7 minute read

How engineers can address the data scientist gap

How engineers can

address the data scientist gap

Despite a worldwide shortage of data scientists, automotive companies are undaunted and continue to look for and recruit “unicorn” data scientists: unique candidates who know statistics and computer science, and have domain expertise about the business. While the word “unicorn” may imply that such people are impossible to find, companies may achieve better results if they’d focus on the 3rd skill: relevant industry domain expertise. This facet is often overlooked, yet it is key to the success of data science projects.

Domain knowledge is what enables a practitioner to make quick, educated decisions as they analyze new datasets. Because these employees are intimately familiar with the data being analyzed, they can easily distinguish between signal and noise, between correlation and causation, between insignificant anomalies and major changes in vehicle operating conditions. This level of expertise is often found in research and engineering departments with established cultures around understanding the products they design and build. These teams already use statistical and mathematical tools in their everyday work, which makes the jump to the machine learning tools of the data science world quite manageable.

Enabling the domain experts

A natural question to ask at this point is: How can newer techniques like machine learning be made accessible to engineers with domain expertise?

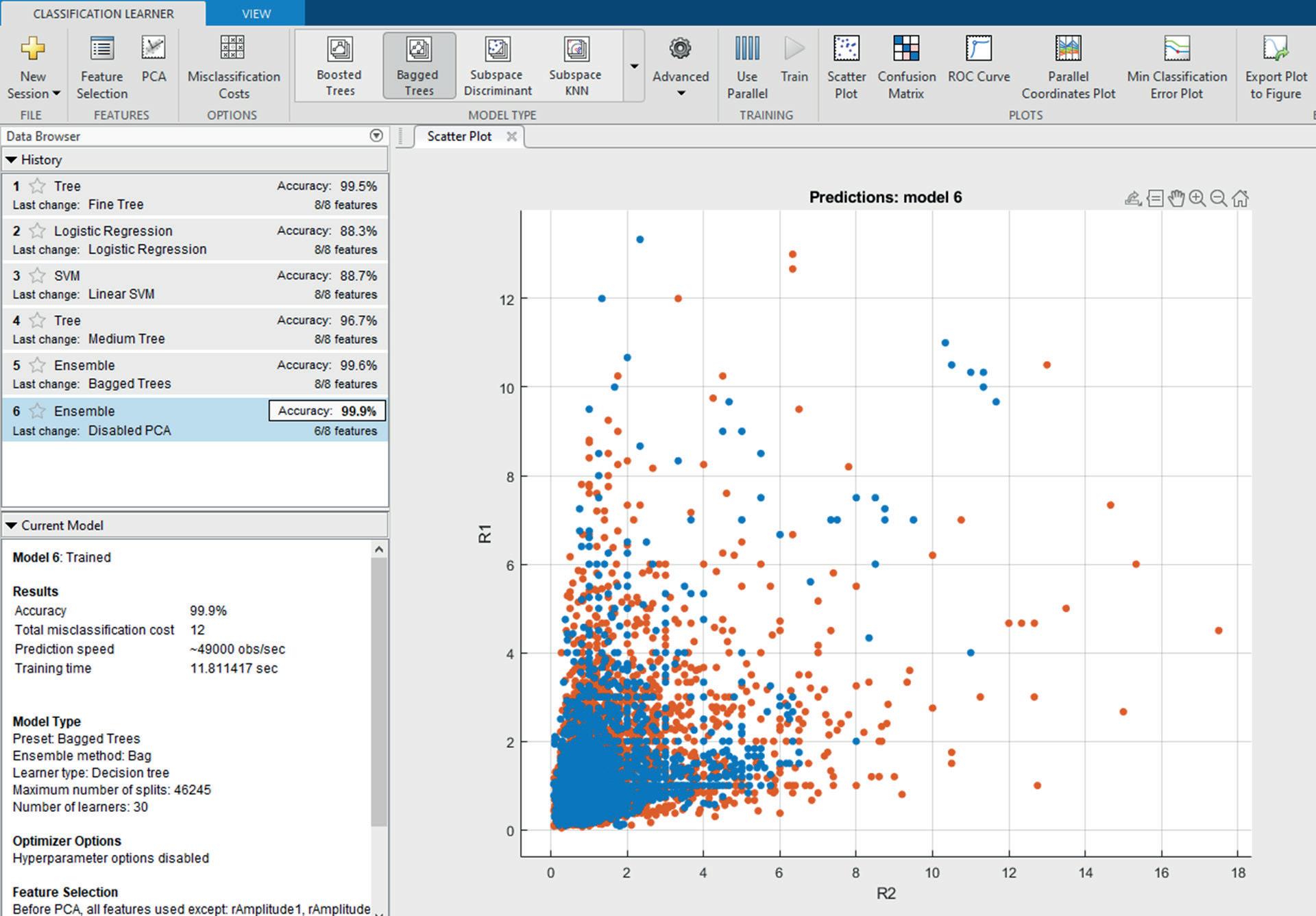

Machine learning is used to identify the underlying trends and structures in data. Many different machine learning algorithms have been developed and each has its own strengths and limitations. However, it is hard to know which one of these algorithms will be most suitable for tackling a particular problem. The best thing to do is often to try them all out and compare results. This can be quite a challenge in some environments, but it is critical for identifying “quick wins” where machine learning provides improvement over traditional methods. Tools such as MATLAB address this problem by providing point-and-click apps that train and compare multiple machine learning models.

MATLAB® and Simulink® are registered trademarks of The MathWorks, Inc. See mathworks.com/trademarks for a list of additional trademarks. Other product or brand names may be trademarks or registered trademarks of their respective holders.

In the hands of domain experts, machine learning tools can yield significant results. For example, engineers at Baker Hughes used machine learning techniques to predict when pumps on their gas and oil extraction trucks were going to fail. They collected nearly a terabyte of data from their trucks and used signal processing techniques to identify relevant frequency content. They applied machine learning techniques that can distinguish a healthy pump from an unhealthy one. The resulting system is projected to reduce overall costs by $10 million. Throughout the process, the engineers’ knowledge of the systems on the pumping trucks enabled them to dig into the data and iterate quickly. Solution: Engineers with domain knowledge should look for tools that enable them to get up and running quickly. Point-and-click apps like those offered in MATLAB can serve as an easy starting point. Businesses should also look for training courses that can help engineers ramp up much faster, instead of just learning by trial and error.

The large amount of cutting-edge research in the data analytics space creates a wave of new technologies that have the potential to disrupt. In the wake of that wave, successful tools arise that are general enough for engineers with domain knowledge to use.

Challenges and solutions for the road ahead

Learning curve for new technology

Challenge: The pace of innovation in the data analytics space is very fast and each new piece of technology has its own learning curve. In many cases, the original technology is developed by computer scientists, with the intended audience also being people with very strong programming skills. This means that the learning curve can be very steep for those who do not write code full-time.

is developed in a tool that is suitable for research and development, but not for running the analytic in production. The analytic will therefore have to be recoded into a different programming language before it can be deployed. This process typically takes several weeks or even months and can introduce all kinds of bugs.

Where does an analytic end up?

Challenge: Analytics may be integrated with servers maintained by the IT organization, or deployed to embedded devices (such as edge nodes in an Internet of Things system). Traditionally, the analytic Solution: Platforms for developing analytics offer ways to package the algorithm to run in different production environments. Look for a tool that provides integration paths and applications servers for use with common IT systems as well as targeting embedded devices. For example, MATLAB provides deployment paths for integrating analytics with programming languages commonly used in IT systems (e.g., Java and .NET), as well as integrating machine learning models with Simulink for targeting embedded devices.

Caption: Using machine learning models in Simulink enables the deployment of machine learning to embedded systems.

Technologies that enable domain experts to apply machine learning and other data analytics techniques to their work are here to stay. They provide exciting opportunities for engineering teams to innovate – in both their design workflows and the products they create. Their knowledge of the business and the products it produces positions them well to find innovative ways to apply data analytics technologies.

Seth DeLand,

Product Manager

Disruptive governments

This inaugural issue of the RAI Automotive Industry NL magazine has been packed with innovative, cutting-edge companies that provide employment and prosperity to many. What often remains hidden from view is that these companies also contribute to the goals we’ve set as a society, namely zero emissions, zero accidents and zero congestion. Reading the magazine, we find even more ambitious goals that are not talked about as often, such as circular economies, preventing resource depletion and promoting accessible mobility.

The common thread throughout these stories are major transitions, mainly towards self-driving transport without any emissions. This brings to the fore the question how market-disruptive governments should or shouldn’t be in achieving their objectives, and whether governments should operate in technology-neutral ways. These topics should be weighed and debated, but what remains paramount is that we cannot operate without regulations. In the case of electric passenger cars, European emissions legislation has proved indispensable in making the transition to electric transportation possible, albeit somewhat slowly. If things had been left solely to the market, there would be only a few electric cars on the road today.

The best technology does not always win

I have studied many historical inventions and innovations, together with the predictions surrounding them and the actual outcomes. From hybrid cars built in the early 1900s to the electric car revival of the 1990s and the self-driving cars of the past 50 years. Many people have the misconception that the best technology will automatically win. That is by no means always the case. It is mainly about which technology is invested in the most, or which is best regulated.

When the Wankel rotary engine met the strict NOx requirements in the US in the 1970s, the best analysts projected that it was heading toward a 20–60% market share by 1980. It eventually gained a share of 0.2%, because the requisite NOx legislation was delayed by 18 years. Furthermore, one technology cannot be said to be “better” than another technology if € 99 billion is invested in one and only € 10 million in the other.

When we write history, we write it after everything has happened, since that is when everything is known. This was by no means the case during the entire process of innovation and market introduction. The Battery Electric Vehicle (BEV) is currently the best option for passenger cars in terms of efficiency and sustainability. That could have been different. If car manufacturers had fulfilled the promises they made in the late 1990s, we would now have cheap fuel cells and a comprehensive hydrogen infrastructure, and the fuel cell car would be much cheaper than the BEV when Nissan launched their Leaf.

Carbon footprint The future is not happening to us!

In hindsight, it was a good thing that this line of innovation was not pursued at the time, because we may have had much fewer investments in batteries, and the Total Cost of Ownership (TCO) of a BEV would now be much higher. BEVs use energy much more efficiently than a Fuel Cell Electric Vehicle (FCEV), and as long as we do not generate 100% of our electricity in sustainable ways, BEVs also have lower carbon footprints than FCEVs. Some futurists will explain in detail what 2028, 2030 or 2035 will look like. Their predictions often concern technologies that are still in the R&D phase and their future is still unclear. Forecasting is very tricky. Chinese philosopher Lao-Tse said 2700 years ago: “Those who have knowledge, do not predict. Those who predict, do not have knowledge.” The future is not simply going to happen to us – we shape it ourselves. The Dutch automotive and mobility industry is very well equipped to support a bright future.

Jan Wouters, Wautomotive