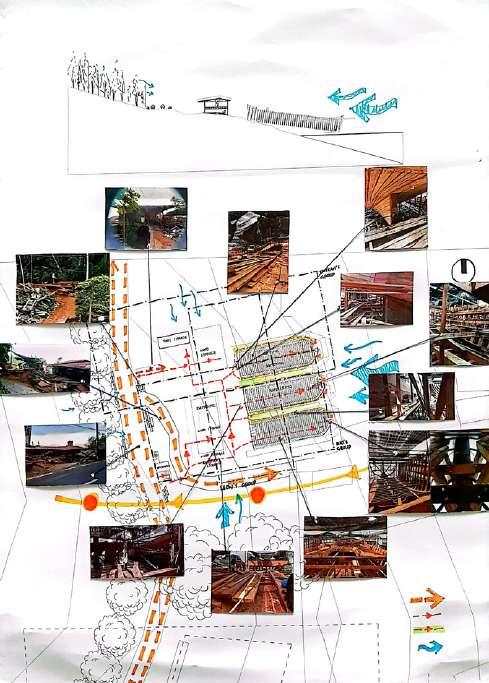

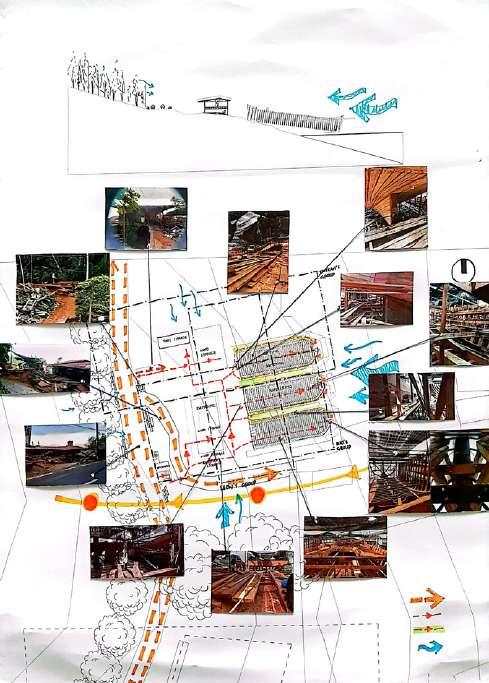

a. pre-site visit research

A thorough research about the site before actually going there, so that we have a vision and imagination, and at least some basic general information

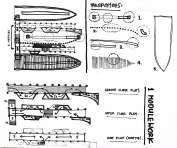

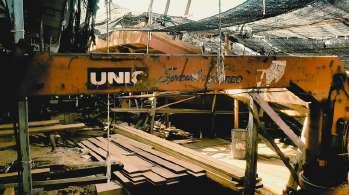

Each group conducted some boards to further study about the trades - boat making factory & anchovies factory, to gain some knowledge upfront that can still be found on the internet.

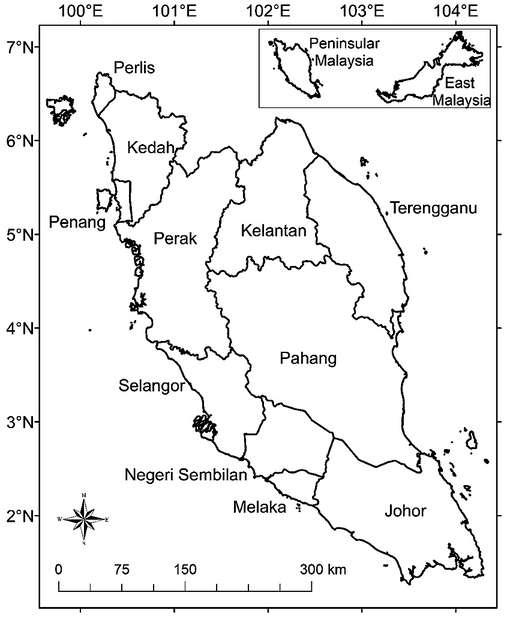

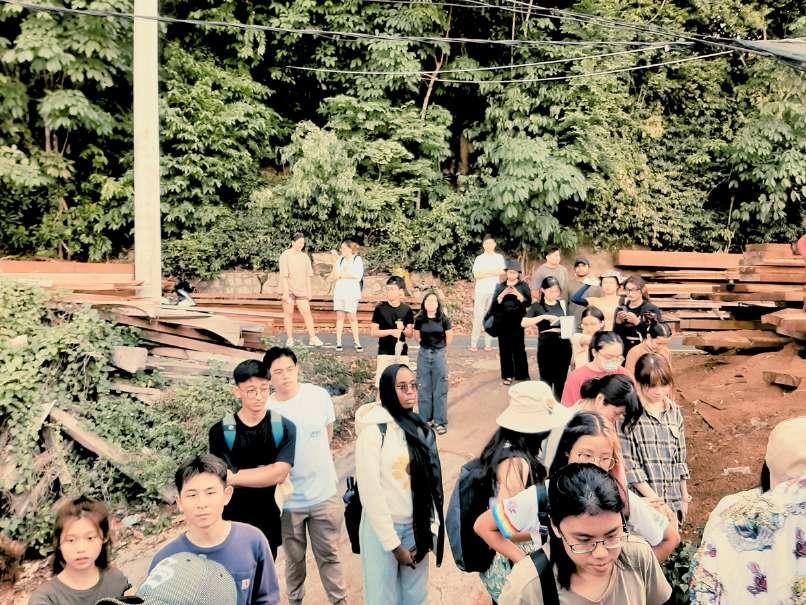

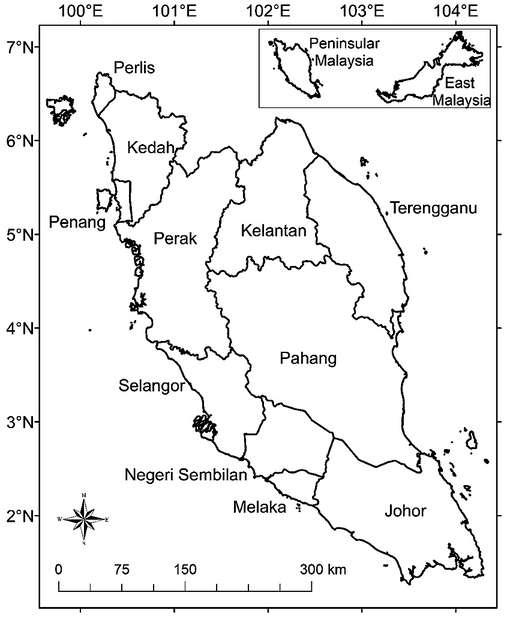

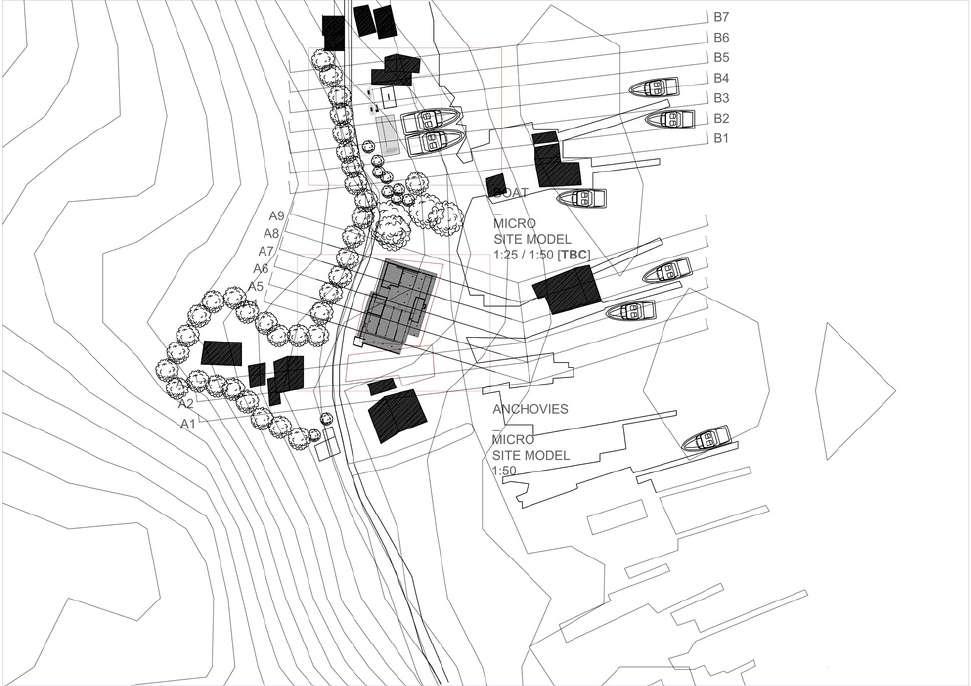

Site location: Hoo Huat Boat Making Factory, Sungai Pinang Kecil, Pangkor, Malaysia

Site visit date: 22th - 26th July 2023

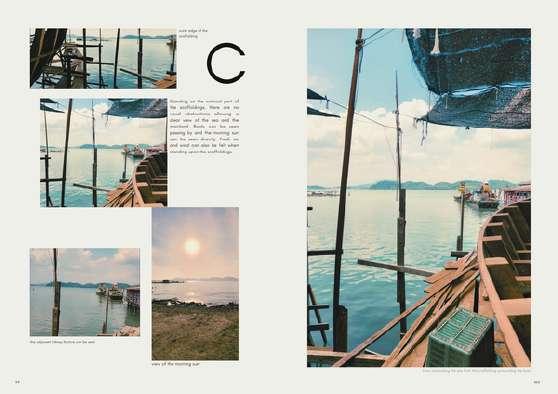

PANGKOR

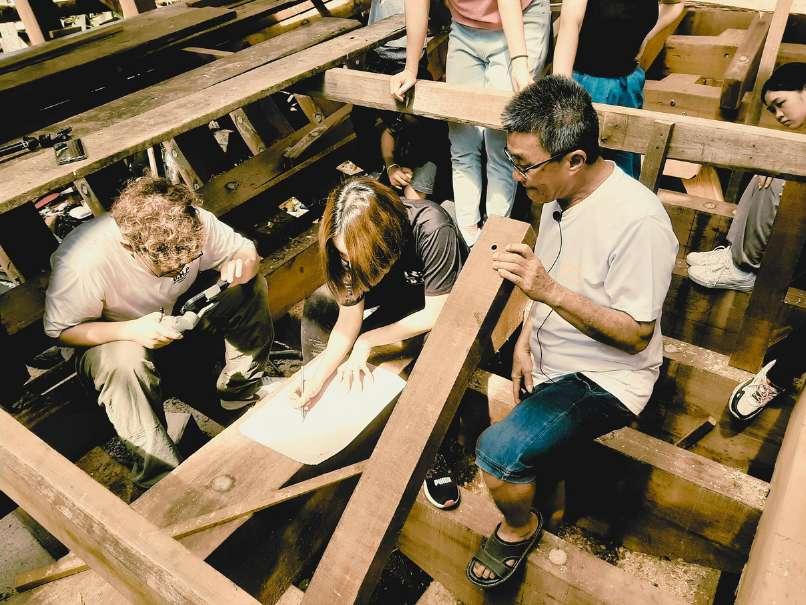

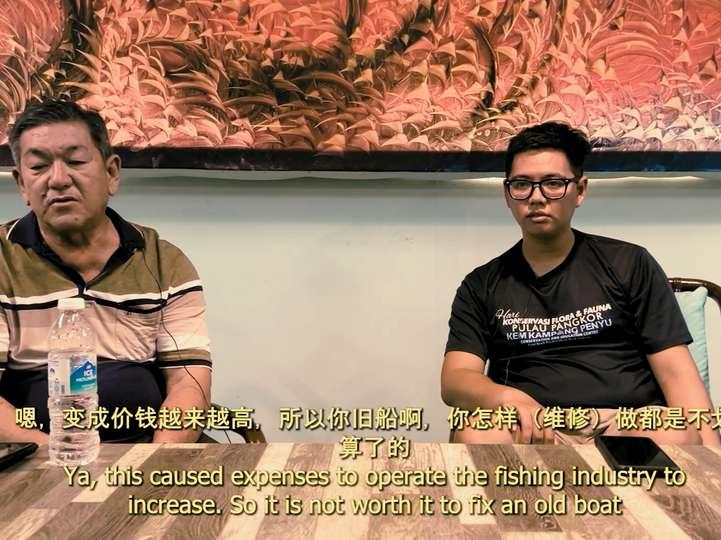

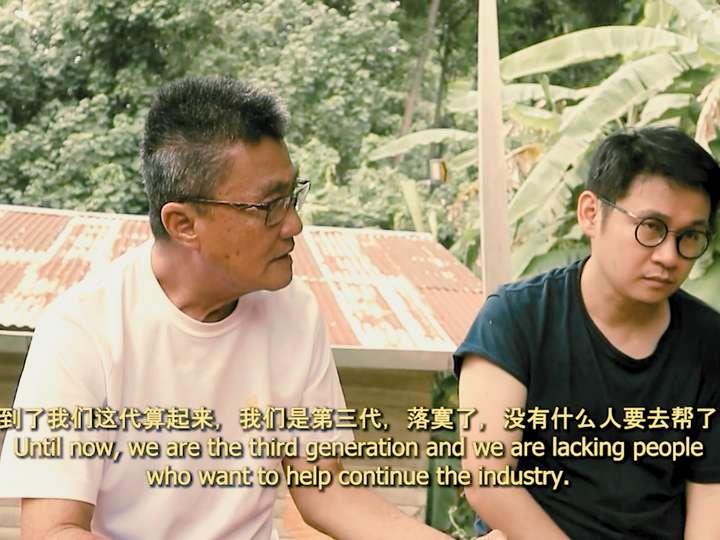

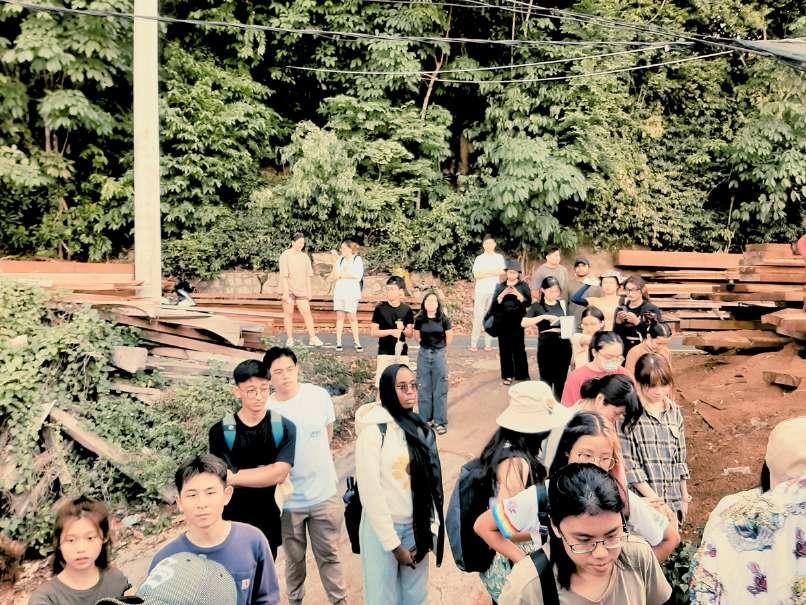

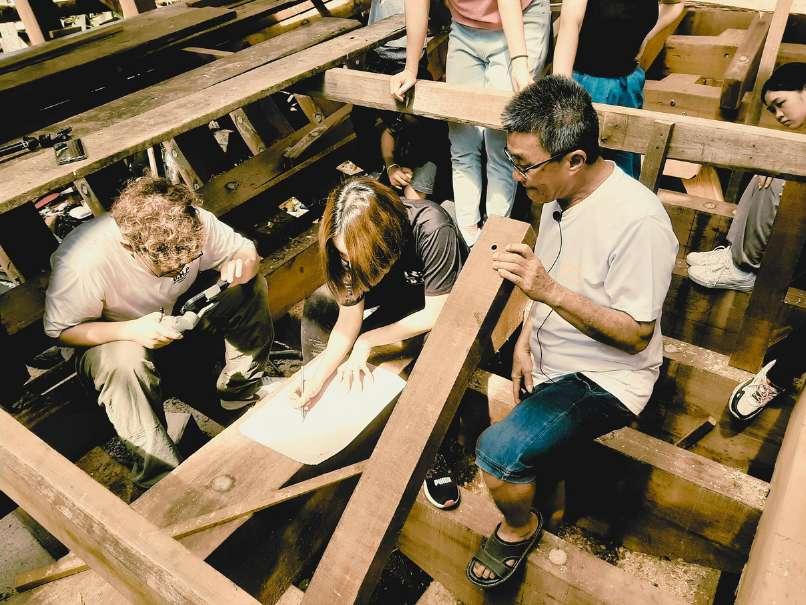

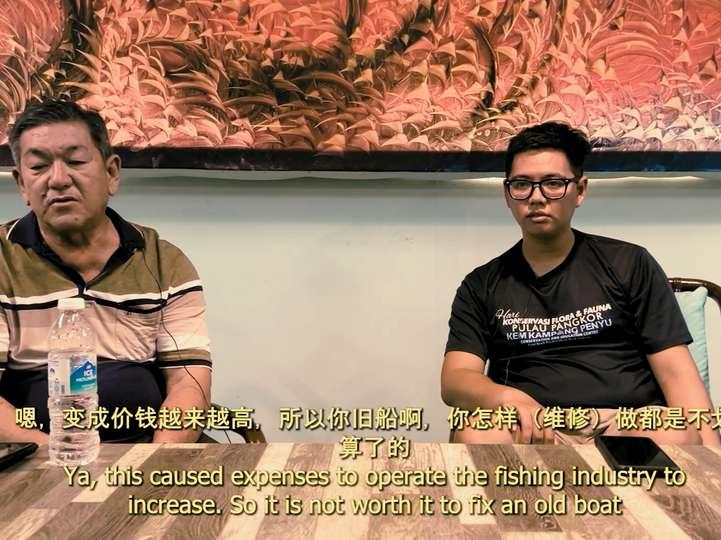

During the 5 days site visit, we tried to collect the data on the site itself, measuring the topography of the site, the boat structure and framings, and etc. We also crosschecked the information that we’ve found during pre-site visit with the local workers there by setting up some formal and informal interview sessions. Beside measuring, documentation was also part of the task By using mixed media, such as images, videos, drawings, we collected quite a sufficient information with the help of our lecturers and experts there also. Daytime was to collect as many information as we can, by documenting, having conversation with the locals, interacting with them. Then, nighttime was to the time to produce the works, basically to transform the information by words into a more visual slides and boards.

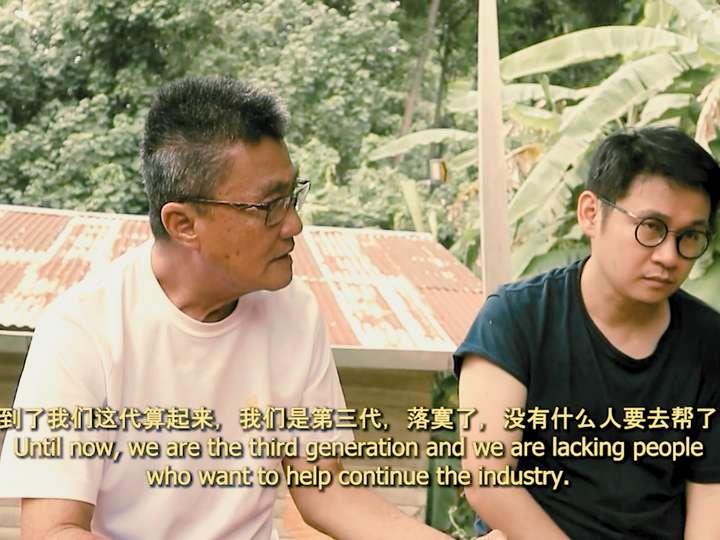

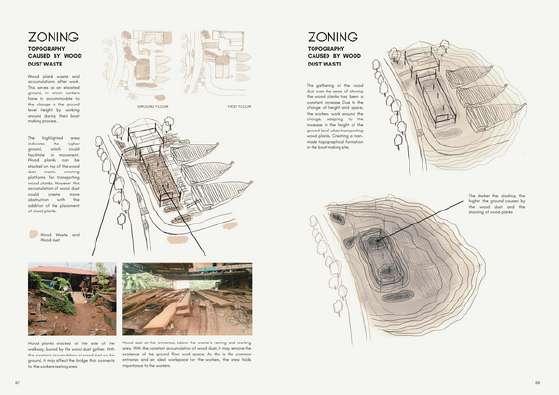

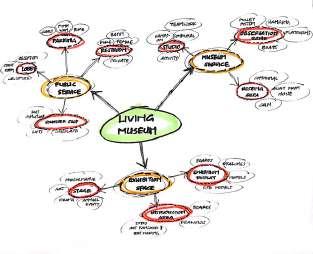

From this site visit, we can conclude that there are intangible and tangible issues. The intangible issue is that these 2 traditional trades, especially the traditional boat making factory is a sunset industry, meaning it’s about to extinct because no younger generation wants to continue this industry, as most of them move to the city for a “better life” The tangible issues are on the site, such as the chaos, no proper arrangement, wood waste, less storage space, the contour, and etc So, our goal is to curate a living museum to preserve this still-ongoing factory/industry, while at the same time allowing more healthy tourism to happen (P S healthy tourism is not just about taking pictures, buy souvenirs, then leave, but instead, it’s more of a learning process that leave some knowledgeable memories for the tourist)

design development

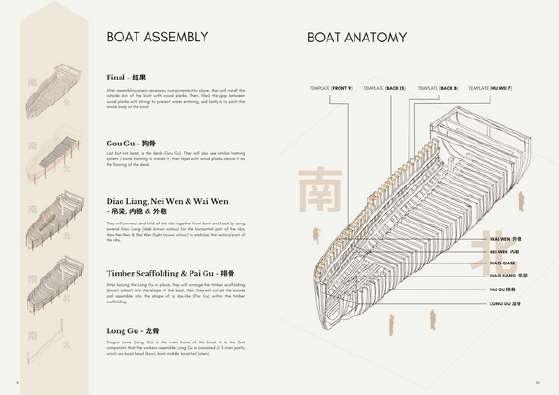

Gou Gu - 狗⻣

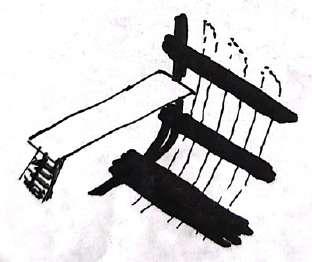

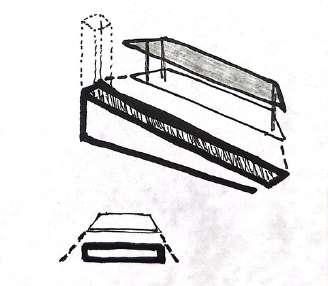

Last but not east, s the deck (Gou Gu). They w l also use s m lar framing system / bone fram ng to create it, then ayer with wood p anks above t as the flooring of the deck

Diao Liang, Nei Wen & Wai Wen

They w l connect and ho d al the ribs together from front and back by us ng severa Diao Liang (dark brown co our) for the horizonta part of the r bs, then Ne Wen & Wa Wen (light brown co our) to stabi ize the vertical part of the ribs

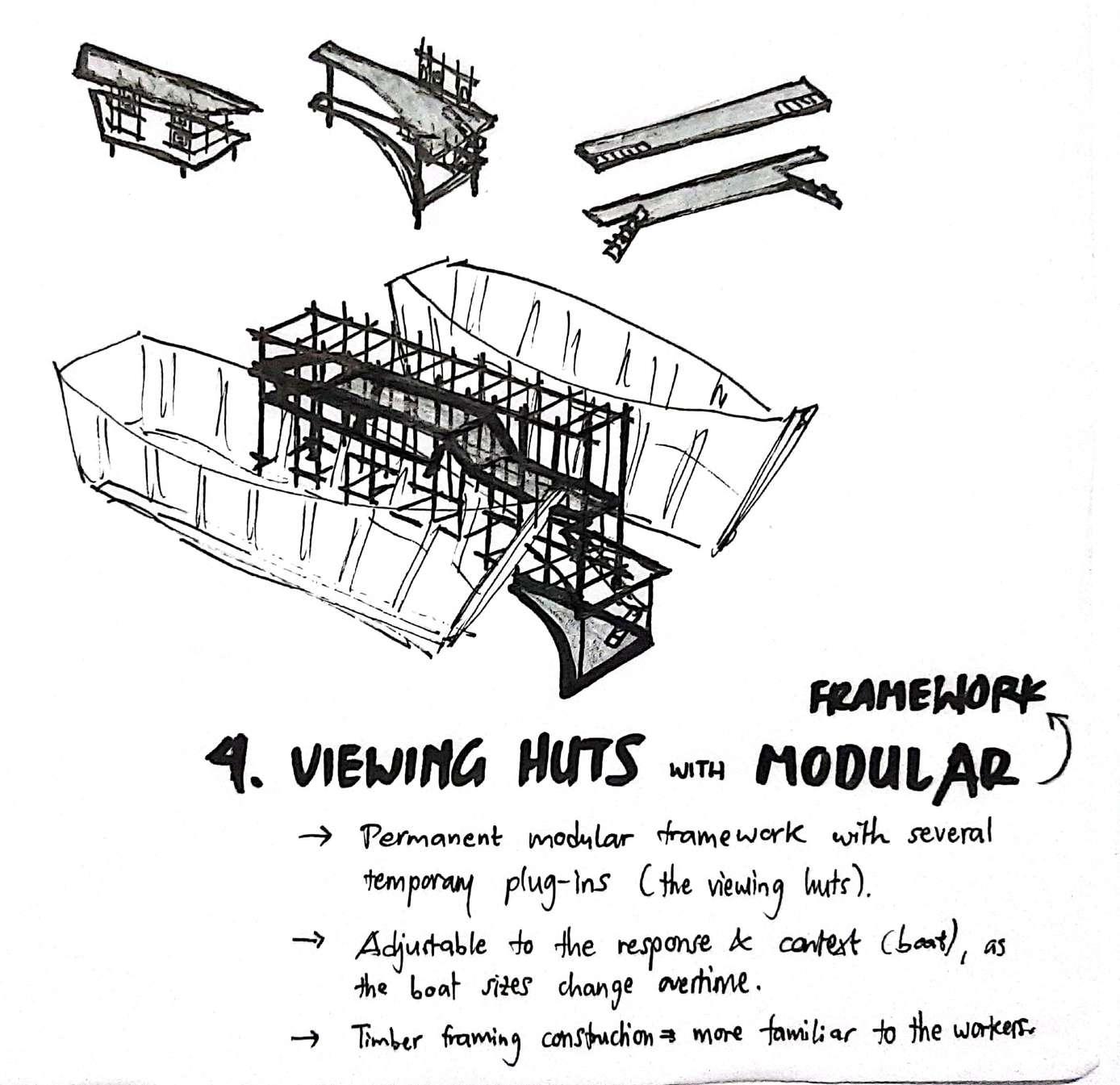

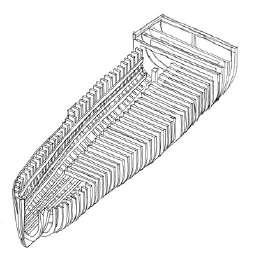

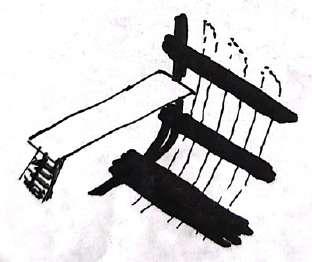

Timber Scaffolding & Pai Gu - 排⻣

After ocking the Long Gu in place, they wil arrange the t mber scaffo ding (brown colour) nto the shape of the boat then they w ll cut al the woods and assemble nto the shape of a ribs-like (Pai Gu) with n the t mber scaffold ng

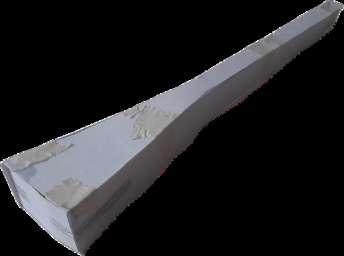

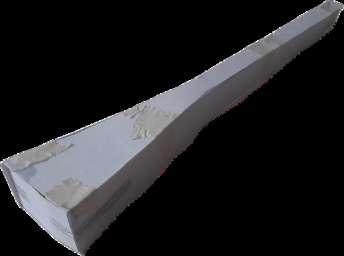

Long Gu - ⻰⻣

Dragon bone (Long Gu) is the main bone of the boat t s the f rst component that the workers assemble Long Gu s consisted of 3 ma n parts, wh ch are boat head (bow), boat midd e, boat ta l (stern)

南

北

南 北 南 北

北 南 北

南

- 吊梁, 内稳 & 外稳

a.

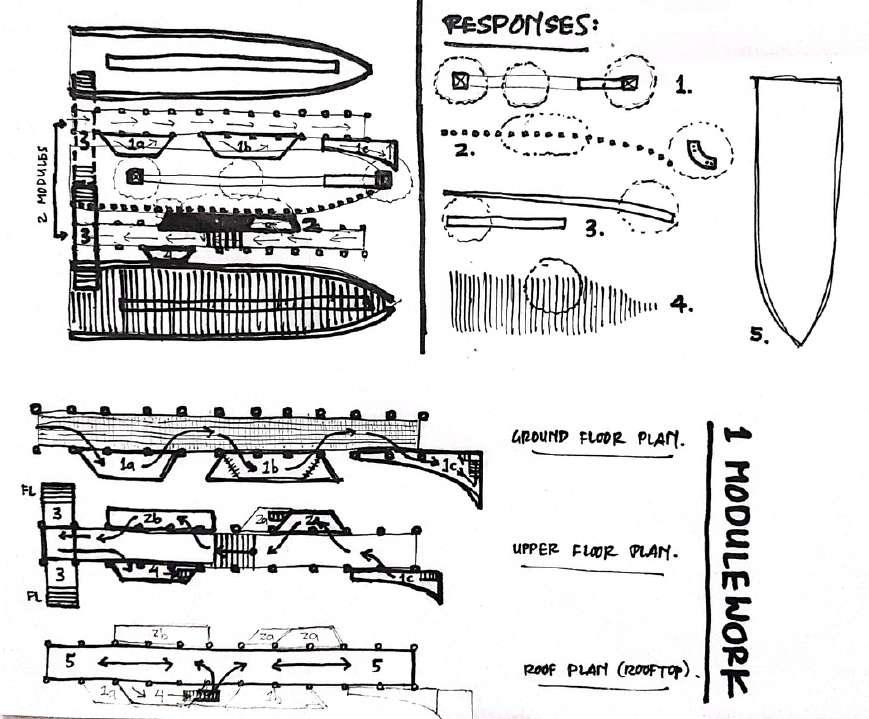

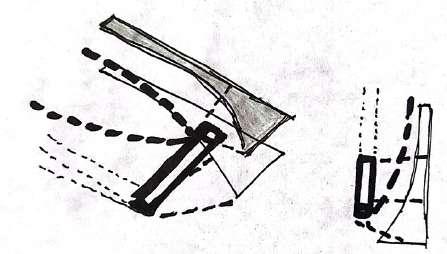

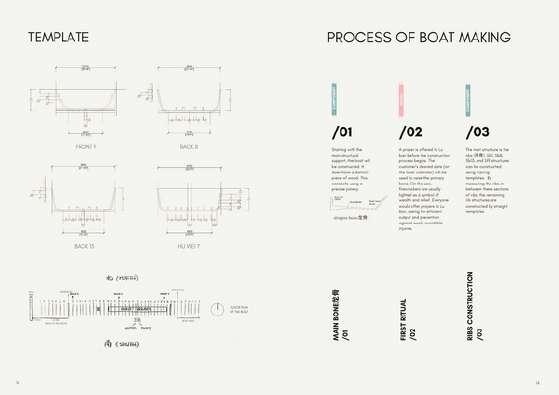

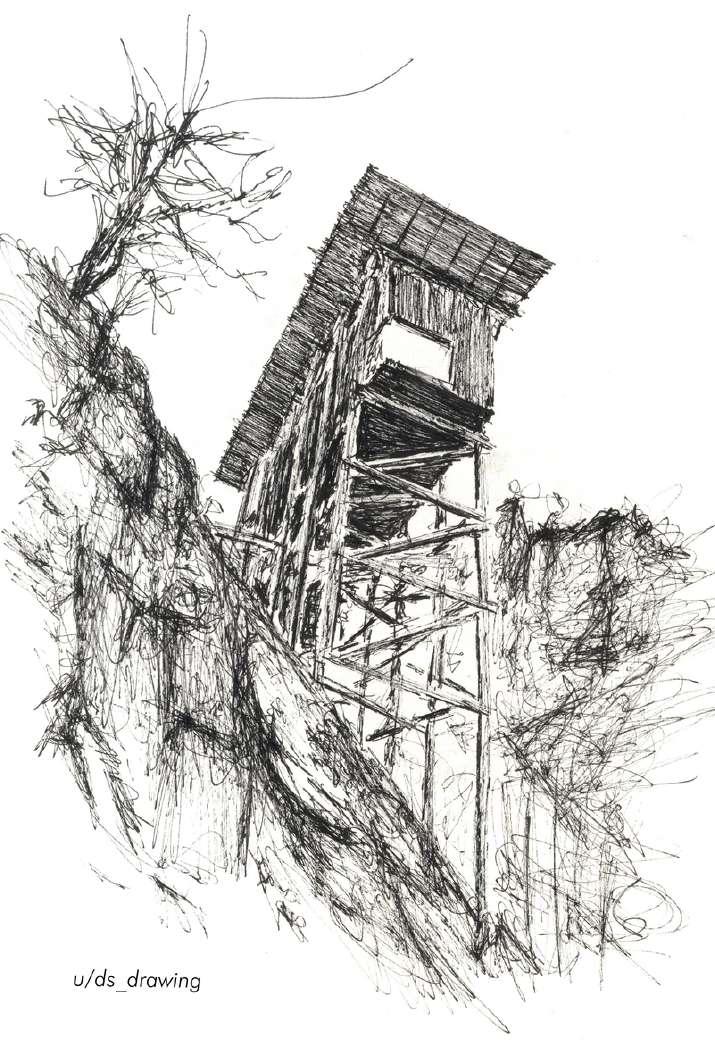

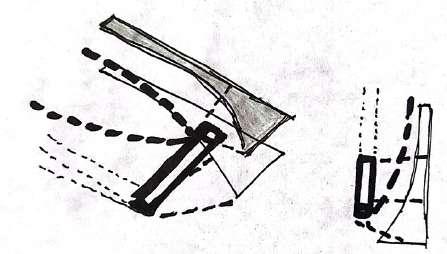

BUTTER PAPER OF SKETCHES NOT TOO SCALE

1

2

1

2

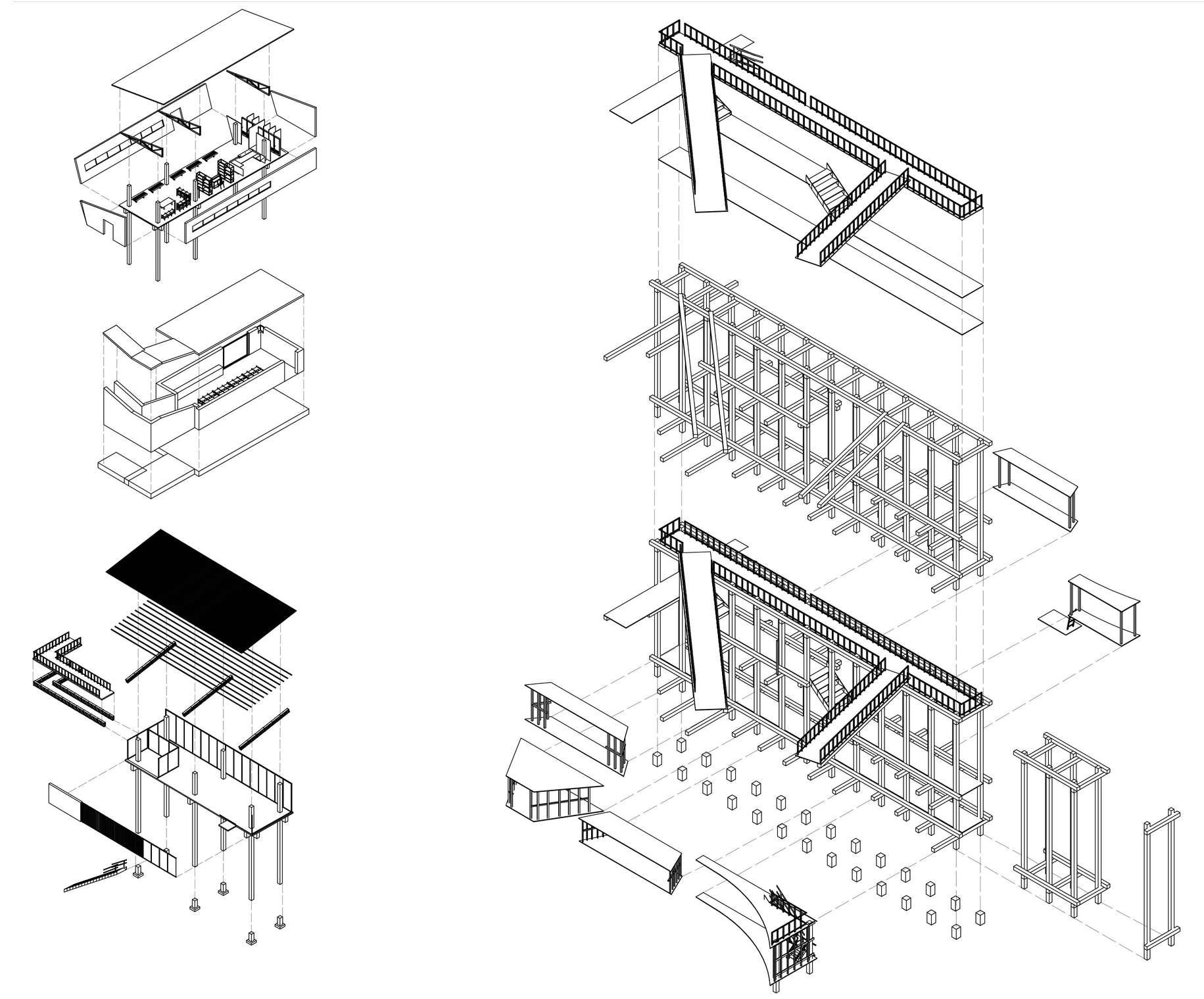

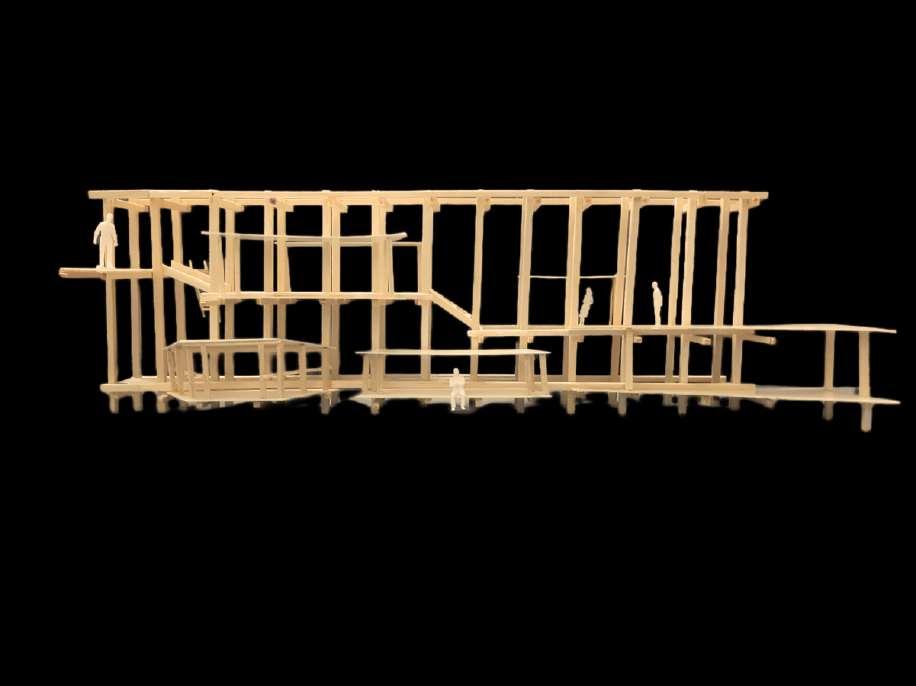

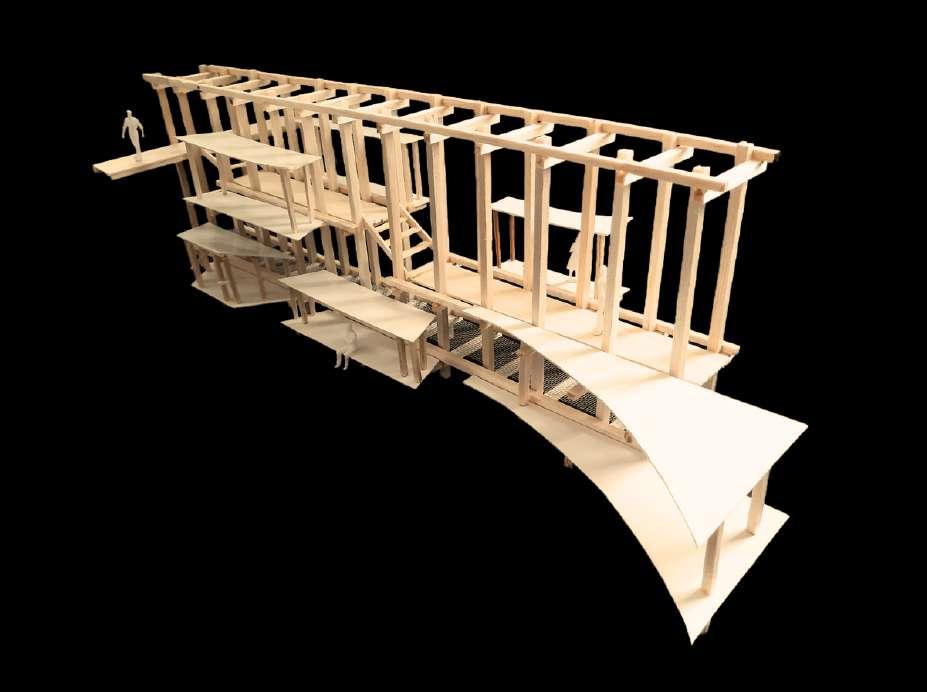

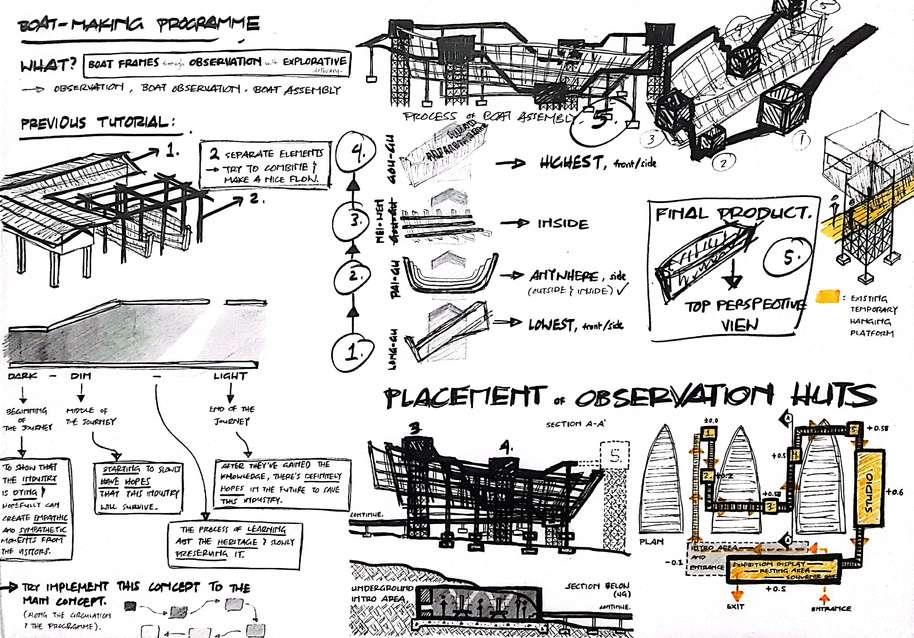

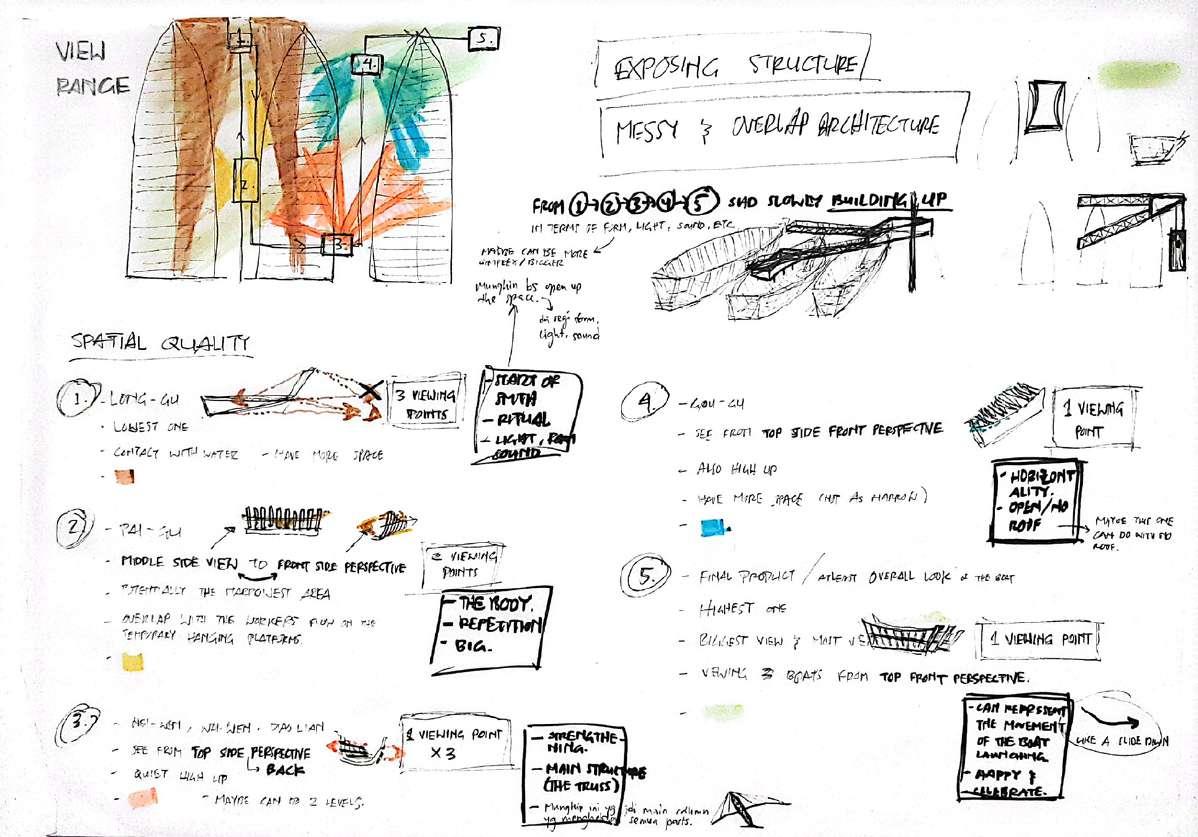

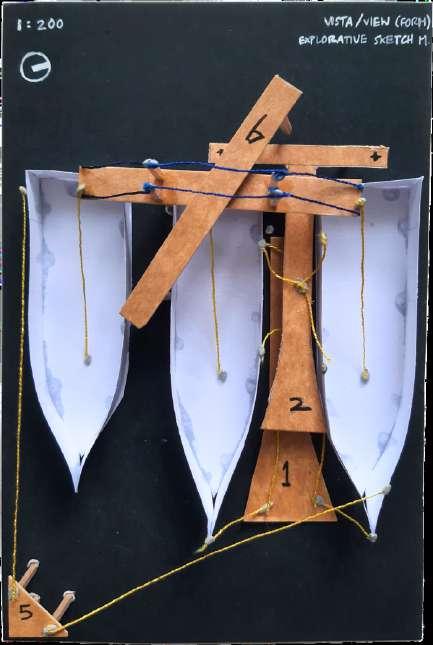

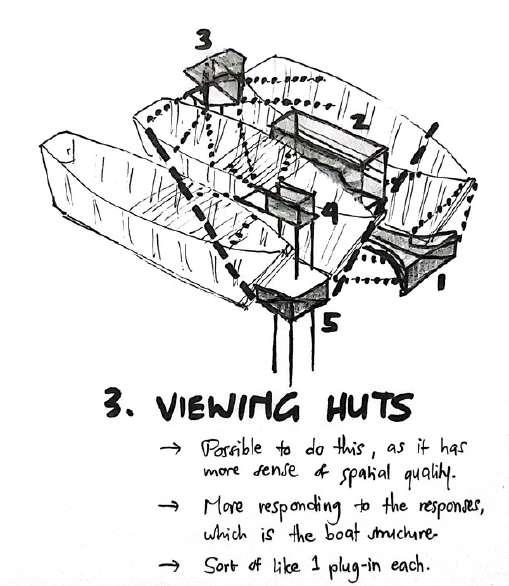

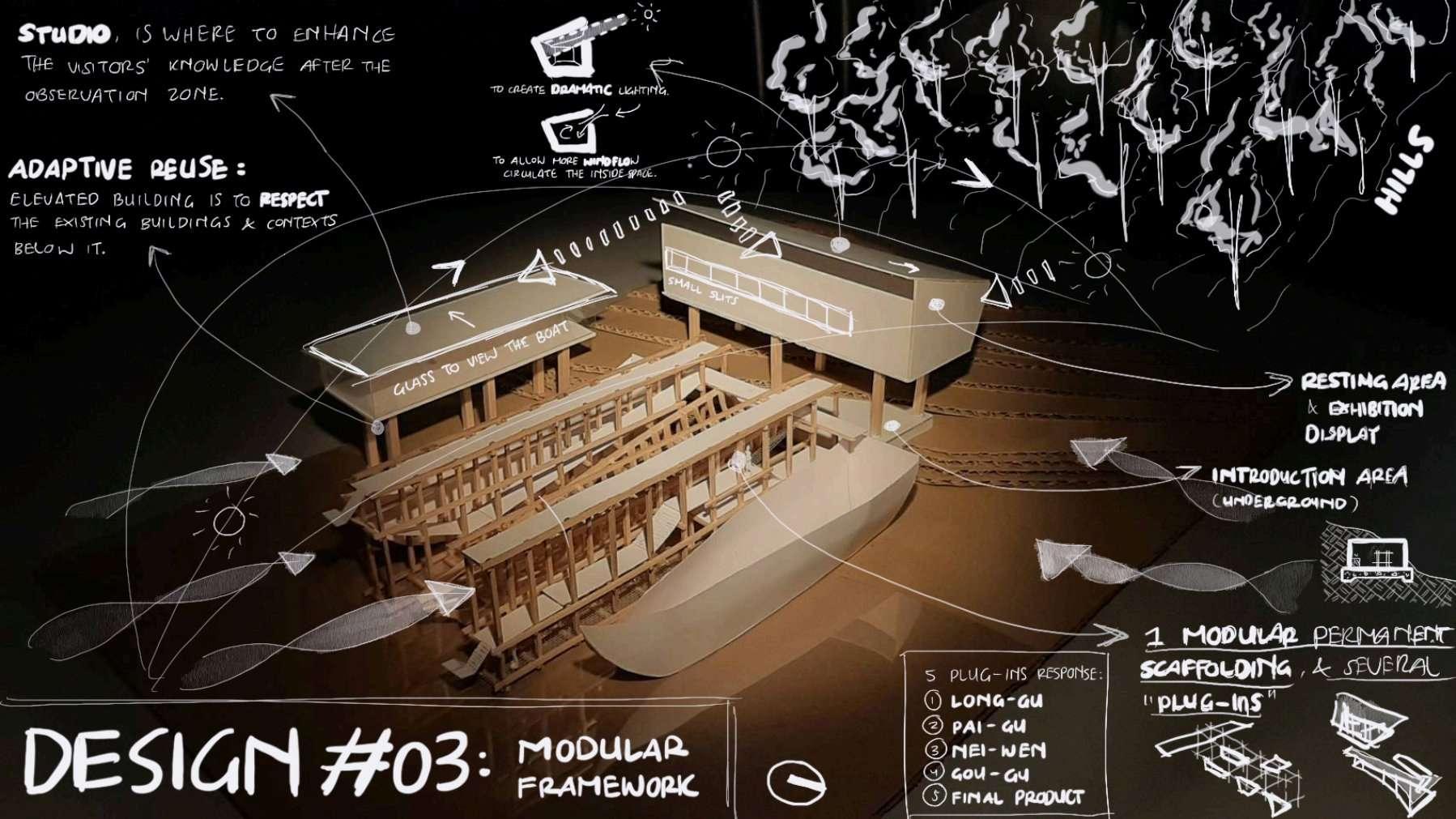

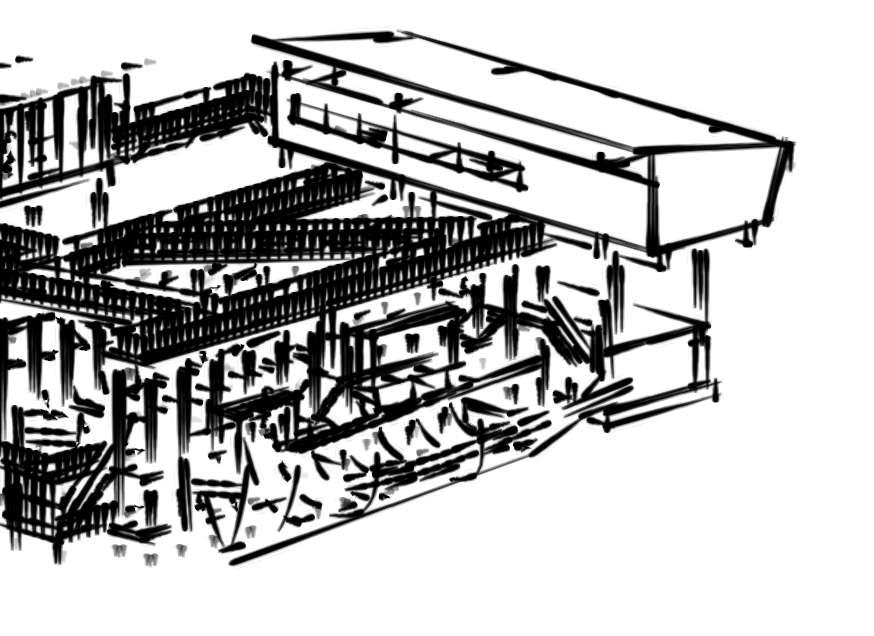

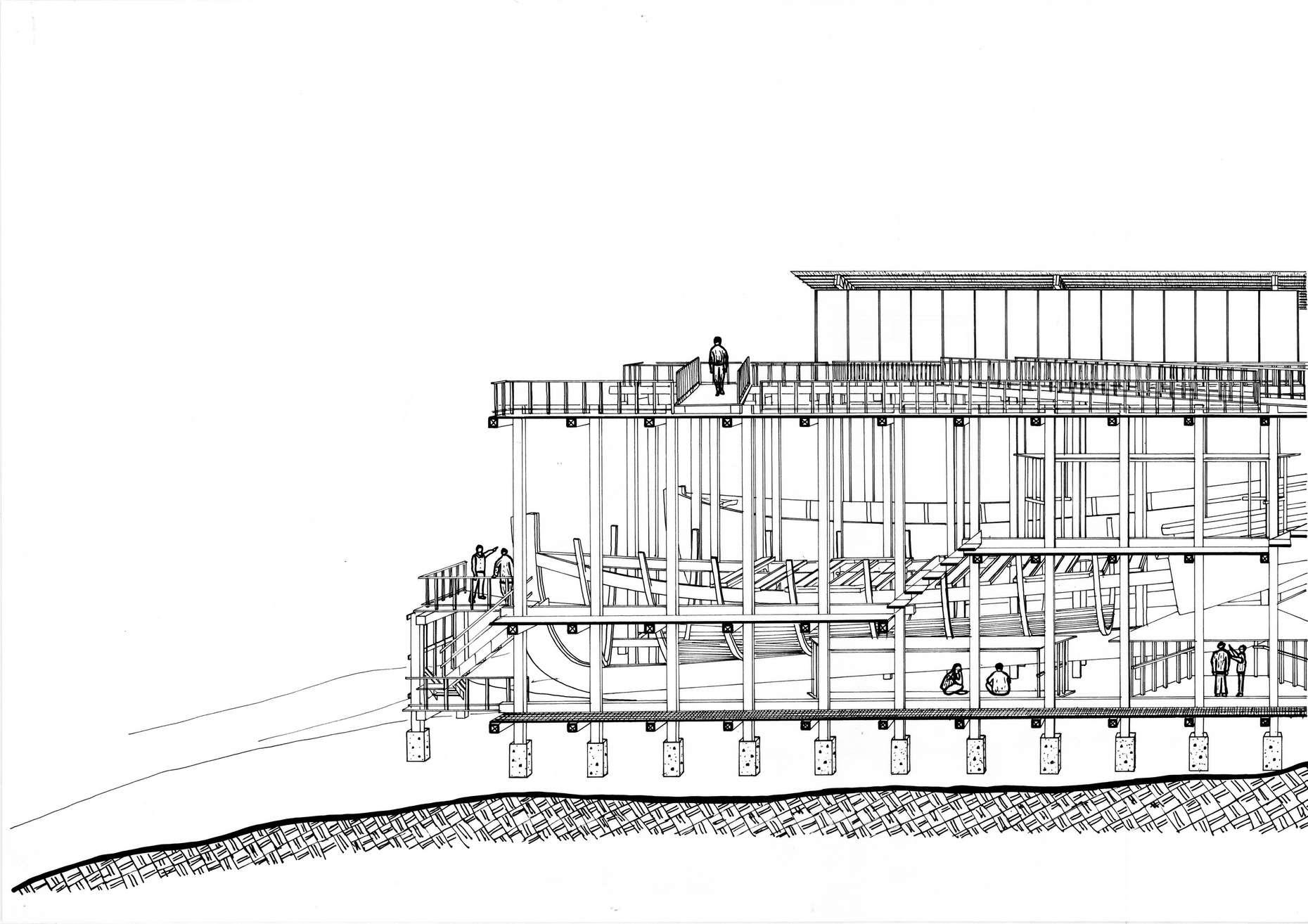

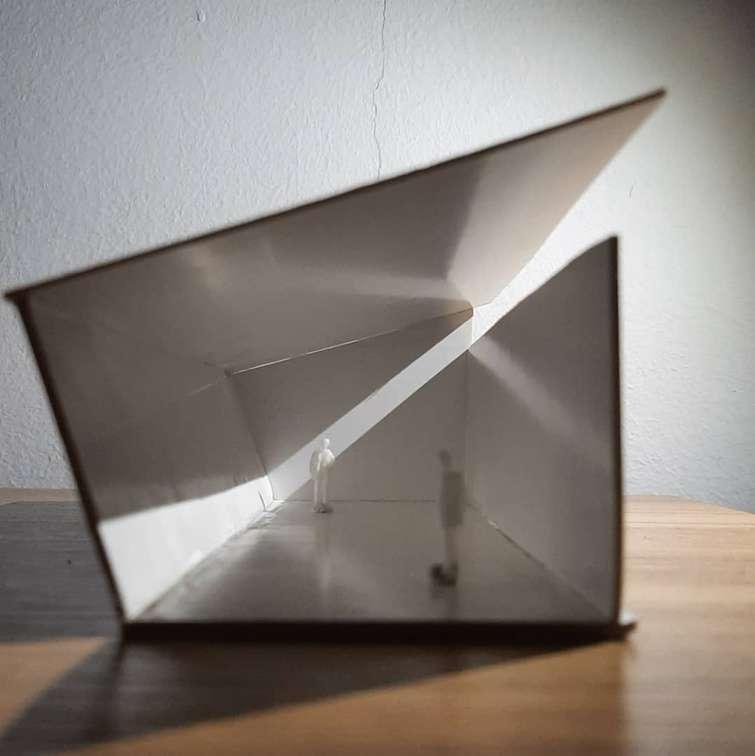

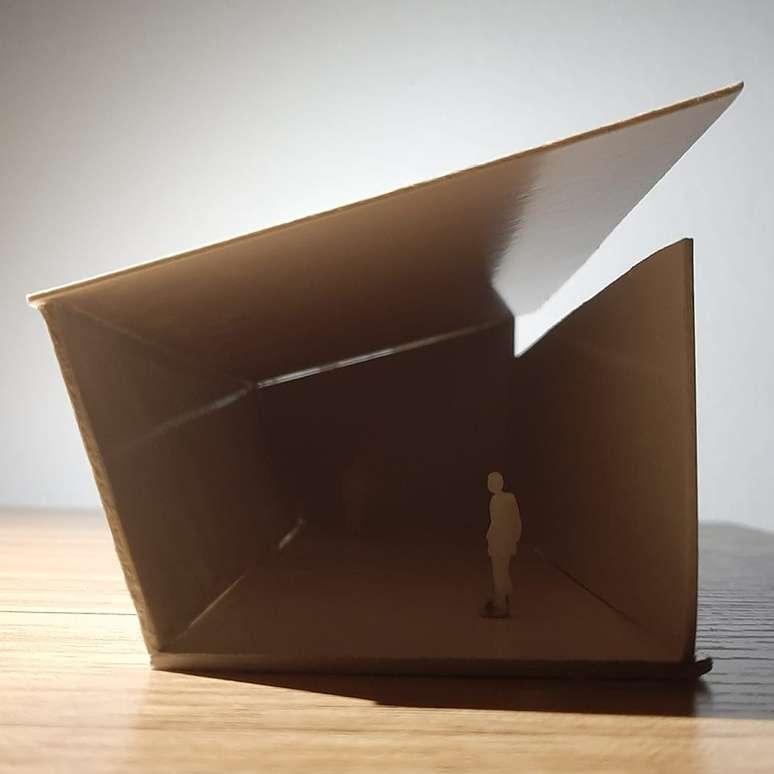

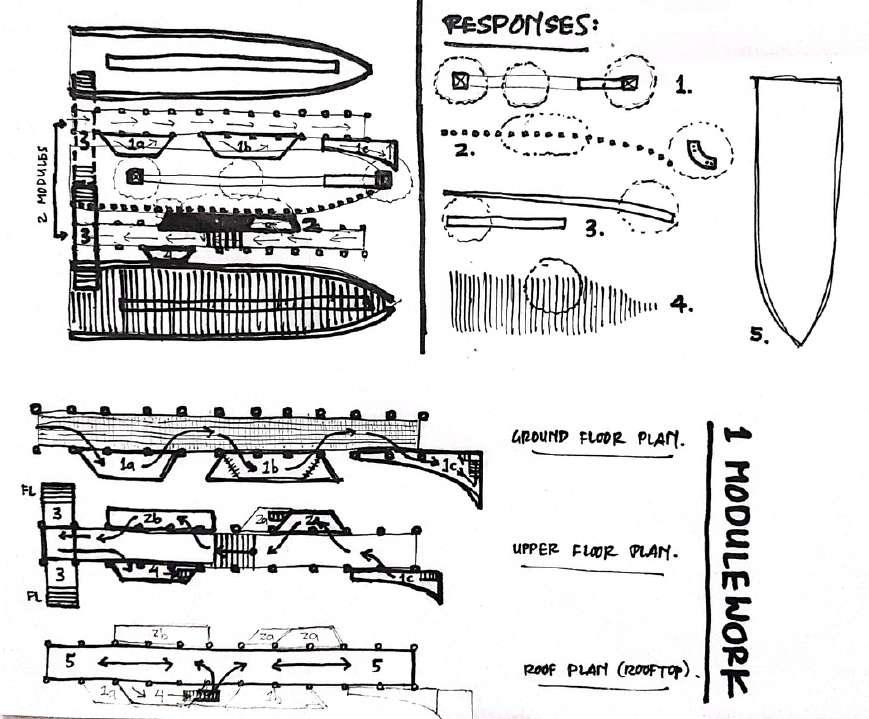

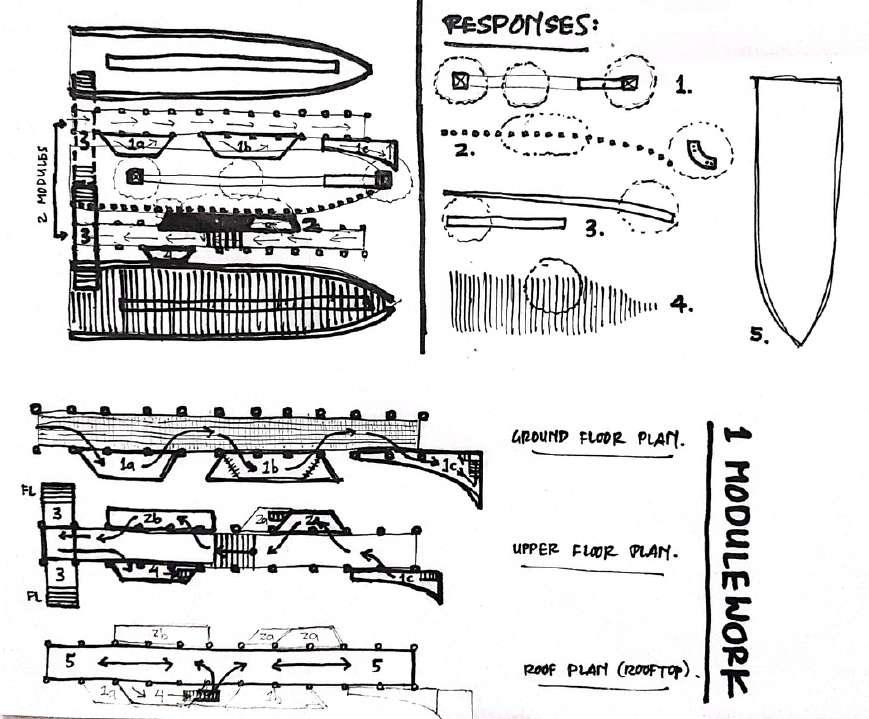

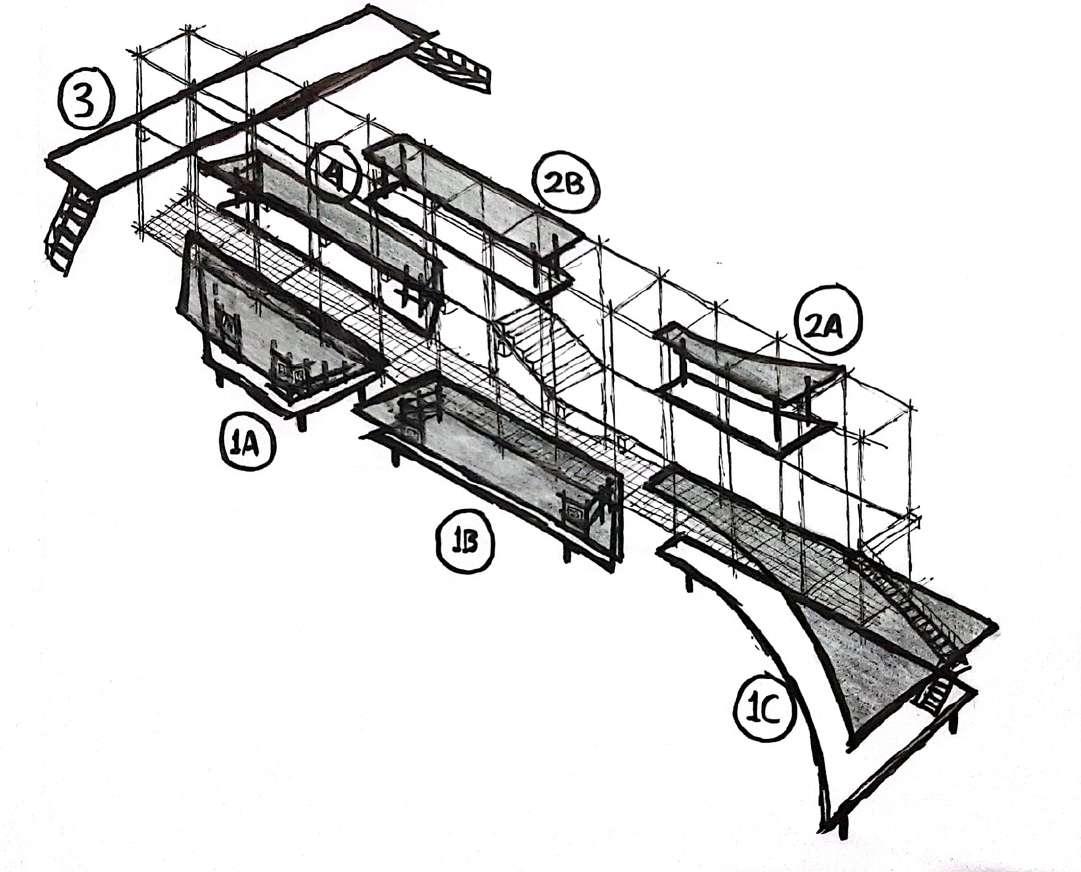

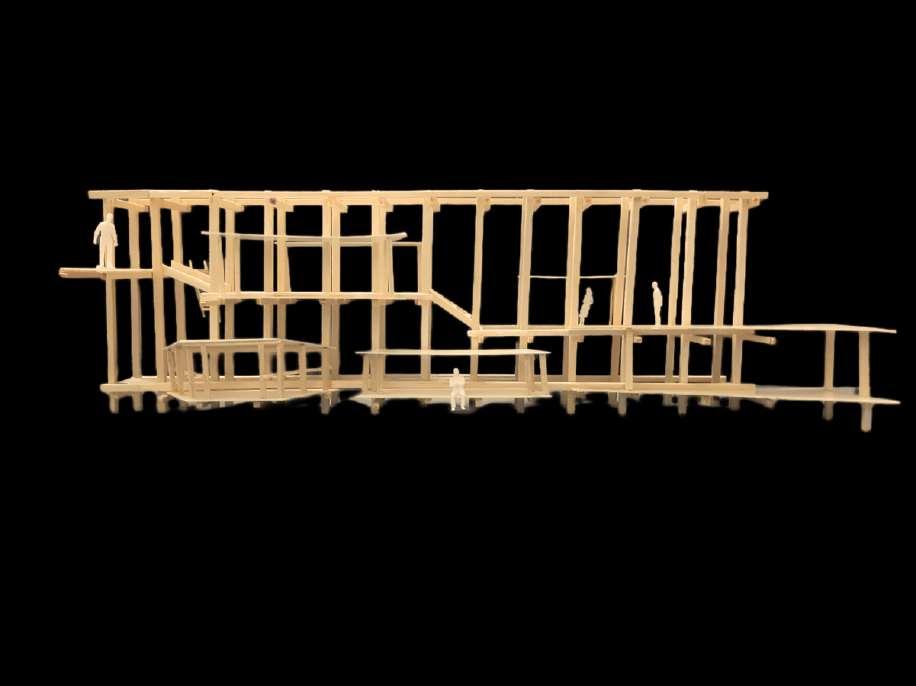

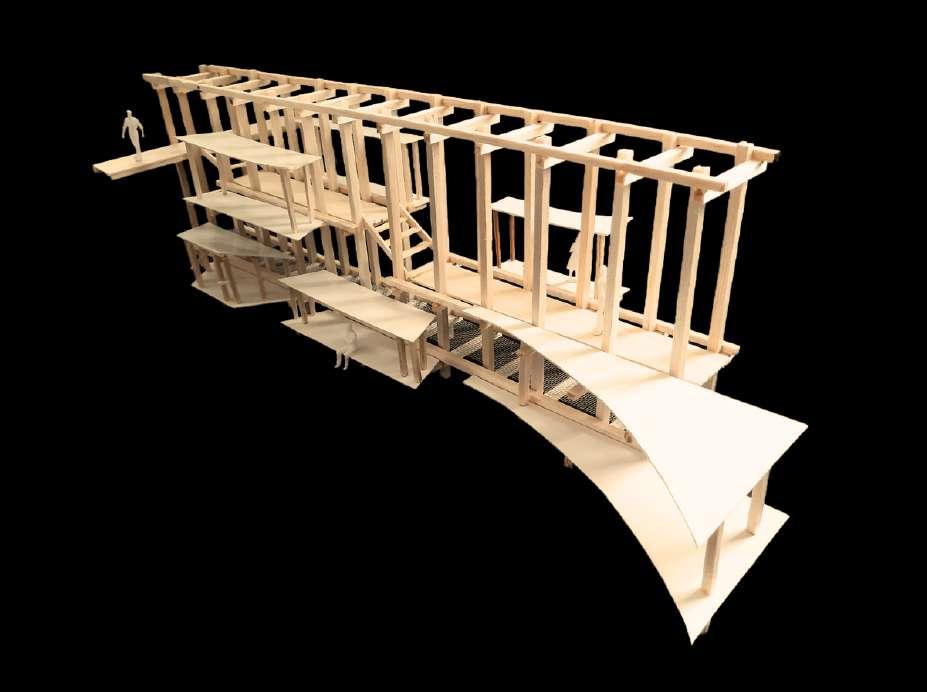

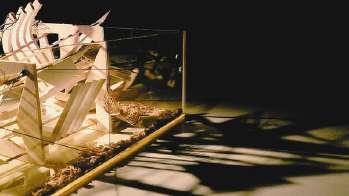

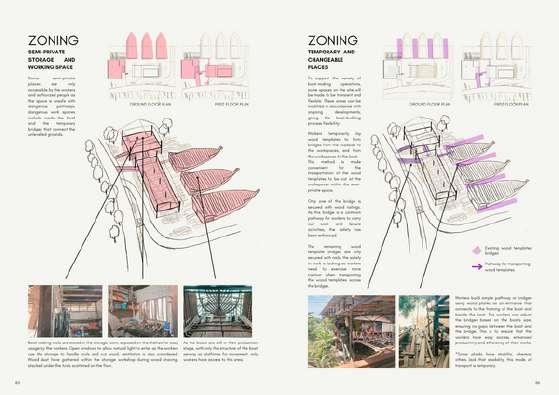

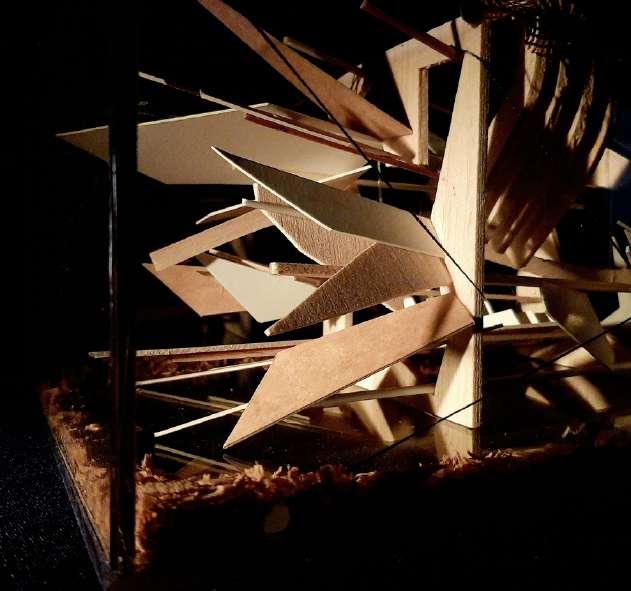

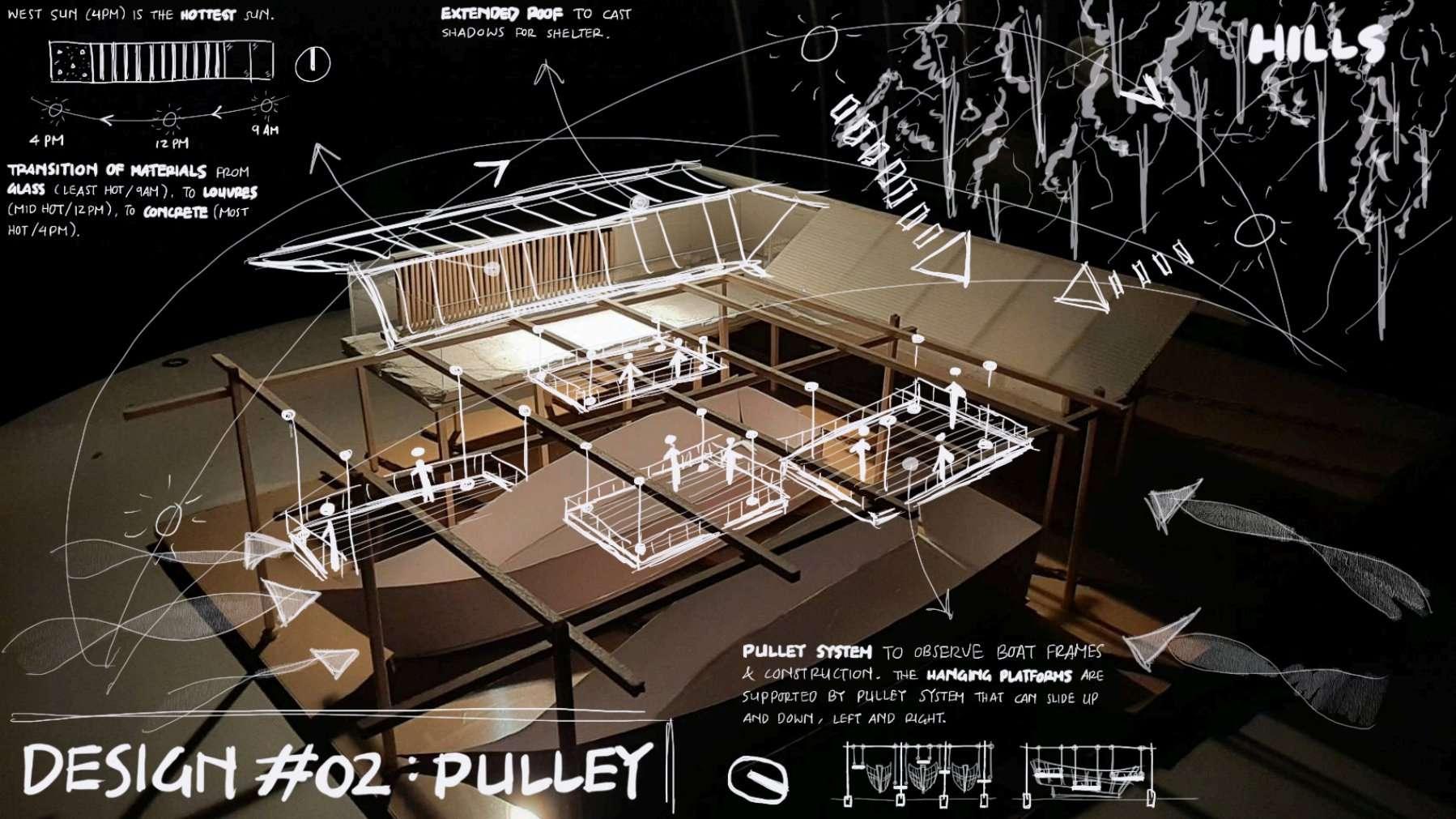

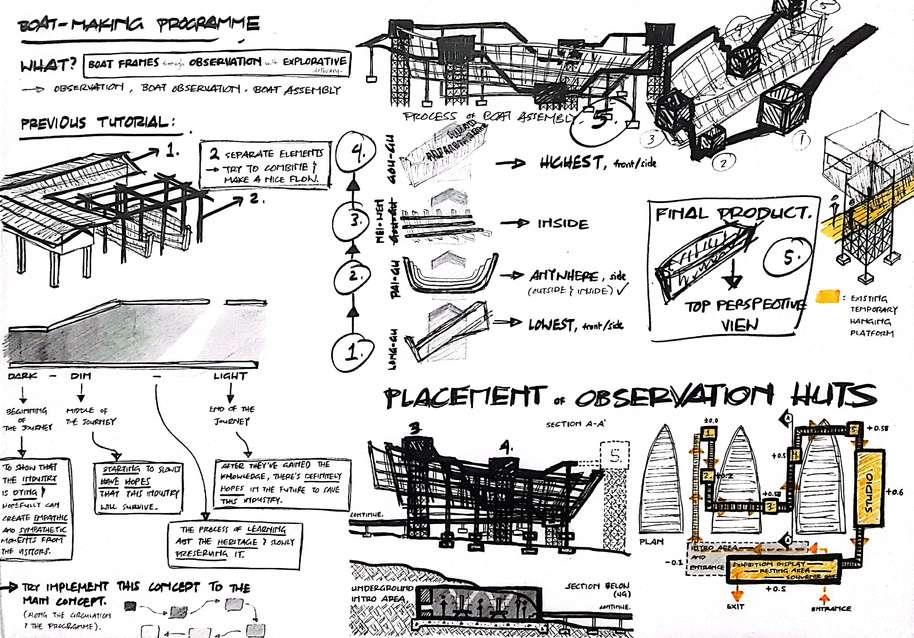

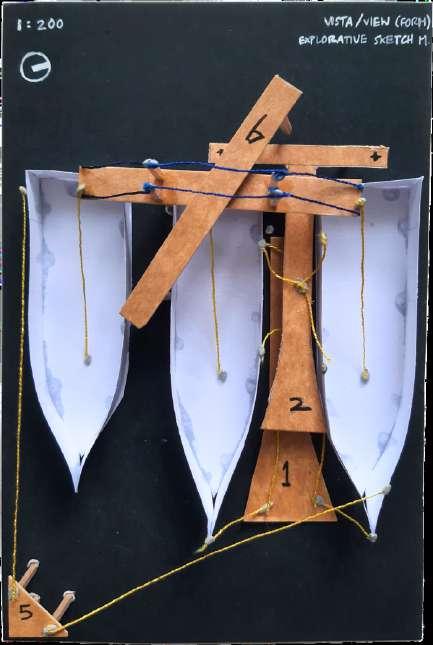

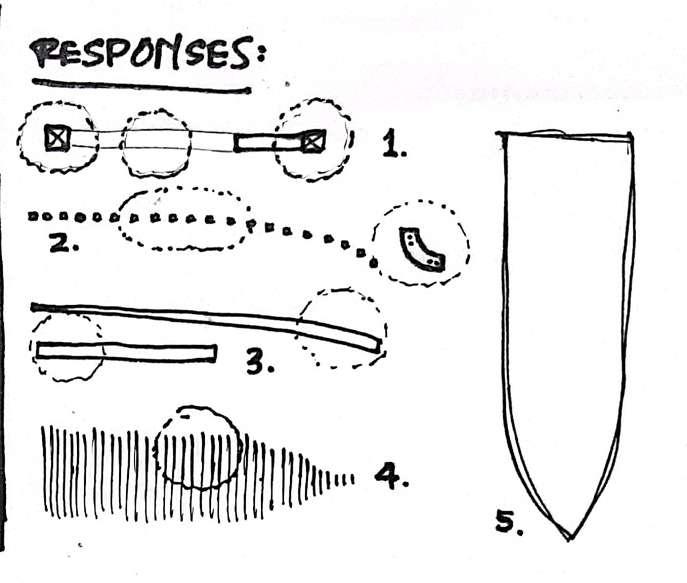

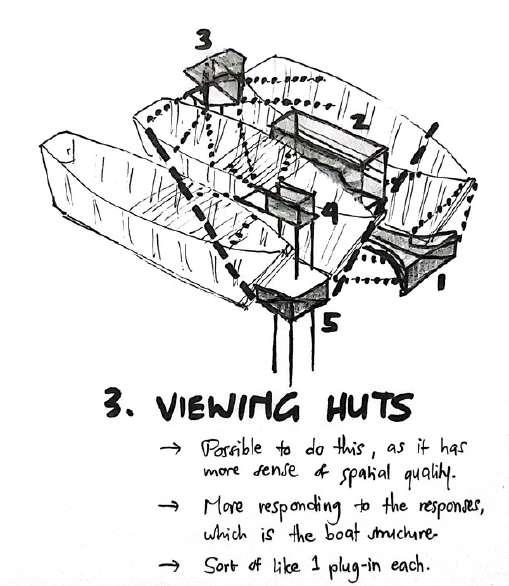

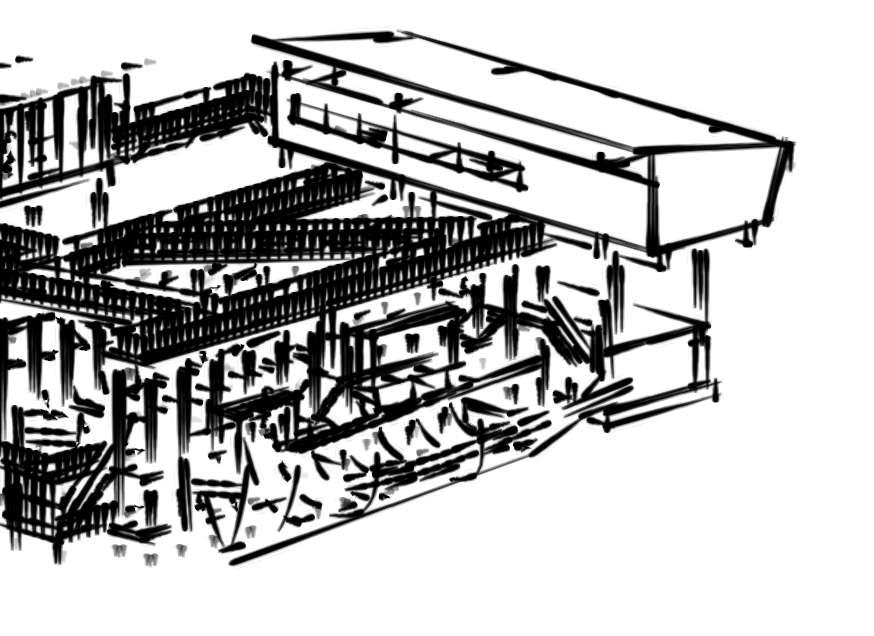

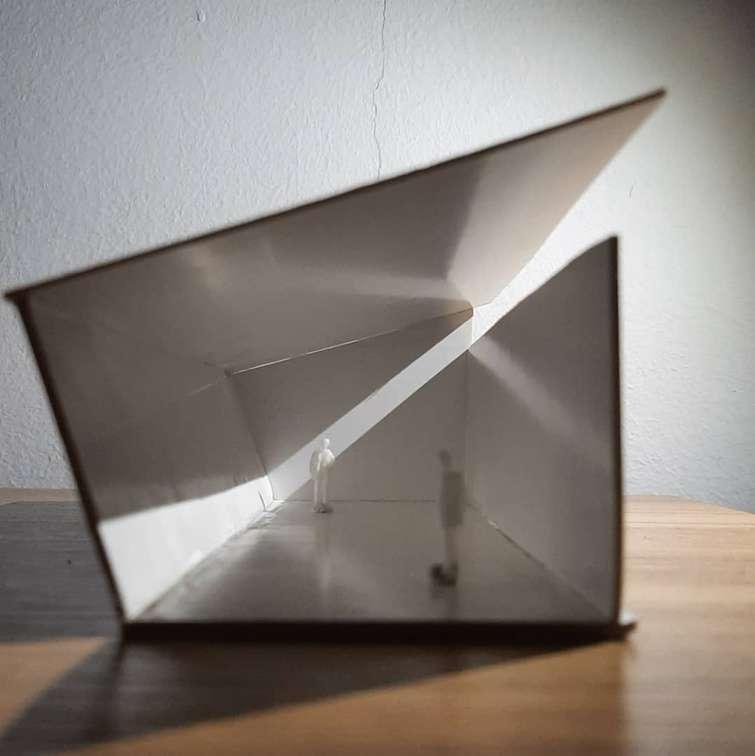

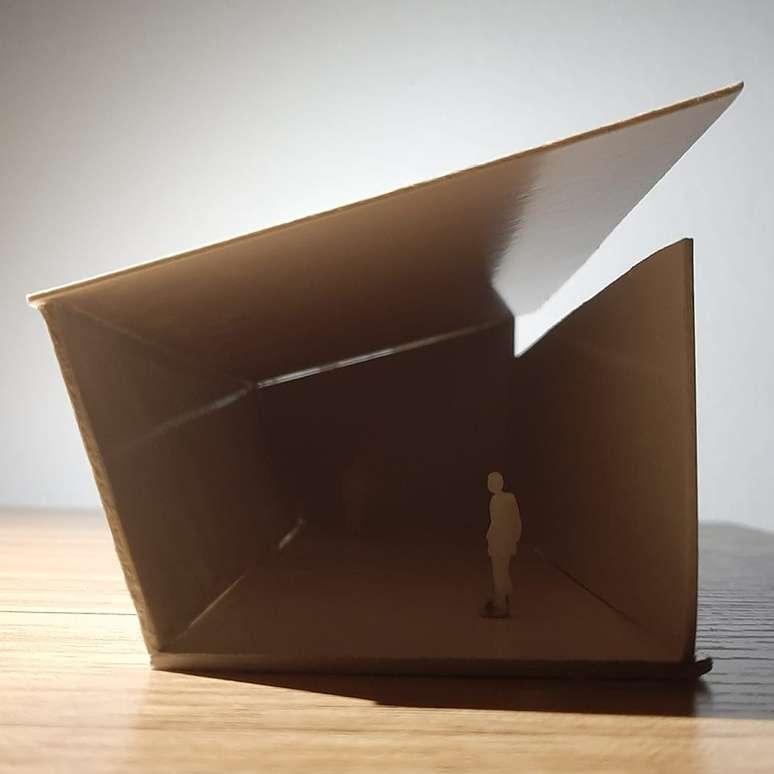

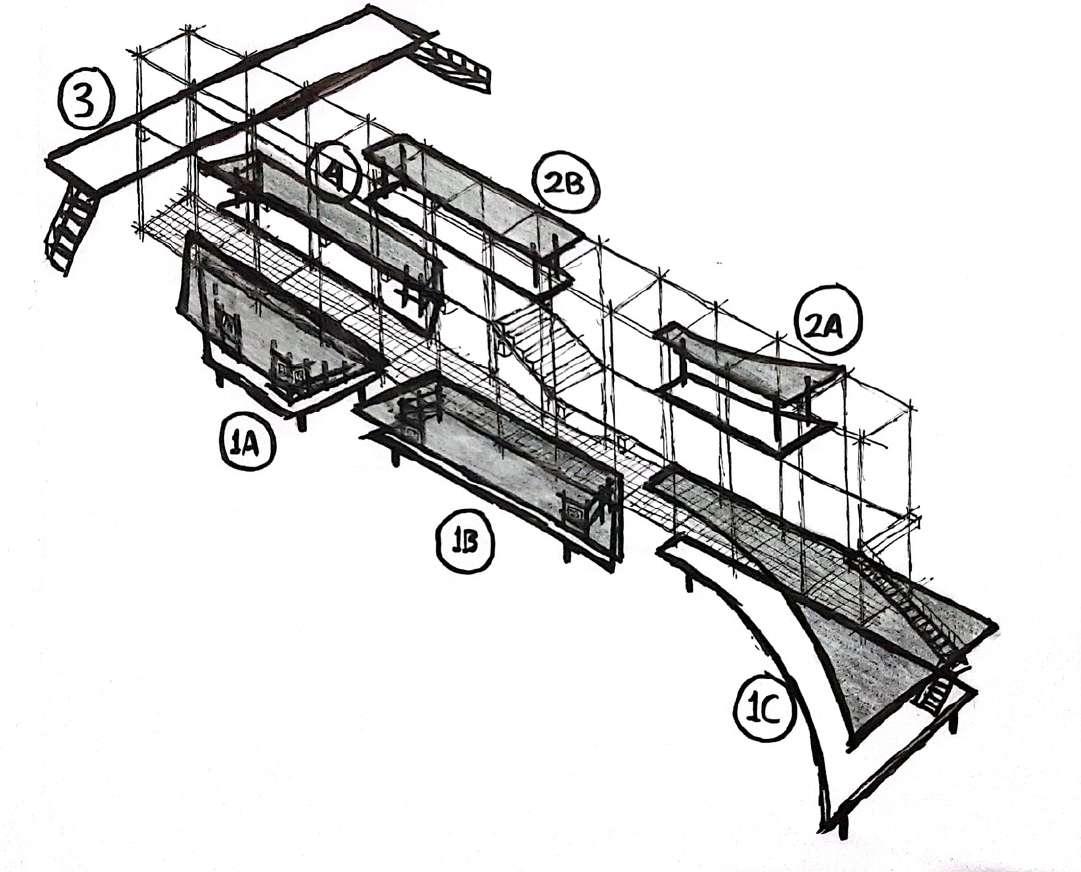

d e s i g n d e v e l o p m e n t w i t h e x p l o r a t i v e s k e t c h m o d e l

design development with explorative sketch model

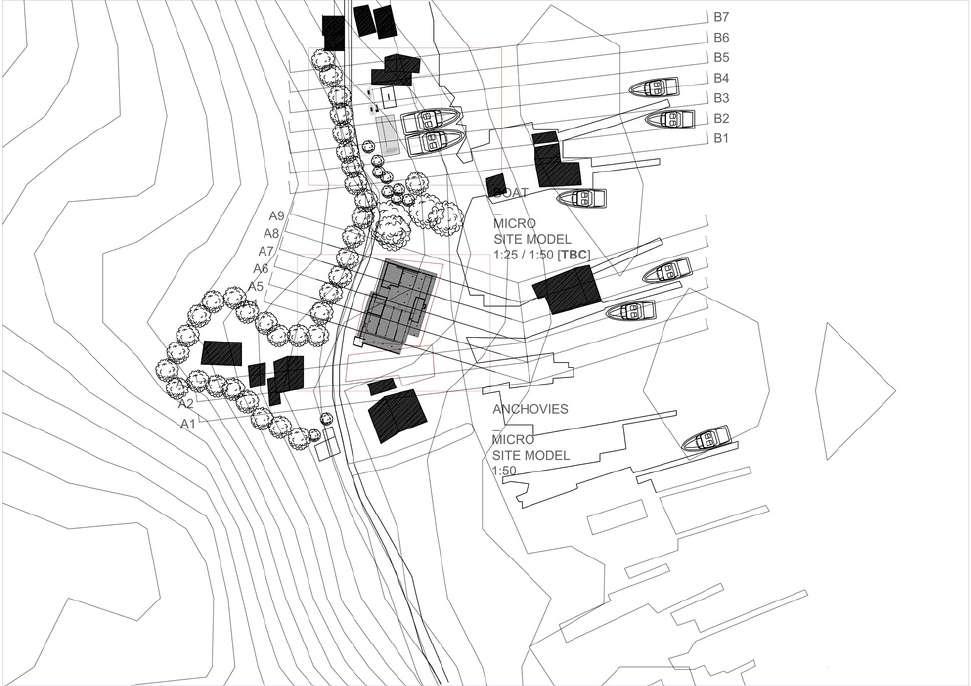

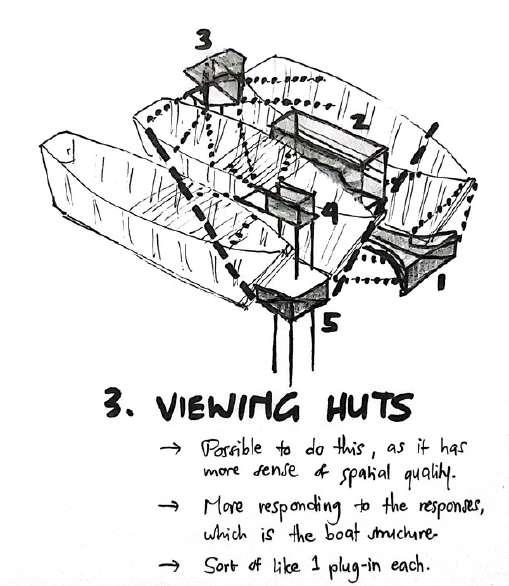

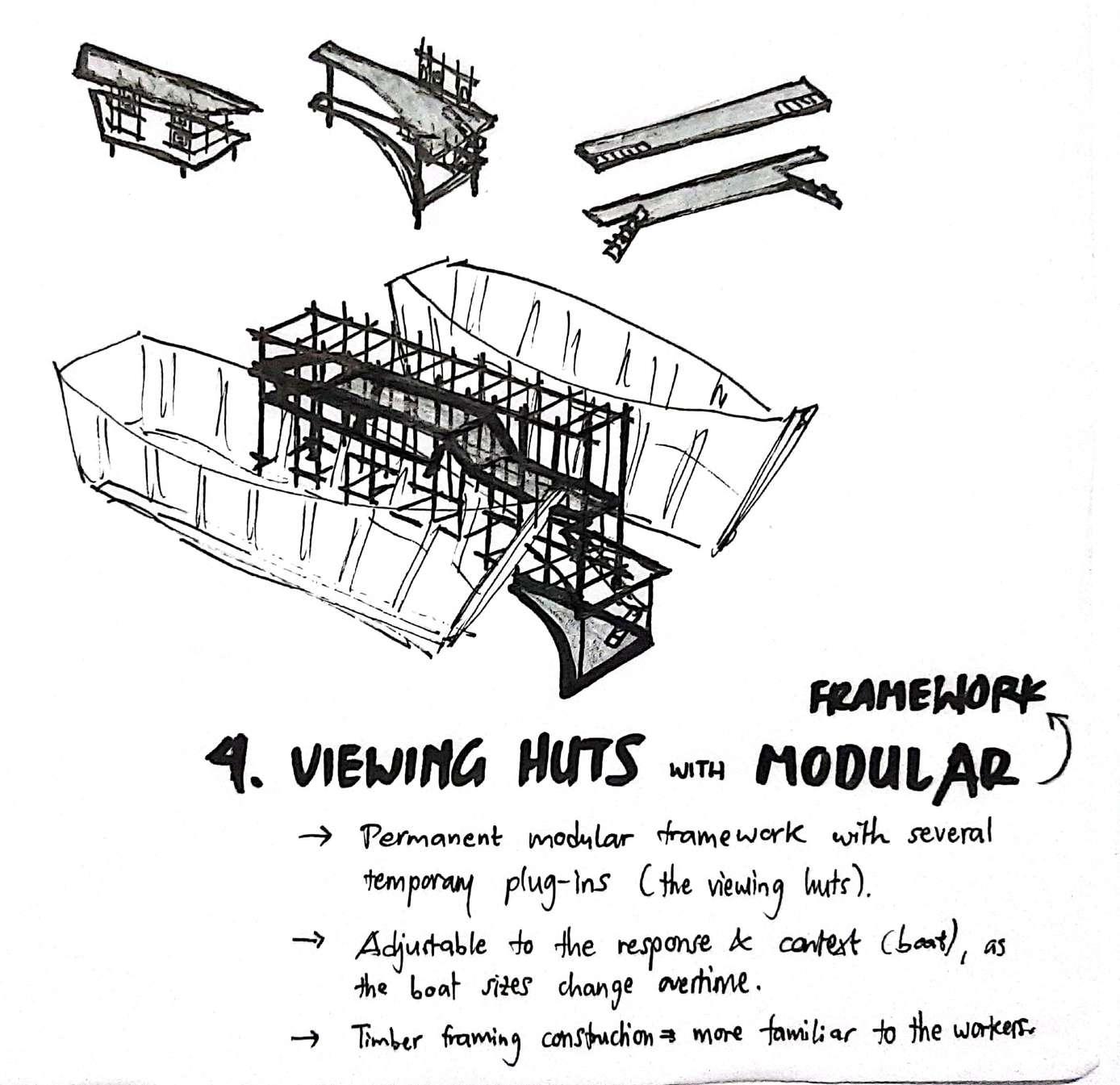

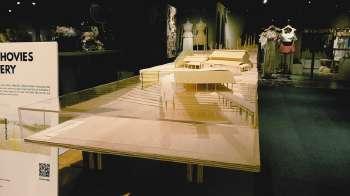

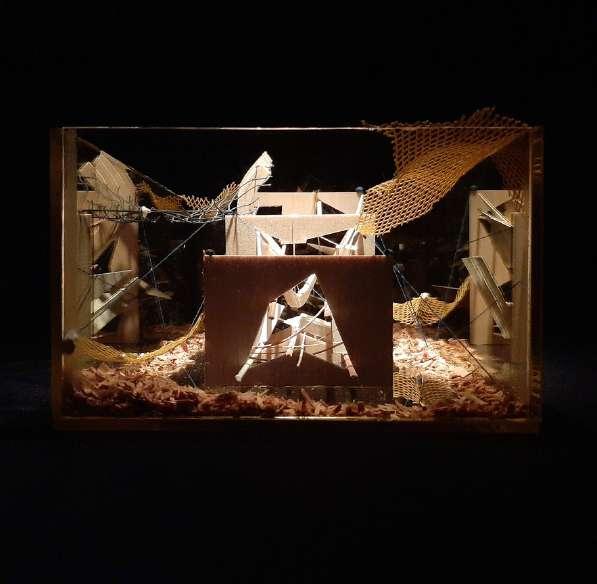

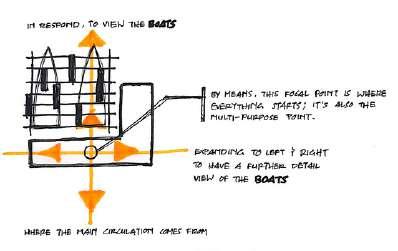

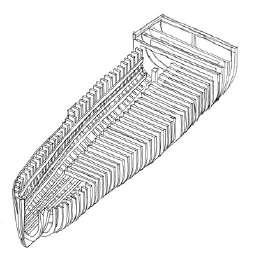

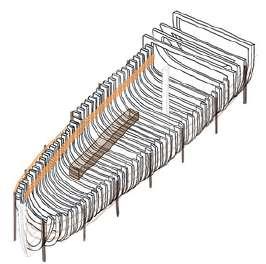

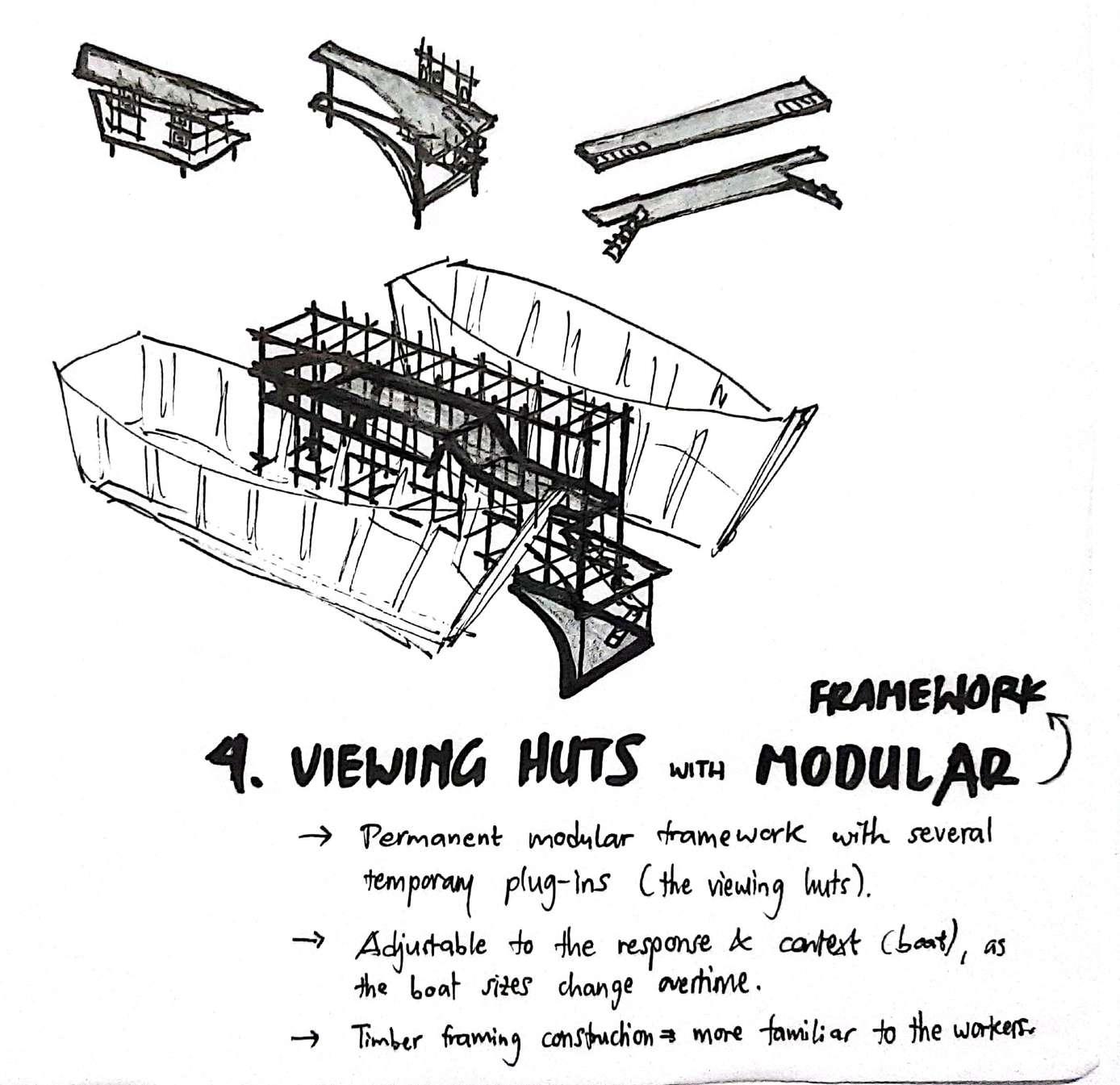

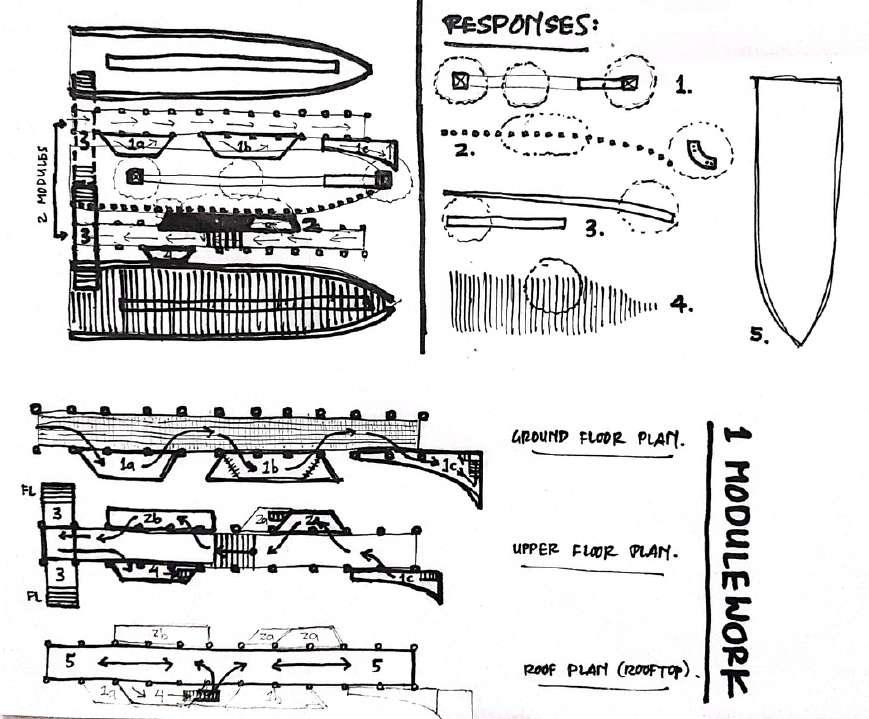

This paper model has a more defined form after the explorative sketch models It follows the function, which is to response (view) the boat structure according to the sequence of 1 2 3 4 5, hence the form is formed.

1 2

3 4 5

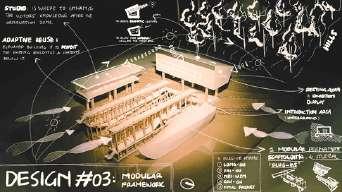

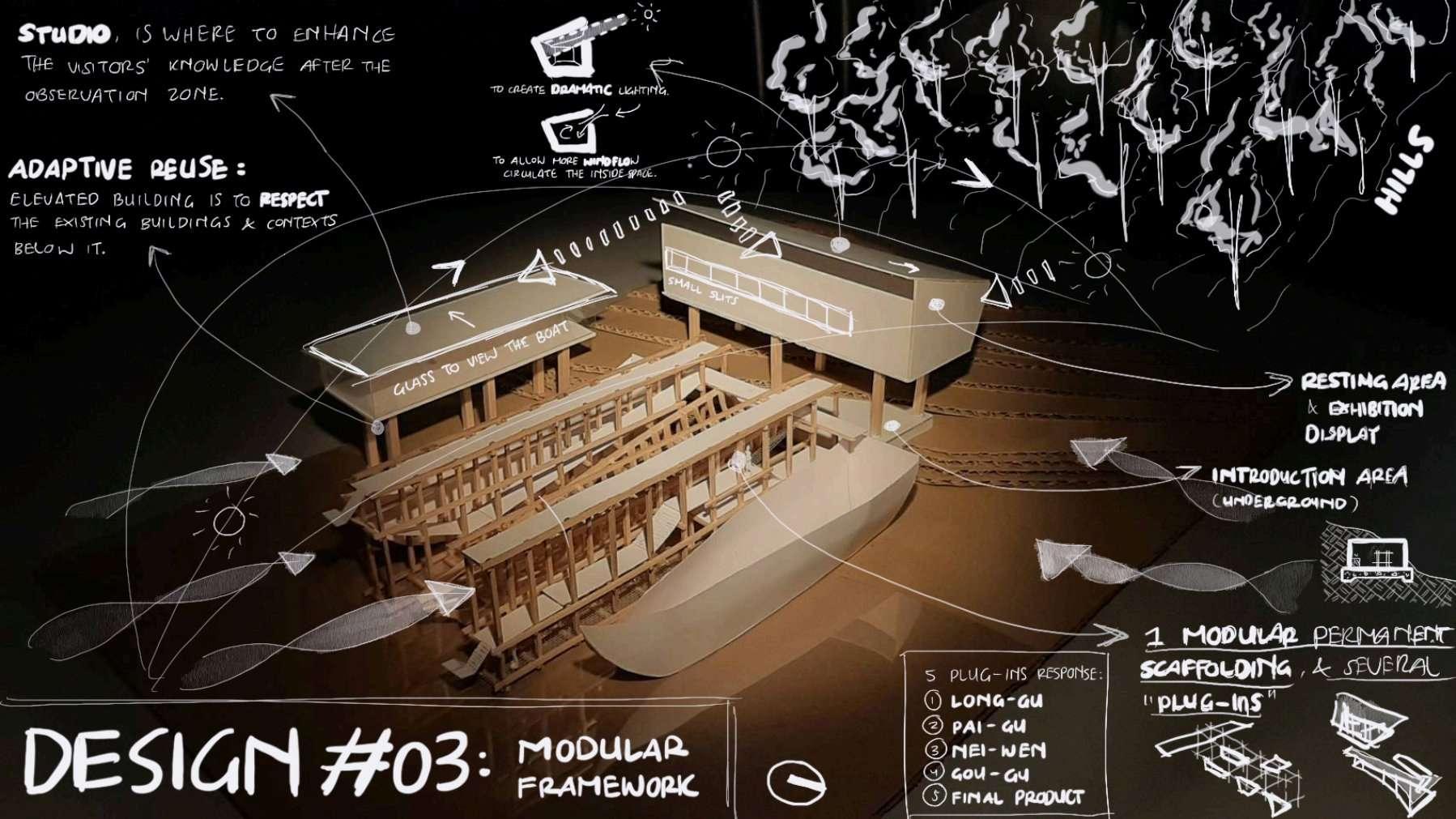

#03 D E S I G N

m e r a n g k a b o t , m e r a n g k a i l m u , m e r a n g k a m a s a h a d a p a n

in collaboration with Hoo Huat Boat Making Factory

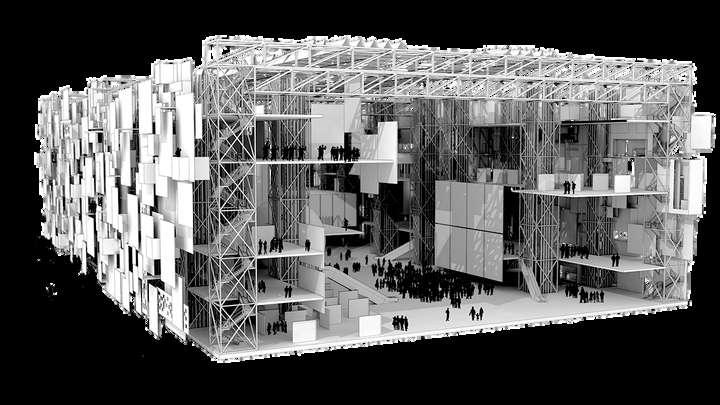

A living museum that exhibits a still-operating factory about traditional boat making, hoping that it can preserve this local heritage that has been passed down through generations.

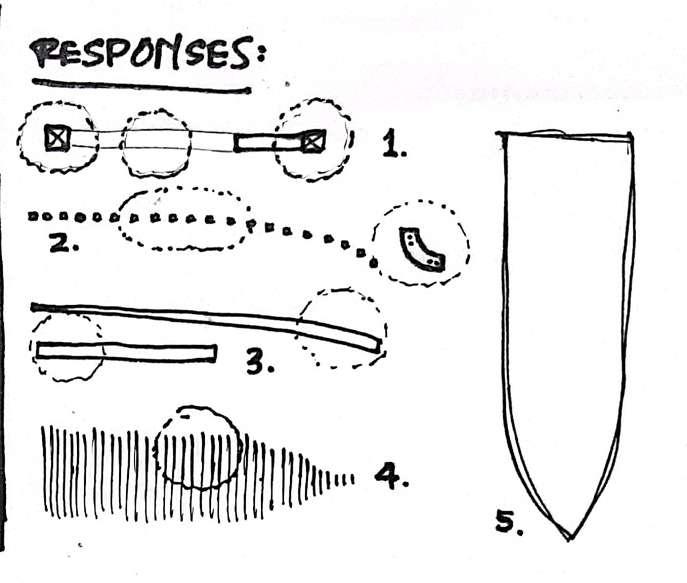

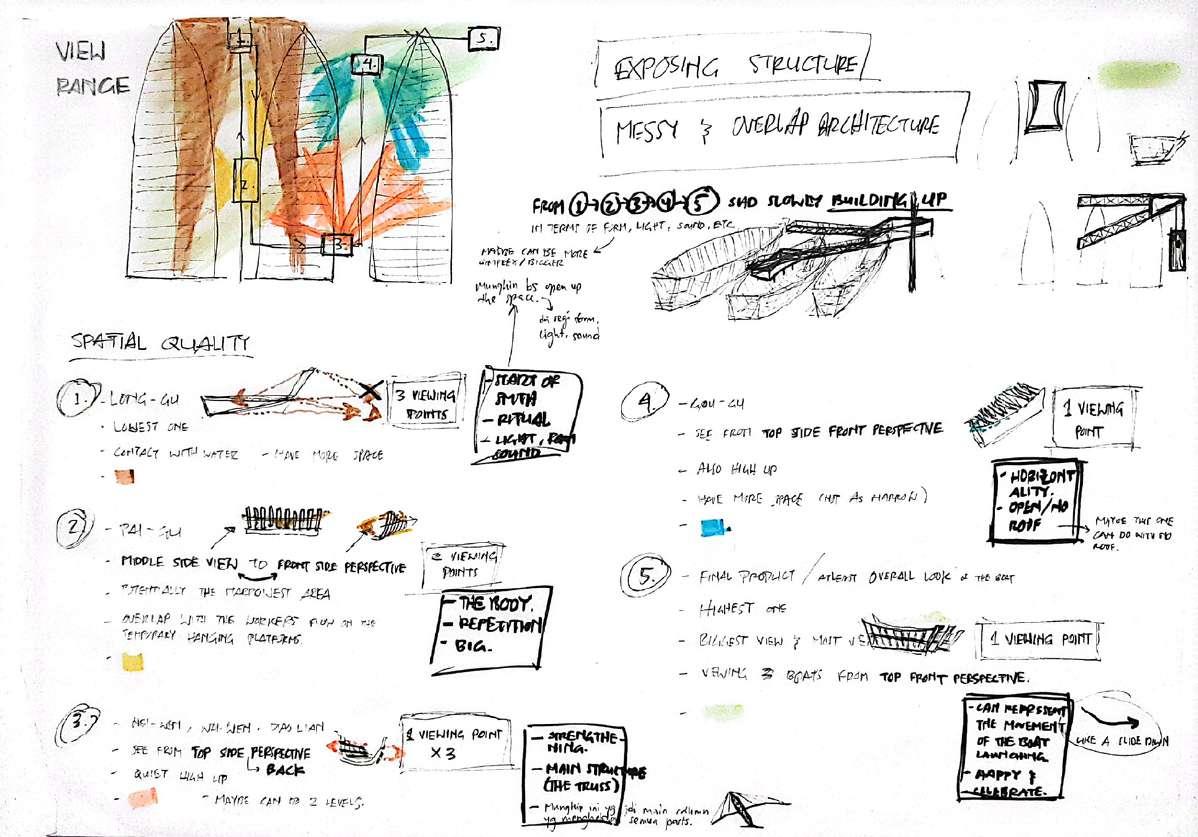

3 main keywords: BOAT FRAMES ASSEMBLY through OBSERVATION with EXPLORATIVE delivery

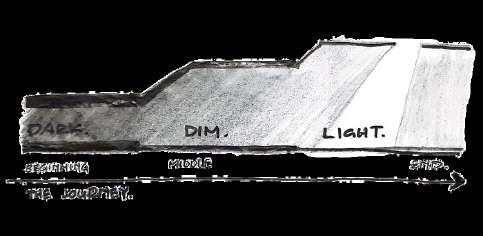

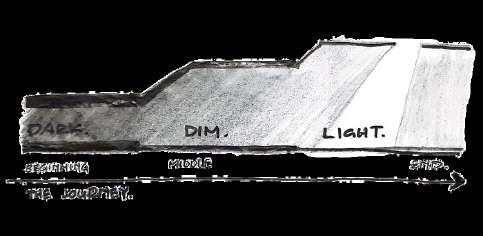

GENERAL NARRATIVE:

Dark: showing the sunset industry, hop ng to de iver a sympathetic & emphatic moment for the visitors

Dim: start to find some hopes for this dying trade, it’s a process in achiev ng that hopes, through the actions

Light: hopes have been gained; a bright future for this industry that it will keep on going for onger time

“RANGKA”

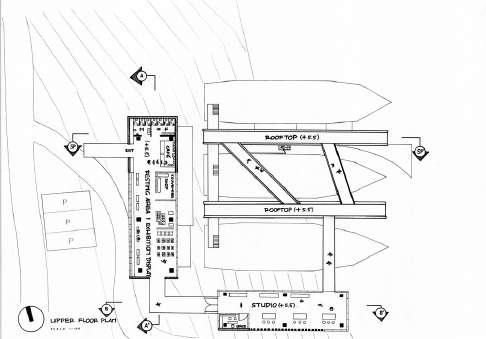

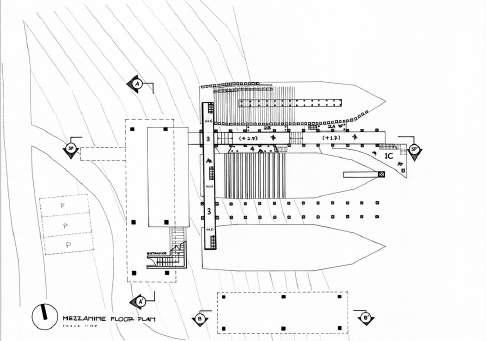

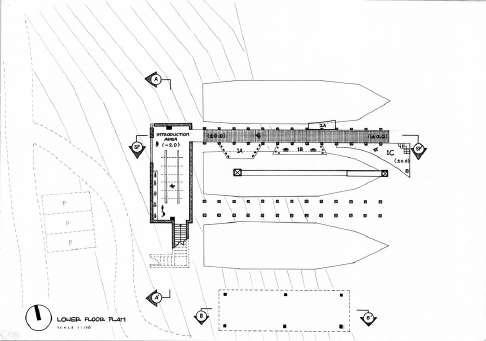

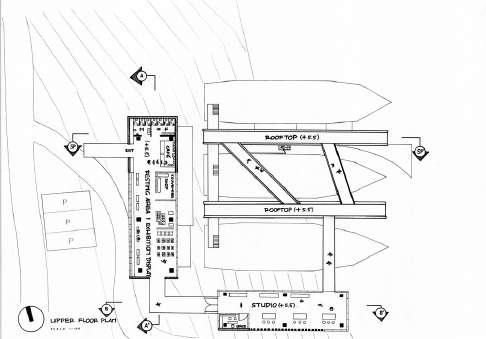

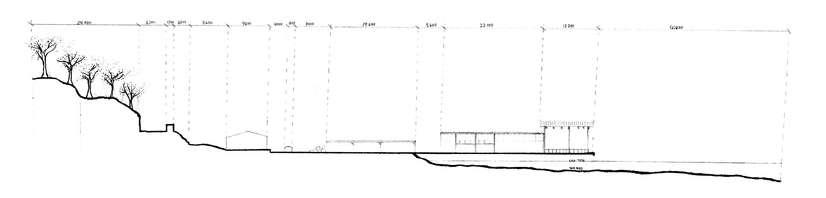

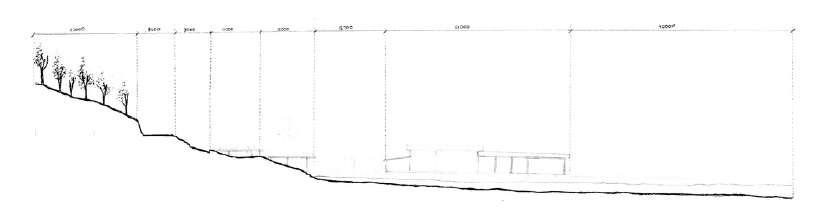

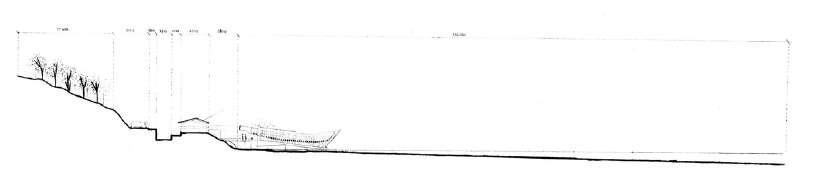

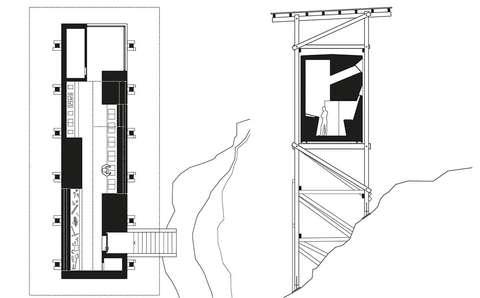

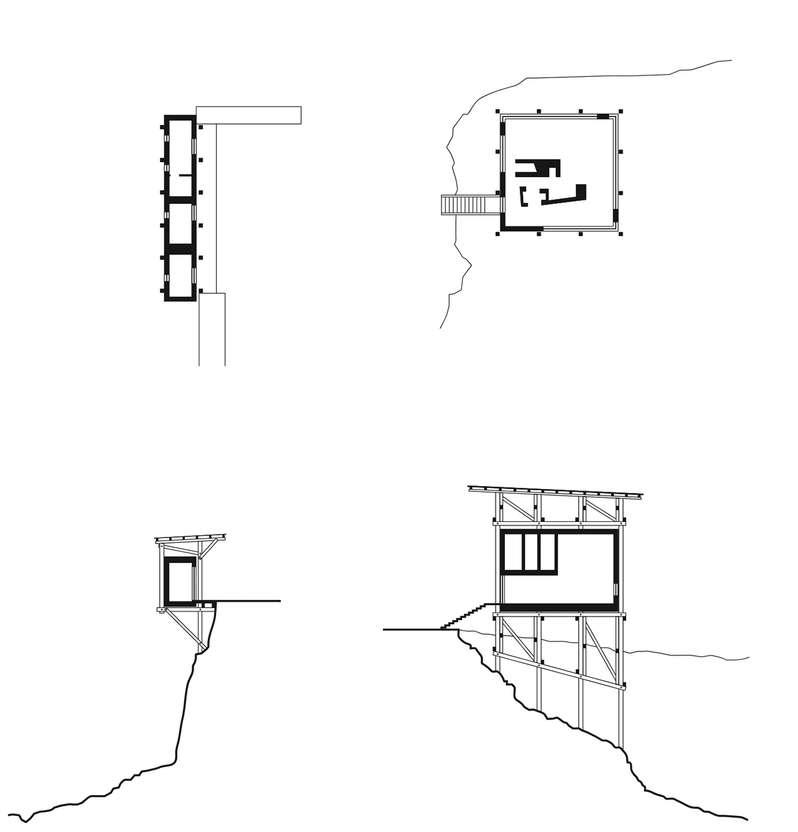

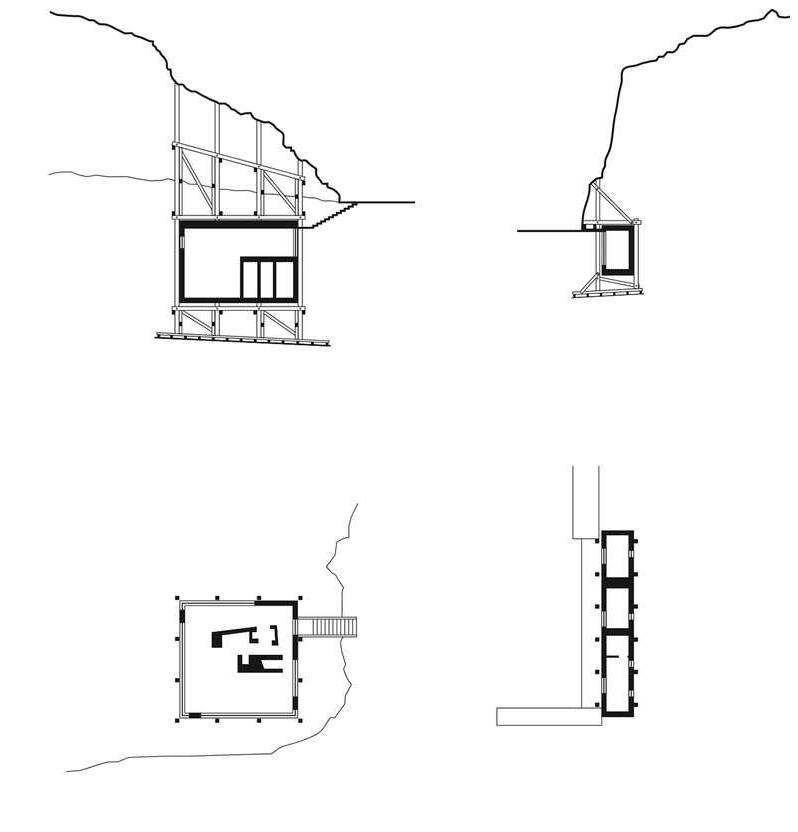

D E S I G N D E V E L O P M E N T

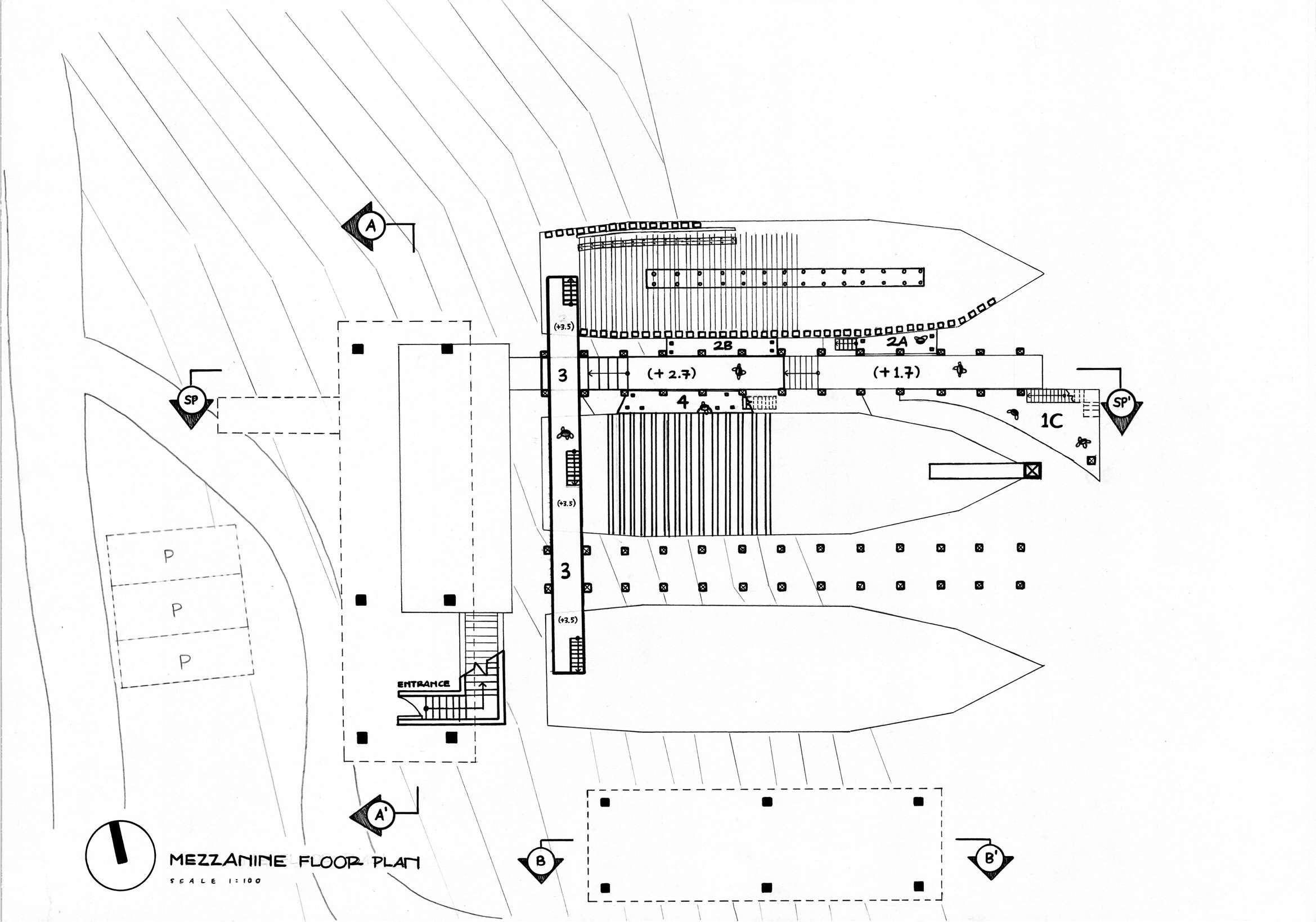

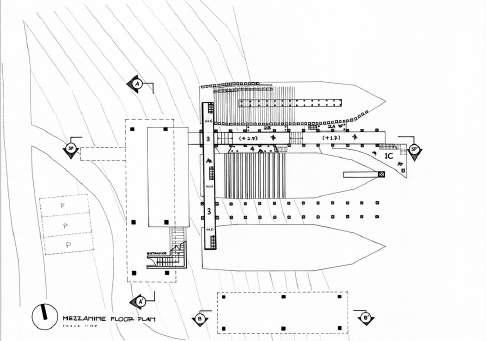

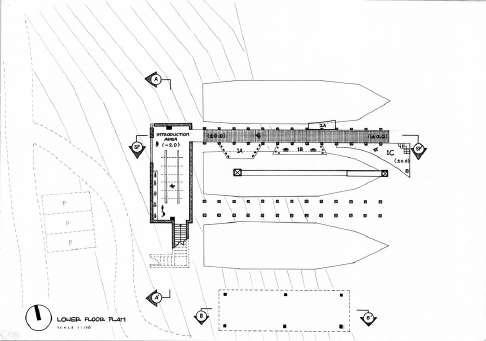

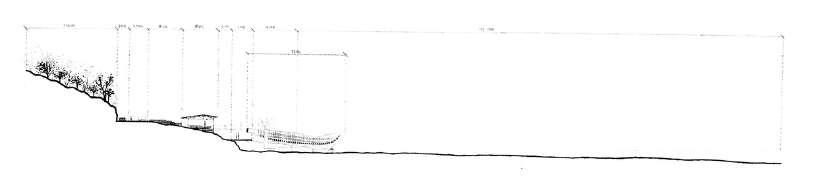

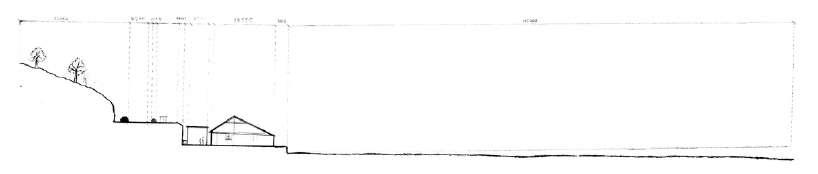

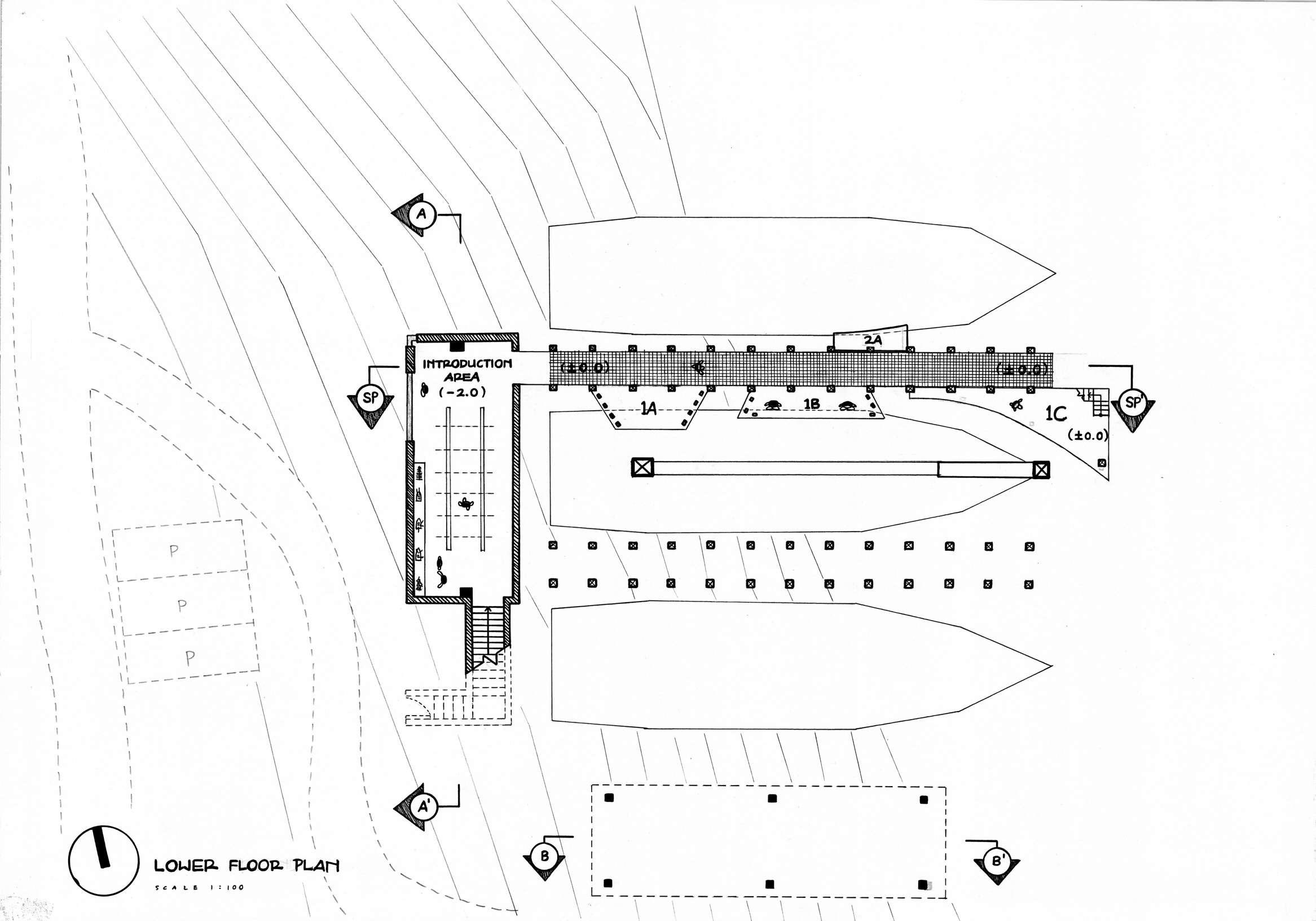

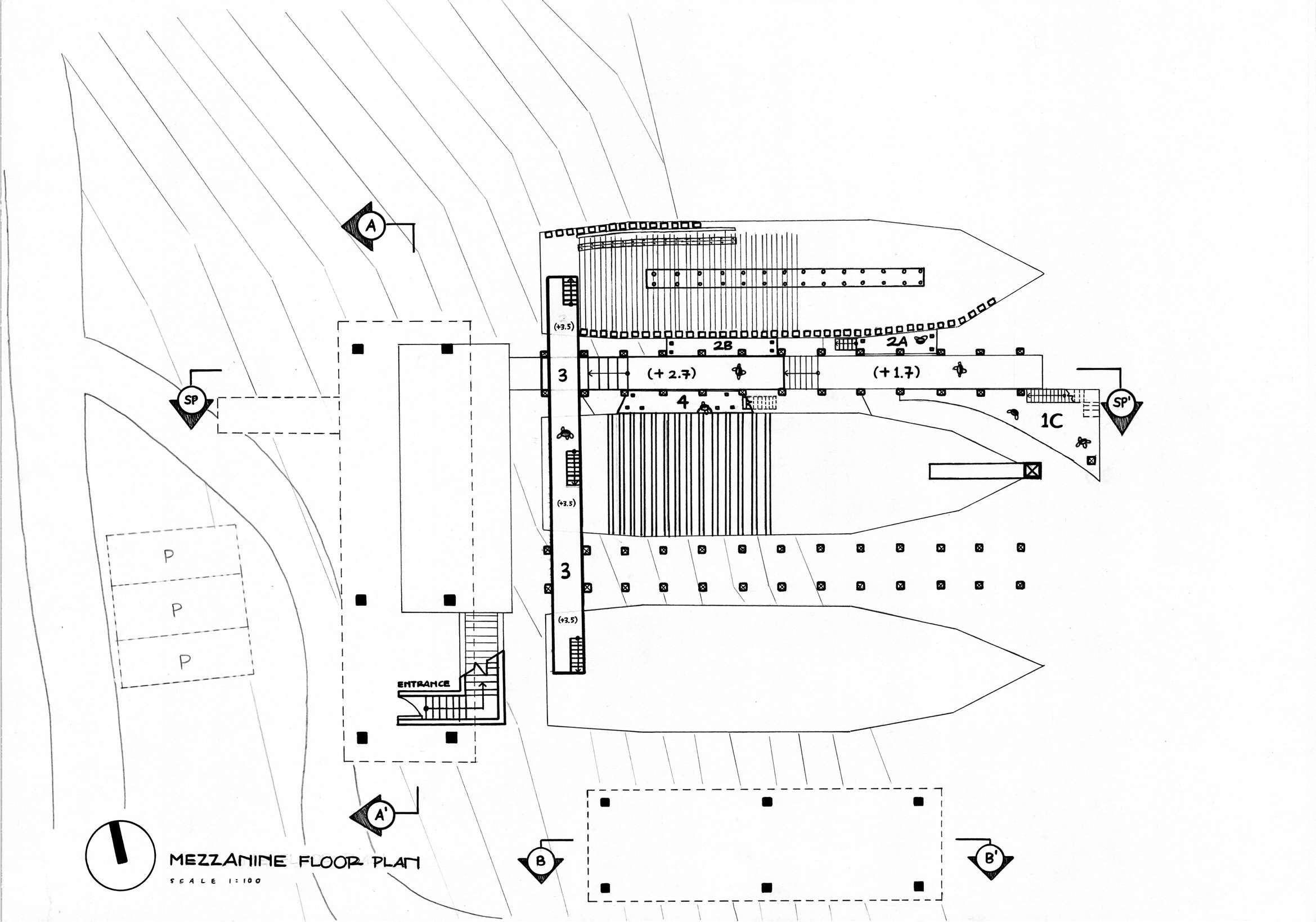

S C A L E 1 1 0 0 @ A 2

S C A L E 1 : 1 0 0 @ A 2

S C A L E 1 : 1 0 0 @ A 2

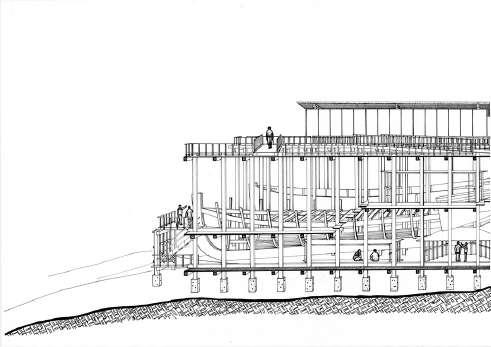

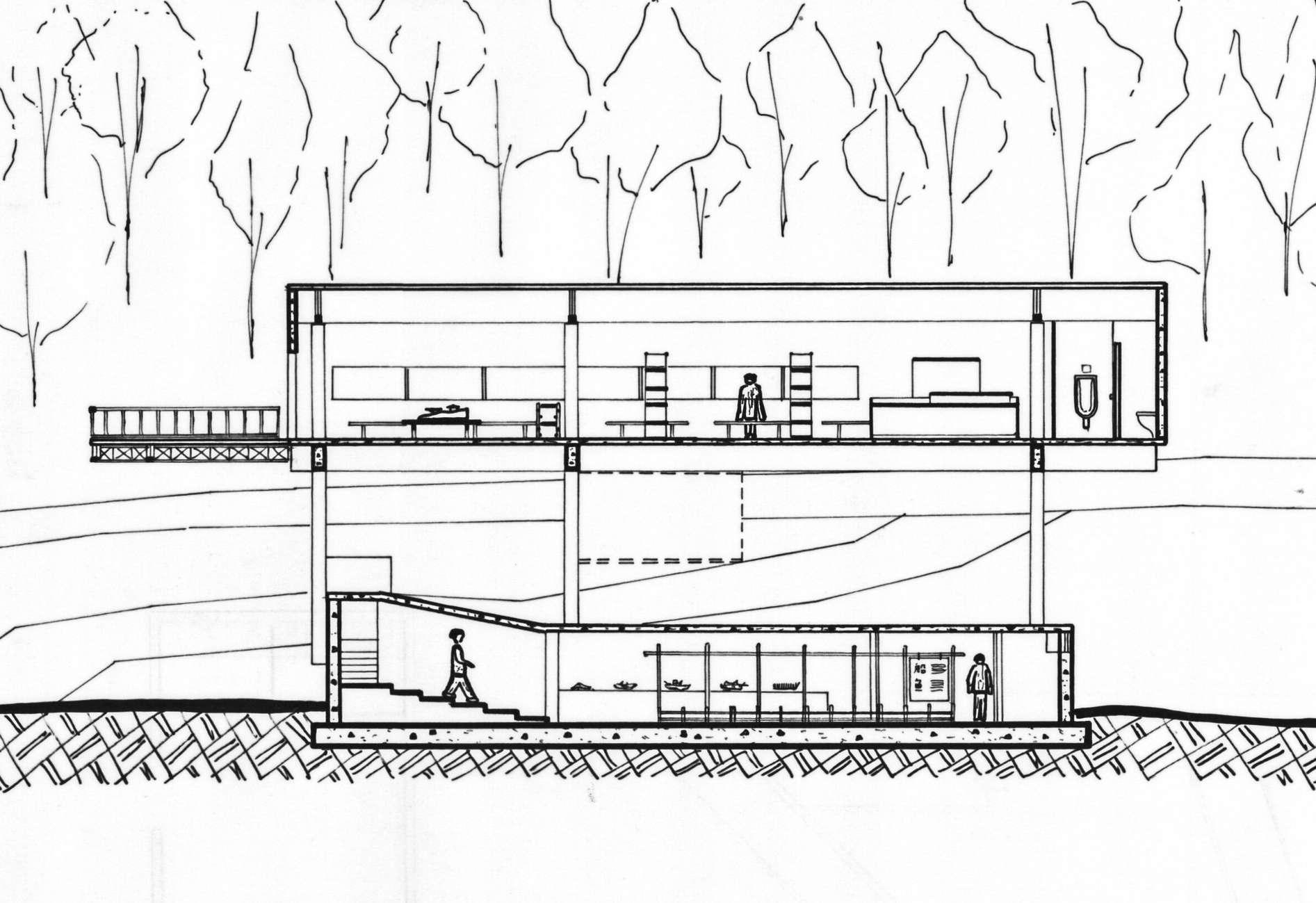

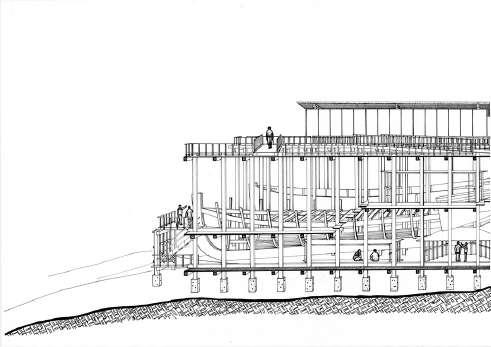

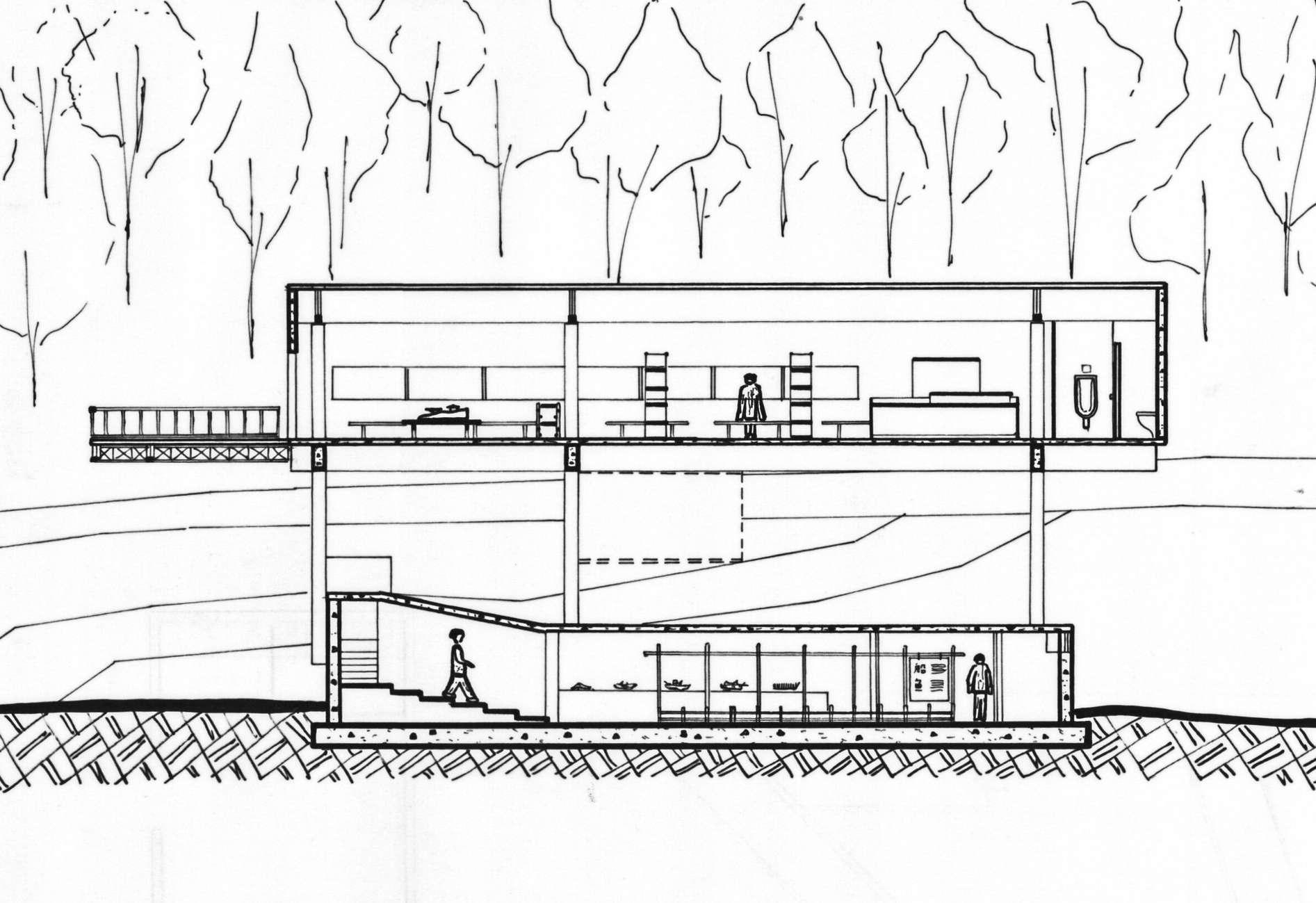

SECTIONA-A’ S C A L E 1 : 5 0 @ A 2

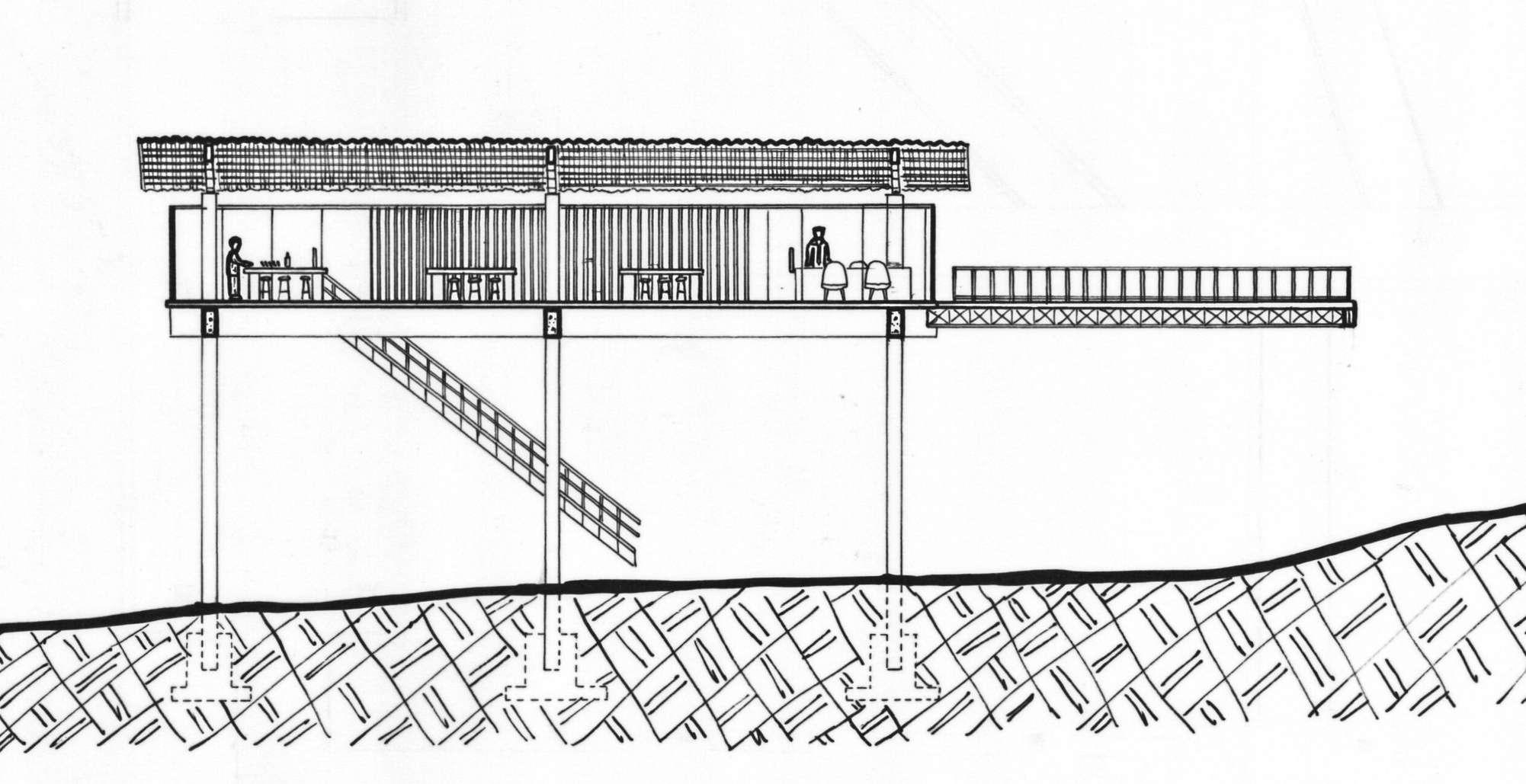

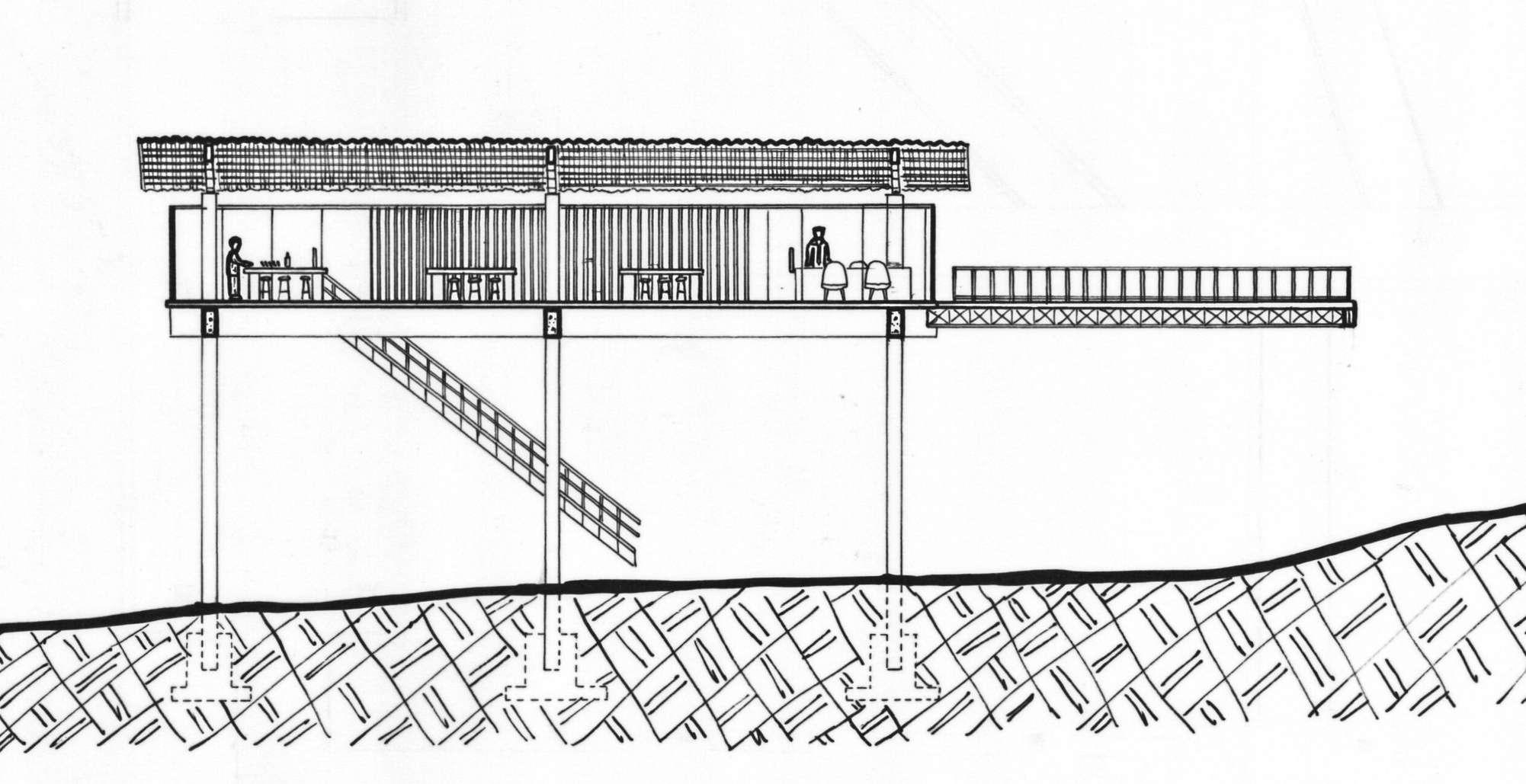

SECTION B-B’ S C A L E 1 : 5 0 @ A 2

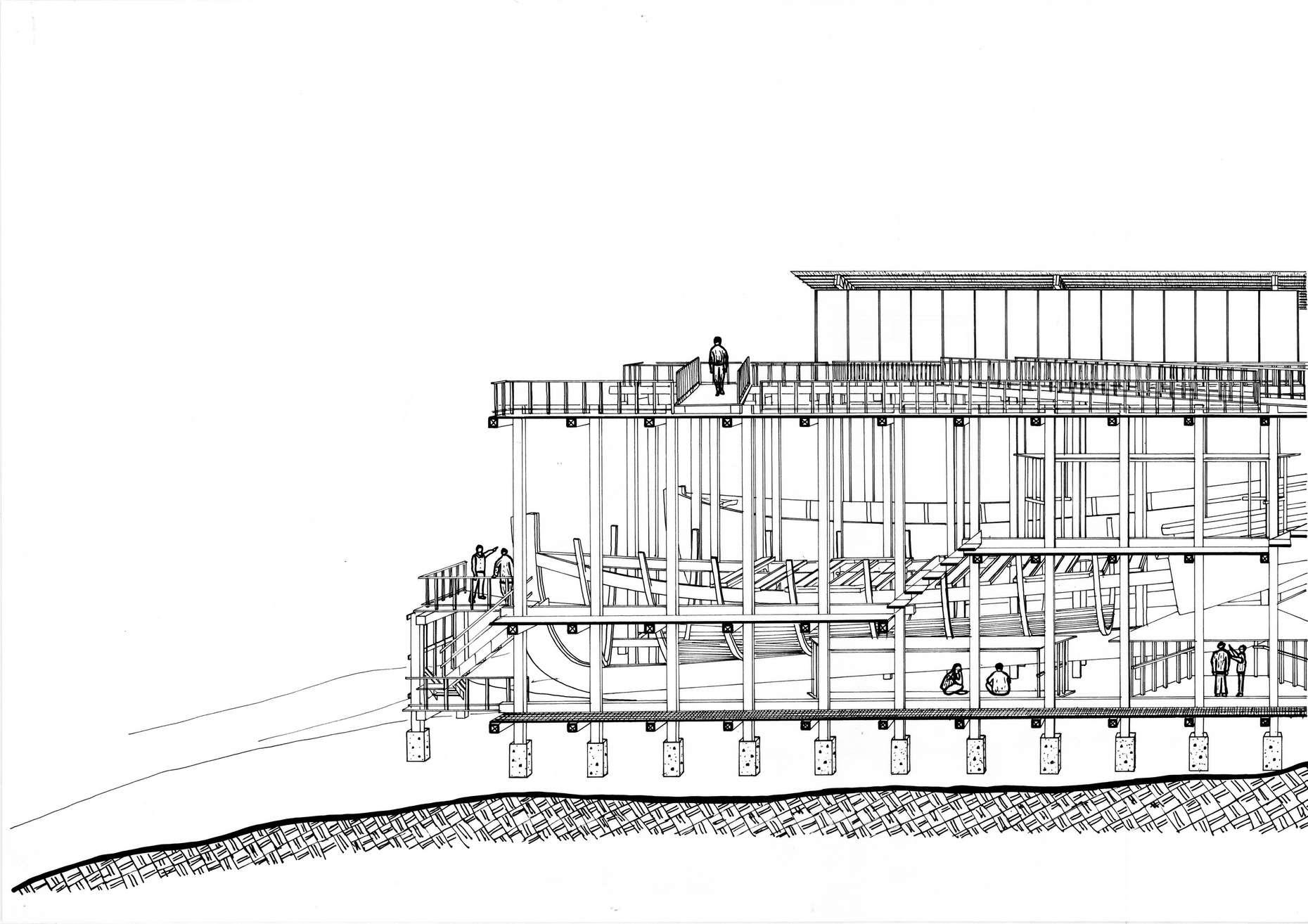

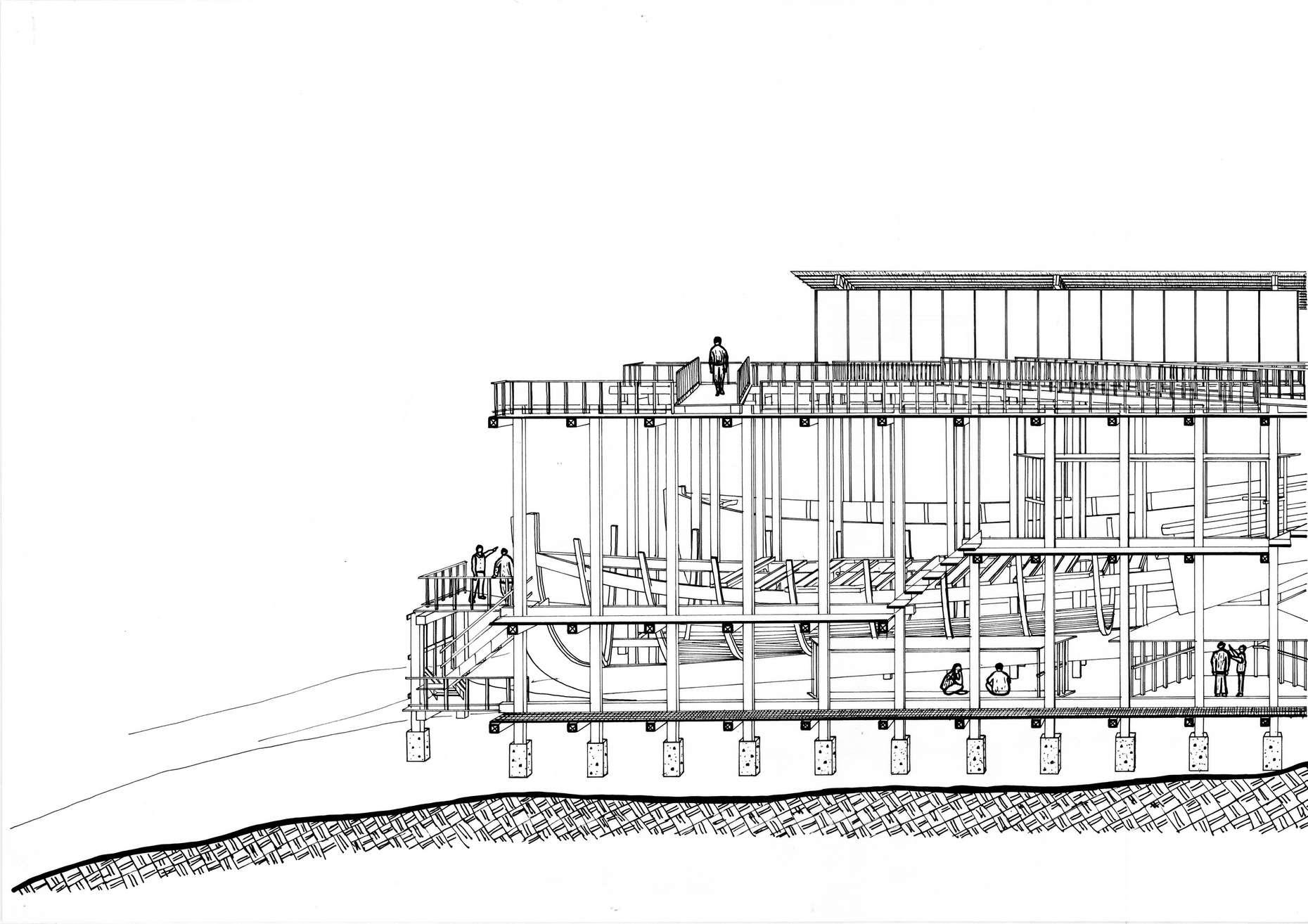

SECTIONAL PERSPECTIVE S C A L E 1 5 0 @ A 0

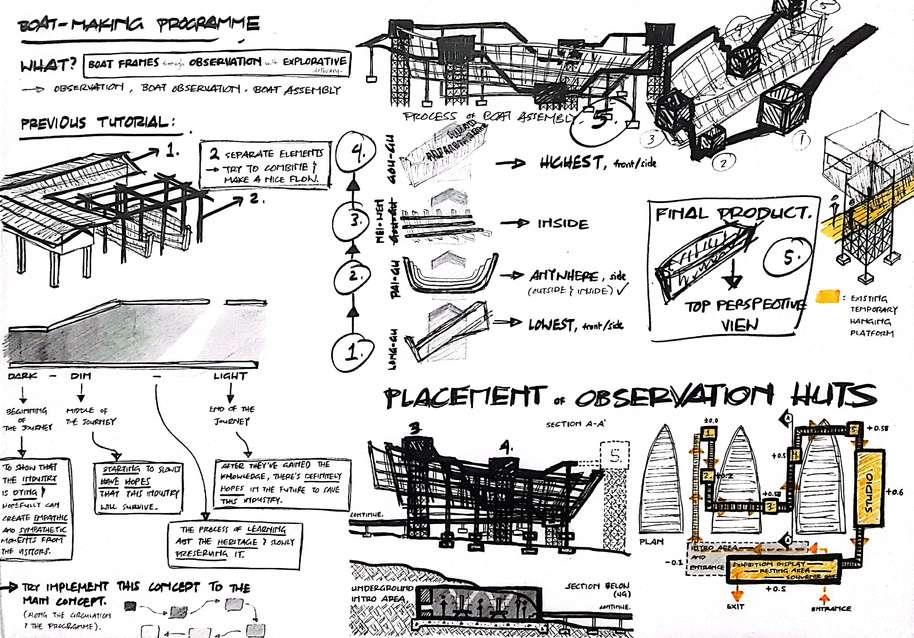

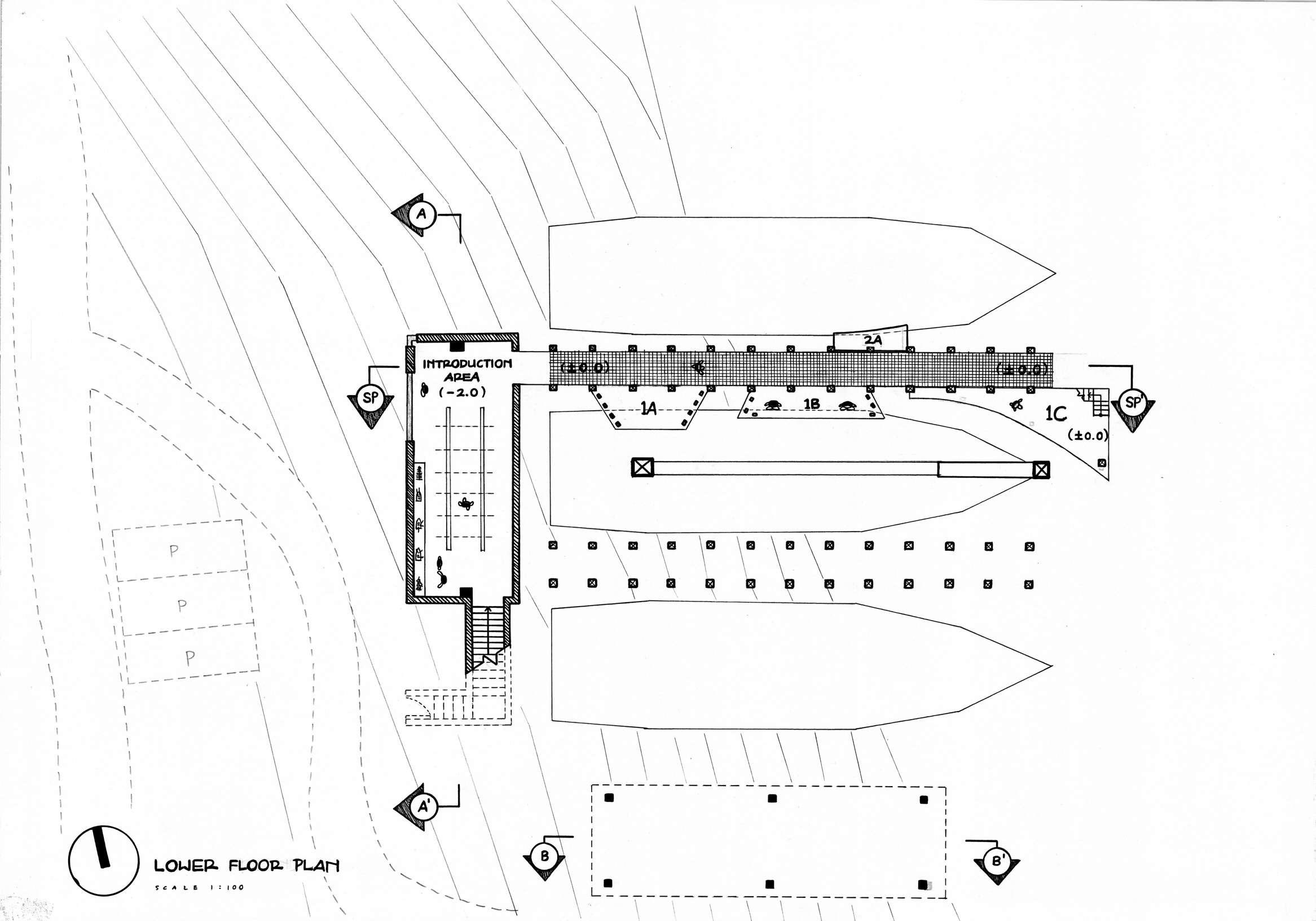

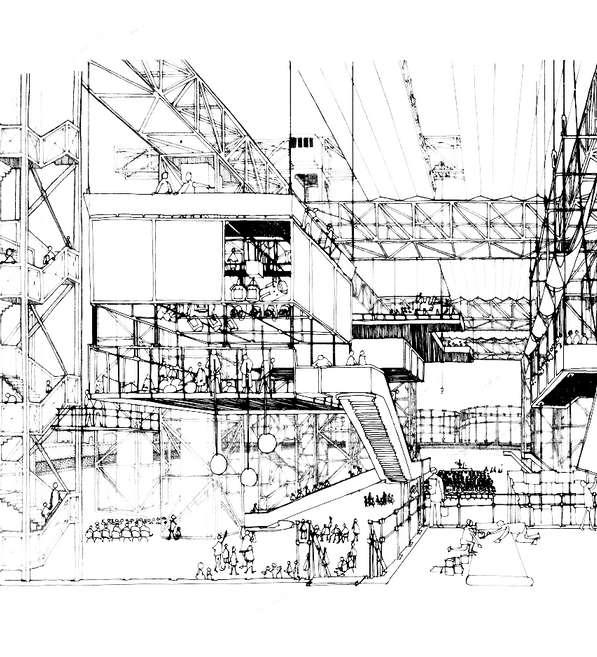

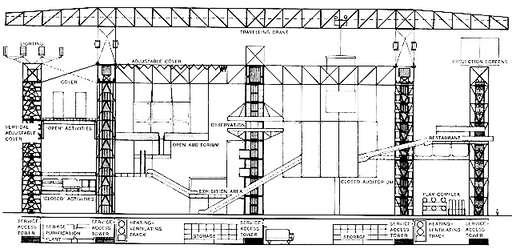

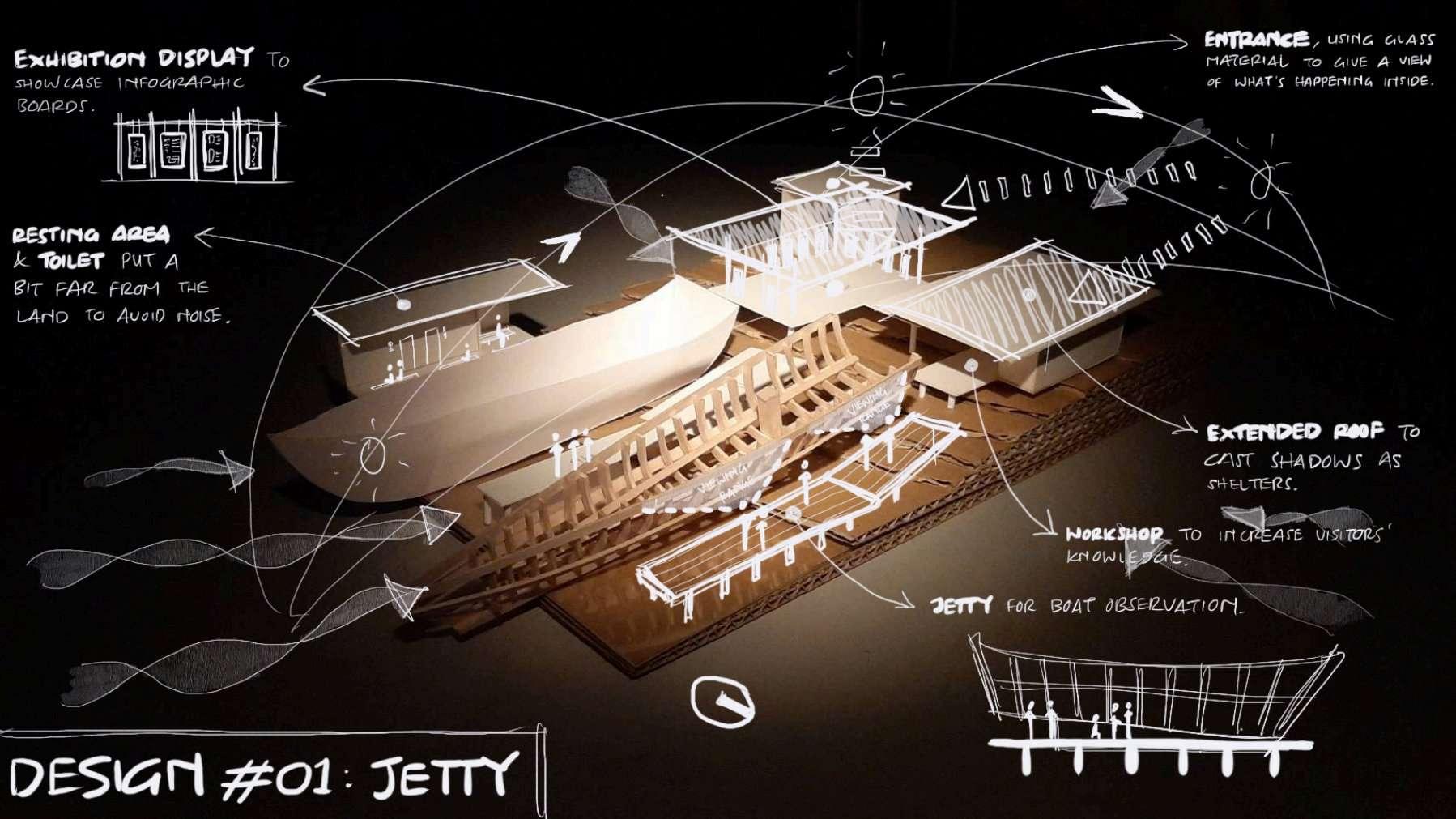

1 ENTRANCE

The entrance doesn’t look and feel like an entrance. It’s ust a sta rcase that going down and leads the v sitors to the introduction area.

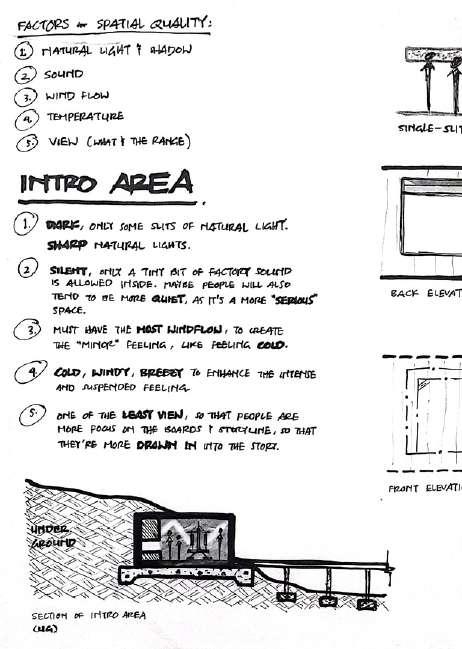

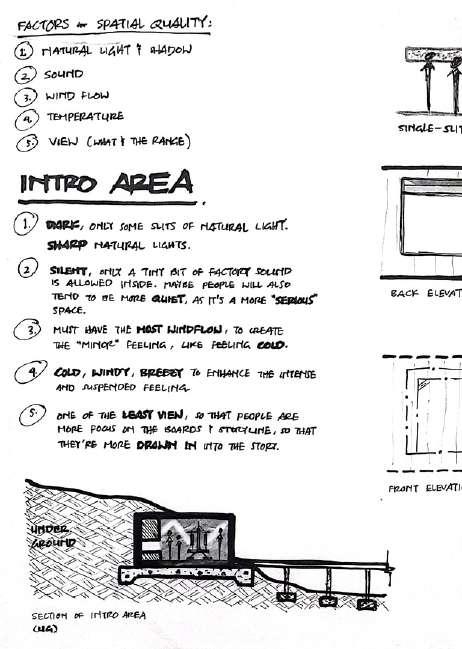

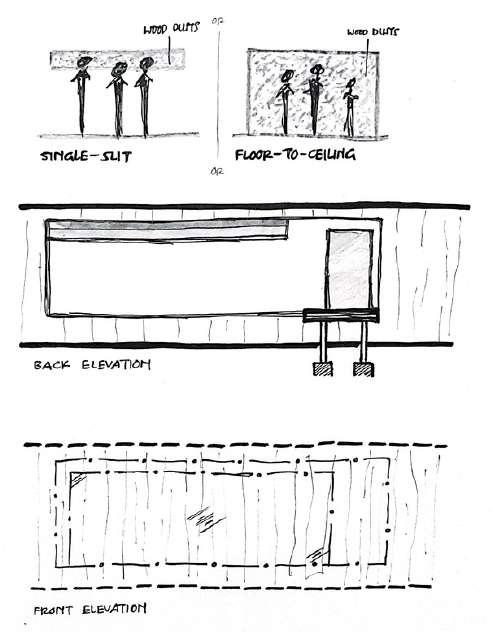

2 INTRODUCTION AREA

This area is all about the introduction of Pangkor and Hoo Huat Boat Making Factory, their general information and history It’s a dark room, as it is also located underground, to convey the message of being burried, which s the message to tell that the industry is dying Hopefully creates a sympathetic and empathic moments for the visitors

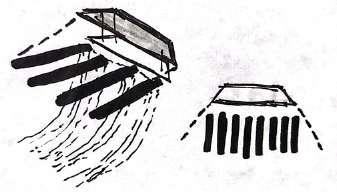

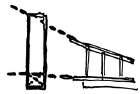

3 METAL GRATING PLATFORM

This is part of the observation zone, where the “action” (dim part) starts Metal grating is to allow the visitors to sort of wa k in the water, especially in high tides

4 VIEWING LONG GU

The first hut/stop to v ew the back part of the Long Gu (main bone) of the boat

5 VIEWING LONG GU

The second hut/stop to view the middle linear part of the Long Gu (main bone) of the boat.

6 VIEWING LONG GU

The third hut/stop to view the front vert cal part of the Long Gu (main bone) of the boat

7 SOLID TIMBER PLATFORM

This is the mezzan ne level of the observation zone, which is made of solid t mber

8 VIEWING GOU GU

This is the fourth hut/stop to view Gou Gu (deck) of the boat The visitors can go straight into the finished deck of the boat to have more experience

9 ROOFTOP/VIEWING BRIDGE

This is the h ghest evel of the observation zone to view the overall boat in a wider view range.

10 STUDIO

Studio/workshop area is about the applications after gain ng knowledge around the observation zone After observing the boat frames assembly, they can do some boat m niature assembly like LEGO in the stud o Beside that, this area can also be the gathering place for outside artists, carpenter, researchers, professionals to have an event or workshop that can enhance the trades more, that it can actually go beyond boat mak ng, such as wood jo neries & etc So, this area s the beginning of the bright/light part

11 EXHBITION DISPLAY & RESTING AREA

The end of the ourney, the resting area that are also showcas ng some exhib tion display related to boat mak ng

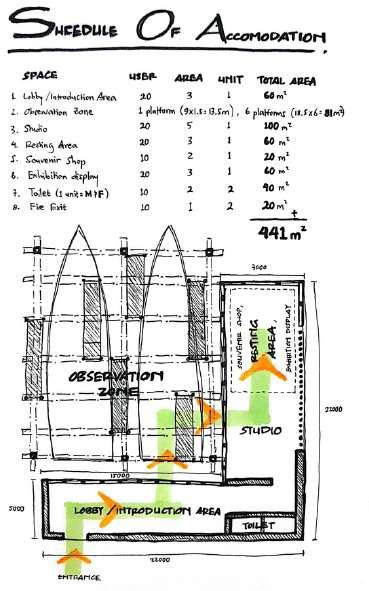

PROGRAMME

SECTIONAL PERSPECTIVE S C A L E 1 5 0 @ A 0 1 2 3 4 5 7 6 8 9 10 11

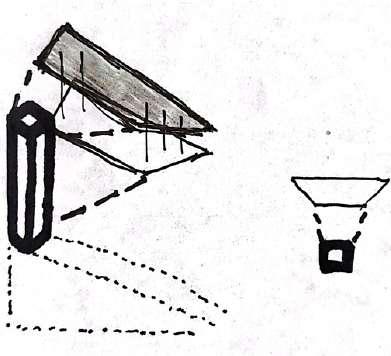

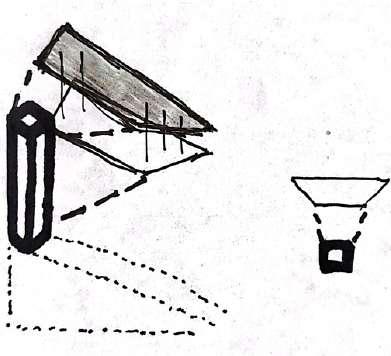

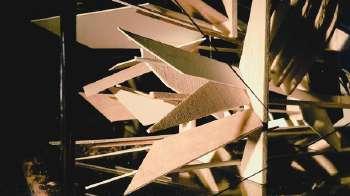

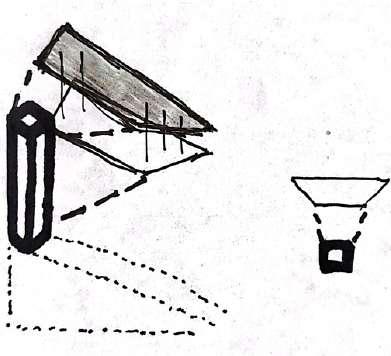

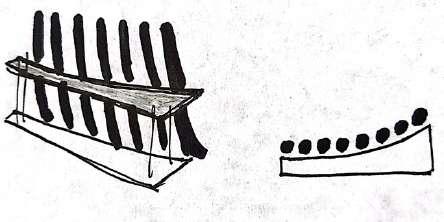

RESTING AREA & EXHIBITION DISPLAY

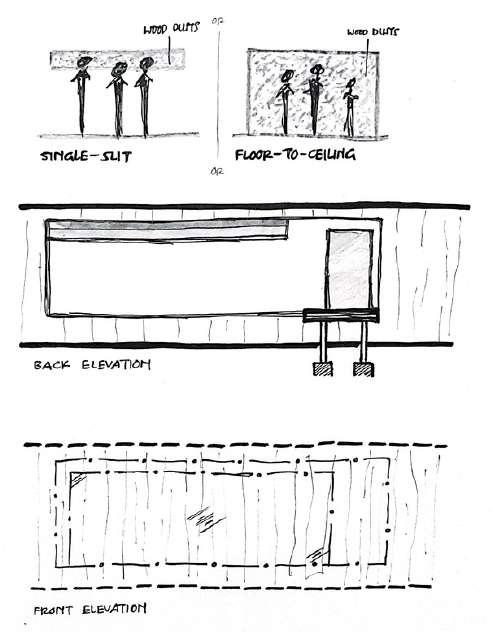

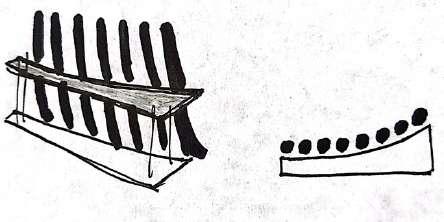

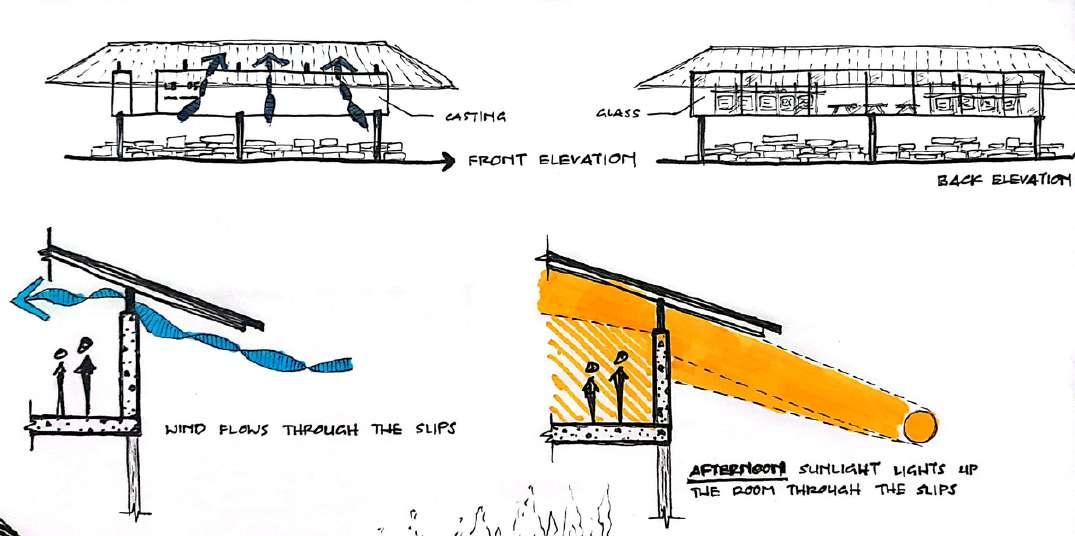

This form of the exhibition display and resting area is to capture the natural light and illuminate the whole interior space, and to create dramatic lightings.

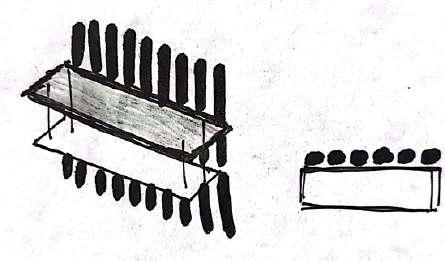

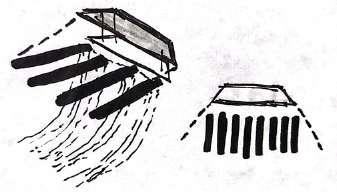

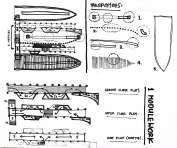

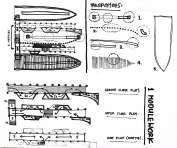

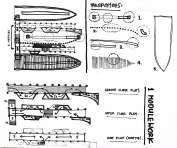

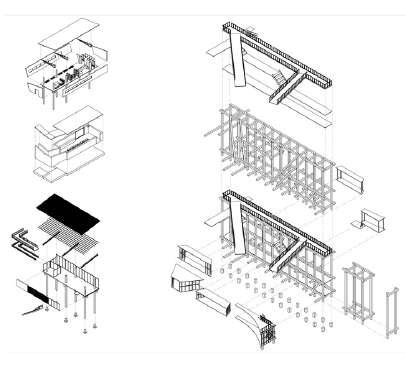

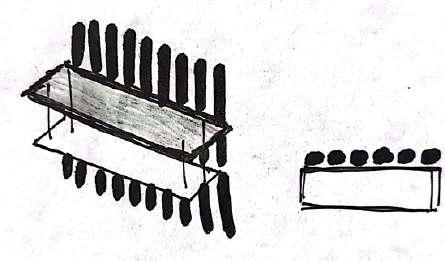

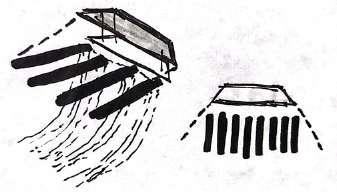

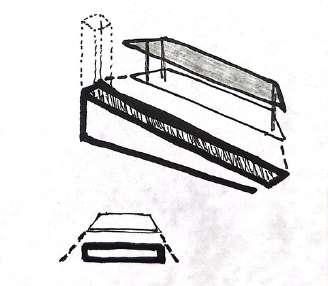

MODULAR FRAMEWORK OBSERVATION

BACK PART OF LONG GU

MIDDLE LINEAR PART OF LONG GU

FRONT PART OF LONG GU

PAI GU FROM PERSPECTIVE VIEW

PAI GU FROM SIDE VIEW VIEW

NEI WEN, WAI WEN, DIAO LIAN

GOU GU

BACK PART OF LONG GU

MIDDLE LINEAR PART OF LONG GU

FRONT PART OF LONG GU

PAI GU FROM PERSPECTIVE VIEW

PAI GU FROM SIDE VIEW VIEW

NEI WEN, WAI WEN, DIAO LIAN

GOU GU

ZONE

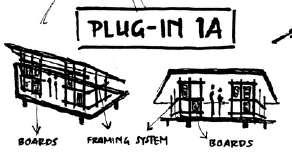

LOOKS ON THE HUTS

DETAIL

(TO

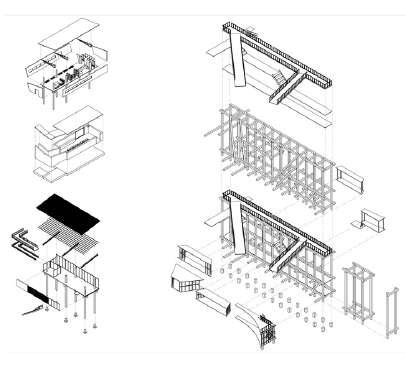

1A. 200mm THICK CONCRETE WALL

1B. 100mm THICK CONCRETE FLOORING

1C. 100mm THICK BRICK WALL LAYERED WITH 20mm THICK PLASTER

1D. 25mm THICK GLASS PANEL

1E. 600mm x 300mm CONCRETE BEAM

1F. 300mm x 300mm CONCRETE COLUMN

2:INTRODUCTIONAREA

2A: 200mm THICK CONCRETE ROOF

2B: 60mm THICK GLASS PANEL

2C: 300mm THICK CONCRETE WALL

2D: 1000mm THICK CONCRETE MAT FOUNDATION

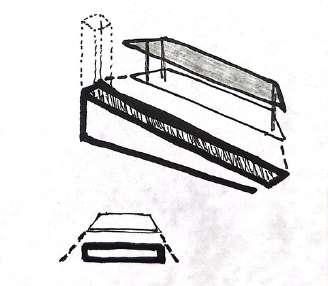

3:STUDIO

3A: 2mm THICK METAL CORRUGATED ROOF PANEL

3B: 30mm x 30mm STEEL ROOF BATEN

3C: 200mm WIDE STEEL ROOF TRUSS

3D: 200mm WIDE STEEL FLOORING TRUSS

3E: 25mm THICK GLASS PANEL

3F: 100mm THICK CONCRETE FLOORING

3G: 60mm x 60mm TIMBER LOUVRES

3H: 600mm x 300mm CONCRETE BEAM

3I: 300mm x 300mm CONCRETE COLUMN

3J: 200mm DEEP CONCRETE PAD FOUNDATION

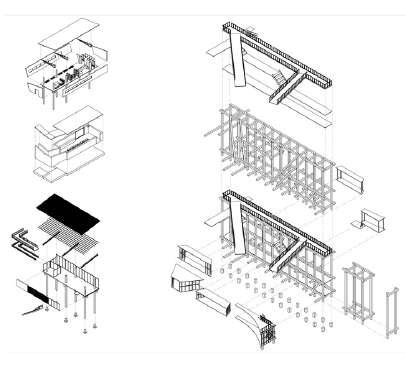

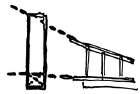

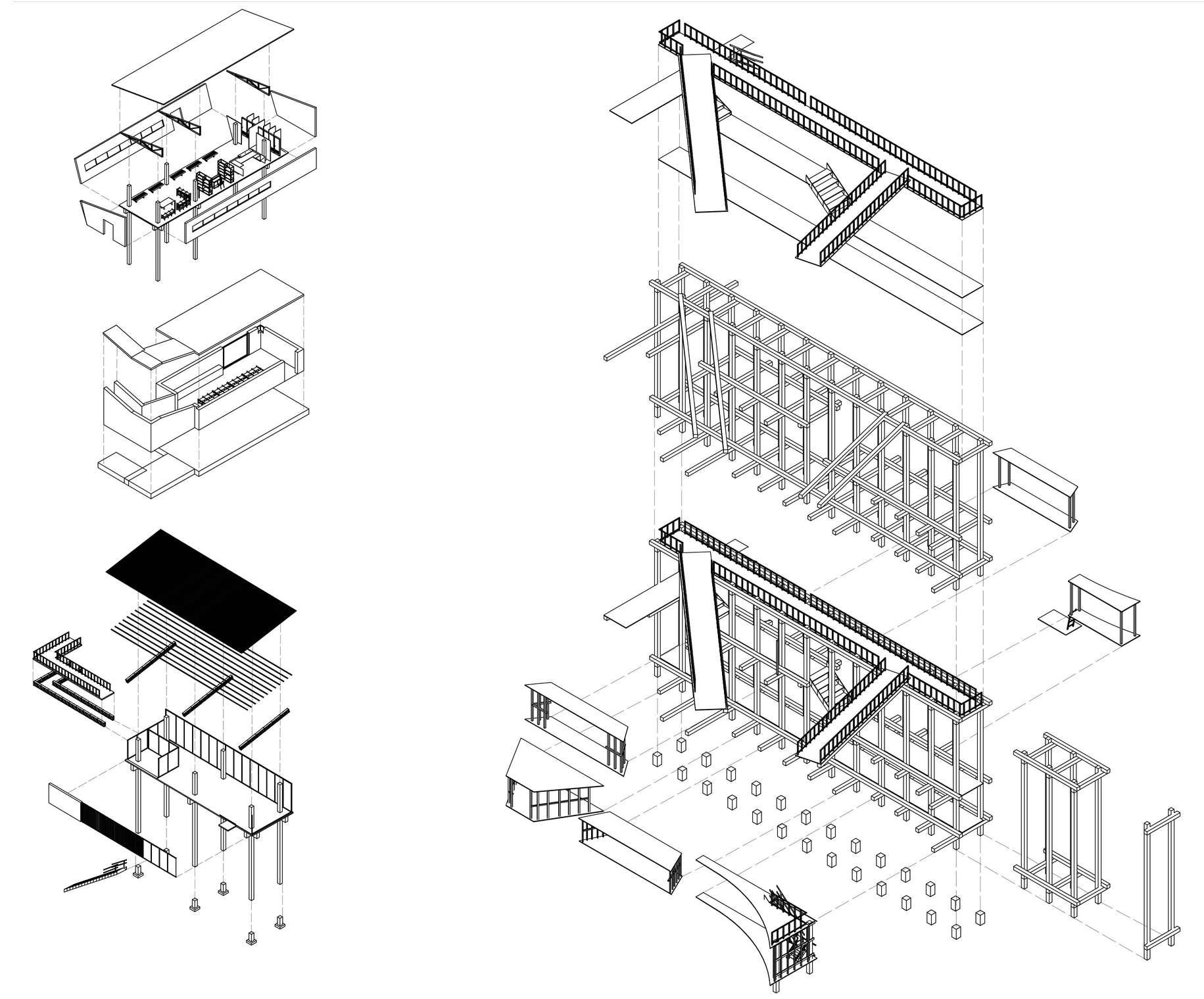

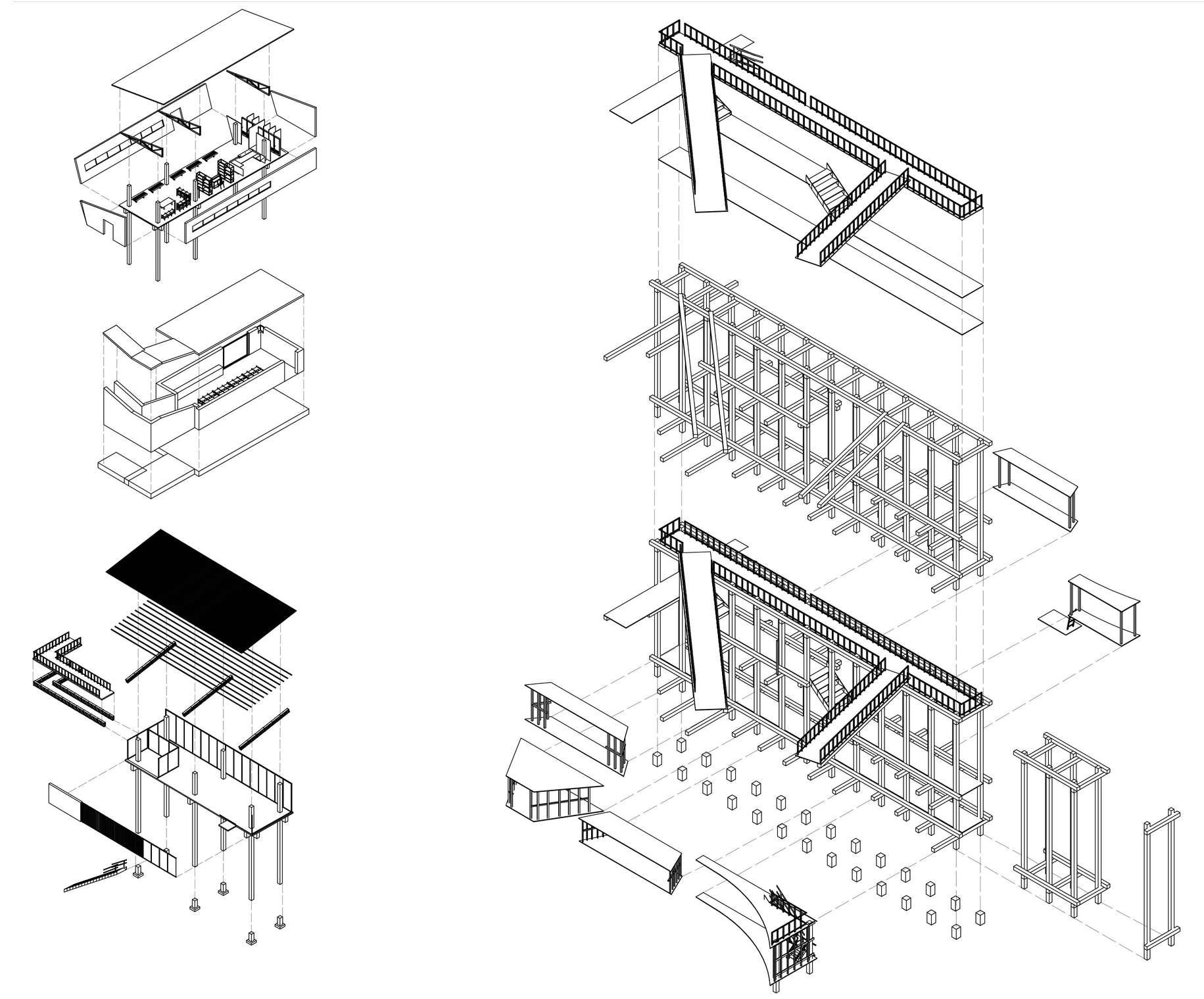

4:MODULAROBSERVATIONZONE

4A: 900mm x 70mm TIMBER FLOOR PLANK

4B: 400mm DEEP STEEL TREAD (1500mm WIDE); 280mm HIGH STEEL RISER (FOR STAIRCASE)

4C: 900mm x 70mm TIMBER FLOOR PLANK

4D: 1500mm WIDE METAL GRATING FLOORING

4E: 900mm x 70mm TIMBER FLOOR PLANK

4F: 70mm x 70mm TIMBER WALL FRAMING

4G: 350mm DEEP STEEL TREAD (510mm WIDE); 250mm HIGH STEEL RISER (FOR STAIRCASE)

4H: 100mm x 100mm TIMBER COLUMN

4I: 100mm x 100mm TIMBER BEAM

4J: 300mm x 300mm CONCRETE PAD FOUNDATION

4 D C 4B F 4G H 4 4 A B D E 1 2A B 2 D A B C D E F 3 3 3

1:RESTINGAREA&EXHIBITIONDISPLAY

EXPLODED AXONOMETRIC

SHOW DETAILED ARCHITECTURE CONSTRUCTION)

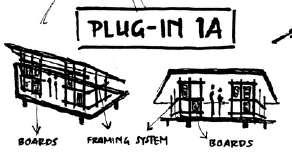

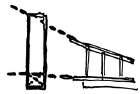

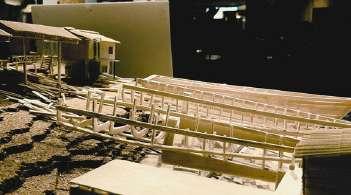

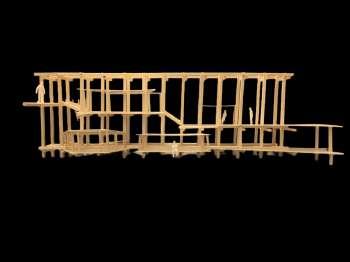

The modular framework (brown balsa) is the main structure that is embedded in the site with pad foundation to the ground, hence, it is a permanent structure.

The detachable huts (white model board) is a temporary structure that can be assemble and disassemble according to the time mapping of the factory.

These huts can be built by the local workers as all of the materials are timber, so it is a more familiar construction system to them Besides, this can be their side job other than boat builder.

“RANGKA”

m m n b hH H oM A nm mh e -o a b a ao man hpg h a e hs ae e a a e s ow ho hg e o 3m e BO RMSASML gOSRA Nw POA GNR ARTV D E S I G N D E V L O P M E N T ECTONA-A ECON-B 1B.100mmTHICKCONCRETEFLOORING 1D.25mmTHICKGLASSPANEL 1E.600mm300mmCONCRETEBEAM R G N 2A:200mmTHICKCONCRETEROOF 2D:1000mmTHICKCONCRETEMATFOUNDATION O 3B:30mm30mmSTEELROOFBATEN 3E:25mmTHICKGLASSPANEL 3F:100mmTHICKCONCRETEFLOORING 300mm300mmCONCRETECOLUMN 4A:900mm70mmTIMBERFLOORPLANK 4B:400mmDEEPSTEELTREAD(1500mmWIDE); 4C:900mm70mmTIMBERFLOORPLANK 4D:1500mmWIDEMETALGRATINGFLOORING 4G:350mmDEEPSTEELTREAD(510mmWIDE);250mm HIGHSTEELRISER(FORSTAIRCASE) 100mm100mmTIMBERBEAM 4J:300mm300mmCONCRETEPADFOUNDATION D O O SETONLESPCTVE ZONG 南 南 南 南 南-BOA SEMB G- ⻣ - ⻣ D WnWW-结FINAL BOARDS

Throughout semester 3, I’ve gained a lot of knowledge, especially about the site Personally, I think that the brief and the site itself is already very challenging, but it gave me room to explore more about design. In my opinion, the purpose of the brief is also very sustainable and interesting and meaningful, as we would like to preserve a dying industry and give them more exposure to the outside world Sort of like to contribute to make this world a better place through architecture and design. Thank you to my Lord, lecturers, friends, parents, and etc. for all the support and knowledge.

I 1002266004 I

Ferdinand

AR315 I Architecture Studio 3

Rio

Halim

BACK PART OF LONG GU

MIDDLE LINEAR PART OF LONG GU

FRONT PART OF LONG GU

PAI GU FROM PERSPECTIVE VIEW

PAI GU FROM SIDE VIEW VIEW

NEI WEN, WAI WEN, DIAO LIAN

GOU GU

BACK PART OF LONG GU

MIDDLE LINEAR PART OF LONG GU

FRONT PART OF LONG GU

PAI GU FROM PERSPECTIVE VIEW

PAI GU FROM SIDE VIEW VIEW

NEI WEN, WAI WEN, DIAO LIAN

GOU GU