ROTECNAWORLD NUMBER FIFTY-THREE 2022 DOWNLOAD ANY APPS FOR READING QR CODE & VIEW ROTECNA.COM 53 DOUBLE STAINLESS-STEEL SWING R3 TECHNOLOGY MARIANO SEÑORÓN: “ROTECNA’S HYDRAULIC PLATES ALLOW US TO HAVE A VERY EFFICIENT CONSUMPTION” GLOBALPIG PIGPRODUCTION FRANCE REMAINS ONE OF THE LARGEST EUROPEAN PORK PRODUCERS BACK TO EUROTIER AND OTHER FAIRS ROTECNA NEWS

Scan the QR code with the mobile camera.

LETTER FROM THE EDITOR

After four years of absence due to the pandemic, EuroTier was last November, once again the epicentre of European livestock activity, the best platform to show off the latest innovations related to all links in the production chain. The event brought together companies, technicians and farmers from all over the world, eager to meet again and see what the new trends in the sector are.

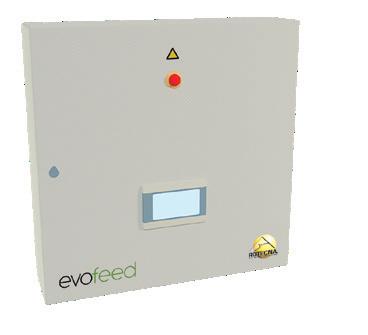

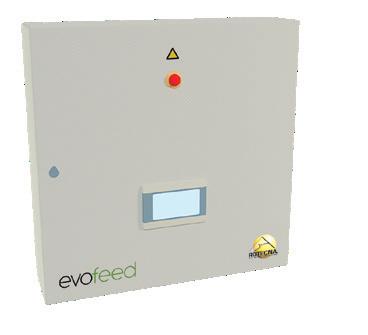

One more edition, on the behalf of Rotecna, we were there to show the more than 20 novelties that the company has launched since the last edition of the fair in 2018, highlighting the brand’s commitment to technology and digitalisation with electronic feeding systems for sows in farrowing and gestation, Dositronic; the multiphase feeding system, Evofeed; new advances in slurry management with the Tecnapur brand; and the automatic silo level control system, Silotronic.

Four days at the fair allowed us to get an impression of the industry in Europe, meet with some of our main customers, and identified what the concerns of the farmers are, enabling us to adapt our solutions to their needs.

With EuroTier, we arrived in December and closed a complex year due to the high costs of raw materials, energy and the inflation suffered by all. However, we face the new year with optimism and with the conviction that together, hand in hand, we will move forward. That is why we commit to being present at the main events. In this regard, we will travel to Thailand in March 2023, to participate in VIV Asia, and we will also participate in a new edition of the main fair by excellence, for the livestock sector in Spain, FIGAN in Zaragoza. In the meantime, we wish all our readers a happy holiday.

Antonio Pinos, CEO, Rotecna.

CONTENTS

4. Rotecna News

Back to Eurotier and other fairs.

6. Something About

Living nativity scene.

8. Technology

Double stainless-steel Swing R3.

10. Global Pig

Mariano Señorón: “Rotecna’s hydraulic plates allow us to have a very efficient consumption”.

14. Future News

Grangenia, ISO 14001 as a result of its sustainability strategy.

18. Pig Production in...

France remains one of the largest European pork producers.

Rotecna World

Director: Antonio Pinos.

Editor: Francisco García, Tamara Lombardo.

Images edition: David Mercado.

Translation: Sam Smith.

Print: Imprenta Barnola. L-41-2007

Rotecna's World's editors accept no liability for contributor's opinion.

DIGITAL VERSION

/issuu.com/rotecnapress

3

Nº 53 December 2022

BACK TO EUROTIER AND OTHER FAIRS

Being present in the most important international fairs of the pork sector is one of the high points of Rotecna’s philosophy. In this sense, the final stretch of 2022 has led us to participate in the leading fair of the livestock sector worldwide, Eurotier, which took place in Hannover, Germany. This, however, has not been the only event that Rotecna has attended during the fourth quarter of the year, since we have also been present in Brazil and Guatemala; in addition, of course, to some of the most traditional national pork events, such as the International Livestock Fair of Zafra, or the Oscars of our sector, the Golden Pig Awards, where Rotecna has also been present.

Eurotier 2022

From November 15th to 18th Rotecna participated in a new edition of Eurotier, in Hannover (Germany). Once again, the event was the perfect stage to present the more than 20 novelties (both completely new products

and innovations in existing products) that the company has launched on the market since the last edition of the fair held in 2018. Among the equipment presented were the feeding systems for sows in farrowing and gestation (Dositronic M and Dositronic G), the electronic multiphase feeding system, Evofeed, the Tecnapur slurry management system, and the sensor with laser technology to measure the content level of the of the silos, Silotronic.

During four days, Rotecna’s stand, with more than 200 m² of the exhibition, welcomed many of its customers, who had the opportunity of discovering the aforementioned novelties with the commercial team. In this way, we were able to know their impressions and concerns first-hand and receive the necessary feedback to continue growing and outdoing ourselves, in addition to assuring our customers, and conveying with all self-confidence, that Rotecna’s solutions are a safe bet.

4 ROTECNA NEWS

Rotecna’s stand at Eurotier (Hannover). Photo: Rotecna.

Rotecna presented 20 novelties in a stand of more than 200 m2.

Under the slogan “Transforming Animal Farming”, Eurotier 2022 hosted more than 1,800 exhibiting companies from 57 countries and welcomed more than 106,000 visitors, numbers that establish once again the enormous potential of this event that has already proven itself as an international benchmark for professionals in the livestock sector.

Pork Expo Brasil

From October 26th to 27th, Rotecna travelled to Foz do Iguaçu, Brazil, where it participated in the Pork Expo fair again, together with its distributor in the country. The event, which on this occasion celebrated its twentieth birthday, had an extensive program with technical and scientific conferences, business talks, etc.

Apogua Congress 2022

Intending to update people’s knowledge about production, health, management, nutrition, technology and prevention of diseases in pigs, the City of Antigua Guatemala hosted the 29th edition of the National Swine Congress. Once again, Rotecna was present with its distributor in this Central American country to take the most efficient solutions in pig equipment there.

International Livestock Fair of Zafra

The International Livestock Fair of Zafra reached its 569th edition between September 29th and October 4th. On this occasion, Rotecna participated in the event through its distributors in the area, who displayed some of our products in pork equipment in their stands.

Porc d’Or Awards

The XXIX edition of the Golden Pig Awards took place on November 25th at the Palacio de Congresos de Toledo. Once again, Rotecna was one of the sponsors of this event that recognises excellence in pork production. On this occasion, IRTA, the organizer of the event, awarded up to 49 farms, recognising their work within the national pork sector in this way.

Horizon 2023

We arrived at the end of 2022 and are already preparing the fair calendar for 2023 because the first quarter of the year will take us to such important events as the VIV Asia fair , in Thailand, or FIGAN Zaragoza, which will be held in March in the Ebro capital. One more year, we will continue betting on being present at the main events of the sector.

5

Pork Expo Brasil. Photo: Rotecna.

Part of the sales team at the Porc d’Or Awards. Photo: Rotecna.

LIVING NATIVITY SCENE

Living nativity scenes are one of the essential activities during the Christmas holidays. Since the beginning of December, living nativity scene troupes have been launching their performances. In this way, many Catalan municipalities revive biblical scenes in one of the most deeply rooted popular cultural traditions.

The oldest living nativity scene in Catalonia

Castell d’Aró, in Girona, can boast of having the oldest living nativity scene in Catalonia. They started in 1959 and have since become one of the most popular. This nativity scene has 400 characters in the two kilometre-long nativity scene, which has more than 50 distinct biblical scenes. In 2011 they received the ‘Creu de Sant Jordi’, one of the most important distinctions in the Catalan cultural field.

A manger in an abandoned village

There is a place where the decoration of the living manger takes on more might than anywhere else. We are talking about the ‘Masia Castelló’, a small town located in Vandellòs and l’Hospitalet de l’Infant (Tarragona). The living manger that is recreated in this town served to salvage a medieval town that was abandoned to its fate year after year. Since 1997, the ‘Masia de Castelló Association’ organizes these recreations that occupy streets and houses and enlarge them with their magic every year.

A manger scene with its own voice

In Gunyoles d’Avinyonet (Barcelona), the living manger sets itself apart from the typical stage marked by tradition and the characters speak in its depictions. This rebirth, with 45 editions behind it, traces a journey around a natural cave in the mountain. The scenes begin in the village with a guide who accompanies the spectators up the hill along a well-lit route. Up to 300 neighbours work in the making of this nativity scene, one of the most popular in its area.

A nativity scene in an old castle

In the small village of Fals, everyone participates in the Christmas performance. For over 40 years, the residents of this rural area of great beauty have recreated the scenes of the birth of Baby Jesus in a privileged setting, with the ‘Torres de Fals’ as the main attraction. In 1992, the Catalan government recognised the work done in this nativity scene with the Award for the Best Popular Artistic Initiative.

6 SOMETHING ABOUT

Image of a living nativity scene.

Since the beginning of December, living nativity scene troupes have been launching their performances.

La Pobla de Montornès, true to the classics

La Pobla de Montornès, in Tarragona, celebrates its living nativity scene in a much more classic way, in which a shepherd guides the attendees along the tour of the 15 biblical scenes in an exemplification that lasts just under an hour. The living nativity scene of this town has more than 40 years of history and adopts the environment of the hermitage of Montornés as a stage, located on a small hill near the municipality.

A cinematic nativity scene in Sant Fost de Campsentelles

The living nativity scene of Sant Fost de Campsentelles boasts many special effects. The creation made by the residents of this municipality leaves its audience mesmerised, with scenes of angels flying over cliffs with lightning and thunder. As every year, the whole town rallies for this depiction, which even has a traditional ‘caganer’.

The manger of Ardèvol

The manger of Ardèvol, in Lleida, lists two hundred actors in its representations, twice as many inhabitants as the municipality. The representation is divided into two parts, a first of biblical inspiration with the gospels and the life of Jesus, and a second in which the story takes a leap in time and recreates life in the eighteenth century borough and how the neighbours were preparing to live the Christmas holidays.

Ancient trades in Sant Guim de la Plana

We end this review of the best living nativity scenes with that of Sant Guim de la Plana (Lleida). This nativity scene starts at the door of the castle of the town, from the twelfth century, and runs throughout all the streets and squares of this small medieval town. The differentiating fact of this living manger is that it focuses on supporting a good part of the traditional field trades that have disappeared nowadays. The ‘nativity scene’ offers thirty-some scenes that end with the birth of Jesus.

DOUBLE

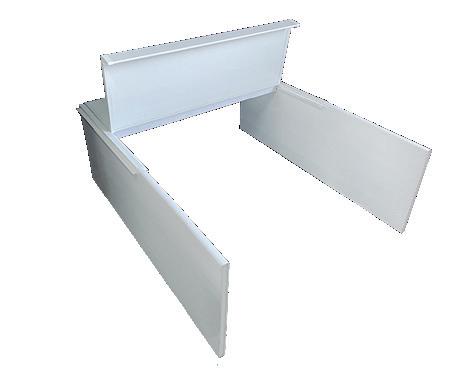

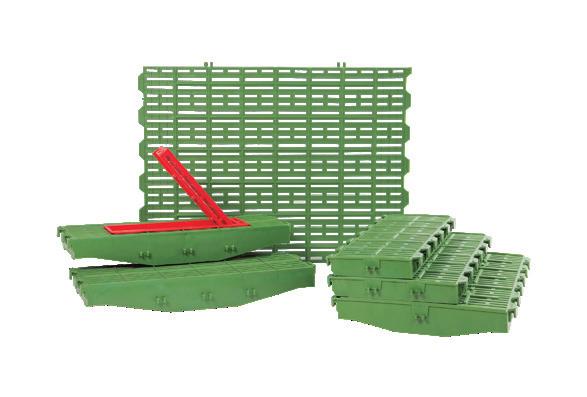

Feeding options on farms are highly variable and depend on many factors: management, markets, climate, facilities distribution, size of pens, etc. That is why Rotecna continues to bet on the development of new models in its broad family of Swing R3 feeders, with the Double Stainless-steel Swing R3.

Placed between panels, the Double Stainlesssteel Swing allows feed to be dispensed to two adjoining pens independently. In this way, it is easier to match the animals’ weights from different pens and allows independent fasting only in the pens where it is necessary. Available in two sizes, with a capacity of 95 and 170 litres, it easily adapts to different types of installation needs.

8

STAINLESS-STEEL SWING

R3

Technology 95 L 170 L Capacity 95 L 170 L Suitable for fattening Feed dry / wet Nº animals / feeder 30 - 50 Animals weight 6 -120 kg Filling height 125 cm (slanted loading inlet) 149 cm (slanted loading inlet) Feed delivery system Tube Pan measurements 70 x 50 x 12 cm Nº nipples 2 Adjustable positions of regulation 24

FEATURES: • Double-sided to independently regulate two adjoining pens. • Sides in embedded stainless steel to eliminate welds and difficult-to-clean corners. • Embedded steel in the centre to increase its resistance. • Sloped bottom for easy cleaning. • Capacity: 95 and 170 L. ADVANTAGES: • Maximizes consumption and minimizes feed and water waste. • Smaller animals’ quick adjustment. • Precise regulation, easy and fast handling. • Design that facilitates the lowering of feed. DISPENSE FEED TO TWO ADJOINING PENS INDEPENDENTLY

MARIANO SEÑORÓN: “ROTECNA’S HYDRAULIC PLATES ALLOW US TO HAVE A VERY EFFICIENT CONSUMPTION”

After finishing his studies at the School of Agricultural Engineering of Badajoz, Mariano Señorón was in charge of the Los Baldíos farm, in Alburquerque (Badajoz), thus following the family tradition. Built in 2002 by his father, the farm currently has 2,500 spots for Iberian sows and 7,000 weaning places. In his commitment to animal welfare, Mariano has been relying on the solutions offered by Rotecna for years, such as hydraulic heated plates or Swing R3 Duo hoppers, which he installed in the weaning rooms.

Why did you decide to commit yourself to pig breeding?

I’ve wanted to since I was little. My father has devoted his whole life to the swine sector and it is something he instilled in me. Over time, I have been learning, I completed the degree of agronomist and I have also studied for a master’s degree in swine, and I have decided to continue with the family business.

What is the origin of this farm?

This farm dates back to 2002. Over time it has evolved; we started with Duroc and then we changed to the Iberian breed. With these changes, we have also increased the farm tally, and we have gone from having 500 Iberian sows to 2,500, in addition to 7,000 weaned piglet places.

How is it distributed?

The farm has a quarantine area with 600 places for first-timers, two insemination areas with 630 cages, a shed for the heat detection of multiparous and first-time sows, and two warehouses dedicated to farrowing with 540 places in total. Finally, we have the confirmed gestation area where we have a total of 1,500 spots and the weaning area with 7,000 places.

Rotecna’s hydraulic heating plates are installed at weaning. Why did you decide to go for this product?

Due to the current situation and how the future looks, we decided to replace our electric heating with the hydraulic heating system with a biomass boiler. Specifically, we went for Rotecna’s plates because of their experience in

10

GLOBAL PIG

With a capacity for 2,500 Iberian sows and 7,000 weaning places, the ‘Los Baldíos’ farm has Rotecna’s hydraulic heated plates and the Swing R3 Duo feeder.

Mariano Señorón in the weaning room. Photo: Rotecna.

the pork sector and the quality of their materials.

What benefits would you highlight from the use of heated plates?

I highlight, above all, the environment, and the thermal feeling that is inside the room where the piglets are. The heated plates offer a pleasant thermal environment, with an adequate temperature. It is also necessary to emphasize the ease of operation of the whole installation.

How do you operate the plates?

We have automatic controllers. This controller reduces the temperature of the plates automatically depending on the piglets’ age until it reaches a point, in the fourth week, in which we close the heating off completely because it is no longer necessary. That way we avoid excessive consumption and generating heat when it is no longer needed. We start with a temperature of 37 degrees, and the regulators are adjusted with a probe that is in contact with the plate itself. Then we measure the temperature with a laser on the surface of the plate and play with that margin a little, between what we measure and what the probe shows,

to establish a comfortable temperature for the piglet.

Are they energy-efficient?

At the end of the day, everything depends on the installation, but yes, Rotecna’s hydraulic plates allow us to have a very efficient consumption. What regulating offers you is not having to be constantly aware of the temperature of the plate, and it automatically regulates the temperature of the same depending on the age of the piglet; that offers many advantages and is very comfortable.

You also have the Swing R3 Duo. Why did you choose this feeder model for weaning?

Mainly because of its ease of handling, the easy adaptation of the piglets and the scarce

waste of feed. It is a hopper that is very easily regulated and that allows, with little effort for the piglet, to always have feed available. It is very simple to use since by only activating the lever, it allows for a good fall of the feed and is regulated very easily. On the other hand, with the Swing R3 Duo, piglets can access food very easily, without having to make an excessive effort to make the feed drop. In the end what we are looking for is that the piglet, when going to the food and water, has it as easy as possible. In addition, it is a hopper to which piglets adapt easily. During the first days of their arrival, at weaning, they require a little more attention, since, no matter how easy the feed drop-ball mechanism is, they must learn how it works.

11

Iberian weaning with Rotecna heated plates. Photo: Rotecna.

As the days go by, with this hopper the waste of feed is practically non-existent.

What other Rotecna products have you installed?

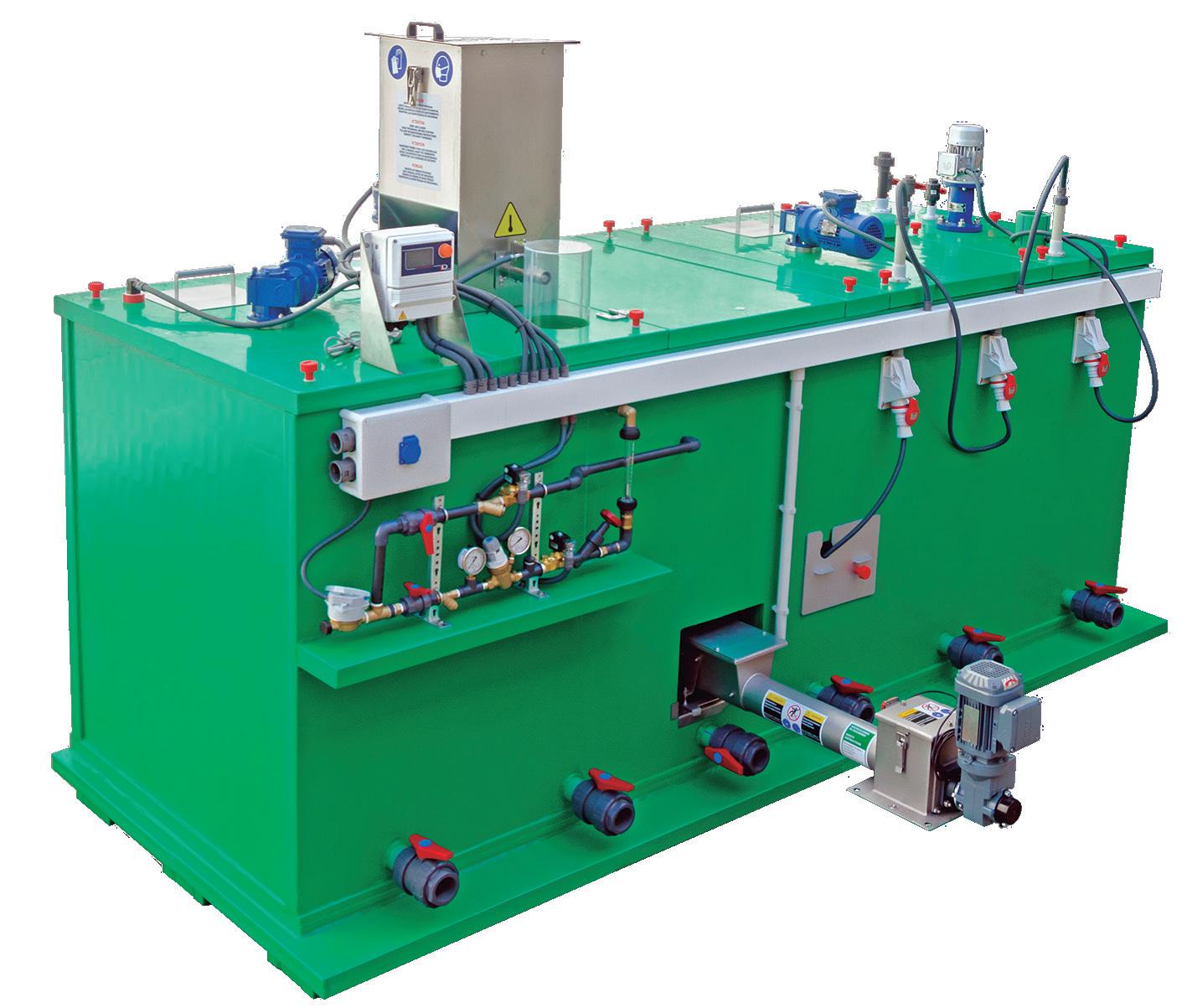

In weaning we have the joists, the Basic Post Beam (support pillar for joists), the slats, the Rotecna separators, and the heated plates; and in farrowing, we have the dispensers. In addition, we have the solid-liquid separator of Tecnapur for slurry management.

Overall, what do you value about Rotecna? The confidence it offers and its product quality. It is a more than established company and very well-known throughout the world, and we rely on it because it gives us security and confidence. When we make a new installation, what we look for is that it is comfortable and, above all, that it is durable over time and Rotecna delivers those two factors.

What biosecurity measures are taken?

We have an exterior fence, something essential and basic. To access the farm, a shower, the use of specific clothing for work areas and the use of

farm footwear are mandatory. On the other hand, as far as animals are concerned, it is mandatory to comply with daily hygienic measures such as changing needles, cleaning rooms, etc.

Finally, what challenges might the future bring for this farm?

Our main challenge is to improve production. In this regard, we have launched a project that wants to ensure that our animals are in the best possible conditions in terms of animal welfare. The project is based on data collection through environmental sensors, which measure parameters such as temperature, humidity, Co2, etc. They are installed in different places on the farm. The sensors send the data every 15 minutes to a blockchain platform. In this way, we can ensure that the pigs have optimal environmental conditions. With this project we want to lay the foundations to be able to incorporate the latest technologies that guarantee animal welfare in all parts of the Iberian pig breeding process, opening a range of opportunities within the pork sector, both regionally and nationally. I should also mention that the farm has piped music in all its facilities, and so manage to generate greater calm in the animals.

12 GLOBAL PIG

Weaning room equipped with Rotecna products. Photo: Rotecna.

We have launched a project that wants to ensure that our animals are in the best possible conditions.

GRANGENIA, ISO 14001 AS A RESULT OF ITS SUSTAINABILITY STRATEGY

Grangenia, one of the leading production centres of the Kerbest group from Avila, obtained an ISO 14001 certification in July, being the first farm of its kind to achieve this environmental distinction, which is another example of its commitment to sustainability, animal welfare and biosecurity in pork production. To know how this whole process has been, what it implies and what are the future challenges of the Kerbest group in this line of continuous improvement, we meet Alberto Pascual, executive director of the group, Pilar Fernández, director of biosafety and environment, and Álvaro García, technical director of development.

What does it mean to have received ISO certification in environmental management?

AG (Álvaro García): It is a recognition of the effort that has been made in terms of the environment, after years of work, especially by Pilar, whose effort has managed to strengthen one of our main pillars: sustainability and respect for the

environment. This ISO recognizes that things are being done well and in a different way within the pork production sector.

AP (Alberto Pascual): On the one hand, there is a well-deserved recognition for the effort and dedication of the last 5-6 years since we established our sustainability strategy, but, above all, we understand that it means the beginning of a path towards the development of a new aspect of our companies, focused on ESG criteria, incredibly important when evaluating and perceiving institutions. We cannot stay on the sidelines and it is something vital if we want our farms to grow as corporations, something that, from this part of the sector we have been asking for, for many years now. We do not want to hide these things or make them up, we seek to professionalize ourselves, even more, to do things as well as possible. The truth is that the process of getting here has been very difficult. We spent two years without being able to certify an environmental management

14 FUTURE NEWS

Alberto Pascual: “Change is costly, but it is necessary for evolution. In this case, it makes us even more efficient and professional.”

Álvaro García, Pilar Fernández and Alberto Pascual at Kerbest.Photo: Rotecna.

system because no certifier could do it. To certify a farm of 3,050 sows, with slurry, grids... it was an impossible mission, but, finally, we managed to make it feasible with AENOR.

You have been one of the first pork production centres to achieve this distinction. Was it one of the goals when you designed Grangenia?

AP: Somehow, when Grangenia was made, we knew that we were going to do something different, for example, working with free maternities, with the recordable pits as trays, looking for the combination of forced and natural ventilation. Grangenia, therefore, was already a farm that was designed with a different aim in mind, in which to reflect what we wanted and then managed to improve with Kerbest. From there, we have been identifying the differentiating points of Kerbest over time, which has had them from the beginning, although perhaps we did not know how to name it.

PF (Pilar Fernández): Actually, we were not looking for Kerbest; the meaning comes from the best care in English (care best), with that idea of looking for the best for the animals, for our environment, for our region, for our peoples, in that special emptied Spain, in a sense. We wanted to make that synergy between livestock and a sustainable rural territory.

What requirements does Grangenia meet in order to receive this recognition?

AP: It is very important to raise awareness and involve the entire team, on the one hand, and on the other the digitalisation and protocolization of all production processes. You have to be very aware of what this certification means and especially what it means on a farm. The professional development policy of our staff is essential, directing it to the achievement of new very transversal competencies, necessary to achieve these certifications and meet the objectives we

set. In this sense, we are very grateful to our entire team, whom we are very proud of and whom we thank for their dedication and commitment. On the other hand, as said, the digitalisation of the farm and its processes is basic. We have to generate traceability in all our processes, not only in the management of our slurry, and this has been possible thanks to our R+D, digitalisation and environmental departments. The work generating applications, platforms, sensors, protocols, etc has been huge. There is so much data that it cannot be collected manually. Therefore, we work with written protocols, which expedite our daily work. To lead several farms with multidisciplinary teams we need to have the necessary tools which will allow us to know every last cubic meter of slurry we produce in each of our production centres. And, it is all this information, all this data, that has allowed us to be awarded ISO 14001.

Can you list specific actions that you have encouraged to minimise the impact of your livestock activity?

PF: Specifically, in Grangenia and the rest of our piglet production farms, we implemented the Smartfert, which is our design for intelligent fertilization with which we optimize the transport of our slurry and customize the dose and type of purification depending on the characteristics of the soil, history of productions and cultivation to be implemented and then planted, thus optimizing the agronomic use of our slurry thanks to the fact that we extract the inefficient water from it with which we certify reductions in GHG emissions, between 600 and 1000 annual CO2

15

We have to generate traceability in all our processes, not only in the management of our slurry.

equivalent tons. Then we also set ourselves the goal of optimizing water management. In this area, we are aware that we cannot reduce the water consumption of animals, but we can reduce losses, reduce water for washing, and so on. And that’s when we started to create new work protocols, to devise how we could improve the washing processes, prepare the rooms... reduce water consumption between 10-15% and, in the end, achieve a decrease of 25%. We did this by improving the management of cleaning work, with the purchase of a robot and with the training of the farm team which on their own provided improvements to save even more. On the other hand, and coming from the debate on how to save water consumption, the idea arose to collect rainwater and use it for washing, and so we do.

What are the control and verification systems that these measurements do in order to obtain the certification?

AG: The main thing is to have all the data under control and be able to share it with the certifiers. What the external auditor does is certify and verify all the data that we provide and everything has to

add up, that is, it has to be verifiable, quantifiable and measurable. From there on, the goal is to preserve the system and improve the data.

Can all commercial farms work towards this certification?

AP: You don’t need to design a new farm to reduce emissions. Any farm can reinvent itself and get an environmental certification, what you have to do is have a different approach to what you are doing. We are now going to certify all our centres and those of our customers, so we are not talking about something for new farms only. It is not an essential condition.

And the industry, do you think it is prepared to take this step?

AP: The sector is increasingly prepared and there are more and more tools to make things easy, more technology, more sensors that allow you to monitor the data... Anyway, we have to keep in mind that we are in a sector in which change is costly, but when it gets on with it, it does things very well. So, I believe that the sector is going to take it and it is going to multiply it for sure, but everything has

16 FUTURE NEWS

Aerial image of Grangenia. Photo: Kerbest.

its time and its path. At first, change is difficult, but what I realise is that these changes save time, we are more efficient and there are also economic savings.

investment is intangible: the time and professionalisation you have to have, the training within the sector, that the team is aware of and wants to participate ... The rest is what you want to invest to meet the objectives you set, although there are also objectives that do not cost money.

What improvements do you see for farmers with the addition of these procedures on their farms?

PF: More work comfort and more efficiency. For example, we had never looked at electrical consumption as we do now. By applying certain measures, we achieve efficiency gains and this often also means saving money and obviously, time. Digitization gives you all of this. It’s a real impact, you just need to believe and want to change.

Can these sustainability certifications improve society’s image of the sector?

AP: Without realising it, you are improving at the productive and image level. The job well done has its reflection and is what is transmitted afterwards. There is much more to what we do than what we can say. In the end, people, and society will see it. What this certification does is that it allows you to get that type of mark that easily guarantees a more sustainable production, because you already have everything certified. Although that is usually more of a marketers’ issue.

Does meeting all these requirements imply a large economic investment?

AP: Obviously, nothing is free, and there is an expenditure of money, time, awareness and commitment. However, the most important

AG: We would say that you have to invest to do things differently, but the good thing is that all these investments have a return on investment that, in addition, is seen in a short time, makes you sustainable and guarantees the future of livestock occupation.

What new challenges do you face by being increasingly sustainable and efficient?

AP: When we talk about sustainability, we are not only talking about the environmental aspect but also the social and economic and it is the combination of these three pieces that gives future viability not only to a company but to an entire sector. Contributing our grain of sand to the entire food chain is a great challenge, and do so in such a way that it returns greater sustainability multiplied “x” times to all the participants in that chain. If we focus on environmental sustainability, the following objectives are closely identified with energy efficiency and nutrient optimisation in organic fertilization, also acting in the all our centres’ processes in such a way that the implementation of this environmental certification and others like the Carbon Footprint certification that we have also seen materialised in recent weeks, suppose a standardised reality that adds to our model “by Kerbest”. Finally, the generation of knowledge is also a priority objective for Kerbest, in which the Cathedra in Agro-environmental Sustainability of the Kerbest Foundation is in sync with the Catholic University of Ávila. We are going to set goals. Where will we have the roof? Well, for now, we don’t see it.

17

By applying certain measures, we achieve efficiency gains and this often also means saving money.

FRANCE REMAINS ONE OF THE LARGEST EUROPEAN PORK PRODUCERS

With a production of 2.26 million tons of pork in 2021, France is the third largest pork producer in the European Union, only behind Spain, which produced 5.18 million tons, and Germany, 5 million tons last year. Additionally, the French pork sector is one of the most important worldwide due to its productive, import and export capacity, as well as the high figure of pork consumption among its population.

Production

The French pork sector is characterised by having a very technical and professionalised production structure, something that has allowed pig breeding to be continued with very similar numbers, practically unchanged, in recent years. According to data from last September, France has a total count of about 13 million heads (931,000 are breeding sows). Numbers linked to meat production have also remained stable and largely unchanged in recent years. The variation registered between 2024 and 2021 has been 4.88%.

Consumption

Like production, pork consumption has stabilized in recent years. However, in recent years there has been a slight trend towards a reduction in pork consumption, both in households and in restaurants, due to the ecologist and animal trends that have been implemented gradually. Despite this, France continues to maintain high pork consumption per capita, and pork products of around 30 kg a year per inhabitant.

Pork trade

Due to its proximity to Spain, its size and its high purchasing capacity, the French pork market is one of the most interesting and a priority for Spanish pigs. Until 2018, France was Spain’s main customer, a situation that changed in 2019, when it became the second due to the increase in Chinese imports caused by African swine fever (ASF).

In 2021 the situation already begun to change and France imported around 300,000 tons of Spanish pork worth 803.7 million euros. During the first half of 2022, the influence of the French market in Spanish exports increased even more, at the same time that the weightiness of China has been reduced because of the increase in its pig herd thanks to their recovery from ASF.

18 PIG PRODUCTION IN

Since 2014, France has maintained similar levels of production, trade and consumption despite the current crisis the sector faces.

Image of a gestation room in France. Photo: Rotecna.

Thus, in the first six months of 2022, pork purchases from Spain represented 10.15% in volume and 10.8% in value of all Spanish pork exports, while exports to China would have fallen to 21.2% in volume and 16.8% in value.

Thus, Spain remains the main supplier of pork to France, followed by Germany, Belgium, Italy, the United Kingdom, the Netherlands, Denmark and Poland. It is worth mentioning that a large part of French imports are fresh or frozen products, with a high degree of preparation and added value, destined for the French charcuterie industry, and processed products for direct consumption.

In terms of exports, France exports about 25% of its production, and the main destinations of its pork are countries of the European Union, although it also exports a percentage to countries such as China and the Philippines.

Current situation

Despite the enormous potential of French pork, the sector is currently facing a crisis resulting from the Covid-19 pandemic and the current armed conflicts in Europe which has led to inflation, especially of agricultural elements and raw materials used for feed production, and the manifestation of African Swine Fever. The French pork sector is facing the strongest price reduction in the last 30 years. In the last year, the price paid to the producer has fallen by 14% while costs have reached 27%. Given the situation, this year the French government has launched a rescue plan bestowed with an amount of up to 270 million euros, as well as a roadmap with short-term measures such as the implementation of promotional campaigns, the reinforcement of biosecurity, or measures to support the opening of export markets.

FEEDERS

GROW

SOW FEEDER Farrowing

SWING R3 DUO Weaning, Fattening, WTF

SWING R3 WET Weaning, Fattening, WTF

SWING R3 TUBE Weaning, Fattening, WTF

TR7D FEEDER Weaning

PANS

MAXI PAN

Adaptation pan - Weaning

MAXI HOPPER PAN Adaptation pan - Weaning

MAXITAINER

TECNA

EASY

Adaptation pan - Farrowing

WALL PAN Adaptation pan - Farrowing

MINI PAN Adaptation pan - Farrowing

MINI HOPPER PAN Adaptation pan - Farrowing

MINITAINER Tank for liquids

TR4

TR2 FEEDER Fattening

TR3D FEEDER Fattening

SF3D FEEDER Fattening, WTF

SOW BOWL Farrowing, Fattening, Gestation FEEDING BALL Farrowing, Gestation

OWN DESIGN AND MANUFACTURE 30 YEARS DEVELOPING HIGH RESISTANCE PLASTIC (POLYPROPYLENE) FEEDERS Rotecna, s.a. Polígono Industrial, s/n, nave-3 · 25310 Agramunt (Lleida) SPAIN · Tel: +34 973391267 · Fax: +34 973391232

para MAXI PAN Tank for liquids

1ª

PAN Plato

edad Adaptation pan - Farrowing

1ª edad

PAN Plato

ANTI-STRESS FEEDER ANTI-STRESS CHAIN

MAXI

FEEDER

Fattening, WTF

MINI

GROW FEEDER

Weaning

FEEDER Weaning

TR5 FEEDER Weaning

BOWLS & VRH-3 VALVE VRH Gestation and farrowing VRH-3D Gestation and farrowing

DRINKER Weaning and fattening

DRIKER MINI Farrowing (piglets)

DRIKER MIDI Weaning

STEEL DRINKERS Sows, weaning and fattening DISPENSERS CLUTCH DISPENSER Gestation and farrowing DOSIMATIC SIMPLEX D-2 FOUR FIVE SIX-D SIX-S SEVEN ELECTRONIC FEEDING MANAGEMENT SYSTEMS DOSITRONIC M Farrowing DOSITRONIC G Gestation EVOFEED Transition SILOTRONIC COVERS AND NI-2 NI-2 CORNER Farrowing NI-2 MOBILE Farrowing NI-2 WEANING 5W LED LAMP

DRINKING

SWING

EASY

EASY

STAINLESS

60Ø / 63 - 70Ø mm ULTRA-RESISTANT

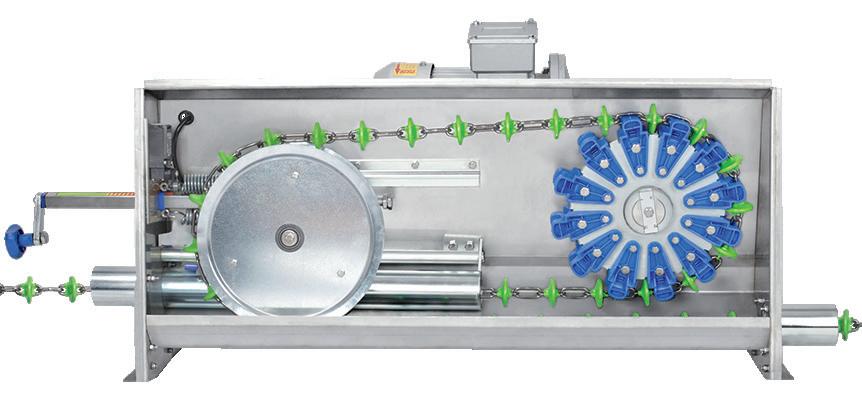

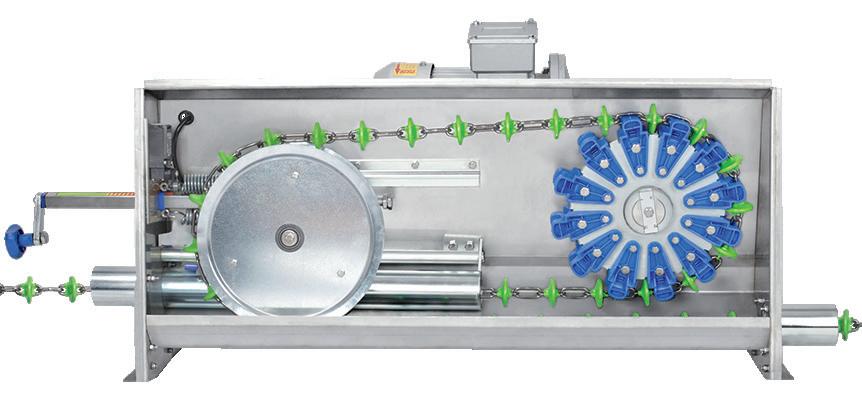

CHAIN AND DISK SYSTEM

• Shock absorbing teeth system. Easy adjustable chain tensioning system with graduation scale.

Corners with easy aperture system. Silo extraction system with an agitator.

AUGER SYSTEM

CHAIN 38Ø / 44Ø mm

EXTENSIVE

OF PRODUCTS FOR PIG EQUIPMENT

GEAR MOTORS TRANSFER UNIT www.rotecna.com EXTRACTION SINGLE / DOUBLE

The silo outlet system consist of a silo boot, a transfer unit and a slide gate assembly that allows horizontal and inclined installation. CORNER 50Ø / 60Ø THE MOST

RANGE

DOWNPIPES 50 - 60 - 90 63Ø mm SPIRALS 55Ø / 75Ø / 90Ø mm

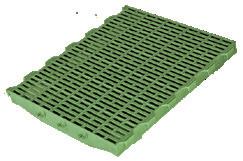

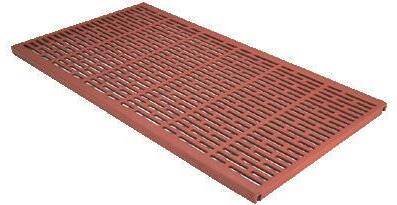

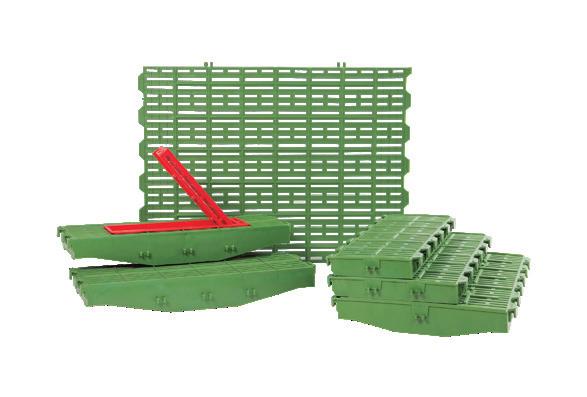

PVC PVC PROFILES (50,25,10 cm) CLOSE PVC PEN DIVIDERS OPEN PVC PEN DIVIDERS DOORS FAST LOCK BRACKETS U BRACKETS SOLID GRIP FLOOR DELTA BEAM PROFILE 135 / 120 T PROFILE Perfil 120 / 90 DELTA NET SYSTEM Raisable flooring system ERGOFIX Bracket for plastic and concrete grills BASIC POST BEAM Stand for pig grill support beams CLICK-IN Insert to blind concrete grills SLATS measurements in cm WEANER 10 10X40 10x50 WEANER 20X40 60X40 60X50 60X60 60X80 BLIND 60X40 60X50 60X60 10% OPEN 60X60 PARTIAL BLIND 60X50 A 60X50 B SOW 60X20 60X30 60X40 60X60 20X60 60X80 TRAP SLAT 60X40* 20X60 WEAN TO FINISH 60X40 60X50 ELECTRIC PLATE 60X40 120X40 120X50 120X60 WATER PLATE 60X40 120X40 120X50 120X60 CAST IRON 60X40 60X60 FERROCAST LEVEL BED 60X60 120X60 FERROCAST RAISED 120X60 100X60 PANELS BLIND PANEL 1200X1000 VENTILATED PANEL 1200X1000 PANELS MADE TO SIZE PROFILES FOR PANELS DOORS POLIAMID UNION BRAKETS FOR PANELS

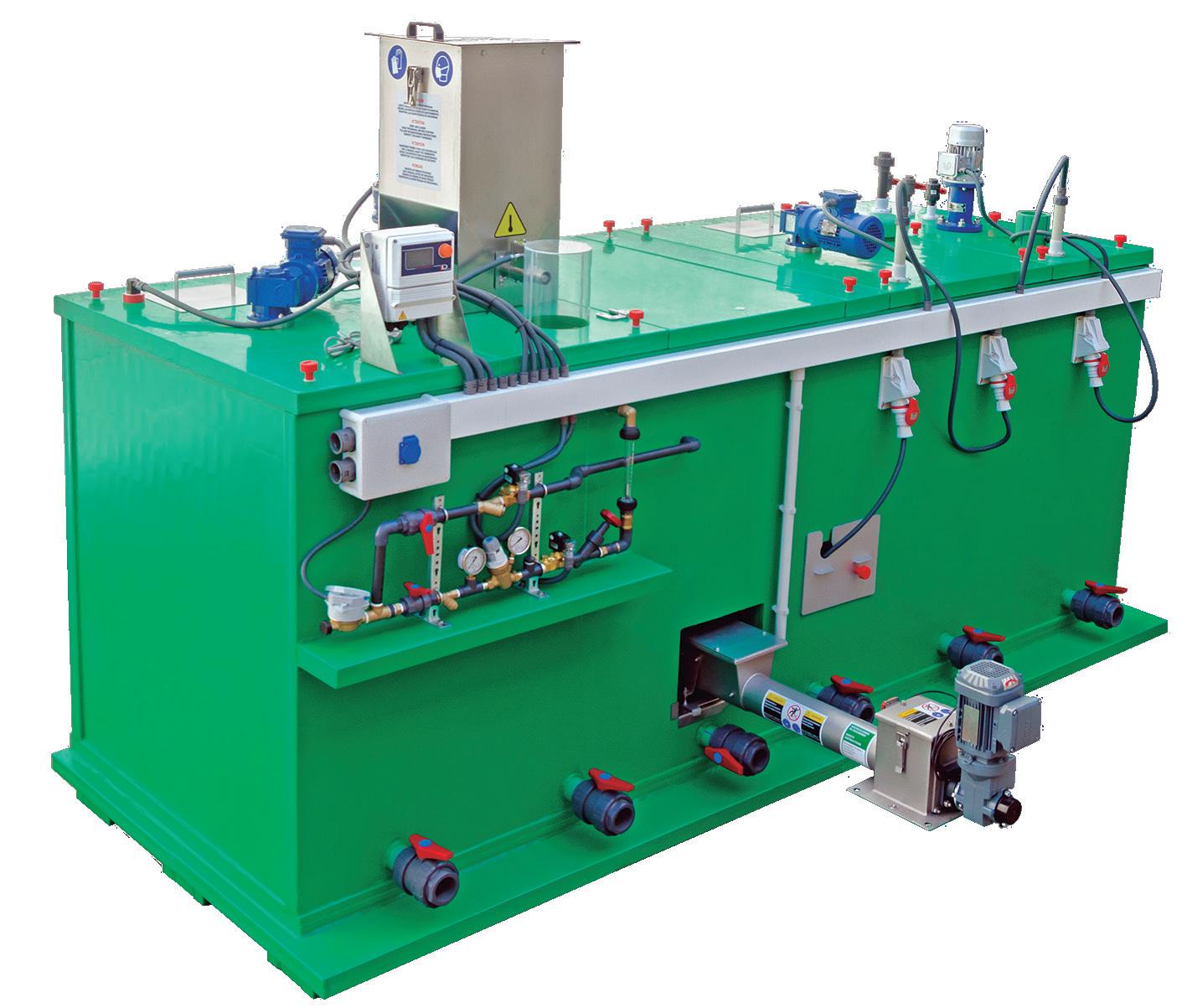

SOLIDS SEPARATOR TP-01 AGITATOR ELECTRONIC FLOW METER SUBMERGIBLE VORTEX PUMP THE MOST EXTENSIVE RANGE OF PRODUCTS FOR PIG EQUIPMENT www.tecnapur.com COMPONENTS OF THE TECNAPUR SYSTEM CONTROL PANELS TECNAPUR is a product by Rotecna, S.A. Pol. Ind. N-3 · 25310 Agramunt (Lleida) Spain • Tel. (+34) 973 39 12 67 • www.rotecna.com • rotecna@rotecna.com PHYSICAL-CHEMICAL REACTOR Scan the QR code with the mobile camera.