue for the remaining HS2 network is its service pattern.

As shown by the diagram, delivery of the originally proposed services to Birmingham, Liverpool, Manchester, Preston, and Glasgow / Edinburgh requires 11 tph.

The command paper does not address this point and just specifies that Euston will have six platforms, which is certainly insufficient for anything like 11 tph.

The priority is thus to build HS2 Euston as cheaply as possible. This decision is economic vandalism as it saves, perhaps, 10% of the cost of HS2 phase one whilst, say, halving its benefits.

The issue of only considering costs, and not benefits, was highlighted by former Minister of Transport Patrick McLoughlin who, in a particularly apt quote, stated:

“Of course, there will always be pressure to look at costs, and to make sure we’re getting the best value for money – it would be insane not to do so. But it would also be insane not to say, ‘what is our transport system going to look like in 30, 40, 50 years’ time?’ and to make sure our great cities have those same opportunities that London has, and make sure that young people look to those cities to base their lives on, and not to move away from them.”

Rail Engineer | Issue 204 | Sept-Oct 2023 FEATURE 15

The now-paused HS2 construction site at Euston

HS2: A glimpse of a green future

Downing Street’s decision to scale back the scope of the HS2 has disturbed the industry and its suppliers, but the project had its fair share of detractors from the off, including those who’d welcome its scrapping on ecological grounds. It is true that HS2, like all infrastructure projects, comes with an unavoidable environmental cost as it is built, but to cheer the abandonment of a game-changer for green transport is as myopic as the current thinking at the top level of UK politics.

A key facet of HS2’s mission has been to minimise disruption to the natural environment, reduce carbon emissions in both the short and long term, and invest in any required natural recovery along its route. The past months have brought a number of developments which have boosted HS2’s environmental credentials, if that’s any consolation for recent developments.

HIGH SPEED TRAINS WIN ACCREDITATION

Such has been HS2’s success in pursuing its environmental targets, in 2020 it was awarded PAS 2080 global accreditation, recognising its plans to reduce carbon through the design, construction and operation of the project. It was the first client organisation in the UK transport sector, and the second in the world, to achieve the standard.

PAS 2080 is a global specification for managing whole-life carbon in infrastructure. Developed by the Construction Leadership Council’s Green Construction Board with the British Standards Institute (BSI), it provides a consistent framework for evaluating and managing carbon across the whole infrastructure value chain. The standard

recognises organisations that have strategies in place to reduce carbon and develop more collaborative ways of working to promote innovation, delivering benefit to society and communities, and making an important contribution to tackling climate change.

Three years later, in September this year, the trains due to start running on the HS2 rail network were awarded PAS 2080 accreditation.

Designed and made in the UK by a Hitachi and Alstom joint venture, HS2 has stressed that the trains will be less carbon intensive throughout their lifecycle than any other high-speed train in design, production or operation today. This accreditation, authored to meet World Trade Organisation standards, backs up this claim.

The newly-designed trains are based on the successful Frecciarossa very high speed train now operating in Italy and Spain, has become the first train in the world to achieve the British Standards Institute’s PAS 2080 global accreditation.

Great effort is going into reducing the train’s energy consumption, including improvements in its aerodynamics. It is, according to HS2, the first high speed train in the world to have a smooth, dynamically efficient underside, cutting its drag coefficient.

Rail Engineer | Issue 204 | Sept-Oct 2023 16 SUSTAINABILITY & ENVIRONMENT

Work during the train’s detailed design will optimise the weight of its carbody, wheelsets, and cabling; and see more of the train built with recycled and recyclable material. Finally, the train’s traction system and electric motors will be highly energy efficient – reducing energy demand for a train that will reach speeds of up to 225mph and is designed to run for 18,500 miles between servicing.

Jim Brewin, chief director of Hitachi Rail UK & Ireland, said: “HS2 challenged us to meet this certification as part of our competitive pitch, and we’re proud to be achieving it. HS2 trains have gone through a design process of unparalleled rigour – becoming more aerodynamic, more energy-efficient, lighter, leaner, and greener.”

The circa £2 billion contract to design, build, and maintain 54 very high speed trains was given to Hitachi Rail and Alstom in December 2021, and they are due to start rolling off the production line around 2027. Further information on the accreditation can be found here:

WORK BEGINS ON LONGEST ‘GREEN TUNNEL’

In May this year, Rail Engineer reported on the construction of HS2’s ‘green tunnels’, which are designed to blend the high-speed railway into the rural landscape and reduce disruption for neighbouring communities. Bob Wright provides an in-depth report on the design and construction of the tunnels, along with their environmental benefits. His article can be viewed here:

Rail Engineer | Issue 204 | Sept-Oct 2023 17 SUSTAINABILITY & ENVIRONMENT

In September, work began on the 2.7km tunnel around Greatworth in West Northamptonshire.

Like its counterparts being built by EKFB (a team made up of Eiffage, Kier, Ferrovial Construction and BAM Nuttall) in Wendover, Buckinghamshire and Chipping Warden, Northamptonshire, the 2.7km tunnel is being built using the ‘cut and cover’ process, which involves excavating a cutting, building the tunnel and then burying it, with trees, shrubs and hedgerows planted on top to blend in with the surrounding countryside.

The tunnel structure is also being made from more than five thousand giant concrete segments, made at a specialist pre-cast factory in Derbyshire, and assembled on site by EKFB.

Applying lessons from the construction of the latest French high-speed lines, EKFB opted for this modular approach - instead of a traditional process of pouring the concrete on site - to boost efficiency and cut the amount of embedded carbon in the structure.

Greatworth is one of five ‘green tunnels’ that are being built on phase one of the HS2 project - three of these are being built by EKFB and two more, to different designs, at Copthall in Hillingdon by Skanska Costain STRABAG (SCS JV), and at Burton Green in the West Midlands by Balfour Beatty and Vinci (BBV).

HS2 Ltd’s Project Client Neil Winterburn, said:

“Greatworth is one of five green tunnels between London and Birmingham designed to protect the natural environment and reduce disruption for local communities - and it’s great to see the first arches in position.

“Our trains will be powered by zero carbon electricity but it’s also important to reduce the amount of carbon embedded in construction.

The off-site manufacturing techniques being used will help cutting the overall amount of carbonintensive concrete and steel in the tunnel and help spread the supply chain benefits of the project across the UK.”

Designed as an m-shaped double arch, the tunnel will have separate halves for southbound and northbound trains. Five different concrete precast segments will be slotted together to achieve the double arch which is the height of two double-decker buses - one central pier, two side walls and two roof slabs.

The tunnel segments are being made by Stanton Precast in Ilkeston, Derbyshire, as part of a contract which is hoped will create up to 100 local jobs. All 5,410 segments will be steel reinforced, with the largest weighing up to 43 tonnes.

By reducing the amount concrete and steel needed for the tunnel, this lighter-weight modular approach is expected to more than halve the amount of carbon embedded in the structure. It also requires fewer people and less equipment on site, improving safety and reducing disruption for residents.

EKFB’s programme director Emmanuel Rossignol, said: “To see the construction start on HS2’s second cut and cover tunnel in Northamptonshire is a proud milestone for the team. The design and construction approach of this tunnel is unique to the UK, and there are many benefits associated with this methodology, including a reduction in our carbon footprint, but it’s not been without its challenges along the way. Our expert teams are to thank for their dedication as we continue to advance the construction programme across the Chipping Warden and Greatworth green tunnels.”

The tunnel will be built in sections, with construction of the main structure expected to take around two years. Local roads such as the B4525, Sulgrave Road, Helmsdon Road and access for Greatworth Park will be realigned to cross the tunnel, as well as local footpaths.

Tailored landscaping design plans are also being developed, with thousands of native trees and shrubs typical to the local area - such as Silver Birch, Oak, Beech and Willow - planted to create new woodland areas around the portals and recreate the hedgerows and field boundaries on top of the tunnel.

Lessons learned during the construction of EKFB’s green tunnel at Chipping Warden are being applied to the delivery of Greatworth. These include changes to quality control and the delivery and installation of the segments.

Follow the QR Code for a timelapse video of the tunnel’s construction:

Rail Engineer | Issue 204 | Sept-Oct 2023 18 SUSTAINABILITY & ENVIRONMENT

PRE PLAN YOUR RAIL FESTIVE BLOCKADES

•

•

•

•

•

•

VIEW AND DOWNLOAD OUR E-BOOK trust us to deliver onSaveC02 emissions with our generatorsbattery

By working in partnership with Speedy Rail, we can:

Deliver a complete managed service for your site

needs

Supply up-to-date quality products / engineers / operators to match your

Reduce carbon footprint

Manage transport costs

Advise the correct products for safely lighting up your site

Contact our

for more information and to plan for your festive blockades SUSTAINABILITY IN A WHOLE NEW LIGHT Portable and managed lighting solutions for every scenario generators We can provide managed site lighting services for all scenarios. • Plan ahead • Save on cost • Reduce risk See how our lighting solutions can reduce your carbon emissions with our online calculator. Visit: speedyservices.com/rail-calculator 01942 277 982 speedyservices.com

Support you with our on-call 24/7 dedicated rail desk

Rail Desk on 01942 277 982

VIADUCT PLANNING GETS GO AHEAD

Moving from travelling below the ground to travelling over it, HS2 was pleased to learn in early September that Solihull Metropolitan Borough Council had approved its plans for the Balsall Common Viaduct. The plans incorporate local feedback focusing on environmental sustainability, landscape integration, visual connectivity, and public access.

The project is being led by HS2’s main works contractor, Balfour Beatty VINCI (BBV), supported by a Design Joint Venture of Mott MacDonald and SYSTRA together with architects Weston Williamson + Partners. They have engaged with people in the local area over the last couple of years to gather feedback on the 425-metre viaduct.

Understanding the landscape context was a key focus of the design, and plans include wet woodland planting using native species to the local area, woodland edge planting to provide screening, and hedgerow planting to improve wildlife connections.

“We’re very pleased to receive planning approval from Solihull Council for the design of the Balsall Common Viaduct,” said HS2 Ltd’s senior project manager for Balsall Common, Alan Payne. “We’ve engaged with the community and local councillors over the last couple of years to incorporate their feedback as much as possible.

“We’re confident that our plans respect and enhance the local history and natural environment of the area and will provide new green areas for people and wildlife to enjoy.”

HS2’s Independent Design Panel had described the viaduct as “a significant and elegant structure which responds sensitively to its context and delivers a high-quality landscape” in its final preSchedule 17 report.

The Design Joint Venture’s Landscape Director Shaun Ruffles said: “The whole design team, encompassing architects, town planners, engineers and environmentalists are delighted with this outcome, which is the result of five years of careful planning and hard work. We now look forward to working with the local community and developers on the Balsall Common Masterplan which aims to integrate a number of local developments into a wider masterplan for Balsall Common.”

A realignment of Bayleys Brook will increase habitat for fish, aquatic invertebrates and potentially water vole. The approved design sees a reduction in the size of the railway embankment running parallel to Bayleys Brook by 75 metres, improving the resiliency of the area to flooding, and enhancing views through the viaduct to the wider landscape.

To improve connections, the Kenilworth Greenway will be extended to Station Road on the south-eastern side of

the existing railway line and a further extension towards Lavender Hall is currently under consideration. Options for cycling and bridleway extensions are also being considered.

BBV will construct a total of 16 piers to carry the viaduct 10 metres above ground, crossing over Station Road, Bayleys Brook, Heart of England Way Walk, and the local floodplain. Construction refinements have reduced the size of each pier by as much as 17% for single piers and 28% for double piers, giving the structure a lighter appearance. Responding to feedback about the look of the viaduct, a section at Station Road will be finished with a bespoke pattern, referencing the local history of the area. The approval comes with conditions that there will be further engagement and more work will be undertaken on the colour and finishes of the concrete and the type of tree planting around the viaduct. CGI images of the viaduct can be found here:

Rail Engineer | Issue 204 | Sept-Oct 2023 20 SUSTAINABILITY & ENVIRONMENT

OVERBRIDGE APPROVED

Sticking with the theme of planning approvals, at the beginning of September, HS2 received Schedule 17 planning approval for the eco-friendly Aston Church Road Overbridge, north-east of Birmingham city centre. New designs ensure that the structure, which will span the line connecting Saltley, Washwood Heath and Nechells, blends sympathetically with the local environment.

Initial designs for the bridge were shared with the public in 2021, with local feedback inspiring changes to provide a wider walkway, creating enough space for cyclists, and an improved lighting strategy. As well as increasing lighting levels for pedestrians and cyclists, the new LED lighting design will also protect wildlife, particularly bats that may forage underneath the bridge, by decreasing overall light pollution.

Public feedback also resulted in the stainless steel finish being replaced with weathered steel panels incorporating a perforated pattern to maximise light and views, making the bridge feel warmer and improving the pedestrian experience.

HS2’s designers, consisting of a Design Joint Venture of Mott MacDonald and Systra working for BBV, have also introduced green spaces by creating new woodland planting in the area around the bridge. This includes silver birch, hazel and hawthorn, and wildflowers and grasses which will provide new wildlife havens and connectivity in the city’s industrial heartland.

Nick McGough, director at Weston Williamson + Partners, and lead architect for the Balfour Beatty VINCI Design Joint Venture, which is constructing the line in the West Midlands, said:

“Our designs balance challenging technical constraints in developing a robust but elegant bridge, whilst seeking every opportunity to both enhance the user experience and increase biodiversity through our adjoining landscape proposals.

“The integrated bridge lighting is particularly innovative and reduces urban light pollution in a way which is sympathetic to local wildlife whilst providing enhanced light levels that will help make the bridge attractive to both pedestrians and cyclists.”

Aston Church Road Overbridge is located two miles north-east of Birmingham city centre. The original bridge will be demolished to create extra space for the HS2 line to pass through, and once built, the new bridge will connect to the existing road network.

Preparatory works, ready for the new bridge, began last year. Main civil works will now commence, and the bridge and associated highway works are due to be finished in summer 2025. HS2 has released CGI images of the bridge:

A WASTED OPPORTUNITY

The developments outlined in this article are a testament to the value that HS2 has placed on delivering a low-carbon, cutting-edge railway while minimising the impact of its build phase on local ecosystems and the environment as a whole. This could not come at a more pertinent time.

We live at a point in human history where environmental change is bringing unprecedented challenges and the actions we take today will have a profound impact, not only on our lives but on those of future generations to come. The way we travel and the way we build our transport networks are critical to our response to the climate emergency.

A key aspect of HS2’s mission is to provide zero carbon rail travel for a greener future. The huge amount of additional rail capacity it could have provided would have significantly reduced UK carbon emissions by enabling rail to accommodate significant modal shift of passengers and freight from roads and planes. It could have been the most sustainable railway of its type as well as a catalyst for economic growth up and down the country. Instead, Government has squandered the opportunity to make HS2 a reality for all regions of the UK, and green transport a way of life.

Rail Engineer | Issue 204 | Sept-Oct 2023 21 SUSTAINABILITY & ENVIRONMENT

Bees, sheep, and trains

Rail Engineer was recently invited to visit the impressive new Siemens Mobility train manufacturing ‘village’ facility at Goole, Yorkshire. Sustainability, environmental protection, biodiversity, social value, community support and engagement, all feature in the £200 million rail village. This was immediately apparent as we were met by a row of electrical vehicle charging points, bordered by wild flower natural floral planting.

The village will create 700 new jobs, and an additional 1,700 indirect supply chain jobs by 2030. From March next year, half of the London Underground’s 94 new Piccadilly line trains will be assembled at Goole before they start entering passenger service in 2025. The other half of the Piccadilly line fleet and all the body shells will be manufactured in Austria. During our visit we learned about the extensive manufacturing and commissioning facilities, offices, warehouses, stabling sidings, and the space for a 1.2km electrified test track to be installed. We also heard about the long-term plans for the site.

WARM WELCOME

We were greeted by Sambit Banerjee, joint CEO; Finbarr Dowling, project director; and Milly Johnston, advanced rail technician. Milly joined Siemens Mobility in 2020 as an apprentice and has spent the last three years training. She has also taken on the role of local beekeeper at the apiary (bee yard) on the site, guided by a trained beekeeper from the Selby and District Beekeeping Association. The wild flowers mentioned earlier help to feed the bees.

Finbarr enthusiastically explained that the site spans 67 acres, which is the size of 35 football pitches. When he joined the project, it was a brownfield site with no buildings or hard standing. Siemens chose the site for a number of reasons, including its close location to Goole inland harbour port, the M62 motorway, and its good rail access.

FUTURE VISION

At the start of the project, Siemens wanted to enthuse visitors to the rail development, but with only architect’s plans and an extremely large, empty field there wasn’t much to see. Clay10 Creative, based in nearby Hessle was brought on board and, working closely with the architects, created an interactive 3D model of the facility. The giant buildings were replicated, and an animation was created showing the site growing and highlighting Siemens’ vision for the future. This allowed visitors (which included the prime minister) to view the whole area at true scale through a smartphone or a tablet. The system also allowed Siemens Mobility to make changes as the project moved forward.

As most of the buildings are now constructed, Finbarr used the interactive 3D model to display a ‘time lapse’ explaining how the site had developed. The site was believed to have been a rail depot many years ago, so the construction of the train manufacturing facility has not involved greenfield construction, nor did the brownfield legacy of the site cause any issues with contaminated land, archaeology, or buried services. The only issue was relocating some newts found on the site.

PAUL DARLINGTON

Rail Engineer | Issue 204 | Sept-Oct 2023 22 SUSTAINABILITY & ENVIRONMENT

The site has initially been set up to build tube trains for London Underground. The current Piccadilly line order is for 94 x 9-car trains (846 vehicles) of which about half will be built in Goole. If Transport for London (TfL) is able to obtain funding for all the options in the contract, there could be work on a total of over 2,300 cars. There is also space to significantly expand the manufacturing/ assembly facility and lengthen the formation/test/ commissioning building to accommodate longer trains if necessary.

Adjacent to the facility is a rail siding which is currently used by two trains a week to a nearby glass factory, so it will have rail access. Siemens originally leased several plots of land on the site, however seeing the site’s potential it was later decided to take up an option to purchase all the 67 acres of land required for the manufacturing facility.

Yorkshire’s GMI Construction was the main contractor and its scope included the necessary rail track for connection to the main railway line. C R Reynolds carried out enablement works and Premier Modular provided the temporary offices.

To the south of the rail village is Oakhill Nature Reserve consisting of over 100 acres. Oakhill, and the associated pools known as the Brickponds, is one of the best Dragonfly and Damselfly sites in Yorkshire. The nature reserve is now also home to nationally threatened declining bird species such as the Willow Tit and over 200 plant and wildflower species are recorded with an ever-increasing wildlife population.

SOCIAL VALUE

Siemens is keen to support the local community and surrounding area, and has assisted with funding £150,000 of improvements to the nature reserve. Work has been completed to improve car parking to make it easier to access the nature reserve. Sculptures and benches have been installed for everyone to enjoy along the nature trail and wildlife haven. The nature reserve is regularly visited by both local residents and Siemens Mobility employees. Plans are also in development to introduce a rare breed of sheep in a field on the rail village site.

Sustainability is at the heart of the village, and to support the organisation’s overall global target to achieve net zero by 2030. Air source heat pumps have been installed across the facility to ensure there is no need for gas heating along with many other net-zero contributions.

Siemens Mobility is very keen to promote engineering to younger and diverse people, and they are working with Primary Engineer and young people aged seven to 10 to inspire them to take STEM subjects and excite them with the career opportunities in rail engineering. It was explained that Siemens Mobility is in Goole for the long term, and helping to develop the next generation of railway technicians and engineers is part of its sustainability and social value objectives.

Rail Engineer | Issue 204 | Sept-Oct 2023 23 SUSTAINABILITY & ENVIRONMENT

Siemens obtained three redundant Heathrow Express carriages and has created an exhibition in one of them to welcome schools to the village and for children to experience and learn about the different roles there are in rail, in a train similar to one they could be building one day. Other social value contributions to the local community include hosting a Primary Engineer event on the rail village site for young people to experience rail design, sponsoring local gay pride events, and hosting a cricket match in July which raised £21,000 for local charities. There are currently 12 apprentices learning their trade at the rail manufacturing facility, with a further three set to join soon. There are also five apprentices working at the Components Facility on the site, covered by Malcolm Dobell in this issue. Siemens is already recruiting staff ready for building trains due to commence in March 2024.

With an emphasis on innovation and creative engineering there is also a £50 million centre of excellence in the village being

developed with the University of Birmingham. Called the Rail Accelerator & Innovation Solutions Hub for Enterprise (RaisE), its 3,200 square metres of commercial floor space with grade-A office and workshop accommodation, high quality conferencing facilities, and a communal café hub, will act as an innovation focal point for the village.

AN EXCITING DEVELOPMENT

The train manufacturing ‘village’ facility is certainly impressive, and it was clear the site has the capability for more rail construction activity in the future. We were enthused to hear of Siemens Mobility’s plans to work with academia, logistic companies, SMEs, hotel companies, and the local community to make the rail village a success. The plans include lots of exciting developments to bring more rail activity to the site for years to come and Rail Engineer looks forward to reporting on these when they are announced.

Rail Engineer | Issue 204 | Sept-Oct 2023 24 SUSTAINABILITY & ENVIRONMENT

Siemens Mobility Goole Component Repair Facility

Whilst the Siemens Mobility

Goole train manufacturing plant and supply chain rail village is still being finished, and no train building work is expected to commence until March 2024, one part is already up and running: its component overhaul business. With nearly 4,000 Siemens carriages in service or on order, most of which Siemens maintains, there was a desire to become self-sufficient for some overhaul work.

Some years ago, Siemens set up facilities in Leeds and Lincoln to overhaul gearboxes/ traction motors and bogies, respectively.

Under the leadership of Craig Beech, service operations manager, the quality and turnround times achieved led to more and more work being taken on and it outgrew the Leeds site.

EXPANSION

In June 2022, Siemens Mobility announced it was “expanding its £200 million rail village in Goole by building a new £7 million component facility which will create up to 30 new jobs.” It was built by local firm GMI. In April 2023, just 10 months later, the facility was opened by Micheal Gove MP, Secretary of State for Levelling Up, and was fully operational a month later.

Already, it employs 40 full-time staff, including five apprentices from the East Riding of Yorkshire and all but five of the Leeds staff had transferred to Goole. The new 4,000 square metre space will allow the facility to take on the maintenance of more components in the future and Rail Engineer was told of plans to increase the workforce to 80 by the end of 2023. Much of the work now done at the site in Goole had previously taken place in mainland Europe.

During a tour of the Goole site (see Paul Darlington’s article on page 22), Rail Engineer was shown around the facility by Rick Birkbeck, head of production.

OVERHAUL

Gearboxes from UK Siemens trains are overhauled at Goole, together with Siemens group manufactured gearboxes for other external customers. A modern train gearbox is a sophisticated piece of kit which is quite heavy and made more difficult to handle as it usually comes attached to half a ton of axle!

The gearboxes arrive for overhaul after the wheels have been removed and with the wheel and axle bearing seats carefully protected. The overhaul process is straightforward, but requires care and precision, especially keeping gear sets together (unless, of course they are damaged or worn beyond limits). Bearings are always replaced typically between four and six bearings per gearbox. Rail Engineer saw machines used to manipulate gearbox housings to enable technicians to work at a convenient height. After assembly and checking alignment/backlash etc., the final task is to check for excess noise or vibration under load using two gearboxes mounted back-to-back in a test cell.

Your writer has watched traction motors being overhauled at various times over a long career, which was usually a skilled task especially when skimming and undercutting the commutator on a DC machine for another four/five years of service. The benefits of three phase induction motors over traditional DC motors really becomes clear when witnessing the overhaul process at Goole. They are much smaller than the equivalent DC motor and there is not much to go wrong.

From L – R, Sambit Banerjee - Joint CEO and Managing Director of Rolling Stock & Customer Services at Siemens Mobility UKI, Huw Merriman - Rail Minister and Rick Birkbeck - Head of Production at the Components Facility, Siemens Mobility

©Siemens

Rail Engineer | Issue 204 | Sept-Oct 2023 FEATURE 26

MALCOLM DOBELL

The overhaul process for Siemens AC motors includes, strip, clean, examine and test for damage or failing insulation, and then rebalance the rotor and reassemble with new bearings. A load test of the motor cannot be performed as they’re not designed to hold high loads as they are always connected to a gearbox that holds the load. A routine electrical and running test is performed at Goole. The third current product line is overhauled air conditioning sets where there is at least one set per carriage on the Siemens fleet.

Rick explained the benefits of overhauling locally. The transit time will be much shorter than shipping the equipment abroad to the OEM site. Moreover, the OEM, even a Siemens group company, might be carrying out work for a number of operators and the customer might not be able to influence the priority of work. This means that a component might be away for many weeks compared with a local supplier. Moreover, Siemens Goole has access to key OEM drawings and other technical information as well as Siemens group experts.

After the tour, it was clear that Sambit Banerjee’s ambitions for the site include expanding the components business and it was obvious that there is plenty of space and capability to do so.

Motor overhaul in progress

Overhauled Gearboxes awaiting dispatch

©Siemens

Motor overhaul in progress

Overhauled Gearboxes awaiting dispatch

©Siemens

Rail Engineer | Issue 204 | Sept-Oct 2023 FEATURE 27

©Malcolm Dobell

Wi-Fi 7

Rthe new kid on the block

ail Engineer 175 (June 2019) ran a feature explaining how and why the future of Wi-Fi technology would be Wi-Fi 6 (IEEE 6802.11ax). But things move fast in telecoms development and, just four years later, the new kid on the block is Wi-Fi 7 (IEEE 802.11be). So why is Wi-Fi 7 needed, how does it work, and what will the benefits be?

Wi-Fi has been a huge success and is now the established technology for providing the final telecoms link to devices in the home, offices, stations, shops, schools, and just about anywhere in the world requiring connectivity. UK-based telecom consultancy Analysys Mason, says Wi-Fi now carries the majority of all wireless network data traffic, and the International Data Corporation (IDC) Wi Fi Technology Forecast says there are 19.5 billion Wi-Fi devices in use around the world. The Wi Fi Alliance, based in the USA, says the global economic value of Wi-Fi is some £2.73 trillion ($3.5 trillion).

Wi-Fi 6 provides a relatively fast 9.6Gbps data download rate, but Wi-Fi 7 will provide an incredible theoretical data download rate of 48Gbps. Wi-Fi 7 will also reduce latency and improve overall network capacity, distance, and reliability.

There is a saying in telecoms engineering that there can never be too much bandwidth in a network. As Wi-Fi network speeds have improved (see table 1) application designers have been quick to design systems that provided even greater benefits, but using the ‘spare’ data rate available. The Covid-19 pandemic changed many things, including the way people work, communicate, socialise, shop, learn, and entertain themselves. Wi-Fi is expected by many to be available at railway stations and its use for monitoring railway equipment is significant.

All aspects of life and industry are more reliant on communications than ever and there has a been a huge increase in the use of such things as video conferencing, video streaming, and online gaming. For example, Microsoft says the use of its remote-meeting software Teams increased by 252% from 2020 to 2022.

Fibre to the home and places of work is also fast becoming a reality with Gbps connections, and Wi-Fi must not become a ‘bottleneck’. Wi-Fi 7 is designed to accommodate modern, data-hungry applications, and will support the inevitable arrival of 8K video streaming, and such things as immersive, low-latency extended reality (XR) applications for social, industrial, and gaming purposes.

2.4 GHZ INTERFERENCE

The first three generations of Wi-Fi used a carrier frequency of 2.4GHz, however Wi-Fi interference can be caused by other devices which also use this frequency. This can include devices such as microwave ovens, security cameras, door alarms, Bluetooth devices, cordless phones, baby monitors, and, in some countries, amateur radio.

A solution from Wi-Fi 4 onwards introduced another carrier frequency of 5GHz. This allowed higher data speeds with less interference, although the higher the frequency of the carrier signal, the shorter the range. This can be an

Rail Engineer | Issue 204 | Sept-Oct 2023

28 SIGNALLING & TELECOMMUNICATIONS

PAUL DARLINGTON

advantage though, allowing the frequency to be reused for another connection not too far away. Wi-Fi 6E (Extended) introduced yet another carrier frequency of 6GHz and Wi-Fi 7 will also use 6GHz, but in a new clever way along with the use of the 2.4GHz and 5GHz carrier frequencies.