10 minute read

Automotive testing solutions enabling autonomous driving

Automotive testing solutions

enabling autonomous driving

Autonomous driving promises users exceptional mobility and travel comfort, while also supporting OEMs and Tier 1s to realize the projected “vision zero” – the EU target of zero traffic fatalities by 2050. However, the success of these efforts depends on several preconditions: diverse automotive components and functions need to be coordinated precisely and must interact without errors. Rohde & Schwarz provides reliability in innovation with its testing solutions for radar, connectivity, infotainment, high-performance computing and EMC. Test it. Trust it.

See-through plastic covers and bumpers

To increase the level of automotive driving autonomy, vehicles will need to be fitted with more and more complex sensors. In the case of automotive radar, the physical placement of these sensors is critical to ensuring that the vehicle is perceiving an accurate picture of the outside world. The car’s ability to accurately determine object target location will be impaired if the radar transceiver is not mounted correctly. Rohde & Schwarz offers an alignment device intended for end-of-line automotive testing. The Rohde & Schwarz QAA (Alignment Analyzer) is able to “see through” a vehicle’s plastic protection, such as car bumpers, to examine the mechanical positioning of the radar transceiver without having to physically remove components. The QAA is designed for automotive end-of-line testing as well as test and repair depots.

Proven test solutions for automotive innovations ACCELERATE AUTOMOTIVE TECHNOLOGIES

We use our unique expertise in technology and solution finding to fuel new ideas from R&D to production. With testing solutions for radar, connectivity, infotainment, high-performance computing, power and EMC, we provide reliability in innovation. Test it. Trust it.

www.rohde-schwarz.com/automotive

C-V2X complete end-to-end-test solution

Rohde & Schwarz offers a variety of electronics test solutions for addressing many of the testing requirements of automotive electronics design engineers. For C-V2X testing, the company offers a complete end-to-end test solution including a PC5 emulator, satellite constellation simulator, PC5 physical layer generator and Vector CANoe software. For radar testing, Rohde & Schwarz offers a complementary set of equipment including a radar target simulator, an automotive radar anechoic chamber with the CATR (Compact Antenna Test Range) reflector for indirect far field measurements, and various spectrum analyzers and signal generators for antenna pattern and interference measurements. In addition, the Rohde & Schwarz QAR (Quality Automotive Radome) tester can make materials measurements of various plastics and paints in matter of seconds. This is necessary when plastic separates the mm wave transceiver from the outside world.

Communication using 5G

Connectivity is an indispensable facet of autonomous driving. One helpful way of looking at this is to consider autonomous vehicles as a part of a larger connected and cooperative system. C-V2X enables vehicles to share critical data with nearby receivers and brings safety applications to life. Communication over a 5G link ensures that data is transferred reliably and it has a very low latency, which is critical for applications like self-driving and remote driving. While building key modules of autonomous vehicles, it is essential to test such modules using lab environment simulations. This will reduce the costs of product development and provides flexibility to the user, who can run test scenarios that are both reliable and instantly repeatable. Rohde & Schwarz offers the CMW500 communicator tester and the SMBV100A/B signal generator, which can be used in conjunction with the CANoe.Car2X software from Vector to emulate C-V2X test scenarios. In addition, the CMX500 can emulate 5G networks in a lab environment ,giving the users an efficient method for testing EMBB (Enhanced Mobile Broadband) and URLLC (Ultra Reliable Low Latency Communications) features available with 5G New Radio.

OTA radiated emissions

The various sub-systems of a vehicle can be developed separately from the complete multiple domain environment. However, it is critical that the system as a whole is tested before any vehicle is released to the public. There are a number of testing requirements that are quite essential for ensuring that the multi-domain ecosystem works correctly. One of these areas is communication between modules through the testing of the Ethernet interfaces and harnesses. Rohde & Schwarz offers the RTO digital oscilloscope and ZND vector network analyzer for TC8 test compliance and the ZNB vector network analyzer for TC9 for compliance testing of 100Base-T1 and 1000Base-T1 networks. Another critical area of testing is EMC coexistence and OTA radiated emissions. Rohde & Schwarz offers complete solutions for these, including test equipment, chambers and services.

Maximum safety

Advanced driver assistant systems (ADAS) will play an increasingly important part in making driving safer and more comfortable. Such systems can save lives, but even a slight error may result in an incorrect assessment of the situation. Because of the sheer complexity of the different technologies being used –including radar, automotive connectivity, V2X communications and emergency calls – comprehensive automotive testing is necessary to ensure correct functionality and maximum safety.

From predevelopment to R&D production

Rohde & Schwarz offers expert know-how for all phases of automotive development – from predevelopment and R&D to production. OEMs, Tier 1s and chip suppliers will benefit from the company’s reliable solutions for high-frequency, high-bandwidth and high-speed test challenges. Rohde & Schwarz is the market leader in testing radar sensors, automotive Ethernet conformance, connectivity (5G, V2X, eCall, GNSS), infotainment, EMI pre-compliance and EMC. The company also offers outstanding solutions for board level tests (ICT/ FCT) during ECU production. All of these test solutions ensure maximum efficiency in compliance with the highest quality standards, assuring that various automotive components function correctly, coexist successfully and communicate with the outside world without errors. Rohde & Schwarz collaborates closely with its customers in the design stage of their products to ensure providing relevant and high-quality test solutions to the automotive industry.

For more information, visit

WWW.ROHDE- SCHWARZ.COM/AUTOMOTIVE

or contact: Rohde & Schwarz Benelux B.V. Ptolemaeuslaan 900 3528 BV | Utrecht | The Netherlands Tel. +31 30 600 1789 info.bnl@rohde-schwarz.com

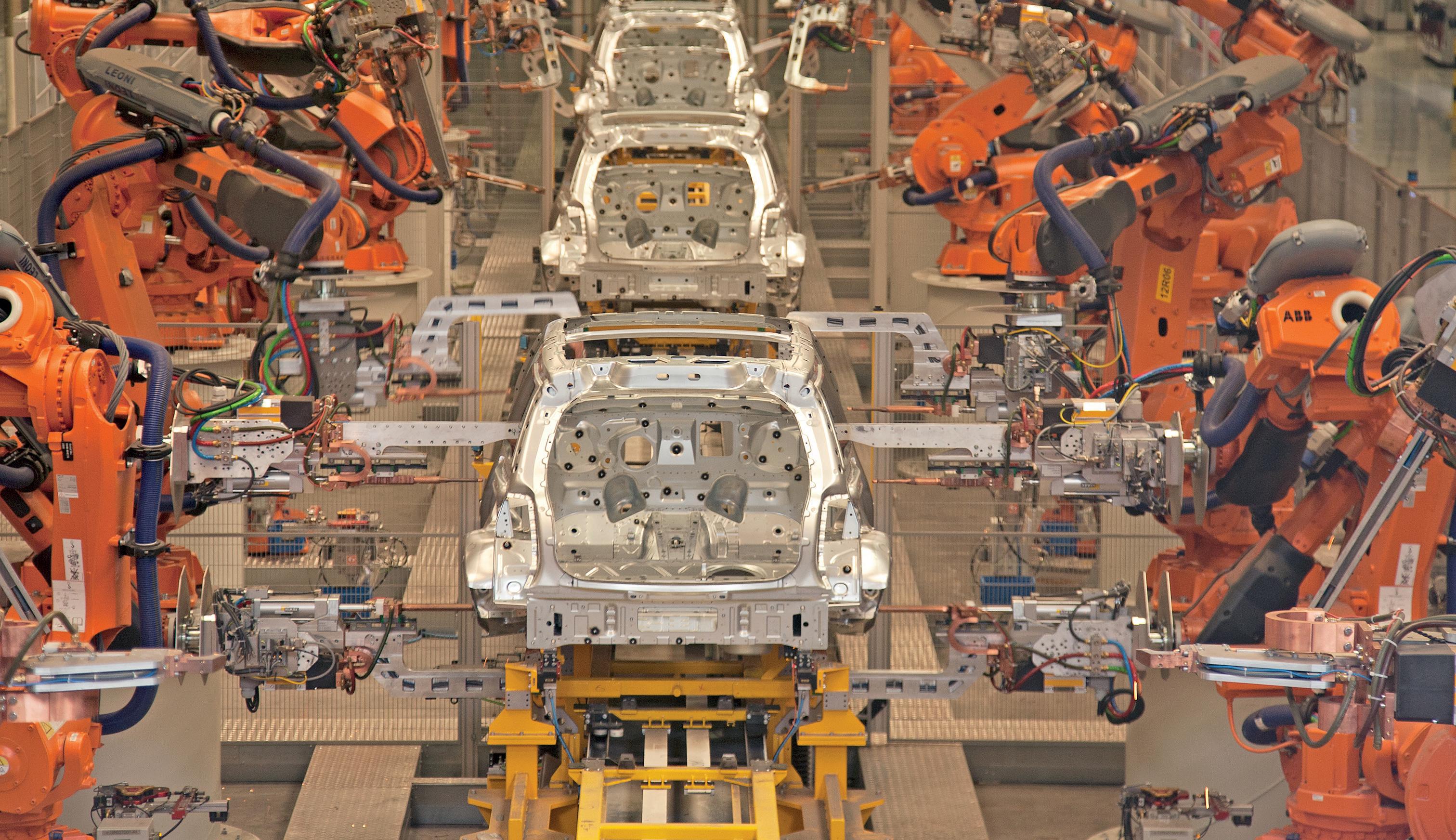

Manufacturing enables innovation

for future mobility

Innovation is the key to success, and it is often associated with the Dutch knowledge economy. Within the automotive industry in areas such as smart mobility, future powertrains and high-tech lightweight materials, manufacturing is a crucial facilitator. However, the Dutch automotive industry consists of so much more than the companies involved in developments within these knowledge areas. And if we look at the number of jobs that are created, people involved in innovation in these fields are in the minority.

Embrace innovation!

80% of employment in the Dutch automotive industry is found in manufacturing-related roles, largely at the level of preparatory secondary vocational education and up to bachelor level, totaling at between 35,000 to 40,000 jobs. A growth of the total number of jobs is one of the industry’s objectives

for 2030, and this will be made possible largely through an increase in manufacturing labor. If we want to ensure that we can achieve this growth in the Netherlands, production/process innovation will be key. This is nothing new: the Dutch manufacturing industry has been embracing innovation for decades, and with great success! RAI Automotive Industry NL supports the automotive manufacturing industry and directs the areas of market development, innovation, cooperation, clustering and knowledge development, in collaboration with governments, knowledge institutions and the business community. An important aim is to stimulate innovation to promote and expand the industry. Manufacturing & Logistics is a key priority within the RAI Automotive Industry NL organization, with manufacturing understood to cover production, process and equipment, and logistics focusing on production logistics.

Reshoring Manufacturing & logistic

Societal challenges

In the national policy discussions about the Netherlands as a knowledge economy, the subject of relocating manufacturing work to other, often low-wage, countries comes up regularly. The realization that manufacturing and development are inextricably linked is growing steadily. Good examples are the VDL Groep, DAF Trucks, ASML, Inalfa roof systems, NXP, etc. Knowledge institutes at secondary vocational education and bachelor levels focus on the manufacturing industry with training in production and process technology. Important contemporary trends are sustainable manufacturing, IT-enabled intelligent manufacturing, high-performance manufacturing and equipment, and exploiting new materials by integrating R&D and manufacturing. But more classic methodologies such as lean manufacturing, six-sigma, WCM (World Class Manufacturing) and standards such as IATF and VDA are still firmly on the agenda as well. With the help of continuous innovations, the manufacturing sector does its part – in addition to providing employment – in addressing societal challenges, such as global warming, air quality and energy consumption. Furthermore, modern factories emit less CO2 and use less energy, solvents, water, etc. than less modern factories, mainly located in low-wage countries.

“High-tech manufacturing companies are the growth engine for the Netherlands.”

Hans de Jong,

President Philips Netherlands, (Source: Trouw).

Protect

your valuables;

How to protect to two most valuable assets of your company.

Almost 50% of work injuries in the automotive industry result in one or more lost workdays, and 25% results in 7 or more lost workdays. In order to prevent work injuries and to give companies the opportunity to prove that they follow an effective work safety management system the British Standard Industry (BSI) developed the BS OHSAS 18001 in 1999. This standard is currently migrating to ISO 45001 which combines Safety and Health management.

ISO 45001 is a standard that integrates responsibility for health and safety issues as part of an organization’s overall management system. It improves leadership and worker engagement, leading to enhanced occupational health and safety performance.

Occupational health and safety is especially important in the automotive industry. Not only does ISO 45001 align with IATF 16949, but it is specifically referenced in IATF 16949’s most recent update. Both standards promote an optimal working environment for employees, which makes it easier and more cost-effective to manage health & safety risks, while realizing the benefits of minimizing and avoiding liabilities and associated costs.

For more information on ISO 45001 Occupational Health & Safety, visit www.lr.org/nlnl/iso-45001/

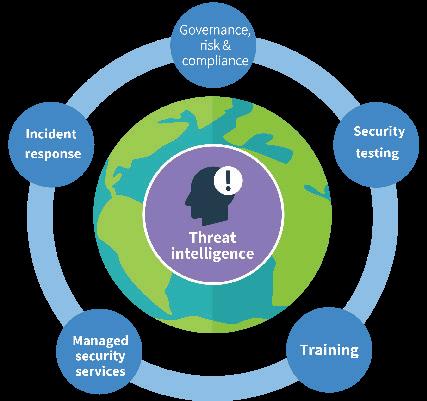

Not only your employees need to be protected, your information as well!

Information is one of the most valuable and business-critical assets for any organisation. In today’s hyperconnected world, organisations are exposed to large scale information security threats and cyberattacks that are more sophisticated and destructive than ever before. Having an effective information security strategy in place has never been more important.

More than 125 million passenger cars with embedded connectivity are forecast to ship worldwide between 2018 and 2022. The global connected car market size post-COVID-19 is projected to reach USD 166.0 billion by 2025, at a CAGR of 25.2% from 2020 to 2025¹. With poor cyber security, hackers can not only gain access to sensitive information, but possibly gain access to a vehicle’s engine, door locks, brakes, and other systems.

Losing control of such systems while a vehicle is in operation is a major safety concern and liability risk.

One of the reasons why companies in the automotive industry, increasingly, are requesting that suppliers prove defined levels of sensitive information and prototype protection. Standards such as ISO 27001 Information security management systems (ISMS) and the implementation of it help companies to securely handle confidential information. This standard provides a common basis when two companies need to exchange confidential data.

Why work with LR?

We understand that people sit at the heart of a successful business. Your customers, suppliers and employees all place their information in your hands and expect you to do everything in your power to protect it. That’s why we go beyond compliance, diving deeper into your business to emerge with meaningful nsights and smarter solutions.

Our assessors and trainers are industry experts who work with you to understand what helps your business operate at its optimum level. They create long lasting value through collaboration, delivering a greater impact on your business, your people and your customers.

For more information on ISO 27001 Information Security, visit www.lr.org/nl-nl/iso27001/

Interested in a ISO 27001 certification? Complete the free Self-Assessment Tool, developed by LR Experts, to easily identify obstacles to a successful certification. www.lr.org/nl

Contact us

Go to www.lr.org/nl for more information, send an e-mail to info.nl@lr.org , or call (+34) 010 250 0500. Lloyd’s Register Nederland K.P. van der Mandelelaan 41a 3062 MB Rotterdam The Netherlands