8 minute read

You’re calibration specialist

As a worldwide specialist in calibration our stated mission is to optimize the industria performance of our different clients by enhancing their measurement processes.

With our “One-Stop-Shop” calibration service we are capable of guaranteeing a multi-service and multi-brand calibration that is independent from manufacturers:

• Full spectrum of high-quality, technical skills and services unique in the world • Close proximity to our clients supported by regional branches and customer satellite facilities • World-recognised expertise based on our global network of ISO/IEC 17025 accredited and ISO 9001 certified laboratories • Comprehensive experience in dynamic asset management and process optimisation • A large team of multi skill technicians for on-site calibrations • Thanks to our own transport service we ensure proper treatment of your instruments • Mastery of quality standards and calibration requirements in the industrial sectors of our customers (ISO 9001, ISO/IEC 17025, ISO/IEC 17020, ISO/AS 9100, ISO/TS 16949, ISO 22716, ISO 14001,

ISO 10012, GMP, GLP etc..)

Beyond our technical services, we provide our clients with our expertise in measurement system acquisition and software asset management solutions.

Trescal also offers technical support services, calibration training and consulting.

3D Measuring

according to IATF 16949 (ISO 17025 accreditated)

Trescal Benelux also has extremely precise 3D measurement machines located in various branches, which allows us to carry out a wide range of product measurements as a service for you. This allows us to make independent measurements based on your production drawings within climate-controlled rooms. Trescal Benelux has five different 3D measurement machines from Zeiss, and using these in combination with our optical equipment, we can measure every dimension for you to determine if it lies within the specified tolerance. By measuring you can check the production and determine whether your product is compliant. We have seen that our customers increasingly want to have these measurements certified, and we can also do this in accordance with ISO 17025. Not just in the automotive, aerospace and defence sectors, but also for die-making facilities, machine manufacturers and suppliers of mechanical components.

Possibilities:

• Pre-manufacturing programming possible. Your measurement programme is ready before your first product is finished (based on CAD files and measurement strategy/measurement report supplied). • Measure products consistently and quickly based on CAD files. • Single pieces, first article inspection & verification. • Geometric and positional tolerancing. • Your measurement reports accredited according to ISO 17025 (RVA, BELAC). • Support for your measurement room by an outsourced 3D specialist. • Consultancy support from 3D specialist for complex programming issues.

Technical specifications

• Zeiss Accura 12/24/8: 1.8 µm + L/350 • Zeiss Contura Navigator 10/16/6: 1.9 µm + L/300 • Zeiss Prismo Navigator 9/12/6: 0.9 µm + L/350 • Zeiss Contura 7/7/6: 2.5 µm + L/250 • Zeiss UPMC 550 CAA 5.5/5/4.5: 0.9 µm + L/400

Virtual reality in the automotive industry

Virtual reality is all about experience and optimization. Application of this technique is aimed at helping companies boost sales, increase the quality of their employees and ultimately save costs. Virtual reality is already being applied within the automotive industry, for example by a number of our members and within our projects. In this article, we want show you what Virtual Reality can do for the Automotive Industry and maybe for your company. Together, we improve!

HAN University of applied sciences

Together Towards a Technological Future HAN University of Applied Sciences Arnhem Nijmegen

The influence of Virtual Reality in business is growing every day. Changes are constantly taking place and the technology offers more and more enticing opportunities. Also for young people who find themselves in a world of technology and automation as a matter of fact. The HAN University of Applied Sciences brings students and the business community together to build a technological future. Today, many companies are curious about what emerging technologies can do for them. In what way does this add value to our business? And how do we implement this in our operations?

Such questions will be answered in the minor “Beyond the Hype” at the HAN University of Applied Sciences. This minor benefits from a combination of classic instruction and actual practice. Together, students investigate the possibilities and limitations of technologies from a practical point of view. ‘It’s all about bringing knowledge together and gaining knowledge,’ says Lambert Zaad, lecturer and researcher at the HAN. ‘Students do the executive work, in which external parties from the industry think along and sometimes collaborate.’

The contents of the minor change year by year, and are adapted to practical innovative developments. For Rosanne Smit, student at the HAN, the focus this year was on Virtual Reality. During a presentation event, she presented a Virtual Reality project together with her fellow students. And their presentation did not go unnoticed by Christian, founder XR Group, a company specialized in high-end 3D, Virtual Reality, Augmented Reality and Mixed Reality. Rosanne quickly scored an internship there.

Companies such as XR Group offer a helping hand in training students in the world of technological innovation. For example, students learn what it takes to create a realistic virtual environment. This is also what Rosanne liked about her internship. ‘Once you know how to work with it, the end result you can achieve with it is absolutely worth it. A concept or the world you’ve designed suddenly becomes a lot more tangible.’

FUTURE PERSPECTIVES

According to Rosanne, there currently is still a high threshold for the application of Virtual Reality in school projects. Mainly because it can seem like a complicated technology to work with. That is why XR Group will launch workshops for Beyond the Hype students in the near future. These workshops will focus on photorealistic Virtual Reality. According to Zaad, ‘specialist companies such as XR Group can help students and teachers show the current possibilities and depth of a particular application.’ By applying innovative technologies in practice, students get a realistic insight into companies and organizations. At the same time, students help companies to get started with technological innovations in an easily accessible way.

Aniek Haenen

SekiSui S-Lec

VR Experience Sekisui S-Lec

Commissioned by Sekisui S-Lec, XR Group created a virtual environment for the Glasstec 2018 trade fair. The goal of implementing Virtual Reality technology was to let customers experience Sekisui S-Lec products in new ways. Using a virtual tour in a demo car on its way to a futuristic city, the VR experience showed various features of the different PVB interlayers. Through the close collaboration with XR Group, the products have been brought to life and we have received positive feedback from our customers. By using four standalone VR headsets, we were quite flexible in the use of the VR on the exhibition stand, where the experience could be shown in different places. We are satisfied with the end result and will use this tool more often in the future.

VR movie of the Dutch Automotive Industry

Dutch AI and Mobility technologies for the automotive industry are highlighted in a 360° video that VR Owl is making for NLinBusiness. The video experience shows the most important activities, products and services that have been realized for three fundamental principles: Zero accidents, zero congestion and zero emission.

• Zero accidents:

Autonomous driving is no longer just a concept – it has become a reality. To ensure autonomous driving does not cause accidents, detailed maps that are updated in real-time are very important. This requires TomTom’s Precise High Definition maps. Most manufacturers use Radar Chip Technology, developed by NXP, to make sure that cars are aware of their environments. This technology is used for adaptive cruise control, crossing traffic alert, parking assistance, automated emergency brake and blind spot detection.

• Zero congestion:

Automotive technology also affects traffic regulation. One example is the TLEX I2V platform, that enables real-time communication. This contributes to the efficiency of the entire ecosystem, making transport smarter, safer, cheaper and more sustainable.

• Zero emission:

Sustainability is an important topic in the automotive industry, for example in the development and production of electric cars. In the Netherlands, several companies are working on switching from fossil fuel vehicles to electric cars.

Dutch companies are currently working on a smart charging network. Cooperation between companies is essential in the development of such a system.

This article has been produced in cooperation with XR Group and VR Owl.C73

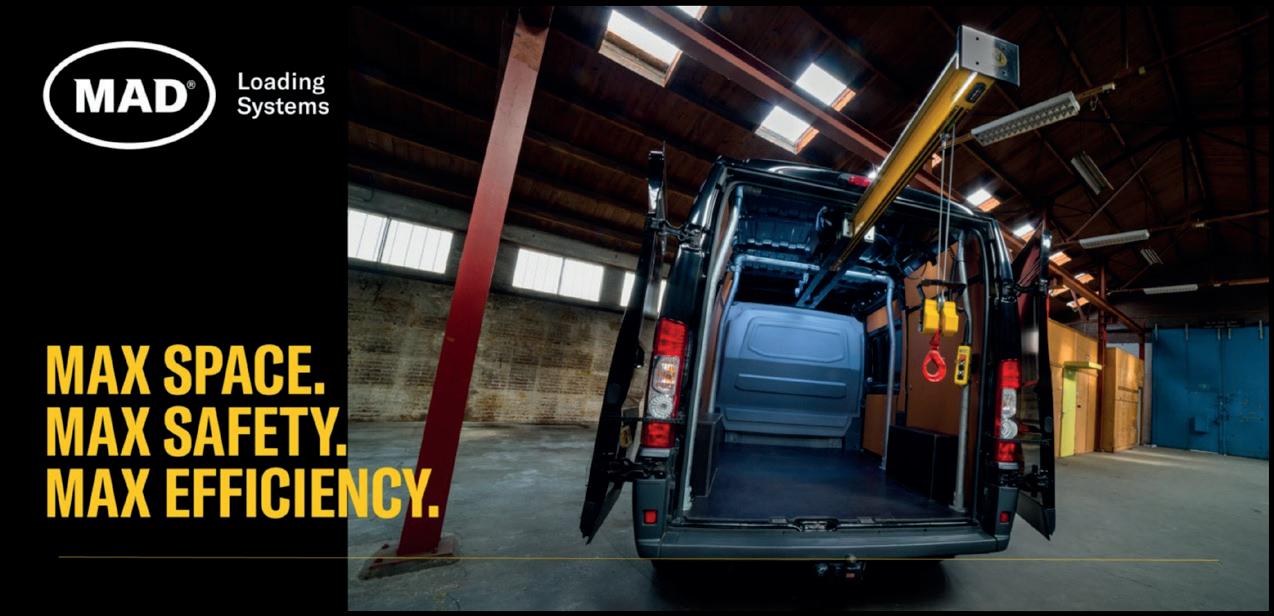

We are MAD

And we are there for you, who can’t settle for the standard. Who wants to go that step further. Don’t let anything stand in your way, to do what you want to do! MAD to the max. That’s our mission, our promise to customers and drivers. Because vehicle manufacturers provide an excellent basis, but sometimes that’s not enough. In that case we provide the solution from our divisions Suspension Systems and Loading Systems. In Veenendaal we see to it each day that our promise is fulfilled throughout the world. There we work closely with our partners on developing and manufacturing solutions that meet international automotive standards. What’s more, our business processes are certified according to the ISO and COP standards. Thus ensuring that we provide the highest quality. International customers and end users have been choosing MAD for well over 40 years now, and that’s something we’re proud of.

In close cooperation with vehicle manufacturers and conversion companies, we develop coil and air suspension systems for the widest range of applications. Whether it’s a van, pick-up truck, motorhome, minibus or ambulance. In specific situations there are often extra demands on the suspension system of the vehicle. Our suspension systems ensure that comfort, drivability and safety remain optimal, in all circumstances.

Wherever loading and unloading heavy loads is an issue, we offer the perfect solution with our EasyLoad systems. Whether it’s about service on site, sewer inspections or roadworks, an EasyLoad provides the solution in all cases. The structure has been designed in a way that the loading space will pretty much stay fully available. And because the entire processing can now be done by a single person on site, this means maximum efficiency under optimal working conditions.

Visit www.mad-automotive.com or call us at +31 318 586 100 for more information.